Abstract

In conventional classification, soft robots feature mechanical compliance as the main distinguishing factor from traditional robots made of rigid materials. Recent advances in functional soft materials have facilitated the emergence of a new class of soft robots capable of tether-free actuation in response to external stimuli such as heat, light, solvent, and electric or magnetic fields. Among the various types of stimuli-responsive materials, magnetic soft materials have shown remarkable progress in their design and fabrication, leading to the development of magnetic soft robots with unique advantages and potential for many important applications. However, the field of magnetic soft robots is still in its infancy and requires further advancements in terms of design principles, fabrication methods, control mechanisms, and sensing modalities. Successful future development of magnetic soft robots would require a comprehensive understanding of the fundamental principle of magnetic actuation as well as the physical properties and behavior of magnetic soft materials. In this review, we discuss recent progress in the design and fabrication, modeling and simulation, and actuation and control of magnetic soft materials and robots. We then give a set of design guidelines for optimal actuation performance of magnetic soft materials. Lastly, we summarize potential biomedical applications of magnetic soft robots and provide our perspectives on next-generation magnetic soft robots.

1. Introduction

Composed of materials with moduli close to those of soft biological materials (i.e., 104 to 109 Pa), soft-bodied robots hold great promise for many important applications, particularly in biomedical areas because of their inherent mechanical compliance that can lead to enhanced safety during their operation. The use of soft materials helps to prevent tissue damage while interacting with biological tissues or organs,1–3 by allowing for continuous deformation4,5 and ensuring the mechanical similarities to the interfacing tissue. Despite the purported advantages of soft robots and burgeoning efforts to utilize them in biomedical applications, the field of soft robotics is still faced with a set of key challenges. First, conventional soft robots based on pneumatic or hydraulic actuation (i.e., fluid-driven) or antagonistic pairs of mechanical wires (i.e., tendon-driven) are mostly heavily tethered for connection to the driving actuators and supporting hardware.1,6,7 This limits their practical use in applications where tether-free actuation is required or preferred, such as implantable devices for internal organ support or controlled drug release and minimally invasive devices for therapeutic or diagnostic operations. Second, most soft robots are difficult to accurately model and control, because their actuation mechanisms often rely on highly nonlinear deformation or even instabilities while requiring complex structural designs with many passive degrees of freedom.1,3,5,8 This elusive nature of soft robots renders the traditional model-based approach for controlling rigid robots largely inapplicable.9 Third, mainstream soft robots with conventional actuation mechanisms are difficult to miniaturize down to sub-millimeter scales, because their fabrication methods are often unfavorable to such small size.3,9,10

The invention of “stimuli-responsive” or “functional” (also referred to as “smart” or “active” in the field) soft materials has led to the development of soft actuators or artificial muscles that can be controlled remotely by means of external stimuli such as heat, light, solvent, or electric or magnetic field.11 Composed of soft polymers (e.g., elastomers or hydrogels) with integrated micro- or nanomaterials as functional components, most stimuli-responsive soft materials by themselves are not new in the field of materials science. However, the recent progress in advanced fabrication techniques for functional soft materials has enabled previously inaccessible and more sophisticated designs across various length scales, facilitating the development of small-scale, untethered soft robots with programmable shape-changing capabilities.2,12,13 Among the various types of soft materials that self-actuate in response to external stimuli, magnetically responsive soft materials have shown remarkable progress in terms of both their design and fabrication, leading to the development of magnetically actuated and controlled soft robots.14–16 These magnetic soft robots possess great potential for biomedical applications because of a set of unique advantages of magnetic actuation. First, natural tissues and organs are transparent to static and low-frequency magnetic fields,17 and magnetic fields can be remotely applied without causing any adverse effects on biological systems over a wide range of actuating field strengths and frequencies.18 Second, magnetic fields are relatively easy to control in that their magnitude, phase, and frequency can be modulated accurately and rapidly.19 For these reasons, magnetic fields can offer a safe and effective means of manipulating untethered soft robots in confined spaces inside the human body.20

