Abstract

This study focuses on the automation of terminal equipment used to handle containers. A dataset was compiled, which includes 63 fully and semi-automated container terminals in operation around the world, their organizational features, technical dimensions, and the maritime and urban markets they serve. The data analysis focuses on where, when, under which conditions, and to what extent container terminals were automated, and who is responsible for implementing terminal automation. Only 3% of the world’s container terminals were found to be either fully or semi-automated. A survey-based analysis of global terminal operators identifies how they implement their automation and the time necessary for terminal operators to start realizing a return on their investment. The results systematically map global automated terminal characteristics. Acknowledging that not all container terminals are candidates for automation of terminal equipment, this paper contributes to extant literature by presenting a systematic review of all global automated terminals in order to substantiate or refute any perceptions that might exist on their characteristics, for example, in terms of minimum cargo volumes needed for automation. The findings can provide some guidance to market actors considering investments in automation and public and private port authority decision makers that might also commit resources to automation.

Keywords: Ports, Container terminals, Terminal automation, Port ownership, Automation investment, Return on investment (ROI)

Introduction

Terminal automation is a full or partial substitution of manned terminal operations by automated equipment and processes. Automation is already present in most terminals, at least in its simplest form, using information technologies to manage terminal assets and supplement human activity. For example, modern container terminals use advanced terminal operating systems (TOSs) to control and optimize the movement and storage of containers in and around the terminal. Terminal operations involve various technologies such as RFID, optical character recognition (OCR), and anti-sway systems in cranes. However, automation can also include ship-to-shore cranes, the movement of containers from the berth to the yard, and yard equipment. The focus of this study is on this latter type of automation.

In the past decade, container terminal automation has attracted much attention in business, policy, and, subsequently, academic circles (Kon et al., 2020, Ghiara and Tei 2021, see also Sect. 3). While not all container terminals are candidates for automation of terminal equipment, no systematic review of all global automated terminals exists to shed light on the typical characteristics of these terminals. This study makes a distinction between fully automated and semi-automated container terminals. In line with earlier works (see, among others: Martín-Soberón et al. 2014; Drewry 2018; McKinsey 2018; Moody's 2019; Camarero Orive et al. 2020; Rodrigue and Notteboom 2021), a semi-automated terminal has automated the vertical movement of containers in the yard, while a fully automated terminal has also automated the horizontal movement of containers from the berth (i.e., the quayside) to the yard (i.e., the container stacking area).

The progressive introduction of semi-automated and fully automated terminal systems is driven, among other reasons, by the need for operations standardization, reduction in manning, increased handling capacity (Zhao et al. 2019), and productivity improvements (McKinsey 2018; Navis 2018; for a literature review see Kon et al. 2020). Nevertheless, as we demonstrate, only 3% of the container terminals are automated. Thus, container terminal automation is still the exception and not the norm (Miller, 2017). Often, a specific physical size of a container terminal or certain operating characteristics, such as a threshold level of TEU handled, is given as necessary to automate a terminal successfully.

This study advances a better understanding of where, when, under which conditions, and to what extent container terminals have been automated and who is responsible for implementing terminal automation. Our dataset explores the geography of the 63 automated container terminals (62 operating and one under construction), their organizational features, technical dimensions, the type of automation (full or semi), and the maritime and urban markets they serve. A survey of global terminal operators was undertaken to advance the understanding of terminal automation. The survey examined how terminal operators brought about their automated facilities (one or multiple suppliers) and who integrated the automated equipment with the TOS. Finally, the length of time before a terminal operator received a return on investment (ROI) was identified. This analysis provides data useful for terminal operators and investors considering automation investments and public and private port authority decision makers that might also commit resources to automation.

Research design and data collection

The research design addresses the following research questions:

R1: When and to what extent have container terminals been automated, and who is responsible for their operation?

R2: Are there any geographic patterns in the global distribution of automated terminals with some port regions more likely to opt for automation of terminal equipment?

R3: Are there characteristics, such as cargo volume thresholds, or a specific cargo mix between gateway (import/export) and sea–sea transshipment flows that are common to all automated terminals?

R4: How are terminal operators implementing their automation projects with one or multiple suppliers, and who has integrated the TOSs and equipment?

