Abstract

This study aims to review the concept of constructability and evaluate the level of implementation of constructability practices in the construction industry in Muscat Governorate. One hundred and ninety questionnaires were distributed, and 85 complete responses were received, including 10 from owners (12%), 64 from consultants (75%) and 11 from the contractors (13%). The results showed that owners, consultants, and contractors recognize, support, and practice constructability efforts. 45% of the respondents said that constructability efforts typically begin in preconstruction planning, which shows a positive awareness that constructability efforts must start at the earliest stage of a project’s life cycle. In addition, 60% of the respondents indicated that they performed constructability by following a constructability procedure during the design stage. All the respondents agreed that constructability implementation obstacles continued to exist in construction projects in Muscat and the cost and time associated with the implementation of constructability review practices are the most dominant obstacles. Although constructability has been recognized in Muscat’s construction industry, the level of constructability awareness and improvement in cost and time estimation and quality requirements are developing.

Keywords: Constructability, Construction project, Buildability, CII, Muscat, Oman

Introduction

The construction industry in Oman is continuously growing. It contributes to almost 10% of Oman’s gross domestic product (GDP) (Santo, 2019). In addition, the construction industry is the country’s largest employer (Santo, 2019). It is predicted that the Compound Annual Growth Rate (CAGR) of the construction will be around 6% over the forecast period, 2019–2024 (Santo, 2019). With the development of this sector, many strategies and tools were developed and enhanced over time to ensure a successful project adhering to cost, time, and quality constraints. According to Alnuaimi and Al Mohsin (2013), the delay in construction projects in Oman from 2007 to 2009 was approximately 60%. It was also found that the maximum delay was around 300%. Alnuaimi and Al Mohsin (2013) specified several reasons for the delay caused in the construction projects in Oman, one of which related to the planning and construction work. The delay in the construction project can be due to many reasons, but the concept of constructability can be a significant key to reducing the percentage of the project’s delay.

Time and cost overruns create conflicts with the stakeholders (Al Alawi, 2021; Latif et al., 2019). Investigating alternative methods to enhance the project’s performance and preclude time and cost overruns to improve construction project performance is essential. The Business Roundtable discussion organized by the Construction Industry Institute stated that the owners could not see the available opportunities related to cost and time reduction. As such, by introducing new construction methodologies and integrating them into the project’s different phases, such as planning, design, and engineering (Construction Industry Institute, 1993; Ding et al., 2020). For example, applying “Constructability” can save 10–20% of the project’s total cost (Contrada et al., 2019).

Constructability is a technique that can enhance project performance when fully implemented (Anderson et al., 2000; Othman, 2011). The degree of implementation of constructability in construction projects is different from one project. The stakeholders’ awareness of constructability benefits controls the maturity of constructability implementation. Although some research has proved the benefits of constructability, the degree of maturity of constructability practices is still low in some countries (Nima et al., 2001). One of many reasons is the difficulty of getting all stakeholders (i.e., owner, Consultant, and contractor) in one table from the early beginning of the project life cycle (Al Alawi et al., 2015). With the previously mentioned issues in the construction industry in Oman, it is essential to highlight the constructability practices in the construction industry in Oman. Introducing such concepts into the construction industry aims to improve the industry, minimize the issues related to cost and time overruns, and improve quality. Therefore, this study aims to explore the implementation of constructability practices in the construction industry in Muscat, Oman.

Background

Constructability and buildability

Construction Industry Institute (CII) (1986) defined constructability as “the optimum use of construction knowledge and experience in the conceptual planning, detailed engineering, procurement and field operations phases to achieve the overall project objective”. According to the Institution of Professional Engineers New Zealand (IPENZ) (2008), “constructability is a project management technique for reviewing construction processes from start to finish during the preconstruction phase. It will identify obstacles before a project is built to reduce or prevent errors, delays and cost overruns”.

Construction Industry Research and Information Association (CIRIA) (1983) defined buildability as “the extent to which the design of a building facilitates ease of construction, subject to the overall requirements for the completed building”. Wong et al. (2007) defined buildability as “the extent to which a building design facilitates efficient use of construction resources and enhances the ease and safety of construction on site while the client’s requirements are met”. Building and Construction Authority (2017) claims that buildability is “the extent to which the design of a building facilitates ease of construction and the extent to which the adoption of construction techniques and processes affects the productivity level of building works”.

Looking at the various definitions of constructability and buildability, it should be illustrated that some keywords are associated with the mentioned definitions of constructability, such as “integration of construction knowledge/expertise” and “optimum use of construction knowledge and experience”. In contrast to buildability, “ease of construction” is the most frequent keyword in the definitions. Although constructability and buildability can be used interchangeably, minor differences exist between the two terms. Researchers concluded that constructability concerns management functions and systems, and it has a broader scope than the buildability term. As for the buildability term, researchers found that the term is related more specifically to the design (Shaik Hussein et al., 2011).

Benefits of constructability enhancement and improvement

Figure 1 shows the framework to measure the constructability benefits as per Russel et al. (1994). The parameters indicated in the figure reflect the measurement of constructability benefits in construction projects. As shown in the figure, the constructability benefits can be either quantitative or qualitative. The quantitative project performance is measured by comparing the actual project performance with the project plan. The parameters are measured on a scale of 1 to 6, with one being very poor (15% over budget) and six excellent (15% under the budget).

Fig. 1.

