Abstract

Chitin, a fascinating biopolymer found in living organisms, fulfills current demands of availability, sustainability, biocompatibility, biodegradability, functionality, and renewability. A feature of chitin is its ability to structure into hierarchical assemblies, spanning the nano- and macroscales, imparting toughness and resistance (chemical, biological, among others) to multicomponent materials as well as adding adaptability, tunability, and versatility. Retaining the inherent structural characteristics of chitin and its colloidal features in dispersed media has been central to its use, considering it as a building block for the construction of emerging materials. Top-down chitin designs have been reported and differentiate from the traditional molecular-level, bottom-up synthesis and assembly for material development. Such topics are the focus of this Review, which also covers the origins and biological characteristics of chitin and their influence on the morphological and physical-chemical properties. We discuss recent achievements in the isolation, deconstruction, and fractionation of chitin nanostructures of varying axial aspects (nanofibrils and nanorods) along with methods for their modification and assembly into functional materials. We highlight the role of nanochitin in its native architecture and as a component of materials subjected to multiscale interactions, leading to highly dynamic and functional structures. We introduce the most recent advances in the applications of nanochitin-derived materials and industrialization efforts, following green manufacturing principles. Finally, we offer a critical perspective about the adoption of nanochitin in the context of advanced, sustainable materials.

1. Nanochitin and Its Sustainability

1.1. Nanochitin as a Renewable Material

Society is witnessing a global impetus toward regenerative systems that move us closer to the goals of the bioeconomy and fast-changing materials production models,1 directing to improve the quality of life while minimizing or preventing negative impacts on the environment. This requires a shift of material screening from fossil sources to biomass ones,2 wherein accessible bioresources are critical. The ocean ecosystem, covering 71% of Earth’s total surface and containing 97% of all water on our planet, is a source of life3,4 and emerges as an “unlimited” bioresource.5 This is particularly true as the development of aquaculture overcomes many of the issues that are associated with agricultural land use, which can eventually reach saturation. The biomass found in the ocean possesses unique structures compared to that in land organisms;6,7 however, it represents a minor subject in the field of natural biopolymers, vastly outweighed by the popularity of plant-based resources. An exception is the case of biopolymers sourced from algae, which can be envisioned as an active area in future ocean-based biorefineries. On the other hand, chitin is the most abundant biopolymer in the ocean, principally present in the exoskeletons of crustaceans.8,9 Annually, 6–8 million tons of waste crab, shrimp, and lobster shells are produced globally,10 particularly from Asian counties.11 Basically, chitin is a long-chain polymer of (1,4)-β-N-acetylglucosamine, a derivative of glucose,12,13 making it a major precursor of cationic polysaccharides from nature, and exhibits biological activity, biocompatibility, biodegradability, low allergenicity, and easy processability.14−17

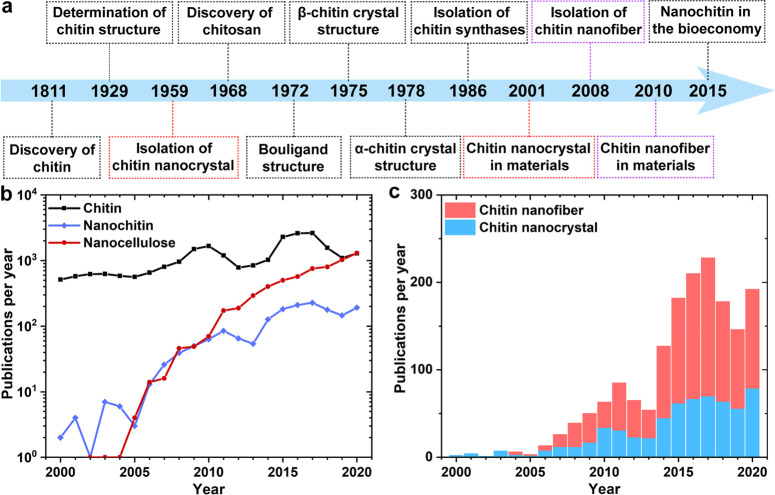

Despite its many attractive features, chitin remains among the least utilized biomass resource given its intractable structure and recalcitrance toward processing.18 Indeed, after its discovery over two centuries ago,19 reports on chitin utilization is only dated in recent decades (Figure 1a). Chitin is mostly used in its highly deacetylated (degraded) form, known as chitosan, which shows good solubility and processability in acidic conditions.20 However, the abundant waste produced in chitosan production can be seen as a limitation to the sustainable use of chitin,21 which justifies the consideration of new strategies with better environmental and economic prospects. Thus, direct processing and conversion of chitin into novel building blocks, fitting material design and creation, represent a green and well justified alternative. To this end, one can take advantage of the structural characteristics of chitin at the nanoscale, referred in this Review as “nanochitin”. Nanochitin is the elementary building block of chitin structures, more precisely, hierarchical mesostructures, featuring similar chemical and biological reactivity compared to the chitin precursor. Understanding the structural construction of nanochitin in nature, as well as its chemical adaptability, will facilitate its adoption toward performance optimization and inspire the design of novel engineered materials. Considering the annual rate of publications in the area, research related to nanochitin follows a much slower rate compared with that of the parent chitin (Figure 1b). Therefore, the characteristics of nanochitin, particularly from the material perspective, remain a topic for upcoming discoveries.

Figure 1.

(a) Timeline of discovery, analysis, extraction, use, and future direction of chitin and nanochitin. Red and purple dashed frames indicate chitin nanocrystal and nanofiber, respectively. Adapted with permission from ref (19). Copyright 2018 Elsevier. Summary of publications relating to (b) chitin, nanochitin, and nanocellulose and (c) comparison of chitin nanofibers and nanocrystals. The number of publications was collected from the Science and Engineering Indicators of the National Science Foundation between 2000 and 2020 using Scopus. The research was limited to titles, abstracts, and keywords as follows: chitin/cellulose (*) nanocrystal and nanofiber, including * nanowhisker, * whisker, * nanorod, * crystallite, nanocrystalline *, * nanofiber, * nanofibril, nanofibrillar *, and nanofibrillated *.

1.2. Nanochitin Characteristics

Structurally, nanochitin is considered as an assembly of semicrystalline chitin nanofibrils that show highly oriented nanocrystals embedded in an amorphous matrix, wherein single nanofibrils are packed into highly orientated microfibrils or fibril bundles that are held together by van der Waals (vdW) forces and hydrogen bonding (H-bonding).22 The attractive properties of nanochitin stem partially from its fibrillar or rodlike nature, nanometer lateral dimension, and tailorable crystallinity, among others. Chemically, nanochitin is confined by a sheath of proteins and is assembled into elongated fibrils that are embedded in a mineral–protein matrix in the exoskeleton of arthropods. Hence, removal of proteins and minerals is a necessary step prior to nanochitin isolation. Unlike other forms of natural nanopolysaccharides, nanochitin contains nitrogen, which is crucial for life.23 The amino groups also endow nanochitin with versatile processing and a vast number of applications that are not typical of their nanopolysaccharide counterparts.

In this Review, we consider two types of nanochitin, chitin nanofiber (ChNF) and nanocrystal (ChNC), which have equally attracted research interests in recent years (Figure 1c). To keep the inherent native crystalline structure, the most common route to access nanochitin is direct disintegration of chitin bundles. Hence, unlike most synthetic nanoparticles, nanochitin is produced top-down and preserves, to some degree, the biological morphology and ordered structure in shells. Thus, different from the regenerated chitin nanomaterials based on the dissolved chitin,18 nanochitin maintains a sophisticated meso-architecture that reflects that of its source, endowing the possibility for reconstruction into structures that take advantage of the features of “nanosized units” essential for nanotechnology as a field.19

The processing methods used to produce nanochain greatly influence its characteristics. ChNC is typically produced by controlled chemical reactions that selectively remove the disordered chitin segments present in the source material, leaving chitin crystallites intact.24 Upon processing, surface charges, either positive or negative, can be installed on the ChNC surface, which ensures colloidal stability in aqueous media. The resultant nanoparticles can be considered as rigid nanorods (highly crystalline chitin assemblies),25 akin to cellulose nanocrystals (CNC).26,27 ChNF, on the other hand, is obtained by disintegrating native chitin using mechanical treatments without removal of the disordered, noncrystalline regions. When no surface chemical treatment is applied to native chitin, mechanical shearing, even under intense conditions, results in ChNF that presents heterogeneously distributed lateral dimensions. On the contrary, more individualized ChNF, e.g., with relatively uniform lateral dimensions, can be achieved by mechanically disintegrating chitin after chemical pretreatment, wherein enhanced interfibrillar repulsion exists given the ionized nanofibril surface. Important features of ChNF include its high axial aspect ratio and flexibility, which promote entanglement and, together with hydration and electrostatic interactions (if present), facilitate the formation of hydrogels at low concentrations.

In the past two decades, nanochitin has increasingly captured the attention of academia, as evidenced by the rapid publication growth (Figure 1b); nevertheless, it still lags behind other biomass-based nanoparticles, such as nanocelluloses,28 particularly in the recent decade (Figure 1b). The main reason for this latter observation is likely related to the fact that although chitin shares many similarities with cellulose, the hydroxyl groups in chitin are partially occupied with acetyl amine, resulting in stronger H-bonding between the neighboring chains.29 This makes chitin more stable and more difficult to be disintegrated or isolated than cellulose, significantly affecting access and conversion of chitin to nanochitin, not to mention that the acceptability of nanochitin in different cultures influences its utilization and commercialization. To conclude, nanochitin has been less popular compared to other renewable nanoparticles but shows significant attractiveness given its remarkable potential, which deserves a systematic investigation in the future and is the main subject of this Review.

1.3. Scope of This Review

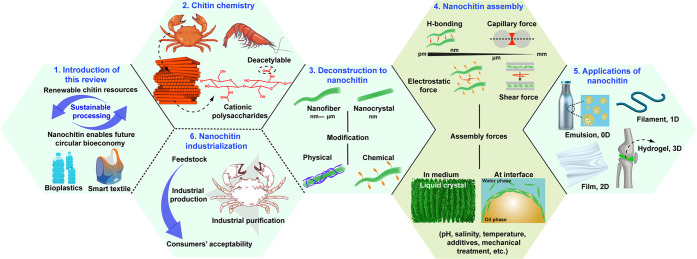

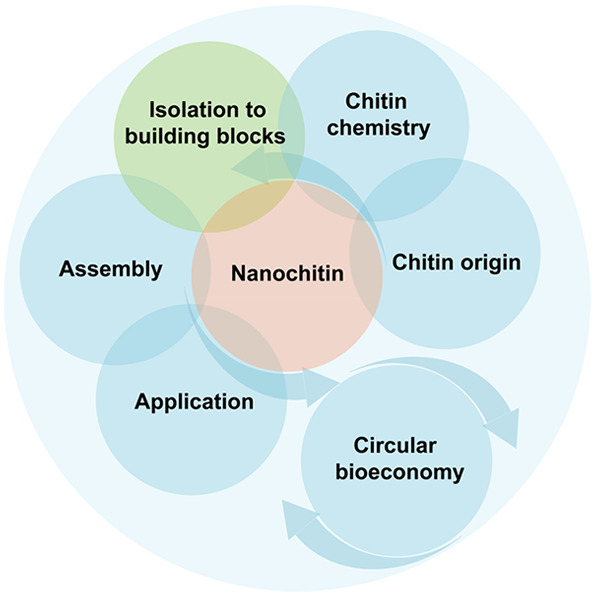

We review the topic of nanochitin as a source of sustainable materials, following the general structure schematically illustrated in Figure 2. We highlight the use of nanochitin to improve the accessibility and utilization of ocean and other resources and emphasize a performance that matches or surpasses that of other biomass-based nanomaterials (Figure 2, panel 1). Several recent reviews have considered nanochitin, mostly focusing on its application and covering topics related to material development and associated physicochemical properties. Here, we comprehensively discuss aspects related to nanochitin colloidal interactions and assemblies to develop new functions. We address the possibility of harnessing the fundamental chemical and structural characteristics of nanochitin to guide material assembly, design, and development, highlighting the significance and uniqueness of each involved step, including isolation, modification, processing, reconstruction, and industrialization. Particularly, we refer to advances in nanochitin produced from top-down strategies, acknowledging bottom-up synthesis routes.18,30 Herein, we first discuss the origin and biological and chemical features of chitin, which are key aspects relevant to its deconstruction into nanochitin, giving an accent to the superiority of top-down approaches and highlighting the adaptability of nanochitin (Figure 2, panels 2 and 3). The assembly interactions that take part in the multiscale structuring of nanochitin in a variety of media are then summarized (Figure 2, panel 4), bearing in mind that processing conditions greatly influence the suprastructures of assembled nanochitin. We further show the potential of nanochitin as a building block of multidimensional bioproducts and discuss the relevant structure–process–property relationships, considering dynamic assembly strategies (Figure 2, panel 5). We close the Review by discussing upcycling and industrialization opportunities with an eye on the future, taking (nano)chitin as an enabler for circular and sustainable manufacturing (Figure 2, panel 6).

