Abstract

2,5-Diketopiperazine derivatives, consisting of benzylidene and alkylidene substituents at 3 and 6 positions, have been considered as a core structure for their antiviral activities. Herein, the novel N-substituted 2,5-Diketopiperazine derivatives were successfully prepared and their antiviral activities against influenza virus were evaluated by monitoring viral propagation in embryonated chicken eggs. It was found that (3Z,6Z)-3-benzylidene-6-(2-methyl propylidene)-4-substituted-2,5-Diketopiperazines (13b–d), (3Z,6E)-3-benzylidene-6-(2-methylpropyli dene)-1-(1-ethyl pyrrolidine)-2,5-Diketopiperazine (14c), and Lansai-C exhibited negative results in influenza virus propagation at a concentration of 25 µg/mL. Additionally, molecular docking study revealed that 13b–d and 14c bound in 430-cavity of neuraminidase from H5N2 avian influenza virus and the synthesized derivatives also strongly interacted with the key amino acid residues, including Arg371, Pro326, Ile427, and Thr439.

Keywords: 2,5-Diketopiperazines; antiviral activity; influenza virus; molecular docking; Lansai C; Lansai D

1. Introduction

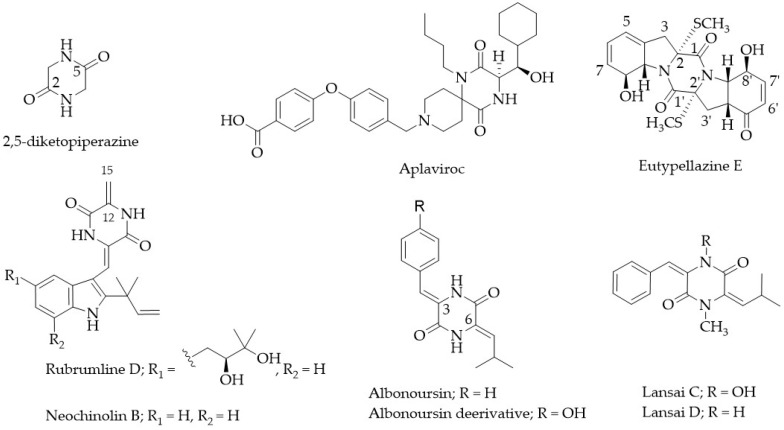

2,5-Diketopiperazine (2,5-DKP) is a six-membered cyclic dipeptide which is often found alone or embedded as a part of a compound in a variety of natural products from microorganisms, plants, and animals. 2,5-DKP can bind to a wide variety of receptors due to its unique structure, which includes a rigidity, chirality, and a variety of side chains. As a result, 2,5-DKP scaffolds are widely used for drug discovery [1,2,3,4,5]. Additionally, 2,5-DKP compounds exhibit many bioactivities, which include antiviral activity [6].

For example, Aplaviroc exhibited high binding affinity to chemokine co-receptor 5, and was developed for the treatment of patients with human immunodeficiency virus type 1 (HIV-1) [1]. Eutypellazine A–L isolated from fungus Eutypella sp. MCCC 3A00281 could inhibit the replication of HIV-1 with low toxicity (CC50 > 100). Eutypellazine E showed an inhibitory effect at IC50 3.2 + 0.4 µM. The structure–activity relationship study of these 2,5-DKP compounds showed that the thiomethyl group at C-2/C-2′ and the double bond at C-6′/C-7′ in Eutypellazine E remarkably enhanced the activity compared with analogs [7]. In addition, Rubrumlines D and Neoechinulin B isolated from the fungus Eurotium rubrum exhibited antiviral activity against the influenza A/WSN/33 virus with inhibitory rates of 52.64% and 70.48% (IC50 126.0 and 27.4 and CC50 > 200), respectively. The presence of a double bond at the ∆12,15 unit of Rubrumlines D remarkably enhanced the antiviral activity. On the contrary, Neoechinulin B, containing the absence of isoprenyl or an oxygenated isoprenyl group at the indole ring (Figure 1), showed the highest antiviral activity [8]. Additionally, Wang and co-workers reported that Albonoursin and its derivative (R=OH, (3Z,6Z)-3-(4-hydroxybenzylidene)-6-isobutylidenepiperazine-2,5-dione) showed influenza virus activity against H1N1 with IC50 at 41.5 ± 4.5 and 6.8 ± 1.5 µM, respectively [9].

Figure 1.

Structure of 2,5-DKP derivatives.

The other derivatives of 2,5-DKP are Lansai C (LS-C) and Lansai D (LS-D), which can be obtained from Streptomyces sp. SUC1 isolated from the aerial roots of Ficus benjamina in our campus [10,11]. LS-C and LS-D exhibit an anti-inflammatory effect on RAW 264.7 cells [12,13]. The structures of LS-C and LS-D contain benzylidene and alkylidene substituents at 3 and 6 positions, which are similar to that of Albonoursin, except their double bond configurations. Thus, LS-C and LS-D and their antiviral activities are worth investigation. Moreover, the modification of the N-substituents of 2,5-DKPs of Albonoursin is interested, since the functionalized chains of 2,5-DKPs and their orientations can affect the binding affinity of 2,5-DKPs to the receptors and the biological activities of 2,5-DKPs compounds [14].

In this research, the novel 2,5-DKP derivatives, which were designed by emulating Albonoursin, LS-C, and LS-D scaffolds with the addition of substitution group at the position of nitrogen atoms of the 2,5-DKP ring by N-alkylation reaction, were successfully prepared. The preliminary antiviral activity test against influenza virus (H5N2) of our 2,5-DKP derivatives, LS-C, and LS-D was then performed by hemagglutination assay. In addition, a molecular docking study was conducted to investigate how the derivatives interact with amino acids in the binding pocket of neuraminidase from H5N2 avian influenza virus (H5N2, PDB ID: 5HUK). Our work could contribute to and benefit the design and development of novel 2,5-DKP derivatives as a potential antiviral drug.

2. Results and Discussion

2.1. Synthesis

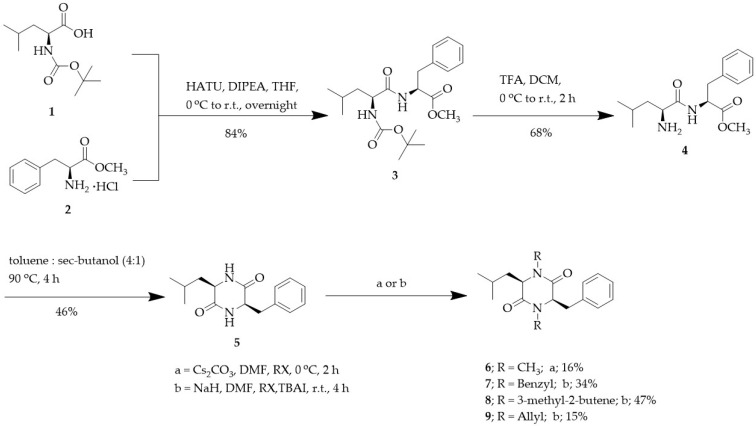

The steps to synthesize tetrasubstituted 2,5-DKP derivative 5 were as follows. N-Boc-Leucine 1 and Phenylalanine methyl ester 2 were reacted to obtain dipeptide 3. Then, the deprotection of the Boc group, followed by ring formation of the dipeptide 3, was conducted to obtain 2,5-DKP derivative 5. Finally, N-substitution of the 2,5-DKP derivative 5 led to the formation of tetrasubstituted 2,5-DKP derivatives 6–9 (Scheme 1) in fair yields.

Scheme 1.

Synthesis of tetrasubstituted 2,5-DKP derivatives 6–9.

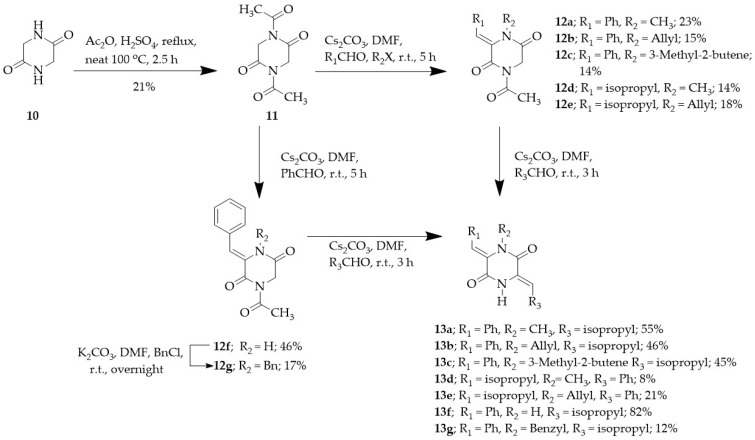

The 2,5-DKP ring 10 was constructed with moderated yield (56%) in accordance with previous literature to obtain benzylidene and alkylidene substituents at 3 and 6 positions of the 2,5-DKP core structure [15]. N-acylation of 10, by refluxing in acetic anhydride, provided 1,4-Diacetyl-2,5-diketopiperazine 11 in fair yield (Scheme 2).

Scheme 2.

Synthesis of 2,5-DKP derivatives.

1,4-Diacetyl-2,5-diketopiperazine 11 underwent aldol addition–acetyl migration–elimination cascade with Cs2CO3, alkyl halide, and various aldehydes [16] to provide highly (Z)-stereoselective products 12a–e (Scheme 2). This reaction was supported by the Zimmerman–Traxler model, which was reported by Balducci and co-workers [17]. In the case of N-benzyl derivative 12g, the cascade reaction using benzyl chloride failed to provide the desired product, probably because of the steric hindrance with the benzylidene substituent. Thus, the benzylidene derivative 12f was further benzylated to provide compound 12g. Then, the next aldol condensation was accomplished to provide trisubstituted 2,5-DKP derivatives (13a–g). However, 13a–g have low solubility in chromatographic solvent, leading to low product yields [18].

