Abstract

Development process of rice analogues by utilising the broken rice (BRF) and broken pigeonpea dhal (BPDF) flours together with water and sodium alginate as binding agent through extrusion was carried out. Two variable viz., BPDF (20, 30 and 40%) and moisture content (25, 30 and 35%) were controlled in the study to produce rice analogue resembling the raw rice. The optimum combination of flour mixture established for 30% BPDF and 30% water content with highest desirability of 0.855. The optimum combination had highest crude protein, carbohydrate and ash contents of 12.70, 71.72 and 0.99%, respectively. The colour values L*, a* and b* were found to be 68.30, 4.62 and 25.91, respectively. The pasting temperature and peak viscosity were 78.68 °C and 23,173.3 cP. The physico-chemical and pasting properties can be modified by altering the different constituents for specific quality requirements.

Keywords: Broken rice and dhal utilisation, Rice analogue, Extruded rice and rice like grains

Introduction

Rice is one of the leading food crops and sustains two third of the world’s population, providing 20% of the world’s dietary energy supply (Choi et al. 2010) and staple food for 2.5 billion people (Khan et al. 2009). The slogan “Rice is Life” can be considered appropriate for India as this crop plays a vital role in our national food security and is a means of livelihood for millions of rural households (Deshwal et al. 2019). Rice is a rich source of macro and micronutrients in its unmilled form (Steiger et al. 2014) but milling is an important criterion for obtaining whole rice kernel. An issue of concern during rice milling is breakage of kernels (30–50% Patel et al. 2001) and removal of micronutrient-rich bran layer. The broken grains are mainly used as feed or brewing raw materials, which has a low economic value (Mishra et al. 2012). However, there is considerable potential for value addition of this relatively cheaper by-product of rice milling industry. This would not only supplement nutrition for a large part of population but could also help in conservation of food and additional monetary benefit to the rice milling industry (Steiger et al. 2014).

Pulses are another important global food crops providing much needed protein to the carbohydrate rich vegetarian diet (Yadav et al. 2019). It is therefore popularly known as “Poor man’s meat”, contributing significantly to the nutritional security of the country (Singh et al. 2015). Pigeonpea (Cajanas cajan) is an important pulse crop in India followed by gram contributing 15 to 20% in the total production. Pigeonpea is consumed in the form of dehusked split pulse known as dhal. Processing of pulses into dhal is being coupled with losses and wastage estimated to be about 10–25% (Singh 1995). Utilising these milling by-products would supplement nutrition to a large part of population and economic benefit to the pulse milling industry.

Despite being a primary food, rice is low in protein and high in starch. The low protein levels in rice cause deficiencies of protein and some essential amino acids in people who take it as their primary diet. One approach to overcome the problems is to produce “faux” rice kernels using milling by-products of rice and dhal mills by extrusion technology (Dexter 1998). Based on the above facts the investigation was undertaken to standardize the composite flour for production of rice analogues using by-products of rice and dhal mills by extrusion processing and analyze the quality parameters.

Materials and methods

Raw materials

The raw material used for the study viz., whole rice grains and broken rice (BPT 5204) were procured from M/s. Radhe Agro Industries, Raichur and broken pigeonpea dhal (TS-3R) were procured from M/s. Raghavendra Pulses, Kalaburagi. The broken grains were ground using hammer mill and then sieved manually by using 150 µ sieve to obtain flour of uniform particle size (Patel et al. 2001). The broken rice flour is represented as BRF and broken pigeonpea dhal flour as BPDF in the paper.

