Abstract

Polyolefins are formed by the polymerization of olefin monomer units such as ethylene, styrene, and vinyl chloride. Polyolefins composites are a mixture of polyolefins with different types of other polymers, reinforcements, or fillers. Blending neat polyolefins with composites widens its uses in various applications that require high efficiency in the areas of environmental degradation, impact resistance, fire and chemical resistance, or strength. In this review, the effects of blending neat polyolefin with other types of polymers or wood fibers on the properties of neat polymers have been represented. Moreover, this review reveals the importance of a coupling agent or compatibilizer in the improvement of the polyolefin’s compatibility with the other added components.

Keywords: High-density polyethylene, Polystyrene, Polyvinyl chloride, Polymer blending, Polymer composites

High-density polyethylene; Polystyrene; Polyvinyl chloride; Polymer blending; Polymer composites.

1. Introduction

Polymer blending is a cheap way to innovate new materials that have the advantageous properties of more than one polymer and get materials with improved properties and cost. This process needs to utilize appropriate compatibilizers to enhance the difficult polymers’ dispersion in each other and to avoid the phase separation that occurs under stress due to their immiscibility and incompatibility [1, 2, 3].

Compatibilizers are always added in a concentration range of 2–5 wt.% during the manufacturing process. During the manufacturing process, the melting point is an essential factor that enables the polymers to flow easily in the extruder. Mao et al. [4] proved that if a mixture consisted of more than one polymer type, the processing temperature should have been above any polymer’s melting point to avoid the thermal degradation of that polymer which led to weakness in the mechanical properties. Mixing immiscible polymers have various types of morphologies depending on components, viscosity ratio between the ingredients, interfacial tension, elasticity, and the conditions of the processing [5, 6].

Polyolefins and wood flour (WF) or fiber have poor compatibility with each other due to the non-polar hydrophobic nature of the polyolefins which interferes with the polar hydrophilic nature of the wood [3]. Therefore, a coupling agent or compatibilizer is necessary to ensure a homogeneous mixture [7]. Compatibilizer such as maleic anhydride is fundamental to making a crosslinking structure on the surface of wood, enhancing the compatibility of polymer wood composites via grafting the polymer matrix onto wood [8].

Wood-plastic composites (WPCs) represent considerable merits like higher durability, absorbing lower humidity, requiring less maintenance, and having higher resistance to fungi activities when exposed to water since WPCs absorb lower amounts of water [9, 10]. Sun et al. [11] stated that it was suitable for wood-plastic composites (WPC) manufacturing to utilize polymer that had a melting point lower than wood degradation temperature (200 °C). Hence, the mixing temperature should be less than 200 °C which is compatible with many types of polymers as shown in Table 1 that can form good mixtures with wood. Despite polystyrene’s high melting temperature (240 °C), it can form a suitable mixture with WF at a mixing temperature lower than 200 °C [12, 13].

Table 1.

Melting points of different polymers.

| Polymer | Melting point (°C) |

|---|---|

| HPDE | 130 |

| PS | 240 |

| LLDPE | 123 |

| PP | 170 |

| PVC | 180 |

Polymer compounding has been improved for enormous piping applications such as chemical-resistant trim, exterior body trim and molding, tubing, hoses, gear shifter knobs, and interior console covers [14, 15]. Polymer compounding has been utilized extensively in a wide range of construction products for more than 50 years such as [16]: Window seals, drywall accessories, weather-strip, and screen spline, flooring, roofing, concrete water stops, weatherable cap stock for exterior trim, and electrical insulators. Moreover, polymers compounds are also utilized in medical applications for more than 50 years due to their safety, low cost, chemical stabilization, and biocompatibility [14, 15].

In this review, different polymer mixtures with wood and other types of polymers have been represented and the effects of mixing wood fiber on the mechanical properties of polyolefins have been investigated.

2. Polystyrene—wood fiber blend

Wood fiber is a hydrophilic material owing to the presence of hydroxyl groups, however, polystyrene (PS) is a non-polar hydrophobic material, leading to poor compatibility between PS and wood fiber. Ferraz et al. [17] evaluated the suitability of wood fibers for general-purpose polystyrene in the existence of coupling agent isocyanate. The usage of coupling agents such as isocyanate was fundamental to boosting the mechanical properties of wood-polystyrene composites. The mixing temperature between 175-190 °C represents the best mechanical properties enhancement. Table 2 represents the enhancement of the polystyrene mechanical properties after adding the wood fiber [18]. The results revealed that adding wood fiber up to 30 wt. % improves the stress, above this amount, the stress decreases. For elongation, it decreases with raising the amount of wood fiber, while the modulus increases proportionally with the wood fiber amount.

Table 2.

The influence of blending the wood fiber with polystyrene on the mechanical properties.

| Fiber content (wt.%) | Stress (MPa) | Elongation (%) | Modulus (10 −2 MPa) |

|---|---|---|---|

| 0 | 34.2 | 2.6 | 15.9 |

| 10 | 37.5 | 2.8 | 16.5 |

| 20 | 37.7 | 2.5 | 18.8 |

| 30 | 39.1 | 2.4 | 20.1 |

| 40 | 38.6 | 2.2 | 21.5 |

Kosonen et al. [19] revealed that hydrophilic-hydrophobic block copolymers such as polystyrene-block-poly (styrene-co-methacrylic acid) can be utilized to improve the PS and WF compatibility by producing hydrophobic coatings on the wood surfaces. The results proved better mechanical properties such as yield strength, ultimate stress, and ultimate strain of the WF coated with polystyrene-block-poly (styrene-co-acrylic acid) than the uncoated one. These testimonies evidence that subjecting block copolymers on wood surfaces can produce a homogenous mixture with better mechanical properties of wood-thermoplastic composites in a manner that is both economic and environmentally friendly [19, 20].

