Abstract

Microbial fuel cells (MFCs) are a technology that can be applied to both the wastewater treatment and bioenergy generation. This work discusses the contribution of improvements regarding the configurations, electrode materials, membrane materials, electron transfer mechanisms, and materials cost on the current and future development of MFCs. Analysis of the most recent scientific publications on the field denotes that dual-chamber MFCs configuration offers the greatest potential due to the excellent ability to be adapted to different operating environments. Carbon-based materials show the best performance, biocompatibility of carbon-brush anode favors the formation of the biofilm in a mixed consortium and in wastewater as a substrate resembles the conditions of real scenarios. Carbon-cloth cathode modified with nanotechnology favors the conductive properties of the electrode. Ceramic clay membranes emerge as an interesting low-cost membrane with a proton conductivity of 0.0817 S cm−1, close to that obtained with the Nafion membrane. The use of nanotechnology in the electrodes also enhances electron transfer in MFCs. It increases the active sites at the anode and improves the interface with microorganisms. At the cathode, it favors its catalytic properties and the oxygen reduction reaction. These features together favor MFCs performance through energy production and substrate degradation with values above 2.0 W m−2 and 90% respectively. All the recent advances in MFCs are gradually contributing to enable technological alternatives that, in addition to wastewater treatment, generate energy in a sustainable manner. It is important to continue the research efforts worldwide to make MFCs an available and affordable technology for industry and society.

Keywords: Anode, Cathode, Membranes, Electron transfer mechanism, Materials cost, Microbial fuel cell

Anode; Cathode; Membranes; Electron transfer mechanism; Materials cost; Microbial fuel cell

1. Introduction

Water and energy have a close connection. Water is required for all sources of energy production, including the electrical energy production, and energy is necessary for the disposal of water and the treatment of wastewater [1]. Water is an essential natural resource for humans and all life in the earth. It is an important component in ecosystems health, food production, socio-economic progress, and energy production. Water and sanitation systems must work together to ensure the human health and development [2].

However, according to The United Nations and Water Security and Sustainable Management Report 2020 [3] data, 1.8 million people lack of safe managed sanitation services. Moreover, more than 80 percent of wastewater returns to ecosystems without being treated. This wastewater discharged without any treatment generates negative effects on human health, natural environment, and global economics, in both, local population and far-away population from the pollution source. According to the World Health Organization [4], it is estimated that in middle-and-low development countries, 842,000 of annual deaths are related to wastewater and sanitation. From the environmental point of view, untreated or partially treated wastewater generates contamination of surface water, soil and groundwater. When it is discharged into natural water bodies such as lakes and rivers, this water can infiltrate into aquifers and deteriorate the quality of fresh water. Also, the untreated wastewater that reaches the oceans contributes increasing the number of de-oxygenated dead zones. The marine ecosystem damage is estimated to reach an area of 245,000 . This has a direct impact on the economy of the fishing industry, livelihoods, and food chains. Therefore, poor water quality interferes with economic development [5].

On the other hand, access to energy is key to social development. According to the British Petroleum Statistical Review of World Energy data from 2020 [6], the global energy consumption grew at a rate of 1.3 percent. This growth was less than the growth reported in 2018 with 2.8 percent. Although the energy production was led by natural gas and renewable sources, global carbon dioxide emissions keep growing. While the growth rate 0.5 percent in 2019 was less than the annual average of 1.1 percent reported since 2010, it is still imperative to try to curb its growth. Notice that, is the most abundant greenhouse gas that is mainly generated by burning fossil fuel and it is directly related to the global temperature and sea-level rise, sudden weather changes, and other adverse effects of unprecedented scale [7]. The world population continues to increase, and fossil fuels are being over-exploited faster than new sources are being discovered. It is important to develop green energies to reduce the negative effects of fossil fuel [8].

Therefore, wastewater treatment and alternative energy production is of main concern worldwide, as a society. Treatment of wastewater not only reduces pollutants from the water, but also enables the reuse of water [9]. A significant fraction of the world's energy demand can be obtained from wastewater, which contains an average chemical energy of 1.9 kWh m−3 stored as organic compounds, as long as it is converted into useful and economic energy [10], [11], [12], [13]. It has been estimated that domestic wastewater approximately contains 9 times the amount of energy that is used to treat it [14]. Additionally, the development of renewable energy sources contributes to the reduction of greenhouse gas emissions and their associated negative effects. All this is reflected in positive effects on health, society, economics, and natural environment.

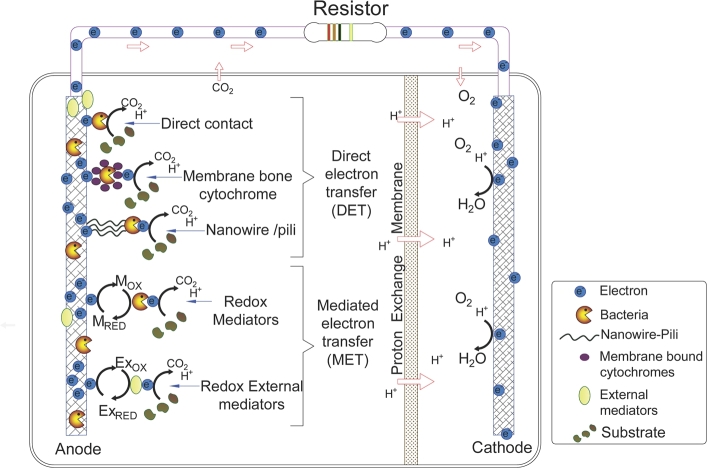

An emerging technology that has aroused great interest among the scientific community due to its great potential to treat wastewater and generate bioenergy, are the microbial fuel cells (MFCs). These devices use bacteria as a catalyst to oxidize organic and inorganic matter and generate electrical current. Bacteria degrade the substrate contained in the wastewater, generate protons, and release electrons and carbon dioxide. Typical configuration of MFCs consists of an anode chamber, a cathode chamber, a membrane between the chambers, and an external electrical circuit. The released electrons flow from the anode (negative terminal) to the cathode (positive terminal), through a conductive material [15]. The electrons, protons, and oxygen present in the cathode (conventional configuration) react to form water [16].

In recent years, there have been important advances in MFCs research. Some studies have reported applications of MFCs at pilot-scales and field-scales (30 L [17], 200 L [18], 225 L [19], 1,000 L [20]) that allow to visualize the potential of MFCs in more realistic scenarios and the importance of further work on scaling up. The aim of this study is to review and analyze the most recent scientific publications on MFCs technology. Particular emphasis is done on the analysis of the configurations, anode, cathode and membrane materials, as well as the mechanisms for electron transfer and their influence on MFC performance. In addition, the study discusses the strategies implemented to improve those elements, and the effect they have on the ability of MFCs to treat wastewater and generate bioenergy. Furthermore, a cost analysis of the main MFCs materials (anode, cathode and membrane) is conducted. Finally, the areas with the greatest potential to promote the development of MFCs effectively and economically are identified.

2. Trends of microbial fuel cell research

In 1911 Michael C. Potter [21] made the first observations that relate the electrical energy with the metabolic activity of bacteria. In 1962 Davis and Yarbrough Jr. [22] carried out experiments on a microbial fuel cell using a hydrocarbon as food to generate electrical energy. Then in 1983 in an effort to construct a better MFCs, Bennetto, et al. [23] evaluated a microbial fuel cell and perform potentiometric and amperometric measurements. They used an MFC with glucose as a substrate, and microorganisms Escherichia coli or yeast in the anode, and investigated the catalytic effects of thionine and resorufin as a redox mediator. Subsequent MFCs investigations were done with the use of chemical mediators or electron shuttles. It was not until 1999, that MFC investigations began to be conducted without the use of mediators.

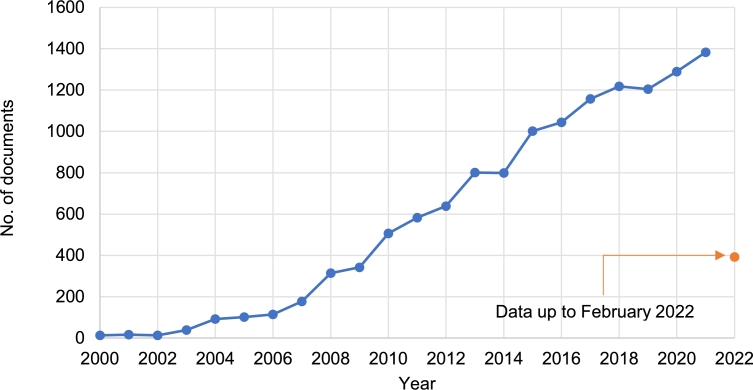

As Kim, et al. [25] did in their work in which they evaluated an MFC type biosensor for lactate using a metal-reducing bacterium without an electrochemical mediator. Then it was recognized that the mediators were not required and consequently increased the interest in MFCs [26]. In the following years, the interest in MFCs continue to rise. Fig. 1 shows the trend in the number of publications regarding MFCs. It is observed that between 2000 and 2005, published MFCs research did not exceed 100 articles per year, and the trend remained upward until 2007 with 177 publications. This slightly increase could be attributed to the disclosure of the feasibility of working MFCs without the use of chemical mediators. After that, a tremendous increase is observed in the following 17 years, in 2021 with 1,383 and in the first two months of 2022 with 392 published articles [24]. This confirms that the research and technology have captured the attention of the scientific community, due to the capability of the MFCs to transform organic waste into electricity [27].

Figure 1.

Publishing trend of MFCs scientific research reports (Data from Scopus Elsevier). [24].

The growing participation of the scientific community in the development of MFCs is also reflected in the increase of MFCs review articles. Table 1 shows a summary of the main subjects discussed in 100 review articles, published between 2015 and 2022.

Table 1.