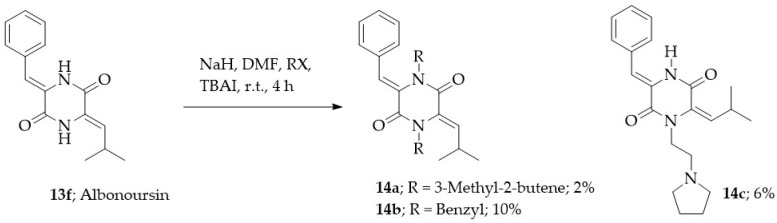

Compound 13f was a natural product from Streptomyces noursei, which was known as Albonoursin [19]. N-alkylation of compound 13f with NaH, benzyl chloride, and 1-chloro-3-methyl-2-butene provided disubstituted products 14a and 14b. However, only monosubstituted product, 14c, was obtained when using the bulky 1-ethyl pyrrolidine chloride. The propylidene was then converted to E-configuration, probably because of the steric hindrance (Scheme 3).

Scheme 3.

N-alkylation of 2,5-DKP derivatives.

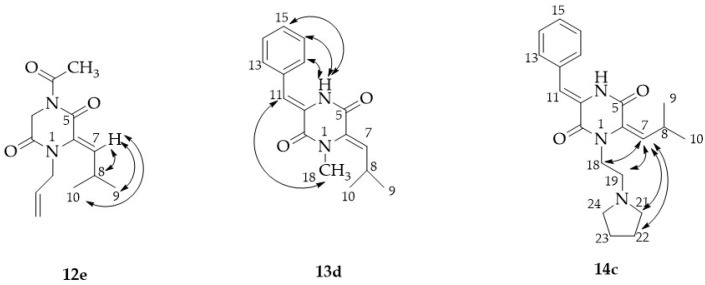

The configuration of the double bond was confirmed by NMR spectroscopy. In this research, each proton NMR spectrum of the C=CH double bond in 6-(2-methylpropylidene) was observed at 6.01–6.13 ppm, which might be the indication of (6Z)-configuration similar to the observation of Fairhurst and co-workers’ work, in which the chemical shifts of proton of Z- and E-isomers at the position of an alkylidene double bond (C=CH) in complex tert-butyl-3-(2-methylpropylidene)-2,5-dioxopiperazine-1-carboxylate were 6.14 and 5.42 ppm, respectively [20]. The NOEDIFF spectra of compound 12e showed that the proton on the alkylidene double bond (C=CH) only enhanced the proton of isopropyl moiety. Thus, the alkylidene double bond of compound 12e was characterized as (Z)-configuration. Another NOEDIFF analysis of compound 13d showed that 4-NH and H-11 enhanced Ar-H of benzylidene moiety and 1-N-CH3, respectively. Thus, compound 13d was characterized as (3Z,6Z)-3-benzylidene-6-(2-methylpropylidene)-1-methyl-2,5-diketopiperazine (Figure 2). Other results showed steric hindrance between the proton of the aromatic ring and the carbonyl and steric repulsion between hydrogen atoms in benzylidene and the N-alkylated group, which could be caused by (3Z)-selectivity. Further, NOESY analysis was used to confirm the stereochemistry of (6E)-configuration in compound 14c. NOE enhancement from H-7 to H-18, H-19, H-21, H-22, H-23, and H-24 was observed, whereas NOE enhancement of H-8 was not found. This result indicated (6E)-configuration (Figure 2).

Figure 2.

NOEDIFF and NOE contracts for stereoisomers of compounds 12e, 13d, and 14c.

2.2. Virus Propagation Inhibition Assay

The efficacy of LS-C, LS-D, and 2,5-DKP derivatives to influenza virus (H5N2) propagation inhibition was evaluated at various concentrations in embryonated chicken eggs. A hemagglutination test was performed to estimate virus propagation. The summary results are displayed in Table 1. The negative control (PBS) showed the ratio of the last dilution at 1:3072, indicating complete agglutination. On the other hand, 1-adamantanamine hydrochloride and oseltamivir carboxylate were used as the positive controls. The results show that they exhibited the virus inhibition at 12.5 µg/mL while all of our tested compounds could not inhibit the virus propagation at a concentration of 12.5 µg/mL.

Table 1.

Summary of influenza virus (H5N2) propagation inhibition in embryonated chicken eggs of LS-C, LS-D, and 2,5-DKP derivatives detected by hemagglutination assay and the cytotoxicity activity (IC50) against LLC-MK2.

| Compounds | HA Titer * Concentrations (µg/mL) | IC50 (µg/mL) | |||

|---|---|---|---|---|---|

| 100 | 50 | 25 | 12.5 | LLC-MK2 | |

| LS-C | Negative | NT | Negative | >1:3072 | 507.84 |

| LS-D | 1:12 | NT | 1:24 | >1:3072 | 437.33 |

| 6 | 1:48 | 1:12 | 1:6 | >1:3072 | NT |

| 7 | Negative | 1:6 | 1:6 | >1:3072 | NT |

| 8 | 1:24 | 1:1.5 | 1:3 | >1:3072 | NT |

| 9 | Negative | 1:6 | 1:24 | >1:3072 | NT |

| 13a | Negative | Negative | 1:1.5 | >1:3072 | NT |

| 13b | Negative | Negative | Negative | >1:3072 | 330.28 |

| 13c | Negative | Negative | Negative | >1:3072 | 386.42 |

| 13d | Negative | Negative | Negative | >1:3072 | 353.51 |

| 13e | 1:24 | 1:1.5 | 1:6 | >1:3072 | NT |

| 13g | 1:6 | 1:1.5 | 1:384 | >1:3072 | NT |

| 14a | 1:12 | 1:786 | 1:6 | >1:3072 | NT |

| 14b | 1:24 | 1:6 | 1:1.5 | >1:3072 | NT |

| 14c | Negative | Negative | Negative | >1:3072 | 287.65 |

| 1-Adamantanamine hydrochloride | Negative | Negative | Negative | Negative | NT |

| Oseltamivir carboxylate | Negative | Negative | Negative | Negative | NT |

| PBS | >1:3072 | NT | |||

* Negative = no virus propagation; the ratio (1:xx) is ratio of RBCs to the virus quantity, reported at the highest dilution of the virus suspension, found the virus propagation; NT stands for the substance that, at that concentration, was not tested.

LS-C showed the virus inhibition at concentration of 25 µg/mL, whereas LS-D could not inhibit virus propagation even at a high concentration (100 µg/mL). The result indicated that N-OH group of LS-C were essential for the antiviral activity. Moreover, compound 13d, containing opposite double bond configuration to LS-D, showed an inhibition against influenza virus (H5N2) propagation at a concentration of 25 µg/mL, suggesting that the double bond in Z-configuration might enhance the activity of the compound. Additionally, either the unprotected nitrogen or protected nitrogen with alkyl substituents such as allyl and 3-methyl-2-butene adjacent to (Z)-benzylidene inhibited virus propagation at a concentration of 25 µg/mL, as was observed in compounds 13b–d and compound 14c. In contrast, the benzyl substituent 13g had a different impact on the antiviral activity, thus there should not be any substitution on nitrogen adjacent to isopropylidene, for the isopropylidene is in Z-configuration in order to maintain the antiviral activity. The presence of double bonds was also important for the antiviral activity in compounds 6–9.

In addition, the cytotoxicity of LS-C, LS-D, 13b–d, and 14c, which exhibited the virus inhibition at a concentration of 25 µg/mL, were investigated against Rhesus monkey kidney epithelial cells (LLC-MK2 cell lines). It was found that their cytotoxicity activities (IC50) against LLC-MK2 were 287.65 to 507.84 µg/mL, indicating that cytotoxicities of these compounds were negligible to the normal cells.

2.3. Molecular Docking Study

The molecular docking is a computer-aided procedure that generates ligand with different orientations and conformation and predicts the best match between ligand and protein target, where the lower the binding energy of a complex indicates that the complex is more stable [21]. Herein, molecular docking approach is employed not only to visualize how our compounds interact with neuraminidase from H5N2 avian influenza virus, which was the well-known drug target to prevent the spread of influenza infection [22], but also to gain valuable guidance at a molecular level for the development of new 2,5-DKP derivatives as the antiviral drugs.

According to the virus propagation inhibition assay results, the following compounds: LS-C and compounds 7, 9, 13a–13d, and 14c, which serve as virus propagation inhibitor, were selected. Molecular docking study was performed using iGEMDOCK v.2.1. [23] and the images were prepared using BIOVIA Discovery Studio Visualizer [24]. Additionally, an antiviral medication used to treat and prevent influenza viruses, including oseltamivir carboxylate [25,26], zanamivir [27], and peramivir [28], were docked into neuraminidase from H5N2 avian influenza virus, and their docking results were compared with our potential antiviral drugs (LS-C and compounds 7, 9, 13a–13d, and 14c). The initial structures of oseltamivir carboxylate, zanamivir, and peramivir were taken from crystal structures of neuraminidase-inhibitor complexes PDB ID: 2HU4, 3CKZ, and 3K39, respectively.

