Abstract

This is a critical review of artificial intelligence/machine learning (AI/ML) methods applied to battery research. It aims at providing a comprehensive, authoritative, and critical, yet easily understandable, review of general interest to the battery community. It addresses the concepts, approaches, tools, outcomes, and challenges of using AI/ML as an accelerator for the design and optimization of the next generation of batteries—a current hot topic. It intends to create both accessibility of these tools to the chemistry and electrochemical energy sciences communities and completeness in terms of the different battery R&D aspects covered.

1. Introduction

The latest reports on climate change from the United Nations show that humanity has a few years’ budget of CO2 emissions at the present rate to keep the temperature rise below 1.5 °C by 2100.1 This remains true despite the temporary slight decrease in global CO2 emissions due to the COVID-19 pandemic.2,3 In order to mitigate this and limit the damages, urgent and massive deployment of emissionless energy sources, such as nuclear and renewable, is required. Renewable energy sources are fluctuating, and hence, their deployment has to be accompanied by efficient energy storage, where rechargeable batteries are at the forefront for short- to medium-term storage, due to operation efficiency and flexibility. Among them, lithium-ion batteries (LIBs) constitute one of the most influential technologies of the modern society, which has enabled the wide emergence of portable electronics devices and which is triggering the growth of the electric vehicle (EV) market.4,5 Even if LIBs have been very significantly improved, by more than 200% in energy density since the first LIB cells were successfully commercialized by Sony in 1991,6 their massive deployment for EV or stationary applications requires them to be even further optimized in terms of performance, durability, safety, cost, as well as reducing their CO2 footprint and increasing their reusability and recyclability. This is true for both current LIBs and any next generation batteries currently being developed or produced.

Several international initiatives have been created to develop novel tools and protocols for reducing the number of experiments in battery research by a factor of 3,7 and, more generally, for boosting the pace of material discovery for energy applications by a factor of ∼10.8 Artificial intelligence (AI), and particularly its fruitful branch known as machine learning (ML), stands out as a promising approach that could lead to a paradigm shift in the way we do battery R&D,9 hopefully enabling us to overcome the major challenges dealing with a vast number of variables and large quantity of data:

Battery R&D is a complex multivariable problem, where very different properties, such as performance, life-cycle analyses, safety, cost, environmental effects, and resource issues, are contained. Furthermore, the overall battery circular economy should eventually be included—from the mining, production, and assembly stage via the long usage phase to the final reuse and recycling processes. The present research workflow, however, relies heavily on a forward trial-and-error approach and is largely materials centered: synthesizing materials, manufacturing electrolytes and electrodes, assembling cells, and finally assessing performance. Even considering only these aspects, there are >10100 possibilities to synthesize active materials and prepare electrolytes,10 almost an infinite number of possibilities for choosing the electrode manufacturing parameters and dozens of possible cell formats, which is far greater than what a human brain can handle. This makes difficult the emergence of inverse design tools enabling the prediction of the battery component properties needed for a given performance target and cell format.

The amount of battery R&D data grows exponentially, following the world data-sphere trend.11 For example, BASF, the second largest chemical producer in the world, recently announced that they produce >70 million battery characterization data points per day,12 and in an academic context, as an example, the French Network on Electrochemical Energy Storage (RS2E) with its 17 academic partners13 generates ca. 1 petabyte of battery data per year. These enormous data sets are currently not accessible to the scientific community as a whole, but actions have been taken toward establishing open and FAIR14 battery databases.15−17 Furthermore, there is already a massive amount of data spread out in scientific publications: almost 30,000 LIB publications already exist, and this number is growing rapidly.18 A researcher reading 200 papers per year will need nearly 150 years to read all of the LIB publications available today.

AI and ML will thus need to assist researchers to efficiently solve the parameters and data challenges of LIBs19 as well as assist the R&D of battery technologies beyond LIBs—such as Na-ion, all-solid-state, and Li–S batteries—and electrochemical capacitors (supercapacitors). For this to become true, several challenges need to be tackled, for instance, defining widely accepted standards in battery R&D combined with systematic data disclosure,20 the identification of the most suited descriptor(s) for a certain ML model, or the determination of the associated error, among others. In addition, different battery technologies bring different challenges and AI- and ML-based approaches can be already helpful in many aspects, as ML-assisted operando imaging techniques aiming to study Li dendrite formation and growth for all-solid-state batteries (ASSBs). Other examples could be the increase in time and length scales of current physics-based simulations or the development of innovative multiscale approaches.21−23

This Review aims at providing a comprehensive, authoritative, and critical, yet easily understandable, review about AI and ML of general interest to the chemistry and electrochemical energy sciences community. It addresses the concepts, approaches, tools, outcomes, and challenges of using them as an accelerator for the design and optimization of batteries. Making the booming and highly dynamic AI-related literature more accessible to the battery community as a whole is critical. To move AI applied to batteries from hype to reality, a strong collaboration between experimentalists, modeling specialists, and AI experts is needed; thus, AI and ML must be properly explained and reviewed in a way suitable for a broad audience. We aim here to create better accessibility of these tools and completeness in terms of the different battery R&D aspects currently covered.

In addition, the multitude of battery R&D fields in which AI and ML are being applied lead to heterogeneity in the terminology used and a lack of clarity on both the direction that AI/ML applied to batteries is undertaking and the main challenges that need to be overcome. Reviews in the field have so far focused either on battery diagnosis of, e.g., LIBs or solely on materials, with few examples at the full battery level.24−29 No review so far has provided an overview of applications across the full range of battery R&D across multiple scales (from materials to cells), as we aim to do here.

The aim of this first section is offering to researchers with no or little knowledge on the topic a simplified but easily understandable idea of how AI (and more specifically ML) works. We hope this can assist them in reading in a critical way modern scientific literature where AI or ML are applied to battery research, as well as easing the collaboration between AI/ML experts and other researchers in the field. Readers interested in more detailed discussions on AI/ML in general can refer to the many excellent books already published on the topic.30−40Subsection 1.1 defines AI and ML, giving a short historical perspective. Then, the importance of data (subsection 1.2) and the differences between supervised and unsupervised (subsection 1.3) ML methods are discussed, together with the importance of their hyperparameters (subsection 1.4). Afterward, we describe in an accessible way the working principles behind the most widely used ML techniques (subsection 1.5) and the programming languages and software available to develop them (subsection 1.6). Finally, the outline of the rest of the Review (next sections) is presented (subsection 1.7).

1.1. What Is AI?

AI is ubiquitous in our modern world, equipping many modern digital devices.41 AI equips Internet search engines like Google to learn from our search habits and suggest the most relevant results to us. It is implemented in social networks, like Facebook or Twitter, and Amazon for personalizing news feeds, recognizing people or objects in photos, offering machine translations, or detecting inappropriate content, among other uses. Online video-on-demand services, like Netflix, use AI to personalize movie offerings, and our cell phones use AI as personal assistants (e.g., Siri, Google Now, and Bixby). Other widely adopted AI applications have capabilities spanning from sorting spam and performing speech recognition to making personalized sales offers in e-commerce, among others. Another widely known example of application is gaming, whose major breakthroughs are the chess-playing computer Deep Blue,42 AlphaGo,43 and Watson.44 AI is also at the heart of the development of modern robotics,45 autonomous driving,46 and smart power grids.47 Chemistry fully follows this trend. Aiming to decrease the cost and increase the quality of their products, chemical industries are investing in AI and digitalization to accelerate their R&D,48 while academics intend to use AI and ML to accelerate research on materials, pharmaceuticals, catalysts, and more.49−52

In spite of this, for the vast majority of its history, AI was not as widely accepted as it is today.53−55 Even if typically associated with the fields of informatics and computer science, the concept of AI also belongs to fields like philosophy and psychology, interrogating on the relationships between human beings and machines. From the beginning of human history, the development of new machines and tools guaranteed the survival of humankind, resulting in a strong relationship between humans and machines since early times. An example of this can be found in the Egyptian society, in which the announcement of the next pharaoh was indicated to the population by the God Amon’s statue, through a mechanically moveable arm.56,57 However, the emergence of the AI concept and the development of computers, both originating from the English mathematician Alan Turing, triggered a revolution in this relationship. For the first time in human history, the question about the capability to develop machines able to reason as humans raised from the ground, as formalized in the philosophical question “Can machines think?” by Alan Turing himself.58 In his publication of 1950, he proposed a test, today known as the Turing test, whose aim is to verify if a human being, who is asked to interact with either a human or a machine through a few questions and without knowing her/his/its identity, is capable of distinguishing machines from humans.59 Despite the limitations of such a test,30 it enabled Turing to speculate about a time in which machines will become smart enough to reproduce human intelligence, giving birth to the era of modern AI.

