Abstract

Stevia rebaudiana has been used since hundreds of years as a natural sweetener, it is 300–450 times sweeter than sugar. The study aimed at incorporation of S. rebaudiana in traditional Indian desserts and test its sensory profile, storage properties, textural and color attributes. Carrot halwa (CH) and kesar peda (KP) were prepared with variations such as complete replacement of sugar in variation 1 (V1: CHV1 & KPV1) and 40% replacement of sugar in variation 2 (V2: CHV2 & KPV2) with stevia. Standard methods such as Quantitative Descriptive Analysis scores for sensory profile, fat oxidation for storage studies and surface morphology, texture profile and color analysis of samples were studied. Sensory profile revealed higher taste acceptability in CHV1 and KPV2. During storage, the maximum peroxide value was 5 mEq/kg in all products of refrigerated KP. Microstructural studies revealed changes in surface morphology wherein stevia incorporation increased ragged edges in CH and porosity in KP. Both products exhibited increased hardness, gumminess and chewiness during storage. There was no major change in the color profile of products. Overall, incorporation of stevia in Indian desserts can significantly reduce the use of sugar and can be relished by people who are health conscious.

Keywords: Indian desserts, Fat oxidation, Microstructural changes, Textural properties, Color properties, Stevia, Peda, Carrot halwa

Introduction

Stevia is a genus belonging to the sunflower family Asteraceae [also known as Compositae]. They usually grow in grasslands to subalpine vegetation, semidry mountainous terrains as annuals and as perennial herbs and shrubs (Soejarto et al. 1983). Only 18 of the 110 known species of Stevia have been found to have the characteristic intense sweetness, with Stevia rebaudiana Bertoni being the sweetest of them all.

The extracts of S. rebaudiana contain steviol, a sweet-tasting diterpenoid glycosides called as steviol glycosides of the aglycone type. The main glycosides present in large amounts are stevioside (300 times sweeter than sucrose), rebaudioside (Reb) A (250–450 times sweeter), Reb B (300–350 times), Reb C (50–120 times), Reb D (250–450 times) and Reb E (150–300 times). Other glycosides in smaller amounts includes steviobioside (100–125 times), dulcoside A (50–120 times), isosteviol and dihydroisosteviol. The dry weight of the leaves of wild Stevia plant contain two main glycosides which are the sweetest compounds, namely, stevioside (5–10%) and Reb A (2–4%) (Chatsudthipong and Muanprasat 2009).

Stevioside is a crystalline white powder with a bitter aftertaste, frequently described as a ‘licorice’ taste, that may have a lingering effect or a certain degree of pungency. It makes up the majority of the sweetener (60–70 percent of the total glycosides content). Reb A is usually present as 30–40% of total sweetener and has the sweetest taste with no bitter aftertaste and lingering effect. If Reb A is present in equal quantities to stevioside, it appears that the aftertaste is eliminated (Yadav et al. 2011).

The main group of foods, in which Stevia and its products have been used is quite surprising, namely salty products/food/snacks. It has been reported that the combination of stevioside with sodium chloride gives a dish softness, and therefore it is widely used in the production of pickled vegetables, dried seafood, soy sauces and miso products. Furthermore, sweet Stevia leaves are also utilized in beverages of reduced energy content, candies, chewing gums, baked goods, yogurts, ice creams, teas, and finally constitute a component of numerous toothpastes and mouthwashes. Stevia is also used directly as a sweetener in the form of liquid, powder and tablet (Kobus-Moryson and Gramza-Michałowska 2015).

India has a diverse multi-ethnic, multi-religious, and multi-cultural heritage. The cuisine of India is as varied as the country itself. Desserts and sweets from India have long been a part of every celebration, including festivals, marriages, and other social gatherings. Mysore pak, peda, gulab jamun, carrot halwa, laddu, sandesh, shrikhand, payasa, barfi, phirni, and kulfi are some of the most popular Indian sweets and desserts. Although the sweets vary, the majority are prepared using sugar, flour, clarified butter, and milk, making them concentrated sugar and fat sources.

Addition of S. rebaudiana may not always be suitable in all the desserts due to the after taste. Therefore, screening for the suitability of use of S. rebaudiana in the desserts is important. Hence, the main aim of the study was to investigate suitability of incorporation of S. rebaudiana in selected Indian desserts to replace sugar without altering the sensory and physico-chemical characteristics. The sensory profile, physico-chemical characteristics, storage and microstructure of the variations were analysed.

Materials and methods

The research work was carried out in the Department of Food Science and Nutrition, University of Mysore, Manasagangotri, Mysuru; and Flour Milling, Baking and Confectionery Technology, CSIR–Central Food Technological Research Institute, Mysuru.

