Abstract

To meet future energy demands, currently, dominant lithium‐ion batteries (LIBs) must be supported by abundant and cost‐effective alternative battery materials. Potassium‐ion batteries (KIBs) are promising alternatives to LIBs because KIB materials are abundant and because KIBs exhibit intercalation chemistry like LIBs and comparable energy densities. In pursuit of superior batteries, designing and developing highly efficient electrode materials are indispensable for meeting the requirements of large‐scale energy storage applications. Despite using graphite anodes in KIBs instead of in sodium‐ion batteries (NIBs), developing suitable KIB cathodes is extremely challenging and has attracted considerable research attention. Among the various cathode materials, layered metal oxides have attracted considerable interest owing to their tunable stoichiometry, high specific capacity, and structural stability. Therefore, the recent progress in layered metal‐oxide cathodes is comprehensively reviewed for application to KIBs and the fundamental material design, classification, phase transitions, preparation techniques, and corresponding electrochemical performance of KIBs are presented. Furthermore, the challenges and opportunities associated with developing layered oxide cathode materials are presented for practical application to KIBs.

Keywords: cathode materials, intercalation chemistry, layered oxides, phase transitions, potassium‐ion batteries

Layered oxide cathodes for potassium‐ion batteries have gained considerable attention in recent years. This review provides outline of recent research advances in layered cathodes including conceptual understanding, synthesis methods, structural characteristics, and electrochemical properties. In addition, some future research directions to further improve overall performance of layered oxide cathodes in potassium‐ion batteries are presented.

1. Introduction

The ever‐growing energy demand and alarmingly increasing environmental pollution caused by the massive consumption of fossil fuels have driven the research community to focus on developing sustainable clean energy technologies.[ 1 ] Toward this goal, energy conversion and storage devices are both equally important for overcoming the global energy crisis.[ 2 , 3 , 4 , 5 ] Among various energy storage systems, lithium‐ion batteries (LIBs) have been the predominant power sources for consumer electronics and smart wearable devices owing to their high energy density, long cycling life, and easy maintenance.[ 6 , 7 ] Recently, LIBs have been utilized in transportation fields to power (hybrid) electric vehicles, which minimize CO2 emissions and noise pollution.[ 8 ] However, LIBs alone may not meet the future energy demands associated with the rapid growth of the electric vehicle market and stationary storage systems. Lithium is scarce and unevenly distributed in Earth's crust, which raises concerns about the soaring price of LIBs and the sustainability of lithium for meeting future energy demands.[ 9 , 10 ] Therefore, developing economical, high‐performance post‐LIBs is critical. Hence, sodium‐ion batteries (NIBs) and potassium‐ion batteries (KIBs) are promising alternatives or complements to LIBs because sodium and potassium are both abundant.[ 9 , 11 , 12 ] Interestingly, like LIBs, NIBs and KIBs operate by a similar “rocking‐chair” mechanism. Therefore, extensive knowledge about LIBs enables the rapid development of NIBs and KIBs. A schematic illustrating the KIB operating principle is shown in Figure 1a. Clearly, K+‐ions shuttle between the cathode and anode during charging and discharging.[ 13 , 14 ]

Figure 1.

a) Schematic illustration of working mechanism of KIB, b) standard redox potential of various metal anodes, and c) comparison of Shannon's ionic radius and Stokes radius in propylene carbonate of Li+, Na+ and K+.

Recently, KIBs have attracted considerable research interest because they have some advantages over NIBs and exhibit some properties comparable to those of LIBs. For instance, well‐established LIB graphite anodes are easily transferrable to KIBs because graphite can reversibly accommodate K+‐ions forming intercalation compounds such as KC8 [ 15 , 16 ] in contrast to the formation of NC70, which limits Na+‐ion intercalation into graphite.[ 17 ] The standard redox potentials of Li/Li+, Na/Na+, and K/K+ are −3.04, −2.71, and −2.93 V versus a standard hydrogen electrode (SHE), respectively (Figure 1b). The standard redox potential of K/K+ is comparable to that of Li/Li+ in aqueous electrolytes. Furthermore, the K/K+ redox couple exhibits even lower standard redox potentials than Li/Li+ in nonaqueous electrolytes such as propylene carbonate (PC) (−0.09 V vs Li/Li+) and a mixture consisting of ethylene carbonate and diethyl carbonate (EC:DEC) (−0.12 V vs Li/Li+).[ 18 , 19 ] The low K/K+ redox potential leads to a wider potential window for operating KIBs and will eventually achieve high‐energy‐density batteries. Alkali metal ion (e.g., Li+, Na+, and K+) transport properties influence the rate performance of this battery class. As shown in Figure 1c, although K+ (1.38 Å) ions are larger than Na+ (1.02 Å) and Li+ (0.76 Å) ones, K+ ions exhibit lower charge density and the lowest solvation and desolvation energies among the alkali metal ions, which facilitates rapid desolvation at the electrode–electrolyte interface. Furthermore, because K+‐ions weakly interact with solvent molecules, the smaller K+‐ion Stokes radius (Figure 1c) results in higher ionic conductivities and transference numbers.[ 20 , 21 ] Another advantage of KIBs over LIBs is that inexpensive aluminum current collectors can be used on both the cathode and anode sides because unlike lithium, potassium does not alloy with aluminum—which reduces the KIB cost and weight.[ 22 , 23 ] Regarding safety, NIBs exhibit an Na+‐ion insertion potential of 0.05 V versus Na/Na+ for a hard carbon anode, which is too close to the sodium metal plating potential, implying that dendrites will form in NIBs cycled at high current rates. In contrast, KIBs exhibit an average K+‐ion intercalation potential of 0.2 V versus K/K+ for most carbon anodes, which is well above the potassium metal plating potential, suggesting that KIBs are safer than NIBs.[ 24 , 25 ] However, although all these advantages make KIBs a promising alternative to LIBs, potassium metal must be handled with the utmost care when fabricating half cells because potassium metal is highly flammable.

The reversible intercalation of K+ ions into graphite anodes has shifted the research focus to designing and exploring suitable cathode materials for practical application to KIBs. Obviously, the cathode is the key component determining the KIB electrochemical characteristics, energy density, and cost. Recently, extensive research efforts have led to the development of various cathode materials such as Prussian blue analogs,[ 26 , 27 ] layered metal oxides,[ 28 , 29 ] polyanionic frameworks,[ 30 , 31 ] and organic compounds.[ 32 , 33 ] The application of layered metal‐oxide cathodes (such as LiCoO2) to commercial LIBs has attracted considerable interest in storing K+ ions in layered metal‐oxide cathodes for application to KIBs because the cathodes exhibit high capacity, large K+‐ion diffusion paths, and scalable synthesis. Recently, various groups have published reviews of KIB electrode materials and electrolytes.[ 9 , 14 , 18 , 19 , 20 , 21 , 23 , 34 , 35 , 36 , 37 , 38 ] From this perspective, a comprehensive review of cathode material advantages and challenges is critical to further develop KIBs.

Therefore, we report recent research progress on layered metal oxide cathodes for application to KIBs. First, we introduce the KIB charge storage mechanism and the advantages of KIBs over NIBs and LIBs. Then, the layered metal oxide structural classification and phase transitions are discussed. Recent works related to layered metal oxide cathodes for application to KIBs are summarized based on the number of transition metals used by focusing on the structural transformations and electrochemical performances of half‐ and full‐cell configurations. Finally, some strategies are proposed to suppress irreversible phase transitions and enhance the overall performance for future KIB development.

2. Structural Classification of Layered Transition‐Metal Oxides

Layered transition‐metal oxides can be represented by the formula A x MO2 (0 < x < 1), where A represents alkali metal ions (e.g., Li+, Na+, and K+), and M can be one or more transition‐metal ions in various oxidation states. Typically, layered K x MO2 compounds are formed with alternately stacked edge‐sharing MO6 octahedral layers and K+‐ion layers. P2‐, P3‐, and O3‐type layered K x MO2 can be synthesized based on the surrounding K+‐ion environment and the number of unique oxide layer stacking sequences.[ 39 ] P and O indicate whether K+ ions are in a prismatic or an octahedral coordination environment, respectively. Numbers 2 and 3 indicate the number of oxide layers in a single unit cell. Figure 2 shows a schematic illustrating the O3, P3, and P2 crystal structures. In O3 crystals, all the K+‐ions occupy octahedral sites, and oxide layer stacking follows the AB–CA–BC pattern. At high K+ concentrations (e.g., x = 1), strong electrostatic K+–K+ repulsion destabilizes K x MO2 layered compounds. O3‐KCrO2 is the only electrochemically active K x MO2 layered compound that forms O3 crystals.[ 40 ] In P3 crystals, oxide layer stacking follows the AB–BC–CA pattern, and K+ ions are at prismatic sites. P2 compounds are formed by AB–BA oxide layer stacking. In P2 crystals, K+ ions occupy distinct edge‐ or face‐sharing prismatic sites.[ 41 ] A prime symbol (ʹ) is used to specify the in‐plane distortion of hexagonal crystal lattices such as monoclinic Pʹ3‐K0.8CrO2.[ 42 ]

Figure 2.

Crystal structures of O3‐, P3‐, and P2‐type layered metal oxides.

The reaction temperature is critical for obtaining different crystals. Most P2 compounds stabilize at higher temperatures than P3 ones. For instance, P3‐K x CoO2 and P2‐K x CoO2 are synthesized at 400 ° C and 600 ° C, respectively.[ 43 ] The P3–P2 phase transformation occurs by breaking M—O bonds at high temperatures. Layered compound electrochemical behaviors are influenced by both the initial pristine compound K+‐ion content and structural stability. During K+‐ion extraction/insertion, O3 transitions to other phases because the MO2‐layer glides without breaking any M—O bonds. When a trace of K+‐ions is extracted, layer gliding changes the O3 oxide stacking pattern to the P3 one, which may be because larger K+‐ions prefer to occupy energetically favorable prismatic sites rather than smaller octahedral ones.[ 40 ] Neither O3 nor P3 materials can electrochemically transform into P2 ones because M—O bonds cannot break to form P2 materials during charging and discharging. However, P2 materials transition to O2 ones when the maximum K+‐ion concentration is extracted.[ 41 , 44 ] Therefore, owing to fewer phase transitions, P compounds are structurally more stable than O layered compounds.