The idea of Turing rapidly attracted the interest of the scientific community, leading to the Dartmouth AI summer research conference in 1956, widely considered as the founding event of the field and where the term artificial intelligence was first proposed. The aim of this conference was defined by its organizer, John McCarthy, who stated: “Every aspect of learning or any other feature of intelligence can in principle be so precisely described that a machine can be made to simulate it”.60 Considering this as the starting point of the field, it is not surprising that the first attempts to develop AI algorithms aimed to simulate the human brain behavior.61,62

Historically, AI has been defined as making machines think humanly, act humanly, think rationally, or act rationally.30 The Turing test discussed above required the machine to act humanly, for instance. However, clearly the definition of what is acting or thinking humanly/rationally is in constant evolution, and it is not linked to computer science alone. It is rather interconnected to other disciplines such as philosophy, psychology, neurobiology, logic, and mathematics, just to cite a few.30 AI could also be defined as “the science and engineering of making computers behave in ways that, until recently, we thought required human intelligence”.63 However, similarly to the previous case, which behaviors we classify as requiring human intelligence or not are time and society dependent. Some decades ago, it would have been believed by many that playing games or interpreting human behaviors to send personalized feeds would require human intelligence, while today these are tasks that we recognize machines can do.43,64 All the above makes AI a moving target, whose exact definition is not trivial. However, the majority of AI systems in current use have in common the capability of learning from experience. The most widely adopted approach to make machines doing so is through algorithm architectures known as ML,30 which are the ones employed nowadays in battery R&D and will be the main subject of this Review. These algorithms have tremendous capabilities to assess multidimensional data sets (i.e., data sets containing multiple variables), discover patterns in data, and unlock applications that are difficult to exploit by using other approaches.23,27,65−67 This is of high relevance for the fields of battery material discoveries or battery manufacturing optimization, in which a multitude of parameters should be considered simultaneously.68 The discovery capabilities of modern ML algorithms rely on the quantity, quality, and veracity of data. Therefore, the first step for any ML-based approach is to build a suitable and complete enough data set.27 Afterward, the ML model should be trained and, when possible, evaluated. In the most common case (supervised models), this is achieved by using a part of the data set to train the algorithm (training step), whose predictive capability is assessed by comparing values predicted by the model and data that were not used for the training step. This is generally referred to as a test step. If the so-obtained model proves to be trustable along this step, the supervised ML algorithm is ready to be used (Figure 1).

Figure 1.

Overall working principles of a ML approach for supervised/unsupervised and classification/regression methods. For simplicity, here classification is represented as the only application of unsupervised ML, despite other applications, for instance dimensionality reduction, existing.

ML algorithms can be classified as supervised, unsupervised, or semisupervised methods.69,70 Supervised approaches employ data sets that are pretreated to define certain variables as inputs and others as outputs. This prior information is missing for the case of unsupervised ML algorithms, whose goal is to find patterns in the data set. Within supervised ML, it is possible to distinguish between regression and classification, where the latter indicates a ML approach analyzing the data set in terms of classes, while the former analyzes it in terms of continuous values. The classes used for a supervised ML can come from the operator or from an unsupervised ML. Semisupervised approaches are somewhere in between the two and utilize data sets containing both labeled and unlabeled data. Besides the type used, classical ML algorithms rely on data and are rather agnostic to physics, meaning that they could aim, for instance, to determine the relationship between different variables interpolating the training data, rather than offering any physical interpretation of such a relationship. However, physical-informed ML approaches exist, for example, when using ML algorithms to solve or discover partial differential equations,71−73 among others.74−76

1.2. About the Importance of Data and Good Practices

All ML algorithms rely on data, which are vital to develop accurate ML models. As widely known, the amount of data is critical, and it is typically believed that higher amounts of data leads to more accurate ML models. Even though this is generally true, the data quality is not a negligible factor and it should be considered, as well. Data sets containing too little data or containing poor quality data (e.g., data difficult to reproduce or affected by significant errors) can lead to wrong ML predictions, biasing the associated result interpretation. In this context, the first step to develop a reliable ML model is building a data set representative of the problem under analysis. Good experimental practices in terms of both design of experiments77 and experimental procedures78,79 are needed to ensure the reliability of data sets and ML results. Defining effective experimental strategies is even more critical when applying ML-driven methods to rare failure scenarios, as recently highlighted by Finegan et al.80 In terms of variables to be considered, it is a good practice to consider as many variables as possible to have a global perspective on the problem under study. However, to simplify the ML model development for the case of multivariable problems, unsupervised techniques, such as principal component analysis (PCA), can be used. In particular, PCA is able to project the original data onto a low-dimensional subspace identified by convenient axes, also known as principal components, arising from linear combinations of the original variables, ordered by the variance they represent in the data set. Once the principal components accounting for the vast majority of the variance are identified, the ML model can be trained using these instead of the original variables, leading to a dimensionality reduction.81

Similar to experimental measurements, AI algorithms themselves should be subjected to good standards and protocols to ensure that no bias is made during data processing and predictions. For instance, the data set and how the quality of the trained model was evaluated (if this was possible) should be systematically disclosed. The latter is relatively easy for the case of supervised models (the most commonly employed ones in the battery field), but evaluating the quality of unsupervised ones can be rather challenging, as it will be shortly discussed in the next subsection. Taking the case of supervised methods, the model accuracy can be assessed by comparing the outputs predicted by the ML model when considering inputs not used during the training step and the real outputs, which were previously measured. The data set used to carry out this procedure is typically known as a test set. If the results predicted by the ML algorithm are equal, or close enough, to the real outputs, the model can be considered correct and can be used for predictions. A simple way to quantify this is through regression plots, which are obtained by plotting the data in the test set (true results) and the predictions coming from the trained ML model (predicted results). The predictive accuracy of the model can be quantified as the R-square82 of the points obtained when compared to the first bisector (true results = predicted results) of the regression plot. As is intuitive, an R-square ranging from 0 to 1 stands for a predictive accuracy ranging from 0 to 100%. However, the use of only the R-square as a metric to evaluate the predictive accuracy could lead to errors in certain cases. An example of this is when using a ML algorithm to predict the energy of a molecule (section 2) while the energy of the system is shifted for instability (or others) reasons, which could lead to high R-square and high mean-squared error (that, on the contrary, should be minimized). Therefore, other metrics, such as the root-mean-square error or the mean absolute error, can be substituted for or can be associated with the R-square, in order to better verify the predictive accuracy of the model. In addition, it should be stressed here that each model has a limit of validity that should be taken in mind. Indeed, if the model is used to predict results associated with inputs that are significantly different from the ones used for the training and test steps, it is likely that the predictions will not be as accurate as desired. For a more detailed discussion on the importance of good practices in machine learning, the interested readers are referred to ref (83).

1.3. Supervised and Unsupervised Methods

Supervised ML algorithms aim to

identify the relationships between

inputs and outputs building a numerical model based on the data used

during the training process. The algorithm architecture used to develop

such a model varies as a function of the ML method used (as will be

discussed more in detail afterward), but the result of any supervised

ML approach is a numerical model linking some outputs  to certain inputs (

to certain inputs ( ). Both inputs and output(s) can be either

continuous values or classes. This distinguishes supervised ML algorithms

as classification (classes) or regression (continuous) methods, as

schematized in the right column of Figure 1.