Main subjects discussed in MFC review articles between 2015 to 2022.

| Anode | Cathode | Membrane | Cost | Electron Acceptor | Electron Transfer | Biofouling | Configuration | Microorganisms | Hydrogen | Substrate | Models | Catalyst | Nanomaterials | Applications | Scaling up | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ■ | [28], [29], [30], [31], [32] | |||||||||||||||

| ■ | ■ | ■ | ■ | [33] | ||||||||||||

| ■ | ■ | ■ | [34] | |||||||||||||

| ■ | ■ | [35], [36], [37] | ||||||||||||||

| ■ | [38], [39], [40], [41], [42] | |||||||||||||||

| ■ | [43], [44] | |||||||||||||||

| ■ | [45], [46], [47], [48], [49] | |||||||||||||||

| ■ | [50], [51], [52], [53], [54], [55], [56] | |||||||||||||||

| ■ | [57], [58] | |||||||||||||||

| ■ | [59] | |||||||||||||||

| ■ | [60], [61], [62] | |||||||||||||||

| ■ | ■ | ■ | ■ | [63] | ||||||||||||

| ■ | ■ | [64] | ||||||||||||||

| ■ | ■ | [65] | ||||||||||||||

| ■ | ■ | ■ | ■ | [66] | ||||||||||||

| ■ | ■ | ■ | [67] | |||||||||||||

| ■ | ■ | ■ | [68] | |||||||||||||

| ■ | ■ | [69] | ||||||||||||||

| ■ | [70] | |||||||||||||||

| ■ | [71], [72] | |||||||||||||||

| ■ | ■ | [73], [74] | ||||||||||||||

| ■ | ■ | [75], [76] | ||||||||||||||

| ■ | [77] | |||||||||||||||

| ■ | ■ | ■ | [78] | |||||||||||||

| ■ | ■ | ■ | [79] | |||||||||||||

| ■ | ■ | ■ | ■ | [80], [81] | ||||||||||||

| ■ | ■ | [82] | ||||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | [83] | ||||||||

| ■ | ■ | ■ | [84] | |||||||||||||

| ■ | ■ | ■ | [85] | |||||||||||||

| ■ | ■ | [86] | ||||||||||||||

| ■ | ■ | [87] | ||||||||||||||

| ■ | ■ | ■ | ■ | [88] | ||||||||||||

| ■ | ■ | ■ | [89], [90] | |||||||||||||

| ■ | ■ | ■ | ■ | [91] | ||||||||||||

| ■ | ■ | [92], [93] | ||||||||||||||

| ■ | [94] | |||||||||||||||

| ■ | [95] | |||||||||||||||

| ■ | ■ | ■ | [96] | |||||||||||||

| ■ | ■ | ■ | ■ | [97] | ||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | [98] | |||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | [99] | ||||||||||

| ■ | ■ | ■ | ■ | [100] | ||||||||||||

| ■ | ■ | ■ | ■ | [101] | ||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | [102] | |||||||||

| ■ | ■ | ■ | ■ | ■ | [103], [104] | |||||||||||

| ■ | ■ | ■ | ■ | ■ | [105] | |||||||||||

| ■ | ■ | [106] | ||||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | [107], [108] | ||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | [109] | ||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | [110] | ||||||||

| ■ | ■ | ■ | [111] | |||||||||||||

| ■ | ■ | ■ | ■ | ■ | [112] | |||||||||||

| ■ | ■ | ■ | ■ | [113] | ||||||||||||

| ■ | ■ | ■ | ■ | [114] | ||||||||||||

| ■ | ■ | ■ | [115] | |||||||||||||

| ■ | [116] | |||||||||||||||

| ■ | ■ | ■ | ■ | [117] | ||||||||||||

| ■ | [118] | |||||||||||||||

| ■ | ■ | ■ | [27] | |||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | [119] | ||||||

| ■ | ■ | ■ | ■ | ■ | [120] | |||||||||||

| ■ | ■ | ■ | [121] | |||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | [122] | ||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | [123] | ||||||||

| ■ | ■ | ■ | [124] | |||||||||||||

| ■ | ■ | ■ | ■ | ■ | ■ | [125] | ||||||||||

| 37% | 41% | 21% | 8% | 23% | 9% | 3% | 31% | 27% | 9% | 12% | 3% | 8% | 9% | 22% | 14% | Discussion frequency |

In recent years, the number of review articles has increased, which is associated with the impact generated by COVID-19 worldwide. In this period, access to research centers may have been scarce or nonexistent due to health restrictions. Therefore, literature review emerged as a safest option to work during this time. In Table 1 the subjects with the highest and lowest frequency of discussion are clearly and precisely identified. On one hand, there are commonly reviewed subjects such as those related to the anode, the cathode and the MFCs configurations, with frequencies of 38%, 44% and 31%, respectively. These high percentages are attributed to the fact that electrodes and configurations are essential in the construction of MFCs and any slight modification on these elements affects the MFCs performance. On the other hand, some of the subjects with less discussion are related to costs, electron acceptor and biofouling, with frequencies of 9%, 9% and 2%, respectively. These subjects can be considered as indirect MFCs factors; however, its low discussion frequency does not mean less relevance in the MFCs performance. On the contrary, these are research areas that could contribute importantly on the MFCs performance. Analyzing the frequency of topics discussed in reports included in Table 1, as well as their direct link with MFCs performance, the issues discussed in this work were selected. Thus, even though MFCs configurations, anode, cathode and membrane materials are the main subjects reported in previous review papers, they were selected because their great contribution on the MFCs performance. Additionally, subjects such as biofouling, electron acceptor, electron transfer and costs, are discussed in this review. The aim is to contribute on the identification of progress trends, as well as gaps and challenges that will be addressed in the coming years to maximize the benefits of MFCs and continue advancing in their development and application in the real world.

3. MFC configurations

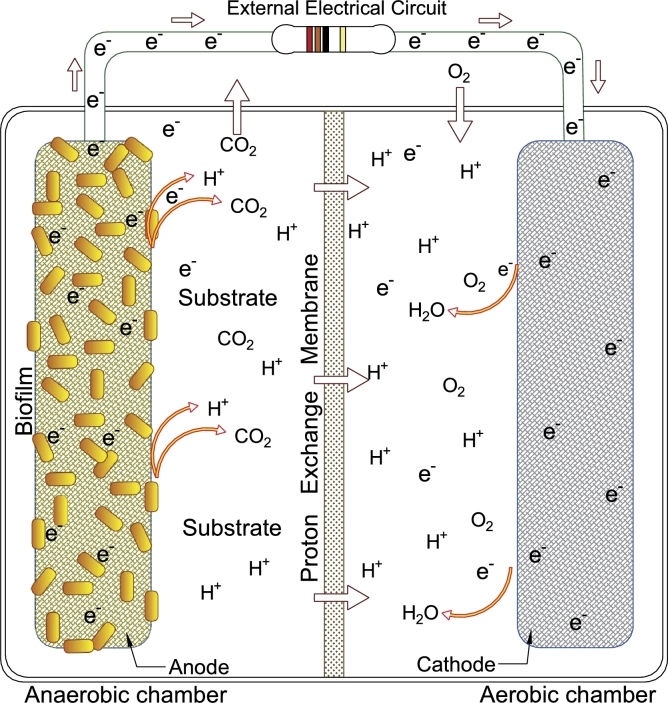

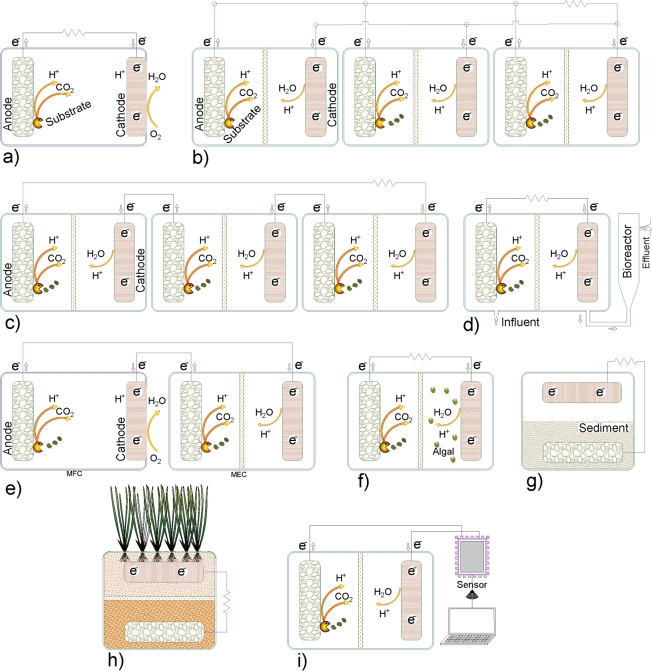

Figure 2, Figure 3 show some MFCs configurations, including the most commonly used, and their main advantages and challenges are highlighted.

Figure 2.

Schematic representation of a dual-chamber microbial fuel cell.

Figure 3.

Examples of microbial fuel cell configurations. a) Single-chamber MFC [146], b) Stacked MFC connected in parallel, c) Stacked MFC connected in series [131], d) MFC + Bioreactor [133], e) MFC + Microbial electrolysis cell [135], f) Microalgal-MFC, g) Benthic microbial fuel cell [138], h) Constructed wetland + MFC, i) Biosensor-MFC.

Dual-chamber microbial fuel cell (DC-MFC) is the typical architecture reported in the literature (Fig. 2). The DC-MFCs are integrated with an anodic chamber, a cathodic chamber, a proton exchange membrane (PEM) between the chambers, an external electrical circuit, and microorganisms in the anode. The main advantage of this configuration is to keep the liquids of the cathodic chamber and the anodic chamber separated by a membrane. The anodic chamber is under anaerobic conditions, to promote microbial growth and to avoid that the oxygen inhibits electricity generation. Microorganisms adhere to the anode surface and form a biofilm of exoelectrogenic microorganisms, which carry out the bio-electrochemical reactions to oxidize organic matter via metabolic reactions. This anaerobic digestion release electrons, protons, and carbon dioxide to the solution. The protons flow from the anodic chamber into the cathodic chamber through the proton exchange membrane. The cathodic chamber is characterized to work under aerobic conditions, since the oxygen acts as an electron acceptor resulting in the formation of water [108].