Framework for determining constructability benefits (Russel et al., 1994)

At the start, the benefits of the enhanced constructability are often confirmed in terms of cost savings. Hence, it was predicted that good constructability would eventually produce benefits of almost 20 times the cost of accomplishing it. In addition, other studies, such as Anderson et al. (2000) and Acker (2003), have stated that with the inclusion of construction suggestions and knowledge into the design stage, the reserved cost was estimated to be between 1 and 15% of the capital cost. The authors also claimed that with the lower bidding price, the number of site labor was reduced, the cost-effectiveness increased, and resource utilizations improved.

More studies showed that the inclusion of constructability concepts throughout the project stages resulted in benefits related to time, quality, cost, the decrease of unanticipated difficulties, improvements in labor relations, teamwork, and communication, as well as an increase in both client and employee satisfaction and loyalty, alongside with the development of friendly working relationships among stakeholders (Elgohary et al., 2003; Pheng Low, 2001). The benefit associated with time was the early completion of a project. Implementation of constructability concepts increased productivity. Not only that, but the project’s total duration also decreased whenever constructability implementation was introduced earlier in the project stages. Furthermore, the quality of the end product increased. As for safety in the workplace, implementing constructability resulted in a safer environment on-site and better safety performance (Low & Abeyegoonasekera, 2001).

According to Lam (2002) and Pheng Low (2001), the three most generally used methods are quantified design evaluation, constructability review, and implementation of constructability programs. Singapore’s Buildable Design Appraisal System uses a quantitative method to assess, requiring a minimum constructability performance as a prerequisite for building plan approval.

The benefits of the constructability evaluation process extend to the entire project, not just the construction phase. It may improve conceptual planning, procurement processes, and building methods and include stakeholders in decision-making to meet their needs (Griffith & Sidwell, 2000). According to Douglas and Gransberg (2009), the constructability technique aims to pinpoint the following:

A flaw in the design process, such as measurements or material choices.

The project’s challenging specification or its hefty construction costs.

Project characteristics that are beyond the construction process’s capabilities to adequately implement.

Not easily understood project aspects that are difficult to bid for accurately.

Arditi et al. (2002) have identified some benefits related to design firms when constructability concepts are applied to a construction project. It was found that developing better relationships with clients and contractors had the highest ranking among five other benefits. Bakti and Trigunarsyah (2003) discussed a case study related to constructability implementation at a corporate level. A case study was conducted at an Indonesian construction firm that uses the design-build project delivery technique for industrial plant projects. The purpose of the case study was to look in-depth at constructability and to focus on the implementation of constructability in the planning and design stages at the corporate level. The study was carried out mainly to study the associated benefits of implementing constructability, identify the challenges and the barriers that could prevent the implementation of constructability, and provide recommendations about implementing constructability that is believed to improve the process. The study’s main result was that implementing constructability during the phases of planning and designing improved the project’s performance, especially the schedule of the project, as it was the most influenced factor. In addition, the constructability implementation in planning and the design phase can increase project performance. Moreover, the study supported that implementing the lessons learned from previous similar projects had a significant effect on improved project performance.

In addition, Motsa et al. (2008) has identified and rated the significant benefits behind implementing constructability in his study, which initially looked into finding the benefits of implementing constructability in the design phase. The better design was found to be the highest ranked benefit of implementing constructability. Garcia (2009) studied the benefits of a project’s schedule and the cost gained by implementing constructability. It was found that constructability has a medium impact on schedule reduction and has a low to medium impact on cost savings when the owners are concerned. Since the owner finances the project, they shall be pleased to see constructability applied to reduce cost and execution time.

Othman (2011) has highlighted some benefits of applying constructability throughout the project’s life span. He emphasized the importance of incorporating constructability early in the design process and regarded it as a critical rule throughout the entire building process. Contractors can help reduce construction waste and improve building performance during the design stage by using their construction knowledge and experience. Oludare and Olugboyega (2016) conducted a study to measure the concepts of constructability and enhancement of constructability within site team members in Nigeria. They found that the inclusion of a project construction plan improves constructability.

Kordestani et al. (2017) carried out a systematic literature review on the studies that investigated the benefits of implementing constructability, operability, and maintainability in the construction industry. The main result was that implementation of the constructability, operability, and maintainability had increased rapidly over the years, indicating awareness among the professional community in the construction industry.

Al Mussad (2018) introduced the benefits of implementing constructability in the Saudi Construction Projects. The findings showed a 40% reduction in change order values. In private sector projects, the baseline percentage of change orders value to the total projects value is 24.94% for projects that do not implement constructability; this is reduced to 15.24% after adopting constructability. As for the schedule benefits, the optimisation of the schedule occurred when the constructability concepts were implemented as early as possible in the construction projects. Both private and government sectors claimed that the schedule optimizations are around 20% when implemented in the conceptual planning phase. On the other hand, the schedule optimisation during the construction phase, when constructability concepts are implemented at the construction phase, is approximately 8% only. As for the cost, the author indicated that implementing the constructability concept in the early stages can save some amount of the total cost as many unexpected issues can be sorted out from the start of the project, which means reducing the risk of not incorporating any issues that can occur later on the project’s life cycle.

Construction Industry Institute (CII) (2019) claimed that considering constructability during project development and implementation improved cost and schedule performance by about 6% and 7%, respectively. The organization also added that in terms of value addition, due to constructability reviews, the cost–benefit ratio increased to a range of 1:10. Gil et al. (2020) showed the benefits of implementing constructability on the project’s schedule and cost whenever the contractor is considered. It was found that implementing constructability throughout the project’s life cycle decreased the schedule of the project with a considerably high impact on schedule reduction. The same is to be said for the project’s cost, as the impact of constructability on the project cost was a quite high, which reduced the price allocated for the project.

