Abstract

The rising prevalence of impaired wound healing and the consequential healthcare burdens have gained increased attention over recent years. This has prompted research into the development of novel wound dressings with augmented wound healing functions. Nanoparticle (NP)-based delivery systems have become attractive candidates in constructing such wound dressings due to their various favourable attributes. The non-toxicity, biocompatibility and bioactivity of chitosan (CS)-based NPs make them ideal candidates for wound applications. This review focusses on the application of CS-based NP systems for use in wound treatment. An overview of the wound healing process was presented, followed by discussion on the properties and suitability of CS and its NPs in wound healing. The wound healing mechanisms exerted by CS-based NPs were then critically analysed and discussed in sections, namely haemostasis, infection prevention, inflammatory response, oxidative stress, angiogenesis, collagen deposition, and wound closure time. The results of the studies were thoroughly reviewed, and contradicting findings were identified and discussed. Based on the literature, the gap in research and future prospects in this research area were identified and highlighted. Current evidence shows that CS-based NPs possess superior wound healing effects either used on their own, or as drug delivery vehicles to encapsulate wound healing agents. It is concluded that great opportunities and potentials exist surrounding the use of CSNPs in wound healing.

Keywords: Biopolymer, Chitosan nanoparticle, Nanotechnology, Wound dressing, Wound healing

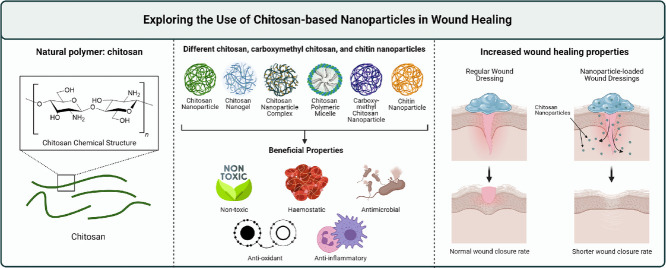

Graphical abstract

1. Introduction

The prevalence of wounds in the global community is a rising concern. Data collected by numerous studies have brought light to a trend of increasing occurrence of wounds in tertiary care [1,2]. This has been highlighted by observational clinical studies conducted in several countries across the globe. In the United Kingdom, a cohort study reported a 71% increase of wound incidence from 2012 to 2018 within the National Health Service (NHS) [3]. Cases of chronic wounds increased from 0.94% in 2014 to 2.11% in 2018 in hospitals in Northern China, whereby the mean duration of hospitalization was 13 days [4]. Similarly, a 95.1% increase in wound episodes per 1000 patient admissions from 2013 to 2017 was reported by a case-control study conducted in Singapore [5]. The rising incidence of both acute and chronic wounds has imposed substantial burdens on healthcare. Data from the NHS shows that the estimated average costs per healed and unhealed wounds have increased by about 30.0% and 73.90% respectively from 2012 to 2018 [3].

Despite being a common presentation in the clinical setting, provision of optimal wound care remains a challenge to many physicians, especially in developing nations due to the limited resources available, coupled with the rising cost of wound care. In an effort to combat the significant difficulty in managing certain wound conditions and to alleviate the healthcare burden of treating wounds, development of novel wound treatment options warrants necessary attention [6]. Affordable wound treatments capable of improving wound healing outcomes are desirable and beneficial to both patients and the overall healthcare system [6]. Considering this notion, a great number of studies have explored numerous pharmaceutical formulations, utilising new technology and biomaterials with favourable properties to develop modern wound dressings [7], [8], [9].

This review aims to provide in depth discussion surrounding the use of chitosan (CS)-based nanoparticles (NPs) for the application in wound healing, which have been widely reported to have improved wound healing outcomes compared to CS alone and other forms of CS-based formulations. The small sizes of these CS-based NPs allow better permeation and distribution around the wound area [10]. We provide critical analysis on the various mechanisms on wound healing elicited by CS-based NPs, and their in vitro and in vivo effects. The main type of CS-based NP discussed in this review are CS NPs (CSNPs) which are polymeric NPs, either nanocapsules or nanospheres, formulated using CS. Other types of NPs such as nanogels, NP complexes, and polymeric micelles were also among some of the studies reviewed. The NPs were either used on their own or as a transport vehicle to deliver therapeutic agents such as antibiotics, natural compounds, and peptides. We include studies using different forms and derivatives of CS such as chitin, CS oligosaccharide (COS), and carboxymethyl CS (CMCS). Effects of CS-modified metal NPs were also highlighted in the context of wound healing. Discussion of the studies was categorised according to the wound healing mechanisms, namely haemostasis, antimicrobial effects, antioxidant effects, inflammatory response, angiogenesis, collagen deposition and wound closure rate acceleration. Research gap and future prospects in this research area were also addressed in this article.

2. The wound healing process

2.1. Skin physiology and wound healing

Representing the largest organ by surface area, the skin is the first line of defence separating the internal bodily environment from harmful external factors [11], [12], [13]. A breach in this defense and disruptions to the important functions of the skin may occur in the event of an injury [12]. Fortunately, regeneration of damaged skin tissue can be achieved to a certain extent through the process of wound healing [11]. Despite exhaustive efforts and extensive research in unraveling its physiological process, the complete mechanism surrounding wound healing still remains elusive [14]. Current evidence on the wound healing process can be categorised into chronological phases which overlap and are strongly dependent on each other [11].

2.2. Phases of wound healing

Haemostasis is the crucial first step in starting the wound healing process [11]. To prevent excessive blood loss, vasoconstriction of nearby vessels and aggregation of platelets take place to form a platelet plug in the initial stages almost immediately [11,14]. This is followed by the formation of thrombus via the coagulation cascade to temporarily seal any opening on the skin due to the wound [11].

The next chronological phase involves infiltration of immune cells, beginning with neutrophils and followed by macrophages to engulf any foreign invaders and debris present at the wound site [15,16]. The early inflammation phase involves the pro-inflammatory M1 macrophage phenotype, which releases cytokines such as interleukin (IL)−6 and IL-1β, as well as proteases known as matrix metalloproteinases (MMPs) [15]. During the late inflammation phase, anti-inflammatory M2 macrophages release several growth factors such as vascular endothelial growth factor (VEGF), insulin-like growth factor 1 (IGF-1) and transforming growth factor (TGF)-β along with anti-inflammatory cytokines such as IL-10 [11,15].

Subsequently, the proliferation phase kicks in, with the deposition of new granulation tissue, re-epithelialisation, and angiogenesis [12]. Fibroblast cells begin manufacturing new extracellular matrix (ECM) components such as collagen III, fibronectin, and hyaluronic acid [17,18]. Newly differentiated myofibroblasts also exert contractile forces to physically pull the edges of the wound together to facilitate wound contraction [17,18]. Meanwhile, a fresh epidermal layer begins to form on the surface of the wound through the proliferation and migration of keratinocytes during the process of re-epithelialisation [19]. Previously damaged or lost blood vessels are also slowly replaced during the process of angiogenesis [11,12].

Complete healing is characterised by a sealed opening, based on physical appearances on the external surface [11], [20]. This is followed by the remodeling phase, which can last for several months or years after the wound has fully closed and involves the maturation of underlying skin tissue along with the manifestation of scars [11], [20]. Changes which gradually occur during this phase include the replacement of type III collagen with type I collagen, along with the degradation of unnecessary ECM components by MMPs [11], [21]. During this time, leaky new blood vessels undergo several changes to form more well-perfused vessels [11].

3. CS as a natural bioactive polymer

Mainly sourced from the exoskeletons of marine crustacean life, chitin is the second most abundantly occurring polysaccharide in nature [23]. However, its poor solubility in aqueous solutions limits its application [23]. Deacetylation of chitin results in the formation of CS, which comprises of d-glucosamine and N-acetyl d-glucosamine subunits linked together by β−1,4 glycosidic bonds [23]. Protonation of the amino groups along the CS polysaccharide chain makes it soluble under acidic conditions [23]. Studies have explored the benefits of CS in a wide range of applications across various research disciplines, including drug delivery vehicles, water treatment systems, and tissue engineering, to name a few [23,24].

Several features exhibited by CS and its derivatives have garnered attention from researchers to investigate its application in wound regeneration. Studies exploring the development of these materials have consistently shown accelerated wound healing rates and improved healing outcomes [25], [26], [27], [28]. Its exceptional biocompatibility further substantiates its suitability for use in wound dressings [25].

4. CS and wound healing

4.1. Wound healing properties of CS

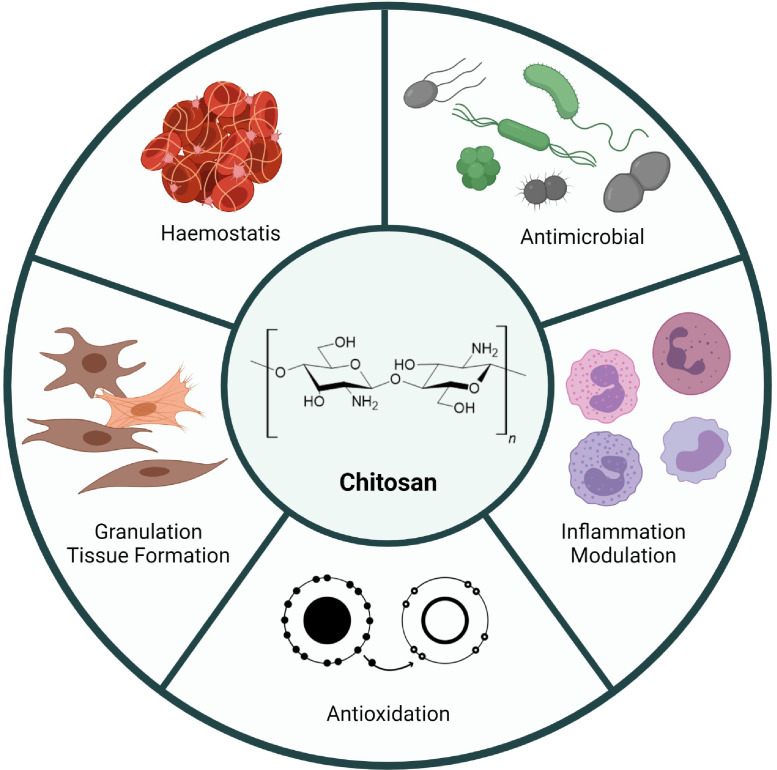

CS exerts its wound healing effect via several well-studied mechanisms. These include promotion of haemostasis, antimicrobial activity, free radical scavenging activity, and regulating the inflammatory response.

