Abstract

Yoghurt is one of the health-functional foods and its nutritive value can be enhanced by adding native fruit. This study aimed to produce novel functional probiotic yoghurt using Bifidobacterium longum (B. longum) strain and White sapote fruits pulp (WSP) at levels of 5, 10, and 15%. WSP contains 19.87% carbohydrates, 0.90% protein, 0.35% fat, 0.78% fiber, 0.6% ash, 48.70 (mg GAE/100 g) total phenolic, 28.25 (mg/100 g) ascorbic acid and 153.53 (IC50 (mg/mL)) for antioxidant activity. Physicochemical, microbiological and sensory evaluation of flavored yoghurt samples were investigated during storage at 5 ± 1 °C for 21 days. The results revealed that increases in total solids, protein, ash, and carbohydrates content were observed in the flavored probiotic yoghurt compared to the control sample. Syneresis and WHC values of flavored yoghurt were influenced by supplementation with WSP whether in fresh or stored samples. Furthermore, significant (P< 0.05) increases in ascorbic acid, antioxidant activity, total phenols, vitamins, and minerals were observed in flavored probiotic yoghurt. Molds & yeast were not detected in all samples except in both control and probiotic yoghurt samples that appeared after 14 and 21 days. Similarly, coliforms were not found in all fresh and stored yoghurt samples. Sensory evaluation results showed that probiotic yoghurt flavored with 10% WSP had the highest acceptance scores compared to other treatments.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-022-05393-5.

Keywords: Probiotic yoghurt, White sapote fruits, Physicochemical properties, Antioxidant, Minerals

Introduction

Yoghurt is one of the most widely distributed dairy products and it is available in different forms throughout the world (Tarakçi and Küçüköner 2003). It is considered safe and highly accepted fermented dairy product due to its taste, perceived therapeutic activity and high nutritive value. In general, yoghurts are made by lactic acid fermentation of milk by the starter culture Streptococcus thermophilus (S. thermophilus), and Lactobacillus delbrueckii subsp bulgaricus (L. bulgaricus) actions (Adolfsson et al. 2004). Other lactic acid bacteria (LAB) such as some strains belonging to the genus Lactobacillus or Bifidobacterium have attracted great attention due to their properties. Yoghurt produced using these types of cultures are called probiotics or bio-yoghurt with unique characteristics. The potential health benefits of bifidobacteria include inhibition of bacterial pathogens, reduction of serum cholesterol levels and colon cancer risks, stimulation of the immune response, improvement of lactose tolerance, calcium absorption, and vitamin synthesis (Akalın et al. 2004). According to Shah (1997), using of B. longum for manufacturing fermented products should be encouraged because of the better tolerance to acid and hydrogen peroxide than other strains of bifidobacteria. Because the produced acid and acetaldehyde in yoghurt are compatible with the flavor of fruits, it is ideal for blending with the majority of them. Additionally, the use of fruits will enhance the natural flavors, nutritive, functional, and sensory characteristics of yoghurt (Cakmakcı et al. 2012).

Casimiroa edulis is a Rutaceae family member that is native to Mexico and Central America. It’s called “Mexican apple”, “white sapote”, “Casimiroa”, and “Sapote blance” by native people (Satheesh 2015). The tree is cultivated in Egypt for its edible fruits. Because of its medicinal properties, fresh white sapote has gained popularity in the US and other countries. The fruit has a greenish-yellow to golden peel and its diameter measures about 6–11 cm and weighs 70–700 g. Some varieties of White sapote seedling have a slightly bitter aftertaste, particularly the part of pulp near the peel. The matured fruit pulp is white, cream, or yellowish and very soft, with a few / without fiber had sweet and presents a gritty texture. Its flavor is similar to peach or banana (Morton 1987). The fruit is a good source of different nutrients such as sugar, protein, bioactive compounds (ascorbic acid, phenols, carotenoids, and polyunsaturated fatty acids), and minerals like sodium, potassium, magnesium, iron, calcium, phosphorus, copper, and zinc (Moo-Huchin et al. 2014). Reducing sugars account for 66.2% of total sugars in the pulp, which has a Brix of 14.7 (Samaha 2002). The fruit has anti-mutagenic and anticancer effects and is often used in the different formulations of Folk- medicine (Satheesh 2015). Several studies reported that Casimiroa edulis can be considered a valuable fruit usually eaten fresh alone as a dessert or mixed in fruit cups and salads. It is best to cut into slices and served with cream and sugar, and can be added to ice cream mix or milkshakes or prepared to marmalades. It can also be used to produce different products like juice, jam, sherbet, tart, and biscuit (Samaha 2002; Yahia and Gutierrez-Orozco 2011). Therefore, the objective of this study is to investigate the influence of supplementation with White sapote fruits pulp and probiotic culture on the physicochemical, microbiological, and sensory evaluation of the flavored yoghurt during storage.

Materials and methods

Materials

Fresh cow’s milk was collected from the dairy unit of the Dairy Science and Technology Department, Faculty of Agriculture & Natural Resources, Aswan University, Egypt. White sapote fruits of high quality (Supplementary materials, Fig. S1) were collected from a private garden in El-Gharbia governorate, Egypt. The plant identification was verified by the staff of Horticulture Department, Faculty of Agriculture, Suez Canal University, Egypt. Sugar (sucrose), skim milk powder (97% TS, product of Dairy America™), were purchased from a local market. Pure cultures of S. thermophilus, L. bulgaricus and B. longum were obtained from Egypt Microbial Culture Collection (EMCC). Individually, these strains were activated by 3 successive transfers in a sterilized 10% reconstituted skim milk.

All chemicals used in this study were analytical grade and purchased from Sigma-Aldrich Co. (St. Louis, Mo., U.S.A.). The current study was conducted in cooperation between the Department of Dairy Science and Technology, Faculty of Agriculture & Natural Resources, Aswan University, and Dairy Science Department, Faculty of Agriculture, New Valley University, Egypt.

Methods

Preparation of white sapote fruits pulp

Fresh ripe White sapote fruits (Casimiroa edulis Llave et Lex (Rutaceae)) were gently washed, then the peel and seeds were removed. The pulp was mixed in blender, and the resultant mixture (15.60 (TSS) as Brix and 0.16% acidity) was heated at 90 °C for 5 min, cooled rapidly, and stored in the refrigerator until used.

Preparation of yoghurt

Cow`s milk (3% fat, 3.5% protein, 12% total solids (TS), and 0.17% acidity), was standardized to 14% TS by skim milk powder. The mix was pasteurized by heating at 90 °C for five minutes in a boiling water bath, and then cooled to 45 °C. The milk was divided into 3 portions: The first one was inoculated with 2% yoghurt starter (S. thermophilus and L. bulgaricus) as control yoghurt (CY). The second was inoculated with 2% of mixed yoghurt starter and B. longum (1:1) as probiotic yoghurt (PY). The third was prepared as flavored probiotic yoghurt (PFY) by adding 8% sugar to milk and incorporated by White sapote fruit pulp on ratios of 0, 5, 10, and 15%, immediately inoculated with 2% of mixed (1:1) yoghurt starter and B. longum as flavored probiotic yoghurt (PFY0, PFY1, PFY2, and PFY3, respectively). The inoculated samples were filled into 125 mL plastic cups and incubated at 42 °C until pH reaches 4.7. After complete coagulation, all yoghurt samples were stored in the refrigerator at 5 ± 1 °C for 21 days. The samples were subjected to physicochemical, microbial, antioxidant compounds and sensory evaluations analyses when fresh and after 7, 14, and 21 days, respectively. Moreover, minerals and vitamins were analyzed when fresh. All determinations were carried out in triplicate.