Methodology

The study aims to explore and identify the implementation of constructability in the construction sector in Muscat. Pocock et al. (2006) proposed survey questions were adopted in this study. Members of the Constructability Committee of the Construction Industry Institute (CII) drafted the survey questions. The survey questions intended to assess the state of constructability practices in the United States. Further, the nature of the questions is not country-specific; instead, it is concept-specific. Therefore, it is possible to use these questions in the context of the Oman construction industry. In addition, using the same questions will allow a comparison between the outcomes from the Oman construction industry with results generated from the United States. Table 1 shows the list of the questions.

Table 1.

Best of practices survey questions

| No | Questions |

|---|---|

| 1 | For this survey, constructability is defined as “the integration of construction knowledge and experience in the planning, design, procurement, and construction phases of projects consistent with overall project objectives” |

| 2 | Which of the following best describes your role in the design/construction process? (Owner; owner’s representative; architect; engineer; consultant working primarily in design; construction contractor; subcontractor working primarily in construction; or construction manager |

| 3 | During which project phase do constructability efforts typically begin? (Pre-project planning; conceptual design; detailed design; contract award; construction; or other—please briefly describe) |

| 4 | During design, what mechanisms are most commonly used to address constructability on your projects? Check all that apply. (None; peer reviews; follow the CSI’s manual of practice; design review by construction expert; a constructability review activity on your project schedule; construction expert on the design team; implement database or checklist to avoid common construction errors; and other—please briefly describe) |

| 5 | During construction, what mechanisms are most commonly used to address constructability on your projects? Check all that apply. (None; apply innovative construction means and methods; pre-task planning; incorporate construction expert into preconstruction planning; coordinating construction trades; hire a consultant; apply appropriate construction means and methods; or other—please briefly describe) |

| 6 | For the forms(s) of constructability you selected above, who usually performs this role? Check all that apply. (Owner; owner’s representative; architect; engineer; consultant working primarily in design; contractor; construction manager subcontractor working primarily in construction; or construction manager.) |

| 7 | For the forms(s) of constructability you selected above, who usually requires constructability? Check all that apply. (Owner; owner’s representative; architect; engineer; consultant working primarily in design; contractor; construction manager subcontractor working primarily in construction; or construction manager.) |

| 8 | What are the major benefits of implementing constructability? Check all that apply. (Enhances project quality; reduces project duration; reduces project cost; enhances partnering and trust among project team; increases owner satisfaction; minimizes contract change orders and disputes; or other-please briefly describe) |

| 9 | What problems in construction that you observe could be prevented by improved constructability? (Please type your answer) |

| 10 | What are the major obstacles to implementing constructability? Check all that apply. (Project delivery methods (e.g., design-bid-build); contract type; not enough resources; lack of adequate construction experience; it is currently not part of the process; too costly; lengthens the project; lack of open communication between designers and constructors; difficulty in coordinating disciplines; or other—please briefly describe) |

The questions start by first assessing the definition of constructability. As per “Background”, the concept of constructability has different meanings, driven by the understanding of practicing engineers. Therefore, it is essential to assess industry knowledge about constructability because identifying the gap in knowledge of this area can help propose solutions or plans for improvement. The rest of the questions centered upon asking about:

the mechanism of constructability, who performs or requires it;

when constructability efforts should start;

what constructability methods were used;

the benefits of practicing constructability; and

the problems and obstacles hindering the best practices of constructability.

The survey questions were developed using Google Form. The form was distributed using emails, social media applications, and personally handing over hard copies to engineering offices. The third method was not successful due to COVID-19 implications; however, phone call interviews were used to ease the process of collecting the data. The survey questions were distributed to stakeholders who have been involved in construction projects, such as clients, engineers, contractors, and architects. The estimated sample size (n) was calculated using the following equation:

| 1 |

where n is the estimated sample size; N is the population; is the percentile of normal distribution; is the confidence interval; is the margin error; is the population proportions.

Using a total population of 190 of engineering offices in Muscat and using the Z of 1.96, 0.95 confidence level, marginal error of 0.05 and the population proportions of 0.25, and the estimated sample size of the study was found to be 128. The results were presented in percentages and graphically illustrated in the results.

Results

Eighty-five participants out of the 128 targeted sample size were involved in completing the survey and their complete answers were presented. Although the questionnaire survey was distributed to engineering offices, some of the received data represented contractors and clients. Thankfully, we realized that some of the engineering consultant offices had asked some of the contractors and clients to participate in the study. Therefore, the 85 participants in the survey represented project owners, consultants, and contractors in Muscat. The collected data were divided into three groups (Client/Owner, Consultant, and Contractor); see Fig. 2, and the Engineering Consultant Offices represent 75% of the total responses.

Fig. 2.