The physicochemical properties of CS and its polycationic nature allow it to promote haemostasis around the wound area through a few possible mechanisms identified by the current literature [29]. Positively charged CS is able to promote the aggregation of both negatively charged erythrocytes and platelets along with plasma proteins such as fibrinogen [29]. Collectively, these interactions help to facilitate blood aggregation and haemostasis.

To prevent unwanted infections at the wound site, CS exerts its antimicrobial effect via interactions between the polycationic polysaccharide chain with the negatively charged membrane components of bacterial cells [30,31]. Its ability to chelate trace amounts of metal ions on the surface membrane of bacterial cells also contributes to its antimicrobial properties to a smaller extent [30,31].

Over-production of reactive oxygen species (ROS) around the wound site can lead to direct damage in the form of lipid peroxidation and DNA modification to surrounding tissue; and indirect damage through the continuous promotion of pro-inflammatory cytokine release [32,33]. Having moderate scavenging activity against free radicals, CS is able to reduce ROS molecules by donating a hydrogen atom [34,35]. Both the hydroxyl groups and amino groups along the polymer chain contribute to this free radical scavenging effect [34,35]. However, the strong intermolecular and intramolecular hydrogen bonding within and among the CS polymer chains restrict the ability of these hydroxyl and amino groups from reacting with free radicals [34,35]. Hence, CS tends to exhibit mild anti-oxidative effects.

Any extension of inflammation beyond the healthy amount can disrupt the wound healing process and lead to chronic wounds [22,36]. CS with its immune stimulatory characteristics has been found to regulate both pro- and anti-inflammatory cytokines [37], [38], [39]. Inclination towards either pro- or anti-inflammatory activity of CS may be largely influenced by its physicochemical properties [40], [41], [42]. A small number of studies found and discussed that the inflammatory activity of CS may involve binding with CD14, TLR4, and CR3 receptors on macrophages [40], [41], [42]. Subsequent downstream effects involving production of tumor necrosis factor (TNF)-α, IL-6, nitric oxide, inducible nitric oxide synthase (iNOS) expression, nuclear factor kappa B (NF-κB) activation, and phosphorylation of mitogen-activated protein kinase (MAPK) signaling proteins are also found to be affected [40], [41], [42].

4.2. Influence of polymer properties of CS on wound healing effects

Being a natural polymer, variations in the molecular weight (MW) and degree of deacetylation (DDA) can have a significant influence on the wound healing properties of CS. The effects of these variations have been investigated in a number of studies.

4.2.1. Molecular weight

Generally, higher MW CS can be seen to be more favourable for haemostasis than lower MW CS to an extent [43,44]. It has been reported that CS oligomers with a MW of less than 8.6 kDa may not induce significant blood aggregation [43]. However, an increase in MW above 380 kDa was not found to produce notable changes in blood aggregation either [44]. Essentially, lower MW CS grant the benefit of larger surface area to volume ratios while higher MW CS provides greater amount of amine groups for interaction. A required balance between these two may be an explanation to the moderate range of MW producing optimal blood aggregation.

Under neutral pH conditions, lower MWs produce an overall improvement in antibacterial activity of CS [45]. Inversely, higher MWs have been correlated with an increase in antibacterial effects under acidic conditions [45]. These observations may possibly be due to the physical state of CS. The relatively small size of low MW CS may have more interactions with bacteria cells due to a larger surface area to volume ratio. However, under acidic conditions, the larger positive charge of high MW CS may outweigh the benefits granted by the smaller sized low MW CS. Nevertheless, the antibacterial effects of CS based on its physicochemical properties tend to be difficult to predict due to various confounding factors. In fact, studies have reported varying results of the influence of MW on the antibacterial effects of CS [45], [46], [47].

In terms of free radical scavenging ability, studies have found a trend of lower MW CS leading to an increase in scavenging activity. Typically, as the MW of CS increases, the polymer chain lengthens [48], [49], [50], [51]. This could possibly result in denser and more compact structures with an increase in intramolecular hydrogen bonding [48], [49], [50], [51]. As a consequence, the ability of hydroxyl and amino groups present along the chain to reduce free radicals may be reduced [48], [49], [50], [51].

Differences in immunological response have also been found between CS bearing different MWs. Although studies investigating this phenomenon are few in number, it has been found that low MW CS promote pro-inflammatory activity while high MW CS promote anti-inflammatory activity [40], [41], [42]. More studies will be required to describe these effects in greater detail.

4.2.2. Degree of deacetylation

Similar to the effects of MW, moderate DDA is found to produce better results in haemostasis [43,44,52]. Studies evaluating different DDA values have described either 68%, 64% – 72%, or 75% – 88% DDA produce the best haemostatic effects [43,44,52]. Striking a balance between the positive charges of CS with the negatively charged blood components is vital in producing optimal haemostatic effects [43].

Effects of DDA on the antibacterial properties of CS appear to be more straightforward than the effects of MW. Current literature generally reports a connection between increasing DDA with increasing antibacterial activity [46,53,54]. As DDA increases, the amount of amino groups available for ionisation increases. Consequently, the overall positive charge of CS increases, which enables stronger antibacterial effects.

A higher DDA may be correlated with higher free radical scavenging activity. Park et al. reported the highest scavenging effect when using hetero-CS with 90% DDA followed by 75% and 50% DDA [55]. These results were most prominent in 2,2-diphenyl-1-picrylhydrazyl (DPPH) radicals and not observed in hydroxyl radicals and superoxide radicals [55].

5. The use of NPs in wound management

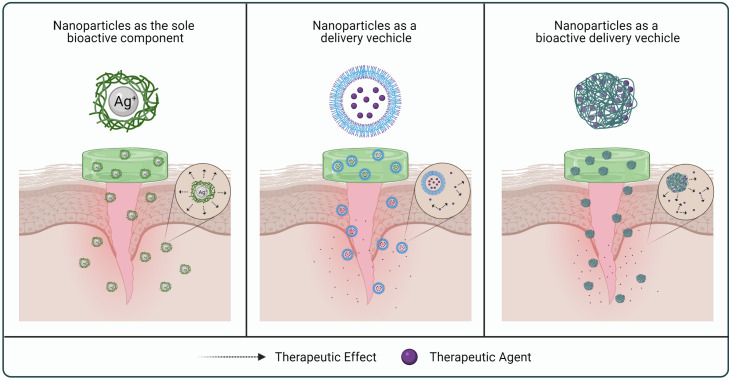

NPs have emerged as a major developmental tool in diverse areas of medical and pharmaceutical research [56]. Their great potential owes largely to the incredibly small sizes, readily modifiable characteristics, as well as the ability to achieve controlled and targeted drug release [57]. In the development of wound dressings, NPs have been used either as a delivery vehicle or as a bioactive component on their own to achieve better wound healing outcomes (Fig. 2) [10,58,59].

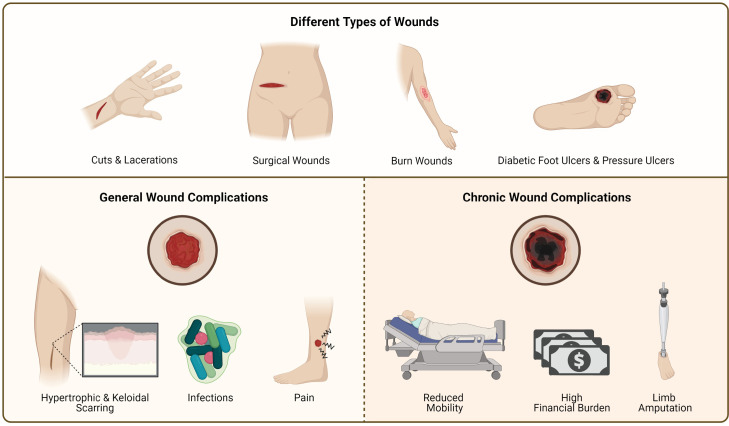

Fig. 1.

Illustration of the types of wounds and problems associated with wounds.

Fig. 3.

Summary of the wound healing properties exerted by CS.

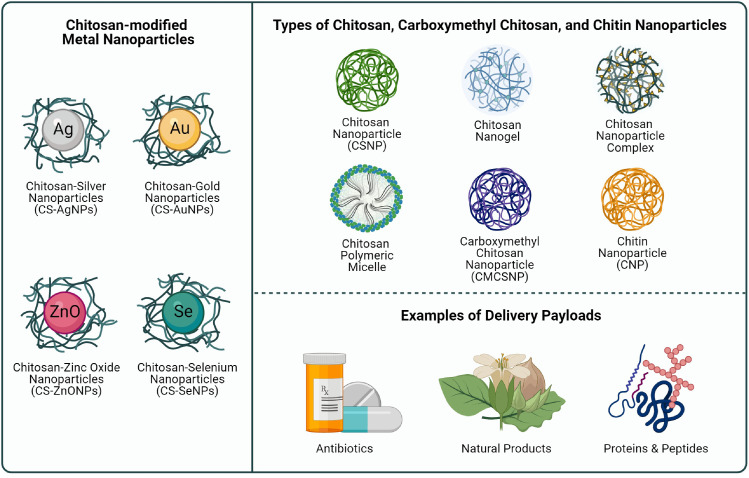

Fig. 4.

Illustration of the types of CS-based NPs, CMCSNPs, CNPs, and CS-modified NPs included in this literature review.