Single-chamber microbial fuel cell (SC-MFC) is another type of configuration (Fig. 3-a), which consists of a single chamber where the anode and the cathode are placed in opposite sides. The cathode is located with one face in direct contact with the electrolyte and the opposite face in direct contact with air. The most important characteristic of SC-MFC is their operation without the use of any separators or PEM. Some of the main advantages of using SC-MFC are reduction of the overall system cost, favor mass transfer from the anode to the cathode, and reduced of the chamber volume [126], [127]. A challenge to address in these configurations is the formation of biofouling on the surface of the water-side air cathode. Some efforts have already done, for example Rossi et al. [128] implemented a magnet on both sides of the cathode to daily clean the biofouling from the water-side surface, which results in an increase of the SC-MFC performance. The use of cathode catalyst agents as anti-biofouling is also another mechanism than can be employed to solve this problem [129], [130].

The stacking MFCs are another type of configurations, this consist of a connection of several MFCs, they can be connected in series, in parallel, and series/parallel (Fig. 3-b and 3-c). The objective of this configuration is to increase the power generation. The main disadvantage of using this configuration is the presence of losses due to the connections between the MFCs, which is reflected in the difference between the final voltage and the sum of the individual voltages. However, recent studies recommend the use of this design as a feasible alternative on larger scales [131], [132].

There are also combinations of MFCs with other types of technologies, their main objective is to improve the performance of the different technologies involved. The enhancing strategies include the use of MFC energy production for the operation of coupling technology, and the use of a coupling technology to improve the quality of the wastewater treatment. In the literature are reported combination such as: i) MFC + anaerobic fluidized bed bioreactor with the advantage of increasing the wastewater treatment efficiencies with a lower energy consumption [133]; ii) MFC + anaerobic digestion to produce biohydrogen and biomethane, and improving wastewater degradation [134]; iii) MFC + microbial electrolysis cell [135]; and iv) MFC + ammonia electrolysis cell [132], these last two with the aim of producing biohydrogen [16], [26] (Fig. 3-d and 3-e).

Microalgae technology has also been used in MFCs [136], [137]. Several advantages of using this combination are reported: i) microalgae can be used in the anodic and cathodic chamber, ii) microalgae can supply oxygen to the cathodic chamber, iii) microalgae contribute to the nutrients removal, iv) helps to the mitigation, v) helps to the carbohydrates-proteins-lipids accumulation and vi) promote biomass production (Fig. 3-f).

Benthic microbial fuel cell (BMFC) [138], this configuration is mainly used for marine applications. BMFCs operate in the benthic zone of the ocean (lowest level of a body of water, including the sediment surface bed). The cathode is immersed in seawater and the anode is introduced into the anoxic sediment surface bed. The use of freshwater sediment has also been reported [139]. This technology can be used to provide energy to small devices like marine sensors in remotes location, or even for remote sensors in environments with dangerous conditions [140]. Some challenges faced by BMFCs are the cost of the electrodes and the low power generation, which has limited it to be marketable (Fig. 3-g).

Constructed wetland microbial fuel cell (CW-MFC) or plant microbial fuel cell (Fig. 3-h) is also a type of system used to treat organic matter of wastewater. This configuration is characterized for the use of wetland plants, soils and microorganisms in their design. Examples for these plants are macrophyte (aquatic plants) such as Pharagmites australis [141] and rhizodeposits (roots of plants). The CW-MFC combine physical, chemical and biological process to treat wastewater and produce energy. An advantage of this system is its low-cost of the CW mechanism, besides, it has been reported the improvement in the efficiency of wastewater treatment and energy production when CW systems are coupled with MFCs. However, a constraint in its operation is the emission of greenhouse gases from CW, such as , methane () and nitrous oxide (). Then, research on the performance of CW-MFC coupling still requires further investigation.

Biosensor-MFC configuration (Fig. 3-i) is developed from the need of on-site monitoring of water or wastewater quality. In this configuration, the biosensor captures the output voltage coming from the MFC and interprets it as a result representing the concentration of a specific parameter. The output signal of MFCs is directly related to the electron transfer. This electron transfer depends on the behavior of the biofilm on the anode, which is susceptible to variations in the concentrations of the species in the medium. Parameters that have been controlled with this configuration of MFCs include P-nitrophenol [142], cadmium [143], chromium, benzoylecgonine (a metabolic product of cocaine) [144], biochemical oxygen demand [145], volatile fatty acids. The biosensor could be implemented in SC-MFC or DC-MFC depend on the purpose of each study. The use of micro-scale MFCs (proximal to >25 mL) is common in studies reporting the use of biosensor-MFCs. Therefore, it is considered that there is still a wide field for the development of this technology. Particularly with the development of larger scale prototypes to increase the volume of wastewater treatment and simultaneously energy production.

Table 2 shows a compendium of several MFC configurations, in which the main characteristics and their efficiency in terms of degraded organic matter and energy produced is highlighted. The Table identifies different MFC configurations and the frequency of their use, for instance, the configurations with the highest usage rate are DC-MFC [147], [148], [149], [150], [151], [152], [153], [154], [155], followed by SC-MFC [16], [84], [126], [127], [132], [146], [156], [157], [158]. On one hand, the main advantage of using DC-MFC configuration, as previously mentioned, is allowing the liquid of the anodic and cathodic chamber to be separated using a PEM, which favors the reaction in each chamber. On the other hand, the advantage of using SC-MFC configuration is the cost savings, since its configuration does not include the PEM. Another relevant data showed in Table 2 are the energy production and the substrate removal, which allow identifying additional advantages between the use of different MFC configurations. The studies carried out with DC-MFC configurations report the highest rate of energy production that oscillate between 2,100 mW m−2 to 3,600 mW m−2 [148], [149], [154], [159]. Followed by studies using SC-MFC configurations reporting power densities of 400 mW m−2 to 1,500 mW m−2 [126], [127], [156]. The table also includes some MFC configurations with a reduced number of publications and a low energy production such as: i) stacking MFCs that report a power density of 1,287 mW m−2 [131] and 536 mW m−2 [132]; ii) combination of MFC with anaerobic fluidized bed membrane bioreactor reports 89 mW m−2 [133]; iii) MFC + Anaerobic digestion reports 1.98 mW m−2 [134]; iv) MFC + Microbial electrolysis cell reports 343 mA m−2 [135]; v) MFC + microalgal reports 466.9 mW m−3 [136] and 54.48 mW m−2 [137]; vi) and for specifics uses in marine environments the BMFC configuration reports power density of 190 mW m−2 [138].

Table 2.

MFC configurations, electrode materials, membrane materials and performance.

| Design | Resistance | Material |

Substrate | Biofilm | %COD | Energy | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|

| Ω | Anode | Cathode | Membrane | Removal | |||||

| DC-MFC | 100 | Plain Graphite | Plain Graphite | Ultrex, membrane international | Glucose | Mixed consortium | 85.0 | 3,600.0 mW m−2 | [159] |

| DC-MFC | 0-10 KΩ | Graphene- modified plain stainless-steel mesh | Carbon paper | Nafion 112, DuPont | Glucose | Escherichia coli | - | 2,668.0 mW m−2 | [154] |

| DC-MFC | 1,000 | Stainless steel-based with a thin layer of graphene | Carbon felt | Ultrex, membrane international | Domestic wastewater | Mixed consortium | - | 2,143.0 mW m−2 | [149] |

| DC-MFC | 100 | Graphite | Graphite | Nafion 117, DuPont | Domestic wastewater | Mixed consortium | 95.0 | 2,100.0 mW m−2 | [148] |

| SC-MFC | 100 | Graphite fiber brush | Carbon Cloth | - | Acid elutriatione | Mixed consortium | 93.0 | 1,553.0 mW m−2 | [127] |

| DC-MFC | - | Chitosan/ vacuum - stripped Graphene | - | - | - | Mixed consortium | - | 1,530.0 mW m−2 | [152] |

| DC-MFC | 500 | GO | Carbon felt | Nafion 117, DuPont | Domestic wastewater | Mixed consortium | - | 1,390.0 mW m−2 | [151] |

| 3-DC-MFC series | 300 | Carbon felt | Carbon felt | Ultrex CMI 7,000 membrane international | Wastewater -Sodium Acetate | Mixed consortium | 57.6 | 1,287.0 mW m−2 | [131] |

| SC-MFC | 1,000 | Carbon Cloth | GO-Zn/Co | - | Acetate | Mixed consortium | - | 773.0 mW m−2 | [156] |

| 4-SC-MFC serie | 1,000 | Carbon fibers brush | Platinum layer | - | Glucose- ammonium mixture | Mixed consortium | 86.9 | 536.0 mW m−2 | [132] |

| SC-MFC | 218 | Carbon paper | Carbon paper | - | Acetate | Mixed consortium | 99.0 | 506.0 mW m−2 | [126] |

| SC-MFC | 1,000 | Carbon fibers brush | Platinum layer | - | Glucose- ammonium mixture | Mixed consortium | 99.1 | 414.0 mW m−2 | [132] |

| SC-MFC | 1,000 | Carbon paper | Carbon paper | - | Butyrate | Mixed consortium | 98.0 | 305.0 mW m−2 | [126] |

| SC-MFC | 980 | Graphite fiber brush | Carbon Cloth | - | Raw piggery waste | Mixed consortium | 84.0 | 192.0 mW m−2 | [127] |

| DC-MFC | 100 | Carbon felt | Titanium Plate | Nafion 117, DuPont | Glucose | Mixed consortium | - | 156.0 mW m−2 | [155] |

| 4-SC-MFC serie | 1,000 | Carbon fibers brush | Platinum layer | - | Landfill leachate | Mixed consortium | 62.6 | 143.0 mW m−2 | [132] |

| SC-MFC | 0.4 to 100 | Graphite fiber/ Ti | Stainless steel | – | wastewater | Mixed consortium | 82.0 | 101.0 mW m−2 | [146] |

| SC-MFC-AFMB | Graphite fiber brushes with a titanium wire core | Carbon cloth | - | Domestic wastewater | Mixed consortium | 92.5 | 89.0 mW m−2 | [133] | |

| SC-MFC | 33 – 22 KΩ | Carbon paper | Carbon Cloth | Nafion 117, DuPont | Domestic wastewater | Mixed consortium | 42.0 | 72.0 mW m−2 | [16] |

