Abstract

Injuries associated with hands and fingers are highly prevalent in mining and identifying factors associated with these injuries are critical in developing prevention efforts. This study identifies nonfatal injury incidence rates, nature of injury, work activities, glove usage, and sources of hand and finger injuries in the U.S. mining industry, as reported to the Mine Safety and Health Administration (MSHA) from 2011 – 2017. Hand and finger injuries occur at a rate of 6.53 per 1000 full-time employees, which is nearly double the rate of the next highest affected body part, the back. Most of the hand and finger injuries were classified as cuts/lacerations/punctures (53%) followed by bone fractures/chips (26%). Materials handling and maintenance/repair were common activities at the time of the incident with miscellaneous metals (pipe, wire, guarding) and hand tools as the primary sources of hand and finger injury. Although the information on glove use was limited, leather gloves were most often worn when an injury occurred. When worn, gloves were found to contribute to 20% of the injuries, indicating their potential to protect the hands, but also potentially put the hands at risk. Further research is necessary to determine performance requirements for gloves used in mining operations, specifically those offering cut and puncture resistance.

Keywords: Hand injury, Finger injury, Mining industry, Protective gloves, Occupational injury

1. Introduction

The hand is a worker’s most utilized body part and allows a worker to perform a myriad of tasks due to its dexterity, flexibility, and tactile sensitivity. Jobs that involve rigorous hand work, such as mechanics, welders, machinery maintenance workers, manual handlers of materials, and laborers, have a high incidence of acute traumatic hand injuries [1, 2]. These injuries also extend into other occupations, with hand and finger injuries accounting for almost 15% of lost-time occupational injuries across all industries and approximately 121,000 lost-time injury cases in 2019 in the USA [3]. It is also recognized that hand injuries sustained by these manual workers result in more time lost from work than in other jobs [4, 5]. The US mining community is not exempt and has been plagued by hand and finger injuries for decades [6, 7]. Coleman et al. [8] identified the fingers as the most frequently injured body part for coal and metal/nonmetal mining, accounting for over 16% of all injuries between 2003 and 2007. More recently, a substantial number of hand and finger injuries were found to occur in mining mills and preparation plants [9] and during machine maintenance and repair [10]. These types of injuries may be omitted from many injury analyses because they are thought to have reduced costs and time away from work when compared to more cumulative injuries such as back and shoulder strains/sprains. However, the high prevalence of hand and finger injuries in mining mills and preparation plants, as well as during machine maintenance and repair activities, is alarming and may pose a significant burden on mining company finances and worker quality of life [11].

Gloves are a common means of protecting hands and fingers. Although there are numerous types of gloves on the market, the availability and efficacy of gloves remain unclear for specific mining tasks. Hand protection is not always required by law and is not explicitly stated in any Mine Safety and Health Administration (MSHA) regulations. Hand and finger protection may be inferred as regulated when considered as protective equipment and clothing for hazards and irritants. These regulations state, “Special protective equipment and special protective clothing shall be provided, maintained in a sanitary and reliable condition and used whenever hazards of process or environment, chemical hazards, radiological hazards, or mechanical irritants are encountered in a manner capable of causing injury or impairment [12, 13]” (30 CFR § 57.15006 and 30 CFR § 56.15006). Although the Occupational Safety and Health Administration (OSHA) does not regulate the mining industry, they provide more specific regulations regarding the use of hand and finger protection under 29 CFR 1910.138(a), which includes hazards such as severe cuts and lacerations but does not state fracture. The 29 CFR 1910.138(b) expands on this regulation stating, “Employers shall base the selection of the appropriate hand protection on an evaluation of the performance characteristics of the hand protection relative to the task(s) to be performed, conditions present, duration of use, and the hazards and potential hazards identified [14].”

Much of the regulations for hand and finger protection put the burden on the employer to identify and select the appropriate type of protection. Employers depend on manufacturer recommendations and equipment performance standards when determining appropriate hand protection for their workers as there is limited science-based guidance on hand protection. While most employers are aware of the potential hazards of the workplace, an employer may not be equipped with the knowledge to select the best available products to provide the necessary protection for their employees. Gloves provided for workers may even contribute to worker injury or development of cumulative trauma disorders [15–18]. Several studies have evaluated the reduced hand performance when wearing protective gloves of all types [16, 19, 20]. It is commonly accepted that gloves reduce power and pinch grip strength, impair dexterity and flexibility, and drastically diminish tactile sensitivity [16, 17, 19]. They may also alter the muscle recruitment and force generation ability of the forearm muscles, which, over time, could lead to cumulative trauma disorders [18].

Many factors play a role in a worker sustaining a hand injury. Common factors with hand and finger injuries include poor tool design, handling debris and heavy objects, and operating heavy power tools [1, 10]. Five transient risk factors found to play a role in occupational traumatic hand injury are as follows: using equipment that is performing in an abnormal way, using a different work method to do a task, doing an unusual task, being distracted, and rushing to complete a job task [21]. Unusually performing work equipment, for example a machine jamming up, generally involves servicing equipment. Although it is a rare risk factor, a previous study found this scenario associated with a large relative risk (RR = 11.0) of hand injury [21]. Performing a task for which a worker has not received correct training has also been shown to be a factor in many job-related injuries [22]. All these risk factors have preventable aspects to them, beyond gloves. This is especially true for mining, as recent evaluation of commonly used metacarpal gloves showed a wide range of effectiveness [23]. Therefore, the prevention of hand and finger injuries in mining should focus on areas beyond just hand protection and should include work activities, environmental factors, and job design.

There is a need for improved hand and finger protection and injury prevention strategies in mining. A recent mining hand and finger injury analysis focused on injury severity to guide future prevention and intervention programs [24]. While severity measures are critical for evaluating injury burden, identifying tasks performed and causes of injury are necessary to identify the exposures related to hand and finger injuries that need to be mitigated. A detailed descriptive analysis of hand and finger injuries sustained by mine workers is needed to help determine performance metrics for improved glove design and highlight factors associated with injuries that may not have been alleviated by gloves. This paper identifies non-fatal injury incidence rates, nature of injuries, activities, tasks, and sources of hand and finger injuries in the mining industry, according to MSHA injury data from 2011 – 2017. Costs of hand and finger injuries in the mining industry are also presented. In addition, glove use and their relation to hand and finger injuries are explored for the same period.

2. Methods

2.1. Data Sources

The data for this analysis came from public domain datasets provided by the Mine Safety and Health Administration. Under the US Code of Federal Regulations 30 CFR Part 50—Notification, Investigation, Reports and Records of Accidents, Injuries, Illnesses, Employment, and Coal Production in Mines—MSHA maintains databases of reported employment and reported cases of accident/injury/illness in order to provide mandated surveillance information. This reporting requirement applies to mine operators, as well as independent contractors working on mine property. A Mine Accident, Injury, and Illness Report (MSHA Form 7000–1) must be completed for all reportable accidents, injuries, or illnesses occurring at US mining facilities. Reportable occupational injuries include all incidents that require medical treatment or result in death, loss of consciousness, inability to perform all job duties on any workday after the injury, or temporary assignment or transfer to another job. Mine operators and independent contractors whose employees perform mining work on mine property are also required to file a Quarterly Mine Employment and Coal Production Report—(MSHA Form 7000–2) within 15 days after the end of each calendar year quarter. This information becomes a part of MSHA’s address and employment files and includes contact information, production of clean coal tonnage, average number of persons employed during the reporting period, and the corresponding number of employee hours worked [25]. These datasets are in the public domain and are provided in SPSS software format by the National Institute for Occupational Safety and Health (NIOSH). Accident, injury, and illness reports as well as employee hours worked (excluding office workers) were obtained for a 7-year period, 2011 through 2017. All reports selected for inclusion were for a hand or finger (including the thumb) as the part of body injured. NIOSH’s Safety Pays in Mining web application [26] was used to estimate direct and indirect costs of hand and finger injuries.

