Abstract

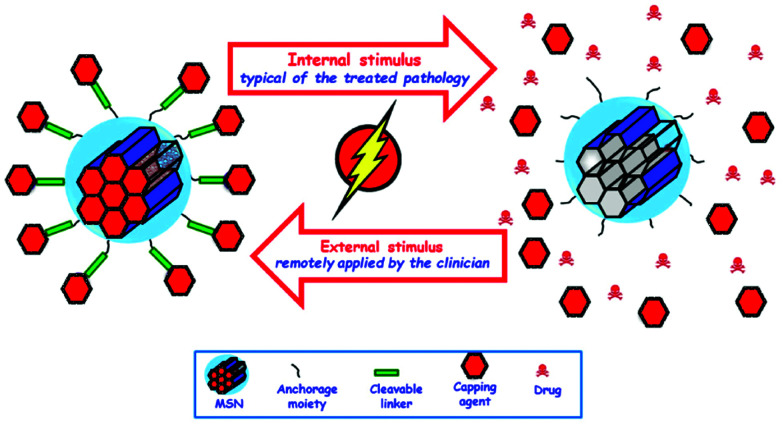

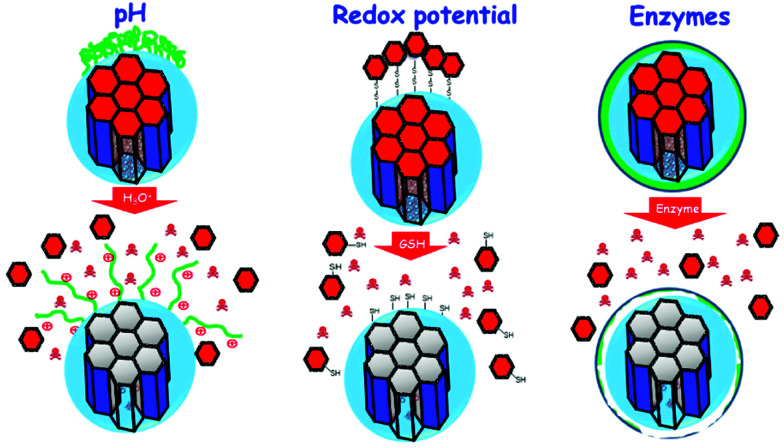

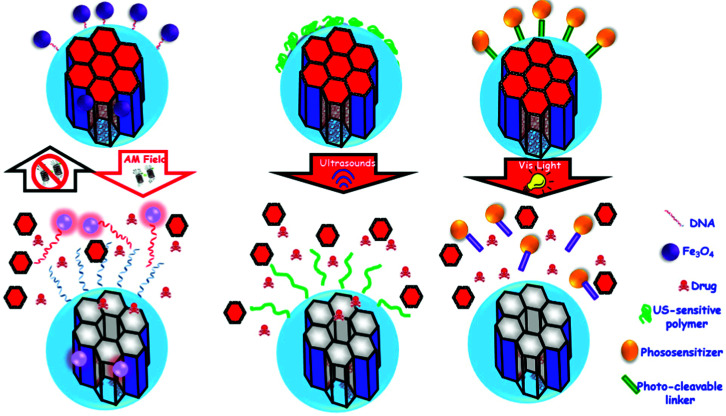

The present review details a chronological description of the events that took place during the development of mesoporous materials, their different synthetic routes and their use as drug delivery systems. The outstanding textural properties of these materials quickly inspired their translation to the nanoscale dimension leading to mesoporous silica nanoparticles (MSNs). The different aspects of introducing pharmaceutical agents into the pores of these nanocarriers, together with their possible biodistribution and clearance routes, would be described here. The development of smart nanocarriers that are able to release a high local concentration of the therapeutic cargo on-demand after the application of certain stimuli would be reviewed here, together with their ability to deliver the therapeutic cargo to precise locations in the body. The huge progress in the design and development of MSNs for biomedical applications, including the potential treatment of different diseases, during the last 20 years will be collated here, together with the required work that still needs to be done to achieve the clinical translation of these materials. This review was conceived to stand out from past reports since it aims to tell the story of the development of mesoporous materials and their use as drug delivery systems by some of the story makers, who could be considered to be among the pioneers in this area.

This review details the huge progress in the design and development of mesoporous silica nanoparticles for biomedical applications during the last two decades.

1. Introduction

1.1. Historical background of the synthesis of ordered mesoporous materials

Carriers for controlled drug delivery had traditionally been based on biopolymers or synthetic polymers,1 but in the 1990s, silicas, especially in the form of nanoparticles, moved into the field of interest for scientists working on drug delivery;2–5 early silica-based systems were porous glasses or disordered silica gels. However, at about the same time, ordered mesoporous silicas, based on mesostructuring using surfactants, were discovered independently by one of Kazuyuki Kuroda's groups6 and by scientists at Mobil Oil Corp.7 Since both fields were in their very infancy in the 1990s, it took about 10 years for these separate fields of research to come together. As far as we know, the first potential use of ordered mesoporous materials for drug delivery is mentioned, just as a “buzzword”, in the abstract of a little known paper from 1998 by one of the authors of this review, with no further explanation or discussion of this possible application in the main text of that publication.8 The first real description of such silicas as drug delivery matrices was given by Vallet-Regí et al.9 This seminal paper initiated the broad research field of biomedical applications of ordered mesoporous silicas, a field with very high current activity and more than a thousand publications appearing each year.

Ordered mesoporous silicas have a number of features, which make them highly suitable for drug delivery applications:10

An ordered porous network, which is very homogeneous in size and allows fine control of the drug load and release kinetics;

A high pore volume to host the required amount of pharmaceuticals;

A high surface area, which implies high potential for drug adsorption;

A silanol-containing surface that can be functionalized to allow better control over drug loading and release.

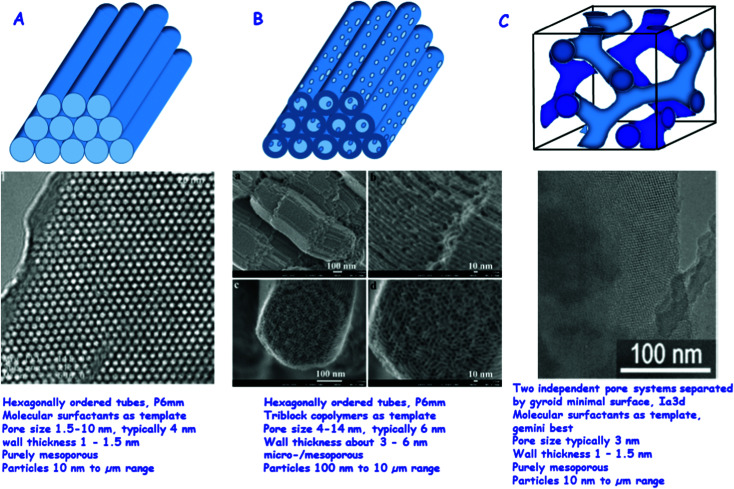

Fig. 1 gives an overview of the more important ordered mesoporous silicas, which are being used as drug release vectors.11,12

Fig. 1. Most relevant ordered mesoporous materials for drug delivery: (A) MCM-41, top: schematic of the hexagonally ordered system of pores, middle: TEM of a high quality MCM-41 sample (reproduced with permission from ref. 11), bottom: typical parameters of MCM-41. (B) SBA-15, top: schematic of the hexagonally ordered system of pores with the micropores in the walls connecting the ordered mesopores, middle: HR SEM images of SBA-15, also here micropores are visible (reproduced with permission from: ref. 12), bottom: typical parameters of SBA-15. (C) MCM-48, top: schematic of the two independent pore systems separated by a gyroid minimal surface, middle: TEM image of MCM-48 (reproduced with permission from: ref. 34), bottom: typical parameters of MCM-48.11,12,34 Adapted with permission from ref. 11, 12 and 34. Copyright 2002, 2008 and 2009, Wiley, ACS, Elsevier Ltd.

Some of these features can also be realized with other materials, such as silica xerogels or aerogels or porous glasses, but all of these properties simultaneously exist only in ordered mesoporous materials. Moreover, to date, various facile methods for the synthesis of ordered mesoporous silica in the nanoparticulate form have been developed, which have several physiological advantages as carriers for bioactive agents. In the following, we will first discuss the early work on ordered mesoporous materials preceding the first publication on drug release and then cover the different pathways for the synthesis of such materials, with a focus on those most relevant for drug delivery. In the final part of the synthesis section, we will address approaches to create ordered mesoporous silica nanoparticles (MSNs), which is the form in which they are best applicable in the biomedicine field.

Surfactants, the key ingredients in the synthesis of ordered mesoporous materials, had been used in silica chemistry before for various purposes, and it is thus not completely surprising that materials resembling ordered mesoporous silicas disclosed in the early 1990s had been synthesized before. Probably the first synthesis of an ordered mesoporous material was described as early as 1971 in a patent,13 since an exact repetition of the patent procedure led to the formation of an ordered material having similar features to MCM-41.14 However, this initial patented procedure cannot be considered as the discovery of the material, since except for a low bulk density no specific properties are reported in the patent, and therefore the remarkable features of these surfactant-templated materials, such as their regular and ordered pore systems, were not observed. Moreover – and perhaps more importantly from a fundamental point of view – no ideas concerning supramolecular templating as a new synthetic concept were formulated.

The real discovery of the materials and the processes leading to these materials can be dated back to the end of the 1980s/beginning of the 1990s. The first description of a material having linear pores in the size range of 4 nm, which were hexagonally ordered, was published by Kuroda and coworkers.6 This paper, however, initially went largely unnoticed, attracting only six citations in the first four years until 1993 (according to the Web of Science, the current citation count is above 1500). This was both due to the journal in which it was published, which is not widely read, and due to the limited scope of the synthetic pathway: the intercalation of sheet silicates and subsequent transformation to ordered mesoporous solids did not seem to be a general route to a large variety of different materials.