| DC-MFC | 100 | Carbon felt | Titanium Plate | Nafion 117, DuPont | Acetate | Mixed consortium | - | 64.3 mW m−2 | [155] |

| DC-MFC | 100 | Carbon felt | Titanium Plate | Nafion 117, DuPont | Propianate | Mixed consortium | - | 58.0 mW m−2 | [155] |

| DC-MFC | 100 | Stainless steel | Carbon felt | - | Synthetic wastewater | Mixed consortium /bio-cathode algae Chlorella vulgaris | 75 | 54.48 mW m−2 | [137] |

| DC-MFC | 100 | Carbon felt | Titanium Plate | Nafion 117, DuPont | Butyrate | Mixed consortium | - | 51.4 mW m−2 | [155] |

| DC-MFC | 100 | Carbon felt | Carbon felt | SBC-600 | Synthetic wastewater | Mixed consortium | 81.0 | 41.08 mW m−2 | [160] |

| SC-MFC | - | Carbon fiber graphite brush | Carbon Cloth coated with platinum black | Nafion 112, DuPont | Synthetic wastewater | Lactobacillus pentosus | 42-58 | 5.04 mW m−2 | [157] |

| SC-MFC +AD | 1 MΩ - 100 | Graphite plate | Graphite plate | - | Domestic wastewater | Mixed consortium | 25.2 | 1.98 mW m−2 kg | [134] |

| DC-MFC | 100 | Crumpled graphene-modified | Carbon brush | Ultrex CMI 7,000 membrane international | Synthetic wastewater | Mixed consortium | - | 3,600 mW m−3 | [153] |

| PMFC | 500 | Carbon brush | Carbon brush | Nafion 117, DuPont | Synthetic wastewater | Mixed consortium /bio-cathode algae Chlorella vulgaris | 93.2 | 466.9 mW m−3 | [136] |

| SSM-MFCs | 562 | Carbon Fiber Veil | AC-PTFE | - | Urine | Mixed consortium | - | 15.74 μ W cm−3 | [161] |

| MFC | - | Roughened Glassy Carbon plates | - | - | - | Shewanella oneidensis | - | 40μA cm−2 | [162] |

| SC-MFC+ MEC | 10 | Carbon paper | Carbon paper | - | Propionate | Mixed consortium | - | 343 mA cm−2 | [135] |

| SC-MFC+ MEC | 1,000 | Carbon paper | Carbon paper | - | Propionate | Mixed consortium | - | 81 mA cm−2 | [135] |

| DC-MFC | - | Carbon Cloth | Carbon Cloth | Internal Nanoscale polypyrrole | Molasses wastewater | Mixed consortium | 25.24 | 0.0173 V | [147] |

| DC-MFC | - | - | - | - | Synthetic wastewater | Sulfate- reducing bacteria | 30-40 | - | [150] |

| 4-SC-MFC series + AEC | 1,000 | Pt/N-rGO/ Carbon felt | Mo2C/N-rGO/ Carbon felt | Nafion 117, DuPont | Glucose- ammonium | Mixed consortium | 70.7 | - | [132] |

DC=Dual Chamber, SC=Single Chamber, MEC=Microbial Electrolysis Cell, AD=Anaerobic Digestion, AFMB=Anaerobic fluidized bed membrane bioreactor, AEC=Ammonia Electrolysis Cell, PMFC=Microalgal-based photoautotrophic microbial fuel cell, GO=graphene oxide, SSM-MFCs=self-stratifying microbial fuel cells, AC-PTFE=activated carbon with polytetrafluoroethylene

Regarding the ability of MFCs to degrade the substrate, the information in Table 2 shows different percentages of substrate removal (this data is only reported in some studies). For instance, for DC-MFC configurations a substrate removal between 25% to 95% [147], [148] is reported, for SC-MFC values between 42% and 99% [126], [134], and for MFC + Microalgal the removal varies from 75% to 93% [136], [137].

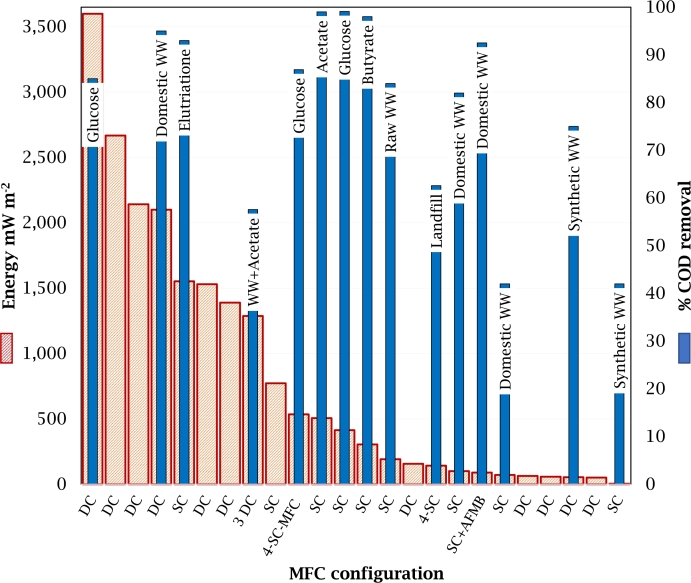

Fig. 4 summarizes graphically the different MFC configurations and the link to their performance. It is observed that the use of DC-MFCs reports the highest power generation values, followed by the use of SC-MFC configurations. Furthermore, if the ability to degrade the substrate is considered, the same trend of high removal rate is observed for these configurations. However, the SC-MFC configurations present the highest COD removal values when the substrate used are acetate or butyrate. Also, MFC + microalgal configuration provides good removal of substrate, as well as nutrients; however, bioenergy production is lower in comparison with the previous configurations. Therefore, based on this analysis, it can be inferred that the DC-MFC configuration is the best option for further improvement.

Figure 4.

Performance of different MFC configurations. DC = Dual-chamber MFC; SC = Single-chamber MFC; AFMB = Anaerobic fluidized bed membrane bioreactor; WW = Wastewater.

4. Materials of MFC components

Among the main elements of a DC-MFC include the anode, the cathode, and the membrane. It is important to make a good selection of these elements to maximize the power generation, the coulombic efficiency (CE), the ratio of the total number of electrons transferred to the anode from the substrate and the maximum possible number of electrons if the entire substrate were degraded and produce current), and to favor the degradation of organic matter [15]. In the following sections analysis and discussion of the components of MFCs is done.

4.1. Electrodes

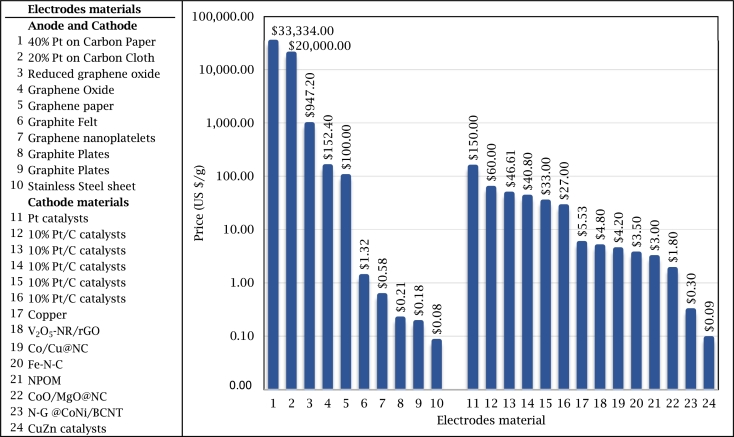

As already mentioned, the electrodes have a direct effect on MFCs performance. Among the electrode materials, the most common reported are carbon-base materials and metal-base materials.

Carbon-based materials are commonly used to make MFCs electrodes because of their i) low cost due to their high availability; ii) high surface area; iii) excellent biocompatibility, these last two facilitate bacterial adhesion and allow the formation of a uniform biofilm when the material is used as anode; iv) chemical inertness; v) high conductivity that serve to transfer the electrical energy; and vi) good stability such as high melting point that allows its use at high temperatures without changes [163], [164]. Examples of them are carbon cloth, carbon paper, carbon fibers brush, carbon felt, graphite plate, graphite fibers brush and graphite felt, graphite granules, rods, foam, reticulated vitreous carbon, glassy carbon, activated carbon cloth [165], and in recent years graphene. This last one is a newly created material that is formed from a layer of graphite. Graphene is a material with a low production cost and also high porosity. Since the isolation of graphene in 2004, researchers have found a variety of unique properties [76] such as high electron transfer rate and large active surface area, excellent biocompatibility and strong resistance to corrosion [166]. Graphene is a two-dimensional carbon nanomaterial, consisting of a single layer of cohesion carbon atoms through sp2 hybridization bonds, with a structure similar to that of a honeycomb. There are also publications reporting its use in electrochemical energy-storage devices [167]. This material has a special structure, it allows electrons to move freely across the plane in delocalized orbitals [168].

Metal-based materials are also used to make MFCs electrodes, some of them are titanium, platinum, stainless steel, copper, nickel, gold, cobalt and silver. These materials are used mainly for the different properties that favor the MFCs performance. For example, platinum is one of the most commonly used material as cathode catalyst, due to the rapid kinetics of the oxidation-reduction reaction [169]. Titanium has excellent corrosion resistance [170]. Silver, copper and gold have excellent conductivity 62.1 MS m−1, 58.5 MS m−1 and 44.2 MS m−1, respectively [171], [172]. Then it is possible to say that metal-based electrodes provide great advantages in the performance of MFCs. However, these metal-based materials have significant limitations, making them difficult to use for larger-scale projections. For example, platinum [165], titanium, gold, and silver are very expensive. Besides titanium and cobalt has low biocompatibility [172]. Platinum tends to be toxic when the substrate is wastewater and can harm microorganisms, furthermore, the catalytic activity of Pt can be significantly decreased when sulfur-containing pollutants are present. And cooper and stainless steel are susceptible to corrosion that limited their biocompatibility [170], [173], [174].

