Abstract

ZnO nanoparticles embedded in a magnetic isocyanurate-based periodic mesoporous organosilica (Fe3O4@PMO–ICS–ZnO) were prepared through a modified environmentally-benign procedure for the first time and properly characterized by appropriate spectroscopic and analytical methods or techniques used for mesoporous materials. The new thermally stable Fe3O4@PMO–ICS–ZnO nanomaterial with proper active sites and surface area as well as uniform particle size was investigated for the synthesis of medicinally important tetrazole derivatives through cascade condensation and concerted 1,3-cycloaddition reactions as a representative of the Click Chemistry concept. The desired 5-substituted-1H-tetrazole derivatives were smoothly prepared in high to quantitative yields and good purity in EtOH under reflux conditions. Low catalyst loading, short reaction time and the use of green solvents such as EtOH and water instead of carcinogenic DMF as well as easy separation and recyclability of the catalyst for at least five consecutive runs without significant loss of its activity are notable advantages of this new protocol compared to other recent introduced procedures.

Subject terms: Catalysis, Coordination chemistry, Environmental chemistry, Green chemistry, Inorganic chemistry, Materials chemistry, Medicinal chemistry, Organic chemistry, Surface chemistry, Chemical synthesis

Introduction

Since it’s first introduction by K. Barry Sharpless in 1999, “Click Chemistry (CC)” has been emerged as a very popular topic for the synthesis of heterocyclic compounds. In 2001, Sharpless defined CC reactions as a set of organic transformations with specific characteristics such as modular, wide in scope, affording high yields and produce only harmless byproducts that can be removed by non-chromatographic separation techniques1–7. 1,3-dipolar cycloaddition reactions are one of the most popular CC reactions8. When such concerted reactions are performed through multicomponent reaction (MCR) strategy, they can be widely used for the synthesis of important heterocyclic compounds including triazole and tetrazole derivatives9–15.

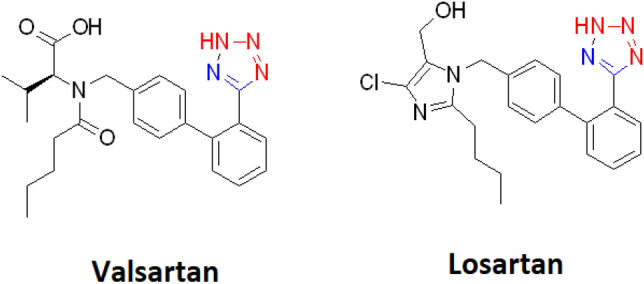

The presence of four nitrogen atoms in the heteroaromatic five-membered ring of tetrazole gives rise to nitrogen-rich planar structural features16–21. Furthermore, the acidic nature of tetrazoles is due to the presence of free N–H in their structure and this property can lead to the formation of more complex aliphatic and aromatic heterocyclic compounds through nucleophilic substitution22,23. Indeed, the heterocyclic tetrazole moiety can stabilize the negative charge of the corresponding anion by charge displacement and show same pKa values of the corresponding carboxylic acids24. As a result, tetrazoles can be used as a metabolic substitutes (bioisoesteres) for the carboxylate functional group. Hence, these two groups of organic compounds are similar at pKa = 4.9 and become deprotonated at physiological pH25. Also, tetrazoles have higher nitrogen content than other heterocycles and require almost the same electronic space as carboxylates. Consequently, these features have improved their uses in a wide range of applications including pharmaceuticals and drug design, food industries, explosives, agrochemicals, materials science, coordination chemistry, etc.26–36. Especially, the tetrazole structures are similar to the pharmacological core of the Saran’s family, which are in fact angiotensin II receptor blockers (ARB). Angiotensin II is a bioactive peptide that narrows the vessels through the contraction of the muscles around the heart37. These drugs are used in to lower blood pressure and heart failure. Among the most important pharmaceuticals in this category of drugs are losartan and valsartan (Fig. 1). Indeed, these two active pharmaceutical ingredients are the first of a new class of drugs, which have been introduced for the clinical use in hypertension38,39. Furthermore, many chemical studies on other tetrazole analogue compounds have described antibacterial and antifungal properties. Tetrazole derivatives also show anti-inflammatory, analgesic, anti-cancer, anticonvulsant and antidiabetic kidney disease activities32. Therefore, tetrazole chemistry has yet remained as a fascinating research area for different scientists.

Figure 1.

Valsartan and losartan as two active pharmaceutical ingredients with tetrazole moiety.

Since the preparation of the first tetrazole compound in more than a hundred years ago, many scientists have invented or described different methods for preparation of tetrazole compounds35. The most common of these methods is a 1,3-dipolar cycloaddition reaction between different simple nitrile derivatives and azide ion or hydrazoic acid under pressure. This approach has been more developed using different catalytic systems or altering of substrates during different decades35,40–42. Some recent examples include the use of L-cysteine complex of palladium onto mesoporous channels of MCM-4143, Fe3O4@L-lysine-Pd(0)43, copper(I) salt26, copper catalyst on biochar nanoparticles44, guanidine complex of copper supported on boehmite nanoparticles45, zinc(II) salts46, Zn/Al hydrotalcite47, NiFe2O448, TMSCl and Bu2SnO or N-methyl-2-pyrrolidone49, FeCl3–SiO250, Amberlyst-1528, MCM-41-SO3H51, 1-disulfo-[2,2-bipyridine]-1,1-diium chloride ionic liquid52 mainly at elevated temperatures, or dialkyl aluminum azides as the substrate and catalyst36. Furthermore, Sharples and his colleague have reported improved intermolecular [3 + 2] ring closures between an azide and p-toluenesulfonyl cyanide or acyl cyanide under solvent-free conditions at elevated temperatures to afford good to excellent yields of the corresponding products using easy procedurs53,54. Moreover, the use of more complex nitrile derivatives such as benzylidenemalononitriles would be more desirable in terms of abundance of functional groups in the corresponding products55. Indeed, this route for the synthesis of tetrazoles involves the multicomponent reactions (MCRs) strategy between aldehydes, sodium azide and nitriles. One of the advantages of this strategy is the use of available, easy and inexpensive basic compounds, namely aldehydes and sodium azide along with relatively expensive nitriles, which has made these reactions economically viable and easy to do on an industrial scale56–60. Among different catalytic systems for benzylidenemalononitrile derivatives, which are generally prepared by condensation of aldehydes and molononitrile, Fe3O4@BNPs-CPTMS-Chitosan-Pd(0)61, Cu(II) immobilized on Fe3O4@HNTs–tetrazole nanocomposite62, secondary amine/Cu(II) bifunctional magnetic nanoparticles63, Fe3O4 magnetic nanoparticles under microwave irradiation64, NiO2 nanoparticles65, silica molybdic acid66 and Cu2(BDC)2(DABCO) metal–organic framework67 could be mentioned. In spite of their merits, there are some disadvantages to the most of previously reported protocols for the synthesis of tetrazoles. These include low boiling point of hydrazoic acid (37 °C), the use of expensive catalytic systems, high pressure conditions, toxic and carcinogenic solvents including DMF, or elevated temperature for the explosive azide ion component.

Periodic mesoporous organosilicas (PMOs) have been also emerged as one of the important issues of research in recent years. PMOs which were reported for the first time in 1999 are a new branch of mesoporous materials. They are organic–inorganic hybrid materials with high-ordered structures and uniform pore sizes68–82. PMOs are essentially unique because of the advantage of combining a strong porous inorganic framework with the inherent properties of organic components having different functionalities71,83–86. In this regard, precursors of bridged organosilica bearing hetero-aromatic isocyanurate moieties with high thermal stability and low toxicity would be very desirable82,85–88. On the other hand, PMOs demonstrate other distinguishing characteristics such as large and hollow spaces, high surface area, regular cavity wall structure, low density and good membrane permeability, and material loading in large quantities. Therefore, PMOs have been effectively used in many applications such as drug and gene delivery, gas and molecule absorption, sensors, active agents for smart anticorrosive organic coatings, and catalysis85,86,89–107.

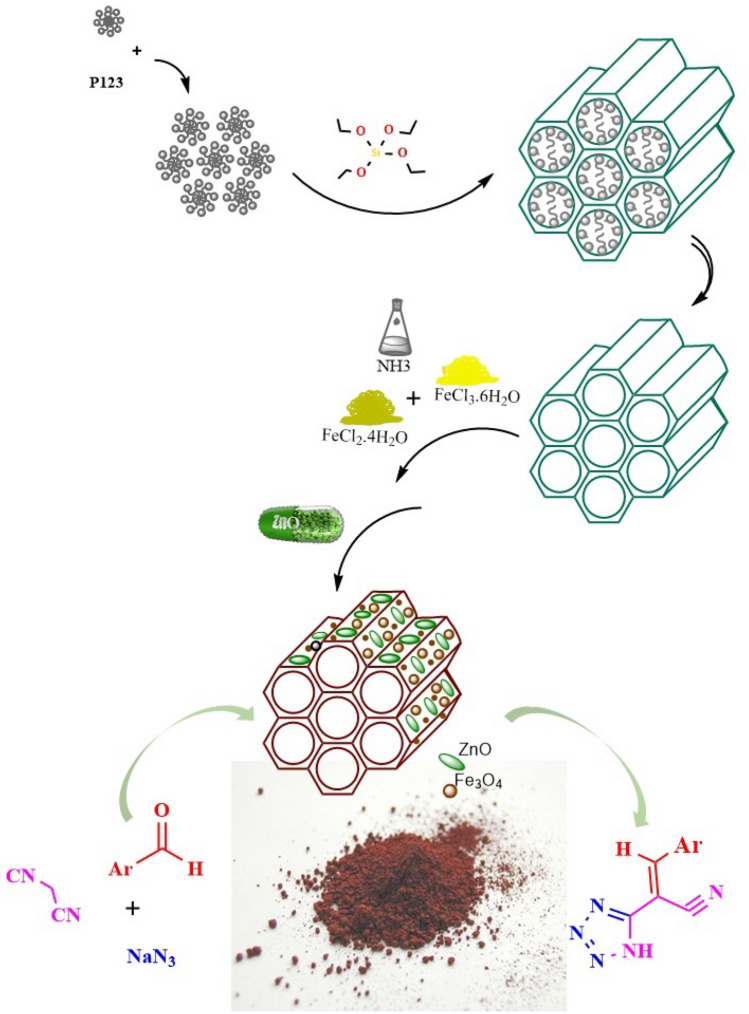

To address the above challenges and in continuation of our studies to explore the catalytic activity of ZnO species108,109 as well as PMOs91,94–99, we wish to report herein the new ZnO nanoparticles embedded in a magnetic isocyanurate-based periodic mesoporous organosilica (Fe3O4@PMO–ICS–ZnO) for the cascade reaction of different aromatic aldehydes and malononitrile to afford the corresponding Knoevenagel intermediate, and subsequent [3 + 2] cycloaddition with sodium azide (Fig. 2). Indeed, diverse tetrazole derivatives 5a–o were prepared efficiently using low loading of Fe3O4@PMO–ICS–ZnO, as a magnetically recoverable catalytic system, in EtOH under reflux conditions in short reaction times.