This was different from the work published by the Mobil group in 1992;7,15 it had previously been patented and also been presented as a recent research report poster at the 9th International Zeolite Conference in Montreal. This poster was probably the most intensively discussed and photographed poster at any conference the authors are aware of, and also some of the authors of this review took photos to immediately replicate the synthesis in their laboratories. In the written form, this work was published in high profile journals, and especially the very comprehensive J. Am. Chem. Soc. paper15 has a density of new information, which is rarely seen in publications. The extremely high long-term impact of these papers (together around 25 000 citations to date) was probably not due to the description of a material with unusual textural properties; the decisive point appears to be the formulation of possible liquid crystal templating mechanisms, even if they were at that initial stage in a rather general and not very specific form. This introduced a novel concept for the creation of highly ordered, porous inorganic materials beyond the molecular scale, using supramolecular arrays as templates. An account of the history of discovery from the perspective of the Mobil-scientists was given in 2013.16

Following this seminal series of papers, important work expanding these discoveries was published. A more detailed formulation of the mechanism was put forward by the group of G. Stucky,17 who proposed that under most synthesis conditions the organic/inorganic mesostructure forms cooperatively via the interaction between multiply charged silicate oligomers and the positively charged surfactants. Subsequently, in a joint paper by Stucky's group and Schüth's group, the concept was generalized to other conditions, and, maybe more importantly, to other compositions.18 A major conceptual development with respect to the mechanism which helps to rationalize many of the synthetic pathways was also introduced by Stucky's group, first only briefly mentioned and not strongly elaborated on in 1995,19 but fully developed in a subsequent paper one year later.20 It is based on the surfactant packing parameter introduced into surfactant science by Israelachvili,21 and allows the prediction of the development of certain phases based on simple geometric arguments.

Another major development line, which started in the middle of the 1990s, was the use of polymeric surfactants. Pinnavaia's group pioneered this approach with poly(ethyleneoxide) based surfactants,22 using dilute concentrations, while Attard et al.23 used similar surfactants, but at such high concentrations that a liquid crystalline phase was present before the addition of an inorganic precursor. This so-called “true liquid crystal templating” (TLCT) introduced a new concept into the synthesis of ordered mesoporous materials. However, the element of predictability, which Attard et al. mentioned in their contribution, does not seem to be fully exploitable, since the addition of a precursor to the inorganic material in many cases seems to destroy the liquid crystalline phase, which subsequently reforms as an organic–inorganic composite. The pathway introduced by Pinnavaia and coworkers using more dilute surfactant systems was thus the more influential one.

The use of polymeric surfactants culminated in the discovery of SBA-15 in the Santa Barbara groups of Stucky and Chmelka.24 The synthesis of SBA-15 is probably the most important single breakthrough after the original synthesis published in 1992. The properties of the material, such as the tunability of the pore sizes over a wider range than for MCM-41, thicker walls and correspondingly enhanced stability, and the connections between the mesopores through the micropores in the walls, make the material more promising than the original MCM-41 for most applications. This is the reason why over recent years SBA-15 and related materials seem to have been used perhaps even more than MCM-41, judging from the personal impression of the authors and also citation data.

Relying on pre-formed ordered mesoporous materials, Ryoo introduced a novel concept for the negative replication of such systems, first for the formation of a MCM-48 structure as a carbon replica material (CMK-1),25 following a related, but not quite as successful, attempt at replicating the pore structure of a zeolite.26 This approach has now substantially been broadened, and many different materials are accessible via this nanocasting process.

Surface modification of silica is a highly important feature for biomedical applications. In fact, it was back in 1990 when the Japanese Research Group headed by Kuroda reported for the first time the reaction of kanemite-derived mesoporous silica with a trimethylsilylating reagent to form a trimethylsilylated derivative.27 Due to calcination of the silylated material at 700 °C, this functionalization was lost, though, in the final porous silica. Later on, a similar functionalization strategy was also applied by the Mobil team to perform the trimethylsilylation of the surface of MCM-41 pores,15 resulting in trimethylsilylated porous silica. This method established pathways for the silylation of mesoporous silica. For conventional silicas, also the synthesis of organosilicas from organically bridged silsesquioxanes was well established.28 Based on this well-developed chemistry, also ordered mesoporous organosilicas, where each silicon atom in the structure is connected via an organic molecule to another silicon center, were created. Such materials are synthesized from organically bridged bis(trialkoxysilane) precursors. The process was independently discovered by three groups: Inagaki et al.,29 Stein et al.30 and Ozin et al.31 Inagaki subsequently also found that organosilicas bridged with phenylene groups had partly ordered wall structures,32 a feature which had been searched for essentially from the beginning of the research on ordered mesoporous materials, and only partly been achieved in the synthesis of block copolymer templated SBA-15 type materials, where the walls in some cases consist of nanocrystalline metal oxide domains.33,34

1.2. Synthetic pathways for the production of ordered mesoporous materials

After the discussion of the major development lines in the early days of this research field, which had established the main classes of ordered mesoporous materials, especially silicas, we will take a closer look at the synthetic pathways available. The discussion will focus on silica, since this is the major matrix for biomedical applications. We will also highlight the options to modify and adapt properties towards specific application fields, such as for drug delivery or other biomedical applications. For the synthesis of specific ordered mesoporous silica, the collection of verified syntheses by Meynen, Cool and Vansant35 is a great resource. This compilation does not specifically address the use of ordered mesoporous silicas for biomedical applications, but it is a perfect starting point for obtaining insight into the more often studied structures, their characterization and their synthesis. Moreover, many reviews that focus on the synthesis of ordered mesoporous materials exist; however, we would like to mention only a few focusing on different aspects.36–39 Such a deep level of treatment as in these dedicated reviews cannot be given in an article focusing on drug delivery, but the following section serves as an introduction to the more important aspects in the synthesis of ordered mesoporous silica, and provides access to more detailed accounts in the literature.

1.2.1. Creation of the mesostructure

The production of ordered mesoporous materials can conceptually be divided into three different steps: (i) creation of the mesostructure, (ii) creation of porosity, and (iii) functionalization of the mesoporous solid. While the steps cannot always be completely separated, such as, for instance, in the controlled condensation of organosilane precursors to organosilicas, the separation is helpful for the subsequent discussion. However, before the details of the more important synthesis pathways will be discussed, it appears to be helpful to briefly discuss the aqueous chemistry of silicon and the basics of surfactant behaviour in an aqueous solution. The discussion will focus on water as the solvent, since this is the most often used system, although often alcohol is present, from the hydrolysis of silicon alkoxides or because it was deliberately added. In addition, also non-aqueous systems, in which only reagent amounts of water were used to induce hydrolysis and condensation of the silica precursors, have been reported in the literature.40 Those non-aqueous syntheses are reviewed elsewhere.39,41

1.2.2. Silica and silicates in solution

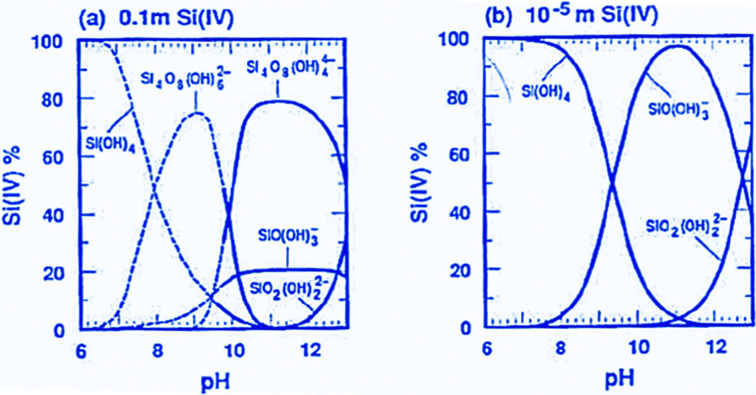

Silicates condense under a wide range of conditions, including different pH values, temperatures, concentrations, additional electrolytes, and others. The chemistry of silica and silicates has been covered extensively in two excellent monographs: the classical book of Iler,42 and a broader treatment by Brinker and Scherer,43 which also includes a treatment of the sol–gel chemistry of oxides other than silica. In addition, also a review article by Brinker provides a great overview of the dependencies of the different types of reactions on the reaction conditions.44 Silica has a point of zero charge at around pH = 2, which also approximately is the isoelectric point. This means that silica is negatively charged at pH values higher than the point of zero charge, so that silanol groups are deprotonated, and at pH values lower than about two, silica surfaces are partially protonated and thus positively charged. Silicic acid or monomeric/small oligomeric silicates are less acidic, so that a higher fraction of negatively charged small silicon containing units only become predominant around neutral pH values (Fig. 2).

Fig. 2. Speciation of silicates in solution at different concentrations over pH (reproduced with permission from Brinker and Scherer, Sol–Gel Science, Academic Press, Boston 1990).43 Adapted with permission from ref. 43, Copyright 1990, Academic Press.

As a first guideline, it is thus useful to distinguish ordered mesoporous silica syntheses proceeding under alkaline conditions, where silicate species are negatively charged in solution and thus have a direct Coulomb-interaction with positively charged surfactants. On the other hand, in the pH range below 7, at least the smaller species only carry little charge, so that more hydrogen bonding interactions between silicic acid species and neutral surfactants predominate in the mesophase formation. Only under very strongly acidic conditions, the species and surfaces are protonated to an appreciable extent, and thus positively charged. For silicas to be applied in drug release or related applications, the point of zero charge around pH = 2 should be kept in mind, if charged bioactive species should be loaded into them. A proper pH range has to be selected, so that electrostatic repulsion is suppressed. On the other hand, too strong electrostatic attraction may lead to difficulties in releasing the adsorbed species. Similar considerations hold for silicate species in solution, but here one has to keep in mind that at low pH, silica gels form rapidly, and solution concentrations of silicon-containing species are rather low.