2.2. Identifying Hand and Finger Injury Cases

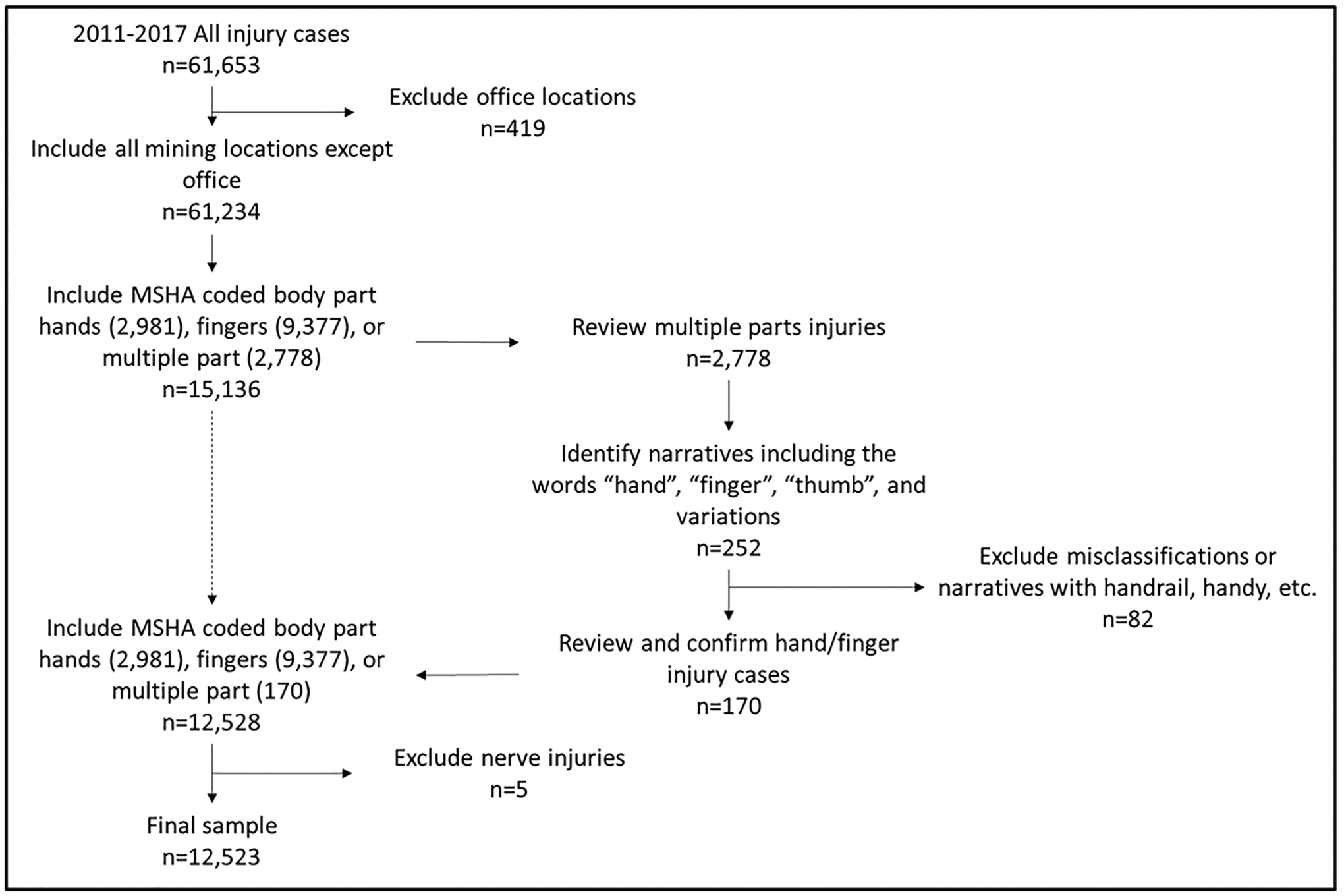

For the selected years 2011–2017, injuries were included if the injured part of body included hands, fingers, or multiple parts. Office employees were excluded (subunit = 99) as they are not likely to be exposed to mining hazards as part of their normal work activities. For injuries coded with a part of body as multiple parts, a narrative text search was performed in the injury narrative field for “hand,” “finger,” and “thumb,” including spelling variations. This text search identified 252 injury cases that matched the narrative criteria. Two authors with significant experience at coding MSHA injury narratives and fatal reports independently reviewed narratives to verify the coding. After excluding misclassifications (handrail, handy, etc.), 170 cases were identified as hand and finger injuries that affected multiple parts and were included in the analysis. This initial narrative analysis also identified additional exclusionary criteria such as numbness or tingling symptoms, which are indications of nerve injury and not necessarily an acute hand/finger injury. The vague nature of injury values (unclassified, others not elsewhere classified, and multiple injuries) (n = 302) was reviewed, and five cases indicating nerve injury were excluded. The final dataset included 12,523 hand and finger injuries for the 7-year period of interest. Figure 1 shows a detailed flowchart of how cases were selected.

Fig. 1.

Case selection flowchart

2.3. Injury Rates and Summary Injury Statistics

For this analysis, the fingers and hands were combined as the injury prevention efforts are generally combined for these two body parts. Due to the way mining employment data is collected, annual and overall injury rates can be calculated for coal and non-coal sectors but cannot be calculated by commodity (stone, metal, etc.). Injury rates for the most common body parts injured were calculated from the initial 2011–2017 data set (n = 61,653) by dividing the number of injuries for each specific body part by the total number of hours worked for that year and then multiplied by 2,000,000 (hours) to calculate the rate in terms of 1000 full-time equivalent (FTE) workers per year. Rate ratios and their corresponding 95% confidence intervals were calculated to compare rates. Descriptive summary statistics are also provided for hand and finger injuries (n = 12,523) based on the commodity mined, operating location, nature of injuries sustained, and total days lost. The total days lost per injury were calculated by using the larger of either statutory days assigned to the injury or actual days lost from work (including restricted activity days). The statutory days charged are prescribed from a table of standard charges, which may be much greater than actual days of missed work [27].

2.4. Glove Use

Injuries that involved gloves were identified from the final dataset (n = 12,523) via a narrative text search. A narrative text search for “glove” and “PPE” (personal protective equipment)—including spelling variations—identified 938 possible cases. In 854 cases, “glove” was explicitly mentioned, and in 84 cases, “glove” was not mentioned but “PPE” was. Three authors independently reviewed and coded these narratives to determine the variables of interest as outlined in Table 1. Any discrepancies in coding were discussed until a unanimous decision was made for that variable. Results highlight glove usage and type and compare gloves used with the nature of injury sustained, the glove protection characteristics desired, and the location of injury on the hand as it relates to glove protection characteristics.

Table 1.