Chemicals

All the chemicals used in the storage studies were of analytical grade.

Procurement of food ingredients

All of the food ingredients, packaging material for storage studies such as glass bottles and paper board boxes were procured from a local supermarket of Mysuru, India. Commercial Stevia extract (containing Rebaudioside A) was purchased from e-market. As per the label, 1 g of commercial Stevia was equal to 10 g of refined sugar.

Selection of Indian desserts

Five Indian desserts viz., Rasgulla, Gulab Jamun, Besan laddoo, Carrot halwa (CH) and Kesar Peda (KP) were selected for the study. Preliminary studies were carried out using stevia in place of sugar and subjected to sensory acceptance. Rasgulla and Gulab jamun were not acceptable since the stevia syrup was not comparable to sugar syrup; and Besan laddoo was unacceptably bitter. Based on physical and sensory scores, CH and KP prepared with stevia were chosen for further investigation.

Preparation of selected desserts

The Controls (C) of CH and KP were prepared following the standard recipe. Two variations of the recipes were formulated by replacing sugar with stevia viz., complete replacement in variation 1 (V1) and 40% replacement in variation 2 (V2).

Preparation of carrot halwa

Carrot Halwa Control (CHC) was prepared using the standard recipe given by Saxena et al. (2014) with slight modifications. Carrots, Ooty variety, (200 g) were peeled and grated. Grated carrots were roasted in 15 ml of ghee (clarified butter) for a while followed by the addition of 200 ml of toned milk (milk standardized to adjust the milk fat to 3%). On complete condensation of milk, sugar (45 g) was added and free moisture was allowed to evaporate completely. Cardamom powder was added followed by the addition of ghee to prevent the product from sticking to the pan. The prepared halwa (250 g) was cooled and stored in glass bottles in the refrigerator. Following the control recipe, in Carrot Halwa Variation 1 (CHV1) 4.5 g of stevia was added, and in Carrot Halwa Variation 2 (CHV2) both stevia (1.8 g) and sugar (27 g) were added. 30 g of khoa (unsweetened semi dehydrated whole milk product) was added in all the products towards the end of the cooking.

Preparation of kesar peda

Kesar Peda Control (KPC) was prepared using the standard recipe (Pal 2006) (Banjare et al. 2015). Commercial unsweetened khoa (100 g) was melted in ghee (1.25 g) on a pan followed by the addition of 16.8 g of sugar. On concentration of khoa, few strands of kesar were added in hot milk separately and was added to the khoa. Cardamom powder was added for flavour. On formation of a dough, pedas were rolled, formed into shapes and kept in paperboard boxes for storage in the refrigerator. Following the control recipe, in Kesar Peda Variation 1 (KPV1), 1.6 g of stevia was added and in Kesar Peda Variation 2 (KPV2) both stevia (0.6 g) and sugar (10 g) were added.

Sensory analysis

Sensory analysis was carried out by 30 semi-trained panelist selected among staff and students of the Department of Food Science and Nutrition, University of Mysore, Mysuru (Singh et al. 2019). Screening of panelists was performed based on the threshold of bitter and sweet taste using Threshold tests (Höehl et al. 2014) with slight modifications. The samples were coded with three random digits. Sensory analysis was performed on freshly prepared desserts. Quantitative Descriptive Analysis (QDA) was used to conduct the sensory evaluation of both CH and KP. Sensory analysis of CH and KP was done on different days. Sensory attributes, their descriptors and intensity scale were decided prior to the analysis. The QDA scorecard consisted of attributes with the intensity scale from 1 to 15 cm; where a score of 1 means “attribute is not acceptable” and 15 means “attribute is acceptable”. Panelists were asked to rate the samples based on specified intensity of the given attributes (ex. Attribute: Taste; Intensity: Bitter at 1 cm and sweet at 15 cm) by drawing a vertical line on the intensity scale and writing the given code for the samples. Mean values of each attribute rated by the panelists were calculated (Itagi et al. 2013; Stone et al. 1974).

Storage studies of selected desserts

CH was studied at refrigerated temperature (4 °C) for 7 days by storing in a glass bottle (Meeshi and Hiremath 2014). KP was stored at refrigeration (4 °C) in paperboard boxes lined with wax paper as described by Jha et al. for 12 days (Jha et al. 2014). For physicochemical parameters, products were analysed at 0th, 4th, 7th day in CH and 0th, 6th, 12th day in KP. For microstructural, textural and color changes, all products were studied on first and last days of storage.

Determination of fat oxidation

Determination of peroxide value (PV) was followed according to the standard method (Food Safety and Standard Authority of India 2015). 5 g of each sample was taken for the experiment. The peroxide value was expressed as milli equivalent of peroxide oxygen per kg sample (meq/kg).

