Abstract

The field of tissue engineering continues to advance, sometimes in exponential leaps forward, but also sometimes at a rate that does not fulfill the promise that the field imagined a few decades ago. This review is in part a catalog of success in an effort to inform the process of innovation. Tissue engineering has recruited new technologies and developed new methods for engineering tissue constructs that can be used to mitigate or model disease states for study. Key to this antecedent statement is that the scientific effort must be anchored in the needs of a disease state and be working toward a functional product in regenerative medicine. It is this focus on the wildly important ideas coupled with partnered research efforts within both academia and industry that have shown most translational potential. The field continues to thrive and among the most important recent developments are the use of three-dimensional bioprinting, organ-on-a-chip, and induced pluripotent stem cell technologies that warrant special attention. Developments in the aforementioned areas as well as future directions are highlighted in this article. Although several early efforts have not come to fruition, there are good examples of commercial profitability that merit continued investment in tissue engineering.

Impact statement

Tissue engineering led to the development of new methods for regenerative medicine and disease models. Among the most important recent developments in tissue engineering are the use of three-dimensional bioprinting, organ-on-a-chip, and induced pluripotent stem cell technologies. These technologies and an understanding of them will have impact on the success of tissue engineering and its translation to regenerative medicine. Continued investment in tissue engineering will yield products and therapeutics, with both commercial importance and simultaneous disease mitigation.

Keywords: 3D bioprinting, organ-on-a-chip, regenerative medicine, stem cells, tissue engineering

Introduction

Tissue defects and organ loss can result from congenital problems, disease, damage, or surgical removal1,2 and thus, tissue defects need to be regenerated and repaired. In addition, organ function needs to be regained. This is the promise of tissue engineering. Because of the shortages in organ and tissue supply,3 many patients die every day while waiting for a transplant.4,5 Tissue engineering and its popular and governmental support in concept was driven by this organ and tissue deficiency. Therefore, methods to develop autograft-like replacement tissues have been explored and demanded by the funding agencies. The major advance has been the development of the tissue engineering concept in the late 1980s and early 1990s.6

Tissue engineering aims at producing functional tissue constructs for use in reconstruction or regeneration of damaged or lost tissues and organs,7,8 such as skin,9 spinal cord,10 and other organs.11 In addition, secondary gain has been the development of models to study function,12 disease13 and test and develop drugs.14 Tissue engineering can be achieved either ex vivo15 or in situ16 by using various molecules, materials, or cells to stimulate local tissue regenerative capacity. It is important to note that this effort of tissue engineering was a fundamental shift in the approach to the treatment of tissue loss. With the end goal being functional organs with a complex interplay of different cell signals and scaffolds, the effort mandated a “system” approach with engineering principles instead of the traditional reductionist methodology of experimentation. The ultimate end goal was beyond the knowledge of a fundamental mechanism, but rather a product to mitigate or cure a disease state.

The field of tissue engineering; however, continues to advance, taking advantage of recent developments in areas such as smart biomaterials,16–18 induced pluripotent stem cell (iPSC),19 three-dimensional (3D) bioprinting20,21 technologies, and dynamic culture methods.22,23 It is also renewed by new technologies such as genetic engineering, extracellular vesicles (EVs), and artificial intelligence. Literature in the field is vast, and there are excellent reviews of different aspects of tissue engineering.24–26 Therefore, the purpose of the current article is to highlight only major and recent advances in the field (Fig. 1).

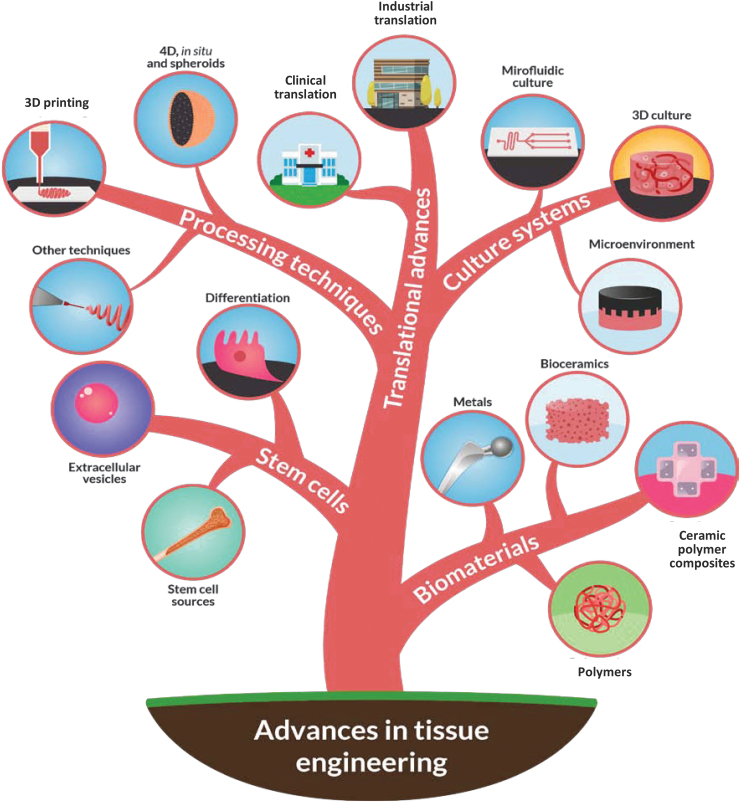

FIG. 1.

Schematic illustration showing overview of major and recent advances in tissue engineering. 3D, three-dimensional; 4D, four-dimensional. Color images are available online.

Advancing Frontiers in Tissue Engineering

Advances in biomaterials and their application in tissue engineering

In tissue engineering, biomaterials are used to provide micro- and nanostructural characteristics, morphology, and surface properties that support cells and can be loaded with appropriate growth factors. Biomaterials used, in the form of matrices or scaffolds for tissue engineering, can be engineered in a way that helps to direct cell growth through specific designs.27 Although biomaterials have been used in tissue engineering since the early 1990s,6,28 how they have been used and the applications they are used for are constantly evolving. Outlined here are recent advances in the use of biomaterials for tissue engineering (Table 1). It is important to note that the field often has an eye on commercialization, such that the Food and Drug Administration (FDA) approval for a new biomaterial may be a hurdle that shapes the evolution of tissue engineering constructs. It is important to note that this barrier can and has in part limited the imagination of the field, because it is often more expeditious to adapt a natural biomaterial or harness one that has an FDA track record instead of designing de novo a material that will require significant vetting before its clinical use.

Table 1.

Advantages, Disadvantages, or Limitations of Different Biomaterials Used for Tissue Engineering

| No. | Biomaterial | Advantages | Disadvantages/limitations | Types of tissue engineering products | Refs. |

|---|---|---|---|---|---|

| A | Polymers | ||||

| 1 | Natural polymers | • Biocompatibility • Cell adhesion motifs • High processability • Elasticity • Degradability |

• Limited mechanical properties | • Various tissues such as heart, bone, liver, and cartilage |

27–31 |

| 2 | ECM | • Mimicking native tissue | • Tissues such as bone, skin, meniscus, and kidney | 32–36 | |

| 3 | Synthetic polymers | • Can be bioresorbable and processed in a controlled way • High mechanical properties |

• Inflammation • No cell adhesion molecules |

• Tissues such as bone, cartilage, nerve, and brain | 37–40 |

| 4 | Hydrogels | • Cells, drugs, and biomolecule delivery • Minimally invasive techniques |

• Mechanical properties • Adhesive strength • Cell adhesion |

• 3D bioprinting • Injectable materials and drug delivery vehicles for regeneration • Minimally invasive regenerative therapeutics • Cartilage regeneration |

41–43 |

| 5 | Smart and functional polymers—composites | • Biological properties • Antibacterial activity • Physical properties, e.g., self-healing, shape-memory, stimuli-responsiveness |

• Controllability of responsiveness may be affected by environment | • Injectable regenerative therapeutics for treating bone defects | 8,44,45 |

| B | Bioceramics | • Bioactive • Biocompatible • High compression strength • 3D printed scaffolds with mechanical characteristics comparable to human cortical bone |

• Low tensile strength • Brittleness • Weak under cyclic or high loads |

• Hard tissue engineering such as bone, cartilage, and tooth | 46–51 |

| C | Ceramic-polymer composites | • Cell incorporation • Enhanced tissue infiltration |

• Brtittleness | • Injectable or 3D-printed composites for dental and cartilage tissue engineering | 52–55 |

| D | Metals | • Biocompatibility • Degradable metal alloys • Improved mechanical properties |

• Uncontrolled corrosion | • Absorbable implants for bone repair • 3D porous scaffolds |

56,57 |

3D, three-dimensional; ECM, extracellular matrixes.