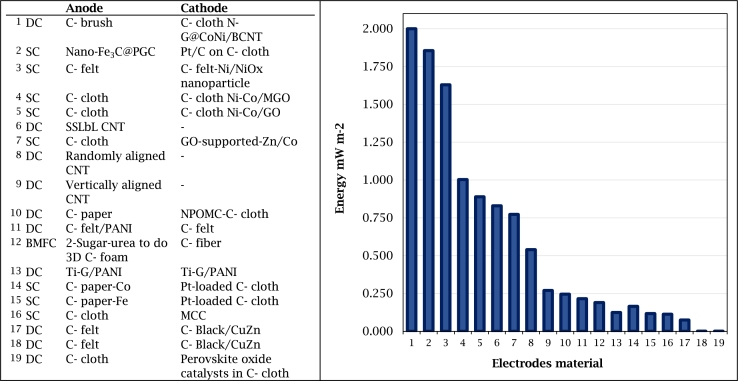

The scientific community has implemented different mechanisms to enhance the performance of MFCs electrodes made of either carbon-based or metal-based materials. Some reported techniques include the use of doping, coating, synthesis, or nanotechnology. Regarding the use of nanostructures, they are mainly used in carbon-based materials to improve hydrogen and electricity production [8]. These techniques have been used with specific objectives of improving the anode and the cathode, Table 3 and Fig. 5 show some relevant results reported by several authors and there are analyzed below.

Table 3.

Electrode materials, configurations and performance of MFCs.

| Anode | Cathode | Design | Volume | Power Densities | Reference |

|---|---|---|---|---|---|

| Carbon brush | Carbon cloth N-G@CoNi/BCNT | DC-MFC | 270 mL | 2.000 W m−2 | [177] |

| Nano-Fe3C@PGC | Pt/C on carbon cloth | SC-MFC | 28 mL | 1.856 W m−2 | [176] |

| Carbon felt | Carbon felt-Ni/NiOx nanoparticle | SC-MFC | 100 mL | 1.630 W m−2 | [169] |

| Carbon cloth | Carbon cloth Ni-Co/MGO | SC-MFC | - | 1.003 W m−2 | [173] |

| Carbon cloth | Carbon cloth Ni-Co/GO | SC-MFC | - | 0.889 W m−2 | [173] |

| SSLbL CNT | - | DC-MFC | μL | 0.830 W m−2 | [140] |

| Carbon cloth | GO-supported-Zn/Co | SC-MFC | 28 mL | 0.773 W m−2 | [156] |

| Randomly aligned CNT | - | DC-MFC | μL | 0.540 W m−2 | [140] |

| Vertically aligned CNT | - | DC-MFC | μL | 0.270 W m−2 | [140] |

| Carbon paper | NPOMC-Carbon cloth | DC-MFC | cc 10 mL | 0.245 W m−2 | [178] |

| Carbon felt/PANI | Carbon felt | DC-MFC | 250 mL | 0.216 W m−2 | [175] |

| 2-Sugar-urea to do 3D Carbon foam | Carbon fiber | BMFC | 1000 mL | 0.190 W m−2 | [138] |

| Ti-G/PANI | Ti-G/PANI | DC-MFC | 1400 mL | 0.124 W m−2 | [179] |

| Carbon paper-Co | Pt-loaded carbon cloth | SC-MFC | 80 mL | 0.165 W m−2 | [163] |

| Carbon paper-Fe | Pt-loaded carbon cloth | SC-MFC | 80 mL | 0.117 W m−2 | [163] |

| Carbon cloth | MCC | SC-MFC | 520 mL | 0.113 W m−2 | [180] |

| Carbon felt | Carbon Black/CuZn | DC-MFC | cc150 mL | 0.075 W m−2 | [181] |

| Carbon felt | Carbon Black/CuZn | DC-MFC | 25,000 mL | 0.00032 W m−2 | [181] |

| Carbon cloth | Perovskite oxide catalysts in Carbon cloth | DC-MFC | 450 mL | 0.00139 W m−2 | [182] |

| - | Fe-AAPyr catalyst in RRDE | SC-MFC | 125 mL | 262μW cm−2 | [183] |

| Graphite fiber brush | Fe-BZIM-AB RRDE | SC-MFC | 28 mL | 162μW cm−2 | [184] |

| Graphite fiber brush | Fe-ABZIM RRDE | SC-MFC | 28 mL | 159μW cm−2 | [184] |

| Graphite fiber brush | Activated carbon | SC-MFC | 28 mL | 100μW cm−2 | [184] |

| 3D N-doped-GA | Carbon cloth | DC-MFC | 25 mL | 750.0 W m−3 | [11] |

| Fe/N/S-doped CT | Fe/N/S-doped CT | SC-MFC | 28 mL | 479.0 W m−3 | [185] |

| Multilayer Carbon flet/N-doped-CNT/PANI/MnO2 | 5-graphite rod | DC-MFC | – | 13.8 W m−3 | [186] |

| SSLbL CNT | DC-MFC | 12.5 μL | 3,320.0 W m−3 | [140] | |

| 8-TNs-modified | 1-TNs-modified | DC-MFC | ac800 mL cc100 mL | 12.7 A m−2 | [170] |

| Carbon veil | Conductive latex | SC-MFC | 15 mL | 0.092 W | [187] |

PANI=polyaniline; CNT=carbon nanotubes; MCC=modified clay cup; TNs=titanium dioxide nanotubes; cc=cathodic chamber; ac=anodic chamber; MGO=silanefunctionalised graphene oxide; GO=graphene oxide; CT=carbon tubes; BMFC=benthic MFC; RRDE=rotating ring disk electrode; Fe-AAPyr=Fe-Aminoantipyrine; Nano-Fe3C@PGC=iron carbide nanoparticles dispersed in porous graphitized carbon; GA=graphaerogel; Fe-ABZIM=Iron nitrate with aminobenzimidazole; Fe-BZIM=Iron nitrate with benzimidazole; NPOMC=Nitrogen-phosphorus-doped mesoporous carbon; AB=airbreathing; G/PANI=graphene/polyaniline SSLbL=spin-spray layer by layer; BCNT=bamboo-like carbon nanotube

Figure 5.

Electrodes material and MFC performance.

Anode. This is an essential component in MFCs, some of its main functions are as a support for bacteria and the conduction of electrons. The efficiency of the anode is directly related with the generation of electricity of the MFCs. The most important characteristics that should be taken into an account in the selection of the anode material are: available surface area, roughness, conductivity, biocompatibility, microorganisms and substrates [26], [154].

Carbon-base materials as an anode are widely used and different investigations focus their objectives on the improvement of these materials through their modification [138], [162], [175] (Table 3 and Fig. 5). Pushkar et al. [138] evaluated a sugar-urea carbon foam as anode in a BMFC. They used 1.5L of sediment and seawater from Dumas seashore, Surat, Gujrat, India. The sugar-urea carbon foam anode was submerged into the sediment. In the cathodic electrolyte a carbon fiber cathode was placed, and an aerator was used to supply oxygen. The external electrical circuit was operated with 100 Ω and 10 Ω resistors. They reported a maximum power density of 0.190 W m−2 that was higher than the results obtained with carbon felt 0.0085 W m−2. They attributed this result to the synthesized carbon foam anode that provided a large surface area, hydrophilicity and biocompatibility properties. Particularly the good biocompatibility was attributed to the presence of functional groups as -CN, -OH and -CO, these groups provide polarity to the anode and favor the attachment of exoelectrogens microorganisms. Rajesh et al. [175] also used a carbon-base material, they evaluated a carbon felt coating with polyaniline (PANI) as the anode in a DC-MFC with a pretreated inoculum using Chaetoceros, and synthetic wastewater as substrate. Their results showed a maximum power density of 0.216 W m−2 and an improvement on the CE by 17% and generating a total of 42.45% compared with the unmodified anode and without pretreatment inoculum. Ye et al. [162] evaluated carbon plates as an anode, through the physical modification of the surface. They compared two glassy carbon plates with different uniform roughness, 10 and 100 nanometers each. Their results show that the rougher surface of the electrode increases the biomass growth; therefore, it produces higher power densities, 40 μ A cm−2 than the smoother electrode, 10 μ A cm−2. The three techniques applied for modifying carbon-base materials (synthesized, coating, and physical modification) show the possibility to potentiate some anode characteristics such as the surface area, the biocompatibility and the roughness. These characteristics favor the microbial adhesion, electrogenic activity and reduce the charge transfer resistance. Comparison of these studies shows that the use of carbon felt coating with PANI as anode produced the highest power density. However, it is interesting to evaluate a new scenario that combines the advantage obtained from each study. For instance, evaluation of urea-sugar carbon foam as anode on DC-MFC with a pretreated inoculum and synthetic wastewater, could be interesting research, taking advantage of the low cost and natural origin of this anode material and the good performance with a pretreated inoculum. Thus, expanding the application of such material in DC-MFC beyond it use in benthic zones.

Metal-based materials are also widely reported as anode material. Baudler et al. [172] evaluated the biocompatibility of different materials (gold, silver, copper, nickel, cobalt, titanium and stainless steel) to be used in an MFC. Their results showed that copper was the material with the highest biocompatibility with the electrochemically active bacteria. And even with the antimicrobial properties of cooper, bacteria were able to tolerate and adapt. However, it is important to note that the advances in carbon-based materials reported in recent studies offer even greater advantages compared to metal-based materials.

Nanomaterials are another type of material used as anode. In the literature, different applications from non-structure to carbon-base and metal-base materials are reported, such as carbon nanotubes (CNT), nanoparticles of graphene (GN), PANI, 3D graphene-based material,Ti-TiO2, and nanoparticles of metals. The last are commonly used as carbon-base anode coating, example of these metal nanoparticles are Fe, Zn, Ni, Co, and Cu [11], [151], [163]. Some studies that have used the nanotechnology in carbon-base material are those conducted by Hu et al., Ren at al., and Hou et al. [140], [151], [176] (Table 2, Table 3).

