Abstract

Edible oils include triglycerides that are extracted from oil seeds or fruits such as sunflowers, palms, olives, soys, rapeseeds, cocoa and many others. They are the elementary origins of unsaturated fats and vitamins especially vitamin 'E' in people’s diets. Edible oils are at risk of intentional (such as inadequate storage conditions) and unintentional adulteration, so it is necessary to pay attention to their safety, health and fraud. Generally, this evaluation can be destructive or non-destructive. There are numerous methods to evaluate quality of edible oils which include sensory analysis, chemical analysis, chromatography, ultrasound, etc. The Ultrasonic approach is a non-destructive way and also fast, accurate, inexpensive, repeatable, portable and simple. Combination of ultrasound with other techniques such as electronic nose, electronic tongue, visible spectroscopic fingerprints, chemical descriptors, Raman spectroscopy, mid-infrared and machine vision, will improve quality evaluation and detection accuracy. This review summarizes the ultrasound idea and the latest knowledge of its application with other techniques on evaluation of edible oils.

Keywords: Ultrasound, Edible oil, Non-destructive, Quality evaluation

Introduction

Edible oils include about 96 percent triacyl-glycerides which are collected from different fatty acids. A few other groups of compounds such as phospholipids, phytosterols, free-fatty-acids, tocopherols and other antioxidants or waxes can also be found. The third largest agricultural product after cereals and meat as the world's strategic products are edible oils; so these are considered as an important part of agricultural economy. Lipids are a valuable source of energy and provide over 35–40% of daily human calories and produce energy twice more than carbohydrates and proteins. Some fatty acids are essential and human body is not able to produce them, due to lack of enzymes and should be fed through foods. Linoleic-acid (Omega-6) and alpha-linolenic-acid (Omega-3) are two essential fatty-acids for humans that play an important role in the body. Essential fatty-acids are supplied from fats and edible oils (Popkin 2011).

Serving edible oils regularly is necessary because of the important role edible oils have in our diets. They supply essential fatty acids and also energy and solve soluble vitamins of fat. They also protect body tissues such as eyes, skin, breasts and liver. Edible oils are mostly used for cooking and frying. Formulations of foods are derived from plant sources, specifically from oil-seeds such as sunflower seeds, soybean, canola, cottonseed and peanuts. Edible vegetable-oils are liquid-form at room temperature and mainly are comprised of triacyl-glycerides which include 3 fatty acids joined to molecule of glycerol through ester bonds whereas animal fats are mostly solid at room temperature. Quality of edible oils is evaluated in terms of health aspects and nutritional value (adding low-value additives to high-value oils). Among the oily plants, five oilseeds including palm fruit, soy, canola, cottonseed and peanut have had the highest oil production in recent years.

However, the most application of edible oil evaluation is fraud detection. In the process of manufacturing fried food (Mumith et al. 2014), consumption of edible oil (He et al. 2013; Wrona et al. 2013) is very large. Replacing old frying oil with new edible-oil after the production, leads to oil wasting and increasing in the cost of production. A process of production on the premise of food security, taking some old frying oil out and adding a noticeable proportion of the new edible-oil can be used to solve the problem. This leads to improving edible-oil utilization rate and reduction in the cost of production. However, higher amount of old frying oil has many problems. Contacting oil molecules with air oxygen leads to reactions such as hydrolysis, polymerization and oxidation which result in high peroxide value and viscosity and types of cancers (Zhao et al. 2013). All the mentioned issues are good reasons to show the necessity of edible oil fraud detection (composing low-quality oils with fresh high-quality edible oils).

In the production of food, the Quality Control (Q.C.) is an important parameter. This parameter's aim is validation of food quality in aspect of safety. New approaches in quality control are developed by researchers and related organizations according to consumer's needs. Evaluation techniques are generally divided into two categories: destructive and non-destructive tests.

There are several approaches to evaluate quality of edible oils. In general, these methods can be taken into the following categories: 1. Sensory analysis, 2. Physical analysis including microscopic and macroscopic methods like calorimetry (Van Wetten et al. 2015), 3. Chemical analysis like chromatography (Jabeur et al. 2016), 4. Spectroscopic-based methods (Ok 2017; Torrecilla et al. 2010; Rizki et al. 2016; Zhao et al. 2015; and 5. Electronic-based methods like EC or capacitance or machine vision (Jafari et al. 2014; Jafari et al. 2012). These approaches are mostly referenced in many standards and regulations.

The traditional approach of edible oil quality evaluating is using people called “tasters”. These trained people can check and evaluate oils by tasting different oils. However, some methods such as chromatography, are mostly used in identifying the edible oil quality. This method is based on the fragmentation of the matter into its component parts. Other methods such as thermometry, ultrasound, electronic tongue and nose, near infrared spectroscopy, machine vision and Nuclear Magnetic Resonance (NMR) are also used to determine quality of edible oils and their fraud detection. Non-destructive and non-contact testing methods are certainly very important. Contact tests have microbial pollution potential.

However, compared with all these methods, ultrasound has many advantages. The ultrasound approach is fast, highly accurate, non-destructive, inexpensive, repeatable and portable. In this review, we will concentrate on application of ultrasound in evaluating quality edible oils and also their combination with other techniques.

Overview on the ultrasound techniques

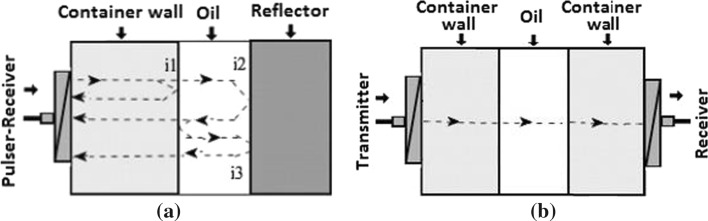

Ultrasound is a mechanical wave. In general, waves are classified in two types: longitudinal (or compression) wave and transverse (horizontal) wave. In longitudinal waves, direction of particles’ oscillatory movement is parallel to direction of the wave propagation, in contrary, in the transverse wave, particles oscillatory movement is perpendicular to the wave propagation direction. The longitudinal wave propagates almost in all materials but transverse wave propagates just in solid materials. The ultrasonic is a category of longitudinal waves which is defined by the modified compression and rarefaction cycles of the material that a wave spreads in it. Difference in the compression of the material causes moving particles to transfer energy. Generally applications of ultrasound in characterization of edible oils can be used in two types: pulser-receiver (single sensor) and transmitter–receiver (two sensors) (Fig. 1).