Figure 2.

Structure of this Review, which includes a brief introduction (panel 1, section 1) and introduces the relationship between chitin chemistry (section 2) and its deconstruction into nanochitin (panel 3, section 3). The Review also covers the main interactions (panel 4, section 4) that rule the multiscale structuring of nanochitin in a variety of media, resulting in diverse applications. The latter take advantage of multidimensional phenomena (panel 5, section 5). Finally, we present the promise of nanochitin in relation to industrialization and to accelerate materials development in the context of the bioeconomy (panel 6, section 6).

2. Origin, Biological, and Chemical Features of Chitin

2.1. Biological Origins of Chitin

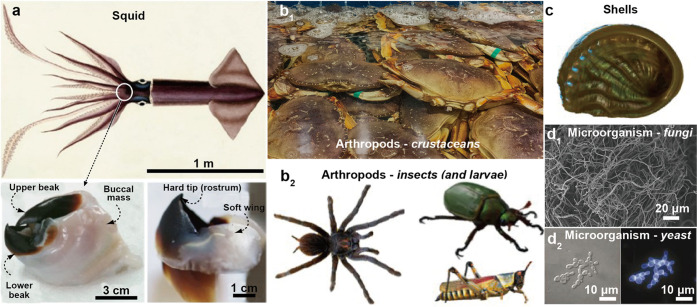

Chitin makes up parts of many different organisms with unique molecular structures (Figure 3).31 In this subsection, chitin sources are introduced along with their main features. Although different classes of organisms, e.g., terrestrial or marine, fungi, or insects, are considered in many instances, a small subset of species has been explored in the context of chitosan and chitin valorization. In most cases, these are associated with waste streams such as silk-work larvae, seafood byproducts, or simply processing food-waste derived from insect biomass.8,32 However, there is a very large set of chitin-synthesizing organisms, namely, nearly all insects, fungi, crustaceans, seashells, and mollusks. These organisms use chitin for a range of functions that include scaffolding during growth, mechanical strength and toughness, controlled opacity and light reflection, adhesion, and communication and as a first line of defense against microorganisms and pathological stress.33−36 Herein, we introduce the biosynthesis of chitin and chitin suprastructures found in organisms. Regarding chitin metabolism, superstructures, and functions, it is important to note that insects are most studied since they are easily accessible and common subjects of developmental biology. Furthermore, their body parts do not present a high mineral content compared to crustaceans or seashells, enabling a more facile identification of chitin-related intricate structures.

Figure 3.

Variety of organisms associated with chitin, including, to cite only a few examples: (a) Squid, typically in the beak and pens. Adapted with permission from ref (37). Copyright 2008 American Association for Advancement of Science. Arthropods including (b1) crustaceans and (b2) insects and their larvae. (c) Shells, from terrestrial, river, or sea mollusks. Microorganisms including (d1) fungi and (d2) yeast. The dispersed mycelium in d1 is harvested from Aspergillus niger, and the yeast pseudohyphae in d2 is stained by Calcofluor white. Adapted with permission from refs (38) and (39). Copyright 2021 and 2002, respectively, Springer Nature.

2.1.1. Chitin’s Multiscale Structures and Functions

Chitin nanofibrils are arranged following a wide variety of biological architectures. The arrangement of nanofibrils enable tethering of a range of macroscopically observable properties. This includes networks of chitin and proteins in the exoskeleton of arthropods to achieve a remarkable combination of strength and toughness. However, chitin nanofibrils also form structures used for adhesion, enabling adhesion to a wide range of surfaces that support the full animal body weight or, for specific reflection of light, in a palette that finds no match in current synthetic colors. We introduce these aspects as a premise to reverse engineering chitin nanofibrils.

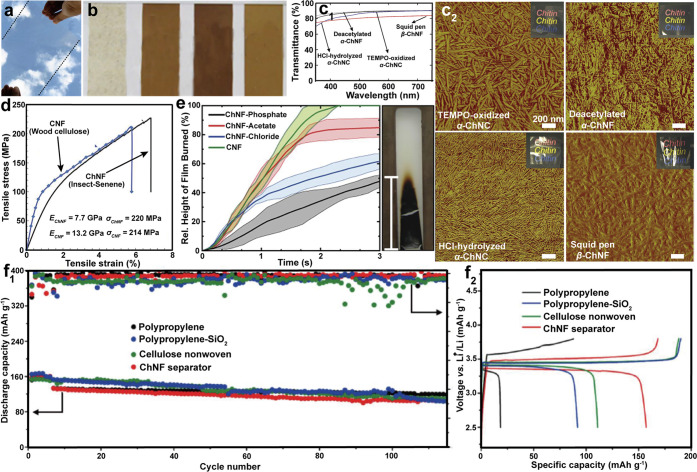

2.1.1.1. Nanochitin Structures and Mechanical Resilience

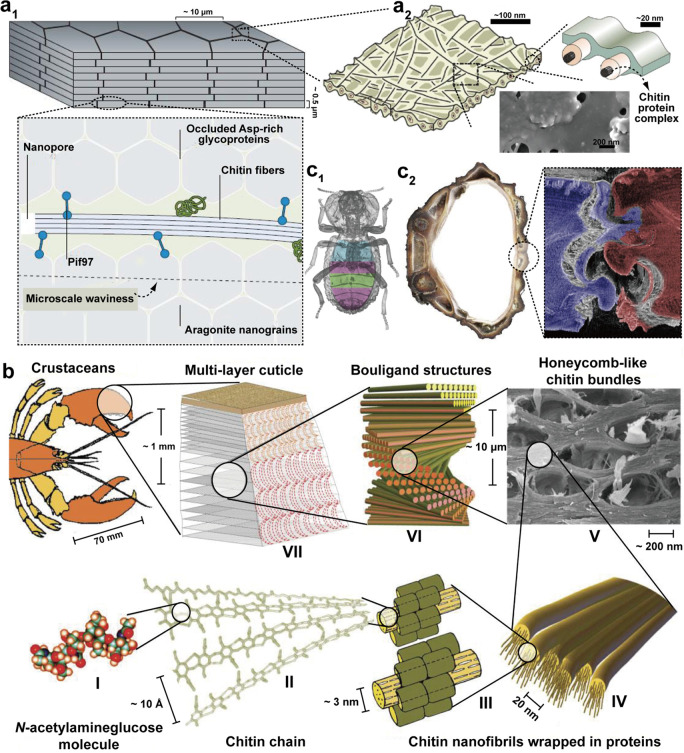

When put to scale, chitin structures, particularly in insects, seashells, and crustaceans, possess an ideal combination of strength and toughness-to-body weight ratio. Most structures are expressed asbrick-and-mortar architectures, where energy dissipation occurs via a fracture and follows a tortuous path, i.e., energy dissipating along soft layers surrounding hard, generally minerals, e.g., calcium carbonate layers. Such architectures are typically observed in nacre or crustaceans (Figure 4a1)40 and have inspired many efforts in biomimicry.41 Although chitin is strong, with an axial tensile strength of the order of a gigaPascals,42 the chitin–protein bundles act as soft layers (Figure 4a2). Moreover, the interactions between individual components are extremely strong, contributing to overall mechanical toughness exhibited by the respective organisms. As determined by X-ray diffraction, the axial modulus of a dry α-chitin crystal has been estimated to be 41 GPa, making the fibers both strong and stiff in the axial direction.43 The axial Young’s modulus of such nanofibers is generally an order of magnitude higher than the transversal modulus, associated with the directionality of the fibrous networks with macroscopic stiffness. Importantly, the flexural anisotropy can be completely removed at the macroscopic scale by arranging the fibers hierarchically.44 In insects, chitin plays a role as hard component since there are no minerals.

Figure 4.

Examples of multiscaled chitinous structures present in biological constructs. (a1) Mineral platelets organized within nacreous structures, e.g., in seashells, wherein the plates are cemented by calcite–protein–chitin complexes. Adapted with permission from ref (49). Copyright 2016 Springer Nature. (a2) Chitin fibril bundles within the protein matrix between inorganic plates. Adapted with permission from ref (60). Copyright 2021 American Chemical Society. (b) Multiscaled structures found in crustaceans. The monomeric unit (I) is polymerized into chitin polymers (II), which form bundles within proteins with specific binding sites (III). The bundles are arranged in a number of structures that optimize fracture deflection and strain-dependent response, herein exemplified with the honeycomb structure (V) and helicoidal Bouligand structures found at multiple scales within the cuticle (VI, VII). Adapted with permission from ref (44). Copyright 2010 John Wiley and Sons. (c1) Plane view of diabolical ironclad beetle, highlighting three distinct internal regions with variable spacing between organs and elytra. (c2) The jigsaw-type joints in the beetle yield a sequential manner, through delamination of the joints (right panel: computed tomography reconstruction of fractured suture), resulting in the highest resistance to compression in the animal kingdom. Adapted with permission from ref (53). Copyright 2020 Springer Nature.

Beyond nanoscaled brick-and-mortar architectures, there are a range of structures found in insects and crustaceans that elevate the potential for energy dissipation (Figure 4b).45,46 At each scale, these structures optimally dissipate various compressive, tensile, or flexural macroscopic stresses occurring from multiple directions. In comparison, collagen, silk, or cellulose nanofibrils (CNF) take up only relatively simple conformations, although also multiscaled.22 These simple conformations are aligned in the case of collagen or silk and twisted around the cell walls in the case of cellulose. Most of the chitinous architectures observed in arthropods present the so-called Bouligand structures. They correspond to stacked and rotated fibrous microstructures, forming lamellae or layers that resemble plywood (Figure 4b). Therein, aligned fibrils enable in-plane isotropy, and particularly, adjacent layers are progressively rotated with respect to their neighboring ones. This helicoidal architecture efficiently deflects fractures and cracks as a function of the twist angle, typically small (<10°), and results in three-dimensional dissipation of the stresses and higher angles to delamination. This type of hierarchical structure is generally convoluted with topographical motifs. Thereafter, the sheetlike helicoidal layers are curved into periodic structures or spheroidal contours.47,48 This is the case of the mantis shrimp that exhibits some of the best combinations of strength and toughness, as found in its hammerlike appendage. This added level of hierarchy enables the hammer of the mantis shrimp to easily fracture seashell nacre, although both are mineralized structures comprising proteins and chitin.49 Beyond Bouligand structures, a range of “lock-in” mechanisms can be found from chitinous architectures, where the radius of curvature within jigsawlike structures, combined with their tilt angle, provides optimal stress dissipation mechanisms.50−52 This has most recently been highlighted in the diabolical ironclad beetle that presents one of the most remarkable displays of resistance to compression in the animal kingdom while possessing a rather low density body (Figure 4c).53 This is achieved by combining a delaminating chitinous structure with jigsaw joints that help with transduction of the stresses across the joined interfaces. Lastly, a typical structure combined with the previously mentioned configurations is that of honeycomb, where chitin bundles are organized in an architecture within each of the layers, which can be arranged in Bouligand structures across planes. The stiffness of these planes can be modulated for efficiently dissipating in-plane stresses as a function of the ratio of chitin bundle thickness to the segment length of the hexagonal structures.54