Physicochemical properties analysis

Total solids, protein, fat, ash, fiber, acidity, and pH values were determined according to AOAC (2005). Total carbohydrate was calculated by difference [100 − (moisture + protein + fat + ash + fiber) %]. The total soluble solids (TSS) content of White sapote fruit pulp was measured using a refractometer (Abbe Hergestellt in der DDR, Germany) at 20 °C with values expressed as °Brix. Gross energy of yoghurt was calculated using the following equation: GE (Kcal) = [(protein × 4) + (lipid × 9) + (carbohydrates × 4)].

Syneresis was estimated as described by Al-Kadamany et al. (2003). Ten grams of yoghurt samples were placed on a filter paper resting on the top of a funnel. After 30 min of drainage, the whey quantity of remained curd was weighted and syneresis was expressed as volume of free whey.

The water-holding capacity (WHC) was determined as described by Arslan and Ozel (2012). Ten grams of yoghurt samples were centrifuged at 3000 × g for 30 min (at 15 °C). The WHC was expressed as a percentage of pellet weight relative to the original weight of yoghurt.

Phenolic content, antioxidant activity and vitamins analysis

Extractions of samples for total phenolics and antioxidant analysis were prepared as described by Selçuk and Yılmaz (2009). Total phenolic contents of the samples were measured using Folin-Ciocalteu reagent and expressed as milligrams of Gallic acid equivalents (GAE)/100 g, and antioxidant activity was determined using 2, 2-diphenyl-1-picrylhydrazyl (DPPH) method as described by Thaipong et al. (2006). The absorbance of the mixture (A) was measured at 515 nm by using spectrophotometer (model 6505 UV/Vis, JENWAY, UK). The DPPH solution was used as a blank. The antioxidant activity was calculated as follows: DPPH radical–scavenging activity (%) =

The IC50 value (mg/mL) was defined as the concentration of the extract required to quench 50% of the initial amount of DPPH under the given experimental conditions.

Ascorbic acid was measured using the method of AOAC (2005). Thiamine (B1), riboflavin (B2) and niacin (B3) were determined by the method of Rudenko and Kartsova (2010).

Mineral contents analysis

The mineral contents of White sapote fruit pulp and yoghurt samples including calcium (Ca), iron (Fe), and zinc (Zn) were determined using Perkin-Elmer Atomic Absorption Spectrophotometer as reported by AOAC (2005). Phosphorous (P) was estimated calorimetrically according to AOAC (2005).

Microbial analyses

The resultant yoghurt samples were microbiologically examined for total bacterial count, mold & yeast counts and coliform group according to American Public Health Association (APHA 1992). L. bulgaricus, and S. thermophilus counts were measured by the method of Tharmaraj and Shah (2003). B. longum was counted according to Dinakar and Mistry (1994).

Sensory evaluation

Yoghurt samples were sensory evaluated when fresh and after 7, 14, and 21 days of cold storage at (5 ± 1 °C) by 10 semi-trained panelists consisting of students of Department of Dairy Science and Technology, Faculty of Agriculture & Natural Resources, Aswan University, Egypt. For this experiment, the cups that contained 100 ml of yoghurt sample at 25 °C were provided. Each sample was assessed by a person with three repeats. The scoring system for sensory attributes was as follows: the flavor (60 points), body and texture (30 points), and appearance (10 points), which gave (100 points) overall acceptability.

Statistical analysis

SPSS (Version 11.0) software was used for all statistical analyses. The effects of different treatment and storage periods on yoghurt properties were assessed using analysis of variance (ANOVA). Significant means were compared using Duncan’s test at the level of P < 0.05.

Results and discussion

Proximate composition of white sapote fruits pulp

Physicochemical properties of White sapote fruit pulp (WSP) used for flavored yoghurt making are shown in Table 1. Data showed that the protein, fat fiber, ash and carbohydrate contents were 0.90, 0.35, 0.78, 0.60 and 19.87%, respectively. The content of protein, fat and ash were higher but carbohydrates and fiber were lower than those reported by Samaha (2002). The high amount of the carbohydrate in WSP is a good indication that these fruits are a good source of gross energy (86.23 kcal). Satheesh (2015) reported that Casimiroa edulis fruits had higher energy than an apple, banana, mango, and guava. As well as, Casimiroa edulis fruits had higher ash content than apples. The high ash content indicates that the fruit may be a good source for minerals, which is very important for metabolism. The mineral composition of WSP was P (65.00 mg/100 g), Ca (37.70 mg/100 g), Zn (5.11 mg/100 g) and Fe (2.70 mg/100 g). The contents of all minerals were higher than those reported by Morton (1987). Minerals are very important substances and essential ingredients of the diet required for normal metabolic activities of the body tissues.

Table 1.

Proximate composition, minerals, total phenols, antioxidant activity and vitamins contents of White sapote (Casimiroa laliave) fruit pulp

| Ingredient | Value |

|---|---|

| Proximate composition | |

| Moisture (%) | 77.50 ± 0.43 |

| Dry matter (%) | 22.50 ± 0.60 |

| Total soluble solid (TSS) 0brix | 15.60 ± 0.42 |

| Total carbohydrates (%)* | 19.87 ± 0.33 |

| Crude protein (%)* | 0.90 ± 0.06 |

| Crude fat (%)* | 0.35 ± 0.03 |

| Total dietary fiber (%)* | 0.78 ± 0.02 |

| Ash content (%)* | 0.60 ± 0.02 |

| Energy (K Cal.) | 86.23 ± 0.04 |

| pH | 5.80 ± 0.06 |

| Titratable acidity (%) as citric acid | 0.16 ± 0.02 |

| Minerals | |

| Phosphorus (mg/100 g)* | 65 ± 4.00 |

| Calcium content (mg/100 g)* | 37.70 ± 6.00 |

| Zinc content (mg/100 g)* | 5.11 ± 0.04 |

| Iron content (mg/100 g)* | 2.7 ± 0.11 |

| Antioxidants | |

| Total phenolic compounds (mg GAE /100 g) | 48.70 ± 9.00 |

| Antioxidant activity—IC50 (mg/mL) | 153.53 ± 3.31 |

| Ascorbic acid (mg/100 g) | 28.25 ± 1.50 |

| Vitamins | |

| Thiamine (B1) (mg/100 g)* | 0.061 ± 0.00 |

| Riboflavin (B2) (mg/100 g)* | 0.073 ± 0.00 |

| Niacin (B3) (mg/100 g)* | 0.551 ± 0.03 |

Results are mean of three determinations ± SD (standard deviation)

*Dry weight basis; Total protein = TN × 6.25

Results presented in Table 1 also indicate that WSP has a pH value (5. 80) and acidity (0.16% as citric acid) which makes it very appropriate for food fortification especially in foods with mild acidity like yoghurt. These values are important when fruits added to yoghurt as a flavoring agent will not affect the characteristics of the final product. In addition to that, WSP has good contents of TSS (15.60 Brix), total phenolic (48.70 mg GAE /100 g), ascorbic acid (28.25 mg/100 g), thiamine (0.061 mg/100 g), riboflavin (0.073 mg/100 g), niacin (0.551 mg/100 g) and antioxidant as IC50 (153.53 mg/mL). These results were similar to those obtained by Samaha (2002). The observed increase in the vitamin content could be a justification of the report by Satheesh (2015) who found that vitamins such as thiamine, riboflavin and niacin content are greater in the Casimiroa edulis than Apple. Linares and Bye (1990) reported that Casimiroa edulis fruit is rich in vitamins and contains high levels of carbohydrates. Based on the obtained results, WSP could be a good source of energy and nutritive components.