Hu et al. [176] reported the use of iron carbide nanoparticles dispersed in porous graphitized carbon (Nano-Fe3C@PGC) as anode and carbon cloth with catalyst Pt/C as cathode, connected with a 1,000 Ω external loading resistance. They used a 28 mL SC-MFC, inoculated with activated anaerobic sludge. Their results showed a maximum power density of 1.856 W m−2 that was better than the results on the same conditions but using carbon felt with 0.487 W m−2. These results were attributed to the electrocatalytic activity and conductivity provided by the iron carbide nanoparticles (Nano-Fe3C@PGC) anode. Ren at al. [140] evaluated a CNT anode on a micro-scale 25 μL DC-MFC. They used an inoculum (Geobacter) obtained from a MEC and sodium acetate as substrate. Their results showed an improvement with the use of spin-spray layer by layer (SSLbL)CNT anode with a power density of 0.83 W m−2 greater than that of the bare gold anode control of 0.48 W m−2. Additionally, a grater biofilm thickness was observed in CNT than in the bare gold, 9.0 μm and 1.8 μm, respectively. Therefore, it can be said that the SSLbL-CNT anode favors the attraction of exoelectrogenic microorganisms due to a higher biocompatibility. Hou et al. [151] tested a reducing graphene oxide coating with PANI nano-fibers anode on a DC-MFC. They obtained a maximum power density of 1.390 W m−2. This result was attributed to the high conductivity of graphene and the large surface area provided by PANI.

The use of nanotechnology in metal-base material was reported by Feng et al. and Su et al. [170], [188] (Table 3 and Fig. 5). Feng et al. [170] reported in their work the evaluation of modified titanium electrodes in DC-MFC. The modification consisted of the onsite growth of titanium dioxide nanotubes (TNs) on the surface of electrodes. They reported a maximum current density of 12.7 A m−2, which was higher than that provided by the bare titanium electrode. It was also observed coverage of almost 100% biofilm on the TNs anode surface, different from the poor coverage in the bare titanium. The nanoscale titanium tubes provided an increased and rougher electrode surface area, and favored its biocompatibility, hydrophilicity, and conductivity. Su et al. [188] used the TiO2@TiN nanocomposite as anode to develop a hybrid biofilm with Shewanella Ioihica in a DC-MFC. Their results showed a maximum power density of 0.064 W m−2, which was higher than the 0.0334 W m−2 of DC-MFC with pure biofilm; this improvement was attributed to the nanocomposite that favored the biocompatibility and conductivity of the anode.

In the analysis of the application of nanotechnology in carbon-based and metal-based materials, it was found that their use does favor them. This translates into better performance as electrodes in MFCs, where energy production is the parameter commonly used to quantify these improvements. However, it can highlight that the nanotechnology applied in carbon-based materials presented the best energy production efficiencies in MFCs. The work of Hou et al. [151] reported a maximum power density of 1.39 W m−2 using graphene with PANI, which represents a large difference in contrast to the achieved maximum power density of 0.064 W m−2 using TiO2@TiN nanocomposite [188]. Therefore, it can be suggested that the application of nanotechnology in carbon-based materials used as electrodes in MFCs could be a promising alternative for future research.

As already discussed, the selection of the anode material and the different techniques to increase its performance are very important. However, the microorganisms and substrate selection also play a crucial role on the anode performance. Therefore, some of the most important consideration to carry out a successful selection are discussed below. Microorganisms form the biofilm and they are responsible for degrading the substrate, as well as generating the energy. The commonly used way to quantify the ability of microorganisms to degrade the substrate is through the reduction of Chemical Oxygen Demand (COD). Substrate degradation is carry out by the action of anaerobic microorganisms present in the anodic chamber, which are exoelectrogenic and also called electroactive [189]. They can be divided into two general types, mixed cultures, and pure cultures. The first one contain various types of microorganisms especially present in wastewater, and the advantage of using them are low cost, presence of self-mediators and good performance [127], [148], [149], [152]. The main challenges to overcome is the internal microbial competition reaction, which is reflected in the undesirable reactions such as methanogenesis that transform the organic matter into methane and CO2 instead into CO2 and electrons [14], which reduces electricity generation. The second type, pure cultures, contain only one type of microorganisms for example, Escherichia coli [154], Shewanella oneidensis [162], Lactobacillus pentosus [157], among others. The advantage of the use of this type of pure cultures is the reduction of reaction between microorganism and substrate. Also, allows the study of specific objectives such as biocompatibility analysis, electron transfer mechanisms and substrate degradation [163], [169].

Once the MFCs consortium has been selected, it is necessary to select the substrate and analyze the effect on the MFCs performance. Some examples of substrates are: acetate, glucose, propionate, butyrate, sucrose, complex substrates such as synthetic wastewater, animal waste, and real wastewater. In Table 2 is possible to identify different types of substrates and microorganism. On one hand, studies using mixed cultures reported the highest rates of COD removal on the order of 99%, 98% and 93%, for acetate, butyrate and acid elutriatione; and reached power densities of 506 mW m−2, 1,553 mW m−2 and 305 mW m−2, respectively [126], [127]. Other works have presented the highest power densities using glucose as substrate, even when their COD removal rates are not the highest as mentioned in the previous paragraph. In their work, Rabaey et al. [159] used glucose in a DC-MFC with a mixed consortium, and they reported a maximum power density of 3,600 mW m−2 and a COD removal of 85%. Follow by the works that used domestic wastewater as substrate which presented power densities between 1,287 mW m−2 and 2,143 mW m−2, and the highest COD removal of 95% for 2,100 mW m−2 [131], [148], [149], [151]. Regarding the use of animal waste, Chandrasekhar et al. [127] reported 84% of COD removal and 192 mW m−2 of energy production, both lower than the other substrates. On the other hand, investigations using pure cultures report percentages of COD removal between 30% and 50% and power density of 5.04 mW m−2 [131], [157]. But some of them using Escherichia coli reports high energy production about 2,700 mW m−2 and 80% of COD removal [154]. Therefore, according to this analysis the use of mixed cultures offers greater advantages even on a laboratory scale. Regarding the substrate, the use of glucose reports the highest energy production following by wastewater. However, if the objective is to apply MFCs in real scenarios, the most certain suggestion is to use wastewater as an energy source with a mixed culture (usually found in wastewater). These conditions allow generating very similar or equal scenarios to which the MFCs will be subjected in practical situations. In addition, the percentages of COD removal and energy production will also be similar to those expected at larger scales, which will allow better decisions-making.

The studies revised and summarized in Table 2, Table 3 and Fig. 5 provide evidence that even when several strategies have been evaluated to improve the anode performances, still do not represent a significant breakthrough in MFC performance, compared to unmodified anode materials. However, it was possible to identify opportunities to continue the research in order to improve carbon-based anode materials such as the use of nanotechnology. Additionally, the use of mixed cultures as biomass and wastewater as substrate is desirable.

Cathode. In the cathode occurs an electrochemical reduction reaction in which an oxidant is reduced [184]. The most relevant properties that are searched in the cathode are catalytic qualities, high surface area and high conductivity [190], [191], and some of the main challenges on cathode materials to face include poor oxygen reduction reaction, low catalytic activity, and biofouling [137], [169], [183]. A detailed review of the studies focused on improving the cathode properties and enhancing the MFCs efficiency through different strategies is done.

Regarding the catalytic properties of the cathode, there are two types biotic and abiotic catalysts, both can be used in neutral conditions. The biotic catalysts are mainly bacteria and enzymes. However, bacteria catalysis for oxygen reduction reaction (ORR) is sluggish and enzymes are active and selective but expensive and no eco-friendly. On the other hand, there are abiotic catalyst that are commonly used because are durable and resistant to most pollutants. Examples of them are platinum group metal (PGM) catalysts, platinum group metal-free (PGM-free) catalysts, and carbonaceous materials [161], [183], [184]. PGM cathode catalysts were commonly used in MFC in the past decades [187]. Currently due to the low durability and high cost of platinum-based materials, scientific efforts have been made to develop alternative catalysts [161]. PGM-free catalysts have been reported to be efficient for catalyzing oxygen in neutral media [187]. Examples of these catalysts based on transition metals include Mn, Fe, Co and Ni, and although their durability and performance are high, their cost is also high, making it difficult to project their use on a large-scale [161], [178]. Carbonaceous materials have been used as cathode catalysts in MFCs due to its low cost. Some examples of these materials are activated carbon (AC), modified activated carbon, AC mixed with polytetrafluoroethylene (PTFE) and pasted on a stainless steel mesh, carbon black, carbon black modified with aerogel, carbon nanotubes (CNT), carbon nanofibers (CNF), and graphene [161], [184], [187].

Santoro et al., Mecheri et al., and Song et al. [178], [183], [184] (Table 3 and Fig. 5) conducted researches with catalytic modified materials as cathodes. Santoro et al. [183] evaluated the effect of the catalyst loading of the cathode in the MFC power generation. Their results showed that a rotating ring disk cathode with 10 mg cm−2 of Fe-Aminoantipyrine catalyst in a SC-MFC achieved 262 μW cm−2 of maximum power density. They suggested that a high catalyst load results in high power output of the MFC, but they recommend continuing the research to reduce the cost of the catalyst. Mecheri et al. [184] also, carried out a similar work in which they used iron nitrate with benzimidazole (Fe-BZIM) and iron nitrate with aminobenzimidazole (Fe-ABZIM) as cathode catalyst, tested in rotating ring disk electrode (RRDE). They used graphite fiber brush as anode and a 28 mL SC-MFC connected with an external resistance of 1 kΩ. They reported a maximum power density of 162 μW cm−2 for the catalysts Fe-BZIM integrated into an air-breathing (AB). This is higher than the power density of Fe-ABZIM 159 μW cm−2, and the activated carbon control, but not higher than the maximum power density obtained by Santoro et, al [183] as is shown in Table 3 and Fig. 5. Song et al. [178] evaluated a nitrogen-phosphorus-doped mesoporous carbon (NPOMC) as a cathode catalyst in a DC-MFC. Their results showed a maximum power density of 245.8 mW m−2, which represented 75% of the power density obtained by Pt/C catalyst 329.8 mW m−2. They observed that the mesoporous structural catalyst provides a large surface area with a higher electrochemical charge transfer. Although the power density was lower than that obtained with the Pt/C catalyst cathode, a comparison with the Santoro and Mecheri studies mentioned in the previous paragraph shows that the power density obtained by the NPOMC of Song was higher. In addition, the most relevant achievement of this study was the low cost of the NPOMC catalyst which represented less than 5% of the price of the Pt/C catalyst.