In another implementation, macroscaled porosity within the chitin-based skeleton of the squid pen enables multiscaled buoyancy chambers, which can resist the varying hydrostatic pressures of the ocean.55 At the macroscale, a large range of architectures can be observed, with animal cales and armors being typical examples as well as patterned armor of certain animals.56,57 In the case of fungi, the diversity in chitin long-range order is considerably reduced with much less intricate designs. In contrast, in insects and crustaceans, many structures have been optimally designed to dissipate stress, relevant to the direct environment associated with the respective organisms. These structures are the subject of ongoing studies that aim to generate materials following the concepts of biomimicry, from the nano- to macroscale. At the nanoscale levels, liquid crystals (LCs) are used to reproduce related architectures. At the macroscale, interesting developments take place in designs for the automotive and aeronaval industries, which can take advantage of the physical and mechanical features found in nature,50,58 for instance, exemplified by the strategies used in mechanical fasteners, similar to those found in turbine engines or dovetails in turbine blades as well as landing gear fittings.53,59

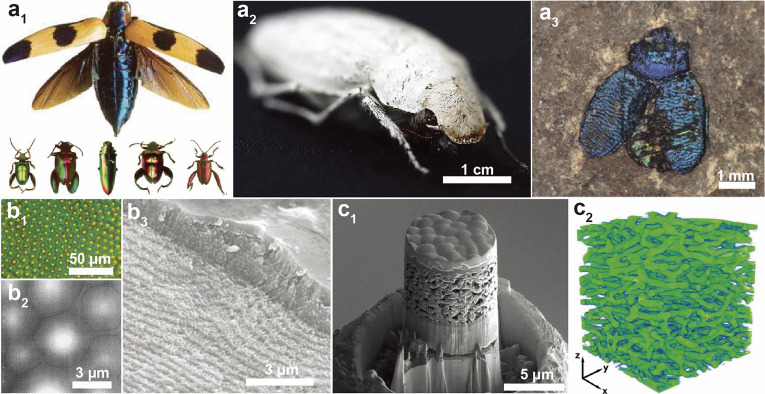

2.1.1.2. Nanochitin Structures and Selective Light Reflection

In addition to the mechanical properties, the long-range order of chitin-based structures results in a wide range of optical properties, associated with structural color, where periodical features generate a broad range of optical phenomena (Figure 5a1 and 5b1), enabling color mixing, angle-dependent color (iridescence), circular polarization, and selective filters, among others.61−64 Color production is typically generated via pigmentation (typically from amino acids aromatic residues), interference, diffraction, and scattering or a combination of these four phenomena.65 Within very thin layers (<10 μm) present on given animals, these “colors” range from highly white (Figure 5a2) or black layers to broadband or very narrow band specific reflections (Figure 5a1). These reflections are considerably more resistant to fading than those obtained from pigments. Indeed, fossils that are a million years old still show high intensity reflections (Figure 5a3).66 While the wings of butterflies generally result in colors by a combination of phenomena, the reflections from beetles or crustaceans are more typically associated with light interference and that of the moth is associated with diffraction gratings.65 In recent days, interference is the most studied case, principally from films or layered structures. Specific iridescent reflections, where color display is angle-dependent, are a result of such interference phenomena.67 Nanostructured fibrils present in the chitin-containing species are organized into hierarchical, periodic thin films structures with scales matching the visible spectrum, between ca. 300 and 800 nm.68 These films can be curved, which results in direction-controlled color where the refractive index (RI) difference is generated between the chitin fibrils and that of the surrounding matrix. Although not fully addressed in the scientific literature, there also exist examples of iridescent fungi, for instance, Elaeomyxa cerifera, where chitin plays a key role.

Figure 5.

Chitin structures and associated colors found in beetles. (a1) Range of structural colors in various beetles. Adapted with permission from ref (74). Copyright 2008 John Wiley and Sons. (a2) Highly scattering shell of Cyphochilus sp. yielding a superwhite appearance. Adapted with permission from ref (72). Copyright 2018 John Wiley and Sons. (a3) Preserved 40 million year old beetle cuticle showing light (Chrysomelids from Eckfeld). Adapted with permission from ref (66) . Copyright 2012 The Royal Society. (b1) Optical micrograph of the exoskeleton of beetle Chrysina gloriosa showing bright yellow reflections from the core of each cell and greenish reflection from the edges. (b2) AFM and (b3) SEM images for the orientation of the Bouligand structures into semispheres in the epicuticle. Adapted with permission from ref (63). Copyright 2009 American Association for Advancement of Science. (c1) Cross-sectional SEM and (c2) 3D reconstruction of structures of white reflecting epicuticle as displayed in a3. Adapted with permission from ref (72). Copyright 2018 John Wiley and Sons.

The best understood structures generating structural colors in the animal realm are based on chiral-nematic order, associated with Bouligand structures (Figure 5b2 and b3).63 Such color strategy enables selective polarization reflection, depending on the helicoidal turn taken by chitin nanofibrils, typically filtering light into left-handed polarized reflections. This is used as visual cues between animals that possess circularly polarized sensitive vision.69 When observing the helicoidal turns in Bouligand structures, the pitch that corresponds to half a full turn determines the reflected colors, with a larger pitch resulting in colors of larger wavelengths being reflected.70 In animals, reflections outside the visible range are commonly found. Structural colors are generally more pronounced in beetles due to their proportionally thicker cuticle.71

Beyond specific reflections, chitinous networks can form highly scattering layers (white), highly absorbing layers (black), or even high transmittance layers (transparent). Black structures are generally the result of a high concentration of cross-linked aromatics, typically melanins or pterins.65 An example of superwhite structures is reported for beetles, where assemblies (2 μm in thickness) efficiently reflect broadband color, i.e., white colors using inhomogeneous scattering from a perfectly isotropically, three-dimensionally ordered network of fibrils (Figure 5c).72 The multiscaled width and orientation of the bundles are critical to achieve high scattering over such a thick film. Angle-independent specific reflections can also be obtained by spherical features,71,73 although these are also structural colors, i.e., not involving pigments. Broadband reflections can also be induced by the introduction of a pitch gradient, where both mechanical and optical properties are matched.73 In the case of transparent structures, where reflections are minimized by conical features on the surface of the film, a quasi-monolithic layer constitutes the thin film to reduce the reflections. Therein, disorder of the conical structures enhances nonspecific reflections, contrasting directly with structural color generation.36

2.1.1.3. Other Nanochitin-Based Functional Structures

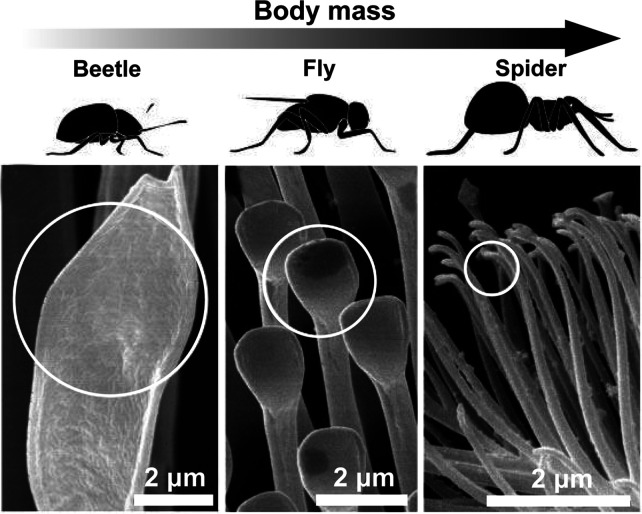

Setae and other pronglike appendages are intricate spatula- and spindlelike organizations found across the animal kingdom that control friction at interfaces, among other functions. Interestingly, these can be formed by chitin33 and other nonchitinous elements,75 typically found in lizards and insects. They are well studied in insects, since they promote a strong adhesion to a range of surfaces, including loose and hydrophobic surfaces. The relation between the structure and the density of adhesive setae is directly related to the body weight of the animal. For instance, spiders have smaller setae but at a higher areal density on their legs when compared to smaller insects, such as beetles, where setae are larger but in reduced numbers (Figure 6). Flies with intermediate sizes also bear intermediate spatula size and areal density.76 A gradient of mechanical stiffness, for instance, ranging from 1 MPa at the tip to 10 GPa at the base,77 is present along these appendages to enhance flexural properties and to match various surface topographies. Furthermore, the tip of the setae may be convoluted with microstructures, such as fingerprint-like structures, conical spikes, or corrugated ridges, to further increase the relative friction.78 In fact, adhesive structures can be found to scale continuously from such nanometric structures, toward millimetric claws, including intermediate micrometric setae arranged onto larger pads.79 Importantly, setae and other hair-type elements require optimal adhesive power since a too high adhesion leads to reduced cleaning potential, where dirt cannot be removed. This was demonstrated for bees, where a strong adhesion to pollen resulted in its permanent attachment.80 Chitin can also have a structural role, although rare, in excreted adhesives. This is the case of barnacle adhesives, which require a high resistance to mechanical stresses beyond a strong adhesion.81

Figure 6.

SEM images of the spatula- and spindlelike adhesive structures found in various insects (beetle, fly, and spider), indicating that heavier insect bodies exhibit finer adhesive structures. Adapted with permission from ref (76). Copyright 2003 National Academy of Sciences.

Beyond color, adhesion, and structural mechanics, one should note that chitinous architectures have been considered in other roles.82 For instance, the antibacterial activity of chitin has been used in material science. Protection from pathogens is associated with the biological activity of chitin, for instance, for application in healthcare. Spindlelike chitinous structures can serve as vibration sensors or defense tool against predators.82,83 The latter urticating structures are typically observed in caterpillars,84 and longer extraction devices can be found in mosquitoes and butterflies, where the mechanical properties of theses constructs are optimized as a function of the target. Other examples include hydrophilicity and mostly superhydrophobicity at the interface,35 motion-generating structures,85,86 and vibrating structures used for sound generation.87,88

2.1.2. Biogenesis of Chitin

We introduce the structure found within different organisms and the biosynthetic pathways leading to the formation of chitin. It is important to note that chitin synthesis is a highly complex process, where chitin is dynamically synthesized, degraded, bundled, and translocated and continuously forms superstructures. To date, many of these mechanisms are only partially known and put forward from indirect evidence.89 The synthesis of chitin is catalyzed by chitin synthases, glycosyltransferase enzymes, which are membrane complexes that polymerize N-acetylglucosamine into linear chains of β-(1,4)-acetylglucosamine.90 A three-dimensional structure can be predicted for chitin synthase, templated from its counterpart, namely, bacterial cellulose synthase (Figure 7). The synthesis takes place over three steps; i.e., the junction between monomeric units is made on the cytoplasmic side, followed by transmembrane transfer of the chain, and finally self-assembly of the polymers into fibers.91 The monomer used for synthesis is generally a phosphorylated precursor, N-acetylglucosamine-1-phosphate, that is appended the “UDP” functional group into the final precursor to chitin, UDP-N-acetylglucosamine.92 The general mechanism is the same for all glycosyltransferase, i.e., cellulose and hyaluronan.93 Therein, the enzyme exploits the difference in reactivity associated with the directionality of the reactivity of the growing chain due to the reducing end being more reactive.

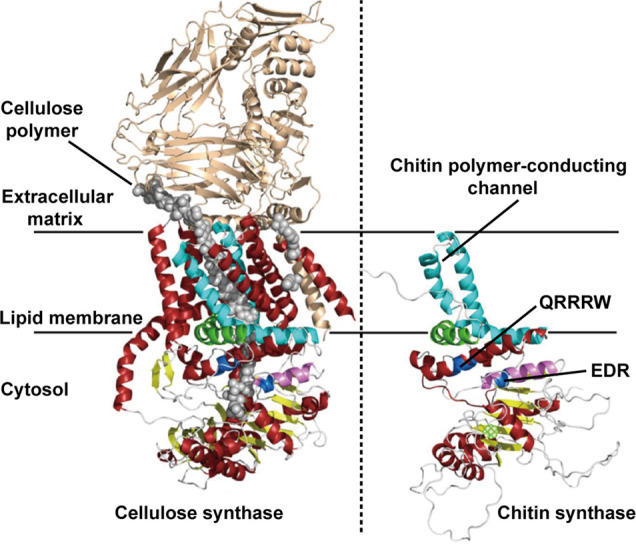

Figure 7.