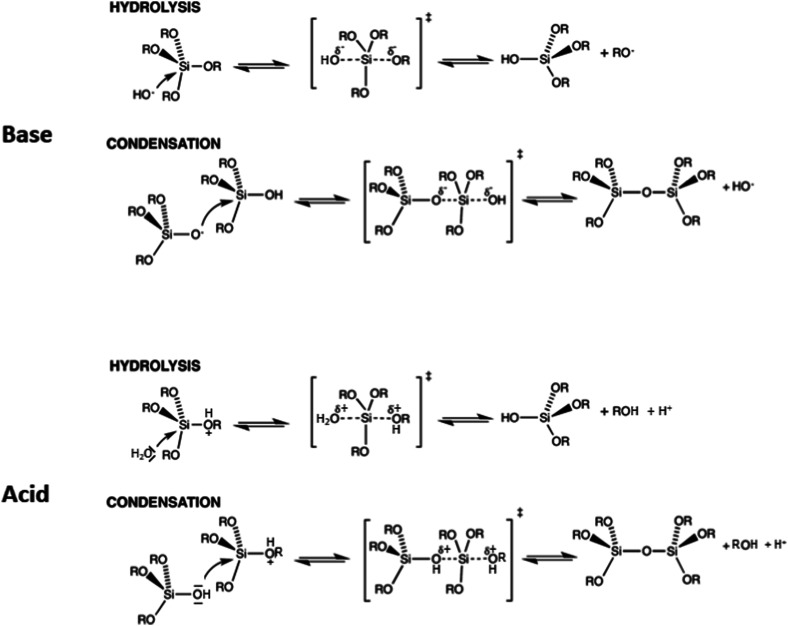

As in most solid-state structures of silicates, silicate chemistry in solution is governed by silicon atoms in tetrahedral oxygen coordination. Both hydrolysis and condensation reactions proceed via nucleophilic substitution, typically following SN2-type reactions via a pentacoordinated transition state, although different variants of such reactions are discussed.44Fig. 3 gives an overview of the major types of reactions that occur. Under alkaline conditions, OH− typically acts as a nucleophile in the hydrolysis reactions of precursor species, such as alkoxysilanes, with alcoholate species as leaving groups, which are directly protonated after being cleaved off the silicon atom. If highly condensed silica is exposed to alkaline conditions, the nucleophilic attack of an OH− ion can lead to cleavage of silioxane bonds, leading eventually to the dissolution of silica to oligomeric and monomeric species, depending on the pH-value.

Fig. 3. Hydrolysis and condensation reactions of silicon alkoxides and condensation under (top) basic conditions and (bottom) acidic conditions.

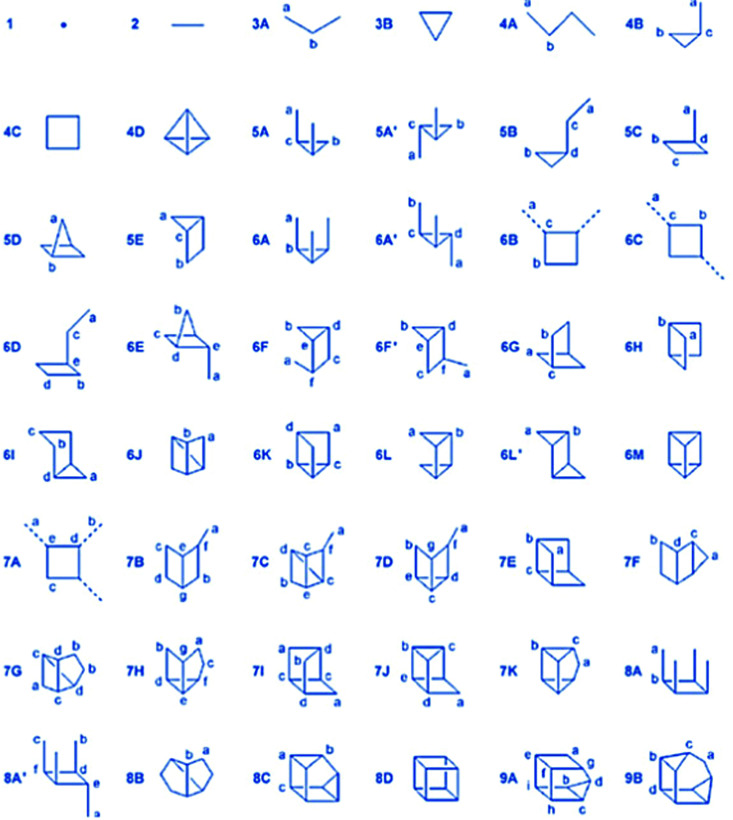

Silicate species formed by the initial hydrolysis reaction under alkaline conditions are typically deprotonated, and these species are able to initiate a nucleophilic attack on other hydrolysed silica species, leading to the condensation to a siloxane bond. Since more highly condensed silicates are more acidic than monomeric species, they are preferably deprotonated and attack less highly condensed/monomeric species. The systems are dynamic, and depending on alkalinity or other solution conditions, an equilibrium between different silicate monomers and oligomers is established. Fig. 4 summarizes the structures of silicate oligomers, which were detected by 29Si NMR spectroscopy under alkaline conditions.

Fig. 4. Structure of silicate ions identified in alkaline solution by 29Si NMR spectroscopy (reproduced with permission from ref. 48). Adapted with permission from ref. 48, Copyright 2007, Wiley-VCH GmbH.

The reactions are different under acidic conditions. Here, potential leaving groups (alkoxy or hydroxyl) are protonated, which makes them more electron withdrawing and easier to be replaced. Under such conditions, the basicity of water is sufficient to allow efficient nucleophilic attack, leading to hydrolysis of the alkoxide group. If the silanol of a monomeric or oligomeric silicic acid is the nucleophile, then a new siloxane bond is formed, leading to condensation to more extended oligomers. A major difference between alkaline and acidic conditions is the fact that siloxane bonds are essentially stable under acidic conditions, i.e. oligomers and solid polymeric species are not dissolved, and silica formation is irreversible, while under alkaline conditions, hydrolysis/recondensation reactions prevail, and even for extended silica, exchange reactions proceed to a substantial extent on the surfaces.

For immobilization of drug molecules, the use of more hydrophobic silica could be advantageous. Such silicas are accessible via condensation of functional silanes, with pending or bridging organic groups. Organic substituents on the silicon atoms reduce the acidity of silanol groups, and thus they would slow down reactions under alkaline conditions, where silicate anions are the nucleophiles in the condensation reactions, while under strongly acidic conditions, the presence of alkyl groups accelerates the reactions, due to the higher basicity of the oxygen in the silicates. These factors are important in controlling the homogeneity of the alkyl functionalization, since too strong differences in the condensation rates of silicates and partially organically substituted silicates can lead to preferential reaction of one over the other in different stages of condensation reactions, and thus to inhomogeneity in the distribution of the organic groups.

1.2.3. Surfactants in solution

Surfactants are the key ingredients in the synthesis of ordered mesoporous silicas. While initial studies have focused on alkylammonium surfactants, typically with three short chain substituents on the nitrogen atom (mostly trimethyl) and one long chain alkyl group (hexadecyl as the prototypical example), currently, there is a plethora of different surfactants, which have been used for the creation of mesostructured silicas. Ref. 45 gives a great overview not only of the more common types of surfactants that are useful in the synthesis of different ordered mesoporous materials, but also of surfactants useful for other purposes, which could give some inspiration also in the field of mesostructured silica. On a very general level, the charge in the hydrophilic part of the surfactants (positive, negative, zwitterionic, or neutral) governs the type of interaction with the silicon-containing precursors, while the overall geometry of the molecules is important in controlling the type of mesostructure formed. However, eventually the overall conditions of the synthesis are decisive, and the control of the synthesis can hardly be reduced to a single factor.

At low concentrations, surfactants are located at interfaces and in aqueous bulk solution in the monomeric form. At a certain threshold concentration (critical micelle concentration (cmc)), they typically form micelles, mostly spherical in shape. For ionic surfactants, the typical concentration range is 10−3–10−2 mol L−1, while for non-ionic surfactants, micelles already form at about one order of magnitude lower concentrations. At higher concentrations, the spherical micelles may undergo transitions to other shapes, such as elongated or rod-like micelles, and/or they may assemble into two- or three-dimensional ordered structures. A simple and intuitive conceptual framework for the prediction of the kind of structures, which form, is provided by the surfactant packing parameter concept developed by Israelachvili.21 Structures of micelles are predicted based on geometric constraints, and certain threshold-values for the parameter g = V/(a0 × l) indicate the transition points between the structures, where V is the volume of the surfactant hydrophobic chain, l is the length of the extended hydrophobic chain, and a0 is the surfactant headgroup area per molecule at the surface of the hydrophobic core. With increasing packing parameter, the expected sequence of structures is shown in Table 1.20

Description of micelle types depending on the packing parameter.

| Micelle type | Mesostructure | Packing parameter |

|---|---|---|

| Spherical | Cubic (Pm3n) | 1/3 |

| Rod-like | Hexagonal (P6m) | 1/2 |

| Complex | Cubic (Ia3d) | 1/2–2/3 |

| Lamellar | Layered | 1 |

These values give indications as to which molecular parameters of the surfactant should be changed if the synthesis should be directed from one structure to another under otherwise identical conditions (if this is possible). While this concept has proven to be very powerful in rationalizing and predicting the formation of certain mesostructures, one should keep in mind that it has originally been developed for equilibrium systems, and even under equilibrium conditions, other solution parameters can strongly influence the formation of specific micelles.46,47 A more important point, however, is the fact that the formation of ordered mesostructured materials is normally a kinetic phenomenon, in which the structure forms cooperatively between silicates and surfactants. So, trends can often be well predicted, while precise numerical values for transitions between structures are more difficult to derive.