R5: How long before a terminal operator realizes a ROI?

The above research questions require a systematic review of all global automated terminals in order to substantiate or refute any perceptions that might exist on the characteristics of these terminals. To answer the above research questions, we first compiled a list of automated terminals, thereby distinguishing between fully and semi-automated terminals. This distinction is made also in order to analyze whether the above characteristics or trends vary between fully and semi-automated terminals. Our review of extant literature and port and terminal company information identifies the precise number and geographical distribution of semi-automated and fully automated container terminals worldwide and their characteristics in terms of technical layout and equipment use, year of automation, and governance-related characteristics, such as type of terminal operator. This exercise resulted in 63 container terminals worldwide that are fully or partially (semi) automated. At the beginning of 2022, 62 automated terminals were in operation, with one more planned to be operational in 2024 (Table 1).

Table 1.

List of 63 automated terminals as of January 2022

| Countries | Terminal names | Ports | Type automation |

|---|---|---|---|

| Belgium | Antwerp Gateway* | Antwerp | Semi |

| China |

Xiamen Ocean Gate Terminal* Qingdao New Qianwan Container Terminal* Tianjin Port Second Container Terminal* Tianjin Port Container Terminal* Yang Shan, Phase 4* Hong Kong International Terminals* |

Xiamen Qingdao Tianjin Tianjin Shanghai Hong Kong |

Full Full Full Full Full Semi |

| England |

London Gateway* Liverpool2 Container Terminal |

Stanford-le-Hope Liverpool |

Semi Semi |

| Germany |

CTB - Container Terminal Burdhardkai* CTA - Container Terminal Altenwerder* |

Hamburg Hamburg |

Semi Full |

| Ireland |

Dublin Ferryport Terminal* Belfast Container Terminal* |

Dublin Belfast |

Semi Semi |

| Israel |

Bayport Haifa* Hadarom Container Terminal |

Haifa Ashdod |

Semi Semi |

| Italy | APM Vado Ligure* | Vado Ligure | Semi |

| Japan |

Tobishima Container Berth Co., Ltd.* Oi Container Terminal (Berth 6)* |

Nagoya Tokyo |

Full Semi |

| Korea |

Pusan Newport International Terminal (PNIT)* Busan Newport Container Terminal (BNCT)* Pusan New Port Company (PNC) Hanjin New Port Company (HJNC) HMM PSA Newport Terminal (HPNT) Hanjin Incheon Container Terminal |

Busan Busan Busan Busan Busan Incheon |

Semi Semi Semi Semi Semi Semi |

| Indonesia |

Tanju Emas Semarang Terminal Petikemas |

Java Island East Java |

Semi Semi |

| Mexico |

Tuxpan Port Terminal* APM Lazaro Cardenas* New Port Veracruz |

Veracruz Lazaro Cardenas Veracruz |

Semi Semi Semi |

| Netherlands |

Rotterdam World Gateway* ECT Delta Terminal ECT Euromax Terminal |

Rotterdam Rotterdam Rotterdam |

Full Full Full |

| Panama | Manzanillo International Terminal* | Colon | Semi |

| Singapore |

PSA Pasir Panjang Terminal, 1–2–3* PSA Pasir Panjang Terminal, 4–5–6* Tuas Container Terminal Phase I |

Singapore Singapore Singapore |

Semi Semi Full |

| Spain |

Barcelona Europe South Terminal (BEST)* Total Terminals International |

Barcelona Algeciras |

Semi Semi |

| United Arab Emirates |

DP World Jebel Ali* Khalifa-TIL Khalifa-TIL2 Khalifa COSCO |

Dubai Abu Dhabi Abu Dhabi Abu Dhabi |

Semi Semi Semi (2024) Semi |

| United States |

Long Beach Container Terminal* TraPac* APM Terminal Pier 400* Norfolk International Terminal* Virginia International Gateway* Global Container Terminal* |

Long Beach, CA Los Angeles, CA Los Angeles, CA Virginia Virginia NY/NJ |

Full Full Full Semi Semi Semi |

| Spain |

Total Terminals International Barcelona Europe South Terminal* |

Algeciras Barcelona |

Semi Semi |

| Morocco | APM Terminals MedPort Tangier | Ksar es Seghir | Semi |

| Australia |

Brisbane AutoStrad Terminal DP World Australia Brisbane Terminal Brisbane Container Terminal Victoria International Container Terminal Sydney AutoStrad Terminal Sydney International Container Terminal |