3. Layered Metal Oxide Cathodes for KIBs

3.1. Single Metal Oxides

3.1.1. Manganese‐Based Electrodes

Vaalma et al. demonstrated the first‐ever nonaqueous KIB utilizing layered K0.3MnO2 as cathode, which exhibited an initial discharge capacity of 70 mAh g−1 and a reasonable capacity retention of 57% over 685 cycles at 27.9 mA g−1 in the potential window 1.5–3.5 V versus K/K+ (Figure 3a).[ 45 ] Nevertheless, K0.3MnO2 exhibited considerable capacity fading under the higher cutoff condition (1.5–4.0 V) possibly because of irreversible phase transitions at higher potentials. Furthermore, a KIB full cell was constructed as a proof‐of‐concept model, with K0.3MnO2 as the cathode and a hard carbon/carbon black composite as the anode, which encouraged researchers to develop different KIB electrode materials.[ 45 ] The number of K+‐ions in layered oxides plays a crucial role in obtaining different structures, morphologies, and electrochemical performances. Liu et al. synthesized P2‐K0.3MnO2 and P3‐K0.45MnO2 layered oxides by varying the K+‐ion concentration under the same experimental conditions.[ 46 ] Reportedly, the higher‐K+ P3‐K0.45MnO2 displayed smaller particles and slightly better cycling stability and rate performance than P2‐K0.3MnO2 (Figure 3b). In a wider potential window of 1.5–4.0 V versus K/K+, P3‐K0.45MnO2 delivered a specific capacity of 128.6 mAh g−1 at 20 mA g−1 and better rate performance with a specific capacity of 51.2 mAh g−1, even at a current density of 200 mA g−1.[ 46 ]

Figure 3.

a) Potential profiles of the 2nd and 50th cycle at 0.1 C in the voltage range 3.5–1.5 and 4.0–1.5 V. Reproduced with permission.[ 45 ] Copyright 2016, Electrochemical Society. b) Cycling performance of P2‐K0.3MnO2 and P3‐K0.45MnO2 at 20 mA g−1. Reproduced with permission.[ 46 ] Copyright 2019, Elsevier. c) Structural changes of P3‐K0.5MnO2 during charge and discharge. Reproduced with permission.[ 47 ] Copyright 2017, Wiley.

Kim et al. investigated the P3‐K0.5MnO2 electrochemical performance and structural changes during reversible K+‐ion deintercalation/intercalation.[ 47 ] The in situ XRD patterns generated during charging/discharging and corresponding computations elucidated the P3‐K0.5MnO2 K+‐ion storage mechanism and how the K+‐content influenced the phase changes. As shown in the in situ XRD patterns (Figure 3c), P3‐K0.5MnO2 reversibly transitions among P3, O3, and X during K+‐ion extraction and reinsertion. P3‐K0.5MnO2 delivered a specific capacity of 106 mAh g−1 when cycled between 1.5 and 3.9 V versus K/K+, and further increasing the potential to 4.2 V resulted in considerable stacking‐fault‐induced capacity fading when more K+‐ions were extracted at high potentials; thus, the voltage range must be appropriately tuned to optimize durable performance.[ 47 ] Structural morphology and particle size also play important roles in improving electrochemical performance. For instance, Peng et al. prepared P3‐K0.5MnO2 hollow submicrospheres (HSMSs) using two‐step self‐templating.[ 48 ] When tested as a KIB cathode material in the range 1.5–3.9 V versus K/K+, the P3‐K0.5MnO2 HSMSs demonstrated a capacity of 104 mAh g−1 at 10 mA g−1 and excellent capacity retention of 89.1% over 400 cycles at 200 mA g−1. The enhanced electrochemical performance was ascribed to the synergy between the particle size and the hollow spherical morphology. The full cell assembled with a graphite anode and the P3‐K0.5MnO2 HSMS cathode delivered an energy density of 100.7 Wh kg−1 at an average output of 2.09 V, which highlights the HSMS feasibility for practical application to KIBs.[ 48 ]

The major issues with manganese‐based layered cathodes are Jahn–Teller (J–T) active Mn3+ ions and the associated disproportionation reaction (2Mn3+ → Mn2+ + Mn4+), which generate an asymmetric cathode structure and lead to Mn2+‐ion dissolution into the electrolyte during cycling.[ 49 , 50 , 51 , 52 ] To circumvent these issues and stabilize Mn‐based cathode performance, different strategies have been employed. Notably, Lei et al. reported the in situ formation of a dual interface on an Mn‐based P2‐K0.67MnO2 cathode consisting of an inactive K‐poor spinel interlayer and a stable solid–electrolyte interface (SEI) film (Figure 4a). The dual interface layers accommodated J‐T distortion, alleviated Mn dissolution, and improved the K+‐ion diffusion kinetics, which resulted in good rate performance, a small volumetric change of 9.9%, stable operation for 300 cycles, and a capacity retention of 90.5% at 50 mA g−1.[ 53 ]

Figure 4.

a) Formation mechanism of the dual interphase layers composed of a SEI layer and spinel interlayer on P2‐KMO during cycles. Reproduced with permission.[ 53 ] Copyright 2019, Elsevier. b) Schematic illustration of the synthesis process of AlF3@S‐KMO. c) Cycling performance at 50 mA g−1 before and after refreshing the potassium metal anodes and electrolyte. Reproduced with permission.[ 54 ] Copyright 2019, Wiley.

Zhao et al. coated the surface of K1.39Mn3O6 microspheres with AlF3 to enhance their electrochemical performance (Figure 4b).[ 54 ] The AlF3‐coated K1.39Mn3O6 delivered a specific capacity of 110 mAh g−1 at 10 mA g−1 and outstanding cycling stability with a capacity retention of 94.9% over 100 cycles, which was far superior to the electrochemical performances of both the noncoated microspheres and the bulk counterpart (Figure 4c).[ 54 ] Therefore, surface modification is an efficient method of mitigating unwanted parasitic reactions and stabilizing cathode interfaces.[ 54 ]

3.1.2. Cobalt‐Based Electrodes

Although Delmas et al. synthesized and structurally characterized K x CoO2 crystals in 1975,[ 55 ] K+‐ion deintercalation/intercalation was not studied for K x CoO2 compounds until 2017 by Hironaka et al.[ 43 ] Because the synthesized P2‐K0.41CoO2 and P3‐K2/3CoO2 were moisture sensitive, they had to be handled in an argon atmosphere. Both P2‐K0.41CoO2 and P3‐K2/3CoO2 delivered similar specific capacities of ≈60 mAh g−1 in the potential window 2.0–3.9 V versus K/K+. The multistep voltage profile originated from strong K+/vacancy ordering, which is supported by the operando XRD results. Compared to O2‐LiCoO2, P2‐Na2/3CoO2 and P2‐K0.41CoO2 both displayed a steep voltage drop (Figure 5a), which mainly depended on the ionic radius interslab distance and determined the alkali‐metal ion battery working voltage.[ 43 ] P2‐K0.6CoO2 synthesized with a higher K+‐ion content delivered a specific capacity of 80 mAh g−1 at 2 mA g−1 and average output of 2.7 V versus K/K+.[ 56 ] P2‐K0.6CoO2 maintained the P2 structure when the K+‐ion content was varied between 0.33 and 0.68, thereby implying a reversible topotactic reaction (Figure 5b); however, P2‐K0.6CoO2 exhibited poor cycling stability likely due to side reactions with the electrolyte.

Figure 5.

a) Voltage curves of A//AxCoO2 (A = Li, Na, and K). Reproduced with permission.[ 43 ] Copyright 2017, Royal Society of Chemistry. b) Typical charge/discharge profile at a current rate of 2 mA g−1 and in situ XRD patterns of P2‐K0.6CoO2. Reproduced with permission.[ 56 ] Copyright 2017, Wiley. c) Rate capability of s‐KCO and i‐KCO at different current rates; Typical charge‐discharge curves of s‐KCO//K and hard carbon//K in a half‐cell and s‐KCO//hard carbon full‐cell configurations. Reproduced with permission.[ 57 ] Copyright 2018, American Chemical Society.

In another study, P2‐K0.6CoO2 (s‐KCO) microspheres were synthesized using self‐templating.[ 57 ] The s‐KCO electrode demonstrated a high specific capacity of 82 mAh g−1 at 10 mA g−1, high‐rate capability, and excellent cycling stability with 87% capacity retention over 300 cycles at 40 mA g−1 (Figure 5c). The hierarchical microsphere structure provided fast K+‐ion and electron transport pathways and minimized the contact area between the electroactive materials and the electrolyte, thus reducing undesirable side reactions and enhancing K+‐ion storage in P2‐K0.6CoO2. Furthermore, the s‐KCO//hard carbon full cell exhibited a high capacity of 71 mAh g−1 at 30 mA g−1 and excellent capacity retention (>80%) after 100 cycles.[ 57 ]

3.1.3. Chromium‐Based Electrodes

Most layered K+‐ion compounds prepared are having lower K+ concentrations than sodium and lithium analogs[ 43 , 58 , 59 , 60 ] because strong K+–K+ repulsion cannot accommodate all the K+ ions in the K+‐ion layer, thus generating K+‐deficient compounds (K x MO2; x ≤ 0.7). Computational studies have indicated that only KScO2 and KCrO2 are thermodynamically stable layered compounds (Figure 6a). Kim et al. prepared stoichiometrically layered O3‐KCrO2 and investigated its electrochemical performance as a KIB cathode.[ 40 ] The layered KCrO2 was stabilized owing to the unusual Cr3+‐ligand‐field preference for octahedral sites, which compensated for the K+–K+‐repulsion‐induced energy penalty. O3‐KCrO2 delivered a discharge capacity of 92 mAh g−1 at 5 mA g−1 and exhibited a multistep voltage profile (Figure 6b). During charging, the O3‐KCrO2 cathode reversibly transitioned among O3–Oʹ3–Pʹ3–P3–Pʹ3–P3–O3 (Figure 6c). These phase transitions are more complex than those observed for O3‐NaCrO2, which is attributed to strong K+–K+ interactions. Moreover, the incomplete recovery of K+ ions—even at the end of discharging—shows that the Oʹ3 structure is not converted into the O3 one, which is likely owing to the sluggish K+‐ion kinetics when x ≈ 1 in K x CrO2. The full cell constructed using the O3‐KCrO2 cathode and a graphite anode exhibited a capacity of ≈82 mAh g−1 at 5 mA g−1.[ 40 ] This work provides insight into the design of stoichiometrically layered compounds for application to KIBs. Naveen et al. synthesized layered O3‐KCrS2 with a stoichiometric amount of K+. O3‐KCrS2 exhibited high electrochemical reversibility between P3‐K0.39CrS2 and O3‐K0.80CrS2 because the material mostly retains the P3 structure

Figure 6.

a) Thermodynamic stability of layered KMO2 compounds. b) Typical voltage‐capacity curves at a current rate of 5 mA g−1 and c) in situ XRD patterns of O3‐KCrO2. Reproduced with permission.[ 40 ] Copyright 2018, American Chemical Society.