Alkaline pathways

Both the initial pathways for ordered mesoporous materials, the one described by Yanagisawa et al.6 and the one introduced by the Mobil team,7 proceed under alkaline conditions, albeit at rather different levels of alkalinity. While the latter uses fairly high concentrations of OH− (approximately 0.1 M, the OH is introduced with the trimethylammonium surfactant), the conversion of Kanemite takes place at a pH in the range of 8–9. While this difference on first sight does not appear to be very substantial, with respect to silicate chemistry these conditions lead to totally different speciation: at high pH, silicates are typically present in monomeric or small oligomeric form, with a high number of different species structurally identified by 29Si NMR spectroscopy.48 Under relatively high alkalinity, these species convert rapidly between each other, and there is a condensation/hydrolysis equilibrium, which is dependent on various parameters, such as pH, concentration of silicate, additional ions and species present in solution, and temperature.42,43 In contrast, at a pH in the range of 8–9, siloxane bonds are relatively stable, and depolymerisation of condensed silica phases is very slow. This particular feature of silicate chemistry led to the formulation of the model of layer buckling for the conversion of intercalated kanemite to ordered hexagonal structures, as opposed to a dissolution/reprecipitation mechanism, which might prevail at a higher pH.49 Due to the sensitivity of silicate chemistry – and thus the synthesis of ordered mesoporous silica – on pH, pH control during formation of the mesostructure can be highly important to influence the quality of the final product. This has first been introduced by Ryoo and colleagues,50 who adjusted the pH to 11 for optimum mesostructuring under the conditions used, and subsequently in various publications. Overall, the pH value for synthesis under alkaline conditions mostly seems to be in the range between approximately pH = 9 and pH = 12.

There is one class of ordered mesoporous silicas, which are synthesized at relatively low alkalinity, almost close to neutral pH, which are the anionic surfactant templated mesoporous silicas (AMS) introduced by Che et al.51 and reviewed by her in 201352 and described in more detail in a recent book.53 Up to the initial publication on AMS, synthesis attempts using anionic surfactants had not been very successful. Under acidic conditions, where at least weakly positively charged silicon-containing species exist in solution, the anionic surfactants are typically protonated and thus neutral, resulting only in weak interactions. Under basic conditions, the anionic surfactants are indeed anionic, but also the silicate species carry negative charges. Any charge interaction thus needs to be mediated by cations, also resulting in interactions too weak for the formation of a well-developed mesostructure. A successful solution to this problem was the use of a dual-functional co-structure directing agent (CSDA). This on the one hand can link to the silicate precursor, and on the other hand provides a charge interaction with the anionic surfactant. A prototypical example for such species is 3-aminopropyltrimethoxylsilane, which reacts in a “neutralization” reaction with an acidic precursor of an anionic surfactant on the one hand and co-condenses with tetraethoxysilane with the silane moiety of the CSDA. Alternatively, the positive charge interacting with the anionic surfactant can directly be introduced into the CSDA, for instance in N-trimethoxysilylpropyl-N,N,N-trimethylammonium chloride; the trimethoxysilyl-part again co-condenses with the TEOS. A broad range of different materials with various structures can be formed via this pathway, and the materials include those with mesoscopic chirality.52 AMS type materials have also been studied with respect to their drug release properties, with the advantage that some anionic surfactants are physiologically less critical than most other surfactants and may thus be left in the material to control release.54

As opposed to acidic and near neutral conditions, more strongly alkaline conditions allow a greater variability in the nature of the silica precursor. Under acidic conditions, solid silica or silica sols essentially do not dissolve and are thus not suitable as precursors; hence, typically alkoxysilanes are used as the silica source. Under alkaline conditions, such silanes are suitable precursor species as well, but also basic silicate solutions with different cations (alkali ions, tetraalkylammonium), fumed or colloidal silicas as well as silica gels can be converted to ordered mesoporous materials. In fact, in the original synthesis reported by the Mobil team, a mixture of tetramethylammonium silicate and precipitated silica was employed,7 but already in the broader follow-up publication, a wider range of silica precursors was studied. The nature of the silica precursor certainly does have an influence on the synthesis and needs to be taken into account, but under suitable conditions, it seems that almost any silica precursor can be converted to ordered mesoporous silica. Care has to be taken that highly condensed silica is depolymerized at least to some extent before the mesophase formation, and complex precursors should at least be hydrolysed to some extent, but then addition of the surfactant and adjustment of pH will induce mesophase formation under the right conditions, which is only little dependent on the silica source.

The key element to structure the mesophase is the surfactant, but its influence is moderated by the synthesis conditions, i.e., temperature and ratios of the concentrations of silicate, surfactant and alkalinity. In the Mobil publications, two structures were introduced, MCM-41 and MCM-48, in addition to the layered MCM-50, which is unstable upon calcination and will not be further considered here. Both were synthesized using cetyltrimethylammonium bromide (CTAB), but cubic Ia3d MCM-48 formed at CTAB/Si ratios exceeding 1 under precisely defined conditions, while the hexagonal tubular MCM-41 formed at lower CTAB/Si ratios over a broader range of conditions. This, however, is also dependent on the surfactant chain length and other synthesis parameters.55 MCM-48 is substantially more difficult to synthesize than its hexagonal MCM-41 counterpart. It seems that the best approach for its controlled synthesis is the use of gemini surfactants instead of the CTAB and related surfactants, since this allows better control over the surfactant packing factor18,56 in controlling drug release and thus important to be controlled for this and related applications.57 Over a relatively small range, the pore size of the resulting silica can be adjusted by the length of the hydrophobic chain of the surfactant, with a longer surfactant tail leading to bigger pores. However, above a certain threshold around C20/C22 high quality hexagonal mesophases do not form any more, and there are only scattered reports in the literature in using such long-chain surfactants, which demonstrate that precise control of conditions is required to obtain the desired mesostructure.58 Further expansion of pore sizes has to be achieved by adding auxiliary organics, such as trimethylbenzene, which is incorporated in the hydrophobic part of the micelles and thus leads to swelling. This allows expansion of pore sizes for the hexagonal material to about 10 nm, although control becomes increasingly difficult towards the higher end of the pore size. By judicious choice of conditions, additives, and hydrothermal conditions, pore sizes can be controlled fairly precisely for MCM-41-type materials between approximately 1.5 nm and close to 10 nm.59

For biomedical applications, one highly important factor is the control of size and shape of the ordered mesoporous silica, since this governs on the one hand the transport of silica in the organism, and on the other hand it is important – among other factors – for the kinetics of, for instance, drug release. However, since this is a crucial factor in the context of this review, it will not be discussed here, but a separate section below will be devoted to this aspect.

Acidic pathways

Acidic synthesis pathways were introduced in the publication of Huo et al. in 1994.18 Generally, under acidic conditions the synthesis temperature tends to be somewhat lower than that of alkaline systems; often the synthesis is carried out at room temperature or even below, while under alkaline conditions, the temperature is often above room temperature up to about 120 °C. In the publication by Huo et al., in addition to the S+I− and S−I+ pathways (S surfactant, I inorganic species) for the formation of mesostructured materials, two mediated pathways (S+X−I+ and S−M+I−) were introduced, in which anions, such as halogenides, or metal cations mediate the Coulomb-interaction between surfactant and condensable species. For the synthesis of silica via the S+X−I+ pathway, the reaction was carried out at very low pH (1–7 M HCl or HBr) so that silicon containing species are positively charged. In addition to the hexagonal phase and the lamellar phase also obtained under basic conditions, a cubic Pm3̄n mesophase was formed (in a later study labelled SBA-1)20 with surfactants with a larger headgroup (alkyltriethylammonium, cetylethylpiperidinium) to adjust the packing parameter towards high curvature structures. The Pm3̄n phase was known also for the pure surfactant systems in formamide, but it could be created as a surfactant–silica composite under acidic conditions.60 Support for the mediated pathway comes from the facts that the chlorine to surfactant ratio is one, and the surfactant can easily be removed by washing in ethanol. In addition – as generally valid for silica formation under acidic conditions – the synthesis proceeds with TEOS or SiCl4, but not with condensed silica, such as Cab–O–Sil, because this does not depolymerize under acidic conditions, so that insufficient silicon containing oligomers are in the solution to form the mesophase. With tailored surfactants, under highly acidic conditions also a hexagonal phase termed SBA-2 is obtained, which can be described as a hexagonally close packed array of surfactant silicate micelles with the P63/mmc space group.20 This is one of the surfactant–silica mesophases which do not have a corresponding pure surfactant analogue – at least as yet, although recently indications of the presence of a P63/mmc phase were reported in a glycerol monooleate/oleic acid system.61 Overall, however, SBA-1 and SBA-2 have not been explored as extensively as many other ordered mesoporous silica, although the structures are interesting and they can be obtained in the form of well-developed single crystals of different morphology.62 A recent, comprehensive survey on ordered mesoporous silica synthesized under acidic conditions via the S+X−I+ pathway has been given by Jarmolinska et al.63

A very important – and by now possibly most often used – class of ordered mesoporous silicas is synthesized using non-ionic surfactants. At moderate acidity or near neutrality, silicon-containing oligomers carry almost no charge, and thus hydrogen-bonding interactions with the surfactants are playing the major role in structure direction. The use of non-ionic surfactants under such conditions (S0I0) was pioneered by Pinnavaia's group, who first used long-chain amine surfactants64 to synthesize materials resembling MCM-41, but with thicker pore walls. Template molecules could be extracted, because they are more weakly bonded to the silicate. While this synthesis proceeds at pH slightly above neutral due to the weakly basic properties of the alkylamine, the process using polyethyleneoxide-based neutral surfactants, also introduced by Pinnavaia's group only a few months later, proceeds at very mild acidity at around pH = 6.22 Here, hydrogen bonding interactions are the dominating force, and interestingly, the hydrolysis of the TEOS precursor proceeds rapidly within a few minutes in the presence of the surfactant, while it takes hours without it. The products, labelled MSU-1, are less ordered than the other ordered mesoporous silicas described above and rather have wormhole structures, but pore size distribution is almost as sharp and well defined as in MCM-41.