Representative groups of the respondents

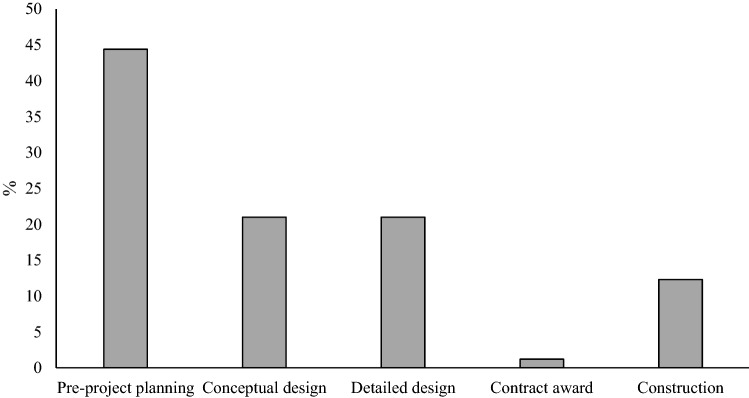

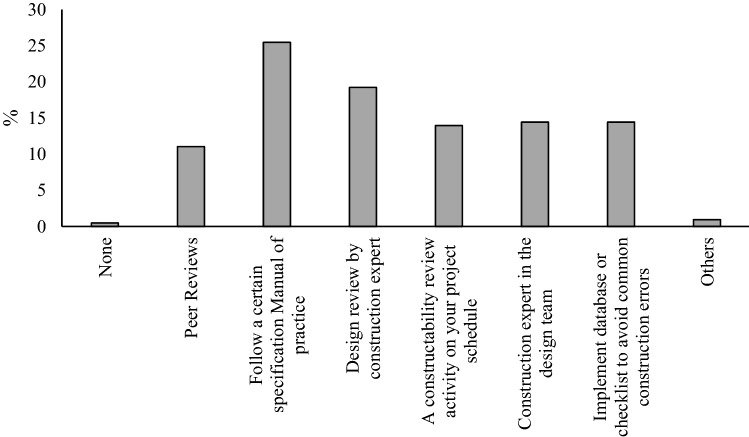

Figure 3 shows the project phases at which constructability efforts should start. 86% of the respondents believe that constructability should be practiced in the pre-contract stage (pre-project planning, conceptual design, and detailed design stages). The respondents were also asked what constructability mechanisms could be used during the design stage. Following a certain specification manual of constructability practice was the preferable mechanism followed by a design review by a construction expert. Reviewing constructability, employing a construction expert during the design and using a design review checklist to avoid common omissions during construction were of equivalent weight.

Fig. 3.

The project phases at which constructability efforts should start in

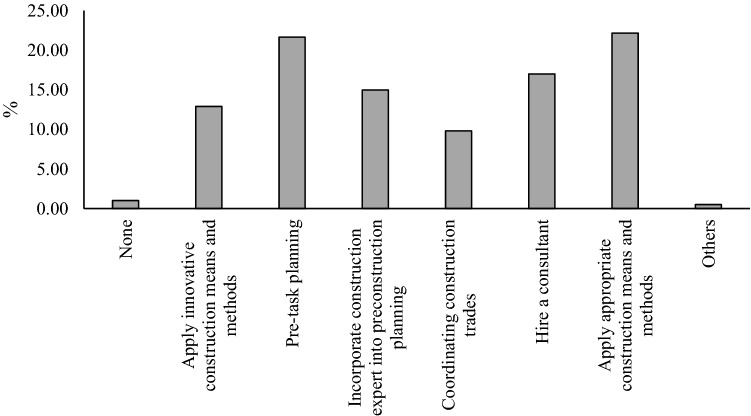

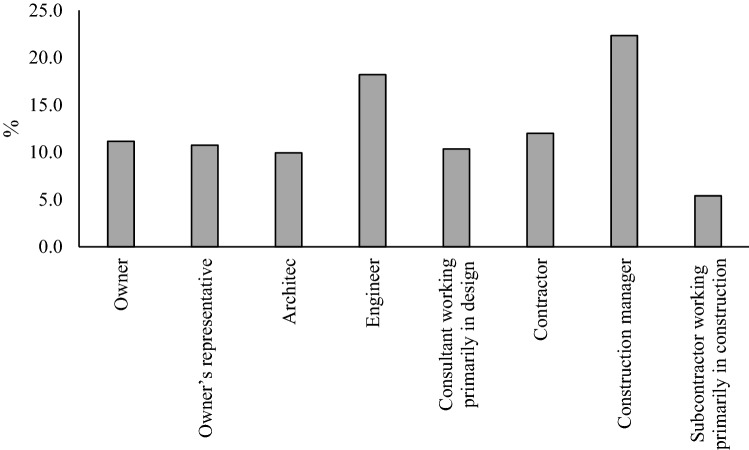

Figure 4 shows the findings of which constructability mechanism is most used during the project’s construction phase. Applying appropriate construction means and methods and applying pre-task planning are the most constructability practices used during construction, followed by applying innovative construction methods and utilization of construction engineering experts’ knowledge during the preconstruction planning. Figure 5 identifies who should perform constructability. The majority of the respondents think that construction managers and engineers are the ones who should handle the constructability review of a project. Surprisingly, the respondents believe that the owner should have a specific role in constructability review. It does not mean that the project client should review the project himself, but he should hire someone to perform the constructability review for his project.

Fig. 4.

Constructability mechanisms during construction phase

Fig. 5.

Who performs constructability as per the respondents?

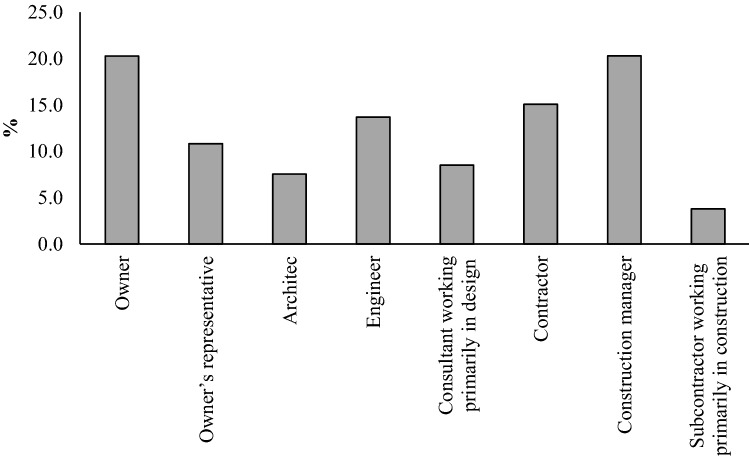

Figure 6 shows what are the necessary needs for constructability. The respondents’ results show that most stakeholders require constructability for the owner and the construction managers. However, it is essential to highlight that usually the owners of the contractors hire construction managers to perform constructability reviews. The construction managers provide constructability services as required by the other project stakeholders.

