Abstract

This Review provides an overview of the emerging concepts of catalysts, membranes, and membrane electrode assemblies (MEAs) for water electrolyzers with anion-exchange membranes (AEMs), also known as zero-gap alkaline water electrolyzers. Much of the recent progress is due to improvements in materials chemistry, MEA designs, and optimized operation conditions. Research on anion-exchange polymers (AEPs) has focused on the cationic head/backbone/side-chain structures and key properties such as ionic conductivity and alkaline stability. Several approaches, such as cross-linking, microphase, and organic/inorganic composites, have been proposed to improve the anion-exchange performance and the chemical and mechanical stability of AEMs. Numerous AEMs now exceed values of 0.1 S/cm (at 60–80 °C), although the stability specifically at temperatures exceeding 60 °C needs further enhancement. The oxygen evolution reaction (OER) is still a limiting factor. An analysis of thin-layer OER data suggests that NiFe-type catalysts have the highest activity. There is debate on the active-site mechanism of the NiFe catalysts, and their long-term stability needs to be understood. Addition of Co to NiFe increases the conductivity of these catalysts. The same analysis for the hydrogen evolution reaction (HER) shows carbon-supported Pt to be dominating, although PtNi alloys and clusters of Ni(OH)2 on Pt show competitive activities. Recent advances in forming and embedding well-dispersed Ru nanoparticles on functionalized high-surface-area carbon supports show promising HER activities. However, the stability of these catalysts under actual AEMWE operating conditions needs to be proven. The field is advancing rapidly but could benefit through the adaptation of new in situ techniques, standardized evaluation protocols for AEMWE conditions, and innovative catalyst-structure designs. Nevertheless, single AEM water electrolyzer cells have been operated for several thousand hours at temperatures and current densities as high as 60 °C and 1 A/cm2, respectively.

1. Introduction

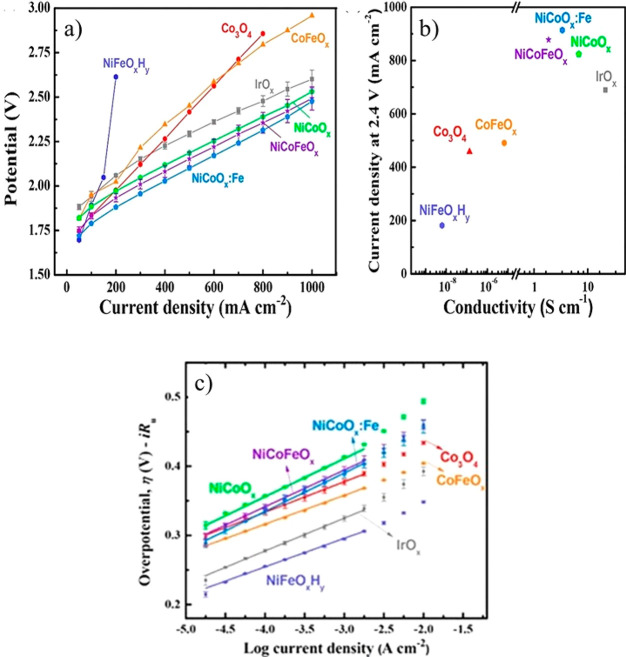

Hydrogen has played a key role throughout the industrial life of humankind, and the global demand for H2 has continuously increased, in fact tripling since 1975.1,2 Today’s global H2 production exceeds 70 million metric tons (MMTs)/year and is consumed by the oil and gas industry and by metal refineries or turned into value-added products such as NH3, feedstock chemicals such as CH3OH, or specialty chemicals.1 H2 can be considered a commodity of increasing need, with its importance already being reflected in its 117 billion US$ global market value.3Figure 1 shows the trend for the global demand for H2 divided into end-use sectors. The actual H2 demand per sector depends on the country, e.g., in the United States, the oil and gas sector consumes 80% of the produced H2. The future demand for H2 may experience an additional increase due to H2’s physical properties such as its high gravimetric standard heat of formation (being the highest among fuels)4 and its standard heat of formation value (H2’s high heating value is 142 MJ/kg5), which is up to 3 times higher than that for liquid hydrocarbon fuels.6 Unfortunately, the volumetric density of H2 of 8 MJ/L is 4 times lower than the 32 MJ/L value of gasoline,7 thus requiring a high storage volume or significant gas compression.2

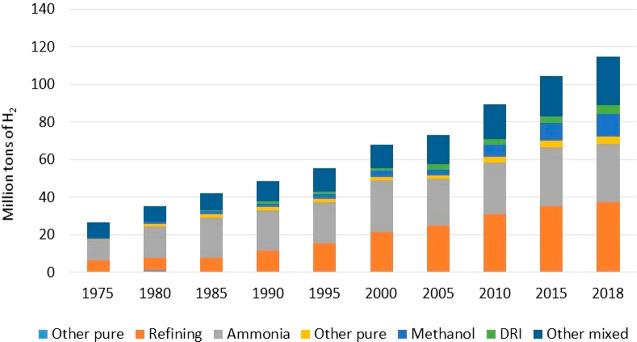

Figure 1.

Historical trend of the global usage of H2 predominantly produced by utilizing a fossil fuel feedstock divided into industrial sectors. “Other pure” stands for applications needing high-purity H2, “DRI” stands for direct reduced iron steel production, and “Other mixed” stands for applications using H2 as a mixture gas, e.g., fuel or feedstock synthesis gas. Made from ref (1). Copyright 2019 U.S. Department of Energy.

Since the late 1950s, steam methane reforming (SMR) has been predominantly used to produce H2 followed by coal gasification and water electrolysis (WE), although the latter only contributes 2–4% to today’s global H2 production.8,9 The heating value of CH4 is high (the HHV is 55.5 MJ/kg5), making the production of H2 via SMR, which is in the range of 2 €/kg H2,9−11 economically attractive. Today, 96% of H2 is produced from fossil fuel-based feeds (48% from natural gas, 30% from heavy oils and naphtha, and 18% from coal).1,6 H2 production from fossil-based sources and moreover from CH4, which is an ∼30 times more potent greenhouse gas than CO2,12,13 is a net emitter of CO2 and other air pollutants. On the basis of calculations and a large set of reported data, Sun et al.14 concluded average CO2/H2 values of 9 kg/kg and 75.4 kg/MJ, translating into 720 MMT/year of CO2 emitted for 70 MMT/year H2 produced from SMR. The latter suggests that H2 produced from SMR alone contributes 1.7% to the 43.1 billion metric tons worldwide emissions from humans in 2019.15,16 Furthermore, the SMR process also produces H2 of low purity (95–98%), requiring upgrading steps such as pressure swing absorption for many applications (e.g., fuels, specialty chemicals, and the ceramic and electronics industries).17 A mechanical compression step, which can be costly, also needs to be added.18 WEs have an advantage of generating higher-purity and already partially compressed H2.

H2 as a fuel for the H2 economy is still a topic of interest.19,20 Much of the interest is driven by our increasing demand for energy based on cleaner sources.21 Correspondingly, H2 is considered for energy storage (ES) and as a fuel.11,21 The driving forces for the H2 economy are different across the globe depending on the resources, potential for energy generation, and political landscape of a country.

To understand the feasibility for a specific H2 production or storage route, technical gaps need to be identified and examined while keeping the cost in mind. The complete cycle needs to be considered including the end use of H2, which can be manifold and may be different depending on the locations of H2 production and consumption. H2 is suitable for short-, medium-, and long-term energy storage. H2 could, e.g., be reelectrified and injected back into the grid considering payback options known as power to power, which is used as a grid service to balance the grid when demand is high and production is low, or that known as price arbitrage, or to avoid the building of new grid connections.11,22−24 In addition, H2 can also be transformed to a liquid organic hydrogen carrier (LOHC), enabling safer transport for later use.25−29

In this Review, the feasibility of H2 produced from electrochemical water splitting coupled with renewable energies is of interest. The anion-exchange membrane water electrolysis (AEMWE) is one of three types of low-temperature (<100 °C) WEs. The other two are proton-exchange membrane water electrolysis (PEMWE) and traditional electrolysis, which uses highly caustic KOH as the electrolyte and a porous separator. Among the three low-temperature WEs, AEMWE is the least-mature technology, and prior to implementation, significant technological hurdles need to be overcome. Many of the hurdles lie in the AEMWE components’ chemistries, which will be discussed in this Review. References are made where needed to scientific knowledge established for well-studied PEMWEs and fuel cells (FCs). This Review differs from recent publications30−41 as it presents a comprehensive analysis of all components of an AEMWE up to the single-cell level and reviews AEMWE single-cell performances for cells that have shown at least 100 h of operation. Performance results and needs of materials development and engineering are given based on high-level analyses.

2. To and from H2 Produced via Water Electrolysis: Sources, Cost, Conversion, and Principles

Biomass

and water are renewable sources that potentially allow

clean H2 production.6,42 Vast amounts of biomass

are available, but the production of H2 from water is more

advanced; hence, H2 derived from biomass is viewed to be

implemented in the long term. H2 production from water splitting  can be divided into low- and high-temperature

electrolysis, thermochemical water splitting, and photoelectrochemical

processes. Due to the absence of carbon-based reaction fuels, water

splitting offers the cleanest way of producing H2, provided

clean sources of electricity are used.

can be divided into low- and high-temperature

electrolysis, thermochemical water splitting, and photoelectrochemical

processes. Due to the absence of carbon-based reaction fuels, water

splitting offers the cleanest way of producing H2, provided

clean sources of electricity are used.

Fossil fuel-free energy sources, such as nuclear and renewables, can be low or CO2-free forms of energy. Nuclear offers several advantages as vast amounts are available and excess energy during low demands can be stored via, e.g., electrolysis. The outlet temperatures of nuclear reactors are in the range of 300–950 °C. Such a range can be attractive for higher-temperature electrolyzers, e.g., solid oxide electrolysis cells and thermochemical water splitting. However, these high-temperature electrolysis methods are not yet mature and suffer material-corrosion issues above 100 °C.6,43

Solar and wind provide intermittent forms of energy. Solar is currently the fastest growing energy source due to the many investments made globally. Solar energy supplied just above 2% of the global electricity usage in 2018, while wind energy provided ∼5%.44 The global capacity and usage of wind energy may well grow, as it is not costly and the technology is continuously advancing, even though on-shore wind farms require thousands of acres of land.44 Electrochemical WE is best suited in combination with wind energy, which calls for storage in the MW range.45 WE not only is able to provide large-scale storage but also offers medium- and longer-term storage unlike, e.g., flywheels, which are low cost but only allow short-term storage.46 In addition, WEs can accept high-current inputs per surface area, operate in dynamic modes, and can be ramped up quickly, which are all requirements for storage of intermittent energy sources.11,45,41 Batteries are not suitable as a storage option for wind energy because they only accept low currents per surface area and have high self-discharge rates.32,47,48 Thermal molten salts are another high-energy storage density option being developed.49 However, it is based on exchanging heat. The heat is stored in a molten salt (which is thermally insulated) and released when needed. In addition, a WE is better suited than a battery for operations in cold climates because WEs can be heated using internal electrical currents without compromising their lifetime.50,51 Unfortunately, the intermittent nature of renewable energy lowers the annual operating hours, thus increasing the cost of the technology.9

The coupling of wind and solar energy with WEs provides many advantages; nevertheless, clear challenges exist. Table 1 provides a summary of the H2 production characteristics from SMR and WEs. It is seen that a challenge of H2 produced by WEs is the cost, which can be captured in the sum of the operating (OPEX) and capital (CAPEX) investment costs.

Table 1. H2 Production Characteristics of Steam Methane Reforming (SMR) versus Electrochemical (<100 °C) Water Electrolyzers (WEs).

| characteristic | SMR | WE |

|---|---|---|

| feed | fossil fuel | H2O |

| estimated CO2 emissions per kg H2 (kg/kg H2) | 9a | 0.4–0.9b |

| global CO2 emissions (MMT/year) (2019) | 720 | 32–72b |

| % of global CO2 emissions 2019 (est) | 1.7 | 0.08–0.17b |

| H2 production cost (2019) (€/kgH2) | 2 | >3.8c |

| driving force for reaction | heat | electrical energy |

| catalysts | sulfur- and coke-tolerant (nickel, nanosized nickel, platinum, rhodium) | acidic: Pt (cathode), IrO2 (anode) |

| alkaline: nickel-based or Pt (cathode), often nickel-based (anode) | ||

| H2 purityd (%) | 95–98 | PEMWE: 99.9–99.999e |

| AEMWE: 99.4 |

Taken from ref (15).

The data are for traditional alkaline water electrolyzers coupled with wind energy and estimated from refs (52−55). Fewer carbon-footprint studies are available for water electrolysis coupled with wind than from SMR processes. However, all of these studies consistently show water electrolyzers coupled with wind to be one of the lowest CO2 emitters.

An estimate of 3.8 €/kg H2 is for coupling with wind, minimal operating hours of 7000 of 8760 per year, i.e., 80% capacity, a CAPEX of 800 €/kW, WE efficiency of 80%, and renewable electricity cost of 70 € M/Wh.10

H2 purity without purification processes as pressure or temperature swing adsorption.

Typically at 30 bar outlet pressure.

For low-temperature WEs the price of electricity is often taken as the OPEX value because electricity prices often dominate the cost of H2 production and reliable data for operating large-scale WEs are lacking.9 However, it is advisible to also include the cost of water (which needs to be of drinking water quality), specifically for operation at remote locations, as well as the WE maintenance costs.

The CAPEX cost is typically given as the investment cost per kW of electrical capacity and sometimes as the cost per nominal H2 production rate (in m3/h). In general, the definition of the CAPEX value in the form of cost per nominal capacity or cost per nominal H2 production rate is not complete.56 Neither of the two include relevant electrolyzer information such as the lifetime and the H2 production efficiency. A few approaches have been suggested to calculate the contribution of the CAPEX to the cost of H2 production in order to include the actual performance capabilities of different WEs.56 Villagra and Millet defined the CAPEX contribution to the total H2 cost (“CAPEX”) in €/kg of H2 produced as follows:56

| 1 |

In eq 1, n is the number of electrons (2 for H2 electrolysis), F is the Faraday constant (96 485 C/mole–), IC is the initial WE cost, LT and A are the lifetime and geometrical electrode area of the WE, respectively, MH2 is the molecular H2 weight, and jo is the operational current density. This definition gives a clearer indication of the WE characteristics that influence the H2 production cost as compared to the traditionally used CAPEX values. However, eq 1 does not include the efficiency of the WE, which could simply be introduced as a term in the dividend in eq 1.