Brisbane Brisbane Brisbane Melbourne Sydney Sydney |

Full Semi Full Full Full Semi |

| New Zealand | Fergusson Container Terminal | Auckland | Semi |

| Taiwan |

Kaohsiung Intercontinental Terminal (Terminal 4) Kao Ming Container Terminal Taipei Port Container Terminal |

Kaohsiung Kaohsiung Taipei |

Semi Semi Semi |

| Saudi Arabia | Red Sea Gateway Terminal | Jeddah | Semi |

| India | Vizhinjam | Vizhinjam | Semi |

*Completed survey

To address research questions R1 to R3, we collected a wide range of characteristics of automated terminals. Fifty-nine different features of a terminal were identified for our database. These were broadly grouped into the following categories: operations, environmental and energy saving, financial and cost savings, social, safety/security and resilience factors, and marketplace position. In addition, a miscellaneous category would note special circumstances like a local mandate for zero emissions, port authority funding to help defray costs typically born by terminal operators, equipment supplied by manufacturers for demonstration purposes, etc. Data was collected from port and terminal operator websites, industry journals and publications, and personal communications. Not all information was available for all 62 terminals, so a subset of critical data was identified that would be readily available and relevant to answer R1 to R3. This data subset included:

In relation to R1: fully or semi-automated terminal; the year the terminal opened; the year the terminal was automated; the terminal ownership profile (identifying the single owner or multiple companies having a shareholding in the terminal); and, the name of the terminal operator;

In relation to R2: the location of the terminals in terms of country and port region (North America, Central America, North Europe/Atlantic, the Mediterranean, Pacific Asia and South Asia/Middle East, Oceania);

In relation to R3: the length of berths; the maximum ship size handled; the maximum draft; the terminal capacity in TEU; the transshipment incidence, defined as the share of sea–sea transshipment (unloading of a container plus loading onto another vessel) in the total TEU throughput; and the total container throughput in TEU.

Descriptive statistics analysis was performed to provide a detailed explorative overview of automated terminal technical characteristics, corporate and institutional aspects, and geo-economic characteristics, exploring whether there are differences between fully and semi-automated terminals.

In addition to the data analysis of all terminals, a survey of automated terminals was undertaken by email in February–July 2021, to collect data for answering questions R4 and R5. The survey included questions about how automation was implemented and the (expected) length of time for a ROI. Senior representatives of the terminal operating companies that manage automated container terminals completed the surveys. The survey questionnaire asked terminal operators the following questions:

How long (in months) was the testing period of the automation equipment/system?

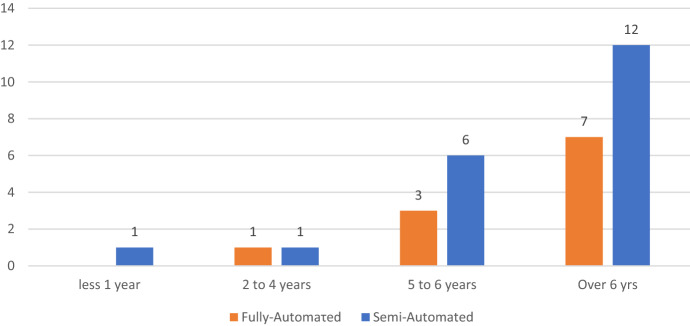

How many years will it take to realize (or has it taken to realize) a ROI for your automated system? Response options were: Just months after, 1–2 years, 2–4 years, 5–6 years, or over 6 years.

How was automation implemented (in terms of equipment suppliers and software integration)? The response options were: one supplier as a turnkey project; one supplier with systems integration by the terminal operator; multiple suppliers with system integration by the main supplier; multiple supplies with system integration by the terminal operator or other arrangements (to be specified by the respondent).

More than half of the world's automated terminals participated in the study (51.6%) by returning valid and usable filled-out surveys. Responses came from all automated terminal operators in the United States, China, Germany, and Ireland, along with terminals in Europe, Korea, Japan, and the Middle East ports. Table 1 lists the 63 automated terminals included in this study, using an asterisk to identify the 32 terminals that completed the survey.