Fig. 6.

Who requires constructability as per the respondents?

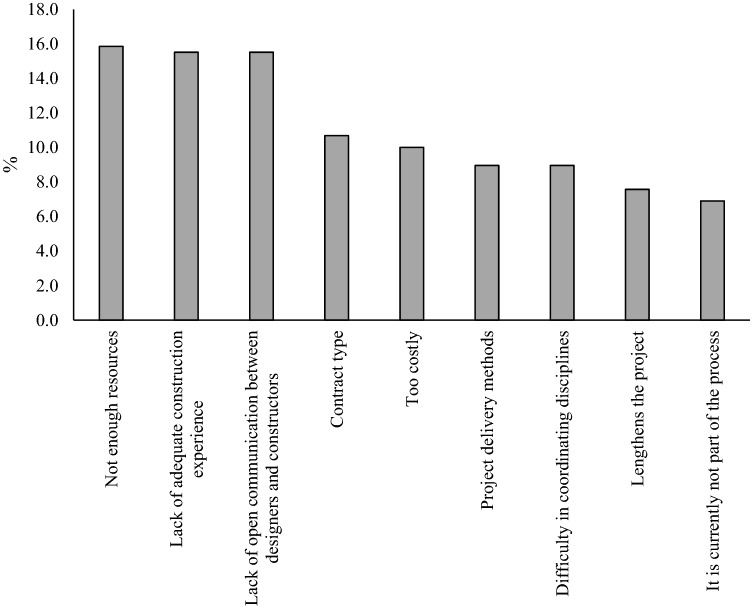

Table 2 shows the barriers to the implementation of constructability. Cost and the time (written as “Delay”) associated with implementing constructability are the main barriers. Figure 7, on the other hand, identifies the obstacles/challenges related to implementing constructability practices. The most challenging obstacles are the lack of resources, adequate construction experience, and proper communication between the designers and contractors. The other factors showed almost similar weight.

Table 2.

Barriers to constructability implementation

| Problem | % of respondents (%) |

|---|---|

| Frequent changes | 24 |

| Delays | 30 |

| Cost overruns | 32 |

| Implementation issues | 5 |

| Design errors | 17 |

| Professionalism of the work | 5 |

| Lack of experience | 4 |

| Performance | 3 |

| Poor quality | 4 |

| Poor communication | 6 |

| Material waste | 4 |

| Repeated problems | 4 |

| Poor planning | 18 |

| Trade coordination | 2 |

| Safety | 7 |

Fig. 7.

Constructability obstacles identified by the respondents

Discussion of results

Constructability definition

As for the survey’s first question, the respondents were given the CII definition of constructability. The respondents’ opinions and suggested improvements were invited on the definition of constructability. CII defined constructability in 1986 as “the optimum use of construction knowledge and experience in planning, design, procurement, and field operations to achieve overall project objectives” (CII, 1986). In 1991, the ASCE Construction Division’s Construction Management Committee declared that “constructability is the ability to be constructed.” A constructability program is the application of a disciplined, systematic optimization of the construction-related aspects of a project by knowledgeable, experienced construction personnel who are part of a project team during the planning, design, procurement, construction, test, and start-up phases. The program aims to improve the project’s overall goals (ASCE, 1991).

For the survey, the respondents were offered a definition that covers those used by the CII and ASCE: “Constructability is the integration of construction knowledge and experience in the planning, design, procurement, and construction phases of projects consistent with overall project objectives.” Those taking the survey were asked, “If you do not agree with the definition, how would you change it?” Forty-seven responses were recorded, with most participants agreeing with the definition, but seven respondents offered comments on changing or improving it. These included the following:

“Constructability includes project pre-management and review of entire construction processes before starting the project “.

“Constructability is the effective and timely integration of construction knowledge into the conceptual planning, design, construction, and field operations of a project to achieve the overall project objectives in the best possible time and accuracy at the most cost-effective levels with no compromise of quality and safety “.

“Constructability implies that something is in kit form and may realistically be assembled or constructed. So, a design may have fantastic features, but its ‘constructability’ would be low or limited if it were challenging to construct, even once”.

“Constructability is a technique that uses the knowledge and construction experience in planning, engineering, procurement, and field operations to achieve the overall objectives”.

“Material availability at market and site location can be added to the definition since the constructability implementation begins with site selection “.

“Constructability means doable from all prospects (design, economics, socially and environmental) “.

“Implementation of constructability is involved in the stages of construction from the first step to the last step”.

Although only 47 responses were recorded out of 85 replies for this question, it is assumed that other than the 7 participants that presented a change or improvement to the definition, the majority agree with the definition provided. This is because usually, not writing or suggesting improvements means the definition is complete, and those participants agree.

Constructability efforts against project phases

The second question is enquiring about the role of the respondent. In this study, most of the participants are engineers, with a percentage of 60% of the total number of respondents. Figure 3 also indicates that all the roles shown in the study apply to the different roles of the participants that took part in this study. It is an advantage to have this study considered by different people with different roles. Hence, the study results are expected to cover the aspects to constructability from a different point of view.