Variables of interest for glove-related injury coding and their associated definitions

| Variable | Categories | Definition |

|---|---|---|

| Gloves worn | Yes/no/unknown | Narrative indicates the injured worker was wearing gloves at the time of the injury |

| Glove type | List | Description of glove worn by worker |

| Worker removed glove(s) | Yes/no/unknown | Narrative indicates that the worker removed one or both glove(s) prior to the injury |

| Gloves contributed to injury | Yes/no/unknown | Narrative clearly states that the glove became entangled, caught on, caught in, or was pinched between something that the mine worker was handling before injury occurred |

| Would a glove prevent injury | Yes/no/unknown | Authors used judgment to decide if the indicated injury could be prevented or have a reduced severity by wearing a more appropriate glove for the task of interest |

| Glove characteristics needed to prevent injury | List | If the authors determined that a glove could have prevented the injury or reduced the severity of the injury, the specific characteristics that would have been necessary to prevent or reduce the severity of the injury |

| Area needing protection | List | If the authors determined that a glove could have prevented the injury or reduced the severity of the injury, which part of the hand required protection |

2.5. Work Tasks and Injury Sources

Work tasks were first analyzed for the entire dataset (n = 12,523) by the accident classification variable, which identifies the circumstances that contributed most directly to the accident. In addition, mine worker activity, the source of injury, and mining machine were evaluated, individually and in combination, to explore work tasks and sources of injury. Mine worker activity was the activity in which the worker was engaged when the injury occurred. The source of injury was defined as the object or exposure which directly inflicted the reported injury and was directly related to the nature of the injury. Mining machine was connected to the injury source and describes the machinery (or tools) involved in an accident. To identify if nature of injury was related to work task, the distribution of nature of injuries sustained due to work tasks identified was compared to all other tasks using a chi-squared test. For the chi-squared test, the nature of injury was condensed down to six categories including amputation or crushing; burns; cut, laceration, or puncture; fracture or chip; sprain, strains, or other soft tissue injury; and other injury or not elsewhere classified. For work tasks, contingency tables were constructed to calculate odds ratios to identify if wearing gloves during that task had higher odds of contributing towards the injury compared to all other tasks.

While coding the narrative text for glove-related cases (see previous subsection on Glove Use), patterns of specific work tasks and tool use emerged, which warranted further exploration related to specific activities of maintenance, repair, and tool use. An additional narrative text search was performed on the hand and finger injury dataset (n = 12,523) to investigate these work tasks and tool use as described below. All text searches were reviewed by at least one author for accuracy and context.

2.5.1. Using Utility Knives

The use of a utility knife is quite common in a mining environment. To identify the use of utility knives, a text search of injury narratives was conducted for the text “utility” or a Source of Injury coded as “knives.”

2.5.2. Splice Cable or Conveyor Belt

Power cables and conveyor belts are commonly spliced with a hand tool or knife during repair. To identify the task of splicing a cable or conveyor belt, a text search of injury narratives was conducted for the text “splice” or a source of injury coded as “belt conveyor” or “conductors, electric cables, and trolley poles.”

2.5.3. Removing Strapping/Banding

Heavy items are usually shipped on pallets and secured with straps or bands, and roof bolts and bolting supplies may also be strapped together for shipment. To identify the task of removing strapping/banding, a text search of injury narratives was conducted for the text “strap” or “band.”

2.5.4. Grinding Tasks

Grinding is a common maintenance and repair task which involves the use of a tool such as a portable or stationary grinder with a rotating wheel. To identify grinding tasks, injury cases that had a mine worker activity of “grinding” were included. Additionally, a text search of injury narratives was conducted for the text “grind.” The narrative text was then reviewed to include only injuries resulting from the spinning/rotation of the grinding wheel. Narratives which described other causes, such as the grinding wheel breaking or the tool itself causing the injury, were excluded.

2.5.5. Torque Tools Use

The use of powered torque tools such as impact wrenches is common to fasten and loosen nuts and bolts during maintenance and repair. The prior review of narratives indicated that the torque generated and the resulting rotation can lead to injury. To identify when torque tool rotation was a hazard, a text search of injury narratives was conducted for the text “impact,” “torque,” “spin,” “spun,” or “nut.” Those where mine worker activity was related to roof bolting and where the source of injury was a roof bolt or drill steel were excluded as roof bolting was independently its own hazard. The narrative text was reviewed to include only injuries caused by the rotation or spinning generated by the torque tool. Narratives related to the tool, bolt, nut, or wrench slipping, falling or breaking, hammer bouncing or missing, movement of a large piece of equipment, roof bolting, valve spinning, or movement of the steering wheel when the vehicle hit a rut or pothole were excluded.

2.6. Injury Costs

Costs of hand and finger injuries were estimated with NIOSH’s Safety Pays in Mining web application [26]. The total costs (direct and indirect costs) are estimated based on worker’s compensation insurance claims for the mining industry using data from the Ohio Bureau of Workers’ Compensation [28].

3. Results

3.1. Injury Rates

Patterns of injury rates across commonly injured body parts have generally remained consistent across 2011–2017 (Fig. 2), but all nonfatal injuries and hand/finger rates had a similar slight decline. From 2011 to 2017, the hands and fingers have the highest injury rate (6.53 injuries per 1000 FTE workers), followed by the back, knees, and shoulders (3.41, 2.22, and 1.94 per 1,000 FTE workers, respectively). The average rate of hand and finger injury was nearly two times the average back injury rate (rate ratio = 1.91; 95% CI: 1.86–1.97) and 4.84 times that of the average eye injury rate (95% CI: 4.65–5.06).

Fig. 2.

Injury rates per 1000 full-time equivalent mine workers for the most common body parts injured

3.2. Summary Injury Statistics

Table 2 gives the number and rates (per 1000 FTE miners) of injuries by mining sector and operating location. Of the 12,523 hand and finger injuries identified, 43% was at coal mines, 26% was at stone mines, and 16% was at metal mines. Miners at coal mines had 1.34 times the rate of hand and finger injuries compared to non-coal mines (rate ratio = 1.34; 95% CI: 1.30–1.39). Injuries were most common at underground operations (37%) with an incidence rate of 11.43 hand and finger injuries per 1000 FTE mine workers. Compared to surface mines, underground mines had about 2.5 times the rate of hand and finger injuries (rate ratio = 2.45; 95% CI: 2.38–2.58) and mills/preparation plants had 1.4 times the hand and finger injury rate (rate ratio = 1.38; 95% CI: 1.32–1.44). Not surprisingly, 87% of the hand and finger injuries that occurred underground were from underground coal mining operations. At underground locations, coal miners had 1.8 times higher rate of hand and finger injuries than non-coal miners (rate ratio = 1.80; 95% CI: 1.66–1.96). At surface operations, injuries were commonly at stone (33%) and coal (23%) mining operations. Most hand and finger injuries at mill and prep plants occurred at stone mining operations (49%).

Table 2.