Advances in polymeric biomaterials

Natural polymers

Natural polymers that are most commonly used in tissue engineering are collagen,29 gelatin,30 chitosan,31 alginate,32 hyaluronic acid (HA),33 and polyhydroxyalkanoates (PHAs),34 because of their availability and biocompatibility.35,36 Peptides present on some of them, such as collagen, help cell attachment, migration, and function.29 Silk, a natural polymer,37 has been increasingly popular in many tissue engineering applications due to its high processability, strength, and elasticity.38,39 The PHAs comprise another group of natural polymers with special interest, as they are characterized by degradation through surface erosion that helps to maintain their general structure.40

Guided growth of neuronal cells was observed in vitro following the use of highly aligned electrospun fibers of a blend of the poly(3-hydroxybutyrate) [p(3HB)], and poly(3-hydroxyoctanoate) [p(3HO)].41 In another application, p(3HO) was used to produce cardiac patches, which exhibited favorable mechanical properties closely matching those of native cardiac muscle, and surface topography that enabled efficient cell adhesion and proliferation.42 To produce new constructs with improved properties, polymers can also be used in combination, for example, electrospun fibers made from a combination of chitosan and gelatin were found to enhance bone regeneration capability.43 When PHAs were blended with the synthetic polymer polycaprolactone (PCL) to produce a scaffold that delivers seeded cardiac progenitor cells and implanted in the postmortem murine heart, the implants enabled the adhesion of cardiac progenitor cells, stem cell proliferation, and retention.44

Natural extracellular matrixes

Natural extracellular matrixes (ECM) have been used in a wide range of tissue engineering applications.45,46 The ECM provides a natural structure that maintains some of the biological cues of the native tissues. The ECM chemical cues also help with cell attachment, differentiation, and function. There are various methods that have been used for the preparation of mammalian-tissue-based decellularized matrices, including chemical, biological, and physical methods and their combinations.47 The majority of research, though, has been focused on the decellularization of tissues or organs.48 It was shown that seeding decellularized hearts can result in obtaining contractile hearts by day 4 after keeping them in a bioreactor.49 Using electrical stimulation and physiological load, constructs pump function was achieved by day 8. This represents an interesting area for the application of decellularized ECM in the tissue engineering of various organs.

Kusuma et al. made a major advance by demonstrating that immortalized cell lines can produce high-quality ECM from a single cell source.50 Moreover, processing steps such as homogenization, pepsin digestion, or urea extraction have been used to create solutions that can be used to create surface coatings that retain some of the key properties of the native ECM. The ECM is proposed for numerous applications, due also to its versatile processing characteristics that have already allowed its use in 3D printing51 and electrospinning.52 For example, Kim et al.53 used skin-derived ECM bioink for the 3D printing of skin tissue, with some success. Further, Carvalho et al.54 combined cell-derived ECM with PCL and electrospun the solution to create microfibrous scaffolds for bone tissue engineering. The incorporation of ECM in the fibers enhanced cell proliferation and osteogenic differentiation, maintaining similar mechanical properties to PCL alone. The regulatory requirements of the field allow the strategy for efficient decellularization to appear to be one of the most viable pathways toward a product in short order.49

Despite the many positive attributes of the decellularized matrix for use in the field of tissue engineering, it does also come with limitations. One such limitation is its degradation rate, and this is a property that often needs consideration when using biomaterials for tissue engineering. For optimal regeneration, the degradation rate of decellularized matrix should be closely matched with the regeneration rate of the target tissue, and in many of applications this means that the degradation rate needs to be reduced.55 Current decellularization methods and processes achieve both a thorough removal of all cells and retention of other nonantigenic parts of the original tissue composition that can aid/guide in tissue regeneration.56

Decellularization is also not a “one-size-fits-all” approach, and the protocols must be adapted for different tissue types while integrating factors such as their density and the matrix components. Decellularized matrix produced from tissues, which have specific mechanical properties, must maintain structural matrix components such as collagen fibers and many proteins that are necessary as endoskeleton and thus decellularization protocols need to be tuned to preserving these components. Increased preservation of active factors and structural components would also increase the bioactivity of decellularized matrix, making it an even better natural guidance material for tissue engineering.57

It is important to note why this strategy is imperative and that it is linked to the “systems approach” already mentioned in contrast to precedent scientific reductionist work. In a system approach, the “principle” is that the ECM or the scaffold is imperative to drive and maintain differentiation. One can ask the fundamental question as to whether an osteoblast is an osteoblast when it is not surrounded by its ECM. Many in the stem cell field would argue that the cells and the ECM are intrinsic to one another and that molecular flexibility in differentiation and dedifferentiation occur without the union of the cell and the ECM. With this principle in mind, the strategies of decellularized matrices are rational because we do not have all the cues that are both physical and chronologic to the complex interplay between the cell and its ECM. Certainly, with further study and insight, smart or rational designs will incorporate the natural cues found in the natural ECM and allow synthetic polymers to support cell differentiation with similar efficiency to natural polymers.

Synthetic polymers

Synthetic polymers have been widely used in tissue engineering because they are widely available and inexpensive; can be bioresorbable; and can be processed in a controlled and multitude of ways to make them suitable for different applications. Commonly used synthetic polymers include polylactide (PLA),58–60 polyglycolide (PGA),58 poly(lactide-co-glycolide) (PLGA),59,61,62 PCL,60,63,64 poly(glycerol sebacate) (PGS),64 and polydimethylsiloxane (PDMS). The PDMS has unique applications in tissue engineering among synthetic polymers due to high oxygen (O2) diffusivity, ease of fabrication, biocompatibility, and flexibility.65 It has been explored for engineering of cell sheets,66 and it is widely used for the development of 3D organ-on-a-chip (OoC) cultures67 that helped advancing the field of engineering tissue models tremendously (see the Advances in Microfluidic Culture Systems section). The PDMS is a nonbiodegradable polymer, and it was therefore used more commonly in ex vivo rather than implantable tissue engineering constructs.67

Blends of synthetic polymers were also explored to combine the properties of different materials.68 Synthetic polymers have been also used in combination to build different phases in the resulting structure. For example, Fang et al. used PLA to produce shell and PGA to produce core in electrospun nanofibres.58 The materials were found to accelerate wound healing in vivo. Synthetic polymers can also be combined with natural biomaterials to form semi-synthetic polymers. For example, Jiao et al.63 melt-blended PCL and HA to 3D print scaffolds for bone tissue engineering. Constructs had improved mechanical characteristics as compared with those that were made from PCL alone.

The bioresorbability of many synthetic polymers poses advantages in many tissue engineering applications. However, controlling the rate at which degradation occurs can be a clinical challenge. Xu et al.62 experimented with adding magnesium to PLGA to make composite films with low ranges of magnesium weight percentages, and they found that magnesium extended the duration of degradation and also improved the tensile strength of the films.

Hydrogels

Another advancing recent frontier has been in the area of hydrogels. Hydrogels have been extensively used for 3D bioprinting, which has been a very active area of research in the past few years.69 Hydrogels can be made from various natural or synthetic polymers and have been used for the engineering of different tissues, because of their ability to encapsulate cells,70,71 while having the permeability required for the diffusion of O2 and nutrients across the material. An aspect in which previously they have fallen short is their mechanical properties72 and the lack of adhesiveness.73 Recently, however, these problems were largely addressed. For example, Shirzaei Sani et al.74 produced an adhesive HA/elastin-like polypeptide hybrid hydrogel, which is characterized by remarkable adhesive, antimicrobial activity, and tunable physical properties. This enhances the translation of the hydrogels to the clinical practice as it was limited due to their poor mechanical characteristics, low adhesive strength, and their weakness to inhibit bacterial colonization.