during K+ deintercalation/intercalation, thereby enabling fast K+‐ion diffusion through larger prismatic sites. The O3‐KCrS2 cathode delivered a specific capacity of 71 mAh g−1 and excellent cycling stability with ≈90% capacity retention over 1000 cycles owing to the soft sulfide framework, which buffered the K+‐deinsertion/insertion‐induced stress.[ 61 ]

Hwang et al. prepared another Cr‐based cathode, P3‐K0.69CrO2, from O3‐NaCrO2 through electrochemical ion exchange, which is an efficient process when synthesizing layered compounds is difficult using the conventional solid‐state method.[ 62 , 63 , 64 , 65 ] The P3‐K0.69CrO2 cathode exhibited a discharge capacity of 100 mAh g−1 at 10 mA g−1 in the range 1.5–3.8 V versus K/K+. Although this cathode exhibited staircase‐like voltage profiles, it reversibly transitioned between P3 and P″3 and exhibited outstanding long‐term cyclability at 100 mA g−1 with 65% capacity retention over 1000 cycles.[ 66 ] Further studies are required to optimize the electrolyte and reduce the slow ion exchange to improve the potential for practical applications. Naveen et al. developed a facile method of synthesizing Pʹ3‐K0.8CrO2.[ 42 ] The Pʹ3‐K0.8CrO2 cathode displayed different O3‐KCrO2 phase transitions, resulting in different electrochemical performances. The absence of the O3 phase and persistence of the Pʹ3 ones in most redox states contributed to limited volumetric changes (ΔV = 1.08%) and rapid K+‐ion diffusion, which eventually resulted in improved cyclability and 99% capacity retention at 218 mA g−1 after 300 cycles.[ 42 ]

3.1.4. Vanadium‐Based Electrodes

Vanadium oxides have been investigated as cathode and anode materials for application to rechargeable batteries owing to their versatile structures, multiple vanadium valence states, high specific capacities, and high electrochemical reactivity.[ 67 , 68 , 69 , 70 ] K0.5V2O5 exhibits a layered structure formed by edge‐sharing octahedral VO6 and K+ ions sandwiched between the layers (Figure 7a).[ 71 ] The K0.5V2O5 cathode delivered a specific capacity of 90 mAh g−1 at 10 mA g−1 in the range 1.5–3.8 V versus K/K+. To prepare a full cell using carbon‐based anodes, a suitable cathode must exhibit numerous extractable K+ ions because the cathode serves as a reservoir for reversible K+ ions. Although only a trace of K+ ions was extracted from K0.5V2O5 during the initial charging (Figure 7b), this problem was solved by prepotassiation.[ 71 ] Clites et al. prepared K+‐preintercalated bilayered K x V2O5·nH2O by the sol–gel method.[ 72 ] During synthesis, K+ ions and water molecules are trapped between growing vanadium oxide bilayers to form δ‐K x V2O5·nH2O (Figure 7d). The δ‐K x V2O5·nH2O cathode demonstrated a high initial capacity of 226 mAh g−1 at 20 mA g−1. K+‐ion extraction and insertion were accompanied by a reversible change between V5+ and V3+ involving two electrons. The enhanced δ‐K x V2O5·nH2O performance is attributed to well‐defined sites for electrochemically cycled K+ ions and the large interlayer spacing achieved through chemical preintercalation.[ 72 ]

Figure 7.

a) Crystal structure of K0.5V2O5, b) galvanostatic charge/discharge voltage profiles, c) rate capability of K0.5V2O5. Reproduced with permission.[ 71 ] Copyright 2018, Wiley. d) Schematic illustration of chemical pre‐intercalation synthesis approach. Reproduced with permission.[ 72 ] Copyright 2018, American Chemical Society. e) Ex situ XRD patterns of the K2V3O8 electrode at various charge/discharge states at 10 mA g−1. Reproduced with permission.[ 73 ] Copyright 2019, Royal Society of Chemistry.

Yang et al. hydrothermally synthesized K2V3O8, and the cathode delivered a discharge capacity of 107.8 mAh g−1 at 10 mA g−1.[ 73 ] The use of a highly concentrated electrolyte [7 m potassium bis(fluorosulfonyl)imide (KFSI) dissolved in EC:DEC] supported K2V3O8 cycling in a wide potential range 4.5–1.5 V versus K/K+, and the cathode discharged an average of 2.7 V. However, the cathode exhibited poor cycling stability with only 73% capacity retention after 50 cycles. Ex situ XRD (Figure 7e) revealed that the capacity degraded because K2V3O8 undergoes nontopotactic K+‐ion extraction/insertion and reversibly changes between K2V3O8 and K2V3O8 accompanied by huge volumetric changes (ΔV ≈ 23.4%), which caused the electrode materials to mechanically fail.[ 73 ] In the context of layered compounds prepared with high initial K+‐ion contents, Zhang et al. synthesized K0.83V2O5.[ 74 ] The cathode delivered an initial charge capacity of 86 mAh g−1 and a reversible capacity of 90 mAh g−1 at 10 mA g−1. Furthermore, it exhibited cycling stability with 86% capacity retention over 200 cycles. The full cell fabricated using the K0.83V2O5 cathode and a graphite anode demonstrated an energy density of 136 Wh kg−1 with an average output of 2.4 V. This study provides some insights for designing high‐K+‐content layered cathode materials for application to emerging practical KIBs.[ 74 ]

In short, the layered single metal oxide cathodes demonstrated reversible K+ deintercalation/intercalation suitable for K+ storage in KIBs. However, these single metal compounds suffer from poor air stability, complex phase transitions, slope voltage, capacity fading, and insufficient cycling stability. Therefore, modifying the structure and composition by substituting suitable metals could alter the crystal lattice parameters and thus leading to improved structural stability and electrochemical performance.

3.2. Dual Metal‐Based Electrodes

Although researchers initially focused on single metal oxide‐based electrodes to explore layered cathodes for application to KIBs, the shortcomings of single metal oxide‐based cathodes such as low capacity, structural instability, multistep voltages, rapid capacity decay, and low average voltages must be overcome to design efficient and durable cathodes for application to practical KIBs. Although Mn‐based layered compounds appear to be promising materials because of their reasonable capacities, low cost, and environmentally benign manganese, Mn3+‐induced J‐T distortion and related structural changes lead to poor electrochemical performance.[ 75 , 76 , 77 ] To circumvent these issues, many researchers have doped Mn with other metals and eventually enhanced electrochemical performance.

3.2.1. Mn/Fe‐Based Electrodes

Designing electrodes using low‐cost abundant materials is attractive because it will reduce the overall battery cost. Wang et al. reported the first‐ever abundant Fe/Mn‐based K0.7Fe0.5Mn0.5O2 layered oxide cathode nanowires, which delivered a high discharge capacity of 178 mAh g−1 at 20 mA g−1.[ 78 ] The unique interconnected K0.7Fe0.5Mn0.5O2 nanowire morphology resulted in superior cycling stability with 87% capacity retention at 500 mA g−1 after 200 cycles. Furthermore, the K0.7Fe0.5Mn0.5O2//soft carbon full cell exhibited a capacity of 119 mAh g−1 at 20 mA g−1, thereby demonstrating its suitability as a cathode material for application to KIBs.[ 78 ] P2‐K0.65Fe0.5Mn0.5O2 microspheres (s‐KFMO) were solvothermally prepared by Deng et al. The cathode material exhibited a highly reversible K+‐ion storage capacity of 151 mAh g−1 at 20 mA g−1. The CV curves (Figure 8a) show that the charge compensation mechanism involves both low‐spin Mn3+/Mn4+ and high‐spin Fe3+/Fe4+ redox couples above 3.6 V. A full cell constructed using an s‐KFMO cathode and a hard carbon anode demonstrated long‐term cycle stability with 80% capacity retention over 100 cycles (Figure 8b). The secondary microsphere structure decreases the contact area between the active materials and the electrolyte, thus minimizing unwanted side reactions and leading to high Coulombic efficiency.[ 44 ]

Figure 8.

a) CV curves of s‐KFMO electrode at a scanning rate of 0.1 mV s−1 and charge/discharge curves of s‐KFMO cathode at 20 mA g−1, b) cycling performance of s‐KFMO//hard carbon full cell. Reproduced with permission.[ 44 ] Copyright 2018, Wiley.

Liu et al. synthesized a series of Fe‐doped K0.45Mn1− x Fe x O2 (x ≤ 0.5) to study the influence of Fe substitution on the electrochemical performance. Among the synthesized materials, K0.45Mn0.8Fe0.2O2 delivered a discharge capacity of 106.2 mAh g−1 at 20 mA g−1 and the best cycling and rate performances. Excess Fe doping (x > 0.3) decreases the electrode capacity because most electroactive Mn ions are replaced by Fe ions, which do not participate in the redox reaction. Optimizing the Fe doping content could reduce the cathode material polarization and enhance the cathode structural stability.[ 79 ] Masese et al. developed a unique K0.4Fe0.5Mn0.5O2 layered oxide cathode comprising trivalent Fe3+ and tetravalent Mn4+, unlike other Fe/Mn‐based layered oxides comprising both trivalent Fe3+ and Mn3+.[ 80 ] This cathode material delivered a reversible specific capacity of 120 mAh g−1 and an average discharge of 2.8 V. X‐ray absorption near‐edge structure (XANES) spectra revealed that charge compensation involved the cumulative participation of transition‐metal cations and oxygen anion redox reactions during K+‐ion extraction and reinsertion.[ 80 ] Because such an oxygen anion redox mechanism is rarely observed for K+‐ion layered oxides, more investigations are required to elucidate anion redox chemistry.

In short, the Fe metal doping in K x MnO2 system enhanced specific capacity and an average voltage corresponding to Fe3+/4+ redox couple. From the viewpoint of commercial batteries, the Mn/Fe‐based electrodes may be a more suitable choice as these elements are earth abundant, low‐cost, and nontoxic. However, the J–T effect of Mn3+ and Fe4+ ions must be tackled, and thus further studies are necessary to optimize these materials for achieving durable battery performance.

3.2.2. Mn/Co‐Based Electrodes

Single transition‐metal oxides such as P3‐K0.5MnO2 and P2‐K0.6CoO2 exhibit multistep voltage profiles owing to multiple phase transitions and K+/vacancy ordering.[ 47 , 56 ] In the binary metal oxide compound P3‐K0.45Mn0.5Co0.5O2, the Mn and Co in the lattice structure suppress the K+/vacancy ordering and stabilize the cathode structure, resulting in a smooth voltage profile (Figure 9a). The P3‐K0.45Mn0.5Co0.5O2 cathode delivered a specific capacity of 140 mAh g−1 involving both the Mn3+/Mn4+ and Co3+/Co4+ redox couples and exhibited cycling stability with 80% capacity retention after 50 cycles (Figure 9b).[ 81 ] Mn3+‐induced J‐T distortion unidirectionally increases the MnO6‐octahedral Mn–O distance in discharged Mn‐based cathode materials. Choi et al. obtained P3‐K0.54[Co0.5Mn0.5]O2 in which Co3+ replaced half the Mn3+ and increased the Mn oxidation state above 3.5+, thus minimizing the J‐T distortions.[ 82 ] First‐principles calculations predicted the formation energies of several stable intermediate phases as functions of K+‐ion content (Figure 9c).