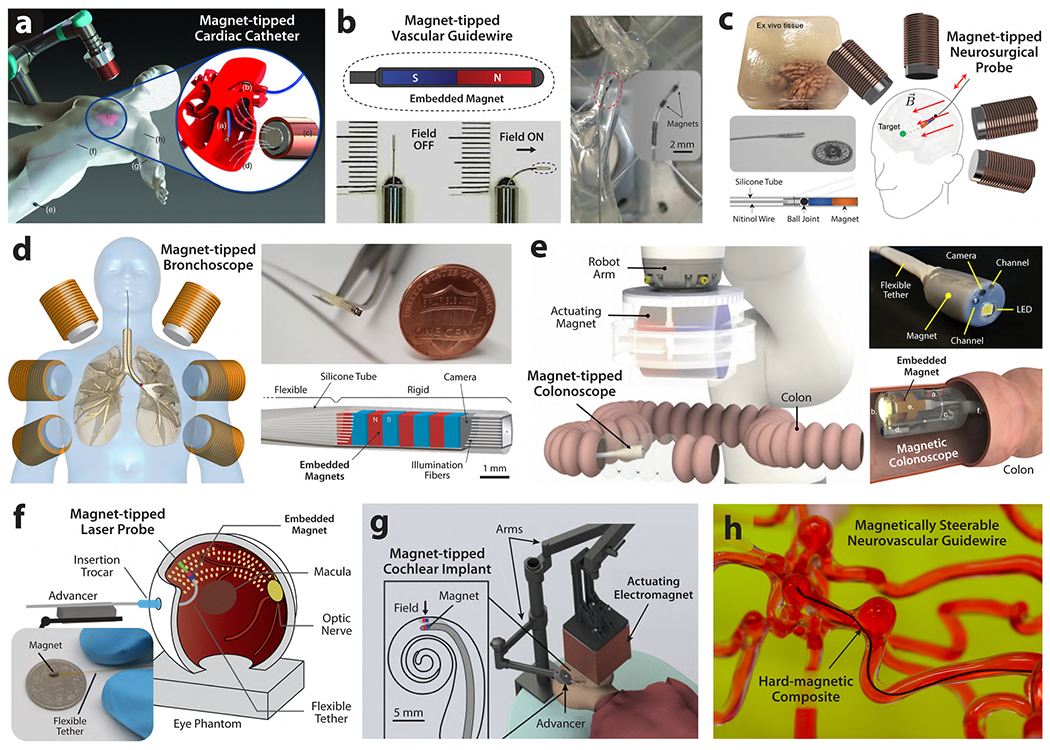

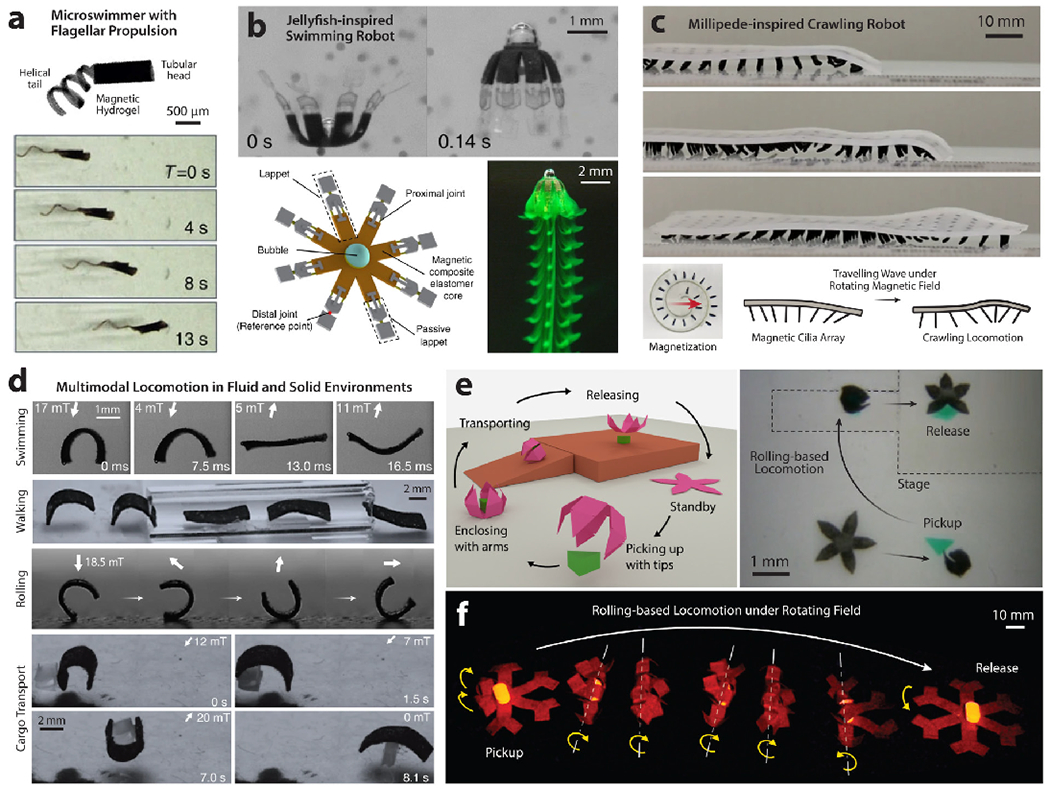

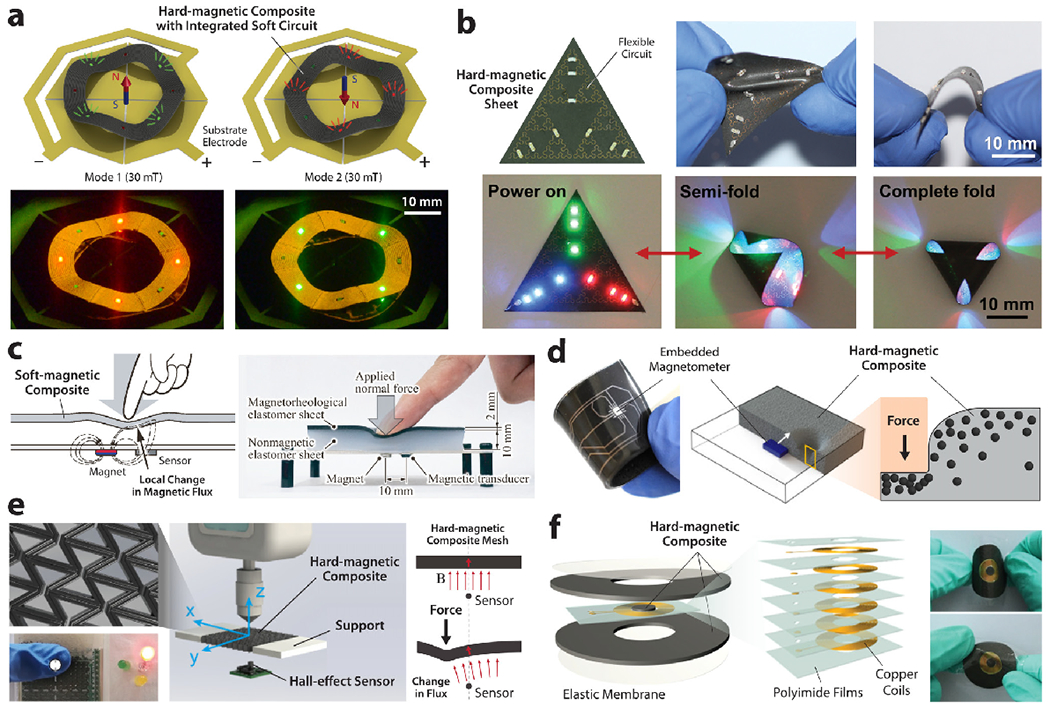

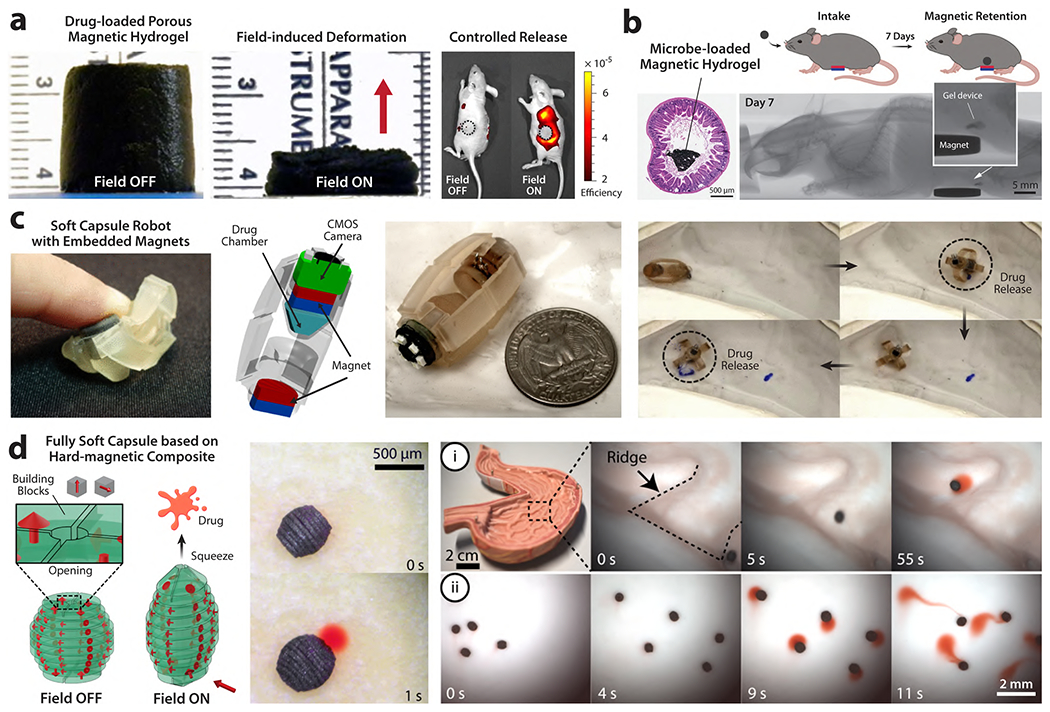

The potential of magnetic soft robots for biomedical applications has been demonstrated in a number of impressive examples. For instance, self-folding “origami” robots have been reported that can crawl through the gut, patch wounds, and dislodge swallowed objects;21,22 and soft “capsule” robots have been made that roll along the inner surface of the stomach and can perform biopsies and deliver medicine.23–25 Magnetically steerable robotic catheters have also been developed, which can perform minimally invasive therapeutic or diagnostic operations on the heart26–29 or in the lung airways.30 Much thinner thread-like robots have also been developed that can navigate the narrow and complex vasculature of the brain to treat intracranial aneurysms or stroke.31 Ranging from hundreds of micrometers to a few centimeters in diameter, these small-scale robots would not damage interfacing tissues owing to their soft and flexible nature. Despite the promising developments and demonstrated potential of magnetic soft robots, much work still needs to be done to make them practically useful and applicable in clinical settings. Further advancements in the field of magnetic soft materials and robots would require a comprehensive understanding of physical and chemical properties of magnetic materials and fundamental principles of magnetic actuation as well as quantitative modeling of the behavior of magnetic soft materials under applied magnetic fields. Identifying key scientific and technical challenges that remain to be overcome will also be important for developing next-generation magnetic soft materials and robots.

In this review, we discuss recent developments in the field of magnetic soft materials and robots. We first discuss various types of magnetic soft materials with different characteristics depending on the chosen magnetic and polymeric substances as well as their microscopic morphologies and configuration in the composite. Then, we discuss common strategies and underlying principles for different types of magnetic soft actuators, based on which we further discuss the quantitative modeling of magnetic soft materials and robots. We also review recent developments in the related areas of additive manufacturing and microfabrication as well as magnetic manipulation platforms as they pertain to the design, fabrication, actuation, and control of magnetic soft materials and robots. We then discuss applications of magnetic soft materials to soft robotic or electronic devices and also highlight their biomedical applications, in which we see the greatest potential of magnetic soft robots for societal impact. Finally, we provide considerations for future developments of next-generation magnetic soft materials and robots, focusing on unmet needs and remaining challenges.

2. Composition, Structure, and Properties

2.1. Classification of Magnetic Soft Materials

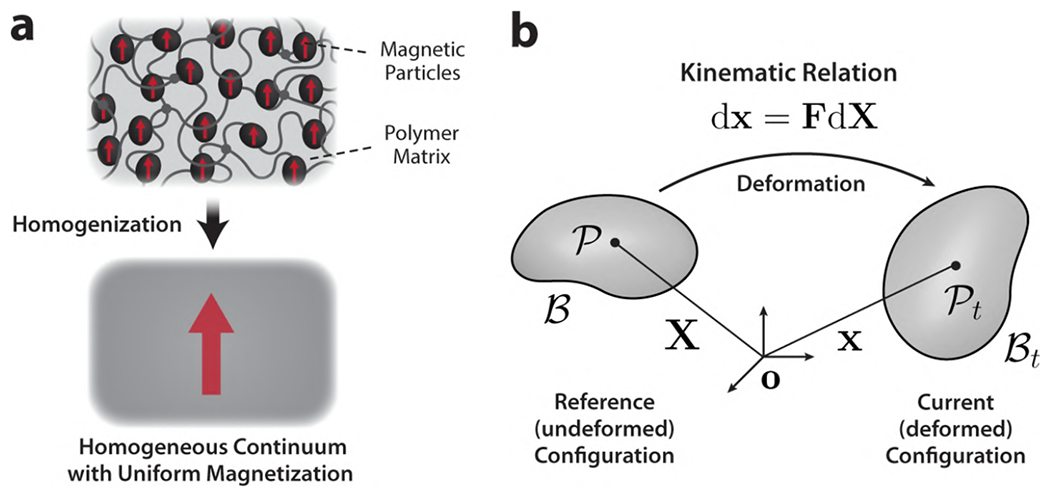

Historically, magnetically responsive soft materials in the form of elastically deformable solids have been referred to by a variety of terms such as magnetorheological,32–36 magnetoactive,37,38 or magnetosensitive39–41 elastomers or gels or, simply ferrogels,42–45 depending on their applications or the type of materials used. For simplicity, we refer to such elastic solids with mechanical softness or compliance as well as magnetic properties as magnetic soft materials. In our definition, and throughout this review, the term “magnetic” generally implies “strongly magnetic”. Accordingly, we will use the term “magnetic materials” to generically refer to “ferromagnetic” or “ferrimagnetic” materials that are strongly attracted to a magnet due to spontaneous magnetization (i.e., magnetic moments present in the material even in the absence of an external magnetic field). Magnetic soft materials in general have at least two constituent materials to form a composite, in which magnets of varying sizes (from nanometers to millimeters) are attached to or integrated into deformable bodies made of soft materials or flexible structures.20

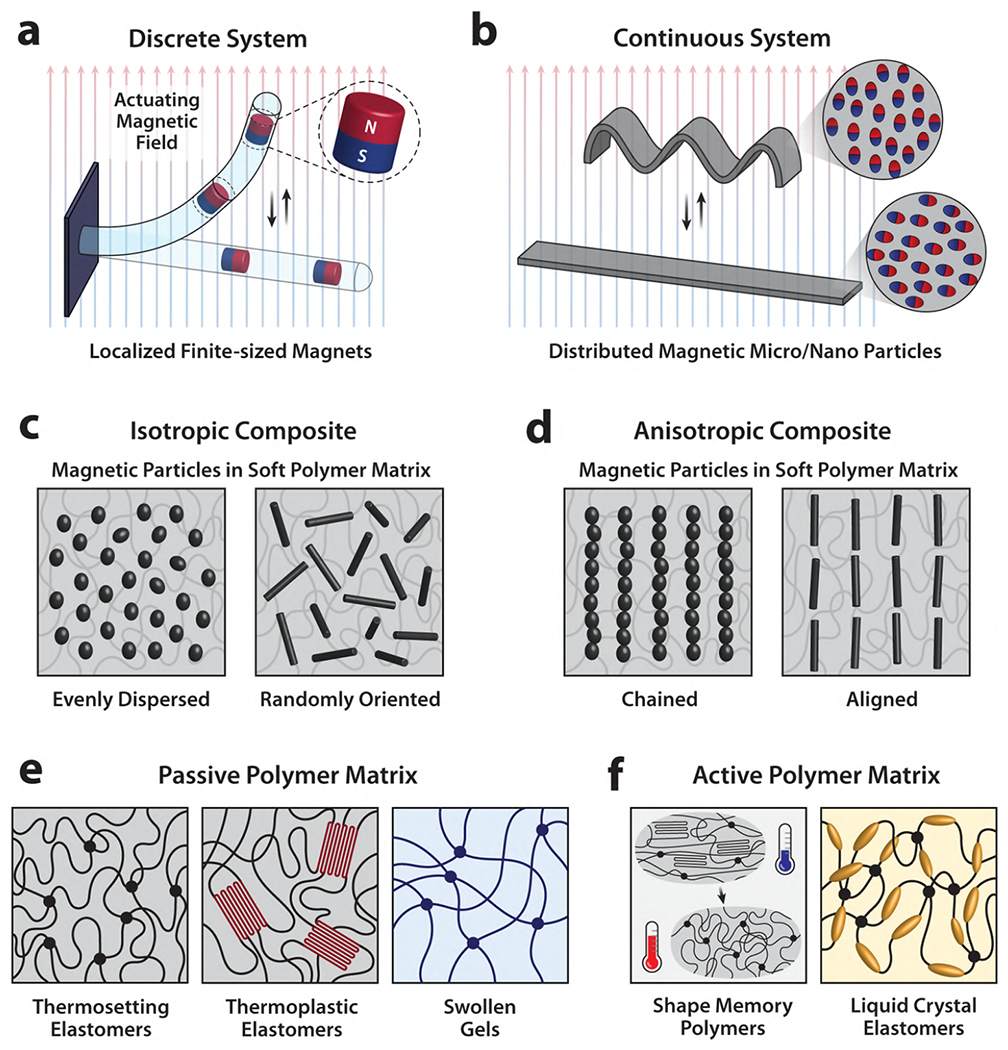

Depending on the composite structure, magnetic soft materials can be classified into either discrete or continuous systems. Discrete systems have one or a few finite-sized magnets or some patches of magnetic composite attached to or embedded in the deformable body21,22,24,25,46 and hence feature highly concentrated and localized magnetic moments (Figure 1a). Continuous systems have dispersed magnetic materials usually in the form of micro- or nanoscale particles, which give rise to diluted and distributed magnetic moments throughout the composite matrices (Figure 1b). Continuous magnetic soft materials can be further divided into either isotropic or anisotropic composites, depending on the distribution and orientation of the embedded magnetic particles in the composite matrix. In isotropic composites, the magnetic particles are uniformly dispersed and randomly oriented (Figure 1c), regardless of whether the particles themselves are isotropic or anisotropic in shape. In anisotropic composites, however, the embedded magnetic particles are either connected to form microscopic chains that are aligned in the same direction or all oriented toward the same direction (Figure 1d), both of which can result from an external magnetic field applied during the solidification of the soft polymer matrix to immobilize the aligned particles.

Figure 1. Classification and composition of magnetic soft materials.

Magnetic soft materials can be classified into either (a) discrete or (b) continuous systems depending on whether the magnetic components are in the form of finite-sized magnets embedded in the flexible structure or micro- or nanoparticles dispersed in the soft polymer matrix. Continuous magnetic soft materials can be further categorized into either (c) mechanically isotropic or (d) anisotropic composites depending on the microscopic structure or arrangement of the magnetic filler particles in the host polymer matrix. The polymeric component of magnetic soft materials can be classified into either (e) passive polymeric materials such as thermosetting or thermoplastic elastomers and swollen gels or (f) active polymeric materials such as shape memory polymers or liquid crystal elastomers depending on whether the polymer matrices themselves are responsive to external stimuli to change their physical properties or produce actuation via deformation.

In the following sections, we summarize some common types of magnetic materials as functional components and discuss their physical properties and magnetic characteristics in the context of actuating magnetic soft materials. We then discuss common materials for host polymers or flexible substrates of magnetic soft materials and robots across various length scales.