Hand and finger injury counts and rates* by mining sector and operating location, 2011–2017

| Mining sector | Underground operations | Surface operations | Mill or preparation plants | Total |

|---|---|---|---|---|

| Coal count (rate) | 3,924 (12.73) | 1,056 (3.52) | 400 (4.96) | 5,380 (7.81) |

| Non-coal | 654 (7.07) | 3,481 (5.10) | 3,008 (6.62) | 7,143 (5.81) |

| Metal count | 441 | 804 | 816 | 2,061 |

| Nonmetal | 133 | 292 | 523 | 948 |

| Stone | 80 | 1,475 | 1,669 | 3,224 |

| Sand and Gravel | 0 | 910 | 0 | 910 |

| Total count (rate) | 4,578 (11.43) | 4,537 (4.62) | 3,408 (6.37) | 12,523 (6.53) |

Rates are presented per 1000 full-time equivalent mine workers. Due to the way MSHA collects contractor employment data, rates can only be calculated for coal and non-coal employment categories. Non-coal consists of metal, nonmetal, stone, and sand and gravel mining sectors

Cuts, lacerations, and puncture injuries were the most common nature of injury with 6682 cases (53.4%), followed by bone fracture/chip injuries with 3295 cases (26.3%). Bone fracture/chip injuries accounted for the most total days lost from work between 2011 and 2017, accounting for 94,897 total lost days. Amputations were the 5th most common nature of injury, with 392 cases (3.1%) but associated with the second largest total days lost from work, with 78,736 total lost days. Amputation injuries had the highest median and mean days lost from work. All the amputation injuries (and one bone fracture) were classified as “total, partial, or permanent disability” injuries. All natures of injury and their associated days lost from work are reported in Table 3.

Table 3.

Nature of hand and finger injuries and resulting days lost, 2011–2017

| Nature of injury | Frequency | Percent | Cases reporting days lost | Total days lost | Mean days lost | Median days lost |

|---|---|---|---|---|---|---|

| Cut, laceration, puncture | 6,682 | 53.4 | 5,950 | 54,679 | 9 | 0 |

| Bone fracture, chip | 3,295 | 26.3 | 3,107 | 94,897 | 31 | 14 |

| Crushing | 615 | 4.9 | 581 | 19,250 | 16 | 11 |

| Contusion | 559 | 4.5 | 536 | 8,790 | 16 | 4 |

| Amputation | 392 | 3.1 | 392 | 78,736 | 201 | 100 |

| Sprain, strains | 274 | 2.2 | 265 | 9,453 | 36 | 8 |

| Unclassified, not determined | 150 | 1.2 | 144 | 5,045 | 35 | 8 |

| Burn or scald (heat) | 127 | 1.0 | 121 | 1,943 | 16 | 5 |

| Other injury, NEC | 101 | 0.8 | 98 | 2,413 | 25 | 3 |

| Multiple injuries | 78 | 0.6 | 75 | 2,261 | 30 | 9 |

| Dislocation | 71 | 0.6 | 65 | 1,599 | 25 | 1 |

| Noncontact electric arc burn | 47 | 0.4 | 44 | 1,117 | 25 | 12 |

| Scratches, abrasions | 40 | 0.3 | 40 | 786 | 20 | 3 |

| Joint, tendon, or muscle inflammation or irritation | 36 | 0.3 | 29 | 635 | 22 | 4 |

| Electrical burn | 25 | 0.2 | 23 | 448 | 20 | 6 |

| Burn, chemical | 16 | 0.1 | 15 | 368 | 25 | 5 |

| Dermatitis | 10 | 0.1 | 7 | 9 | 1 | 0 |

| Freezing, frostbite | 5 | 0.0 | 5 | 1 | - | - |

| Total | 12,523 | 100.0 | 11,497 | 282,430 | - | - |

3.3. Glove Use

Nearly all 84 narrative text matches, where “glove” was not mentioned but “PPE” was, were too vague to code and were excluded from the glove analysis. Of the 854 narrative text matches where “glove” was mentioned, 754 (88%) were identified by the authors as cases where gloves were worn by the injured worker. Of these 754 injuries, wearing gloves contributed to 159 (21%) of injuries, meaning the narrative clearly states that the glove became entangled, caught on, caught in, or was pinched between something that the mine worker was handling before injury occurred. In most of these cases (76%), injuries where the glove contributed to the event resulted in the hand being caught in, under, or between an object or machine. Other injury types where the glove contributed to the injury were due to being struck by (11%), having contact with or abrasion (9%), and struck against (4%). When gloves contributed towards the injury, the worker was most often performing maintenance and repair activities (20%) or handling supplies or materials (19%), followed by roof bolting (17%), and using powered hand tools (14%). The injuries sustained included cut, laceration, puncture (39%); fracture, chip (28%); amputation (8%); and burn or scald from heat (7%) injuries.

3.3.1. Types of Gloves

Only 192 narratives indicated the type of gloves worn when an injury occurred. There were ten main types of gloves identified: cut-resistant, grip, heavy duty, latex/nitrile, leather, mechanics, metacarpal/impact, rubber/PVC, welding, and general work gloves. Leather gloves were by far the most common identified, with 90 cases (46.9%) mentioning leather gloves. Metacarpal gloves were the second most common type of glove identified, with 38 cases (19.8%). Table 4 lists the gloves identified and their associated nature of injury.

Table 4.

Types of gloves worn by mine workers identified in the narrative by the nature of injury sustained

| Nature of injury | Cut-resistant | Grip | Heavy-duty | Latex/nitrile | Leather | Mechanics | Metacarpal/impact | Rubber/PVC | Welding | Work gloves | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cut, laceration, puncture, contusion | 9 | 3 | - | 7 | 81 | 6 | 21 | 6 | 10 | 7 | 150 |

| Fracture, chip, crushing | 2 | 1 | 3 | - | 5 | 1 | 16 | 1 | 1 | 1 | 29 |

| Burn or scald (heat) | - | - | - | 1 | - | - | 1 | 2 | 2 | - | 6 |

| Amputation | - | - | - | - | 1 | - | 1 | - | - | - | 2 |

| Other injury or unclassified | - | - | - | 1 | 3 | - | 1 | - | - | - | 5 |

| Total | 11 | 4 | 3 | 9 | 90 | 7 | 38 | 9 | 13 | 8 | 192 |

A dash (-) indicates a value of 0 for that cell

3.3.2. Removal of Gloves

There were 29 injury cases identified from the glove usage data where the mine worker removed their glove(s) before the injury occurred. About 40% of the time, they were removed during maintenance and repair (12 cases). Gloves were also removed when handling supplies and material (4 cases) and welding and cutting (4 cases). The worker typically sustained a cut, laceration, or puncture (20 cases) to the hand or finger after removing the glove(s). Burns or scalds from heat also occurred in 6 cases.

3.3.3. Protection Characteristics

Of the 754 injuries identified in which gloves were worn, 418 (55%) were identified by the authors as possible cases that could have been avoided or resulted in a less severe injury if a glove offered optimal protection. Glove characteristics were identified as offering protection from abrasions, chemicals, cold temperatures, cuts, electrical conductivity, grinding, heat and fire, impact, injections, hazards entering through glove cuff, and punctures. These are listed in Table 5 along with the specific location on the hand that these characteristics were needed. Locations were as specific as the narrative indicated; however, 131 cases (32%) only referred to “hand,” which was followed by 61 thumb cases and 58 index finger injuries. Cut protection was the most needed form of protection for all the identified locations. The back of the hand also included the knuckles.

Table 5.