The first survey question about constructability practice was the third question in the survey: “During which project phase do constructability efforts typically begin?”.

ASCE’s constructability White Paper (ASCE Construction Division, 1991) stated the standard for ideal constructability: “The maximum benefits to be derived will result when the people with construction knowledge and experience become involved at the beginning of a project.”

Figure 3 shows the responses, in terms of percentage, regarding the first question, which looks into the project’s phase where constructability effort typically begins. It can be seen that almost 44.4% of the respondents believe that constructability is preferable to be implemented during the pre-project planning phase. The survey results are encouraging and promising as they indicate that constructability is best started as early as possible in the project life cycle. Looking at the stages before the construction phase, the majority said that the constructability effort typically begins before the construction phase, 44.4% pre-project planning, 21% conceptual design, and 21% detailed design. On the other hand, only 1.2% answered that constructability effort should begin at the contract award phase, 12% believe constructability should start during construction. This question shows that the efforts of constructability can be applied during any project’s phase, although the best practice would be to start the efforts in the earliest stage of a project. Hence, even if the constructability efforts began in later phases of the project, according to the respondents, the issues found in the project can be minimized and reduced by the implementation of constructability.

Constructability mechanisms

Question four in the survey concerned the mechanisms implemented in the design phase to address constructability in different projects. The question was, “during design, what mechanisms are most commonly used to address constructability on your project?”. It can be seen from Fig. 8 that, according to the participants, the most mechanism used to address constructability during the design phase is following a certain specification manual of practice, representing almost 25.5%. That indicates the use of certain specification manuals during the design phase and therefore ensures the proper implementation of the manual specifications into the design of a certain project. The second used mechanism as per the respondents is design review by construction experts with a percentage of 19.2%. In addition, the three mechanisms were almost the same in terms of the used mechanisms to address constructability during the design phase. These are constructability review activity on the project schedule (13.9%), construction expert in the design team (14.4%), and Implementing database and checklist to avoid common construction errors (14.4%). After that, the peer review mechanism, with a percentage of 11%, was the least used mechanism among the suggested mechanisms. This mechanism can be known as having another professional design review the design team’s work, usually as design milestones are completed. Finally, only three respondents either stated that there are no constructability mechanisms used to address constructability or selected the other option without specifying what those mechanisms are.

Fig. 8.

Constructability mechanisms during design phase

A constructability review was previously defined as an internal assessment by someone with a construction background in the design organization, searching for constructability flaws in the design as it was finished. However, the use of a construction expert as a member of the design team and participation in the process of reviewing the design is considered to be the right direction towards the best practice that describes constructability since this method denotes a greater level of construction skill that might be used in the design. That is why the results of this survey are promising. It shows that 49% was attributed to the mechanism of design review by construction experts. This early involvement of the experts will eventually avoid some of the scheduled events that can cause delays and possibly cost overruns.

Question 5 is exactly the same as question four, but this time, the respondents were asked about constructability mechanisms during the construction phase. The highest selected mechanism by the respondents was “apply appropriate construction means and methods” with 22.2%. The second highest selected mechanism was the pre-task planning, with almost the same percentage as the highest selected mechanism with a rate of 21.65%. Following these mechanisms, the respondents selected the mechanism of “hire a consultant” with a percentage of 17%. With a percentage of 15%, the following nearest mechanism was the “incorporate construction expert into the preconstruction planning”. The following highest mechanism selected by the respondents (12.9%) was the “apply innovative construction means and methods” mechanism to address constructability during the construction phase. Almost 9.8% of the respondents selected “coordinating construction trades” as one of the mechanisms representing constructability during the construction phase. Only 1.5% in total were given to the “none” and the “others” options, which indicates that the majority believes that the suggested mechanisms represent the mechanisms generally used to address constructability during the construction phase.

Constructability responsibilities

The survey included two questions related to responsibilities in constructability. One of the questions concerns who performs constructability (question 6), and the other question concerns who require constructability (question 7). These two questions were based on the previous question’s answers (questions 4 and 5). The results show that those with engineering skills and construction experience tend to take on the role of constructability review responsibility. More than half of the respondents answered that the one performing constructability was the construction manager, with a percentage of approximately 22.3%. The second highest percentage was given to the engineer, as they are mainly responsible for implementing constructability, with 18.2%. The contractor was the third most selected body that performs constructability, with a percentage of 12%. The owner, owner representatives, and the consultant working primarily in the design and architecture were selected with almost the same percentage ranging from 32.9 to 10.7%. Finally, the subcontractor working primarily in construction was selected with nearly 5.4%. Suppose the owner and the owner representatives are considered as one category. In that case, the two of them will represent 21.8%, almost the same percentage given to the construction manager. That can be reasoned that the owner or the owner representatives are considered the ones who have the permission to implement constructability or not, as the two have the power to generally make any decisions related to a specific project.

As for the question related to who requires constructability, shown in Fig. 6, the respondent agreed that both the owner and the owner representatives are the ones who include constructability and are responsible for implementing constructability into a specific project with a percentage of 31.1%. According to the respondents, those with construction experience such as the contractors, construction manager, and the subcontractor working primarily in construction, require constructability as much as the owners and even more with a percentage of more than 39.2%. The same importance can be attributed to the architects, engineers, and consultants, as all of them represent a percentage of 29.7%. Hence, it can be seen that the respondents agreed that all the different parties involved in a project require constructability.

