Abstract

In rapidly changing business conditions, it has become extremely important to ensure the sustainability of supply chains and further improve the resiliency to those events, such as COVID-19, that can cause unexpected disruptions in the value supply chain. Although globalized supply chains have already been criticized for lack of control over sustainability and resilience of supply chain operations, these issues have become more prevalent in the uncertain environment driven by COVID-19. The use of emerging technologies such as blockchain, Industry 4.0 analytics model and artificial intelligence driven methods are aimed at increasing the sustainability and resilience of supply chains, especially in an uncertain environment. In this context, this research aims to identify the problematic areas encountered in building a resilient and sustainable supply chain in the pre-COVID-19 era and during COVID-19, and to offer solutions to those problematic areas tackled by an appropriate emerging technology. This research has been contextualized in the automotive industry; this industry has a complex supply chain structure and is one of the sectors most affected by COVID-19. Based on the findings, the most important problematic areas encountered in SSCM pre-COVID-19 are determined as supply chain traceability, demand planning and production management as well as purchasing process planning based on cause and effect groups. The most important issues to be addressed during COVID-19 are top management support, purchasing process planning and supply chain traceability, respectively.

Keywords: Sustainable supply chain, Resilience, Emerging technologies, Artificial intelligence, Decision support system

Introduction

The supply chain (SC) is transforming into a more delicate and complex structure due to increasing competition, costs and rapid technological developments worldwide (Kumar & Kumar Singh, 2021; Wong et al., 2020). This drives supply chain management (SCM) toward achieving green growth, although this is challenging from the sustainability perspective (Mathiyazhagan et al., 2016; McGrath et al., 2021). It becomes difficult for these SSCs to be monitored, controlled and to be sustainable and resilient (Majumdar et al., 2020; Wang-Mlynek & Foerstl, 2020). Furthermore, being sustainable (Rahman et al., 2021) and resilient has now emerged as the most important issue for companies throughout the world (Golan et al., 2021; Paul et al., 2021a).

Sustainable supply chain management (SSCM) is the management of supply chain operations, resources, information and funds to maximize social welfare (Karmaker et al., 2021) and supply chain profitability while minimizing environmental impacts (Wang-Mlynek & Foerstl, 2020). Moreover, SC resilience can be defined as the power of supply chains to cope with unexpected changes at the minimum level (Alonso-Muñoz et al., 2021), to resist crises and to maintain their continuity despite changes in the market (Sharma et al., 2020). Therefore, sustainability and resilience of SCs are concepts that affect each other (Singh et al., 2020). In order to build an effective sustainable SSCM concept (Karmaker et al., 2021) and further increase its performance (Sarker et al., 2021) and resilience, organizations can adopt emerging technologies such as blockchain (Bayramova et al., 2021; Kurpjuweit et al., 2021), Industry 4.0 and artificial intelligence (Birkel & Müller, 2020). Using these emerging technologies, especially artificial intelligence (AI), greatly benefits organizations to become more sustainable and resilient to cope with disruptions occurring in SSCs (Singh et al., 2020).

AI is a branch of computer science (Di Vaio et al., 2020a, 2020b; Gupta et al., 2021), with a main goal of developing computer technology that can act and think like a human being. These thinking machines can then imitate, learn and eventually replace human intelligence (Jarrahi, 2018). AI is a technology that can be used especially for SSC planning, demand forecasting and optimization (Muñoz-Villamizar et al., 2020). One of the most critical benefits of AI is that it can analyse data and ensure the continuous improvement of SSC processes (Wu et al., 2021).

When studies on the use of AI in SSCs are analysed, AI is often defined as intelligence visualized by machines where action-based abilities mimic autonomy instead of process-oriented intelligence (Paul & Tresita, 2020). From a SSC perspective, optimization in warehouse management (Wu et al., 2021), autonomous tools for logistics and transportation (Alonso-Muñoz et al., 2021), supplier relationship management predictive analytical studies, stock control and planning, purchasing process planning (Min, 2010) and demand planning (Muñoz-Villamizar et al., 2020) can all be effectively performed with AI technology at minimum cost to business.

Although there are the same problematic areas in SSCs before and during the period of COVID-19 (Paul et al., 2021b), different problems have grown as a threat to resilience in SSCs during the COVID-19 period (Alonso-Muñoz et al., 2021; Sharma et al., 2020). Problems that were previously at an acceptable level are now more complex in the COVID-19 era (Aday & Aday, 2020; Chowdhury et al., 2020). When problems in SSC grow as an effect, having a more resilient SSC is important (Paul et al., 2021c; Sarkis et al., 2020; Shahed et al., 2021). In this sense, AI can help in finding solutions to confront these problems (Muñoz-Villamizar et al., 2020). Although AI is a type of technology that existed pre-COVID-19, the necessity of AI comes to the forefront in times of unexpected disruption such as COVID-19 (Sharma, Srivastava, et al., 2021; Sharma, Thomas, et al., 2021; Singh et al., 2020). In existing literature, the impact of COVID-19 in SSC (Alzoubi et al., 2022; Pimenta et al., 2022) has been recently studied. Moreover, AI solutions for SSC problems have been conducted Faasolo & Sumarliah, 2022; Singh et al., 2022). However, studies on the use of AI techniques to increase the sustainability and resilience of supply chains during COVID-19 are lacking.

There is a need to understand the importance of using AI in SSCM and to study those problematic areas related to sustainable and resilience supply chains both pre-COVID-19 and during COVID-19 that require the use of AI. Therefore, this work aims to identify problematic areas related to a sustainable and resilient supply chain pre-COVID-19 and during COVID-19 and to match appropriate AI technologies as a solution. As a result, the research questions of this study can be summarized as follows:

RQ1: What are the problematic areas related to sustainable and resilient supply chains pre-COVID-19 and during COVID-19?

RQ2: Which AI technologies can be used to solve these problems by comparing the problematic areas experienced in SSCM both in the pre-COVID-19 era and during COVID-19?

The sustainability and resilience of supply chains of different industrial sectors have been questioned during COVID-19 (Wong et al., 2020). The automotive and electronics sectors have been the sectors where the effect on operations has been particularly damaging. For this reason, there needs to be thorough testing in long and complex SSC structures to see the impact of COVID-19 (Mofijur et al., 2020; Singh et al., 2020). For instance, food SCs are smaller than automotive SSCs and it is difficult to see the impact of COVID-19 in detail (He & Huang, 2020). Therefore, identifying these problematic areas is an issue that should be focused on in order to find permanent solutions for SSCs in the future. Hence, the motivation of the research is to address SSCs and to identify the problematic areas that arise against resilience and sustainability in SSCs before and during COVID-19, and to find solutions to these problems in the post-COVID-19 environment.

In order to address the research questions, one of the main objectives of the study is to investigate the availability of AI driven solutions to the problematic areas arising in SSCs during COVID-19. Driven by previous literature and experts’ opinions on the subject, six important problematic areas arising in SSCM before and during COVID-19 are identified. In addition, these problematic areas related to sustainable and resilient supply chains pre-COVID-19 and during COVID-19 should be evaluated to rank the AI driven solutions according to their importance. In this study, the fuzzy DEMATEL method, one of the best multi-criteria decision-making techniques, is used to analyse cause and effect relations of the criteria themselves. Moreover, to match problematic areas with AI technologies, the Delphi method, a structured communication technique developed as a systematic, interactive forecasting tool based on a panel of experts, is implemented towards the end of the study.

Section 2 addresses the problematic areas encountered in resilience and SSCM in pre-COVID-19 times and during COVID-19; the importance of AI and its use in SSCM is also examined. Section 3 covers methodology with Sect. 4 detailing the case study undertaken. Section 5 highlights the discussions that have emerged and the conclusions drawn.

Literature review

Problematic areas encountered in resilience and SSCM Pre-COVID-19 and during COVID-19

COVID-19 causes differences in business models and SC operations. For this reason, the supply chain problems encountered before COVID-19 may differ from those during COVID-19. Six problematic areas related to sustainable and resilient supply chains pre-COVID-19 and during COVID-19 were determined from the literature review. These problems are referred to as criteria in the implementation of the study; it is denoted by the capital letter C. The final set of problematic areas include Inventory Management (C1), Optimization in Logistics Operations (C2), Purchasing Process Planning (C3), Demand Planning and Production Management (C4), SC Traceability (C5) and Top Management Support (C6). These problematic areas are listed in Table 1 and explained in detail below.

Table 1.

The Problematic Areas Encountered in Resilience and SSCM in the Pre-COVID-19 era and During COVID-19 (Criteria)

| Criteria | Author(s) |

|---|---|

| Inventory Management (C1) | Gunasekaran et al., (2015), Eaneff et al., (2020), Paschen et al., (2020), Preil & Krapp, (2021) |

| Optimization in Logistics Operations (C2) | Foster & Rhoden, (2020), Mouammine et al., (2020) |

| Purchasing Process Planning (C3) | Min, (2010); Dumitrascu et al., 2020, Rodríguez-Espíndola et al., (2020) |

| Demand Planning and Production Management (C4) | Nguyen et al., (2018), Raut et al., (2019), Husna et al., (2020) |

| SC Traceability (C5) | Kamble et al., (2020), Wu et al., (2021) |

| Top Management Support (C6) | Ferenhof et al., (2019) |

Inventory Management (C1): In order to reduce the difficulties faced by companies in stock management, it is necessary to accurately predict the amount of stock and determine optimum stock levels (Eaneff et al., 2020). Inventory management becomes complicated in developed SSCs (Paschen et al., 2020). Demand changes can be experienced especially in situations such as sudden disruption in SCs (Maslaric et al., 2013). These demand fluctuations cause problems in the current inventory management of many companies (Klibi et al., 2018). Therefore, in order to increase resilience in SC, companies have to give importance to real-time inventory management, optimization of production and stocks by providing visibility, automation of replenishment strategies and safety stocks (Gunasekaran et al., 2015). For this reason, there is a need for the adoption of technologies such as AI.