Physicochemical properties of yoghurt

The chemical constituents of the CY, PY, and PFY samples during the storage period are given in Table 2. Total solids, protein, fat, ash and carbohydrate contents of CY were insignificantly (P > 0.05) differed compared to PY. Similarly, Ayad et al. (2010) stated that total solids, protein and fat contents in bifidus yoghurt-like products were not affected by Bifidobacteria incorporation with yoghurt-like products. PFY had significantly higher total solids, protein, ash and carbohydrate and lower fat contents than those of the CY and PY samples. Sweetened probiotic yoghurt (PFY0) is the only treatment that had the lowest protein content compared to CY and PY samples; this may be due to the increase in total carbohydrates content than the rest of other components. The levels of these parameters were increased with increased ratio of WSP. PFY3 samples had the higher levels than other treatments. These findings are in accordance with the results of Matter et al. (2016) who observed that total solids, protein, ash and carbohydrate were increased and fat content was decreased with the increase in fruits pulp (papaya and cactus pear) that were added to yoghurt. This was associated with the increase in total solids and decrease in fat contents of WSP than milk. It is clear that during storage periods all components were increased gradually in all treatments except fat content was decreased up to the end. The reduction in fat content under the effect of storage could be attributed to lipolytic effect of bio-yoghurt culture.

Table 2.

Effect of flavoring with White sapote fruit pulp on the chemical composition of yoghurt samples during storage at 5 ± 1 °C for 21 days

| Yoghurt sample | Storage period (day) | Total solids (%) | Protein (%) | Fat (%) | Ash (%) | Total carbohydrates (%) |

|---|---|---|---|---|---|---|

| CY | Fresh | 14.81 ± 0.60 cA | 3.49 ± 0.06 bA | 3.90 ± 0.10 a A | 0.88 ± 0.01 dC | 6.54 ± 0.66 cA |

| 7 days | 15.11 ± 0.12 eA | 3.58 ± 0.01 c A | 3.91 ± 0.04 bA | 0.89 ± 0.01 cBC | 6.73 ± 0.11eA | |

| 14 days | 15.23 ± 0.03 e A | 3.50 ± 0.11 cA | 3.89 ± 0.00 a A | 0.90 ± 0.06 fAB | 6.94 ± 0.10 dA | |

| 21 days | 15.33 ± 0.01 eA | 3.53 ± 0.11 bA | 3.82 ± 0.05 aA | 0.91 ± 0.01 dA | 7.08 ± 0.11 dA | |

| PY | Fresh | 14.64 ± 0.39 cB | 3.48 ± 0.03 bA | 3.90 ± 0.05 aB | 0.88 ± 0.01 d B | 6.38 ± 0.33 cB |

| 7 days | 15.04 ± 0.09 d A | 3.58 ± 0.01 cA | 4.02 ± 0.02 aA | 0.89 ± 0.01 cB | 6.56 ± 0.07 dA | |

| 14 days | 15.32 ± 0.40 d A | 3.59 ± 0.01 bcA | 3.91 ± 0.01 aB | 0.91 ± 0.03 eA | 6.91 ± 0.41 cA | |

| 21 days | 15.39 ± 0.42 dA | 3.60 ± 0.01 bA | 3.85 ± 0.05 aB | 0.92 ± 0.06 dA | 7.02 ± 0.43 cA | |

| PFY0 | Fresh | 22.94 ± 0.06 bB | 3.44 ± 0.04 bA | 3.70 ± 0.10 bA | 0.92 ± 0.02 cC | 14.88 ± 0.18 bB |

| 7 days | 23.09 ± 0.11 cB | 3.47 ± 0.06 dA | 3.77 ± 0.03 cA | 0.94 ± 0.00 bBC | 14.91 ± 0.08 cB | |

| 14 days | 23.27 ± 0.29 cAB | 3.52 ± 0.09 cA | 3.63 ± 0.11bA | 0.95 ± 0.01 dAB | 15.16 ± 0.35 bB | |

| 21 days | 23.56 ± 0.22 cA | 3.56 ± 0.09 bA | 3.43 ± 0.11 bB | 0.97 ± 0.02 cA | 15.60 ± 0.10 bA | |

| PFY1 | Fresh | 23.30 ± 0.33 b C | 3.60 ± 0.01 aB | 3.50 ± 0.02 c A | 0.94 ± 0.05 bC | 15.26 ± 0.32 abC |

| 7 days | 23.48 ± 0.28 b BC | 3.69 ± 0.02 b A | 3.55 ± 0.05 e A | 0.95 ± 0.01 bB | 15.29 ± 0.21 bC | |

| 14 days | 23.82 ± 0.02 bAB | 3.69 ± 0.03 abA | 2.96 ± 0.00 dB | 0.96 ± 0.04 c A | 16.20 ± 0.04 aB | |

| 21 days | 23.96 ± 0.03 bA | 3.71 ± 0.02 aA | 2.65 ± 0.07 dC | 0.97 ± 0.01 cA | aA16.64 ± 0.11 | |

| PFY2 | Fresh | 23.68 ± 0.18 a C | 3.64 ± 0.09 aB | 3.50 ± 0.00 cA | 0.95 ± 0.00 b B | 15.59 ± 0.15 aC |

| 7 days | 23.87 ± 0.07 aB | 3.71 ± 0.02 b A | 3.57 ± 0.06 deA | 0.96 ± 0.00 b B | 15.64 ± 0.04 aC | |

| 14 days | 23.99 ± 0.02 abAB | 3.72 ± 0.01 aA | 3.04 ± 0.02 cdB | 1.04 ± 0.01 bA | 16.18 ± 0.02 aB | |

| 21 days | 24.09 ± 0.05 abA | 3.73 ± 0.03 aA | 2.62 ± 0.06 dC | 1.05 ± 0.03 bA | 16.70 ± 0.11 aA | |

| PFY3 | Fresh | 23.84 ± 0.14 a C | 3.66 ± 0.05 aA | 3.40 ± 0.20 cA | 1.02 ± 0.02 aB | 15.75 ± 0.26 aC |

| 7 days | 24.01 ± 0.10 aB | 3.78 ± 0.01 aA | 3.43 ± 0.06 dA | 1.04 ± 0.04 aAB | 15.76 ± 0.12 aC | |

| 14 days | 24.22 ± 0.03 a A | 3.78 ± 0.01 aA | 3.07 ± 0.01 cB | 1.07 ± 0.01 a A | 16.30 ± 0.01 aB | |

| 21 days | 24.36 ± 0.03 aA | 3.79 ± 0.01 aA | 2.78 ± 0.04 cC | 1.09 ± 0.00 aA | 16.71 ± 0.05 aA |

Mean (± SD) with small letters (abc) indicate significant differences among probiotic yoghurts flavored with different white Sapote fruit pulp levels. (in rows), P < 0.05.Mean (± SD) with capital letters (ABC) indicate significant differences among probiotic yoghurts samples during storage (in columns), P < 0.05

where: CY, control yoghurt; PY, probiotic yoghurt; PFY0, flavored probiotic yoghurt without fruit pulp; PFY1, flavored probiotic yoghurt with 5% fruit pulp; PFY2, flavored probiotic yoghurt with 10% fruit pulp; PFY3, flavored probiotic yoghurt with 15% fruit pulp