Fig. 1.

two types of traditional ultrasound system in food characterization a. pulser-receiver b. pulse-echo

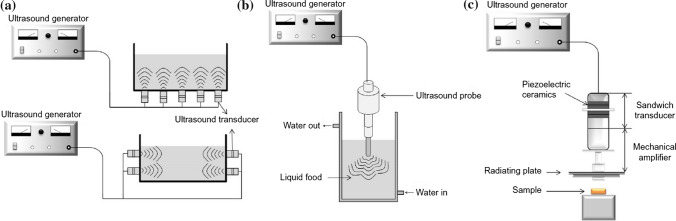

Ultrasound is a longitudinal compression wave with higher than the upper level of audible range of human hearing frequencies. Some various ultrasound wave applications in foods include: Blending and homogenization (Mason et al. 2005), drying and refinement (Tao and Sun 2015), collapsing and degassing of foams (Dedhia et al. 2004), odor derivation (Chemat et al. 2017), nucleation of foods (Kiani et al. 2011), airborne powders precipitation (Mason et al. 2005), meat tenderization (Alarcon-Rojo et al. 2015), deep-washing vegetables and oil extraction. Ultrasound technique is a technology that is developed to improve quality, minimize processing and ensure the safety of food products. (Fig. 2).

Fig. 2.

Schematic of ultrasound systems available for food processing: a Bath type (contact), b Probe type (contact) and c Non-contact type (Charoux et al. 2017)

Principles of measurement

Diagnostic ultrasound method is based on the difference in the wave velocity, the attenuation coefficiency and so on. The ultrasound features of each material are unique; so it can be used for classification and quality evaluation of foods. As the ultrasound wave is transmitted in a matter, it gradually loses its energy, which is represented as an attenuation. Attenuation coefficient (α) is obtained according to Eq. 1:

| 1 |

where A0 and A, are the initial amplitude and amplitude of wave after traveling x distance in the matter. Each ultrasound system is composed of some parts which include: signal generator, transmitter and receiver transducer and a programmable system such as a PC.

Generally, ultrasonic transducers are classified into three main types: 1- fluid-driven type, 2- magnetostrictive type and 3- piezoelectric type (Mulet et al. 2003). The first type, fluid-driven transducers generate vibration at the range of ultrasonic frequencies by pressing liquid to a thin metal blade. This can be applied in systems such as mixing and homogenization type. The magnetostrictive transducers are generally composed of a kind of ferro-magnetic materials. Using these materials near the magnetic fields leads to change dimensionally and this change occurs after mechanical vibration. This type of ultrasonic system has low efficiency and about 60% transfer to acoustic energy (Leadley and Williams 2006). In the third type (the piezoelectric transducers), electrical signals cause change in dimensions of materials such as 'barium titanate', 'lead zirconate titanate' and 'lead metaniobate'. These kinds of transducers are very popular and most frequently used and are more popular with high performance (80%- 95% transfer to acoustic energy) (Mulet et al. 2003; Leadley and Williams 2006).

Types of ultrasonic transducer

Ultrasonic waves are produced by moving elements from a vibrating material. Generated mechanical waves from these elements may go through liquid, solid and gas. Every change in the material which waves pass through it will affect the wave characteristics. Ultrasound transducers can measure basic and practical features of foods on-line or off-line.

In commercial application, ultrasonic systems for diagnostic applications are classified into two parts: non-contact and contact systems (Charoux et al. 2017). In contact systems, an ultrasonic system uses liquid (water, oil, etc.) as a couplant. When ultrasound signals pass through a liquid, test sample is impressed chemically and physically. (Ojha et al. 2018). These types of ultrasound systems, are good for several food processing applications which include degassing of liquids (Liu et al. 2017), heat and mass transfer amplification (Gondrexon et al. 2015), milk pasteurization and homogenization (Czank et al. 2010), emulsification (Reboredo- Rodriguez et al. 2014), fat separation (Torkamani et al. 2016), powder hydration (Bhandari and Zisu 2016), extraction of bioactives (Kumari et al. 2018), enhancement of drying rate (Magalhaes et al. 2017), freezing rates (Islam et al. 2017), etc.

Recently along with development in science of materials, ultrasound sensors made of materials including ceramics, quartz, pyrex, polyether ether ketone, or poly-tetra-fluro-ethylene have dominated some of the restrictions of metal horns (Capelo-Martinez 2009). Sensors that airborne ultrasound applies, are non-contact type and are able to transmit ultrasound signals to the object by means of air as a couplant (Charoux et al. 2017).

Piezoelectric transducers

Piezoelectric materials are generally applied to manufacture ultrasonic sensors. Figure 3 shows that applying pressure to piezoelectric material, causes electrical output:

Fig. 3.

Piezoelectric effect

In contrast, electric pulses affect piezoelectric shape. (Fig. 3).

Generally, an ultrasonic piezoelectric probe was produced to transmit compressive waves and/or receiving: every change in piezoelectric dimensions will affect generating signals properties. One of the important disadvantages of regular piezoelectric probes is that it is necessary that the material under test and the ultrasound probes have effective contact with each other to convey ultrasound energy to the material to be inspected. Necessity of contact limits the application of piezoelectric probes and the detection speed of such transducers. Generally water is applied as a coupling material.

These non-contact probes include air coupled transducers, laser-ultrasound systems and Electro-magnetic acoustic transducers (EMAT). Air coupled transducers are mostly used, so we will introduce them briefly here.

Air coupled ultrasound

Several researches have been done on air coupled ultrasonic inspection fields (Bhardwaj 2000; Fathizadeh and Aboonajmi 2017).

Air-coupled ultrasound testing methods are becoming more important every day. This is primarily due to the possibility of a "coupling agent-free" measurement and the associated benefits. Simultaneously, the equipment technology and the ultrasonic transducers continue to develop. Air-coupled ultrasonic testing is predominantly used in process control in production chains and is ideally suited for testing materials and structures such as composites, adhesives and honeycomb structures.

Air-coupled ultrasound is a non-contact technique for detection of defect or foreign body and measuring properties or amount of certain additives in food products in other uses which is growing for non-destructive testing, as food products should not be contaminated during manufacturing by couplings used in usual ultrasonic testing such as water and oil. This method is very useful to test large samples. Generally, according to the specific mechanism transducers being employed, we have two kinds of air coupled ultrasonic transducers. The first kind applies a piezoelectric rule, and the second uses an electrostatic (capacitance) rule. The main problem in piezoelectric type is to remove the mismatch of acoustic impedance between a piezoelectric material and the air.

Ultrasound approach is an attractive subject in food industry whose application is increasing more and more. There are three types of ultrasound applications which include: 1- Direct application to the product, 2- Coupling with the device and 3- Submergence in an ultrasonic bath (Chemat et al. 2011). Also, in another category, ultrasonic usages in food applications are classified in two classes. This classification is according to the power that ultrasound probe generates. These two classes include high and low power ultrasounds which are classified based on their sound power (W), sound intensity (W/m2) and sound energy density (W.s/m3). Applications of low energy ultrasound (low-intensity, low-power) include lower than 1 W/cm2 intensity and more than 100 kHz frequencies. Low power level is used for low intensity ultrasound. It means it has no physically or chemically bad effect on food, so it is non-destructive. One of the usages of ultrasound is to do with analytical applications of foods to have physicochemical properties data. Some of these properties include composition, structure and physical state (Knorr et al. 2004; Gallo et al. 2018).