Optimization in Logistics Operations (C2): Problems arising from lack of optimization in logistics operations are experienced in complex and multi-supplier SSC structures (Foster & Rhoden, 2020) as they become more vulnerable to disruptions. Failure to achieve optimization in logistics operations in SCs harms resilience of the SC (Pavlov et al., 2019). In logistics processes, the role of logistics facilities, warehouses, the geographical area where the facilities are located, the capacity of warehouses, information and technological infrastructures must all be fully planned (Kaur & Singh, 2019). Therefore, technologies that emerge as a result of AI are required to manage the SC as they minimize the errors that may occur in the logistics process and facilitate optimization in operations (Mouammine et al., 2020).

Purchasing Process Planning (C3): Increasing competition in the business environment requires companies to make better quality purchasing decisions with lower costs (Dumitrascu et al., 2020; Min, 2010). Decisions made in the purchasing process are extremely difficult and strategic (Rodríguez-Espíndola et al., 2020). In order to ensure resilience and sustainability, especially in the face of unexpected situations (Pereira et al., 2020), companies should also show alternative planning behaviors in their purchasing process planning (Ambulkar et al., 2015). For this reason, companies may need systems that include technologies such as AI in their purchasing processes to determine alternative purchasing scenarios and to put them into operation (Allal-Chérif et al., 2021).

Demand Planning and Production Management (C4): Demand planning and production management are the most important factors to determine the performance of SSCs (Nguyen et al., 2018). Effective demand planning and production management ensure the correct functioning of operations in the SSC (Raut et al., 2019). Unexpected events may cause unexpected fluctuations in demand and cost increases in SC; this affects production management (Nguyen et al., 2018). In unexpected crisis environments, it becomes difficult for companies to maintain resilience in their SCs. In other words, traditional demand and supply planning approaches are inadequate; sharp changes in market and commercial dynamics, pandemics or natural disasters can cause damage to the resilience of SCs (Purwaningsih & Hermawan, 2021). Therefore, in companies with high and increasing demand levels, the adoption of technologies such as AI is necessary to balance supply and demand and to plan future production processes (Husna et al., 2020).

SC Traceability (C5): Monitoring every stage in multi-layered global SSCs makes it easier to take measures against unexpected problems (Kamble et al., 2020). The traceability of the SC helps to find instant solutions to the problems that arise in the SC, to eliminate problems without delay in the other processes and to ensure the resilience of the SC (Roy, 2021). An increase in efficiency is observed in the operations of a company with high SC traceability; the traceability of SSCs is possible with the implementation of digital technologies such as AI (Wu et al., 2021).

Top Management Support (C6): Integration of digital technologies into operations in corporate companies with a developed SSC structure is possible with high levels of management support. The use of digital technologies in SSC structures supported by management brings operations closer to perfection. Top management support acts as a decision-making mechanism in order to find solutions to problems that arise in SSCs and to increase the resilience and sustainability of SSCs (Olaleye et al., 2021). Especially in disruptive times, it is necessary to adopt digital technologies such as AI.

From the literature review, it can be seen that there is a research gap in defining which problems are encountered before and during COVID-19 and whether there is a difference in importance of the problems. To sum up, emerging technologies provide increased resilience and sustainability in SCs (Ramirez Lopez & Grijalba Castro, 2021). AI is an emerging technology associated with the decision-making processes in companies; to a large extent, AI improves SSC tracking systems, tactical planning and execution, allowing managers to learn the complex patterns that lead to errors (Dauvergne, 2020). AI technology already plays an important role in advanced SSCM and logistics solutions, increasing efficiency and effectiveness, resilience and sustainability (Singh et al., 2020). Therefore, in the following section, the importance of AI and its use in SCM is explained.

AI applications to enhance resilience and sustainability of SCs

The pandemic has affected almost the entire world with its speed and rate of spreading (Gunessee & Subramanian, 2020). COVID-19 affects not only human health, but the global SSCs of nearly all countries (Deloitte, 2020). Many difficulties have emerged—an increase in production costs, access to raw materials, logistics, stock management problems and labour availability (KPMG, 2020). The main reason why the impact of this pandemic on global SSCs is so great is that it spread from China, an important buyer of industrial products and the primary producer of high value-added products (Majumdar et al., 2020); many countries are dependent on China in terms of raw material supply (Elavarasan & Pugazhendhi, 2020).

Since the beginning of the pandemic, the closure of factories has caused production to come to a halt (Belhadia et al., 2021). This has negatively affected the manufacturing sector, mostly in the sustainability and resilience of SSCs (Mageto, 2021). One of the industries most affected in the manufacturing sector is the automotive industry. In terms of the automotive industry, China is the country that produces most automotives and automotive parts in the world (Ivanov & Dolgui, 2020). This has meant that the pandemic period has witnessed a sharp decline in the automotive industry. Large companies around the world had to stop production because they could not access supply parts from China (Ivanov, 2020; Queiroz et al., 2020).

AI technology may be needed at every stage of a SSC (Dauvergne, 2020). For example; the most effective management elements in SSCM are matching demand and supply (Singh et al., 2020). However, information gaps may occur due to various reasons—incorrect demand forecasting which causes demand and supply to be mismatched in SSCs and communication problems between SC partners (Queiroz et al., 2020). This situation causes distortions in the SSC. In this environment, AI technology, which can be used to match demand and supply, will prevent an information gap since it will operate using real data (Pereira & Frazzon, 2020).

Recently, digital transformations have been introduced worldwide with Industry 4.0 (I4.0) technologies coming to the fore in this digital revolution (Michel-Villarreal et al., 2021; Zhou et al., 2020). The most prominent technology among I4.0 technologies such as blockchain, internet of things and cloud technologies is seen as AI technology (Singh et al., 2020). AI is defined as the ability of machines to communicate and imitate human capabilities (Nesmachnow et al., 2007; Paschen et al., 2020). AI is now seen as a means to providing competitive advantage (Kaur et al., 2020). Therefore, many companies prefer to switch from remote monitoring to control, optimization (Notte et al., 2020) and advanced autonomous AI-based systems to improve resilience of their SSCs (Paschen et al., 2020). Although AI technologies can be used in many areas such as marketing, logistics and production, they can also be used in almost all areas and sub-fields of SSCM, providing advantages such as high accuracy, solving problems with more inputs and producing high-speed solutions (Jones et al., 2020).

Planning is one of the most important issues in SSCM. Problems such as errors made in the planning period, prolonged delivery times or fluctuations in the preparation times of products can be eliminated by AI technologies (Grover et al., 2020). In addition, problems that arise in manufacturing processes (machine failure, product related problems etc.) may cause delay in shipments and interruption to the SSC, threatening resilience in SSCs (Gunasekaran et al., 2015). AI technology provides real-time and continuous information about machine failures, thus improving the process (Grover et al., 2020).

Methods such as genetic algorithms, ant colony optimization (Pedemonte & Cancela, 2010) machine learning, artificial neural networks and data clustering are sub-technologies of AI; these should be applied at different stages of SSCs as solutions to different problems (Dzalbs & Kalganova, 2020). AI in SCM provides improved SC automation through the use of virtual assistants, both in a specific organization and between SC members (Schniederjans et al., 2020).

One AI technology, the genetic algorithm, is frequently used to solve complex problems that are difficult to decipher with traditional methods (Gholizadeh & Fazlollahtabar, 2020). The genetic algorithm makes the SSC more efficient by conducting surplus and deficiency analyses, especially in stock management, in order to minimize the costs arising in SSCM (Rostami et al., 2020).

Ant colony optimization algorithms are derived from ants that leave a volatile substance called "pheromone" when searching for food (Pedemonte et al., 2011; Vijayan et al., 2018). Ant colony optimization in SSCM aims to find optimal results with different algorithm options (Delgoshaei et al., 2019). For example, distribution time optimization in logistics operations, network optimization or ant colony optimization can be used to minimize losses (Zhang et al., 2019).

Machine learning, another sub-technology of AI, enables us to discover patterns in SSC data by relying on algorithms; these quickly determine the most effective factors for the success of supply networks while learning about the process (Benbarrad et al., 2021). Machine learning supports other AI technologies and enables effective management of optimization and planning processes by making predictions with zero error (Li et al., 2021).

Artificial neural network is a new AI technology that has been proposed based on modern biology research processes of human brain tissue (Chawla et al., 2019). It is a technology that simulates the structure and behaviour of the human brain. Neural network is now the most popular computing technology to solve demand planning problems in the SSC (Zhang, Srivastava, et al., 2021). Artificial neural networks provide benefits such as automation of production systems in demand planning and production management, control of the production process and quality control (Chawla et al., 2019).