3. High-density polyethylene-wood blend

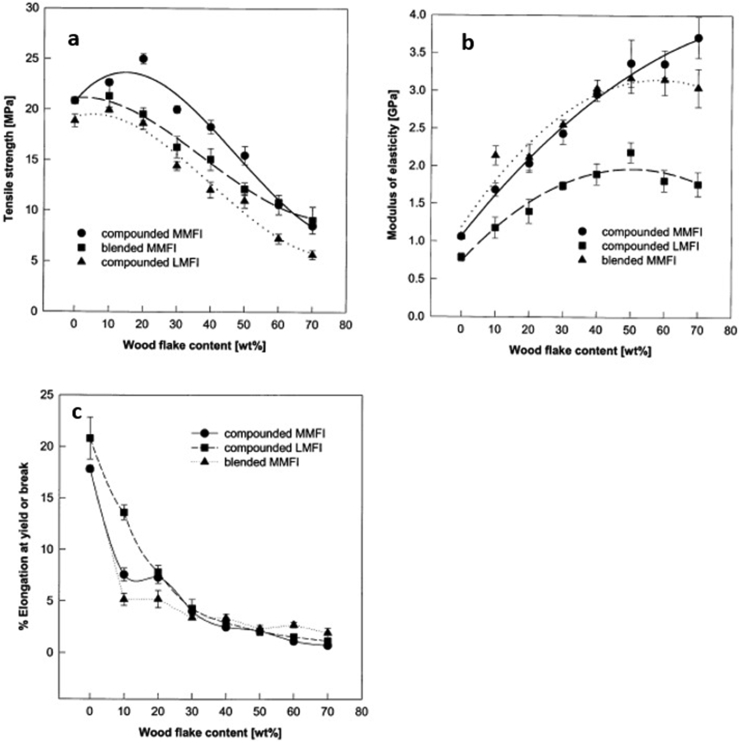

Wood fibers could not mix readily with non-polar polyolefins such as high-density polyethylene (HDPE). The tensile strength decreases and the modulus of elasticity increases for the HDPE/Wood blend with raising the wood content because of the weak dispersion of wood during the blending fabrication as shown in Fig. 1a, b, and c.

Figure 1.

Influence of the wood fiber weight percentage on the mechanical properties of wood HDPE composites. (a) tensile strength, (b) modulus of elasticity, and (c) elongation at yield or break [21].

Consequently, a compatibilizer such as stearic acid is utilized to improve the fiber dispersion in the HDPE and enhance the mixture properties [22, 23]. Moreover, maleated polyethylene (MAPE) or maleic anhydride grafted–polyethylene (MA-g-PE) is exceedingly utilized as a coupling agent in HDPE-wood composites [24].

Kalmegh [25] inspected the influence of WF particle size on the mechanical properties of the wood-HDPE mixture. The wood polymer composite (WPC) was synthesized by mixing HDPE (30 wt.%) with wood (70 wt.%) at a temperature of 185 °C in presence of maleic anhydride polypropylene (MAPP) as a compatibilizer. The wood’s two-particle sizes were 40 and 80 mesh. The study revealed that the modulus of elasticity (MOE), modulus of resilience (MOR), and maximum tensile strength (MTS) increased by raising the particle size from 40 to 80 mesh.

John Z. Lu et al. [26] evidenced that the coupling agent type has a great influence on the homogeneity of the wood fiber-HDPE composites. They reported that MAPE achieved better improvement in the WPC than the oxidized polyethylene (OPE) as a result of its stronger interfacial bonding [27]. The coupling agents of high molecular weight and moderate acid number are used at low concentration amounts to strengthen the interfacial adhesion in the polyolefin blends since the interfacial bonding strength is directly proportional to the coupling agent’s molecular weight [28].

Table 3 shows the mechanical and physical properties of different coupling agents [26]. From Table 3, the MAPE has a higher molecular weight than OPE, therefore, it shows better adhesion strength and interfacial properties.

Table 3.

Properties of coupling agent.

| Coupling agent | Density (Kg/m3) | MW (g/mol) | Acid number (KOH/g) | Tensile strength (MPa) | Storage modulus (GPa) |

|---|---|---|---|---|---|

| MAPE | 960 | 59700 | 6 | 22.55 | 4.09 |

| OPE | 960 | 7500 | 17 | 19.46 | 3.39 |

Lu et al. [29] stated that the process parameters affect the mixing process. The optimum parameters for the wood-HDPE blends were 10 min mixing time at a temperature of 180 °C and 60 rpm for the one-step process using a rotor mixer. For the mixing speed of 90 rpm, the optimum operating conditions were 10 min mixing time at a temperature of 165 °C. Therefore, a short mixing time with proper mixing temperature at a moderate mixing speed enhanced the compatibility of the mixture and the mechanical properties of the composite.

Hao et al. [30] utilized nano cellulose (NC) as a reinforced filler on the PE as a result of the lightweight, high mechanical properties, and aging-resistant properties of NC. It was proven that adding NC enhances the mechanical properties and environmental friendliness of PE. The new composites of NC/PE can be used in many applications like automotive components, home appliances, aerospace, building, furniture, and sports equipment.

4. High-density polyethylene-polystyrene blend

The high-density polyethylene-polystyrene blend is formed by joining polyethylene and polystyrene mixtures together under high heat and pressure levels to form solid planks, beams, or sheets. In many cases, colorants are added to give a more brilliant and attractive appearance [31]. These colors are incorporated into the composition of the material for long-lasting protection from removal by breaking or chipping. Moreover, a high-density polyethylene-polystyrene blend composite can be painted to obtain the desired finish. Also, it can be produced with reliefs to the better mimic appearance of the wood and can be coated with layers of material resistant to ultraviolet rays to prevent discoloration due to sunlight.

The creep resistance of the PS/HDPE blends has been increased by increasing the PS content. The PS/PE ratios (50:50) and (75:25) represented a higher creep resistance than 100% PS or 100 % PE [32, 33]. Ratanakamnuan and Aht-Ong [34] recorded depression in both tensile strength and elongation at break (EB) by increasing the PS/HDPE ratios. This may be due to the absence of compatibility between the hydrophilic and hydrophobic blend ingredients, leading to phase separation. Wei et al [35] stated that the addition of polyethylene-graft-maleic anhydride as a coupling agent increased the homogeneity, tensile strength, the elongation at break, and elasticity modulus of the composite.

5. High-density polyethylene-polystyrene-wood fiber blend

Chuayplod et al. [36] evaluated the addition of wood fiber filler to the high-density polyethylene-polystyrene blend (65% PE - 35% PS) at 190 °C. The results proved that the stiffness and brittleness of the PE/PS blend have been increased by adding the wood filler.