Extrusion of rice analogues

Cold extruder (La Monferrina, Dolly mini, Italy) was used for development of rice analogues. The unit is basically a single screw extruder consists of a stainless steel screw having 3:1 barrel length to diameter ratio with uniform pitch. It was powered by a 2.25 kW electrical motor through a speed reduction system. For preparation of the rice analogues with desirable internal and apparent good texture, the blended broken rice flour, dhal flour and binding agent were tempered by adding a predetermined amount of water (25–35%) by spraying and mixing for 30 min for equilibrium (Yogeshwari et al. 2019). The operating conditions were fixed at 55 rpm screw speed and 1.5 kg/h feed rate. The temperature profile in the barrel zone towards rice shaped die was 60 °C. After obtaining the dough of required consistency, extruder was operated to produce the rice analogues with desired size using cutter blade attached at the outlet of the die and the cutter blade was operated at 90 rpm. The extrudates were collected, cooled at room temperature and dried using a tray drier at 40 °C for 1 h.

Fabrication of die for extrusion of rice analogues

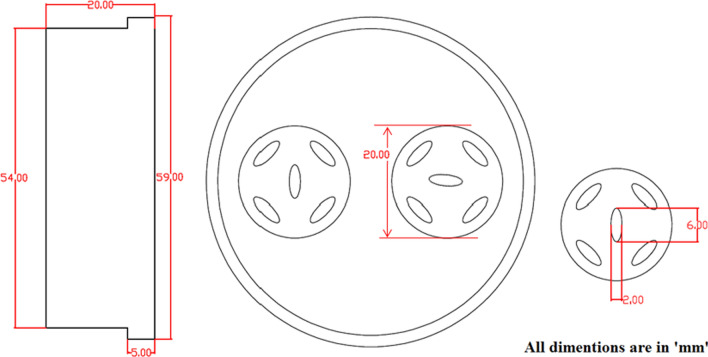

The extruder die with elliptical shaped die holes resembling the rice kernel was fabricated based on the size of the whole rice kernel. The size of the whole rice kernel was determined by the standard procedures and instruments explained by Mohsenin (1986). The average kernel dimensions determined for the whole rice grains (5.330 mm length, 1.799 mm width and 1.455 mm thickness) were used and the die hole dimensions selected for fabrication were 6.0 mm length and 2.0 mm width (at the center) as shown in Fig. 1. The die hole dimensions selected were larger than the average size of the rice grain considering the reduction in the size due to shrinkage after drying. The cold extruder die having the external dimensions of 59.00 mm diameter and 20 mm thickness was fabricated to fit in the existing cold extruder machine.

Fig. 1.

Schematic diagram of cold extruder die and die hole

Composite flour formulation for development of rice analogue

The process flow chart for the production of extruded rice analogues is presented in Fig. 2. The process mainly involved the optimization of composite flour containing appropriate proportion of BPDF, BRF and water. The BPDF at different levels viz., 20, 30 and 40 per cent were blended with remaining proportion of base material BRF to bring the mixture to 100 per cent. The initial moisture of the flour determined was 5% and the moisture content of composite flour was achieved by adding the water at 26.7, 35.7 and 46.2 ml/100 g to obtain moisture content of 25, 30 and 35 per cent. Sodium alginate at 1% (Cox and Cox 1993) was added as binding agent to provide cohesive powder mixture forming rice analogues due to the poor binding ability of rice flour (Pagani 1986; Patel et al. 2001). Mixing of the flour was continued until the mixture was homogeneous (approx. 10 min) and the dough was rested for 2 h before putting it into the extruder (Budi et al. 2015). The rice analogues were extruded in a cold extruder with cutter blade. After reaching a steady operating state and producing good extrudate (uniform), the product was dried to moisture content not more than 15 per cent on wet basis (Steiger 2010) using a tray drier at 40 °C for 1 h (Patel et al. 2001).

Fig. 2.

Process flow chart for development of rice analogues

Development of fortified rice analogues using broken rice and pigeonpea dhal

Rice analogues were produced by the process of extrusion using laboratory scale cold extruder. The extruded rice analogues developed using different treatment combinations of moisture content and pigeonpea dhal flours. The process mainly involved the formulation of appropriate flour mix of broken rice, broken pigeonpea dhal, binding agent and moisture content as per the treatment combinations. The flour mixture was then extruded in a cold extruder through rice shaped die and dried to a moisture content of not more than 15% on wet basis.