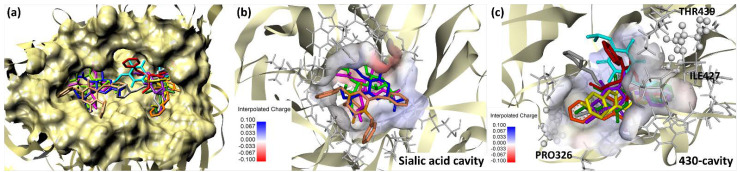

The comparison of binding positions of our selected compounds with virus propagation inhibitor (LS-C and compounds 7, 9, 13a–13d, and 14c) in the active site of H5N2 was displayed in Figure 3a. The binding energies, amino acid interaction, along with hydrogen bond length of our compounds bound in the active site of receptors, were also demonstrated in Table 2. As can be seen in Figure 3b and Table 2, oseltamivir carboxylate, zanamivir, and peramivir fit and interact with amino acids in the sialic acid cavity of H5N2 in similar manner to the observation in the crystal structures of neuraminidase-inhibitor complexes [29,30,31], which validates our docking method. Moreover, compound 7 binds in the front of sialic acid cavity of H5N2 and forms hydrogen bond with ASN249 due to its large structure containing three benzyl moieties.

Figure 3.

Comparison of the binding position of oseltamivir carboxylate (blue), zanamivir (pink), peramivir (light green), LS-C (sky blue), compound 7 (light brown), 9 (purple), 13a (orange), 13b (red), 13c (yellow), 13d (dark green), and 14c (gray) in whole cavity (a), in the sialic acid cavity (b) and in the 430-cavity (c) of neuraminidase from H5N2 avian influenza virus.

Table 2.

Summary of binding energies, amino acid interaction, and hydrogen bond length of 2,5-diketopiperazine derivatives, oseltamivir carboxylate in molecular docking studies.

| Compounds | Binding Energy (kcal/mol) | Amino Acid Residues | H–bond Length (Å) |

|---|---|---|---|

| 7 | −85.34 | ASN249 | 1.84 |

| 9 | −77.18 | ARG371 | 2.09 |

| 13a | −85.09 | ARG371 | 2.45 |

| 13b | −77.87 | ARG371, GLN432 | 2.58, 1.87 |

| 13c | −91.93 | ARG371, ARG371, GLN432 | 2.76, 2.18, 2.84 |

| 13d | −101.86 | ARG371 | 2.24 |

| 14c | −102.25 | ARG371 | 1.84 |

| LS-C | −81.02 | ARG371 | 3.00 |

| Oseltamivir carboxylate | −93.75 | ASP151, ARG152, ARG292, ARG371, TYR406 | 2.58, 1.94, 1.95, 1.95, 2.49 |

| Zanamivir | −107.07 | ARG118, GLU119, ASP151, ASP152, TRP178, GLU277, ARG292, ARG294, ARG371 | 2.15, 3.02, 2.68, 2.39, 2.87, 2.28, 2.80, 2.05, 2.06, |

| Peramivir | −115.88 | ARG118, ASP151, ARG152, GLU277, ARG292, ARG371 | 2.25, 2.11, 1.91, 2.43, 2.49, 2.37 |

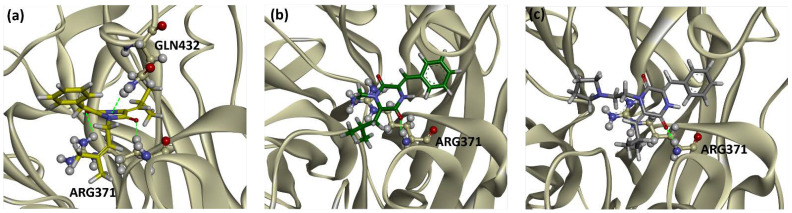

On the other hand, the LS-C and compound 9, 13a–13d, and 14c, are located in a hydrophobic 430-cavity of H5N2, as shown in Figure 3c. The interaction between these compounds and key amino acid residue, PRO326, ILE427, and THR439, are also observed. Moreover, their carbonyl groups on 2,5-DKP scaffold strongly interact with ARG371, which is one of the arginine triad residues (ARG118-ARG292-ARG371), indicating the important role of 2,5-DKP scaffold for H5N2-binding and H5N2 inhibition. Hydrogen bond interactions between some of our compounds (13c, 13d, and 14c) are represented in Figure 4. In comparison to binding energy, our compounds have higher binding energy (−102.25 to −77.18 kcal/mol) than zanamivir and peramivir (−107.07 and −115.88 kcal/mol, respectively), while only compound 13d and 14c exhibit lower binding energy (−101.86 and −102.25 kcal/mol, respectively) than oseltamivir carboxylate (−93.75 kcal/mol). This result suggests that the hydrophilic substitute groups on 2,5-DKP scaffold are required for increasing the binding efficiency and development of the novel antiviral drugs.

Figure 4.

Hydrogen bond interactions of compound 13c (a), 13d (b), and 14c (c) in the cavity Avian influenza virus H5N2 (PDB ID: 5HUK).

3. Materials and Methods

3.1. General Experimental Procedures

All reactions sensitive to air or moisture were carried out under anhydrous conditions, unless otherwise stated. Solvents and reagents were used without further purification. The reagents were purchased from Sigma–Aldrich (Darmstadt, Germany), Tokyo Chemical Industry (Tokyo, Japan), and Fluka Chemical (Buchs, Switzerland) Companies. 1H- and 13C-NMR spectra were measured in CDCl3 or DMSO-d6 by a Bruker Avance 300 spectrometer (Bruker, Massachusetts, USA; 300 MHz for 1H, 75 MHz for 13C). Melting points were measured by using a Stuart Scientific SMP 2 melting point apparatus (Cole-Parmer Ltd., Staffordshire, UK). Mass spectra were measured by using micrOTOF (Bruker, Billerica, MA, USA). The reactions were monitored by thin-layer chromatography (TLC) and by using an aluminum sheet pre-coated with silica gel 60 F254 (Merck, Darmstadt, Germany). Column chromatography was conducted on Merck Kieselgel 60 (Merck, Darmstadt, Germany). (N-tert-butoxycarbonyl)-l-leucine 1 and l-Phenylalanine methyl ester hydrochloride 2 were prepared in accordance with the previous literatures [32,33]. Lansai A, Lansai B, LS-C, and LS-D were isolated, purified, and identified as previously described [10,11]. The 1H-NMR, 13C-NMR, HRMS spectra of the synthesized compounds were recorded, as shown in the Supplementary Materials.

3.2. Synthesis of 2,5-DKP Derivatives

3.2.1. Methyl (N-tert-butoxycarbonyl)-l-leucyl-l-phenylalaninate (3)

(N-tert-butoxycarbonyl)-l-leucine (1) (0.11 g, 0.40 mmol) was dissolved in dry THF (3.0 mL) under argon atmosphere and the reaction was kept at 0 °C in an ice bath. The solution was treated with HATU (0.25 g, 0.70 mmol) and DIPEA (0.11 mL, 0.60 mmol) and allowed to stir at 0 °C for 10 min. Then, l-phenylalanine methyl ester hydrochloride (2) (0.09 g, 0.50 mmol) was added, and the reaction was stirred at room temperature overnight. After completing the reaction, the solvent was removed under vacuum, and the residue was dissolved with EtOAc. The EtOAc solution was extracted with 2N HCl (2 × 20.0 mL) and saturated NaHCO3 (2 × 20.0 mL). The organic phase was washed with brine (2 × 20.0 mL), dried with anhydrous Na2SO4, and evaporated under reduced pressure to provide the crude product. The crude product was purified by column chromatography using hexane:EtOAc (4:1) to obtain a colorless oil ((0.11 g, 84%yield); 1H-NMR (300 MHz, CDCl3) δ 7.30–7.19 (m, 3H), 7.12–7.10 (m, 2H), 6.72 (m, 1H), 5.03 (s, 1H), 4.84 (dd, J = 13.5, 6 Hz, 1H), 4.10 (m, 1H), 3.68 (s, 1H), 3.14 (dd, J = 13.8, 5.7 Hz, 1H), 3.06 (dd, J = 13.8, 6.3 Hz, 1H), 1.69–1.25 (m, 2H), 1.49–1.39 (m, 1H), 1.43 (s, 3H), 0.91 (d, J = 6.3 Hz, 3H), 0.90 (d, J = 6 Hz, 3H); 13C-NMR (300 MHz, CDCl3) δ 172.3, 171.7, 155.5, 135.8, 129.3, 128.5, 127.0, 80.0, 53.1, 52.2, 52.1, 41.2, 37.9, 28.2, 24.6, 22.8, 21.9.

3.2.2. Methyl-l-leucyl-l-phenylalaninate (4)

Methyl (tert-butoxycarbonyl)-l-leucyl-l-phenylalaninate 3 (0.54 g, 1.40 mmol) was dissolved in DCM (5.0 mL). Trifluoroacetic acid (0.2 mL, 2.60 mmol) was added to the solution at 0 °C. The reaction mixture was stirred at room temperature for 2 h. Then, the excess reagent and solvent were removed under reduced pressure. The resulting oil was treated follows: neutralized by saturated NaHCO3, extracted with DCM (2 × 30.0 mL), dried with anhydrous Na2SO4, and evaporated under reduced pressure. The crude product was purified by column chromatography using 5% MeOH in DCM to obtain a colorless oil (0.28 g, 68% yield); 1H-NMR (300 MHz, CDCl3) δ 7.72 (d, J = 8.1 Hz, 1H), 7.30–7.20 (m, 3H), 7.13–7.11 (m, 2H), 4.83 (dd, J = 13.8, 7.5 Hz, 1H), 3.70 (s, 3H), 3.36 (m, 1H), 3.16 (dd, J = 13.8, 6.0 Hz, 1H), 3.05 (dd, J = 13.6, 6.9 Hz, 1H), 1.70–1.55 (m, 1H), 1.60–1.52 (m, 1H), 1.25–1.17 (m, 1H), 0.92 (d, J = 6.3, Hz, 3H), 0.88 (d, 6.3 Hz, 3H); 13C-NMR (300 MHz, CDCl3) δ 175.7, 172.3, 136.1, 129.2, 128.5, 127.0, 53.3, 52.8, 52.3, 43.9, 37.9, 24.7, 23.2, 21.4.