From eq 1 it is seen that the CAPEX contribution to the cost of H2 produced decreases with an increase in the WE lifetime, electrode surface area, operating current density (j), and average efficiency of the H2 produced.56 Logically, a lower initial cost of the WE, which is influenced by materials and manufacturing costs, also reduces the cost of H2 production. To obtain the full cost of H2 production, the OPEX and CAPEX are combined. The joint OPEX and CAPEX costs define the technical targets the technology needs to achieve to be competitive for deployment. According to Table 1, WEs must produce H2 at a cost below 2 €/kgH2 to be cost competitive. The price for H2 production by WE coupled with wind energy could be below 3.8 €/kgH2 if the WE is used at an 80% annual capacity, has a CAPEX value of 800 €/kW, and has a cell efficiency of 80% at OPEX costs corresponding to renewable electricity costs of 70 €/MWh.9 Proost and others suggest that WEs could become more competitive to SMR as CAPEX prices of WEs are predicted to decrease with an increase in manufacturing (taking advantage of the economy of scale) and to a lesser extent also continue to decrease through additional research and development contributions.9,52,57 This seems reasonable considering that the CAPEX prices of PEMWEs decreased by 1 order of magnitude between 2000 and 2010 and continue to steadily decrease, as demonstrated in Table 2.18−59 These trends suggest that H2 production by WEs will become competitive if low-cost electricity is used.9,60

Table 2. Evolution of CAPEX Values for PEMWEs.

2.1. H2 Conversion to Chemical Raw Materials or LOHCs

A scheme demonstrating the coupling of wind with WE and the possible uses of the stored H2 is shown in Figure 2. Much of the wind resources are located in remote areas, and transport of H2 in pipelines is only feasible over limited distances in the 100–200-mile range.

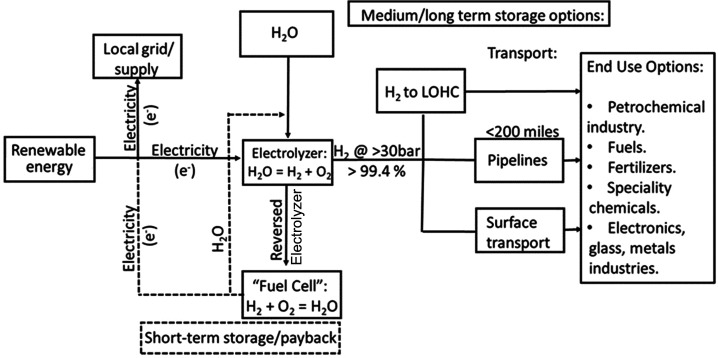

Figure 2.

Schematic for the coupling of renewable (wind or solar) energy with water electrolysis. The figure shows options for short-, medium-, and long-term storage for the energy in the form of H2 and possible end uses including payback options. LOHC stands for liquid organic hydrogen carrier.

Several studies61,62 proposed to transform the H2 into a chemical raw material or LOHC (liquid organic hydrogen carrier), which are H2 carriers that can allow for safer transportation. The chemical raw materials could be CH3OH, dimethyl ether, gasoline, ammonia, and Fischer–Tropsch fuels. Examples of LOHC systems are N-alkylcarbazoles and derivatives.63 An early LOHC system was toluene/cyclohexane, but dehydrogenation in the liquid phase with easy condensation of the evaporated parts of the H2 carrier is also possible for higher-boiling aromatics and heteroaromatics.27,64,65 The LOHC is formed by a catalytic hydrogenation and a reversible dehydrogenation reaction. LOHC systems are liquids and can be used in the existing fuel infrastructure. LOHCs are also reloadable without the release of CO2. LOHCs offer higher volumetric energy densities than H2 and can be a room-temperature, long-term storage option. They could serve as a H2 supplier for arbitrary applications such as energy or specialty chemicals. CH3OH could be formed from CO2 concentrated from the atmosphere and H2 from electrolysis. CH3OH has a high acceptance level due to its similarity to existing fuels, although a 2014 techno-economic study showed that the cost of CH3OH via the route of using clean H2 is over the market price.66 Similarly, NH3 can be formed by electrolysis,67 which according to recent studies releases less CO2, when coupled with wind or solar energy, than the traditional Haber–Bosch process.68

2.2. Electrochemical Water Electrolyzers

Low-temperature water electrolyzers (WEs) can be divided into alkaline and acidic systems. They are further divided into finite and zero-gap electrolyzers (Figure 3). The schematics show the principles of a single WE cell, while an actual system consists of an assembly of many cells known as a stack. The anode and the cathode in a WE are spaced using a separator to avoid mixing of the H2 and O2 gases.

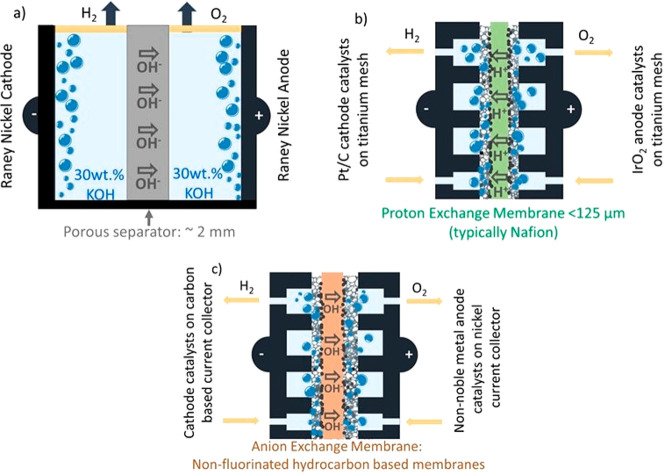

Figure 3.

Schematic of the three types of WEs as (a) traditional alkaline finite WE (AWE), (b) zero-gap PEMWE running under acidic conditions using an H+ conducting membrane, and (c) zero-gap AEMWE utilizing an OH– conducting membrane. The goal is to use noble metal-free catalysts for the cathode and anode of an AEMWE.

The terms finite and zero gap are related to the distance of the separator between the anode and the cathode, where the O2 evolution reaction (OER) and the H2 evolution reaction (HER) take place. Finite-gap alkaline WEs employ a porous separator and aqueous, e.g., 30 wt % (5 M) KOH, conducting solutions (Figure 3a).50,69 This is a proven technology and has been deployed in MW scales since the late 1950s.50,70 A well-known advantage of alkaline conditions, specifically pH > 13, is the stability of the non-platinum group metal (non-PGM)-based catalysts for the OER and HER, unlike for acidic media needing platinum group metal catalysts.42,44,50 Typically, high-surface-area Raney nickel electrodes are used in an infinite-gap alkaline electrolyzer.71,72 The use of a porous separator, such as Zircon and Perl UTP 500,73−75 calls for a large distance (>2 mm) between the anode and cathode to reduce H2 and O2 gas crossover, which unfortunately is accompanied by a high ohmic resistance due to the direct dependency of ionic resistance on electrolyte thickness. The latter limits the maximum current densities (jmax) that can be reached.46,56,76 Typically the jmax value for a finite-gap alkaline WE is 0.25 A/cm2, which is too low for integration with renewables, such as wind, that need ES technologies that are able to accept current densities in the several A/cm2 range as well as with fast dynamic responses.24,44 New WE designs are being developed that incorporate one electrode of minimized or even zero-gap distance to the separator.42,76−78 Examples explored are alkali-doped ion-solvating membranes in combination with, e.g., 24 wt % KOH electrolytes.79−81 Single-cell tests using a KOH-doped ion-solvating membrane and Raney nickel electrodes yielded a low cell voltage of 1.8 V at j values of 1.7 A/cm2.80

The zero-gap WE design reduces the internal resistance as thin polymer-based membranes of low H2 and O2 crossover are employed. Proton-exchange membranes (PEMs, also referred to as cation-exchange membranes) and anion-exchange membranes (AEMs) are used for acidic (Figure 3b) and alkaline (Figure 3c) zero-gap WEs, respectively. Consequently, zero-gap WEs are predicted to achieve higher j values than finite-gap electrolyzers. In the case of commercial PEMWEs, j values of up to 1–3 A/cm2 at lifetimes (LTs) of 15 000–20 000 h using membranes as thin as 50–200 μm PEMs have been demonstrated. PEMWEs are much more mature than AEMWEs. This is related to the fact that PEMs, which typically consist of a perfluorosulfonic acid that is known under the trademarks Nafion and Aquivion, have a significantly higher stability than anion-exchange membranes (AEMs), although the stability of Nafion is limited to 80 °C operations. In fact, PEMWEs using a Nafion separator are typically operated at 60 °C.18 Only in recent years have achievements been made to increase the stability of AEMs and single-cell AEMWEs run in the several A/cm2 range, although proof of extended durability and performance is still needed.73,77,82−84

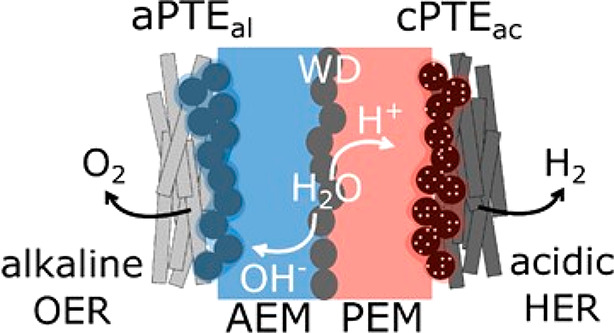

Recent developments in the field of bipolar membranes (BPMs) have opened new opportunities.85 The BPM’s principal lies in linking the advantages of the PEM and AEM system where low-cost anode materials (alkaline media) and active and durable cathode catalysts (acidic media) are used. In the BPM system, a cation-exchange membrane (CEM) and an AEM are in direct contact to form a bipolar interface (Figure 4).85 A water dissociation or water recombination catalyst is added between the two membranes to enhance the performance.86−88 Activities of such bilayer catalysts have been shown to be close to those of alkaline HER catalysts.86

Figure 4.

Schematic of a bipolar membrane (BPM) WE employing a solid AEM (blue) and PEM (red) with a water-dissociation (WD) catalyst layer located at the AEM|PEM interface. The OER and HER take place at the anode, indicated as aPTEal, and the cathode, indicated as cPTEac, respectively. Reprinted with permission from Open Access article.89 Copyright 2021 Royal Society of Chemistry under CC Attribution 3.0 Unported License https://creativecommons.org/licenses/by/3.0/.

Another difference between finite and zero-gap alkaline WEs is that zero-gap WEs operate on a pure water feed or dilute alkali electrolytes.90 The use of pure water theoretically eliminates issues related to the reaction of cations such as K+ with CO2 to form carbonates in OH– environments but requires an OH– conductive polymer, an anion-exchange ionomer (AEI), to be present in the catalyst layer.46,91,92 However, even at low KOH concentrations, or in pure water, the complete exclusion of CO2 is a challenge because CO2 is present in the air and can easily dissolve in water (0.75 g/L at 50 °C). Much of the research and development on zero-gap systems has focused on PEMWEs because the implementation of AEMWEs still strongly depends on the availability of AEMs, which show long-term stability at elevated temperatures, although low-power (e.g., 0.5–1 N·mH23/h) AEMWE systems are commercially available.39,93,94 The commercial system from Enapter (formerly Acta) offers high-purity (99.9%) H2 and 99.999% H2 with an optional dryer.94 An advantage of membranes, i.e., the zero-gap WEs, is to obtain a higher-purity H2 directly from the cell (section 6). WEs should last >50 000 h under high j values and ideally also under pressure of 50–80 bar and higher (≥60 °C) temperatures. Today’s commercial PEMWEs have shown long (at least 20 000 h) lifetimes at low temperatures and 30 bar.39,43

2.3. Thermodynamics for WEs

The water splitting reactions in acidic and alkaline media are overall comparable, although in alkaline media OH– is the conducting ion, while in acidic media H+ assumes this role. In the case of alkaline WEs, the reactions are as follows,

| 2 |

| 3 |

| 4 |

where SHE stands for standard hydrogen electrode and E° is the reversible potential. In alkaline conditions, the cathode needs two water molecules per H2 produced, and thus the water transport from the anode to the cathode is a crucial factor to be considered in the cell design, materials selection, and operation mode of the WE. The OH– needed at the anode is provided through the cathode reaction and needs to be transported through the catalyst layer and membrane to the catalyst sites in the anode layer.

The standard reversible potential (E°rev) for the water splitting reaction is −1.23 V, i.e., the reaction is endothermic and does not occur at a cell voltage (Ecell) below 1.23 V. For the water splitting reaction, the standard enthalpy and entropy are 285.84 and 163.6 kJ/molH2, respectively.43 This difference indicates a large entropy change of the reaction system when liquid H2O changes into the two gaseous products H2 and O2. Electrolysis at higher T values (>100 °C), or more precisely using a H2O steam reactant, reduces the energy requirements of the electrolysis as this entropy change is eliminated. Reference is also made to the thermoneutral voltage (E°tn), which for the water splitting reaction is 1.48 V, reflecting the transition point between endothermic and exothermic, i.e., the potential at which the reaction proceeds without heat input.