2.2. Magnetic Components

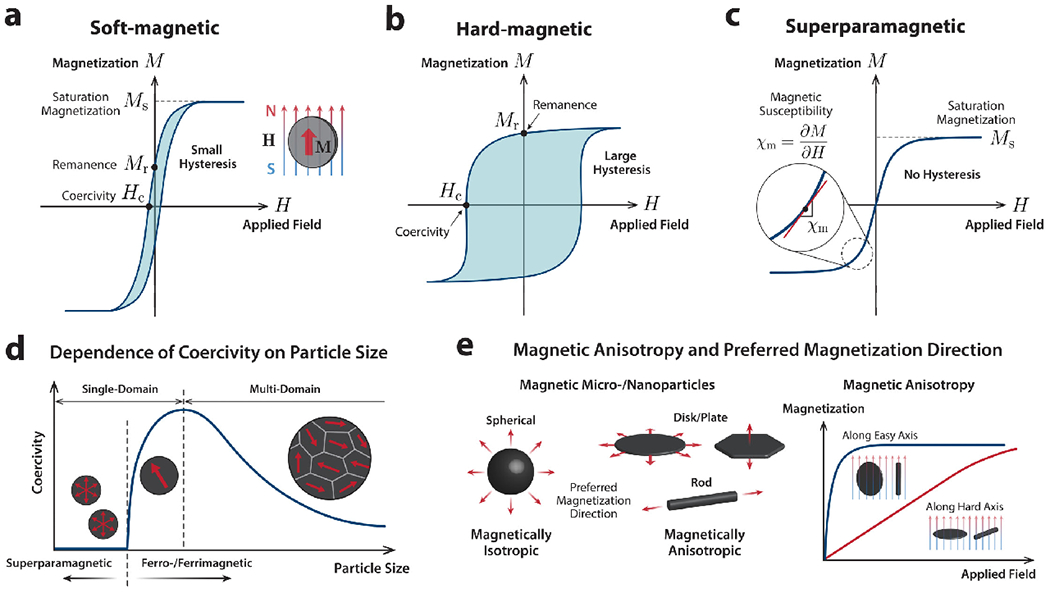

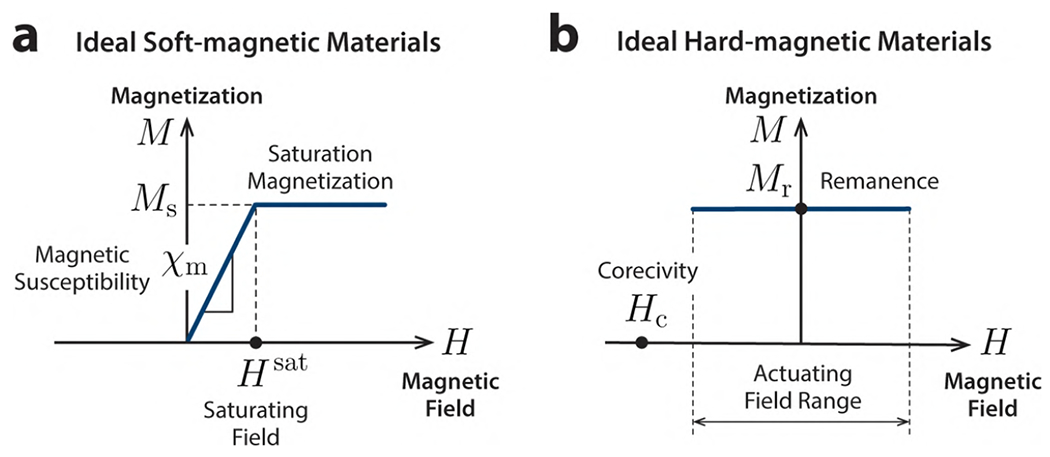

Among the different classes of magnetic materials, the focus here is primarily on ferromagnetic or ferrimagnetic substances, which are generally considered “magnetic” due to their strong response to an externally applied magnetic field. Depending on the magnetization characteristics, these strongly magnetic materials can be classified into three categories: soft-magnetic, hard-magnetic, and superparamagnetic. The key difference among these types of magnetic materials can be described by the qualitatively different features of their magnetization curves (Figure 2, a–c). In doing so, two quantities of particular importance are the remanence (or remanent magnetization), Mr, and the coercivity (or coercive field), Hc. The remanence denotes the magnetization that remains in the material even in the absence of external actions once the material is magnetized by a large magnetic field. The coercivity represents the resistance to being demagnetized and measures the magnetic field strength required to reverse the remanent magnetization in the material. Other important parameters are the magnetic susceptibility χm, and the saturation magnetization Ms. The magnetic susceptibility indicates how much of the material of interest will be magnetized in a given applied magnetic field and corresponds to the slope of the magnetization curve (i.e., , where M is the induced magnetization and H is the applied magnetic field) in a differential sense for magnetically isotropic materials. As the field strength H increases, the material becomes further magnetized and eventually saturated when all moments are aligned substantially with the applied magnetic field, with the induced magnetization, M(H), approaching the saturation magnetization Ms.

Figure 2. Classification of magnetic materials and characteristics of magnetic particles with different sizes and shapes.

(a-c) Magnetic component of magnetic soft materials can be divided into three categories (soft-magnetic, hard-magnetic, and superparamagnetic) depending on their magnetization characteristics. In general, soft-magnetic materials are characterized by their high saturation magnetization (Ms), low coercivity (Hc), and low remanence (Mr) with narrow hysteresis curves, whereas hard-magnetic materials are characterized by large hysteresis due to their high coercivity and remanence. Superparamagnetic materials exhibit no hysteresis and become quickly saturated under relatively low fields. (d) Qualitative behavior of coercivity of magnetic particles depending on their size. The coercivity increases as the particles become smaller to approach the single-domain regime, but the coercivity disappears below a certain critical size to enter the superparamagnetic regime as the smaller particles become more susceptible to thermal fluctuation and hence cannot retain stable magnetism in the absence of external fields. (e) Magnetic particles can also be classified into magnetically isotropic or anisotropic particles depending on their particle morphology and preferred magnetization direction.

2.2.1. Soft-Magnetic Materials

Soft-magnetic materials such as iron and nickel- or silicon-based alloys of iron are characterized by high magnetic susceptibility and saturation magnetization but relatively low remanence and coercivity (Figure 2a). Owing to these properties, soft-magnetic materials are strongly attracted to a magnet and easy to magnetize, but at the same time, they are easily demagnetized as well by a relatively weak magnetic field. Conventional magnetic soft composites based on magnetorheological elastomers and ferrogels mostly use carbonyl iron or iron oxide particles embedded in soft polymer matrices. This type of composite exhibits soft-magnetic characteristics (i.e., low remanence and low coercivity) while being mechanically soft (i.e., low Young’s modulus), and we therefore refer to this type as soft-magnetic soft materials.

In general, the response of soft-magnetic soft materials to externally applied magnetic fields is complex and largely dependent on the microstructure of the composite as well as the concentration and configuration of the embedded soft-magnetic particles.47–49 Our focus here is on the qualitative description of the most representative behavior of soft-magnetic soft materials. In an unstructured isotropic composite, the application of a uniform magnetic field induces dipole-dipole interactions between the neighboring particles that are magnetized by the applied field, provided that the particles are close enough to each other due their sufficient volume fraction (Figure 3a). Under a sufficiently strong field, the magnetized particles tend to align themselves with the applied field, causing changes in their microscopic arrangement in the composite matrix and associated physical interaction between the particles and the polymer matrix. The microscopic rearrangement of the magnetized particles leads to macroscale material response, causing the matrix to elongate in the applied magnetic field direction (Figure 3a).50 Such magnetically induced deformation is often referred to as “magnetostriction” in the literature.38,47,49–52

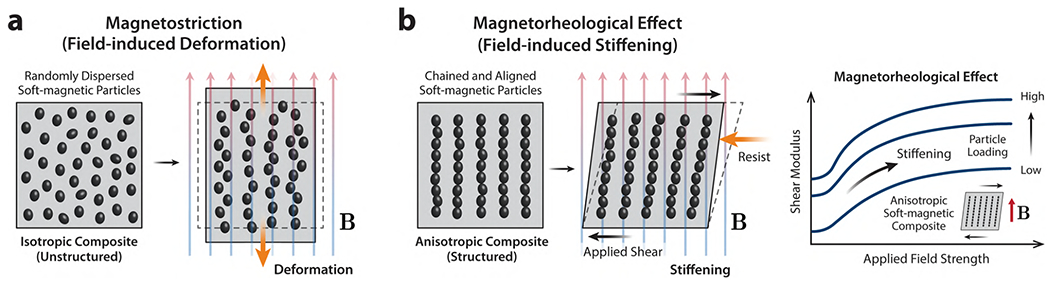

Figure 3. Traditional magnetic soft materials and their response to externally applied magnetic fields.

(a) Field-induced deformation (magnetostriction) of isotropic soft-magnetic soft materials with randomly dispersed particles. (b) Field-induced stiffening (magnetorheological effect) of anisotropic soft-magnetic soft materials with chained particles.

Anisotropic composites with chain-like microstructures can be obtained by applying an external magnetic field to the uncured mixture of soft-magnetic particles and polymer resin/solution during the fabrication process (Figure 3b). The applied field magnetizes the particles and induces dipolar coupling between the magnetized particles during the solidification of the composite mixture, after which the particle chains are immobilized within the polymer matrix, resulting in an anisotropic (or transversely isotropic) composite. When an external magnetic field is subsequently applied to this anisotropic composite along the chained particles, magnetic forces arise from the dipole-dipole interaction between the magnetized particles and help them maintain the interparticle orientation to oppose mechanical deformations, thereby increasing the apparent stiffness or modulus of the composite (Figure 3b),36,38,53 which is often termed the “magnetorheological effect” or field-induced stiffening. Owing to their ability to rapidly modulate the viscoelastic properties (stiffness and damping) in a reversible and controllable manner, magnetorheological elastomers and gels have found utility in vibration isolation or absorption applications.54–59

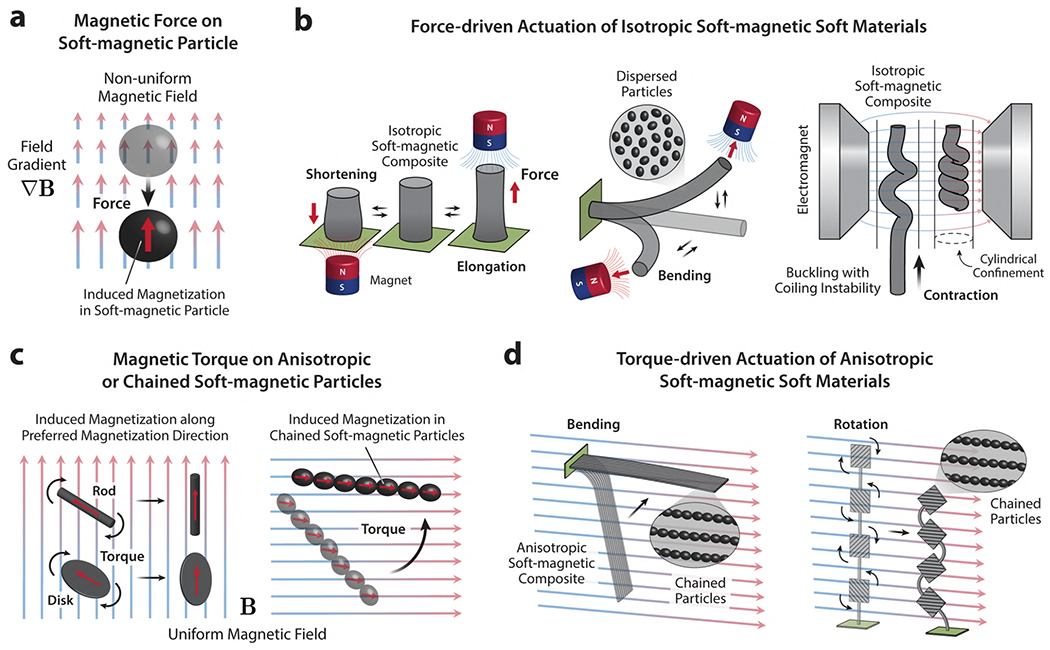

In the context of soft robotic applications, however, traditional soft-magnetic soft materials in the form of magnetostrictive or magnetorheological elastomers and gels have somewhat limited utility in terms of creating useful functions to perform a set of different tasks. For instance, it is challenging to reproduce walking gaits or grasping tasks, which typically utilize bending motions or complex shape changes, using the simple deformation based on uniaxial elongation of isotropic composites (Figure 3a). Magnetic torques can help to increase the level of complexity in terms of available actuation modes and achievable shapes by introducing additional degrees of freedom associated with the rotation of body parts. However, when the embedded soft-magnetic particles have spherical shapes, the individual particles cannot produce magnetic torques. This is because the induced magnetic moment in each particle is always aligned with the applied magnetic field, meaning zero torque, as a consequence of the spherical particles being magnetically isotropic to have no preferred magnetization direction (Figure 2e). For this reason, typical magnetosensitive elastomers and gels based on isotropic soft-magnetic soft materials have utilized force-driven magnetic actuation to create material deformation (shortening,60 elongation,42 or bending61) (Figure 4b) based on the attractive force acting on the magnetized particles under spatially nonuniform actuating fields (Figure 4a). Another force-driven actuation mode for isotropic soft-magnetic soft materials in the shape of a cylindrical rod utilizes buckling and coiling instability in the presence of confinement under a strong magnetic field,62–64 which leads to contraction of the rod in the axial direction to function as an artificial muscle (Figure 4b).

Figure 4. Different actuation modes of soft-magnetic soft materials.

(a) Magnetic force acting on a single soft-magnetic particle under spatially nonuniform magnetic fields. (b) Force-driven actuation modes for isotropic soft-magnetic soft composites under spatially nonuniform actuating fields: shortening,60 elongation,42 bending,61 and contraction based on buckling and coiling instability.62–64 (c) Magnetic torque acting on anisotropic or chained soft-magnetic particles under spatially uniform magnetic fields. (d) Torque-driven actuation of anisotropic soft-magnetic soft composites with chained soft-magnetic particles.65–67 It should be noted that the principle of torque-driven actuation of anisotropic composites based on chained soft-magnetic microparticles65 also holds for superparamagnetic nanoparticles.66,67

To produce magnetic torques from soft-magnetic materials, one needs to break the symmetry in their response to an externally applied magnetic field by introducing some form of magnetic anisotropy in the composite matrix. Such magnetic anisotropy can be introduced by either forming chains of isotropic particles to create asymmetry at the composite level65–67 (Figure 4c,d) or employing anisotropic filler particles with nonspherical shapes (e.g., rods, spheroids, platelets)68–71 to produce local asymmetry at the particle level (Figure 2e).18,69,72 However, the magnetic torque arising from the broken symmetry due to either anisotropic particle arrangement or anisotropic particle shape is intrinsically nonlinear and hence nontrivial.73 Unlike isotropic particles in which the magnetization is always induced along the applied field, the induced magnetization in a chain of spherical particles or in a non-spherical particle (Figure 4c) is largely dependent on their shape and orientation relative to the applied magnetic field. The magnetic torque produced by a chain of isotropic soft-magnetic particles or an anisotropic particle under an applied actuating field will be described more quantitatively in Section 3.2.2, where we discuss the principles of torque-driven actuation for anisotropic soft-magnetic materials based on idealized magnetic constitutive laws.