3.2.3. (3S,6S)-3-Benzyl-6-isobutyl-2,5-diketopiperazine (5)

Methyl-l-leucyl-l-phenylalaninate (4) (0.31 g, 1.10 mmol) was dissolved in sec-buthanol:toluene (1:4, 12.0 mL). The solution was refluxed at 90 °C for 4 h. Then, the reaction was worked up by removing solvent under vacuum. Finally, the residue was triturated with MTBE to obtain a white solid (0.12 g, 46% yield); m.p. 258 °C–259 °C (Lit [34] 263 °C–264 °C); 1H-NMR (300 MHz, CDCl3) δ 7.34–7.30 (m, 3H), 7.25–7.22 (m, 2H), 6.21 (s, 1H) 6.13 (s, 1H), 4.26–4.22 (m, 1H), 3.36–3.32 (m, 1H), 3.31 (dd, J = 13.9, 3.8 Hz, 1H), 3.05 (dd, J = 13.8, 7.8 Hz, 1H), 1.76–1.71 (m, 1H), 1.69–1.64 (m, 1H), 1.57–1.50 (m, 1H), 0.92 (d, J = 6.2 Hz, 3H, 0.83 (d, J = 6.2 Hz, 3H); 13C-NMR (300 MHz, CDCl3) δ 168.7, 167.7, 135.0, 129.7, 129.0, 127.6, 56.1, 52.7, 41.8, 39.8, 24.1, 23.1, 21.0.

3.2.4. (3S,6S)-3-Benzyl-6-isobutyl-1,4-dimethyl-2,5-diketopiperazine (6)

(3S,6S)-3-Benzyl-6-isobutyl-2,5-diketopiperazine (5) (0.08 g, 0.30 mmol) was dissolved in DMF (3.0 mL) under argon atmosphere. Cs2CO3 (0.32 g, 0.90 mmol). Next, methyl iodide (0.06 mL, 0.90 mmol) was added to the solution. The reaction mixture was then stirred at 0 °C for 2 h. After that, the reaction was quenched with brine and extracted with EtOAc (2 × 20.0 mL). The organic layer was washed with brine (3 × 20.0 mL) and dried with anhydrous Na2SO4. Finally, the crude product was obtained by removing EtOAc solvent under reduced pressure and purified by preparative TLC using methanol in DCM (5%) as a mobile phase to obtain a colorless oil ((0.01 g, 16% yield); 1H-NMR (300 MHz, CDCl3) δ 7.32–7.24 (m, 3H), 7.12–7.09 (m, 2H), 4.18 (t, J = 4.6 Hz, 1H), 3.60 (dd, J = 9.2, 4.2 Hz, 1H), 3.30 (dd, J = 13.9, 4.8 Hz, 1H), 3.16 (dd, J = 13.9, 4.5 Hz, 1H), 2.95 (s, 3H), 2.86 (S, 3H), 1.76–1.63 (m, 1H), 0.82 (d, J = 6.5 Hz, 3H), 0.70 (d, J = 6.6 Hz, 3H), 0.69–0.60 (m, 1H), 0.29–0.19 (m, 1H); 13C-NMR (300 MHz, CDCl3) δ 166.5, 165.1, 153.6, 130.0, 128.8, 127.6, 63.9, 60.0, 42.4, 37.6, 32.8, 32.5, 25.1, 22.7, 21.4; HRMS [ESI]+ calculated for C17H24N2O2: 311.1730 [M + Na]+; found: 311.1733).

3.2.5. General Procedure for the Synthesis of (3S,6S)3-Benzyl-1,4-disubstituted-6-isobutyl-2,5-diketopiperazine (7–9)

(3S,6S)-3-Benzyl-6-isobutyl-2,5-diketopiperazine 5 (0.40 mmol) was dissolved in DMF (3.0 mL) under argon atmosphere. The solution was cooled to 0 °C followed by addition of NaH (2.2 eq), and the mixture was stirred at 0 °C for 15 min. Next, alkyl halide/aryl halide (2.0 eq) and TBAI (0.2 eq) were added to the solution. The reaction was stirred at room temperature for 4 h. The reaction was then quenched with saturated NH4Cl and extracted with EtOAc (3 × 20.0 mL). After that, the organic layer was washed by water (3 × 20.0 mL) then dried with anhydrous Na2SO4, followed by evaporation under reduced pressure. Finally, the crude product was purified by preparative TLC (silica gel, EtOAc: hexane, 1:4).

(3S,6S)-1,3,4-Tribenzyl-6-isobutyl-2,5-diketopiperazine (7)

Following the general procedure, the product was obtained as a colorless oil (0.07 g, 34% yield); 1H-NMR (300 MHz, CDCl3) δ 7.36–7.27 (m, 9H), 7.18–7.12 (m, 4H), 7.10–7.07 (m, 2H), 5.37 (d, J = 15.4 Hz, 1H), 5.32 (d, J = 15.4 Hz, 1H), 4.23 (dt, J = 5.2, 0.9 Hz, 1H), 3.78 (d, J = 15 Hz, 1H), 3.74 (dd, J = 10.2, 3.9 Hz, 1H), 3.57 (d, J = 15 Hz, 1H), 3.31 (dd, J = 14.0, 4.7 Hz, 1H), 3.23 (dd, J = 14.1, 6.0 Hz, 1H), 1.79–1.74 (m, 1H), 1.02–0.93 (m, 1H), 0.82 (d, J = 6.3 Hz, 3H), 0.76 (d, J = 6.6 Hz, 3H), 0.69–0.60 (m, 1H); 13C-NMR (300 MHz, CDCl3) δ 166.9, 165.9, 136.0, 135.7, 135.6, 129.9, 128.9, 128.8, 128.1, 128.0, 127.9, 127.6, 60.6, 56.9, 47.1, 47.0, 42.7, 38.1, 25.2, 22.9, 21.4; HRMS [ESI]+ calculated for C29H32N2O2: 463.2356 [M + Na]+; found: 463.2362).

(3S,6S)-3-Benzyl-6-isobutyl-1,4-bis(3-methylbut-2-en-1-yl)-2,5-diketopiperazine (8)

Following the general procedure, the product was obtained as a colorless oil (0.07 g, 47% yield); 1H-NMR (300 MHz, CDCl3) δ 7.32–7.20 (m, 3H), 7.15–7.12 (m, 2H), 5.12–5.09 (m, 1H), 5.08–5.04 (m, 1H), 4.58 (dd, J = 14.7, 5.7 Hz, 1H), 4.40 (dd, J = 14.9, 5.6 Hz, 1H), 4.24 (T, J = 4.9 Hz, 1H), 3.72 (dd, J = 10.1, 3.7 Hz, 1H), 3.46 (dd, J = 14.8, 8.2 Hz, 1H), 3.37 (dd, J = 14.8, 8.5 Hz, 1H), 3.25 (dd, J = 14.1, 5.1 Hz, 1H), 3.14 (dd, J = 14.1, 4.8 Hz, 1H), 1.75–1.69 (m, 1H), 1.72 (s, 3H), 1.71 (s, 3H), 1.65 (s, 3H), 1.63 (s, 3H), 0.83–0.75 (m, 1H), 0.82 (d, J = 6.5 Hz, 3H), 0.70 (d, J = 6.6 Hz, 3H); 13C-NMR (300 MHz, CDCl3) δ 166.4, 165.3, 137.8, 137.1, 136.0, 130.0, 128.7, 127.4, 118.5, 118.1, 60.3, 56.9, 42.2, 41.8, 41.5, 37.8, 25.8, 25.7, 24.9, 23.0, 21.2, 18.0, 17.9 HRMS [ESI]+ calculated for C25H36N2O2: 419.2669 [M + Na]+; found: 419.2673).

(3S,6S)-1,4-Diallyl-3-benzyl-6-isobutyl-2,5-diketopiperazine (9)

Following the general procedure, the product was obtained as a colorless oil (0.02 g, 15% yield); 1H-NMR (300 MHz, CDCl3) δ 7.33–7.25 (m, 3H), 7.15–7.12 (m, 2H), 5.78–5.71 (m, 1H), 5.70–5.64 (m, 1H), 5.23 (ddd, J = 10.2, 4.2, 0.9 Hz, 2H), 5.14 (ddd, J = 17.1, 9.6, 0.9 Hz, 2H), 4.68 (tdd, J = 15.0, 4.8, 1.5 Hz, 1H), 4.54, (tdd, J = 15.0, 4.8, 1.5 Hz, 1H), 4.28 (t, J = 5.0 Hz, 1H), 3.75 (dd, J = 9.8, 3.8 Hz, 1H), 3.36 (dd, J = 15.0, 7.5 Hz, 1H), 3.27–3.15 (m, 1H), 3.22–3.18 (m, 2H), 1.80–1.64 (m, 1H), 0.90–0.81 (m, 1H), 0.84 (d, J = 6.6 Hz, 3H), 0.73 (d, J = 6.6 Hz, 3H), 0.53–0.40 (m, 1H); 13C-NMR (300 MHz, CDCl3) δ 166.5, 165.3, 135.8, 131.8, 131.4, 130.0, 128.8, 127.5, 119.1, 118.8, 60.5, 57.0, 46.6, 42.6, 37.9, 25.2, 22.9, 21.3; HRMS [ESI]+ calculated for C21H28N2O2: 341.2224 [M + H]+; found: 341.2224).