Free Fatty Acids (FFA) estimation was followed according to the AOAC, 2000 with minor modifications (Otemuyiwa and Adewusi 2013). 5 g of sample was weighed and 50 ml of alcohol: ether (1:1) solution was added. The mixture was kept for fat extraction and filtered through Whatmann No. 1 filter paper in a conical flask. The filtrate was titrated against 0.1 N KOH solution using phenolphthalein indicator with constant shaking until pink color persisted for 15 s. Readings were taken in triplicate. Acid value was expressed as number of mg of KOH required to neutralize the free fatty acids present in one gram of fat.

Thiobarbituric acid (TBA) was according to method of Sidwell et al. with slight modifications. 2 g of sample was taken and blended with 50 ml of 20% trichloroacetic acid and 50 ml of distilled water. The contents were left undisturbed for 10 min followed by filtration. 5 ml filtrate was pipetted out in each test tube and 5 ml of 0.01 M TBA was added. The test tubes were heated in boiled water bath for 30 min at 100 °C for color development. The contents were cooled to 30 °C temperature and TBA was expressed as absorbance at 532 nm. Blank determinations were made using distilled water in place of sample (Sidwell et al. 1955).

Surface morphology by scanning electron microscopy (SEM)

Scanning Electron Microscopy (SEM) analysis was conducted as per the method given by Patil et al. with slight modifications (Patil et al. 1992). The first and last days of storage products, both of CH and KP, were stored for 24 h and then weighed (1 g). They were freeze dried in a ModulyoD freeze dryer (Thermo Electron Corporation, USA) for 8 h. On complete elimination of moisture, the samples were de-fatted by petroleum-ether crude fat extraction method. The products were gold coated using Sputter Coater. JEOL, Japan (JSM-IT300LV) was used for SEM images. Suitable images at 1000 × and 500 × magnification were taken at 15 kV voltage.

Analysis of textural properties

Texture profile analysis (TPA) was carried out in a texture analyser (Lloyd Instruments LR-5 K, UK) by double compression method as given by Itagi et al. (2013). Samples were cut or made into cylinders of 4 cm diameter and 1 cm thickness and exposed to an 80 mm diameter cylindrical plunger at a cross head speed of 50 mm/min at 90° of compression with time gap between the two compressions varying between 6 and 7 s. The following textural parameters were determined i.e., hardness, cohesiveness, springiness, gumminess, chewiness, adhesiveness and stiffness. Hardness is the maximum force of the first compression. Cohesiveness is how well a product can withstand the second deformation. A cohesive product adheres to itself under compression. Springiness is how well a product can spring back after the deformation. Gumminess and chewiness are applicable for semi-solid products. Chewiness is applicable to solid food and depends on the gumminess and springiness of the product. Adhesiveness is the stickiness of a product. Stiffness is the extent to which a product resists deformation in response to the force applied.

Analysis of color properties

Color analysis was conducted and interpreted accordingly as per Kumar Puri and Geevarghese (Kumar Puri and Geevarghese 2015); and Vaquil et al. (2018) using HunterLab’ ColorFlex EZ Spectrophotometer, USA. The prepared product for storage was analysed as it is. Before the test, the instrument was calibrated with standard black glass and white tile as specified by the manufacturer. Data were received from the software in terms of L* [Lightness, ranges 0 (black) to 100 (White)], a* [Redness, ranges from + 60 (red) to − 60 (green)], and b* [Yellowness, ranges from + 60 (yellow) to − 60 (blue)] in values of the International color system. L*a*b* values were assessed to study the changes in brightness, redness and yellowness of the products.

Statistical analysis

The data on texture analyses and oxidative stability are expressed as mean values. Sensory analysis and color (L*a*b) characteristics are expressed as mean ± SD and comparison between the groups is analysed by one-way ANOVA with Tukey’s HSD post hoc test using SPSS v16.0. The values are considered significant at p ≤ 0.05.