Possibly the most versatile synthetic routes make use of block copolymer templates, with different types of blocks, and most of these syntheses are carried out again under strongly acidic conditions. Under these conditions, it is assumed that a combination of Coulomb interactions, hydrogen bonding interactions, and van der Waals interactions is responsible for the formation of the mesophase. In the shorthand notion this is labelled as (S0H+)(X−I+), i.e. the alkylene oxide moieties are partially protonated under strongly acidic conditions, the positively charged silicon-containing units have halogenide or other anions coordinated to them, and the superposition of different interactions controls the formation of the mesostructure.65 The details of the contributions of each of them is certainly governed by the exact synthesis conditions.

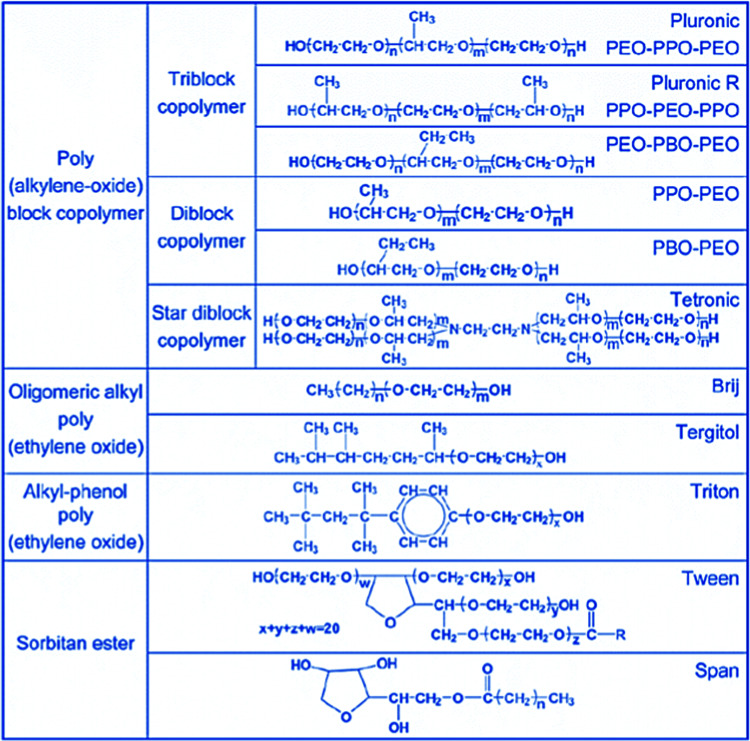

Most often used are probably the block copolymers of the Pluronic™ type, (IUPAC name: poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol), often, however, labelled as poly(ethyleneoxide)poly(propyleneoxide)poly(ethyleneoxide), and abbreviated as PEO–PPO–PEO. These types of surfactants were introduced in the field of ordered mesoporous silica by Zhao et al.24,65 The compositions, which have been created using block copolymer surfactants, are excellently reviewed in ref. 39, but the most often used one is certainly Pluronic P123 (EO20PO70EO20; note that compositions are only approximate). The use of this surfactant results very reliably in the formation of the hexagonally ordered SBA-15 over a wide range of synthesis conditions at pH-values below 2. Also KIT-6, the block copolymer-templated analogue of Ia3d MCM-48 and another highly popular material for many applications, can be synthesized using P123 by modifying the synthesis conditions, especially by adding n-butanol.66 By adjusting the block length in these block copolymers, other structures are synthesized. Pluronics F127 (EO101PO56EO101), for instance, leads to the formation of SBA-16, a cubic cage structure with the space group Im3̄m. The comprehensive publication by the Santa Barbara team65 describes a wide range of different polymer surfactant types, with several members tested for each of these. In particular, for applications in drug release, control of the channel length can be important, and the verified synthesis publication by Meynen et al.35 gives guidelines how to produce especially SBA-15 with short channels.

At first sight, MCM-41 and SBA-15 (and analogous other structure pairs, such as MCM-48 and KIT-6) appear to be rather similar, with the exception of the wall thickness. However, there is an additional difference, which is less obvious, and this is the presence of micropores in the walls of the block copolymer templated materials, connecting the mesopores, which was first inferred from nitrogen sorption analysis.67 Later these micropores were directly imaged as bridges between the mesopores after replication of the pore structures using platinum.68 These micropores are formed, because the poly(ethyleneoxide) moieties of the block copolymer surfactants as the more hydrophilic part are embedded in the pore walls, and upon calcination are removed to result in micropores connecting the mesopores.69 These micropores in the walls of block copolymer templated silicas are important with respect to the replication of the pore system, but also for potential application as matrix for drug release, since the adsorption in these micropores can be stronger than that in the mesopores, provided that they are sufficiently big for adsorption of the payload.

In addition to block copolymers, alkyl poly(ethyleneoxide) surfactants were also found to be highly versatile in this and many other studies. Fig. 5, taken from ref. 39, gives an overview of the type of non-ionic surfactants used in the synthesis of ordered mesoporous silica. By now, syntheses under acidic conditions using polymeric and block polymeric surfactants seem to have superseded the original alkaline synthesis routes, at least judging from citation numbers (WoS for the last five years: SBA-15: 4357 citations, MCM-41: 3143 citations, KIT-6: 496 citations, and MCM-48: 263 citations).

Fig. 5. More important polymeric surfactants used for the synthesis of ordered mesoporous materials. Reproduced with permission from ref. 39, Copyright 2007, The Royal Society of Chemistry.

1.2.4. Nanocasting

The nanocasting pathway is mentioned here only for completeness. In nanocasting, initially formed ordered mesoporous materials synthesized by solution methods are used as hard templates for the replication of the pore system by another solid phase. This has first been demonstrated in the synthesis of CMK-1 by Ryoo's group,70 in which the pore structure of MCM-48 was replicated as a carbon material after infiltration with a suitable carbon precursor. There are several very useful reviews and books available, in which nanocasting is treated in detail.71–77 However, for applications in drug delivery, nanocasting is of limited use, since it is mostly used for the synthesis of non-siliceous materials, with mesoporous silica as a hard template. Non-silica materials are not well suited for drug delivery, since most compositions are physiologically less favourable than those with silicas and have thus only little been used for such purposes. Nanocasting can indeed be used for the synthesis of ordered mesoporous silica, for instance by repeated nanocasting, where first a carbon replica is obtained from a silica, and the carbon in turn is replicated as silica again.78 However, although the repeated nanocasting does result in replicas with somewhat altered properties compared to the original template, access to such silica by direct synthesis is mostly much more straightforward and easier. Thus, while nanocasting is highly valuable for the synthesis of non-silica mesostructures, its relevance for drug delivery applications is very low.

1.2.5. Template removal

For drug delivery applications, the drug needs to be loaded into the carrier, in the case discussed here into ordered mesostructured silica, and for this, the template typically has to be removed from the mesostructure first. In principle, it is possible to incorporate the payload directly during synthesis, if the drug molecules are not degraded during the synthesis of the mesostructure – which is more probable for syntheses close to neutral pH. However, even then regulatory issues with potential degradation products may arise, and thus the in situ incorporation does not seem to be a practical method for drug delivery applications. Moreover, if the surfactant template is not removed, one has to consider the physiological effects of the surfactant as well. There are isolated reports that for innocuous surfactants they can remain in the material also for drug release applications,54 but such approaches do not seem to be widespread.

Thus, in order for mesoporous silica to be useful as a carrier for drugs, the templates have to be removed from the pore system, before the drug is loaded into the carrier. Conventionally, this is done by calcination, typically at temperatures exceeding 500 °C, at which essentially all organic matter present in the material is combusted. Final temperatures are normally reached by controlled heating ramps, typically 1 K min−1. Also potential residues from different anions are removed, for instance, chloride as HCl.79 Depending on the exact nature of the mesostructured material and the nature of the template present, different processes, like Hoffmann degradation of ammonium or amine species, oxidation, carbonization, or oxidation of carbonaceous species, may occur and may be superimposed in different temperature regimes.79 While calcination leads to the removal of the surfactant template, also the silica is changing. Typically, the degree of condensation increases, as visible in a change in the Q3/Q4 ratio detected by 29Si NMR spectroscopy, which often leads to substantial shrinkage of the unit cell parameter. Also, the population of silanol groups on the surface is a function of the calcination temperature. Since this is an important parameter for the possibility to adjust the surface chemistry, for instance by alklysilylation, one should keep this factor in mind, since often calcination is uncritically used following standard protocols.

In order to allow – at least thermally – more gentle calcination, some additional protocols have been developed, already early highlighted by Patarin.80 Better control is reported for template removal by glow discharge,81 non-thermal plasma treatment,82 or dielectric barrier discharge plasma,83 which results in higher silanol surface population and lower shrinkage of the mesostructure. Surprisingly, also microwave treatment seems to work for template removal. While first only a combination of solvent extraction and microwave treatment was shown to work,84 later microwave treatment alone was found to be successful in removing the P123 template. About 95% of the template was reported to be removed by treatment for 40 min at 700 W power and 2.45 GHz microwave frequency.85 The resulting detemplated material had substantially increased pore volume and surface area.