3.2.6. 2,5-Diketopiperazine (10)

Methyl (tert-butoxycarbonyl) glycyl glycinate [35] (12) (0.54 g, 1.40 mmol) was dissolved in DCM (5.0 mL). Trifluoro acetic acid (0.2 mL, 2.60 mmol) was added to the solution at 0 °C. The reaction mixture was left at room temperature for 2 h. Next, the excess reagent and solvent were removed under reduced pressure. The resulting oil was then neutralized by saturated NaHCO3, followed by extraction by DCM (2 × 30.0 mL), drying with anhydrous Na2SO4, and evaporation under reduced pressure to obtain a colorless oil. After that, the crude product was dissolved in sec-buthanol:toluene (1:4, 12.0 mL). The prepared solution was refluxed at 90 °C for 4 h. The reaction was then worked up by removing solvent under vacuum. Finally, the residue was triturated by MTBE to obtain a white solid (0.25 g, 56% yield); m.p. 309 °C–310 °C (Lit [36] 311 °C–312 °C); 1H-NMR (300 MHz, CDCl3) δ 4.04 (s, 2H); 13C-NMR (300 MHz, CDCl3) δ 168.6, 43.9.

3.2.7. 1,4-Diacetyl-2,5-diketopiperazine (11)

2,5-Diketopiperazine (10) (0.51 g, 4.5 mmol) was suspended in acetic anhydride (6.0 mL) followed by the addition of two drops of concentrated H2SO4. The reaction mixture was refluxed at 100 °C for 2.5 h. The reaction provided the red solution, which was diluted with EtOAc and filtered through celite. The filtrate was concentrated to obtain the crude product as a yellow oil. The yellow oil was recrystallized by using excess isopropanol and was then stored in a fridge to obtain the precipitated pure product as a colorless needle crystal. The crystal was filtered and was then washed by cold isopropanol (0.19 g, 21% yield); m.p. 99–100 °C (Lit [37] 102–103 °C); 1H-NMR (300 MHz, CDCl3) δ 4.60 (s, 2H), 2.59 (S, 3H); 13C-NMR (300 MHz, CDCl3) δ 170.7, 165.8, 47.1, 26.7.

3.2.8. General Procedure for the Synthesis of (3Z)-4-Acetyl-3-benzylidene-1-substituted-2,5-diketopiperazine (12a–e)

A 10 mL round bottom flask, which contained 1,4-diacetyl poperazine-2,5-dione (11) (0.10 g, 0.54 mmol, 1.0 eq), aldehyde (1.40 mmol, 2.5 eq), alkyl halide (1.40 mmol, 2.5 eq), Cs2CO3 (1.40 mmol, 2.5 eq), and dry DMF (4.4 mL), was filled with argon atmosphere. The reaction mixture was stirred at room temperature for 4 h. Next, the mixture was poured into crushed ice water to obtain the precipitate. The precipitate was then filtered and washed by water. In the case of there being no formation of the precipitate, the solution would be extracted by EtOAc (3 × 15.0 mL). After that, the organic layers were combined and washed by water (2 × 15.0 mL). The organic layer was then dried by anhydrous Na2SO4 and evaporated under reduced pressure to obtain the crude product. Finally, the product was purified by preparative TLC or column chromatography (silica gel, hexane:EtOAc (4:1)).

(3Z)-1-Acetyl-3-benzylidene-4-methyl-2,5-diketopiperazine (12a)

Following the general procedure, the product was obtained as a white solid (0.03 g, 23% yield); m.p. 160–161 °C; 1H-NMR (300 MHz, CDCl3) δ 7.42–7.37 (m, 3H), 7.34–7.31 (m, 2H), 4.54 (s, 2H), 2.91 (s, 3H), 2.64 (s, 3H); 13C-NMR (300 MHz, CDCl3) δ 171.5, 164.9, 163.8, 132.7, 131.6, 129.6, 129.4, 128.6, 125.5, 45.3, 34.4, 26.7; HRMS [ESI]+ calculated for C14H14N2O3: 281.0897 [M + Na]+; found: 281.0896.

(3Z)-1-Acetyl-4-allyl-3-benzylidene-2,5-diketopiperazine (12b)

Following the general procedure, the product was obtained as a white solid (0.02 g, 15% yield); m.p. 142–144 °C; 1H-NMR (300 MHz, CDCl3) δ 7.44–7.34 (m, 5H), 7.31 (s, 1H), 5.57–5.46 (m, 1H), 5.03 (dd, J = 10.2, 1.2 Hz, 1H), 4.74 (dd, J = 16.8, 1.2 Hz, 1H), 4.54 (s, 2H), 4.11 (d, J = 5.6 Hz, 2H), 2.63 (s, 3H); 13C-NMR (300 MHz, CDCl3) δ 171.3, 164.8, 164.3, 132.6, 131.0, 129.7, 129.6, 129.3, 128.7, 126.6, 118.8, 46.4, 45.2, 26.6; HRMS [ESI]+ calculated for C16H16N2O3: 307.1053 [M + Na]+; found: 307.1050.

(3Z)-1-Acetyl-3-benzylidene-4-(3-methylbut-2-ene-1-yl)-2,5-diketopiperazine (12c)

Following the general procedure, the product was obtained as a colorless oil (0.11 g, 14% yield); 1H-NMR (300 MHz, CDCl3) δ 7.43–7.36 (m, 5H), 7.29 (s, 1H), 4.87 (tq, J = 6.9, 1.2 Hz, 1H), 4.50 (s, 2H), 4.11 (d, J = 6.9 Hz, 2H), 2.62 (s, 3H), 1.57 (s, 3H), 1.20 (s, 3H); 13C-NMR (300 MHz, CDCl3) δ 171.4, 164.7, 164.4, 132.5, 131.2, 129.6, 129.5, 129.3, 128.4, 121.5, 118., 46.0, 45.1, 26.6; HRMS [ESI]+ calculated for C18H20N2O3: 335.1366 [M + Na]+; found: 335.1352.

(6Z)-4-Acetyl-6-(2-methylpropylidene)-1-methyl-2,5-diketopiperazine (12d)

Following the general procedure, the product was obtained as a brown oil (0.08 g, 14% yield); 1H-NMR (300 MHz, CDCl3) δ 6.17 (d, J = 11.1 Hz, 1H), 4.39 (s, 2H), 3.26 (s, 3H), 2.84–2.72 (m, 1H), 2.56 (s, 3H), 1.13 (d, J = 6.3 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 171.4, 164.7, 164.0, 137.0, 131.1, 45.3, 34.8, 27.4, 26.6, 22.3; HRMS [ESI]+ calculated for C11H16N2O3: 247.1053 [M + Na]+; found: 247.1044.

(6Z)-4-Acetyl-1-allyl-6-(2-methylpropylidene)-2,5-diketopiperazine (12e)

Following the general procedure, the product was obtained as a yellow oil (0.10 g, 18% yield); 1H-NMR (300 MHz, CDCl3) δ 6.17 (d, J = 10.8 Hz, 1H), 5.88–5.75 (m, 1H), 5.18 (dq, J = 18.9, 1.2 Hz, 2 H), 4.38 (s, 2H), 4.28 (at, J = 5.7, 1.5 Hz, 2H), 2.77–2.69 (m, 1H), 2.56 (s, 3H), 1.08 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 170.3, 163.6, 163.4, 137.0, 130.9, 128.9, 116.7, 48.1, 44.3, 26.2, 25.5, 20.9; HRMS [ESI]+ calculated for C13H18N2O3: 273.1210 [M + Na]+; found: 273.1207.

3.2.9. (3Z)-1-Acetyl-3-benzylidene-2,5-diketopiperazine (12f)

1,4-Diacetyl piperazine-2,5-dione (11) (0.50 g, 2.5 mmol) was dissolved in dry DMF (10.0 mL) under argon atmosphere. Next, Cs2CO3 (0.80 g, 2.5 mmol) and benzaldehyde (0.2 mL, 1.8 mmol) were added into the solution. The mixture was then stirred at room temperature for 3 h. After the reaction was completed, the mixture was poured into crush ice water. (3Z)-1-Finally, Acetyl-3-benzylidene-2,5-diketopiperazine was precipitated as a white solid, which was filtered and washed by excess water (0.28 g, 46% yield); m.p. 185–189 °C (Lit [38] 195–197 °C) 1H-NMR (300 MHz, CDCl3) δ 7.93 (br s, 1H), 7.50–7.45 (m, 2H), 7.41–7.38 (m, 3H), 7.19 (s, 1H), 4.52 (s, 2H), 2.66 (s, 3H); 13C-NMR (300 MHz, CDCl3) δ 172.5, 162.7, 159.9, 132.5, 1129.6, 129.4, 128.5, 125.7, 119.9, 46.1, 27.2.

3.2.10. (3Z)-1-Acetyl-4-benzyl-3-benzylidene-2,5-diketopiperazine (12g)

(3Z)-1-Acetyl-3-benzylidene-2,5-diketopiperazine (0.10 g, 0.4 mmol) was treated by K2CO3 (0.11 g, 0.8 mmol) with dry DMF (3.0 mL). Next, Benzyl chloride (0.06 g, 0.5 mmol) was added to the solution. The mixture was then stirred at room temperature overnight. After the reaction was completed, the reaction mixture was poured into water and extracted by EtOAc (3 × 15.0 mL). After that, the organic layer was washed with water and dried with anhydrous Na2SO4. Finally, the organic solvent was removed under reduced pressure to provide the crude product. (3Z)-1-Acetyl-4-benzyl-3-benzylidene-2,5-diketopiperazine (18) was then obtained as a pale yellow solid by column chromatography using Hexane:EtOAc (4:1) as an eluent (0.02 g, 17% yield); m.p. 117–120 °C; 1H-NMR (300 MHz, CDCl3) δ 7.50–7.39 (m, 5H), 7.21–7.19 (m, 3H), 6.88–6.85 (m, 2H), 4.67 (s, 2H), 4.55 (s, 2H), 2.54 (s, 3H); 13C-NMR (300 MHz, CDCl3) δ 171.3, 165.1, 164.3, 135.8, 132.6, 129.9, 129.7, 129.6, 128.9, 128.6, 127.9, 127.8, 126.9, 47.2, 45.2, 26.5; HRMS [ESI]+ calculated for C20H18N2O3: 357.1210 [M + Na]+; found: 357.1205.