Three-dimensional schematic illustration of the structure of trans-membranous chitin synthase. The left panel is the crystal structure of the bacterial cellulose synthase complex from Rhodobacter sphaeroides. Here, the cellulose polymer is shown with gray spheres. The right panel corresponds to a computed 3D structure of the C-terminal parts of chitin synthase. The crystal structure of the bacterial cellulose synthase (left panel) was used as a template for structural predictions. The highly conserved amino acid sequences include QRRRW (product binding site) and EDR (saccharide binding site), found in other glycosyltransferases such as cellulose synthases. Adapted with permission from ref (94). Copyright 2017 MDPI.

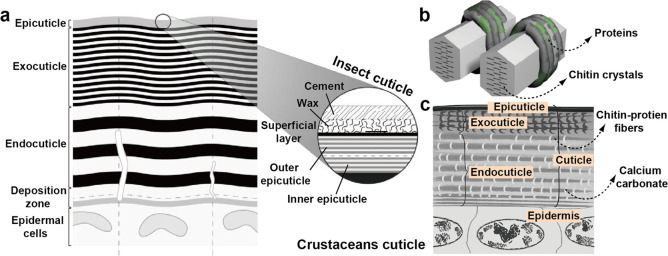

2.1.2.1. Structure of Chitin in Insects

Due to their facile collection, laboratory breeding techniques, and nonmineralized shells, insect chitins are the most well studied systems. However, despite over 100 years of studies dedicated to insect chitin biogenesis, many questions remain unanswered, including how the organization of chitin occurs. In insects, chitin synthesis takes place in the body wall or cuticle, in the gut lining or peritrophic matrix, in the salivary glands, trachea, and eggshells, and in the extremities of the muscles.95 Therein, both synthesis and degradation take place simultaneously and to different extents, which depends on the developmental stage. In insects, chitin contains a small fraction of glucosamine, making insect chitin an inherently heterogeneous polymer. The chitin fibrils within the gut and cuticle are organized into nanofibrils and sheets, which are themselves embedded into a protein matrix. At this stage, it seems more likely for the proteins to interact supramolecularly with chitin,96 although it is likely that phenol- or, more likely, catechol-amine reactions occur. Although polar in nature, the dehydration of chitins may be favored by interactions with hydrophobic proteins.97 In this so-called tanning process, hydrophobic proteins expel water and cross-link chitins via oxidation of the proteinaceous phenols into catechols, which can readily react with the amine group of chitin,98 this leads to very stiff insect parts.99 The process of cross-linking induced by dehydration is essential and is a key synergy between high-histidine content proteins and chitin. The soft insect cuticle contains up to 75% water, while the hard cuticle has a water content reduced to 15%. The phenolic-containing proteins that are oxidized to bear a high catechol content cross-link the proteins and chitins, tuning the mechanical properties of the constructs. The Young modulus of soft insect cuticles ranges from 1 kPa to 50 MPa, while that of tanned cuticles can reach up to 20 GPa. The presence of heavy metals, e.g., Zn, Mn, or Fe, further cross-links catechols.100,101 The elasticity is also modulated by resilin.102,103 Thereafter, chitin deacetylases play an important role in enhancing the interaction potential of the chitin fibrils with the extracellular matrix.104 Chitin microfibril synthesis occurs in the extracellular space, where proteins organize their three-dimensional layout. The main difference for the synthesis of chitin between organisms is the source of the glucose precursor. In the case of insects, it can even be body fat in the form of glycogen.

Insects periodically replace their outer shell as protein-based dehydration, i.e. tanning, rendering the shell too rigid for growth, which is achieved by secretion of the molten fluid containing chitinases and proteases. This process involves various steps that are crucial in various development stages or to answer to environmental stresses.105 The chitin content and obtainable yield of chitin fibrils is thereafter directly impacted by molting, wherein the chitin content is minimal right after molting. Chitin is hydrolyzed into oligomers by chitinase and β-N-acetylglucosaminidases that further degrade the oligomers into the monomer.106,107

In insects, chitin is highly associated with proteins throughout their bodies. The chitin–protein matrix defines entirely the stiffness of the insect’s shell by modulating interactions with water. Larval bodies and wings are highly flexible, while the heads and mandibles are the most rigid parts. Chitin binding proteins are either directly secreted into the extracellular matrix or stored in vesicles for later payload release. There is a wide range of proteins containing chitin binding motifs, which serve various functions, including structural consolidation, immunity enhancement, bactericidal effects, etc.(108) Many of the enzymes involved in the degradation of chitin possess such chitin binding domains.109−112 Another set of proteins, Knickkopf proteins, takes part in the organization of chitin within the body of insects, although the exact mechanisms involved in chitin translocation and bundle formation are unclear. This set of proteins is known to participate in the remodeling of chitin fibers since their absence in insects results in a lack of fibril alignment and lamination.113,114 Furthermore, there is a clear indication of fibrillar rotation during embryogenesis, suggesting an active formation of the structures.115,116 In the end structure, through post-tanning, chitin nanofibrils form bundles within the proteinaceous matrix of up to 100 nm, which are arranged at the macroscale.

The degree of crystallinity of chitin varies among different insects. However, the superstructure within arthropods generally presents a long-range order. For instance, a regular spacing of 7 nm and crystallites of 2 nm were reported in thin sections of a fly.117 This observation was further extended to chitin in arthropods.118 Chitin is then found across the cuticle of insects forming various structures. The cuticles contain the epidermal cells, where the chitin fibrils are synthesized, followed by the deposition zone where the initial chitin–protein biogenesis occurs. This is followed by the endocuticle, exocuticle, and epicuticle, where varying densities of chitin bundles and protein complexes are observed as a function of various tanning processes (Figure 8a).74 The epicuticle determines the hydrophobicity of the animal skin and is generally covered in wax and minerals. The epicuticle is typically 2 μm thick, while the exocuticle is about 1.5 orders of magnitude thicker, in the range of 100 μm. Epicuticle multilayers are generally thinner than those of the exocuticle. The basal chitinous layer, the endocuticle, presents a looser network of fibrils and a considerably lower extent of tanning.

Figure 8.

(a) Schematic illustration of a typical cross-sectional structure of an insect cuticle in the premolt stage, showing the most important layers, with a fully developed endo- and exo-epicuticle. (b) Model of complex protein–chitin superstructures via post tanning/sclerotization, wherein proteins (dark and green tubes wrapping around the chitin crystals) specifically interact with the multiple faces of chitin crystals as well as with the amorphous domains. Note: different colors represent different proteins. Adapted with permission from ref (74). Copyright 2008 John Wiley and Sons. (c) Simplified structure of crustacean cuticle, highlighting the mineralized domains within the cuticle, wherein the network of minerals is considerably more continuous in crustaceans than in seashells. Adapted with permission from ref (119). Copyright 2017 Elsevier.

2.1.2.2. Structure of Chitin in Crustaceans

In crustaceans, chitin organization generally resembles that found in insect shells, forming microfibrillar bundles in strong and tough composites. The structure is usually mineralized with calcium carbonate structures. A range of structures is found in crustaceans wherein stiffness is mostly modulated by proteins, as is the case of insects. This is also the case of the squid beak, where histidine-rich proteins and α-chitin exist (ca. 2:1 ratio) in the absence of minerals.37 The mostly organic structure presents remarkable stiffness and hardness, making it possible to fracture the shells of gastropods. The highly cross-linked structure is resistant to proteolysis and is generally not digestible. Such cross-linking strategy is reminiscent of the tanning (sclerotization) process in insects, wherein a darkened color is observed as a result of aromatic cross-linking points (Figure 8b). The tanning process forms gradient-like structures, where the apex of the beak is the hardest while the base is hydrogel-like.

The crustacean cuticle possesses all of the layers found in the cuticle of insects,54 typically containing higher carotenoid content, which results in an orange appearance.120 Contrary to the case of insects, α-chitin structures in crustaceans mineralizes on the surface of the fibers into calcium carbonate crystals via calcification. As such, the chitin–protein complexes determine the cationic planes, which leads mineral plates. Initially, amorphous calcium carbonate precursors form highly ordered mesoscaled crystals,121 resulting from the highly crowded cellular environment.122 Their thickness can vary in the order of a few micrometers. Aragonite and calcite can be found in mollusk shells and sea urchins, respectively. Both amorphous calcium carbonate and calcite are found in crustaceans, with some amount of calcium phosphate.123,124 Mineralization occurs principally in the exocuticle and endocuticle (Figure 8c).107 The other polymorph, β-chitin, is commonly found in squid pens, making 31% dry matter equivalent, with a degree of acetylation (DA) of 96% and over 75% crystallinity.125 The structures formed by the fibrils are generally considerably softer than what is found in typical arthropod cuticles.

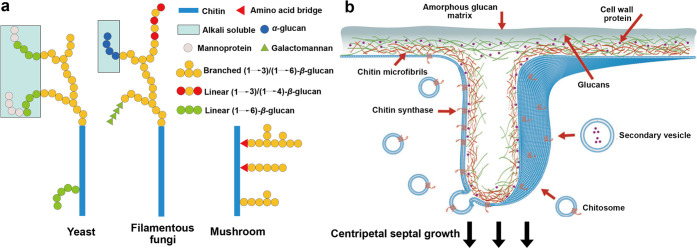

2.1.2.3. Structure of Chitin in Other Organisms

In addition to arthropods, fungi contain chitin in the range of 5–27% as dry mass,126 which is principally found in the ring necessary for mitosis of the fungal cells127 and in the growing hyphal tip.128 The deacetylated form of chitin, chitosan, can also be found in fungi cell walls. Chitin is identified as a branched structure within a branched architecture composed of β-1,3 and β-1,6 glycans arranged within a highly hydrated amorphous matrix (Figure 9),126 located at the core of the branched polysaccharide superstructure or at its edges (Figure 9a).129,130 Chitin synthases in fungi are found principally within chitosome (Figure 9b), which are spherical lipid–protein assemblies with a diameter of 40–70 nm and a membrane of ca. 7 nm.131,132 They make the main constructs that deliver chitin synthase, a membranous protein, to the surface where chitin nanofibrils are assembled.133 It is believed that other chitin-forming entities also use chitosome-like structures for the translocation of chitin synthases. For instance, a high density of synthases was found at the apical region of microvilli in insects.134 As cellulosomes for cellulose, membrane enzymes are not soluble, producing polymers and fibrils through interfacial biogenesis. Microfibrils superstructured in triple helices can be found in the cell walls of mushrooms. They are composed of a range of glucans sparsely branched by chitin fibers. In the mycelium, the vegetative growth state of fungi filaments, a network with a high content of chitin (with other glucans), forms three-dimensional architecture of the growing organism.135,136 Nematodes and single cell organisms such as yeasts or protozoa can also form chitin,137,138 although their purpose may be more functional than structural since the chains remain relatively short and mediate hydrophilicity of the cell walls.103 Chitin in yeasts is also one of the elements that leads to mitosis of yeast cells.139

Figure 9.

(a) Schematic illustration showing chitinous structures found in microorganisms. The chitin–glucan complex models include Saccharomyces cerevisae and Candida albicans for the yeast, Aspergillus fumigatus for the filamentous fungi, and Schizophyllum commune for the mushroom. Adapted from ref (135). Copyright 2020 American Chemical Society. (b) Three-dimensionally schematic illustration of the use of chitosome, a chitin-generating complex and its structure in fungi. Adapted with permission from ref (132). Copyright 2013 Elsevier.