Location of injury by the needed glove characteristics to prevent the injury

| Location of injury | Cut | Puncture | Impact | Heat resistant/fire retardant | Tight cuff | Grinding | Injection | Other* | Total |

|---|---|---|---|---|---|---|---|---|---|

| Thumb | 46 | 11 | 2 | - | - | - | 2 | - | 61 |

| Index finger | 47 | 5 | 4 | - | - | - | 2 | - | 58 |

| Middle finger | 25 | 4 | 3 | - | - | - | - | - | 32 |

| Ring finger | 10 | 2 | 1 | - | - | - | - | - | 13 |

| Pinky/little finger | 13 | 2 | 4 | - | - | - | - | - | 19 |

| Finger (generic) | 17 | 8 | 2 | - | - | - | 1 | - | 28 |

| Fingertip | 2 | - | - | - | - | - | - | - | 2 |

| Multiple fingers | 2 | - | 1 | - | - | - | - | - | 3 |

| Between index and thumb | 8 | 2 | 2 | - | - | - | - | - | 12 |

| Between ring and pinky | 2 | - | - | - | - | - | - | - | 2 |

| Palm | 32 | 6 | 1 | - | - | - | - | - | 39 |

| Back of hand | 10 | 3 | 5 | - | - | - | - | - | 18 |

| Hand (generic) | 52 | 12 | 11 | 21 | 12 | 11 | 2 | 10 | 131 |

| Total | 266 | 55 | 36 | 21 | 12 | 11 | 7 | 10 | 418 |

A dash (-) indicates a value of 0 for that cell.

Other includes: Abrasion/chemical resistance, cold protection, electrical, improved glove hygiene, and improved grip

3.4. Work Tasks and Injury Sources

Based on the accident classification, handling materials were the most prevalent, accounting for 6021 (48%) hand/finger injuries, followed by hand tools (2795 (22%)), and machinery (1849 (15%)). Similarly, looking at the mine worker activity at time of the injury, the top five activities, elaborated on below, made up 75% of the injuries.

3.4.1. Materials Handling

Handling supplies/materials were the most common worker activity in which a hand/finger injury occurred, with 2808 injury cases (22%), with the items handled (source of injury) being mainly miscellaneous metals (pipe, wire, hand tools), metal guards, steel rail, and conveyor belts. Although the nature of injury associated with materials handling was statistically significantly different from other mine worker activities (χ2 (5, N = 12,523) = 12.32, p = 0.031), the differences were marginal, with material handling following similar trends to other activities and those shown in Table 3. Wearing gloves during material handling was associated with a lower likelihood of the glove contributing to an injury compared to those injured performing other activities (OR: 0.63 [95% CI: 0.41–0.96]).

3.4.2. Machine Maintenance and Repair Activities

Machine maintenance and repair activities were the second most common activity reported with 2735 (22%) hand/finger injuries. The sources of these injuries were similar to handling materials as they mainly were miscellaneous metals (pipe, wire, hand tools), metal guards, pumps, fans and engines, and drums/pulleys. Machine maintenance and repair activities often involved using hand tools and performing maintenance/repair activities on a variety of mining equipment including front end loaders, conveyors, haul trucks, crushers/mills, dozers, and screens. The natures of injury associated with machine maintenance and repair were significantly different from other mine worker activities (χ2 (5, N = 12,523) = 53.93, p < 0.001) with more than expected amputations or crushing, burns, or fracture or chips and less than expected cuts, lacerations, or punctures, and strain, sprain, or soft tissue injuries. Wearing gloves did not significantly change the likelihood of the glove contributing towards an injury for machine maintenance and repair.

3.4.3. Non-powered Hand Tools

The third most common mine worker activity reporting a hand/finger injury was using non-powered hand tools, with 2609 injury cases (21%). Most of the non-powered hand tools were knives (32%), followed by axe/hammer/sledge, miscellaneous metals, crowbar/pry bars, and wrenches. The natures of injury associated with non-powered hand tools were significantly different from other mine worker activities (χ2 (5, N = 12,523) = 311.18, p < 0.001), with more than expected cuts, lacerations, or punctures and less than expected amputations or crushing, burns, fracture or chips, and strain, sprain, or soft tissue injuries. Cut, laceration, or puncture injuries were most common with 1766 (68%) and followed by fractures, with 523 (20%). Knives were the leading cause of cut, laceration, or punctures (48%), followed by metal NEC (14%). In comparison, axes/hammers/sledges were the leading cause of fracture/chips (38%), followed by crowbars (14%) and wrenches (13%). Wearing gloves when using non-powered hand tools was associated with a much lower likelihood of the glove contributing to an injury compared to those injured performing other activities (OR: 0.08 [95% CI: 0.03–0.22]). This suggests gloves may protect against injuries from non-powered hand tools without creating an additional hazard.

3.4.4. Roof Bolting

There were 896 hand/finger injuries identified during roof bolting activities, making up 7% of all hand/finger injuries. Roof bolting activities included drilling, inserting bolts, and tramming. Drill steels caused 262 (29%) of these injuries, falling rock caused 215 (24%), the roof bolting machine caused 203 (23%), and the roof bolts contributed to 63 (7%) injuries. The natures of injury associated with roof bolting were significantly different from other mine worker activities (χ2 (5, N = 12,523) = 70.02, p < 0.001), with more than expected fractures or chips, and strain, sprain, or soft tissue injuries and less than expected amputations or crushing, burns, and cuts, lacerations, or punctures. Wearing gloves when roof bolting was associated with a higher likelihood of the glove contributing to an injury compared to those injured performing other activities (OR: 4.87 [95% CI: 2.72–8.71]), with nearly all of these injuries classified as caught in, under, or between moving objects.

3.4.5. Powered Hand Tools

There were 480 (4%) hand/finger injury cases that occurred during the use of powered hand tools. Drills, grinders, and air tools were the most common tools used. The natures of injury associated with powered hand tools were significantly different from other mine worker activities (χ2 (5, N = 12,523) = 32.39, p < 0.001) and followed a similar trend as non-powered hand tools with more than expected cuts, lacerations, or punctures and less than expected amputations or crushing, burns, fractures or chips, and strain, sprain, or soft tissue injuries. Wearing gloves when using powered hand tools is associated with a higher likelihood of the glove contributing towards an injury compared to those injured performing other activities (OR: 1.96 [95% CI: 1.14–3.38]), with 80% of these injuries classified as caught in, under, or between moving objects and 20% classified as struck by injuries.

3.4.6. Additional Specific Activities

Utility Knife Use

There were 892 knife/blade-related injuries with 276 (31%) injuries identified that involved the use of utility knives. Mine workers were injured by utility knives while cutting a variety of materials—wire, tubing, conduit, conveyor belt, etc. Knife-related incidents almost exclusively (99%) resulted in cut, laceration, and puncture injuries. Ninety-two injury cases mentioned gloves, and 71 (77%) of them involved wearing gloves. Glove type was identified in only 27 cases (38% of cases where gloves were mentioned), and 17 of these were leather gloves. None of these gloves were identified as contributing towards the injury.

Splicing Cables and Conveyor Belts

There were 147 injuries identified where a mine worker was splicing a cable or conveyor belt. Most of these injuries were hand tool related, with 80 (54%) injuries resulting from knives and 33 (22%) resulting from axes/hammers. There were only 24 cases where use of a utility knife and splicing overlapped. Splicing cables and belts resulted in 107 (73%) cut, laceration, and puncture injuries and 28 (19%) fractures. Only 11 of these injuries mentioned gloves and in 9 (82%) of these cases workers were wearing gloves.