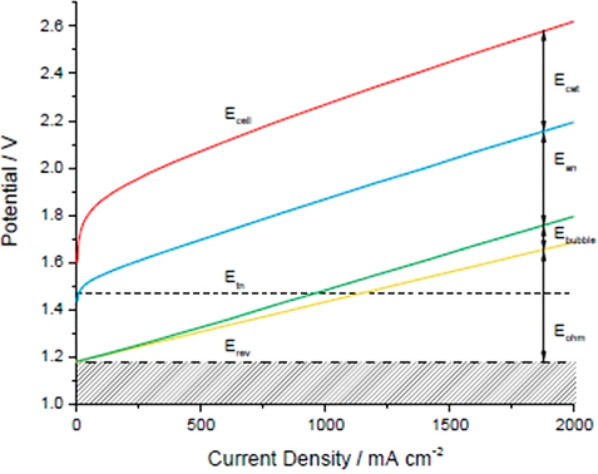

To understand the WE cell performance, the difference between Eanode and Ecathode, i.e., the cell potential (Ecell), is plotted versus j (Figure 5). Ecell depends on the reversible potential (Erev). However, an operating WE also experiences voltage losses as overpotentials (η) at the anode (ηan) and cathode (ηcat) and iR drops induced by the cell resistance (Rcell):

| 5 |

In eq 5, Rcell is a lump resistance term made of a number of resistances including contributions from the membrane, polar plates, interfaces, system circuits, and mass-transport losses. Mass-transport losses are losses that result from the nonstoichiometric supply of reactants to the active catalyst centers.95 The formation of oxygen and hydrogen bubbles is one possible effect. Product gas bubbles in contact with the electrodes reduce the electrode contact with the liquid water, which in turn decreases the active electrode areas. All of the voltage loss terms in eq 5 increase with an increase in the current (i), i.e., j as shown in Figure 5. For well-designed low-temperature WEs, iR drops across the catalyst layers and other components such as the gas diffusion layer (GDL) and bipolar plates (BPs) are negligible.96 For today’s AEMWEs, the membrane resistance dominates the voltage.97 This of course can change with the continued development of AEMs.

Figure 5.

Typical potential (Ecell)–current density (j) curves using arbitrary values demonstrating the cumulative contributions of different voltage losses. The anode and cathode voltages (Ean and Ecat) can be reduced by using catalysts of higher activity and improved catalyst layers, while the ohmic voltage (Eohm) loss depends on both electrode conductivity and membrane ionic conductivity. Both,= potential losses due to gas bubble formation (Ebubble) and ohmic losses (Eohm) are reflected in the iRcell term shown in the simplified eq 5. Many factors influence the actual E losses thar are demonstrated in the figure. Reprinted with permission from (98). Copyright 2017 DTU Energy, Department of Energy and Energy Storage.

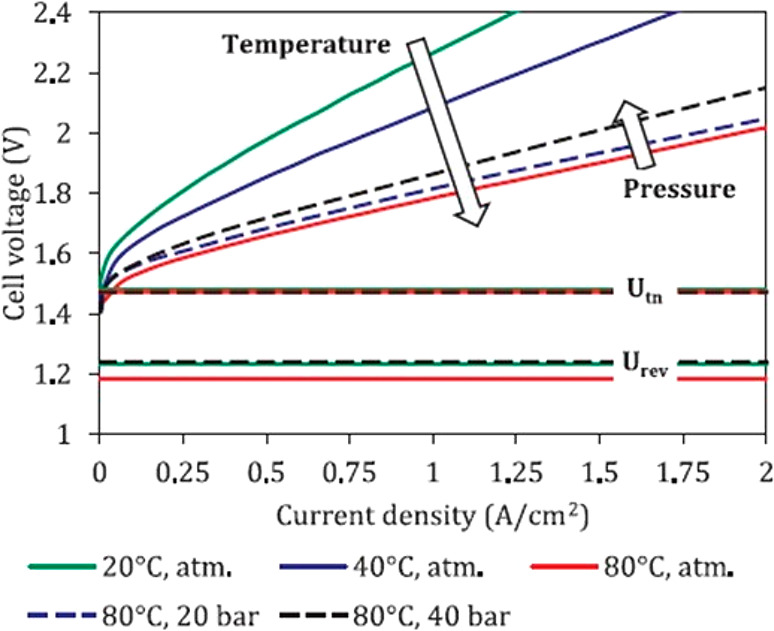

As seen from Figure 6, a higher temperature (T) lowers Ecell, which is beneficial for the electrochemical reactions, increases the counterion transport, and facilitates H2 and O2 separation as the gas solubility decreases with increasing T.99−101 A higher pressure (P) increases Ecell according to the Nernst equation, although the increase is not pronounced. In fact, the availability of compressed H2 directly from a WE is a benefit, reducing the cost of mechanical H2 compression provided that the compression remains in the 30–50 bar range.24,35,102 WE operation at higher pressures can require the reinforcement of thinner membranes (e.g., in the case of PEMWEs < 125 μm)103 to increase their mechanical strength and achieve higher WE efficiencies.

Figure 6.

Cell voltage (Ecell)–curve as a function of the applied current density for a PEMWE. The influences of T and P are shown. The thermoneutral voltage of 1.48 V, labeled as Utn, and the reversible voltage of 1.23 V, labeled as Urev, are also shown. Reprinted with permission from ref (24). Copyright 2018 Elsevier.

2.4. Key Target Performance Characteristics

To make H2 production via PEMWEs economically competitive, the CAPEX cost needs to drop below 750 €/kW. This is at an electricity (OPEX) cost of <70 €/MWh.9 On the basis of extrapolations of experimental voltage versus current curves for single-cell PEMWEs, this goal has been suggested as feasible for WEs operated at ≥80 °C and current densities of 10 A/cm2, using a thin (25 μm) Nafion 212 membrane, and achieving a WE lifetime exceeding both 15 000 h and efficiencies of 75%.56 These data can be used as a guideline to approximate the target characteristics and potential cost savings when changing to more-abundant materials for the milder AEMWE conditions. This assumes that the economy of scaling to a fully integrated AEMWE system follows at least the same beneficial trend as observed for PEMWEs and relies on the development of AEMWE component materials matching lifetime and performance needs.18

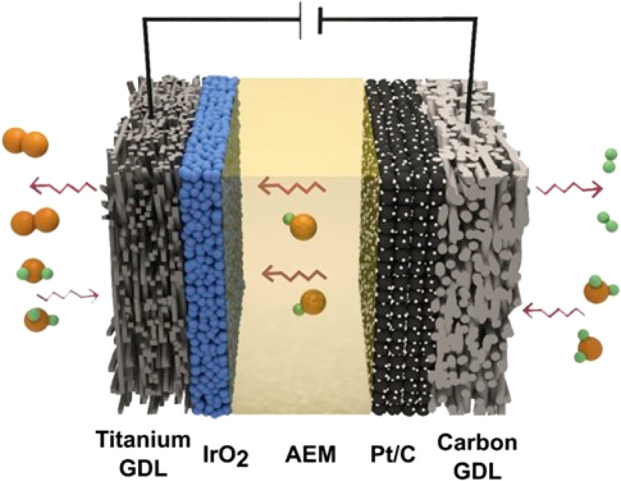

Cost data for PEMWEs suggest that the stack makes up 60% of the CAPEX amount.11 The stack is made of the individual WE cell and the appropriate separators. The cell contains the heart of the WE: the membrane electrode assembly (MEA). The MEA is made of the anode and cathode catalyst layers, which are interfaced with the porous transport layers (PTLs) and sandwich the AEM. Typically in water electrolysis, metal-based PTLs are used at the anode; in alkaline conditions, a variety of Ni-based materials are used in single-cell tests. Because, in practice, the cathodic environment is less corrosive, more cost-efficient PTLs are in use at the cathode. These are mostly carbon-based (e.g., carbon fibers, carbon paper, or carbon cloth) and therefore often referred to as gas diffusion layers (GDLs); see, e.g., Figure 7.

Figure 7.

Schematic diagram of components for a single cell of an AEMWE. In this schematic, IrO2-based catalysts and a porous titanium transport layer (PTL) are used at the anode. (The titanium PTL is referred to as GDL in the schematic.) At the cathode (right-hand side), carbon-supported Pt (Pt/C) catalysts and a porous carbon GDL are used. H2O, OH–, and gas (H2 and O2) molecule flow are also indicated in the figure. Depending on the AEMWE, other catalyst compositions, e.g., Ni- and Fe-based anode catalysts, are often used. Reprinted with permission from ref (107). Copyright 2019 Elsevier.

The MEA, in turn, is sandwiched between two flow fields known as bipolar plates (BPs) that allow water, H2, and O2 to flow and conduct the current (Figure 7). For oxidative and acidic conditions, the BPs are typically made of costly titanium104−106 and dominate the cost, making up 51% of the stack costs, followed by the manufacturing costs of the MEA (10%) and the cost of the cathode (9%) and anode (8%) current collectors. The cost of the PEMWE anode catalyst and membrane are comparable at 6% and 5%, respectively, while research and development efforts resulted in cost reductions of the cathode to 1%. Changes in the BPs, e.g., by switching to stainless steel (even when noble metal coated for high potential corrosion protection),103 offer the potential for large reduction costs for AEMWEs compared to PEMWEs. In the case of other components such as the catalysts, the cost reduction by employing less-expensive materials alone is in the few to several % range. This indicates the need for AEM and catalyst improvements and calls for innovative material and component designs to assist in making AEMWEs viable.

3. HER and OER Catalysts

Enhancing the activity and stability of both the HER and OER electrocatalysts is crucial to make AEMWEs viable for large-scale deployment. OER catalyst improvements are urgently needed as the OER is a sluggish reaction, resulting in high overpotentials (ηs). A number of studies focused on gaining a detailed understanding of the HER and OER mechanisms in order to eventually create more-active catalysts. Reaction mechanistic understandings are important, but the creation of catalysts displaying high activities and stabilities in MEAs is crucial. Studies that focus on the AEMWE elecrocatalyst development often involve the preparation of catalyst powders. The catalyst powders can be subsequently transformed into catalyst layers (CLs) that can be up to several tenths of a micrometer thick. The activity of a catalyst measured in its powder form, i.e., prior to integration into a CL, and the activity of a catalyst in an actual CL of an MEA can be different (section 6). In some studies, thin catalyst films are also deposited onto solid and smooth electrode substrates such as gold foils. The latter can be valuable model catalysts, but for practical applications, porous current collectors enabling facile flow for the reactants and reaction products are needed. Therefore, the preparation of HER and OER electrocatalysts for AEMWEs often focuses on powder catalysts. However, the deposition of catalysts directly onto the porous and high-surface-area current collectors to be used in an MEA is also receiving attention, and recent literature has shown that such designs could open up AEMWE operation into high-current-density (>5 A/cm2) regimes.108

3.1. Metrics for Electrocatalysts

3.1.1. Mass and Intrinsic Activity

Both the HER and OER are heterogeneous reactions; thus, electron transfer from and to the reactants occurs across the electrode surface. Modifications of the electrocatalyst generally have the goal to lower the energy barrier of the reaction, which in electrocatalysis is observed as a lower overpotential (η) and an overall increase in the electrochemical activity. The two main approaches used to increase an electrocatalyst’s activity are (1) increasing the number of active surface sites and (2) increasing the catalyst’s intrinsic activity.109 An obvious strategy lies in increasing the electrochemical surface area (ECSA) of the electrocatalysts. Many approaches involve the preparation of catalysts of nanometer dimensions to reach maximal increases in the ratio of surface to bulk atoms. However, studies in actual AEMWE cells are needed to confirm if catalysts of nanosized dimensions (specifically if they are unsupported) retain their high-surface-area benefit. In an MEA, the electrocatalysts need to form an electronically conductive network without hindering the flow of reactants and products.

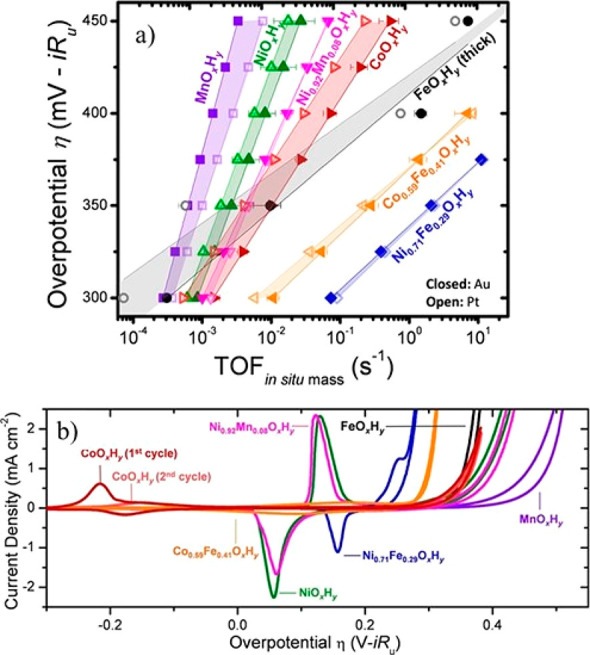

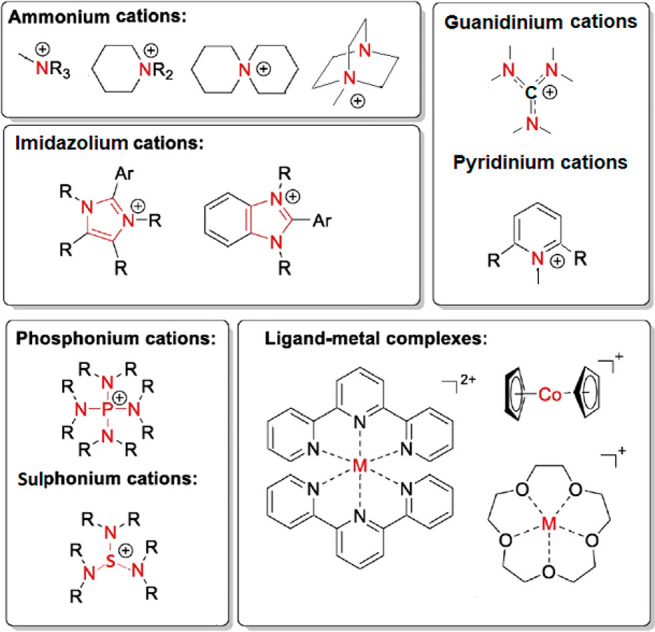

The exchange current density (jo) and the current measured at a specific η are indicators of the activity of a catalyst and are often presented as mass activity (current per catalyst mass) or intrinsic activity (current per ECSA). The mass activity is of practical relevance, but as already mentioned, the intrinsic activity is a measure of the actual catalytic activity. Unfortunately, an accurate measurement of the ECSA value of many electrocatalysts other than platinum, specifically when of high surface area, can be challenging,110,111 and it is further discussed in the activity testing procedure section presented in the Supporting Information. Therefore, grouping catalysts according to their intrinsic activities can be difficult. In addition, there are inconsistencies in the measurement of catalyst activities. Data are extracted for different electrolytes and are often reported as η at a specific current density per electrode area (cmgeom2). Such values are extremely difficult to compare because the loading of the catalysts on the electrode can be different and, of course, different catalysts can have widely different ESCA values. Another metric used in some studies is the turnover frequency (TOF), which is a function of the amount of H2 or O2 gas produced at a specific η resembling an equation as TOF in s–1: (the amount of gas produced at a specific η)/(F × ne × n), where F is the Faraday constant, ne is the number of electrons involved, and n is the number of catalyst atoms. However, there are a great deal of inconsistencies in calculating the TOF number specifically in the estimation of the amount of gas produced and the use of the number of catalyst atoms (n). For example, some authors use the total number of metal atoms of a catalyst, while others use the number of atoms on the catalyst surface; in some cases, the measured HER or OER current density is used as the amount of gas produced, while others measure the amount of gas produced. Therefore, the TOF values reported in the literature do not allow for an easy comparison of catalyst performances between different studies. If measured consistently, the TOF number could be a useful engineering metric. However, the consistent reporting of simply the current density (per mass and if possible per ECSA of the catalyst) at a specific η value (and preferably for the same electrolyte) rather than the TOF seems preferable for catalyst materials’ research purposes and presents fewer complications. Such an approach is consistent with a recent study by Anderson et al., who used a measurement protocol for OER catalysts, which reported current densities measured at a specific η value.112