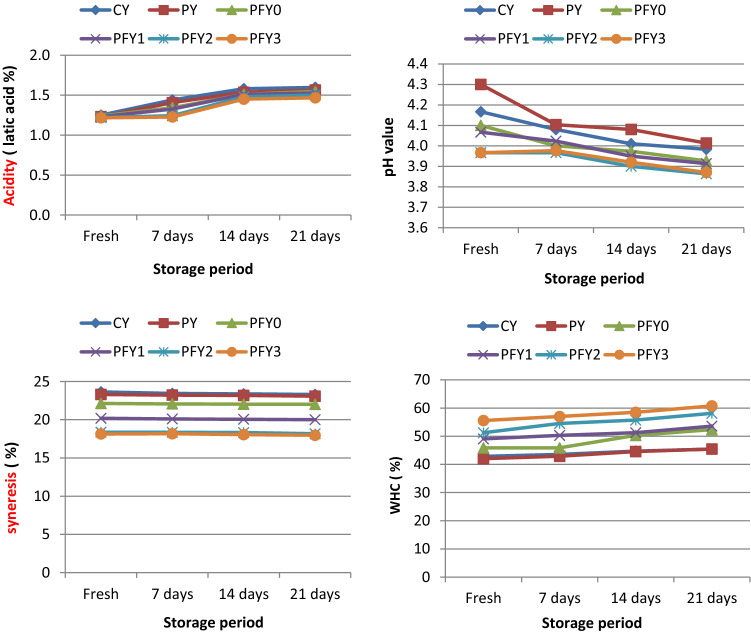

Physical properties of the CY, PY, and PFY are illustrated in Fig. 1. The data show that slight differences between CY, and PY for titratable acidity (% lactic acid), and pH value from the beginning and the final storage time 21st day. PY had lower titratable acidity while higher pH values as compared with CY. This result corresponds with that of Ranathunga and Rathnayaka (2013). In the PY samples, lactic acid and acetic acid are produced by L. bulgaricus and B. longum, respectively. In the CY samples, lactic acid is produced by S. thermophilus and L. bulgaricus. Thus, a higher rate of post acidification was observed in CY compared to PY. Moreover, addition of sugar (PFY0) resulted in significant decrease the pH values of the sample. This result was expected because addition of sugar source may help lactic acid bacteria to produce more acid. Furthermore, PFY had a lower pH value and titratable acidity than CY and PY. The decrease in acidity of PFY might be due to the low acidity of WSP. On the other hand, the total acidity was increased gradually by increasing WSP percentage which confirms their stimulation effect on the starter bacteria and B. longum. Similar findings were reported by Matter et al. (2016) for yoghurt flavored with fruit pulp such as papaya and cactus pear at the rates of 5%, 10% and 15%. Acidity percent of all yoghurt samples continuously developed and pH value dropped throughout the storage. These results, agree with the data obtained by Hossain et al. (2012), who demonstrated that the increase in titratable acidity during storage may be due to conversion of lactose to lactic acid. Generally, the acidity values of yoghurt samples were stable, as the low temperature (5 °C) of storage affected the growth of microorganisms.

Fig. 1.

Effect of flavoring with White sapote fruit pulp on some physicochemical properties of yoghurt samples during storage at 5 ± 1 °C for 21 days. Where: CY, control yoghurt; PY, probiotic yoghurt; PFY0, flavored probiotic yoghurt without fruit pulp; PFY1, flavored probiotic yoghurt with 5% fruit pulp; PFY2, flavored probiotic yoghurt with 10% fruit pulp; PFY3, flavored probiotic yoghurt with 15% fruit pulp

Syneresis or whey separation, the loss out of liquid from yoghurt, is one of the most common defects in fermented dairy products and especially set-type yoghurts. It is due to several reasons such as high incubation temperatures or inadequate storage temperature and lower solids content (Amaya-Liano et al. 2008). It is a significant visible flaw that occurs during storage and can influence the preference of the final product because texture with minimal syneresis is of interest to the consumer. Syneresis values of CY were slightly higher than that of PY (Fig. 1). This corroborates with the work of Ranathunga and Rathnayaka (2013) they found that protein network has been well formed in probiotic yoghurt samples. Probiotic bacteria have been involved in the formation of protein network of yoghurt which leads to form a better protein network in probiotic yoghurt than that of natural yoghurt. As seen in Fig. 1, the syneresis and WHC values in all samples of CY and PY were insignificant differed (P > 0.05) in fresh and during storage. The syneresis and WHC values of yoghurts were affected significantly (P< 0.05) by sugar addition, WSP ratios and storage time. It was determined that addition of sugar and WSP to the milk led to decrement in syneresis and increment in WHC value. The lowest mean syneresis and highest WHC values were recorded in PFY3 treatment at fresh and during storage for 21 days. Similarly, Mahmoud et al. (2008) found that the syneresis of stirred yoghurts blended with apple and banana fruits decreased throughout storage periods. Decrease in levels of syneresis can be attributed to decrease in pH through the storage interval. The trend of WHC for all samples increased throughout the storage period; it is due to the high total solids of PFY compared to CY and PY samples.

Minerals and vitamins content in fresh yoghurt

The results in supplementary materials (Table S1) showed the minerals and vitamins content in fresh yoghurt. The results, revealed that the average of calcium values were 724.0, 726.0, 726.0, 755.00, 767.67 and 779.00 mg/kg while phosphorus recorded; 626.0, 625.67, 620.33, 650.00, 671.67 and 683.00 mg/kg and zinc contents 1.22, 1.24, 1.32, 1.56, 1.68 and 1.73 mg/kg and iron contents 2.41, 2.44, 2.37, 2.61, 2.68 and 2.74 mg/kg for CY, PY, PFY0, PFY1, PFY2 and PFY3 samples, respectively. The contents of thiamine were 1.71, 1.70, 1.70, 1.73, 1.78 and 1.82 mg/kg and for riboflavin 2.56, 2.55, 2.51, 2.63, 2.70 and 2.76 mg/kg meanwhile, the niacin contents were 2.15, 2.15, 2.16, 2.17, 2.18 and 2.21 mg/kg for the different treatments, respectively. As seen in supplementary materials (Table S1), the minerals content (Ca, P, Zn, and Fe) and vitamin B (Thiamine, Riboflavin and Niacin) in all samples of CY, PY and PFY0 were insignificant differed (P > 0.05). Yoghurts PFY with fruit pulp had higher minerals and vitamins contents than that of other samples. By increasing the amount of WSP, the concentrations of minerals and vitamins in yoghurt increased. Furthermore, our results are in parallel with the results of McCanceet (1993) who stated that adding fruits such as strawberries, raspberries and wild blackberries to yoghurt increases the contents of the minerals. A similar increase in vitamins was also observed by Ihemeje et al. (2015), where pepper fruit, ginger, carrot, and pineapple were used in flavored yoghurt production. Finally, adding WSP to yoghurt had increased the concentrations of Ca, P, Zn, and Fe, as well as Thiamine, Riboflavin and Niacin and consequently increased its nutritive value.