Generally, wood polymer composites have higher resistance to rot, greater dimensional stability, and higher resistance to environmental factors such as rain and temperature. In addition, wood polymer composites are stiffer than polymers alone [36, 37]. The contradiction in hydrophilic-hydrophobic properties of wood and most polymers respectively prevent the good mixing required for the dispersion of wood in polymers and destroys the properties of the polymer [38, 39].

Xu et al. [23] explored the influence of adding PS to HDPE at percentages of (100:0, 75:25, 50:50, 25:75, 0:100). They also investigated the influence of adding WF at dosages from 10 to 40 wt.% at different ratios of PS to HDPE. They proved that MOE increased by raising the WF and PS content due to the higher MOE of PS. The ultimate stress increased by raising WF content for the blends of the high amount of HDPE but up to 30 wt.% of WF. The higher WF amounts decreased the properties because of the weak dispersion of WF.

The ultimate stress is depressed by increasing the WF amount for the blends of high PS amounts. This is owing to the that PS has brittle fracture mechanics. Increasing the WF content decreases the ultimate stress and changes the type of the fracture from yield one to brittle stress. Therefore, a coupling agent is required to enhance the interaction between PS/WF and HDPE/WF composite systems [40, 41]. The appropriate coupling agent used in this mixture is MAPE.

6. Polystyrene/calcium carbonate

Calcium carbonate or limestone (CaCO3) is a known compound found in the form of rocks. In Egypt, CaCO3 is extracted from the stone pit in Giza. Moreover, it is extracted from snails’ shells, pearls, and eggshells as well because it is their main ingredient of them. Limestone has the advantages of low viscosity and high thermal conductivity and produces a high homogenous mixture with good dispersion in the polymer matrix [42, 43, 44, 45, 46].

Wu et al. [45] recorded that the toughness of PS increased with the addition of 1 wt.% CaCO3 of particles size (55 nm, 70 nm, 10 μm) and the impact strength increased by 52, 95, and 190%, respectively. The scanning electron microscope proved that the best complete dispersion of CaCO3 particles was achieved at 1 wt.%.

7. High-density polyethylene-calcium carbonate

Tanniru et al. [46] revealed that the addition of CaCO3 to HDPE increased the crystallinity, modulus, and impact strength. Table 4 shows the physical and mechanical properties of calcium carbonate reinforced high-density polyethylene composites. The crystallinity was raised by adding CaCO3 as it increased from 47 to 53% by adding 5 wt.% of CaCO3. Moreover, both yield stress and modulus are also increased by adding CaCO3. The excess of CaCO3 amount raises the stress, modulus, and crystallinity. While the melting temperate is affected slightly. Figure 2 represents the impact strength for 20% CaCO3/HDPE at different temperatures. The results proved that the impact strength is improved greatly by adding CaCO3.

Table 4.

The properties of HDPE/CaCO3 composite.

| Crystallinity (%) | Melting temperature (°C) | Modulus at 50 mm/min (MPa) | Yield stress at 50 mm/min (MPa) | |

|---|---|---|---|---|

| PE | 43 | 133 | 1050 | 24 |

| PE/5% CaCO3 | 53 | 137 | 1190 | 26 |

| PE/10% CaCO3 | 57 | 136 | 1365 | 27 |

Figure 2.

The Impact strength vs temperature for HDPE-CaCO3 composite [46].

Table 5 shows the tensile properties of HDPE/CaCO3 blends at room temperature with an initial deformation rate of 1.67 10−2 S−1 [47]. Young’s modulus increased gradually by increasing the CaCO3 amount. Yield stress, strain, elongation at break, and stress at break have an inverse relation with the CaCO3 amount.

Table 5.

Mechanical properties of HDPE/CaCO3 blends at an initial deformation rate of 1.67 10−2 S−1

| Vol.% | Young’s Modulus (Mpa) | Yield Stress (Mpa) | Yield Strain (Mpa) | Stress at break (Mpa) | Elongation at break (Mpa) | |

|---|---|---|---|---|---|---|

| HDPE | 100:0 | 756 | 24.9 | 11.5 | 14.5 | 730 |

| HDPE/CaCO3 | 90:10 | 896.8 | 21.9 | 10.3 | - | 319 |

| 80:20 | 1235 | 19.6 | 7.6 | - | 36 | |

| 75:25 | 1274 | 18.8 | 7.8 | 11.7 | 64 | |

| 70:30 | 1806 | 15.6 | 3.3 | 11.8 | 10 |

Figure 3 shows the schematic of the extent of initiation and propagation zones as a function of temperature in neat PE and 20% CaCO3-PE [48]. The initiation zone increased by adding HDPE, while the propagation zone depressed.

Figure 3.

Schematic of the extent of initiation and propagation zones vs temperature in (a) neat PE and (b) 20% CaCO3—PE composite [46].

8. High-density polyethylene-poly vinyl chloride blend

Pure polyvinyl chloride (PVC) is a white, brittle material and it is the third-largest polymer produced after polyethylene and polypropylene as its production rate is 40 million tons yearly. The basic structure of PVC is (C2H3Cl)n and it has been produced by polymerization of the vinyl chloride monomer (VCM) with a polymerization degree ranging from 300 to 1500. The chlorine content in PVC is about 57% by weight, which makes it less dependent on hydrocarbon content [49, 50].

There are two categories of PVC which are rigid and flexible. The rigid PVC type does not contain plasticizers and is used in construction activities. Whereas the flexible type is fabricated by adding plasticizers to the rigid form. Rigid PVC is a very important type of PVC as it is used in building construction, piping, signs, roofing sheet material, and other products [51]. The flexible types of PVC are used as an alternative to rubber and are applied in plumbing, electrical cable insulation, imitation leather, flooring, manufacturing of clothing, footwear/boot grades, upholstery, and electrical and cable compounds [38, 52, 53]. PVC is a thermoplastic with low thermal stability, hence, the use of PVC polymer is limited in the industry that requires high temperature [54, 55].

Neat PVC polymer is not a flexible compound with commercial restrictions. In addition, the processing of PVC as a neat raw material at high temperatures and pressure contributes to the severe breakdown of the PVC structure. Therefore, before using PVC, it should be treated with suitable additives. The most pivotal additives are fillers, processing aids, impact modifiers, pigments, plasticizers, heat stabilizers, and lubricants [56, 57]. The additives are effective for enhancing the mechanical, thermal, color, clarity, light, and electrical properties of PVC. The additives are blended with the PVC via a compounding process [54, 58].