Overview on oil extraction by ultrasound

Oil extraction by ultrasound is a green extraction technique. Green Food Processing is based on the discovery and design of technical processes which will reduce energy and water consumption, allows recycling of by-products through bio-refinery, and ensure a safe and high quality product (Chemat et al. 2017). A few reviews on the Ultrasound-Assisted Extraction (UAE) were published within the last years (Shaterabadi et al., 2020; Tiwari 2015; Shirsath et al. 2012; Chemat et al. 2011). Breaking cell walls in fruits and agricultural products along with improving in solvent penetration leads to better and sometimes more targeted extract yields of flavorings and nutraceuticals from plants, herbs and seeds (Kumari et al. 2018).

Oilseeds are renewable resources available in the world. About 70% of the production of oilseeds in the world is soybean. Both sunflowers and rapeseeds with about 15% share are in the next position in production rate (Chemat et al. 2017). Rapeseed cultivation in Europe leaves sunflowers behind. Soybean and flaxseed occupy a noticeable share in France. Oilseeds also can be found in some fruits (nuts, papaya seeds, almonds and kernels). Generally, extraction of oilseeds is done by two conventional approaches: cold or hot pressing (like flaxseed oil extraction), solvent extraction (Soxhlet). Sometimes a combination of the processes is used for extraction (like rapeseed oil extraction). Traditionally, a pressing procedure was done to push the oil out of oil seed. When the amount of oil in an oilseed is more than 30% (fox example rapeseed normally has about 50%), extraction process is not simple. In this condition, it is necessary to use more than a simple way to achieve maximum oil extraction efficiency. At first, pressing, extracts part of the oil, then the solvent extraction is being used. In industry, solvent extraction is generally performed in countercurrent extractors using large amounts of hexane. Ultrasound approach has been applied to the Soxhlet extraction using a sonosoxhlet (Luque-Garci and Luque 2004; Djenni et al. 2013).

Khadhraoui et al. (2018) concluded that UAE (Ultrasound-Assisted Extraction) has a great potential to be a rapid and effective method to extract rosmarinic acid from rosemary leaf. Ultrasound-induced physical impacts enabled to overcome the resistance of Rosemary cell wall and particularly the impermeability of adaxial cuticle limiting the intracellular transfer of the leaf metabolites in the case of conventional treatment.

Ultrasound extraction technique benefits include lessening the extraction cost, health and quality of oil, improvement in production performance and so on. Besides, the ultrasound extraction technique extracts bioactive composition from agricultural products with unique performance as well (Rodrigues et al. 2015). Processes used in industries for edible oils extraction from seeds, generally include this phase of solvent extraction. In terms of safety, using organic solvents leads to attempts to develop aqueous extraction. Goula et al. (2018) used ultrasound-assisted aqueous enzymatic extraction for extraction of pomegranate seeds oil. They found that this approach enhanced extraction by 18.4%, whereas the extraction time got shortened by 91.7%. They concluded that combination of the ultrasonic emerging technique and enzymes applying to extraction aim is an affordable substitute to ordinary extraction ways meeting the needs of industry and sustainable development.

Adulteration detection

Some primary methods of detecting food quality which is still extensively used, include simple methods of tasting, smelling, optical inspection, and bioassay through ingestion. These methods are simply accomplished by everyone, but professional tasters and inspectors in food industry need experience and lots of training to do them properly. Basically, all foods should be inspected in at least one of these traditional ways, which are combined with both new and old gauges of controlling quality and safety of foods so as to decrease acute food poisoning and to result in chronic health conditions.

Regulations and laws without considering force are only license, and inspecting of regulated and illegal matter in foods and beverages are essential components in food safety systems worldwide. Compulsory acts almost always depend on analytic outcomes as evidence, and because lives are most at stake, the applied approaches are necessary to be demonstrated to yield accurate and reliable results. These analyses have benefits for human and animal health and are also intended to protect the ecosystem from unacceptable use of agrochemicals. Providing a deterrent to unacceptable practices also profit from food producers who follow the rules. Food adulteration is a danger that human beings have faced since the beginning of civilization, as it not only reduces the quality of food products but also leads to some problems such as endangering human health and of course financial loss.

Oil adulteration detection by ultrasound

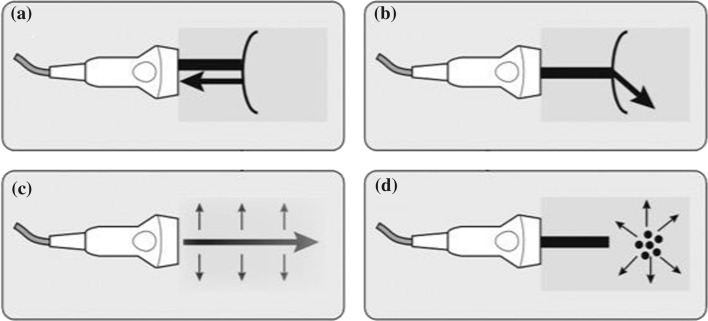

Ultrasonic energy is decreased exponentially with distance as it travels in the medium; which is represented by signal amplitude decreasing as the length of the path increases. Attenuation is known by the attenuation coefficient which has units of dB/cm or simply 1/cm. Attenuation occurs as the result of: a. reflection, b. refraction, c. absorption, and d. diffraction which is shown in Fig. 4 (Martin et al. 2015).

Fig. 4.

different sources of acoustic attenuation (Martin et al. 2015)

Much research has been done on food quality assessment by ultrasound (Zarezadeh and Aboonajmi 2018; George et al. 2017; Izbaim et al. 2010 etc.). George et al. (2017) applied Artificial Neural Network (ANN) based on ultrasound approach for coconut oil adulteration detection. The integrated ultrasound signals propagation properties such as attenuation and reflection coefficient and propagation velocity to identify virgin (pure) and adulterated oil. One MHz ultrasonic transducer system with COMSOL 4.4 was designed and applied to measure their experiments. An algorithm based on artificial neural network was also developed for completing the effectiveness of this technique. They reached a high percentage of adulteration detection rate (99.53%) for sunflower oil mixed with pure coconut oil and 98.82% for palm oil mixed with pure coconut oil. (Some other researchers evaluated oils and fats by ultrasound: McClements and Povey (1992); Singh and Dwivedi (1995)). (Table 1).

Table 1.