Table 2 indicates the regional distribution as well as the number of semi-automated and fully automated terminals that contributed to the survey-based part of the study by region.

Table 2.

Number of survey responses by region and by type of terminal automation

| Region | Total replies | Fully automated | Semi-automated | |||

|---|---|---|---|---|---|---|

| No | % of total | No | % of total | No | % of total | |

| North America | 6 | 100 | 3 | 100 | 3 | 100 |

| Central America | 3 | 75.0 | – | – | 3 | 75.0 |

| North Europe/Atlantic | 7 | 63.6 | 2 | 20.0 | 5 | 83.3 |

| Mediterranean | 3 | 50.0 | – | – | 3 | 50.0 |

| Pacific Asia | 12 | 54.5 | 6 | 85.7 | 6 | 42.9 |

| South Asia/Middle East | 1 | 14.3 | 1 | 14.3 | ||

| Total | 32 | 50.7 | 11 | 61.1 | 21 | 46.6 |

Descriptive statistics facilitated an analysis of the technical characteristics of the terminals. Survey results (length of testing period, time for ROI, and how the terminal equipment was integrated) were subjected to correlation analysis. The number of replies, while over 50% of the total, and thus, representative of the actual situation, is at the lower limit of the number of observations needed when considering the application of any advanced statistical methods.

Empirical findings

Fully and semi-automated terminals

A first attribute in answering research question 1 (R1) relates to the nature of the automation of terminal equipment. Eighteen (18) of the 63 automated terminals, or 29% of the total, are fully automated. Automated stacking cranes (ASCs) are widely used in yard operations. ASCs are automated rail-mounted gantry cranes (ARMGs) that are generally aligned perpendicular to the berth. In some cases, such as at the Alterwerder Terminal in Hamburg, two ASCs with different dimensions (allowing one to pass under the other) work together on the same stack. The term ASC covers ARMG, C-ARMG (cantilever ARMG), and ARTG (automated rubber-tired gantry crane). Automated straddle carriers (AutoStrad) are less common. AutoStrads are unmanned straddle carriers used for quay to stack operations and stack to truck loading operations. Examples include Brisbane AutoStrad Terminal and Sydney AutoStrad Terminal, both operated by Patrick Terminals in Australia.

Berth to yard automation typically relies on unmanned automated terminal tractors, automated guided vehicles (AGVs), or runners (low straddle carriers without a driver onboard). Such automated horizontal transfer systems are quite common. Diesel-hydraulic engines powered the first generation of AGVs, and movement was restricted to fixed tracks on the terminal floor. The latest generation of AGVs is guided by GPS technology and is battery powered, resulting in zero CO2 emission and noise reduction. AGV speed can reach 6 m/s. Some terminals, such as APMT in Rotterdam, use ‘lift AGVs’ to lift and stack containers.

A few fully automated terminals can also have remotely operated ship-to-shore cranes for the vessel-to-quay transfer. These cranes use single or dual hoist technology. Examples are found in Rotterdam (APMT at Maasvlakte 2), Shanghai (phase 4 of Yang Shan Terminal Complex), and Qingdao (Qingdao New Qianwan Container Terminal or QQCTN). While these remotely operated cranes are still manned, their operators may have different skills and pay scales compared with traditional crane operators on the berth.

Automation can also be achieved in the fourth main functional area of a container terminal, which is the in–out gate function. Automation in this area primarily concerns automated truck gates. However, this type of automation is not considered when distinguishing between fully and semi-automated terminals.