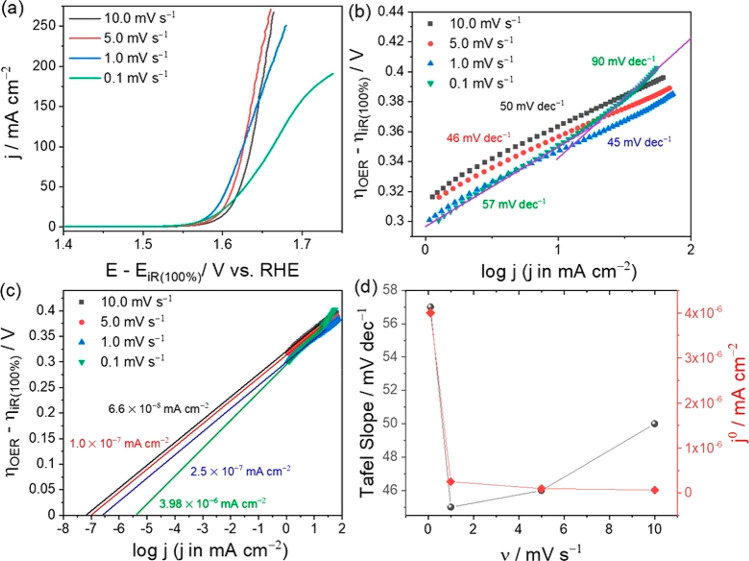

The Tafel equation reflects kinetic information and yields the Tafel slope value (b) as follows: η = a + b × log(j). The Tafel slope yields reaction mechanistic information. To be valid, the Tafel slope needs to be determined at a η value exceeding RT/F, i.e., typically higher than at least 45–50 mV in order to neglect contributions from the back reaction.113 Smaller Tafel slopes are favorable as an increase in j, i.e., an increase in the HER and OER rates is accompanied by a smaller increase in both η and Ecell (eq 5). The η value is specific to a catalyst, indicating how the catalyst surface binds, interacts, and releases various reaction intermediates. The reaction kinetics are dependent on many experimental factors including the nature and morphology of the catalyst and the final electrode. Catalytic activities are influenced by the bulk and surface properties of a catalyst. It is well-known that catalyst activities can be tuned by means of alloying and introducing shape and ligand effects.114 Extrapolation of a Tafel plot to a η of 0, i.e., to the potential equaling the standard potential, yields jo. Tafel slope values need to be obtained from steady-state measurements (such as a constant-current or constant-potential experiment) because a Tafel slope depends on the surface coverage of adsorbed intermediate species. Many recent studies extracted mechanistic and Tafel slope information from slow-sweep linear voltammetry. Slow-sweep linear voltammetry does not provide steady-state conditions and hence can yield incorrect values. This has recently been emphasized by Anantharaj et al. and is demonstrated in Figure 8, which shows results for iR-corrected [ΔmV/Δdec] slopes extracted at different sweep rates for the example of a Co foil measured in 0.1 M KOH.115 It was demonstrated that the [ΔmV/Δdec] slopes depended on the sweep rate varying between 45 and 90 mV/dec, while the actual Tafel slope for this system extracted from constant-potential experiments yielded a value of 60 mV/dec.

Figure 8.

Demonstration of the erroneous impact of attempted Tafel slope measurements using slow-sweep voltage polarization, i.e., a nonsteady-state method. The data are for a Co foil measured using a 0.1 M KOH electrolyte. Reprinted with permission from ref (115). Copyright 2021 American Chemical Society.

Furthermore, the highest Tafel slope value measurable is 120 mV/dec (at 20 °C). Slopes exceeding 120 mV/dec are not Tafel slopes, i.e., their values cannot be interpreted as electrochemical reactions following Butler–Volmer behavior. Slopes higher than 120 mV/dec are observed and are a result of factors such as changes in the catalyst/electrode structure, which could be the formation of a resistive surface oxide and/or other changes in the catalyst structure.113

3.1.2. Metrics Including the Catalyst Stability

The development of catalysts often focuses on developing a material exhibiting a high electrocatalytic activity. However, the activity of a catalyst does not always correlate with the lifetime of a catalyst. Therefore, other metrics to assess catalysts can be useful, such as the recently suggested S-number.116 The S-number is the ratio between the amounts of evolved H2 or O2 gas versus the amount of dissolved catalyst metal.116,117 The amount of gas evolved is normalized using the ECSA value. The S-number appears to be a good indicator providing a comparative and balanced measure of catalytic activities and stability. However, care needs to be taken with the measurement of the S-number because the ECSA of a catalyst can change during the course of the measurement. Other similar metrics that could be useful reflect the catalyst utilization and lifetime in CL layers and MEAs for operating AEMWE conditions.

3.2. HER Catalysts

The kinetic pathway of the HER generally follows the Volmer–Heyrovskey or Volmer–Tafel mechanism.118 Both consist of water adsorption, followed by water dissociation (Volmer step, eq 6), and then either hydrogen dissociation via chemical desorption (Tafel step, eq 7) or electrochemical desorption (Heyrovsky step, eq 8) to form H2:118

| 6 |

| 7 |

| 8 |

In eqs 6–8, the * indicates a surface-bound species. Tafel slopes of −30, −40, or −120 mV/dec measured at 20 °C may be observed if the Heyrovsky, Tafel, or Volmer reaction, respectively, is the rate-determining step (rds).118−120 However, it is impossible to distinguish the actual reaction routes for the HER in the case of a −120 mV/dec Tafel slope.119 The energy barriers associated with each step play a role in determining the catalytic activity. It was suggested that the HER current density can be correlated with the calculated hydrogen-binding energy (HBE) on metal surfaces,121 and the HBE was shown to play a dominant role for the HER activity.121−124

The HER is one of the most studied electrochemical reactions, but compared to acidic conditions limited data is available in alkaline electrolytes. The HER activity decreases monotonically with increasing pH, supporting the theory of the higher HBE suppressing the catalytic activity.125 Furthermore, the HER takes place at more-negative potentials than the OER. Therefore, a higher number of stable materials are available for HER than for OER catalysts. These less-severe HER conditions also offer a wider range of electronically conductive and high-surface-area support materials for HER versus OER catalysts.

3.2.1. Platinum Group Metal-Based Catalysts

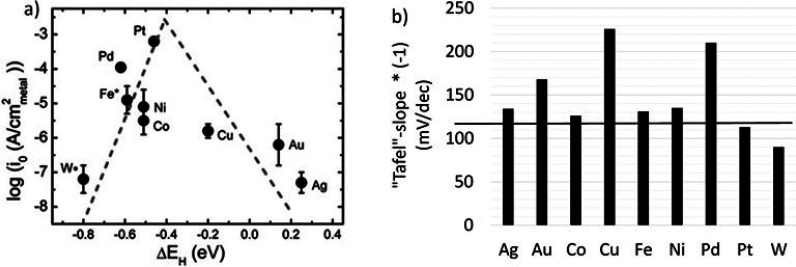

Among many systems studied, Pt and Pt-based catalysts show the highest intrinsic HER activities in alkaline and acidic electrolytes.126,127 Typical jo values for bulk and polycrystalline Pt measured in 0.1 M KOH are 0.62 ± 0.01 mA/cmPt2, and the HER kinetics for Pt are slowed by 2 orders of magnitude in alkaline versus acidic media due to an extra water-dissociation step.128 Similarly, the Tafel slope of Pt is favored (i.e., lower), namely, −30 mV/dec, in acidic solutions versus approximately −120 mV/dec for alkaline solutions.121,128 The following order was extracted from HER measurements carried out in 0.1 M KOH using smooth, single-metal bulk catalysts: Pt ≫ Pd > Ni > Fe ≈ Co > W > Cu > Au > Ag.121Figure 9a shows that the exchange current density, jo, and HBE values follow a Volcano-plot dependence in alkaline electrolytes, as is the case for acidic media. The HER activities, measured as jo, of these bulk metal electrodes show up to ∼4 orders of magnitude differences. A closer inspection of the Tafel slopes (Figure 9b) reported for this series shows high slopes from −90 to −216 mV/dec and only two catalysts, namely, W and Pt, show actual Tafel slopes, i.e., values less than −120 mV/dec. In the case of W, it is questionable if the HER was actually studied on the metal surface because, in aqueous solutions, the surface of tungsten will be covered with oxides, which are difficult to reduce to the metallic surface state in this electrolyte. The same could apply to the Ni, Fe, and Co catalysts studied because surface oxides form easily on these metals, and their complete reduction to the metallic surface state can be challenging. Additionally, hydride incorporation into metals such as Ni and Pd can further complicate HER activity measurements. In fact, a recent study using ambient-pressure X-ray photoelectron spectroscopy (XPS) suggests the formation of Pt–H components and their transformation and/or H intercalation in subsurface Pt layers to possibly take place on Pt in alkaline conditions.129

Figure 9.

HER results measured for bulk, single-metal electrodes in 0.1 M KOH. (a) jo versus calculated HBE (ΔH) values revealing a Volcano-plot relationship. (b) Tafel slope values as reported. The horizontal line at −120 mV/dec [shown in (b)] indicates the highest value a Tafel slope can display. (a, b) Reprinted with permission from ref (121). Copyright 2013 American Chemical Society.

Just as for acidic conditions, the surface orientation impacts the activity of a catalyst. The lower density and stepped surfaces of Pt are more active for the HER.130 Pt(110) exceeds the HER activities of Pt(100), and dense surfaces like Pt(111) show drastically lower activities.130 The use of single-crystal electrodes is not practical for AEMWE applications. However, the results show that tuning the catalyst’s morphology and working with nanoparticles can change the intrinsic activity in addition to increasing the surface-to-bulk atom ratio. The use and development of nanostructured and nanoengineered catalysts is important, but structural changes and agglomeration of small, specifically nanosized particles can take place during electrolysis, reducing the activity of a catalyst.131

The high cost of Pt is an issue for large scale applications. Correspondingly, Pt nanoparticles of <5 nm size, supported on carbon blacks such as Vulcan XC-72 and referred to as supported Pt/C catalysts, are often employed. These catalysts benefit from high ECSAs and correspondingly high mass activities. Sheng et al. carried out the careful extraction of jo values and activation energies (Eact) for the HER and H2 oxidation reaction (HOR) for bulk metal, polycrystalline Pt, and a commercial 46 wt % Pt/C catalyst in KOH electrolytes.128 The data shown in Table 3 suggest that the intrinsic exchange current density (jo,intr) and the Eact values are essentially the same for the bulk metal Pt and the 46 wt % Pt/C catalysts.

Table 3. Summary of Average HER/HOR Results for Polycrystalline Pt and Commercial Pt/C Catalysts128.

| electrolyte | jo,intra (at 21 ± 1.5 °C) (mA/cmPt2) | jo,massa (at 21 ± 1.5°C) (mA/mgPt) | Eact (kJ/mol) | Tafel slopea (at 21 ± 1.5°C) (mV/dec) | |

|---|---|---|---|---|---|

| Pt (pc)b | 0.1 M KOH | 0.62 ± 0.01 | n.a.c | 28.9 ± 4.3 | 109 |

| Pt/Cd | 0.1 M KOH | 0.57 ± 0.07 | 0.35 ± 0.05 | 29.5 ± 4 | n.r.c |

Measured at 21 ± 1.5 °C.

Polycrystalline bulk metal Pt.

n.a. and n.r. stand for not applicable and not reported, respectively.

Commercial 46 wt % Pt/C (Tanaka Kikinzoku International, Inc.). Measured ECSA = 62 m2/gPt.