Ascorbic acid, total phenols and antioxidant activity of yoghurt samples

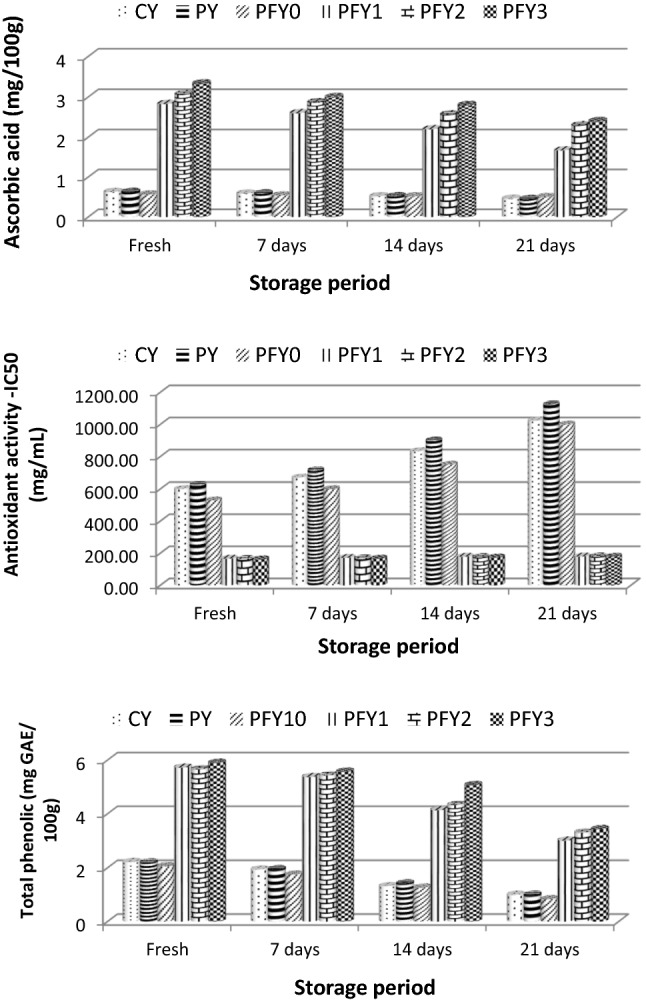

Regular intake of fruit and vegetables is related to the reduction of risk of diseases such as cancer and cardiovascular diseases, because they include natural antioxidants. Ascorbic acid, total phenols and antioxidant activity (expressed as IC50) values of yoghurt samples are presented in Fig. 2. There were no significant differences (P > 0.05) among samples of CY, PY and PFY0. On the other hand, samples of PFY with fruit pulp had significantly higher amounts for ascorbic acid, phenolic contents, and antioxidant activity than other samples and increased by increasing the level of WSP hence Casimiroa edulis fruits are considered good source of ascorbic acid, total phenols and antioxidants (Samaha 2002). Ascorbic acid, total phenols, and antioxidant activity were found to be high in PFY3 treatment. Abd-Eltawab and Ebid (2019) reported similar increases in antioxidant activity and total phenols content by adding fig fruit into stirred yoghurt. Ascorbic acid, total phenols and antioxidant activity decreased gradually for all yoghurt treatments during storage. These results are in line with those of Acıkgozoglu (2008) who detected a decrease in antioxidant activity values in yoghurts prepared with pomegranate juice concentrate and sour cherry juice concentrate during the storage period. This could be attributed to the decomposition of some phenolic compounds contents by LAB to aromatic acids such as phenyl acetic, phenyl propionic and benzoic acid, and then phenolic compounds could be divided into subgroups as phenolic acids, flavonoids and tannins. As well, Khalil (2013) reported that antioxidant activity tends to decrease through the storage period, as a result of possible oxidation.

Fig. 2.

Effect of flavoring with White sapote fruit pulp on ascorbic acid, antioxidant activity, and total phenolic contents of yoghurt samples during storage at 5 ± 1 °C for 21 days. Where: CY, control yoghurt; PY, probiotic yoghurt; PFY0, flavored probiotic yoghurt without fruit pulp; PFY1, flavored probiotic yoghurt with 5% fruit pulp; PFY2, flavored probiotic yoghurt with 10% fruit pulp; PFY3, flavored probiotic yoghurt with 15% fruit pulp

Microbiological quality

Microbial quality of the CY, PY and PFY during the storage at 5 ± 1 °C for 21 days is shown in Table 3. It could be noticed that total bacterial counts of CY sample were lower than that of PY in fresh and through the storage period. This may be due to the post acidification was higher in CY compared to PY samples which affect the survival of bacteria. Moreover, the microbial growth of PFY0 sample was high compared to CY and PY samples. As the growth of microorganisms was affected by the addition of WSP, that is increased with the increase in fruit addition. The total count of bacteria reaches its highest level when using 10% of WSP on the 14th day of storage. However, total bacterial counts of all samples were decreased at the end of storage. This decrease could be evidently attributed to the increase in acidity which controlled the rate of bacterial growth or acted as a bactericidal agent. This can be supported by the study of Buriti et al. (2014).

Table 3.

Effect of flavoring with White sapote fruit pulp on the microbiological quality of yoghurt during storage at 5 ± 1 °C for 21 days

| Storage period (day) | Yoghurt sample | |||||

|---|---|---|---|---|---|---|

| CY | PY | PFY0 | PFY1 | PFY2 | PFY3 | |

| Total bacteria count (Log CFU /g) | ||||||

| Fresh | 4.8 ± 0.10 dD | 5.27 ± 0.15 cD | 5.87 ± 0.25bB | 6.9 ± 0.10 aD | 7.13 ± 0.12 aC | 6.97 ± 0.15a D |

| 7 days | 10.9 ± 0.20 aA | 10.9 ± 0.02 aA | 10.53 ± 0.45 aA | 10.7 ± 0.10 aC | 10.5 ± 0.30 aB | 10.7 ± 0.10 aC |

| 14 days | 9.0 ± 0.20 e B | 9.8 ± 0.10 dB | 10.60 ± 0.36 cA | 11.3 ± 0.20 bB | 12.2 ± 0.10 aA | 12.0 ± 0.10 aA |

| 21 days | 7.5 ± 0.20 eC | 8.1 ± 0.10 d C | 10.43 ± 0.32 cA | 11.1 ± 0.10 bA | 12.3 ± 0.20 aA | 11.0 ± 0.10 Bb |

| S. thermophilus (Log CFU /g) | ||||||

| Fresh | 4.3 ± 0.20 cA | A4.6 ± 0.10 b | 4.63 ± 0.25 bB | 4.8 ± 0.10 abC | 5.0 ± 0.10 aB | 5.0 ± 0.10 aA |

| 7 days | 3.2 ± 0.10 eB | 4.3 ± 0.10 dB | 6.07 ± 0.25 aA | 6.3 ± 0.10 aA | 5.6 ± 0.20 bA | 4.6 ± 0.10 cB |

| 14 days | 2.5 ± 0.10 eC | 3.9 ± 0.10 dC | 4.97 ± 0.25 bB | 6.0 ± 0.10 aB | 5.8 ± 0.10 aA | 4.3 ± 0.10 cC |

| 21 days | 1.9 ± 0.1 0eD | 3.2 ± 0.20 dD | 3.93 ± 0.15 cC | 4.6 ± 0.10 aD | 4.8 ± 0.10 a B | 4.3 ± 0.10 bC |

| L. bulgaricus (Log CFU /g) | ||||||

| Fresh | 6.5 ± 0.30 bB | 6.0 ± 020 cB | 6.83 ± 0.15 abB | 7.1 ± 0.20 aB | 7.1 ± 0.20 aC | 6.6 ± 0.10 bB |

| 7 days | 7.1 ± 0.30 bA | 6.4 ± 0.10 cA | 6.97 ± 0.25 bAB | 7.8 ± 0.10 aA | 8.1 ± 0.20 aB | 7.1 ± 0.10 bA |

| 14 days | 4.6 ± 0.10 e C | 4.3 ± 0.10 eC | 6.37 ± 0.35 dA | 7.8 ± 0.10 bA | 8.6 ± 0.10 aA | 7.1 ± 0.10 c A |

| 21 days | 3.7 ± 0.10 dD | 2.7 ± 010 fD | 5.50 ± 0.20 bC | 5.0 ± 0.10 cC | 6.0 ± 0.10 aD | 3.0 ± 0.30 eC |