The number and temporal development of automated container terminals

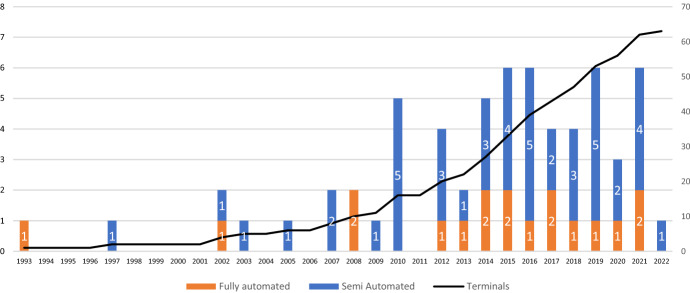

A second aspect of R1 focuses on the number of automated terminals and their related growth pattern over time. Such an analysis helps to identify any temporal waves in terminal automation and the overall adoption of full- and semi-automation on a global scale. By the end of the twentieth century, the total number of automated container terminals amounted to just two. Full terminal automation was first implemented in 1993: the ECT Delta SeaLand Terminal at Maasvlakte 1 in Rotterdam became the first terminal in the world to use AGVs and ASCs. Six years later, in 1999, PSA opened the semi-automated Pasir Panjang Container Terminal 1–2–3 in Singapore. Six more automated container terminals were in operation when the global financial crisis of 2008/2009 hit the port industry. While the crisis changed the port sector in many respects (Pallis and Langen 2010; Notteboom and Rodrigue 2012; Notteboom et al. 2021), the trend toward automation continued. In the period 2008–2012, 12 more terminals were automated.

In early 2022, 62 fully or partially (semi-) automated container terminals were operating worldwide. Forty-seven terminals were automated in the decade 2012–2021 (Fig. 1). The first phase of the Tuas Terminal Complex in Singapore opened in December 2021. The most recent addition in the list, Hadarom Container Terminal at Ashdod Israel, plans to operate as a semi-automated terminal in 2022. Khalifa-TIL2 in Abu Dhabi is planned to become operational in 2024.

Fig. 1.

Cumulative number of automated terminals*. *Note N = 63; as of January 2022

The real acceleration of container terminal automation, thus, occurred in the last decade. The development of automated container terminals has been gaining popularity, particularly since 2012. As noted in other reports (PEMA 2016; ITF 2021), most automated terminals developed since the 2010s, after a very gradual uptake in the 1990s and 2000s. The trend seems to continue, as in early 2022, Busan announced the intention to open the first berth of a new semi-automated container terminal (BCT) that will eventually handle more than 2 million TEU with three berths (Wallis 2022).

Still, the number of fully or semi-automated terminals remains relatively small compared to the scale of the global container terminal business. Drewry (2018) identified about 1300 full container terminal facilities worldwide, with just over 3% classed as automated. Moody's (2019) specified 46 semi-automated or fully automated container terminals worldwide. Rodrigue and Notteboom (2021) identified 58 automated terminals globally, of which nine were in a planning phase (see also: Notteboom et al. 2022). Alho (2019) counted 60 automated terminals globally, mainly in Europe and Asia, with forecasts to reach 200 in the next 5 years. Camarero Orive et al. (2020) listed 44 container terminals in the world using automated handling technology. Kon et al. (2020) reported that 54 automated terminals were opened between 1993 and 2020. ITF (2021) reports 53 automated container terminals, representing around 4% of the total global container terminal capacity. Most of them are located in Europe (28%), Asia (32%), Oceania (13%), and the United States (11%), and all of them are included in the list of automated terminals in the present study. The difference between the 63 terminals identified in this study and the number reported in other studies might be explained by differences in the period considered and the applied terminal automation definitions (for example, some studies do not consider terminals that have only automated part of the terminal site).

Operators that opted to automate terminals

A last aspect of R1 refers to the ownership and operator profile of automated terminals. An analysis of terminal ownership and operators can reveal whether certain ownership configurations and/or terminal operator types are more likely to result in a decision to opt for automation of terminal equipment. In the port operating industry, internationalization shifted from a dominantly regional structure, sometimes focusing on a single port, to several port terminal operators establishing a global portfolio. The terminal operating industry is increasingly complex, with competition, objectives, and entry strategies diverging between heterogeneous terminal operators (Olivier 2005; Olivier et al. 2007; Notteboom and Rodrigue 2012; Parola et al. 2013, Parola et al. 2015) and differences in local market entry conditions (Pallis et al. 2008). Several categorizations of terminal operating companies have been proposed (see: Bichou and Bell 2007; Olivier et al. 2007; Parola and Musso 2007). In this study, terminal operating companies are classified into the following three categories (see also Notteboom and Rodrigue 2012), based on the origins and strategic rationale to invest in the global terminal infrastructure network:

Carrier-linked terminal operators. In recent decades, container shipping lines have developed dedicated terminal capacity to support their core shipping business. The derived benefits involve cost control, operational performance, profitability, and the ability to prioritize their ships during port calls. Excess capacity can go unused in a terminal dedicated only to a particular line or alliance. Other terminals in the same port may be congested, leading to uneven and less efficient asset utilization. Terminal operating companies are separate business units or sister companies with terminal facilities operated on a single-user dedicated base or open to third-party shipping lines. For example, AP Moller-Maersk operates a network of container terminals through its subsidiary APM Terminals, a sister company of Maersk Line. CMA CGM (through a majority shareholding in Terminal Link), MSC (via a majority shareholding in Terminal Investment Limited, TIL), and COSCO (through fully owned COSCO Shipping Ports) are also among the most involved shipping lines in terminal operations.

Financial holdings. Port terminals have attracted several investment banks, retirement funds, and sovereign wealth funds, as an asset class with a potential for revenue generation over long periods (on the financialization of the container terminal industry and the increasing role of such entities since the early 2000s, cf. Rodrigue et al. 2011). Most acquire an asset stake and leave operations to the existing operating company. Others directly manage terminal assets through a separate terminal operating company,

Pure stevedores. This group includes independent port terminal operators offering container handling services to a broad customer base. They can be privately owned or part of the port authority, tool port, or public service port portfolio.

The involvement of the above types of terminal operating companies can range from a minority shareholding to full ownership. In quite a few cases, multiple actors team up in a joint venture or consortium. For example, stevedores such as Hutchison Ports or PSA mitigate risks through terminal joint ventures with shipping lines, making terminal ownership structures and partnership arrangements increasingly complex.

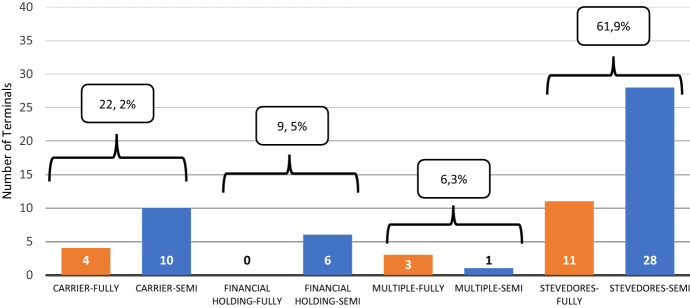

The results show some spread in operator types, although pure stevedores are by far the most important type, both for full- and semi-automated terminals. Eighteen pure stevedoring companies operate 39 automated terminals or 61.9% of all terminals (Fig. 2). Eleven of them are fully automated.1 Hutchison Ports operates six terminals, more than any other terminal operator. The portfolio of Hutchison Ports spreads in five different regions and includes the 1993-automated ECT Delta Terminal in Rotterdam. PSA is the operator of five automated terminals. These terminals are in two ports in South East Asia, Singapore (three terminals) and Busan (two terminals). One of them, PSA Hyundai Pusan Newport Terminal, is operated by a partnership between PSA and Hyundai. Sixteen other stevedoring companies operate one or two terminals. Stevedoring companies (i.e., D.P. World) and carriers (i.e., COSCO Shipping Ports, APM Terminals) are also involved as partners in one or more of the four automated terminals operated by consortia (6.3% of all automated terminals)—these are the fully automated Rotterdam World Gateway, Tianjin Port Second Container Terminal and the Qingdao New Qianwan Container Terminal, and the semi-automated Antwerp Gateway Terminal.

Fig. 2.

Automated container terminals per type of operator. N = 63; as of January 2022

Carriers who have assumed responsibility to operate container terminals (such as APM Terminals—part of Maersk, Evergreen, MSC (via TIL), COSCO Shipping Ports, MOL, and NYK) operate 10 semi-automated terminals. They also operate four fully automated ones, two of them in Los Angeles, USA (MOL’s TraPac Terminal and the APM Terminals in Los Angeles), one in Rotterdam, Europe (the APM Terminals Maasvlakte II), and one in Nagoya, Japan (Tobishima Container Berth). Financial holding companies are also engaged in the operation of container terminals. They operate six automated terminals (9.7%) in the UK, Australia, South Korea, and UAE.