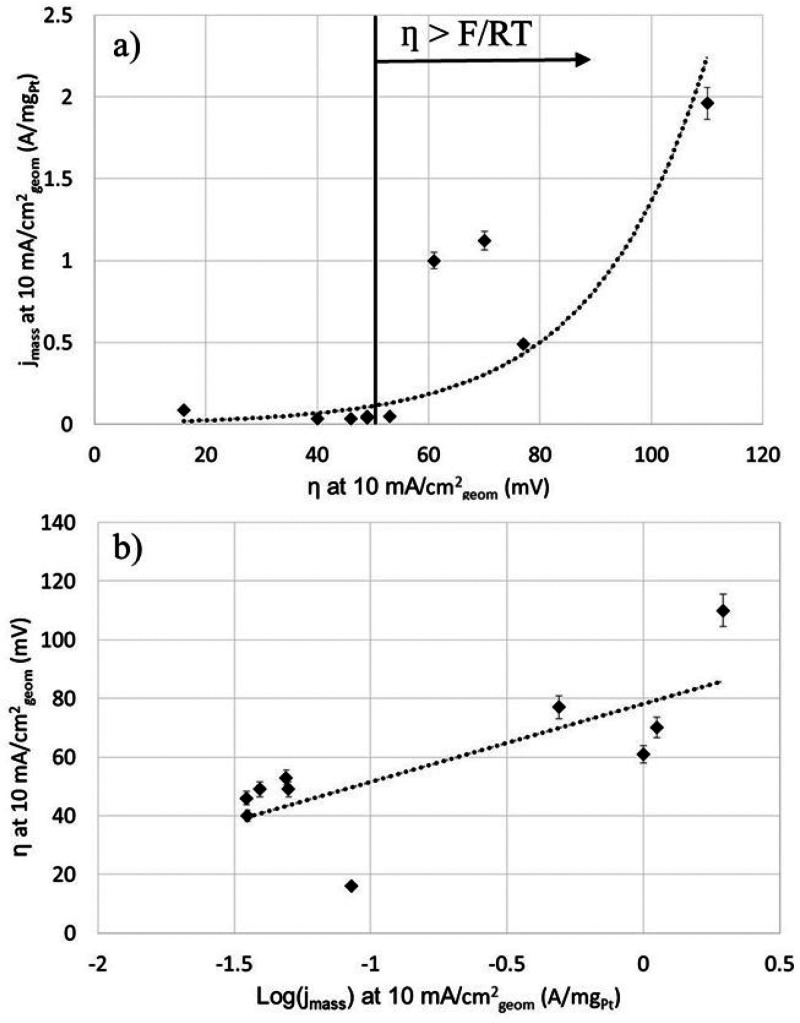

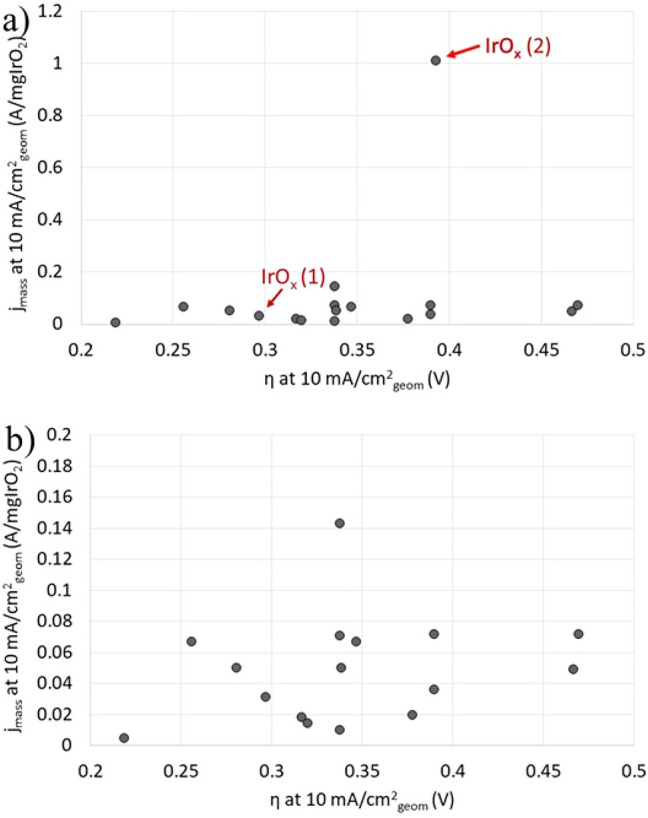

It is important to validate studies of new catalysts by HER activity measurements of a commercially available Pt/C catalyst. Table S1 shows a summary of literature data for Pt/C catalysts as well as for other HER catalysts. Some of the HER (and also OER) activity data tables shown in the Supporting Information were built using data made available by Kibsgaard and Chorkendorff,132 but many additional catalysts and other relevant metrics (when available) such as the Tafel slopes, η range used for the Tafel slope measurements, and ECSA values were added in this Review. The reported HER characteristics for the Pt/C catalysts (most are commercial catalysts from a number of suppliers) differ substantially. The Tafel slope values show a large variation among the Pt/C catalysts, the majority of which are reported as negative slopes ranging between 36 and 55 mV/dec, while the slopes of two Pt/C catalysts are close to −120 mV/dec. A closer inspection of the η range used to extract the Tafel slopes (Table S1) reveals that the two Pt/C catalysts with the higher, i.e., close to −120 mV/dec, slope were measured at a valid η (>RT/F) range of >0.05 V. Furthermore, the majority of the HER activities shown in Table S1 were measured at 10 mA/cm2 geometrical electrode area (cmgeom2), which makes a direct comparison and validation of catalyst performances difficult because the catalyst loading on the electrode (mg/cmgeom2) can differ significantly. Mass and surface area normalized HER activities measured at the same η value are better for comparison; however, data for such measurements are rare. A plot of the mass activity of the Pt/C catalysts versus the corresponding η values, i.e., both measured at 10 mA/cmgeom2, is shown in Figure 10a and reveals an expected increase of jmass with η in an exponential manner. The latter is confirmed by plotting the same data as η versus the log10 of jmass (Figure 10b). Both plots demonstrate the scatter in the data, which can be at least partially ascribed to experimental variations as the majority of the studies use nonsteady-state polarization curves and different sweep rates for recording. The purpose of Figure 10b is to demonstrate the scatter in the results reported in different studies rather than suggesting the extraction of a Tafel slope, which would not be a valid approach using such data.

Figure 10.

Mass current density (jmass) for Pt/C catalysts reported in the literature versus the corresponding η value, both of which were measured at 10 mA/cmgeom2. Additional information about the Pt/C catalysts and the literature references are given in Table S1. (a) The data follow an exponential-type relationship, which is confirmed by (b), which shows essentially the same as (a) but as a plot of η versus the log 10 of jmass of the Pt/C catalysts.

The measurement of intrinsic activities is needed and can be obtained for Pt-based catalysts because the ECSA of Pt can be estimated using the charge resulting from adsorption and desorption of H (Hads/des).133,134 For the 15 Pt/C catalysts shown in Figure 10, ESCA values for three catalysts are reported. Only one group reported data that allow the estimation of the intrinsic HER activity at the same η (of −70 mV), suggesting intrinsic activities of 0.88 and 1.4 mA/cmPt2 for a commercial Pt/C and homemade Pt nanowire (NW) catalyst. The number of data points (measured at consistent conditions) is insufficient to draw conclusions and validate the activity values. However, the results emphasize the need for proper and consistent measurements and also for the establishment of a valid baseline using a Pt/C catalyst. Results reported for various HER catalysts are discussed in the following sections and will also be compared to the Pt/C activities shown in Table S1 and Figure 10.

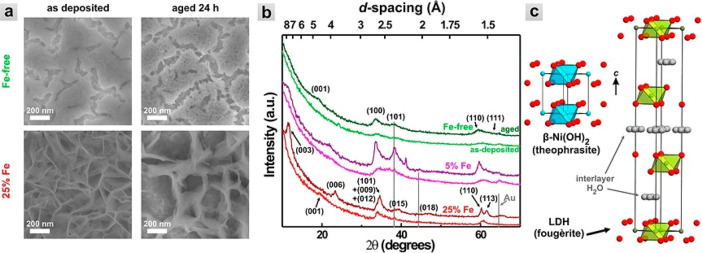

3.2.1.1. Combinations of Pt and Ni

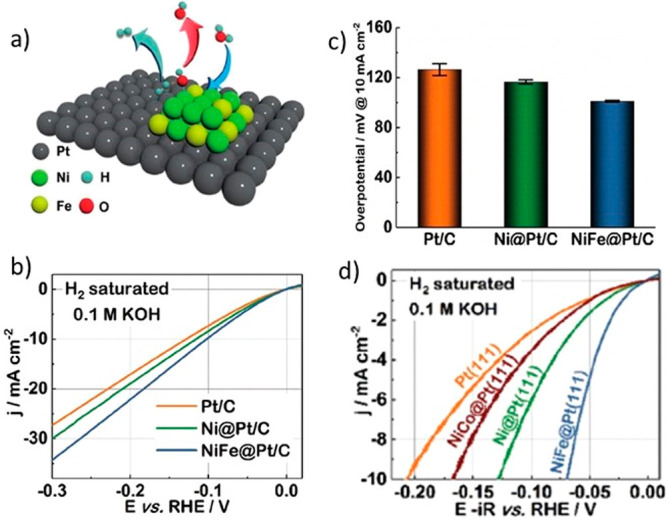

Combinations of Pt with Ni135 such as alloys and Ni deposits on Pt are recognized as being able to exceed the HER activity of Pt in alkaline media135−139 A synergistic effect between Pt and Ni exists, benefiting the HER. Xue et al. demonstrated this effect using a model catalyst formed by the growth of ultrathin Ni(OH)2 [and in subsequent work also thin NiFe(OH)2] clusters140 of 15–20% surface coverage onto Pt(111).135 The Ni(OH)2 clusters on Pt(111) demonstrated an 8-fold increase in the intrinsic activity compared to bare Pt(111), which was suggested to take place through a H-spillover mechanism from Pt to Ni(OH)2. The HER activity was further increased by adding cations such as Li+ to the electrolyte, which enhanced the formation of hydrogen intermediates. The same authors deposited such clusters on more practical Pt/C powder catalysts and also observed such a synergetic effect. Figure 11a shows a schematic demonstrating the H-spillover effect for the case of NiFe(OH)2 clusters on Pt. Furthermore, polarization curves (Figure 11b) and η values measured at 10 mA/cmgeom2 for Pt/C and Ni(OH)2 or NiFe(OH)2 clusters on a Pt/C powder catalyst (labeled as Ni@Pt/C or NiFe@Pt/C, respectively) are shown in Figure 11c. It is seen that the NiFe(OH)2 clusters formed on the Pt/C powder show the highest HER activity. The same is the case for NiFe(OH)2 clusters formed on bulk Pt(111) crystals (Figure 11d). Furthermore, NiCo(OH)2 clusters on Pt(111) show the lowest HER enhancement, i.e., lower than Ni(OH)2 and NiFe(OH)2 (Figure 11d).

Figure 11.

(a) H-spillover mechanism and enhancement of HER activities created by various Ni(OH)2-type clusters deposited on (b, c) Pt/C and (d) bulk Pt(111) crystals. A NiFe(OH)2 cluster on Pt is used to demonstrate the H-spillover mechanism in (a), while Ni(OH)2 and NiFe(OH)2 clusters are deposited on Pt/C powder catalysts for the polarization curves and η values shown in (b) and (c), respectively. (d) Polarization curves for NiCo(OH)2, Ni(OH)2, and NiFe(OH)2 clusters deposited onto bulk Pt(111). The abbreviations NiCo@, Ni@, and NiFe@ for the NiCo(OH)2, Ni(OH)2, and NiFe(OH)2 clusters, respectively, are used in the graphs. Reprinted with permission from ref (140). Copyright 2020 Wiley.

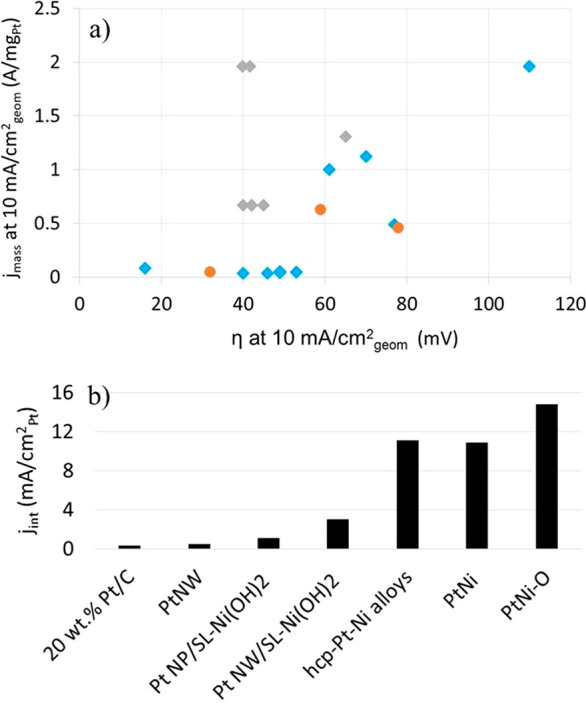

A number of studies report the synthesis of various forms of combined Pt and Ni-based catalyst powders with the goal to produce catalysts of higher HER activities by introducing the synergetic H-spillover effect. In most cases, the mass activity per mg Pt and the η values were measured at 0.01 A/cmgeom2 and are shown in Figure 12a. Data for the commercial Pt/C catalysts are also shown. Some authors also reported the intrinsic activities measured at η = 0.07 V and the ECSA values. These results are summarized in Figure 12b. Yin et al.138 formed Pt nanowires and also Pt nanoparticles on single-layer Ni(OH)2 sheets (the latter were formed by exfoliation of layered Ni(OH)2). At η = 0.07 V and in 1 M KOH, superior intrinsic activities (measured as j per Pt area) of up to approximately 8 and 3 times were reported for the two Pt catalysts formed on the single-layer Ni(OH)2 sheets compared to the commercial Pt/C and homemade Pt-only nanowires, respectively. The single Ni(OH)2 layers offer a high surface area for the dispersion of the Pt catalysts. However, a possible contribution of the high number of Ni(OH)2 surface sites to the HER was not considered in the j/cmPt2 measurements and cannot be completely ruled out on the basis of the reported measurements. The authors further reported that the combination of the Pt nanowire with the single-layer Ni(OH)2 structure also increases the catalyst’s stability, although the stability experiments were carried out over a short period of 4000 s.

Figure 12.