The PVC resins are classified by the K-value, which points to the polymerization degree and the molecular weight [59]. PVC that has a K-value of 57 is a low molecular weight type and it is used in bottles, blow sheets, packaging films, and injection shapes. whereas PVC which has a K-value of 70–75 is a high molecular weight type and has the advantage of high mechanical properties, however, it is processed difficultly. This type of PVC can be utilized for flooring, pipes, rigid parts, high-performance cables, and profiles. Plastisols or latex is the emulsion PVC that can be utilized in special applications such as multilayer films, coatings, and battery separators [60, 61].

Blends of immiscible polymers represent different kinds of morphologies that depend on the viscosity ratio, composition, interfacial tension, elasticity ratio between the components, and process conditions [62]. Table 6 shows the difference between HDPE and PVC properties [63, 64].

Table 6.

The difference between HDPE and PVC properties.

| Property | HDPE | PVC |

|---|---|---|

| Acid resistance | Excellent | Good |

| Alkali resistance | Excellent | Good |

| Chlorinated hydrocarbon resistance | Very Good | Poor |

| Ultimate tensile strength | >4,000 psi | <2,300 psi |

| Ultimate tensile elongation | >700% | <500% |

| Crosslinking due to UV | No | Yes, and causes cracking |

| Low-temperature brittleness | < -90 °C | -40 °C |

| Permeability | <1 × 10−12 cm·s−1 | 1 × 10−10 cm·s−1 |

Thongpin et al. [65] explored the mechanical properties and melt flow indexes (MFI) of different content PVC-PE composites. By investigating the structure and thermal degradation of the composites, it has been recorded that the addendum of PE led to higher thermal stability for the neat PVC and raised the PVC decomposition temperature. At high PE content (more than 50%), the PVC exhibits higher degradation properties because PE radicals consume the heat stabilizer additives. The content of PE has a high influence on the PVC properties and structure. Whereas the MFI does not affect the PVC properties and structure. The PE dispersion in the PVC phase has a crucial role in the properties of the PVC-PE mixtures. Therefore, a coupling agent like chlorinated is important to increase the homogeneity of the PVC-PE composite.

Abdomohammadi et al. [66] revealed that adding PE to the PVC blend (50% HDPE and 50% PVC) has a significant change in the PVC structure since the mechanical properties of PVC decreased gradually. Tables 7 and 8 represent the mechanical properties of PVC/HDPE (5 MFI HDPE) and PVC/HDPE (20 MFI HDPE), respectively [67]. Adding HDPE to the PVC decreases the decomposition temperature slightly and nearly does not affect the glass transition temperature (GTT). The addition of HDPE depresses greatly the young modulus, yield stress, elongation at break, and impact strength.

Table 7.

Mechanical properties of PVC/HDPE (5 MFI HDPE).

| HDPE (%) | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Decomposition temperature (°C) | 317 | 320 | 319 | 317 | 316 | 314 | 315 |

| GTT (°C) | 82.5 | 81.5 | 81.5 | 82 | 82.5 | 82.7 | 82 |

| Young modulus (MPa) | 950 | 960 | 950 | 900 | 900 | 900 | 850 |

| Yield stress (MPa) | 49 | 47 | 40 | 35 | 30 | 28 | 24 |

| Elongation at break (%) | 40 | 32.5 | 12.5 | 10 | 9 | 8.5 | 5.5 |

| Impact strength (kJ.m−2) | 88 | 100 | 78 | 10 | 5 | 5 | 5 |

Table 8.

Mechanical properties of PVC/HDPE (20 MFI HDPE).

| HDPE (%) | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Decomposition temperature (°C) | 317 | 325 | 321 | 318 | 314 | 316 | 319 |

| GTT (°C) | 82.5 | 80.5 | 80.5 | 81.2 | 81.5 | 81.7 | 82 |

| Young modulus (MPa) | 950 | 900 | 875 | 790 | 785 | 784 | 782 |

| Yield stress (MPa) | 49 | 42.5 | 38 | 34 | 30 | 25 | 24 |

| Elongation at break (%) | 40 | 30 | 12.5 | 13 | 8 | 5.5 | 5 |

| Impact strength (kJ.m−2) | 88 | 84 | 68 | 9 | 6 | 5 | 4 |

9. Wood fiber-poly vinyl chloride blend

Owing to the hydrophilic properties of WF and hydrophobic properties of PVC, the dispersion of wood in the PVC is weak [68]. WF/PVC is a novel composite, made by adding WF to the PVC in the presence of a coupling agent due to the absence of interfacial modifiers [69]. It is exceedingly utilized in the applications of building and construction fields such as decking, fencing, and lineal windows or doors. Furthermore, it is also utilized in automotive, marine, consumer goods, and a variety of other products [70].

Maleic anhydride can be utilized as a compatibilizer for the WF-PVC composite as it reacts with the hydroxyl groups (OH) of wood and cellulosic materials by esterification. Therefore, it decreases the WF hydrophilic characteristic and enhances the compatibility between WF and PVC [71]. Silane is an essential coupling agent in the plastics industry since it can join the inorganic fillers to the polymer matrix [72]. Hydrolysis of silane coupling agent leads to produce silanol that can react with the hydroxyl group of WF to form stable covalent bonds as shown in Figure 4a. To increase the silanes reactivity, vinyl, mercapto, and azido groups were introduced onto the WF surface in presence of alkaline medium such as sodium hydroxide (KOH) as a catalyst as shown in Figure 4b. The results proved that the reactivity of silanes increased in the order vinyl-silane, azido-silane to mercapto-silane [73].

Figure 4.

Surface hydrophobization of WF using silanization modification. a) mechanism of silanization modification; b) silanization procedures [73].

Maleated polypropylene (MAPP) and poly methylene-polyphenyl isocyanate (PMPPIC) are the best compatibilizers for the WF-PVC composite [8, 71]. Lubricants, dyes, impact modifiers, and thermal stabilizers are other additives that could be used for the WF-PVC bonding [74, 75]. These additives are required to improve the mechanical properties of the manufactured composites [76].