Results and discussion

Sensory analysis

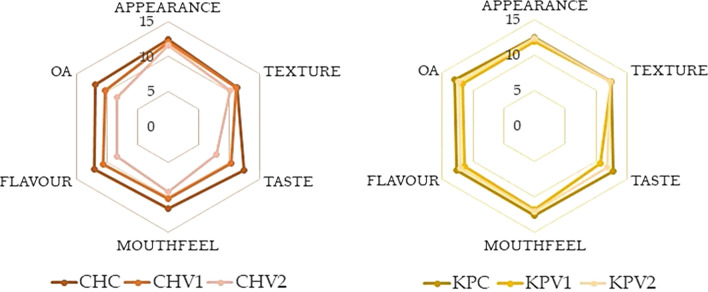

The sensory analysis of products is presented in Fig. 1. In CH, CHV2 scored the least in all the parameters with taste (7.92 ± 3.51, p < 0.05) being the lowest. However, the sensory profile increased with complete replacement of sugar with stevia in CHV1 (10.33 ± 3.00). The appearance of all the products remained unaffected by replacement with stevia and by total elimination of sugar. The partial replacement of sugar with stevia in CH had enhanced bitter taste than the complete replacement with stevia. The potency of stevia has been reported at about 152 times than sucrose at equi-sweet concentration of 3% sucrose (Cardello et al. 1999) which made the complete stevia replacement product more sweeter, acceptable and comparable to control in amounts of 4.5 g but due to its interaction with carrots and sugar together, the sweetness was reduced. Stevia with carrots tasted much more bitter along with sugar due to water-soluble phenolics present in carrots (Ahmad et al. 2017) contributing to the enhanced bitter taste. Stevia extract on its own had a milder taste when compared with sugar (Escutia-López et al. 2019). In a study conducted on CH, sensory scores of overall acceptability of stevia as a total replacement for sugar was substantially higher as compared to sugar (Mogra and Dashora 2009).

Fig. 1.

Sensory analysis of the products. OA overall acceptability, CHC carrot halwa control, CHV1 carrot halwa variation 1, CHV2 carrot halwa variation 2, KPC kesar peda control, KPV1 kesar peda variation 1, KPV2 kesar peda variation 2

KPV1 scored the least in all the parameters with least scores in taste (10.67 ± 2.96). However, the acceptability increased with the addition of sugar and partial replacement with stevia as observed in KPV2 (11.80 ± 2.26) and was comparable to the control (12.71 ± 1.45) with no statistical significance between the variations (p > 0.05). KPV2 scored better in taste than KPV1. The bitter aftertaste of stevia in KPV1 was prominent than KPV2 due to complete replacement with stevia. The partial replacement of sugar with stevia in KP was sweeter, had a better sensory profile and comparable to that of control.

The sweetness of stevia differed in both the products at different concentrations. 100% replacement with stevia was more accepted in vegetable-based dessert CH whereas, 40% replacement with stevia was more acceptable in milk-based dessert KP. Alizadeh (2014), reported that the acceptability of fruit based milkshakes was highest in stevia to sugar ratio and complete sugar replacement than other decreased level of addition of stevia (Alizadeh 2014). Verruma-Bernardi et al. (2015) reported similar results wherein school age children preferred the use of stevia and sucrose together than stevia alone in chocolate milk (Verruma-Bernardi et al. 2015). It has also been observed that in milk-based products such as ice cream mixtures and strawberry flavoured yoghurt had better sensory profile when sucrose was partially replaced with stevia than with stevia only (Gandhi et al. 2018). Cardello et al. (1999) studied sweetness equivalence of stevia with sucrose and reported stevia had increased bitter aftertaste at increased concentrations, tasting bitter at equi-sweet concentrations of 20% sucrose and higher (Cardello et al. 1999). The level of sweetening potency and bitter aftertaste of stevia gets affected by the concentration of stevia addition, viscosity of the product, synergistic or inhibitory effect with food ingredients and dispersion media (McCain et al. 2018). The potency of stevia differs with different products (Cardello et al. 1999). Consumers in recent times prefer “naturally sweetened” product than an “artificially sweetener used” labelled product but natural non-nutritive sweetener like stevia scored less in terms of taste, flavour when compared with an artificial sweetener (McCain et al. 2018).

Storage studies of selected desserts

Fat oxidation

The fat oxidation values of PV, FFA and TBA of both the desserts is depicted in Fig. 2. In CH, PV value increased marginally in all the products while FFA and TBA increased till 4 mg/KOH and 0.3 respectively. Due to the addition of khoa, ghee and milk, the products were assessed for oxidative deterioration (Mannion et al. 2016) and the rate auto-oxidation was not affected by either partial or complete replacement with stevia. The acceptable range of PV value for food products is 10–20 mEq/kg and the results obtained were lesser than the acceptable range. In KP, all three fat oxidation parameters increased progressively in all the variations. KP was made entirely from condensed milk product, khoa and hence, oxidative deterioration was analysed. Partial replacement with stevia in all the products had higher values for PV (day 0, 1.9 mEq/kg; day 12, 2.9 mEq/kg) than complete replacement and control due to the addition of combination of stevia and sugar. Saxena et al. reported change in fat oxidation at a slower pace in frozen Carrot Halwa (Saxena et al. 2014). Jha et al. reported gradual increase in FFA and TBA values in Kesar Peda at refrigeration (Jha et al. 2014).

Fig. 2.