Experimental design

The experiments were designed according to the general factorial design. The numerical optimization was carried out using Design Expert software 7.7.0 (Statease Inc., Minneapolis, USA) for two independent variables of extrusion flour mix viz., BPDF and moisture content at three levels each as shown in Table 1. The dependent variables/responses selected for optimization process were the quality characteristics viz., crude protein, carbohydrate, ash and colour values.

Table 1.

Treatment combinations for standardization of composite flour

| Treatments | Broken rice flour (%) | Pigeonpea dhal flour (%) | Moisture content (%) |

|---|---|---|---|

| T0 | 100 | 0 | 30 |

| T1 | 80 | 20 | 25 |

| T2 | 80 | 20 | 30 |

| T3 | 80 | 20 | 35 |

| T4 | 70 | 30 | 25 |

| T5 | 70 | 30 | 30 |

| T6 | 70 | 30 | 35 |

| T7 | 60 | 40 | 25 |

| T8 | 60 | 40 | 30 |

| T9 | 60 | 40 | 35 |

T0—Dhal-0%, M.C-Avg. of 25, 30 and 35%, T1—Dhal-20%, M.C-25%; T2—Dhal-20%, M.C-30%; T3—Dhal-20%, M.C-35%; T4—Dhal-30%, M.C-25%; T5—Dhal-30%, M.C-30%; T6—Dhal-30%, M.C-35%; T7—Dhal-40%, M.C-25%; T8—Dhal-40%, M.C-30%; T9—Dhal-40%, M.C-35%

Quality characteristics of extruded rice analogues

The selected proximate characteristics were determined for the developed rice analogues with different treatment combinations. The crude protein, carbohydrate and total ash content were analysed by the AOAC (2005) and the colour values (L*, a* and b*) were determined by Hunter’s Lab Colorimeter (Hunterlab, CLFX-45, Reston, USA). The pasting properties of rice analogues were determined by a modular compact rheometer (Anton-Paar GmbH, MCR 102, Graz, Austria) as per the procedure explained by Kim et al. (2009).

Economics of production of rice analogues

The significant part of rice analogues development depends not only on their legal status, expected bioavailability, stability and sensory acceptability but also on the cost effectiveness. The cost of production for rice analogues was calculated using two importance cost concepts viz., fixed costs and variable costs.

Results and discussion

Dimensions of whole rice kernels

The average values of dimensions in terms of length width and thickness of the whole rice grains were found to be 5.33 ± 0.04 mm, 1.79 ± 0.0 mm and 1.45 ± 0.01 mm, respectively. The dimensions were used for fabrication of the die hole resembling the rice kernel for extrusion of rice analogues. The results of the dimensions were similar to that reported earlier (L—6.61 mm, W—1.75 mm and T—1.40 mm) by Ghadge and Prasad (2012).

Effect of BPDF and moisture content on biochemical properties of rice analogues

The important components of proximate composition which have the major effect on the optimisation of composite flour viz., crude protein, carbohydrate, ash and colour values for different treatment combinations of extruded rice analogues were estimated and are shown in Table 2.

Table 2.

Proximate composition and colour values of extruded rice analogues

| Treatments | Proximate composition and colour values of extruded rice analogues | |||||

|---|---|---|---|---|---|---|

| Crude protein (%) | Carbohydrate (%) | Ash (%) | L* value | a* value | b* value | |