Studies on diagnostic ultrasound

| Food | Mode | Frequency | Result | Reference |

|---|---|---|---|---|

| extra virgin olive oil (EVOO) | Pulser-receiver | 2 MHz | Fraud detection and quality evaluation | Zarezadeh et al., 2021a |

| Some vegetable oils | Pulser-receiver | 1 MHz | Identifying oil types and their mixtures | Rashed and Felfoldi 2018 |

| Coconut oil | Pulse-echo | 1 MHz | Adulterating detection | George et al. 2017 |

| Olive oil mixtures | Pulse-echo | 5 MHz | Detection of olive oil adulteration | Alouache et al. 2016 |

| Some Liquid Mixtures | Pulse-echo | 100 Hz | Temperature, carbon chain length, molecular shape, and intermolecular forces have significant effects on UT parameters | William and Cooke 2016 |

| Olive oil | Pulse-echo | 2.25 MHz | Characterization of Olive Oil | Alouache et al. 2015 |

| Oranges | Pulse-echo | 100 kHz | fruit quality determination | Morrison and Abeyratne 2014 |

| Frying Oils (USBO, PHSBO) | Pulser-receiver | 5 MHz | Frying duration, frying temperature and degree of hydrogenation | Izbaim et al. 2010 |

| Olive oil | No data | 20 kHz | Determination of the oxidative stability | Canizares-Macias et al. 2004 |

| Frying oil | Pulser-receiver | 1 MHz | Quality evaluation of oil during frying | Benedito et al. 2002 |

Zarezadeh et al. (2021a) evaluated the quality of extra virgin olive oil (EVOO) which blended with common frying oil by means of a couple of (Transmitter and receiver) 2 MHz ultrasonic probes (DIO 1000 STARMANS diagnostic ultrasound). They used seven different classification algorithms including “Naïve Bayes, support vector machine, gradient boosting classifier, K-nearest neighbors, artificial neural network, logistic regression, and AdaBoost”. They found that the Naïve Bayes algorithm with 90.2% provided the highest accuracy among the others, and the support vector machine and gradient boosting classifier with 88.2% were in the next ranks.

Izbaim et al. (2010), evaluated the frying stability of Unhydrogenated Soybean Oil (USBO) and Partially Hydrogenated Soybean Oil (PHSBO) by applying ultrasound approach. They found that the ultrasound signal velocity and its attenuation varied with the change in the physicochemical properties of the oil. According to Fig. 5, increasing the oil temperature in USBO frying process leads to decreasing in ultrasound velocity. Also, it can be concluded that oils with more frying time (in the range of 8 to 32 h) have higher wave velocity.

Fig. 5.

effect of oil temperature on velocity of ultrasound signal during frying unhydrogenated soybean oil (Izbaim et al. 2010)

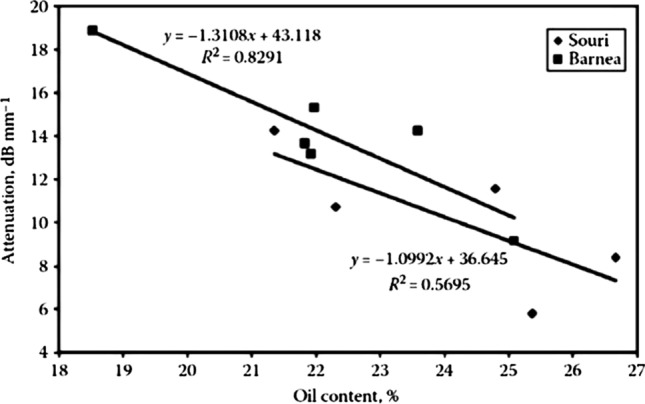

One of the interesting applications of ultrasound is that it can determine the percentage of oil content of seeds and fruits before oil extraction. In one research, percentage of oil in the olive fruit was estimated nondestructively by extracting ultrasonic properties (Mizrach et al. 2006). They found that wave attenuation has reverse and linear correlation with the percentage of oil in the olive fruit. According to Fig. 6, increasing the oil content from 19 to 27%, leads to decreasing attenuation from 19 to 9 (dB.mm−1). Estimation of oil content of olive fruit will help farmers to harvest at the appropriate time.

Fig. 6.

Trends of signal attenuation with oil content of olive fruit (Souri and Barnea species)

Fusion of ultrasound with other non-destructive techniques

Ultrasound is a powerful approach to evaluate oil quality. Combining this method with other non-destructive methods will enhance its benefits. In addition to the ultrasonic method, quality evaluation of foods has been done by non-destructive approaches including electronic nose, visible Spectroscopic fingerprints, chemical descriptors, electronic tongue, Raman spectroscopy, mid-infrared, dielectric spectroscopy, machine vision and so on (Apetrei et al. 2012; Pizarro et al. 2013; Roy et al. 2014; Sanaeifar et al. 2018).

Data fusion be defined as integration of outputs of multiple sources to obtain better data and information. Most data fusion researchers agree with the following definition of data fusion presented by the joint directors of laboratories: “A multi-level process dealing with the association, correlation and combination of information from single and multiple sources to identify estimates, achieve refined positions and complete and assess threats, situations and their significance.” Data fusion is the process of complementing multiple data sources to make more consistent, accurate, and useful information than that provided by individual data sources. The goal of using data fusion in multisensor environments is to detect and lower possible errors and higher reliability by using data from multiple distributed sources (Castanedo 2013).

Fats and oils are beneficial food materials used in many products. The solid fat content of foods such as margarine, butter, chocolate, shortening and creams, including significant amounts of fats determines many of the sensory properties such as texture and mouth-feel. Thus, determination of solid fat content is a useful analytical way to ensure product quality during processing (Martini et al. 2005). Solid fat content is traditionally measured by pulsed field nuclear magnetic resonance technique (p-NMR) (Awad 2004). Online measurements of NMR are difficult to perform and this is a major disadvantage. Characterization of edible fats and oils and assessing the physical and chemical properties such as crystallization and melting temperatures, SFC, hardness, oil content and oil composition are most important applications of low intensity ultrasound. (Awad 2004; McClements and Povey 1992; Saggin and Coupland 2002; Singh and Dwivedi 1995).

Alouache et al. (2015) evaluated olive oil adulteration which was mixed with sunflower and soya oil by ultrasonic method compared with physico-chemical properties such as rancidity degree, acid index, UV specific extinction coefficient and viscosity. Their experimental setup consisted of an ultrasonic transducer (2.25 MHz, 0.5 inch diameter, Panametrics, Olympus), excited with a Sofranel 5073PR pulser-receiver. Results showed the ability of ultrasound methods to characterize olive oil and to detect its possible adulterating by soya and sunflower oil.

Extra virgin olive oil (EVOO) adulteration was detected and analyzed by Zarezadeh et al., (2021b). Fusion of two non-destructive methods including ultrasound and electronic nose has been used. They used seven different machine learning classification algorithms which gradient boosting classifier represented the best classification accuracy (97.75%).

Extreme Learning Machines (ELM) are feed-forward neural networks for classification, regression, clustering, sparse approximation, compression and feature learning with a single layer or multiple layers of hidden nodes, where the parameters of hidden nodes need not be tuned. This method can be used in such cases as data mining. (Table 2).

Table 2.