Lastly, data clustering is the process of grouping data according to their similarity to each other for uncertain or imprecise data (Dong et al., 2021). Due to the decision support system it creates in SSCs, it enables effective decisions to be made in purchasing processes (Yung et al., 2021). To sum up, AI is an emerging technology which provides more resilient and sustainable SCs to cope with sudden disruptions such as COVID-19 by considering all steps of SSCs rationally and effectively.

By addressing the problems determined in this study, it is aimed to find causal relationships between these criteria. For this reason, fuzzy DEMATEL is used to show the order of importance and relations of the criteria related to sustainable and resilient supply chains pre-COVID-19 and during COVID-19. The research method is explained in the next section.

Methodology

The DEMATEL method is a method used to determine affected and affecting factors that have a complex structure in developing events (Saroha et al., 2021). The most important advantage of the DEMATEL method is that it covers indirect relationships with a compromised cause-effect model (Saroha et al., 2021); it reveals the relationships between criteria, the priorities of the criteria according to the type of relationships and the severity of the effects of the criteria on other criteria (Patil & Kant, 2014). The DEMATEL method divides the factors into cause and effect groups, giving the opportunity to plan and solve problems as a draft (Jindal et al., 2021). Due to its nature, DEMATEL can give logical results in complex and dynamic environments (Ahmadi et al., 2020). With the visual and bilateral relations it offers as a result of implementation, DEMATEL can provide solutions to dynamic decision-making problems (Yazdi et al., 2020). Regarding disadvantages, when compared to the Interpretive Structural Modelling method, the DEMATEL model is based on a one-way relationship between criteria, while the Interpretive Structural Modelling method looks at the reciprocal relationships between criteria. Basically, this method aims to draw meaningful results by visualizing complex cause and effect relationships (Jindal et al., 2021). However, it is very difficult to determine the degree of interaction between factors in these relationships (Wu & Lee, 2007). This is because of the problems in quantitatively expressing the interactions between factors (Saroha et al., 2021). Therefore, Lin and Wu carried the DEMATEL method to the fuzzy environment (Wu & Lee, 2007).

The fuzzy DEMATEL has a specific procedure for implementation. The first step of the method is a determination of criteria and creation of a fuzzy scale. In this step, criteria should be determined in order to make an evaluation (Patil & Kant, 2014). In order to determine the influencing and affected factors, meaningful relationships between these factors should be established by experts (Yazdi et al., 2020). After these relationships are established, binary comparisons between criteria should be made (Kang et al., 2019). However, to determine to what extent one factor affects another factor when making a comparison is quite difficult (Patil & Kant, 2014). A fuzzy scale has been proposed to overcome this difficulty (Kang et al., 2019). According to this scale, the effect of a factor on another factor is considered as a linguistic variable. This is expressed in five linguistic terms ranging from excess, to normal to very little (Başhan & Demirel, 2019). In linguistic terms, it is expressed in triangular fuzzy numbers (Yazdi et al., 2020).

The second step of this method is to create the direct relationship matrix. In this step, to measure the level of relationships between the criteria {C1, C2, …, Cn}, each expert creates a binary comparison matrix with linguistic expressions (Kang et al., 2019). Assuming that the decision group consists of p elements, a p decision matrix is obtained (Başhan & Demirel, 2019).

The third step of the method is creating the normalized direct relationship matrix. The total relationship matrix is created in step four (Yazdi et al., 2020). After the (D-R) and (D + R) groups are determined, the defuzzification process is carried out (Başhan & Demirel, 2019). Then, an analysis is made by drawing a cause-effect relationship diagram with the help of the defuzzification process (Kang et al., 2019). At the end of the implementation, the causal relationships between criteria are found.

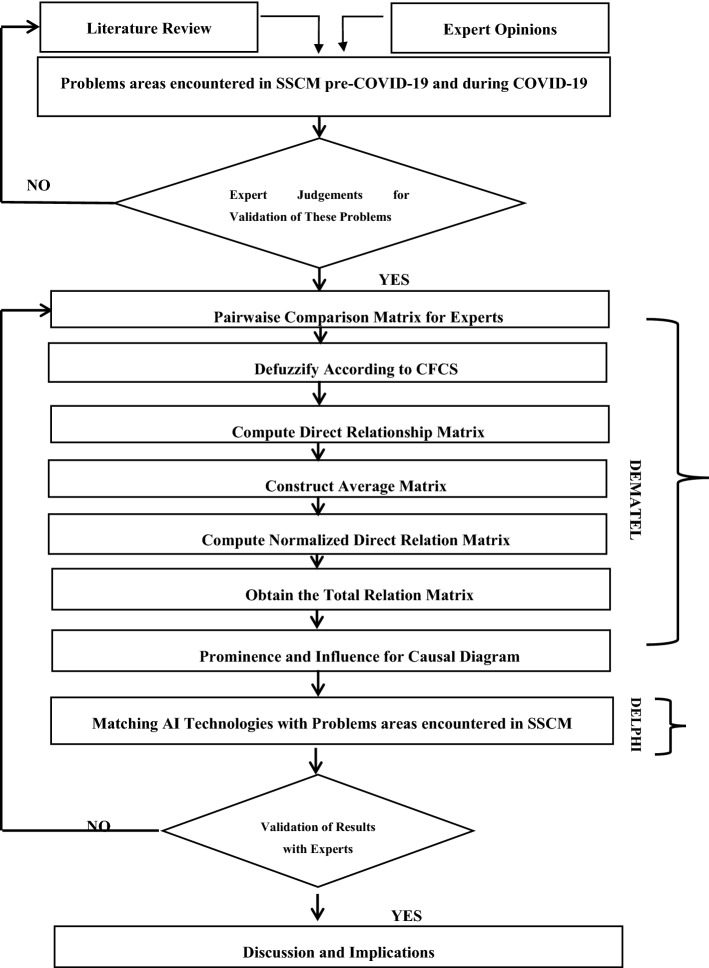

The research flowchart for this work is given in Fig. 1.

Fig. 1.

Flowchart of the study

As shown in Fig. 1, a detailed literature review around problematic areas encountered in resilience and SSCM pre-COVID-19 and during COVID-19 was conducted to determine these problematic areas; this was supplemented with expert opinions. After consideration of the comprehensive literature review and opinions expressed by experts, a priority set of criteria was established for different companies working in the automotive sector in Turkey; the final set was ratified by five experts. These are SCM and logistics academics, representatives of the ministry of industry and industry experts. The industry experts are also members of the Automotive Industry Association in Turkey. In order to answer the second research question, the Delphi method is implemented. Using the Delphi method helps in matching the determined problems with AI technologies.

The case study is explained in the next section.

Case study

The automotive sector is one of the industries most affected in the context of resilience and suitability in the COVID-19 period. The SC of the automotive industry needs to be controlled and managed to ensure smooth operations. The automotive industry has faced many challenges due to its complex SSC structure (He & Huang, 2020). Problematic areas experienced in the SC, especially with the supply of raw materials, caused major disruption of processes in the automotive industry; this resulted in increased costs. Notably, Turkey is one of the largest automotive production bases in Europe (Ünal, 2020). Therefore, as a case study, the SC of the automotive sector in Turkey is significant. In this context, the study is organized based on the flow chart as shown in the previous section (Fig. 1).

After a detailed literature review, the problematic areas, the criteria set, were finalized based on expert opinions. These experts have experience in different companies in the automotive industry in Turkey. Although these problematic areas are the same for pre-COVID-19 and during COVID-19, it is expected that there will be a difference in their priority of concern. Therefore, a different expert group, consisting of SCM and logistics academics, representatives of the ministry of industry and industry experts, was convened to evaluate these problematic areas to determine their priority and inter-relationships using fuzzy DEMATEL. After the criteria set was verified, it was evaluated by nine experts working at highly responsible levels in the SCM fields of automotive companies in Turkey. The details of these nine experts are shown in Table 2.

Table 2.

Characteristics of experts

| Gender | Area of expertise | Department | No. of years in the company | Total work years |

|---|---|---|---|---|

| Male | SCM | Logistics | 8 | 15 |

| Male | Demand Planning | SC | 5 | 10 |

| Male | Automotive Spare Parts / SC | Purchasing | 3.5 | 9 |

| Male | Spare Parts | Purchasing | 10 | 10 |

| Male | SCM | Purchasing | 1 | 10 |

| Female | SCM | SCM | 1.5 | 20 |

| Female | Logistics | Purchasing and Logistics | 5 | 13 |

| Male | Warehouse and Logistics Organization | Logistics | 6 | 4 |

It is critical to find causal relationship between criteria and match the determined problems with AI technologies by using the Delphi method. It is expected that there will be a stage for companies to increase their AI applications in SCM by arranging their SC structures according to the criteria they should attach most importance to.

Application of fuzzy DEMATEL

Before proceeding with the implementation of the study, the following steps are followed to summarize the procedure; stages of the implementation for the case study are presented.

Step 1: Determination of problematic set based on literature and expert opinions (given in Sect. 2).