Another method for milder template removal is the use of ozone instead of air in the calcination process.86–88 Conventional thermal treatment usually results in a highly exothermic uncontrollable reaction, but treatment with ozone was possible, leading to larger pores than for conventional calcination. Additionally, a higher silanol density was retained.

Recently, an ozone treatment protocol was described, which avoids the problem of the vigorous reaction, so that also dry, powdered ordered mesoporous materials could be calcined under gentle conditions.88 Both cetyltrimethylammonium and Pluronic P123 could be removed by ozone treatment at temperatures around 80 °C to reach carbon levels in the lower single digit percent range.

An alternative to thermal removal of the templates from ordered mesoporous silica is extraction or reactive extraction, i.e. destruction of the template species in the pores, followed by extractive removal from the pores. Moreover, also partial destruction of the templates in the pores by treatment with a specific reagent, followed by a thermal treatment step under more gentle conditions than those of a single calcination step, is an option.89 This method was used to remove the P123 surfactant first from the mesopores of SBA-15, leaving the micropores in the walls blocked, then removing the template from the micropores by milder calcination. Such a process makes selective functionalization of the walls of the mesopores and the walls of the micropores possible.

Extractive template removal had already been attempted early on in the field of mesoporous silica. For MCM-41 and related systems, this is difficult, since there is a Coulomb interaction between the positively charged surfactant and the silicate wall. Thus, a solvent alone is normally insufficient, and an additional charge compensation has to be supplied, for instance in the form of protons. This was clearly demonstrated by a removal level of only about 20% of the surfactant after stirring at 78 °C in ethanol or isopropanol, while around 70% were extracted, when the solvent contained additional ions, such as protons, ammonium, or sodium.90 Also in follow-up studies it became clear that template removal was not complete in an extraction process and small amounts of template still remained in the sample.91 The latter study also included attempts at reactive extraction, and H2O2 was used for degradation/extraction of the template. The use of H2O2 had been introduced earlier for template removal from SBA-15, also in combination with UV irradiation.92 Neither UV nor H2O2 treatment alone was sufficient, but the combination was claimed to remove all template species from the material.

Overall, it seems easier to remove templates extractively, if the original ordered mesoporous silica had been prepared under acidic conditions either via the S+X−I+ pathway or with neutral templates, such as long chain amines or polyethyleneoxide based ones. This had already been described in the early publications on these materials18,22 Extraction of the Pluronic block copolymer surfactant, on the other hand, is more difficult, because the ethyleneoxide blocks are embedded in the silica walls and thus relatively tightly anchored there. Nevertheless, substantial removal of the P123 template was reported after extraction with ethanol-water 1 : 1 (in the same paper, for MCM-41 an ethanol/aqueous HCl mixture had been used).93

Reactive (i.e. oxidative) extraction is able to reduce the template content of different ordered mesoporous silica to very low levels, while retaining good textural properties and a high concentration of silanol groups. Tian et al.94 used microwave heating of SBA-15, SBA-16, FDU-1, or MCM-41 suspended in highly concentrated HNO3/H2O2 to degrade the surfactant to carbon contents below the detection limit of 0.3%, while essentially retaining the silanol groups of the as-synthesized material. A related version, but using reflux at 80 °C instead of microwave heating, was used to produce high-silanol group containing mesoporous silica to be used as hard templates.95

A direct comparison of different template removal methods (calcination, extraction with ethanol/HCl, and H2O2 treatment) from SBA-15 was recently provided by Barczak.96 It can be clearly observed that the properties of the resulting material with respect to porosity, surface area, and silanol content were rather different, with the calcination method resulting in a strong loss of silanol groups, while the two other methods resulted in high silanol concentrations, with the oxidative treatment even inducing a substantial increase as compared to the as-synthesized material.

Overall, if a silanol-rich pore surface is desired, either for more hydrophilic behaviour or subsequent functionalization, extraction or reactive extraction seem to be the better options for template removal. In addition, extractive methods are clearly preferable, if template should be removed from organically functionalized silicas obtained by co-condensation with organosilanes. While it may be possible to leave the incorporated or pending organic groups in or on the silica basically untouched by carefully adjusted calcination protocols,97 or a combination of short extraction and mild calcination, extraction is a more generally applicable method.

1.2.6. Surface modification

The surface properties of ordered mesoporous silica can be modified by the incorporation of inorganic species, or by grafting or incorporating various organic groups. However, while silica is physiologically not problematic, this does not hold for many metal ions which may be used to modify silica, and thus inorganic surface modification will not be discussed here; further discussion will focus on organic groups.

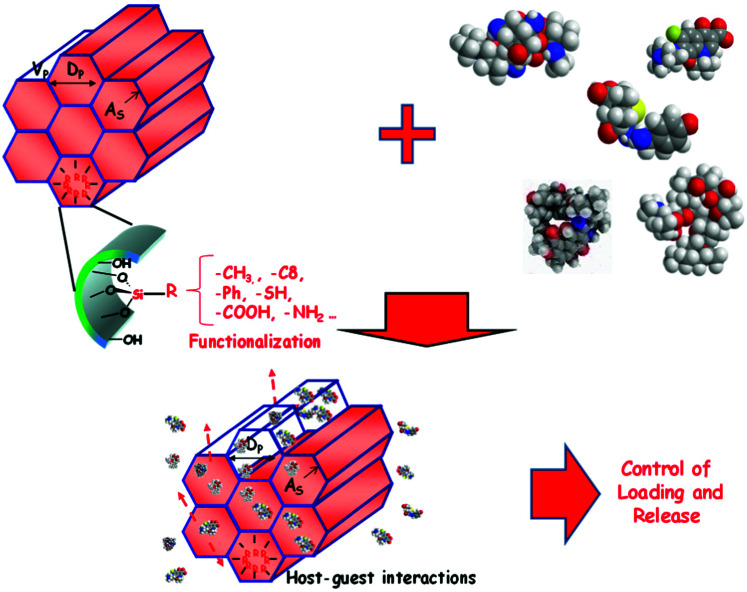

In the previous section, the different concentrations of silanol groups after using different ways to remove the surfactant template from the pores of ordered mesoporous silicas have already been discussed. This is of high relevance for the use of ordered mesoporous silicas as a drug delivery agent, since surface functionality is decisive for the interaction of potential drug molecules with the surface, and thus loadability and release kinetics of the drug. Surface properties already differ as a consequence of different silanol densities, but beyond the difference in silanol density surface properties can be adjusted by grafting of specific groups or co-condensation with functional silanes.98,99

There are different types of silanol groups on the surface of silica, i.e. isolated SiOH groups, geminal groups (two OH-groups on one silicon atom), and vicinal groups, (two OH-groups close enough to form a hydrogen bridge between them, normally on neighboring silicon atoms). The population of these silanols is temperature dependent.100 Hydroxylated amorphous silica has – basically independent of the source of the silica and the surface area – a silanol density of around 5 nm−2 of these groups, as has been shown in an extensive study by Zhuravlev, in which a high number of different silicas resulting from different syntheses and with widely differing surface areas had been analyzed.101,102 Incidentally, this number approximately agrees with the density of silicon atoms on the octahedral face of β-cristobalite,102 and thus appears to be in the right range. There are reports in the literature claiming higher concentrations up to 8 nm−2, and the deviations were at least partly explained by a possibly overestimated surface area in the work of Zhuravlev.103 Also other explanations for discrepancies of reported data are discussed in the literature.93 There is agreement in any case that thermal treatment – such as calcination – leads to a reduction of the silanol density, with the density being reduced to about half of the original value by vacuum treatment at 400 °C,102 and it is thus no surprise that ordered mesoporous silicas detemplated by different types of low temperature processes have higher silanol densities and are thus more hydrophilic than calcined samples.

There are indications that calcined MCM-41 shows heterogeneity of the silanol surface coverage.104 However, after extraction or calcination/re-hydroxylation by various methods, the surface properties seem to approach the situation of regular amorphous silica, with a silanol density of around 4.5 nm−2 for MCM-41.93 Silanol concentrations are reported to be somewhat higher for SBA-15 than for MCM-41, but this could be related to more pronounced degradation during re-hydroxylation of SBA-15, or to problems in determining precise values for surface areas in the micro-mesoporous SBA-15 compared to the purely mesoporous MCM-41. Ibuprofen sorption capacity also correlates with silanol density and thus hydrophilicity of MCM-41. Materials with densities between 4.2 SiOH nm−2 and 5 SiOH nm−2 were studied, and for the more hydroxylated material, the ibuprofen loading increased by about a factor of 1.5.105 Nevertheless, although general statements with respect to silanol density on the surface of ordered mesoporous silica are possible, as discussed above, exact values are dependent on the synthesis protocol and history of the materials, so that analysis of the used sample is required to obtain information on specific materials. If this is not possible or does not seem to be required, the value for hydroxylated silica of about 5 nm−2 seems to be a good approximation for most materials, based on the available data in the literature.

Surface modification by grafting

The silanols on the surface of silica are the reactive sites, which can be used for functionalization. The different types of silanol groups have different reactivity, with the isolated silanols normally being the most reactive ones. Another important factor is the accessibility of the groups, which is also a function of the size of the species to be grafted onto them.