| TR | 8.51 ± 0.05 | 78.05 ± 0.31 | 0.52 ± 0.02 | 93.69 ± 0.00 | 0.08 ± 0.03 | 5.54 ± 0.06 |

| T0 | 8.37 ± 0.32 | 78.42 ± 0.62 | 0.50 ± 0.01 | 86.50 ± 1.88 | 1.65 ± 0.26 | 10.48 ± 0.67 |

| T1 | 10.84 ± 0.06 | 74.65 ± 0.24 | 0.58 ± 0.01 | 67.51 ± 0.20 | 4.34 ± 0.09 | 26.25 ± 0.15 |

| T2 | 11.00 ± 0.02 | 73.97 ± 1.48 | 0.63 ± 0.01 | 69.01 ± 0.31 | 3.74 ± 0.05 | 25.70 ± 0.57 |

| T3 | 11.08 ± 0.04 | 73.00 ± 0.57 | 0.65 ± 0.03 | 72.89 ± 0.60 | 3.54 ± 0.07 | 24.09 ± 0.73 |

| T4 | 12.38 ± 0.02 | 72.76 ± 1.27 | 0.97 ± 0.03 | 66.17 ± 1.37 | 4.78 ± 0.32 | 27.18 ± 0.59 |

| T5 | 12.70 ± 0.03 | 71.72 ± 0.82 | 0.99 ± 0.02 | 68.30 ± 0.76 | 4.62 ± 0.10 | 25.91 ± 0.22 |

| T6 | 12.71 ± 0.02 | 70.84 ± 0.61 | 1.01 ± 0.01 | 70.87 ± 0.79 | 4.56 ± 0.19 | 26.30 ± 0.40 |

| T7 | 13.02 ± 0.01 | 70.24 ± 0.31 | 1.06 ± 0.02 | 64.58 ± 0.78 | 5.07 ± 0.33 | 28.73 ± 0.58 |

| T8 | 13.43 ± 0.31 | 70.04 ± 0.19 | 1.12 ± 0.00 | 66.12 ± 1.16 | 4.95 ± 0.29 | 27.66 ± 0.54 |

| T9 | 13.47 ± 0.07 | 69.54 ± 0.53 | 1.18 ± 0.02 | 69.17 ± 1.28 | 4.80 ± 0.15 | 27.22 ± 0.61 |

| CD@1% | 0.417 | 2.208 | 0.066 | 2.921 | 0.610 | 1.527 |

| SE(m) ± | 0.141 | 0.748 | 0.022 | 0.990 | 0.207 | 0.517 |

| CV | 2.112 | 1.775 | 4.589 | 2.372 | 9.349 | 3.863 |

| Significance | S | S | S | S | S | S |

*S, Significant; NS, Non significant

TR—Raw rice (Control), T0—Dhal-0%, M.C-Avg. of 25, 30 and 35%, T1—Dhal-20%, M.C-25%; T2—Dhal-20%, M.C-30%; T3—Dhal-20%, M.C-35%; T4—Dhal-30%, M.C-25%; T5—Dhal-30%, M.C-30%; T6—Dhal-30%, M.C-35%; T7—Dhal-40%, M.C-25%; T8—Dhal-40%, M.C-30%; T9—Dhal-40%, M.C-35%

Crude protein

The addition of pigeonpea flour was focused on utilizing the brokens and enhancing protein content of analogue rice. The result presented in Table showed significantly higher protein in the extruded rice analogues with BPDF (10.84 ± 0.06 to 13.47 ± 0.07%) per cent as compared to raw rice (8.51 ± 0.05%) and rice analogue without BPDF (8.37 ± 0.32%). It was observed that, the crude protein content of the rice analogues increased with increase in pigeonpea level and moisture content. The high protein content of pigeonpea flour (20.893 ± 0.58%) contributed in increasing the protein content of extruded rice analogues and in-situ development of temperature might have destructed the protein levels resulting in lower levels of protein in low moisture extrusion. The results reported by Patel et al. (2001) for protein (11.63%) content of rice analogues produced by broken rice and blackgram and Khairunnisa et al. (2017) for production of high protein (11.34%) rice analogues by incorporation of soybean flour were in agreement with the results.

Carbohydrate

The results of carbohydrate content in the extruded rice analogues showed the values ranging from 69.54 ± 0.53 to 74.65 ± 0.24 per cent as compared to 78.05 ± 0.31 per cent in raw rice and rice analogue without BPDF 78.42 ± 0.62 per cent. The carbohydrate content of rice analogues decreased with the increase in BPDF and moisture content and might be due to increase in the protein contributed from BPDF. Similar results of carbohydrate contents of 71.94% were reported by Sumardiono et al. (2014) for production of rice analogues using composite flour and Khairunnisa et al. (2017) for production of high protein rice analogues by incorporation of 30% soybean flour.