). Both inputs and output(s) can be either

continuous values or classes. This distinguishes supervised ML algorithms

as classification (classes) or regression (continuous) methods, as

schematized in the right column of Figure 1.

To better understand the philosophy behind this approach, it is useful to compare how ML algorithms learn and how the human brain learns. Typically, humans learn through examples. In other words, the brain collects information from the external environment through the sensory apparatus. It elaborates this information in order to identify patterns, which are stored to use this knowledge when needed. As an example, learning that a wild animal is dangerous allows one to react as fast as possible when such an animal is in your proximity, increasing the chances to escape and survive. Similarly, ML algorithms learn through examples that are given in the form of data. These data are used to numerically identify patterns and develop a numerical model able to describe these patterns. Once that model is obtained, it is possible to use this knowledge to predict new results. However, these predictions can lead to errors from time to time. How often, and then how trustable the model is, depends on the model accuracy, discussed in the previous subsection.

Several regression methods were applied in the LIB literature up to date. The most known and widely adopted approaches are briefly discussed in subsection 1.5, but some of them were excluded for the sake of shortness. This small paragraph aims to offer a short list of the approaches not discussed in detail, allowing the readers to recognize these techniques when cited in the Review and offering references where the interest readers can find more detailed information. As mentioned above, regression-based methods aim to fit the training high-dimensional data (xi) and the output (y) by searching an approximation of the relationship between the two. In that sense, this process can be simplified as searching an appropriate functional form (herein called f), where y ≈ f(x). Several famous techniques are based on this approach, such as multiple linear regression84 (MLR) or multivariate curve resolution alternating least squares85 (MCR-ALS), least absolute shrinkage and selection operator86 (LASSO), and ridge and kernel ridge regression87 (KRR). The differences between these approaches rely on the underlying mathematical approach used to find the best functional to describe the data set provided. Other approaches able to deal with high-dimensional data sets are least-angles regression88 (LAR) and sure independent screening and sparsifying operators89 (SISSO), based on linear and nonlinear regression, respectively. Lastly, other approaches do not fit the complete training data with a certain functional, but they divide the data set into different pieces and fit each of them with a certain functional. An example of this is the multivariate adaptive regression splines90 (MARS) model.

Contrary to supervised ML methods, unsupervised ones use unlabeled data sets. These methods are typically used for: (i) identifying groups of data (also called clustering methods) or (ii) dimensionality reduction to identify the most relevant/impactful variables. In that sense, the difference between unsupervised classification (i.e., clustering) and its supervised counterpart is that the former does not require indicating in the data set what is input and what is output. However, the advantage of using approaches that do not require any previous knowledge about the relationship between data is counterbalanced by the lack of information about the nature of the clusters identified and the difficulty to assess the quality of the trained model. In other words, after the clustering through unsupervised ML, it is up to the human operator to assign each identified cluster its physicochemical meaning, and the quality assessment of the clustering or dimensionality reduction performed largely depends on the specific scope for which unsupervised ML is used and it is not always possible. An example in which quality evaluation is possible is clustering, where the distance between elements of the same cluster (intracluster distance) and the distance between different clusters (intercluster distance) can be used as metrics. If using such a metric, the higher the intercluster distance and the lower the intracluster distance (i.e., the clusters are well-defined and separated), the better the model.

As mentioned in the Introduction of this Review, the amount of human-produced data is growing exponentially. However, the majority of these data are not preprocessed, making unsupervised ML particularly suited for their analysis. An example of this is text mining applied to material discovery, for which unsupervised ML methods can be used to classify texts based on similarities between words and sentences.91,92

1.4. Hyperparameters

The reliability of any ML approach depends not only on the method employed but also on its hyperparameters (HPs), which are controllable by the operator and specific to each ML architecture. HPs are defined as parameters influencing the training process, which ultimately affect the model reliability. Therefore, HPs should be optimized for the specific model developed to avoid both underfitting and overfitting. Underfitting refers to a ML model that it too simplistic for the problem under analysis, such as a model not trained enough, while overfitting refers to a model that is too specific, e.g., describing correctly the training data only and having low predictive capability.30,93 A classic example of HP is the number of layers in a neural network (NN), affecting the error propagation in the NN architecture during the training step. In order to optimize the model’s HPs, optimization techniques as particle swarm optimization94 (PSO), artificial bee colony95 (ABC), and genetic algorithms96 (GAs) can be used. The algorithm architectures behind these approaches differ; however, the basic idea behind them is similar and typically relies on minimizing a cost function (linked to the model error) by changing the HP value. In addition, cross-validation (CV) is a useful procedure to assess the quality of the HPs employed. CV is typically based on the k-folds approach,97 which splits the training data set into k subsets. Afterward, the model is trained k times by using k – 1 subsets and tested on the remaining one, where at each iteration the subsets used for the training and test change in order to consider all of the possible combinations. This approach allows testing deeply the prediction capability of the ML model, minimizing the risk of underfitting or overfitting. Even if based on the same principle, it should be mentioned that other CV approaches have been developed, such as stratified k-fold CV98 or leave-one-out CV.68

1.5. Most Used Machine Learning Methods

In the following, we describe the working principles of the most used ML methods in battery R&D. All of these methods are referred to in the application sections 2, 3, 4, 5, and 6.

1.5.1. Neural Networks

A NN algorithm architecture reproduces in silico the working principles of a human brain.31,99−101 Each neuron contains just a small piece of the global information, which is shared between the different neurons through their interconnections (synapses) and transmitted through electrical pulses. Similarly, the NN algorithm architecture relies on interconnected “neurons,” hereafter referred to as nodes, each of them storing just one small piece of the global information. The nodes are divided into layers, which can be classified as input, output, or hidden layers. The number of nodes in the input layer is equal to the number of model inputs, while the output layer consists of one node for each output. The hidden layer(s) are composed by n nodes. The number of hidden layers and the number of nodes for each layer are HPs that have to be optimized for the case under study.

The training procedure of a generic NN algorithm (Figure 2a) can be described as follows. The value of each node (except for the input ones) is defined as the sum of the value of each node belonging to the previous layer multiplied by a coefficient, which is specific to each node and is adjusted during the training. Each node has a value associated to it that depends on the sum of the value of each node belonging to the previous layer(s) multiplied by a coefficient (except for the input ones). This coefficient is specific to each node and is adjusted throughout the training. This value is then used as argument of the activation function (one HP of the model), which outputs the final value associated to this specific node. This operation is accomplished for all the nodes, going from the input to the output ones. Once the output node values are calculated by the NN, they are compared to the output values in the training data set. Following a back-propagation process, the difference between the predicted and real results is used to modify the coefficient matrix, i.e., the coefficient associated to each node. This process is performed n times (where n is a HP) in order to find the optimal coefficient matrix that numerically describes the relationships between inputs and outputs. The values of the coefficients at the beginning of the training process are chosen randomly, while the values associated with the input nodes are the values associated with the inputs in the training data set.