Reinforcement of hydrogels can be achieved through interpenetrating secondary networks.75 The addition of a second network enables conventional hydrogels to be used in many emerging biofabrication techniques toward achieving hierarchical architectures and developing personalized medicine. These interpenetrating hydrogels can find applications in tissue engineering and drug delivery systems as well as in developing in vitro disease models for drug discovery and screening. Hybrid hydrogels were found to have greater adhesive strength to the tissue being engineered, as compared with commercially available tissue adhesives. A great potential of hydrogels is their use as injectable materials to deliver cells, drugs, and biomolecules16 for regenerative purposes that can often be achieved by using minimally invasive techniques.76,77

A recent study78 looking into cartilage repair found that HA hydrogels could be used to encapsulate chondrocytes and support cell survival and the regeneration of cartilaginous tissue. Aside from HA, alginate, and collagen, ECM hydrogels have been used in tissue engineering, and also for cell encapsulation. In addition, microencapsulation of cells to produce microgels was also explored.79–81 Hydrogels such as these can be blended and processed through 3D bioprinting, where cells are encapsulated and printed into designed structures and then crosslinked to provide appropriate mechanical properties. For example, 3D-printed scaffolds of collagen/alginate hydrogel have been used for cartilage tissue engineering82 and ECM hydrogel for cardiac patches.83

The regeneration of damaged tissue can be achieved either via ex vivo or in situ methods. In ex vivo tissue engineering, scaffolds are combined with cells and biomolecules outside the body to obtain cell-laden tissue constructs for implantation (Fig. 2A).16 However, the ex vivo tissue regeneration has limitations, such as tissue morbidity and the lack of reliable cell sources. On the other hand, in situ tissue engineering requires precise control of the biochemical and biophysical cues to stimulate resident host cells and attract cells to the site of injury requiring regeneration (Fig. 2B). On the other hand, in situ tissue regeneration can be achieved by stimulating endogenous cells using either extracellular signals or cell reprogramming. In the first approach, cells are primed via extracellular factors, such as through modulating the biophysical and biochemical characteristics of the biomaterial (Fig. 2B).16 In the second approach, direct manipulation of the cellular gene- expression program is accomplished through cellular reprogramming (Fig. 2B).16 Because of its relation to biomaterials, we review the first approach in this section.

FIG. 2.

Schematic illustration showing (A) Use of traditional ex vivo tissue engineering approach, which is based on the use of cells (1) cultured (2) with growth factors (3) and scaffolds (4) to develop pre-seeded constructs (5) outside the body before their implantation (6). (B) Use of in situ tissue regeneration to harness the innate regenerative capacity in the body either through extracellular signal manipulation by using bioactive (1) or immunomodulatory (2) biomaterials or bioactive molecules (3), or through an intracellular reprograming approach, which employs epigenetic transformation (4), transcription factors (5), gene editing (6), or an RNA-based approach (7). Created with Biorender.com. Color images are available online.

Smart and functional polymers

Smart polymers used in tissue engineering include those with self-healing,84–86 shape memory,76,87–89 or stimuli-responsiveness18,90–92 properties. The ability to change the shape of 3D-printed objects via environmental stimuli, such as heat, moisture, water, pH, or light as a function of time, is known as four-dimensional (4D) printing, and it also has recently gained considerable interest.93 For example, Invernizzi et al. have developed a novel 4D-printable smart material, using PCL and 2-ureido-4[1H]-pyrimidinone (UPy), which is a thermally activated shape memory polymer with self-repairing abilities.94 The incorporation of methacrylates bearing UPy (UPyMA) monomers had provided self-healing properties to the 4D-printed structures, and the possibility to print actuators for soft robotics had been shown for the first time in this work. Synthesizing smart hydrogels that provide both self-healing and shape memory properties at the same time is expected to be further investigated in the following years.95–97

Although there are many clear reasons why smart and functional polymers have gathered attention, they do have drawbacks that should be considered. For example, in the body environment, triggering thresholds of changes, for example, temperature or pH, may affect the responsiveness of these polymers, which, in turn, will affect controllability of the construct and the included cells.69 A shape memory material implanted in the body may lead to injury of the neighboring tissues or loss of function when it returns to its original shape.98 These challenges have to be mitigated before full benefits can be gained from utilizing smart polymers for tissue engineering.

Stimuli-responsive and self-healing hydrogels have also emerged as pharmaceutical carriers for tissue engineering.84,94–105 One such example application of these self-healing hydrogels that is being explored is bone regeneration that can be achieved by providing an optimal microenvironment for new bone formation and for therapeutic drug delivery. Unlike conventional hydrogels, these constructs can resist mechanical stress, while protecting their therapeutic cargos from degradation and maintaining their sustained release for the long-term performance required for bone tissue healing.84,99 To this end, a hydrogel made of chondroitin sulfate (ChS), known for its regenerative capacities, was developed for bone tissue repair with the material being cross-linked to mimic cranial bone characteristics.100

With excellent self-healing, injectability, and in vivo tissue adhesion abilities, ChS-based hydrogel exhibited good cytocompatibility when it was used to encapsulate rat-derived mesenchymal stem cells (MSCs). Most importantly and compared with phosphate-buffered saline-loaded hydrogel, the injection of bone morphogenetic protein (BMP)-4 loaded hydrogel into a murine bone defect model led to defect repair through the formation of new cranial bone tissue, with a significant decrease in the defect size after 12 weeks.

Over the past few years, significant progress in the development of advanced functional polymers with tunable chemical, physical, and biological properties has been achieved.101,102 This resulted in novel applications in 3D and 4D bioprinting103 and drug delivery.104–106 For example, Zhang et al. recently developed a biocompatible hydrogel ink, which contains self-healing precrosslinked hydrogel microparticles of chitosan methacrylate and polyvinyl alcohol hybrid hydrogels. Their results showed advanced structures with a high aspect ratio, and excellent shape accuracy at organ-proper scales could be quickly produced.107

Several drug delivery systems have been based on the use of advanced polymers. Consequently, functional hydrogels that can provide the required dosage in both proper chronicity and location can mitigate complications and enhance success with clinical application.108–110

Advances in bioceramic biomaterials

Ceramics are attractive materials for tissue engineering, because of their highly bioactive and biocompatible characteristics.111 Ceramics, including bioactive glass ceramics, have been used in bone tissue engineering applications for many years due to their well-matched mineral characteristics.112–114 They are strong and osteoconductive, which makes them ideal for application in hard tissue engineering.66–69 They are strong in compression, however, weak in tension, and very brittle. Bioactive ceramic and glass-ceramic scaffolds were also produced by 3D printing processes such as “robocasting”115 and the “freeze extrusion fabrication” that combines extrusion printing with freeze-drying.116 The high strength values of scaffolds fabricated by additive manufacturing result from their ability to maintain highly interconnected channels with high alignment, at a porosity of 50–60%. These scaffolds presented an elastic response under compression, with an average compressive strength of 140 MPa and an elastic modulus of 5–6 GPa, which are comparable to those of the human cortical bone.

Although bioactive ceramic and glass-ceramic scaffolds can effectively mimic porous bone, provide required compressive strength,117 and contain channels in their 3D structure for tissue ingrowth,115 they are brittle and not suitable for applications in locations exposed to cyclic or high loads. Thus, scaffolds made of pure ceramics were not very successful when they were used in load-bearing regions of the body.118 It is also imperative to note that these scaffolds, in particular once seeded with cells and remodeled by biologic ingrowth and calcified ECM production, will change their structural capacity and thus often can be used as a bridge technology. Therefore, the development of advanced scaffolds that can maintain bioactivity properties is required. To achieve this, the obvious engineering solution that has been implemented was the development of composite materials.

Advances in ceramic polymer composite biomaterials

Bioactive glass was used in the form of particles,119 fibers,120 or scaffolds,121 and it was combined with polymers to develop various composites for tissue engineering. For example, bioactive glass nanoparticles have been incorporated into freeze-cast gelatin-chitosan foams with a pore size range between 150 and 300 μm.122 The low strength of the composite was improved by a decrease in its porosity. Bioactive glass–collagen–phosphatidylserine scaffolds (65 wt.% 58S sol–gel bioactive glass) were developed with 75% porosity, a pore size of 300 μm, and a compressive strength of 1.5 MPa.123 However, connectivity between pores was poor, limiting scaffold application in tissue engineering.

In addition, Nikpour et al.124 developed a composite with bioactive glass-ceramic and dextran hydrogel because of its biocompatibility and hydrophilicity, which enable the incorporation of cells and nanoparticles in the structure. Chatzistavrou et al. also looked at the combination of bioactive glass-ceramic particles with appropriate matrixes (e.g., ECM, collagen–fibrin microspheres) and stem cells to enhance odontogenic differentiation and trigger new dentine formation in dental tissue engineering approaches.125,126 Another study also looked at producing nano-bioactive glass-ceramic particles that were incorporated with Calcarea phosphorica aiming at assessing the effect of these nanoparticles on osteoblast differentiation.127 It was found that these particles had osteogenic potential, as they promoted mouse mesenchymal cell proliferation.