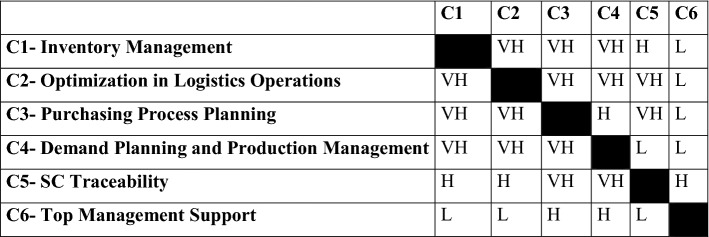

Step 2: Data collection from nine experts (expert characteristics as shown in Table 2). Using the linguistics terms of the DEMATEL method (VH- very high, H- high, L- low, VL- very low etc.), the experts evaluated the problems in the list (as an example, Expert 1’s assessment is given in Table 3.)

Table 3.

Example of expert 1 linguistic assessment case (during COVID-19)

After expert linguistic assessments, each expert's opinion is defuzzied on Excel by using CFCS. Then, a direct relationship matrix is computed and an average matrix (Appendix 1) is constructed. After that, the normalized direct relationship matrix (Appendix 2) is created. The total relationship matrix (Appendix 3) is constructed; D + R and D-R Values (Appendix 4) are calculated.

For data collection, according to the fuzzy DEMATEL application, nine experts made bilateral comparisons between the problematic areas encountered in SSCM pre-COVID-19 and during COVID-19; the causal relationships between these problematic areas are investigated. The relationships between the identified problematic areas were evaluated by experts. As previously mentioned, by following the steps of fuzzy DEMATEL, the D + R and D-R values are shown on the graph; the relationships between the problematic areas are analysed.

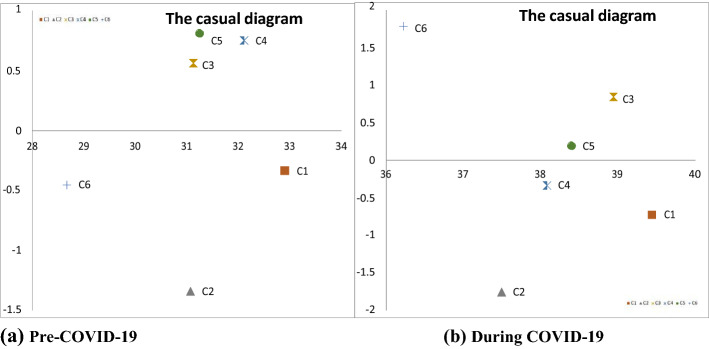

The same processes are repeated for pre-COVID-19. The causal diagrams according to the D + R and D-R results for pre-COVID-19 and during COVID-19 are shown in Fig. 2a and b. In Fig. 2a and b, comparative diagrams for the problematic areas encountered in SSCM before and during COVID-19 are given.

Fig. 2.

P a Pre-COVID-19. b During COVID-19

In Fig. 2a, the reason group includes purchasing process planning (C3), demand planning and production management (C4) and SC traceability (C5). In Fig. 2b, the reason group consists of the support of the top management (C6), the planning of the purchasing process (C3) and the traceability of the supply chain (C5). In Fig. 2a, the effect group includes the senior management support (C6), inventory management (C1) and optimization in logistics operations (C2). In Fig. 2b, demand planning and production management (C4), inventory management (C1) and optimization in logistics operations (C2) are included in the effect group.

Based on Fig. 2a and b, the most important problematic areas encountered in SSCM pre-COVID-19 were identified as SC traceability (C5), demand planning and production management (C4) and purchasing process planning (C3), respectively. The most important problematic areas encountered in SCM during COVID-19 were top management support (C6), purchasing process planning (C3) and SC traceability (C5).

The problematic areas with lowest importance in the effect group were optimization in logistics operations (C2), top management support (C6) and inventory management (C1) for pre-COVID-19. During COVID-19, optimization in logistics operations (C2), inventory management (C1) and demand planning and production management (C4) were in the effect group. The results are shown in Table 4.

Table 4.

Cause and Effect Groups for pre-COVID-19 and during COVID-19

| Pre-COVID-19 | During COVID-19 | ||

|---|---|---|---|

| Cause group | Purchasing Process Planning (C3) | Cause group | Top Management Support (C6) |

| Demand Planning and Production Management (C4) | Purchasing Process Planning (C3) | ||

| SC Traceability (C5) | SC Traceability (C5) | ||

| Effect group | Top Management Support (C6) | Effect group | Demand Planning and Production Management (C4) |

| Inventory Management (C1) | Inventory Management (C1) | ||

| Optimization in Logistics Operations (C2) | Optimization in Logistics Operations (C2) | ||

According to the results of fuzzy DEMATEL, the problematic areas are both prioritized and the relationships between them are revealed. It is therefore possible to offer solutions in order to eliminate the most critical and highly important problematic areas related to sustainable and resilience in supply chains pre-COVID-19 and during COVID-19. Implementation of fuzzy DEMATEL identifies problematic areas related to a sustainable and resilient supply chain pre-COVID-19 and during COVID-19. Matching AI technologies for sustainable and resilient SCs are recommended.

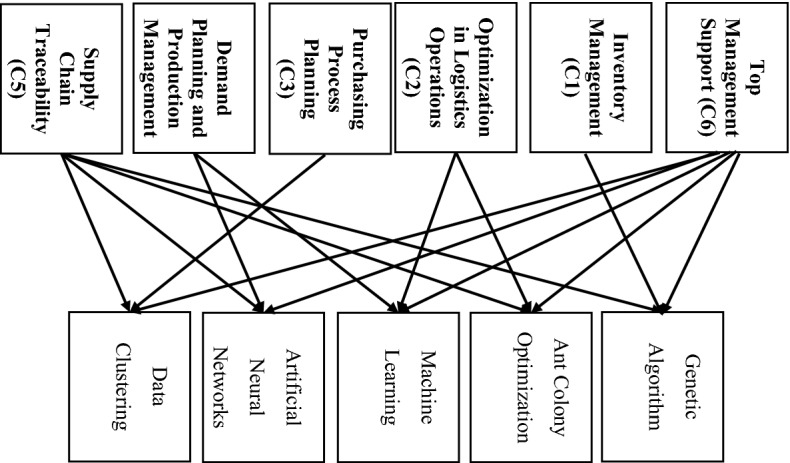

Delphi application—matching AI technologies to problematic areas

After determining the problematic areas with fuzzy DEMATEL, the opinions of the same expert group are taken in order to find solutions to these problems with AI technologies through the Delphi method. The implementation of the Delphi method consists of systematic stages—revealing the approaches and perspectives of the experts on the problem situation, examining them and reaching a consensus (Hosseini et al., 2022). Expert opinions are collected for six problematic areas separately, using the Delphi method. For example, experts evaluated the use of five different AI technologies; these are genetic algorithm, ant colony optimization, machine learning, artificial neural networks and data clustering for the inventory management (C1) problem. As a result of conducting the Delphi method, AI technologies recommended by each expert for each problem area are determined for the case study.

The results from the Delphi study are combined with observations from literature to determine which AI technologies would be most beneficial to use for each of the problematic areas. Therefore, based on the results obtained from the Delphi method, AI sub-technologies that can be used in problematic areas encountered in SSCs are presented (Fig. 3).

Fig. 3.

Matching AI Technologies with Problematic Areas Encountered in SSCs by Using the Delphi Method

According to the fuzzy DEMATEL results, the most important change is seen in the support of top management (C6). The support of top management was in the effect group before COVID-19; however, it became the most important in the cause group during COVID-19. Top management support becomes crucial to arrange funding, provide necessary support to the workforce and deal with the ongoing crisis. AI accelerates the decision-making process of top management in order to increase the resilience in SSCs during such disruptions (Rodríguez-Espíndola et al., 2020). Based on implementation of the Delphi study, it is seen that genetic algorithm, ant colony optimization, machine learning, artificial neural networks and data clustering technologies are beneficial in supporting top management (C6). In the automotive industry, these technologies provide traceability, tracking and control of SC operations.

Another important change is seen in demand planning and production management (C4). Demand planning and production management has passed from the cause group to the effect group. Due to fluctuations in demand during COVID-19, demand planning is among the problematic areas affected. Firms organize their capacity and stock plans with their product development processes according to the demand information provided for analysis (Raut et al., 2019). The efficiency of production management is dependent on the demand planning processes (Husna et al., 2020). For this reason, these decisions have great importance for companies operating in an uncertain environment posing a threat to resilient SSCs. As seen with COVID-19, companies with complex SSCs have problems managing their demand planning processes and accordingly experience difficulties in production management (Muñoz-Villamizar et al., 2020). Again, AI driven applications can help managers in such situations. Based on expert opinion, machine learning and artificial neural networks are recommended as the most important AI technologies that can be used in demand planning and production management (C4) in the automotive industry. Predicting zero error in demand planning with machine learning could be one solution. As an example, there are some start-ups in the automotive industry using machine learning for demand planning e.g. SPARK, SONAH etc. Also, artificial neural networks provide benefits such as automation of production systems in demand planning and production management, control of the production process and quality control (Husna et al., 2020; Singh et al., 2020).