Total ash

Ash content represents the total of minerals in the extruded rice analogue. The ash content was ranging from 0.58 ± 0.01 to 1.18 ± 0.02% compared to raw rice (0.52 ± 0.02%) and rice analogue without BPDF (0.50 ± 0.01%). It was observed that, with an increase in the amount of pigeonpea flour, the ash content of the blends increased significantly. The increase in the ash content was probably due to the addition of pigeonpea flour which had higher amount of ash content (Kaushal et al. 2012). While, increase due to increase in moisture content might be attributed to the addition of minerals through process moisture during extrusion and also from the extruder barrel (Singh et al. 2000). Similar results were reported by Khairunnisa et al. (2017) while producing high protein rice analogues by incorporation of soybean flour.

Colour (L*, a* and b*)

The colour values were significant among all the treatments. L* (whiteness) value ranged from 64.58 ± 0.78 to 72.89 ± 0.60 compared to raw rice (93.69 ± 0.00) and rice analogue without BPDF (86.50 ± 1.88). It was observed that, the value of whiteness (L*) decreased with the increase of BPDF lead to dark colored rice analogue might be attributed to the composition of the flour and colored pigments of the flours, which in turn depends on the botanical origin of the plant (Aboubakar et al. 2008). Whereas, the L* decreased with the decrease in the moisture content due to higher temperature generation during the process of extrusion.

The a* (redness) value was recorded to be ranged from 3.54 ± 0.07 to 5.07 ± 0.33 for rice analogues and for raw rice and rice analogue without BPDF were 0.08 ± 0.03 and 1.65 ± 0.26, respectively. The values of b* (yellowness) for extruded rice analogues ranged from 24.09 ± 0.73 to 28.73 ± 0.58 whereas, raw rice and rice analogue without BPDF were 5.54 ± 0.06 and 10.48 ± 0.67, respectively. The redness (a*) and yellowness (b*) increased with increase in BPDF and decreased with increase in moisture. The increased a* and b* was due to colored pigments of BPDF based on botanical origin (Aboubakar et al. 2008) and the development of non-enzymatic browning of carbohydrates. Similar results were reported by Khairunnisa et al. (2017) for production of high protein rice analogues by incorporation of soybean flour decreased the L* (67.22 to 57.68) increased the a* (1.63 to 2.22) and b* (11.98 to 13.42) values.

Pasting properties of extruded rice analogues

The important pasting properties viz., peak viscosity and pasting temperature were determined and data on mean values are summarized in Table 3.

Table 3.

Pasting properties of extruded rice analogues

| Treatments | Peak viscosity (cP) | Pasting temperature (°C) |

|---|---|---|

| TR | 31,340 ± 240.9 | 76.43 ± 0.17 |

| T0 | 29,752 ± 689.4 | 77.09 ± 0.50 |

| T1 | 24,678 ± 146.2 | 77.29 ± 0.08 |

| T2 | 24,444 ± 197.5 | 77.65 ± 0.26 |

| T3 | 24,310 ± 292.6 | 77.79 ± 0.26 |

| T4 | 23,373 ± 191.6 | 78.34 ± 0.25 |

| T5 | 23,173 ± 153.7 | 78.68 ± 0.34 |

| T6 | 23,120 ± 100.6 | 78.94 ± 0.49 |

| T7 | 22,673 ± 172.4 | 79.09 ± 0.18 |

| T8 | 22,623 ± 213.2 | 79.30 ± 0.19 |

| T9 | 22,350 ± 132.8 | 79.46 ± 0.18 |

| CD@1% | 816.8 | 0.927 |

| SE(m) ± | 276.7 | 0.314 |

| C.V | 1.940 | 0.696 |

| Significance | S | S |

*S, Significant

TR—Raw rice (Control), T0—Dhal-0%, M.C-Avg. of 25, 30 and 35%, T1—Dhal-20%, M.C-25%; T2—Dhal-20%, M.C-30%; T3—Dhal-20%, M.C-35%; T4—Dhal-30%, M.C-25%; T5—Dhal-30%, M.C-30%; T6—Dhal-30%, M.C-35%; T7—Dhal-40%, M.C-25%; T8—Dhal-40%, M.C-30%; T9—Dhal-40%, M.C-35%