Effect of storage on fat oxidation of the products. Note: a Peroxide value, b free fatty acids and c thiobarbituric acid

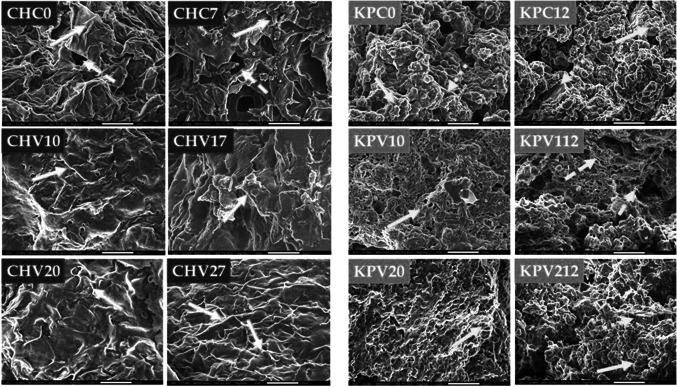

Microstructural properties

To study the effect of substitution of sugar with stevia at different levels in the desserts and observe the structural changes in the dessert during storage, SEM was conducted. The surface of the products at first and last days of their respective storage days are shown in Fig. 3. In micrographs of CH, silky edges and porosity were observed in CHC0 due to addition of sugar. On addition of sugar during cooking, moisture is released which hydrates and swells the carrots. Subsequently, due to complete sublimation of water on freeze drying, porosity was observed. However, when compared with CHV10, reduced silkiness and ragged, uneven surfaces were observed due to addition of stevia alone in the dessert. Since stevia does not release moisture on application of heat like sugar, it made the product drier and decreased the moisture content in the dessert. While in CHV20, smoother edges were observed because of 60% addition of sugar and reduced porosity due to 40% addition of stevia. On comparing all the products of CH with the last day of storage i.e. 7th day, the products were drier and had rough edges due to refrigeration temperature.

Fig. 3.

Scanning electron micrographs of the products during storage. Note: Micrographs taken during storage of carrot halwa at 0th day (CHC0, CHV10 and CHV20) and 7th day (CHC7, CHV17 and CHV27) and of kesar peda at 0th (KPC0, KPV10 and KPV20) and 12th day (KPC12, KPV112 and KPV212). In carrot halwa, solid orange arrow indicates silky edges and square arrows indicate porosity. In kesar peda, solid gold arrows indicate sugar–protein complexes, dotted arrows indicate lactose slabs and square arrows indicate rough, barren edges. All mircographs were taken at × 500 and 1.5 kV (color figure online)

In micrographs of KP, round globular protein mass aggregated on long rectangular slabs of lactose and sugar were observed in KPC0. This can be attributed to sugar which when added to the product containing protein forms a clear globular network. The extent of globule formation is evident in KPC0 when compared with KPV10, which had more porosity due to absence of globule formation of sugar–protein complexes. Along with stevia not releasing moisture on heat, it did not combine with protein from milk and form a complex on top of lactose slabs. Hence, the images have a ripped appearance on the surface. In KPV20, where sugar is partially replaced with stevia, rounded edges with uneven surfaces were seen. While cooking, khoa formed a dough more pliable due to release of moisture from sugar on application of dry heat with lactose crystals coated with the sugar–protein aggregates. However, in the total replacement of sugar with stevia, a dry dough was formed which stuck to the pan easily than compared to partial replacement of sugar with stevia. On the last day of storage i.e. 12th day, KPC12 has more depth indicating increased hardness, brittleness and thereby dryness in the product. KPV112 on the other hand, has more hollows than depth signifying increased dryness due to addition of stevia and refrigeration storage temperature. Conversely, hollow or depth is not as much in KPV212 due to presence of 60% of sugar.

Food matrix plays a major role in the perceived intensity of the sweetener and thereby, texture and fat plays a role in sugar-reduction as they influence highly the perception of sweetness. Sugar is a bulking agent, providing texture, adding viscosity and colors to food products (McCain et al. 2018). When non-nutritive sweetener like stevia is used to replace sugar for the intense sweet taste, specific sensory parameters such as texture, color and flavour get compromised. Therefore, complete or partial substitution of sugar with stevia is not just dependent on the perceived equi-sweet taste or equivalent sweet taste of stevia with sugar in water. It also depends on the food matrix or microstructure to study the control of flavour release and sweetness perception during consumption. Hence, whenever stevia is added, partially or completely in place of sugar, additives such as bulking agents, hydrocolloids, etc. are added to compensate for the loss of texture (Gandhi et al. 2018). Instead of using additives, food ingredients such as khoa was added to CH to recompense for color, flavour and texture. In case of dairy products like KP, no bulking agents were used. The microstructure of complete replacement with stevia in CH displays reduced porosity and silkiness, yet it tasted better than partial replacement while in KP, partial replacement with stevia displays similar properties to control and tasted better than complete replacement.