Ceramics are also being coated with polymers, which can help in achieving surface functionalization, controlled delivery of growth factors and drugs, and enhanced bioactivity.128 In one example, Luginina et al.64 combined bioactive glass particles with electrospun PGS/PCL for the engineering of cartilage. This combination helped to maintain smaller projected cell areas as well as rounded cell phenotype. Scaffolds made of 13–93 bioactive glass were seeded with rat-bone-marrow-derived MSCs and implanted in the subcutis of rats for 4 weeks, which resulted in tissue infiltration of the scaffolds.121 Moreover, vessels can form inside scaffolds in in vitro cultures and when the construct is implanted in vivo newly formed vessels may connect to the host blood vessels.129 Further, scaffolds made from bioactive glass fibers and PLGA mesh were also developed and investigated for bone tissue engineering using osteoprogenitor cells representing craniosynostotic osteoprogenitors, with the view of using this approach for the reconstruction of the crania of these patients using autologous cells derived from removed tissues.130

Advances in metal biomaterials

Metals are a group of interesting materials that can also be used for developing scaffolds for tissue engineering. At a historic level, gold and other materials with malleable properties have been used before the time of Hippocrates. Because most of metals are not biodegradable, they cannot be replaced by tissues. Therefore, the use of this group of materials for tissue engineering has been very limited except for the recent activity in biodegradable metal alloys, which represents an expanding research frontier. These materials combine both the properties of metals and biodegradability sought in polymers. In addition, their use helps to avoid many problems associated with the use of biodegradable polymers, such as inflammation131,132 and osteolysis.133 In this group of biodegradable metals, magnesium-based alloys have been explored and various implants have been developed especially for application in the treatment of bone tissue.134 A combination of both biodegradable polymers and metals has also been investigated,135 for example, a biodegradable magnesium-reinforced biodegradable PLA membrane was developed for application in guided bone regeneration.136 In future, it is expected to see more studies on the combination of metals with polymers.

Metals, in general, exhibit improved mechanical properties (i.e., yield strength, ultimate tensile strength, hardness, etc.), and they are considered the best alternative for structural support. In addition to mechanical performance, absorbable metals should be compatible and nontoxic with controlled corrosion behavior. A metal that can be considered absorbable should corrode in the body's environment without generating toxic corrosion products. Thus, they should meet an appropriate balance between maintaining the required mechanical performance and corroding within a required period while the native tissue is regenerating.

Iron (Fe), magnesium (Mg), and their alloys have been investigated as absorbable metals, for biomedical applications in cardiovascular and orthopedic surgery. Mg is biocompatible, reduces thrombogenicity, and is critical for several cellular functions, such as intracellular transport, signal transduction, and energy metabolism.137 Absorbable stents138 and bone screws139 made of Mg-based alloys are already commercially available.140,141

However, the uncontrolled and fast corrosion of Mg in biological environments remains a challenge.142 Mg-based alloys are still being optimized toward meeting the expectations of absorbable metallic implants.132 Zinc (Zn) was incorporated as an alternative to Mg, because of its moderate corrosion rate in simulated body fluid.143 In one study, Bowen et al.144 presented an outstanding corrosion behavior and biocompatibility of Zn vascular stents in rat aorta. Current research proposes that Zn alloys could potentially overcome the challenges of Mg alloys used as absorbable implants. Current research work also includes advances in other biomedical applications such as 3D porous Zn scaffolds.145

Through previous research it became clear that each biomaterial brings with it certain advantages and disadvantages, and to create specialized scaffolds and other tissue engineering constructs we must be able to utilize multiple materials in combination, so that their varied advantages can be exploited. In some sense, this requires that the engineering process begins with a clinical problem that dictates the design and needs of the bioresorbable material properties. Early tissue engineering began with a polymer or a construct and looked to find an application. Therefore, as the field has advanced, our approach to design and fabrication should also evolve.

Advances in stem cells and their application in tissue engineering

Although primary cells can be used for tissue engineering,146 the use of stem cells offers the advantage of access to cells that can be directed to differentiate to the desired cell type.147 The use of autologous cells, in particular, can help to avoid the problems associated with allo-transplantation. Therefore, stem cells represent a very important and almost inexhaustible source for tissue engineering148,149 and regenerative medicine.150,151 Stem cells can also be used for engineering tissues either with or without a biomaterial as a matrix152 (Fig. 3). In addition to engineering tissues for regenerative purposes, stem cells were recently used for the engineering of cancer spheroids to develop models for cancer studies.153

FIG. 3.

Engineering of cell sheets composed of cells only using a modified poly(N-isopropylacrylamide) (PNIPAAm) surface.430 Color images are available online.

Advances in stem cell sources

Stem cells are divided according to their differentiation potency into various lineages as totipotent, pluripotent, and multipotent. Totipotent stem cells can give rise to the three primary germ cell layers of the embryo and also give rise to extra-embryonic tissues.154 Pluripotent stem cells can give rise to all tissues in the body, except the placenta and umbilical cord. Embryonic stem cells (ESCs) represent an important type of pluripotent stem cells that were explored for cell therapy and tissue regeneration.155,156 Because of the associated ethical issues and regulatory restrictions, research continued to explore other possibilities.157

In 2006, scientists succeeded in developing pluripotent stem cells from adult somatic cells,19 that is, iPSCs, by using clustered regularly interspaced short palindromic repeats (CRISPR) technology, which can be used for either the activation (CRISPRa) or interference (CRISPRi) with the expression of certain genes.158 The iPSCs are currently being intensively studied because of their pluripotency but without having many of the issues associated with ESCs.159 Today, they represent an advancing frontier in tissue engineering, because of their potential to differentiate into many cell types.158 For example, iPSCs that were generated from human anterior cruciate ligament were used in the repair of ligaments and tendons. Further, iPSCs will be an invaluable tool for the development of personalized therapeutics.160,161

Compared with pluripotent cells, multipotent stem cells such as MSCs can produce only certain cell types.162 MSCs are derived from mesodermal embryonic tissues, have high regenerative ability, and are precursors of different mesenchymal tissues such as bone and cartilage.163 MSCs can be isolated from different tissues such as bone marrow,164 adipose tissue,165–167 amniotic membrane,168 umbilical cord,168–170 placenta,171 dental pulp,172 and other sources that are being continuously explored.173

Recently, MSCs that were isolated from the synovial fluid and synovial membrane were investigated for cartilage tissue engineering.174 Among these, adipose tissue represents an attractive source175 because of its abundance, easiness of accessibility, and the possibility of retrieval of stem cells that were proved to differentiate to different lineages such as fat, bone, and cartilage.176 Generally, MSCs have been the most widely investigated stem cells177,178 for various tissue engineering applications.179 Their versatile behavior in vivo and in vitro made stem cells favorable for research and clinical applications.180,181 Stem cells can also be used for immunomodulation,182,183 which can be explored for application in tissue engineering and regenerative therapy.184

Recent advances in stem cell-derived extracellular vesicles

In addition to iPSCs, advancing frontiers in stem cell technology and its application in tissue engineering include stem cell-derived EVs. EVs are produced by cells in the form of exosomes, microvesicles, or apoptotic bodies; they carry peptides, lipids, or nucleotides such as RNA and DNA, and they have been increasingly recognized as an important means of molecular communication between cells and organs.185 In particular, EVs secreted by MSCs have been investigated for tissue regeneration since they can produce important effects without the need to use cells. They have been investigated for skin, bone, cartilage, and neuronal regeneration.178,186

To increase the efficacy of EVs, MSCs were preconditioned by using hypoxia to produce primed MSCs.187 This paves a new way of devising regenerative strategies based on the use of stem cell-derived EVs, which will help to eliminate many of the problems associated with the use of cell-based products. It is expected that research in this area will expand and extend to clinical translation in the future. It also underscores the importance of closing the knowledge and understanding gap that we still have in relation to the stem cell microenvironment.

Advances in stem cell differentiation

The most important challenge in the development of stem cell-based treatments in tissue engineering applications is the identification of biophysically and biochemically different tissue-specific environments.188 In this process, besides defining differentiation and growth factors that mimic the stem cell environment, it has been reported that determining the physical properties and mechanical forces of stem cell matrix such as morphology and stiffness are also important.189 Studying the effects of ECM biological, physical, and chemical effects on stem cells will help to develop methods that can influence cell differentiation.190 It was also found that making the surface architecture and the stiffness properties of the biomaterials similar to those of certain native tissues favors the differentiation of the stem cells to cells specific to these tissues.191

Stem cell fate control is a crucial issue for stem cell research and applications. In a recent study, magnetic nanoparticles were used to guide stem cell differentiation,192 with the help of an externally applied magnetic field that was used to pull iron oxide particle-laden ESCs together and form spheroids. Then, opposing magnetic fields were used to stretch them and lead to cardiac lineage differentiation. When both physical and chemical factors were combined and applied to ESC, significantly higher myogenic differentiation was observed.193,194

Differentiation of stem cells into desired cell type is possible by identifying factors such as matrix microenvironment and epigenetic mechanisms195 that regulate the fate of stem cells.190,194,196 For instance, an injectable hydrogel was developed by using HA, horseradish peroxidase, galactose oxidase, and tyramine; it was used as a crosslinker. Experiments in mice demonstrated the biocompatibility of the material, which makes it a good candidate for use in biomedical applications such as tissue engineering applications.197

In a recent study, the porosity of hydrogel biomaterial was shown to influence MSCs and their response to insulin-like growth factor-1 (IGF-1).198 Unlike nanoporous alginate hydrogel, microporous ones could sensitize MSCs to the growth factor. Adding cell–cell adhesion mediating molecule (N-cadherin) mimicking peptide to nanoporous alginate added the effect that macroporous had in eliciting MSCs paracrine activity in response to IGF-1. This demonstrated the role of physical properties of the biomaterials further, and also the possibility to influence this by using chemical ways. Combined, these methods will help us to control the behavior of stem cells further in the future and tailoring it toward desired activity and fate, for regenerating desired tissues.