Figure 2.

Schematic preparation of the Fe3O4@PMO-ICS–ZnO (1) catalyst and its application in the synthesis of tetrazoles derivatives 5a–o.

Results and discussion

After preparation of the Fe3O4@PMO-ICS-ZnO nanomaterial, its structural, morphological and textural properties were characterized by Fourier transform infra-red (FTIR) and X-ray powder diffraction (XRD) spectroscopy, field emission scanning electron (FESEM) microscopy, thermogravimetric analysis (TGA), N2 adsorption–desorption isotherms and vibrating sample magnetometer (VSM).

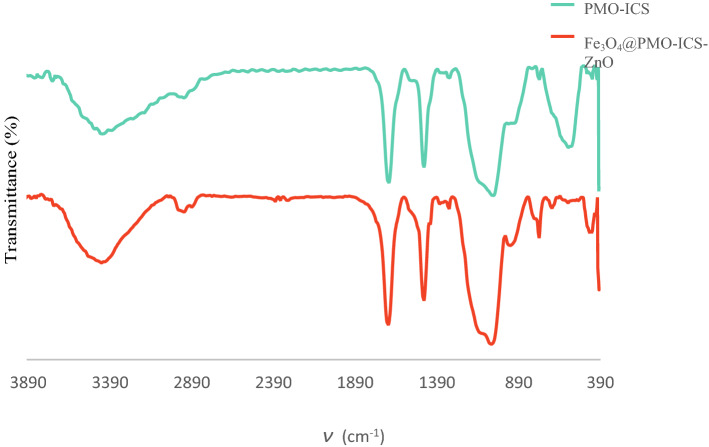

The FT-IR spectra of both PMO-ICS and Fe3O4@PMO-ICS-ZnO have been presented in Fig. 3. It was observed that the free O–H stretching mode of the silanol groups on the PMO surface appear at 3415 cm−1. Also, sharp absorption bands were observed at 1689 and 1471, which are related to the vibrations of carbonyl and C–N bonds in the isocyanurate ring within the framework of the prepared nanocatalyst, respectively. The signals appearing in 2939 and 2889 cm−1 are related to the stretching vibrations of aliphatic moiety of PMO-ICS. Furthermore, the observed bands at 1108, 1056 and 943 cm−1 correspond to the asymmetric and symmetric stretching vibrations of siloxane Si–O–Si bonds. On the other hand, the signals at 570 cm−1 are related to the stretching vibration of the Fe–O–Fe bonds. The Zn–O stretching vibration modes are observed, as a relatively weak band at 493 cm−1, which merge with the nearby signal of Fe–O bonds.

Figure 3.

FTIR spectra of the PMO-ICS and magnetic Fe3O4@PMO-ICS-ZnO nanoporous catalyst (1).

The energy dispersive X-ray (EDX) spectrum of the catalyst has been shown in Fig. 4. Indeed, the signals of iron, nitrogen, silicon, carbon, oxygen and zinc atoms were observed in the studied sample. It is well known that three peaks of iron are observed in the EDX spectrum for magnetic iron oxides. Furthermore, this analysis successfully confirms that ZnO nanoparticles are well embedded into the magnetic catalyst.

Figure 4.

EDX spectrum of the magnetic Fe3O4@PMO-ICS-ZnO mesoporous catalyst (1).

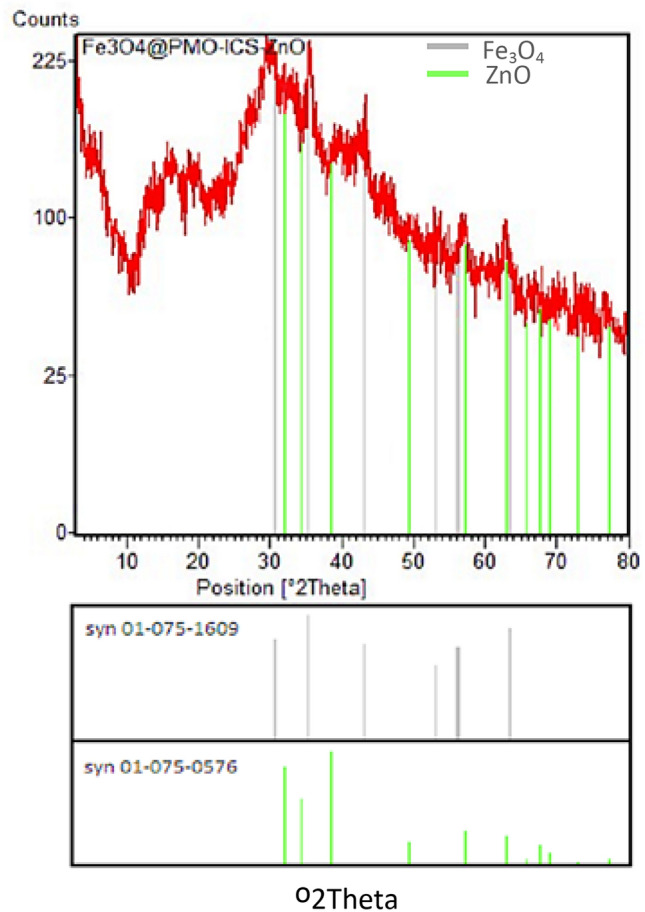

The structure of Fe3O4@PMO-ICS-ZnO nanoparticles was also analyzed by XRD spectroscopy. The wide angle XRD pattern shown in Fig. 5 determined the crystallinity and arrangement of both PMO and Fe3O4 components in the structure of Fe3O4@PMO-ICS-ZnO nanomaterial. Indeed, a broad diffraction peak of 2θ near to 3.9° and five sharp peaks at 2θ = 29.5°, 35.4°, 43.2°, 56.9°, and 62.7° demonstrate corresponding reflections of amorphous silica as well as Fe3O4 and ZnO phases, respectively.

Figure 5.

X-ray powder diffraction (XRD) pattern for the Fe3O4@PMO-ICS-ZnO nanoporous catalyst (1).

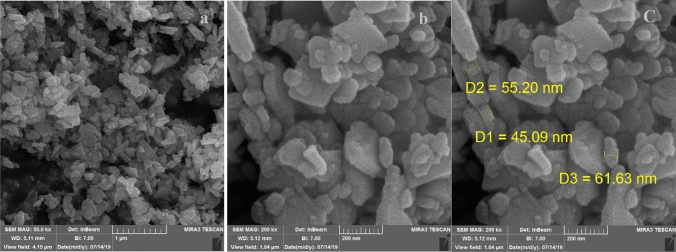

The morphology, distribution and size of the particles of Fe3O4@PMO-ICS-ZnO nanoporous material (1) were analyzed using field emission scanning electron microscope (FESEM, Fig. 6). A uniform and well-defined distribution as well as almost nano-rod morphology were observed for the ZnO nanoparticles embedded in the magnetic periodic mesoporous organosilica. Furthermore, the average particle sizes of Fe3O4@PMO-ICS-ZnO nanoporous material (1) was found to be in the range of nano scale and about 45–62 nm.

Figure 6.

FESEM images of the magnetic nanoporous Fe3O4@PMO-ICS-ZnO catalyst (1).

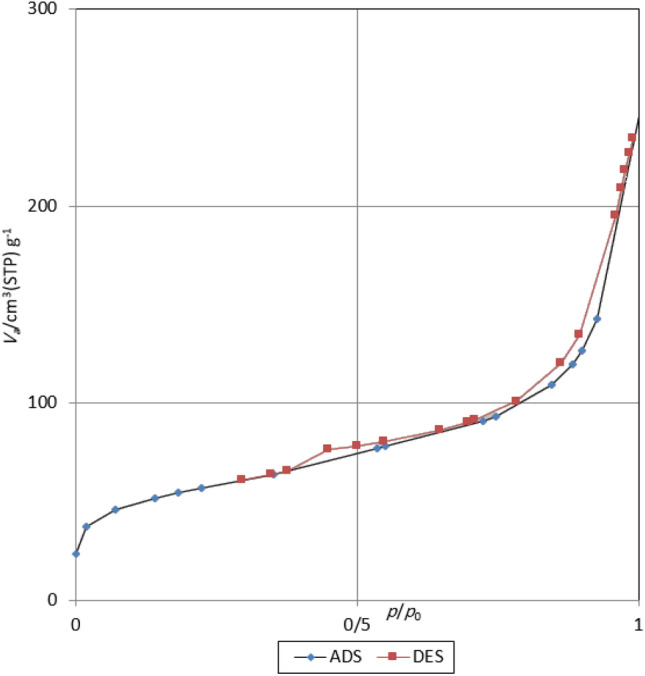

Furthermore, the specific surface area and pore size of nano-ordered Fe3O4@PMO-ICS-ZnO material 1 were determined using N2 adsorption–desorption isotherms through Brunauer–Emmett–Teller (BET) and Barrett-Joyner-Halenda (BJH) methods (Fig. 7). In fact, the observed data demonstrated that this material has a typical mesoporous structure and a type IV isotherm, which is due to the presence of cylindrical pores on the mesoporous scale. Specific surface area, average pore size and total pore volume are approximately 194.9 m2 g−1, 7.3 nm, and 0.36 cm3 g−1, respectively. Comparison of the obtained BET and BJH data of Fe3O4@PMO-ICS-ZnO material 1 with the similar data for PMO-ICS86 and Fe3O4@PMO-ICS87 shows decreasment in the amount of surface area and total pore volume (Table 1). Therefore, it can be concluded that ZnO nanoparticles were firmly-embedded and fixed in the magnetic periodic mesoporous organosilica channels.

Figure 7.

BET isotherm of the mesoporous Fe3O4@PMO-ICS-ZnO nanocatalyst (1).

Table 1.