Some researches on food quality evaluation by fusion of two or more approaches

| Sample | Methods of evaluation | Results | Reference |

|---|---|---|---|

| Extra virgin olive oil | Electronic nose and ultrasound | Fraud detection | Zarezadeh et al. 2021b |

| Meat | Spectroscopy and olfactory | Determine the amount of fat and peroxide | Aheto et al. 2020 |

| Sesame oil | Dielectric spectroscopy and chemical method | Adulteration detection | Firouz et al. 2020 |

| Saffron | olfactory, mass spectrometry and chromatography | Species and age detection | Rocchi et al. 2019 |

| Olive oil | Dielectric spectroscopy and machine vision | Determination of properties during storage | Sanaeifar et al. 2018 |

| Extra virgin olive oil | Raman and mid-infrared spectroscopy | Adulteration detection | Georgouli et al. 2017 |

| Olive oil | Electronic nose and tongue | Some properties Determining | Apetrei et al. 2012 |

| Tea | Electronic nose and tongue | Adulteration detection | Roy et al. 2014 |

| Edible oils | Electronic nose and tongue | Adulteration detection | Men et al. 2014 |

| Olive oil | Visible spectroscopy and chemical descriptors | classification | Pizarro et al. 2013 |

| Wine | Electronic nose, tongue and eyes | Monitoring of evolution during red wine aging | Apetrei et al. 2012 |

Challenges in this context

Ultrasound approach has many advantages; it is fast, accurate, user-friend, non-destructive and can be applied to systems that are not visible or not accessible like quality of can contents. Sometimes this method of evaluation has a considerable disadvantage named cavitation. When small gas bubbles are generated in a sample, they can attenuate so much signal that waves could not be transmitted through the sample. This problem can sometimes be overcome by taking reflection rather than transmission measurements; however, the signal from the bubbles may obscure those from other components.

Cavitation is often unwanted and problematic in practice but can be effective in some applications like navy weapons such as torpedoes to increase its speed. Ultrasonic cleaning system is another application of cavitation which is used to clean small objects (bubble implosions clean unreachable surfaces). In medical science, removing kidney stones (lithotripsy) by applying controlled cavitation is possible. It is precisely crushed through the formation of microbubbles that implode the solid formations inside the kidney (Ikeda et al. 2016). Another challenge in this method is that information about the thermophysical features of material should be available for theoretical predictions of its ultrasonic properties. Theoretical analysis of the data from systems containing many components with unknown properties may therefore be limited. Even so, this should not be a problem if the same system that is being studied is examined routinely. In addition, it is possible to use ultrasound in a purely empirical fashion, by preparing a calibration curve of some measurable ultrasonic parameter versus the physical property of interest. One other challenge in ultrasonic detection is that it normally requires a coupling material to enhance the transfer of sound energy into the test specimen. The most used materials for coupling are oil (Meftah and Mohd Azimin 2012) and water (Haeggstrom and Luukkala 2001; Zhao et al. 2003; Kananen et al. 2016). In Diagnostic ultrasound, it is necessary that medium temperature remain steady or if temperature change is inevitable, temperature effects on some ultrasound parameters such as velocity must be considered.

The most important application of diagnostic ultrasound is pulse-echo. In this technique, a transmitter and a receiver are located just on one side of the material (in our case study, oil), and different signal properties between pulse and echo signals have to do with oil quality. Multiple reflected signals (i3 in Fig. 1a) create errors. These reflections may be repeated more and more. These signals may overlap with the signals a2 and a3 (Fig. 1a). So, it is necessary to adjust the dimension of the cell to avoid these overlaps. George et al. (2017) minimized these errors by adjusting the accurate length for L2 (L1 and L3 are constant) in Fig. 1a.

One of the other challenges in quality evaluation of edible oils is presence of aflatoxins in them. An edible oil may be properly extracted its oil and stored in good condition, but it cannot be proven to be safe; because the oilseed may contain aflatoxins that have been transferred to the oil after extraction. Long time consuming of aflatoxin contaminated food could be resulted in some problems include acute liver cancer. Ultrasonic sensing systems combined with spectroscopy approach can be an alternative to aflatoxin detection. Such idea can be followed in future trends. Good results were obtained from the destruction of aflatoxins by ultrasound treatment (Mortazavi et al. 2015; Liu et al. 2019).

Conclusion

Edible oils are vital components of our diets, which provide energy, essential fatty acids and serve as a carrier of fat soluble vitamins. So it is important to realize their quality and safety. According to the reviewed paper, ultrasonic evaluation has been demonstrated as a powerful tool for analysis in a wide range of food industry applications especially in edible oils. Among the different methods of evaluation of edible oils, ultrasound approach is fast, accurate, non-destructive, inexpensive, repeatable, portable and simple. In spite of the mentioned advantages, it also has some disadvantages including attenuation in presence of small gas bubbles, cavitation and requiring a coupling material (between ultrasonic probe and sample test). Fusion of ultrasonic results with other methods like electronic tongue and nose, machine vision, thermometry, NMR, and NIR is a promising technique and will compensate the mentioned weaknesses of the ultrasound method.

Authors' contributions

MR, Zarezadeh(Writing the manuscript) M,Aboonajmi(corresponding author and writing assistance) M. Ghasemi-Varnamkhasti(proof reading and editing).

Declarations

Conflict of interest

The authors declare that they have no conflict of interest to declare.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Mohammad Reza Zarezadeh, Email: Mr.zarezadeh@ut.ac.ir.

Mohammad Aboonajmi, Email: abonajmi@ut.ac.ir.

Mahdi Ghasemi-Varnamkhasti, Email: ghasemymahdi@gmail.com.

References

- Aheto JH, Huang X, Tian X, Ren Y, Ernest B, Alenyorege EA, Dai C, Xiaorui Z, Wang P. Multi-sensor integration approach based on hyperspectral imaging and electronic nose for quantitation of fat and peroxide value of pork meat. Anal Bioanal Chem. 2020;412(5):1169–1179. doi: 10.1007/s00216-019-02345-5. [DOI] [PubMed] [Google Scholar]

- Alarcon-Rojo AD, Janacua H, Rodriguez JC, Paniwnyk L, Mason TJ. Power ultrasound in meat processing. Meat Sci. 2015;107:86–93. doi: 10.1016/j.meatsci.2015.04.015. [DOI] [PubMed] [Google Scholar]

- Alouache B, Boutkedjirt T, Laux D (2016) Ultrasonic assessment of olive oil mixtures properties. 2016 IEEE International Ultrasonics Symposium (IUS) (pp. 1–4). IEEE.