2.2. Chitin Chemistry

We next introduce chitin chemistry, from the molecular level, as in saccharide rings, to structural chemical organizations, as in raw chitin. Three aspects are considered: structural chemistry, surface chemistry, and bioactivity. In the first subsection, we discuss the various assemblies of chitosan into fibrils composed of given chitin polymorphs. We then introduce the surface chemistry of these fibrils, followed by a discussion about the impact of these fibrils in interfacing with microorganisms and complex living tissues.

2.2.1. Chitin’s Structural Chemistry

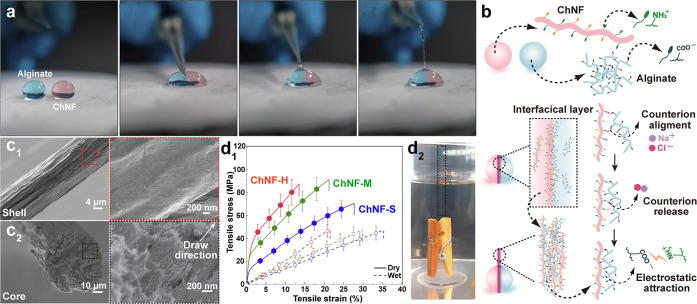

The molecular organization of chitin, as an abundant amino polysaccharide, involves rings in macromolecules and interactions with other elements, covalent or supramolecular, defining many of the functions in the living organism, within which they are synthesized. Nano- and microfibrils interact via H-bonding between amine and carbonyl groups. Small crystalline domains are embedded within pseudocrystalline and amorphous domains along the fibrils. The main crystalline allomorphs, namely α-, β-, and γ-chitin (Figure 10), are associated with a directionality with respect to its reducing end, which is a tautomer in equilibrium between the closed ring and open aldehyde forms. In the α-form, the chitin chains are arranged in an antiparallel fashion; on the contrary, the β-form has a parallel arrangement, while γ-chitin has two parallel chains neighboring one antiparallel one (Figure 10a).90 α-Chitin is the most abundant allomorph and is found in fungal and yeast cell walls as well as in arthropods, including crustaceans and insects. Compared with cellulose fibrils, chitin nanofibrils are generally considerably less polar but still highly hydrated in most animals, prior to tanning. Their hydrophobicity may be enhanced by biosynthesized hydrophobic proteins.97 β-Chitin has reduced H-bonding interactions compared to α-chitin and forms softer fibrils that are more susceptible to hydrolysis and overall swelling. α-Chitin is present in hard materials, while β- and γ-chitins are present in flexible structures.140

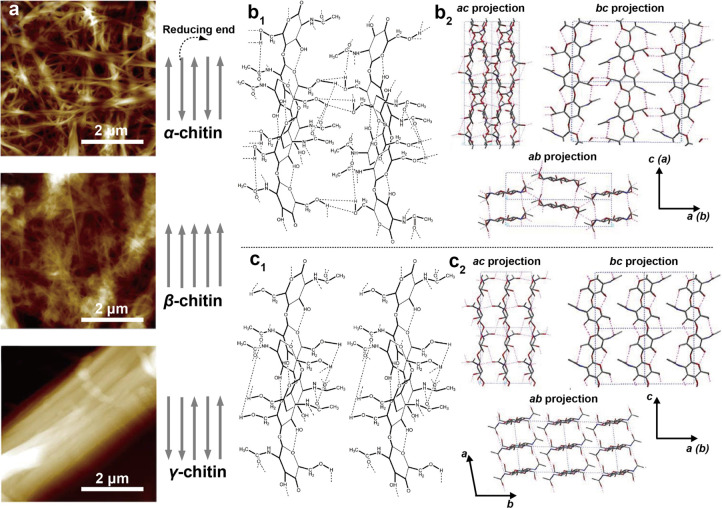

Figure 10.

Illustration of three main polymorphs of chitin. (a) AFM images of three polymorphs of ChNFs obtained from the same acid/base extraction process. α-Chitin can be extracted from crab shells (Potamon ibericum), β-chitin from squid pens (Sepia sp.), and γ-chitin from moth cocoons (Orgyia dubia). Adapted with permission from ref (151). Copyright 2017 Elsevier. The gray arrows indicate the orientation of chitin macromolecules within the crystalline domains, with the arrows pointing away from the reducing end. Molecular structure and hydrogen H-bonding in (b1) α-chitin and (c1) β-chitin. Note: the intersheet bonding is absent in the case of β-chitin. Adapted with permission from ref (152). Copyright 2009 Elsevier. Structure of (b2) α-chitin and (c2) β-chitin in different projection planes (ac, bc, and ab). Adapted with permission from ref (9). Copyright 2006 Elsevier.

α-Chitin, an allomorph that is insoluble in most solvents, forms orthorhombic crystals, presenting both inter- and intrasheet bonding (Figure 10b). The theoretical axial elastic modulus of α-chitin is 150 GPa,102 with 59 GPa being the experimental value.141 The surface energy of different facets are affected by the crystalline allomorph. For instance, in the (010) face of α-chitin, the distance between available H-bonding groups matches that of a proteinaceous β-sheet such as silk.142 In fact, the (010) face is suggested to present the strongest interaction with proteins in general and proteinaceous residues are expected on this face after isolation of the fibers,102,143 which demonstrates that the optimization between the protein-chitin interface also exists in most chitin-containing animals.

β-Chitin, found as a hydrogel-like structure within the squid pen, sea tubeworms, and diatoms and most famously within the squid beak,37,144−147 is a monoclinic crystal that has no intersheet bonds (Figure 10c).146 β-Chitin is more susceptible to deacetylation by acid-based hydrolysis,144 and can be transformed into α-chitin when exposed to concentrated NaOH or HCl.148,149 Particularly, although β-chitin is insoluble in many solvents, it exhibits better solubility than α-chitin does; for instance, it is soluble in formic acid.150 γ-Chitin exists scarcely in nature and is found, for instance, in certain species of squid or beetles.140,150 α-Chitin and γ-chitin decompose at 330 and 310 °C, respectively, while β-chitin decomposes at a lower temperature, 230 °C. γ-Chitin was found to present microscaled fibers when extracted from the cocoon of the moth (Orgyia dubia), with extremely tightly bonded nanofibers as obtained from typical extraction processes (strong acid/base treatments).151 Accordingly, γ-chitin is digested at a slower rate compared with α- and β-chitin. Because chitin macromolecules are arranged in sheets and in β-chitin these sheets interact weakly, several polar molecules can penetrate β-chitin such as alcohols. In contrast, intersheet networks of α-chitin are tightly held by H-bonding.9

The solubility of chitin in aqueous media depends on the crystal allomorph and degree of surface acetylation.152 The highly deacetylated form of chitin, chitosan, forms highly viscous acid solutions and is generally insoluble above pH 6 due to its pKa of 6.3.153,154 Meanwhile, chitin is insoluble in water at any pH condition. However, inorganic salts, such as Ca(CNS)2, CaI2, CaBr2, or CaCl2, have been found to facilitate chitin dissolution.155 The dissolution and regeneration of chitin result in materials with properties that are highly dependent on the solvents used.156 For example, lyotropic LCs form when chitin is dissolved in lithium chloride/dimethylacetamide at 2 wt %, where phase transitions are concentration-dependent, which can be used to enhance the long-range order of the polymers in the regenerated fibers.157 In addition to the lyotropic, a thermotropic behavior also exists, where phase transitions are temperature-dependent.158,159

2.2.2. Chitin’s Surface Chemistry

The unique cationic character of chitin derives from the hydrolysis of surface acetyl groups, which dictates the properties of nanochitin. Here we discuss the chemistry of such surface groups and their distribution along the biosynthesized polymer, the interaction with the surrounding biological matrix, and the resulting superstructures upon extraction. The impact of other functional groups, e.g., hydroxyls, other glucans, and residual proteins, is also discussed.

The most important aspect of chitin surface features is the presence of amine groups that result from a variable degree of deacetylation (DDA). Below pH 6, the ammonium ion bears a positive charge in aqueous media, which infers long-range electrostatic interactions prevailing over the short-range H-bonding interactions. At pH > 6, all of the hydroxyl, ether, acetyl, and amine groups contribute to H-bonding, forming a complex intracrystalline and interfacial H-bonding network. Furthermore, the ether and acetyl groups, considerably less polar, likely impart amphiphilicity. The number and distribution of amine groups are highly dependent on the source type and processing. For instance, yeast and, more commonly, fungi present a highly deacetylated β-chitin, in general more easily deacetylated due to the hydrated nature of the crystal. In contrast, chitin obtained from the endocuticle and exocuticle of arthropods is highly acetylated (>98%). Moreover, initial deacetylation is expected to occur more easily on the groups outside of the crystalline domains and in the amorphous regions; therein one group every two glucose units is first deacetylated.160 Thereafter, a broad range of deacetylation degree distribution is expected. Therefore, in typical chitin samples, a fraction is predominantly charged while another fraction may present rather low charges.160 Compared with cellulose, the presence of amine groups implies simpler modification routes, for instance, by using a wide range of functionalization approaches.161 Furthermore, amine groups, in addition to the primary hydroxyl groups, infer two functionalities for modification. Orthogonal chemistry can be used to exploit the considerably higher reactivity of the amine groups.162 There are numerous examples of chitin modification with hydrophobic groups, e.g., to reduce their hydrophilicity or improve their compatibility with other surfaces,163 which will be comprehensively discussed in the following subsection. Beyond surface energy, amine groups enable coordination bonds with heavy metals, making chitin a suitable option for water remediation and heavy metal separation.164

Commonly, surface chemistry of chitin extracted from arthropods is affected by proteinaceous residues that remain after extraction.165 In most arthropods, supramolecular and covalent interactions are extremely strong; for instance, interaction of chitin and protein is optimal when the protein forms β-sheet domains, wherein the spacing between the domains of the sheets matches that found between the monomeric saccharide units of chitin.102,142,143 Other chitin binding domains can be found on chitinases, also leading to strong supramolecular interactions.166 The surface chemistry of chitin extracted from glucan, in contrast to that extracted from arthropods, is highly contaminated with other glucans.167,168 The range of accessibility of glucan structures is rather wide.135 For instance, the water contact angle of films made from fungi chitin ranged from 24° to 66°, regardless of whether the fibrils were isolated from a mushroom stalk, cap, or paragus or from a mixture.169 The fungal source also significantly affects the surface charge; for instance, the zeta potential of nanofibrils ranges from −10 to −25 mV when extracted from Agaricus bisporus or Daedaleopsis confragosa.170

2.2.3. Chitin’s Bioactivity

Chitin possesses principally a structural role in biological systems, but it also has immune-defensive and antibacterial activities. The bioactivity of chitin is mostly similar to and related to that of homologous chitosan, with additional implications of antifungal and antioxidant effects and uses reported in regenerative medicine and other applications.130,171

Chitosan has been extensively explored since its introduction in bactericide-related applications.172−174 The action of chitosan against microorganisms is reported to occur by several mechanisms, many of which are still unclear. Chitosan action as far as the disruption of the cell wall and subsequent microorganism lysis is assigned to its antibacterial activity, which is associated with charge matching with the anionic cell wall of the microorganisms.175 Gram-positive bacteria contain on the surface negatively charged teichoic acids, while Gram-negative bacteria are negatively charged given the presence of lipopolysaccharides.176 The disruption of the membrane is found to increase by quaternization of the charged groups of chitosan,177 which also affects certain fungi.178 Another mechanism is associated with small chitosan and endosomal escape, wherein interactions with messenger ribonucleic acid in the targeted microorganisms disrupt the synthesis of key proteins.179 This mechanism is also responsible for the lysis of yeasts and fungal cells by chitosan. Chitosan as an adjuvant increases the potency and control internalization/release mechanisms of active compounds affecting mammalian cells.180 The chelation potential of chitosan at neutral pH and above is another route that leads to the disruption of the metabolic activity of microorganisms.181 This is because both Gram-positive and Gram-negative bacteria require divalent ions for proliferation. High-molecular-weight chitosan also impacts the proliferation of bacteria by adsorbing and crowding on the surface, preventing the uptake of key nutrients.181 Overall, the antibacterial and antifungal activity of chitosan is well documented and used to prevent infection in a range of biomedical and agro-industrial applications, for instance, to protect plants such as tomatoes and cucumbers as well as to prevent dental and respiratory infections.182