| B.longum (Log CFU /g) | ||||||

| Fresh | ND | 6.0 ± 0.20 c B | 6.47 ± 0.25 bB | 6.7 ± 0.10bB | 7.0 ± 0.10 aC | 6.5 ± 0.20 bB |

| 7 days | ND | 6.4 ± 0.10 dA | 7.00 ± 0.20 cA | 7.6 ± 0.10 bA | 8.0 ± 0.10 aB | 7.1 ± 0.10 cA |

| 14 days | ND | 4.6 ± 0.10 dC | 6.43 ± 0.42 cB | 7.6 ± 0.10 bA | 8.3 ± 0.20 aA | 6.6 ± 0.20 cB |

| 21 days | ND | 3.7 ± 0.10 dD | 5.63 ± 0.15 bC | 5.6 ± 0.10 b C | 6.3 ± 0.10 a A | 4.1 ± 0.10 cC |

| Mould & Yeast (Log CFU /g) | ||||||

| Fresh | ND | ND | ND | ND | ND | ND |

| 7 days | ND | ND | ND | ND | ND | ND |

| 14 days | 0.70 ± 0.20 bA | 0.95 ± 0.20 aB0 | ND | ND | ND | ND |

| 21 days | 0.43 ± 0.20 bB | 1.15 ± 0 40 aA | ND | ND | ND | ND |

| Coliform group (CFU/g) | ||||||

| Fresh | ND | ND | ND | ND | ND | ND |

| 7 days | ND | ND | ND | ND | ND | ND |

| 14 days | ND | ND | ND | ND | ND | ND |

| 21 days | ND | ND | ND | ND | ND | ND |

Mean (± SD) with small letters (abc) indicate significant differences among probiotic yoghurts flavored with different white Sapote fruit pulp levels. (in rows), P < 0.05.Mean (± SD) with capital letters (ABC) indicate significant differences among probiotic yoghurts samples during storage (in columns), P < 0.05

where: CY, control yoghurt; PY, probiotic yoghurt; PFY0, flavored probiotic yoghurt without fruit pulp; PFY1, flavored probiotic yoghurt with 5% fruit pulp; PFY2, flavored probiotic yoghurt with 10% fruit pulp; PFY3, flavored probiotic yoghurt with 15% fruit pulp

The beneficial effects of the regular consumption of yoghurt on the consumer’s health have always been related to the presence of a high concentration of viable lactic acid bacteria in the product. The data also showed that the yoghurt bacteria of both S. thermophilus and L. bulgaricus survived well in yoghurt until the date of use. Significant changes in the counts of S. thermophilus and L. bugaricus were noticed in yoghurt when fresh and through the storage period. The L. bulgaricus counts in the CY samples were significantly higher but S. thermophilus counts were lower compared with that of PY samples over the time of storage. In addition, the growth of beneficial microorganisms (lactic acid bacteria) in yoghurt was enhanced by the addition of sugar. Furthermore, the addition of WSP had a significant positive impact on the viability of both lactic acid bacteria strains. The initial numbers of L. bulgaricus were higher than S. thermophilus but more marked decrease than S. thermophilus was observed during storage. The results indicated that a gradual increase was observed throughout the storage time to reach the maximum at the 7th day in all treatments except trail PFY2 continued to 14th day and then decreased in all yoghurts to the end of storage period. At 21st day of storage, the counts of L bulgaricus and S. thermophilus for all yoghurt samples showed a sharp decline which was significantly different (P < 0.05) from the primary counts. The decrease in lactic acid bacterial counts at the end of storage may be due to the sensitivity of these bacteria to the acid developed during the storage period. These observations are in line with those of Buriti et al. (2014) for dairy beverages prepared using guava, and sour pulps.

Differences were found in B. longum counts between yoghurt samples for different treatments with extending the storage period (Table 3). B. longum counts in PFY samples were significantly (P< 0.05) higher in comparison with that of PY over the time of storage. The increase was proportional to the increase in fruit pulps added in all treatments. The highest count of B. longum was recorded in yoghurt contains 10% of WSP. In the light of these results, we can conclude that White sapote fruits acted as prebiotic of bifidobacteria and consequently increases the activity of the probiotics of the yoghurt. These results are in agreement with those of Blassy et al. (2020) they noticed that addition of guava pulp led to an increase in the total viable LAB count of yoghurt. Jin et al. (2018) reported that fruits and vegetables contain bioactive compounds that can be used as substrates for probiotic bacteria growth. During the storage period, the counts of B. longum increased until 7 days except treatment PFY2 continued up to 14 days production date. On the other hand, the decline in the viable count that showed at the end storage period may be attributed to the higher levels of these acids in yoghurt (Buriti et al. 2014). Regarding the mold & yeast counts were not detected until the end of storage except for CY and PY were detected on 14th day and continued until the 2st day from the storage period. The appearance of mold & yeast could be attributed to post contamination during storage. The results are in harmony with the results of Tarakçi and Küçüköner (2003). All yoghurt samples when fresh and throughout the storage were free of coliforms. This might be due to the efficiency of heat treatment of milk which inhibits the vegetative cells, also the sanitation and hygienic conditions during the manufacture of the product.

Sensory quality

Food preferences and consumer acceptance are dramatically based on sensory properties such as flavor, color, texture, and taste. Therefore, the popularity of yoghurt as a food component depends mainly on its sensory characteristics, and added flavors to yoghurt have been found to increase options for consumers and helps in marketing. The sensory evaluation of fresh and stored CY, PY and PFY samples is shown in Table 4. Higher values were given by the panelist for the appearance, body & texture, and flavor of PY than CY. In general, according to the overall acceptability, the PY was preferred by the panelist over CY. Shihata and Shah (2002) found that using probiotic cultures to produce yoghurt resulted in a fine, mild taste and low post acidification. The results were in harmony with those obtained by Baraka et al. (2011) who cleared that the yoghurt sample made by adding of Bifidobacteria to yoghurt culture gained the highest scores for appearance, body & texture and flavor, among all the treatments. Ranathunga and Rathnayaka (2013) found that the color of the probiotic yoghurt was whitish creamy and natural yoghurt was yellowish. This may be due to the high production of compounds responsible for the color by the bacteria in starter culture used in natural yoghurt production than that of probiotic yoghurt production. The sensory attributes of the PFY were significantly (P< 0.05) improved by adding sugar and WSP. Adding sugar to yoghurt may be represented as a factor for consistency in the mouth and overall acceptability. Panelists have rated likeness higher in sweetened yoghurts compared with CY and PY samples. There were clear improvements in all sensory attributes, which significantly increased by increasing the level of WSP when fresh and throughout the storage period. Generally, the data obtained showed that probiotic strain and fortification with WSP at a ratio of 10% led to higher scores for acceptability, compared with the others, suggests that the consumer acceptance was influenced by the addition of WSP. The use of different fruits or additives in fruit yoghurt making resulted in enhancement of its nutritional, functional and sensorial characteristics (Cakmakcı et al. 2012). However, the sample PFY2 containing 10% WSP was quite good, gained the uppermost scores, and remained the highest acceptance up to 21 days of the storage period compared to the other types of flavored yoghurts. Increasing WSP fortification level to 15% decreased appearance, body & texture, flavor and overall acceptability. The score values of overall acceptability gradually decreased after the 14th day along the storage period could be due to the acidity development or the production of microbial metabolism which slightly harmed the rheological and sensory properties of the product.

Table 4.