Textural parameters of the PMO-ICS and Fe3O4@PMO-ICS-ZnO (1) samples.

| Sample | BET surface area (m2/g) | Total pore vol. (cm3/g) (P/P0: 0.989) |

Pore size (nm) |

|---|---|---|---|

| PMO-ICS | 570.03 | 5.0 | 4.160 |

| Fe3O4@PMO-ZnO | 194.88 | 0.35 | 3.312 |

Thermogravimetric analysis (TGA) was measured for the prepared catalyst 1 at temperatures between 40 and 804 °C. Figure 8 shows three distinct weight loss for the Fe3O4@PMO-ICS-ZnO (1). The first step, with 3.56% weight loss between 40 and 270 °C, is corresponded to the removing of alcoholic or water solvents remaining from the extraction process. The second and main weight loss (14. 20%) at 270 to 570 °C region is attributed to the elimination of 1,3,5-tris(1,3-propylen) isocyanurate bridges incorporated into the PMO framework as well as condensation of its silanol groups. Finally, the last weight loss (2.26%) was observed in the range of 570–804 °C, which is attributed to more condensation of inorganic moieties present in the structure of catalyst 1 including silica and ZnO. These data clearly shows good thermal stability of the Fe3O4@PMO-ICS-ZnO, which is very important in design and application of recyclable heterogeneous catalytic systems.

Figure 8.

TGA curve of the Fe3O4@PMO-ICS-ZnO catalyst (1).

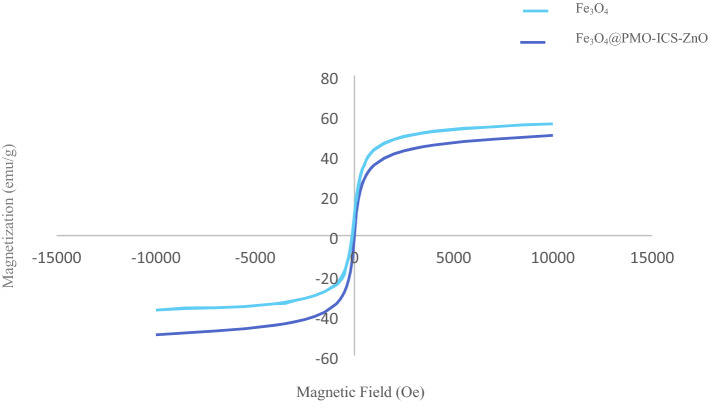

The magnetization of Fe3O4@PMO-ICS-ZnO (1) sample was measured using vibrating sample magnetometer (VSM) experiment. As can be seen in the Fig. 9, the hysteresis phenomenon was not observed. Instead, the observed “S” like curve at room temperature is also a proof of the paramagnetism of the prepared Fe3O4@PMO-ICS-ZnO. The saturation magnetization value was strongly enhanced by the external magnetic field strength at the low field region and found to be 49.56 emu/g for the Fe3O4@PMO-ICS-ZnO at − 10 to 10 KOe. Indeed, the magnetic property of the Fe3O4@PMO-ICS-ZnO is sufficiently enough to be easily separated by an external magnet from the reaction mixture.

Figure 9.

VSM magnetization curves for the Fe3O4 and Fe3O4@PMO-ICS-ZnO (1).

Optimization of conditions for the synthesis of tetrazole derivatives in the presence of magnetic Fe3O4@PMO-ICS-ZnO nanocatalyst (1)

After characterization of the magnetic Fe3O4@PMO-ICS-ZnO nanocatalyst (1), its efficiency was investigated for the synthesis of 1H-tetrazole derivatives. Therefore, the effect of different catalyst loadings, solvent and temperature on the yield and required time of reaction were systematically investigated in this step to find optimal conditions for the synthesis of 1H-tetrazole derivatives. Hence, the reaction of malononitrile (2, 1 mmol) and sodium azide (3, 1.2 mmol) 4-chlorobenzaldehyde (4a, 1 mmol), was selected as the model reaction. The results have been summarized in Table 2. Initially, the model reaction was examined in the absence of any catalyst under various conditions such as in EtOH at ambient temperature or under reflux conditions. The dependence of obtained yield of the model reaction to the catalyst and temperature was evident because of very low yields of the desired product, (E)-3-(4-chlorophenyl)-2-(1H-tetrazol-5-yl)acrylonitrile, 5a under solvent-free conditions at room temperature or reflux conditions after prolonged reaction times (entries 1,2, Table 2). Interestingly, the obtained yield of desired product 5a was significantly improved in the presence of Fe3O4@PMO-ICS-ZnO nanocatalyst (1) after very short reaction times (entries 3–5, Table 2). These findings demonstrate high catalytic activity of the magnetic nanocatalyst for the synthesis of the desired product 5a, which originates from very good dispersion of active catalytic sites and proper surface area of the Fe3O4@PMO-ICS-ZnO. In the next experiments, the effect of different solvents such as water, EtOH, water/EtOH mixture, toluene, DMF, EtOAc and CH3CN as well as solvent-free conditions on the reaction rate was investigated (entries 6–12, Table 2). Indeed, both water and EtOH solvents afforded excellent yields of the desired product 5a after same reaction time (entries 5, 6, Table 2). However, separation of the magnetic catalyst 1 is much easier in EtOH than water due to higher solubility of the desired 1H-tetrazole products at elevated temperatures and remaining the heterogeneous catalyst 1. Therefore, 10 mg Fe3O4@PMO-ICS-ZnO loading in EtOH under reflux conditions was selected as the optimized conditions for further experiments (entries 3, 13, 14, Table 2). On the other hand, both pure PMO-ICS and magnetic PMO-ICS afforded lower yields of the desired product 5a under similar conditions compared to the Fe3O4@PMO-ICS-ZnO nanocatalyst (1) (entries 15, 16, Table 2). All of these data show effective role of ZnO nanoparticles embedded in the thermally stable magnetic periodic mesoporous organosilica.

Table 2.

Optimization of conditions in the reaction of malononitrile (2), NaN3 (3) and 4-chlorobenzaldehyde (4a) under different conditions.

| ||||||

|---|---|---|---|---|---|---|

| Entry | Catalyst | Catalyst loading (mg) | Solvent | Temperature (°C) | Time | Yielda (%) |

| 1 | – | – | Solvent-Free | rt | 24 h | 78 |

| 2 | – | – | EtOH | Reflux conditions | 20 h | 62 |

| 3 | Fe3O4@PMO-ICS-ZnO | 10 | EtOH | Reflux conditions | 3 min | 98 |

| 4 | Fe3O4@PMO-ICS-ZnO | 15 | EtOH | Reflux conditions | 5 min | 97 |

| 5 | Fe3O4@PMO-ICS-ZnO | 20 | EtOH | Reflux conditions | 5 min | 98 |

| 6 | Fe3O4@PMO-ICS-ZnO | 10 | H2O | Reflux conditions | 5 min | 95 |

| 7 | Fe3O4@PMO-ICS-ZnO | 10 | H2O/EtOH (1:1) | Reflux conditions | 40 min | 80 |

| 8 | Fe3O4@PMO-ICS-ZnO | 10 | Toluene | Reflux conditions | 45 min | 90 |

| 9 | Fe3O4@PMO-ICS-ZnO | 10 | DMF | Reflux conditions | 60 min | Trace |

| 10 | Fe3O4@PMO-ICS-ZnO | 10 | EtOAc | Reflux conditions | 30 min | 72 |

| 11 | Fe3O4@PMO-ICS-ZnO | 10 | CH3CN | Reflux conditions | 10 min | 70 |

| 12 | Fe3O4@PMO-ICS-ZnO | 10 | Solvent-Free | 100 | 20 min | 97 |

| 13 | Fe3O4@PMO-ICS-ZnO | 10 | EtOH | 60 | 7 min | 86 |

| 14 | Fe3O4@PMO-ICS-ZnO | 10 | EtOH | rt | 10 min | 97 |

| 15 | PMO-ICS | 10 | EtOH | Reflux conditions | 45 min | 70 |

| 16 | Fe3O4@PMO-ICS | 10 | EtOH | Reflux conditions | 40 min | 78 |

Reaction conditions: malononitrile (2, 1 mmol), NaN3 (3, 1.2 mmol) and 4-chlorobenzaldehyde (4a, 1 mmol) were added into the solvent (2.0 mL) in the presence of Fe3O4@ PMO-ICS-ZnO (1) unless otherwise stated.

aIsolated yields.

Significant values are in bold.

In the next step, the optimized conditions were expanded to other aromatic aldehydes 4b–o to investigate the scope of reaction for the preparation of diverse 1H-tetrazole derivatives in the presence of magnetic Fe3O4@PMO-ICS-ZnO nanocatalyst (1). Excellent yields were obtained from a variety of aromatic carbocyclic or heterocyclic aldehydes 4a–o under optimized conditions. As data in Table 3 show, high to excellent yields of the desired products 5a–o were obtained within short reaction times. In this regard, aromatic aldehydes with carbocyclic ring bearing electron withdrawing groups 4a–g and electron-deficient heterocycle 4h were examined (entries 1–8, Table 3). On the other hand, aromatic aldehydes with carbocyclic ring bearing electron donating groups 4j–n as well as electron-rich heterocycle 4o survived to involve in the optimized conditions to afford the corresponding 1H-tetrazole derivatives 5j–o (entries 10–15, Table 3).

Table 3.

Synthesis of 5-substituted-1H-tetrazole derivatives 5a–o catalyzed by the Fe3O4@PMO-ICS-ZnO nanocatalyst (1) via the three components reaction strategy.

| Entry | Aldehyde 4 (Ar) |

Product 5 | Time (min) | Yielda (%) | MP °C (Obs.) | MP °C (Lit.) |

|---|---|---|---|---|---|---|

| 1 |

4-ClC6H4 4a |

|

5 | 98 | 157–159 | 158–160110 |

| 2 |

4-FC6H4 4b |

|

5 | 78 | 175–177 | 176–179111 |

| 3 |

3-BrC6H4 4c |

|

5 | 80 | 162–163 | 165–167112 |

| 4 |

2-ClC6H4 4d |

|

15 | 97 | 171–173 | 175–17764 |

| 5 |

2,4-Cl2C6H3 4e |

5e 5e

|

30 | 95 | 150–152 | 142–143113 |

| 6 |

4-NO2C6H4 4f |

|

25 | 95 | 167–169 | 166–168112 |

| 7 |

3-NO2C6H4 4g |

|

30 | 92 | 161–163 |

159–163 |

| 8 |

|

|

8 | 88 | 187–188 | 185–186113 |

| 9 |

C6H5 4i |

5i |

5 | 97 | 165–167 | 168–170112 |

| 10 |

4-CH3C6H4 4j |

|

5 | 97 | 186–188 | 189–191114 |

| 11 |

4-MeOC6H4 4k |

|

20 | 90 | 150–152 | 153–15566 |

| 12 |

4-HOC6H4 4l |

|

5 | 88 | 161–164 | 159–161112 |

| 13 |

2-MeOC6H4 4m |

|

7 | 90 | 157–159 | 150–152115 |

| 14 |

4-Me2NC6H4 4n |

|

25 | 88 | 167–168 | 171–172113 |

| 15 |

|

|

15 | 80 | 88–90 | 85–86113 |

Reaction conditions: malononitrile (2, 1 mmol), aldehyde (4, 1 mmol), and NaN3 (3, 1.2 mmol) were added into the EtOH (2.0 mL) in the presence of 10 mg of Fe3O4@ PMO-ZnO (1).

aIsolated yields.