(a) Mass current activities per amount of Pt versus the corresponding η for various Pt–Ni catalysts, both measured at 10 mA/cmgeom2. (b) Plot of the intrinsic activity per ECSA of Pt (jint) measured at η = 70 mV for two Pt-based and a number of Pt–Ni-based catalysts. The data used for (a) and (b) are shown in Tables S2 and S3, respectively. The blue diamonds represent Pt/C, the gray diamonds represent PtxNiy alloys, and the orange circles represent the Pt nanosized catalysts wih Ni(OH) in (a).

Abbas et al. deposited Pt nanoparticles of 1.7–3.1 nm onto nickel urchin-like structures, referred to as xPt@Ni-SP.141 They reported that the HER mass activity per weight Pt in 1 M NaOH was up to 3.15 times higher for the xPt@Ni-SP catalysts compared to a 40 wt % Pt/C commercial catalyst. Differences in the intrinsic activities, measured as A/cmPt2, were smaller: the 0.75Pt@Ni-SP catalyst showed the highest increase of 1.3 times, while some xPt@Ni-SP catalysts exhibited a lower intrinsic activity over the Pt/C catalyst. The use of the nickel-based support might be beneficial to the catalysts’ long-term performance, as the authors reported a higher stability of the xPt@Ni-SP catalysts over the commercial carbon-supported Pt catalysts. Tafel slopes in the −30 mV/dec range were reported for all Ptx(x>0.5)@Ni-SP catalysts and the Pt/C catalysts, suggesting that the Volmer reaction was the rate-determining step. However, the reported Tafel slopes were extracted from nonsteady-state polarization curves. Chen et al. explored the deposition of Pt onto honeycomb-like NiO@Ni-film catalysts.137 The Ni films were actual Ni nanofoams that could also serve as current collectors in an MEA. The intrinsic HER activity per Pt surface area did not seem to vary remarkably among the catalysts. One catalyst, namely, Pt on the honeycomb-like NiO@Ni-nanofoam substrate, was reported to have a 15 times higher HER activity per mass of Pt compared to a commercial Pt/C catalyst. This increase may be at least partially due to a H-spillover effect. However, the direct deposition of the catalysts onto the current collector may also contribute to a higher mass activity by increasing the utilization of the catalyst (in this case the Pt onto honeycomb-like NiO@Ni-film) compared to a powder catalyst. Powder catalysts are typically transformed into electrodes using an ionomer and/or binder, which can block catalyst sites (see also section 6). Measurements of η at 10 mA/cmgeom2 showed an increase of ∼40% for both the Pt onto honeycomb-like NiO@Ni-film and the Pt/C powder catalysts over a period of 24 h. All of these results show that the combination of finely dispersed Pt on high-surface-area nickel present as, e.g., Ni(OH)2 layers can potentially offer HER catalysts of higher mass activity per Pt. It is therefore not surprising that other metal additions such as Fe and Co are being explored. It was already mentioned that the deposition of NiFe(OH)2 clusters on Pt(111) crystals further promotes the HER activity, suggesting that Fe assists Ni in the water-dissociation step.140 It is also claimed that Fe increases the conductivity and the oxidation state of Ni in its vicinity. Wang et al. decorated Co nanowires grown on a Ti mesh with Pt–Co alloys.142 Only one of the Pt–Co catalysts exceeded the HER mass activity of the commercial Pt/C catalyst, which seemed to be measured in A per geometrical electrode area, and only the less-active catalysts showed stable catalytic activities for 50 h.

However, the highest HER activities among these types of catalysts seem to be achieved by PtxNiy alloy particles, as suggested by the data also presented in Figure 12. Wang et al. prepared, by annealing, various Pt–Ni nanowire catalysts that were shown to consist of different alloy phases such as Pt3Ni4, Pt3Ni3, Pt3Ni2, Pt3Ni, and NiOx.136 They reported up to ∼12 times higher HER mass activity in 1 M KOH for their Pt–Ni nanowire catalysts than for a commercial Pt/C catalyst. The higher mass activity was assigned to the many interfaces of Pt3Ni and NiOx being created upon an optimized annealing process. The NiOx surface is proposed to accept the OH– produced in the H2O splitting reaction, while nearby Pt sites accept the Hads and produce the H2. The intrinsic HER activity was not measured, and the onset potential for the HER appears to be the same for all catalysts studied, including the commercial Pt/C catalyst.

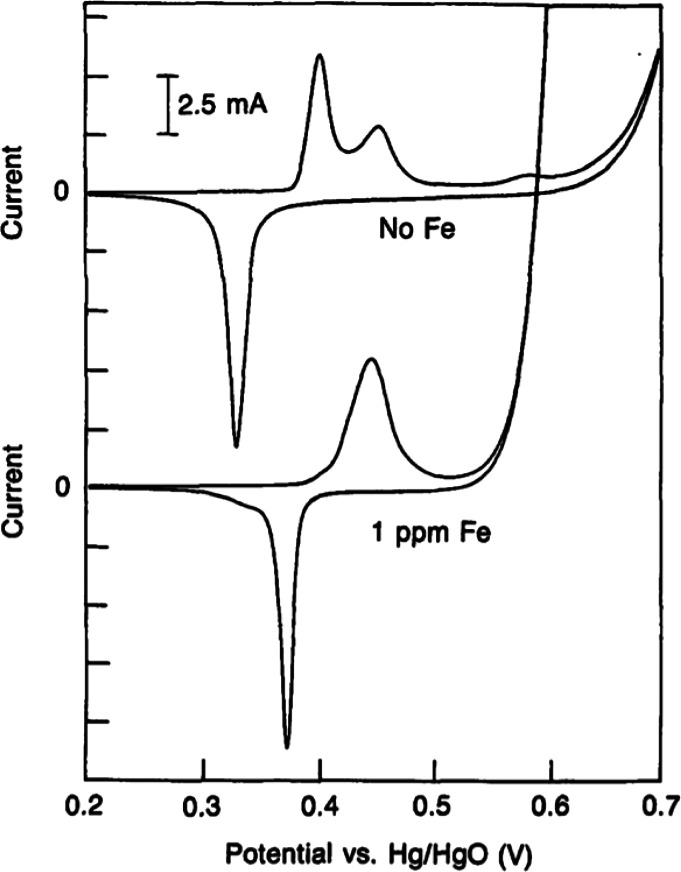

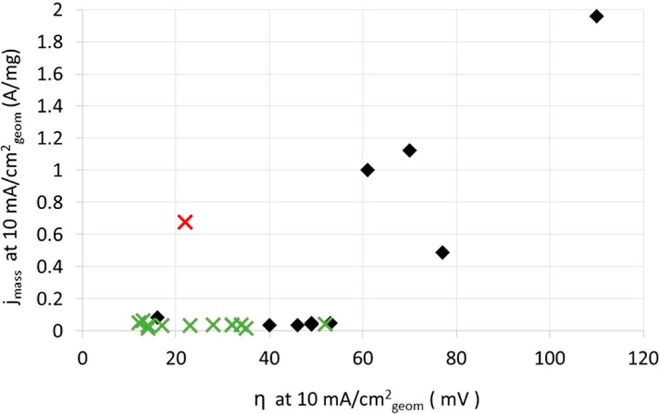

3.2.1.2. Ru HER Catalysts

Ru is another PGM that is attracting attention as apotential HER catalyst for acidic as well as alkaline electrolytes. The ∼65 kcal/mol H-bonding energy of Ru is similar to that of Pt.141 While not as expensive as Pt, Ru is scarce. Therefore, Ru will only become a viable candidate for large-scale AEMWEs if Ru catalysts of high HER activities and long-term stability can be made using affordable materials and routes for the synthesis of both the catalyst and the support. Recent activities on the development of Ru-based HER catalysts for AEMWEs have focused on the formation and anchoring of Ru and also PtRu alloy nanosized particles on conductive carbon-based supports. High-surface-area carbon supports such as phosphorus carbon nanosheets and N-doped holey two-dimensional carbon sheets consisting of repeat units of, e.g., C2N structures were synthesized to allow the anchoring of the Ru-based particles.143 Density functional theory (DFT) calculations suggest that the H-binding energy is lowered for Ru particles embedded into these C2N and C2N2 structures and that both the Ru and the adjunct carbon atoms act as catalyst sites.141−144 The HER activities and catalyst loadings on the electrode seem to be given as total catalyst mass, i.e., including Ru and other components such as the supports in many of these studies. Furthermore, ECSA measurements are rare, which may be due to the fact that the reliable extraction of the ECSA values for Ru-based catalysts can be challenging. Double layer capacitance values and COads stripping measurements have been used to gain ECSA information, but Ru forms many different oxides at low potentials, each yielding a different Cdl value, and COads only adsorbs on metallic surfaces.110 Similarly, the method of Cu underpotential (Cuupd) deposition can be applied to catalyst sites in the metal state but not to oxides.110 Nevertheless, according to thin-layer catalyst measurements, some of the Ru-based catalysts show promise, as shown in Figure 13. Figure 13 is a plot of the mass activities versus the corresponding η values (both measured at 10 mA/cmgeom2) for Ru-based versus Pt/C powder catalysts. The results for the majority of HER activities for the Ru catalysts are underestimated due to the fact that the total catalyst weight is used for the mass activity calculation (the Ru loading for many of these catalysts does not seem to have been determined), while the activities for the Pt/C catalysts (black diamonds) and the supported Pt1Ru1.54 alloy (red cross) catalysts are per total noble metal weight. Figure 13 suggests that the Ru-based catalysts show mass activities as high as and exceeding that of Pt/C. In the case of the 2.5 nm Pt1Ru1.54 alloy catalyst formed on phosphorus carbon nanosheets, the activity per total noble metal loading seems to exceed that of the commercial Pt/C catalysts.145

Figure 13.

Mass activities (jmass) versus the corresponding η values of various supported catalysts, namely, Ru nanoparticles (green crosses), a 2.5 nm Pt1Ru1.54 alloy (red cross), and Pt/C (black diamonds). The jmass and η values are measured at 10 mA/cmgeom2 in 1 M KOH. The mass activities are measured in A/mg noble metal catalyst for the supported Pt1Ru1.54 alloy and the Pt/C catalysts, while in the case of the supported Ru catalysts, the mass activities are in mg per total catalyst, i.e., including the carbon support. Details about the catalysts, the actual values, and the corresponding references are given in Table S4.

The 2.5 nm Pt1Ru1.54 alloy catalyst reported to exceed the Pt/C catalyst and a homemade Pt catalyst supported on phosphorus carbon nanosheet were made by Li et al.145 The authors suggested that the observed enhancement of the Pt1Ru1.54 alloy catalysts was due to the electronic interactions between the nanosized Pt1Ru1.54 catalyst and the phosphorus carbon nanosheet, thus resulting in the enhancement of the H2O dissociation kinetics.