Inventory management (C1) is one of the most important problematic areas encountered in SSCM and is in the effect group before and during COVID-19. Sudden disruptions in the SSC does not only cause problematic areas for resiliency of SSCs, but also cause problematic areas in the realization of companies' stock plans (Eaneff et al., 2020; Paul et al., 2021d). It is in the effect group before and during COVID-19 but there is an increase in the magnitude of the problem. Those problematic areas that arose during the COVID-19 period and the problematic areas experienced in the stock estimation and determination of optimum stock levels affect businesses negatively and damage their orientation towards sustainability and resilience (Paschen et al., 2020). The inventory planning system is generally seen as a complex assignment in SSCs (Rostami et al., 2020). With the help of AI, visibility, simultaneous tracking and planning can be included in stock management (Notte et al., 2016; Schniederjans et al., 2020). Based on expert opinions, genetic algorithm, one of the sub-technologies of AI, creates prediction models with the least error rate and provides improvement in inventory management in the automotive industry. With the help of a genetic algorithm, stock status can be monitored and stock holding costs in the network can be minimized (Rostami et al., 2020). For example, with the genetic algorithm, a certain aspect in stock management can be provided by analyzing data such as the sales amount, sales price and production costs of any product.

Optimization in logistics operations (C2) is one of the important problematic areas in global SSCM. Especially with COVID-19, this problem has become very prominent. AI technologies should be used to optimize the logistics performance (Muñoz-Villamizar et al., 2020). According to the results of expert interviews, among the five listed AI technologies, machine learning and the ant colony optimization algorithm are technologies that can be used for optimization in logistics operations by introducing SPARK, SONAH etc. Various start-ups have optimized their SC operations by using AI such as Optimal Dynamics, Akua, Revvo etc. Ant colony optimization is used to produce the closest to optimum solution in complex optimization problematic areas (Dzalbs & Kalganova, 2020; Zhang, Che, et al., 2021). Looking at the results, optimization in logistics operations is in the effect group both pre-COVID-19 and during COVID-19.

In summary, inventory management (C1) and optimization in logistics operations (C2) are among the important problematic areas pre-COVID-19. Some companies adopted just-in-time production pre-COVID-19. Although delays in operations are not tolerated in crisis environments, security stocks also remain at a certain level (Gunasekaran et al., 2015). Disruptions in SSCs have shown that inventory management and optimization in logistics operations are important if we are to maintain sustainable and resilient SCs (Grover et al., 2020). Although they are in the effect group for both periods, there has been an increase in their degree of effect.

Planning the purchasing process (C3) turns into a complex structure in companies given the increasingly competitive environment (Min, 2010). The purchasing process before and during COVID-19 is in the cause group. Organizations need to improve their purchasing planning mechanism to produce high competitive advantage (Rodríguez-Espíndola et al., 2020). Although it remains in the same group, it increases in terms of the magnitude of the problem. Data clustering, one of the AI technologies, is beneficial in terms of decision-making and process planning. It can be used in complex and uncertain systems (Dong et al., 2021). Data clustering algorithms try to group the elements in the data set and produce results without the need for a mathematical model (Yung et al., 2021). Planning of procurement processes that has become difficult with COVID-19 becomes easier with the help of data clustering (Dzalbs & Kalganova, 2020). For example, making data clustering analyzes based on data and indicators, especially during the planning stages of supply chains, ensures effective planning procurement.

The traceability of the SC (C5) is in the effect group before and during COVID-19. Although the traceability of the SC was a difficult and problematic process pre-COVID-19, it became even more important and problematic during COVID-19. The traceability of the SC should be supported by genetic algorithm, ant colony optimization, machine learning, artificial neural networks and data clustering as supported by expert opinions. The effective application of AI technologies increases traceability in SCs (Kamble et al., 2020). Recently, many companies such as Baidu, Google, Flatiron Health etc. have started to profit from the benefits of AI.

Discussions

This research examines the problematic areas encountered in SSCM before and during-COVID-19. The results of previous studies that deal with similar issues and methods are examined for more in-depth insights. Gultekin et al. (2022) listed the risks arising from COVID-19; they presented the risk of change in demand in the cause group, while in this study, demand planning and production management problems are seen in the effect group during the COVID-19 period. From Zhan et al. (2021)’s study, sales criteria is found to be the most important among the criteria they considered to measure resilience. Purchasing process planning is included in the cause group of problems listed in our study. These results show that the issue of purchasing process planning is extremely important with or without disruptions in SSCs. In contrast with this study, Jindal et al., (2021) focused on improving the agility of supply chains.

Similar to our study, Finkenstadt and Handfield (2021) stated that SC traceability and visibility are crucial problematic areas in SC; they concluded that if you can’t trace, you can’t manage your SC operations. Gunessee and Subramanian (2020) and Hakovirta and Denuwara (2020) determined that demand management is one of the problems areas in SC before and during COVID-19; this is in agreement with our study. They stated that problems occur when there are fluctuations in demand leading to failure in delivery times. This has increased due to COVID-19. Moreover, decreasing production capacity and workforce unavailability may cause production planning problems according to Lozano-Diez et al. (2020); this is also in agreement with our study. Lozano-Diez et al. (2020) stated that these problems occurring in SCs are among the major threats to resilience and sustainability of a SC.

According to studies prepared during the COVID-19 period (Di Vaio et al., 2020a, 2020b; Ivanov, 2020), the adoption of AI technologies in SC structures will increase the resilience of SSCs. However, in most previously conducted studies (Yadav et al., 2020), problematic areas encountered in SSCs are not addressed in detail, as we have done in this study. According to Belhadi et al. (2021), emerging technologies are beneficial to increase resilience and sustainability in SCs. Similar to our study, Singh et al. (2020) stated that AI provides more resilient and sustainable SCs. The uniqueness of this study can be seen in the matching of AI applications with the problems that arise in the SC before and during COVID-19. Most recent studies are focused on problems that occur in SCs (Queiroz et al., 2020; Shahed et al., 2021; Sharma et al., 2020) as we did in this study. But, as a solid contribution to the body of knowledge, our study matches the AI driven technologies to the listed problematic areas to improve the overall sustainability and resilience of SCs.

Implications

Companies are beginning to better understand the importance of AI and are increasing their investments in this direction. Given the emerging problems during COVID-19, companies have become more willing to invest in AI supported supply chains. Based on discussion with the experts, they stated that AI technologies should be used for processes that are critical in the supply chain; they highlighted inventory control, demand planning and purchasing. Moreover, AI technologies are recommended by companies because they provide many benefits such as optimizing stock levels in an increasingly competitive environment, managing purchasing decision processes with faster, higher quality and lower costs and being able to analyse data and plan demand.

Managerial implications have arisen from this study. Since global SSCs in the automotive industry include high production rates and high costs, the industry has been badly affected by COVID-19. During COVID-19, the necessity of technology has emerged. Being able to use technologies in SSC structures efficiently is one of the most important issues to be addressed. The levels of financial outlay must also be faced by management. Especially in the COVID-19 period, the adoption of new technologies has become extremely important to improve the sustainability of global SSCs. In addition, shutdowns in factories and the inability to supply raw materials has caused huge disruptions in global SSCs. Allocating sufficient financial resources to new technologies will also provide quick solutions to the problematic areas encountered in global SSCs. Moreover, one of the most important requirements for new technologies to be adopted and implemented in global SSCs is to provide a qualified workforce. Especially in large institutions, trained personnel who are knowledgeable about technologies should be employed.

Another implication, in events that lead to sudden disruptions in global SSCs such as the COVID-19 period, is the support provided by management. Financial resources for new technologies and employing qualified personnel are areas of focus for management in order to ensure sustainability. As can be seen from the results, the support of the executive management becomes even more important in the COVID-19 period. The vision of management and its enthusiasm for technologies will increase the sustainability and resilience of companies.

One recommendation for policymakers is that incentive programs should be prepared in order to implement new technologies such as AI in the public sector and state institutions; laws should be revised accordingly. The study of traceability in multi-tier global SSCs is also extremely important for sectors such as the automotive industry. With government incentives, it is necessary to increase the applications of AI in particular sectors, especially in complex multi-layered SCs. AI is an important subject that needs to be embraced and applied in SC management. For this reason, it is extremely important for policymakers to provide training for personnel. Furthermore, policymakers should provide incentives to increase uptake of AI in SCs. This can encourage companies to learn about and apply AI in their operations. Lastly, one of the most important aspects of AI is awareness. Companies should be made aware about the benefits of AI in their operations. Therefore, policymakers should organize awareness campaigns to increase knowledge about AI.

Conclusion

The structures of the SSC are evolving to a more complex and global dimension; this global nature makes SSCs sensitive to disruptions caused by sudden events with resilience of a SSC threatened. Recently, the COVID-19 pandemic, on a universal level, has negatively affected not only human health but also many activities across many countries. Since the start of the pandemic in China, countries continue to depend on China for production, so that almost every sector and SSC structure have been affected. This virus, spreading around the world, causes chaos in SSC structures. Research shows that the manufacturing sector is one of the most affected sectors in the world in terms of SSC structure from a resilience and sustainability perspective. Within the manufacturing sector, the automotive industry is the most affected and difficult sector. The automotive sector has complex and challenging SSC operations. Moreover, because of COVID-19, the problematic areas around resilience and sustainability of SC operations have grown.