Fig. 2.

Illustration of the use of NPs in wound healing.

As drug delivery vehicles, NPs are great carriers to transport active compounds to improve wound healing outcomes. They could also offer protection and prolong the half-lives of short-lived therapeutic agents, such as growth factors which are readily degraded by proteolytic enzymes; as well as nitric oxide which is generally transient in nature [58,59]. They have also been used to achieve effective and controlled delivery of antimicrobial agents and natural products for wound treatments [58,59]. Gene therapy which facilitates wound healing through modification of the wound microenvironment has also relied on nanoparticulate systems to deliver specific genetic material to the wound site [60].

Apart from serving as a delivery vehicle, some NPs have been explored extensively in promoting the wound healing process due to their intrinsic antibacterial properties [59]. Metallic NPs such as silver NPs (AgNPs), gold NPs (AuNPs), zinc oxide NPs (ZnONPs), copper NPs (CuNPs) and selenium NPs (SeNPs) have been widely studied for this purpose [59,61]. On the other hand, bioactive polymers such as alginate or CS and their derivatives represent another attractive source of building material for NP systems with exceptional wound healing effects [59,62,63].

6. CS-based NPs

6.1. An introduction to CS-based NPs

Scientific literature surrounding CS-based NPs is continuously growing at a rapid pace. In this review, CS-based NPs are defined as particles below 1000 nm in size synthesised using CS as the base material [64,65]. Numerous studies have been undertaken to identify the suitability of applying CS-based NPs in various biomedical fields such as wound healing and drug delivery [64], [65], [66].

CSNPs are the main type of CS-based NPs covered in this review article and comprise of polymeric NPs, either nanocapsules or nanospheres, synthesised using CS as the primary component [67]. Other types of NPs encountered while reviewing the literature include, CS-based nanogels, NP complexes, and polymeric micelles. Nanogels are nano-sized hydrogels which are composed of an interwoven network of cross-linked hydrophilic polymer chains such as CS [68]. NP complexes or nanoplexes have been defined as a drug-NP complex whereby an oppositely charged drug and polyelectrolyte interact to form a nanoplex [69]. A polymeric micelle is a self-assembled NP with a hydrophobic core and a hydrophilic shell prepared using amphiphilic polymers [70]. Other terms used in this review include carboxymethyl chitosan NPs (CMCSNPs) and chitin NPs (CNPs), which are polymeric NPs prepared using CMCS and chitin as the primary component, respectively. CS-modified metal NPs such as CS-modified AgNPs (CS-AgNPs), CS-modified AuNPs (CS-AuNPs), CS-modified SeNPs (CS-SeNPs), and CS-modified ZnONPs (CS-ZnONPs) will also be discussed in the following sections.

6.2. Advantages of using CS-based NPs for wound healing

Various formulations of CS are reported in the literature for wound healing, including but not limited to sponges and films which are made from CS as the base material. The effects of these relatively larger structures are not comparable to that of CS-based NPs, with their distinctive advantage of having significantly smaller particle sizes [71]. The nano-sized particles allow for improved penetration across skin tissue and possibly into the wound area for more efficient wound healing effects [71]. Additionally, the positive charge of polymeric CS-based NPs offers a unique range of benefits. As most CS-based NPs carry a strong positive charge due to the nature of the polymer, most CS-based NP formulations have good stability due the repulsion of like charges to prevent aggregation [72]. Strong positive charges on the surface of CS-based NPs also allow them to interact more readily with many negatively charged components such as cell surfaces, mucosal surfaces, and bacteria cells [72,73].

Having intrinsic wound healing properties, CS-based NPs can be used on their own, or as a vehicle to deliver therapeutic compounds to the wound. This further opens up more opportunities for enhancing wound healing effects, which can be achieved by engineering the CS-based NPs to prolong the half-life of a specific compound, achieve a controlled-release effect, and enable targeted delivery of therapeutic compounds [10,65]. Therapeutic compounds with low stability can also be protected by the NPs in the drug delivery process for improved efficacy [10,57,74]. Problems associated with poor solubility of certain compounds can also be overcome by embedding them within CS-based NPs to be delivered efficiently [10,57,74]. By virtue of these two advantages, compounds which are not able to be ordinarily used therapeutically can now be feasible. The high surface to volume ratio also means that there is significantly more surface available for interaction to trigger the wound healing mechanism [75]. This enhanced feature could also be further exploited to distribute high amounts of active wound healing compounds more efficiently around the wound site [10,65]. Therapeutic compounds delivered using CS-based NPs have been shown to possess the added advantage of enhanced skin penetration and deposition [76], [77], [78]. Furthermore, compounds which exhibit toxicity at high concentrations may also show reduced cell toxicity by encapsulating them within CS-based NPs [79]. This shows that the safety of therapeutic compounds could also be improved through the formulation of CS-based NPs.

6.3. Preparation methods of CSNPs, nanogels, NP complexes, and polymeric micelles

Various methods in formulating different types of CS-based NPs have been studied extensively over the years. Different methods used in the preparation of CSNPs, CS-based nanogels, CS-based NP complexes, and CS-based polymeric micelles are discussed below.

6.3.1. CSNPs

6.3.1.1. Ionic gelation

Since the discovery of CSNPs, multiple preparation methods have been tested and evaluated to efficiently synthesize these NPs under different conditions. The most commonly reported method is the ionic gelation or ionotropic gelation method. This method takes advantage of the polycationic nature of CS where an oppositely charged ionic cross-linker, usually sodium tripolyphosphate (TPP), is added to induce the formation of NPs via electrostatic interactions [80]. CS is usually initially dissolved in an acetic acid, prior to the addition of TPP or other cross-linkers in this method [80]. The simplicity and efficiency of this method make it highly popular as it can be easily performed, and the NP properties can also be readily manipulated by adjusting the ratio of CS to the cross-linker added [80]. This method does not require the use of organic solvents.

6.3.1.2. Polyelectrolyte complex method

The polyelectrolyte complex method is also fairly simple, where electrostatic interactions between a polycation such as CS take place with an anionic molecule to form polyelectrolyte complexes. Examples of common polyelectrolyte complexes are NPs formed by the spontaneous self-assembly of polycationic CS with alginate, chondroitin sulfate, hyaluronate, dextran sulfate, and carboxymethyl cellulose [81], [82], [83]. In some instances, anionic molecules intended to be incorporated into the NP can interact with CS to form these polyelectrolyte complexes [84,85].

6.3.1.3. Microemulsion method

As opposed to the ionic gelation and polyelectrolyte complex methods, the microemulsion method requires the use of organic solvent. CS is initially prepared in an acidic aqueous solution, usually low concentration acetic acid, along with a cross-linker such as glutaraldehyde [86], [87], [88]. The solution is then added into a mixture of an organic solvent such as hexane containing a surfactant [86], [87], [88]. Cross-linking and the formation of CSNPs will then ensue while the mixture is allowed to stir for a duration of time [86], [87], [88]. Removal of the organic solvent can then be done by evaporation under low pressure [86], [87], [88]. Addition of calcium chloride and centrifugation also assists in the removal of excess surfactant via precipitation [86], [87], [88]. Purification of the NPs through processes such as dialysis followed by lyophilisation can then be done to obtain the final product.

6.3.1.4. Coprecipitation method

By taking advantage of the solubility of CS at different pH values, the coprecipitation method is rather simple and can be easily performed. This method begins with dissolving CS in a low pH acidic solution such as acetic acid. The dissolved CS is then slowly added dropwise to an alkaline solution of pH 8.5 – 9.0 under continuous stirring which advertently causes its precipitation [89]. NPs can then be separated via centrifugation and reconstituted in an aqueous solution for further analysis [89]. This method has also been found to be applicable for both CS and lactic acid-grafted-CS copolymers along with the preparation of CS-coated magnetic NPs [89], [90], [91], [92].

6.3.1.5. Emulsification solvent diffusion method

The emulsification solvent diffusion method requires a large amount of shear force typically provided by high pressure homogenisation to synthesize CSNPs. In this method, aqueous CS solution is carefully added to a mixture of an organic solvent with a stabiliser to produce an emulsion [93], [94], [95]. The resulting mixture is then subjected to high pressure homogenisation to form NPs [93], [94], [95]. After applying high pressure homogenisation, the NPs can be separated by centrifugation or other means [93], [94], [95]. Addition of cross-linkers such as glutaraldehyde or ionic cross-linkers such as poly-γ-glutamic acid (γ-PGA) have been used by some studies in combination with this method to further facilitate NP formation [94,95].

6.3.2. CS-based nanogels

6.3.2.1. Physical gelation

CS-based nanogels can be synthesised through the gelation of CS polymers under certain conditions. The physical gelation of CS to form nanogels through reverse emulsion can be achieved by mixing CS solutions within an emulsion containing a surfactant, followed by the addition of a base, such as ammonia to increase the pH to 9.0 [96]. This ensures the precipitation of the nanogels due to the poor solubility of CS under alkaline conditions [96].

6.3.2.2. Ionic gelation

Similar to CS-based NPs, nanogels can also be synthesised through the ionic gelation of CS using a suitable cross-linker [97,98]. TPP again represents the most commonly used cross-linker for the synthesis of CSNPs as well as CS-based nanogels [97,98]. In this case, the gelation of CS occurs via ionic cross-linking to form a three-dimensional polymer network to form nanogels.

6.3.2.3. Inverse microemulsion

Inverse microemulsion is a method whereby two microemulsions are prepared separately, one containing CS and another containing the cross-linker such as genipin or poly(ethyleneglycol bis(carboxymethyl)ether), PEGB(COOH)2 [99,100]. The two microemulsions are then mixed together while stirring to allow nanogels to form via cross-linking [99,100]. After the nanogels have formed, they can then be separated through precipitation with ethanol [99,100].