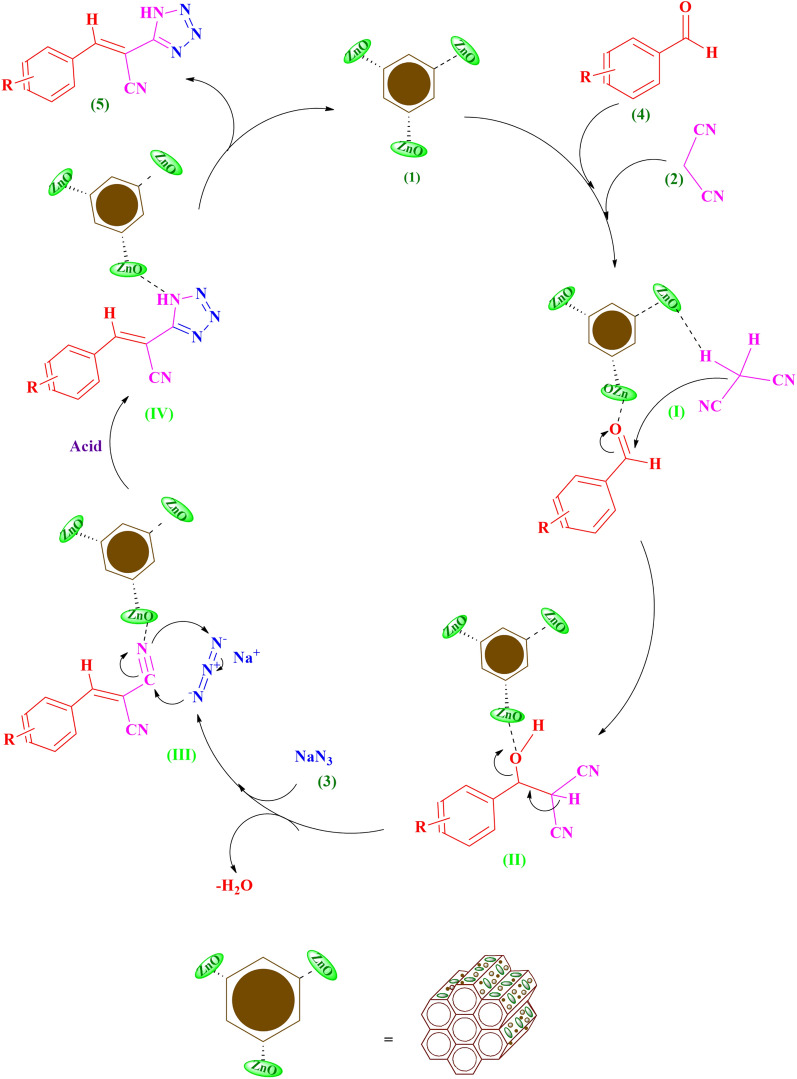

Proposed mechanism for the preparation of 5-substituted-1H-tetrazole derivatives catalyzed by Fe3O4@PMO–ICS–ZnO (1)

A trajectory for the cascade one-pot preparation of (E)-2-(1H-tetrazole-5-yl)-3-aryl/heteroarylacrylenenitrile derivatives 5a–o using Lewis acidic ZnO nanoparticles embedded in the magnetic isocyanurate-based periodic mesoporous organosilica (Fe3O4@PMO–ICS–ZnO, 1) is shown in Fig. 10. In the first reaction step, the aromatic aldehydes (4) are activated by the Fe3O4@PMO–ICS–ZnO step by step to condensate with the malononitrile C–H acid (2) and finally affording the Knoevenagel aryl/heteroarylidine malononitrile intermediate (III). This intermediate is subsequently involved in the concerted [3 + 2] cycloaddition with sodium azide (3) to produce 5-membered tetrazole ring.

Figure 10.

A reasonable mechanism for the one-pot preparation of (E)-2-(1H-tetrazole-5-yl)-3-aryl/heteroarylacrylenenitrile derivatives 5 using the magnetic nano-ordered Fe3O4@PMO–ICS–ZnO catalyst (1).

Investigating of the reusability of magnetic Fe3O4@PMO–ICS–ZnO (1) for the synthesis of 5-substituted-1H-tetrazole derivatives 5

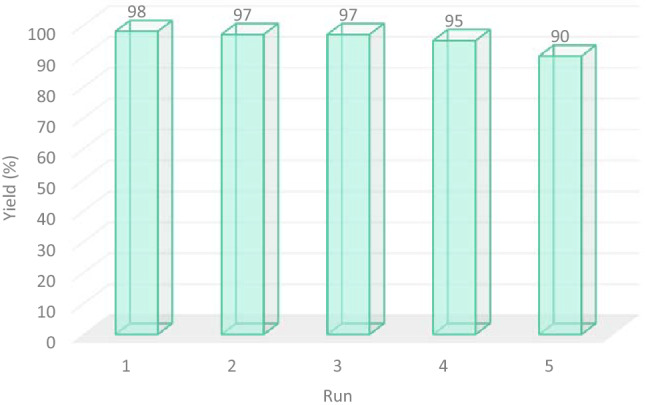

As a part of our study, the reusability of magnetic Fe3O4@PMO–ICS–ZnO (1) for the synthesis of (E)-3-(4-chlorophenyl)-2-(1H-tetrazol-5-yl)acrylonitrile 5a was investigated in the next step. The catalyst 1 was easily separated after completion of the model reaction under optimized conditions by an external magnet. The recycled Fe3O4@PMO–ICS–ZnO was separately dispersed in EtOH and EtOAc for 15 min, respectively. The recycled catalyst was kept in an oven at 60 °C for 1 h and then reused for the next runs. The results of the catalyst recycling for five consecutive runs are given in Fig. 11. As data in Fig. 10 demonstrate, only a slight decrease in reaction yield was observed after fourth run. These findings indicate the structural stability of magnetic the Fe3O4@PMO–ICS–ZnO (1) during synthesis of 5-substituted-1H-tetrazole derivatives 5.

Figure 11.

Reusability data for the magnetic Fe3O4@PMO-ICS-ZnO mesoporous catalyst (1) in the synthesis of 5a.

Comparison of the catalytic activity of nano-ordered Fe3O4@PMO–ICS–ZnO (1) in the synthesis of tetrazole derivatives with other catalytic systems

Table 4 compares the previously reported methods for the synthesis of tetrazole 5a with the present protocol. It is apparent that high to excellent yields, avoiding the use of toxic or carcinogenic solvents such as DMF, short reaction time and easy separation of the catalyst from the reaction mixture are the advantages of the present protocol compared to the most of previously reported methods.

Table 4.

Comparison of the catalytic efficiency of the Fe3O4@PMO-ZnO (1) with other heterogeneous or homogeneous catalytic systems for the synthesis of 5a.

| Entry | Catalyst | Catalyst loading (mg) | Conditions | Time (h) | Yield 4a (%) |

Ref. |

|---|---|---|---|---|---|---|

| 1 | NiO nanoparticles | 4.5 | DMF/70 °C | 6 | 87 | 65 |

| 2 | Silica molybdic acid | 200 | H2O/MW/50 °C | 20 min | 91 | 66 |

| 3 | Zn (Metallic) | 130.7 | H2O/50 °C | 3 | 68 | 110 |

| 4 | Fe(OAc)2 | 17.4 |

DMF/H2O (9:1) 80 °C |

24 | 89 | 116 |

| 5 | (CuOTf)2.C6H6 | 36.2 | Toluene/rt | 7 | 81 | 117 |

| 6 | Montmorillonite K 10 | 10.0 | H2O | 17 | 29 | 118 |

| DMF | 38 | |||||

| 7 | Cu(OAc)2 | 45.4 | DMF/120 °C | 12 | 96 | 119 |

| 8 | Catalyst-Free | _ | Solvent-Free | 24 h | 78 | _ |

| 9 | OPNSA | 45.4 | Solvent-Free | 8 | 90 | 120 |

| 10 | H3PW12O40 | 20.2 | Solvent-Free/120 °C | 6 | 93 | 121 |

| 11 | NH–Cu(II)@MNP | 20.0 | EtOH/80 °C | 5 | 92 | 111 |

| 12 | Fe3O4@PMO–ICS–ZnO | 10.0 | EtOH/reflux | 3 | 98 | This work |

Significant values are in bold.

Experimental

Reagents and instruments

All chemical substances and reagents with high purity were purchased from Merck or Aldrich and used as received, except for liquid aldehydes which were distilled before their using. The progress of reactions and the purity of the obtained products were monitored by thin layer chromatography (TLC) using Merck aluminum plates coated with 0.2 mm silica gel F254. Melting points were measured using an Electrothermal 9100 device and are uncorrected. Characterization of the magnetic catalyst 1 as well as identification of products was performed using KBr discs on a Shimaduzu FTIR-8400S spectrometer. A Bruker DRX-500 Avance spectrometer was used for recording of 1H NMR (500 MHz) and 13C NMR (125 MHz) spectra of products in DMSO-d6 at ambient temperature. The BET specific surface area analysis was performed using ASAP 2020™ instrument. Thermal gravimetric analysis data was obtained by a Bahr company STA 504 equipment. X-Ray diffraction pattern was prepared using a STOE apparatus with CuKα radiation source. Field emission scanning electron microscopy images were recorded by a Zeiss (EM10C) device. VSM analysis was performed using a Lakeshore 7410 series instrument (Supplementary file).