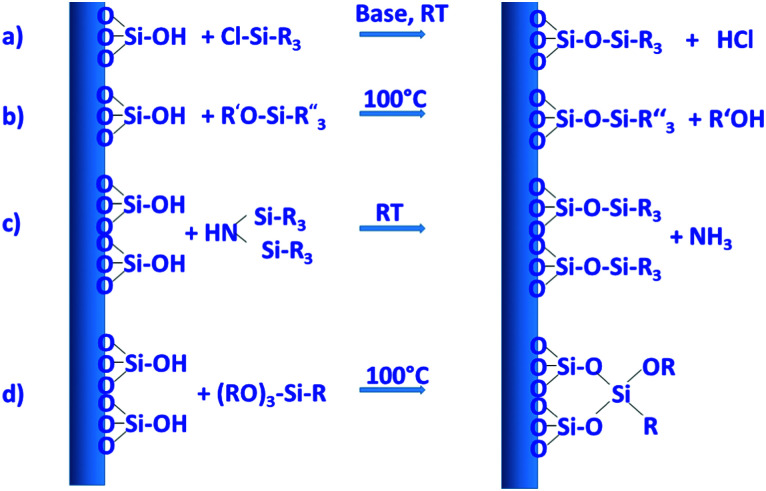

By far the most often used method for introducing different types of functional groups to the surface is the reaction with functional silanes. Functional silanes contain hydrolyzable groups, which react with the silanol groups of the surface to create a siloxane bond. Suitable precursors are chlorosilanes, alkoxysilanes, or disilazanes (Fig. 6), of which many derivates are commercially available. If controlled surface functionalization is desired, water needs to be excluded, so that the silanes only react with the surface silanol groups and not with water, which would lead to uncontrolled hydrolysis and potential (partial) self-condensation/oligomerization/polymerization of the silanes.100 Typically, silylation proceeds in organic solvents, but gas-phase silylation is an alternative, which works for reasonably volatile silanes.100 A very simple, fast, and convenient method, which was recently described, uses mechanochemical silylation.106 SBA-15 silica was mixed with silane and loaded into the jars of a shaker mill. After relatively mild milling for typically less than 10 min, surface functionalization was complete, for alkoxy- and chlorosilanes bearing different organic groups. No solvent or base are required for this functionalization route; hence it appears to be a convenient alternative.

Fig. 6. Important reactions with functional silanes for surface modification. Reactions mostly proceed in a solvent, water is typically excluded, because otherwise the silanization agents are hydrolyzed in an uncontrolled manner away from the surface. (a) Functional monochlorosilane, (b) functional monoalkoxysilane, (c) functional disilazane, silicon atoms in the disilazane can also be bridged via R-groups, and (d) functional trialkoxysilane, here attachment via one, two, or three siloxane bonds to the surface is possible, moreover, functional silanes can crosslink with themselves and thus produce oligomeric/polymeric surface-bound species. The example shown has one alkoxy group left for further crosslinking. As in general silicate chemistry, silicate species avoid edge or face sharing tetrahedra linked to each other.

Silylation with silanes bearing only one hydrolyzable group, with chlorotrimethylsilane as the prototype example, allows cleanest functionalization, since there is essentially no crosslinking between the grafted groups, and the surface functional groups reach a high density, because each silicon atom carries three such groups. On the other hand, only one siloxane bond needs to be broken to remove the grafted species, so that under conditions, where siloxane bonds are attacked, the functionalization may be lost, at least partly. Three hydrolyzable groups on the silane, such as, for instance, in trimethoxypropylsilane, may form a less defined organosiloxane polymer bound to the surface with different motifs; however, since the siloxane network is more extended and crosslinked, the functionalization can be more stable.

Several comparative studies have shown that silylation with hexamethyldisilazane is the most effective silanization method, reaching high degrees of functionalization under gentler silylation conditions. In each case, however, the reaction is strongly dependent on the chemical nature and steric requirements of the functional groups on the silane.107,108 The basic type of functionalization is just used to control the hydrophilic/hydrophobic surface properties by introducing nonpolar alkyl groups, in the simplest case methyl groups, but also longer alkyl chains can be used. Effectiveness of the silanization reaction is improved, if nucleophiles are present to promote the hydrolysis/condensation reactions.107 If silanes with functional groups beyond alkyl groups are grafted to the silica, the additional nucleophile might not be necessary, if the functional group itself provides the nucleophiles. This is the case, for instance, for aminopropyl-groups, which were often used to introduce basic functionality or to allow further modification.

Using these and related techniques, essentially any functional group can be anchored to the surface of silica. For modified silica to be used as drug release agents, especially introduction of acidic or basic surface groups, beyond adjustment of hydrophobicity, appears to be interesting, because this allows controlled interaction to adjust uptake and release properties. To create basic sites, the aminopropyl-group mentioned above is probably the most often used type of functional group, with 3-aminopropyltrimethoxysilane, due to its ready commercial availability and ease of use, being the most popular silane. Acidic sites are somewhat more difficult to generate. Silanol groups react directly with chlorosulfonic acid with the elimination of HCl to produce directly anchored sulfonic acid groups.109 However, a two-step pathway, first involving anchoring of a thiol group with a functional silane to the silanol group, followed by oxidation of the thiol to sulfonic acid, seems to be more often used to introduce acidic groups.109

The field of silica surface modification has been very well developed over more than 50 years, not only for the functionalization of ordered mesoporous silica, but for many types of silica, for instance to tailor materials for chromatography. More detailed information can be found in various, partly quite extensive, reviews.98,100,109,110

Co-condensation with functional silanes

The creation of organosilicas, i.e. silicas, in which silicon-carbon bonds exist, is also possible using one-step procedures, if silanes with corresponding moieties are used as silica precursors. Such functional silanes can be used for the synthesis of mesostructured silica without additional surfactants, if a condensable silane, for instance with trialkoxy-groups, contains also one long chain hydrocarbon, such as octadecyltrimethoxysilane. If such precursors are co-condensed with a tetraalkoxysilane, the silane with the long hydrocarbon chain acts as a porogen.111 However, for drug release applications, this is of little use, since the pore system is then occupied by the alkyl chains, which have to be removed by calcination, resulting in an essentially pure silica material without organic functionalization. More interesting for drug release applications are co-condensation synthesis protocols, where a functional silane with shorter organic groups is reacted with, for instance, TEOS in the presence of separate surfactant molecules, an approach, which had already been introduced in 1996,112,113 and many different functional groups can be incorporated via this pathway.114 For the prototypical MCM-41, but also for other materials, a fraction of functional silane of up to about 20% still results in the formation of well-developed mesostructures, depending on the nature of the organic group99,115 but the nature of the phase formed might change at high fractions of organoalkoxysilane.116 However, with organically bridged silsesquioxanes, it is possible to produce ordered mesoporous organosilicas (PMOs) with exclusively organically modified silicon atoms.29–31 Adjustment of the content of the functional silane and the nature of the pending organic groups allows fine control of the hydrophobicity of the materials.117

For co-condensation pathways, there is one feature, which seems to be little explored. The hydrolysis rates of organoalkoxysilanes substituted to different degrees with alkyl groups are very different: under basic conditions, the higher the level of substitution with alkyl groups, the slower the hydrolysis, which is the other way round under acidic conditions.118 It would be expected that this would lead to incorporation of organoalkoxysilanes into the framework formed at different stages of the synthesis, which could lead to inhomogeneity of the distribution of organic groups over the material, and thus could affect drug uptake and release properties. This effect, however, does not seem to have been studied in any detail as yet. The difference in accessibility of grafted and co-condensed surface groups, as reported by Rosenholm and Lindén,119 may be related to different reactivity of the silanes. Also in drug-release experiments, SBA-15 modified by co-condensation did not perform as well as similar materials obtained by grafting, which may again be related to the location of the functional groups.120

It had already been mentioned above, that ordered mesoporous materials containing exclusively silicon atoms bound to one carbon atom are accessible by the condensation of organically bridged siloxanes, such as bis(triethoxysilyl)ethane and related compounds, in the presence of surfactants. Such precursors can be used in co-condensation reactions with tetraalkoxysilane, but also as the sole silicon source. In such cases each silicon atom in the material is connected via an organic bridge to one other silicon atom. This means that not only the surface of the solids, but also the bulk within the walls is exclusively organically modified, often resulting in a higher hydrothermal stability. Under well controlled conditions and using bis(triethoxysilyl)benzene as a precursor, it is even possible to synthesize ordered mesoporous silica with a crystalline order within the walls, achieved by benzene stacking.121 Generally, the synthesis proceeds as that for purely siliceous ordered mesoporous silica. The surfactant and either base or acid are added to water or water mixed with other solvents, often alcohols; as a next step, the organically bridged silane (pure or as mixtures) is added and the reaction system reacted at a given temperature for a duration of typically several hours. The solid is recovered and the surfactant template is removed, mostly by extraction, but due to the high thermal stability of Si–C bonds and selected organic bridges, in specific cases, using carefully established protocols, also calcination may be possible to at least partially remove the surfactant, while retaining the organic groups in the framework.122,123

PMOs have not been as extensively studied for use in drug delivery as their pure silica counterparts (possibly modified with pending organic groups). This has been attributed to the more difficult synthesis of uniform and discrete PMO nanoparticles (NPs) with adjustable properties on the one hand, and lack of information on bio-safety of PMO nanoparticles on the other.124 However, in principle, they have favourable properties, such as the adjustable hydrophobicity and the possibility to control biodegradability. This has been extensively covered in excellent recent reviews.124–126 Degradation of PMOs with inert bridging groups in water or simulated body fluids, such as ethane or benzene, was found to be remarkably slower than that of pure silica NPs, which was attributed to the high hydrophobicity and the more stable Si–O-bonds in silsesquioxanes.125 This higher stability, however, can be modified, if organic groups, which can be cleaved enzymatically or via redox reactions, are incorporated in the PMO framework. This is treated in depth in ref. 125. The overall degradation is then a complex interplay between the decomposition of the organic groups and the remaining silica framework.