6.3.3. CS-based NP complexes

Electrostatic interactions between negatively charged drug molecules with positively charged polycationic CS have been seen to produce NP complexes or nanoplexes via electrostatic interactions. Nguyen et al. described the preparation of ionised curcumin (CUR3−) which was mixed with a solution of CS with stirring to form curcumin (CUR)-CS NP complexes [101]. By using this method, changes to the NP properties could be easily adjusted by manipulating the concentration of CUR3−, pH of the solution, and CS: CUR3− ratio [101]. The NP complex was also able to be formed with CUR3- and COS [102].

6.3.4. CS-based polymeric micelles

CS exists as a hydrophilic polymer which does not self-assemble under normal conditions. To form an amphiphilic copolymer, hydrophobic modification of CS can be achieved by grafting hydrophobic molecules onto the polysaccharide chain of CS [103]. The hydrophobic components can be fatty acids, cholesterol, other polymers, along with many others [103]. After modifying CS with the hydrophobic component, the new amphiphilic molecule will be able to self-assemble upon reaching a critical concentration in an aqueous solution [103]. If an organic solvent is required to dissolve certain components in the formulation, other methods of self-assembly can be employed, such as co-solvent evaporation, thin film hydration, and dialysis, to facilitate the removal of the solvent during or after the process [104,105].

7. Wound healing studies using CS-based NPs and CS-modified metal NPs

7.1. Haemostasis

7.1.1. CSNPs

Inadequacies in the haemostasis process can lead to catastrophic outcomes due to the inability to prevent excessive blood loss [106]. In a study using a thrombin generation assay, blood treated with CSNPs displayed two times higher thrombin levels than control, recording levels of 250 ng/ml and 120 ng/ml respectively [107]. This observation was explained through the polycationic nature of the CSNPs, which allows them to interact with negatively charged erythrocytes, causing quicker aggregation rates [107]. Additionally, the large surface area presented by the CSNPs provides a suitable site for platelet adhesion as well as adsorption of fibrinogen and plasma proteins, which assists in accelerating the haemostasis process [107]. Two studies have both demonstrated haemagglutination occurring in erythrocytes treated with blank CSNPs formed via ionic gelation with TPP [108,109]. Neutralistion of the samples with NaOH was found to improve the haemagglutination effect of CSNPs in one of the two studies [109]. Gopalakrishnan et al. had also found blank CSNPs to exhibit similar reductions in blood clotting time as ellagic acid when used at higher concentrations [108]. When combined as ellagic acid-loaded CSNPs, the effect on blood clotting time was found to be considerably enhanced [108]. Based on the proposed mechanism, CSNPs have an advantage over CS in promoting haemostasis as the smaller sizes of CSNPs grant them a greater surface area to volume ratio which enables better haemagglutination, platelet aggregation, and plasma protein adsorption. Under the same reasoning, smaller particle sizes and higher surface charges which lead to larger total surface area to volume ratios and attraction of negatively charged erythrocytes would improve haemostatic effects.

7.1.2. CS-modified metal NPs

A separate study had examined the effects of thiol-modified CS (TMC)-immobilised AgNP-loaded dressings on wound haemostasis in vivo [110]. This study used two separate animal models involving a liver injury model in mice and a rabbit ear model simulating venous rupture [110]. In both models, TMC and TMC-immobilised AgNP treatment groups showed similar blood clotting ability, achieving haemostasis in the shortest time, followed by the CS only group. All CS-based treatment groups had superior haemostatic activities compared to commercial poly(vinyl alcohol) dimethyl-formal (PVF) sponge and medical cotton group [110]. TMC and TMC-immobilised AgNP-loaded dressings were also found to produce a significantly lower amount of blood loss as compared to CS-based dressing alone, commercial PVF sponge, and medical cotton [110]. The authors proposed that the observed enhancement in haemostatic activity by TMC in contrast to CS could be due to the thiol group, which could potentially promote the activation of tissue factor, an important initiator of the coagulation cascade [110]. However, further investigation is needed to validate this notion.

7.2. Antimicrobial properties

7.2.1. CSNPs

The antibacterial mode of action of CS has been previously elaborated in the earlier section of this review. Antibacterial effects of polycationic CS are proposed to typically revolve around its interaction with negatively charged cell surfaces and chelation of metals. Interestingly, shorter-chained low MW CS and CSNPs have shown additional antimicrobial effects compared to larger-sized CS structures, in which the latter typically only involve interactions with bacterial cell surfaces [30,31,73,111]. The small sizes of CSNPs allow them to act locally on bacterial cell membranes and permeate across the bacterial cell wall to interfere with intracellular processes such as DNA transcription and mRNA synthesis [30,31,73,111].

A few studies have investigated the use of unloaded CSNPs for the purpose of wound healing in terms of their antimicrobial effects (Table 1 & Table 2). Wang et al. reported a statistically significant difference in antibacterial activity between CSNP-loaded calcium alginate hydrogels and CS-calcium alginate hydrogels [75]. At a concentration of 100 µg/ml CS in both groups, the CSNP-loaded calcium alginate hydrogel had more than twice the antibacterial activity against E. coli, and about three times the antibacterial activity against S. aureus as compared to the CS-calcium alginate hydrogel [75]. Overall, the calcium alginate hydrogel in combination with CSNPs produced a notably better antibacterial effect than the calcium alginate hydrogel formulated with unmodified CS [75]. This further supports the idea that CSNPs produce enhanced antibacterial activity than CS alone. Sami et al. had similarly demonstrated that CSNPs had higher antibacterial activity against S. aureus than E. coli [75,112]. Both of these studies had CSNPs with similar surface charges of +24.2 mV and greater than +30 mV, respectively [75,112]. The positive surface charge of the CSNPs in these two studies are reflective of the cationic nature of CS, which can be seen as a significant contributor to its antibacterial effects.

Table 1.

Summary of wound healing studies evaluating the antimicrobial properties of CS-based NPs, CMCSNPs, and CS-modified metal NPs in vitro.

| NP formulation | Active ingredient | Encapsulation efficiency | Size | Surface charge | Microbe | Key findings | Ref. |

|---|---|---|---|---|---|---|---|

| Blank CS-based NPs | |||||||

| CSNPa | – | – | 141.20 nm† | – | S. aureus, P. aeruginosa | • Dose-dependent antibacterial activity was observed against S. aureus. • Consistent antibacterial activity was observed for all concentrations of CSNPs against P. aeruginosa (63% – 69%). |

[113] |

| CSNPa | – | – | 77 nm† | > +30.00 mV | S. aureus, E. coli | • CSNPs displayed dose-dependent bacterial inhibition. • Higher inhibitory effects were observed against S. aureus (<50% survival) compared to E. coli (>50% survival). |

[112] |

| CSNPa | – | – | 208.40 ± 15.70 nm† | +24.20 ± 3.90 mV | S. aureus, E. coli | • CSNP-loaded calcium alginate hydrogels exhibited a dose-dependent antibacterial effect with greater effects against S. aureus than E. coli. • CSNP-loaded calcium alginate hydrogels had significantly higher antibacterial activity than CS-calcium alginate hydrogels. |

[75] |

| Therapeutic compound loaded CS-based NPs | |||||||

| Lecithin-coated CSNPa | Tigecycline (TGC) | 22% | 235 ± 20 nm† | +19 ± 5 mV | S. aureus | • TGC-loaded CSNPs had significantly lower minimum inhibitory concentration (MIC) values than TGC-loaded lecithin-coated CSNPs. • Unloaded CSNPs had consistently lower MIC values than unloaded lecithin-coated CSNPs. • The MIC values for unloaded CSNPs, TGC-loaded CSNPs, lecithin-coated CSNPs, and TGC-loaded lecithin-coated CSNPs were 0.3, 0.1, 1.2, and 0.4 mg, respectively. |

[125] |

| CSNPb | SSD | 89.71% ± 11.01% | 51.67 ± 12.55 nm† | – | S. aureus, P. aeruginosa, E. coli, B. subtilis, C. albicans | • SSD-loaded CSNPs showed higher antibacterial activity against Gram-positive bacteria than Gram-negative bacteria. • Antifungal activity of SSD-loaded CSNPs ranged from 20.35% – 36.85% reduction rates. |

[126] |

| CSNPa | Cefazolin (CEZ) | 94.80% ± 0.47% | 227.40 nm† | +48.80 mV | S. aureus | • Sodium alginate and pectin films containing the CEZ-loaded CSNPs achieved 100% inhibition at 24 h incubation. | [127] |

| CSNPa | CUR | 99.93% ± 3.43% | 279.70 ± 20.30 nm† | +52.40 ± 1.50 mV | S. aureus, P. aeruginosa | • Similar inhibitory activity was observed for both S. aureus and P. aeruginosa for all treatment groups. • CUR-loaded CSNPs had significantly higher inhibitory activity than blank CSNPs. • At 1000 µg, CUR-loaded CSNPs had a ZOI of ∼25 mm while the positive control, gentamicin had a ZOI of 25 – 30 mm for both S. aureus and P. aeruginosa |

[128] |

| Gelatin/CSNPc | EGCG | 45.80% ± 3.70% | 236.60 ± 7.80 nm† | +28.90 ± 1.20 mV | S. aureus, P. aeruginosa, E. coli | • EGCG-loaded gelatin/CSNPs with gentamicin had significantly larger ZOI than commercial AquacelⓇ Ag+ dressings. • Largest ZOI was observed in P. aeruginosa followed by S. aureus, and E.coli. |

[129] |

| CSNPa | H. pineodora | 27.56% | 158.70 nm† | +24.10 mV | S. aureus, MRSA, P. aeruginosa, E. coli, B. subtilis, B. cereus, P. mirabilis, S. typhimurium, Yersinia sp., K. pneumoniae, S. boydii, A. anitratus, C. albicans, C. utilis |

• H. pineodora encapsulated in CSNPs had significantly larger ZOI than H. pineodora essential oil, CSNPs and chloramphenicol across all microorganisms tested except for C. albicans. • H. pineodora encapsulated in CSNPs showed 90.0% – 99.9% synergism between the H. pineodora and CSNP. • Up to 83.03% and 80.71% reduction in colony counts were observed in an in vitro collagen wound model and simulated wound fluid, respectively. |