Typical procedure for the preparation of PMO-ICS

The periodic mesoporous organosilica denoted PMO-ICS was prepared according to the method introduced by Jaroniec122. This PMO-ICS was synthesized by self-assembly of tris[3-(trimethoxysilyl)propyl] isocyanurate (ICS, Aldrich), tetraethyl orthosilicate (TEOS, Aldrich) in the presence of poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) triblock copolymer (Pluronic 123, Aldrich, average Mw ≅ 5800 Dalton) under acidic conditions. In a typical experiment, P123 (2.0 g) was added into a 250 mL beaker and a mixture of deionized water (15 mL) and hydrochloric acid solution (2.0 M, 60 mL) was slowly added and stirred until P123 is completely dissolved. Then, ICS (0.01 mol, 3.08 g) and TEOS (0.03 mol, 3.12 g) were simultaneously added dropwise into the obtained solution. After that, the obtained white gel and precipitates was stirred at room temperature for 24 h in a round bottom flask. Then, the mixture was aged at 100 °C for 48 h without stirring. The solid was filtered off and washed thoroughly with hot EtOH/HCl (60 mL of 96% EtOH and 2 mL of 12.0 M HCl) using a soxhelet apparatus for 72 h to remove the surfactant molecules. The obtained white powder was finally dried in air at 100 °C overnight.

General procedure for the preparation of magnetic Fe3O4@PMO-ICS

PMO-ICS (2.0 g) was dispersed in toluene (20 mL) at room temperature. After 15 min stirring, FeCl2.4H2O (2.0 g) and FeCl3.6H2O (4.0 g) were added to the above mixture under nitrogen atmosphere. The reaction mixture was heated in an oil bath at 80 °C during stirring, Then, ammonia solution (25% w/w, 20 mL) was added dropwise into the mixture over a period of 30 min until pH 11.0 is reached and allowed to stir for one hour at the same temperature. The obtained black precipitate was finally collected by an external magnet, washed with deinozed water and EtOH and then dried at 100 °C for 2 h.

Preparation of ZnO nanoparticles embedded in the mesoporous Fe3O4@PMO-ICS (Fe3O4@PMO–ICS–ZnO, 1)

At this stage, Zn(OAc)2 in the presence of PEG-600 surfactant was used to embed ZnO nanoparticles into the channels of Fe3O4@PMO-ICS. Zn(OAc)2 (0.1 g) and PEG (0.1 g) were added to a mixture of Fe3O4@PMO-ICS (3.0 g) dispersed in twice-distilled water (50 mL). Then, NH3 solution (25% w/w) was added dropwise to the obtained mixture and adjusting pH to 10.0 and then heated for 8 h at 80 °C. Finally, the mixture was cooled to ambient temperature and the obtained crimson Fe3O4@PMO–ICS–ZnO powder was magnetically separated. The powder was washed with deionized water twice and then dried at 100 °C for 2 h.

General procedure for the synthesis of 5-substituted-1H-tetrazoles derivatives 5a-o catalyzed by Fe3O4@PMO–ICS–ZnO (1)

In a single-neck round-bottom 10 mL flask equipped with a condenser, a mixture of malononitrile (2, 1 mmol), sodium azide (3, 1.2 mmol) and aldehyde (4, 1 mmol) was heated in the presence of Fe3O4@PMO–ICS–ZnO catalyst 1 (10 mg) in EtOH under reflux conditions for the time indicated in Table 3. The reaction progress was monitored by TLC (Eluent: EtOAc/n-hexane, 1:3). After completion of the reaction, Fe3O4@PMO–ICS–ZnO catalyst was easily separated from the reaction mixture using an external magnet and the desired product 5 was crystallized by dropwise adding of distilled water to the ethanolic solution. The structure of products 5a–o was confirmed by melting point as well as FTIR, 1H NMR and 13C NMR spectroscopy.

Conclusions

Novel magnetic Fe3O4@PMO–ICS–ZnO nano-ordered catalyst was prepared through a modified environmentally-benign procedure and properly characterized. The catalytic activity of the new thermally stable Fe3O4@PMO–ICS–ZnO nanomaterial was demonstrated in the one-pot synthesis of tetrazole derivatives through cascade condensation and concerted 1,3-cycloaddition reactions as a representative of the Click Chemistry concept. Different aromatic aldehydes survived to involve smoothly in the optimized conditions affording the corresponding 5-substituted-1H-tetrazole derivatives in high to quantitative yields and good purity. Low catalyst loading, the use of green solvents such as EtOH or water instead of carcinogenic DMF and short reaction time as well as easy separation and recyclability of the catalyst for at least five consecutive runs without significant loss of its activity are notable advantages of this new protocol compared to other recent introduced procedures.

Supplementary Information

Acknowledgements

The authors thank The Research Council of Iran University of Science and Technology (IUST), Tehran, Iran (Grant No 160/20969) for their support. We would also like to acknowledge the support of Iran Nanotechnology Initiative Council (INIC), Iran.

Author contributions

S.S. worked on the topic as her MSc. thesis and prepared the initial draft of the manuscript. M.G.D. is the supervisor of both S.S. and A.A. as his MSc. students. Also, he edited and revised the manuscript completely. A.A. worked closely with S.S. for doing experimental section and interpreting of the characterization data. M.R.N.-J. is the advisor of S.S. and the supervisor of A.A. He also helped to interpret data and edited the manuscript partially.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-022-13011-9.

References

- 1.Ugi I, Domling A, Werner B. Since 1995 the new chemistry of multicomponent reactions and their libraries, including their heterocyclic chemistry. J. Heterocycl. Chem. 2000;37:647–658. doi: 10.1002/jhet.5570370322. [DOI] [Google Scholar]

- 2.Meghani NM, Amin HH, Lee B-J. Mechanistic applications of click chemistry for pharmaceutical drug discovery and drug delivery. Drug Discov. Today. 2017;22:1604–1619. doi: 10.1016/j.drudis.2017.07.007. [DOI] [PubMed] [Google Scholar]

- 3.Hein CD, Liu X-M, Wang D. Click chemistry, a powerful tool for pharmaceutical sciences. Pharm. Res. 2008;25:2216–2230. doi: 10.1007/s11095-008-9616-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Tiwari VK, et al. Cu-catalyzed click reaction in carbohydrate chemistry. Chem. Rev. 2016;116:3086–3240. doi: 10.1021/acs.chemrev.5b00408. [DOI] [PubMed] [Google Scholar]

- 5.Boukis AC, Reiter K, Frölich M, Hofheinz D, Meier MA. Multicomponent reactions provide key molecules for secret communication. Nat. Commun. 2018;9:1–10. doi: 10.1038/s41467-018-03784-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Xiong Q, Dong S, Chen Y, Liu X, Feng X. Asymmetric synthesis of tetrazole and dihydroisoquinoline derivatives by isocyanide-based multicomponent reactions. Nat. Commun. 2019;10:1–10. doi: 10.1038/s41467-018-07882-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Mardirossian M, et al. D-BMAP18 antimicrobial peptide is active in vitro, resists to pulmonary proteases but loses its activity in a murine model of Pseudomonas aeruginosa lung infection. Front. Chem. 2017;5:40. doi: 10.3389/fchem.2017.00040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Breugst M, Reissig H-U. The Huisgen reaction: Milestones of the 1,3-dipolar cycloaddition. Angew. Chem. Int. Ed. 2020;59:12293–12307. doi: 10.1002/anie.202003115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Neochoritis CG, Zhao T, Dömling A. Tetrazoles via multicomponent reactions. Chem. Rev. 2019;119:1970–2042. doi: 10.1021/acs.chemrev.8b00564. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kang X-M, Tang M-H, Yang G-L, Zhao B. Cluster/cage-based coordination polymers with tetrazole derivatives. Coord. Chem. Rev. 2020;422:213424. doi: 10.1016/j.ccr.2020.213424. [DOI] [Google Scholar]

- 11.Matthews DP, Green JE, Shuker AJ. Parallel synthesis of alkyl tetrazole derivatives using solid support chemistry. J. Comb. Chem. 2000;2:19–23. doi: 10.1021/cc990035z. [DOI] [PubMed] [Google Scholar]

- 12.Bhaskar V, Mohite P. Synthesis, characterization and evaluation of anticancer activity of some tetrazole derivatives. J. Optoelectron. Biomed. Mater. 2010;2:249–259. [Google Scholar]

- 13.Agalave SG, Maujan SR, Pore VS. Click chemistry: 1,2,3-Triazoles as pharmacophores. Chem. Asian J. 2011;6:2696–2718. doi: 10.1002/asia.201100432. [DOI] [PubMed] [Google Scholar]

- 14.Hou J, Liu X, Shen J, Zhao G, Wang PG. The impact of click chemistry in medicinal chemistry. Expert Opin. Drug Discov. 2012;7:489–501. doi: 10.1517/17460441.2012.682725. [DOI] [PubMed] [Google Scholar]

- 15.Heravi MM, Zadsirjan V, Dehghani M, Ahmadi T. Towards click chemistry: Multicomponent reactions via combinations of name reactions. Tetrahedron. 2018;74:3391–3457. doi: 10.1016/j.tet.2018.04.076. [DOI] [Google Scholar]

- 16.Pandya J, Verdia J, Joshi N. An improved novel process for the synthesis of antihypertensive drug, Irbesartan. Afinidad. 2014;71:567. [Google Scholar]

- 17.Koguro K, Oga T, Mitsui S, Orita R. Novel synthesis of 5-substituted tetrazoles from nitriles. Synthesis. 1998;1998:910–914. doi: 10.1055/s-1998-2081. [DOI] [Google Scholar]

- 18.Konrad W, et al. A combined photochemical and multicomponent reaction approach to precision oligomers. Chem. A Eur. J. 2018;24:3413–3419. doi: 10.1002/chem.201705939. [DOI] [PubMed] [Google Scholar]

- 19.Kakuchi R. The dawn of polymer chemistry based on multicomponent reactions. Polym. J. 2019;51:945–953. doi: 10.1038/s41428-019-0209-0. [DOI] [Google Scholar]

- 20.Afshari R, Shaabani A. Materials functionalization with multicomponent reactions: State of the art. ACS Comb. Sci. 2018;20:499–528. doi: 10.1021/acscombsci.8b00072. [DOI] [PubMed] [Google Scholar]

- 21.Ruijter E, Scheffelaar R, Orru RV. Multicomponent reaction design in the quest for molecular complexity and diversity. Angew. Chem. Int. Ed. 2011;50:6234–6246. doi: 10.1002/anie.201006515. [DOI] [PubMed] [Google Scholar]

- 22.Esirden İ, Erken E, Kaya M, Sen F. Monodisperse Pt NPs@ rGO as highly efficient and reusable heterogeneous catalysts for the synthesis of 5-substituted 1 H-tetrazole derivatives. Catal. Sci. Technol. 2015;5:4452–4457. doi: 10.1039/C5CY00864F. [DOI] [Google Scholar]