The main contribution of this study is to identify the problematic areas related to sustainable and resilient supply chains pre-COVID-19 and during COVID-19 and to match AI technologies as a solution to these problematic areas to increase resilience and sustainability in operations. In the study, six problematic areas encountered in automotive SSCs were identified. According to the results obtained, the most important change before and during COVID-19 was the transition of top management from the affected group to the cause group. In addition, although there is no change in the group of problematic areas such as stock management and optimization in logistics operations, the effect sizes have increased during COVID-19. Based on these findings, it is recommended that AI technologies should be adopted to confront these problematic areas in SSCs. Moreover, to match these problematic areas with AI technologies, the Delphi method is applied. As a result of the Delphi method, solutions are suggested—for inventory management problems, introduce genetic algorithm; for demand planning and production management problems, artificial neural networks and machine learning can be used. For management problems, all AI technologies can be beneficial to manage SSCs. Data clustering, genetic algorithm, ant colony optimization and artificial neural networks provide benefits for supply chain traceability. It is critical to use machine learning and ant colony optimization for optimization in logistics operational problems. Data clustering is beneficial to address purchase and planning problems.

One of the limitations of the study concerns the research being conducted in the automotive industry in Turkey. It has been difficult to collect data over time due to the current complicated environment resulting from COVID-19. Results may vary according to country and sector. Also, as AI is a relatively new topic, there is a lack of in-depth literature. As changes in COVID-19 occur in the coming years, the problems addressed may differ and the list of problem areas may need to be revised. In future, the listed AI driven technologies may also be modified. The case study can also be carried out in other sectors other than the automotive industry to obtain more widespread findings. Moreover, it can be handled on a stage-by-stage basis in automotive SSCs. Considering the changing conditions of COVID-19, a new perspective including post-COVID-19 problems can be added by using suitable decision-making models. Finally, the agility of the supply chains can also be included in the model in future.

Abbreviations

- DEMATEL

Decision making trial and evaluation laboratory

- SSC

Sustainable supply chain

- SSCM

Sustainable supply chain management

- SCM

Supply chain management

- AI

Artificial intelligence

- I4.0

Industry 4.0

Appendix

Appendix 1: Average Matrix (Implementation for during COVID-19)

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 0.0 | 0.9 | 0.8 | 0.9 | 0.9 | 0.7 |

| C2 | 0.9 | 0.0 | 0.8 | 0.8 | 0.8 | 0.7 |

| C3 | 09 | 0.8 | 0.0 | 0.9 | 0.9 | 0.8 |

| C4 | 0.9 | 0.9 | 0.8 | 0.0 | 0.8 | 0.7 |

| C5 | 0.9 | 0.8 | 0.9 | 0.8 | 0.0 | 0.8 |

| C6 | 0.9 | 0.8 | 0.9 | 0.8 | 0.8 | 0.0 |

Appendix 2: Normalized Direct Relationship Matrix (Implementation for during COVID-19)

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 0.0 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| C2 | 0.2 | 0.0 | 0.2 | 0.2 | 0.2 | 0.2 |

| C3 | 0.2 | 0.2 | 0.0 | 0.2 | 0.2 | 0.2 |

| C4 | 0.2 | 0.2 | 0.2 | 0.0 | 0.2 | 0.2 |

| C5 | 0.2 | 0.2 | 0.2 | 0.2 | 0.0 | 0.2 |

| C6 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.0 |

Appendix 3: Total Relationship Matrix (Implementation for during COVID-19)

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| C1 | 3.25 | 3.36 | 3.24 | 3.29 | 3.26 | 2.92 |

| C2 | 3.17 | 2.93 | 3.00 | 3.02 | 3.01 | 2.71 |

| C3 | 3.52 | 3.43 | 3.17 | 3.37 | 3.35 | 3.02 |

| C4 | 3.34 | 3.27 | 3.16 | 3.03 | 3.17 | 2.86 |

| C5 | 3.4 | 3.33 | 3.25 | 3.26 | 3.09 | 2.93 |

| C6 | 3.36 | 3.27 | 3.20 | 3.21 | 3.19 | 2.74 |

Appendix 4: D + R and D-R Values (Implementation for during COVID-19)

| C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|

| D + R | 39.4 | 37.5 | 39 | 38.1 | 38.4 | 36.2 |

| D-R | − 0.7 | − 1.8 | 0.8 | − 0.3 | 0.2 | 1.8 |

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Ipek Kazancoglu, Email: ipek.savasci@ege.edu.tr.

Melisa Ozbiltekin-Pala, Email: melisa.ozbiltekin@yasar.edu.tr.

Sachin Kumar Mangla, Email: sachinmangl@gmail.com, Email: smangla@jgu.edu.in.

Ajay Kumar, Email: akumar@em-lyon.com.

Yigit Kazancoglu, Email: yigit.kazancoglu@yasar.edu.tr.

References

- Aday S, Aday MS. Impact of COVID-19 on the food supply chain. Food Quality and Safety. 2020;4(4):167–180. doi: 10.1093/fqsafe/fyaa024. [DOI] [Google Scholar]

- Ahmadi, O., Mortazavi, S. B., Mahabadi, H. A., & Hosseinpouri, M. (2020). Development of a dynamic quantitative risk assessment methodology using fuzzy DEMATEL-BN and leading indicators. Process Safety and Environmental Protection, 142, 15–44.

- Allal-Chérif O, Simón-Moya V, Ballester ACC. Intelligent purchasing: How artificial intelligence can redefine the purchasing function. Journal of Business Research. 2021;124:69–76. doi: 10.1016/j.jbusres.2020.11.050. [DOI] [Google Scholar]

- Alonso-Muñoz S, González-Sánchez R, Siligardi C, García-Muiña FE. New circular networks in resilient supply chains: An external capital perspective. Sustainability. 2021;13(11):6130. doi: 10.3390/su13116130. [DOI] [Google Scholar]

- Alzoubi HM, Elrehail H, Hanaysha JR, AI-Gasaymeh A, AI-Adaileh R. The role of supply chain ıntegration and agile practices in ımproving lead time during the COVID-19 crisis. International Journal of Service Science, Management, Engineering, and Technology (IJSSMET) 2022;13(1):1–11. [Google Scholar]

- Ambulkar S, Blackhurst J, Grawe S. Firm's resilience to supply chain disruptions: Scale development and empirical examination. Journal of Operations Management. 2015;33:111–122. doi: 10.1016/j.jom.2014.11.002. [DOI] [Google Scholar]

- Başhan V, Demirel H. Application of fuzzy Dematel technique to assess most common critical operational faults of marine boilers. Politeknik Dergisi. 2019;22(3):545–555. [Google Scholar]

- Bayramova A, Edwards DJ, Roberts C. The role of blockchain technology in augmenting supply chain resilience to cybercrime. Buildings. 2021;11(7):283. doi: 10.3390/buildings11070283. [DOI] [Google Scholar]

- Belhadi A, Kamble S, Jabbour CJC, Gunasekaran A, Ndubisi NO, Venkatesh M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technological Forecasting and Social Change. 2021;163:120447. doi: 10.1016/j.techfore.2020.120447. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benbarrad T, Salhaoui M, Kenitar SB, Arioua M. Intelligent machine vision model for defective product inspection based on machine learning. Journal of Sensor and Actuator Networks. 2021;10(1):7. doi: 10.3390/jsan10010007. [DOI] [Google Scholar]

- Birkel HS, Müller JM. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. Journal of Cleaner Production. 2020;289:125612. doi: 10.1016/j.jclepro.2020.125612. [DOI] [Google Scholar]

- Chawla, A., Singh, A., Lamba, A., Gangwani, N., & Soni, U. (2019). Demand forecasting using artificial neural networks—a case study of American retail corporation. In Applications of artificial intelligence techniques in engineering (pp. 79–89). Springer, Singapore.

- Chowdhury, M. T., Sarkar, A., Paul, S. K., & Moktadir, M. A. (2020). A case study on strategies to deal with the impacts of COVID-19 pandemic in the food and beverage industry. Operations Management Research, 2020, 1–13.

- Dauvergne, P. (2020). Is artificial intelligence greening global supply chains? Exposing the political economy of environmental costs. Review of International Political Economy, 1–23. 10.1080/09692290.2020.1814381

- Delgoshaei A, Aram A, Ali A. A robust optimization approach for scheduling a supply chain system considering preventive maintenance and emergency services using a hybrid ant colony optimization and simulated annealing algorithm. Uncertain Supply Chain Management. 2019;7(2):251–274. doi: 10.5267/j.uscm.2018.10.001. [DOI] [Google Scholar]

- Deloitte (2020). COVID-19 Managing supply chain risk and disruption. Report Authors; Kilpatrick, J. & Barter, L. Contributors; Alexander, .C, Brown, J., Calderon, R., Carruthers, R., Joyce, P. & Xu, L. Deloitte Development LLC. Deloitte Design Studio, Canada. 20–6536T.