Texture attributes

Texture Profile Analysis (TPA) of the products is presented in Fig. 4. The hardness, gumminess and chewiness of CH increased whereas, the springiness decreased upon storage at 4°C. CHC was better than the variations in all parameters, except for hardness, in which CHV1 was harder than CHC and CHV2 due to lack of moisture from sugar.

Fig. 4.

Texture profile analysis of the products. Note: a Hardness, b springiness, c chewiness, d cohesiveness, e gumminess, f adhesiveness

The hardness, springiness, chewiness and gumminess of KP increased rapidly upon storage at 4°C. KPV1 had more hardness compared to the other products. Cohesiveness decreased in KPV1 due to lack of sugar and increased rapidly in KPV2. Jha et al. observed similar increment in hardness, chewiness, gumminess and adhesiveness of the control lal peda (Jha et al. 2014) which holds true for stevia-based product as stevia does not provide moisture to KP. This increases the hardness making it more adhesive and gummy in nature. Cohesiveness decreased due to reduced water content.

Color attributes

The results of the color attributes are shown in Table 1. The L value indicates that CHC became lighter in color upon storage as compared to CHV1 and CHV2. All the three variations of CH showed an increased intensity of red color during the 7 days storage period. This observation may be due to loss of moisture in CH during refrigeration which might result in color intensification and not necessarily indicate increase in carotenoid pigments which contribute to the reddish orange color in CH. The difference in color is noted in the dE values during the storage period. Nonetheless, refrigeration has been useful in stabilizing the carotenoid pigment during storage (Jintasataporn and Yuangsoi 2012).

Table 1.

Colour (L*a*b*) analysis of products during storage at refrigerated temperature (4°C)

| Samples | L | A | B | dE |

|---|---|---|---|---|

| 0th day | ||||

| CHC | 43.22 ± 1.05a | 17.06333 ± 0.5c | 19.89333 ± 0.33a | 55.37 ± 0.91c |

| CHV1 | 44.88333 ± 1.1a | 12.39 ± 0.84a | 19.78 ± 0.89a | 52.55 ± 0.72b |

| CHV2 | 47.99667 ± 0.51b | 13.95333 ± 0.07b | 22.44333 ± 0.16b | 50.84 ± 0.17a |

| 7th day | ||||

| CHC | 50.14 ± 0.54b | 18.965 ± 0.63a | 21.97 ± 0.47cb | 50.685 ± 0.51a |

| CHV1 | 42.5925 ± 0.58a | 18.9225 ± 0.64a | 20.98 ± 0.315b | 55.775 ± 0.35cb |

| CHV2 | 44.275 ± 0.61a | 18.2275 ± 0.80a | 19.7 ± 0.66a | 55.49 ± 0.4b |

| 0th day | ||||

| KPC | 56.68667 ± 0.05b | 3.943333 ± 0.04a | 21.16333 ± 0.05b | 40.61 ± 0.07a |

| KPV1 | 49.60667 ± 0.12a | 7.016667 ± 0.04c | 20.04333 ± 0.05a | 46.98667 ± 0.10b |

| KPV2 | 56.95 ± 0.54cb | 4.683333 ± 0.23b | 21.68333 ± 0.23c | 40.62333 ± 0.30a |

| 12th day | ||||

| KPC | 62.955 ± 1.58a | 1.9 ± 0.17a | 21.34 ± 0.28a | 35.07 ± 1.21a |

| KPV1 | 63.785 ± 1.10ab | 2.3325 ± 0.37a | 21.7325 ± 0.36a | 35.0875 ± 0.74a |

| KPV2 | 66.01 ± 0.54b | 2.78 ± 0.49a | 23.14 ± 0.15b | 33.67 ± 0.28a |

Mean ± SD values (n = 3) containing three different superscript letters a, b, c differ significantly (p ≤ 0.05)

CHC carrot halwa control, CHV1 carrot halwa variation 1-100% Stevia, CHV2 carrot halwa variation 2-60:40 of refined sugar: Stevia, KPC kesar peda control, KPV1 kesar peda variation 1-100% Stevia, KPV2 kesar peda variation 2-60:40 of refined sugar: Stevia.

All the variations of KP showed increase in lightness during the storage period. The lightness can be compared to that of a study which reported Peda without Kesar (Kumar Puri and Geevarghese 2015). Although there were differences observed between the L and A values of the variations on the first day of storage, the values were comparable on the 12th day. Refrigeration therefore caused differences in color during storage period in control and stevia-based variations of KP.