2.2.2. Hard-Magnetic Materials

The most distinctive feature of hard-magnetic materials is that they can become a stable and permanent source of magnetic field after being magnetized, due to their large magnetic hysteresis characterized by the high coercivity and high remanence (Figure 2b). For example, the coercivities of alnico (iron alloys consisting of aluminum, nickel, cobalt, and copper) range from 30 to 150 kAm−1, which is orders of magnitude greater than that of soft-magnetic materials. In hexagonal ferrites, such as barium hexaferrite (BaFe12O19)34,46,74 or strontium hexaferrite (SrFe12O19), the coercivity can be around 300 kAm−1. It can even exceed 1000 kAm−1 in rare-earth magnets such as samarium-cobalt (SmCo5 or Sm2Co17) or neodymium-iron-boron (Nd2Fe14B). The high coercivity allows them to be relatively insensitive to external conditions (e.g., temperature and magnetic fields) and have much greater resistance to being demagnetized when compared with soft-magnetic materials. In other words, hard-magnetic materials can retain their high remanent magnetization even when exposed to external magnetic fields (below the coercive field at which the magnetization reversal occurs) or elevated temperature (below the Curie point at which the material begins to lose its remanence). When hard-magnetic particles are incorporated into a soft polymer matrix, the resulting composite can exhibit hard-magnetic characteristics (i.e., high remanence and high coercivity) while being mechanically soft, acting as a flexible and deformable permanent magnet. We refer to this type of magnetic soft composite as hard-magnetic soft materials.

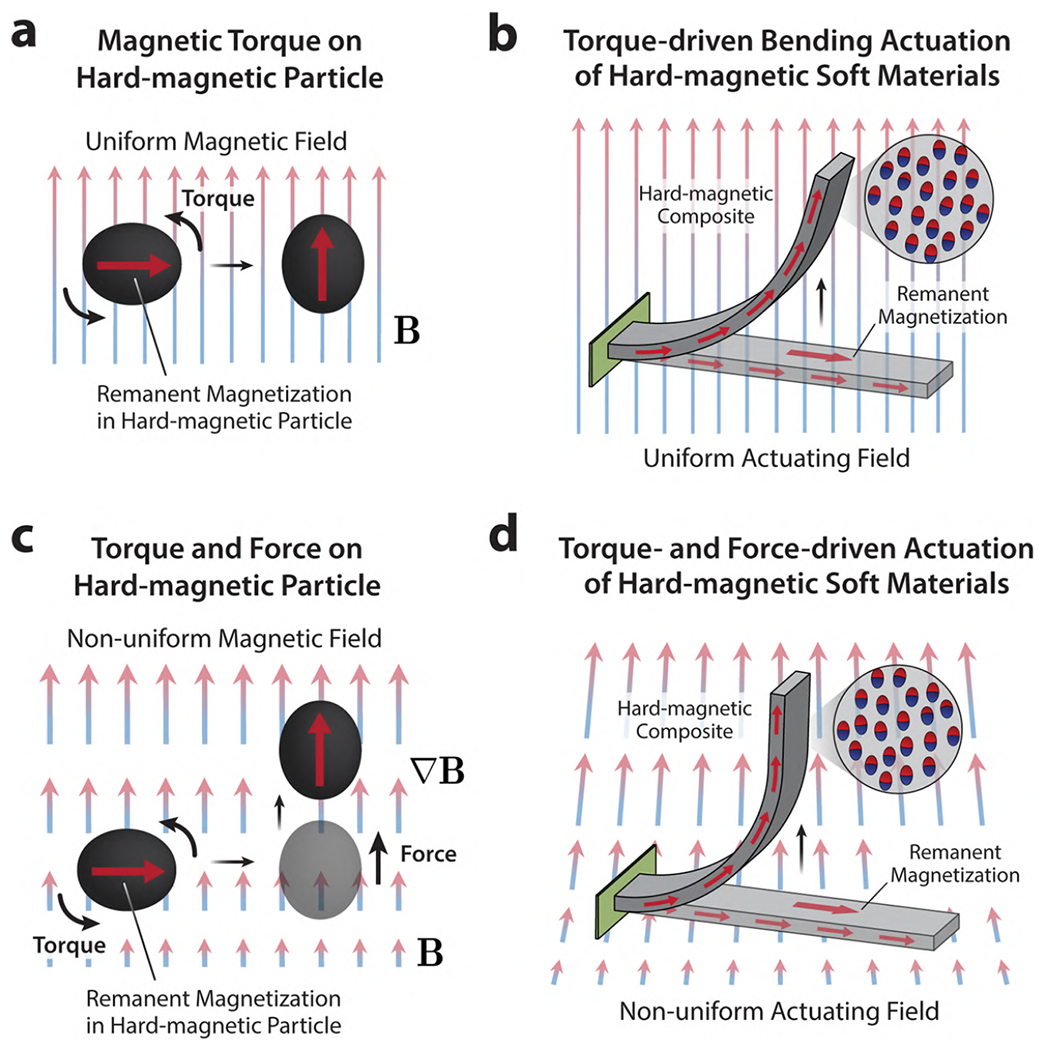

One of the unique advantages of using hard-magnetic materials is that magnetic torques can be readily exploited from individual magnetic dipole moments, which act as distributed and stable actuation sources under spatially uniform magnetic fields (Figure 5a). Once the embedded hard-magnetic particles are magnetized to saturation, their remanent magnetization can be considered almost independent of the external actuating field below the coercivity. The implication of this stable remanence is that the magnetic torque acting on the material linearly increases with the applied field within the actuation range below the coercivity. As a representative example of hard-magnetic soft actuators, we consider a simple rectangular beam composed of a hard-magnetic soft material that is uniformly magnetized to have its remanent magnetization formed along the length direction (Figure 5b). Under a spatially uniform actuating field that is applied perpendicularly to the beam, the embedded hard-magnetic particles tend to align their remanent magnetization with the actuating field due to the magnetic torques, creating bending actuation of the beam toward the applied field direction (Figure 5b). Under spatially nonuniform magnetic fields, magnetic forces as well as the magnetic torques act on the particles such that they are attracted toward the direction in which the field strength increases (Figure 5c), which helps to further increase the deflection of the beam (Figure 5d).

Figure 5. Torque- and force-driven bending actuation of hard-magnetic soft materials.

(a) Magnetic torque acting on a magnetized hard-magnetic particle under a spatially uniform magnetic field. (b) Rectangular beam made of a hard-magnetic soft composite that is uniformly magnetized along the length direction and its torque-driven bending actuation under a uniform actuating field that is applied perpendicularly to the beam’s remanent magnetization. (c) Magnetic torque and force acting on a magnetized hard-magnetic particle under a spatially nonuniform magnetic field, in which the particle not only rotates due to the magnetic torque but also moves toward the direction of the increasing field due to the attractive magnetic force. (d) Bending actuation of hard-magnetic soft materials under nonuniform actuating fields is initially driven by the magnetic torque and further supported by the increasing magnetic force as the body deforms to align its remanent magnetization with the applied field.

For such bending actuators, either isotropic or anisotropic hard-magnetic particles can be used. When using magnetically anisotropic hard-magnetic particles as distributed actuation sources (e.g., platelet-shaped barium hexaferrite particles), the neighboring particles should be oriented toward the same direction (Figure 1d) to be able to create macroscale bending actuation of the composite using the magnetic torques generated by the particles. This is because the preferred magnetization directions of magnetically anisotropic particles are constrained to their easy axes due to the shape-induced or magnetocrystalline anisotropy (Figure 2e). If the magnetized rods or platelets were randomly oriented in the composite (Figure 1c), with their magnetic moments pointing in different directions, the magnetic torques produced by the particles would cancel each other out to yield zero net torque at the composite level. The necessity of such particle alignment in the composite to produce a nonzero net torque implies that the composite is likely mechanically anisotropic to have greater stiffness along the aligned particles which essentially act as rigid, reinforcing elements.

For simplicity, it is also possible to use magnetically isotropic hard-magnetic materials such as rapidly solidified (e.g., melt-spun or gas-atomized) neodymium-iron-boron microparticles.75–77 Upon rapid quenching of the molten alloy, the solidified microparticles can develop nanocrystalline or amorphous microstructure with nanoscale grain size comparable to or less than a single magnetic domain, giving rise to their isotropic magnetization properties. Therefore, when magnetically isotropic hard-magnetic particles are used, the magnetic torque can be readily exploited regardless of the shape and orientation of the embedded particles, and thus the remanent magnetization within the composite matrix can be designed in a more flexible manner. Recent advances in the fabrication techniques have facilitated engineering hard-magnetic soft materials with programmable, complex shape-changing capabilities by enabling design of intricate magnetization patterns within the composite matrix. The resulting structures, as we shall see later, have demonstrated a rich array of actuation behavior due to the additional degrees of freedom controlled by the magnetic torque.

2.2.3. Superparamagnetic Materials

It is worth noting that the magnetization characteristics of certain magnetic materials are not necessarily their intrinsic material properties. That is, the same magnetic material can exhibit different magnetization behavior depending on its size, shape, crystalline microstructure, etc. For example, typical soft-magnetic materials such as iron, nickel, and cobalt can have relatively stable remanent magnetization when they are in the form of single-domain particles with anisotropic shape (e.g., nanorods or nanowires) due to the enhanced coercivity, which increases with their aspect ratios.78–81 The coercivity of magnetic materials is largely dependent on the particle size as well. When the size is sufficiently small (e.g., below a micrometer in diameter), magnetic particles prefer to stay uniformly magnetized and to avoid the formation of magnetic domains, exhibiting single-domain characteristics with high remanence. However, when the particles become smaller than a certain critical size, the coercivity starts to decrease drastically as the particles become more susceptible to thermal fluctuation and relaxation (Figure 2d). Hence, ferro- or ferrimagnetic particles smaller than the critical size would behave in a way analogous to paramagnetic materials with no hysteresis (i.e., no remanence in the absence of an external magnetic field), except for the fact that it still retains relatively high magnetic susceptibility (i.e., remaining strongly magnetic in the presence of an external field). For this reason, this type of behavior has been denominated as superparamagnetism. The magnetization curve of a superparamagnetic particle is characterized by the near absence of remanence and coercivity and is therefore typically modeled with the Langevin function (Figure 2c). Iron oxide nanoparticles, particularly magnetite (Fe3O4), are most commonly used for biomedical applications because of their biocompatibility.82–84

Magnetic soft composites with embedded superparamagnetic nanoparticles, which we refer to as superparamagnetic soft materials, are similar to soft-magnetic soft materials in the sense that they cannot produce magnetic torques without columnar microstructures of chained particles for providing magnetic anisotropy. Magnetic torques generated by the chained superparamagnetic nanoparticles have been demonstrated to be an effective means for driving small-scale soft bending actuators (Figure 4d).67,85,86 However, the maximum particle loading at which the nanoparticles are uniformly dispersed in the soft polymer matrix is in general far lower (i.e., typically below 10 vol%) than that of soft- or hard-magnetic microparticles.87,88 This can be attributed in part to the propensity of nanoscale magnetic particles to cluster and aggregate due to attractive van der Waals forces between the particles when the interparticle distance decreases as the particle volume fraction increases.89–91 For better dispersion and colloidal stability, magnetic nanoparticles need to be coated or functionalized with polymers to have thin shells to increase the electrostatic repulsion and steric interaction to balance the attractive forces.88–92 With the relatively low particle concentration, the field-induced stiffening or elongation behavior under an applied field is generally less pronounced in superparamagnetic soft materials than in magnetorheological elastomers or gels based on soft-magnetic microparticles. For these reasons, previously reported superparamagnetic soft materials mostly utilized magnetic forces acting on the embedded particles in the presence of field gradients (i.e., under nonuniform magnetic fields) to induce deformations at the composite level (Figure 2c),60,61,93,94 commonly in the form of macroporous sponge-like composites to maximize the strain. Overall, the relatively low particle concentration in superparamagnetic soft materials leads to low magnetic moment density per unit volume and therefore low magnetic torque and force densities in general, when compared with the other types of magnetic soft materials.