Lubricants, such as metallic stearates, fatty acids, and waxes, are utilized in WF/PVC composites to facilitate wood dispersion, and to increase the processing output of extrusion. It can provide good overall processing characteristics and significantly inhibit edge tear and melt fracture when combined with suitable impact modifiers [71, 77]. The mechanical properties of WF/PVC composites are affected by the WF content and particle size. Generally, increasing the WF content increases modulus but reduces the stress at break [78, 79]. Table 9 compares the mechanical and physical properties of WF/PVC composites and other wood composites [80]. The best properties of the polyolefin and wood fiber are WF/PVC as it provides the highest flexural strength and flexural modulus.

Table 9.

Mechanical and physical properties for PVC/WF composites and other wood composites.

| Properties | PVC/WF | HDPE/WF | PP/WF |

|---|---|---|---|

| Flexural strength (MPa) | 42 | 19.6 | 47.9 |

| Flexural modulus (GPa) | 5.2 | 3.8 | 3.3 |

| Water absorption (%) (D1037) | 1.3 | 0.7 | 1.1 |

Fang et al. [78] reported that adding the WF to the PVC improved the thermal degradation, the weight loss rate, and the smoke release rate. Cong et al. [81] explored the thermal degradation mechanism, fire resistance, and mechanical properties of WF/PVC. Thermogravimetric analysis (TGA) tests proved that adding WF significantly improved the thermal degradation behavior of PVC since WF decreased the initiation temperature for thermal degradation of PVC and delayed the thermal decomposition of PVC in the early stage. Fourier transform infrared (FTIR) was utilized to detect the mechanism of thermal decomposition. It was found that there is a decrease in C–H bonds and an increase in C=C bonds as WF promoted the crosslinking and charring reactions of PVC. According to the cone calorimetry (CONE) tests, WF had a positive influence on the fire performance of PVC but had little effect on smoke suppression [81]. Table 10 summarizes the effect of adding wood to different polyolefin types [82, 83].

Table 10.

An overview of the influence of adding wood to different polyolefin types.

| Wood/PVC | Wood/PE | |

|---|---|---|

| Usage | Used in building and construction fields such as decking, fencing, and lineal windows or doors. It is also used in automotive, marine, consumer goods, and a variety of other products. |

Used as compatibilizers in HDPE/wood composites. |

| Examples and functions of used coupling agent |

|

|

| The composite advantages | The composite decreases the thermal degradation temperature, the mass-loss rate, and the smoke release rate more than that of PVC. | The composite has better performance due to its stronger interfacial bonding. |

10. Mixing processes

10.1. Compounding mixing

Compounding mixing (dry blending) includes using a strong high-speed mixer that mixes all the components to produce powder [38, 39].

10.2. Extruder mixing

Extruder mixing includes mixing the ingredients with a low or high-speed extruder mixer, then the mixture is transferred to melt the mixture by heaters. The mixture is cooled and cut into granules for processing [84, 85]. Figure 5 represents the extruder components.

Figure 5.

Extruder components.

11. Conclusion

This paper reveals the importance of polymers compounds in our lives owing to their uses in many applications from bags, bottles, toys, and televisions, to fashion, construction, petroleum pipes, and medical applications.

Blending polymers with other types of polymer or fibers enhances the properties of polymers and widens the uses of the polymer blend. The polymer blend should be performed with limits as the excess polymer or fiber might lead to the deterioration of the original polymer properties. Coupling agents or compatibilizers are essential additives as they improve the WF dispersion in the polymer matrix, hence they can unify the final properties and shape. There are many types of compatibilizers used in the polymer blend such as silane, and maleic anhydride. Much research is required to improve the polymer blending industry.

Declarations

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Garza-Montelongo E., Pérez-Rodríguez N.A., Sánchez-Anguiano M.G., Rivas-Quiroz B., Elizondo-Martínez P. Molecularly imprinted polymer for the binding and recognition of basic blue 41 dye. J. Chil. Chem. Soc. 2021;66(2):5215–5219. [Google Scholar]

- 2.Ghaderi J., Hosseini S.F., Keyvani N., Gómez-Guillén M.C. Polymer blending effects on the physicochemical and structural features of the chitosan/poly (vinyl alcohol)/fish gelatin ternary biodegradable films. Food Hydrocolloids. 2019;95:122–132. [Google Scholar]

- 3.Balzade Z., Sharif F., Anbaran S.R.G. Alkenes-Recent Advances, New Perspectives and Applications. IntechOpen; 2021. Extending alkenes’ value chain to functionalized polyolefins. [Google Scholar]

- 4.Mao K., Greenwood D., Ramakrishnan R., Goodship V., Shrouti C., Chetwynd D., Langlois+ P. The wear resistance improvement of fibre reinforced polymer composite gears. Wear. 2019;426:1033–1039. [Google Scholar]

- 5.Hammani S., Moulai-Mostefa N., Samyn P., Bechelany M., Dufresne A., Barhoum A. Morphology, rheology and crystallization in relation to the viscosity ratio of polystyrene/polypropylene polymer blends. Materials. 2020;13(4):926. doi: 10.3390/ma13040926. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Ajitha A., Thomas S. Compatibilization of Polymer Blends. Elsevier; 2020. Introduction: polymer blends, thermodynamics, miscibility, phase separation, and compatibilization; pp. 1–29. [Google Scholar]

- 7.Quitadamo A., Massardier V., Valente M. Eco-friendly approach and potential biodegradable polymer matrix for WPC composite materials in outdoor application. Int. J. Polym. Sci. 2019 [Google Scholar]

- 8.Anbupalani M.S., Venkatachalam C.D., Rathanasamy R. Influence of coupling agent on altering the reinforcing efficiency of natural fibre-incorporated polymers–a review. J. Reinforc. Plast. Compos. 2020;39(13-14):520–544. [Google Scholar]

- 9.Kuo P.-Y., Wang S.-Y., Chen J.-H., Hsueh H.-C., Tsai M.-J. Effects of material compositions on the mechanical properties of wood–plastic composites manufactured by injection molding. Mater. Des. 2009;30(9):3489–3496. [Google Scholar]

- 10.Najafi S.K. Use of recycled plastics in wood plastic composites–A review. Waste Manag. 2013;33(9):1898–1905. doi: 10.1016/j.wasman.2013.05.017. [DOI] [PubMed] [Google Scholar]

- 11.Sun H., Cao W., Zang N., Clemons T.D., Scheutz G.M., Hu Z., Thompson M.P., Liang Y., Vratsanos M., Zhou X. Proapoptotic peptide brush polymer nanoparticles via photoinitiated polymerization-induced self-assembly. Angew. Chem. 2020;132(43):19298–19304. doi: 10.1002/anie.202006385. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Painter P.C., Coleman M.M. Routledge; 2019. Fundamentals of Polymer Science: an Introductory Text. [Google Scholar]