- Alouache B, Khechena FK, Lecheb F, Boutkedjirt T. Characterization of olive oil by ultrasonic and physico-chemical methods. Phys Procedia. 2015;70:1061–1065. doi: 10.1016/j.phpro.2015.08.226. [DOI] [Google Scholar]

- Apetrei IM, Rodriguez-Mendez ML, Apetrei C, Nevares I, Del Alamo M, De Saja JA. Monitoring of evolution during red wine aging in oak barrels and alternative method by means of an electronic panel test. Food Res Int. 2012;45(1):244–249. doi: 10.1016/j.foodres.2011.10.034. [DOI] [Google Scholar]

- Awad TS. Ultrasonic studies of the crystallization behavior of two palm fats O/W emulsions and its modification. Food Res Int. 2004;37(6):579–586. doi: 10.1016/j.foodres.2004.03.003. [DOI] [Google Scholar]

- Benedito J, Mulet A, Velasco J, Dobarganes MC. Ultrasonic assessment of oil quality during frying. J Agric Food Chem. 2002;50(16):4531–4536. doi: 10.1021/jf020230s. [DOI] [PubMed] [Google Scholar]

- Bhandari B, Zisu B. Effect of ultrasound treatment on the evolution of solubility of milk protein concentrate powder. Handbook Ultrason Sonochem. 2016;6:1–19. [Google Scholar]

- Bhardwaj MC. High transduction piezoelectric transducers and introduction of non-contact analysis. NDT. Net. 2000;5(1):871. [Google Scholar]

- Canizares-Macıas M, Garcia-Mesa JA, de Castro ML. Fast ultrasound-assisted method for the determination of the oxidative stability of virgin olive oil. Anal Chim Acta. 2004;502(2):161–166. doi: 10.1016/j.aca.2003.10.022. [DOI] [Google Scholar]

- Capelo-Martinez JL. Ultrasound in chemistry: analytical applications. Wiley; 2009. [Google Scholar]

- Castanedo F. A review of data fusion techniques. Scientif World J. 2013;2013:1–19. doi: 10.1155/2013/704504. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Charoux CMG, Ojha KS, O’Donnell CP, Cardoni A, Tiwari BK. Applications of airborne ultrasonic technology in the food industry. J Food Eng. 2017;208:28–36. doi: 10.1016/j.jfoodeng.2017.03.030. [DOI] [Google Scholar]

- Chemat F, Khan MK. Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem. 2011;18(4):813–835. doi: 10.1016/j.ultsonch.2010.11.023. [DOI] [PubMed] [Google Scholar]

- Chemat F, Rombaut N, Sicaire AG, Meullemiestre A, Fabiano-Tixier AS, Abert-Vian M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. Rev Ultrason Sonochem. 2017;34:540–560. doi: 10.1016/j.ultsonch.2016.06.035. [DOI] [PubMed] [Google Scholar]

- Chemat F, Rombaut N, Meullemiestre A, Turk M, Perino S, Fabiano-Tixier AS, Abert-Vian M. Review of green food processing techniques. preservation, transformation, and extraction. Innov Food Sci Emerg Technol. 2017;41:357–377. doi: 10.1016/j.ifset.2017.04.016. [DOI] [Google Scholar]

- Czank C, Simmer K, Hartmann PE. Simultaneous pasteurization and homogenization of human milk by combining heat and ultrasound: effect on milk quality. J Dairy Res. 2010;77(2):183–189. doi: 10.1017/S0022029909990483. [DOI] [PubMed] [Google Scholar]

- Dedhia AC, Ambulgekar PV, Pandit AB. Static foam destruction: role of ultrasound. Ultrason Sonochem. 2004;11(2):67–75. doi: 10.1016/S1350-4177(03)00134-2. [DOI] [PubMed] [Google Scholar]

- Djenni Z, Pingret D, Mason TJ, Chemat F. Sono–Soxhlet: In situ ultrasound-assisted extraction of food products. Food Anal Methods. 2013;6(4):1229–1233. doi: 10.1007/s12161-012-9531-2. [DOI] [Google Scholar]

- Fathizadeh Z, Aboonajmi M (2017) Nondestructive air-coupled ultrasound measurement in the food industries. In Proceedings of the 4th Iranian International NDT Conference 26–27

- Firouz MS, Rashvand M, Omid M. Rapid identification and quantification of sesame oils adulteration using low frequency dielectric spectroscopy combined with chemometrics. LWT. 2020;140:110736. doi: 10.1016/j.lwt.2020.110736. [DOI] [Google Scholar]

- Gallo M, Ferrara L, Naviglio D. Application of ultrasound in food science and technology: a perspective. Foods. 2018;7(10):164. doi: 10.3390/foods7100164. [DOI] [PMC free article] [PubMed] [Google Scholar]

- George T, Rufus E, Alex ZC. Artificial neural network based ultrasonic sensor system for detection of adulteration in edible oil. J Eng Sci Technol. 2017;12(6):1568–1579. [Google Scholar]

- Gondrexon N, Cheze L, Jin Y, Legay M, Tissot Q, Hengl N, et al. Intensification of heat and mass transfer by ultrasound: Application to heat exchangers and membrane separation processes. Ultrason Sonochem. 2015;25:40–50. doi: 10.1016/j.ultsonch.2014.08.010. [DOI] [PubMed] [Google Scholar]

- Goula AM, Papatheodorou A, Karasavva S, Kaderides K. Ultrasound-assisted aqueous enzymatic extraction of oil from pomegranate seeds. Waste Biomass Valorization. 2018;9(1):1–11. doi: 10.1007/s12649-016-9740-9. [DOI] [Google Scholar]

- Haeggstrom E, Luukkala M. Ultrasound detection and identification of foreign bodies in food products. Food Control. 2001;12(1):37–45. doi: 10.1016/S0956-7135(00)00007-4. [DOI] [Google Scholar]

- He J, Xu W, Shang Y, Zhu P, Mei X, Tian W, Huang K. Development and optimization of an efficient method to detect the authenticity of edible oils. Food Control. 2013;31(1):71–79. doi: 10.1016/j.foodcont.2012.07.001. [DOI] [Google Scholar]

- Ikeda T, Yoshizawa S, Koizumi N, Mitsuishi M, Matsumoto Y. Focused ultrasound and lithotripsy in therapeutic ultrasound. Cham: Springer; 2016. [DOI] [PubMed] [Google Scholar]

- Islam MN, Zhang M, Adhikari B. Ultrasound-assisted freezing of fruits and vegetables: DESIGN, development, and applications Global food security and wellness. New York, NY: Springer; 2017. pp. 457–487. [Google Scholar]

- Izbaim D, Faiz B, Moudden A, Taifi N, Aboudaoud I. Evaluation of the performance of frying oils using an ultrasonic technique. Grasas Aceites. 2010;61(2):151–156. doi: 10.3989/gya.087709. [DOI] [Google Scholar]

- Jabeur H, Zribi A, Bouaziz M. Extra-virgin olive oil and cheap vegetable oils: distinction and detection of adulteration as determined by GC and chemometrics. Food Anal Methods. 2016;9(3):712–723. doi: 10.1007/s12161-015-0249-9. [DOI] [Google Scholar]

- Jafari A, Fazayeli A, Zarezadeh MR. Estimation of orange skin thickness based on visual texture coarseness. Biosys Eng. 2014;117:73–82. doi: 10.1016/j.biosystemseng.2013.08.010. [DOI] [Google Scholar]

- Jafari, A., Zarazadeh, M. R., & Fazayeli, A. (2012). Orange grading based on visual texture features. In International Conference of Agricultural Engineering, CIGR-AgEng (pp. 8–12).