[119] |

| CSNPa | Insulin | 77% | 294.50 ± 21.92 nm† | +17.89 ± 0.74 mV | – | • Samples treated with wound dressings containing insulin-loaded CSNPs had lower microbial penetration across the wound dressing. • Optical density of the Brain heart infusion broth of the positive control (absorbance≈30) was significantly higher than dressings containing insulin-loaded CSNPs (absorbance<5), by Day 7. |

[130] |

| CMCSNPs | |||||||

| CMCSNPd | OH30 | 82.46 ± 1.11% | 258.70 ± 13.30 nm† | +30.20 ± 5.10 mV | E. coli | • OH30-loaded CMCSNPs sustained 100% antibacterial activity while the unloaded CMCSNPs peaked at less than 50%. | [120] |

| CMCSNPe | OH30 | 92.14 ± 1.05% | 164.60 ± 5.00 nm† | −37.60 ± 1.50 mV | S. aureus, E. coli | • Dressings containing OH30-loaded CMCSNP produced >80% antibacterial activity against both S. aureus and E. coli. • Unloaded dressings produced around 40% and 20% antibacterial activity against S. aureus and E. coli, respectively. |

[121] |

| CS-modified metal NPs | |||||||

| CS-ZnONP || | ZnO | – | ∼180 nm¶ | – | S. aureus, E. coli, M. luteus | • Nanocomposites loaded with CS-ZnONPs had higher antimicrobial activity on Gram-positive bacteria than Gram-negative bacteria. • At 7.5 wt% concentration, CS-ZnONPs had ≈1.6, ≈3.0, and ≈3.0 antibacterial activity against E. coli, S. aureus and M. luteus, respectively. |

[131] |

| CS-AgNP# | Ag | – | 5 – 50 nm§ | – | S. aureus, P. aeruginosa, E. coli | • CS-AgNPs cross-linked with genipin showed significant antimicrobial activities and inhibition of bacterial growth. • The highest antimicrobial activity was observed in P. aeruginosa (ZOI≈4 mm), followed by E. coli (ZOI≈3 mm) and S. aureus (ZOI≈2 mm). |

[132] |

| CS-SeNP# | Se | – | 55 – 500 nm* | – | S. aureus, MRSA, E. coli | • No significant antimicrobial activity against E. coli. • CS-SeNPs achieved up to 52% growth inhibition in S. aureus and 54% growth inhibition in MRSA. |

[133] |

| PVA/CS-AgNP# | Ag | – | 190 – 200 nm†,§ | – | S. aureus, P. aeruginosa, E. coli, M. luteus S. enterica, S. typhimurium, B. cereus, E. faecalis | • Higher AgNO3 concentrations in PVA/CS-AgNPs led to higher antibacterial activity. • PVA/CS-AgNPs showed highest inhibitory activity against S. aureus (ZOI=21 ± 1 mm) and M. luteus (ZOI=20 ± 0.5 mm). • PVA/CS-AgNPs showed the lowest inhibitory activity against E. coli (ZOI=13 ± 0.5) and S. typhimurium (ZOI=10 ± 0.1) |

[134] |

| COS-AgNP# | Ag | – | 15.70 ± 4.73 nm§ | – | S. aureus, E. coli | • A significantly larger ZOI was observed in plates treated with COS-AgNPs than AgNPs. • Inhibition ratio of S. aureus treated with COS-AgNPs and AgNPs were ≈100% and ≈90%, respectively, after about 5 h. • Inhibition ratio of E. coli treated with COS-AgNPs and AgNPs were ≈80% and ≈60%, respectively, after about 5 h. |

[123] |

| 2-mercapto-1-methylimidazole (MMT)-CS-AuNp# | Au | – | 10.07 ± 2.34 nm† | - | S. aureus, MRSA, E. coli | • MMT-CS-AuNPs had similar inhibition ratios (between 90% - 100%) as ampicillin for S. aureus and E. coli. • MMT-CS-AuNPs (>90%) had a significantly higher inhibition ratio than ampicillin for MRSA (10% – 20%). |

[135] |

| CS-AgNP# | Ag | – | 22.80 nm† | −45.90 mV | E. coli | • CS- AgNP-loaded CS films (62.22% ± 0.91%) produced the highest E. coli inhibition as compared to CS-AgNP solution (58.52% ± 0.52%), blank CS film (16.67% ± 0.91%), and CS solution (29.63% ± 1.05%). | [124] |

| CS-AgNP# | Ag | – | 225.30 nm† | −21.40 mV | S. aureus, P. aeruginosa | • The MIC of CS-AgNPs (2.98 µg/ml) were significantly lower than unmodified AgNPs (4.68 µg/ml) and CS alone (3.10 µg/ml) against S. aureus. • The MIC of CS-AgNPs (1.92 µg/ml) were significantly lower than unmodified AgNPs (3.5 6 µg/ml) and CS alone (2.84 µg/ml) against P. aeruginosa. |

[136] |

| CS-AgNP# | Ag | – | 10 – 30 nm§ | – | MRSA | • There was no significant difference in bactericidal activity against MRSA between CS-AgNPs, PVP-AgNPs, and AgNPs with all of them achieving 100% bactericidal activity at 8 µg/ml and having an IC50 of about 4 µg/ml. | [137] |

| CS-SER-AgNP# | Ag | – | 96.93 ± 0.50 nm† | −0.42 ± 0.12 mV | S. aureus, MRSA, P. aeruginosa, S. epidermis, A. baumannii |

• CS-SER-AgNPs (31.24 ± 0.43 mm & 29.17 ± 0.41 mm) had larger ZOIs than CS-AgNPs (15.33 ± 0.25 mm & 23.33 ± 0.58 mm) when tested against MRSA and P. aeruginosa, respectively. • CS-SER-AgNPs (11.25 ± 0.43 mm & 13.75 ± 0.43 mm) had smaller ZOIs than CS-AgNPs (27.00 ± 0.78 mm & 16.75 ± 0.50 mm) when tested against S. aureus and A. baumannii, respectively. • CS-SER-AgNPs (22.50 ± 0.53 mm) had similar ZOIs as CS-AgNPs (22.00 ± 0.76 mm) when tested against S. epidermis. |

[138] |

| CS-SER-AgNP# | Ag | – | 239.90 ± 1.56 nm† | +37 ± 3.6 mV | S. aureus, E. coli | • The ZOI of CS-SER-AgNPs (21.00 ± 1.50 mm) was larger than AgNPs (8.00 ± 1.50 mm) when tested against E. coli. • The ZOI of CS-SER-AgNPs (17.00 ± 1.45 mm) was larger than AgNPs (7.00 ± 1.00 mm) when tested against S. aureus. |

[139] |

| CS-AgNP# | Ag | – | 10 – 50 nm§ | – | MRSA, P. aeruginosa |

• MIC of CS-AgNPs (1.84 ± 0.17 µg/ml & 3.78 ± 1.70 µg/ml) were significantly lower than unmodified AgNPs (2.65 ± 1.40 µg/ml & 4.89 ± 1.80 µg/ml) and CS alone (3.84 ± 1.80 µg/ml & 5.10 ± 2.20 µg/ml) against P. aeruginosa and MRSA, respectively. • ZOI of CS-AgNPs (20 ± 0.2 mm & 18 ± 0.6 mm) were significantly higher than unmodified AgNPs (10 ± 0.9 mm & 9 ± 1.1 mm) and CS alone (12 ± 0.4 mm & 10 ± 1.8 mm) against P. aeruginosa and MRSA, respectively. |

[140] |

| TMC-immobilised AgNP ‡ | Ag | – | – | – | S. aureus, P. aeruginosa, E. coli | • Sponges loaded with TMC-immobilised AgNPs displayed antibacterial effects against S. aureus (ZOI≈7 mm), P. aeruginosa (ZOI≈8 mm), and E. coli (ZOI≈7 mm). • TMC and CS sponges did not show any antibacterial activity. |

[110] |

Prepared using ionic gelation method with TPP as a cross-linker;.

Prepared using ionic gelation method with carboxymethyl-β-cyclodextrin (CM-β-CD);.

Prepared by gelation of CS and gelatin mixture;.

Prepared using ionic gelation method with a mixture of CMCS and OH30;.

Prepared using electrostatic droplet method;.

Prepared using precipitation method;.

Prepared using chemical reduction method;.

Prepared using template method;.

Size measured using dynamic light scattering (DLS);.

Size measured using scanning electron microscopy (SEM);.

Size measured using transmission electron microscopy (TEM);.

Method used unspecified.

Table 2.

Summary of wound healing studies evaluating the antimicrobial properties of CS-based NPs and CS-modified metal NPs in vivo and ex vivo.

| NP formulation | Active ingredient | Encapsulation efficiency | Diameter | Surface charge | Wound model (Microbe) | Key findings | Ref. |

|---|---|---|---|---|---|---|---|

| Therapeutic compound loaded CS-based NPs | |||||||

| Lecithin-coated CSNPa | TGC | 22% | 235 ± 20 nm† | 19 ± 5 mV |

Ex vivo porcine skin (S. aureus) |

• S. aureus survival rate was decreased by approximately 2-fold in the presence of TGC-loaded lecithin-coated CSNPs. • CFUs were markedly lower for CSNPs as compared to lecithin-coated CSNPs. |

[125] |

| CSNPf | CDX | 84.25% ± 0.02% | 408.30 ± 53.17 nm† | +22.80 ± 0.57 mV |

In vivo wound infection (S. aureus) |

• Inhibition percentage in the CDX-loaded CSNP group was consistently 20% higher than the CDX group, up to Day 4. • Greater than 90% inhibition was obtained in the CDX-loaded CSNP group on Day 5. |

[118] |

| CS-modified metal NPs | |||||||

| CS-AgNP# | Ag | – | 15 nm§ | – |

In vivo burn wound (No specific bacterial species) |

• Wounds treated with CS-AgNPs (≈2.8Log CFU/cm−2) had significantly lower bacterial counts than untreated wounds (≈3.6Log CFU/cm−2) and SSD-treated wounds (≈3.6Log CFU/cm−2). • Bacterial counts for CS-AgNP treated wounds were about 7–10 times less than SSD treated wounds. |

[141] |

| CS-AgNP# | Ag | – | 10 - 30 nm§ | – | In vivo infected full-thickness wound (MRSA) | • Similar antibacterial effects were observed for uncoated AgNPs, PVP-AgNPs, and CS-AgNPs. • MRSA was not detected in all treatment groups beyond day 3 post-wounding. |

[137] |

Prepared using ionic gelation method with TPP as a cross-linker;.