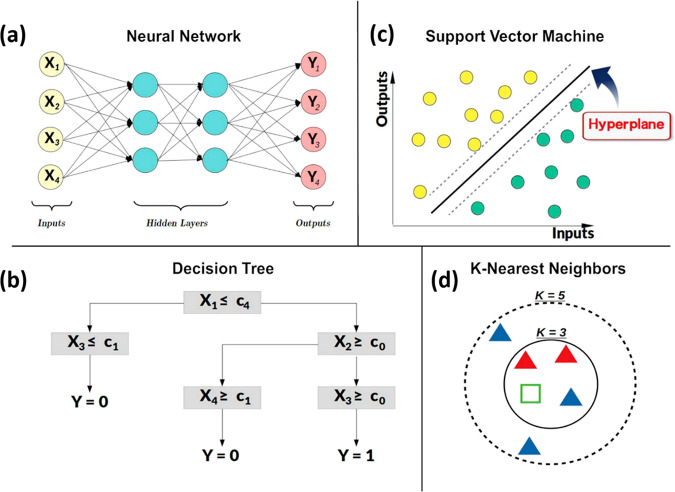

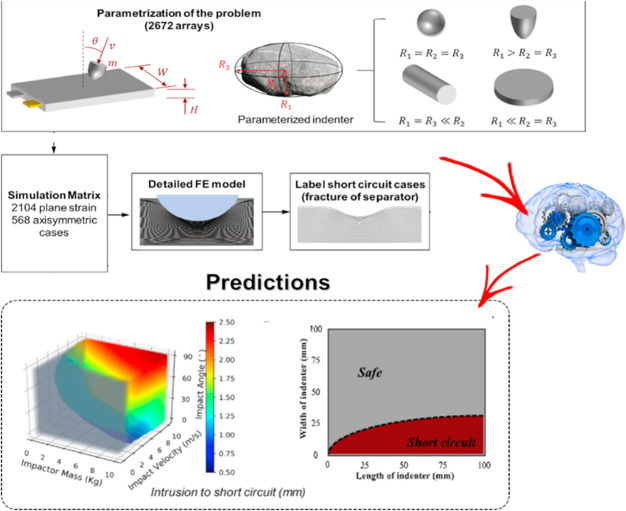

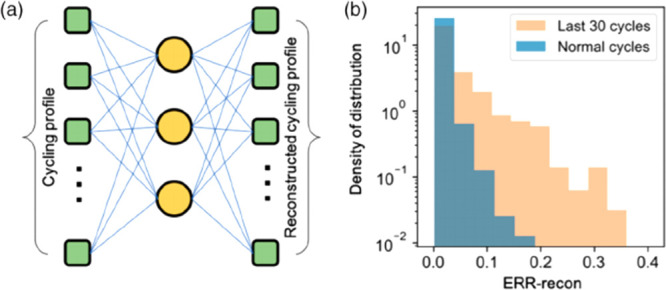

Figure 2.

Workflows of some of the most common ML techniques: (a) neural network; (b) decision tree; (c) support vector machine; (d) k-nearest neighbors (k-NN).

In the following, we discuss briefly the most used NN architectures in the battery field. However, it should be stressed that different definitions with respect to the ones discussed here can be found in the literature, as the nomenclature of different NN techniques is not well standardized among the ML community. The simplest NN model is known as the perceptron NN, containing several inputs and only one output and without any hidden layer. If only one or more hidden layer(s) is (are) used, the method is generally referred to as artificial neural network (ANN) or multi-layer perceptron (MLP) and deep neural network (DNN), respectively. The difference between MLP and DNN is that MLP use only “classical” nodes in its hidden layers (the ones discussed above), while DNN is more generic and can encompass more complex mechanisms, for instance convolutional layers, which are discussed below. In addition, all the nodes can be connected (i.e., they share information with other nodes) or not. The procedure used to “disconnect” (typically randomly) certain nodes is generally referred to as dropout.

A special class of NNs, of particular interest for image analysis, is the convolutional neural network (CNN). The main difference between CNN and other NNs is the use of convolutional layers (CLs) together with classical hidden layers. CLs are able to recognize specific patterns in images, which makes them particularly suited for tasks as object recognition. The pattern identification is performed through filters embedded in the nodes of the CLs. These filters are constituted of matrixes of dimension n × m, and, instead of analyzing the image pixel by pixel, the CLs analyze blocks of n × m pixels. Thanks to these characteristics, if the filter is well developed and trained, it can be used to recognize automatically specific patterns in images, enabling, for instance, distinguishing between different phases (as active material, carbon-binder domain, and pores) in electrode tomography images, automatizing and easing the segmentation procedure. An alternative to classical CNN is the Bayesian convolutional neural network102 (BCNN), which offers information about the error on the predicted output. Another NN method of interest is known as wavelet neural network103 (WNN), whose main characteristic is that its inputs are curves and not multivariate data.

Even more complex NN architectures can be developed. For instance, recurrent neural network104 (RNN) and long–short-term memory105 (LSTM) were conceived to “remember” information during the training step. The first difference between these two approaches and the ones discussed above is that the inputs can be linked, meaning that they are not independent, as in Figure 2a. An example could be the use of RNN for reproducing texts, in which one word and the following one are linked. Concerning LSTM, this technique is more suited to time-dependent data, which can be of interest for operando applications. Lastly, another approach of interest is the extreme learning machine (ELM), which is a NN using a single hidden layer with better generalization performance than the classical back-propagation NN.106

1.5.2. Decision Tree, Random Forest, Boosting, and Bagging Approaches

The basic idea of a decision tree (DT) is to divide a complex problem into n smaller ones through a treelike structure. In this representation, each node of the tree represents one small subproblem, while the tree as a whole constitutes the solution to the overall problem.36 At the beginning of the training process, the data contained in the data set is injected in the root, i.e., the first node in the upper part of the DT (top of Figure 2b). Afterward, the algorithm searches for the input that best discriminates between the outputs. In other words, it searches which value (ci) of which variables splits the initial data set in such a way to separate as many outputs as possible, minimizing the associated error in the meantime. This leads to the bifurcation of the node (and of the data set) into two “paths”, one for values of the selected inputs lower than ci and the second one for values higher than ci. Iterating this procedure leads to a series of paths linking each possible input to a certain output, resulting in the tree shape reported in Figure 2b. One of the main advantages of this approach is that it produces a self-speaking and easy-to-understand representation of the links between inputs and output (X and Y in Figure 2b). However, this approach is often too simplistic to allow reaching high prediction accuracy. For this reason, the random forest (RF) method was developed to combine the simplicity of DT with an improved predictive capability. The idea behind RF is that, if a single DT is not enough to obtain stable/accurate results, the results obtained averaging the outputs of a multitude of DTs can lead to more trustable predictions. This results in a significant increase of the prediction accuracy, which makes RF-suited to solve complex problems.70,99,107

Boosting and bagging approaches are based on the same idea as RF, i.e., using several DTs to reduce the bias and the variance of the model while improving its predictive accuracy. The main difference between RF and boosting/bagging is the sampling method used,108 while the bagging and boosting approaches are differentiated by the procedure adopted for the training step.

1.5.3. Support Vector Machine

Support vector machine (SVM) aims at finding the best hyperplane(s) (i.e., multidimensional plane) to separate the inputs as a function of their associated output(s).70 In other words, SVM identifies which hyperplanes better separate the hyperspace of inputs and outputs in n zones (where n depends on the number of initial classes), while minimizing the associated model error and maximizing the probability that each zone is well separated from the others (Figure 2c). The degree of separation of these zones can be modulated by some HPs of the SVM method, typically referred to as cost, gamma, and the kernel used.98 During the last decades, different methods based on SVMs were developed, as for example the multikernels support vector machine109 (MSVM), which does not use one single kernel but a linear combination of kernels. Other examples could be the support vector regression110 (SVR), applied for quantitative supervised learning, and least squares support vector machines111 (LSSVMs) or relevance vector machines112 (RVMs), that were specifically developed to solve linear equations and to use Gaussian kernels, respectively.

1.5.4. k-Nearest Neighbors

k-Nearest neighbors (kNN) is a well-known ML method applied for both regression and classification, relying on variable similarity in the data set.70 This is quantified by calculating the distances between the raw data points in the multidimensional feature space, i.e., the space defined by each input feature. Data that are close enough in the feature space are grouped together, which allows identifying clusters of data. Once the different groups are defined through the training data set, this method allows predicting the class or the output associated with new inputs by comparing them to the “k” nearest neighbors in the multidimensional feature space. As an example, for the case of a classification algorithm that uses a k value of 3, the three nearest neighbors will be considered, and if at least two out of three nearest neighbors belong to a certain class, the new input is classified accordingly (Figure 2d). The optimal value of k is typically identified by maximizing and minimizing the intergroup and intragroup variance, respectively, aiming to obtain well separated clusters.