Figure 9.

a) Charge–discharge curves of P3‐K0.45Mn0.5Co0.5O2, b) cyclic stability of P3‐K0.45Mn0.5Co0.5O2. Reproduced with permission.[ 81 ] Copyright 2019, Elsevier. c) Formation energy of P3‐K x [Co0.5Mn0.5]O2 (0 ≤ x ≤ 1), d) comparison of experimentally measured GITT charge/discharge curve and predicted voltage profile, and comparison of Mn—O bonding distances between e) P3‐K0.75MnO2 and f) P3‐K0.75[Co0.5Mn0.5]O2. Reproduced with permission.[ 82 ] Copyright 2019, Elsevier.

The predicted voltage profile matched well with the experimental galvanostatic intermittent titration technique (GITT) measurements and exhibited a smooth voltage profile compared to nondoped K x MnO2 cathodes (Figure 9d). In addition, two types of Mn—O bonds were longer than the others in MnO6 octahedra in the pristine P3‐K0.75MnO2 structure. All the MnO6 octahedra Mn—O bond lengths are similar in the Co‐substituted P3‐K0.75[Co0.5Mn0.5]O2 structure (Figure 9e,f), which implies that Co substitution effectively mitigated the Mn3+‐induced J‐T structural distortion.[ 82 ] The P3‐K0.48Mn0.4Co0.6O2 cathode exhibited a discharge capacity of 64 mAh g−1 and an average output of 3.0 V owing to the solid‐solution K+ deintercalation/intercalation mechanism. Furthermore, the cathode displayed stable cycling and good capacity retention (81%) after 180 cycles. These studies indicate that further optimizing the layered oxide Mn/Co content could lead to the design of high‐performance KIB cathodes.[ 83 ]

Briefly, the optimal amount of Co3+ substitution was found to effectively suppress the J–T distortions caused by Mn3+ and thus make possible to obtain smoother voltage curves without multiple steps. However, the Co is toxic and expensive which hampers its use in practical batteries.

3.2.3. Mn/Ni‐Based Electrodes

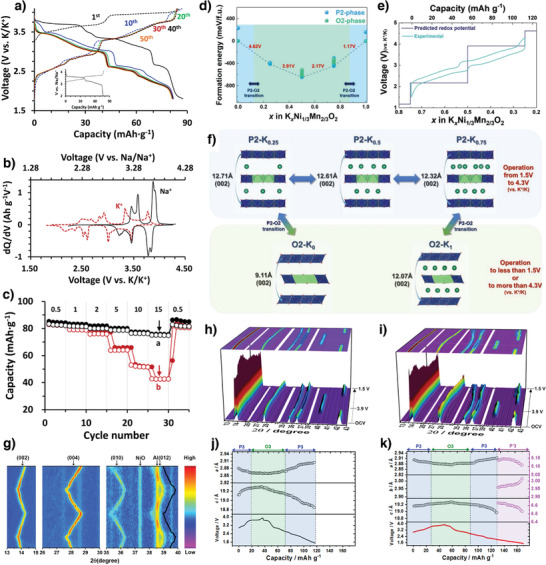

Incorporating Ni2+ into K x MnO2 could replace the J‐T distortion‐active Mn3+ ions, and Ni2+/4+ redox couple in the high‐voltage region to contribute to high energy density. Nathan et al. developed a layered P2‐K≈2/3[Ni1/3Mn2/3]O2 (KNMO) cathode through electrochemical ion exchange from sodium compounds.[ 41 ] When P2‐Na0.64[Ni1/3Mn2/3]O2 (NNMO) was continuously cycled in a K+‐containing electrolyte, nearly all the Na+ ions were progressively replaced by K+ ones. The KNMO exhibited more voltage steps than NNMO, indicating that frequent K+/vacancy ordering is required to transport larger K+ ions compared to Na+ ones (Figure 10a,b). The higher K+‐ion preference at prismatic sites transitioned the P2 to O2 at a higher voltage (4.65 V vs K/K+). The decelerated P2–O2 transition and rapid diffusion during K+‐ion extraction enabled KNMO charging, even at a high (15 C) rate (2850 mA g−1). The cathode delivered a discharge capacity of 82 mAh g−1 and exhibited excellent rate capability by maintaining the P2 phase in a wide potential window 1.5–4.5 V versus K/K+ (Figure 10c).[ 41 ] Adopting the same electrochemical ion‐exchange method, P2‐K0.75[Ni1/3Mn2/3]O2 was synthesized when ions were exchanged in a slightly wider range 1.5–4.3 V versus K/K+.[ 84 ] The cathode delivered a high reversible capacity of 110 mAh g−1 at 20 mA g−1 and exhibited excellent cycling stability with 83% capacity retention over 500 cycles at 1400 mA g−1. The XANES measurements showed that P2‐K0.75[Ni1/3Mn2/3]O2 involves the Ni2+/Ni4+ redox couple, while Mn4+ is inactive during K+‐ion extraction/insertion. However, because the Mn4+ does provide structural stability, the material undergoes a single‐phase reaction that maintains the P2 phase in the operation voltage range. The experimental results were supported by first‐principles calculations. The calculated formation energies predicted that P2‐K x [Ni1/3Mn2/3]O2 was more stable than O2‐K x [Ni1/3Mn2/3]O2 (Figure 10d). As shown in Figure 10e, the predicted redox potential is in line with the experimentally measured charge–discharge profile. The predicted structural changes are plotted as functions of K+‐ion content in Figure 10f. When x approaches ≈ 0 or 1 in P2‐K x [Ni1/3Mn2/3]O2, the variation in the prismatic (P2) structure causes layer gliding along the c‐axis, resulting in the formation of octahedral (O2) structures.[ 84 ] Similarly, Choi et al. prepared a high‐energy‐density Pʹ2‐K0.83[Ni0.05Mn0.95]O2 cathode by electrochemically ion‐exchanging Pʹ2‐Na0.67[Ni0.05Mn0.95]O2. The Pʹ2‐K0.83[Ni0.05Mn0.95]O2 cathode delivered a high specific capacity of 155 mAh g−1 and exhibited a high energy density of 420 Wh kg−1. Interestingly, the cathode demonstrated excellent structural stability by maintaining the Pʹ2 phase without transitioning to the OP4 one during K+‐ion deintercalation/intercalation compared with other Pʹ2‐based layered cathode materials for application to NIBs.[ 85 , 86 , 87 ] Notably, the low activation barrier energy (271 meV) for K+‐ion transport enables the high‐rate performance of 78 mAh g−1 at 2600 mA g−1. Furthermore, the full cell assembled using the Pʹ2‐K0.83[Ni0.05Mn0.95]O2 cathode and a hard carbon anode delivered a capacity of 135 mAh g−1 and exhibited long‐term cycling stability with 80% capacity retention after 300 cycles.[ 88 ]

Figure 10.

a) Charge–discharge profiles of NNMO during K+ exchange process, b) comparison of dQ/dV curves of NNMO in Na+ and K+ electrolytes. c) Comparison of rate capability of KNMO. Reproduced with permission.[ 41 ] Copyright 2019, Elsevier. d) Formation energies of P2/O2‐Kx[Ni1/3Mn2/3]O2 with various K contents. e) Comparison between experimentally measured charge/discharge curves and redox potentials predicted from first‐principles calculations, f) predicted structural change of P2/O2‐K x [Ni1/3Mn2/3]O2 as a function of K content. Reproduced with permission.[ 84 ] Copyright 2020, Wiley. g) In situ XRD patterns of P2‐K0.44Ni0.22Mn0.78O2 electrode collected during the first and second charge/discharge at 10 mA g−1 in the voltage range of 1.5–4.0 V. Reproduced with permission.[ 89 ] Copyright 2019, Wiley. Operando synchrotron XRD patterns and calculated lattice parameters for h,i) K0.5MnO2 and j,k) K0.5[Ni0.1Mn0.9]O2. Reproduced with permission.[ 76 ] Copyright 2019, American Chemical Society.

Zhang et al. used a solid‐state method to synthesize a P2‐K0.44Ni0.22Mn0.78O2 cathode, which delivered a specific capacity of 125.5 mAh g−1 at 10 mA g−1 and retained 67% of its initial capacity after 500 cycles. Notably, a trace of NiO impurities in the as‐synthesized material was electrochemically inactive during charging and discharging. The in situ XRD patterns (Figure 10g) show that this material undergoes a single‐phase transition and exhibits a small volumetric change (1.5%) upon K+‐ion extraction/insertion.[ 89 ] Partially substituting Ni2+ for Mn3+ in P3‐K x MnO2 effectively mitigated the structural deterioration due to the Mn3+‐ion‐induced J‐T effect.[ 76 ] The P3‐K0.5[Ni0.1Mn0.9]O2 cathode delivered a specific capacity of 121 mAh g−1 with 82% capacity retention after 100 cycles. The operando synchrotron XRD patterns revealed the structural evolution during K+‐ion extraction/insertion in the developed compounds (Figure 10h–k). P3‐K0.5[Ni0.1Mn0.9]O2 reversibly transitions among the phases P3, O3, P3, and Pʹ3 during charging and discharging. When the K+ ions were extracted, the interlayer distance increased owing to oxygen–oxygen repulsion, which is reflected in the c‐axis parameters (Figure 10k). The variation in the transition‐metal valence states (i.e., Ni2+/4+ and Mn3+/4+) influences the a‐axis parameter because of the bond between the transition metal and the oxygen in the layered compounds. Compared to pristine P3‐K0.5MnO2, Ni‐substituted P3‐K0.5[Ni0.1Mn0.9]O2 exhibited better structural stability because of its smaller lattice changes (Figure 10i,k).[ 76 ]

Bai et al. used a solid‐state method to synthesize a series of P3‐K0.67Mn1− x Ni x O2 (x = 0, 0.08, 0.17, and 0.33) layered compounds. The P3‐K0.67Mn0.83Ni0.17O2 compound prepared using the optimal Ni‐content effectively suppressed the Mn3+‐induced J‐T distortions, reduced the structural deterioration, and eventually enhanced the cathode electrochemical performance. The P3‐K0.67Mn0.83Ni0.17O2 cathode delivered a specific capacity of 122 mAh g−1 at 20 mA g−1 and exhibited good cycling stability with 75% capacity retention at 500 mA g−1 after 200 cycles.[ 77 ] K+/vacancy ordering limits K+‐ion diffusion kinetics and the practical capacity of layered compounds and causes layered oxides to exhibit step‐like voltage profiles and numerous CV‐curve redox peaks.[ 41 ] Xiao et al. studied the effect of the K+‐ion content on the transformation from a K+/vacancy‐ordered structure to a K+/vacancy‐disordered one.[ 90 ] The high K+‐ion content affects the interlayer K+–K+ electrostatic repulsion and reduces the K+‐ion site energy differences, thus breaking the K+/vacancy‐ordered structure. K+/vacancy‐disordered K0.7Mn0.7Ni0.3O2 exhibits much better rate performance and a higher discharge capacity than K+/vacancy‐ordered K0.4Mn0.7Ni0.3O2. The full cell assembled using the K0.7Mn0.7Ni0.3O2 cathode and a soft carbon anode delivered a capacity of 95.1 mAh g−1 at 100 mA g−1 and retained 86.4% of its initial capacity after 100 cycles.[ 90 ]

In summary, the partial substitution of Ni2+ replaced J–T active Mn3+ and suppressed the P2‐O2 phase transitions and structural degradation. Further, the Ni2+/4+ redox couple is able to provide high average voltage, which is beneficial for developing high‐energy density batteries. But the Mn/Ni‐based compounds commonly suffer from K+/vacancy ordering which leads to multiple voltage steps. The design of K+/vacancy disordered structures by tuning the elemental composition is found to be efficient strategy to improve the performance.