Peak viscosity (PV) is the rapid increase in viscosity when sufficient number of sample granules becomes swollen. The peak viscosity ranged from 22,350 ± 132.8 to 24,678 ± 146.2 cP compared to the raw rice (31,340 ± 240.9 cP) and rice analogue without BPDF (29,752 ± 689.4 cP). The peak viscosity decreased with increase in BPDF and moisture content. Pasting temperature (PT) is another important component of pasting property indicating the minimum temperature required to cook the flour. The PT was observed to be ranging from 79.46 ± 0.18 to 77.29 ± 0.08 °C as compared to raw rice (76.43 ± 0.17 °C) and rice analogue without BPDF (77.09 ± 0.50 °C). The PT increased with increase in pigeonpea dhal flour. The changes in the pasting properties could be attributed to the swelling power of pigeonpea containing protein as high protein and starch content in the flours might cause the starch granules to be embedded within a stiff protein matrix which limits the access of the starch to moisture and restricts the swelling (Kaushal et al. 2012).

Optimisation of BPDF and moisture content for production of extruded rice analogues

Numerical optimization was performed using statistical models to determine the optimal flour composition containing BPDF and moisture content for production of rice analogues. In the present investigation, the independent variables were kept within the range and dependent variables were chosen as maximum and minimum. The goal of optimization was fixed as maximization of protein, ash, L* and peak viscosity values and minimization of carbohydrate, a*, b* and pasting temperature values based on quality of rice analogues resembling natural rice. The values of all the responses at operating conditions were converted to a desirability function. The desirability values of the minimum and maximum were configured as 0 and 1, respectively. The maximum desirability function obtained was taken as the optimum operating condition (Krishnaiah et al. 2015). Optimisation process established 9 solutions, but only several points were chosen as optimum points, on condition that it satisfied the criteria mentioned. The optimimum desirability of 0.855 was obtained for flour composition having 30 per cent BPDF and 30 per cent moisture content for production of rice analogues as depicted in Fig. 3.

Fig. 3.

Desirability graph for combinations of BPDF and moisture content for development of rice analogues

Economics of rice analogues production

The cost involved in production of rice analogue was calculated as per the standard procedures based on the fixed cost and variable cost (Roks 2014). The fixed cost for the machinery/equipment used was calculated to be Rs. 5.20 per kg of analogues produced. The variable cost including cost of raw materials, labour, electrical energy and repair and maintenance was calculated to be Rs. 35.90 per kg of rice analogues. The total cost involved in production of one kg of rice analogues using cold extruder was worked out to be Rs. 41.0. The production seems to be costly whereas, increase in the cost can be mitigated by adding the nutrients in the rice analogues and mixing with raw rice @ 1:50 ratio. The fortification process involves simple operations and minimum additional investment is needed in particularly rice consuming states as a whole to accomplish fortification to combat the malnutrition. Given the present technology, a set of equipments for blending fortified rice analogues with raw rice could be accomplished easily in any rice mill.

Conclusion

The rice analogues were developed utilising the broken rice and broken pigeonpea dhal flours along with water and binding agent in an extruder. The laboratory model cold extruder could be used to produce rice analogues resembling the rice kernels with similar physico-chemical properties. The process optimisation was carried out for optimum combination of the broken pigeonpea dhal flour and moisture with the broken rice flour as base material. Addition of pigeonpea dhal flour in the extruded rice analogue flour mix contributed to the increased protein and ash contents along with decreased peak viscosity and increased pasting temperature. The rice analogue production technology can be utilized for fortification process involving simple operations and minimum additional investment needed in particularly rice consuming states as a whole to accomplish fortification to combat the malnutrition.