- 23.Kritchenkov AS, et al. Synthesis of novel 1H-tetrazole derivatives of chitosan via metal-catalyzed 1, 3-dipolar cycloaddition. Catalytic and antibacterial properties of [3-(1H-tetrazole-5-yl) ethyl] chitosan and its nanoparticles. Int. J. Biol. Macromol. 2019;132:340–350. doi: 10.1016/j.ijbiomac.2019.03.153. [DOI] [PubMed] [Google Scholar]

- 24.Varala R, Babu BH. Molecular Docking. IntechOpen; 2018. [Google Scholar]

- 25.Ballatore C, Huryn DM, Smith AB., 3rd Carboxylic acid (bio)isosteres in drug design. ChemMedChem. 2013;8:385–395. doi: 10.1002/cmdc.201200585. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Zhao S, Zhang S, Xu J, Hu L. Synthesis and comparative study of emulsifying and biological properties of triazolated glucolipids. Tetrahedron. 2020;76:131517. doi: 10.1016/j.tet.2020.131517. [DOI] [Google Scholar]

- 27.Bakthadoss M, Vinayagam V. Construction of hybrid polycyclic quinolinobenzo [a] phenazinone architectures using solid-state melt reaction (SSMR) Mol. Diver. 2020;25:1–12. doi: 10.1007/s11030-020-10090-6. [DOI] [PubMed] [Google Scholar]

- 28.Shelkar R, Singh A, Nagarkar J. Amberlyst-15 catalyzed synthesis of 5-substituted 1-H-tetrazole via [3+2] cycloaddition of nitriles and sodium azide. Tetrahedron Lett. 2013;54:106–109. doi: 10.1016/j.tetlet.2012.10.116. [DOI] [Google Scholar]

- 29.Duncia JV, Pierce ME, Santella JB. Three synthetic routes to a sterically hindered tetrazole. A new one-step mild conversion of an amide into a tetrazole. J. Org. Chem. 1991;56:2395–2400. doi: 10.1021/jo00007a027. [DOI] [Google Scholar]

- 30.Hirata T, et al. Acyliminothiadiazoline derivatives: New, highly potent, and orally active angiotensin II receptor antagonists. Bioorg. Med. Chem. Lett. 1996;6:1469–1474. doi: 10.1016/S0960-894X(96)00250-8. [DOI] [Google Scholar]

- 31.El Anwar S, Růžičková Z, Bavol D, Fojt L, Grüner B. Tetrazole ring substitution at carbon and boron sites of the cobalt Bis(dicarbollide) ion available via dipolar cycloadditions. Inorg. Chem. 2020;59:17430–17442. doi: 10.1021/acs.inorgchem.0c02719. [DOI] [PubMed] [Google Scholar]

- 32.Wei C-X, Bian M, Gong G-H. Tetrazolium compounds: Synthesis and applications in medicine. Molecules. 2015;20:5528–5553. doi: 10.3390/molecules20045528. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Abdollahi-Alibeik M, Moaddeli A. Multi-component one-pot reaction of aldehyde, hydroxylamine and sodium azide catalyzed by Cu-MCM-41 nanoparticles: A novel method for the synthesis of 5-substituted 1 H-tetrazole derivatives. New J. Chem. 2015;39:2116–2122. doi: 10.1039/C4NJ01042F. [DOI] [Google Scholar]

- 34.Gyoung YS, Shim J-G, Yamamoto Y. Regiospecific synthesis of 2-allylated-5-substituted tetrazoles via palladium-catalyzed reaction of nitriles, trimethylsilyl azide, and allyl acetates. Tetrahedron Lett. 2000;41:4193–4196. doi: 10.1016/S0040-4039(00)00563-3. [DOI] [Google Scholar]

- 35.Mittal R, Awasthi SK. Recent advances in the synthesis of 5-substituted 1H-tetrazoles: A complete survey (2013–2018) Synthesis. 2019;51:3765–3783. doi: 10.1055/s-0037-1611863. [DOI] [Google Scholar]

- 36.Aureggi V, Sedelmeier G. 1,3-Dipolar cycloaddition: Click chemistry for the synthesis of 5-substituted tetrazoles from organoaluminum azides and nitriles. Angew. Chem. Int. Ed. 2007;46:8440–8444. doi: 10.1002/anie.200701045. [DOI] [PubMed] [Google Scholar]

- 37.Li N-C, et al. Use of angiotensin receptor blockers and risk of dementia in a predominantly male population: Prospective cohort analysis. BMJ. 2010;340:b5465. doi: 10.1136/bmj.b5465. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Bhardwaj G. How the antihypertensive losartan was discovered. Expert Opin. Drug Discov. 2006;1:609–618. doi: 10.1517/17460441.1.6.609. [DOI] [PubMed] [Google Scholar]

- 39.De Vogel S, Hoorn EJ, Papademetriou V. Losartan in cardiovascular disease. Future Cardiol. 2005;1:433. doi: 10.2217/14796678.1.4.433. [DOI] [PubMed] [Google Scholar]

- 40.Bhatt U. Five-membered heterocycles with four heteroatoms: Tetrazoles. In: Alvarez-Builla J, editor. Modern Heterocyclic Chemistry. Wiley; 2011. pp. 1401–1430. [Google Scholar]

- 41.Gutmann B, Roduit JP, Roberge D, Kappe CO. Synthesis of 5-substituted 1H-tetrazoles from nitriles and hydrazoic acid by using a safe and scalable high-temperature microreactor approach. Angew. Chem. Int. Ed. 2010;49:7101–7105. doi: 10.1002/anie.201003733. [DOI] [PubMed] [Google Scholar]

- 42.Clémençon IF, Ganem B. Tandem multicomponent/click reactions: Synthesis of functionalized oxazoles and tetrazoles from acyl cyanides. Tetrahedron. 2007;63:8665–8669. doi: 10.1016/j.tet.2007.03.127. [DOI] [Google Scholar]

- 43.Nikoorazm M, Moradi P, Noori N. L-cysteine complex of palladium onto mesoporous channels of MCM-41 as reusable, homoselective and organic–inorganic hybrid nanocatalyst for the synthesis of tetrazoles. J. Porous Mater. 2020;27:1159–1169. doi: 10.1007/s10934-020-00894-0. [DOI] [Google Scholar]

- 44.Moradi P, Hajjami M, Tahmasbi B. Fabricated copper catalyst on biochar nanoparticles for the synthesis of tetrazoles as antimicrobial agents. Polyhedron. 2020;175:114169. doi: 10.1016/j.poly.2019.114169. [DOI] [Google Scholar]

- 45.Jafari F, Ghorbani-Choghamarani A, Hasanzadeh N. Guanidine complex of copper supported on boehmite nanoparticles as practical, recyclable, chemo and homoselective organic–inorganic hybrid nanocatalyst for organic reactions. Appl. Organomet. Chem. 2020;34:e5901. doi: 10.1002/aoc.5901. [DOI] [Google Scholar]

- 46.Himo F, Demko ZP, Noodleman L, Sharpless KB. Why is tetrazole formation by addition of azide to organic nitriles catalyzed by zinc(II) salts? J. Am. Chem. Soc. 2003;125:9983–9987. doi: 10.1021/ja030204q. [DOI] [PubMed] [Google Scholar]

- 47.Kantam ML, Shiva Kumar KB, Phani Raja K. An efficient synthesis of 5-substituted 1H-tetrazoles using Zn/Al hydrotalcite catalyst. J. Mol. Catal. A Chem. 2006;247:186–188. doi: 10.1016/j.molcata.2005.11.046. [DOI] [Google Scholar]

- 48.Abrishami F, Ebrahimikia M, Rafiee F. Synthesis of 5-substituted 1H-tetrazoles using a recyclable heterogeneous nanonickel ferrite catalyst. Appl. Organomet. Chem. 2015;29:730–735. doi: 10.1002/aoc.3358. [DOI] [Google Scholar]

- 49.Cantillo D, Gutmann B, Kappe CO. Mechanistic insights on azide–nitrile cycloadditions: On the dialkyltin oxide–trimethylsilyl azide route and a new Vilsmeier–Haack-Type Organocatalyst. J. Am. Chem. Soc. 2011;133:4465–4475. doi: 10.1021/ja109700b. [DOI] [PubMed] [Google Scholar]

- 50.Nasrollahzadeh M, Bayat Y, Habibi D, Moshaee S. FeCl3–SiO2 as a reusable heterogeneous catalyst for the synthesis of 5-substituted 1H-tetrazoles via [2+3] cycloaddition of nitriles and sodium azide. Tetrahedron Lett. 2009;50:4435–4438. doi: 10.1016/j.tetlet.2009.05.048. [DOI] [Google Scholar]

- 51.Matloubi Moghaddam F, Eslami M, Ghadirian N. MCM-41-SO3H as an effcient reusable nano-ordered heterogeneous catalyst for the synthesis of divers 1- & 5-substituted 1H-tetrazoles. Sci. Iran. 2019;26:1463–1473. doi: 10.24200/sci.2018.21088. [DOI] [Google Scholar]

- 52.Aali E, Gholizadeh M, Noroozi-Shad N. 1-Disulfo-[2,2-bipyridine]-1,1-diium chloride ionic liquid as an efficient catalyst for the green synthesis of 5-substituted 1H-tetrazoles. J. Mol. Struct. 2022;1247:131289. doi: 10.1016/j.molstruc.2021.131289. [DOI] [Google Scholar]

- 53.Demko ZP, Sharpless KB. A Click chemistry approach to tetrazoles by huisgen 1,3-dipolar cycloaddition: Synthesis of 5-sulfonyl tetrazoles from azides and sulfonyl cyanides. Angew. Chem. Int. Ed. 2002;41:2110–2113. doi: 10.1002/1521-3773(20020617)41:12<2110::AID-ANIE2110>3.0.CO;2-7. [DOI] [PubMed] [Google Scholar]

- 54.Demko ZP, Sharpless KB. A click chemistry approach to tetrazoles by huisgen 1,3-dipolar cycloaddition: Synthesis of 5-acyltetrazoles from azides and acyl cyanides. Angew. Chem. Int. Ed. 2002;41:2113–2116. doi: 10.1002/1521-3773(20020617)41:12<2113::AID-ANIE2113>3.0.CO;2-Q. [DOI] [PubMed] [Google Scholar]