Values of implementing constructability

The survey investigated the value of implementing constructability to respondents by asking them, “What are the major benefits of implementing constructability?” The survey offered six possible benefits, and all received very strong and even supported. The benefits listed included “enhances project quality” (80.5%), “reduces project cost”, and “reduces project duration” both shared the same percentage of 72%, “increases owner satisfaction” (59.8%), “minimizes contract change orders and disputes” (58.5%), “enhances partnering and trust among project team” (40.2%), and “other” (7.3%). The respondents see a wide range of good reasons for implementing constructability efforts. One of the written comments included the aspect of safety and that constructability supports the safety aspect of a project.

“What problems in construction that you observe could be prevented by improved constructability?” the survey questioned, considering the importance of addressing constructability from a different perspective. Unlike the majority of the survey questions, this one did not provide suggested answers and instead required respondents to submit their responses. The five most commonly cited problems were cost overruns (32%), delays (30%), frequent changes (24%), poor planning (18%), and design errors. Most of these specified problems identified by the respondents are in accordance with different authors presenting the benefits of implementing constructability. Motsa et al. (2008) identified that some of the benefits gained by implementing constructability involve “better design”, “cost reduction”, and “more effective construction planning”. Those comply with the previously mentioned problems specified by the survey’s respondents regarding the issues of not implementing constructability.

Obstacles to constructability

Finally, the survey asked, “What are major obstacles to implementing constructability?” The survey offered ten possible obstacles, and the results are presented in Fig. 7. The major obstacle identified by the respondents was “not enough resources” (15.9%). With just one percentage difference, the second highest selected obstacles by the respondents were “Lack of adequate construction experience” and “Lack of open communication between designers and constructors” (15.5%). “Contract type” was the third obstacle identified by the respondents, with 10.7%. “Too costly” was the next obstacle according to the respondents with a percentage of 10%. Both “Project delivery methods” and “Difficulty in coordinating disciplines” were the following selected obstacles, with both given a percentage of 9%. “Lengthening the project” and “It is currently not part of the process” were the least chosen obstacles with percentages of 7.6% and 6.9%, respectively.

Conclusion

The main aim of this study is to review the concept of constructability and to explore the implementation of constructability practices in the construction industry in Muscat, Oman. Conducting the questionnaire resulted in different aspects regarding constructability practice in Muscat engineering offices. The main conclusions are summarized as follows:

Owners, designers, and builders acknowledge, encourage, and practice constructability activities, suggesting that constructability is widely accepted in the industry.

Constructability activities start in the early stages of a project; 45% of respondents indicated constructability efforts usually begin with pre-project planning.

Different mechanisms are implemented in the construction industry to address constructability, which improves the construction industry.

The owner, the owner representatives, and the construction manager are responsible for performing constructability. That can be reasoned that the owner or the owner representatives are considered the ones who have the permission whether to implement constructability or not, as the two have the power to make any decisions related to a project generally.

Efforts to improve constructability start earlier for designers and builders than for owners.

A wide range of constructability approaches is employed.

Constructability can solve issues that can occur to a certain project such as delays in both cost and time, frequent changes, and design errors.

Obstacles to enhancing constructability still exist, but they may change as the industry and constructability improve.

The collected data showed good constructability practices and a sufficient understanding of its benefits. This fact can be noticed from the respondents’ results, where the majority indicated that constructability must be implemented pre-contract stage. It is interesting to see all respondents agree that all project stakeholders have to take a role in applying constructability to a project. Although, it cannot be applied to all types of projects because of the different project delivery methods applied in the construction industry. In addition, the results showed that construction engineers and construction managers are the major stakeholders who can are responsible for constructability review. This is a good indication showing the importance of integrating construction knowledge during all project phases.

Research limitation

The size of the collected data is the main limitation. In addition, the majority of the collected data represents the engineering/consultant offices’ perception. Limited data from the contractor and the client were received. In addition, conducting interviews with experts in construction engineering is essential and captures the most out of the constructability practices in the construction industry. The future direction of this study is to expand the collection of data and conduct interviews to generalize the outcomes of the survey in the Omani construction industry context.

Funding

The authors have not disclosed any funding.

Declaration

Conflict of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acker DE. Integrating constructability into cleanroom design. Journal of Construction Engineering and Management. 2003;2003:21–715. [Google Scholar]

- Al Alawi M. Delay in payment effects on productivity of small and medium construction companies in Oman: Exploration and ranking. Asian Journal of Civil Engineering. 2021;2021:1347–1359. doi: 10.1007/s42107-021-00387-8. [DOI] [Google Scholar]

- Al Alawi, M., Ali, M., Johnson, S., Han, S., & Mohamed, Y. (2015). Constructability: capabilities, implementation, and barriers. International Construction Specialty Conference (pp. 14–1). Vancouver, British Columbia: University of British Columbia. 10.14288/1.0076375.

- AlMussad, A. (2018). Constructability Implementation State of Practice in Saudi Construction Projects. Dhahran, Eastern Province, Saudi Arabia.

- Alnuaimi, A.S., & AlMohsin, M.A. (2013). Causes of Delay in Completion of Construction Projects in Oman. International Conference on Innovations in Engineering and Technology (ICIET'2013), (pp. 267–270). Bangkok, Thailand.

- Anderson SD, Fisher DJ, Rahman SP. Integrating constructability into development: A process approach. Journal of Construction Engineering and Management. 2000;126:81–88. doi: 10.1061/(ASCE)0733-9364(2000)126:2(81). [DOI] [Google Scholar]

- Arditi D, Elhassan A, Toklu YC. Constructability analysis in the design firm. Journal of Construction Engineering and Management. 2002;128:117–126. doi: 10.1061/(ASCE)0733-9364(2002)128:2(117). [DOI] [Google Scholar]

- ASCE Construction Division T. (1991). Constructability and constructability programs:White paper. Journal of Construction Engineering and Management 117, 67–89.