3.2.4. Mn/Mg‐Based Electrodes

Doping electrochemically inactive elements is an efficient strategy for improving the electrochemical performance of layered oxide cathodes. Although the nonredox behavior of dopants minimizes the overall material charge storage, dopants can stabilize crystal structures, suppress phase transitions, eliminate unwanted order–disorder transitions, and act as pillars to strengthen mechanical properties.[ 91 ] Liu et al. partially substituted inactive Mg for Mn and stabilized the P3‐K0.45Mn0.9Mg0.1O2 structure during cycling. X‐ray photoelectron spectroscopy (XPS) indicated that substituting Mg2+ for Mn3+ could increase the Mn4+ content, which is beneficial for suppressing the J‐T distortion (Figure 11a,b).[ 92 ] The initial discharge capacities of the pristine K0.45MnO2 and doped K0.45Mn0.9Mg0.1O2 cathodes were 116.3 and 108 mAh g−1, respectively. K0.45Mn0.9Mg0.1O2 exhibited a lower initial capacity because electrochemically inert Mg2+ ions had partially substituted for some active Mn3+ ions. However, the doped K0.45Mn0.9Mg0.1O2 demonstrated improved cycling stability and rate performance compared to pristine K0.45MnO2 because substituting Mg2+ reduces the volumetric change, increases the lamellar spacing for rapid K+‐ion extraction/insertion, and contributes to the high‐rate performance.[ 92 ] Similarly, Mg‐substituted hierarchical H‐K0.7Mn0.7Mg0.3O2 microparticles exhibited a high reversible capacity of 144.5 mAh g−1 at 20 mA g−1. The Mg‐substituted H‐K0.7Mn0.7Mg0.3O2 cathode displayed fewer voltage steps and less polarization than the pristine H‐K0.7MnO2 one (Figure 11c,d). Furthermore, the full cell assembled using the H‐K0.7Mn0.7Mg0.3O2 cathode and a hard carbon anode delivered a discharge capacity of 73.5 mAh g−1 at 100 mA g−1 and retained 75% of its initial capacity after 100 cycles.[ 93 ]

Figure 11.

High‐resolution XPS spectra of a) Mn 2p and b) Mg 2p in H‐K0.7Mn0.7Mn0.3O2. Reproduced with permission.[ 92 ] Copyright 2019, Wiley. Galvanostatic charge–discharge profiles of c) H‐K0.7MnO2 and d) H‐K0.7Mn0.7Mg0.3O2. Reproduced with permission.[ 93 ] Copyright 2020, Elsevier. In situ XRD patterns and corresponding voltage–capacity curve of e) P2‐ K5/9MnO2 and f) P2‐ K5/9Mn7/9Ti2/9O2 at 10 mA g−1. Reproduced with permission.[ 29 ] Copyright 2020, Elsevier. Dimensional changes at various states‐of‐charge in g) P2‐K0.7[Cr0.85Sb0.15]O2 and h) P2‐K0.62Na0.08[Cr0.85Sb0.15]O2. The solid and hollow circles denote changes in the c‐axis and a‐axis lengths, respectively. The XRD patterns for (002) and (010) peaks are shown in the left and right panels, respectively. The (010) peaks are magnified by 10. Reproduced with permission.[ 12 ] Copyright 2020, Electrochemical Society.

Xu et al. substituted inactive Ti4+ for active Mn4+ in P2‐K5/9MnO2 to prepare a series of P2‐K5/9Mn1− x Ti x O2 (0 ≤ x ≤ 4/9) compounds.[ 29 ] In situ XRD analysis revealed cathode structural changes during K+‐ion extraction and insertion. Pristine P2‐K5/9MnO2 displayed structural degradation and multiple transitions among the P2, Pʹ2, O2, OP4, Pʹ2, and P2 phases (Figure 11e). In contrast, the Ti‐doped P2‐K5/9Mn7/9Ti2/9O2 XRD pattern showed the opposite trend (Figure 11f), thus providing improved electrochemical performance. Therefore, Ti4+ effectively diminished TMO2 slab gliding and prevented the destructive P2‐O2 phase transition by promoting the highly reversible P2‐OP4 phase transition during charging and discharging.[ 29 ] Nathan et al. synthesized inactive Sb5+‐doped P2‐K0.70[Cr0.85Sb0.15]O2 (KCSO) by a solid‐state method and then compared its electrochemical properties with those of P2‐K0.62Na0.08[Cr0.85Sb0.15]O2 prepared using electrochemical ion exchange.[ 12 ] The ion‐exchange P2‐K0.62Na0.08[Cr0.85Sb0.15]O2 (IE‐KCSO) was obtained by cycling the P2‐Na0.70[Cr0.85Sb0.15]O2 sodium compound in the K+‐ion electrolyte. Notably, the IE‐KCSO contained Na+ ions, even after prolonged cycling, and demonstrated superior electrochemical performance by retaining 96% of its initial capacity after 100 cycles in contrast to only 76% capacity retention for KCSO. As shown in Figure 11g,h, a trace of Na+ ions remaining in IE‐KCSO causes smaller dimensional changes in IE‐KCSO and facilitates K+‐ion diffusion during charging and discharging, which contributes to the superior cyclability and rate capability.[ 12 ] This result was further supported by a systematic study of the influence of Na+ substitution on the cathode electrochemical performance by Liu et al., who varied the Na content to synthesize layered K0.67− x Na x Ni0.17Co0.17Mn0.66O2 (x ≤ 0.5) by coprecipitation followed by a solid‐state reaction.[ 94 ] Reportedly, introducing Na+‐ions affects the crystal structure, the electrode morphology, and eventually the electrochemical behavior. Compared with pristine P3‐K0.67Ni0.17Co0.17Mn0.66O2, the Na+‐substituted compounds exhibited improved electrochemical performance. However, excess Na+‐ion substitution (x > 0.3) suppressed K+‐ion migration during charging and discharging; thus, an efficient cathode was obtained when the Na+‐ion content was suitably adjusted within a reasonable range.[ 94 ]

In summary, the doping of electrochemically inactive elements (Mg2+, Ti4+) is a useful strategy to suppress the structural transition and improve the long‐term cyclability of the layered compounds. The Mg2+ mitigated J–T distortions and increased interlayer spacing for K+ diffusion leading to high rate capability. The Ti4+ substitution prevented layer gliding and thus improved structural stability during charge/discharge. The excess doping of inactive elements decreases the specific capacity, so the dopant concentration must be carefully tuned for designing efficient electrode materials.

3.3. Multimetal‐Based Electrodes

Although the binary metal oxide cathodes demonstrate enhanced electrochemical performance compared to the single metal oxide systems, they could not meet the requirements of practical KIBs. Therefore, the design of new materials with multiple metals could combine the synergistic effect of different metals and thus leading to improved performance. The commercialization of ternary compounds LiNi x Co y Mn z O2, where x + y + z = 1 (NMC) and LiNi0.85Co0.1Al0.05O2 (NCA) for application to LIBs[ 95 ] and Na–NCM layered cathodes for application to NIBs[ 96 ] paved the way for designing K+‐containing ternary metal layered cathodes for application to KIBs. However, K+‐containing ternary metal layered cathodes may not be directly applicable to KIBs because larger K+ ions cause such cathodes to exhibit more structural evolution and complex electrochemical behavior. From the knowledge gained by exploring LIB and NIB cathodes, Liu et al. developed a K0.67Ni0.17Co0.17Mn0.66O2 layered ternary material. The cathode delivered a reversible capacity of 76.5 mAh g−1 and an average output of 3.1 V. The charge‐storage mechanism was accompanied by Mn3+/Mn4+ and Ni2+/Ni4+ redox reactions, while Co doping supposedly stabilized the cathode structure.[ 97 ]

Furthermore, designing specially structured layered cathode materials can facilitate rapid K+‐ion transport owing to short diffusion paths and can accommodate stress induced by continuous K+‐ion extraction/insertion. The P3‐K0.5Mn0.72Ni0.15Co0.13O2 microspheres tested as cathodes exhibited improved electrochemical performance with an initial discharge capacity of 82.5 mAh g−1 and excellent cycling stability with 85% capacity retention after 100 cycles at 50 mA g−1.[ 98 ] In another study, Dang et al. improved the P3‐K0.45Ni0.1Co0.1Mn0.8O2 electrochemical performance by doping Mg2+ and Al3+ into Mn sites.[ 99 ] Mg2+/Al3+ doping increased the K+‐layer interlayer spacing, which may decrease K+ migration resistance during cycling. Compared to the pristine sample, the doped samples exhibited lower discharge capacities because of the lower Mn3+/4+ active redox content because Mg2+/Al3+ did not participate in charge compensation (Figure 12a). However, Mg2+ and Al3+ doping improved the cathode cycling stability (Figure 12b) by minimizing the Mn3+‐induced J‐T distortion, enlarging the K+‐ion diffusion layer, and enhancing the cathode structural stability.[ 99 ]

Figure 12.