Prepared using W/O/W type double emulsification;.

Prepared using chemical reduction method;.

Size measured using DLS;.

Size measured using TEM

Concentration-dependent reductions in bacterial growth was reported in a study evaluating CSNP loaded in polyurethane membranes [113]. However, the increase in antibacterial activity due to increasing CSNP concentration was only observed against the Gram-positive S. aureus, while the activity against the Gram-negative P. aeruginosa remained constant regardless of CSNP concentration [113]. Despite this fact, the developed CSNPs in this study clearly exhibited greater antibacterial activity against P. aeruginosa than S. aureus, with differences between percentage reduction ranging from approximately 20% to 40% across all samples tested for both bacterial strains [113]. Other studies have also described lower minimum inhibitory concentration (MIC) values for CS against P. aeruginosa as compared to S. aureus [114]. Generally, there are conflicting results in the current literature surrounding the effects of CS against P. aeruginosa and S. aureus as there have been some studies showing the opposite to occur as well [115]. In principle, the most profound antibacterial activity of CS is thought to be derived from the electrostatic interactions between the cationic polymer with the negatively charged bacterial cell wall [116]. In accordance with this, Gram-negative bacteria have been proposed to be more susceptible to the antibacterial effects of CS as they have a larger negative charge than Gram-positive bacteria due to their lipopolysaccharide (LPS)-rich outer membrane [116]. Further supporting this idea is a study by Raafat et al. which reported a S. aureus mutant strain lacking any negatively charged teichoic acid on the cell wall displaying significant resistance against CS [117]. Meanwhile, a S. aureus mutant strain which carried a higher negative charge due the lack of the D-alanine modification in teichoic acids had an increase in susceptibility by about 100 times [117]. Nevertheless, there are a number of studies with evidence suggesting otherwise; whereby the antibacterial effects of CS are more prominent against Gram-positive bacteria [116]. The antibacterial nature of CS most likely stems from a complex combination of events which collectively contribute to bacterial cell death [117]. To truly understand the reasoning behind the different extents in antibacterial activity of CS against Gram-negative and Gram-positive bacteria, more evidence surrounding its possible modes of action will need to be uncovered.

Meanwhile, another study described the antibacterial effects of CSNPs in combination with a first-generation cephalosporin, cefadroxil (CDX) [118]. Wounds treated with in situ gels containing CDX-loaded CSNPs had more than 60% inhibition of S. aureus growth, as compared to gels only containing CDX which had about 40% inhibition [118]. These observations show the enhanced antibacterial effect which can be achieved when using CSNPs in combination with an antibiotic.

The antimicrobial activity of CSNPs for wound healing applications have also been studied in combination with natural active constituents. A thorough study evaluating the synergistic effects of CSNPs and Homalomena pineodora (H. pineodora) essential oil against clinical isolates of common diabetic wound pathogens has been reported [119]. The study found that CSNPs loaded with H. pineodora essential oil exhibited synergism (Fractional inhibitory concentration, FIC indices ≤ 0.5) against S. aureus, B. cereus, B. subtilis, methicillin-resistant S. aureus (MRSA), P. mirabilis, A. anitratus, S. boydii, and C. albicans [119].

7.2.2. Carboxymethyl NPs

Two separate studies by Sun et al. and Zou et al. reported the use of CMCSNPs together with a bioactive OH—CATH30 (OH30) peptide for the purpose of wound healing [120,121]. In contrast to CS-based NPs, CMCSNPs typically carry an overall negative charge due to the presence of carboxylic acid functional groups instead of amino groups. The negatively charged OH30-loaded CMCSNPs incorporated into polyvinyl alcohol (PVA)/CS nanofibres reported by Zou et al. produced significant antimicrobial activity against both S. aureus and E. coli when compared to unloaded PVA/CS nanofibres, with a larger difference observed against E. coli. [121]. In another study, unloaded CS-coated CMCSNPs only had modest inhibitory activity against E. coli with less than 50% inhibition, which decreased over time. However, the OH30-loaded CS-coated CMCSNPs exhibited 100% inhibition which was sustained over 24 h [120]. Interestingly, the authors of this study compared the effects of negatively charged OH30-loaded CMCSNPs (zeta potential, ζ = −36.7 ± 3.3 mV) with positively charged OH30-loaded CS-coated CMCSNPs (zeta potential, ζ = +30.2 ± 5.1 mV) [120]. The positively charged OH30-loaded CMCSNPs had significantly greater antibacterial effects than their negatively charged counterparts [120]. Findings from this study further highlight the importance of particle surface charge on the antibacterial effects even when being used as a delivery vehicle for antimicrobial compounds such as the OH30 peptide.

7.2.3. CS-modified metal NP

CS-modified metal NPs, particularly CS-AgNPs have been widely studied for their antimicrobial wound healing applications [122]. PVA/COS-AgNPs were compared with PVA/COS/AgNO3 and unloaded PVA/COS nanofibres in terms of their antimicrobial activity against S. aureus and E. coli [123]. In this study, the unloaded PVA/COS nanofibres exhibited the lowest antimicrobial activity with no noticeable zone of inhibition (ZOI) [123]. On the other hand, the PVA/COS-AgNP group produced the greatest antimicrobial activity, with an inhibition ratio of 100% against S. aureus and an inhibition ratio greater than 80% against E. coli after 5 h of incubation [123]. In contrast, PVA/COS/AgNO3 only had an inhibition ratio of greater than 80% for both bacteria after 5 h of incubation and a smaller inhibition zone than PVA/COS-AgNPs [123]. Similar findings were reported in a study evaluating the antimicrobial activity of CS-AgNPs and CS solution alone [124]. The CS-AgNPs had an average ZOI diameter of 5.27 cm and 58.52% inhibition while CS solution alone only had an average ZOI diameter of 2.67 cm and 29.63% inhibition when tested against E. coli, demonstrating superior antimicrobial effects by CS-AgNPs [124]. When used in combination with other materials with intrinsic antimicrobial properties such as transition metals, antibiotics or natural products, CSNPs, CMCSNPs and CS-modified metal NPs are capable of producing enhanced antimicrobial effects [111].

7.3. Oxidative stress and anti-oxidative properties

7.3.1. CSNPs

The formation of CSNPs with or without other active ingredients may take advantage of the mild anti-oxidative properties of CS to further improve wound healing outcomes by preventing excessive oxidative stress around the wound area.

A study by Sami et al. reported very little to no significant antioxidant activity in the tested CSNPs [112]. Interestingly, this study used a modified 4,5-dimethylthiazole-2-yl)−2,5-diphenyltetrazolium bromide (MTT) assay without any cell cultures [112]. Only the reagent and experimental treatments were used on the formulated CSNPs to quantify its antioxidant activity [112]. The most common application of MTT lies in determining cell viability, proliferation, and cytotoxicity instead of antioxidant activity [142]. In this scenario, the basic principle of the assay was employed, whereby the soluble MTT reagent is reduced to insoluble formazan by nicotinamide adenine dinucleotide phosphate (NADPH) produced by cell metabolism [112,142]. This was used by the authors to quantify the reduction of MTT by the antioxidant, CSNP, in the absence of any cells [142]. There is currently limited evidence to support the reliability of an MTT assay in quantifying antioxidant activity in comparison to more commonly used assays such as the DPPH free radical scavenging method [142]. Therefore, the findings could be further investigated with other commonly used antioxidant assays for validation purposes.

Gallic acid (GA) is a plant polyphenol known for having potent antioxidative properties. The antioxidative properties of GA-loaded CSNP incorporated into collagen-fibrin scaffolds were evaluated for the purpose of wound healing [143]. Authors of this study compared the DPPH scavenging activity of collagen-fibrin scaffolds containing GA-loaded CSNPs against unloaded collagen and collagen-fibrin scaffolds [143]. The antioxidant activity was found to increase substantially to about 90% with the addition of GA-loaded CSNPs in comparison to the unloaded collagen and collagen-fibrin scaffolds which only produced about 10% antioxidant activity [143]. Combination of the highly potent antioxidant, GA with the mildly antioxidative CSNPs resulted in a significant boost in antioxidant activity higher than each of these components on their own. [143]. An interesting note is when GA is conjugated to CS as GA-grafted-CS, but not formulated as NPs, the antioxidative effects from DPPH, 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), and oxygen radical scavenging assays were lower than or equal to GA alone [144]. However, when GA is encapsulated in CSNPs in a different study, the antioxidative effects were increased above GA alone [143,144].

Mangiferin-loaded CSNPs were similarly observed to strengthen the free radical scavenging effect of mangiferin in a separate study by Samadarsi and Dutta [145]. Statistically higher antioxidative effects were seen in DPPH, ferric reducing antioxidant power (FRAP), and ABTS assays when comparing mangiferin-loaded CSNPs to mangiferin alone [145]. The same was observed for naringenin-loaded CSNPs compared to naringenin alone whereby higher hydroxyl, DPPH, and nitrite free radical scavenging activity was obtained in the former group [146]. These studies had all used the ionic gelation method with TPP as the cross-linker to prepare the CSNPs [143,145,146]. NP sizes and surface charges determined by dynamic light scattering (DLS) in these studies ranged from 91.0 nm to 446.7 nm and +22.0 mV to +58.4 mV, respectively [143,145,146]. Encapsulation efficiency of these natural compounds were also found to range between 73% to 85% [143,145,146]. The differences in active compound tested in each of these studies limit the comparison of beneficial CSNP effects in relation to these important properties. Moreover, notice should be taken regarding the range of particle size, surface charge, and encapsulation efficiency reported in these studies, which could all influence the effects of the CSNPs, leading to the observed findings.