Removal of Strapping/Banding

There were 114 injuries resulting from the removal of strapping or banding, and 93 (82%) of these injuries were cuts, lacerations, and punctures, and 17 (15%) were bone fractures. Miscellaneous metal (49, 43%) and knives (25, 22%) were the most common source of these injuries. Only 15 of these injuries mentioned gloves, and in 13 (87%) of them workers were wearing gloves.

Grinding Tasks

There were 141 injuries resulting from the rotation of a grinding wheel during grinding tasks. From the mine worker activity variable, 112 grinding activities were identified, but 16 were excluded due to not meeting the authors’ definition for grinding injury. An additional 45 cases that met the definition from the narrative search were included. Most of these injuries (131, 93%) resulted in cuts, lacerations, and punctures. Inadvertent contact with the spinning wheel was mostly due to kickback when grinding, grinder or part getting caught, and grinder slipping, jumping, or falling. Only 27 (19%) injury cases mentioned wearing gloves and of these, 6 specified glove type, with 4 identified as leather. Gloves contributed towards the injury for six cases.

Torque Tool Use

There were 235 injuries identified as resulting from using torque-related tools. Miscellaneous metals (nuts and bolts) were identified as the injury source for 117 injuries (50% of the time), while hand tools/wrenches made up 95 (40%) of these injuries. Most of the injuries (167, 71%) were cuts, lacerations, or punctures, while 42 (18%) of the injuries were fractures. The most common cause of injury from torque tools was a worker holding onto a nut and using an impact driver to remove the bolt; this caused the nut to spin and lacerate the hand. The narrative mentioned gloves for 50 of the cases, and the injured worker was wearing gloves for 47 (94%) of these cases. Of those wearing gloves, 8 (17%) cases were identified as the glove contributing towards the injury. Looking at the mine worker activity for these injuries, 135 (57%) were considered powered hand tools, 47 (20%) were classified as non-powered hand tools, and 44 (19%) were classified as machine maintenance and repair injuries. Many of these injuries were specifically from removing/installing the cutting edge on a loader bucket.

3.5. Injury Costs

Hand and finger injuries can result in substantial costs for self-insured mining companies. These companies do not have workers’ compensation insurance and pay the direct costs (medical and indemnity payments) out of pocket. Indirect costs include work stoppage and administrative and training costs; lost productivity; and cleanup, repair, or replacement of damaged property. These indirect costs and consequences of injury can be substantial for hand and finger injuries [11, 29]. NIOSH’s Safety Pays in Mining web application [26] can estimate direct and indirect costs of specific mining injuries. For example, a finger amputation has an estimated median direct cost of USD $10,800 (25th percentile or P25 = $5700, 75th percentile or P75 = $18,600) and an estimated indirect cost of USD $22,896, resulting in a total estimated cost of USD $33,696 to a mining company. Hand and finger fractures and crushing injuries have an estimated median direct cost of USD $1900 (P25 = $900, P75 = $9000) and an estimated indirect cost of USD $4028, resulting in a total estimated cost of USD $5928 to a mining company. Hand and finger lacerations have an estimated median direct cost of USD $900 (P25 = $600, P75 = $1300) and an estimated indirect cost of USD $1929, resulting in a total estimated cost of USD $2839 to a mining company.

4. Discussion

The goal of this paper is to highlight the burden and provide a descriptive analysis of hand and finger injuries in the mining industry. Even though the rates of hand and finger injuries declined slightly between 2011 and 2017, the high hand and finger injury rates (6.53 injuries per 1000 FTE mine workers), in comparison to other injury rates, emphasize the need to better understand and prevent hand and finger injuries at mines, especially in underground coal which had the highest rates of injury. The findings reinforce the previous work that found fingers as the most frequently injured body part at coal and metal/nonmetal mines [8]. Although the median days lost for most types of hand and finger injuries (other than amputations) and the costs associated with each injury were low compared to the other commonly injured body parts, a high percentage of incidents (91.8%) led to days lost, with an average of 40,347 days lost per year (about 5% of all days lost per year). This high percentage indicates that hand and finger injuries pose a burden to the mining industry. This supports existing research which shows that the severity of hand and finger injuries has increased over time [24]. It is noteworthy that the high mean and median days lost due to amputation injuries are due to the way the total days lost are calculated in the MSHA dataset, which considers statutory days lost for serious injuries [27]. Serious injuries like amputations, even though small in numbers, should not be discounted as they do lead to significant loss of function and quality of life [30, 31].

4.1. Glove Use

From a personal protective equipment standpoint, the mention of gloves in the hand and finger injury narrative was very low (7.5% of overall sample). This could be due to the lack of specificity in the narratives but could also indicate that gloves are not used often. Even with the small sample on glove use, some inferences can be drawn to help create prevention practices. In about 20% of the cases, the gloves contributed to the incident due to the hand being caught in, under, or between an object or machine. This supports the need to ensure that loose-fitting gloves or gloves which can get caught easily are not used when a risk exists for gloves getting caught in the equipment. This may also indicate another potential solution for gloves (or parts of gloves) which break away when they get caught, preventing the mine worker’s hand from being pulled into the equipment, provided they deliver the necessary level of protection in other scenarios.

When glove type was reported, leather gloves were the most used, and nearly 90% of these cases report cut, laceration, or puncture injuries. In general, leather gloves are not considered cut resistant, unless specially coated, lined, or otherwise specified by the manufacturer. Hand and finger lacerations were the most common nature of injury, and these injuries occurred frequently in spite of mine workers wearing gloves. When an injury occurred from using a knife, 77% of mine workers were wearing gloves, when information on glove use was available. Mining companies should ensure that they provide and encourage the use of appropriate gloves with adequate protection based on task and risk.

It is worth noting that there are not many non-healthcare occupational studies on glove effectiveness for reducing the risk of hand and finger injury. Furthermore, there is no consensus, as two studies identified a significant risk of injury when wearing gloves [32, 33] and five indicated gloves had a slight protective effect [2, 21, 34–36]. Sorock et al. (2004) performed the most extensive glove analysis identified to date and found an overall statistically significant protective effect (RR = 0.40; 95% CI: 0.34–0.48) across all occupational groups, especially for lacerations and punctures [21]. This lack of evidence as well as the results of this analysis supports the need for glove effectiveness research as well as understanding how glove performance specifications relate to mining-specific tasks.

It was surprising to note that in 42% of cases where metacarpal/impact gloves were used, the injury was related to crushing, fracture, and chips. Similarly, in a few cases, cutresistant gloves still resulted in a mine worker sustaining a cut. This can indicate that either the protection was not on the appropriate location of the hand, the protection was somehow deteriorated (such as with wear), or the incident was serious enough where the gloves could not provide the necessary level of protection needed to combat the hazard. This is supported by a recent laboratory evaluation of two types of metacarpal gloves commonly used in mining and oil and gas operations, which revealed that, depending on hand position, protection ranged from no change to a 23% reduction in peak reaction force [23]. This lends credence to the notion that PPE, like gloves, should be the last line of defense and that other changes should be made to prevent exposure to hazards.