Chitosan has been demonstrated to be nontoxic to a range of mammalian cell lines.183 In wound treatment applications, it stimulates the immune system, accelerating the onset of the inflammatory phase and thus the overall healing process.184 The potential of chitosan in regenerative medicine is associated with its similarity to glycosaminoglycans, which are the main components of the extracellular matrix guiding injury regeneration.185 During the inflammatory response, chitosan has been shown to interact with immune cells, such as macrophages and neutrophils.186 In turn, chitosan enhances fibroblast proliferation,187 which relates to the interactions with anionic biomacromolecules, such as heparin or proteins recruited on site.188 Chitosan is documented to form complexes that induce flocculation, most relevant in water treatment, but it is also generally recognized as safe by the U.S. Food and Drug Administration.189 Thus, it is extensively used in the food and beverage industry for its antimicrobial and antioxidant activity.190,191 When applied to oysters (for raw consumption), it suppresses bacterial growth and extends the shelf life.192,193

Mirroring the biological activities of chitosan, it is reasonable to expect that chitin should exhibit similar functions.194,195 However, since many of the bioactivities of chitosan are associated with chitosan’s cationic surface charges, the biological activity of chitin is considerably lower. Chitin is known to decrease the proliferation of fibroblasts, while highly deacetylated chitosan (>80%) significantly increases the proliferation.187 Besides the biological activity of chitin,17,196−198 rapid erythrocyte aggregation and fast subsequent clotting has been shown to be induced by chitin.199 It can be biomineralized with hydroxyapatite for tissue regeneration applications.200,201 Moreover, chitin fibers have been proposed for sutures due to their resorbability;202 meanwhile, chitin mats showed potential use as temporary skin for open wounds.203 Generally, the antimicrobial activity of chitin is associated with its molecular weight, and, as expected, with DDA.204 A higher DDA results in increased biocompatibility, antimicrobial, antioxidant, and hemostatic activity as well as mucoadhesion.171 Such effects depend on the chitin source; for instance, the antimicrobial activity of fungal chitin is higher compared to that derived from crab.205 This is related to the presence of residual proteins in the latter and the higher DDA of the former. Strategies to enhance biological functions use knowledge about the structural chemistry of chitin and upcoming explorations involve the use of nanochitin and methods to control its surface functions (charges, chemical groups, etc.)

3. Isolation and Engineering of Nanochitin

The insolubility of chitin in water challenges processing,12 particularly for the direct production of chitin nanomaterials.206 The preparation of nanochitin has greatly advanced in recent decades given the knowledge gained about chitin and its assembly in biological materials. The routes used in nanochitin isolation include top-down and bottom-up approaches, e.g., direct isolation of chitin nanoparticles from the biological materials and assembly of chitin molecules into nanofibrils, respectively.18,207 Accordingly, we emphasize the top-down approaches owing to the structural benefits of nanochitin encoded in the living materials. The most recent progress in nanochitin isolation and chemistry is presented next.

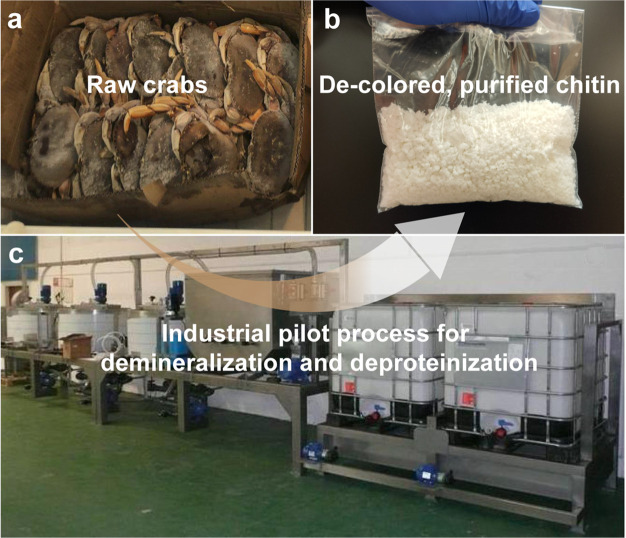

3.1. Chitin Extraction

In principle, elementary chitin nanofibrils are wrapped by proteins forming chitin–protein complex superstructures, embedded in minerals (crystalline calcium carbonate and a small amount of calcium phosphate) when forming the hard stratum corneum of crustacean shells.208 Thus, the procedure for nanochitin isolation from crustacean shells usually starts with chitin extraction (purification), demineralization (DM), deproteinization (DP), and discoloration (Figure 11).

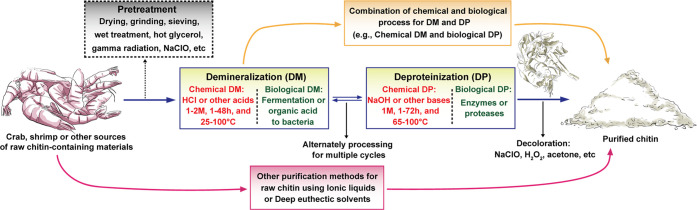

Figure 11.

Overview of chitin extraction from crustacean shells that involves demineralization (DM), deproteinization (DP), and discoloration (all shown in solid boxes) as well as alternative pretreatments (dashed box). New extraction methods are emerging given considerations of environmental impact and sustainability.

DM and DP are used to remove calcium minerals and proteins complexed with chitin, respectively, which frees tightly bound chitin and might require multiple cycles, depending on the chitin source and intended uses.209 The discoloration, e.g., using sodium hypochlorite, acetone, or hydrogen peroxide, removes pigments adhered on the shells, e.g., astaxanthin and β-carotene, so that colorless chitin is generated prior to nanofibrillation.16,210 Apart from these procedures, pretreatments involving size reduction, drying, grinding, sieving, and wet processing of crustacean shells are applied before DM and DP, which facilitate the extraction and increase the efficiency of the process.211,212 For instance, a pretreatment using hot glycerol, a plasticizing agent, improved the efficiency of chitin extraction from prawn shells,213 and utilization of 3% NaClO before DM and DP reduced the processing time and energy consumption.214 There are reports on the use of atmospheric pressure dielectric barrier discharge plasma or gamma irradiation to increase the removal of minerals and proteins.215,216 Although other treatments might facilitate chitin extraction, impurities or uncontrolled degradation may occur, which would affect the properties of chitin and the obtained nanochitin.

A typical method for chitin extraction involves acids and bases for DM and DP, respectively, where DM implies the use of acid–base reactions to release water-soluble calcium salts, carbon dioxide, and water. Meanwhile, the DP process dissolves proteins adhered to chitin by using alkaline solutions.217 As a consequence, the extraction conditions are important since they determine the purity and type of chitin, as well as the total cost.165,218−221 In the case of DM, HCl is the most commonly used acid, for instance, at 0.3–2 M concentration, 1–48 h, and 25–100 °C.165 Other acids, such as HNO3, H2SO3, or organic acids including CH3COOH, HCOOH, C6H8O7, and their combinations, have been used to remove minerals from the shells.222 For DP, a typical procedure is to treat the shells with NaOH, for instance, 1 M concentration, 1–72 h, and 25–100 °C.165 Similarly, different types of alkaline reagents, e.g., Na2CO3, NaHCO3, KOH, K2CO3, Ca(OH)2, Na2SO3, NaHSO3, CaHSO3, Na3PO4, and Na2S, have been successfully applied.209 Although chemical extraction of chitin from different crustaceans is well established, recent studies focus on optimizing the conditions to minimize the impact on chitin’s molecular weight, to improve the yield and to decrease the processing cost. Microwave radiation has been used as a heating mechanism for chitin extraction, leading to reduced treatment time;223,224 likewise, sonication has been shown to improve the efficiency of chemical DP to produce chitin from shrimp.225

Chemical extraction has some disadvantages, such as environmental and sustainable impacts; for instance, the solubilized minerals and proteins are side streams that are not recovered or used.210 Thus, efforts in recent years have been directed to develop environmentally friendly chemical methods,226 and have included considerations to biological routes (Figure 11). An emerging area is that of chitin biorefineries, wherein all the byproducts generated, including proteins and pigments, are reused.227 For instance, DM that used citric acid combined with biological methods (pancreatic enzymes) at relatively low temperature (40 °C) have achieved good extraction yields.213 The biological treatments can access microorganisms that ferment the waste from DM,228,229 and the use of enzymes, including proteases, has been reported for DP.209 The fermentation of chitin shells using organic acids, either in the presence or absence of lactic acid bacteria, allowed efficient removal of minerals upon extraction.230,231 In addition, such processes can be extended to dual or multiple stages that involve fermentation, cofermentation, postfermentation, or autofermentation from endogenous microorganisms.16,232 On the other hand, treatment of chitin shell residues with proteases enables the replacement of chemical DP, for instance, using proteolytic enzymes such as chymotrypsin, papain, pancreatin, and others.233 Despite the environmental advantages of biological processes for chitin extraction, they usually require long processing times and are more expensive. Meanwhile, they present relatively low yields and so far are mostly limited to laboratory scales.210 However, a comparison of chemical and biological treatments for chitin extraction from crustacean shells on a pilot scale, based on sustainability parameters, underscored the great promise of biological processes.234 Recently, ionic liquids and deep eutectic solvents have been considered for chitin extraction from shells.235−237 For instance, 1-ethyl-3-methylimidazolium acetate was applied to process shrimp, wherein chitin in the shells was first solubilized and then precipitated as purified solid for further processing.238 Deep eutectic solvents are considered for fast, easy, and ecofriendly chitin extraction and typically involve a mixture containing choline chloride with an active ingredient, e.g., thiourea, urea, glycerol, and organic acid.239−241 However, similar to biological treatments, practical use has been limited by considerations of supply, scale, and cost.

3.2. Isolation of Nanochitin

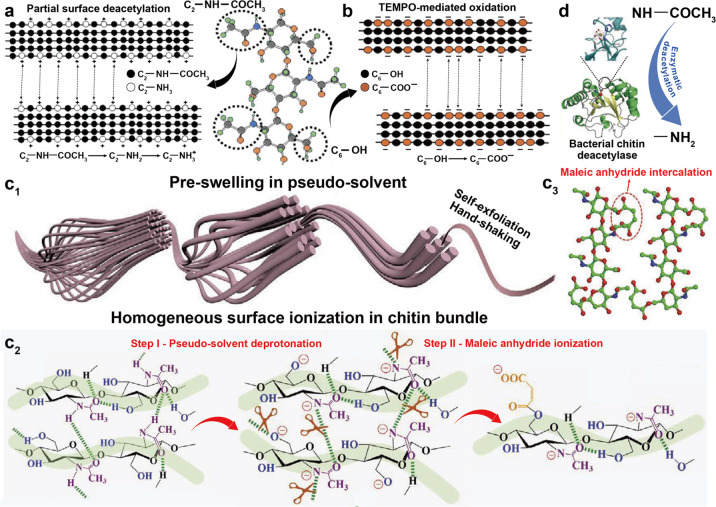

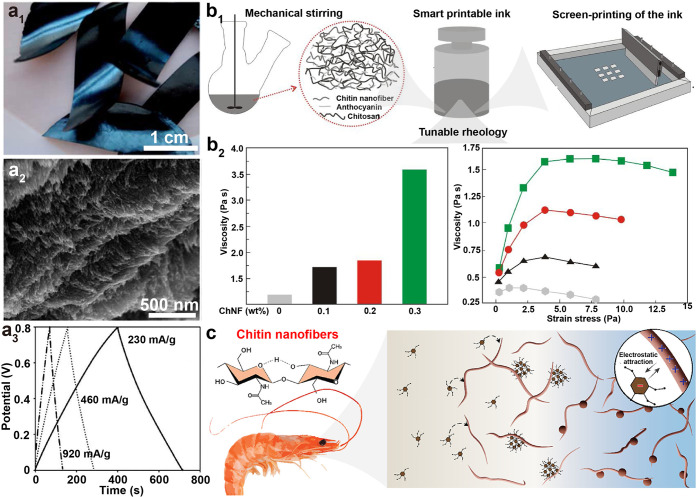

There is a great interest in the isolation of fibrillar chitin because the structural, chemical, and biological advantages can be gained from their morphological and nanoscale aspects.242 To this end, the top-down approach is widely used due to the possibility of maintaining chitin’s semicrystalline structures, 1D nanofibrous morphology, and thereby intrinsic performance.243 Typically, two types of nanochitin, chitin nanofibers (ChNF) and chitin nanocrystal (ChNC), can be isolated, Figure 12. The properties of nanochitin depend on the source of chitin, its isolation conditions and modification strategies, as well as the specific requirements for the desired applications. The mechanism for isolating ChNF considers the mechanical fibrillation of the chitin bundles, leading to nanoscaled lateral sizes with enhanced interfibrillar repulsion, most often generated by the nanofibrils’ ionized surfaces that retain both the amorphous and crystalline regions (Figure 12a). By contrast, the preparation of ChNC involves chemicals that exfoliate the surface of the chitin nanofibrils and remove the disordered chitin structures to yield ordered, crystalline ones (Figure 12b). Thus, the isolation of ChNF utilizes mechanical nanofibrillation with the assistance of chemical or biological processing,244 while strong acid hydrolysis or oxidation is used for ChNC production.