Moreover, co-condensation of organically bridged silsesquioxanes with alkoxysilanes or alkylalkoxysilanes creates materials with organic functional groups in the bulk of the material, possibly pending organic groups, and silanol groups, which can be further modified by different surface groups. Thus, bi- or trifunctionalized materials, comprehensively covered in ref. 124, are accessible, which broadens the scope of such materials even more. Due to these additional possibilities, it can be expected that PMOs will play a more important role in the field of drug delivery in the years to come.

1.3. Synthesis of mesoporous silica nanoparticles

The sections above mainly dealt with the adjustment of the mesostructures and the control of the surface chemistry of ordered mesoporous silica. However, for use in biomedical applications, the morphology of the individual particles is of high importance. While in the early days of research on ordered mesoporous silica the morphology was more or less accepted as obtained from a particular synthesis protocol, it is not sufficient anymore for a number of advanced applications. For drug delivery purposes the drug carrier particles need to be isolated and in the size range of around 10 nm to approximately a few hundred nanometers.126,127

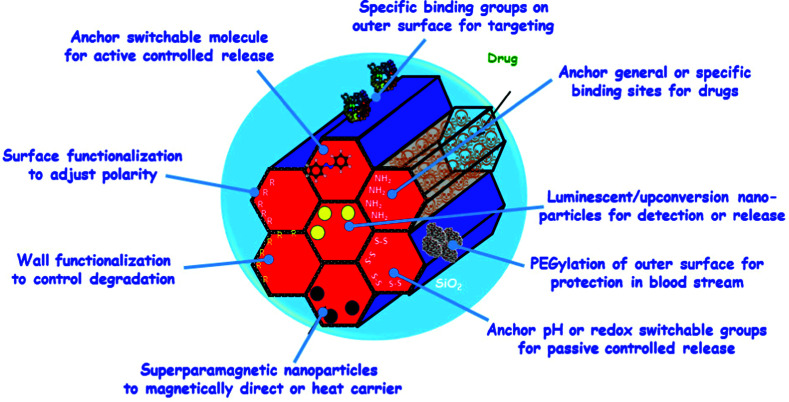

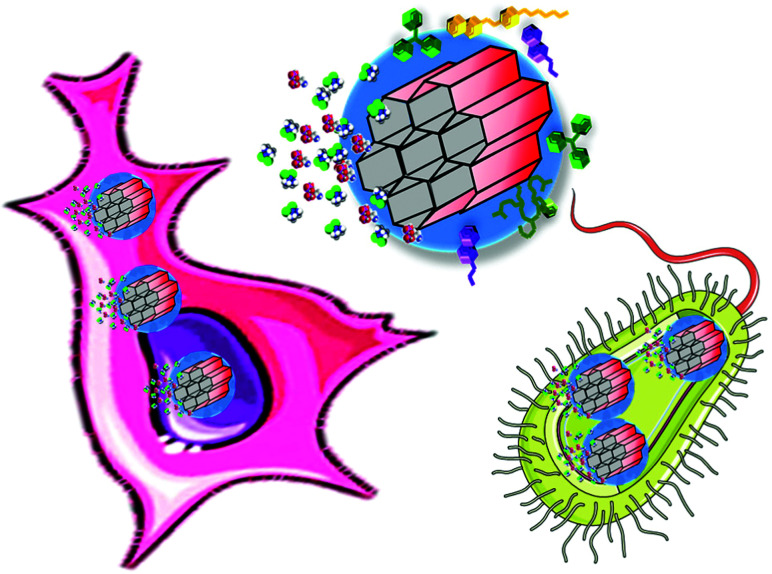

The excellent textural properties of mesoporous silica materials together with their ability to be used in drug delivery technology inspired the rapid translation from bulk to the nanoscale dimension. The reason that fueled this transition to the nanoscale could be found in the unique physicochemical properties that mesoporous nanoparticles could offer to drug delivery technologies. Among them, we like to highlight their great pharmacokinetic profile, the improved drug stability and solubility, and their outstanding control over the timing and location of the therapeutic release, which would contribute to reduce the potential toxicity of the therapeutic agent.

In the race of developing mesoporous silica nanoparticles for drug delivery technologies, the contribution of Victor Lin should be highlighted. Even though Prof. Lin passed away in 2010 at the age of 43,128 his seminal contributions were essential for the development and applications of mesoporous silica nanoparticles, a term that he coined to illustrate nanoparticles made of mesoporous silica with a well-defined and controllable morphology.129–132 He was also able to demonstrate the possibilities of MSNs through their application in a variety of different scientific areas, such as heterogeneous catalysis,133 renewable energy,134 biosensing135 and nanomedicine,136,137 among others.

However, strictly speaking, Stöber was the real pioneer in developing the synthesis of spherical monodisperse micron size silica particles.137 Since then, many modifications have been made to the so-called Stöber method to yield many different types of monodispersed mesoporous nanosized silica particles. The reason for such popularity relies on the fact that manipulating the reaction parameters might result in materials with different morphologies (such as films, fibers, monoliths or particles) and sizes (macro, micro or nano-particles). In this sense, the first time that the Stöber method was modified towards the production of mesoporous silica particles was carried out by Grün et al., when they introduced a cationic surfactant to produce micrometer spheres of ordered mesoporous oxide MCM-41-like particles.138 Then, nano-sized mesoporous silica particles were reported by the research teams of Cai,139 Mann140 and Ostafin.141 And then, Victor Lin was the one who popularized the term MSNs referring to mesoporous silica nanoparticles.130 Since then, MSNs with a variety of morphologies, dimensions, pore sizes and pore structure have been explored by many different research groups. The conventional synthesis of MSNs is performed at low surfactant concentration to force the assembly of the ordered mesophases to depend on the interaction between the cationic surfactant and the growing anionic oligomers of the silica precursor, which in turn restraint the assembly of mesophases to small sizes. Once the reaction is complete, the organic surfactant is removed by either solvent extraction or calcination and the silica particles might be isolated. However, the synthesis conditions of MSNs can be modified in different aspects, such as the pH of the reaction mixture, the type of surfactants or copolymers employed as structure directing agents, or the concentrations and different types of silica precursors. There are outstanding reviews in the literature where the principles of the different synthetic methods employed for the formation of various MSNs are introduced and explained, together with their influence on the final properties.38,127,142–145

There are several reasons, why for drug delivery applications NPs should be used – although MSNs have not been approved by the US Food and Drug Administration for medical applications, yet.127 Such nanoparticles are isolated and can be made colloidally stable, which is crucial when a preparation for medical applications should be stored without settling of the solid fraction. The payload in porous silica NPs can be made high, if porosity is high, the surface can be functionalized almost at will by the methods discussed above, and with proper synthetic protocols, the size can be adjusted to pass certain barriers in the body.126 As compared to bigger particles, NPs are more easily degraded and can thus leave the body faster. Biodegradability can be tuned over rather wide margins, so that release rates can be adjusted (although degradation of the carrier is not the only release mechanism).125,127 The final degradation product of the silica moiety of the drug carrier is silicic acid, which is physiologically unproblematic and has thus been considered safe by the US FDA for 50 years.126

Due to the high interest in MSNs and organosilicas, there is a vast number of review articles. These can certainly not all be listed here, since as of 2017 approximately 350 such review papers were identified.126 However, several of these more recent reviews shall be highlighted here, since they are particularly useful and relevant in the field of drug delivery vectors. Some of these originate from the group of one of the authors of this review. In ref. 127, the field is broadly covered, while ref. 146, updated four years later147 is focused on stimuli responsive drug delivery systems. Ref. 124 specifically covers organosilica nanoparticles for biomedical applications. Möller and Bein give an overview with an emphasis of different aspects of the synthesis and application of silica nanoparticles, amongst others for use in medicine.148 Ref. 149 treats various types of silica NPs for biomedical applications, and MSNs are placed in this context. Sun et al. treat different methods and describe in detail influential factors to control the morphology of mesoporous silica, not only to produce NPs, but also other morphologies.150 Croissant et al. provide broad coverage of biosafety and degradation of MSNs.125,126 Two reviews from the group of Lindén address the medical applications with respect to materials properties and also discuss biodistribution and safety.151,152 As stated above, this list falls very short of being complete, even with respect to review papers only. However, it allows access to the literature on this field from rather different angles, all with relevance to biomedical applications.

The most versatile method for the synthesis of ordered mesoporous silica combines two well-known approaches in silica chemistry, i.e. the so-called Stöber-method for the synthesis of monodisperse silica spheres with sizes in the low hundred nanometer size range, and templating of mesopores by different types of surfactants, as discussed extensively in the previous sections. The versatility of the synthesis of monodisperse, sub-μm sized silica spheres was described in a publication in 1968,153 based on earlier observations of Kolbe.154 The key element of the Stöber-synthesis is the addition of an alkoxysilane (mostly tetraethoxysilane is used) to an ammonia solution (mostly in ethanol/water with excess ethanol, but other solvent systems are also possible) under agitation at relatively high dilution. This results in the formation of solid monodisperse silica spheres with sizes typically in the range of 100–400 μm, but systems producing spheres somewhat outside of this range are also known. The key ingredient, which induces the formation of monodisperse spheres, is ammonia (ethanolamine and basic amino acids are alternatives), and thus the Stöber method typically proceeds under alkaline conditions. While the Stöber synthesis in the first decades after its description was only known to experts, it became highly popular for various applications around 2000, which recently led Ghimire and Jaroniec to speak about a renaissance of the method in a very useful recent review on this synthesis.155 The synthesis is well established, and a hands-on guide for the synthesis of solid and porous Stöber-type spheres can be found in a methods and protocols paper, which focuses on hollow spheres, but contains much useful information also on the regular Stöber-process.156 Giesche described in detail the precise adjustment of particle sizes by a seeded growth process, with control of sizes between about 20 nm and 3.5 μm; moreover, description of a continuous synthesis is included as well.157