For cases where the authors identified that possible injury could have been avoided or less severe (given a glove offered optimal protection), the most affected parts of the hand were the index fingers and thumbs. These parts of the hand are often used for dexterous tasks and for a pinch grip, followed by the palm and middle finger. Additional protection would be beneficial in these areas but may result in a trade-off between protection and reduced hand performance in terms of loss of dexterity and tactile sensitivity and reduced grip strength. We identified a few instances where workers removed their gloves during maintenance and repair activities, possibly due to better dexterity or tactile sensitivity. Finally, although glove designs that protect against impact, heat/fire, and grinding injuries are beneficial for the mining industry, the most critically needed protection is by far cut and puncture resistance, which Sorock et al. (2004) specifically identified as the injury types that gloves are effective in preventing [21].

4.2. Work Tasks and Injury Sources

Materials handling, as a primary activity at the time of the hand and finger injuries, has not received much attention. The previous work highlighted that handling debris and heavy objects contribute to hand and finger injuries [1]. However, in the mining industry, these injuries often occur when handling metal supplies such as metal parts, hardware, tools, guards, and belts. Hand and finger injuries associated with maintenance and repair are not surprising since these tasks are often non-routine tasks during which equipment does not perform as anticipated [21]. However, it is enlightening to identify that the source of injury for maintenance and repair injuries is similar to material handling and includes miscellaneous metals (pipe, wire, hand tools) and metal guards. This paper does not attempt to further investigate the causal factors or the etiology of hand and finger injuries due to material handling or maintenance and repair, but these factors do warrant further investigation in the mining industry to help with injury prevention efforts. As handling metal parts and supplies are significant contributors to injury, there is a need for not only improved engineering design of these components to possibly reduce sharp edges but also to install them in a way that reduces repeated handling. Injuries associated with handling metal parts also demonstrates a possible need for policies that require wearing appropriate hand protection when handling these components.

While reading, interpreting, coding, validating, and analyzing injury narratives can be time consuming, the large investment of time is justified as reading each narrative field did provide detailed information on specific tools and activities that contribute to hand and finger injuries. The number of cut, laceration, or puncture injuries was higher when using non-powered tools such as knives, hammers, crowbar/pry bars, and wrenches, as well as powered tools such as drills, grinders, and torque tools. Tool manufacturers can provide specific protection guidance to workers and those who design and direct workers’ jobs to help prevent hand and finger injuries. In addition to protection, guidance on the hazards associated with these tools and the limitations of protective gloves can be provided as hazards may not be obvious to mine workers [37]. For example, using a wrench instead of a gloved hand to hold onto a bolt while using an impact wrench is preferred since gloves may not protect the operator in this scenario. There are opportunities to improve tool design for the mining industry to help reduce hand and finger injuries—for example, designing improved cutting alternatives, similar to safe box cutters [38], or safer task-specific tools for band and strap removal and splicing conveyer belts. Roof bolting is known to be a significantly hazardous task [39], and even the severity of hand and finger injuries associated with roof bolting has been documented [24]. This analysis further highlights the need for improved hand and finger protection for roof bolting activities. Preferably, this is accomplished at higher levels of the hierarchy of hazard controls as compared to implementing personal protective equipment or gloves as a solution.

4.3. Limitations

Injury rates could only be calculated at the overall injury level (by year and body part) due to limitations in available data sources. Exposure information for work task or activity is not available, hence outcomes on these variables were limited to counts and percentage. The total days lost were reported including statutory days lost, which are days lost assigned by MSHA. Sammarco et al. (2016) highlight the limitations and advantages of this approach [27]. Statutory days lost were reported in 393 injury cases. Of these, 108 (27%) reported only statutory days lost, as they had no restricted nor lost days reported. While including statutory days may artificially inflate the “lost” days from work, they do reflect the most serious injuries. The injury codes in the MSHA dataset sometimes appear to be inconsistent with the narrative descriptions, as seen in the investigation of work tasks and sources of injury. For example, hand tools are sometimes referred to as unclassified metals, and the task of handling supplies and materials sometimes includes hand tools or other equipment/machinery. Despite its limitations, the dataset is by far the most complete and detailed source of information and is very helpful in providing insights into hand and finger injuries and possible prevention efforts. Lastly, the MSHA 7000–1 form for reporting accidents and injuries does not require information related to glove use. We were only able to identify glove usage if the injury narrative included “glove,” and the narrative field is an open-ended portion of the report, filled in at the discretion of the person reporting the incident. While any analysis of glove use is limited to where gloves are mentioned, it is the first step in understanding performance requirements and use scenarios for gloves in the mining industry.

5. Conclusions

From 2011 to 2017, the rate of hand and finger injuries in the US mining industry slightly decreased but remains dramatically higher than any other injured body part. Manual material handling, machine maintenance and repair, and hand tool use were the most common activities associated with hand and finger injuries. While the currently available data does not allow for analysis on the effectiveness of gloves for preventing injury, evidence exists where glove protection failed and even where glove use contributed towards injury. There is a need for further evaluation into hand protection strategies in the mining industry that goes over and above PPE or gloves and includes all levels of the hierarchy of hazard controls. Moreover, the glove design should be improved to ensure that gloves do not create additional hazards when in use.

Acknowledgements

This manuscript was originally published as THE NECESSITY FOR IMPROVED HAND AND FINGER PROTECTION IN MINING in the proceedings of the MINEXCHANGE 2022 SME Annual Conference & Expo in Salt Lake City, UT. Minor editorial changes may have been made to conform to the journal’s requirements.

Footnotes

Conflicts of Interest: The authors declare no competing interests.

Publisher's Disclaimer: The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. Mention of any company or product does not constitute endorsement by NIOSH.

Data Availability

Mining employment and injury data is available on the NIOSH Mining Data and Statistics webpage: https://www.cdc.gov/niosh/mining/data/default.html

References

- 1.Oleske DM, & Hahn JJ (1992). Work-related injuries of the hand: data from an occupational injury/illness surveillance system. Journal of community health, 17(4), 205–219. 10.1007/BF01321653 [DOI] [PubMed] [Google Scholar]

- 2.Sorock GS, Lombardi DA, Hauser RB, Eisen EA, Herrick RF, & Mittleman MA (2002). Acute traumatic occupational hand injuries: type, location, and severity. Journal of occupational and environmental medicine, 44(4), 345–351. 10.1097/00043764-200204000-00015 [DOI] [PubMed] [Google Scholar]

- 3.U.S. Bureau of Labor Statistics (2020) TABLE R2. Number of nonfatal occupational injuries and illnesses involving days away from work by industry and selected parts of body affected by injury or illness, private industry, 2019

- 4.Johns AM (1981). Time off work after hand injury. Injury, 12(5), 417–424. 10.1016/0020-1383(81)90015-2 [DOI] [PubMed] [Google Scholar]

- 5.Wong JYP (2008) Time off work in hand injury patients. J Hand Surg 33(5):718–725. 10.1016/j.jhsa.2008.01.015 [DOI] [PubMed] [Google Scholar]

- 6.Morgan W, Harrop S (1985) Hand injuries in south Wales coal miners. Occup Environ Med 42(12):844–847 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sanders M, Krohn G, Downing J, Shaw B (1985) Personal equipment for low seam coal miners: development and testing of knit fabric gloves. Bureau of Mines, Pittsburgh [Google Scholar]

- 8.Coleman P, Brune J, Martini L (2010) Characteristics of the top five most frequent injuries in United States mining operations, 2003–2007-introduction. Trans Soc Min Metall Explor 2010(326):61–70 [Google Scholar]

- 9.Heberger JR, Pollard JP (2011) Machine maintenance and repair injuries in mining mills and preparation plants. National Occupational Injury Research Symposium, Morgantown [Google Scholar]

- 10.Pollard J, Heberger J, & Dempsey PG (2014). Maintenance and repair injuries in US mining. Journal of quality in maintenance engineering, 20(1), 20–31. 10.1108/JQME-02-2013-0008 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Robinson LS, Sarkies M, Brown T, O’Brien L (2016) Direct, indirect and intangible costs of acute hand and wrist injuries: a systematic review. Injury 47(12):2614–2626. 10.1016/j.injury.2016.09.041 [DOI] [PubMed] [Google Scholar]

- 12.(2020) Safety and health standards, surface metal and nonmetal mines, Mine Safety and Health Administration Part 56

- 13.(2020) Safety and health standards, underground metal and nonmetal Mines, Mine Safety and Health Administration Part 57, 2020.