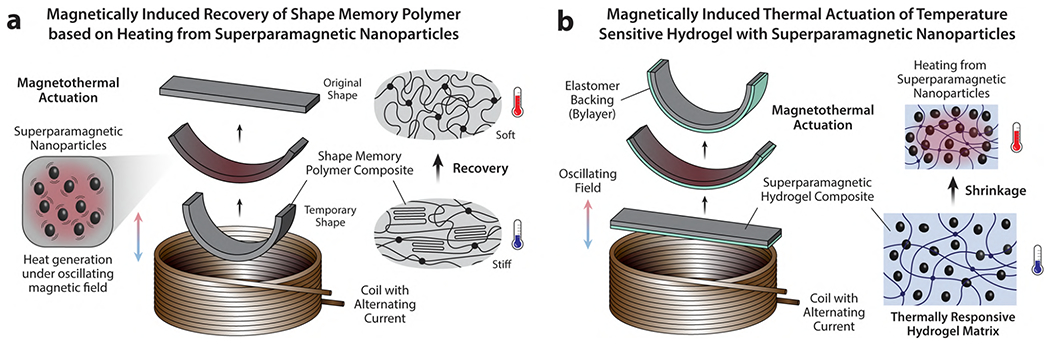

Although superparamagnetic nanoparticles may not be ideal for producing actuation due to the limitations discussed above, they could offer a unique advantage in converting electromagnetic energy into heat via thermal relaxation under an alternating magnetic field.83,95,96 Ferromagnetic microparticles can also produce heat by dissipating energy through other mechanisms such as magnetic hysteresis, where the area of the hysteresis loop is proportional to the dissipated energy. However, the energy dissipation in ferromagnetic microparticles during the cycle of magnetization and demagnetization would require either high field strength due to their greater coercivity or low frequency due to the longer time scale in their magnetization/demagnetization behavior, rendering it less effective and energy-efficient than generating heat using superparamagnetic nanoparticles. When superparamagnetic nanoparticles are incorporated into thermally responsive polymeric materials, such as shape memory polymers,97–102 liquid crystal elastomers,103,104 and temperature-sensitive hydrogels,105,106 internal heating through the released energy from the nanoparticles under alternating magnetic fields can be harnessed to induce programmed shape changes (Figure 6a) or control swelling/deswelling behavior of the composite (Figure 6b), producing indirect actuation that is different from direct magnetic actuation based on magnetic forces or torques.

Figure 6. Magnetothermal actuation of superparamagnetic soft materials based on thermally responsive polymer matrices.

The programmed shape changes of the composite structures are triggered by field-induced heating through thermal relaxation of the embedded superparamagnetic nanoparticles under alternating fields, which leads to (a) recovery of the shape memory polymer into the original shape or (b) deswelling (shrinkage) of the temperature-sensitive hydrogel in the form of bilayer structure.

2.3. Polymeric Components

Polymeric components of magnetic soft materials account for the elasticity of the composite matrices in which the magnetic filler particles are embedded. Forces and torques acting on the individual particles under an external magnetic field generate internal mechanical stresses, causing the soft polymer matrix to deform, the extent of which is determined by how soft or flexible the material or structure is and how the polymeric material behaves under the applied stress. A variety of soft elastomers and gels can be used as host polymers for the embedded magnetic fillers, and the choice of polymeric substances depends on various factors: desired mechanical (viscoelastic) properties of the composite, physicochemical properties of the chosen polymers and their compatibility with magnetic filler particles (especially when the particles are surface-treated or functionalized), required functions and target applications, environmental conditions, fabrication schemes, and so on. In the traditional sense of magnetic soft materials, polymeric components are mostly passive (Figure 1e), while the activeness comes only from the embedded magnetic particles in response to the actuating field. More recent studies have demonstrated multifunctional magnetic soft materials that utilize thermal or photothermal actuation in tandem with magnetic actuation by using stimuli-responsive materials such as shape memory polymers107–111 and liquid crystal elastomers112 as active polymeric components (Figure 1f). In the following sections, we discuss some commonly used soft polymeric materials and their characteristics in the context of magnetic soft actuators.

2.3.1. Passive Polymer Matrices

2.3.1.1. Elastomers

Among the various types of rubber-like soft materials, silicone-based thermosetting elastomers (Figure 1e) have been most commonly used as host polymers for magnetic soft materials, primarily because they are relatively easy to handle during the fabrication process for producing composite materials. In addition, there is a wide range of commercial products with different mechanical properties available off the shelf. Some of the representative products include Sylgard 184 (Dow Chemical), Ecoflex 00-10/00-20/00-30 (Smooth-On, Inc), and Elastosil RT604/RT625/RT745 or M4601/M4644 (Wacker Chemie AG), which are addition-curing type silicone elastomers that can be cured at either elevated temperature (faster curing) or room temperature (slower curing) upon the addition of platinum-based catalysts. Unless too heavily loaded, magnetic particles can be mixed easily with the base liquid of uncured silicone resin using a planetary centrifugal mixer before adding the catalysts. However, it is worth noting that microparticles or agglomerates of nanoparticles can settle in the uncured mixture after some time due to gravitational sedimentation of the dispersed particles, leading to phase separation in the composite mixture. For composites based on hard-magnetic microparticles, it has been shown that the uncured composite mixture can become a thixotropic paste when the dispersed particles are permanently magnetized, which helps to prevent the sedimentation of the dispersed particles over time.31 After mixing with the curing agent (catalysts), the composite mixture can be cast, molded, or printed to obtain desired shapes upon curing and solidification. The inclusion of rigid filler particles generally leads to the reinforcement of the elastomer, making the composite stiffer and less stretchable than unfilled elastomers. The increased stiffness and reduced stretchability can be compensated to some extent by lowering the cross-linking density of the silicone elastomer network by reducing the amount of the cross-linking agent during the fabrication process.

Thermoplastic elastomers have also been used as the host polymers for magnetic soft composites, where common types of materials include thermoplastic polyurethane65,66,113 and styrene-ethylene-butylene-styrene (SEBS),114–116 which are essentially block copolymers with alternating rigid and flexible segments. The rigid crystalline segments serve as physical cross-links to form a copolymer network (Figure 1e), while the flexible amorphous segments provide the network with elasticity.117 At elevated temperature, the rigid segment becomes disentangled and softer, making the polymers melt-processable. Upon cooling, the rigid segment solidifies again, and the material regains its strength and elasticity. Magnetic particles can be mixed into the molten thermoplastic elastomers through a process called melt blending or compounding, typically using a twin-screw extruder, and then formed into desired shapes through different manufacturing processes such as extrusion, injection, blowing, and compression molding. However, such melt-processing requires dedicated facilities that are often too bulky and costly for a single laboratory to have for research purposes. Hence, it is not uncommon to use organic solvents (i.e., tetrahydrofuran65 or dimethylformamide31) to dissolve the thermoplastic elastomers for blending with magnetic particles as well as processing at room temperature. The mixture can be cast, molded, or printed into desired forms that solidify upon evaporation of the solvent. This method, so-called solvent casting, however, inevitably entails a certain level of shrinkage of the composite volume during the solidification process as a result of the evaporation of the solvent molecules.

Thermoplastic elastomers in general have more desirable mechanical properties in terms of the strength and toughness and are hence more durable than silicone elastomers. However, magnetic soft composites based on thermoplastic elastomers generally exhibit smaller deformations due to their higher modulus values, when compared with softer silicone-based composites under the same conditions in terms of the geometry, magnetic particle concentration, and actuating field strength. Therefore, when it comes to design and actuation, magnetic soft materials and robots based on thermoplastic elastomers often require their structural rigidity (i.e., bending stiffness) to be smaller or the actuating magnetic fields to be stronger when compared with silicone-based magnetic soft materials and robots. In the context of biomedical applications, there exist medical-grade silicone and thermoplastic elastomers that are mechanically soft while at the same time biocompatible to be used for medical devices. Being thermosetting polymers, silicone elastomers are resistant to heat, and hence silicone-based magnetic soft materials can be readily sterilized by heat (dry heat or steam autoclave). When hard-magnetic components are used, however, elevated temperature can potentially affect the programmed magnetization pattern and the magnetization strength due to thermal relaxation and randomization as discussed earlier. Therefore, if applicable, the heat sterilization should precede the magnetization process during the fabrication; otherwise, other sterilization methods such as ethylene oxide treatment are preferred. Electron beam or gamma ray irradiation can be used, in principle, but these sterilization methods based on ionizing radiation can cause changes in the mechanical properties of silicone and thermoplastic elastomers,118,119 which may affect the actuation performance as well.

2.3.1.2. Gels

Gels generically refer to semisolids composed of cross-linked or colloidal polymer networks with entrapped liquids throughout the entire volume of the swollen polymer network (Figure 1e). With a relatively low polymer content, gels are generally much softer than elastomers. The focus here, in the context of magnetic soft materials and robots, is primarily on cross-linked gels (elastic solids), which exhibit much greater elasticity than colloidal gels (complex fluids with finite yield stresses). Composed of hydrophilic polymers, gels containing water as a swelling agent are referred to as hydrogels, while gels swollen in organic solvents or oils are referred to as organogels. Organogels based on styrenic block copolymers such as styrene-ethylene-butylene-styrene (SEBS) or styrene-butadiene-styrene (SBS) swollen in paraffin or mineral oils120–122 as well as polyurethane or silicone gels123 have been used with carbonyl iron particles, mostly for vibration isolation and absorption applications. For biomedical applications such as targeted drug delivery, hydrogels have been more commonly used because of their purported advantages in terms of biocompatibility or biodegradability.124 As the host polymers for magnetic filler particles, hydrogels based on naturally occurring polysaccharides such as alginate,60,93 carrageenan,59,125–127 and scleroglucan128 or hydrogels based on synthetic polymers such as poly(vinyl alcohol),43,129–131 poly(N-isopropylacrylamide),105,132–134 and polyacrylamide135–137 have been used. Poly(N-isopropylacrylamide) has been used to design thermally responsive magnetic soft robots with dual (magnetic and photothermal) actuation for multimodal locomotion134 or thermal actuation combined with magnetic guidance or navigation.132 When compared with elastomers, hydrogels are in general mechanically weak and brittle138,139 due mainly to their high water content (i.e., low polymer content), and so are most of the hydrogel-based magnetic soft composites. To improve their mechanical robustness while maintaining the softness, highly stretchable and tough hydrogels based on double networks of polyacrylamide-alginate61 or physically cross-linked poly(N,N-dimethylacrylamide) by nanoclays140 have also been adopted for magnetic soft materials.

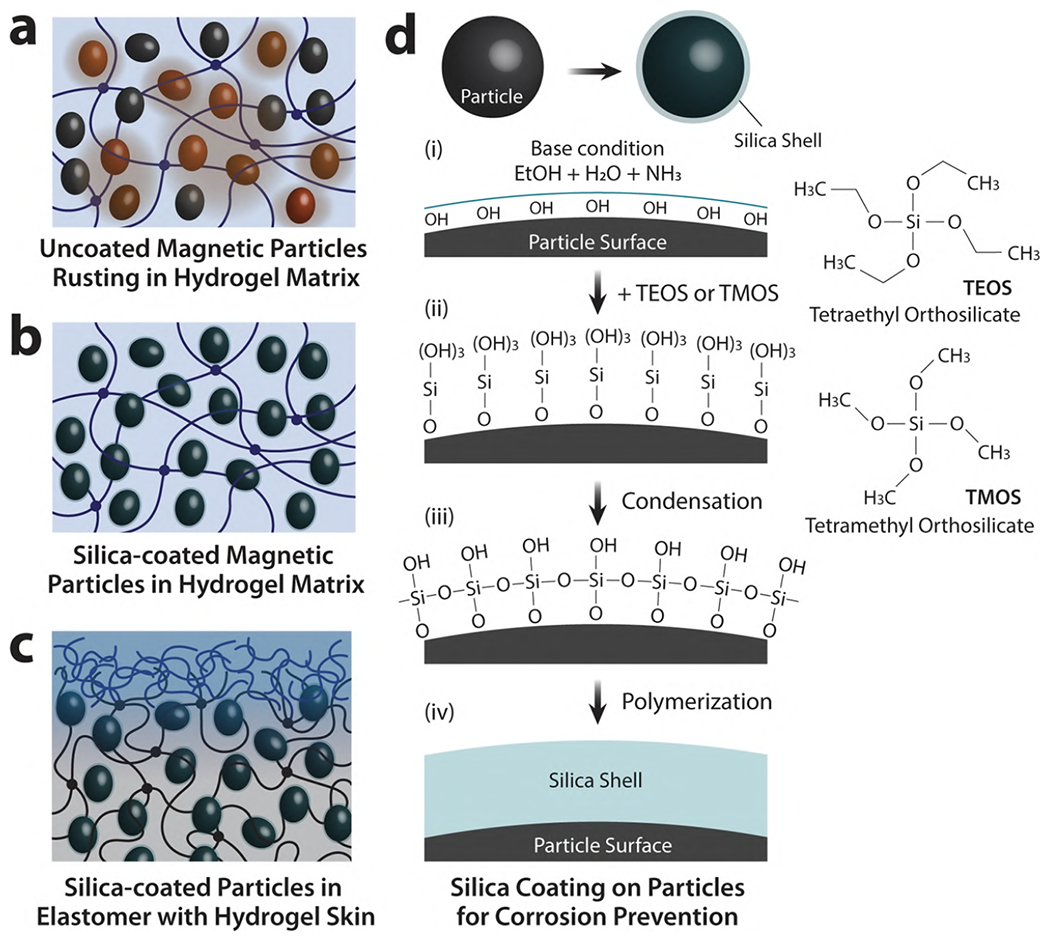

For hydrogel-based magnetic soft materials, it should be noted that ferromagnetic particles can be corroded in the aqueous environment of hydrogels (Figure 7a). The corrosion process can be accelerated in the presence of dissolved ions which are used as physical cross-linkers for ionically cross-linked hydrogels (e.g., alginate, chitosan, hyaluronan, etc.). Partly because of this corrosion problem, relatively inert (i.e., already oxidized) iron oxide nanoparticles have been more commonly used as filler particles for magnetic soft composites based on hydrogels. To prevent corrosion of ferromagnetic particles in hydrogels, protective coating can be applied to the particle surface (Figure 7b) through different methods. As an example, microparticles of carbonyl iron141–143 and neodymium-iron-boron31 can be coated with a thin layer of silica (SiO2) through hydrolysis and condensation of tetraethyl or tetramethyl orthosilicates (TEOS/TMOS), also known as the Stober method, followed by the nucleation of silica around the magnetic particles (Figure 7d). Other methods for introducing an inert passivation layer on the surface of ferromagnetic particles include plasma electrolytic deposition,144 atomic layer deposition,145,146 chemical vapor deposition,147 and those based on chemical reactions for surface polymerization and polymer grafting.148–150 Anti-corrosion coating is also useful for elastomer-based composites, when they are coated with hydrogel skin (Figure 7c) to enhance lubrication and biocompatibility for biomedical applications.31

Figure 7. Silica coating on magnetic particles for corrosion prevention.