7.3.2. CS-modified metal NPs

Results from a study using CS-AgNPs showed that an increased incubation time of 1 h to 24 h consistently improved the scavenging rate of CS-AgNPs by about 5% across all tested concentrations [141]. The CS-AgNPs also showed a dose-dependent increase in scavenging rate which gradually increased from about 70% at 0.004 ng/ml to about 85% at 0.13 ng/ml [141]. Meanwhile, Haiji et al. thoroughly examined the antioxidant properties of PVA/CS-AgNPs compared to CS alone using both in vitro and in vivo techniques [134]. Significant antioxidant activity from PVA/CS-AgNPs was observed, which was comparable to butylated hydroxyanisole (BHA) and L-mannitol that were used as positive controls [134]. CS alone had lower antioxidant activity than PVA/CS-AgNPs in all of the in vitro antioxidant assays [134]. The in vivo assay revealed increased expression of antioxidative enzymes, namely catalase (CAT), superoxide dismutase (SOD), glutathione peroxidase (GPx) following treatment with PVA/CS-AgNPs in comparison to the control group [134]. Lower levels of lipid peroxidation were also reported for wounds treated with PVA/CS-AgNPs when compared to the control group [134]. Overall, the findings from these studies indicate that CSNPs and CS-modified metal NPs are capable of producing antioxidative effects which may be beneficial to wound healing.

7.4. Inflammatory response regulation

7.4.1. CSNPs

Formulation of CSNPs from different types of CS polymers were shown to improve the permeation and distribution of CS across the wound site and increase the internalisation of CS by macrophages [147]. This may lead to more profound effects observed in CSNPs than unmodified CS, as they have easier access to target cells in terms of regulation of immune responses.

An in vitro study involving LPS-treated RAW264.7 cells had reported significant decrease of IL-6 and TNF-α expression following treatment with CUR-loaded CSNPs and free CUR alone in a dose-dependent manner [148]. The downregulation of both pro-inflammatory cytokines was significantly greater in the CUR-loaded CSNP group than the free CUR group [148]. CUR-loaded CSNPs were able to significantly reduce the inflammation produced by LPS-stimulated macrophages in vitro [148]. A separate study investigated the effects of vaccarin (VAC), VAC-loaded CSNPs, and unloaded CSNPs on the expression of TNF-α and IL-1β in an in vivo full-thickness excisional wound model [149]. Findings from this study suggested that VAC-loaded CSNPs were capable of up-regulating the expression of IL-1β [149]. Another interesting result obtained from this study was a significantly elevated level of TNF-α in VAC-treated wounds which was not observed in any other groups, including the VAC-loaded CSNP group [149]. Similarly, Choudhary et al. had reported a markedly lower expression of TNF-α in wounds treated with quercetin (QUE)-loaded CSNPs when compared to wounds treated with bulk QUE alone [150]. Meanwhile, the anti-inflammatory IL-10 and TGF-β1 were significantly elevated in wounds treated with QUE-loaded CSNPs when compared to control wounds and QUE-treated wounds [150]. Authors in these three studies utilised the ionic gelation method with TPP as the cross-linker to synthesize the CSNPs [148], [149], [150]. The NP sizes ranged from 91.3 nm to 361.2 nm across the three studies [148], [149], [150]. Only Hou et al. had reported the zeta potential of the VAC-loaded CSNPs, which averaged at +37.1 mV [149]. Collectively, these results highlight the important role of CSNPs as drug delivery vehicles for regulating inflammation during wound healing, improving the effects of the active ingredients when delivered in CSNPs.

7.4.2. CMCSNPs

In a study evaluating OH30-loaded CMCSNPs coated with a layer of CS, elevated levels of TNF-α were reported in wounds treated with OH30 alone while lower levels were observed in wound treated with OH30-loaded CMCSNPs coated with CS [120]. Other pro-inflammatory cytokines, IL-6 and IL-8 were initially expressed at higher levels in OH30-loaded CS-coated CMCSNP-treated wounds but steadily declined to levels lower than or similar to untreated wounds [120]. OH30-loaded CS-coated CMCSNPs also displayed a longer sustained increase in IL-10 expression than OH30 alone, but a consistently lower expression of TGF-β1 than untreated wounds throughout the study duration [120]. NPs formulated in this study had an average size of 258.7 nm and the outer layer of CS coating the CMCSNPs granted a positive surface charge of +30.2 mV [120]. The particle size and surface charge of the CS-coated CMCSNPs in this study are similar to those reported for the studies on CSNPs previously discussed.

The effect of CSNPs and CMCSNPs carrying different types of therapeutic agents produced varying results in terms of the expression of pro- and anti-inflammatory cytokines. This highlights the complex interactions between the CSNPs and CMCSNPs together with their therapeutic cargo with the surrounding immune cells during the inflammatory phase. It was interesting to note that in three separate in vivo studies involving VAC, QUE, and OH30, CSNPs and CS-coated CMCSNPs were able to reduce the expression of TNF-α which was significantly elevated in treatment groups involving the active therapeutic compounds alone [120,149,150]. The diverse effects of CSNPs and CMCSNPs on these cytokines during wound inflammation can be further connected to other effects observed, such as in collagen deposition or angiogenesis due to the varied nature of these cytokines.

7.4.3. CS-modified metal NPs

Significantly lower levels of IL-1β mRNA expression following treatment with CS-AgNP was reported in an in vivo burn wound study [141]. The levels reported were lower than both the control group and positive control group with silver sulfadiazine (SSD) as the treatment throughout the duration of the study [141]. In contrast, TGF-β1 mRNA expression appeared to be significantly higher in wounds treated with CS-AgNPs than in control wounds and SSD-treated wounds, but only on day 7 [141]. This could be due to the fact that CS-AgNP treated wounds had achieved almost complete closure by day 7, which explains the possible peak in TGF-β1 expression at this point [141]. Other treatment groups experienced an elevation in TGF-β1 mRNA at later timepoints where the levels in the CS-AgNP group began declining as the wound healed earlier [141]. Overall, the results from this study showcased the ability of CS-AgNPs to act as an anti-inflammatory agent by modulating both IL-1β and TGF-β1 levels [141].

7.5. Angiogenesis and new vessel formation

7.5.1. CSNPs

The relationship between CS and angiogenesis is not as clearly described in the current literature as its other properties. Minor effects of CS on angiogenesis are attributed to its indirect mechanisms on inflammation and oxidative stress [148]. Angiogenesis is initiated by a hypoxic wound environment, the release of pro-angiogenic growth factors, and the release of proteases [151,152]. This helps to deliver nutrient-rich blood to sustain the regeneration of skin tissue and ECM around the wound bed [151,152]. Nevertheless, excessive levels of angiogenesis have been linked to hypertrophic scar formation. Hence, optimal wound healing outcomes require a healthy level of angiogenesis [153]. Numerous studies have investigated the application of CS and its derivatives in formulating drug delivery systems for pro-angiogenic uses in wounds [154,155].

The difference in angiogenic effect of CS and CSNPs on human umbilical vascular endothelial cells (HUVEC) were examined by Wang et al. [75]. It was revealed that calcium alginate hydrogels containing CSNPs produced significantly higher cell migration, tubule formation, and VEGF expression in HUVEC as compared to CS-calcium alginate hydrogels [75]. A significant increase in ROS production was observed in HUVEC treated with calcium alginate hydrogels containing CSNPs in comparison to CS-calcium alginate hydrogels [75]. In addition, when cells were treated with calcium alginate hydrogels containing CSNPs together with a strong antioxidant, N-acetyl cysteine (NAC), the ROS production dropped to levels similar to control cells [75]. This combination of calcium alginate containing CSNPs with NAC also did not show any significant changes in HUVEC migration, tubule formation, or VEGF expression, suggesting the possible role of ROS upregulation by CSNPs in facilitating angiogenesis [75]. The authors attributed the differences in the results between CSNPs and unmodified CS to the enhanced cellular uptake of CSNPs [75].

In a separate in vitro study, CUR-loaded CSNPs were evaluated using high glucose induced HUVEC (HG-HUVEC) and RAW264.7 to mimic diabetic wound conditions [148]. Following treatment with CUR-loaded CSNPs and CUR alone, an increased HG-HUVEC cell migration, tubule formation, and VEGF expression was observed in cultures incubated together with RAW264.7 and LPS [148]. The increased cell migration, tubule formation, and VEGF expression was observably higher in CUR-loaded CSNPs than CUR alone. In this study, the angiogenic effects of CUR-loaded CSNPs and CUR alone were explained based on their ability to reduce RAW264.7 induced inflammation [148]. This was supported by their findings whereby a high concentration of CUR-loaded CSNPs was able to restore HG-HUVEC migration, tubule formation, and VEGF expression to values similar to HG-HUVEC incubated without RAW264.7 and LPS [148]. CUR-loaded CSNPs were also shown to elevate the number of blood vessels in a separate in vivo wound healing study by more than two times when compared to untreated wounds [156]. When used in combination with a polymeric fibre mat, CUR-loaded CSNPs further increased the number of blood vessels formed as compared to using the polymeric fibre mat alone [156].