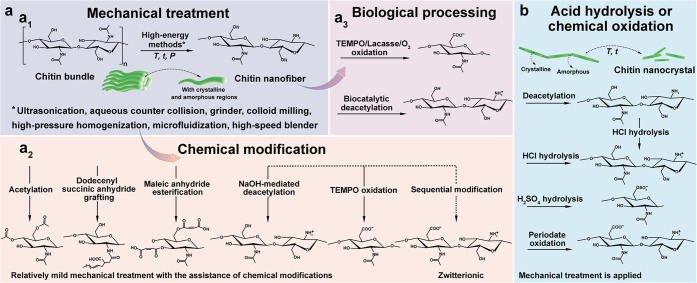

Figure 12.

Overview of the methods used for isolation of (a) ChNF and (b) ChNC. ChNF containing crystalline and disordered structures is produced by (a1) mechanical treatment or mechanical treatment assisted by (a2) chemical modification and (a3) biological processing. The main goal of the chemical and biological modifications is to endow additional chemical features that facilitate mechanical fibrillation. ChNC is produced by surface exfoliation and by removal of disordered chitin structures using strong chemical processing with acids or oxidizing agents.

3.2.1. Isolation of Chitin Nanofiber, ChNF

3.2.1.1. Mechanical Treatment

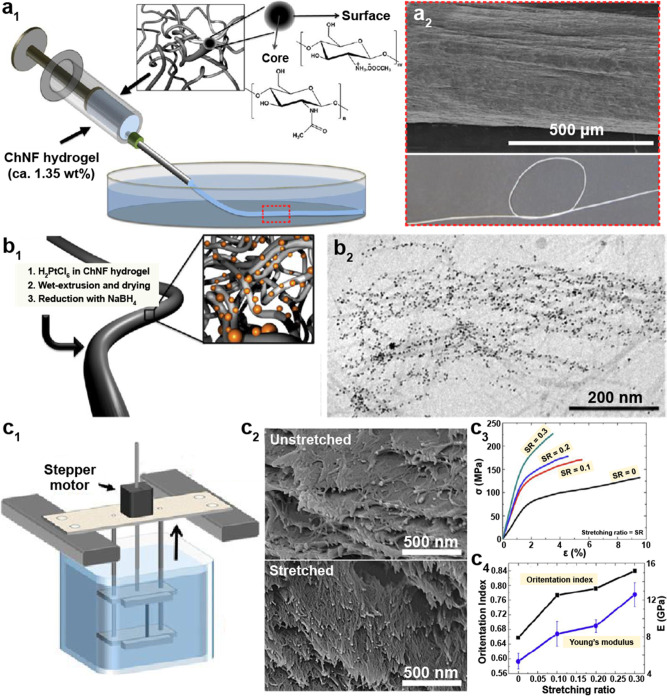

In principle, ChNF isolated by mechanical nanofibrillation yield long, fibril-like morphologies (submicrometers to micrometers) with widths of the order of a few nanometers up to tens of nanometers, leading to structures of high aspect ratio, which is dependent on the chitin source and the choice of the mechanical treatment used. Representative mechanical methods that have been reported for nanofibrillation of chitin into ChNF are listed in Figure 12a. Ultrasonication is a simple high-energy method to disassemble natural chitin fibers into ChNF.245,246 For instance, ultrasonication at 20 kHz, 900–1000W, and 30 min in water at neutral pH was used to fibrillate chitin into nanofibers (widths of 25–120 nm) (Figure 13a).247 Acoustic cavitation at high frequency caused the formation, growth, and collapse of microbubbles in aqueous media to provoke microjets and shock waves on the surface of the chitin fibers, which etched them and promoted their disintegration along the axial direction. The ultrasonication process has also been applied in acid media.248 At pH 3–4, a transparent (85% for visible light) and viscous suspension containing individualized ChNF (length of several micronmeters and width of 3–4 nm) was obtained by ultrasonicating squid pen β-chitin (19.5 kHz, 300 W and relatively short duration). In this procedure, a thin ChNF was produced under short processing times with low energy input compared with that prepared by ultrasonication at pH 7 in water. Moreover, the obtained ChNF presented a DA of 0.9, indicating the presence of amino groups. Thus, protonation of amino groups on the crystalline surface of β-chitin in acidic medium enabled cationic surfaces. Together with the weak intermolecular forces in β-chitin, efficient nanofibrillation took place due to the electrostatic repulsive forces generated between the nanofibers in the β-chitin bundles. Such conditions are not effective in the case of crab α-chitin given its high DA, strong intermolecular forces, high crystallinity, and different packing arrangement of chains.

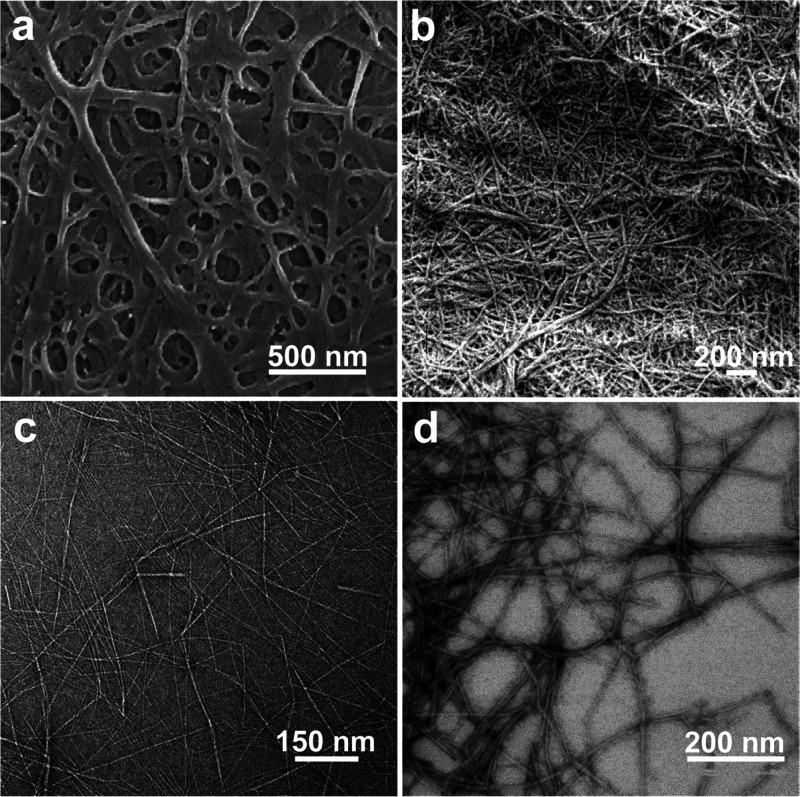

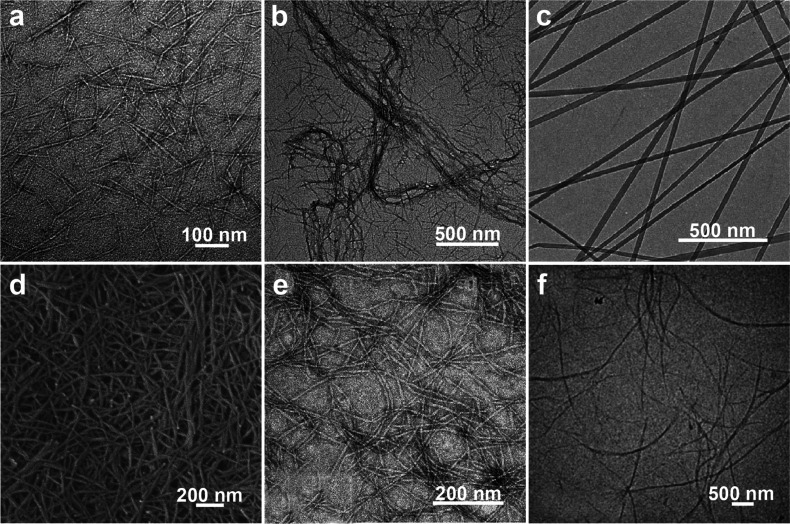

Figure 13.

Microscopic images of ChNF prepared by typical mechanical nanofibrillation. SEM images of (a) ChNF isolated from chitin via ultrasonication in water and (b) ChNF isolated from crab shell α-chitin after one-pass grinding in acetic acid medium. Adapted with permission from ref (247). Copyright 2007 AIP Publishing LLC. Adapted from ref (250). Copyright 2009 American Chemical Society. TEM micrographs of (c) ChNF produced from squid pen β-chitin by one-pass microfluidization in acetic acid medium and (d) low-protein ChNF produced from lobster exoskeletons by microfluidization. Adapted with permission from ref (258). Copyright 2019 The Royal Society of Chemistry. Adapted with permission from ref (259). Copyright 2014 Elsevier.

Grinding is another mechanical method that disintegrates chitin into ChNF,249 wherein the breakage of chitin bundles to thin nanofibers is caused by the continuous shear generated between grinding stones operated under a small gauge. ChNF was prepared by passing a never-dried crab chitin through a grinder (pH 3, 1500 rpm and 0.15 mm milling gap), which resulted in a gel-like suspension containing long nanofibers with 10–20 nm in width (Figure 13b).250 Meanwhile, dried chitin powder from crab shells was adequately fibrillated via grinding under acidic conditions, leading to ChNF (10–20 nm width) of high aspect ratio, similar to that obtained from never-dried chitin.251 In these cases, although the DDA of native chitin was relatively small, the electrostatic repulsion generated by the amino groups on the chitin in acidic medium was sufficient to break the strong H-bonding between nanofibers in the bundles. Besides acidic conditions, ChNF with a width of 10–20 nm and uniform shape was directly prepared from prawn shells using 1500 rpm grinding in water at neutral pH.252 The reason that nanofibrillation of chitin from prawn shells effectively occurs in neutral media is a consequence of the prawn exoskeleton, which is made up of exocuticle, a structure that is finer than that of crab shells, which are made up of 90% endocuticle, thus allowing easier disintegration, even under weak electrostatic repulsion.

High-pressure homogenization has been widely used to disintegrate bulk materials, which is suitable to produce ChNF from chitin.253,254 For example, dynamic high-pressure homogenization was utilized to isolate ChNF from lobster residues following 40 passes at 1000 bar.255 Through this process, nanofibers (width in the range of 80–100 nm) of high aspect ratio were obtained. Particularly, homogenization is a complete mechanical process that does not require the addition of acids or other chemical treatments, thereby causing little change to the chemical or crystalline structure of chitin. However, owing to the intense nanofibrillation, it is still interesting to understand how the surface properties of chitin change during processing. For this purpose, ChNF was prepared from purified crab shell chitin by repeated high-pressure homogenization (200 MPa with 10 passes) in water. Such a process yielded a heterogeneous network of nanochitin with widths ranging from a few nanometers to several tens of nanometers.256 Solid-state 13C NMR spectra revealed that the chemical shifts of all carbons remained unchanged before and after nanofibrillation and all C6-OH groups had the gauche–gauche conformation. Nevertheless, the weight-average molar mass of ChNF was only approximately 60% that of the original chitin, and the DA of ChNF increased from 0.83 to 0.98, indicating that the C2-NH2 groups presented in original chitin were partially removed during high-pressure homogenization in water. Thus, high-pressure homogenization alters the surface properties of the as-prepared ChNF.