- 13.Elgharbawy A.S. A review on high density poly ethylene as engineering polymer. Quaestus. 2021;18:455–459. [Google Scholar]

- 14.Deep A., Bhatt D., Shrivastav V., Bhardwaj S.K., Malik P. Sustainable Polymer Composites and Nanocomposites. Springer; 2019. Synthesis, characterization and applications of polyolefin based eco-friendly polymer composites; pp. 65–103. [Google Scholar]

- 15.Jubinville D., Esmizadeh E., Saikrishnan S., Tzoganakis C., Mekonnen T. A comprehensive review of global production and recycling methods of polyolefin (PO) based products and their post-recycling applications. Sustain. Mater. Technol. 2020;25 [Google Scholar]

- 16.Grigsby W.J., Torayno D., Gaugler M., Luedtke J., Krause A. Chemical imaging of the polylactic Acid− wood adhesion interface of bonded veneer products. Fibers. 2022;10(2):17. [Google Scholar]

- 17.de Almeida Monteiro Melo Ferraz M., Henning H.H., Ferreira da Costa P., Malda J., Le Gac S.v., Bray F., Van Duursen M.B., Brouwers J.F., Van De Lest C.H., Bertijn I. Potential health and environmental risks of three-dimensional engineered polymers. Environ. Sci. Technol. Lett. 2018;5(2):80–85. doi: 10.1021/acs.estlett.7b00495. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Doroudiani S., Kortschot M.T. Expanded wood fiber polystyrene composites: processing–structure–mechanical properties relationships. J. Thermoplast. Compos. Mater. 2004;17(1):13–30. [Google Scholar]

- 19.Kosonen M.L., Havukainen M.L. 2012. Sairaanhoitajien Kokemuksia Lääkehoidon Uudesta Toimintaohjeesta Espoon Sairaalassa. [Google Scholar]

- 20.Poletto M., Dettenborn J., Zeni M., Zattera A.J. Characterization of composites based on expanded polystyrene wastes and wood flour. Waste Manag. 2011;31(4):779–784. doi: 10.1016/j.wasman.2010.10.027. [DOI] [PubMed] [Google Scholar]

- 21.Balasuriya P.W., Ye L., Mai Y.W. Mechanical properties of wood flake-plyethylene composites. Part I: effects of processing methods and matrix melt flow behaviour. Compos. Appl. Sci. Manuf. 2001;32(5):619–629. [Google Scholar]

- 22.Hanif M., Supri A., Firuz Z. Applied Mechanics and Materials. Trans Tech Publ; 2014. Effect of wood fiber treated with salicylic acid/ethanol on tensile properties and thermal stability of recycled high density polyethylene/wood fiber composites. [Google Scholar]

- 23.Xu B. 1999. Studies of Polystyrene (PS) High Density Polyethylene (HDPE) and PS/HDPE/wood Composites from an Extrusion Process: Mechanical Properties, Rheological Characterization and Morphology. [Google Scholar]

- 24.Savas L.A., Tayfun U., Dogan M. The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos. B Eng. 2016;99:188–195. [Google Scholar]

- 25.Kalmegh S. Analysis of weka data mining algorithm reptree, simple cart and randomtree for classification of indian news. Int. J. Innovat. Sci. Eng. Technol. 2015;2(2):438–446. [Google Scholar]

- 26.Lu J.Z., Wu Q., McNabb H.S. Chemical coupling in wood fiber and polymer composites: a review of coupling agents and treatments. Wood Fiber Sci. 2000;32(1):88–104. [Google Scholar]

- 27.Lu J.Z., Wu Q., Negulescu I.I. Wood-fiber/high-density-polyethylene composites: coupling agent performance. J. Appl. Polym. Sci. 2005;96(1):93–102. [Google Scholar]

- 28.Mohanty A.K., Vivekanandhan S., Pin J.-M., Misra M. Composites from renewable and sustainable resources: challenges and innovations. Science. 2018;362(6414):536–542. doi: 10.1126/science.aat9072. [DOI] [PubMed] [Google Scholar]

- 29.Lu J., Wu Q., Negulescu I. Wood-fiber/high-density-polyethylene composites: compounding process. J. Appl. Polym. Sci. 2004;93(6):2570–2578. [Google Scholar]

- 30.Hao W., Wang M., Zhou F., Luo H., Xie X., Luo F., Cha R. A review on nanocellulose as a lightweight filler of polyolefin composites. Carbohydr. Polym. 2020;243 doi: 10.1016/j.carbpol.2020.116466. [DOI] [PubMed] [Google Scholar]

- 31.Jiang Y., Mi D., Wang Y., Wang T., Shen K., Zhang J. Insight into understanding the influence of blending ratio on the structure and properties of high-density polyethylene/polystyrene microfibril composites prepared by vibration injection molding. Ind. Eng. Chem. Res. 2018;58(3):1190–1199. [Google Scholar]

- 32.Dobrovszky K., Ronkay F. Investigation of compatibilization effects of SEBS-g-MA on polystyrene/polyethylene blend with a novel separation method in melted state. Polym. Bull. 2016;73(10):2719–2739. [Google Scholar]

- 33.Wu L., Zhu J., Liao X., Ni K., Zhang Q., An Z., Yang Q., Li G. Effect of confinement on glass dynamics and free volume in immiscible polystyrene/high-density polyethylene blends. Polym. Int. 2015;64(7):892–899. [Google Scholar]

- 34.Chuayplod P., Aht-Ong D. A study of microcrystalline cellulose prepared from parawood (Hevea brasiliensis) sawdust waste using different acid types. J. Met. Mater. Miner. 2018;28(2) [Google Scholar]

- 35.Tang G., Zang Z., Huang W., Huang J., Wang D., Wei G., Mi W. The oxidation of carbon fiber on the interlaminar shear strength and tribological properties of high-density polyethylene composites. J. Thermoplast. Compos. Mater. 2014;27(5):586–593. [Google Scholar]

- 36.Wei X., Lu Y., Huang L. Mechanical properties and morphology of UHMWPE/PC/HDPE-g-MAH blends. Polym.-Plast. Technol. Eng. 2011;50(2):190–195. [Google Scholar]