(a) Corrosion of ferromagnetic particles in the aqueous environment of magnetic soft composites based on hydrogels. Silica-coated ferromagnetic particles for corrosion prevention in (b) hydrogel-based composites or (c) elastomer-based composites with hydrogel skin for biocompatibility and lubrication. (d) Schematic of the polycondensation reaction of tetraethyl and tetramethyl orthosilicate (TEOS/TMOS) in the presence of catalysts under basic conditions, in which the nucleation and polymerization of TEOS/TMOS give rise to cross-linked layers of silica around the magnetic particles.31

2.3.2. Active Polymer Matrices

Magnetic soft composites based on passive polymer matrices (i.e., elastomers or gels) undergo elastic deformation under an externally applied field and revert to their original shape upon the removal of the applied field. The fact that the deformed state can be maintained only in the presence of an external actuating field may in some cases be considered an inherent limitation of magnetic soft materials for their applications to where semipermanent shape changes are preferred.

Aimed at enabling magnetic soft materials to maintain their actuated state or deformed shape without continuously applying an actuating field, thermally responsive shape memory polymers (Figure 1f) have been adopted as the polymeric component of both soft- and hard-magnetic soft materials.107–111 Thermally activated shape memory polymers are generally stiff below the transition temperature and become softer and more malleable when heated to reach the transition point. When soft-magnetic or hard-magnetic particles are incorporated as distributed actuation sources in shape memory polymers, the composite can be deformed at or above the transition temperature into a desired shape through force- or torque-driven actuation under externally applied magnetic fields. Upon cooling below the transition point, the composite becomes stiffer again to maintain the deformed shape. The deformed composite can revert to its original shape when heated above the transition temperature in the absence of external fields or deform into a new temporary shape when heated in the presence of another actuating field to magnetically induce the deformation. It is worth noting that there is a key difference between this type of magnetically deformable shape memory polymer with shape-locking ability and the conventional type of magnetically activated shape memory polymers97–102 discussed earlier (see Section 2.2.3). The conventional type mostly used heat generated by the embedded superparamagnetic nanoparticles under oscillating fields to trigger the shape memory effect to recover its original shape from the temporary shape (Figure 6a) as an indirect means of magnetic actuation. When the two approaches are combined by adding different types of magnetic particles, such as hard-magnetic microparticles for magnetic actuation and superparamagnetic nanoparticles for magnetic heating, it has been shown that the composite can provide fully magnetically controlled actuation with shape-locking capability.107

Another class of stimuli-responsive polymeric substances for magnetic soft materials is liquid crystal elastomers, which are loosely cross-linked soft polymers containing anisotropic (rod-like) molecules called mesogens that are covalently attached to the polymers96,151 either as side chains or within the main chains (Figure 1f). When heated above their transition temperature, liquid crystal elastomers undergo a large contraction along the direction of mesogen alignment, as the mesogens undergo a phase transition from an ordered (nematic) state to a disordered (isotropic) state. Complex shape changes can be programmed into liquid crystal elastomers by controlling the mesogen alignment in the nematic phase. Unlike shape memory polymers with mostly one-way actuation, liquid crystal elastomers can produce large deformation in a reversible manner. As is the case with shape memory polymers, liquid crystal elastomers have also been used along with superparamagnetic nanoparticles to exploit magnetic heating for triggering the nematic-isotropic phase transition103,104 as discussed in Section 2.2.3. Recently, hard-magnetic soft composites based on liquid crystal elastomers have been used to develop small-scale untethered soft robots capable of distinct locomotion in different environments, such as walking on a solid surface or swimming by helical propulsion in a warm liquid after thermally induced shape change.112

3. Modeling of Magnetic Soft Materials

A comprehensive understanding of the fundamental principles for magnetic actuation, as well as the physical properties and behavior of magnetic materials, plays a key role in the design of magnetic soft materials and robots. When the behavior of magnetic soft materials is modeled, the different magnetic characteristics and constitutive relations for the chosen magnetic and polymeric components should be considered. For example, magnetized hard-magnetic particles can produce torques under externally applied fields, whereas soft-magnetic or superparamagnetic particles do not generate torques unless there is some form of magnetic anisotropy. Therefore, to exploit torque-based actuation with soft-magnetic or superparamagnetic materials, one needs to use particles with asymmetrical shapes or chained particles. In the following sections, we first review some of the fundamental magnetostatic relations and discuss how the magnetic force and torque can be formulated for hard-magnetic, soft-magnetic, and superparamagnetic soft materials.

3.1. Principles of Magnetic Actuation

3.1.1. Force and Torque on a Magnetic Dipole

The actuation of magnetic soft materials relies on forces and torques acting on the embedded magnetic components under externally applied magnetic fields. When a magnetic dipole (point-like source) with the magnetic moment m is located at the position x in free space under an externally applied magnetic field B, it possesses the magnetic potential energy um (also known as Zeeman energy) defined as the dot product of the two vector quantities as

| (1) |

A small variation in the position and orientation of the magnetic moment, with the constraint of fixed magnitude |m|, causes the change in the potential energy, which can be expressed as

| (2) |

For irrotational (i.e., curl-free) magnetic fields with no free electric currents (see Eq.(10) below), Eq.(2) can be transformed using relevant vector and tensor identities into an equivalent form as

| (3) |

where δx is the change in the magnetic moment position, and δθ is a vector that points along the axis of rotation with its magnitude corresponding to the angle of rotation of the magnetic moment m. In Eq. (3), grad B represents the spatial gradient of the applied magnetic field with respect to the point x. It is worth noting that the infinitesimal rotation of the magnetic moment δm is related to δθ by the following cross-product relation: δm = δθ × m. From Eq. (3), the magnetic force, fm, acting on the magnetic moment is given by

| (4) |

while the magnetic torque, τm, acting on the magnetic moment is given by

| (5) |

It is worth noting that Eq.(4) can be expressed equivalently as

| (6) |

using a more common expression in the literature based on the vector operator ∇ = (∂/∂xi) ei (also called the nabla operator), where ei represents the three Cartesian basis vectors (i = 1, 2, 3).

From Eq.(5) we know that the magnetic torque vanishes when the magnetic moment m is aligned (either parallel or antiparallel) with the actuating field B. We also know from Eq.(4) (or equivalently from Eq.(6)) that the magnetic force fm exists only in the presence of magnetic field gradients. This implies that the actuation based on spatially uniform magnetic fields is driven solely by the magnetic torque τm. Under spatially nonuniform actuating fields, magnetic forces as well as torques can contribute to the actuation of magnetic soft materials. In Eq.(6), (m · ∇) denotes the directional derivative in the direction of m multiplied by its magnitude. Physically, this implies that the magnetic force can be produced when there is a variation in the applied field in the direction of the magnetic moment. In general, it is the magnetic torque that drives the actuation by rotating the magnetic object to align its remanent or induced magnetic moment with the applied field, while the magnetic force attracts the aligned object in the direction of increasing field strength (Figure 5, c,d), usually toward the external source of actuating magnetic fields.

3.1.2. Fundamental Equations in Magnetostatics

In the presence of homogeneous magnetizable media, it is often more convenient to introduce an additional field, the H field, which shares with B the name and the status of magnetic field (for differentiation, B is usually termed the magnetic induction or flux density, while H is called the magnetic field).152 B and H fields are related by

| (7) |

where μ0 is the magnetic permeability of free space (vacuum) and M is the magnetization that measures the average magnetic moment density in the magnetic media (per unit volume). The magnetization vector at a material point x can be defined such that

| (8) |

where m is the total magnetic moment and V is the volume of the magnetic media. When the material is uniformly magnetized, Eq.(8) becomes m = VM. It is worth noting that B and H fields are simply related by B = μ0H in the absence of magnetizable media, under which Eqs.(1) to (6) can also be written in terms of H fields.

For magnetostatic systems with no time variation of the pertinent electromagnetic quantities, the Maxwell’s equations in differential forms can be stated as

| (9) |

| (10) |

where div B denotes the spatial divergence of B fields, curl B denotes the spatial curl of B fields, and J is the electric current density. The boundary conditions corresponding to Eqs.(9) and (10) are given by

| (11) |

| (12) |

where n is the outward unit normal to the boundary, ⟦ ⟧ denotes the jump of the field at the interface (i.e., ⟦B⟧ = Bout − Bin), and K denotes the surface current density. Eq.(9) is also known as Gauss’s law for magnetism and states that no magnetic monopoles exist and suggests that B fields should be solenoidal (divergence-free).

Substituting Eq.(7) into Eq.(9) leads to the definition of magnetic charge density, ρm, in the material (per unit volume) which is given by

| (13) |

from the analogy to the description of the electric charge density in electrostatics, except for the absence of magnetic monopoles, which are analogous to unpaired electric charges. Although they have no physical existence, the concept of magnetic charges often provides a useful abstraction when understanding the behavior of a magnetized body (Figure 8).152 Eq.(10) is usually referred to as Ampere’s law and can also be expressed by using Eq.(7) as

| (14) |

where Jf denotes the free electric current density, along with the definition of the magnetization current density Jm given by

| (15) |

with the total current density given by the sum of two: J = Jf + Jm. Eq.(14) requires H fields to be irrotational (curl-free) when there is no free current (i.e., Jf = 0), while Eq.(15) allows the magnetization to be treated as a current.

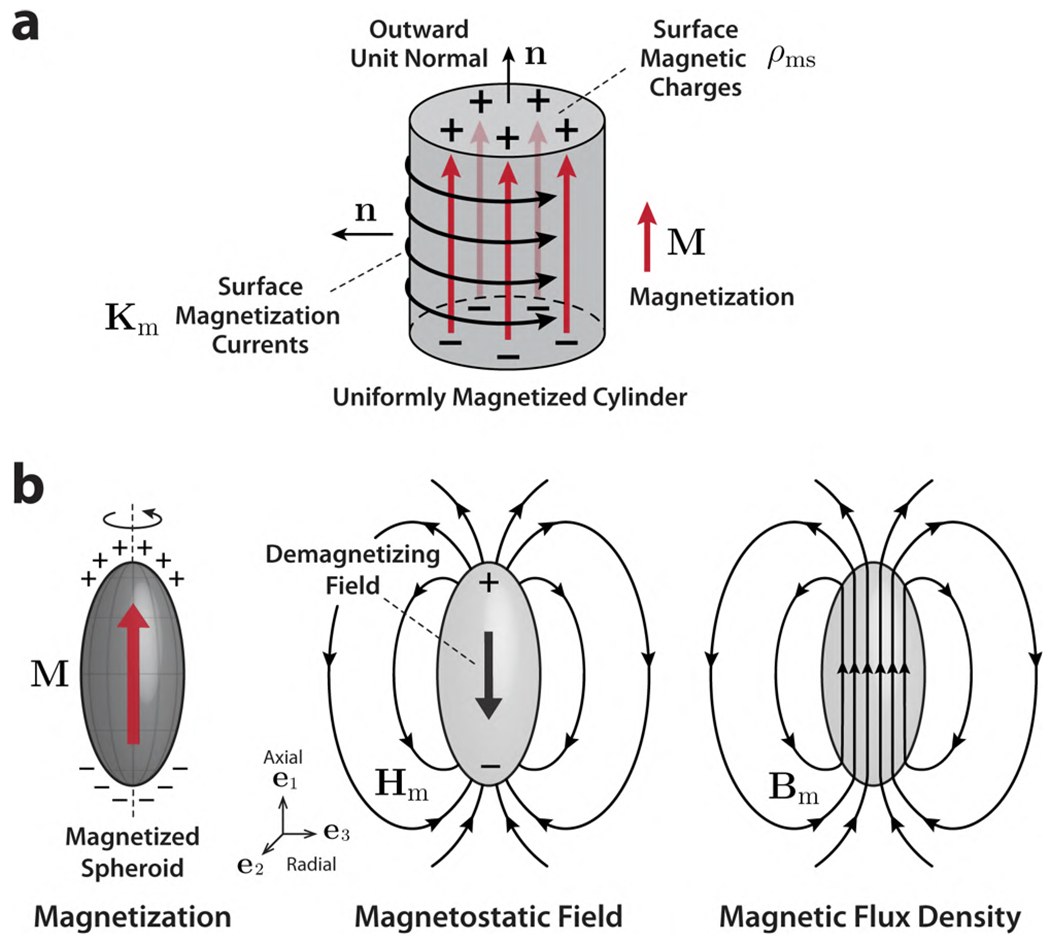

Figure 8. Graphical representation of a uniformly magnetized body.