3.2.11. General Procedure for the Synthesis of (3Z,6Z)-3-Benzylidene-6-(2-methyl propylidene)-4-substituted-2,5-diketopiperazine (13a–f)

The solution of intermediate (12a–f) (0.3 mmol, 1.0 eq) in dry DMF (3.0 mL) was treated by Cs2CO3 (0.4 mmol, 1.5 eq) and aldehyde (0.4 mmol, 1.5 eq) under argon atmosphere. The reaction mixture was stirred at room temperature for 3 h. Next, the mixture was poured into crushed ice water. After the precipitate was formed, it was filtered and washed by water. In case there was not formation of the precipitate, the solution would be extracted by EtOAc (3 × 15.0 mL). The organic layers were then combined and washed by water (2 × 15.0 mL). After that, the organic layer was dried with anhydrous Na2SO4 and evaporated under reduced pressure to obtain the crude product. Finally, the product was purified by preparative TLC or column chromatography (silica gel, hexane:EtOAc (4:1)).

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-4-methyl-2,5-diketopiperazine (13a)

Following the general procedure, the product was provided as a pale yellow solid (0.06 g, 55% yield); m.p. 139–142 °C; 1H-NMR (300 MHz, CDCl3) δ 8.77 (br s, 1H), 7.43–7.31 (m, 3H), 7.28–7.25 (m, 3H), 6.05 (d, J = 10.2 Hz, 1H), 2.94 (s, 3H), 2.75–2.63 (m, 1H), 1.12 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 160.2, 159.7, 134.0, 130.4, 129.4, 128.4, 128.2, 128.0, 124.5, 120.5, 36.5, 25.5, 22.1; HRMS [ESI]+ calculated for C16H18N2O2: 293.1260 [M + Na]+; found: 293.1256.

(3Z,6Z)-4-Allyl-3-benzylidene-6-(2-methylpropylidene)-2,5-diketopiperazine (13b)

Following the general procedure, the product was obtained as a colorless oil (0.05 g, 46% yield); 1H-NMR (300 MHz, CDCl3) δ 9.53 (br s, 1H), 7.41–7.27 (m, 5H), 7.23 (s, 1H), 6.08 (d, J = 10.2 Hz, 1H), 5.59–5.45 (m, 1H), 5.00 (dd, J = 10.2, 1.2 Hz. 1H), 4.74 (dd, J = 17.1, 1.2 Hz, 1H), 4.23 (d, J = 5.7 Hz, 2H), 2.90–2.74 (m, 1H), 1.13 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 161.4, 159.9, 134.0, 131.6, 129.3, 129.1, 128.7, 128.4, 124.7, 121.5, 117.9, 47.7, 25.5, 22.2; HRMS [ESI]+ calculated for C18H20N2O2: 319.1417 [M + Na]+; found: 319.1410.

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-4-(3-methyl but-2-en-1-yl)-2,5-diketopiperazine (13c)

Following the general procedure, the product was obtained as a white solid (0.05 g, 45% yield); m.p. 175–178 °C; 1H-NMR (300 MHz, CDCl3) δ 7.83 (br s, 1H), 7.40–7.27 (m, 5H), 7.23 (s, 1H), 6.03 (d, J = 10.2 Hz, 1H), 4.91 (tt, J = 6.6, 1.5 Hz, 1H), 4.20 (d, J = 6.6 Hz, 2H), 2.59–2.52 (m, 1H), 1.56 (s, 3H), 1.21 (s, 3H), 1.12 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 161.1, 160.0, 136.9, 134.0, 129.4, 128.6, 128.5, 128.3, 128.1, 124.8, 121.6, 118.6, 44.0, 25.6, 25.5, 22.1, 17.7; HRMS [ESI]+ calculated for C20H24N2O2: 347.1730 [M + Na]+; found: 347.1723.

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-1-methyl-2,5-diketopiperazine (13d)

Following the general procedure, the product was obtained as a colorless oil (0.006 g, 8% yield); 1H-NMR (300 MHz, CDCl3) δ 8.05 (br s, 1H), 7.45–7.30 (m, 5H), 7.00 (s, 1H), 6.07 (d, J = 11.1 Hz, 1H), 3.43 (s, 3H), 3.01–2.89 (m, 1H), 1.13 (d, J = 6.5 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 159.6, 159.0, 133.0, 131.7, 129.3, 128.6, 128.5, 128.4, 125.9, 116.5, 35.5, 27.4, 23.0; HRMS [ESI]+ calculated for C16H18N2O2: 293.1260 [M + Na]+; found: 293.1251.

(3Z,6Z)-1-Allyl-3-benzylidene-6-(2-methylpropylidene)-2,5-diketopiperazine (13e)

Following the general procedure, the product was obtained as a pale yellow solid (0.02 g, 21% yield); m.p. 115–119 °C; 1H-NMR (300 MHz, CDCl3) δ 7.95 (br s, 1H), 7.46–7.34 (m, 5H), 7.01 (s, 1H), 6.13 (d, J = 11.4 Hz, 1H), 5.99–5.89 (m, 1H), 5.24 (ddd, J = 19.8, 10.5, 0.9 Hz, 2H), 4.49 (dt, J = 4.5, 1.8 Hz, 2H), 2.93–2.89 (m, 1H), 1.10 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 159.4, 158.5, 133.1, 132.2, 131.7, 129.4, 128.7, 128.4, 127.0, 125.8, 116.5, 116.3, 49.2, 27.0, 22.9; HRMS [ESI]+ calculated for C18H20N2O2: 319.1417 [M + Na]+; found: 319.1420.

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-2,5-diketopiperazine (13f)

Following the general procedure, the product was obtained as a white solid (0.13 g, 82% yield); m.p. 243–246 °C (Lit [39] 271–271.5 °C); 1H-NMR (300 MHz, CDCl3) δ 8.06 (br s, 1H), 7.81 (br s, 1H), 7.48–7.43 (m, 2H), 7.38–7.34 (m, 3H), 6.99 (s, 1H), 6.02 (d, J = 10.2 Hz, 1H), 2.59–2.51 (m, 1H), 1.12 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 157.1, 157.0, 132.7, 129.5, 128.9, 128.3, 126.8, 124.3, 116.2, 29.7, 25.5, 22.0.

(3Z,6Z)-4-Benzyl-3-benzylidene-6-(2-methylpropylidene)-2,5-diketopiperazine (13g)

Following the general procedure, the product was obtained as a colorless oil (0.01 g, 12% yield); 1H-NMR (300 MHz, CDCl3) δ 7.95 (br s, 1H), 7.44–7.32 (m, 4H), 7.30–7.27 (m, 1H), 7.21 (s, 1H), 7.19–7.16 (m, 3H), 6.92–6.83 (m, 2H), 6.05 (d, J = 10.5 Hz, 1H), 4.72 (s, 2H), 2.60–2.50 (m, 1H), 1.11 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 160.6, 160.0, 136.2, 133.9, 129.5, 128.8, 128.6, 128.5, 128.4, 128.3, 127.5, 124.6, 122.0, 48.6, 29.7, 25.7, 22.1; HRMS [ESI]+ calculated for C22H22N2O2: 369.1573 [M + Na]+; found: 369.1567.

3.2.12. General Procedure for the Synthesis of (3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-1,4-disubstituted-2,5-diketopiperazine (14a–b)

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-2,5-diketopiperazine (13f) ((0.08 g, 0.30 mmol) was dissolved in DMF (3.0 mL) under argon atmosphere. Next, Cs2CO3 (0.32 g, 0.90 mmol) and alkyl halide (0.06 mL, 0.90 mmol) were added to a solution. The reaction mixture was then stirred at 0 °C for 2 h. The reaction was quenched with brine and extracted by EtOAc (2 × 20.0 mL). After that, the organic layer was washed by brine (3 × 20.0 mL) and dried with anhydrous Na2SO4. The crude product was obtained by removing EtOAc solvent under reduced pressure. Finally, the product was purified by preparative TLC, using methanol in DCM (5%) as a mobile phase.

(3Z,6Z)-3-Benzylidene-6-(2-methylpropylidene)-1,4-bis(-3-methylbut-2-en-1yl)-2,5-diketopiperazine (14a)

Following the general procedure, the product was obtained as a colorless oil (0.002 g, 2% yield); 1H-NMR (300 MHz, CDCl3) δ 7.36–7.29 (m, 5H), 7.09 (s, 1H), 6.01 (d, J = 10.8 Hz, 1H), 5.23 (tq, J = 6.1, 1.5 Hz, 1H), 4.88 (tq, J = 6.8, 1.4 Hz, 1H), 4.35 (d, J = 6.1 Hz, 2H), 4.09 (d, J = 6.8 Hz, 2H), 2.80–2.68 (m, 1H), 1.71 (sd, J = 1.1 Hz, 3H), 1.68 (s, 3H), 1.55 (sd, J = 0.8 Hz, 3H), 1.25 (sd, J = 0.6 Hz, 3H), 1.09 (d, J = 6.5 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 163.4, 162.9, 136.9, 136.0, 129.9, 129.5, 129.4, 128.6, 128.3, 122.2, 119.5, 118.7, 45.5, 43.3, 27.1, 25.6, 25.5, 22.5, 18.2, 17.6; HRMS [ESI]+ calculated for C25H32N2O2: 393.2537 [M + H]+; found: 393.2542.