Acknowledgements

The authors would like to thank, (1) University of Agricultural Sciences (UAS) Raichur for providing facilities for undertaking research. (2) AICRP on PHET, CIPHET, Ludhiana for providing the financial assistance

Abbreviations

- AOAC

Association of Official Analytical Chemists

- BPDF

Broken pigeonpea dhal flour

- BRF

Broken rice flour

- cP

Centi-poise

- g

Gram

- h

Hour

- kg/h

Kilogram per hour

- kW

Kilowatt

- ml

Milliliter

- mm

Millimeter

- PV

Peak viscosity

- PT

Pasting temperature

- rpm

Revolutions per minute

- µ

Micrometer

Authors' contributions

Dr. AG was responsible for conceiving the idea, carried out the work and wrote the manuscript, while Dr. UN and Dr. HS supervised the work and corrected the manuscript; Dr. KTR and Dr. PFM analysed the data statistically and corrected the manuscript; Dr. NN and Dr. SV have analysed the quality parameters and corrected the manuscript.

Funding

This work was supported by AICRP on PHET, CIPHET, Ludhiana.

Availability of data and material

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Not Applicable.

Declarations

Conflicts of interest

The authors declare that they have no competing interests.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Aboubakar, Njintang YN, Scher J, Mbofung CMF. Physicochemical, thermal properties and microstructure of six varieties of taro (Colocasia esculenta L. Schott) flours and starches. J Food Eng. 2008;86(2):294–305. doi: 10.1016/j.jfoodeng.2007.10.006. [DOI] [Google Scholar]

- Association of Official Analytical Chemists (2005) Official methods of analysis of the AOAC International, 18th edn. Gaithersburg, MD, USA

- Budi FS, Hariyadi P, Budijanto S, Syah D. Effect of dough moisture content and extrusion temperature on degree of gelatinization and crystallinity of rice analogues. J Dev Sus Agric. 2015;10(2):91–100. doi: 10.11178/jdsa.10.91. [DOI] [Google Scholar]

- Choi HJ, Chang JL, Cho EJ, Choi SJ, Moon TW. Preparation, digestibility, and glucose response in mice of rice coated with resistant starch type 4 using locust bean gum and agar. Int J Food Sci Technol. 2010;45(12):2612–2621. doi: 10.1111/j.1365-2621.2010.02434.x. [DOI] [Google Scholar]

- Cox JP, Cox JM (1993) Cohesive vegetable product and process for manufacture. United States Patent, 5252351

- Deshwal R, Sachan SK, Singh G, Singh DV, Singh G, Chand P. Seasonal abundance of insect pests associated with paddy crop in western plain zone of Uttar Pradesh. J Entomol Zool Stud. 2019;7(3):1347–1350. [Google Scholar]

- Dexter PB (1998) Rice fortification for developing countries. Fayetteville, Ark, USA. OMNI/USAID. https://pdfs.semanticscholar.org/b410/d985117cfd0ddd2216668ef91bcac51acf8d.pdf Accessed 25 July 2019

- Ghadge PN, Prasad K. Some physical properties of rice kernels: variety PR-106. J Food Process Technol. 2012;3(8):1000175. doi: 10.4172/2157-7110.1000175. [DOI] [Google Scholar]

- Kaushal P, Kumar V, Sharma HK. Comparative study of physicochemical, functional, antinutritional and pasting properties of taro (Colocasiaesculenta), rice (Oryza sativa) flour, pigeonpea (Cajanus cajan) flour and their blends. LWT - Food Sci Technol. 2012;48(1):59–68. doi: 10.1016/j.lwt.2012.02.028. [DOI] [Google Scholar]

- Khairunnisa K, Budijanto S, Sitanggang AB (2017) Formulation of high protein rice analogue made of cassava, maize starch, and soybean. In: Proceedings of the 24th Tri-University International Joint Seminar and Symposium, Mie University Japan, 23–27 2017