The results of the sensory analysis, storage studies, texture and color profiles indicate that Stevia can be incorporated in Indian desserts such as KP and CH. As per the Food Safety and Standards Regulation (2015) for Food Products Standards and Food Additives, Steviol glycosides and its components can be used at a level of 330 mg/Kg steviol equivalent in Dairy based desserts (Food Safety and Standards Regulations 2015). Thus, the hypothesis can be accepted that incorporation of S. rebaudiana in Indian desserts can replace considerable amount of sugar without significantly altering the sensory and physico-chemical profile.

Conclusion

Stevia-based products made using stevia extract has proven to be beneficial to individuals due to its important function of zero calories and zero sugar. Stevia incorporated in desserts reduces the amount of sugar in the product and can be savoured by individuals with diabetes. In our study, the results of storage studies, textural and color parameters of stevia-based products were comparable to the control. A complete replacement of sugar with stevia in Carrot Halwa; and a combination of sugar and stevia in Kesar peda proved to be better in terms of sensory analysis. Therefore, incorporation of stevia in desserts can be useful for individuals who want to relish desserts and as well be health conscious.

Acknowledgements

The authors dedicate this research work in loving memory of Late Dr. Indrani Dasappa who left us due to untimely demise.

Author contributions

NPK: Methodology, Validation, Formal analysis, revising the Original Draft for intellectual content, Editing manuscript, data interpretation SU: Investigation, Formal analysis, Writing—Original Draft, data interpretation LMS: Methodology, Validation, Formal analysis, Writing—Review & Editing, data interpretation ID: texture and color analysis, data interpretation AU: Conception and design of the study, Resources, manuscript editing, Supervision, Project Administration, Funding Acquisition, final approval before submission.

Funding

This work was supported and funded by University Grants Commission, New Delhi, for research Grants under SAP (Grant number: UGC No. F 640/1/DRS/2013 (SAP-I), dated July 15, 2013) and BSR fellowship awarded to Dr. Namratha Pai Kotebagilu and Dr. Lohith Mysuru Shivanna.

Availability of data and material

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Ahmad T, Cawood M, Batool A, et al. Phytochemicals in Daucus carota and their importance in nutrition—review article. PeerJ Prepr. 2017;5:e3187v1. doi: 10.7287/peerj.preprints.3187v1. [DOI] [Google Scholar]

- Alizadeh M. Effect of Stevia as a substitute for sugar on physicochemical and sensory properties of fruit based milk shake. J Sci Res Rep. 2014;3:1421–1429. doi: 10.9734/jsrr/2014/8623. [DOI] [Google Scholar]

- Banjare K, Kumar M, Goel BK. Effect of storage on chemical, textural and sensory attributes of traditional indigenous sweet peda. Asian J Dairy Food Res. 2015;34:104–108. doi: 10.5958/0976-0563.2015.00021.4. [DOI] [Google Scholar]

- Cardello HMAB, Da Silva MAPA, Damasio MH. Measurement of the relative sweetness of stevia extract, aspartame and cyclamate/saccharin blend as compared to sucrose at different concentrations. Plant Foods Hum Nutr. 1999;54:119–130. doi: 10.1023/A:1008134420339. [DOI] [PubMed] [Google Scholar]

- Chatsudthipong V, Muanprasat C. Stevioside and related compounds: therapeutic benefits beyond sweetness. Pharmacol Ther. 2009;121:41–54. doi: 10.1016/j.pharmthera.2008.09.007. [DOI] [PubMed] [Google Scholar]

- Escutia-López K, Sánchez-Pardo M, Mora-Escobedo RA. A comprehensive review on the nutritional and therapeutical aspects of Stevia rebaudiana Bertoni. J Appl Biotechnol Bioeng. 2019;6:1. [Google Scholar]

- Food Safety and Standard Authority of India (2015) Manual of methods of analysis of foods: oils and fats. Minist Heal Fam Welf 1–96. https://old.fssai.gov.in/Portals/0/Pdf/Draft_Notification_Steviol.pdf

- Food Safety and Standards (Food Products Standards and Food Additives) Regulations (2015) Use of non-nutritive sweetener. Minist Heal Fam Welf 1–5

- Gandhi S, Gat Y, Arya S, et al. Natural sweeteners: health benefits of stevia. Foods Raw Mater. 2018;6:392–402. doi: 10.21603/2308-4057-2018-2-392-402. [DOI] [Google Scholar]

- Höehl K, Schönberger GU, et al. Stimulus and recognition thresholds for the basic tastes in deionized water—are the recommended/concentrations for citric acid too high? Sci Res. 2014;61:130–136. doi: 10.4455/eu.2014.023. [DOI] [Google Scholar]