1.5.5. Probabilistic-Based Approaches

The most known and most used probabilistic models

are the ones based

on Bayesian approaches. These approaches use the a priori probability on the distribution of the training data (in a certain

sense, the error associated with the data) to calculate the a posteriori probability (related to the error of the output)

to enhance the output prediction and offer information on its associated

variance. Therefore, Bayesian models offer an estimation of the error

associated to the predicted outputs, which is rare in the ML field

and extremely valuable for assessing the limit of validity of the

ML model. The theoretical baseline of this approach relies on the

Bayes theorem, which links the a priori and a posteriori probability. The simplest approach is generally

referred to as naive Bayes113 (NB), which

simplifies the calculation of the a posteriori probabilities

by considering that the a priori probabilities of

the inputs are independent. A more complex approach is known as Bayesian

Monte Carlo114 (BMC), in which no approximations

are done. In this case, the resolution of the integrals arising from

the lack of any approximation is simplified through a Monte Carlo

approach. Another important approach is the Gaussian process115 (GP), typically applied to regression. The

working principle of this approach is similar to the Bayesian one,

but it approximates as Gaussian the a priori probability

distribution. An example of predicted function is plotted for six

observations (red points) in Figure 3. The predicted function does not only aim to fit the

data (observations); it also offers a measure of the error (light

gray zone) associated to the predicted function. The prior information

about the GP is usually specified in terms of a kernel function k(x1, x2), which gives the covariance between two data points (x1 and x2). Generally

speaking, kernel approaches refer to a feature transformation of the

initial data in a specific feature space. They allow dot products

of vectors and are often called generalized dot products. In simplified

words, kernel functions are mathematical functions applied to vectors

(as the training data), which are used for data processing. For the

sake of offering a practical example to the readers, a useful example

is the case of an exponential kernel. This uses two vectors (x1 and x2) and outputs

a numerical value that is equal to  (i.e., k(x1, x2) =

(i.e., k(x1, x2) =  ), where e is

Euler’s

number and σ is linked to the variance of the input data (training

data set). Several other kernel types exist, which could lead to more

complex mathematical transformations, but the overall idea is the

one exemplified above. In terms of the most used kernels, the squared

exponential (SE) kernel is a popular choice for vectorial inputs,

while, for molecular data (section 2), the smooth overlap of atomic positions (SOAP) kernel116 is widely employed, among many other possible

alternatives.117

), where e is

Euler’s

number and σ is linked to the variance of the input data (training

data set). Several other kernel types exist, which could lead to more

complex mathematical transformations, but the overall idea is the

one exemplified above. In terms of the most used kernels, the squared

exponential (SE) kernel is a popular choice for vectorial inputs,

while, for molecular data (section 2), the smooth overlap of atomic positions (SOAP) kernel116 is widely employed, among many other possible

alternatives.117

Figure 3.

Example of GP regression. The standard deviation refers to the error associated with the predictions.

Another probabilistic-based approach of interest is known as Bayesian optimization118 (BO), which does not only output a certain function and the associated probability distribution after the training process, but it also aims to identify the “optimal values” of that function, making it particularly suited for optimization purposes.

Lastly, other methods using probabilistic theory are discriminant analysis—such as linear discriminant analysis (LDA), quadratic discriminant analysis (QDA), partial least squares discriminant analysis (PLS-DA), or shrinkage discriminant analysis (SDA)119—and logistic regression120 (LR).

1.5.6. Generative Models and Inverse Design

Generative models are a class of unsupervised ML algorithms that can be used to generate data similar to the ones used for the training. As an example, given a data set of electrode material crystal structures, the trained generative model can be queried to generate more examples that look like the materials in the data set. Similarly, it is possible to use electrode mesostructures121−123 or, in principle, any other battery-related information, instead of crystal structures. This is a useful alternative to high-throughput screening where it can be inefficient, or even impossible, to consider all the possible material candidates even when using cheap surrogate (i.e., simplified) physical models. Traditionally, hand-coded rules or genetic algorithms have been used to generate new material crystals or nanoparticles,124 but in recent years there has been a shift toward deep learning models, particularly variational autoencoders (VAEs),125,126 adversarial autoencoders (AAEs), generative adversarial networks (GANs),121−123,127,128 and reinforcement learning (RL), shown schematically in Figure 4. In a VAE, one tries to learn an encoder and a decoder, which are both DNN models that map, for example, battery active material crystals into a (latent) vector space and from this space back into the original space, respectively. To generate new material crystals, it is possible to sample new points from the latent space and map them back to the input representation. In a GAN, the generator network gets a sample and is asked to generate a “fake” one that looks real. Another network (the discriminator) is trained to distinguish between real and fakes, forcing the generator to make more and more realistic its “fake” samples. In the context of batteries, the samples can be, upon others, electrode microstructures or crystal structures, as will be presented in sections 2 and 4. The AAE combines the idea of VAE and GAN and uses a discriminator to inform whether the encoded sample comes from the prior distribution or from the encoder. Finally, in a RL setting, a sample is thought as being produced by a number of steps taken by an agent. After the creation of the material crystal, the agent is provided with a reward or penalty based on the properties of the generated sample.

Figure 4.

Deep learning architectures for generative modeling.

The generative architectures described above are often used for inverse design purposes (Figure 5), where the goal is to identify the conditions, such as the material to use or manufacturing/cycling protocol to implement, needed to obtain a desired property.129,130 In RL, one can directly incorporate the desired property in the reward signal given to the generating agent, while VAEs, GANs, and AAEs link the latent space to the sample of interest (crystal structure, microstructures, etc.). Then, it is possible to map the latent space searching for a desired optimum. Some of the most popular search methods for this application are gradient descent and Bayesian optimization. It is also possible to train a generator to be directly conditioned on a property.

Figure 5.

Inverse design with deep learning models.

1.6. Programming Languages and Platforms

All of the ML examples discussed above need to be built by using a programming language. In this subsection, the most used programming languages are discussed together with their advantages and disadvantages in terms of developing a ML algorithm.

Python: Widely used open-source language, particularly appreciated by the AI/ML community due to several dedicated easy-to-implement libraries. Created in 1989 in reference to the famous Monty Python’s Flying Circus British TV show,131 this programming language offers many tools to easily manipulate big data sets, displaying results, etc. In addition to these basic features, several Python libraries are specifically devoted to ML algorithms, as Scikit-Learn, Tensorflow, or Keras, just to mention a few. Another advantage of Python is its popularity, thanks to which many dedicated forums and Web sites on the topic are already available.500−502 Generally, Python algorithms are executed under cross-platforms called integrated development environments (IDEs), such as Spyder, Pycharm, and Jupyter Notebook. The last one is attracting increasing attention due to its friendly interface and the possibility of interacting with several other programming languages.

R: Developed during the last decade of the 20th century, R is particularly popular in statistics science. Compared to Python, R is less used to build ML algorithms. However, it offers fully dedicated statistical libraries such as MASS, stats, fdata, car, or glmnet. In addition, the Comprehensive R Archive Network132 (CRAN) reports all the details needed to help users understand how to utilize each specific library/package.

C++ and FORTRAN: Considered as the modern pioneers of programming languages, they are widely used as high-performance languages. The implementation of ML codes by using C++ and FORTRAN is typically more difficult compared to R or Python, and it requires taking care of the memory management (contrary to Python, which is already optimized for it). Nevertheless, famous C++ libraries for ML, such as SHARK or MLPACK, exist.

In terms of computational resources, they are becoming more affordable thanks to platforms created by computer giants like Google Cloud ML Engine,133Microsoft Azure Machine Learning,134 and IBM Watson Machine Learning,135 which allow launching in cloud ML algorithms requiring extensive training. In addition, those platforms offer “ready to use” codes that can be particularly useful for nonexpert users or companies.