Effect of flavoring with White sapote fruit pulp on sensory properties of yoghurt during storage at 5 ± 1 °C for 21 days

| Storage period (day) | Yoghurt sample | |||||

|---|---|---|---|---|---|---|

| CY | PY | PFY0 | PFY1 | PFY2 | PFY3 | |

| Appearance (10) | ||||||

| Fresh | 8.00 ± 1.00 abA | 8.00 ± 0.00 abA | 8.00 ± 1.00 abA | 8.00 ± 0.00 abA | 8.67 ± 0.58 aA | 7.33 ± 0.58 bA |

| 7 days | 8.00 ± 0.00 bA | 8.00 ± 0.00 bA | 8.33 ± 0.58abA | 8.33 ± 0.58 abA | 9.00 ± 0.00 aA | 7.67 ± 0.58 bA |

| 14 days | 7.33 ± 0.58 cAB | 7.67 ± 0.58 cA | 8.67 ± 0.58 abA | 8.67 ± 0.58 abA | 9.00 ± 0.00 aA | 8.00 ± 0.00 bcA |

| 21 days | 6.67 ± 0.58 dB | 7.00 ± 0.00 cdB | 8.33 ± 0.58 abA | 8.33 ± 0.58 abA | 9.00 ± 0.00 aA | 7.67 ± 0.58 bcA |

| Body & texture (30) | ||||||

| Fresh | 24.00 ± 1.00 cA | 25.00 ± 1.00 bcA | 26.00 ± 1.00 bA | 26.00 ± 0.00 bA | 27.67 ± 0.58 aA | 28.33 ± 0.58 aA |

| 7 days | 24.33 ± 0.58 cA | 25.33 ± 1.15 bcA | 26.33 ± 0.58 bA | 26.33 ± 0.58 bA | 28.00 ± 0.00 aA | 28.67 ± 0.58 aA |

| 14 days | 23.67 ± 0.58 cA | 25.33 ± 1.15 bA | 26.33 ± 0.58 bA | 26.33 ± 0.58 bA | 28.67 ± 0.58 aA | 29.00 ± 0.00 aA |

| 21 days | 22.67 ± 1.53 cB | 24.67 ± 1.53 bA | 26.00 ± 0.00 bA | 26.00 ± 0.00 bA | 28.67 ± 0.58 aA | 28.67 ± 0.58 aA |

| Flavour (60) | ||||||

| Fresh | 50.00 ± 0.00 eA | 52.00 ± 1.00 dA | 54.67 ± 0.58 cA | 56.00 ± 1.00 bA | 57.33 ± 0.58 aB | 56.67 ± 0.58 abA |

| 7 days | 52.33 ± 0.58 dA | 52.33 ± 0.58 cA | 55.33 ± 0.58 bA | 56.67 ± 1.53 abA | 58.00 ± 0.00 aAB | 57.67 ± 0.58 aA |

| 14 days | 50.33 ± 0.58 eA | 52.33 ± 0.58 dA | 55.33 ± 0.58 cA | 57.00 ± 1.00 bA | 58.33 ± 0.58 aA | 57.67 ± 0.58 abA |

| 21 days | 48.33 ± 1.53 eB | 50.33 ± 0.58 dA | 55.67 ± 0.58 cA | 57.33 ± 0.58 abA | 58.67 ± 0.58 aA | 56.67 ± 0.58 bcA |

| Overall acceptability (100) | ||||||

| Fresh | 82.00 ± 0.00 dA | 85.00 ± 1.73 cA | 88.67 ± 2.08 bA | 90.00 ± 1.00 bA | 93.67 ± 0.58 aC | 92.33 ± 0.58 aB |

| 7 days | 82.67 ± 0.58 dA | 85.67 ± 0.58 cA | 90.00 ± 1.00 bA | 91.33 ± 2.08 bA | 95.00 ± 0.00 aB | 94.00 ± 1.73 aAB |

| 14 days | 81.33 ± 1.53 eA | 85.33 ± 0.58 dA | 90.33 ± 0.58 cA | 92.00 ± 1.00 bA | 96.00 ± 0.00 aA | 94.67 ± 0.58 aA |

| 21 days | 77.67 ± 2.52 eB | 82.00 ± 1.00 dB | 90.00 ± 0.00 cA | 91.67 ± 0.58 bcA | 96.33 ± 0.58 aA | 93.00 ± 1.00 bAB |

Mean (± SD) with small letters (abc) indicate significant differences among probiotic yoghurts flavored with different white Sapote fruit pulp levels. (in rows), P < 0.05.Mean (± SD) with capital letters (ABC) indicate significant differences among probiotic yoghurts samples during storage (in columns), P < 0.05

where: CY, control yoghurt; PY, probiotic yoghurt; PFY0, flavored probiotic yoghurt without fruit pulp; PFY1, flavored probiotic yoghurt with 5% fruit pulp; PFY2, flavored probiotic yoghurt with 10% fruit pulp; PFY3, flavored probiotic yoghurt with 15% fruit pulp

Conclusion

This study aimed to improve the flavor and nutritional value of yoghurt. White sapote fruit is an excellent source of different nutrients like carbohydrates, ascorbic acid, phenolic compounds, antioxidants activity, vitamins, and minerals. In this research, it was observed that White sapote fruit could serve as a stimulatory nutrient factor for probiotic bacteria. The results indicated that White sapote (Casimiroa edulis) fruit could be used to produce yoghurts with increased functional and health-promoting effects, as well as to develop nutritional characteristics. This product makes a combination of the probiotic properties of yoghurt and the prebiotic properties of the fruit. This study has shown that fortifying yoghurt with 10% White sapote fruit pulp produced an acceptable product with potential beneficial health effects. Generally, data showed that probiotic yoghurt made with B. longum bacteria and/or fortified with White sapote fruit pulp had higher scores for acceptability, compared with the conventional yoghurt.

Supplementary Information

Below is the link to the electronic supplementary material.

Abbreviations

- AOAC

Association of official analytical chemists

- APHA

American public health association

- DPPH

2,2-Diphenyl-1-picrylhydrazyl

- LAB

Lactic acid bacteria

- WHC

Water holding capacity

- CFU

Colony forming unit

- WSP

White sapote fruits pulp

Author contributions

All authors are equal contribution for this paper.

Funding

The authors have no support or funding to report.

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Declarations

Conflict of interest

Authors have no conflicts of interest to declare for this article.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Hesham A. Ismail, Email: h_alshnety@agr.nvu.edu.eg, Email: h_alshnety@yahoo.com

Wael F. Elkot, Email: wael.fathi@agr.aswu.edu.eg

References

- Abd-Eltawab SA, Ebid WMA. Production and evaluation of stirred synbiotic fermented milk fortified with fig fruit (Ficus carica L.) Egypt J Food Sci. 2019;47(2):201–212. [Google Scholar]

- Acikgozoglu AB (2008) Determination of some properties of yoghurts made by addition of some fruit juice concentrates. Selcuk Univ., MSc thesis, Konya, Turkey

- Adolfsson O, Meydani SN, Russell RM. Yogurt and gut function. Am J Clin Nutr. 2004;80:245–256. doi: 10.1093/ajcn/80.2.245. [DOI] [PubMed] [Google Scholar]

- Akalın AS, Fenderya S, Akbulut N. Viability and activity of bifidobacteria in yoghurt containing fructooligosaccharide during refrigerated storage. Int J Food Sci Technol. 2004;39:613–621. doi: 10.1111/j.1365-2621.2004.00829.x. [DOI] [Google Scholar]

- Al-Kadamany E, Khattar M, Haddad T, Toufeili I. Estimation of shelf life of concentrated yoghurt by monitoring selected microbiological and physiological changes during storage. Lebensm-Wiss-Technol. 2003;36:407–414. doi: 10.1016/S0023-6438(03)00018-5. [DOI] [Google Scholar]