- 55.Tisseh ZN, Dabiri M, Nobahar M, Khavasi HR, Bazgir A. Catalyst-free, aqueous and highly diastereoselective synthesis of new 5-substituted 1H-tetrazoles via a multi-component domino Knoevenagel condensation/1,3 dipolar cycloaddition reaction. Tetrahedron. 2012;68:1769–1773. doi: 10.1016/j.tet.2011.12.044. [DOI] [Google Scholar]

- 56.Demko ZP, Sharpless KB. Preparation of 5-substituted 1 H-tetrazoles from nitriles in water. J. Org. Chem. 2001;66:7945–7950. doi: 10.1021/jo010635w. [DOI] [PubMed] [Google Scholar]

- 57.Alvim HG, da Silva Junior EN, Neto BA. What do we know about multicomponent reactions? Mechanisms and trends for the Biginelli, Hantzsch, Mannich, Passerini and Ugi MCRs. Rsc Adv. 2014;4:54282–54299. doi: 10.1039/C4RA10651B. [DOI] [Google Scholar]

- 58.Dekamin MG, Azimoshan M, Ramezani L. Chitosan: A highly efficient renewable and recoverable bio-polymer catalyst for the expeditious synthesis of α-amino nitriles and imines under mild conditions. Green Chem. 2013;15:811–820. doi: 10.1039/c3gc36901c. [DOI] [Google Scholar]

- 59.Naeimi H, Kiani F. Ultrasound-promoted one-pot three component synthesis of tetrazoles catalyzed by zinc sulfide nanoparticles as a recyclable heterogeneous catalyst. Ultrason. Sonochem. 2015;27:408–415. doi: 10.1016/j.ultsonch.2015.06.008. [DOI] [PubMed] [Google Scholar]

- 60.Xie L-G, Dixon DJ. Iridium-catalyzed reductive Ugi-type reactions of tertiary amides. Nat. Commun. 2018;9:1–8. doi: 10.1038/s41467-017-02088-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 61.Khodamorady M, Bahrami K. Fe3O4@BNPs-CPTMS-chitosan-Pd(0) as an efficient and stable heterogeneous magnetic nanocatalyst for the chemoselective oxidation of alcohols and homoselective synthesis of 5-subestituted 1H-tetrazoles. ChemistrySelect. 2019;4:8183–8194. doi: 10.1002/slct.201901497. [DOI] [Google Scholar]

- 62.Hajizadeh Z, Hassanzadeh-Afruzi F, Jelodar DF, Ahghari MR, Maleki A. Cu(II) immobilized on Fe3O4@HNTs–tetrazole (CFHT) nanocomposite: Synthesis, characterization, investigation of its catalytic role for the 1,3 dipolar cycloaddition reaction, and antibacterial activity. RSC Adv. 2020;10:26467–26478. doi: 10.1039/D0RA04772D. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Yuan X, Wang Z, Zhang Q, Luo J. An intramolecular relay catalysis strategy for Knoevenagel condensation and 1,3-dipolar cycloaddition domino reactions. RSC Adv. 2019;9:23614–23621. doi: 10.1039/C9RA04081A. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Akbarzadeh P, Koukabi N, Kolvari E. Three-component solvent-free synthesis of 5-substituted-1H-tetrazoles catalyzed by unmodified nanomagnetite with microwave irradiation or conventional heating. Res. Chem. Intermed. 2019;45:1009–1024. doi: 10.1007/s11164-018-3657-9. [DOI] [Google Scholar]

- 65.Safaei-Ghomi J, Paymard-Samani S. Facile and rapid synthesis of 5-substituted 1H-tetrazoles VIA a multicomponent domino reaction using nickel(II) oxide nanoparticles as catalyst. Chem. Heterocycl. Compd. 2015;50:1567–1574. doi: 10.1007/s10593-014-1625-x. [DOI] [Google Scholar]

- 66.Ahmed N, Siddiqui ZN. Silica molybdic acid catalysed eco-friendly three component synthesis of functionalised tetrazole derivatives under microwave irradiation in water. RSC Adv. 2015;5:16707–16717. doi: 10.1039/C5RA01073J. [DOI] [Google Scholar]

- 67.Tourani H, Naimi-Jamal MR, Dekamin MG. Preparation of 5-substituted-1H-tetrazoles catalyzed by MOFs via two strategies: Direct condensation of aryl nitriles with sodium azide, and tri-component reaction method. ChemistrySelect. 2018;3:8332–8337. doi: 10.1002/slct.201801392. [DOI] [Google Scholar]

- 68.Manayil JC, Lee AF, Wilson K. Functionalized periodic mesoporous organosilicas: Tunable hydrophobic solid acids for biomass conversion. Molecules. 2019;24:239. doi: 10.3390/molecules24020239. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 69.Ha C-S, Park SS, editors. Periodic Mesoporous Organosilicas: Preparation, Properties and Applications. Springer; 2019. pp. 125–187. [Google Scholar]

- 70.Van Der Voort P, et al. Periodic mesoporous organosilicas: From simple to complex bridges; a comprehensive overview of functions, morphologies and applications. Chem. Soc. Rev. 2013;42:3913–3955. doi: 10.1039/C2CS35222B. [DOI] [PubMed] [Google Scholar]

- 71.Climent MJ, Corma A, Iborra S. Heterogeneous catalysts for the one-pot synthesis of chemicals and fine chemicals. Chem. Rev. 2011;111:1072–1133. doi: 10.1021/cr1002084. [DOI] [PubMed] [Google Scholar]

- 72.Li Z, et al. Well-defined materials for heterogeneous catalysis: From nanoparticles to isolated single-atom sites. Chem. Rev. 2019;120:623–682. doi: 10.1021/acs.chemrev.9b00311. [DOI] [PubMed] [Google Scholar]

- 73.Sharma V, Orejon D, Takata Y, Krishnan V, Harish S. Gladiolus dalenii based bioinspired structured surface via soft lithography and its application in water vapor condensation and fog harvesting. ACS Sustain. Chem. Eng. 2018;6:6981–6993. doi: 10.1021/acssuschemeng.8b00815. [DOI] [Google Scholar]

- 74.Sheldon RA, Arends I, Hanefeld U. Green Chemistry and Catalysis. Wiley; 2007. [Google Scholar]

- 75.Astruc D, Lu F, Aranzaes JR. Nanoparticles as recyclable catalysts: The frontier between homogeneous and heterogeneous catalysis. Angew. Chem. Int. Ed. 2005;44:7852–7872. doi: 10.1002/anie.200500766. [DOI] [PubMed] [Google Scholar]

- 76.Yang MM, et al. Lack of association of C3 gene with uveitis: Additional insights into the genetic profile of uveitis regarding complement pathway genes. Sci. Rep. 2017;7:1–8. doi: 10.1038/s41598-016-0028-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 77.Yoshida M, et al. Immobilization of luminescent platinum (II) complexes on periodic mesoporous organosilica and their water reduction photocatalysis. J. Photochem. Photobiol. A. 2018;358:334–344. doi: 10.1016/j.jphotochem.2017.09.008. [DOI] [Google Scholar]

- 78.Rebbin V, Schmidt R, Fröba M. Spherical particles of phenylene-bridged periodic mesoporous organosilica for high-performance liquid chromatography. Angew. Chem. Int. Ed. 2006;45:5210–5214. doi: 10.1002/anie.200504568. [DOI] [PubMed] [Google Scholar]

- 79.Ma X, et al. Hollow periodic mesoporous organosilica nanospheres by a facile emulsion approach. J. Colloid Interface Sci. 2016;475:66–71. doi: 10.1016/j.jcis.2016.04.026. [DOI] [PubMed] [Google Scholar]

- 80.Cornelius M, Hoffmann F, Fröba M. Periodic mesoporous organosilicas with a bifunctional conjugated organic unit and crystal-like pore walls. Chem. Mater. 2005;17:6674–6678. doi: 10.1021/cm051935n. [DOI] [Google Scholar]

- 81.Wang W, Grozea D, Kohli S, Perovic DD, Ozin GA. Water repellent periodic mesoporous organosilicas. ACS Nano. 2011;5:1267–1275. doi: 10.1021/nn102929t. [DOI] [PubMed] [Google Scholar]

- 82.Zebardasti A, Dekamin MG, Doustkhah E, Assadi MHN. Carbamate-isocyanurate-bridged periodic mesoporous organosilica for van der Waals CO2 capture. Inorg. Chem. 2020;59:11223–11227. doi: 10.1021/acs.inorgchem.0c01449. [DOI] [PubMed] [Google Scholar]

- 83.Karimi B, Esfahani FK. Unexpected golden Ullmann reaction catalyzed by Au nanoparticles supported on periodic mesoporous organosilica (PMO) Chem. Commun. 2011;47:10452–10454. doi: 10.1039/c1cc12566d. [DOI] [PubMed] [Google Scholar]

- 84.Borah P, Ma X, Nguyen KT, Zhao Y. A vanadyl complex grafted to periodic mesoporous organosilica: A green catalyst for selective hydroxylation of benzene to phenol. Angew. Chem. 2012;124:7876–7881. doi: 10.1002/ange.201203275. [DOI] [PubMed] [Google Scholar]

- 85.Yaghoubi A, Dekamin MG, Arefi E, Karimi B. Propylsulfonic acid-anchored isocyanurate-based periodic mesoporous organosilica (PMO-ICS-Pr-SO3H): A new and highly efficient recoverable nanoporous catalyst for the one-pot synthesis of bis(indolyl)methane derivatives. J. Colloid Interface Sci. 2017;505:956–963. doi: 10.1016/j.jcis.2017.06.055. [DOI] [PubMed] [Google Scholar]

- 86.Dekamin MG, Arefi E, Yaghoubi A. Isocyanurate-based periodic mesoporous organosilica (PMO-ICS): A highly efficient and recoverable nanocatalyst for the one-pot synthesis of substituted imidazoles and benzimidazoles. RSC Adv. 2016;6:86982–86988. doi: 10.1039/C6RA14550G. [DOI] [Google Scholar]

- 87.Akbari A, Dekamin MG, Yaghoubi A, Naimi-Jamal MR. Novel magnetic propylsulfonic acid-anchored isocyanurate-based periodic mesoporous organosilica (Iron oxide@PMO-ICS-PrSO3H) as a highly efficient and reusable nanoreactor for the sustainable synthesis of imidazopyrimidine derivatives. Sci. Rep. 2020;10:10646. doi: 10.1038/s41598-020-67592-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 88.Zebardasti A, Dekamin MG, Doustkhah E. The isocyanurate-carbamate-bridged hybrid mesoporous organosilica: An exceptional anchor for Pd nanoparticles and a unique catalyst for nitroaromatics reduction. Catalysts. 2021;11:621. doi: 10.3390/catal11050621. [DOI] [Google Scholar]