1.7. Outline/Scope

The first section presented the concepts of AI and ML, briefly introduced some key points of their history, and discussed in an accessible manner the most used ML techniques in the battery field. Numerous applications in battery research exist, which are discussed in detail in the following sections, covering the following aspects: materials design and synthesis (section 2), electrode and cell manufacturing (section 3), electrode architecture and materials characterization (section 4), battery cell diagnosis and prognosis (section 5), and surrogate modeling, recycling, second-life, and text mining (section 6). Each of these sections can be read on its own or in combination with the others, allowing modulation of the reading as a function of the readers' interests. In addition, Figure 6 shows that the battery community did not grant the same attention to each of them, with prognosis/diagnosis (∼40%) and materials design and synthesis (∼27%) being the most studied ones, followed by material and electrode characterization (∼17%) and manufacturing (∼6%), while the rest (∼10%) is accounted for by other applications. Lastly, section 7 presents the overall conclusions and indicates challenges and opportunities for further application of AI/ML in the battery field.

Figure 6.

Percentage of reviewed articles applying AI or ML to the different battery-related topics discussed in this Review. This analysis was performed on ∼200 scientific articles.

2. Application to Materials Design and Synthesis

In this section, we review current advances on the intersection between AI techniques (mainly from the subdomain of ML) and the design and synthesis of battery materials. We first provide in subsection 2.1 a brief overview on recent efforts to develop appropriate materials descriptors, which are often the first difficulty toward implementing meaningful and accurate ML models. Then, we present a variety of examples where ML-based studies are contributing to accelerate the screening and prediction of new battery materials with specific targeted properties. The examples are classified in three main groups: (i) active electrode materials, (ii) solid electrolytes, and (iii) liquid electrolytes. In subsection 2.2, we discuss how ML algorithms are also creating new opportunities for materials simulations, by helping to tackle increasingly complex chemistries, larger length and time scales, and multiscale modeling. In ssubection 2.3, we move to the synthesis of new materials and, in particular, how AI can be applied to effectively plan experiments and mitigate the combinatorial explosion problem associated with the exhaustive rendering of chemical and physical spaces in typical high-throughput (HT) approaches. In this context, we show how ML algorithms are applied to identify relations between variables and to speculate about the outcome of new experiments. Finally, in subsection 2.4, we provide perspectives and identify key future challenges on the use of AI/ML for materials design and synthesis.

2.1. Materials Discovery

Informatics-aided materials discovery and optimization is becoming a powerful tool to analyze experimental and theoretical data and extract key structure–property relationships of functional materials, in general, and battery materials, in particular (recent review articles on the topic include refs (129, 136−145)). Current approaches in this direction typically combine HT screening and ML, aiming to find new active electrode and electrolyte materials for next generation batteries. Common ML methods include DTs, BO, SVM, and ANNs, among others (Figure 7); for a brief and accessible description of the applicability of these methods within the wider domain of materials science, the interested reader can consult refs (136, 137, 146, and 147).

Figure 7.

Infographic on the ML methods recently used in the literature to search for new battery materials with specific target properties, including the corresponding nature (calculated vs experimental data) of the employed databases.

Based on the utilization of high-fidelity data from physical-based simulations, experiments, or both, ML methods are used to find complex nonlinear relationships among a relatively large number of variables. This ultimately helps classify materials with similar characteristics or predict target properties in new materials.

In the case of active electrode materials, typical properties of interest are discharge capacity, capacity retention, volume change, Coulombic efficiency, voltage profile, or redox potential. In the case of electrolytes, current efforts are focused on the search of inorganic solid-state ion conductors with high ionic conductivities and good mechanical properties. A table is provided in the Supporting Information (Table S1) which summarizes recent works in the literature for different materials, data sources, target properties, and employed ML methods. This provides a quick overview of the current research efforts in the area that will be described in detail in the following.

Access to sufficient reliable training data is the first obvious bottleneck for implementing any ML model. Not only does the size of the data set significantly impact the accuracy, but the quality of the data is also paramount. In particular, it is crucial to have properly sanitized data that does not introduce errors in the training process which could prevent a correct fitting of the data or that may later affect the performance of the model. No matter the source of the data, curation is therefore crucial and sine qua non condition for creating an as objective as possible correct database.148,149 High-quality data implies that the real world target property needs to be accurately reproduced by the corresponding experiment or simulation (high fidelity). However, high-fidelity data is often scarce because it is costly to obtain. Moreover, in contrast with scientists’ tendency to report in the literature only the best performing materials, there is also a general need for including poorly performing materials or failed experiments in databases in order to enrich the training sets.

Another key element in ML methods applied to materials science is the underlying mathematical description of different compounds, which needs to be sufficiently rigorous to enable the comparison of different structures and chemistries across large data sets. A critical challenge to apply ML models to a materials science problem is precisely the selection of appropriate descriptors that lead to sufficiently accurate predictions of the intended target property.150 In fact, poor descriptors unrelated to target properties often lower the prediction accuracy of a given ML model. Proposals of materials descriptors are abound in the literature (see, for example, Figure 8): histogram descriptors,151 fingerprints,152 Coulomb matrix,153 atom–atom radial distribution functions,154 and substructure fragmenting based on Voronoi-cell local partitioning,155 among others. However, complete atomic representations of broad chemical spaces are currently a work in progress and finding universal representations that work for all properties remains elusive.126

Figure 8.

Eight different material descriptors to represent a 9,10-antraquinone-2,7-disulfonic acid (AQDS) molecule used in organic redox flow batteries.126 Figure reproduced with permission from ref (126). Copyright 2018 American Association for the Advancement of Science.

It is also germane to point out that AI-aided materials discovery is a rapidly growing field, with several potential research directions ahead. One of those is inverse design to accelerate the discovery of ultrahigh-performance batteries. The so-called Battery Interface Genome (BIG) and the Materials Acceleration Platform (MAP) are promising initiatives in this quest.129 By combining data from multiple experimental techniques and simulation methods, BIG-MAP aims at deploying deep generative models126 capable of generating new data with the target property and, specifically, enable inverse design of high-performance interphases in batteries.

2.1.1. Active Electrode Materials

Min et al. considered an experimental data set and ML-aided analysis to establish optimal synthesis parameters and fulfill target specifications for Ni-rich NMC cathode materials (Figure 9).156 Input variables included, among others, calcination temperatures, Ni content, primary particle size, coating materials, and washing conditions, whereas output variables were initial capacity, cycle life, and amount of residual Li after synthesis. The authors assessed the performance of a range of different ML models (SVM, DT, RF, ridge regression (RR), ERT, and ANN), concluding that extremely randomized tree (ERT) yielded the smallest errors for predicting all of the output variables. In addition, the authors proposed optimal experimental parameters by conducting inverse design, which they successfully validated with additional experiments. In a more recent study, Kireeva and Pervov also considered experimental data sets to identify synthesis and electrochemical property relationships in Li-rich layered oxide cathodes using a SVM model.157 In this case, input variables included composition, synthesis method, Li and transition metal sources, Li excess, temperature, and time of calcination and sintering; whereas initial discharge capacity and Coulombic efficiency were set as output variables. ML analysis allowed for identifying key parameters affecting tailored characteristics such as some processing conditions, Li excess, or the ratio between Li and transition metals.

Figure 9.

Schematic representation of the procedure followed by Min et al. to establish optimal synthesis parameters for Ni-rich NMC cathode materials.156 Figure adapted with permission from ref (156). Copyright 2018 Springer.