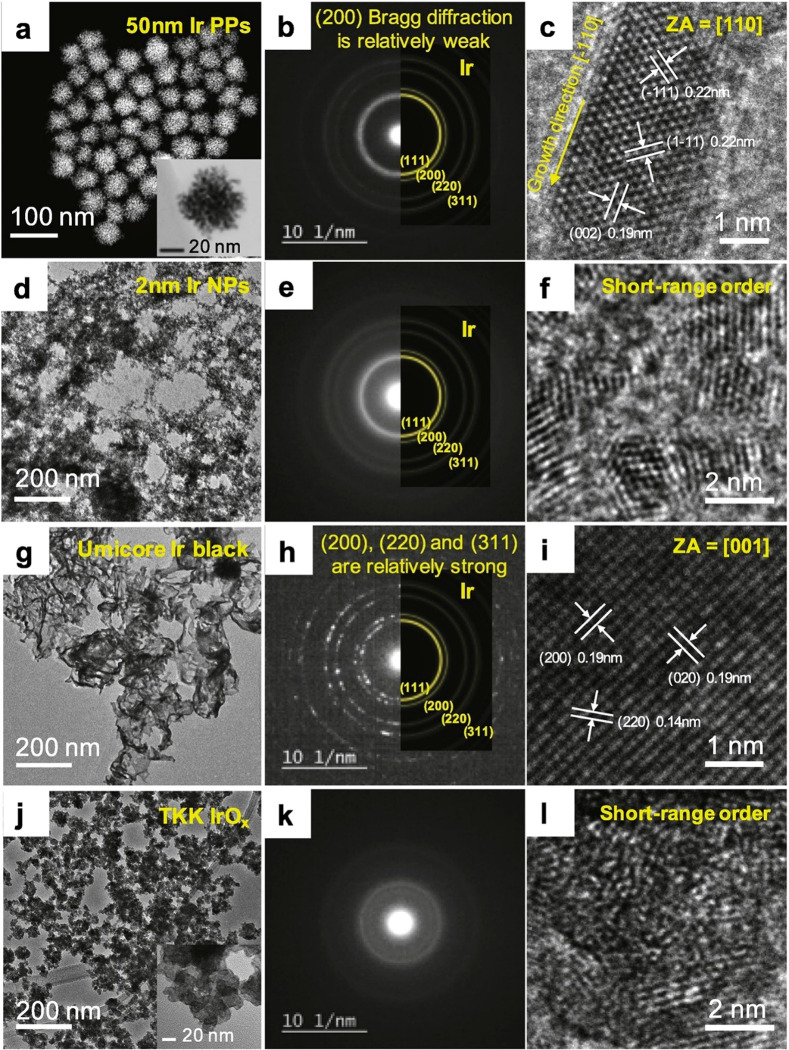

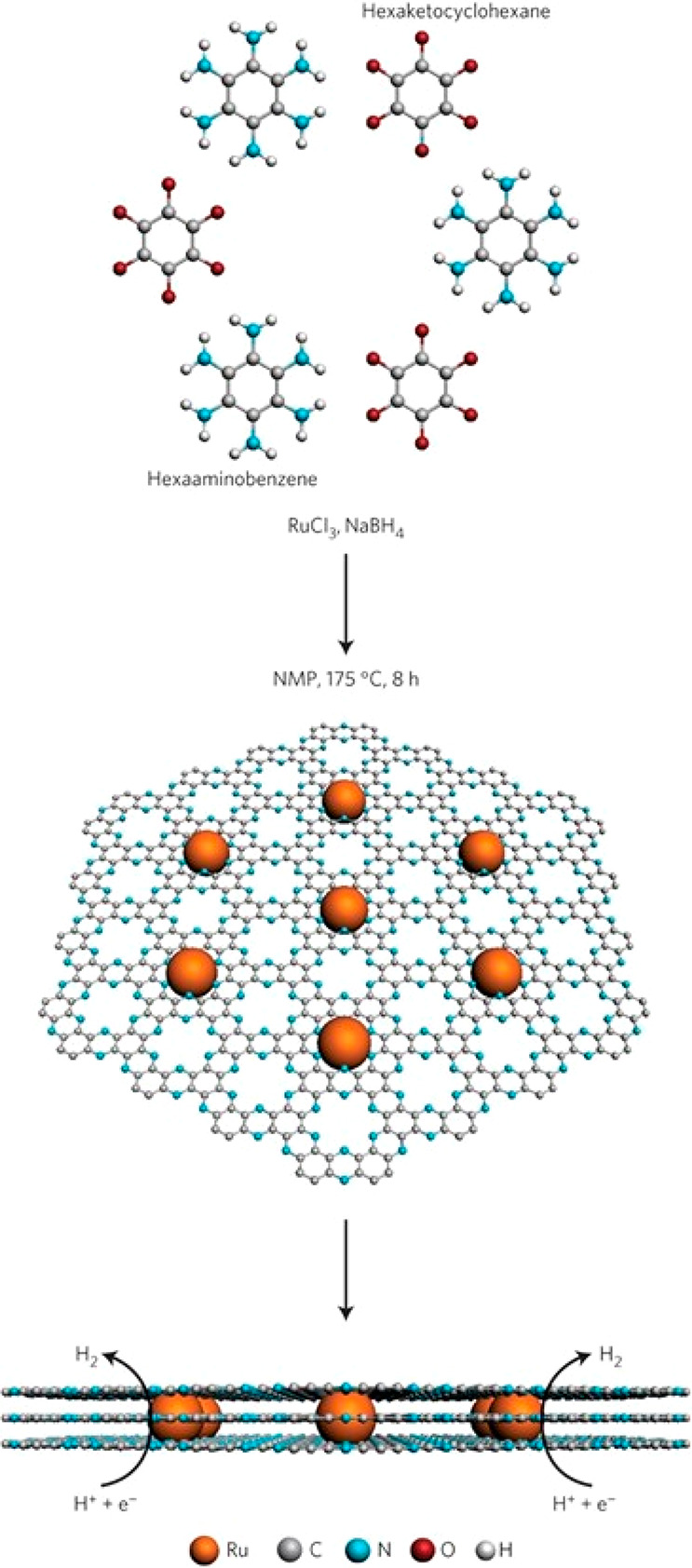

Mahmood et al. dispersed 1.6 nm averaged size Ru particles within holey, two-dimensional carbon nanosheets made of repeating C2N units.143Figure 14 demonstrated the formation and distribution as well as the embedment of the Ru nanoparticles within the layers of the high-surface-area nanosheets. The authors used Cuupd, COads stripping voltammetry, and Hads/des charges to estimate ECSA values and reported the number of active sites for the Ru/C2N to be ∼18% below those of the Pt/C2N and Pt/C catalysts. On the basis of the number of active sites estimated from these three methods, the TOF per active catalyst site (i.e., the intrinsic HER activity of the Ru/C2N) exceeded that of the commercial Pt/C catalysts by a factor of ∼1.7. It is assumed that the ECSA measurement for the Ru/C2N catalyst reflected the Ru sites in the metallic state, as discussed earlier. Only a small drop in the HER activity was reported after 10 000 potential cycles between 0.2 and −0.1 V versus the reversible hydrogen electrode in 1 M KOH. Details about the electrochemical experiments such as whether a high-surface-area Pt-free counter electrode was used were not given.

Figure 14.

Schematic of the synthesis to form nanosized Ru catalysts embedded within holey, two-dimensional carbon nanosheets made of repeating C2N units. Reprinted with permission from ref (143). Copyright 2017 Springer Nature.

Other studies (the results of which are included in Figure 13 and Table S4) also focused on the dispersion of Ru on high-surface-area supports. Lu et al.144 formed Ru nanowires on N-doped carbon nanowires, Zheng et al.146 formed Ru particles of an average 2 nm size in C3N4 matrixes, while Xu et al.147 formed Ru particles of an average 1.5 nm size by pyrolysis at 350 °C using a carbon support of unspecified origin. These catalysts approached the mass activities of commercial Pt/C catalysts at comparable η values (Figure 13). As already noted, the authors appeared to give the loadings of the Ru catalysts as total catalyst loading, i.e., including the carbon support, while the mass activity for the Pt/C is per Pt metal.

Recent studies also involve the Ru–Ni system, which again often focuses on the dispersion of Ru (in the nanosized range) on Ni(OH)2-type matrixes, partially with the goal to take advantage of the two-dimensional high-surface-area structures that Ni-hydroxides can form. Ding et al.148 formed Ru–Ni nanoplates of ∼10–30 nm size, and Chen et al.149 formed RuNi as layered sheets (RuNi-LMH) on nickel nanofoams. Both groups reported lower η values measured at 10 mA/cmgeom2 compared to Pt/C catalysts. Similar to the RuNi system, RuCo catalysts are being explored. A nitrogen-doped carbon-supported Ru–Co alloy catalyst, formed by using the optimized annealing temperature of 600 °C, was reported to show a lower η of 34 versus 49 mV (measured at 10 mA/cmgeom2) versus a commercial Pt/C catalyst. The total catalyst loadings were ∼0.255 mg/cmgeom2, and the RuCo loading on the carbon seemed not to have been measured.150 The addition of Co to Ru was proposed to enhance the H* recombination step.150,151 Mao et al. formed Co-substituted Ru nanosheets and reported that the ∼30 nm Co atoms distributed among the Ru lattice had kinetics (measured as TOF) comparable to those of commercial Pt/C, Ru/C, and homemade RuCo alloy catalysts.152 Details about the calculation of the TOF numbers and the loading of the Pt/C catalyst do not seem to be presented.

In conclusion, activities reported for Ru-based HER catalysts, focusing on the dispersion and anchoring of the Ru catalysts, have shown promise in thin-layer electrode studies. However, a full understanding will require detailed analyses of these catalysts under AEMWE conditions as well as the determination of the Ru content of the catalysts. True Tafel slope measurements carried out under steady-state conditions within a valid η region are also needed. For water electrolysis in alkaline conditions, the stability of Ru is a concern, and it has been established that Ru catalysts have poor stability in alkaline conditions within the OER potential range. Therefore, thorough long-term stability measurements of these proposed Ru-based HER catalysts under conditions reflecting real AEMWE operations, i.e., involving intermittent periods and possible potential reversals, are important.

3.2.2. Ni-Based Catalysts without PGMs

3.2.2.1. Ni Metal HER Catalysts

Ni is an abundant metal and is used in traditional WE electrolyzers as an HER and OER catalyst, thus making it a candidate of high interest to replace Pt- or Ru-based catalysts for alkaline conditions.153−155 Ni metal shows good water adsorption, albeit the hydrogen-bonding energy to Ni metal is high and in general the rate-determining step is the H* recombination reaction.156,157 HER activities of Ni-only catalysts are lower than those for Pt/C catalysts; for example, at 10 mA/cm2, metallic Ni shows an ∼0.15 V higher η than that observed for Pt/C catalysts.157 Also, the HER activity of metallic Ni tends to decrease with the time of electrolysis, which is often attributed to hydride incorporation into the Ni lattice in the bulk and at the electrode surface.71,158 This is specifically strong for catalysts of small grain size, which correspondingly possess a high number of grain boundaries, where preferential H2 adsorption takes place.159,160 Corrosion is another factor eventually reducing the HER activity during electrolysis, as are changes in alkaline concentration induced by OH– adsorption.153 Ni metal surfaces can adsorb oxygen from the electrolyte and react to form NiO.161 NiO is transformed into NiOOH when cycled into positive potential regions, allowing the electrolyte to adsorb onto the surface, reacting with the NiO to form NiOOH penetrating further into the catalyst that results in lower HER activity.161

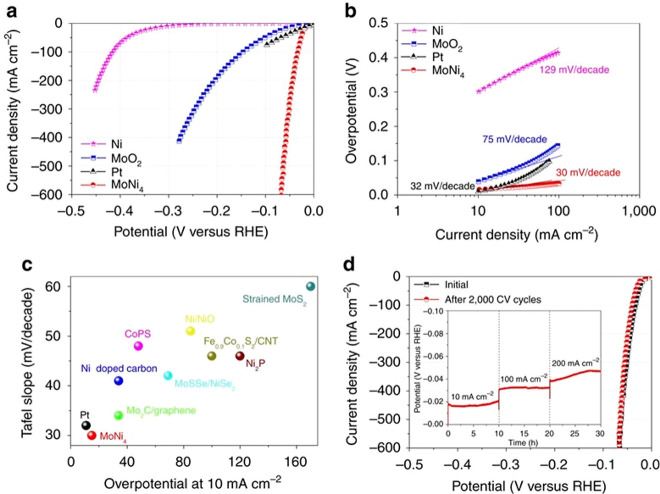

Alloying of Ni has been shown to change the HER activity, as for, e.g., binary NiMo and ternary NiCoMo alloys. An example of alloying Ni and Mo is shown in Figure 15, where the MoNi4 catalyst is reported to have a higher activity than Pt, although the loading of the MoNi4 on the current collector does not seem to be known.162 Other approaches are the interstitial doping of nickel with, e.g., nitrogen. Using this concept, Ni3N nanoparticles (np-Ni3N) were prepared and activities approaching those of commercial 20 wt % Pt/C and 20 wt % PtRu/C catalysts were reported.160 However, the active catalyst component loading of the np-Ni3N catalysts was significantly higher than those for the Pt/C and PtRu/C catalysts, namely, 0.16 mgNi3N/cmgeom2 versus 0.01 mgPt or PtRu/cmgeom2. The np-Ni3N catalyst is embedded in an N-doped graphitic support structure, which is proposed to alter the intrinsic catalytic properties of the Ni and possibly also stabilize the catalyst nanoparticles. Interstitial N-doping and embedment into the N-doped graphitic support of the Ni was carried out via a two-step reaction. The two reaction steps involved the decomposition reaction of preformed K2[Ni(CN)4] to form nanosheets made of Ni-cyano compounds at 450 °C followed by N-doping in a NH3 atmosphere also at 450 °C to form the 5–20 nm sized Ni3N nanoparticles. The N-doped graphitic lattice was formed simultaneously during this process.

Figure 15.

HER data extracted for Ni, Pt, and two Mo-based catalysts in 1 M KOH. (a, b) Slow-sweep polarization curves and Tafel slope values extracted from the polarization curves, respectively. (c) Comparison of Tafel slope values to other catalysts reported in the literature. (d) Results for a stabilization test carried out under potential cycling for the MoNi4 catalyst. Reprinted with permission from ref (162). Copyright 2017 Springer Nature.

CeO2 has been proposed as beneficial catalyst support to anchor metal catalyst sites. The system is of interest for both the HER and OER and may act as a bifunctional electrocatalyst.163−167 The metal-oxide interface of Ni and CeO2, with the latter being deposited on carbon nanotubes (CNTs), was reported to show a synergistic effect, and DFT calculations suggest that the interactions of Ni with CeO2 benefit the HBE, matching that of Pt/C.163 A lower η value for the Ni-CeO2/CNT catalyst compared to Ni/CNTs and CeO2–CNTs catalysts was reported, but the η value was higher than that measured for a commercial Pt/C catalyst of a 40% lower total metal loading. The addition of CeO2 was observed to enable the formation of Ni particles of 4 nm size, i.e., much smaller than the 50–100 nm Ni particles formed on CNTs free of CeO2. Therefore, some of the observed increases in the HER activity are likely due to an increase in the ECSA caused by the smaller Ni particle size of the Ni-CeO2/CNT versus Ni/CNT catalysts.

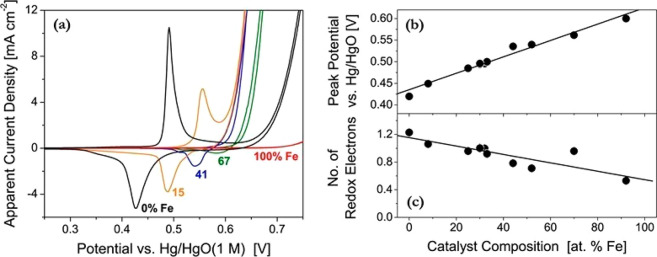

3.2.2.2. Non-PGM Ni Alloys and Mixtures: The Addition of Mo

Other attempts to increase and stabilize the activity of bare Ni catalysts involve the formation of binary and ternary alloys of Ni with different elements such as Co, Fe, Mo, Ce, Zn, and Cu to improve the catalytic activity, prevent hydride formation, and achieve a higher stability.168 Many of these studies originate from the development of HER catalysts for traditional alkaline WEs and also for artificial photosynthesis devices.169,170 Some reports suggest that Ni–Mo alloys have the highest HER activity among non-PGM catalysts30 and that the activity of the Ni–Mo alloys is further improved for ternary alloys.171−174 While Ni–Mo alloys show high HER activities among non-PGM catalysts, the actual measurements are not always conclusive due to issues measuring the ECSA and the intrinsic activities of these catalysts accurately.175 These measurements are complicated by the fact that catalysts of the Ni–Mo combination can have widely different particles sizes and porous structures. In addition, the Ni–Mo system exhibits a pseudocapacitance in the potential region, typically used to estimate the ECSA value.175 Therefore, increases in HER activities reported for Ni–Mo catalysts have been argued to be due to higher surface areas rather than actual beneficial intrinsic catalytic effects.176,177 Nevertheless, it has been shown using nonporous catalysts that Ni–Mo alloys can exhibit increased HER activity over Ni-only catalysts, as demonstrated in Figure 16. Figure 16 shows polarization curves for metallurgical Ni and Ni–Mo alloys of different compositions made by cutting the metallurgical rod into disc-shaped electrodes of the same size. The surfaces of the disc-shaped electrodes were carefully polished to produce smooth surfaces. However, Ni–Mo alloys do not yield the HER activities needed for large-scale AEMWE applications. The stability of Ni–Mo alloys also needs to be proven. Ni–Mo alloy particles of 50–200 nm size have shown stable currents of 0.02 A/cmgeom2 over 100 h in 2 M KOH using a catalyst loading of 1 mg/cmgeom2, but currents of 0.02 A/cmgeom2 are low and an analysis of dissolved metals was not performed.178

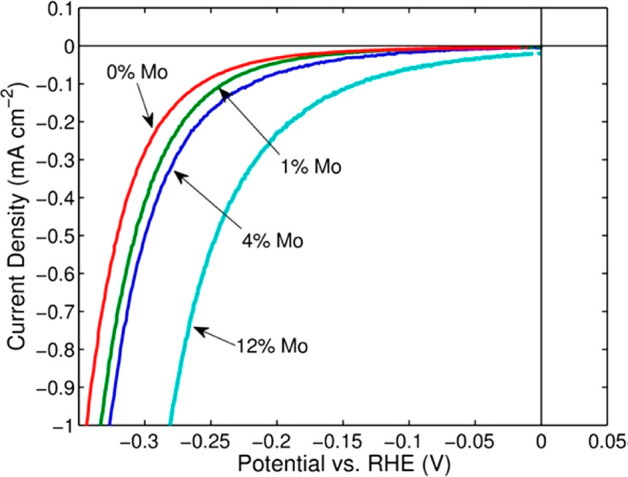

Figure 16.