The electrochemical performances for the pristine P3‐K0.45Ni0.1Co0.1Mn0.8O2, Mg‐doped, and Al‐doped cathodes. a) Galvanostatic charge/discharge curves and b) cycling performance at 20 mA g−1. Reproduced with permission.[ 99 ] Copyright 2020, Elsevier. c) Operando synchrotron XRD patterns for the P3‐K0.5[Mn0.8Fe0.1Ni0.1]O2 and d) the lattice parameters calculated from operando SXRD patterns during the charge–discharge processes. Reproduced with permission.[ 101 ] Copyright 2020, Elsevier. e,f) Schematic from the DFT calculation for Mn–O bonding distances of K0.6MnO2 and K0.6Mn0.8Ni0.1Ti0.1O2, respectively. Predicted K+ diffusion paths and activation barrier energy in the K0.6Mn0.8Ni0.1Ti0.1O2 by first‐principles calculation, g) Kf to Kf, h) Kf to Ke, i) Ke to Ke, and j) corresponding energy barriers for the migration pathways displayed in (g–i) by using the NEB method. Reproduced with permission.[ 103 ] Copyright 2021, Elsevier.

Hwang et al. prepared P2‐K0.75[Mn0.8Ni0.1Fe0.1]O2 by electrochemical ion exchange, and the cathode demonstrated reversible K+‐ion (0.5 mol) storage and thus delivered a capacity of 110 mAh g−1 without transitioning through multiple phases in the range 1.5–3.9 V versus K/K+.[ 100 ] The low K+‐ion diffusion activation barrier (580 meV) was predicted for P2‐K x [Mn0.8Ni0.1Fe0.1]O2 using nudged elastic band (NEB) calculations. Because P2‐K0.75[Mn0.8Ni0.1Fe0.1]O2 exhibited large 2D K+‐ion diffusion pathways and a low activation barrier, it also exhibited excellent rate capability. Moreover, the P2‐K0.75[Mn0.8Ni0.1Fe0.1]O2//hard carbon full cell exhibited excellent long‐term stability over 1000 continuous cycles.[ 100 ] By varying the K+‐ion content, Choi et al. prepared P3‐K0.5[Mn0.8Fe0.1Ni0.1]O2 using a combustion‐assisted solid‐state reaction. Partially replacing Mn3+ with Fe3+ and Ni2+ increased the average Mn valence state to 3.75+, which mitigated the J‐T distortions and structural degradation. The structural evolution (Figure 12c,d) investigated using synchrotron XRD showed that the electrode undergoes reversible phase transitions such as P3‐O3 during charging and O3‐P3‐Pʹ3 during discharging. Because the reversibility slightly varied (≈4.1%) the structure, the P3‐K0.5[Mn0.8Fe0.1Ni0.1]O2 cathode delivered a high discharge capacity of 120 mAh g−1 and retained 74% of its initial capacity after 300 cycles.[ 101 ]

The P3 compounds usually transition from P3 to O3 during K+‐ion extraction, which slows K+‐ion mobility and rapidly degrades the cathode capacity and may be ascribed to a higher activation barrier within the O framework and a substantially contracted crystal structure. Interestingly, Fe3+/Ti4+‐codoped P3‐K0.4Fe0.1Mn0.8Ti0.1O2 demonstrated a solid–solution transition without an obvious P3‐O3 transition during K+‐ion extraction/insertion in voltage window 1.8–4.0 V versus K/K+. The P3‐K0.4Fe0.1Mn0.8Ti0.1O2 cathode delivered an initial capacity of 117 mAh g−1 and exhibited long stability over 300 cycles and negligible volumetric change (0.5%).[ 102 ] Similarly, the P2‐K0.6Mn0.8Ni0.1Ti0.1O2 solid solution did not exhibit any other phase transition (including OP4 or O2) and even charged to a high voltage of 4.2 V. In contrast, pristine P2‐K0.6MnO2 exhibited complex P2‐OP4‐X phase transitions during K+‐ion extraction.[ 103 ] Furthermore, complex phase transitions considerably changed the pristine cathode c‐axis lattice parameter (Δc = 31%), whereas the doped P2‐K0.6Mn0.8Ni0.1Ti0.1O2 cathode exhibited much less variation in the c‐axis parameter (Δc = 2.4%). Clearly, Ni2+/Ti4+ doping not only mitigates J‐T distortions (Figure 12e,f) but also maintains the layer structural integrity, thereby improving the high‐voltage performance. Three possible K+‐ion migration pathways predicted using the climbing‐image nudged elastic band (CI‐NEB) method are shown in Figure 12g–i.[ 103 ]

Recently, Liu et al. studied the influence of Mg2+/Ni2+ codoping on the K x MnO2 electrochemical performance and synthesized various K1/2Mn x Mg(1− x )/2Ni(1− x )/2O2 composite compounds (x = 1, 9/10, 5/6, and 2/3) using the sol–gel method. Mg2+/Ni2+ cosubstitution remarkably influenced the K x MnO2 crystal structure. At low concentrations, Mg2+ and Ni2+ ions reportedly prefer to occupy the TM layer and begin to enter the K+‐ion layer at higher concentrations.[ 104 ] The K+‐ion layer Mg2+ or Ni2+ ions serve as a pillar to prevent layer gliding, and Mg–Ni pinning suppresses multiphase transition in K x MnO2 during K+‐ion extraction/insertion.[ 105 ] Designing high‐voltage K+‐ion‐containing layered cathodes to achieve high‐energy‐density KIBs is currently a hot research topic. Masese et al. reported a unique honeycomb layered K2Ni2TeO6 cathode, which exhibited a high average output of 3.6 V versus K/K+. The Ni2+/Ni4+ redox potential increased because of the [TeO6]6− moiety induction, which is more electronegative than O2 2−.[ 106 ] In addition, they modified the tellurium content and synthesized a P2‐K2/3Ni1/3Co1/3Te1/3O2 multitransitional metal oxide cathode, which although delivered a low discharge capacity, displayed a high output of 4.3 V versus K/K+ and is by far the highest voltage ever recorded for KIB layered cathodes.[ 107 ] A summary of the synthesis method and electrochemical performance of layered oxide cathodes in half‐cell KIBs and full‐cell KIBs are listed in Tables 1 and 2 , respectively.

Table 1.

Electrochemical performance of layered oxide cathodes in half‐cell KIBs

| Material | Synthesis method | Electrolyte | Voltage window [V] | Discharge capacity [mAh g−1]/ current density [mAg−1] | Capacity retention [%]/current density [mA g−1]/cycle | Refs. |

|---|---|---|---|---|---|---|

| K0.3MnO2 | Thermal decomposition | 1.5 m KFSI in EC:DMC | 1.5–3.5 | 70/27.9 | 57/27.9/685 | [45] |

| P3‐K0.45MnO2 | Coprecipitation | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 128.6/20 | 70.8/20/100 | [46] |

| P3‐K0.5MnO2 | Solid state | 0.7 M KPF6 in EC:DEC | 1.5–3.9 | 106/5 | 70/20/50 | [47] |

| P3‐K0.5MnO2 | Two‐step self‐templating | 0.8 M KPF6 in EC:DEC | 1.5–3.9 | 104/10 | 89.1/200/400 | [48] |

| P2‐K0.67MnO2 | Sol–gel | 6.0 M KFSI/diglyme (G2) | 1.7–4.0 | 78/50 | 90.5/50/300 | [53] |

| K1.39Mn3O6 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 110/10 | 94.9/50/100 | [54] |

| P2‐K0.41CoO2 | Solid state | 1.0 M KFSI in EC:DEC | 2.0–3.9 | 57/11.8 | 96/11.8/30 | [43] |

| P3‐K2/3CoO2 | Solid state | 1.0 M KFSI in EC:DEC | 2.0–3.9 | 60/11.5 | 91/11.5/30 | [43] |

| P2‐K0.6CoO2 | Solid state | 0.7 M KPF6 in EC:DEC | 1.7–4.0 | 80/2 | 60/100/120 | [56] |

| P2‐K0.6CoO2 | Two‐step self‐templating | 0.9 M KPF6 in EC:DEC | 1.7–4.0 | 82/10 | 87/40/300 | [57] |

| O3‐KCrO2 | Solid state | 0.7 M KPF6 in EC:DEC | 1.5–4.0 | 92/5 | 67/10/100 | [40] |

| O3‐KCrS2 | Solid state | 1.0 M KFSI in EC:DEC | 1.8–3.0 | 71/8.65 | 90/173/1000 | [61] |

| P3‐K0.69CrO2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–3.8 | 100/10 | 65/100/1000 | [66] |

| P′3‐K0.8CrO2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 91/10.9 | 99/218/300 | [42] |

| K0.5V2O5 | Hydrothermal | 1.0 M KFSI in EC:DEC | 1.5–3.8 | 87.5/20 | 81/100/250 | [71] |

| δ‐K0.42V2O5·0.25H2O | Two‐step synthesis | 0.8 M KPF6 in EC:DEC | 2.0–4.3 | 226/20 | 74/20/50 | [72] |

| K2V3O8 | Hydrothermal | 7.0 M KFSI in EC:DEC | 1.5–4.5 | 107.8/10 | 73/10/50 | [73] |

| K0.83V2O5 | Chemistry route | 7.0 M KFSI in EC:DEC | 1.5–4.3 | 90/10 | 86/10/200 | [74] |

| K0.7Fe0.5Mn0.5O2 | Electrospinning | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 178/20 | 85/500/200 | [78] |

| P2‐K0.65Fe0.5Mn0.5O2 | Solvent thermal | 0.9 M KPF6 in EC:DEC | 1.5–4.2 | 151/20 | 78/100/350 | [44] |

| P3‐K0.45Mn0.8Fe0.2O2 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 106.2/20 | 77/20/100 | [79] |

| K0.4Fe0.5Mn0.5O2 | Solid state | 1.0 M KFSA in Pyr13FSA | 1.3–3.8 | 120/12.5 | 85/12.5/50 | [80] |

| P3‐K0.45Mn0.5Co0.5O2 | Sol–gel | 0.8 M KPF6 in EC:DEC | 1.2–3.9 | 140/10 | 80/50/50 | [81] |

| P3‐K0.54[Co0.5Mn0.5]O2 | Combustion | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 120.4/20 | 85/20/100 | [82] |

| P3‐K0.48Mn0.4Co0.6O2 | Solid‐state | 0.5 M KPF6 in EC:DEC | 1.0–4.2 | 64/6 | 81/12/180 | [83] |

| P2‐K≈2/3[Ni1/3Mn2/3]O2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–4.5 | 82/86 | 99/86/100 | [41] |

| P2‐K0.75[Ni1/3Mn2/3]O2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–4.3 | 110/20 | 86/20/300 | [84] |

| P′2‐K0.83[Ni0.05Mn0.95]O2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–4.3 | 155/52 | 77/520/500 | [88] |

| P2‐K0.44Ni0.22Mn0.78O2 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 125.5/10 | 67/200/500 | [89] |

| P3‐K0.5[Ni0.1Mn0.9]O2 | Combustion | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 121/10 | 82/10/100 | [76] |