- Di Vaio A, Boccia F, Landriani L, Palladino R. Artificial intelligence in the agri-food system: Rethinking sustainable business models in the COVID-19 scenario. Sustainability. 2020;12(12):4851. doi: 10.3390/su12124851. [DOI] [Google Scholar]

- Di Vaio A, Palladino R, Hassan R, Escobar O. Artificial intelligence and business models in the sustainable development goals perspective: A systematic literature review. Journal of Business Research. 2020;121:283–314. doi: 10.1016/j.jbusres.2020.08.019. [DOI] [Google Scholar]

- Dong W, Yang Q, Fang X, Ruan W. Adaptive optimal fuzzy logic-based energy management in multi-energy microgrid considering operational uncertainties. Applied Soft Computing. 2021;98:106882. doi: 10.1016/j.asoc.2020.106882. [DOI] [Google Scholar]

- Dumitrascu O, Dumitrascu M, Dobrotǎ D. Performance evaluation for a sustainable supply chain management system in the automotive industry using artificial intelligence. Processes. 2020;8(11):1384. doi: 10.3390/pr8111384. [DOI] [Google Scholar]

- Dzalbs I, Kalganova T. Accelerating supply chains with Ant Colony Optimization across a range of hardware solutions. Computers & Industrial Engineering. 2020;147:106610. doi: 10.1016/j.cie.2020.106610. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eaneff S, Obermeyer Z, Butte AJ. The case for algorithmic stewardship for artificial intelligence and machine learning technologies. JAMA. 2020;324(14):1397–1398. doi: 10.1001/jama.2020.9371. [DOI] [PubMed] [Google Scholar]

- Elavarasan R, Pugazhendhi R. Restructured society and environment: A review on potential technological strategies to control the COVID-19 pandemic. Science of the Total Environment. 2020;725:138858. doi: 10.1016/j.scitotenv.2020.138858. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Faasolo MB, Sumarliah E. An Artificial Neural Network examination of the intention to implement blockchain in the supply chains of SMEs in Tonga. Information Resources Management Journal (IRMJ) 2022;35(1):1–27. [Google Scholar]

- Ferenhof, H. A., Bonamigo, A., Da Cunha, A., Tezza, R., & Forcellini, F. A. (2019). Relationship between barriers and key factors of dairy production in Santa Catarina, Brazil. British Food Journal.

- Finkenstadt DJ, Handfield R. Blurry vision: Supply chain visibility for personal protective equipment during COVID-19. Journal of Purchasing and Supply Management. 2021;27(3):100689. doi: 10.1016/j.pursup.2021.100689. [DOI] [Google Scholar]

- Foster, M. N., & Rhoden, S. L. (2020). The integration of automation and artificial intelligence into the logistics sector. Worldwide Hospitality and Tourism Themes, 12(1), 56–66.

- Gholizadeh H, Fazlollahtabar H. Robust optimization and modified genetic algorithm for a closed loop green supply chain under uncertainty: Case study in melting industry. Computers & Industrial Engineering. 2020;147:106653. doi: 10.1016/j.cie.2020.106653. [DOI] [Google Scholar]

- Golan, M. S., Trump, B. D., Cegan, J. C., & Linkov, I. (2021). Supply chain resilience for vaccines: review of modeling approaches in the context of the COVID-19 pandemic. Industrial Management & Data Systems.

- Grover, P., Kar, A. K., & Dwivedi, Y. K. (2020). Understanding artificial intelligence adoption in operations management: insights from the review of academic literature and social media discussions. Annals of Operations Research, 308(1), 1–37.

- Gultekin, B., Demir, S., Gunduz, M. A., Cura, F., & Ozer, L. (2022). The logistics service providers during the COVID-19 pandemic: The prominence and the cause-effect structure of uncertainties and risks. Computers & Industrial Engineering, 165, 107950. [DOI] [PMC free article] [PubMed]

- Gunasekaran A, Subramanian N, Rahman S. Supply chain resilience: role of complexities and strategies. International Journal of Production Research. 2015;53(22):6809–6819. doi: 10.1080/00207543.2015.1093667. [DOI] [Google Scholar]

- Gunessee, S. & Subramanian, N. (2020). Ambiguity and its coping mechanisms in supply chains lessons from the Covid-19 pandemic and natural disasters. International Journal of Operations & Production Management, Vol. ahead-of-print No. ahead-of-print. 10.1108/IJOPM-07-2019-0530

- Gupta, S., Modgil, S., Bhattacharyya, S., & Bose, I. (2021). Artificial intelligence for decision support systems in the field of operations research: review and future scope of research. Annals of Operations Research, 308(1), 1–60.

- Hakovirta M, Denuwara N. How COVID-19 redefines the concept of sustainability. Sustainability. 2020;12(9):3727. doi: 10.3390/su12093727. [DOI] [Google Scholar]

- He, P., Huang, Z. (2020). Automotive and Autonomous Mobility, World Economic Forum Beijing, & World Economic Forum. (n.d.). This industry was crippled by the coronavirus—here's how it's fighting back. Retrieved from https://www.weforum.org/agenda/2020/02/coronavirus-china-automotive-industry/

- Hosseini, S. M., Soltanpour, Y., & Paydar, M. M. (2022). Applying the Delphi and fuzzy DEMATEL methods for identification and prioritization of the variables affecting Iranian citrus exports to Russia. Soft Computing, 2020, 1–14. [DOI] [PMC free article] [PubMed]

- Husna, A., Amin, S. H., & Shah, B. (2020). Demand forecasting in supply chain management using different deep learning methods. In Demand forecasting and order planning in supply chains and humanitarian logistics (pp. 140–170). IGI Global.

- Ivanov D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part e: Logistics and Transportation Review. 2020;136:101922. doi: 10.1016/j.tre.2020.101922. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ivanov D, Dolgui A. Viability of intertwined supply networks: extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. International Journal of Production Research. 2020;58(10):2904–2915. doi: 10.1080/00207543.2020.1750727. [DOI] [Google Scholar]

- Jarrahi MH. Artificial intelligence and the future of work: Human-AI symbiosis in organizational decision making. Business Horizons. 2018;61(4):577–586. doi: 10.1016/j.bushor.2018.03.007. [DOI] [Google Scholar]

- Jindal A, Sharma SK, Sangwan KS, Gupta G. Modelling supply chain agility antecedents using fuzzy DEMATEL. Procedia CIRP. 2021;98:436–441. doi: 10.1016/j.procir.2021.01.130. [DOI] [Google Scholar]

- Jones, E., Azeem, G., Jones II, E. C., & Jefferson, F. (2020). Impacting at risk communities using AI to optimize the COVID-19 pandemic therapeutics supply Chain. International Supply Chain Technology Journal, 6(9), 1–12.

- Kamble S, Gunasekaran A, Gawankar S. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. International Journal of Production Economics. 2019;219:179–194. doi: 10.1016/j.ijpe.2019.05.022. [DOI] [Google Scholar]

- Kang HY, Lee AHI, Chan YC. An integrated fuzzy multi-criteria decision-making approach for evaluating business process information systems. Mathematics. 2019 doi: 10.3390/math7100982. [DOI] [Google Scholar]

- Karmaker CL, Ahmed T, Ahmed S, Ali SM, Moktadir MA, Kabir G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustainable Production and Consumption. 2021;26:411–427. doi: 10.1016/j.spc.2020.09.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur H, Singh SP. Sustainable procurement and logistics for disaster resilient supply chain. Annals of Operations Research. 2019;283(1):309–354. doi: 10.1007/s10479-016-2374-2. [DOI] [Google Scholar]

- Kaur, M. J., Mishra, V. P., & Maheshwari, P. (2020). The convergence of digital twin, IoT, and machine learning: Transforming data into action. In Digital twin technologies and smart cities (pp. 3–17). Springer, Cham.

- Klibi, W., Rice, J. B., & Urciuoli, L. (2018, October). Special dossier: quantifying supply chain resilience. In Supply Chain Forum: An International Journal (Vol. 19, No. 4, pp. 253–254). Taylor & Francis.

- KPMG (2020). COVID-19 Gündemi, Yeni Gerçeklikte Makro Trendler. Retrieved from: https://assets.kpmg/content/dam/kpmg/tr/pdf/2020/07/covid-19-gundemi.pdf

- Kumar, P., & Kumar Singh, R. (2021). Strategic framework for developing resilience in Agri-Food Supply Chains during COVID 19 pandemic. International Journal of Logistics Research and Applications, 1–24. 10.1080/13675567.2021.1908524

- Kurpjuweit S, Schmidt CG, Klöckner M, Wagner SM. Blockchain in additive manufacturing and its impact on supply chains. Journal of Business Logistics. 2021;42(1):46–70. doi: 10.1111/jbl.12231. [DOI] [Google Scholar]

- Li L, Rong S, Wang R, Yu S. Recent advances in artificial intelligence and machine learning for nonlinear relationship analysis and process control in drinking water treatment: A review. Chemical Engineering Journal. 2021;405:126673. doi: 10.1016/j.cej.2020.126673. [DOI] [Google Scholar]

- Lozano-Diez JA, Marmolejo-Saucedo JA, Rodriguez-Aguilar R. Designing a resilient supply chain: An approach to reduce drug shortages in epidemic outbreaks. EAI Endorsed Trans. Pervasive Heal. Technol. 2020;6(2020):1–12. [Google Scholar]

- Mageto J. Big data analytics in sustainable supply chain management: A focus on manufacturing supply chains. Sustainability. 2021;13(13):7101. doi: 10.3390/su13137101. [DOI] [Google Scholar]