Both of these studies synthesised CUR-loaded CSNPs using the ionic gelation method with TPP as the cross-linker [148,156]. Although using the same preparation method and similar CS polymers in terms of MW and DDA, the properties of CUR-loaded CSNPs in these studies largely differed. The first study reported an average particle size of 91.3 nm while the second study had a size of 359.0 nm [148,156]. Although zeta potential was only reported in the second study as −12.2 mV, the first study claimed their CUR-loaded CSNPs to have an overall positive surface charge [148,156]. Drug loading and encapsulation efficiency also largely differed, as the first study had a drug loading of 35.1% and encapsulation efficiency of 77.2% while the second study had 4.2% and 93.0% as the drug loading and encapsulation efficiency, respectively [148,156]. These differences highlight the importance of the preparation steps involved in synthesising CSNPs, such as the ratio of each component along with the purification method. However, despite the vastly different NP properties reported, positive outcomes were still achieved by both authors, which further inform us on the degree of flexibility allowed by CSNPs carrying specific compounds in exerting their effects.

Using a scratch assay, Hou et al. reported an increase in HUVEC migration rate for cells treated with VAC, VAC-loaded CSNPs, and unloaded CSNPs; whereby the largest increase was observed with VAC, followed by VAC-loaded CSNPs and unloaded CSNPs [149]. However, a larger number of migrated cells were seen in the VAC group than the VAC-loaded CSNP group when using the transwell cell migration assay [149]. Both groups exhibited higher cell migration rate than untreated cells in the same assay [149]. Furthermore, findings from the same study showed that wounds treated with VAC and VAC-loaded CSNPs both produced significantly higher levels of microvascular density (MVD) in wound tissues as compared to the control group [149]. Platelet-derived growth factor (PDGF)-BB expression of wounds treated with VAC and VAC-loaded CSNPs peaked and declined earlier than control wounds [149]. The outcomes from this study provide evidence that CSNPs are suitable as a delivery vehicle for VAC in supporting healthy angiogenesis in wounds which is beneficial for tissue regeneration.

QUE-loaded CSNPs used in an in vivo study were also shown to be able to increase the VEGF expression in wound tissues [150]. The increase in VEGF expression was higher than the levels obtained from QUE-treated wounds and control wounds [150]. Interestingly, an inverse relationship was observed between the increase in VEGF expression and QUE concentration in QUE-loaded CSNPs [150]. A similar inverse relationship was seen upon histological analysis of blood vessel density between the concentration of QUE in QUE-loaded CSNPs and the number of blood vessels on day 7 of treatment. However, on day 21, this was reversed whereby increasing QUE concentration in QUE-loaded CSNPs led to an increase in number of blood vessels counted. This contrasts the results obtained from a study by Kant et al. whereby VEGF mRNA expression in wound tissues increased following increases in QUE concentration dissolved in DMSO [157]. The QUE concentrations used in these two studies were similarly reported as 0.03%, 0.1% and 0.3% [150,157]. The differences in the findings from these studies may be due to the differences in drug release kinetics and skin permeation offered by QUE-loaded CSNPs as compared to QUE alone applied topically to the wound. Further research into the possible reasons for this observation is required before a clear explanation can be drawn.

Despite the positive results obtained in the in vitro studies using HUVEC under different conditions, the effects of unloaded CSNPs on angiogenesis using in vivo models, in terms of VEGF and PDGF-BB expression, were not as noticeable [75,[148], [149], [150],158,159]. However, when used alongside another active compound, these formulations were capable of producing promising results with higher expressions of pro-angiogenic biomarkers and increased angiogenesis activity which peaked earlier and declined sooner than control groups [148], [149], [150],159].

7.5.2. CNPs

An interesting result obtained by a study measuring the effects of CNPs on neovascularisation revealed that CNP-based aerogels produced the highest amount of neovascularisation in wound tissues on Day 7 of treatment and the lowest amount of neovascularisation on day 14 [158]. The difference in neovascularisation in comparison to all other groups were significantly large [158]. This finding is suggestive of a wound dressing capable of accelerating the wound healing process by facilitating the growth of new vessels earlier without causing excessive growth of vessels at later stages which may cause unwanted outcomes such as hypertrophic scarring [158]. Formation of more structurally mature and larger-sized blood vessels was also observed in CNP-based aerogels in comparison to other groups [158]. This further supports the use of CNPs which enhance the development of blood vessels in wounds in a timely manner without impeding the maturity or structural integrity of newly formed vessels.

7.5.3. CS-modified metal NPs

Li et al. had also reported an increase in VEGF mRNA expression in full-thickness incisional wounds treated with PVA nanofibres containing COS-AgNP which peaked earlier than control wounds and achieved baseline levels quicker than control wounds [159]. The elevation in VEGF mRNA expression was only observed to be statistically significant on Day 7 and 9, while the other time points were not statistically significant [159]. A trend was also noticed whereby the PVA/COS-AgNP nanofibre group displayed an earlier and higher peak in VEGF mRNA than all the other groups which subsequently declined sooner [159]. This is a desirable observation as it depicts quicker vascularisation which generally speeds up wound regeneration. Treatment of wounds with PVA/COS-AgNP together with a TGF-β1 inhibitor produced the slowest but similarly high peak in VEGF mRNA which remained slightly elevated at the study end-point [159]. Authors of this study connected this observation with the wound healing time observed for this treatment group, which was similarly the slowest, and attributable to a slower formation of granulation tissue [159]. This further highlights the intricacy of angiogenesis as part of the wound healing process, where the expression of growth factors can be easily changed by the expression and action of other cytokines.

7.6. Collagen deposition

7.6.1. CSNPs

Reconstruction and reorganization of the ECM are two separate but intertwined processes which are vital for successful wound healing [160,161]. Of the many different components of the ECM, collagen has an important role of maintaining the structural and dynamic integrity of the ECM while serving as a scaffold for other biological processes [160,161]. During the proliferative phase of wound healing, collagen type III is typically present in greater amounts whereas during the remodeling phase, collagen type I becomes dominant in scar tissue [160], [161], [162], [163]. Hydroxyproline is an amino acid which has been commonly used as a means to estimate the amount of collagen due to its high content in collagen [164,165].

A noticeable trend of increasing hydroxyproline content to varying degrees in wounds treated with different CSNPs, CMCSNPs, and CS-modified metal NPs were observed across a number of studies (Table 3). Kaparekar et al. measured the changes in collagen content of wound tissues through estimation using hydroxyproline [143]. The study found that treatment of wounds with GA-loaded CSNPs impregnated into polymeric scaffolds resulted in elevated collagen deposition on Day 4, 8 and 12 when compared to empty polymeric scaffolds and untreated wounds [143]. The increase in collagen content were statistically significant on Days 4 and 8 [143]. Findings from a study using polycaprolactone (PCL)-gelatin scaffolds containing CUR-loaded CSNPs had showed that the treatment of wounds with CUR-loaded CSNPs produced significantly higher collagen content in wound tissues than control and vehicle control groups [156]. Furthermore, this study had also showed a mild increase in collagen content for wounds treated with blank CSNP-loaded PCL-gelatin scaffolds alone [156].

Table 3.

Summary of wound healing studies evaluating the effects of CS-based NPs, CMCSNPs, CNPs, and CS-modified metal NPs on collagen deposition.

| NP formulation | Active ingredient | Encapsulation efficiency | Diameter | Surface charge | Wound model (Animal) | Key findings | Ref. |

|---|---|---|---|---|---|---|---|

| Therapeutic compound loaded CS-based NPs | |||||||

| CSNPa | GA | 73.20% ± 2.10% | 252.90 ± 3.09 nm† | +33.50 ± 0.30 mV | Excision wound (Male Wistar rat) | • Collagen and hexosamine content were the highest in the collagen-fibrin scaffold containing GA-loaded CSNP treatment group (≈0.4 mg/100 mg dry weight) as compared to the control group (≈0.25 mg/100 mg dry weight) and unloaded collagen-fibrin scaffold treatment group (≈0.3 mg/100 mg dry weight). | [143] |

| CSNPa | CUR | 93.00% ± 5.00% | 359 ± 65 nm† | −10.70 ± 0.10 mV | Full-thickness wound (Male Wistar rat) |

• Highest collagen density was obtained in the PCL-gelatin containing CUR-loaded CSNP group (49.6% ± 5.6%) • Control group and PCL-gelatin group had collagen densities of 7.6% ± 3.0% and 12.1% ± 3.2%, respectively. |

[156] |

| Lecithin/CSNPg | MEL | 27% | 160.43 ± 4.45 nm† | +25.00 ± 0.57 mV | Diabetic full-thickness wound (Wistar rat) | • No significant difference in collagen content was observed between MEL-loaded lecithin/CSNP (≈50.7), MEL alone (≈63.0), blank lecithin/CSNPs alone (≈44.8), and the vehicle control group (≈43.5). | [166] |

| CMCSNPs | |||||||

| CMCS-OH30 NPd | OH30 | 82.46% ± 1.11% | 258.70 ± 13.30 nm† | +30.20 ± 5.10 mV | Full-thickness wound (Female Kunming mice) |

• Wounds treated with OH30-loaded CMCSNPs had a collagen I/collagen III ratio of 1.875 while control wounds had a collagen I/collagen III ratio of 12.22. • Highest total collagen content was observed in the control group, followed by the blank CMCSNP group, OH30 group, and the OH30-loaded CMCSNP group. |

[120] |

| ChitinNPs | |||||||

| CNPg | – | – | 14 ± 3 nm§ | – | Full-thickness wound (Male Sprague-Dawley rat) |

• CNP-based aerogel group (collagen density ≈ 40%) had the highest average collagen density. • CNP-based cryogel group (collagen density ≈ 35%) had similar levels of collagen density as the positive control (DuoDERMⓇ) (collagen density ≈ 35%). • The control group only had a collagen density of approximately 20% |

[158] |

| CS-modified metal NPs | |||||||

| PVA/CS-AgNP# | Ag | – | 190 – 200 nm†,§ | – | Full-thickness wound (Male Wistar rat) |

• PVA/CS-AgNPs produced a hydroxyproline content of 27.53 ± 0.47 mg/g which was close to the amount present in the original tissue and was about 1.6 times higher than the control group. | [134] |

| PVA/COS-AgNP# | Ag | – | – | – | Full-thickness wound (Male Sprague-Dawley rat) |