- 14.Occupational safety and health standards, personal protective equipment, hand protection, Occupational Safety and Health Administration Part 1910, 2020.

- 15.Eastman Kodak Company (1983) Ergonomic design for people at work. Wadsworth Publishing Company, Belmont [Google Scholar]

- 16.Rock KM, Mikat RP, Foster C (2001) The effects of gloves on grip strength and three-point pinch. J Hand Ther 14(4):286–290. 10.1016/S0894-1130(01)80007-7 [DOI] [PubMed] [Google Scholar]

- 17.Dianat I, Haslegrave CM, Stedmon AW (2012) Methodology for evaluating gloves in relation to the effects on hand performance capabilities: a literature review. Ergon Rev 55(11):1429–1451. 10.1080/00140139.2012.708058 [DOI] [PubMed] [Google Scholar]

- 18.Kovacs K, Splittstoesser R, Maronitis A, Marras WS (2002) Grip force and muscle activity differences due to glove type. AIHA J 63(3):269–274. 10.1080/15428110208984713 [DOI] [PubMed] [Google Scholar]

- 19.Buhman DC, Cherry JA, Bronkema-Orr L, Bishu R (2000) Effects of glove, orientation, pressure, load, and handle on submaximal grasp force. Int J Ind Ergon 25(3):247–256. 10.1016/S0169-8141(99)00015-3 [DOI] [Google Scholar]

- 20.Sudhakar L, Schoenmarklin R, Lavender S, Marras W (1988) The effects of gloves on grip strength and muscle activity. Proceedings of the Human Factors Society Annual Meeting, vol 32. SAGE Publications Sage, Los Angeles, pp 647–650 [Google Scholar]

- 21.Sorock GS, Lombardi DA, Hauser R, Eisen EA, Herrick RF, Mittleman MA (2004) A case-crossover study of transient risk factors for occupational acute hand injury. Occup Environ Med 61(4):305–311. 10.1136/oem.2002.004028 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.McGwin G Jr, Taylor AJ, MacLennan PA, Rue LW III (2005) Unusual job activities as a risk factor for occupational injuries. Occup Med 55(1):66–68. 10.1093/occmed/kqi020 [DOI] [PubMed] [Google Scholar]

- 23.Sosa EM, Alessa FM (2021) Experimental evaluation of protected and unprotected hands under impact loading. J Biomech 118:110326. 10.1016/j.jbiomech.2021.110326 [DOI] [PubMed] [Google Scholar]

- 24.Alessa FM, Nimbarte AD, Sosa EM (2020) Incidences and severity of wrist, hand, and finger injuries in the U.S. mining industry. Safety Sci 129:104792. 10.1016/j.ssci.2020.104792 [DOI] [Google Scholar]

- 25.Notification, investigation, reports and records of accidents, injuries, illnesses, employment, and coal production in mines, Part 50, 2020.

- 26.National Institute for Occupational Safety and Health. Safety pays in mining. U.S. Department of Health and Human Services. https://www.cdc.gov/niosh/mining/works/coversheet2021.html. Accessed 1 Sept 2021 [Google Scholar]

- 27.Sammarco J, Podlesny A, Rubinstein E, Demich B (2016) An analysis of roof bolter fatalities and injuries in US mining. Trans Soc Min Metall Explor Inc 340(1):11. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5568560/ [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Heberger JR (2018) Demonstrating the financial impact of mining injuries with the “Safety Pays in Mining” web application. Mining Engineering 70(12):37–43. 10.19150/me.8643 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Dias JJ, Garcia-Elias M (2006) Hand injury costs. Injury 37(11):1071–1077. 10.1016/j.injury.2006.07.023 [DOI] [PubMed] [Google Scholar]

- 30.Burger H, Maver T, Marinček Č (2007) Partial hand amputation and work. Disabil Rehabil 29(17):1317–1321. 10.1080/09638280701320763 [DOI] [PubMed] [Google Scholar]

- 31.Davidson JH, Khor KE, Jones LE (2010) A cross-sectional study of post-amputation pain in upper and lower limb amputees, experience of a tertiary referral amputee clinic. Disabil Rehabil 32(22):1855–1862. 10.3109/09638281003734441 [DOI] [PubMed] [Google Scholar]

- 32.Choi W-J, Cho S-I, Han S-H (2012) A case-crossover study of transient risk factors for occupational traumatic hand injuries in Incheon, Korea. J Occup Health 54(1):64–73. 10.1539/joh.11-0101-FS [DOI] [PubMed] [Google Scholar]

- 33.Jin K, Lombardi DA, Courtney TK, Sorock GS, Li M, Pan R, Wang X, Lin J, Liang Y, & Perry MJ (2012). A case-crossover study of work-related acute traumatic hand injuries in the People’s Republic of China. Scandinavian journal of work, environment & health, 38(2), 163–170. 10.5271/sjweh.3262 [DOI] [PubMed] [Google Scholar]

- 34.Liu X-X, Huang G-X, Huang H-Q, Wang S-Y, Zong Y, Chen W-Q (2016) Transient risk factors for acute occupational hand injuries among metal manufacturing workers: a case-crossover study in southern China. Am J Ind Med 59(10):832–840. 10.1002/ajim.22625 [DOI] [PubMed] [Google Scholar]

- 35.Kucera KL, Loomis D, Marshall SW (2008) A case crossover study of triggers for hand injuries in commercial fishing. Occup Environ Med 65(5):336–341. 10.1136/oem.2006.032375 [DOI] [PubMed] [Google Scholar]

- 36.Chow CY, Lee H, Lau J, Yu ITS (2007) Transient risk factors for acute traumatic hand injuries: a case-crossover study in Hong Kong. Occup Environ Med 64(1):47–52. 10.1136/oem.2006.028589 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Eiter BM, Kosmoski CL, Connor BP (2016) Defining hazard from the mine worker’s perspective. Min Eng 68(11):50–54. 10.19150/me.6832 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Cottrell C (2018). POWER WITH PROTECTION: Choosing the right safety knife. Professional Safety, 63(6), 66. Retrieved from https://www.proquest.com/scholarly-journals/power-with-protection-choosing-right-safety-knife/docview/2050597972/se-2?accountid=26724 [Google Scholar]

- 39.Groves WA, Kecojevic VJ, Komljenovic D (2007) Analysis of fatalities and injuries involving mining equipment. J Safety Res 38(4):461–470. 10.1016/j.jsr.2007.03.011 [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Mining employment and injury data is available on the NIOSH Mining Data and Statistics webpage: https://www.cdc.gov/niosh/mining/data/default.html