- Khan AS, Imran M, Ashfaq M. Estimation of genetic variability and correlation for grain yield components in rice (Oryza sativa) Am-Euras J Agric Environ Sci. 2009;6(5):585–590. [Google Scholar]

- Kim SK, Sohn EY, Lee IJ. Starch properties of native foxtail millet (Setaria italica Beauv) J Crop Sci Biotech. 2009;12(1):59–62. doi: 10.1007/s12892-009-0073-0. [DOI] [Google Scholar]

- Krishnaiah D, Bono A, Sarbatly R, Nithyanandam R, Anisuzzaman SM. Optimisation of spray drying operating conditions of Morinda citrifolia L. fruit extract using response surface methodology. J King Saud Univ Eng Sci. 2015;27(1):26–36. [Google Scholar]

- Mishra A, Mishra HN, Rao PS. Preparation of rice analogues using hot extrusion technology. Int J Food Sci Technol. 2012;47(9):1789–1797. doi: 10.1111/j.1365-2621.2012.03035.x. [DOI] [Google Scholar]

- Mohsenin N. Physical properties of plant and animal materials. New York: Gordon and Breach Science Publishers; 1986. pp. 616–681. [Google Scholar]

- Pagani MA. Pasta products from non-conventional raw materials. In: Mercier C, Cantarelli C, editors. Pasta and extrusion cooked foods: Some technological and nutricional aspects. London: Elsevier Applied Science Publishers; 1986. pp. 52–68. [Google Scholar]

- Patel NC, Das SK, Bal S (2001) Process and machine for production of rice analogue from broken rice. ASAE Annual International Meeting, Sacramento Convention Center Sacramento, California, USA. 10.13031/2013.3986. Last accessed 29 Nov 2018

- Roks E. Review of the cost components of introducing industrially fortified rice. Ann New York Acad Sci. 2014;1324(1):82–91. doi: 10.1111/nyas.12480. [DOI] [PubMed] [Google Scholar]

- Singh U. Methods of dehulling of pulses: a critical appraisal. J Food Sci Technol. 1995;32(2):81–93. [Google Scholar]

- Singh D, Chauhan SG, Suresh I, Tyagi SM. Nutritional qualities of extruded snacks developed from composite of rice broken and wheat bran. Int J Food Prop. 2000;3(3):421–431. doi: 10.1080/10942910009524646. [DOI] [Google Scholar]

- Singh AK, Singh SS, Prakash V, Kumar S, Dwivedi SK. Pulses production in India: present status, bottleneck and way forward. J AgriSearch. 2015;2(2):75–83. [Google Scholar]

- Steiger G, Muller-Fischer N, Cori H, Conde-Petit B. Fortification of rice: Technologies and nutrients. Ann New York Acad Sci. 2014;1324(1):29–39. doi: 10.1111/nyas.12418. [DOI] [PubMed] [Google Scholar]

- Steiger G (2010) Reconstituted rice kernels and processes for their preparation. https://patents.google.com/patent/WO2010020640A1/en. Accessed 29 Nov 2018

- Sumardiono S, Pudjihastuti I, Poerwoprajitno AR, Suswadi MS. Physico-chemical properties of analogue rice from composite flour: Cassava, green bean and hanjeli. World Appl Sci J. 2014;32(6):1140–1146. doi: 10.5829/idosi.wasj.2014.32.06.708. [DOI] [Google Scholar]

- Yadav AS, Kumar S, Kumar N, Ram H. Pulses production and productivity: status, potential and way forward for enhancing farmers income. Int J Curr Microbiol App Sci. 2019;8(4):2315–2322. doi: 10.20546/ijcmas.2019.804.270. [DOI] [Google Scholar]

- Yogeshwari R, Hemalatha G, Vanniarajan C, Saravanakumar R, Kavithapushpam A. Development of micronutrient fortified extruded rice analogues. Eur J Nutr Food Saf. 2019;9(1):1–11. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Not Applicable.