| P3‐K0.67Mn0.83Ni0.17O2 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–3.8 | 122/20 | 75/500/200 | [77] |

| P3‐K0.7Mn0.7Ni0.3O2 | Solid state | 0.8 M KPF6 in EC:DEC | 2.0–3.9 | 125.4/100 | 93.6/100/150 | [90] |

| P3‐K0.45Mn0.9Mg0.1O2 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 108/20 | 74.8/20/100 | [92] |

| K0.7Mn0.7Mg0.3O2 | Resorcinol–formaldehyde | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 144.5/20 | 82.5/100/400 | [93] |

| P2‐K0.7[Cr0.85Sb0.15]O2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.5–4.3 | 70/15.4 | 76/77/100 | [12] |

| P2‐K0.62Na0.08[Cr0.85Sb0.15]O2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–4.3 | 78/15.4 | 96/77/100 | [12] |

| P3/P2‐ K0.37Na0.3Ni0.17Co0.17Mn0.66O2 | Coprecipitation | 0.8 M KPF6 in EC:DEC | 2.0–4.3 | 86.1/20 | 62/100/100 | [94] |

| P3‐K0.67Ni0.17Co0.17Mn0.66O2 | Coprecipitation | 0.8 M KPF6 in EC:DEC | 2.0–4.3 | 76.5/20 | 87/20/100 | [97] |

| P3‐K0.5Mn0.72Ni0.15Co0.13O2 | Solvothermal | 0.8 M KPF6 in EC:DEC | 1.5–4.0 | 82.5/10 | 85/50/100 | [98] |

| P3‐K0.45Ni0.1Co0.1Al0.05Mn0.75O2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.5–4.0 | 84.5/20 | 77.4/20/100 | [99] |

| P2‐K0.75[Mn0.8Ni0.1Fe0.1]O2 | Electrochemical ion exchange | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 110/10 | 70/100/200 | [100] |

| P3‐K0.5[Mn0.8Fe0.1Ni0.1]O2 | Combustion | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 120/50 | 74/50/300 | [101] |

| P3‐K0.4Fe0.1Mn0.8Ti0.1O2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.8–4.0 | 117/20 | 74/200/300 | [102] |

| P2‐K0.6Mn0.8Ni0.1Ti0.1O2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.5–4.2 | 118/10 | 88/200/100 | [103] |

| P3‐K1/2Mn5/6Mg1/12Ni1/12O2 | Solid state | 0.5 M KPF6 in EC:DEC | 1.5–3.9 | 83.3/120 | 70.4/120/200 | [105] |

| P2‐Na0.84CoO2 | Solution combustion | 0.8 M KPF6 in EC:DEC | 2.0–4.0 | 82/10 | 58/20/50 | [108] |

| O3‐Na0.9Cr0.9Ru0.1O2 | Solid state | 0.8 M KPF6 in EC:DEC | 1.5–3.8 | 100.6/10 | 81.2/500/500 | [110] |

| P′3‐Na0.52CrO2 | Solid state | 1.0 M KFSI in EC:DEC | 2.0–3.6 | 88/12.5 | 67/500/200 | [111] |

| P3‐K0.48Ni0.2Co0.2Mn0.6O2 | Solid state | 0.8 M KPF6 in EC:PC | 1.5–4.2 | 57/40 | 76.2/40/150 | [112] |

Table 2.

Electrochemical properties of layered oxide cathodes in full‐cell KIBs

| Material | Anode | Electrolyte | Voltage window [V] | Discharge capacity [mAh g−1]/current density [mA g−1] | Capacity retention [%]/current density [mA g−1]/cycle | Refs. |

|---|---|---|---|---|---|---|

| K0.3MnO2 | Hard carbon & Carbon black | 1.5 M KFSI in EC:DMC | 0.5–3.4 | 90/32 | 50/32/100 | [45] |

| P3‐K0.5MnO2 | Graphite | 0.8 M KPF6 in EC:DEC | 0.5–3.4 | 60.2/10 | 66.7/10/50 | [48] |

| P2‐K0.6CoO2 | Graphite | 0.7 M KPF6 in EC:DEC | 1.5–4.0 | 52/3 | 52/3/5 | [56] |

| P2‐K0.6CoO2 | Hard carbon | 0.9 M KPF6 in EC:DEC | 0.5–3.8 | 71/30 | 80/30/100 | [57] |

| K0.83V2O5 | Graphite | 7.0 M KFSI in EC:DEC | 0.5–3.9 | 75/10 | 80/10/30 | [74] |

| O3‐KCrO2 | Graphite | 0.7 M KPF6 in EC:DEC | 0.5–4.0 | 97/5 | 53/5/10 | [40] |

| K0.7Fe0.5Mn0.5O2 | Soft carbon | 0.8 M KPF6 in EC:DEC | 0.5–3.5 | 82/40 | 76/100/250 | [78] |

| P3‐K0.45Mn0.8Fe0.2O2 | Super P | 0.8 M KPF6 in EC:DEC | 0.5–3.5 | 55/50 | 76/50/50 | [79] |

| P2‐K0.65Fe0.5Mn0.5O2 | Hard carbon | 0.9 M KPF6 in EC:DEC | 0.5–3.5 | 75/100 | 80/100/100 | [44] |

| P3‐K0.54[Co0.5Mn0.5]O2 | Hard carbon | 0.5 M KPF6 in EC:DEC | 0.5–3.6 | 96/20 | 82/20/100 | [82] |

| P′2‐K0.83[Ni0.05Mn0.95]O2 | Hard carbon | 0.5 M KPF6 in EC:DEC | 0.5–4.0 | 135/52 | 80/52/300 | [88] |

| P2‐K0.44Ni0.22Mn0.78O2 | Soft carbon | 0.8 M KPF6 in EC:DEC | 0.5–3.5 | 70/50 | 90/50/500 | [89] |

| P3‐K0.7Mn0.7Ni0.3O2 | Soft carbon | 0.8 M KPF6 in EC:DEC | 1.1–3.5 | 95/100 | 86.4/100/100 | [90] |

| K0.7Mn0.7Mg0.3O2 | Hard carbon | 0.8 M KPF6 in EC:DEC | 0.5–3.5 | 73.5/100 | 75/100/100 | [93] |

| P2‐K0.75[Mn0.8Ni0.1Fe0.1]O2 | Hard carbon | 0.5 M KPF6 in EC:DEC | 0.5–3.5 | 60/20 | 60/20/1000 | [100] |

| P3‐K0.5[Mn0.8Fe0.1Ni0.1]O2 | Hard carbon | 0.5 M KPF6 in EC:DEC | 0.5–3.6 | 113/50 | 89/50/150 | [101] |

| P3‐K0.4Fe0.1Mn0.8Ti0.1O2 | Soft carbon | 0.5 M KPF6 in EC:DEC | 0.5–3.8 | 107/50 | 62/50/300 | [102] |

3.4. Na‐Based Cathodes for K+‐Ion Storage

In addition to K+‐ion‐containing layered cathodes, there have been a few reports on Na+‐containing layered materials for efficient K+‐ion storage. For example, Sada et al. demonstrated reversible K+‐ion intercalation in P2‐Na0.84CoO2 wherein the cathode delivered a reversible capacity of 82 mAh g−1 (Figure 13a). The P2‐Na0.84CoO2 cathode was initially charged in a K+‐ion‐containing electrolyte for desodiation. During the subsequent discharge, K+ ions started replacing Na+ ones through progressive intercalation, and Na0.34K0.5CoO2 was formed after several charge–discharge cycles (Figure 13b).[ 108 ] Furthermore, they developed another layered material (Na2Mn3O7) as a K+‐ion‐storage host structure. The Na2Mn3O7 cathode delivered a high capacity of 152 mAh g−1 and an energy density of 320 Wh kg−1.[ 109 ]

Figure 13.

a) Charge–discharge profiles of P2‐N0.84CoO2 in Na‐ion cell and K‐ion cell. b) Ex situ XRD measurements of the pristine, charged, and discharged electrodes depicting the successful desodiation and potassiation of the pristine compound to form K0.5CoO2. Reproduced with permission.[ 108 ] Copyright 2017, Royal Society of Chemistry. c) The diffusivity is calculated from GITT analysis for Na0.9Cr0.9Ru0.1O2. Reproduced with permission.[ 110 ] Copyright 2019, Royal Society of Chemistry. d) Schematic diagram depicting two possible routes for reversible K+‐insertion/deinsertion in P′3‐Na0.52CrO2. Small spheres (blue) represent Na+ ions. Arrows indicate the direction of contraction/expansion along the c‐axis with K+‐insertion. Reproduced with permission.[ 111 ] Copyright 2018, American Chemical Society.

In another study, O3‐Na0.9Cr0.9Ru0.1O2 exhibited enhanced K+‐ion diffusion comparable and even superior to Na+‐ion diffusion (Figure 13c).[ 110 ] During Na+ extraction, Na+ ions do not directly diffuse in O3 crystals, and Na+ ions diffusing through tetrahedral interstitial sites must overcome the high energy barrier therein. During K+‐ion intercalation, on the other hand, K+ ions diffuse from prismatic sites to others in a large interlayer space. The Ru‐substitution‐induced structural support and rapid K+‐ion diffusion kinetics enabled the Na0.9Cr0.9Ru0.1O2 to exhibit an excellent capacity retention of 81.2% after 500 cycles at a high rate (5 C).[ 110 ] Naveen et al. developed Pʹ3‐Na0.52CrO2 as a KIB cathode, which delivered a specific capacity of 88 mAh g−1 and an average discharge potential of 2.95 V versus K/K+.[ 111 ] In contrast to Na0.84CoO2,[ 108 ] the Pʹ3‐Na0.52CrO2 exhibited uniquely distributed Na+ and K+ ions, forming a biphasic structure during K+‐ion insertion (Figure 13d). The reversible transition between monophasic (Na0.5CrO2) and biphasic NaCrO2/K0.6Na0.17CrO2 during cathode charging and discharging, respectively, decreased the volumetric changes and shortened the K+‐ion diffusion path, which contributed to the high‐rate and cycling performance.[ 111 ] These studies provide insights for applying current Na+‐ion‐containing layered materials to K+‐ion storage. Further investigations on Na+/K+‐ion‐containing cathode materials are required to develop efficient KIBs.