(a) Uniformly magnetized cylinder with graphical representations of the surface magnetic charges (ρms) and the magnetization currents (Km). (b) Magnetization (M), magnetostatic field (Hm), and magnetic flux density (Bm) of a uniformly magnetized spheroid, which represent the effect of a demagnetizing field inside the magnetized body.

At the material surface, the magnetic surface charge density (per unit area), denoted by ρms, can be defined from Eq.(13) as

| (16) |

while the boundary conditions for Eqs. (14) and (15) are given by

| (17) |

| (18) |

where Kf denotes the free surface current density and Km is the surface magnetization current density. Since the magnetization is zero outside the body (Figure 8a), which yields ⟦M⟧ = −M, the boundary conditions for a magnetized body given in Eqs. (16) and (18) can be simplified as ρms = μ0M · n and Km = M × n, respectively.

The H fields being irrotational in the absence of free electric currents from Eq.(14) implies that the magnetic scalar potential, denoted by Φ, can be defined such that

| (19) |

from the vector identity, curl (grad f) = ∇ × (∇f) ≡ 0, which holds for any scalar field f(x). Then, from Eqs.(13) and (19), it follows that the magnetic scalar potential Φ obeys Poisson’s equation:

| (20) |

which reduces to ∇2Φ = 0 for uniformly magnetized materials with no divergence (∇ · M = 0).

3.1.3. Magnetostatic and Demagnetizing Fields

In the absence of magnetizable media (i.e., M = 0), the externally applied magnetic field in empty space can be expressed as Ba = μ0Ha from Eq.(7), with the subscript a used to denote the applied fields. When a magnetizable body is introduced into the space, it becomes magnetized by the externally applied field Ha to have the induced magnetization M inside the body. Then, it follows from Eq.(16) that positive and negative magnetic surface charges are induced on its top and bottom surfaces, respectively (Figure 8b). The surface charges induce another magnetic field, often termed the magnetostatic field and denoted by Hm, originating from the positive charge at the top and terminating on the negative charge at the bottom. Then, the total magnetic field H can be expressed as

| (21) |

and from Eq.(7), the corresponding B field (magnetic flux density) becomes

| (22) |

with Bm = μ0 (M + Hm) inside the body and Bm = μ0Hm outside the body and with Ba = μ0Ha everywhere. It is worth noting that because ∇ · Ba = ∇ · μ0Ha = 0 from Eq.(9), that Eqs.(13) and (16) can be expressed in terms of the magnetostatic field Hm by simply replacing H with Hm.

In a uniformly magnetized body, the magnetostatic field Hm acts to oppose the magnetization M and hence reduces the overall magnetization (Figure 8b). For this reason, the magnetostatic field Hm inside the body is often termed the demagnetizing field and is given by

| (23) |

where denotes the demagnetizing tensor. When the coordinate frame is chosen such that the Cartesian axes are aligned with the principal axes of the magnetized body, the demagnetizing tensor becomes diagonal in the following matrix form:

| (24) |

where Ni (i = 1, 2, 3) represents the three eigenvalues that correspond to the demagnetizing factors associated with each of the principal axes. These demagnetizing factors obey the general constraint N1 + N2 + N3 = 1, which suggests that N1 = N2 = N3 = 1/3 when the body is of spherical shape due to symmetry. For an ellipsoidal body with axial symmetry (i.e., the spheroid in Figure 8b), the demagnetizing factors are further constrained by N2 = N3 = (1 – N1)/2, with N1 denoting the demagnetizing factor along the axis of symmetry and N2 = N3 denoting the factors along the radial directions perpendicular to the symmetry axis.

In an idealized sense, a magnetic body can be considered an assembly of magnetic moments that are subject to magnetostatic interactions with each other. Then, the mechanical work spent in building the body by assembling the elementary magnetic moments can be represented by the magnetostatic energy, which is determined by the spatial distribution of the magnetization and by the geometric shape of the magnetic body. The magnetostatic energy density (per unit volume) is defined by

| (25) |

which is calculated as when the coordinate frame is aligned with the principal axes of the body. For isotropic (spherical) particles, the magnetostatic energy density can be expressed as with M denoting the magnitude of the magnetization.

3.2. Modeling of Magnetic Actuation

3.2.1. Idealized Magnetic Constitutive Laws

The constitutive law of a magnetic medium describes the material’s response to the magnetic field acting on it and can be stated in the form of either M(H) or B(H), with H denoting the field experienced by the material. In general, the constitutive laws for ferromagnetic materials can be quite complex when the magnetization process exhibits anisotropic, nonlinear, and hysteretic behavior. Therefore, to simplify the analysis without loss of generality, it is often practically more advantageous to idealize the constitutive laws for typical magnetic materials.

In soft-magnetic materials, the induced magnetization is largely dependent on the applied field and hence the magnetization process should be taken into account when modeling their behavior. In the presence of magnetic anisotropy, the induced magnetization is dependent on the particle orientation and can occur in directions other than that of the applied magnetic field. Ideal soft-magnetic materials are assumed to have no hysteresis (i.e., zero remanence and zero coercivity) as superparamagnetic particles (Figure 2c). In addition, at low fields below the saturating field, Hsat, the induced magnetization M in ideal soft-magnetic materials is assumed to increase linearly with the magnetic field H experienced by the material (Figure 9a), until it reaches the saturation magnitude (denoted Ms in Figure 9a). The constitutive law for such linearly magnetic materials can be stated as

| (26) |

where χm denotes the magnetic susceptibility of the soft-magnetic particle under the applied field and Ms represents the saturation magnetization of the particle. It is worth noting that χm is a dimensionless constant on the order of 103 to 106 for typical soft-magnetic materials. It is also worth noting that the graphical representation of the constitutive law for ideal soft-magnetic materials in Figure 9a shows the representative magnetization curve where both the induced magnetization M and the applied magnetic field Ha point along the same direction.

Figure 9. Idealized magnetic constitutive laws for soft-magnetic and hard-magnetic materials.

(a) Ideal soft-magnetic materials are characterized by the linear relationship between the induced magnetization and the magnetic field with constant magnetic susceptibility before saturation and constant magnetization after saturation without magnetic hysteresis (zero remanence and coercivity). (b) Ideal hard-magnetic soft materials are characterized by large magnetic hysteresis (high remanence and coercivity) to maintain the remanence under an actuating field below the coercivity.

In contrast to soft-magnetic materials, ideal hard-magnetic materials are considered to have strong hysteresis (i.e., high remanence and high coercivity). When hard-magnetic particles are magnetized to saturation, they can be regarded as small permanent magnets whose magnetic moments (or remanent magnetization) are independent of the actuating field below coercivity, Hc (Figure 9b). Thus, in the context of magnetic actuation, the constitutive law for ideal hard-magnetic materials can be expressed as

| (27) |

where Mr is the remanent magnetization of the hard-magnetic particle after magnetization. The constitutive law for ideal hard-magnetic soft materials in Eq.(27) implies that there is no energy transformation related to the magnetization process taking place during actuation.

3.2.2. Ideal Soft-Magnetic Materials

3.2.2.1. Shape-Induced Magnetic Anisotropy

The induced magnetization in soft-magnetic materials is largely dependent on the particle orientation due to the magnetic anisotropy and hence is not necessarily collinear with the applied magnetic field. Among the different causes of magnetic anisotropy, our focus here is on the shape-induced anisotropy, which originates from the magnetostatic energy when the particles are not of spherical shape. Applying the relations given in Eqs.(21) and (23), the linear constitutive law for soft-magnetic particles in Eq.(26) (for ) can be written as

| (28) |

which can be rearranged and expressed as a function of the externally applied field Ha as

| (29) |

where I denotes the identity tensor and is defined for convenience as the apparent magnetic susceptibility tensor,73 which relates the induced magnetization M in an anisotropic particle with the applied magnetic field Ha. Then the idealized constitutive law for soft-magnetic particles can be expressed in terms of the applied field Ha as

| (30) |

with denoting the applied field at which saturation takes place.

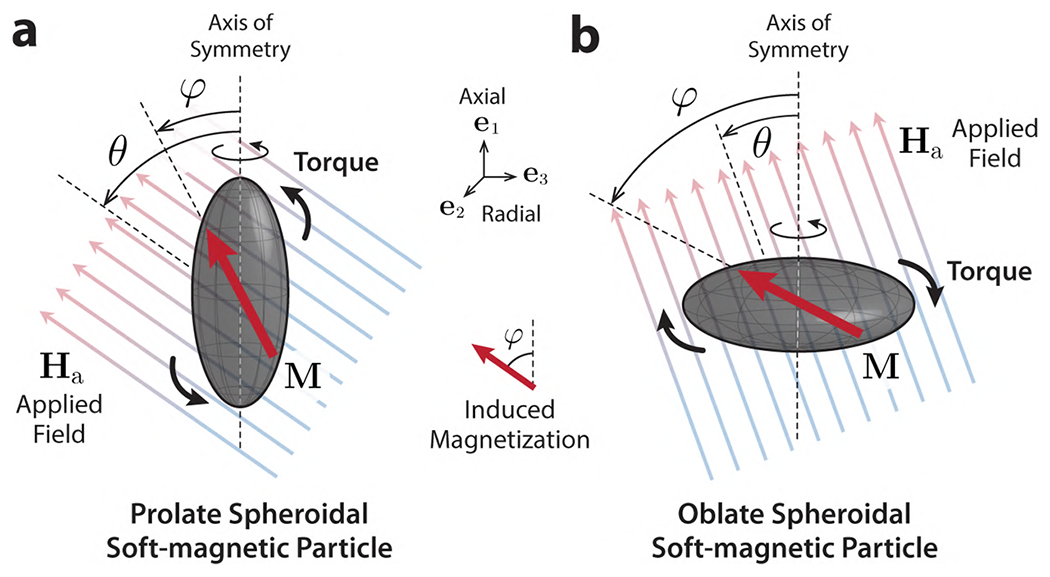

For isotropic soft-magnetic particles of spherical shape, the apparent magnetic susceptibility tensor is given by , which makes the two vectors M (induced magnetization) and Ha (applied magnetic field) collinear so as to produce no magnetic torques. For anisotropic (i.e., nonspherical) soft-magnetic particles, the susceptibility tensor is largely dependent on the particle shape as well as its orientation and hence can be complicated in general. To simplify the analysis while illustrating the soft-magnetic characteristics without loss of generality, we can assume that the particles are of ellipsoidal shape, for which the demagnetizing factors are known to have tractable analytical expressions.153 To make the problem even simpler, we can further assume that the ellipsoidal particles have axial symmetry to be essentially spheroids (Figure 8b). There are two types of spheroids: prolate spheroids have symmetry around their long (i.e., easy) axes (Figure 10a), whereas oblate spheroids are symmetric around their short (i.e., hard) axes (Figure 10b). When the coordinate frame is chosen to be aligned with the principal axes of the spheroidal particle, such that its symmetry axis lies with the Cartesian basis e1 (Figure 10), the demagnetizing tensor becomes diagonal as given in Eq.(24). Then, the apparent susceptibility tensor also takes the diagonal matrix form, which is given by

| (31) |

with N1 = NA denoting the magnetization factor along the symmetry axis of the spheroidal soft-magnetic particle and N2 = N3 = NR along the radial directions perpendicular to the symmetry axis under the constraint NA + 2NR = 1.

Figure 10. Anisotropic soft-magnetic particles of spheroidal shape.

(a) Prolate and (b) oblate spheroidal (ellipsoid with axis symmetry) soft-magnetic particles under externally applied magnetic fields (at an angle θ relative to the symmetry axis) and the induced magnetization (at an angle φ relative to the symmetry axis) that is not parallel to the applied field due to the presence of shape anisotropy.

3.2.2.2. Induced Magnetization Direction

When an actuating magnetic field Ha is applied to a spheroidal soft-magnetic particle at an angle θ with respect to the particle’s axis of symmetry (Figure 10), the magnetization M is induced toward the long axis (i.e., easy axis), forming an angle φ relative to the symmetry axis. Then, from Eqs.(29) and (31), it can be shown that the magnetization direction φ is related to the field angle θ by

| (32) |

where the approximation made can be considered reasonable because the magnetic susceptibility χm is typically very large (χm > 103) for soft-magnetic materials. We know from Eq.(32) that the magnetization direction φ for a given applied field at an angle θ relative to the particle’s axis of symmetry is determined by the ratio of the demagnetization factors along the axial and radial directions (NA/NR) at low fields before saturation (i.e., ).