- 37.Zhao Y., Lu Z., Yao H., Zhang J., Yuan X., Cui Y., Nie Y. Development and mechanical properties of HDPE/PA6 blends: polymer-blend geocells. Geotext. Geomembranes. 2021;49(6):1600–1612. [Google Scholar]

- 38.Boyle D., Catarino A.I., Clark N.J., Henry T.B. Polyvinyl chloride (PVC) plastic fragments release Pb additives that are bioavailable in zebrafish. Environ. Pollut. 2020;263 doi: 10.1016/j.envpol.2020.114422. [DOI] [PubMed] [Google Scholar]

- 39.Farjami M., Vatanpour V., Moghadassi A. Fabrication of a new emulsion polyvinyl chloride (EPVC) nanocomposite ultrafiltration membrane modified by para-hydroxybenzoate alumoxane (PHBA) additive to improve permeability and antifouling performance. Chem. Eng. Res. Des. 2020;153:8–20. [Google Scholar]

- 40.Clemons C. Elastomer modified polypropylene–polyethylene blends as matrices for wood flour–plastic composites. Compos. Appl. Sci. Manuf. 2010;41(11):1559–1569. [Google Scholar]

- 41.Mouillet V., Farcas F., Besson S. Ageing by UV radiation of an elastomer modified bitumen. Fuel. 2008;87(12):2408–2419. [Google Scholar]

- 42.Pashmforoush F., Ajori S., Azimi H. Interfacial characteristics and thermo-mechanical properties of calcium carbonate/polystyrene nanocomposite. Mater. Chem. Phys. 2020;247 [Google Scholar]

- 43.Hayeemasae N., Ismail H. Potential of calcium carbonate as secondary filler in eggshell powder filled recycled polystyrene composites. Polímeros. 2021;31 [Google Scholar]

- 44.El-Sayed E.M., Hamad H.A., Ali R.M. Journey from ceramic waste to highly efficient toxic dye adsorption from aqueous solutions via one-pot synthesis of CaSO4 rod-shape with silica. J. Mater. Res. Technol. 2020;6:16051–16063. [Google Scholar]

- 45.Wu D.Y., Svazas A. Micro-and nano-sized calcium carbonate toughened polystyrene. J. Nanosci. Nanotechnol. 2006;6(12):3919–3922. doi: 10.1166/jnn.2006.663. [DOI] [PubMed] [Google Scholar]

- 46.Tanniru M., Misra R. On enhanced impact strength of calcium carbonate-reinforced high-density polyethylene composites. Mater. Sci. Eng. 2005;405(1-2):178–193. [Google Scholar]

- 47.Chafidz A., Ali I., Ali Mohsin M., Elleithy R., Al-Zahrani S. Atomic force microscopy, thermal, viscoelastic and mechanical properties of HDPE/CaCO3 nanocomposites. J. Polym. Res. 2012;19(4):1–17. [Google Scholar]

- 48.Mohsenzadeh M.S., Mazinani M., Zebarjad S.M. Evaluation of fracture behavior of polyethylene/CaCO3 nanocomposite using essential work of fracture (EWF) approach. Nanocomposites. 2015;1(1):27–35. [Google Scholar]

- 49.Yu J., Sun L., Ma C., Qiao Y., Yao H. Thermal degradation of PVC: a review. Waste Manag. 2016;48:300–314. doi: 10.1016/j.wasman.2015.11.041. [DOI] [PubMed] [Google Scholar]

- 50.Wu P., Cai Z., Jin H., Tang Y. Adsorption mechanisms of five bisphenol analogues on PVC microplastics. Sci. Total Environ. 2019;650:671–678. doi: 10.1016/j.scitotenv.2018.09.049. [DOI] [PubMed] [Google Scholar]

- 51.Patrick S. iSmithers Rapra Publishing; 2005. Practical Guide to Polyvinyl Chloride. [Google Scholar]

- 52.Wang H., Xie G., Fang M., Ying Z., Tong Y., Zeng Y. Electrical and mechanical properties of antistatic PVC films containing multi-layer graphene. Compos. B Eng. 2015;79:444–450. [Google Scholar]

- 53.Giacomucci L., Raddadi N., Soccio M., Lotti N., Fava F. Polyvinyl chloride biodegradation by Pseudomonas citronellolis and Bacillus flexus. New biotechnology. 2019;52:35–41. doi: 10.1016/j.nbt.2019.04.005. [DOI] [PubMed] [Google Scholar]

- 54.Elgharbawy A.S.A.A. Review on corrosion in solar panels. Int. J. Smart Grid-ijSmartGrid. 2018;2(4):218–220. [Google Scholar]

- 55.Elgharbawy A.S., Sadik W.A., Sadek O.M., Kasaby M.A. Maximizing biodiesel production from high free fatty acids feedstocks through glycerolysis treatment. Biomass Bioenergy. 2021;146 [Google Scholar]

- 56.Elgharbawy A. A review on vinasse A by-product from sugarcane industry. Trends Petro Eng. 2021;1(2):1–3. [Google Scholar]

- 57.El-gharbawy A., Sadik W., Sadek O., Kasaby M. A review on biodiesel feedstocks and production technologies. J. Chil. Chem. Soc. 2021;66(1):5098–5109. [Google Scholar]

- 58.Elgharbawy A., Sayed A. Production of biodiesel from used cooking using linear regression analysis. J. Petrol. Min. Eng. 2020;22(2):92–99. [Google Scholar]

- 59.Mahmoud K., Lacomme E., Sayyed M., Özpolat Ö., Tashlykov O. Investigation of the gamma ray shielding properties for polyvinyl chloride reinforced with chalcocite and hematite minerals. Heliyon. 2020;6(3):3560. doi: 10.1016/j.heliyon.2020.e03560. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Elgharbawy A., Sayed A. A review on natural gas previous, current and forecasting prices and demand. J. Petrol. Min. Eng. 2020;22(1):61–64. [Google Scholar]

- 61.Xia X., Sun M., Zhou M., Chang Z., Li L. Polyvinyl chloride microplastics induce growth inhibition and oxidative stress in Cyprinus carpio var. larvae. Sci. Total Environ. 2020;716:136479. doi: 10.1016/j.scitotenv.2019.136479. [DOI] [PubMed] [Google Scholar]