- Kananen V, Eskelinen J, Haeggstrom E (2016) Estimating the size of a scatterer by transmitted signal delay. In Ultrasonics Symposium (IUS), 2016 September. IEEE International 1–3. IEEE

- Khadhraoui B, Turk M, Fabiano-Tixier AS, Petitcolas E, Robinet P, Imbert R, Chemat F. Histo-cytochemistry and scanning electron microscopy for studying spatial and temporal extraction of metabolites induced by ultrasound. Towards Chain Detexturation Mech Ultrason Sonochem. 2018;42:482–492. doi: 10.1016/j.ultsonch.2017.11.029. [DOI] [PubMed] [Google Scholar]

- Kiani H, Zhang Z, Delgado A, Sun DW. Ultrasound assisted nucleation of some liquid and solid model foods during freezing. Food Res Int. 2011;44(9):2915–2921. doi: 10.1016/j.foodres.2011.06.051. [DOI] [Google Scholar]

- Knorr D, Zenker M, Heinz V, Lee DU. Applications and potential of ultrasonics in food processing. Trends Food Sci Technol. 2004;15:261–266. doi: 10.1016/j.tifs.2003.12.001. [DOI] [Google Scholar]

- Kumari B, Tiwari BK, Hossain MB, Brunton NP, Rai DK. Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food Bioprocess Technol. 2018;11(2):223–241. doi: 10.1007/s11947-017-1961-9. [DOI] [Google Scholar]

- Leadley CE and Williams A (2006) Pulsed electric field processing, power ultrasound and other emerging technologies. Food Processing Handbook 201.

- Liu X, Zhang C, Zhang Z, Xue J, Le Q. The role of ultrasound in hydrogen removal and microstructure refinement by ultrasonic argon degassing process. Ultrason Sonochem. 2017;38:455–462. doi: 10.1016/j.ultsonch.2017.03.041. [DOI] [PubMed] [Google Scholar]

- Liu Y, Li M, Bai F, Bian K. Effects of pulsed ultrasound at 20 kHz on the sonochemical degradation of mycotoxins. World Mycotoxin Journal. 2019;12(4):357–366. doi: 10.3920/WMJ2018.2431. [DOI] [Google Scholar]

- Luque-Garcia JL, De Castro ML. Ultrasound-assisted soxhlet extraction: an expeditive approach for solid sample treatment: application to the extraction of total fat from oleaginous seeds. J Chromatogr A. 2004;1034(1–2):237–242. doi: 10.1016/j.chroma.2004.02.020. [DOI] [PubMed] [Google Scholar]

- Magalhaes ML, Cartaxo SJ, Gallao MI, Garcia-Perez JV, Carcel JA, Rodrigues S, et al. Drying intensification combining ultrasound pre-treatment and ultrasound-assisted air drying. J Food Eng. 2017;215:72–77. doi: 10.1016/j.jfoodeng.2017.07.027. [DOI] [Google Scholar]

- Martin D, Wells I, Goodwin C. Physics of Ultrasound. Anesthesia Intensive Care Med. 2015;16(3):132–135. doi: 10.1016/j.mpaic.2015.01.003. [DOI] [Google Scholar]

- Martini S, Bertoli C, Herrera ML, Neeson I, Marangoni A. In situ monitoring of solid fat content by means of pulsed nuclear magnetic resonance spectrometry and ultrasonics. J Am Oil Chem Soc. 2005;82(5):305–312. doi: 10.1007/s11746-005-1071-8. [DOI] [Google Scholar]

- Mason TJ, Riera E, Vercet A, Lopez-Buesa P. Application of ultrasound emerging technologies for food processing. Academic Press; 2005. [Google Scholar]

- McClements DJ, Povey MJW. Ultrasonic analysis of edible fats and oils. Ultrasonics. 1992;30(6):383–388. doi: 10.1016/0041-624X(92)90094-3. [DOI] [PubMed] [Google Scholar]

- Meftah H, Azimin M. Detection of foreign bodies in canned foods using ultrasonic testing. Int Food Res J. 2012;19(2):543–546. [Google Scholar]

- Men H, Chen D, Zhang X, Liu J, Ning K. Data fusion of electronic nose and electronic tongue for detection of mixed edible-oil. J Sens. 2014;2014:840685. doi: 10.1155/2014/840685. [DOI] [Google Scholar]

- Mizrach A, Schmilovitch Z, Avidan B. A Maturity measurements of olive fruits using acoustic and compression methods. Germany: In CIGR XVI Word Congress Bonn; 2006. [Google Scholar]

- Mortazavia SM, Sania AM, Mohsenib S. Destruction of AFT by ultrasound treatment. J Appl Environ Biol Sci. 2015;4(11S):198–202. [Google Scholar]

- Morrison D, Abeyratne U. Ultrasonic technique for non-destructive quality evaluation of oranges. J Food Eng. 2014;141:107–112. doi: 10.1016/j.jfoodeng.2014.05.018. [DOI] [Google Scholar]

- Mulet A, Carcel J, Benedito C, Rossello C, Simal S. Ultrasonic mass transfer enhancement in food processing. Trans Phenomena Food Process. 2003;18:265–278. [Google Scholar]

- Mumith JA, Makatsoris C, Karayiannis TG. Design of a thermoacoustic heat engine for low temperature waste heat recovery in food manufacturing: a thermoacoustic device for heat recovery. Appl Therm Eng. 2014;65(1–2):588–596. doi: 10.1016/j.applthermaleng.2014.01.042. [DOI] [Google Scholar]

- Ojha KS, Tiwari BK, O’Donnell CP. Effect of ultrasound technology on food and nutritional quality. Adv Food Nutr Res. 2018;84:207–240. doi: 10.1016/bs.afnr.2018.01.001. [DOI] [PubMed] [Google Scholar]

- Ok S. Detection of olive oil adulteration by low-field NMR relaxometry and UV-Vis spectroscopy upon mixing olive oil with various edible oils. Grasas Aceites. 2017;68(1):173. doi: 10.3989/gya.0678161. [DOI] [Google Scholar]

- Pizarro C, Rodriguez-Tecedor S, Perez-Del-Notario N, Esteban-Diez I, Gonzalez-Saiz JM. Classification of Spanish extra virgin olive oils by data fusion of visible spectroscopic fingerprints and chemical descriptors. Food Chem. 2013;138(2):915–922. doi: 10.1016/j.foodchem.2012.11.087. [DOI] [PubMed] [Google Scholar]