Using density-functional-theory (DFT)-calculated lattice constants for fully lithiated and delithiated structures and aiming at designing low-strain cathode materials, Wang et al. built a partial least squares (PLS) model for predicting the percentage of volume change of spinel- and layered-type oxides.158 They found that the most important descriptors to predict accurate volume changes were the radius of transition metal ions and transition metal octahedron distortion. Using DFT-calculated voltages reported in the Materials Project (MP) database, Joshi et al. targeted the prediction of voltage profiles of a broad range of active electrode materials for Li-, Mg-, Ca-, Al-, Zn-, and Y-ion batteries (Figure 10).159 In this case, the considered materials descriptors included the nature and concentration of the intercalation cation, the crystal lattice type, and space group numbers as well as other elemental properties of the atomic constituents in each particular compound. The study helped identify potential new electrode materials for Na- and K-ion batteries when considering known Li-based active electrode materials that were not yet proposed for other chemistries.

Figure 10.

Schematic representation of the working procedure followed by Joshi et al.159 and some examples of results. Figure adapted with permission from ref (159). Copyright 2019 American Chemical Society.

In the search of organic electrode materials, Allam et al. constructed a DFT-based database for a selected set of different organic molecules.160 The authors considered both computed electronic properties and optimized geometrical information as input variables for a ANN-based prediction of redox potentials. Using linear correlation analysis based on calculating Pearson correlation coefficients (capturing how linear is the correlation between two variables), 10 main input variables were identified: electron affinity, highest occupied molecular orbital (HOMO), lowest unoccupied molecular orbital (LUMO), HOMO–LUMO gap, and the number of H, C, B, O, and Li atoms and aromatic rings in the molecule. The approach showed a good capability for predicting accurate redox potentials with respect to DFT-computed values when considering molecules not included in the training set.

ML can also be used to classify data sets into specified classes (supervised learning). In this context, Attarian Shandiz et al. considered several algorithms (LDA, QDA, SDA, ANN, SVM, kNN, RF, and ERT) and data from the Materials Project to predict the type of crystal system (monoclinic, orthorhombic, and triclinic) of Li-ion silicate-based cathodes containing Mn, Fe, and Co.161 It was found that RF and ERT classifiers yielded the lowest overall errors and that the crystal volume, number of sites, formation energy, energy above hull, and band gap were the most relevant descriptors.

2.1.2. Solid Electrolytes

The application of ML models to screen battery materials is particularly active in the domain of solid electrolytes. One of the first studies, in 2012, combined computed data with PLS analysis to propose novel olivine-type oxide solid electrolytes with low ionic conductivity.162 Specifically, the authors used the nudged elastic band (NEB) method to compute with DFT Li+ migration energies for a range of ordered LiMXO4 structures within the main group M2+–X5+ and M3+–X4+ pairs. By predicting the existence of materials with Li+ migration energies lower than 0.3 eV, several promising new compositions were proposed, as for example Mg–As, Sc–Ge, In–Ge, and Mg–P as well as Al–X, Ga–X, In–X, and Ca–X pairs, in general. Using instead an ANN model, Jalem et al. also investigated tavorite-type LiMTO4F (with M3+–T5+ and M2+–T6+ pairs) solid electrolytes.163 Predicted compositions with low migration energies included, for example, LiMgSeO4F, LiMgSO4F, or LiGaPO4F. Follow-up studies have shown that BO-based models are a very effective search algorithm to screen fast ion conductors (Figure 11), including Li- and Na-containing tavorite-type compounds164 as well as other Li- and Zn-containing oxides.150 Moreover, in this last study, the authors applied bond-valence-force-field (BVFF)-based calculations instead of DFT to generate the computed database; as compared with DFT, BVFF-based calculations are much less computationally expensive, which facilitates the massive screening of large data sets.165

Figure 11.

Schematic workflow of a BO-based model to search for DFT-computed Li- and Na-ion migration energies (Eb) in tavorite AMXO4Z compounds.164 Figure reproduced with permission from ref (164). Copyright 2018 Springer.

Alternatively, Kireeva and Pervov considered a diverse set of experimental data of garnet-type oxide solid electrolytes, including total Li-ion conductivities and associated activation energies, synthesis parameters, pellet densities, among others.166 Using a SVM model, the authors targeted the prediction of the ionic conductivity of compounds with general formula A3B2(XO4)3. By combining theoretical and experimental data sets, Fujimura et al. directly assessed the ionic conductivity of Li8–cAaBbO4 LISICONs using the SVM method.167 The authors identified several compositions with higher ionic conductivities than known to date LISICONs. In this case, the theoretical data was also obtained at the DFT level, including formation energies and diffusion coefficients extracted from molecular dynamics (MD) simulations, whereas the experimental data involved ionic conductivity measurements at different temperatures. Considering instead an unsupervised learning approach, Zhang et al.168 employed agglomerative hierarchical clustering to group materials in the ICSD with similar experimental X-ray data representations of anion structures and successfully trained the model to cluster compounds into groups of high and low Li-ion conductivity. In another example, combining theoretical data from the Materials Project database with experimental data reported in the literature, Sendek et al. used a classification LR analysis to distinguish between superionic and non-superionic Li-containing solid electrolytes.169 Special attention was paid to assess the predictive power offered by a range of simple atomistic descriptors and combinations of them, concluding that only multidescriptor schemes achieved good enough predictive accuracy. In addition, a follow-up data-driven analysis170 revealed nontrivial correlations between different performance metrics and properties (ionic conductivity, electrochemical stability window, band gap, oxidation potential, reduction potential, materials cost, and anion electronegativity) in a diverse range of solid electrolytes, which highlights the need to tackle the complex problem of battery materials design from different perspectives to successfully identify high-performance outliers.

All of the previously discussed studies focus on ion mobility (migration energies or conductivities) as a target property. However, this is not the only important facet of applicable solid electrolytes; suppressing dendrite growth is an additional requirement that needs to be considered. In this regard, Ahmad et al. conducted a DFT-based computational screening of thousands of inorganic solids assessing their potential ability to suppress dendrite initiation in contact with Li metal.171 To this end, the authors trained the crystal graph convolutional neural network (CGCNN) and KRR models on calculated shear and bulk moduli as well as elastic constants. They found that promising candidates capable of suppressing dendrite growth are generally soft and highly anisotropic, with large mass density, ratio of Li, and sublattice bond ionicity.

2.1.3. Liquid Electrolytes

Liquid electrolytes are, unlike solid electrolytes, highly disordered, making ML studies of energies and electronic and structural properties less straightforward. Hence, there are significantly fewer papers using ML methods on liquid electrolytes. Nevertheless, ML methods can be useful for a variety of purposes also for liquid electrolytes, and in the following, we highlight a few cases. Nakayama et al.172 considered a range of commercially available organic solvent molecules and applied the exhaustive search with a GP (ES-GP) method to predict the cation–solvent interaction energies within liquid electrolytes for LIBs. The interaction energy is a convenient proxy for the Li-ion transport in the electrolytes, as solvation and desolvation of Li-ions at the electrolyte–electrode interfaces are key processes often limiting the overall mass transport. Additionally, Sodeyama et al., using an exhaustive search with linear regression (ES-LiR) model, included the melting point as a target property, which is an important parameter in terms of a wide LIB operating temperature window.173 While the ES-LiR model provided a good balance between prediction accuracy and computational cost as compared to the multiple linear regression (MLR) and least absolute shrinkage and selection operator (LASSO) approaches,173 the ES-GP method is significantly more accurate than ES-LiR.172

A less direct approach is to use ML methods to accelerate the search of the sampling space, for example, ML-enhanced MD simulations to allow simulation of more extreme types of liquid electrolytes. One particular use is when dipole polarization plays a major role for the dynamics, for example, highly concentrated electrolytes (HCE) and ionic-liquid (IL)-based electrolytes. The most direct approach implemented is to learn the polarization term in a cost efficient way by NNs, e.g., refs (174 and 175), but also the surrounding neighborhood can be used to give an atom wise description of the system in order to evaluate the forces acting on a particle (as, for instance, a molecule) using Deep Tensor NN.176,177 This provides an efficient way to generate data, with the caveat that information on the physical interactions is lost. Similar approaches have been used to study electrolytes of Zn2+ in water showing that it is possible to apply ANN to learn an effective physical potential even for highly disordered systems.178 However, it is yet to be proven how this method performs when the system complexity is increased by including both anions and cations, as well as solvent(s). Preliminary results from the Johansson group (Chalmers University of Technology, Sweden) working together with the MIT group176,177,179 indicate that the method works well. They have trained the network on a HCE of LiTFSI in ACN. The network data presented in Figure 12 show a small mean average error (MAE) of 1.2 kcal mol–1 Å–1, which is small, but a larger training data set is needed to comfort the results before publication.