(3Z,6Z)-1,4-Dibenzyl-3-benzylidene-6-(2-methylpropylidene)-2,5-diketo piperazine (14b)

Following the general procedure, the product was obtained as a pale yellow oil (0.02 g, 10% yield); 1H-NMR (300 MHz, CDCl3) δ 7.44–7.27 (m, 5H), 7.25 (s, 1H), 7.23–7.18 (m, 3H), 7.16–7.10 (m, 3H), 7.08–7.01 (m, 2H), 6.79–6.76 (m, 2H), 6.04 (d, J = 10.8 Hz, 1H), 4.94 (s, 2H), 4.63 (s, 2H), 2.79–2.67 (m, 1H), 1.07 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 163.5, 163.0, 136.4, 134.4, 133.4, 129.9, 129.6, 129.3, 129.0, 128.6, 128.4, 127.7, 127.6, 127.5, 126.6, 122.9, 50.2, 48.3, 27.3, 22.2; HRMS [ESI]+ calculated for C29H28N2O2: 459.2043 [M + Na]+; found: 459.2052.

(3Z,6E)-3-Benzylidene-6-(2-methylpropylidene)-1-(1-ethyl pyrrolidine)-2,5-diketopiperazine (14c)

Following the general procedure, the product was obtained as a pale yellow solid (0.01 g, 6% yield); m.p. 158–162 °C; 1H-NMR (300 MHz, CDCl3) δ 8.16 (br s, 1H), 8.05 (d, J = 7.2 Hz, 2H), 7.40–7.28 (m, 3H), 7.27 (s, 1H), 5.56 (d, J = 10.2 Hz, 1H), 4.58 (t, J = 6.0 Hz, 2H), 3.04 (t, J = 6.0 Hz, 2H), 2.76 (m, 4H), 2.66–2.58 (m, 1H), 1.88 (sq, J = 3.3 Hz, 4H), 1.10 (d, J = 6.6 Hz, 6H); 13C-NMR (300 MHz, CDCl3) δ 160.4, 153.6, 135.1, 131.5, 128.7, 128.3, 127.8, 123.0, 121.2, 121.1, 65.6, 54.6, 54.1, 25.0, 23.5, 22.3; HRMS [ESI]+ calculated for C21H27N2O2: 354.2103 [M + H]+; found: 354.2174.

3.3. Virus Propagation Inhibition Assay

Virus propagation inhibition assays were examined by embryonated chicken egg inoculation. One hundred microliters of LS-C, LS-D, and 2,5-DKP derivatives at various concentrations (25, 50, and 100 µg mL−1) in 0.1 M PBS (pH 7.2) (from DMSO stock) were incubated with 100 µL of virus suspension at 37 °C for 30 min. The mixture (100 µL) was inoculated into each embryonated chicken egg and incubated at 37 °C for 4 days. Virus dissolved in saline solution was used as a negative control. The allantoic fluid was investigated by Hemagglutination assay [40].

3.4. Hemagglutination Assay (HA)

Fresh chicken blood was taken in Alsever’s solution and centrifuged at 2000 rpm for 5 min. The chicken red blood cells (RBCs) were separated from the supernatant and washed with PBS until the supernatant was cleared. The 2.5% suspension of RBCs was prepared by mixing with PBS. Later, the allantoic fluid 100 µL, which was harvested from inoculated embryonate chicken eggs, was mixed with PBS 50 µL and diluted with 2-fold serial dilution in PBS from 1:1 to 1:3072 in a 96-well micro titer plate. 1-Adamantanamine hydrochloride (Sigma-Aldrich, St. Louis, MO, USA) used a positive control, and PBS used as negative control, were included on micro plates. The 2.5% RBCs suspension 100 µL was added and mixed to every well. The microplate was kept at 4 °C for 45–60 min. Negative results displayed of the RBCs precipitation by gravity to the bottom of the well demonstrated absence of the virus, while positive results displayed the formation of a diffuse mat on the bottom of the well, leading to a lattice formation of RBCs and the virus. The HA titers were reported as the end point of the virus’s last dilution, showing complete agglutination. The experiments were performed in triplicate.

4. Cytotoxicity

Cytotoxicity was evaluated against normal cell line Rhesus monkey kidney epithelial cells LLC-MK2 (Korean Cell Line Bank, KCLB) by using a MTT assay [41]. A stock solution of LS-C, LS-D, and 2,5-DKP derivatives was prepared at the concentration of 5000 µg/mL in EtOH. The stock solution was further diluted to 128 µg/mL prior to use and added to the first wells. Two-fold serial dilutions were employed to obatin a by culture medium with final concentration of 1 µg/mL. Cells were seeded at a density of 5 × 104 cells/well and incubated for 16 h in a 96 well plate, followed by the treatment with the test compounds. 2.5% DMSO was used as a control culture. After 24 h, LLC-MK2 cells were incubated with MTT (500 μg/mL) for 4 h. DMSO was then added to dissolve the formation of blue formazan crystals. Finally, optical density at 450 nm was determined by a microplate reader.

5. Molecular Docking Study

Molecular docking study was performed using iGEMDOCK (Generic Evolutionary Method for Molecular DOCKing) v.2.1 (Institute of Bioinformatics National Chiao-Tung University, Hsinchu, Taiwan) to investigate the possible binding between neuraminidase from H5N2 avian influenza virus (H5N2, PDB ID: 5HUK) and our compounds (LS-C, compound 7, 9, 13a–13d, and 14c) to explore the capabilities of the compounds as virus propagation inhibitors in comparison to oseltamivir carboxylate, zanamivir, and peramivir. The accurate docking (very slow) with population size (N = 800), 80 generation, and 10 solutions were applied for the docking of each ligand against protein. The docking pose with the lowest binding energy value for each ligand–protein complex was then analyzed and imaged using BIOVIA Discovery Studio Visualizer [24].

6. Conclusions

2,5-Diketopiperazine derivatives have been successfully prepared by addition of benzylidene and isopropylidene substituents based on the structure of Albonoursin. Using hemagglutination assay, their antiviral activity against influenza virus (H5N2) was investigated and compared with those of the natural compounds with a similar structure (Lansai C and D). The results showed that LS-C and compounds 13b–d and 14c exhibited antiviral activity against influenza virus (H5N2) at a concentration of 25 µg/mL. Furthermore, the molecular docking study showed that these compounds could bind and strongly interact to key amino acid residues in 430-cavity of neuraminidase from H5N2 avian influenza virus.

Acknowledgments

We are grateful to Chulabhron Research Institute, Thailand, for high-resolution mass analysis support. We are extremely grateful to Phetchabun Rajabhat University, Thailand, for financial support of C.W. We are also thanking the department of Chemistry, and the department of Micro-biology, Faculty of Science, Silpakorn University, Thailand, for support chemicals, equipment and screen the newly synthesized compounds for antiviral activity.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/molecules27134200/s1, Figure S1–S39: 1H- & 13C-NMR spectra, HRMS.

Author Contributions

Conceptualization, W.S.P.; methodology, W.S.P., C.W., P.T., J.S., T.T.; validation, W.S.P., J.S., T.T.; investigation, C.W., P.T.; writing—original draft preparation, C.W., P.T.; writing—review and editing, W.S.P., J.S., T.T.; supervision, W.S.P., W.P.; project administration, W.S.P., W.P.; funding acquisition, W.P. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

Sample Availability

Not applicable.

Funding Statement

This research received no external funding.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Borthwick A.D. 2,5-Diketopiperazine: Synthesis, reactions, medicinal chemistry and bioactive natural products. Chem. Rev. 2012;112:3641–3716. doi: 10.1021/cr200398y. [DOI] [PubMed] [Google Scholar]

- 2.Timothé M., Nicolas G., Ganesan A., Mihaela G., Dominique B. Three cheers for nitrogen: Aza-DKPs, the aza analogues of 2, 5-Diketopiperazines. RSC Adv. 2020;10:43358–43370. doi: 10.1039/D0RA09457A. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Gong G., Qi J., Lv Y., Dong S., Cao C., Li D., Zhao L., Li Z., Chen X. Discovery of 1,3-Disubstituted 2, 5-Diketopiperazine Derivatives as Potent Class I HDACs Inhibitors. Chem. Pharm. Bull. 2020;68:466–472. doi: 10.1248/cpb.c20-00056. [DOI] [PubMed] [Google Scholar]

- 4.Wang C.Y., Liu X.H., Zheng Y.Y., Ning X.Y., Zhang Y., Fu X.M., Li X., Shao C.L., Wang C. 2,5-Diketopiperazines from a Sponge-Derived Fungus Aspergillus sclerotiorum. Front. Microbiol. 2022;13:1–8. doi: 10.3389/fmicb.2022.808532. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Song Z., Hou Y., Yang Q., Li X., Wu S. Structures and Biological Activities of Diketopiperazines from Marine Organisms: A Review. Mar. Drugs. 2021;19:403. doi: 10.3390/md19080403. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Huang R.M., Yi X.X., Zhou Y., Su X., Peng Y., Gao C.H. An update on 2,5-diketopiperazines from marine organisms. Mar. Drugs. 2014;12:6213–6235. doi: 10.3390/md12126213. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Niu S., Liu D., Shao Z., Proksch P., Lin W. Eutypellazines A–M, thiodoketopiperazine-type alkaloids from deep sea derived fungus Eutypella sp. MCCC 3A00281. RSC Adv. 2017;7:33580–33590. doi: 10.1039/C7RA05774A. [DOI] [Google Scholar]

- 8.Chen X., Si L., Liu D., Proksch P., Zhang L., Zhou D., Lin W. Neoechinulin B and its analogues as potential entry inhibitors of influenza viruses, targeting viral hemagglutinin. J. Med. Chem. 2015;93:182–195. doi: 10.1016/j.ejmech.2015.02.006. [DOI] [PubMed] [Google Scholar]