- 89.Valiey E, Dekamin MG. Pyromellitic diamide–diacid bridged mesoporous organosilica nanospheres with controllable morphologies: A novel PMO for the facile and expeditious synthesis of imidazole derivatives. Nanoscale Adv. 2022;4:294–308. doi: 10.1039/D1NA00738F. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 90.Valiey E, Dekamin MG. Supported copper on a diamide–diacid-bridged PMO: An efficient hybrid catalyst for the cascade oxidation of benzyl alcohols/Knoevenagel condensation. RSC Adv. 2022;12:437–450. doi: 10.1039/D1RA06509B. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 91.Yoo CG, Pu Y, Ragauskas AJ. Ionic liquids: Promising green solvents for lignocellulosic biomass utilization. Curr. Opin. Green Sustain. Chem. 2017;5:5–11. doi: 10.1016/j.cogsc.2017.03.003. [DOI] [Google Scholar]

- 92.Alzeer MI, MacKenzie KJ. Synthesis and catalytic properties of new sustainable aluminosilicate heterogeneous catalysts derived from fly ash. ACS Sustain. Chem. Eng. 2018;6:5273–5282. doi: 10.1021/acssuschemeng.7b04923. [DOI] [Google Scholar]

- 93.Liu L, Corma A. Metal catalysts for heterogeneous catalysis: From single atoms to nanoclusters and nanoparticles. Chem. Rev. 2018;118:4981–5079. doi: 10.1021/acs.chemrev.7b00776. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 94.Cuenya BR, Behafarid F. Nanocatalysis: Size-and shape-dependent chemisorption and catalytic reactivity. Surf. Sci. Rep. 2015;70:135–187. doi: 10.1016/j.surfrep.2015.01.001. [DOI] [Google Scholar]

- 95.Hatton B, Landskron K, Whitnall W, Perovic D, Ozin GA. Past, present, and future of periodic mesoporous organosilicas the PMOs. Acc. Chem. Res. 2005;38:305–312. doi: 10.1021/ar040164a. [DOI] [PubMed] [Google Scholar]

- 96.Chanson R, et al. Damage-free plasma etching of porous organo-silicate low-k using micro-capillary condensation above – 50 °C. Sci. Rep. 2018;8:1–12. doi: 10.1038/s41598-018-20099-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 97.Park SS, Moorthy MS, Ha C-S. Periodic mesoporous organosilicas for advanced applications. NPG Asia Mater. 2014;6:e96. doi: 10.1038/am.2014.13. [DOI] [Google Scholar]

- 98.Shokrian M, Sadrzadeh M, Mohammadi T. C3H8 separation from CH4 and H2 using a synthesized PDMS membrane: Experimental and neural network modeling. J. Membr. Sci. 2010;346:59–70. doi: 10.1016/j.memsci.2009.09.015. [DOI] [Google Scholar]

- 99.Valimaña-Traverso J, et al. Periodic mesoporous organosilica materials as sorbents for solid-phase extraction of drugs prior to simultaneous enantiomeric separation by capillary electrophoresis. J. Chromatogr. A. 2018;1566:135–145. doi: 10.1016/j.chroma.2018.06.043. [DOI] [PubMed] [Google Scholar]

- 100.Wu L, et al. Sulfonated periodic-mesoporous-organosilicas column for selective separation of C2H2/CH4 mixtures. J. Solid State Chem. 2018;264:113–118. doi: 10.1016/j.jssc.2018.03.038. [DOI] [Google Scholar]

- 101.Teng Z, et al. A facile multi-interface transformation approach to monodisperse multiple-shelled periodic mesoporous organosilica hollow spheres. J. Am. Chem. Soc. 2015;137:7935–7944. doi: 10.1021/jacs.5b05369. [DOI] [PubMed] [Google Scholar]

- 102.Ha C-S, Park SS. Periodic Mesoporous Organosilicas. Springer; 2019. pp. 87–100. [Google Scholar]

- 103.Elhamifar D, Ardeshirfard H. Phenyl and ionic liquid based bifunctional periodic mesoporous organosilica supported copper: An efficient nanocatalyst for clean production of polyhydroquinolines. J. Colloid Interface Sci. 2017;505:1177–1184. doi: 10.1016/j.jcis.2017.07.010. [DOI] [PubMed] [Google Scholar]

- 104.Yang Q, Liu J, Zhang L, Li C. Functionalized periodic mesoporous organosilicas for catalysis. J. Mater. Chem. 2009;19:1945–1955. doi: 10.1039/b815012e. [DOI] [Google Scholar]

- 105.Huang J, Zhang F, Li H. Organometal-bridged PMOs as efficiency and reusable bifunctional catalysts in one-pot cascade reactions. Appl. Catal. A. 2012;431:95–103. doi: 10.1016/j.apcata.2012.04.021. [DOI] [Google Scholar]

- 106.Hoffmann F, Cornelius M, Morell J, Fröba M. Periodic mesoporous organosilicas (PMOs): Past, present, and future. J. Nanosci. Nanotechnol. 2006;6:265–288. doi: 10.1166/jnn.2006.902. [DOI] [PubMed] [Google Scholar]

- 107.Olivieri F, Castaldo R, Cocca M, Gentile G, Lavorgna M. Mesoporous silica nanoparticles as carriers of active agents for smart anticorrosive organic coatings: A critical review. Nanoscale. 2021;13:9091–9111. doi: 10.1039/D1NR01899J. [DOI] [PubMed] [Google Scholar]

- 108.Hasanzadeh Banakar S, Dekamin MG, Yaghoubi A. Selective and highly efficient synthesis of xanthenedione or tetraketone derivatives catalyzed by ZnO nanorod-decorated graphene oxide. N. J. Chem. 2018;42:14246–14262. doi: 10.1039/C8NJ01053F. [DOI] [Google Scholar]

- 109.Davoodi F, Dekamin MG, Alirezvani Z. A practical and highly efficient synthesis of densely functionalized nicotinonitrile derivatives catalyzed by zinc oxide-decorated superparamagnetic silica attached to graphene oxide nanocomposite. Appl. Organomet. Chem. 2019;33:e4735. doi: 10.1002/aoc.4735. [DOI] [Google Scholar]

- 110.Behloul C, Benlahrech M, Foubelo F, Nájera C, Yus M. Indium-, magnesium-, and zinc-mediated debenzylation of protected 1H-tetrazoles: A comparative study. Synthesis. 2018;50:3430–3435. doi: 10.1055/s-0037-1610170. [DOI] [Google Scholar]

- 111.Yuan X, Wang Z, Zhang Q, Luo J. An intramolecular relay catalysis strategy for Knoevenagel condensation and 1, 3-dipolar cycloaddition domino reactions. RSC Adv. 2019;9:23614–23621. doi: 10.1039/C9RA04081A. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 112.Tisseh ZN, Dabiri M, Nobahar M, Khavasi HR, Bazgir A. Catalyst-free, aqueous and highly diastereoselective synthesis of new 5-substituted 1H-tetrazoles via a multi-component domino Knoevenagel condensation/1, 3 dipolar cycloaddition reaction. Tetrahedron. 2012;68:1769–1773. doi: 10.1016/j.tet.2011.12.044. [DOI] [Google Scholar]

- 113.Bakherad M, Doosti R, Keivanloo A, Gholizadeh M, Jadidi K. Rapid, green, and catalyst-free one-pot three-component syntheses of 5-substituted 1H-tetrazoles in magnetized water. J. Iran. Chem. Soc. 2017;14:2591–2597. doi: 10.1007/s13738-017-1193-y. [DOI] [Google Scholar]

- 114.Parmar BD, et al. A base-catalyzed, domino aldol/hetero-Diels–Alder synthesis of tricyclic pyrano [3, 4-c] chromenes in glycerol. J. Org. Chem. 2016;81:4955–4964. doi: 10.1021/acs.joc.6b00107. [DOI] [PubMed] [Google Scholar]

- 115.Safaei-Ghomi J, Paymard-Samani S, Zahedi S, Shahbazi-Alavi H. Sonochemical synthesis of 5-substituted 1H-tetrazoles catalyzed by ZrP2O7 nanoparticles and regioselective conversion into new 2, 5-disubstituted tetrazoles. Z. für Nat. B. 2015;70:819–828. doi: 10.1515/znb-2015-0070. [DOI] [Google Scholar]

- 116.Bonnamour J, Bolm C. Iron salts in the catalyzed synthesis of 5-substituted 1H-tetrazoles. Chem. A Eur. J. 2009;15:4543–4545. doi: 10.1002/chem.200900169. [DOI] [PubMed] [Google Scholar]

- 117.Chattopadhyay B, Vera CIR, Chuprakov S, Gevorgyan V. Fused tetrazoles as azide surrogates in click reaction: Efficient synthesis of N-heterocycle-substituted 1, 2, 3-triazoles. Org. Lett. 2010;12:2166–2169. doi: 10.1021/ol100745d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 118.Chermahini AN, et al. Clay-catalyzed synthesis of 5-substituent 1-H-tetrazoles. J. Heterocycl. Chem. 2010;47:913–922. doi: 10.1002/jhet.382. [DOI] [Google Scholar]

- 119.Heravi MM, Fazeli A, Oskooie HA, Beheshtiha YS, Valizadeh H. Click synthesis of 5-substituted 1H-tetrazoles from aldehydes, hydroxylamine, and [bmim] N3 via one-pot, three-component reaction. Synlett. 2012;23:2927–2930. doi: 10.1055/s-0032-1317671. [DOI] [Google Scholar]

- 120.Khaghaninejad S, Heravi MM, Hosseinnejad T, Oskooie HA, Bakavoli M. Regio-selective synthesis of 5-substituted 1H-tetrazoles using ionic liquid [BMIM] N 3 in solvent-free conditions: A click reaction. Res. Chem. Intermed. 2016;42:1593–1610. doi: 10.1007/s11164-015-2105-3. [DOI] [Google Scholar]

- 121.Fazeli A, et al. Heteropolyacid catalyzed click synthesis of 5-substituted 1H-tetrazoles from [bmim] N 3 and nitriles under solvent-free conditions. Monatshefte für Chem.-Chem. Month. 2013;144:1407–1410. doi: 10.1007/s00706-013-1025-4. [DOI] [Google Scholar]

- 122.Olkhovyk O, Jaroniec M. Periodic mesoporous organosilica with large heterocyclic bridging groups. J. Am. Chem. Soc. 2005;127:60–61. doi: 10.1021/ja043941a. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.