- Itagi HBN, Singh V, Indiramma AR, Prakash M. Shelf stable multigrain halwa mixes: preparation of halwa, their textural and sensory studies. J Food Sci Technol. 2013;50:879–889. doi: 10.1007/s13197-011-0423-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jha A, Kumar A, Jain P, et al. Physico-chemical and sensory changes during the storage of lal peda. J Food Sci Technol. 2014;51:1173–1178. doi: 10.1007/s13197-012-0613-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jintasataporn O, Yuangsoi B. Stability of carotenoid diets during feed processing and under different storage conditions. Molecules. 2012;17:5651–5660. doi: 10.3390/molecules17055651. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kobus-Moryson M, Gramza-Michałowska A. Directions on the use of stevia leaves (Stevia Rebauidana) as an additive in food products. Acta Sci Pol Technol Aliment. 2015;14:5–13. doi: 10.17306/J.AFS.2015.1.1. [DOI] [PubMed] [Google Scholar]

- Kumar Puri R, Geevarghese P. Physico-chemical, sensory and colour analysis of peda prepared using Caesalpinia sappan L. as natural colourant. Int J Appl Bio-Eng. 2015;9:7–10. doi: 10.18000/ijabeg.10130. [DOI] [Google Scholar]

- Mannion DT, Furey A, Kilcawley KN. Free fatty acids quantification in dairy products. Int J Dairy Technol. 2016;69:1–12. doi: 10.1111/1471-0307.12301. [DOI] [Google Scholar]

- McCain HR, Kaliappan S, Drake MA. Invited review: sugar reduction in dairy products. J Dairy Sci. 2018;101:8619–8640. doi: 10.3168/jds.2017-14347. [DOI] [PubMed] [Google Scholar]

- Meeshi A, Hiremath U. Study on microbiological quality of safflower and groundnut milk, paneer and halwa: a value- added dairy products. Int J Sci Res. 2014;3:838–842. [Google Scholar]

- Mogra R, Dashora V. Exploring the use of stevia rebaudiana as a sweetener in comparison with other sweeteners. J Hum Ecol. 2009;25:117–120. doi: 10.1080/09709274.2009.11906143. [DOI] [Google Scholar]

- Otemuyiwa IO, Adewusi SRA. Fatty acid, carotenoid and tocopherol content of some fast foods from a Nigerian eatery. J Food Nutr Res. 2013;1:82–86. doi: 10.12691/jfnr-1-5-1. [DOI] [Google Scholar]

- Pal D (2006) National Dairy Research Institute. In: Lecture compendium on developments in traditional dairy products

- Patil GR, Patel A, Allan-wojtas P, Kalab M. Microstructure and texture of Khoa. Food Struct. 1992;11:155–163. [Google Scholar]

- Saxena TM, Raju PS, Bawa AS. Evaluation of sensory acceptability and storage stability of frozen carrot based dessert. J Food Sci Technol. 2014;51:1203–1207. doi: 10.1007/s13197-011-0605-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sidwell CG, Salwin H, Mitchell JH. Measurement of oxidation in dried milk products with thiobarbituric acid. J Am Oil Chem Soc. 1955;32:13–16. doi: 10.1007/BF02636471. [DOI] [Google Scholar]

- Singh A, Kishor K, Prasad SGM, Majumder S. Sensory analysis of gulabjamun prepared by Khoa and Paneer. Int J Food Sci Nutr. 2019;4:66–68. [Google Scholar]

- Soejarto DD, Compadre CM, Medon PJ, et al. Potential sweetening agents of plant origin. II. Field search for sweet-tasting Stevia species. Econ Bot. 1983;37:71–79. doi: 10.1007/BF02859308. [DOI] [Google Scholar]

- Stone H, Sidel J, Oliver S, et al. Sensory evaluation by quantitative descriptive analysis. Food Technol. 1974;28:24–34. [Google Scholar]

- Vaquil PD, Bhardwaj PK, Devi R, et al. Study of textural and instrumental colour characteristics of khoa developed using milk solids. Int J Curr Microbiol Appl Sci. 2018;7:3819–3823. doi: 10.20546/ijcmas.2018.708.390. [DOI] [Google Scholar]

- Verruma-Bernardi MR, Lee K, Palchak T, Bordi P. Chocolate milk sweetened with stevia: acceptance by children. J Obes Overweight. 2015;1:1–5. doi: 10.15744/2455-7633.1.103. [DOI] [Google Scholar]

- Yadav AK, Singh S, Dhyani D, Ahuja PS. A review on the improvement of stevia [Stevia rebaudiana (Bertoni)] Can J Plant Sci. 2011;91:1–27. doi: 10.4141/CJPS10086. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.