Advances in cell maturation strategies

There are several technologies that have been developed to increase cell maturation by using electrical and physical cues. For influencing cell maturation, physical cues such as surface patterning199 or mechanical stretching200 have been investigated. For example, physical conditioning of cardiomyocytes (both primary myocytes and human pluripotent stem cell-derived cardiomyocytes) embedded in a collagen hydrogel was achieved by using an automated stretch device.200 More recently, the effect of electrical stimulation on cell maturation and the differentiation of human induced pluripotent stem cell-derived cardiomyocytes (hiPSC-CMs) was investigated.201 It was found that the application of electrical stimulation during cell differentiation makes hiPSC-CMs behave similar to cardiac cells. It was demonstrated that hiPSC-CMs derived by using electromechanical stimulation can be used to engineer heart tissue.202 In fact, the maturation of early stage cardiomyocytes was achieved by using electrical stimulation for two weeks in the presence of various growth factors. This area represents an advancing frontier in tissue engineering, and it is worth investigating further to also look at the outcome of in vivo applications of cells matured using electrical stimulation.

In another recent study, electrical stimulation of neonatal rat cardiomyocyte-embedded in gelatin hydrogel led to their maturation.203 It was also shown that the organization of the cells within the gelatin hydrogels was improved by employing this strategy. For skeletal muscle tissue engineering, a gelatin-carboxymethyl cellulose biomaterial was combined with carbon nanotubes to increase electrical properties of the biomaterial.204 Electric pulse stimulation was applied and led to enhanced myogenic differentiation and maturation of C2C12 myoblasts to form a skeletal muscle tissue.

Advances in culture systems and their application in tissue engineering

Cell culture is an important and integral part of ex vivo tissue engineering. Because of the rarity of certain cell types in the human body and the potential donor site morbidity associated with the retrieval of cells in large numbers,22,205 cells are propagated outside the body in an environment that can provide nutrients and possible stimulation of cells to proliferate, differentiate, and function.22 This is carried out using static or dynamic culture methods. In recent years, there have been advances in cell culture methods such as 3D, 4D, and microfluidic OoC culture systems. Significant progress has been made in these areas, and therefore, they will be highlighted in this section.

Advances in cell culture microenvironment

The most common drawback of any of cell culture techniques is the need to use media, which may contain animal serum. There is evidence that fetal serum could be the source of endotoxins, mycoplasma, or viral contaminants.206 Also, the serum itself has ECM components that may alter the cell expression of proteins. Human autologous serum can alternatively be used, and it has been shown to be equivalent to fetal animal sera. However, it is often difficult to isolate human autologous serum in sufficient quantities, especially for use in prolonged and large-scale applications.207 Serum-free media tend to substitute individual key components found in serum-containing media, which can be a safer approach.208

Among the key components, are the growth factors specific for the stem cell type and tissue culture application. For instance, Hasegawa and colleagues have created a medium for stem cell culture containing a replacement of wnt with a GSK3β and NFAT inhibitor.209 Despite significant progress made with serum-free media, the use of new approaches for the elimination of protein from the media will make this technology more cost-effective and possible to scale up.

Other parameters of cell culture such as temperature can also be used to influence cells, for example, improving adipogenic differentiation.210 Another area of interest is the co-cultivation induction, where the concomitant culture of stem cells and committed cells is carried out. This technique has been shown to upregulate the properties of the stem cells and to induce a “physiologic” differentiation process without the need for the use of morphogens and other differentiation induction media. In a recent study, cardiomyocytes were cultured together with iPSCs, and it was found that older cardiomyocytes serve as an adequate inducer for stem cell differentiation, recapitulating the environment necessary for cardiac cell differentiation.211

Imprinted micropatterns on the surface of plates allow cell-to-cell adhesion and determine the formation and characteristics of the culture. This approach has seen several potential applications. For example, the use of micropatterned surfaces allowed homogenous stem cell differentiation to chondrocytes.212 In another study, a 3D micropatterned plate was used to culture hepatic endoderm iPSCs.213 The cells quickly reaggregated and formed hundreds of round-shaped spheroids while they efficiently differentiated into hepatocyte-like cells expressing hepatic gene makers. In addition, growth factors can be printed in micropatterned surfaces. For example, a micropattern-immobilized nerve growth factor nanolayer was found to induce neurite growth and regulate neurite formation.214

Advances in 3D culture

Conventional two-dimensional (2D) systems are classically used for stem cell culture. Such culture uses a feeder layer of cells complemented with tissue culture media supplemented with growth factors or cytokines containing cues that support cells and drive them to proliferate or differentiate.215 Two-dimensional cultures have several limitations, including: (1) the deformation of the cells during culture (flattening and elongation), (2) poor differentiation and cell junction formation, (3) unnatural high proliferation rates, and (4) significant differences in gene expression and phenotypes.216 Recent advances in 2D cultures have tried to overcome some of these drawbacks. Adaptations of the tissue culture biomaterial properties have been shown to modify cell fate.

On the other hand, 3D culture systems are better at recapitulating in vivo conditions. Several studies showed the effect of 3D culture systems on improving cell morphology, proliferation, differentiation, and response to stimuli.217 Three-dimensional culture could be divided into either anchorage-dependent (scaffold-based) or anchorage-independent ones using specialized 3D platforms.218 The former can benefit from recent advances in processing techniques mentioned earlier, such as 3D bioprinting20,219,220 and electrospinning,221,222 to create complex structures.223 Such cell culture models should mimic cells' natural environment, providing interactions between the cells and the microenvironment, nutrients, O2, and waste product removal.

Despite several advantages of 3D over 2D culture, 3D culture still have some drawbacks such as uneven distribution of nutrients, growth factors, and O2, which often results in making cells residing far away from the surface of the matrix inactive.224 In addition, many tissue-engineered constructs are looking for regenerative models of culture as opposed to mature quiescent ECM–cell relationships. Increased costs, differences in experiment replication, and data interpretation are additional drawbacks of this type of culture225 that remain to be addressed in future development activities.

Scaffold-based anchorage-dependent culture techniques utilize a scaffold of variable architecture ranging from a simple extracellular-like matrix to complex multilayer structures. Scaffold selection is largely dependent on the target tissue to be engineered, advantaging physical factors providing structural stability and the cellular composition of the target tissue. Three-dimensional bioprinting has revolutionized the construction of such complex structures. However, because the development of functional vasculature in transplantable devices has not been achieved, successful in vivo applications and clinical translation are largely affected.

Special 3D anchorage-independent techniques include the use of a low attachment vessel,226 magnetic levitation,227 or hand-drop technique,228 including the use of magnetic forces.192 The low attachment plate technique uses a culture vessel with an ultra-low attachment coating. Anchorage-independent techniques force cells to aggregate, form spheres, and subsequently create their own ECM. The most common form of these techniques is the spheroid culture, which is used in the engineering of cartilage.229

Magnetic levitation utilizes a magnetic force to levitate cultured cells mixed with magnetic nanoparticles. This technique is shown to have reproducible results and to reduce necrosis in the spheroid core. Stem cells cultured in these conditions maintain their properties and remain quiescent for subsequent clinical use.230 One area of interest in anchorage-independent culture is the development of organoids. Organoid formation involves the utilization of a tissue culture technique that allows self-organizing and self-renewing of 3D cultures. Organoid cultures have been described for several organs, including the kidney, eye, brain, gut, and lungs.231

More recently, Tseng et al. demonstrated the capacity of assembling adipospheres from multiple cell types, including adipose tissue-derived stem cells, endothelial cells, and leukocytes, that recreate tissue organization.232 This technique enabled the formation of vessel-like endothelial structures with lumens and differentiation of unilocular adipocytes. The hand-drop technique utilizes the self-aggregation properties of cells when no attachment wall is found. The cells aggregate to form spheroids, and the control of the volume of the cell suspension enables the control of the spheroid size. The outcome of this type of cell culture is better as compared with that of static cultures.