- Popkin BM. Agricultural policies, food and public health. EMBO Rep. 2011;12(1):11–18. doi: 10.1038/embor.2010.200. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rashed MS, Felfoldi J. Ultrasonic method for identifying oil types and their mixtures. Prog Agric Eng Sci. 2018;14(s1):111–119. [Google Scholar]

- Reboredo-Rodriguez P, Rey-Salgueiro L, Regueiro J, Gonzalez-Barreiro C, Cancho- Grande B, Simal-Gandara J. Ultrasound-assisted emulsification– microextraction for the determination of phenolic compounds in olive oils. Food Chem. 2014;150:128–136. doi: 10.1016/j.foodchem.2013.10.157. [DOI] [PubMed] [Google Scholar]

- Rizki H, Terouzi W, Kzaiber F, Hanine H, Oussama A. Quantification of adulterations in sesame oil with inferior edible oils by using ATR-FTIR coupled to chemometrics. IOSR J Environ Sci, Toxicol Food Technol. 2016;10:2319–2402. doi: 10.9790/2402-100802138145. [DOI] [Google Scholar]

- Rocchi R, Mascini M, Faberi A, Sergi M, Compagnone D, Di Martino V, Carradori S, Pittia P. Comparison of IRMS, GC-MS and E-Nose data for the discrimination of saffron samples with different origin, process and age. Food Control. 2019;106:106736. doi: 10.1016/j.foodcont.2019.106736. [DOI] [Google Scholar]

- Rodrigues S, Fernandes FA, de Brito ES, Sousa AD, Narain N. Ultrasound extraction of phenolics and anthocyanins from jabuticaba peel. Ind Crops Prod. 2015;69:400–407. doi: 10.1016/j.indcrop.2015.02.059. [DOI] [Google Scholar]

- Roy RB, Chattopadhyay P, Tudu B, Bhattacharyya N, Bandyopadhyay R. Artificial flavor perception of black tea using fusion of electronic nose and tongue response: a bayesian statistical approach. J Food Eng. 2014;142:87–93. doi: 10.1016/j.jfoodeng.2014.06.004. [DOI] [Google Scholar]

- Saggin R, Coupland JN. Measurement of solid fat content by ultrasonic reflectance in model systems and chocolate. Food Res Int. 2002;35(10):999–1005. doi: 10.1016/S0963-9969(02)00161-8. [DOI] [Google Scholar]

- Sanaeifar A, Jafari A, Golmakani MT. Fusion of dielectric spectroscopy and computer vision for quality characterization of olive oil during storage. Comput Electron Agric. 2018;145:142–152. doi: 10.1016/j.compag.2017.12.035. [DOI] [Google Scholar]

- Shaterabadi D, Aboonajmi M, Ghorbani Javid M, Arabhosseini A. Effect of power ultrasound on the extraction of black caraway (Carum carvi L.) and evaluation of their qualitative properties using response surface methodology. Food Sci Nutr. 2020;8(8):4361–4369. doi: 10.1002/fsn3.1733. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shirsath SR, Sonawane SH, Gogate PR. Intensification of extraction of natural products using ultrasonic irradiations-a review of current status. Chem Eng Process. 2012;53:10–23. doi: 10.1016/j.cep.2012.01.003. [DOI] [Google Scholar]

- Singh VR, Dwivedi S (1995) Ultrasonic detection of adulteration in fluid foods. In Proceedings of the First Regional Conference, IEEE Engineering in Medicine and Biology Society and 14th Conference of the Biomedical Engineering Society of India. An International Meet 1–73. IEEE.

- Tao Y, Sun DW. Enhancement of food processes by ultrasound: a review. Crit Rev Food Sci Nutr. 2015;55(4):570–594. doi: 10.1080/10408398.2012.667849. [DOI] [PubMed] [Google Scholar]

- Tiwari BK. Ultrasound: A clean, green extraction technology. TrAC, Trends Anal Chem. 2015;71:100–109. doi: 10.1016/j.trac.2015.04.013. [DOI] [Google Scholar]

- Torkamani AE, Juliano P, Fagan P, Jimenez-Flores R, Ajlouni S, Singh TK. Effect of ultrasound-enhanced fat separation on whey powder phospholipid composition and stability. J Dairy Sci. 2016;99(6):4169–4177. doi: 10.3168/jds.2015-10422. [DOI] [PubMed] [Google Scholar]

- Torrecilla JS, Rojo E, Dominguez JC, Rodriguez F. A novel method to quantify the adulteration of extra virgin olive oil with low-grade olive oils by UV− vis. J Agric Food Chem. 2010;58(3):1679–1684. doi: 10.1021/jf903308u. [DOI] [PubMed] [Google Scholar]

- Van Wetten I, Van Herwaarden A, Splinter R, Boerrigter-Eenling R, Van Ruth S. Detection of sunflower oil in extra virgin olive oil by fast differential scanning calorimetry. Thermochim Acta. 2015;603:237–243. doi: 10.1016/j.tca.2014.11.030. [DOI] [Google Scholar]

- William A Cooke (2016) Development of ultrasonic techniques for characterization of liquid mixtures. MSc. Thesis. The University of Western Ontario.

- Wrona M, Pezo D, Nerin C. Rapid analytical procedure for determination of mineral oils in edible oil by GC–FID. Food Chem. 2013;141(4):3993–3999. doi: 10.1016/j.foodchem.2013.06.091. [DOI] [PubMed] [Google Scholar]

- Zarezadeh MR, Aboonajmi M (2018) Detection of foreign bodies in processed food and beverage by means of ultrasound. XIX. International Congress of CIGR. Antalya, Turkey.

- Zarezadeh MR, Aboonajmi M, Ghasemi Varnamkhasti M. Fraud detection and quality assessment of olive oil using ultrasound. Food Sci Nutr. 2021;9(1):180–189. doi: 10.1002/fsn3.1980. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zarezadeh MR, Aboonajmi M, Varnamkhasti MG, Azarikia F. Olive oil classification and fraud detection using E-nose and ultrasonic system. Food Anal Methods. 2021;14:1–12. doi: 10.1007/s12161-021-02035-y. [DOI] [Google Scholar]

- Zhao B, Basir OA, Mittal GS. Detection of metal, glass and plastic pieces in bottled beverages using ultrasound. Food Res Int. 2003;36(5):513–521. doi: 10.1016/S0963-9969(02)00201-6. [DOI] [Google Scholar]

- Zhao MF, Zhang ZW, Wang N. Identification model in frying oil based on interval partial least squares regression analysis. Adv Mater Res. 2013;718:792–796. doi: 10.4028/www.scientific.net/AMR.718-720.792. [DOI] [Google Scholar]

- Zhao X, Dong D, Zheng W, Jiao L, Lang Y. Discrimination of adulterated sesame oil using mid-infrared spectroscopy and chemometrics. Food Anal Methods. 2015;8(9):2308–2314. doi: 10.1007/s12161-015-0125-7. [DOI] [Google Scholar]