Similar study conducted by Huo et al. [177]reported the development of a catalyst based on N-doped bamboo-like carbon nanotube (BCNT) and CoNi-alloy N-G@CoNi/BCNT. Then, they evaluated this catalyst in a DC-MFC in a 130 mL anodic chamber and 140 mL cathodic chamber. Ultrex CMI-7000 was used as cation exchange membrane, carbon brush as anode, and carbon cloth with catalyst as cathode. Their results showed a maximum power density of 2.0 W m−2 for N-G@CoNi/BCNT, this value was lower than the obtained with Pt/C of 2.6 W m−2. However, the power density obtained with this N-G@CoNi/BCNT catalyst was one of the highest reported among those that use carbon-base cathode catalysts in MFC (Table 3 and Fig. 5). It was shown that the N-G@CoNi/BCNT catalyst increased the surface area of the cathode, which favored its electrocatalytic properties, and promoted oxygen reduction reactions. The most outstanding achievement of this study was the low cost of the catalyst compared with the Pt/C, this trend of decreasing costs can also be observed in the work by Song [178] mentioned in the previous paragraph.

The use of nanotechnology in cathodes to improve the MFC performance is another strategy that has been reported [156], [169], [173]. Yang et al. [156] evaluated a modified cathode with graphene oxide (GO) - supported zinc cobalt oxides (GO-Zn/Co) nanocomposites in a SC-MFC. Their results reported an increase in the performance of the electrode with a power density of 0.773 W m−2. They attributed that the (GO-Zn/Co) nanocomposites generated an antibacterial activity on the cathode surface that inhibits the formation of microorganisms on its surface (biofouling). Papiya et al. [173] also evaluated the use of GO cathodes modified with nanocomposites in SC-MFC. The GO were grafted with g-amino propyl tri-ethoxy silane (APTES), and Ni and Co nanoparticles deposited on GO and silane-functionalised graphene oxide (MGO) matrices. They reported the highest power density of 1.003 W m−2 in the Ni-Co/MGO cathode as it is shown in the Table 3. Choi et al. [169] fabricated a nanocatalysts PGM-free cathode, consisted of the deposition of a thin layer of Ni/NiOx nanoparticles on the carbon-felt material. Then they evaluated a carbon-felt Ni/NiOx performance in an MFC, their results showed a power density of 1.631 W m−2 that was higher than a carbon-felt of Pt/C cathode at the same condition with 0.489 W m−2. These results are attributed to the fact that the Ni/NiOx nanoparticles provided a higher surface area and an increase in the active sites of the cathode, which favored the ORR.

New electrode materials have been also tested as an alternative to improve the cathode performance. Liu et al. [180] evaluated clay cathode in an MFC to remove cooper and generated electricity (Table 3 and Fig. 5). They used carbon cloth as anode, and modified clay cup as cathode that was produced by sintering at 1,000∘C temperature. The 520 mL SC-MFC was inoculated with a mixed consortium from a wastewater treatment plant, and sodium acetate was used as a substrate. The anode and the cathode were connected by an external electrical circuit integrated by a 1 kΩ resistor and 0.4 mm titanium wire. They reported a maximum power density of 0.1137 W m−2 and a copper removal of 96.5%. Although, the cooper removal was close to 100%, the power generation was low. Therefore, further research is needed to improve the performances of clay as electrode material. The application of these strategies translates into improvements in the performance of the cathode, as well as in mitigating some cathode challenges such as poor oxygen reduction reaction, low catalytic activity, and biofouling.

Regarding biofouling, it is a limitation that occurs more frequently in single-chamber MFCs and affect the overall MFCs performance. In order to avoid this problem and allow the correct cathode function, it is important to identify its causes and apply possible mitigation techniques. Biofouling consists in a biofilm formed by heterotrophic microorganisms attached in the surface of the material [84]. As already mentioned, its presence is common in membrane-less MFCs, and this is because the cathode is directly in contact with the substrate. The biofouling causes an increase in the charge transfer and ohmic resistance of the cathodes and decreases their performance [187]. Some of the strategies used to mitigate the biofouling problem are the following: i) design adaptation, the reconfiguration of MFC should allow removing the cathode to clean the biofouling and should prevent the contact between the air and the anode; ii) modification of the surface cathode, this strategy could delay the biofouling; iii) clean the electrode, the electrode can be washed with a concentrated acid solution [84], and also the washing of cathode can be conducted periodically to minimize the formation of biofouling [146]. Biofouling is also caused by fungi that can be growth on the cathode surface. This type of biofouling is reported in some studies [181]. They reported the growth of fungi on the surface cathode after 50 days of operation. At the same time, they observed a small decrease in the current production. They use Fluconazole as fungicide, which is spread over the entire cathode surface to mitigate the problem. After this, a positive result is observed with an increase in the current of the system.

Analysis of these studies allow the identification of the benefits obtained by the use of some techniques that improve cathode performance. Among these, the studies focused on the improvement of the catalytic cathode properties are the most reported. This trend can be attributed to the observed increase in ORR when improvements in the catalytic properties of the cathode are obtained, and consequently promotes energy production in the MFCs. In addition, it is important to note that in several studies it was observed that the Pt/C catalyst produced the best energy yield, one of the main reasons for these results is that the use of Pt/C catalyst favors the one-step ORR that occurs with the reduction of oxygen through 4 e− [192], [193]. However, the economic feasibility of using other types of catalysts was identified as the main advantage. Consequently, in order to be a priority for large-scales MFCs systems, more efforts in the development of other catalysts must be done to replace platinum. Regarding the development of alternative cathode materials, such as clay, must be also considered as an opportunity area. Even though the low MFC energy production reported, because of the ability of clay to remove some toxicants in the water such as cooper. Nevertheless, more research should be conducted in this respect. Finally, nanotechnology enhances the cathode performance and increase the energy production; furthermore, nanocomposites generate antibacterial activity on the cathode surface that inhibits the formation of biofouling on its surface.

4.2. Separators

A separator (most commonly, a membrane) is a component that connects and separates both chambers of the dual-chamber MFCs for keeping the anode and cathode liquids separated. Furthermore, it allows protons to permeate from the anodic to cathodic chamber and allows the separation of hydrogen gas (), oxygen (), and substrate [26]. Membrane performance is usually measured with factors such as proton conductivity, permeability to water, ion transport number, biofouling, internal resistance and, mechanical strength, chemical resistance and oxygen diffusion [160], [194]. The surface of the membrane also has an effect in the membrane performance and the power generation in MFCs systems. Oh et al. [15] reported that when the surface area of the membrane increases, the power density increases as well. They reported 45.0 mW m−2 for a proton exchange membrane (PEM) area of 3.5 cm2; 68.0 mW m−2 for a PEM area of 6.2 cm2; and 190.0 mW m−2 for a PEM area of 30.6 cm2. Thus, a desired property of a proton exchange membrane is a large surface area.

Currently, several membranes materials have been reported that function as separators in MFC systems. Commercial membrane materials include Nafion membranes, Ultrex membranes and Zirfon membranes to name a few.

The commonly used membrane is developed by Nafion DuPont Inc. USA, due to its accessibility and good performance. This Nafion perfluorinated membrane has sulfonic acid groups that favor the proton conductivity, transfer protons from the anodic chamber to the cathodic chamber, is selective to small cations, has high permeability to water, and avoid the pass of electrons [195], [196], [197].

Before the Nafion membrane is used, an activation treatment is necessary, which activates its conductive capacity, eliminate possible organic molecules absorbed from the air, and hydrates the membrane. This activation can be carried out with strong acid solutions for example nitric, sulfuric, perchloric, phosphoric and hydrochloric acids [198]. However, the standard activation membrane method uses 1 molar sulfuric acid solution, which continues being the most widely used [197].

The performance of MFC systems using Nafion membrane is variable, for instance Zhang et al. [154] reported a power generation of 2,668 mW m−2 in MFC using Nafion membrane 112, DuPont, and López-Zavala et al. [148] reported a power generation of 2,100 mW m−2 in MFC using Nafion membrane 117, DuPont (Table 2). However, this power density cannot be attributed only to the use of these Nafion membranes but to the participation of the whole MFC system.

The mains limitations to the use of this Nafion material are the high cost, oxygen leakage, substrate loss and biofouling. Additionally, if the substrate in the anode chamber is wastewater, or leaches, it is possible to find the presence of other cation species with concentrations higher than that of the protons, which can interfere with the transport of protons and cause a decrease in the performance of the MFCs [165], [195], [196], [199].

Zirfon is another membrane used in MFC. It is an anion exchange membrane with 15 wt% of polysulfone and 85 wt% of ZrO2. Some studies have reported a good performance of its use. For example, Hernandez-Flores et al. [199] compared the performance of Nafion membrane 117 and Zirfon membrane in a SC-MFC, using leachate as substrate. The highest volumetric power (10,380 mW m−3) was obtained with the use of Zirfon membrane rather than the Nafion membrane. They attributed the low result using the Nafion membrane to the alkalinity of its substrate. Sevda et al. [200] compared Zirfon membrane and Fumasep membrane in an SC-MFC air cathode. And they also reported better performance with the use of Zirfon, measured through the maximum power density (424.5 mW −2). They attributed their results to the lower resistance observed with Zirfon compared with Fumasep. Even with these results, Zirfon is not a commonly used membrane in MFCs. Therefore, it is suggested to continue its evaluation with different scenarios (substrates, MFCs configurations, etc.) to be considered as a possible replacement for the Nafion membrane.