Figure 12.

Preliminary results of an ANN trained on HCE LiTFSI in ACN by Johansson’s and MIT groups.176,177,179

Even if too often forgotten, ML can be applied to electrolyte studies not only from the computational point of view but also from the experimental one. There are several ways ML can be used to aid or enhance experimental studies of electrolytes, ranging from ANN to be applied to interpreting spectroscopy data to (ideas of) fully automated laboratories.180−182 This approach indeed opens up for more efficient experimental studies of liquid electrolytes as well as a solution to many of the problems with simulating complex electrolytes and comparisons with experimental data.

2.2. Accelerated Multiscale Modeling of Materials

From a physical-based modeling viewpoint, first-principles methods from quantum mechanics (e.g., DFT) are the most accurate simulation approaches. These methods are very useful to elucidate specific molecular-scale mechanisms, which we could only speculate on when addressed through experimental techniques. However, the application regime of these methods is nowadays limited to systems consisting of a small number of atoms, mainly due to high computational cost associated with first-principles calculations. First-principles methods are essentially limited in terms of accounting for the length and time scales of relevant phenomena affecting cell performance (e.g., space charge layer formation, interfacial ion transport, degradation reactions, defects formation, etc.). Steady advances in computational power will help to partially mitigate this issue in the future, and simulating larger length and time scales than possible today will eventually be affordable.141 This should enable the consideration of more realistic materials models, ultimately capable of accounting for the underlying chemical and physical mechanisms that often operate at multiple scales simultaneously in battery materials and associated phenomena such as interphase formation and evolution (Figure 13) or ionic transport in composite electrodes.

Figure 13.

Complexity of a typical battery solid electrolyte interphase (SEI) increases continuously, from the molecular level to the macroscale. Assessing the state of the interphase requires therefore the combination of a range of simulation (blue), electrochemical (orange), and characterization (green) approaches.129 Figure reproduced with permission from ref (129). Copyright 2019 Elsevier.

However, accurate first-principles methods will probably be still too computationally costly to be routinely and timely applied and a much less computationally intensive alternative, the so-called interatomic potentials, which are sets of parametrized functions, are available. Interatomic potentials depend on several parameters that need to be fitted empirically to available experimental or high-level quantum mechanical calculations. However, two main limitations of interatomic potentials are their low transferability and nonreactivity. Essentially, this means that a given interatomic potential set is only valid and accurate for the specific model system for which it was fitted. Extending the use of existing interatomic potentials to other systems of interest (even of the same chemical composition) should always require thorough validation and re-parametrization, which is not always possible because of a lack of available experimental or accurate theoretical data. In addition, depending on the functional form used in the interatomic potentials, including chemical reactions may not always be feasible.

The implementation of ML techniques in materials science workflows50 can certainly help accelerate current computational efforts. In particular, ML-assisted approaches could help improve the representation of the local chemical environment used in many-body interatomic potentials.129 In this context, Deringer and Csányi proposed a Gaussian approximation potential (GAP) model to construct interatomic potentials from a ML representation of DFT potential energy surfaces.183 They applied the method to MD simulations of liquid and amorphous carbon materials, including the study of high-temperature surface reconstructions. With an overall performance somehow between DFT and state-of-the-art interatomic potentials, the proposed GAP model showed therefore promising capabilities for large-scale atomistic simulations of amorphous simple materials. Engaged in similar efforts, Li et al. trained an ANN potential using tens of thousands of DFT-computed Li3PO4 structures.184 The resulting ANN potential yielded accurate predictions of Li vacancy formation energies, Li+ migration energies, and diffusion coefficients of crystalline and large-scale amorphous Li3PO4, with predicted activation energies in very good agreement with experimental measurements. In spite of the success of these two studies, it is important to remark that long-ranged electrostatics in ionic systems still remain a challenge for interatomic potentials machine-learned from local structural descriptors. During a recent effort to solve this issue, Deng et al. introduced a new approach that combined a so-called spectral neighbor analysis potential (SNAP) formalism with electrostatic interactions, which the authors named eSNAP.185 Taking as a case study a Li superionic conductor, Li3N, the study showed that the eSNAP model yields significantly better predictive power than traditional Coulomb–Buckingham interatomic potentials when assessing multiple properties, such as lattice constants, elastic constants, phonon dispersion curves, as well as long-time, large-scale Li ionic kinetics. In liquid electrolytes, Shao et al. showed that the ANN potential enables MD simulations of concentration-dependent ionic conductivity in alkaline electrolyte solutions, which are otherwise not feasible with brute-force DFT/MD simulations. In particular, they showed how the ion transport changes from the structural diffusion (Grotthuss mechanism) at the low concentration to the vehicular mechanism at the high concentration.186

The previously discussed studies certainly demonstrate the ability of ML potentials to enable large-scale simulations of complex compounds such as amorphous materials. However, ML-potential-assisted sampling requires evaluating a large amount of reference data points, especially when increasing the number of different chemical species to be considered and dealing at the same time with highly disordered or amorphous structures. Trying to mitigate this issue, Artrith et al. proposed a specific ML potential trained on a much reduced set of DFT calculations that were used to sample exclusively low-energy atomic configurations with a ANN-potential-assisted genetic algorithm.187 For the case study of amorphous LixSi alloys, the authors showed that such an approximated sampling approach was able to accurately reproduce a fully first-principles phase diagram, reducing the number of training first-principles data points by at least 2 orders of magnitude with respect to the construction of a completely converged general ML potential (Figure 14).

Figure 14.

Schematic workflow of an ANN-potential-assisted genetic algorithm used to construct the phase diagram of amorphous LixSi.187 Figure reproduced with permission from ref (187). Copyright 2018 AIP publishing.

ML-assisted development of interatomic potentials has also been applied to estimate the local properties of active electrode materials through cluster expansion (CE) methods. ML is particularly useful to increase the sampling efficiency (smaller clusters) when compared to conventional CE Hamiltonians of complex multibody interactions, as Natarajan and Van der Ven demonstrated by implementing a ANN model to reproduce DFT site energies of Li-vacancies in disordered LiTiS2.188 Similarly, Chang et al. have also integrated ML techniques into the general purpose CE code CLEASE.503 This approach is, in principle, generalizable to the prediction of any scalar property (e.g., formation energy, volume, bulk moduli, etc.) of multicomponent systems as a function of site occupation distribution, making it particularly useful to describe alloys and disordered intercalation compounds.

Jørgensen et al. have developed DeepDFT, a deep learning model formulated as a neural message passing on a graph, consisting of interacting atom vertices to predict the charge density of large systems very fast but still achieve QM accuracy. The model has been tested for NMC cathodes (with any level of Ni:Mn:Co ratio and varying level of lithiation) as well as liquid electrolyte (EC).189

Finally, ML techniques can also help analyze and interpret results of conventional MD simulations. To this end, unsupervised learning methods are particularly suitable. For example, Chen et al. developed a density-based clustering of trajectories (DCT) method to elucidate complex Li diffusion mechanisms from MD simulations of Li7La3Zr2O12 solid electrolyte.190 By calculating nuclear densities from MD trajectories, the DCT was able to recognize lattice sites, classify them into different types, and identify Li+ hopping events. Further spatiotemporal correlation analysis revealed the existence of long-ranged diffusivity or dominance of back-and-forth jumps as a function of the crystal structure (cubic or tetragonal) and Li-vacancy concentration. This information was relevant to identify the uncorrelated (correlated) Li diffusion in cubic (tetragonal) Li7La3Zr2O12.