- Majumdar A, Shaw M, Sinha SK. COVID-19 debunks the myth of socially sustainable supply chain: A case of the clothing industry in South Asian countries. Sustainable Production and Consumption. 2020;24:150–155. doi: 10.1016/j.spc.2020.07.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maslaric M, Backalic T, Nikolicic S, Mircetic D. Assessing the trade-off between lean and resilience through supply chain risk management. International Journal of Industrial Engineering and Management. 2013;4(4):229–236. [Google Scholar]

- Mathiyazhagan K, Haq AN, Baxi V. Analysing the barriers for the adoption of green supply chain management-the Indian plastic industry perspective. International Journal of Business Performance and Supply Chain Modelling. 2016;8(1):46–65. doi: 10.1504/IJBPSCM.2016.076000. [DOI] [Google Scholar]

- McGrath P, McCarthy L, Marshall D, Rehme J. Tools and technologies of transparency in sustainable global supply chains. California Management Review. 2021;64(1):67–89. doi: 10.1177/00081256211045993. [DOI] [Google Scholar]

- Michel-Villarreal R, Vilalta-Perdomo EL, Canavari M, Hingley M. Resilience and digitalization in short food supply chains: A case study approach. Sustainability. 2021;13(11):5913. doi: 10.3390/su13115913. [DOI] [Google Scholar]

- Min H. Artificial intelligence in supply chain management: Theory and applications. International Journal of Logistics: Research and Applications. 2010;13(1):13–39. doi: 10.1080/13675560902736537. [DOI] [Google Scholar]

- Mofijur, M., Fattah, I. R., Alam, M. A., Islam, A. S., Ong, H. C., Rahman, S. A., ... & Mahlia, T. M. I. (2020). Impact of COVID-19 on the social, economic, environmental and energy domains: Lessons learnt from a global pandemic. Sustainable Production and Consumption. [DOI] [PMC free article] [PubMed]

- Mouammine, Z., Ammoumou, A., Nsiri, B., & Bourekkadi, S. (2020). Innovative architecture based on big data and genetic algorithm for transport logistics optimization. Journal of Theoretical and Applied Information Technology, 98(17), 3486–3495.

- Muñoz-Villamizar, A., Rafavy, C. Y., & Casey, J. (2020). Machine learning and optimization-based modeling for asset management: a case study. International Journal of Productivity and Performance Management.10.1108/IJPPM-05-2020-0206

- Nesmachnow S, Cancela H, Alba E. Evolutionary algorithms applied to reliable communication network design. Engineering Optimization. 2007;39(7):831–855. doi: 10.1080/03052150701503553. [DOI] [Google Scholar]

- Nguyen T, Li ZHOU, Spiegler V, Ieromonachou P, Lin Y. Big Data analytics in supply chain management: a state-of-the-art literature review. Computers & Operations Research. 2018;98:254–264. doi: 10.1016/j.cor.2017.07.004. [DOI] [Google Scholar]

- Notte G, Cancela H, Pedemonte M, Chilibroste P, Rossing W, Groot JC. A multi-objective optimization model for dairy feeding management. Agricultural Systems. 2020;183:102854. doi: 10.1016/j.agsy.2020.102854. [DOI] [Google Scholar]

- Notte G, Pedemonte M, Cancela H, Chilibroste P. Resource allocation in pastoral dairy production systems: Evaluating exact and genetic algorithms approaches. Agricultural Systems. 2016;148:114–123. doi: 10.1016/j.agsy.2016.07.009. [DOI] [Google Scholar]

- Olaleye B, Anifowose O, Efuntade A, Arije B. The role of innovation and strategic agility on firms’ resilience: A case study of tertiary institutions in Nigeria. Management Science Letters. 2021;11(1):297–304. doi: 10.5267/j.msl.2020.8.003. [DOI] [Google Scholar]

- Paschen U, Pitt C, Kietzmann J. Artificial intelligence: Building blocks and an innovation typology. Business Horizons. 2020;63(2):147–155. doi: 10.1016/j.bushor.2019.10.004. [DOI] [Google Scholar]

- Patil SK, Kant R. A hybrid approach based on fuzzy DEMATEL and FMCDM to predict success of knowledge management adoption in supply chain. Applied Soft Computing. 2014;18:126–135. doi: 10.1016/j.asoc.2014.01.027. [DOI] [Google Scholar]

- Paul, S. K., Chowdhury, P., Chowdhury, M. T., Chakrabortty, R. K., & Moktadir, M. A. (2021d). Operational challenges during a pandemic: an investigation in the electronics industry. The International Journal of Logistics Management.

- Paul SK, Chowdhury P, Moktadir MA, Lau KH. Supply chain recovery challenges in the wake of COVID-19 pandemic. Journal of Business Research. 2021;136:316–329. doi: 10.1016/j.jbusres.2021.07.056. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Paul, S. K., Moktadir, M. A., & Ahsan, K. (2021a). Key supply chain strategies for the post-COVID-19 era: implications for resilience and sustainability. The International Journal of Logistics Management. 10.1108/IJLM-04-2021-0238

- Paul, S. K., Moktadir, M. A., Sallam, K., Choi, T. M., & Chakrabortty, R. K. (2021b). A recovery planning model for online business operations under the COVID-19 outbreak. International Journal of Production Research, 1–23. 10.1080/00207543.2021.1976431

- Paul V, Tresita M. Artificial Intelligence: Pertinence in Supply Chain and Logistics Management. Uma Devi, N. & Paul V, Maria Tresita (2020). Artificial Intelligence: Pertinence in Supply Chain and Logistics Management. Xi'an Jianzhu Keji Daxue Xuebao/journal of xi'an University of Architecture & Technology. 2020;12:701–709. [Google Scholar]

- Pavlov, A., Ivanov, D., Pavlov, D., & Slinko, A. (2019). Optimization of network redundancy and contingency planning in sustainable and resilient supply chain resource management under conditions of structural dynamics. Annals of Operations Research, 1–30.

- Pedemonte M, Cancela H. A cellular ant colony optimisation for the generalised Steiner problem. International Journal of Innovative Computing and Applications. 2010;2(3):188–201. doi: 10.1504/IJICA.2010.033650. [DOI] [Google Scholar]

- Pedemonte M, Nesmachnow S, Cancela H. A survey on parallel ant colony optimization. Applied Soft Computing. 2011;11(8):5181–5197. doi: 10.1016/j.asoc.2011.05.042. [DOI] [Google Scholar]

- Pereira CR, da Silva AL, Tate WL, Christopher M. Purchasing and supply management (PSM) contribution to supply-side resilience. International Journal of Production Economics. 2020;228:107740. doi: 10.1016/j.ijpe.2020.107740. [DOI] [Google Scholar]

- Pereira MM, Frazzon EM. A data-driven approach to adaptive synchronization of demand and supply in omni-channel retail supply chains. International Journal of Information Management. 2020;57:102165. doi: 10.1016/j.ijinfomgt.2020.102165. [DOI] [Google Scholar]

- Pimenta ML, Cezarino LO, Piato EL, da Silva CHP, Oliveira BG, Liboni LB. Supply chain resilience in a Covid-19 scenario: Mapping capabilities in a systemic framework. Sustainable Production and Consumption. 2022;29:649–656. doi: 10.1016/j.spc.2021.10.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Preil, D., & Krapp, M. (2021). Artificial intelligence-based inventory management: a Monte Carlo tree search approach. Annals of Operations Research, 308(1), 1–25.

- Purwaningsih, R., & Hermawan, F. A. (2021, February). Risk analysis of milkfish supply chains in Semarang using house of risk approach to increase the supply chain resilience. In IOP Conference Series: Earth and Environmental Science (Vol. 649, No. 1, p. 012018). IOP Publishing.

- Queiroz, M. M., Ivanov, D., Dolgui, A., & Wamba, S. F. (2020). Impacts of epidemic outbreaks on supply chains: mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Annals of Operations Research, 1–38. [DOI] [PMC free article] [PubMed]

- Rahman, T., Moktadir, M. A., & Paul, S. K. (2021). Key performance indicators for a sustainable recovery strategy in health-care supply chains: COVID-19 pandemic perspective. Journal of Asia Business Studies. 10.1108/jabs-05-2021-0200-aul

- Ramirez Lopez LJ, Grijalba Castro AI. Sustainability and Resilience in Smart City Planning: A Review. Sustainability. 2021;13(1):181. doi: 10.3390/su13010181. [DOI] [Google Scholar]

- Raut RD, Mangla SK, Narwane VS, Gardas BB, Priyadarshinee P, Narkhede BE. Linking big data analytics and operational sustainability practices for sustainable business management. Journal of Cleaner Production. 2019;224:10–24. doi: 10.1016/j.jclepro.2019.03.181. [DOI] [Google Scholar]

- Rodríguez-Espíndola, O., Chowdhury, S., Beltagui, A., & Albores, P. (2020). The potential of emergent disruptive technologies for humanitarian supply chains: the integration of blockchain, Artificial Intelligence and 3D printing. International Journal of Production Research, 58, 1–21.

- Rostami A, Paydar MM, Asadi-Gangraj E. A hybrid genetic algorithm for integrating virtual cellular manufacturing with supply chain management considering new product development. Computers & Industrial Engineering. 2020;145:106565. doi: 10.1016/j.cie.2020.106565. [DOI] [Google Scholar]