- Bakti, E., & Trigunarsyah, B. (2003). Constructability Implementation at Corporate Level. The Ninth East Asia-Pacific Conference on Structural Engineering and Construction (pp. 88–89). Institut Teknologi Bandung (ITB).

- Building and Construction Authority (BCA). (2017). Building and Construction Authority. A Singapore Government Agency. http://www.bca.gov.sg/BuildableDesign/others/cop2017.pdf.

- CII, C. (2019). CII's Impact. Retrieved from CII: https://www.construction-institute.org/membership/ciis-impact.

- Construction Industry Research and Information Association (CIRIA). (1983). Buildability: An Assessment. London: CIRIA.

- Construction Industry Institute (CII). (1986). Constructability- A Primer. Austin, Tex.: Construction Industry Institute (CII).

- Construction Industry Institute. (1993). Preview of Constructability Implementation. Autin, Texas: Publication.

- Contrada, F., Kindinis, A., Caron, J., & Gobin, C. (2019). An early-design stage assessment method based on constructibility for building performance evaluation. In IOP Conference Series: Materials Science and Engineering. IOP Publishing. 10.1088/1757-899X/609/7/072070.

- Ding CS, Salleh H, Kho MY. Constructability research trends: A review and future. International Journal of Sustainable Construction Engineering and Technology. 2020;2020:7–17. [Google Scholar]

- Douglas EE, Gransberg DD. Implementing project constructability. AACE International. 2009;2009:3–6. [Google Scholar]

- Elgohary M, Fairclough N, Ricciuti R. Constructability—from Qinshan to the ACR. Nuclear Plant Journal. 2003;2003:5–31. [Google Scholar]

- Garcia, M. A. (2009). Introduction to CII Practices. Jacksonville, Florida, United States of America.

- Gil N, Tommelein ID, Kirkendall RL, Ballard G. Contribution of speciality contractor knowledge to early design. Business. 2020;2020:2. [Google Scholar]

- Griffith A, Sidwell AC. Development of constructability concepts, principles and practices. Engineering Construction Architectureal Management. 2000;2000:295–310. [Google Scholar]

- Kordestani GN, Saghatforoush E, JadidolEslami S, Preece C. Research trends on benefits of implementing constructability, operability, and maintainability. Journal of Engineering, Project, and Production Management. 2017;2017:55–62. doi: 10.32738/JEPPM.201707.0002. [DOI] [Google Scholar]

- Lam PT. Buildability assessment: The Singapore approach. Journal of Building and Construction Management. 2002;2002:7–21. [Google Scholar]

- Latif QB, Al Saadi AM, Abdul Rahman I. Identification of delay factor in Oman construction industry. International Journal of Sustainable Construction Engineering and Technology. 2019;2019:34–45. [Google Scholar]

- Low SP, Abeyegoonasekera B. Integrating buildability in ISO 9000 quality management systems: Case study of a condominium project. Building and Environment. 2001;36(3):299–312. doi: 10.1016/S0360-1323(00)00004-4. [DOI] [Google Scholar]

- Motsa, N., Oladapo, A., & Othman, A. A. (2008). The Benifits of using Constructability during the Design Process. In 5th Post Graduate Conference on Construction Industry Development (pp. 158–167). Bloemfontein: South Africa.

- Nima MA, Abdul-Kadir MR, Jaafar MS. Evaluation of the role of the contractor’s personnel in enhancing project constructability. Journal of Construction Engineering and Management. 2001;2001:193–200. [Google Scholar]

- Oludare SO, Olugboyega O. Constructability concepts and enhancement capabilities of construction site team members in Obafemi Awolowo University, Ile-Ife, Nigeria. Civil and Environmental Research. 2016;2016:13–19. [Google Scholar]

- Othman AA. Improving building performance thorough integrating constructability in the design process. Organization, Technology and Management in Construction International Journal. 2011;2011:333–347. [Google Scholar]

- Pheng Low S. Quantifying the relationships between buildability, structural quality and productivity in construction. Structural Survey. 2001;19(2):106–112. doi: 10.1108/EUM0000000005627. [DOI] [Google Scholar]

- Pocock JB, Kuennem ST, Gambatese J, Rauschkolb J. Constructability state of practice report. Journal of Construction Engineering and Management. 2006;2006:373–383. doi: 10.1061/(ASCE)0733-9364(2006)132:4(373). [DOI] [Google Scholar]

- Russel, J. S., Swiggum, K. E., Shapiro, J. M., & Alaydrus, A. F. (1994). Constructability related to TQM, value engineering, and cost/benefits. Journal of Performance of Constructed Facilities, 31–45.

- Santo R. Industry insights: Oman’s infrastructure development 2019. Business Live ME. 2019;2019:5–7. [Google Scholar]

- Shaik-Hussein M, Rosli MZ, Zaimi MA, Zahidi M, Memon AH. Buildability attributes at design phase in Malaysian building construction. International Journal of Sustainable Construction Engineering & Technology. 2011;2011:24–43. [Google Scholar]

- The Institution of Professional Engineers New Zealand Incorporated (IPENZ). (2008). Constructability. Weelington: Wayback Machine Practice.

- Wong FW, Lam PT, Chan EH, Shen LY. A study of measures to improve constructability. International Journal of Quality & Reliability Management. 2007;2007:586–601. doi: 10.1108/02656710710757781. [DOI] [Google Scholar]