- Amaya-Liano SL, Martinez AL, Bustoe F. Acid thinned Jicama and maize starch as fat substitute in stirred yoghurt. LWT-Food Sci Technol. 2008;41:1274–1281. doi: 10.1016/j.lwt.2007.08.012. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 18. Maryland: Association of Official Analytical Chemists; 2005. [Google Scholar]

- APHA . American publish health association compendium of methods for the microbiological examination of foods. 18. Washington D.C, USA: American Public Health Association; 1992. [Google Scholar]

- Arslan S, Ozel S. Some properties of stirred yoghurt made with processed grape seed powder, carrot juice or a mixture of grape seed powder and carrot juice. Milchwissenschaft. 2012;67:281–285. [Google Scholar]

- Ayad E, Darwish A, Darwish S, El Souda M. Production of novel functional yoghurt-like products. Egypt J Dairy Sci. 2010;38(2):183–199. [Google Scholar]

- Baraka AAE, Abeer FZ, Mailam MA. Effect of fortification with honey and bifidobacterium strain on the characteristics of yoghurt. Egypt J Dairy Sci. 2011;39:65–74. [Google Scholar]

- Blassy K, Osman M, Gouda A, Hamed M. Functional properties of yoghurt fortified with fruits pulp. Ismailia J Dairy Sci Technol. 2020;7(1):1–9. doi: 10.21608/ijds.2020.130628. [DOI] [Google Scholar]

- Buriti FCA, Freitas SC, Egitic AS, dos Santos KMO. Effects of tropical fruit pulps and partially hydrolysed galactomannnan from caesalipinia pulchemima seeds on the daitary fiber content, probiotic viability, texture and sensory features of goat dairy beverages. LWT-Food Sci Technol. 2014;59:196–203. doi: 10.1016/j.lwt.2014.04.022. [DOI] [Google Scholar]

- Cakmakcı S, Cetin B, Turgut T, Gurses M, Erdoğan A. Probiotic properties, sensory qualities, and storage stability of probiotic banana yogurts. Turk J Vet Anim Sci. 2012;36:231–237. [Google Scholar]

- Dinakar P, Mistry VV. Growth and viability of Bifidobacterium bifidum in cheddar cheese. J Dairy Sci. 1994;77(10):2854–2864. doi: 10.3168/jds.S0022-0302(94)77225-8. [DOI] [PubMed] [Google Scholar]

- Hossain N, Fakruddin Md, Nurul I. Quality comparison and acceptability of yoghurt with different fruit juices. J Food Process Technol. 2012;3:1–5. doi: 10.4172/2157-7110.1000171. [DOI] [Google Scholar]

- Ihemeje A, Nwachukwu CN, Ekwe CC. Production and quality evaluation of flavoured yoghurts using ginger and peper fruit. Afr J Food Sci. 2015;9(3):163–169. doi: 10.5897/AJFS2014.1244. [DOI] [Google Scholar]

- Jin X, Chen W, Chen H, Chen W, Zhong Q. Comparative evaluation of the antioxidant capacities and organic acid and volatile contents of mango slurries fermented with six different probiotic microorganisms. J Food Sci. 2018;83:3059–3068. doi: 10.1111/1750-3841.14373. [DOI] [PubMed] [Google Scholar]

- Khalil RAM. The use of pomegranate juice as a natural source for antioxidant in making functional yoghurt drink. Egypt J Dairy Sci. 2013;41:137–149. [Google Scholar]

- Linares E, Bye R. Selecciόn de plantas medicinales de México. México: Limusa; 1990. [Google Scholar]

- Mahmood A, Abbas N, Gilani AH. Quality of stirred buffalo milk yogurt blended with apple and banana fruits. Pak J Agric Sci. 2008;45(2):275–279. [Google Scholar]

- Matter AA, Mahmoud EAM, Zidan NS. Fruit flavored yoghurt: chemical, functional and rheological properties. Int J Environ Agric Res. 2016;2(5):57–66. [Google Scholar]

- McCanceet W (1993) The composition of foods (5th revised and extended ed.). The Royal Society of Chemistry and Ministry of Agriculture, Fisheries and Food, Cambridge, UK

- Moo-Huchin VM, Estrada-Mota I, Estrada-Leon R, Cuevas-Glory L, Ortiz-Vazquez E, Vargas y Vargas Mde L, Betancur-Ancona D, Sauri-Duch E. Determination of some physicochemical characteristics, bioactive compounds and antioxidant activity of tropical fruits from yucatan, mexico. Food Chem. 2014;152:508–515. doi: 10.1016/j.foodchem.2013.12.013. [DOI] [PubMed] [Google Scholar]

- Morton J (1987) White sapote. In: Julia F. Morton (Eds) Fruits of warm climates. Miami, FL, pp.191–196

- Ranathunga MTN, Rathnayaka RMUSK. Comparison of physico-chemical and sensory properties of probiotic and natural yoghurt. J Biol Food Sci Res. 2013;2(1):1–6. [Google Scholar]

- Rudenko AO, Kartsova LA. Determination of water-soluble vitamin B and vitamin C in combined feed, premixes and biologically active supplements by reversed-phase HPLC. J Anal Chem. 2010;65(1):71–76. doi: 10.1134/S1061934810010132. [DOI] [Google Scholar]

- Samaha ORA. Characteristics and utilization of white sapote (Casimiroa edulis L. Lave) fruits. Alex J Agric Res. 2002;47(3):49–53. [Google Scholar]

- Satheesh N. Review on distribution, nutritional and medicinal values of casimiroa edulis llave-an underutilized fruit in Ethiopia. Am-Eurasian J Agric Environ Sci. 2015;15(8):1574–1583. [Google Scholar]

- Selçuk AR, Yılmaz Y. İşlenmiş üzüm çekirdeği tozu ilavesinin lokum benzeri bir ürünün toplam fenolik madde içeriği ile antioksidan aktivitesi üzerine etkisi. Acad Food J. 2009;7:56–61. [Google Scholar]

- Shah NP. Bifidobacteria: characteristics and potential for application in fermented milk products. Milchwissenschaft. 1997;52:16–20. [Google Scholar]

- Shihata A, Shah NP. Influence of addition of proteolytic strains of Lactobacillus delbrueckii subsp. bulgaricus to commercial ABT starter cultures on texture of yogurt, exopolysaccharide production and survival of bacteria. Int Dairy J. 2002;12(9):765–772. doi: 10.1016/S0958-6946(02)00071-7. [DOI] [Google Scholar]

- Tarakçi Z, Küçüköner E. Physical, chemical, microbiological and sensory characteristics of some fruit-flavoured yoghurt. YYU Vet Fak Derg. 2003;14:10–14. [Google Scholar]

- Thaipong K, Boonprakob U, Crosby K, Cisneros-Zevallos L, Byrne DH. Comparison of ABTS, DPPH, FRAP and ORAC assay for estimating antioxidant activity from guava fruit extracts. J Food Compos Anal. 2006;19:669–675. doi: 10.1016/j.jfca.2006.01.003. [DOI] [Google Scholar]

- Tharmaraj N, Shah NP. Selective enumeration of Lactobacillus delbrueckii ssp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacteria, Lactobacillus casei, Lactobacillus rhamnosus, and Propionibacteria. J Dairy Sci. 2003;86:2288–3229. doi: 10.3168/jds.S0022-0302(03)73821-1. [DOI] [PubMed] [Google Scholar]

- Yahia EM, Gutierrez-Orozco F. Postharvest biology and technology of tropical and subtropical fruits. Woodhead Publishing; 2011. White sapote (Casimiroa edulis Llave & Lex) pp. 474–482. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, upon reasonable request.