Microfluidization has been developed as a high-energy method to produce ChNF.257 Interestingly, squid pen β-chitin was easily fibrillated into ChNF (1–3 μm in length and 2–7 nm in width) by using a one-pass microfluidization in acetic acid (Figure 13c).258 In addition, the fibers had a DA of 99%, indicating the importance of the amino groups to facilitate nanofibrillation of the chitin bundles. As noted earlier, isolation of nanochitin requires the removal of minerals and proteins; however, microfluidization is capable of producing protein-containing ChNF from mineral-free chitin. For instance, individual ChNF exhibiting nanofiber width of 3–4 nm and low protein content was successfully isolated from lobster exoskeletons by using microfluidization (5 passes, 900 and 1600 bar, Figure 13d).259 Apart from the single homogenization approach, mechanical defibrillation involving several steps was applied to fibrillate chitin into ChNF without changing the chemical or structural features.260 In this procedure, a stage-wise process, including 10-pass grinding (0.2 mm milling gap), 10-pass microfluidization (30 000 psi, 120 mL/min), and homogenization, was developed, resulting in nanofibers with a length of greater than 1 μm and width of approximately 50 nm.

Other high-energy methods, using a high-speed blender or a star burst system,261,262 have been shown effective to produce ChNF from native chitin. For instance, an aqueous counter collision technique was successfully used to prepare ChNF (width in the range of 10–20 nm).263 This process involved wet pulverization of purified chitin and ejection of a liquid dispersions from a pair of nozzles operated at high pressure, as a pair of jets that collide against each other. In this treatment, the interfacial interactions within chitin chains were cleaved solely by the high pressure, with no need for chemical modification. As the number of passes increased, more nanofibers (with smaller width) were dispersed in water. The obtained ChNF showed a favorable network formation in suspension, likely a result of the less charged nature of the ChNFs and their relatively large size.

Mechanical nanofibrillation methods are simple and adaptable, and they yield ChNF with high aspect ratio and with no need for any chemical reaction while keeping most of the original features of the native chitin. Some factors should be considered when choosing the mechanical method. As far as obtaining a higher degree of fibrillation, one should consider: (1) the source of chitin (high DDA, low crystallinity, weak intermolecular interaction forces, and fine exocuticle structures), e.g., squid pens and prawns facilitate production; (2) the apparatus (high energy output, more intense local impact, and multiple processing cycles during disintegration); and (3) the environment (acidic pH condition during processing facilitates nanofibrillation).264 The main drawbacks of mechanical nanofibrillation include the availability of special instruments, relatively high energy consumption, and production cost as well as possible incomplete individualization of ChNF.

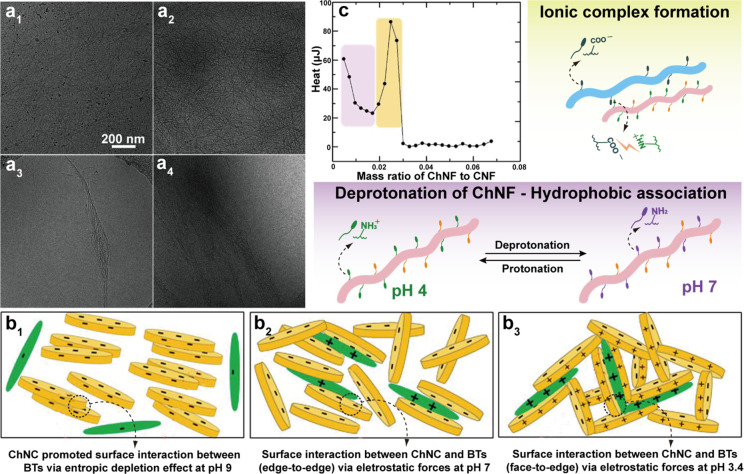

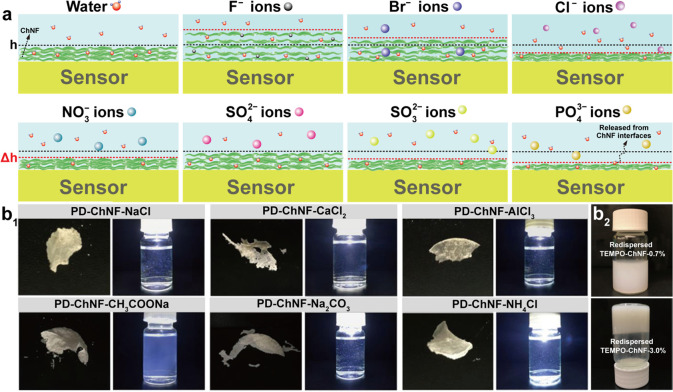

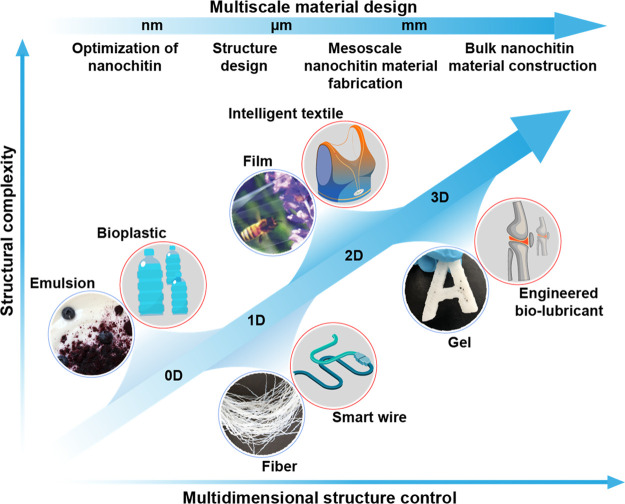

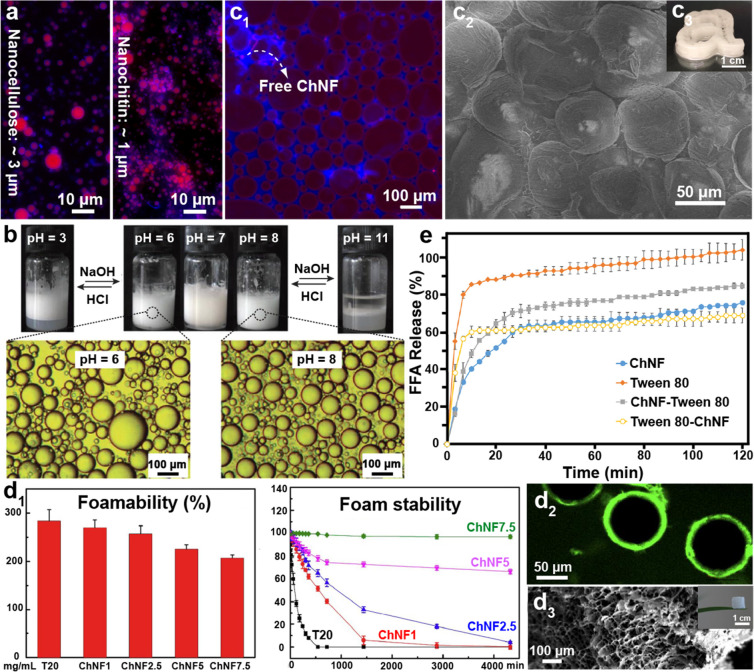

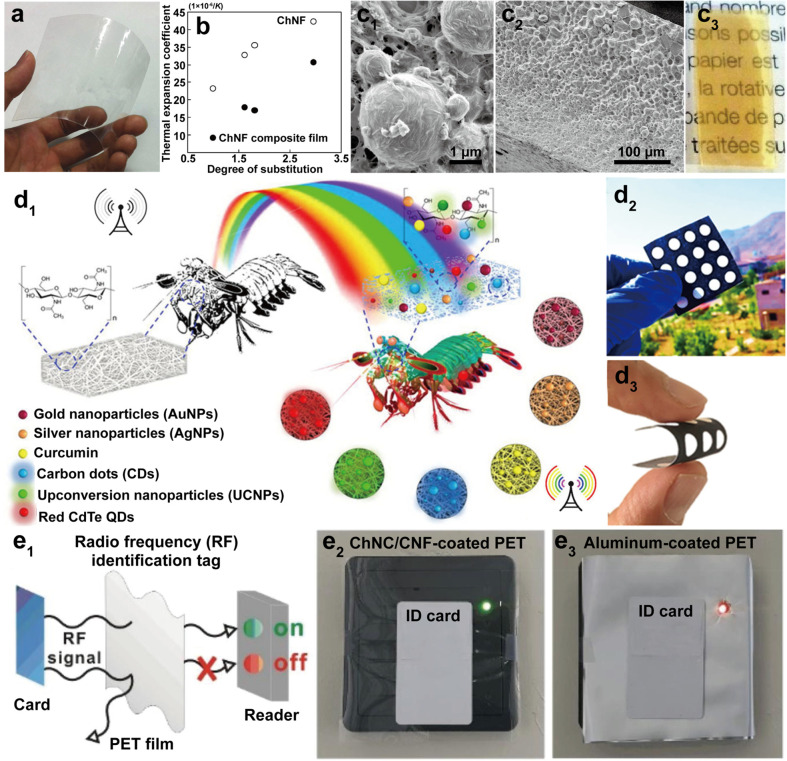

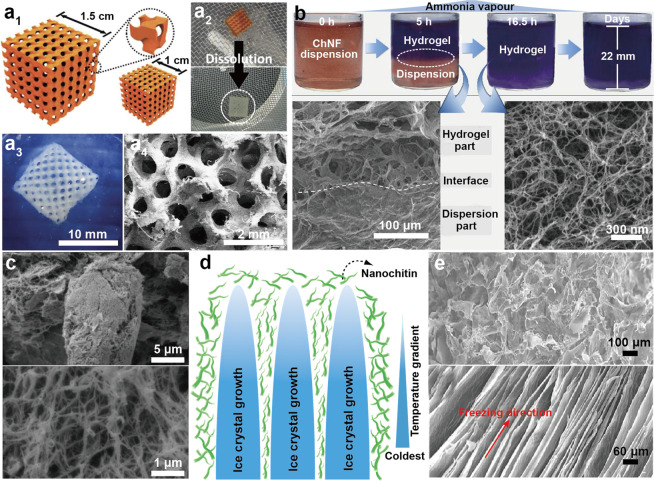

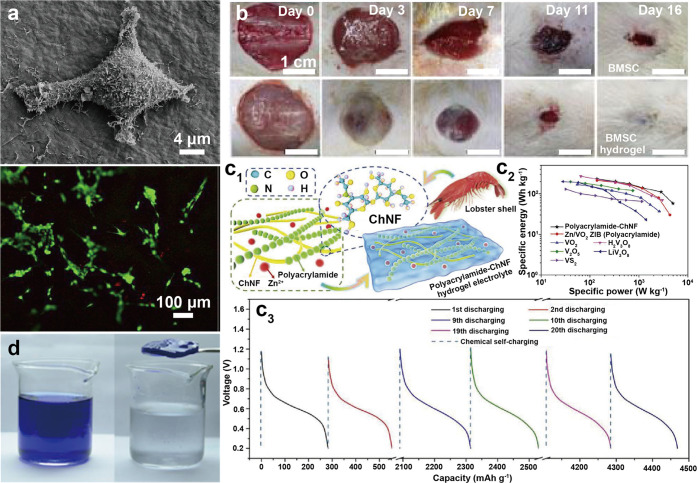

3.2.1.2. Mechanical Treatment Assisted with Chemical Modification