Recently, investigators explored the conversion of adipocytes to cardiomyocytes for application in cardiovascular tissue engineering.233 In applications for retinal degeneration, the hand-drop technique was utilized to convert adipocytes to retinal precursors and showed improved differentiation yield, with these precursor-like cells responding to glutamate neurotransmitters.234 This technique has been used in many other preclinical studies, including cartilage repair, bone healing, and cardiac tissue regeneration.235,236

Four-dimensional culture platforms utilize a complex 3D-bioprinted or imprinted structure with a predetermined time-dependent dynamic morphological change. This is achieved by the control and manipulation of the behaviors of stem cells responding to cues that aim at replicating the topographical and mechano-biological environment of the target tissue. These systems could find applications in studying tissue biology and pathophysiology, preclinical testing, and tissue biofabrication.237–239 As far as tissue engineering is concerned, the use of 4D culture systems is in its infancy. However, some promising studies were published. For example, Miao et al. have utilized this technique to create neural tissue with a time-dependent self-morphing regulation of neural stem cells that enhances neural differentiation of cells along with significant axonal alignment.238 Further studies will be of interest in this area of research, as it is structurally most replicative of the regenerative process of healing.

Advances in microfluidic culture systems

Microfluidic systems are designed for cultures under perfusion, allowing a continuous supply of O2 and nutrients (Fig. 4). This enables the long-term maintenance of constructs at physiologically relevant nutrient supply rates. The use of a microfluidic-based approach in cartilage regeneration allowed enhanced conjugation of the key growth factor, transforming growth factor-beta 3 and its sustained release.240 In another study, biomimetic neural tissue fibers having hierarchically ordered nerve fibers were created by using a microfluidic system, which contained a coaxial triple-channel chip and a stretching loading device.241 Authors reported good performance of the resulting nerve fibers.

FIG. 4.

(A) Schematic illustration of the design of microfluidic chip that has three parallel gel regions, six gel filling ports, and two medium channels connected to four medium reservoirs. The device also contains a surrounding vacuum channel. Scale bar, 2 mm. (B) The device comprises a microfluidic layer on a polydimethylsiloxane membrane featuring two sets of two capped pillars (inset). The membrane is itself bonded to a coverslip. (C) Schematic illustration showing the final coculture arrangement: embedded in a hydrogel, muscle bundles that are wrapped around and exerted force to the pillars. They are innervated by neurospheres, which are placed in the opposite gel chamber separated by a 1-mm-wide gel region. (D) Schematic illustration showing the differentiation process of the ESCs into motor neurons (MNs). Row 2: Schematic illustration displaying the top and front views of the tissue in the microfluidic device. Row 3: Three-dimensional illustrations showing the version of the device used at the corresponding days. ChR2, and Channelrhodopsin-2; CNTF, ciliary neurotrophic factor; EBs, embryoid bodies; ESCs, embryonic stem cells; GDNF, glia-derived neurotrophic factors; HS, horse serum; RA, retinoic acid; SAG, smoothened agonist. Reproduced from Uzel et al.,431 which is an open-access article distributed under the terms of the Creative Commons Attribution license. Color images are available online.

The microfluidic system was also used for the production of a gene delivery system composed of nanocomplexes of plasmids encoding for BMP-2 and chitosan.242 The results demonstrated the potential of using this system for in situ bone tissue regeneration. Another application of microfluidic systems is the development of OoC platforms, which aim at reproducing the function of organs or tissues.243,244 Applications of OoC are currently limited to the development of basic tissue functions and of certain disease models,245–247 and it points to new avenues for the study of novel tissue engineering strategies.

Advances in processing techniques and their application in tissue engineering

There are several techniques that have been used to develop scaffolds, matrices, or tissue constructs, such as salt leaching, molding, spinning, freeze-drying,248 solvent casting and particulate leaching,249 electrospinning,221,222 selective laser sintering and 3D printing,250 and 4D bioprinting.69 However, we will highlight in this section only the recent developments in the most advancing frontiers of fabrication techniques251 (Fig. 5).

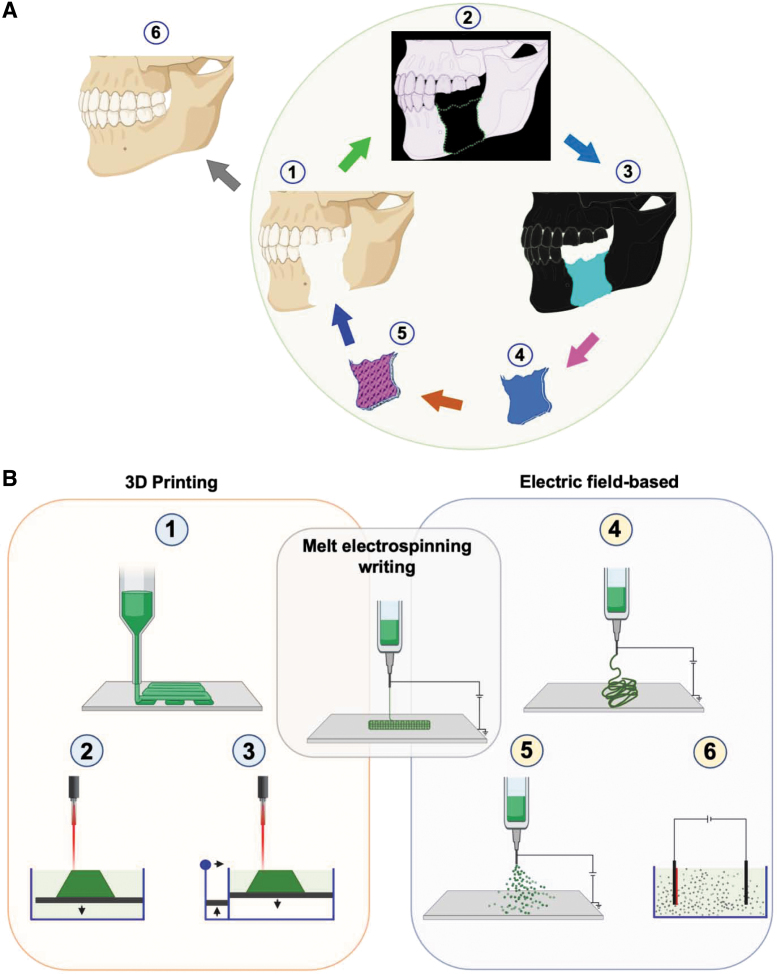

FIG. 5.

Advances in fabrication techniques for tissue engineering. (A) Three-dimensional printing and electric-field-assisted techniques can be very useful for 3D construction of tissue defects (1) based on data-derived from imaging such as computed tomography (2), which is transferred to a design template for 3D bioprinting (4), to produce living constructs (5) that are transplanted to bridge defects and heal damaged tissue (6). (B) In 3D printing (1–3), layer-by-layer deposition of polymeric gel results in the formation of predesigned 3D constructs. In the electric-field-assisted technique (5–6), an electric field is used to control for directing and depositing polymeric fibers. In melt-electrospinning writing (4), both 3D printing and electric-field-assisted methods are combined. Created with Biorender.com. Color images are available online.

Advances in 3D printing

Tissue engineering has adopted the 3D printing technique252 for the fabrication of scaffolds and later to create cell-laden multi-cellular253 and complex254 tissue constructs, and the technique was termed “3D bioprinting.” Three-dimensional bioprinting is gaining increasing popularity, with more companies innovating to produce 3D bioprinters. The method employs most commonly extrusion, inkjet, laser, or stereolithography, with each of these methods having its own advantages and limitations.25,255 Therefore, new approaches include combining 3D bioprinting with conventional manufacturing methods. Different combinations of various fabrication techniques can be used, for example, combining electrospinning with 3D bioprinting256 or 3D printing with 3D bioprinting257,258 to produce advanced scaffolds.

Three-dimensional bioprinting has several advantages over other tissue engineering techniques.259 It allows the creation of well-defined, customized structures that mimic native tissues. These tissues have functional cellular components; therefore, cellular migration from the host is not essential. Further, cellular interaction and key signaling molecules can be incorporated into the design of the printed constructs. The overall cost of 3D bioprinting is lower when compared with currently used graft materials with no donor site morbidity.260 Host tissue regeneration that occurs in pace with the degradation of the implanted 3D-bioprinted construct can hopefully be achieved in future by controlling material properties of the construct bioink. The field is still in its infancy, and therefore we expect to still see shortcomings of current 3D bioprinted constructs.

One problem is the choice of the material that can address both the biology and the anatomy of the tissue to be treated. A lot of our current understanding of these issues is based on our experiments on animals, which may make the design of structures with appropriate properties that fit human tissue structure and function challenging. Further, several aspects of the 3D bioprinting process, such as the isolation of cells, culture conditions, and identification of the signals and growth factors, need to be considered. Our current inability to incorporate vasculature and the potential degradation of the structures limits the success of implanted constructs, and it requires the attention and development of innovative solutions.259,261,262 There are two areas of 3D bioprinting that deserve special discussion, the 4D263 and the in situ264,265 bioprinting.