Other commercial membranes have also been used in MFCs, some examples of them and the main results obtained are shown in the Table 2. For example, Rabaey et al. [159] reported a power density of 3,600 mW m−2 and Hou et al [149] reported a power density of 2,143.0 mW m−2, both in MFC systems using Ultrex membrane. Mehravanfar et al. [131] reported a power density of 1,287.0 mW m−2, and Xiao et al. [153] reported a power density of 3,600.0 mW m−3 in MFC systems using Ultrex CMI 7,000 membrane international. Although the objectives of these studies were not to specifically evaluate the Ultrex membrane performance and its behavior in MFCs, it was possible to observe energy production equal to or higher than those reported in MFCs using Nafion membrane. Even though high energy production has been reported in MFCs using the Ultrex membrane, as well as with Zirfon membrane, the use of these membranes is still lower than the use of the Nafion membrane. Furthermore, these improvements, as well as those already mentioned with the Nafion membrane, cannot be attributed only to the use of the Ultrex membrane and more detailed studies are necessary to be conducted. Some of the strategies carried out by the scientific community to overcome the challenges of using commercial membranes (especially Nafion) in MFCs are membrane modification or the development of new membrane materials.

In the past years, other types of membranes have also been evaluated. For example J-cloth membrane, dynamic membrane, anion exchange membrane and ultrafiltration membrane. J-cloth membrane is a type of coarse pore filter, that can be configured with layers of cloth. This type of membrane has low ohmic resistance, reduces the oxygen diffusion and favors the ion transport. Even with some good results reported by Fan et al. [201] years ago, it is important to overcome the challenges of its use. For example, a disadvantage of this J-cloth membrane is the biodegradability of the cloth, making it difficult to work with for a long time. Li et al. [202] compared the performance of different membranes such as dynamic membrane, anion exchange membrane, cation exchange membrane, ultrafiltration membrane and J-cloth membrane. The dynamic membrane is composed of a nylon support which serves for the adhesion of filamentous bacteria and vorticellidae-like protozoa. The advantage of these microorganisms is that they reduce the oxygen transfer from the cathodic to the anodic chamber by consuming dissolved oxygen. In this study the use of the dynamic membrane presented the highest power density (3,377 mW m−3). In addition, another advantage was the low acquisition cost, compared to the other membranes. It is important to consider these results and evaluate its feasibility in other MFCs configurations.

Ceramic material with different composition has also reported in the development of low-cost membrane. Jadhav et al. [203] reported the use of a ceramic material as PEM, they reported that the main advantages of its use were the low manufacturing cost compared to the Nafion membrane acquisition cost. In addition, the clay membrane allowed the anodic potential to remain stable throughout the test in a DC-MFC with a sodium hypochlorite (NaOCl) catholyte. This behavior is due to the fact that the clay membrane prevents the free passage of anions from the cathodic to the anodic chamber, since the clay mineral provides a negatively charged surface. Hasani-Sadrabadi et al. [195] evaluated a ceramic material of a modified PEM in an MFC. The membrane was prepared based on montmorillonite, first a montmorillonite was organically modified with 2-acrylamido-d-methylpropanesulfonic acid (AMPS); then, the resulting product was incorporated into Nafion solution; finally, they evaluated its performance in an MFC. Their results showed a power density of 88.0 mW m−2 that was higher than the 39.0 mW m−2 for conventional Nafion 117 (Table 4). Das et al. [204] also used montmorillonite in a clayware ceramic membrane. They fabricated three different membranes, using 20% of montmorillonite then pre-treated each with acid, with neutral water and with alkali. This last membrane pre-treated with alkai showed the best performance of the MFCs compared to the other membranes. They obtained a maximum power density of 83.5 mW m−2, a COD removal of 88%, and a coulombic efficiency of 10.2%. These results indicate increased proton transport and decreased diffusion oxygen and substrate across the membrane. Daud et al. [194] also evaluated a ceramic material as PEM in an MFC. They used raw clay to fabricate a porous clay earthenware membrane in a DC-MFC with 16 mL of volume in each chamber, plain graphite felt anode, graphite felt cathode, synthetic wastewater, mixed consortium and a 100 Ω of external resistor. They reported a maximum power density of 2,250 mW m−2, a CE of 44%, and a COD removal of 99%. These results were higher than the obtained using Nafion 117 membrane, maximum power density of 650 mW m−2, a CE of 23 % and a COD removal of 91%. Cheraghipoor et al. [205] evaluated two ceramic membranes in a DC-MFC. They fabricated these membranes using leached and non-leached soil, and added different concentrations of silicon dioxide (SiO2) to each membrane. They reported that membrane porosity, as well as proton diffusion and conductivity, are properties that influence the performance of MFCs. These characteristics were favored in the membrane made from the leached soil, and the addition of SiO2 did not benefit this improvement. They obtained a low internal resistance of 52.81 Ω, a current density of 1,535 mA m−2, a power density of 20.18 W m−3 a coulombic efficiency of 83% and a COD removal of 93.1%. Like Raychaudhuri et al. [206] also evaluated a ceramic membrane modified with silica. They fabricated a clayware ceramic membrane and added different concentration of silica. Their results showed that using a membrane modified with 30% of silica improve the performance of the MFCs. They obtained a maximum power density of 791.72 mW m−3, a coulombic efficiency of 35.77% and a 76.2% COD removal. These results were attributed to reduced oxygen diffusion, and the increased proton transfer.

Table 4.

Membrane proton conductivity.

| Membrane | Proton conductivity (S cm−1) | Reference |

|---|---|---|

| Nafion AMPS-MMT | 0.0817 | [195] |

| Clayware-20%MT-alkali | 0.0179 | [204] |

| Nafion 117 | 0.0810 | [195] |

| Nafion 117 | 0.0900 | [160] |

| Nafion 117 | 0.0185 | [147] |

| TiO2/SiO2 | 0.0166 | [147] |

| Nanoscale polypyrrole | 0.0208 | [147] |

| SBC-600 | 0.0700 | [160] |

AMPS = 2-acrylamido-d-methylpropanesulfonic acid;

MMT = modified montmorillonite

The eco-friendly materials used to manufacture membranes is another line of research with high potential to be developed. An example of organic membrane material (biochar) was presented by Chakraborty et al. [160]. They reported a power density of 41.08 mW m−2 using a membrane (SBC-600) from food waste. First, they used the pyrolysis process at 600∘C, then, sulphonation from poly vinyl alcohol based matrix, and finally evaluated the SBC-600 performance in an MFC. Although lower power density values than the Nafion 117 membrane were obtained in this research, it was possible to develop a low-cost PEM.

Recently, the nanotechnology has also been used to enhance the PEM performance. Fan et al. [147] obtained a potential of 0.0173 V using internal nanoscale polypyrrole membrane, and also reported a higher proton conductivity using this membrane than the conductivity of Nafion membrane data included in their work (Table 4). However, if the conductivity of this nanoscale polypyrrole membrane is compared with the conductivity of Nafion 117 reported by other authors such as those in Table 4, nanoscale polypyrrole would be positioned as a low conductivity membrane. Therefore, further studies are required.

Regarding biofouling, this problem that can appear in the membrane as a thick layer of microorganism attached in the positively-charged surface of the PEM, which clog the membrane and limit the migration of () ions to the cathode. Recent solutions that were reported in the literature to overcome the biofouling include the development of biochar membrane materials. Chakraborty et al. [160] reported that the use of an SBC-600 membrane that provided a negative surface charge and hydrophilic nature matrix that can act as a protection against the biofouling.

The main limitation of commercial Nafion membrane is well known, its expensive acquisition cost which limits the feasibility of scaling up MFCs systems, while continues to lead as the most widely used membrane in MFCs, followed by the Ultrex membrane. This trend could be attributed to the fact that the properties of these commercial membranes favor the performance of MFCs to a greater extent. This can be observed in some studies that use DC-MFCs configurations and include these Nafion or Ultrex membranes. The results showed the highest energy yield values compared to studies using other membranes or in SC-MFCs without membrane (Table 2). However, these results cannot be attributed only to the type of membrane used, so further studies are needed to broaden the understanding of the effect obtained by the use of different commercial membranes on MFCs.

Regarding the use of alternative PEM, significant progress has been accomplished: i) the use of new membrane materials such as the biochar from food waste; ii) the use of nanotechnology such as nanoscale polypyrrole PEM; iii) the use of Zirfon membrane, j-cloth and dynamic membrane. iv) the use of ceramic materials such as montmorillonite, leached soil, silica and clay membrane. Even with the great efforts made, the gap between the efficiency obtained with new or modified membranes and commercial membranes is high. The main benefit identified by using alternative membranes is the low production cost compared to commercial membranes price. The montmorillonite membrane modified with 2-acrylamido-d-methylpropanesulfonic acid, reported one of the highest values of proton conductivity, 0.0817 S cm−1, followed by the SBC-600 membrane with 0.0700 S cm−1. And the clay membrane showed the highest power density of 2,250 mW m−2, which were higher than the results obtained with the Nafion membrane. Therefore, ceramic materials top the list of materials to develop competitive membranes with the greatest potential for low-cost, high-performance membranes.

5. Electron transfer mechanism

In MFCs systems, oxidation and reduction reactions take place here and the Oxidation-Reduction Potential (ORP) can be used to measure the intensity of the systems to accept electrons (reduce) or donate electrons (oxidize). The oxidation reaction is carried out by the anaerobic digestion of exoelectrogenic microorganisms (also called electroactive or electrogenic) attached to the anode [189]. These electroactive microorganisms obtain energy from the oxidation of a substrate that has a low redox potential and released or donated electrons. Electrons are transferred to the cathode through the external electrical circuit to be reduced by a final electron acceptor with a more positive redox potential [207].

An advantage in these systems is that microorganisms have the ability to regenerate and adapt easily to different environmental and substrate conditions. In the anode, microorganisms degrade substrates such as acetate, glucose, sucrose [208], domestic wastewater [209] (as expressed by Eq. (1), (2), (3) and (4), respectively), lactate, ethanol, synthetic wastewater, animal wastewater, and food waste, then the resulting products are carbon dioxide, electrons, and protons. In the cathode, oxygen (the most widely used electron acceptor due to its high redox potential of 1.229V) is reduced by protons and electrons to form water [76], [108], [127], [166], [210].

| (1) |

| (2) |

| (3) |

| (4) |