- 9.Wang P., Xi L., Wang Y., Wang W., Huang Y., Zhu W. Diketopiperazine derivatives from the marine-derived actinomycete Streptomyces sp. FXJ7.328. Mar. Drugs. 2013;11:1035–1049. doi: 10.3390/md11041035. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Tuntiwachwuttikul P., Taechowisan T., Wanbanjob A., Thadaniti S., Taylor W.C. Lansai A–D, secondary metabolites from Streptomyces sp. SUC1. Tetrahedron. 2008;64:7583–7586. doi: 10.1016/j.tet.2008.05.104. [DOI] [Google Scholar]

- 11.Taechowisan T., Wanbanjob A., Tuntiwachwuttikul P., Thadaniti S., Taylor W.C. Phytopharmacology and Therapeutic Value V. In: Singh V.K., Govil J.N., Bhardwaj R., editors. Recent Progress in Medicinal Plants. Volume 23. Studium Press; Houston, TX, USA: 2007. pp. 337–343. [Google Scholar]

- 12.Taechowisan T., Wanbanjob A., Tuntiwachwuttikul P., Liu J. Anti-inflammatory activity of lansais from endophytic Streptomyces sp. SUC1 in LPS-induced RAW 256.7 cells. Food. Agric. Immunol. 2009;20:67–77. doi: 10.1080/09540100902730064. [DOI] [Google Scholar]

- 13.Taechowisan T., Wanbanjob A., Tuntiwachwuttikul P., Liu J. Anti-inflammatory effects of lansai C and D cause inhibition of STAT-1 and NF-κB activations in LPS-induced RAW 256.7 cells. Food. Agric. Immunol. 2010;20:57–64. doi: 10.1080/09540100903419592. [DOI] [Google Scholar]

- 14.Saavedra C.J., Cuevas F., Romero-Estudillo I., Boto A. Synthesis of diketopiperazine scaffolds with tailored N- and α- chains by selective modification of customizable units. Adv. Synth. Catal. 2020;362:3158–3169. doi: 10.1002/adsc.202000470. [DOI] [Google Scholar]

- 15.Rajput S., Mclean K.J., Poddar H., Selvam I.R., Nagalingam G., Triccass J.A., Levy C.W., Munro A.W., Hutton C.A. Structure-acitivity relationships of cyclo(L-tyrosyl-L-tyrpsine) derivatives binding to mycobacterium tuberculosis CYP121: Iodinated analogues promote shift to high-spin adduct. J. Med. Chem. 2019;62:9792–9805. doi: 10.1021/acs.jmedchem.9b01199. [DOI] [PubMed] [Google Scholar]

- 16.Liao S., Qin X., Li D., Tu Z., Zhou X., Wang J., Yang B., Lin X., Liu J., Yang X., et al. Design and synthesis of novel soluble 2,5-diketopiperazine derivatives as potential anticancer agents. Eur. J. Med. Chem. 2014;83:236–244. doi: 10.1016/j.ejmech.2014.06.030. [DOI] [PubMed] [Google Scholar]

- 17.Balducci D., Conway P.A., Sapuppo G., Müller-Bunz H., Paradisi F. Novel approach to the synthesis of aliphatic and aromatic α-keto acids. Tetrahedron. 2012;68:7374–7379. doi: 10.1016/j.tet.2012.06.078. [DOI] [Google Scholar]

- 18.Ando S., Grote A.L., Koide K. Diastereoselective synthesis of diketopiperazine Bis-α,β-epoxide. J. Org. Chem. 2011;76:1155–1158. doi: 10.1021/jo102096d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Lautru S., Gondry M., Genet R., Pernodet J.-L. The albonoursin gene cluster of S. noursei: Biosynthesis of diketopiperazine metabolites independent of nonribosomal peptide synthetases. Chem. Biol. 2002;9:1355–1364. doi: 10.1016/S1074-5521(02)00285-5. [DOI] [PubMed] [Google Scholar]

- 20.Fairhurst M.E., Zeeshan M., Haug B.E., Bayer A. Aldol condensation on a 3-alkylidene-2,5-diketopiperazine: Synthesis of two marine natural products. Synlett. 2018;29:1303–1306. doi: 10.1055/s-0036-1591755. [DOI] [Google Scholar]

- 21.Meng X.Y., Zhang H.X., Mezei M., Cui M. Molecular docking: A powerful approach for structure-based drug discovery. Curr Comput. Aided Drug Des. 2011;7:146–157. doi: 10.2174/157340911795677602. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.BIOVIA Discovery Studio—BIOVIA—Dassault Systèmes®. [(accessed on 31 May 2022)]. Available online: https://www.3ds.com/products-services/biovia/products/molecular-modeling-simulation/biovia-discovery-studio.

- 23.Hsu K.C., Chen Y.F., Lin S.R., Yang J.M. iGEMDOCK: A graphical environment of enhancing GEMDOCK using pharmacological interactions and post-screening analysis. BMC Bioinform. 2011;12:1–11. doi: 10.1186/1471-2105-12-S1-S33. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Achenbach J.E., Bowen R.A. Effect of oseltamivir carboxylate consumption on emergence of drug-resistant H5N2 avian influenza virus in mallard ducks. Antimicrob. Agents Chemother. 2013;57:2171–2181. doi: 10.1128/AAC.02126-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.McClellan K., Perry C.M. Oseltamivir. Drugs. 2001;61:263–283. doi: 10.2165/00003495-200161020-00011. [DOI] [PubMed] [Google Scholar]

- 26.Smith J.R. Oseltamivir in human avian influenza infection. J. Antimicrob. Chemother. 2010;65((Suppl. 2)):ii25–ii33. doi: 10.1093/jac/dkq013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Heneghan C.J., Onakpoya I., Thompson M., Spencer E.A., Jones M., Jefferson T. Zanamivir for influenza in adults and children: Systematic review of clinical study reports and summary of regulatory comments. BMJ. 2014;348:g2547. doi: 10.1136/bmj.g2547. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.McLaughlin M.M., Skoglund E.W., Ison M.G. Peramivir: An intravenous neuraminidase inhibitor. Expert Opin. Pharmacother. 2015;16:1889–1900. doi: 10.1517/14656566.2015.1066336. [DOI] [PubMed] [Google Scholar]

- 29.Russell R.J., Haire L.F., Stevens D.J., Collins P.J., Lin Y.P., Blackburn G.M., Hay A.J., Gamblin S.J., Skehel J.J. The structure of H5N1 avian influenza neuraminidase suggests new opportunities for drug design. Nature. 2006;443:45–49. doi: 10.1038/nature05114. [DOI] [PubMed] [Google Scholar]

- 30.Collins P., Haire L., Lin Y., Liu J., Russell R.J., Walker P.A., Skehel J.J., Martin S.R., Hay A.J., Gamblin S.J. Crystal structures of oseltamivir-resistant influenza virus neuraminidase mutants. Nature. 2008;453:1258–1261. doi: 10.1038/nature06956. [DOI] [PubMed] [Google Scholar]

- 31.Oakley A.J., Barrett S., Peat T.S., Newman J., Streltsov V.A., Waddington L., Saito T., Tashiro M., McKimm-Breschkin J.L. Structural and Functional Basis of Resistance to Neuraminidase Inhibitors of Influenza B Viruses. J. Med. Chem. 2010;53:6421–6431. doi: 10.1021/jm100621s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Pozdnev V.F., Podgornova N.N., Zentsova N.K., Aukone G.I., Kalei U.O. Preparation of tert-butoxycarbonyl derivatives of amino acids using di-tert-butyl pyrocarbonate. Chem. Nat. Compd. 1979;15:471–476. doi: 10.1007/BF00565050. [DOI] [Google Scholar]

- 33.Samsawat T., Jaramornburapong C., Phutdhawong W., Phutdhawong W.S., Taechowisan T. Evaluating the effect of amine-geldanamycin hybrids on anticancer activity. J. Appl. Pharm. Sci. 2021;11:098–107. doi: 10.7324/JAPS.2021.110814. [DOI] [Google Scholar]

- 34.Nitecki D.E., Halpern B., Westley J.W. A simple route to sterically pure diketopiperazines. J. Org. Chem. 1968;33:864–866. doi: 10.1021/jo01266a091. [DOI] [PubMed] [Google Scholar]

- 35.Li L., Hu W., Jia Y. Synthetic studies of cyclic peptides stephanotic cid methyl ester, celogentin C, and moroidin. Tetrahedron. 2014;70:7753–7762. doi: 10.1016/j.tet.2014.05.082. [DOI] [Google Scholar]

- 36.2,5-diketopiperazine. [(accessed on 17 November 2021)]. Available online: http://en.wikipedia.org/wiki/2,5-Diketopiperazine.

- 37.Liao S., Qin C., Yao J., Li J., Zhou X., Wang J., Huang Z., Liu Y. One-pot synthesis of polysubstituted 3-amino-2-oxo-2,7-dihydro-1H-azepines. Synthesis. 2014;46:621–628. doi: 10.1055/s-0033-1340473. [DOI] [Google Scholar]

- 38.Katrizky A.R., Fan W.-Q., Szajda M., Li Q.-L., Caster K.C. Conjugated systems derived from piperazine-2,5-dione. J. Heterocyclic. Chem. 1988;25:591–597. doi: 10.1002/jhet.5570250243. [DOI] [Google Scholar]

- 39.Shin C.-G., Chigira Y., Masaki M., Ohta M. Synthesis of albonoursin. Bull. Chem. Soc. Jpn. 1969;42:191–193. doi: 10.1246/bcsj.42.191. [DOI] [PubMed] [Google Scholar]

- 40.Brauer R., Chen P. Influenza virus propagation in embryonated chicken eggs. J. Vis. Exp. 2015;97:1–6. doi: 10.3791/52421. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Tim M. Rapid Colorimetric Assay for Cellular Growth and Survival: Application to Proliferation and Cytotoxicity Assays. J. Immunol. Methods. 1983;65:55–63. doi: 10.1016/0022-175990303-4. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.