3.5. Hybrid Potassium‐Ion Capacitor (KIC)

Supercapacitors are a class of energy storage systems that exhibit high power density and superior cycle life to secondary batteries but have comparatively low energy density.[ 113 , 114 , 115 ] In recent years, metal‐ion hybrid capacitors (MICs) have been developed that bridge the gap between batteries and supercapacitors by combining battery‐type anodes with capacitor‐type cathodes. Numerous different MICs have been reported in the literature including the lithium‐ion (LIC), sodium‐ion (NIC), potassium‐ion (KIC) and zinc‐ion capacitors (ZIC), among others.[ 116 , 117 , 118 , 119 ] Comte et al. reported the first hybrid KIC using graphite (battery type) as the anode, activated carbon (capacitor type) as the cathode and a 0.8 m KPF6 EC:DMC electrolyte.[ 120 ] During the charging process, the K+ ions are intercalated into the anode while the PF6 − anions in the electrolyte are adsorbed on the cathode surface, forming an electric double layer. During the discharge process, the K+ ions are deintercalated from anode and the PF6 − anions are released from cathode surface diffuse back to the electrolyte.[ 121 ] Most current research efforts are focused on developing battery‐type anode materials for KICs. Such materials include carbon‐based materials, metal oxides, metal chalcogenides, MXenes and organic materials that follow different storage mechanisms such as intercalation, conversion, and alloying (Figure 14a).[ 122 , 123 ] Conversely, carbon‐based capacitor‐type cathodes are extensively studied, but literature reports on the battery‐type cathodes for KIC are rare, perhaps because potassium‐ion storage systems are in an early development stage and suitable battery‐type cathodes have not yet been explored.[ 124 ] Although the anode materials exhibit superior capacities, they must be combined with suitable cathode materials to achieve high energy and power density devices. Ramasamy et al.[ 81 ] reported a non‐aqueous KIC consisting of a layered P3‐K0.45Mn0.5Co0.5O2 battery‐type cathode combined with a commercial activated carbon (AC) anode (Figure 14b). The constructed KIC delivered a high energy and power density of 43 Wh kg−1 and 30 kW kg−1, respectively, and retained 88% of its energy density over 30 000 cycles at 10 A g−1, demonstrating excellent cyclic stability (Figure 14c). The mass ratio between anode and cathode in the full cell KIC must be balanced according to their working potentials to obtain high energy/power density. Wei et al.[ 125 ] fabricated an aqueous KIC with a layered K0.296Mn0.926O2 cathode and AC anode. The K0.296Mn0.926O2//AC displayed high energy and power densities of 70 W kg−1 and 6000 W kg−1, respectively, and a capacitance retention of 89.3% after 10 000 cycles. The unique layered structure facilities the rapid diffusion of K+ ions and provides space for charge storage.

Figure 14.

a) Various battery‐type anode materials tested in KICs. Reproduced with permission.[ 122 ] Copyright 2021, American Chemical Society. b) Schematic illustration of a KIC fabricated with a battery‐type K0.45Mn0.5Co0.5O2 cathode and AC anode. c) Ragone plot of K0.45Mn0.5Co0.5O2//AC device. Inset: First few charge/discharge cycles at 10 A g−1. Reproduced with permission.[ 81 ] Copyright 2019, Elsevier.

The aforementioned studies demonstrate promising methods to construct aqueous or non‐aqueous KICs with battery‐type cathodes and also suggest numerous opportunities for the design of novel electrodes for high‐performance KICs. The rates of cation insertion/desertion and anion adsorption/desorption control the energy and power densities of KICs. The development of KICs is hampered by the sluggish kinetics of the anode and cathode materials; therefore, designing nanostructure and morphology‐controlled electrodes, developing a suitable electrolyte, and an in‐depth understanding of the reaction kinetics and energy storage mechanisms are essential factors for the realization of practical high‐performance KICs.

4. Synthesis of Layered Metal Oxide Electrodes

The methods used in the synthesis of active materials for various energy storage devices greatly influence their properties. The reaction parameters, including the temperature, time, pH, and precursors, affect the structural properties of the material, including the crystallinity, particle size, surface morphology, composition, and phase purity.[ 126 , 127 , 128 ] In addition, the electrochemical properties of the electrode materials, such as the initial capacity, rate capability, and cyclic stability, are also influenced by the preparative techniques.[ 129 , 130 , 131 ] Electrode materials have been synthesized by various techniques, including solid‐sate coprecipitation, sol–gel, hydrothermal/solvothermal, combustion, and electrochemical‐ion exchange reactions, among others. Further, fine‐tuning the reaction parameters and employing multiple synthetic routes may yield electrode materials with the desired stoichiometry, phase, morphology, and electrochemical properties.[ 132 , 133 , 134 ] The remainder of Section 4 will discuss some of the synthetic routes used to produce KIB electrodes and their influence on the properties of the electrodes.

4.1. Solid‐State Reaction

The solid‐state reaction route, which is most commonly used to prepare layered metal‐oxide cathodes for KIBs (Table 1), is a simple method that involves the physical mixing (sometimes solution mixing) and sintering of potassium and transition metal precursors (oxides or acetates) to obtain the final products. For instance, Kim et al.[ 47 ] synthesized P3‐K0.5MnO2 using K2CO3 and Mn2O3 precursors via a conventional solid‐state route. The stoichiometrically mixed powders were ball milled for 4 h before the pelletized mixture was calcined at 800 ° C for 12 h. The required phase structure and crystallinity can be obtained by selecting the appropriate precursors and controlling the calcination temperature. Hironaka et al.[ 43 ] synthesized P3‐K2/3CoO2 and P2‐K0.41CoO2 phases by varying the precursors, composition, and reaction temperatures. P3‐K2/3CoO2 was synthesized by heating a mixture of KOH and Co(OH)2 at 400 ° C for 24 h, while P2‐K0.41CoO2 was obtained by firing a mixture of KOH and Co3O4 at 600 ° C for 4 h. The first charge profiles of the P3 and P2 compounds differed, but otherwise, the two compounds showed similar voltage changes, indicating that the potential primarily depends on the K+/vacancy ordering rather than the crystal structure. Kim et al.[ 40 ] synthesized stoichiometric O3‐KCrO2 by sintering a pelletized mixture of KN3, KNO3, and Cr2O3 under controlled atmosphere and temperature conditions for 42 h. The numerous phase changes in the stoichiometric layered potassium cathode prevented the entire K+ content from being utilized during the charge/discharge process, limiting the cyclability and rate capability of the material. Element doping is one of the most efficient strategies to mitigate the lattice changes and thus improve the structural stability and durability of the cathodes. Liu et al. synthesized a series of P3‐K0.45Mn1‐ x Fe x O2 (x ≤ 0.5) to investigate the effects of Fe doping.[ 79 ] A stoichiometric mixture of K2CO3, Mn2O3, and Fe2O3 was ball milled in a small amount of ethanol for 12 h. Notably, an excess of K2CO3 (5 wt%) was added to compensate for the loss of potassium at high temperature. The dried mixtures were pelletized and sintered at 850 ° C for 15 h. A cathode with superior performance was obtained with a doping level of x = 0.2, whereas excessive doping (x > 0.4) resulted in the formation of some impurities in the cathode, indicating that optimizing the dopant concentration improved the structural and electrochemical properties of the cathode. Xu et al.[ 103 ] reported the synthesis of P2‐K0.6Mn0.8Ni0.1Ti0.1O2 with multiple elements doping. A pelletized mixture of K2CO3 (3 mol% excess), Mn2O3, NiO2, and TiO2 was calcined at 1000 ° C for 15 h. The substitution of Ni2+ and Ti4+ effectively suppressed lattice distortions caused by Mn3+ and inhibited gliding of the TM layer at high charged states and thus improved performance. Though the solid‐state reaction route is straightforward and suitable for mass production, tuning the particle size and morphology of the active materials present significant challenges. As the alkali and transition metal ions diffuse through solid phases to occupy their respective atomic positions, this method often requires time‐consuming, high‐temperature calcination to obtain the desired crystal structure without any impurities. Further, the physical mixing of precursors results in a nonuniform product with impurities and thus researchers have largely adopted solution‐based methods that enable cation mixing at the atomic level and the formation of homogenous precursors in chemically controlled conditions.[ 132 ]

4.2. Solvothermal/Hydrothermal Methods

Solvothermal/hydrothermal methods are facile and environmentally benign processes because the reactions are carried out in closed containers. The hydrothermal method uses an aqueous solvent whereas the solvothermal method uses organic solvents. Yuan et al.[ 68 ] synthesized a K0.486V2O5 cathode via hydrothermal‐assisted heat treatment. Typically, K2CO3 and V2O5 were dissolved in water containing a reducing agent (30% H2O2). The solution was heated in an autoclave 180 ° C for 3 h. After cooling, the precipitate was washed with water and ethanol and finally heated at 450 ° C for 2 h. The SEM image of K0.486V2O5 cathode, which exhibited a high specific capacity of 159 mAh g−1 at 20 mA g−1, revealed a nanobelt morphology. Hydrothermal/solvothermal methods can achieve various morphologies and particle sizes by tuning the reaction conditions and reducing agents. Liu et al.[ 69 ] obtained layered K0.23V2O5 with a flower‐like morphology, which exhibited enhanced electrochemical performance owing to its multilayered microstructure which offered more void space to accommodate volume changes caused by K+ insertion/desertion. Deng et al.[ 44 ] synthesized K0.65Fe0.5Mn0.5O2 cathodes by two different routes (viz. hydrothermal and conventional solid‐state reactions) to demonstrate the influence of the synthetic procedure on the properties of the cathode. Initially, a (Fe0.5Mn0.5)2O3 precursor with homogeneously mixed Fe and Mn at the atomic level was obtained by hydrothermal reaction followed by heat treatment. (Fe0.5Mn0.5)2O3 was then mixed with KOH before the mixture was finally calcined at 1000 ° C for 12 h to yield s‐K0.65Fe0.5Mn0.5O2 microspheres. Conversely, the c‐K0.65Fe0.5Mn0.5O2 synthesized through the solid‐state route by physical mixing and calcined under the same conditions produced irregularly‐shaped particles. The s‐K0.65Fe0.5Mn0.5O2 microspheres exhibited superior capacity and durability to the irregularly shaped c‐K0.65Fe0.5Mn0.5O2 particles. Further, the irregular particles pulverized and formed an unstable passivation layer while the microspheres formed a uniform interface between the cathode and electrolyte and thus inhibited side reactions during cycling. In another work, ternary P3‐K0.5Mn0.72Ni0.15Co0.13O2 microspheres were achieved by solvothermal method.[ 98 ] Secondary microspheres composed of sub‐micron‐sized primary particles minimize the diffusion distance of K+ ions and provide structural stability by acting as buffer during K+ extraction/insertion. Interestingly, P3‐K0.48Ni0.2Co0.2Mn0.6O2 with a mixed morphology containing microspheres and microcubes was achieved by a solvothermal method using glycerol and urea additives.[ 112 ] Though hydrothermal/solvothermal methods provide highly crystalline products with tailored morphologies and uniform particle distributions, their use is limited owing to the necessity of using high‐pressure vessels and their comparatively low product yields.

4.3. Sol–Gel