- 62.Maou S., Meghezzi A., Grohens Y., Meftah Y., Kervoelen A., Magueresse A. Effect of various chemical modifications of date palm fibers (DPFs) on the thermo-physical properties of polyvinyl chloride (PVC)–high-density polyethylene (HDPE) composites. Ind. Crop. Prod. 2021;171:113974. [Google Scholar]

- 63.Deka B.K., Maji T.K., Mandal M. Study on properties of nanocomposites based on HDPE, LDPE, PP, PVC, wood and clay. Polym. Bull. 2011;67(9):1875–1892. [Google Scholar]

- 64.Deka B.K., Maji T. Effect of coupling agent and nanoclay on properties of HDPE, LDPE, PP, PVC blend and Phargamites karka nanocomposite. Compos. Sci. Technol. 2010;70(12):1755–1761. [Google Scholar]

- 65.Thongpin C., Santavitee O., Sombatsompop N. Degradation mechanism and mechanical properties of PVC in PVC-PE melt blends: effects of molecular architecture, content, and MFI of PE. J. Vinyl Addit. Technol. 2006;12(3):115–123. [Google Scholar]

- 66.Abdolmohammadi S., Siyamak S., Ibrahim N.A., Yunus W.M.Z.W., Rahman M.Z.A., Azizi S., Fatehi A. Enhancement of mechanical and thermal properties of polycaprolactone/chitosan blend by calcium carbonate nanoparticles. Int. J. Mol. Sci. 2012;13(4):4508–4522. doi: 10.3390/ijms13044508. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Lodi P.C., Bueno B.d.S., Vilar O.M. The effects of weathering exposure on the physical, mechanical, and thermal properties of high-density polyethylene and poly (vinyl chloride) Mater. Res. 2013;16(6):1331–1335. [Google Scholar]

- 68.Xie Y., Hill C.A., Xiao Z., Militz H., Mai C. Silane coupling agents used for natural fiber/polymer composites: a review. Compos. Appl. Sci. Manuf. 2010;41(7):806–819. [Google Scholar]

- 69.Bai X.-y., Wang Q.-w., Sui S.-j., Zhang C.-s. The effects of wood-flour on combustion and thermal degradation behaviors of PVC in wood-flour/poly (vinyl chloride) composites. J. Anal. Appl. Pyrol. 2011;91(1):34–39. [Google Scholar]

- 70.Yang X., Tang X., Ma L., Sun Y. Sound insulation performance of structural wood wall integrated with wood plastic composite. J. Bioresour. Bioprod. 2019;4(2):111–118. [Google Scholar]

- 71.Jiang H., Kamdem D.P. Development of poly (vinyl chloride)/wood composites. A literature review. J. Vinyl Addit. Technol. 2004;10(2):59–69. [Google Scholar]

- 72.Tee D., Mariatti M., Azizan A., See C., Chong K. Effect of silane-based coupling agent on the properties of silver nanoparticles filled epoxy composites. Compos. Sci. Technol. 2007;67(11-12):2584–2591. [Google Scholar]

- 73.Hao W., Wang M., Zhou F., Luo, Xie X., Luo F., Cha R. A review on nanocellulose as a lightweight filler of polyolefin composites Author links open overlay panel Carbohydrate. Polymers. 2020;243(1):116466. doi: 10.1016/j.carbpol.2020.116466. [DOI] [PubMed] [Google Scholar]

- 74.Feng A., Wu G., Wang Y., Pan C. Synthesis, preparation and mechanical property of wood fiber-reinforced poly (vinyl chloride) composites. J. Nanosci. Nanotechnol. 2017;17(6):3859–3863. [Google Scholar]

- 75.Zong G., Hao X., Hao J., Tang W., Fang Y., Ou R., Wang Q. High-strength, lightweight, co-extruded wood flour-polyvinyl chloride/lumber composites: effects of wood content in shell layer on mechanical properties, creep resistance, and dimensional stability. J. Clean. Prod. 2020;244:118860. [Google Scholar]

- 76.Zong G., Hao J., Hao X., Fang Y., Song Y., Wang H., Ou R., Wang Q. Enhancing the flame retardancy and mechanical properties of veneered wood flour/polyvinyl chloride composites. Polym. Compos. 2020;41(3):848–857. [Google Scholar]

- 77.Davoodi S. Concordia University; 2007. Building Composites Based on By-Products. [Google Scholar]

- 78.Fang Y., Xue A., Wang F., Zhang Z., Song Y., Wang W., Wang Q. The influence of zinc compounds on thermal stability and flame retardancy of wood flour polyvinyl chloride composites. Construct. Build. Mater. 2022;320 [Google Scholar]

- 79.Abdellah Ali S.F., Althobaiti I.O., El-Rafey E., Gad E.S. Wooden polymer composites of poly (vinyl chloride), olive pits flour, and precipitated bio-calcium carbonate. ACS Omega. 2021;6(37):23924–23933. doi: 10.1021/acsomega.1c02932. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 80.Yim H., Kim D.S. Physical properties of PVC/aminosilane-treated wood flour/organoclay composites. Polym. Adv. Technol. 2012;23(11):1441–1445. [Google Scholar]

- 81.Cong D., Yiqun F., Fengqiang W., Yunpeng Y., Datong Q., Zhang X., Qingwen W. Synergistic flame retardancy of nano-BN and ZnO on wood flour-polyvinyl chloride composites. 复合材料学报. 2021;38(4):1147–1154. [Google Scholar]

- 82.Martikka O., Kärki T. Promoting recycling of mixed waste polymers in wood-polymer composites using compatibilizers. Recycling. 2019;4(1):6. [Google Scholar]

- 83.Sobczak L., Brüggemann O., Putz R. Polyolefin composites with natural fibers and wood-modification of the fiber/filler–matrix interaction. J. Appl. Polym. Sci. 2013;127(1):1–17. [Google Scholar]

- 84.Sun Y., Gao M., Chai Z., Wang H. Thermal behavior of the flexible polyvinyl chloride including montmorillonite modified with iron oxide as flame retardant. J. Therm. Anal. Calorim. 2018;131(1):65–70. [Google Scholar]

- 85.Bagherinia M.A., Sheydaei M., Giahi M. Graphene oxide as a compatibilizer for polyvinyl chloride/rice straw composites. J. Polym. Eng. 2017;37(7):661–670. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.