Despite the numerous challenges, in the past decade, an increasing number of studies were published regarding the creation of biomimetic constructs for future clinical applications. The most important applications so far include skin,266 musculoskeletal267 cardiovascular,268 neural,269 and other tissues.270 The studies present developments made in bioinks that are composed of different biomaterials, cell types, and additives such as growth factors, drugs, or osteoconductive elements, which were tested either in vitro or in vivo.271 In addition, 3D-bioprinted products often have significant contributions from established FDA-approved component parts, including cells, signals, and scaffolds, and thus the fabrication technique can often produce and amalgamate products that incorporate existing technology with a novel effect. Available evidence is encouraging; however, we are far from achieving the full complex organ engineering that tissue engineering has promised.

Advances in 4D, in situ, and spheroid printing

Four-dimensional bioprinting uses smart stimuli-responsive materials,18,90 which are programmed to change their properties and bioactivity over time in response to local or external stimuli.272 An example of the application of 4D bioprinting can be in guided nerve generation, using materials such as graphene hybrid in a 4D construct, which can provide physical guidance, chemical cues, dynamic self-entubulation, and seamless integration.273

In addition, in situ bioprinting265 is of great interest. It employs special hardware and it completely eliminates the need for ex vivo manipulation of the grafts.264 This approach can find applications in cases where the exact dimensions of the tissue are not known preoperatively, such as, for example, after debridement of tissues following trauma, infection, or cancer resection. Several hand-held265 or scanner-controlled 3D printing devices have been developed and the available studies show that such structures retain the high resolution of the 3D bioprinting technique and can match the exact needs of tissues to be constructed.274

Spheroids were recently used as building blocks of constructs that were produced by 3D bioprinting. In this method, spheroids are sucked in, and then released in a controlled fashion. This approach tries to lend developmental biology approaches. This technique will allow the development of 3D constructs using biomaterial-free bioinks and precise deposition of spheroids into the resulting construct.275 It was also possible to use spheroid-based 3D bioprinting in combination with the freeform 3D bioprinting method that enabled patterning of the printed spheroids into the desired shape of constructs (Fig. 6A).276

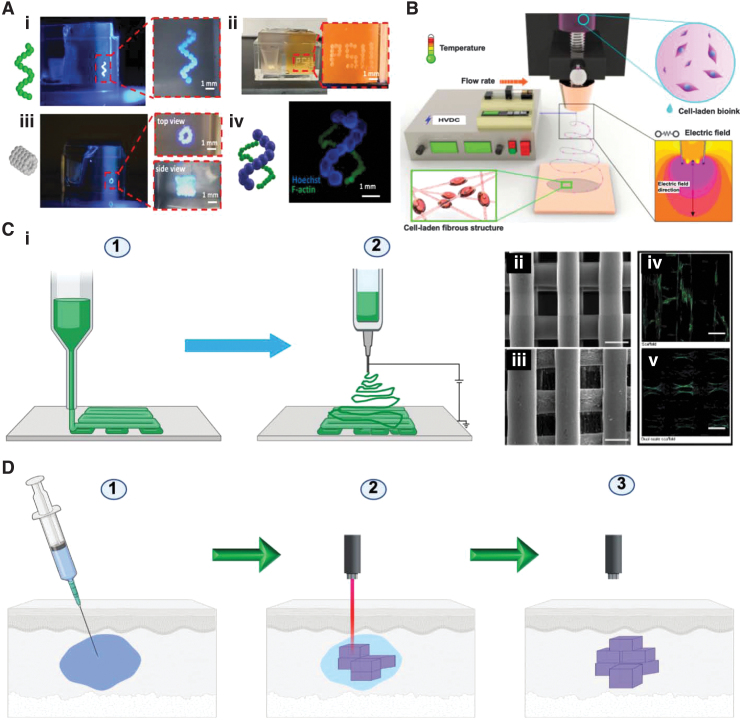

FIG. 6.

Various fabrication techniques for tissue engineering constructs. (A) Use of mesenchymal stem cell spheroids to 3D bioprint a helix shape (i), Penn State University initials (ii), 5-layer tubular structures (iii), and double helix-shape constructs (iv). One hundred fifty micrometers (F-actin) and 450 μm (Hoechst) in radius in 1.2% Carbopol yield-stress gel. Magnified zone is indicated by dashed red line. Reproduced from Ayan et al.,276 which is licensed under a Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/). (B) Cell-electrospinning process with the processing parameters. Reproduced from Hong et al.,432 which is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/). (C) Combined electrospinning and 3D printing. (i) Schematic illustration of the composite scaffold with electrospinning and 3D printing. Step (1) polymer polycaprolactone was used to 3D print the constructs and electrospinning to produce nanofibers, resulting in the formation of dual-scale scaffolds. Created with Biorender.com. Scanning electron microscope images of the scaffolds that were produced by using 3D printing (ii) and dual-scale scaffolds that were produced by using electrospinning and 3D printing (iii) (scale bar = 300 μm). Confocal laser scanning microscopy images of the scaffolds that were produced by using 3D printing (iv) and dual-scale scaffolds that were produced by using electrospinning and 3D printing (v) (scale bar = 300 μm). Reproduced from Vyas et al.,433 which is an open access article distributed under the terms of the Creative Commons CC BY license (ii–v). (D) Intravital 3D bioprinting, which is carried out by injecting a solution of the polymer into a certain tissue site to be treated in a living body. In this example, a two-photon excitation is used for the construction of a 3D object by gelating the polymer solution, and object intravital imaging is used for identification. Created with Biorender.com. Color images are available online.

Advances in other processing techniques

Electrospinning is a versatile technique relying on the use of an electric field to produce thin micro- and nanofibers277 that can also be combined with drugs.222,278,279 This technique has also been used for some time to produce nanofiber-based scaffolds that mimic ECM in several aspects and explored for the engineering of various tissue constructs277,280 such as bone,281 cartilage,282 nerve conduits,283 blood vessels,284 skin,24 and other tissues. In addition to its use for ex vivo tissue engineering, electrospinning was also experimented for in situ applications, for example, for the treatment of skin wounds24 and for ocular drug delivery.285

Different materials have been utilized for electrospinning, and various modifications of the technique of the spinning process have been developed to allow for combining the benefits and properties of more than one material.286 For example, in coaxial electrospinning, it is possible to use a material in the core and a different one in the shell that can have different degradation profiles and can be loaded with different molecules or drugs.287 Examples of the successful use of co-axial287 and triaxial288 electrospinning techniques include the engineering of osteochondral tissues.289 Among the interesting recent advances in electrospinning is cell-laden electrospinning (Fig. 6B), in which muscle cells were encapsulated in fibrin.290 It has been found that incorporating these cells and modifying electrospinning conditions significantly enhanced cell viability under a 4.5 kV electric field.

Another advancing frontier involves the use of electrospinning in combination with 3D printing and bioprinting to bring in various properties, such as reinforcement, to improve the mechanical properties of the resulting 3D-bioprinted constructs.291 In addition, combining electrospinning with 3D printing provides a microporous structure that can enhance cell proliferation and infiltration of the structure292 (Fig. 6C). Further, more control over the process of fiber laying of electrospinning, which classically randomly falls on the collecting surface, enabled the use of the techniques in a similar way as 3D printing.293 Once this is well controlled, it can be one form of 3D printing and bioprinting in future, used on its own.

In addition, melt-spinning has been used for tissue engineering.294 Melt electrospinning-based printing is an emerging printing technique that can print fibers with diameter in the range of nanometers, providing a high degree of resolution, porosity, and pore interconnectivity.295–297 For example, Brown et al. combined melt electrospinning with a digitally controlled collector and developed a new class of 3D printer called melt-electrospinning writing (MEW), which enabled the deposition of well-defined filaments.298 The MEW has the advantage of avoiding problems related to solvents that are used in conventional electrospinning.299

Recently, and for the first time it was possible to have automated coupled melt-electrospinning and melt-electrowriting, by using a modified elongated nozzle to direct-write melt-electrospun polymeric thin fibers onto a collection surface.300 In one interesting development, multilayers were developed by electrospinning, and layers have complementary moieties that lead to the formation of covalent bonds (such as hydrazide and aldehyde groups) between electrospun fibers when they are brought together under mechanical loading.301 The technique can be useful in tissue engineering of advanced structures in future, which can become stronger on exposure to stress, for example, blood vessel engineering,284 guided nerve regeneration,283 or tendon282 and ligament engineering.302

All these advances open new avenues and application territories of the techniques and provide us with more options and versatility toward mimicking the complexity and heterogeneity of the native tissues to be engineered, by combining various processing techniques. With these novel approaches, we come one step closer toward developing successful engineered constructs, ex vivo or in situ.