Polarization data of commercially available and metallurgically prepared Ni and Ni–Mo alloys with varying Mo content. Experiments were performed in 2 M KOH solutions. The Ni and Ni–Mo alloy samples were coin-sized samples prepared by cutting cylindrical rods and were carefully polished to create a smooth surface. Reprinted with permission from ref (178). Copyright 2013 American Chemical Society.

The addition of Mo to Ni, to form intermetallics or disorganized compounds, has been reported to improve the stability and the HER activity compared to Ni-only catalysts. In intermetallic compounds, the atomic fraction of Mo is much larger than that in disordered structures. Examples of intermetallics of Ni and Mo include Ni7Mo7, Ni3Mo, and Ni4Mo. In a recent study, polished samples of Ni7Mo7, Ni3Mo, and Ni4Mo were tested for the HER, and the metal dissolution was measured.179 Substantial dissolution of Mo occurred for Ni7Mo7, leading to an increase in the ECSA, while Ni3Mo and Ni4Mo did not show dissolution at potentials below 0 V versus the reversible hydrogen electrode. However, the stability range of Ni3Mo appears to be relatively narrow (between −0.25 and −1 V versus the reversible hydrogen electrode), and dissolution was reported to take place at open-circuit potentials.117 In comparison to intermetallics, in disordered structures the Mo content only needs to be a few atom % to be effective for the HER.175,179 For disordered structures, a Mo content of ∼10 atom % leads to the highest activity among Ni–Mo disordered catalysts.180

Many studies involve unsupported Ni–Mo catalysts of several hundred of nanometers in size.178 This is much larger than the sub-5-nm size that is typical for Pt/C catalyst,s and the larger size is at least partially responsible for the lower HER mass activities compared to Pt/C. To improve the electrical connectivity, Ni–Mo-based catalysts have been directly deposited onto Ni foam current collector substrates.181,182 A study of the formation of a ternary NixMoyFez alloy on Ni foam reported significantly lower η values than that for Ni only; however, the η values are still higher than that for Pt, and the catalyst loading is not known.174 Another two studies reported improved HER performances of their catalysts over commercial Pt/C powders.182,183 However, the loadings of the Ni–Mo catalysts were higher than the Pt/C catalyst loadings: approximately 55.8 and 44.3 mg/cmgeom2 of MoNi4/MoO2@Ni versus 2 mg/cmgeom2 Pt/C182 and 5.9 mg/cmgeom2 MoNi4/MoO3–x versus 1 mg/cmgeom2 Pt/C.183 Additional studies are needed to deposit lower amounts of Ni–Mo-based catalysts directly on the porous Ni current collectors, and as already mentioned, the long-term stability of Ni–Mo catalysts under AEMWE operating conditions needs to be proven.

In conclusion, it appears that the intrinsic activity of the combined Ni and Mo catalyst system can be higher than that for Ni-only catalysts, although the dissolution of Mo under intermittent electrolyzing conditions at high pH could be an issue. Many Ni–Mo catalysts are unsupported, representing particles in the tenth of a nanometer size range, and are unlikely to be comparable to the mass activity that can be achieved for the catalytically very active and nanosized catalysts such as Pt/C, PtNi/C, and various supported Ru catalysts discussed earlier.

3.2.3. Other HER Catalyst Groups

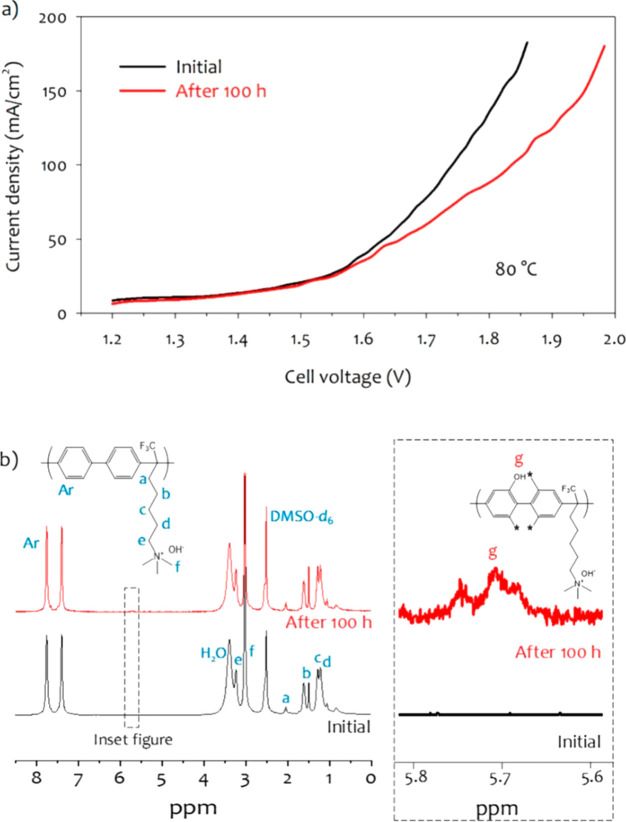

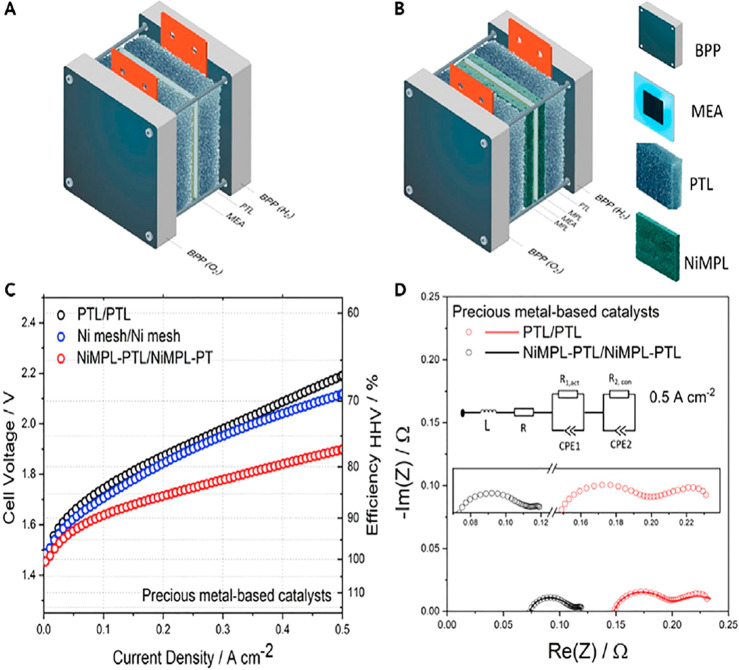

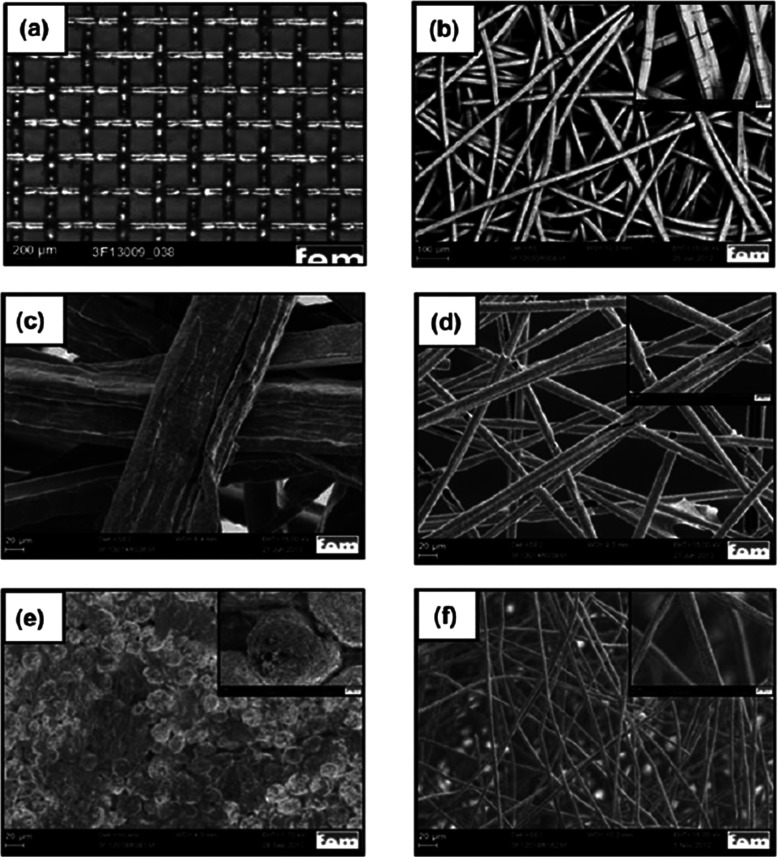

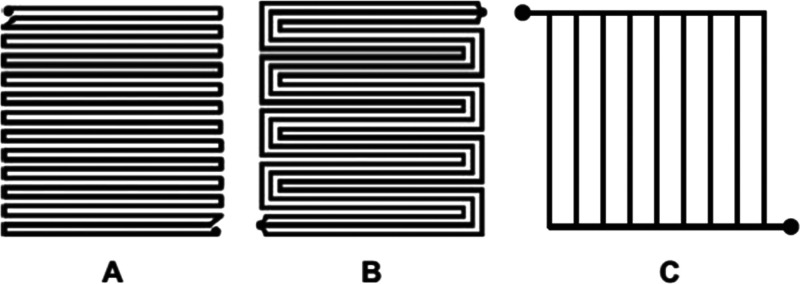

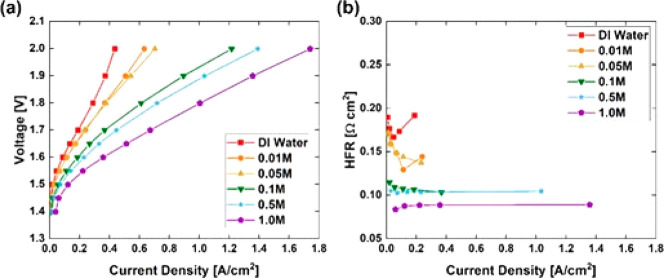

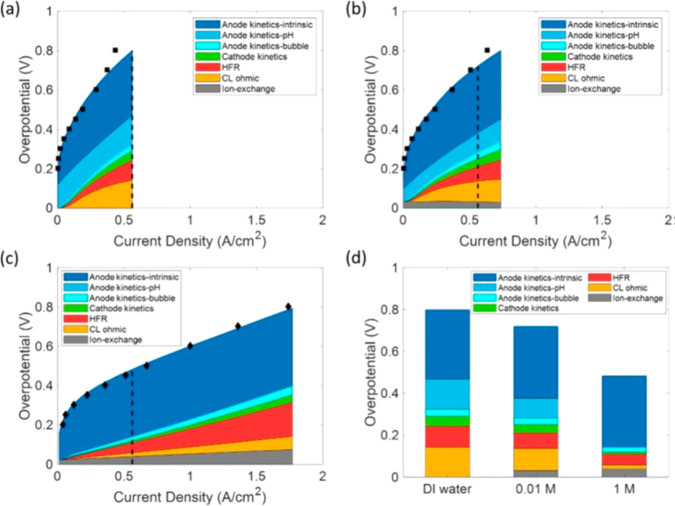

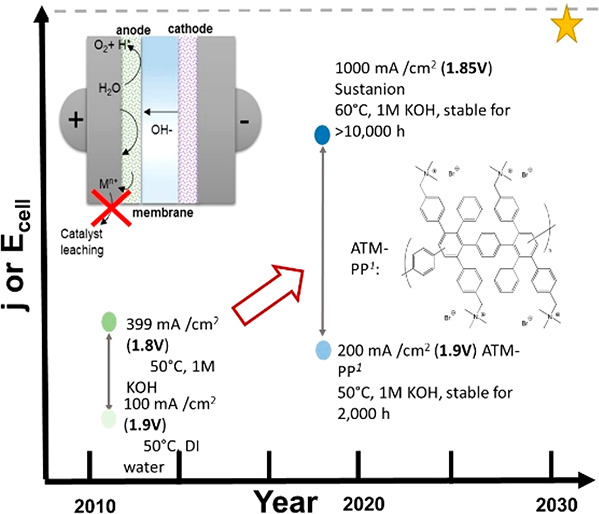

3.2.3.1. Mo Carbides