At high fields beyond the saturating point (i.e., ), the magnetization direction φ can be determined such that it minimizes the magnetic energy. The magnetostatic energy density due to the demagnetizing field can be expressed (per unit volume of the particle) as

| (33) |

from the definition given in Eq.(25), with from Eq.(23) and the magnetization M replaced by the saturation magnetization Ms. For the given configuration in Figure 10, in which the principal axes of the spheroidal soft-magnetic particle are aligned with the coordinate frame to yield , the magnetostatic energy density can be calculated as

| (34) |

where denotes the magnitude of the saturation magnetization vector. The magnetized particle under the applied field Ba = μ0Ha possesses the magnetic potential energy density as well, expressed per unit volume and denoted by Um, which can be given from Eqs.(1) and (8) as

| (35) |

which holds for both the prolate and oblate spheroidal particle configurations in Figure 10. Then the total magnetic energy density is given by the sum of the magnetostatic energy density in Eq.(34) and the magnetic potential energy density Um in Eq. (35). Taking the derivative of this sum with respect to the magnetization direction φ, we know that the total magnetic energy density is minimized at φ = φ* which satisfies the following transcendental equation:

| (36) |

When the applied field is strong enough, we know from Eq.(36) that the induced magnetization direction φ* in the saturated particle approaches the applied field direction θ (i.e., φ* → θ), if the particle is fixed not to rotate despite the influence of magnetic torque.

3.2.2.3. Magnetic Torque on Anisotropic Particles

The magnetic force and torque density (per unit volume) acting on a soft-magnetic particle with the induced magnetization M can be expressed in terms of the applied field Ha as

| (37) |

| (38) |

with the bar symbol used to denote the force and torque density per unit volume, by replacing m with M and B with μ0Ha in Eqs.(4) to (6). Our focus here is on the modeling of the torque-driven actuation of soft-magnetic materials (Figure 4c,d). For the spheroidal soft-magnetic particle in Figure 10, the torque density can be calculated as , where the induced magnetization M is given as a function of the applied field Ha in Eq.(30).

Before saturation (i.e., ), the magnetic torque acting on the spheroidal particle per unit volume can be calculated using the apparent susceptibility tensor given in Eq.(31) as

| (39) |

which can be simplified as

| (40) |

for typical soft-magnetic materials with high magnetic susceptibility χm (e.g., χm > 103). From the equation above, we know that the magnetic torque on the particle is maximized at θ = 45°, when the actuating field (below the saturating field) is applied obliquely to the particle with an angle of 45° relative to the particle’s axis of symmetry (Figure 10).

At high fields beyond the saturating field (i.e., ), the magnetic torque density on the saturated spheroidal particle in Figure 10 can be expressed as

| (41) |

with φ* denoting the magnetization direction in the saturated particle. Using the relation given in Eq.(36), the torque in Eq.(41) can be expressed equivalently as

| (42) |

Since the saturation magnetization Ms and the applied field Ha become collinear at sufficiently high fields (i.e., φ* → θ), we can consider that the magnetic torque is maximized at θ ≈ 45° when the applied field strength is sufficiently high.

It is worth noting that, even when the particles are not of exact spheroidal shape, practical approximation can be made to simplify the analysis. For example, rod-like particles and disk-like particles (Figure 4c) can be approximated as prolate spheroids (Figure 10a) and oblate spheroids (Figure 10b), respectively. When the aspect ratio (i.e., the ratio of the long and short axes) is large enough, the demagnetizing factors for rod-like particles (very slender prolate spheroids) can be approximated as NA = 0 and NR = 0.5, whereas those for disk-like particles (very flat oblate spheroids) can be approximated as NA = 1 and NR = 0.18 Then, for rod-like particles, the magnetic torque density before and after saturation can be approximated from Eqs.(39) and (42) as

| (43) |

Likewise, for disk-like soft-magnetic particles, the magnetic torque density can be expressed as

| (44) |

For both the rod-like and disk-like particles (Figure 4c), the magnetic torque is maximized when θ = 45°, with the long axes of the particle misaligned by 45° from the actuating field below the saturating field (). Before saturation takes place, it is evident from Eq.(32) that the magnetization is induced preferentially along the long dimension of the particles with high aspect ratios, with φ = 0° for rod-like particles and φ = 90° for disk-like particles. When the particles are saturated, we know from Eqs.(41) and (42) that the magnetic torque can still be maximized when θ ≈ 45°, provided that the applied field is sufficiently high.

It should be noted that the analysis above is the first-order approximation that holds for ideal soft-magnetic materials, which are assumed to have no hysteresis, even when the particles are of anisotropic shape, to suppress the highly nonlinear and complex nature of magnetic hysteresis. As discussed in Section 2.2.3, single-domain soft-magnetic particles of anisotropic shape with high aspect ratios (e.g., nanorods or nanowires) can exhibit hysteresis, which is more pronounced in particles with higher aspect ratios.78–81 These single-domain soft-magnetic particles with high aspect ratios can be reasonably considered to have hard-magnetic characteristics, in the context of magnetic actuation, as permanently magnetized particles. When compared with typical hard-magnetic particles, however, they can be more easily demagnetized or remagnetized by lower fields, because their coercivity is not as high as that of typical hard-magnetic materials. For these reasons, the use of anisotropic soft-magnetic particles as distributed actuation sources has been limited mostly to small, thin features that require relatively weak magnetic torques for actuation. The fact that the coercivity of soft-magnetic nanorods varies with their aspect ratios has recently been employed as a strategy for selective magnetic programming in microfabricated shape-morphing structures with patterned nanomagnet arrays80 (see Figure 21a).

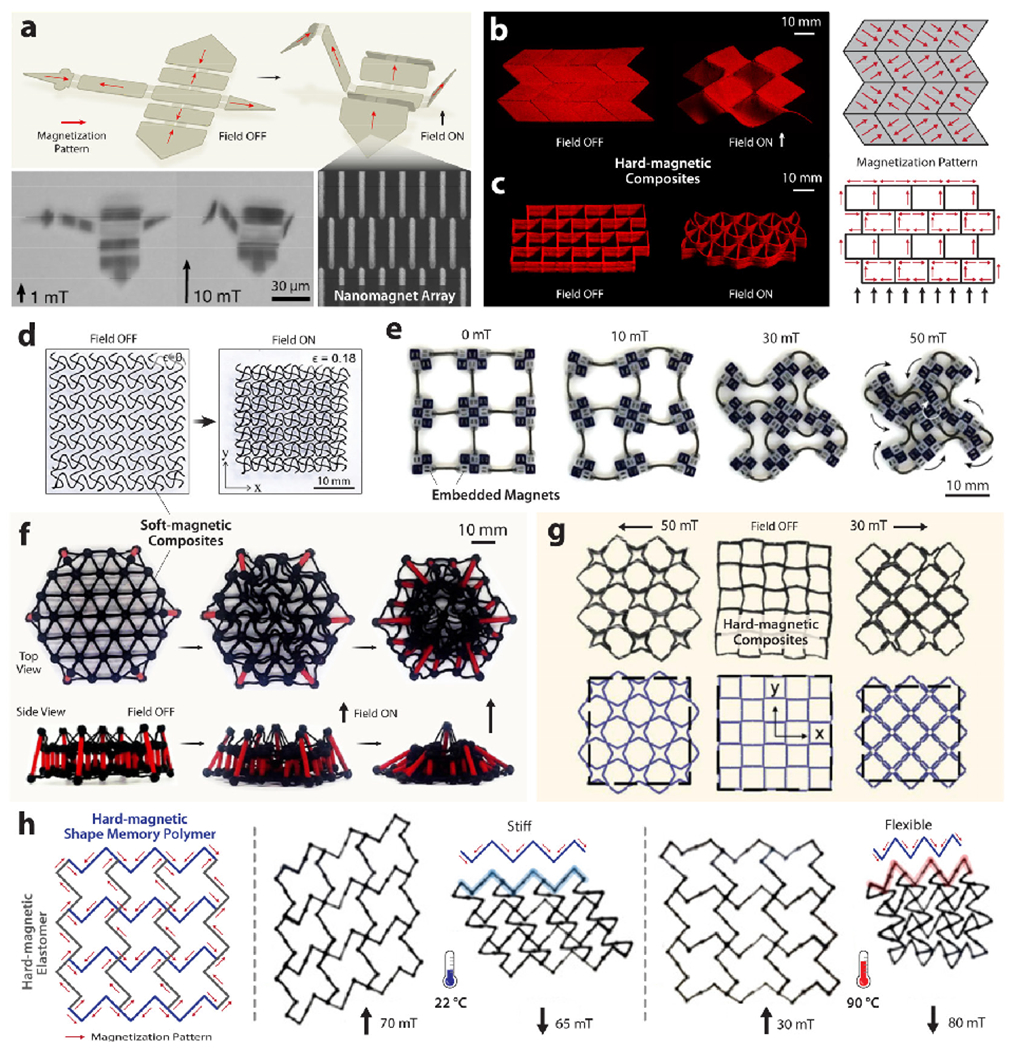

Figure 21. Applications of magnetic soft materials for magnetically reconfigurable active origami and metamaterials.

(a) Rigid panels with patterned nanomagnet arrays connected by microfabricated hinges morphing into a microscopic crane upon the application of an external magnetic field. (b) Miura-ori fold made of a hard-magnetic soft composite encoded with alternating oblique patterns of magnetic polarities. Auxetic structures with negative Poisson’s ratios based on 3D-printed (c) hard-magnetic (torque-driven) and (d) soft-magnetic (force-driven) composites exhibiting shrinkage in both length and width under applied magnetic fields. (e) Torque-driven auxetic behavior of a manually assembled structure based on embedded magnets connected by flexible members. (f) Tensegrity structure based on injection-molded soft-magnetic soft composites exhibiting force-driven auxetic behavior under an applied magnetic field. (g) 2D lattice structure based on manually assembled hard-magnetic composites connected by asymmetrically bendable joints exhibiting different torque-driven auxetic behavior depending on the applied field direction for magnetically tunable acoustic properties. (h) 3D-printed 2D lattice structure based on hard-magnetic elastomer and shape memory polymer exhibiting temperature-dependent torque-driven auxetic behavior. Panel (a) is reproduced with permission from refs 80 and 20 (Copyright 2019 Springer Nature); panels (b) and (c) from ref 156 (Copyright 2018 Springer Nature); panel (d) from ref 173 (Copyright 2019 Wiley); panel (e) from ref 212 (Copyright 2019 American Association for the Advancement of Science); panel (f) from ref 162 (Copyright 2020 American Association for the Advancement of Science); panel (g) from ref 324 (Copyright 2021 Wiley); and panel (h) from ref 110 (Copyright 2021 American Chemical Society).

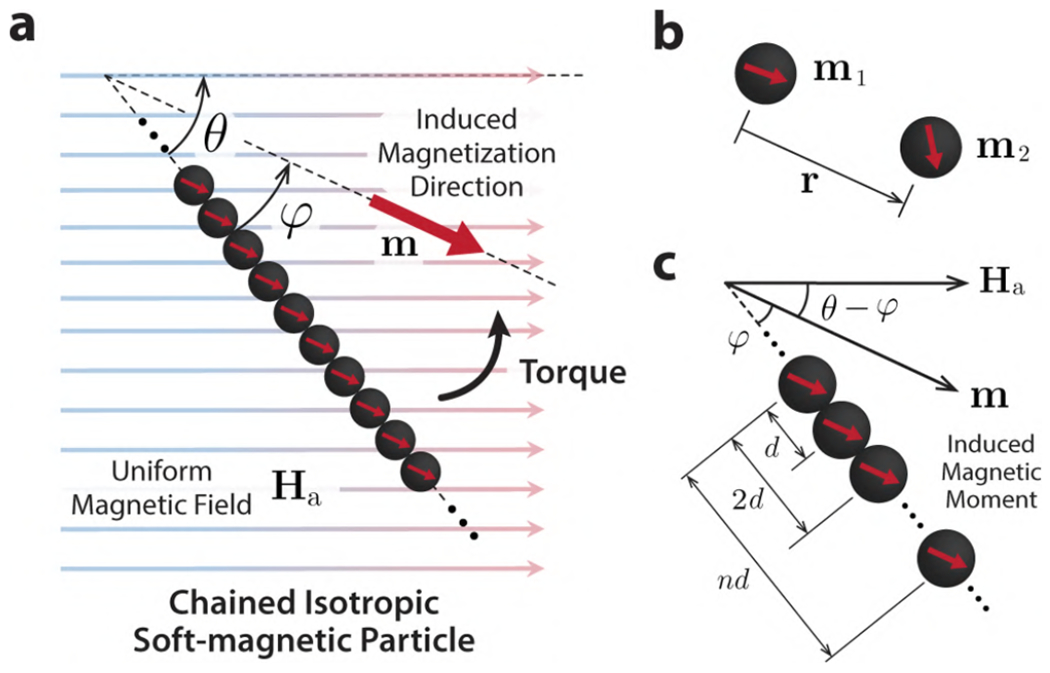

3.2.2.4. Chained Isotropic Soft-Magnetic Particles