Translational advances in tissue engineering

Successful transfer of technology from bench to industrial production of engineered tissue products has been progressive, but slow, in part because the clinicians often do not have embedded design and architecture input to the early stage tissue engineered constructs. Although there was a bolus of products, primarily focused on engineered skin tissue, that was approved in the late 1990s and early 2000s,303 only a few products have subsequently emerged.303 Although a few individuals have gained expertise in translating basic tissue engineering research to commercial products, researchers in the field of tissue engineering and regenerative medicine (TERM), overall, lack experience in translational sciences. One factor that may highlight the impact and enable faster commercial translation is academic–industry partnerships among tissue engineers, clinical investigators, clinicians, and industry partners.

Advances in clinical translation

Influencing factors

Clinical translation is affected by several factors that are related to the technology, approval, and acceptance by doctors304,305 and patients.305 Although there have been advances in the field, clinical translation has been limited, not because of science or technology, but largely due to factors including scalability, cost, regulatory issues, and uptake.305 There are engineered tissue products that are in clinical use or are moving toward clinical translation such as skin, cartilage, bone, vascular grafts, cardiac tissues, and bladder.305,306 More complex structures such as heart, lung, liver, and kidney have been recreated and are still in preclinical animal studies. Clinical translation of complex structures and whole organs face a completely different set of challenges.305

Acellular products

Successful clinical applications of engineered tissue products have flourished in the past couple of decades,304 and they were approved by the United States FDA, for example, Integra for skin and INFUSE for bone regeneration.76,307,308 The former is composed of collagen, glycosaminoglycans, and polysiloxane, and it was approved by FDA in 2002 for use in the treatment of burns307 and then for the treatment of diabetic foot ulcers in 2016.309 INFUSE is a BMP2-containing collagen sponge that was also approved by the FDA in 2002 for use in lumbar fusion.310 In addition to these biomaterials, the FDA has also approved native-tissue derived ECM for application in the treatment of complex wounds311 and nerve regeneration.312

Currently, there are several clinical trials exploring the use of materials in achieving in situ regeneration of nervous,10,313 cardiac,314 and musculoskeletal315 tissues. The Humacyte acellular vascular graft, which is made by laying smooth ECM on PGA with cultured smooth muscle cells that are subsequently removed from the graft,316 is now in an open-label, nonrandomized, phase II clinical trial317 for patients with life-threatening limb or torso vascular trauma. The primary outcome measures include primary graft patency along with frequency and severity of adverse outcomes.

For cartilage and osteochondral repair, TruFit and MaioRegen acellular devices have been developed. TruFit is composed of a PLGA, 10% calcium sulfate, PGA fibers, and surfactant and is used for cartilage repair.318 Unfortunately, a 2-year clinical study showed no significant improvement in knee scores.319 Compared with autologous osteochondral transplantation, knee scores were worse in the group that received TruFit.320 Other clinical studies with TruFit showed improvement in symptoms and radiologic outcomes but lack direct comparison with conventional surgical cartilage repair techniques.321,322 Although there was excitement with MaioRegen (a three-layer scaffold composed of collagen I and hydroxyapatite) for the treatment of osteochondral lesions when medium-term results showed significant improvement of knee scores,323 the 5-year results showed failure of repair.324

Cellular products

Several notable cellular products have been approved by the FDA. In 1997, TransCyte, which is composed of fibroblasts and nylon mesh,325 was approved for the treatment of burns.326 In 1998, Apligraf, which is composed of fibroblasts, keratinocytes, and collagen matrix,327 and another product for the treatment of skin venous ulcers328 were approved. For the treatment of nonhealing diabetic foot ulcers,329 in 2001, the FDA approved Dermagraft, a construct made from a synthetic polymer, PGA with fibroblasts. OrCel is a collagen sponge-based scaffold seeded with keratinocytes and fibroblasts, which was used in the treatment of burns.330 Laserskin and Hyalograft are hyaluronan-based matrices seeded with fibroblasts and keratinocytes, which were used in the treatment of diabetic foot ulcers331 and chronic wounds of the lower extremity.332 Matriderm® is an acellular matrix composed of coupled collagen and elastin,333 which can be seeded with fibroblasts and keratinocytes and used for the treatment of full-thickness skin loss.333

Most of the identified cellularized products are for skin regeneration.334 Although these products are very valuable, it is also important to develop and test cellular products for the treatment of tissues with much less intrinsic regenerative capacity such as the heart.335 Even though many of these products have not yet been approved or are not widely utilized in the field, it is important to mention that an iPSC-derived cell sheet based product (TERUMO BCT) for the treatment of heart failure was developed, but it has not yet been approved by the FDA.336 This cellular therapy may have a major impact on the treatment of heart failure, which constitutes one of the major causes of mortality in the world.337

Autologous cellular products

The FDA-approved autologous cell-based products include matrix-assisted autologous chondrocyte implantation (MACI), which is composed of matrix and chondrocytes and used for the treatment of full-thickness cartilage defects, and they were approved in 2001.76,307 Since 2001, several MACI products have been commercialized,318 including BioSeed®-C338 and Hyalograft® C.339 Fibrin glue is used in BioSeed as a cell carrier, and polyglactin 910/poly-p-dioxanone fleece is used as a scaffold. Significant benefits were demonstrated in clinical studies.338,340 Hyalograft C, which uses HA as a matrix, has been investigated in 28 trials. Relative to microfracture therapy, Hyalograft C showed improved patient scores.318 However, Hyalograft C did not undergo a phase III clinical trial and was withdrawn from the market318 due to problems with manufacturing practices and comparative studies.341

Other MACI products available outside of the United States include CaReS®, which uses collagen type I hydrogel seeded with autologous chondrocytes. The results of a prospective multicenter clinical trial in 116 patients (49 women and 67 men; mean age, 32.5 ± 8.9 years) demonstrated significant improvement in the knee scores at 12–60 months after treatment with CaReS; there was a significant reduction in global pain scores and an improvement in the health-related quality of life (SF-36) scores.342

In 2017, phase III clinical trial of another MACI product, NeoCart®, was completed. NeoCart relies on the use of type I collagen scaffold.343 At the 5-year follow-up, although magnetic resonance imaging showed significant improvements from earlier follow-up time points, subchondral bone lesions were seen in 80% of patients. NOVOCART® 3D, a third-generation ACI, employs type I/III collagen biphasic scaffolds344; clinical trials have been performed.345 and phase III clinical trials are in progress.346–349 One report showed significantly improved knee scores from the preoperative state.350 NOVOCART 3D may serve as the treatment of choice for children and adolescents.351

Several other engineered tissues reached the clinical testing stage but faced several challenges. In 2010, tissue-engineered trachea that employed a decellularized allograft352 along with autologous MSCs was implanted into a 12-year-old boy.353 Though successful, full restoration of the biomechanical properties of the trachea took a long time (18 months). Bladder tissue reconstruction was another success.

In 2005, Atala et al. reported implantation of engineered bladder in patients needing cystoplasty for end-stage bladder disease.354 Collagen or PGA-collagen scaffolds were seeded with the patient's own bladder cells. Unfortunately, a phase II study consisting of children with neurogenic bladder resulting from spina bifida showed no functional improvement in bladder compliance or capacity and the prevalence of serious adverse events prevented further development.355 The performance of the engineered bladder is still far from replacing that conventional use of gastrointestinal tissue for augmentation cystoplasty.306 As a result, a combination of techniques with neurovascular muscle transfer and tissue engineering was proposed.356 The common thread is that neovascularization had to occur in vivo on the construct, because the vascular component of tissue engineering is not optimized.

However, some clinical success was seen in large vessel tissue engineering related to congenital heart disease. In one patient, tissue-engineered pulmonary artery using PCL–PLA copolymer (weight ratio, 1:1) reinforced with woven PGA tubular scaffolds and seeded with autologous peripheral vein-derived cells was found to be successful, and follow-up at seven months showed no evidence of graft occlusion or aneurysms.357

Later, the same group showed both safety and absence of adverse events at four years in a cohort of 25 patients with congenital heart disease who had extracardiac total cavopulmonary surgeries with tissue-engineered vascular grafts serving as conduits.358 One major challenge hindering clinical application of engineered vessel grafts is related to standardizing the engineered parameters such as scaffold structure and materials, for which 3D printing may offer solutions in terms of reproducibility.306 Another interesting product is Holoclar®, which employs autologous stem cells that are cultured on a fibrin matrix and transplanted to treat damaged outer layer of the cornea; Holoclar was approved by the European Commission in 2015.306,359,360