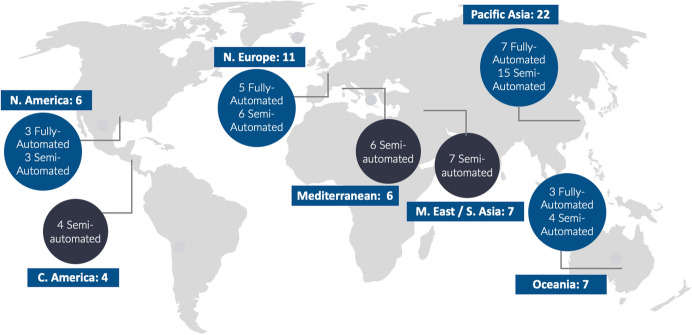

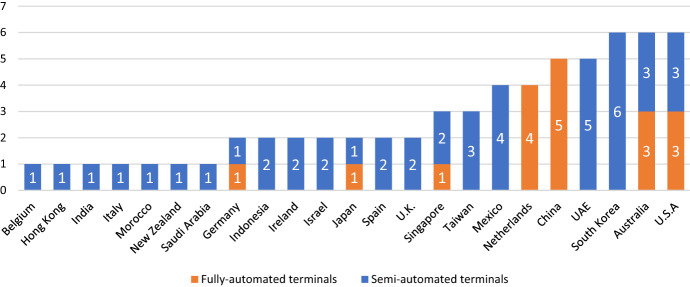

Geographical distribution

Research question 2 (R2) refers to the existence or absence of geographic patterns in the global distribution of automated terminals. The data does not seem to suggest that some port regions are more likely to opt for automation of terminal equipment than others. Semi-automated or fully automated terminals exist in all continents except Africa and Antarctica (Fig. 3). They are located in 23 countries (Fig. 4), evenly distributed between semi-automation and full automation. Australia, China, and the United States each have six terminals. In 20 other countries, the number of automated terminals is smaller. Pacific Asia (22 automated terminals or 35%) and North Europe (11 automated terminals or 17%) are the hotspots for terminal automation in terms of terminal numbers. However, fully automated terminals exist in only four regions; North America (US), Oceania, Pacific Asia, and Europe Atlantic. The geographical distribution of these terminals over time is detailed in Table 3, showing that most regions, with the exceptions of Europe Atlantic and Pacific Asia, are rather late adopters of terminal automation.

Fig. 3.

Geographical distribution of automated container terminals*. *N = 63; as of January 2022

Fig. 4.

Distribution of automated container terminals per country. *Notes N = 63; see Table 1 for a complete list of the identified automated terminals

Table 3.

Evolution of container terminal automation per region

| Total | 1993–1999 | 2000–2007 | 2008–2012 | 2013–2022 | n.a | |

|---|---|---|---|---|---|---|

| North America | 6 | 1 | 5 | |||

| Central America | 4 | 4 | ||||

| Europe Atlantic | 11 | 1 | 2 | 2 | 6 | |

| Mediterranean | 6 | 2 | 4 | |||

| Pacific Asia | 22 | 1 | 1 | 7 | 12 | 1 |

| South Asia/Middle East | 7 | 1 | 5 | 1 | ||

| Oceania | 7 | 2 | 5 | |||

| Total | 63 | 2 | 6 | 12 | 41 | 2 |

Terminal throughput

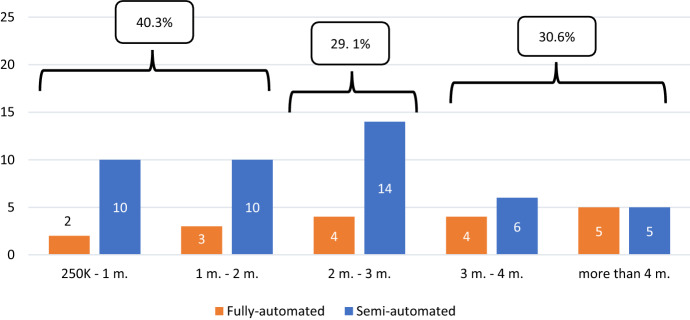

Research question 3 (R3) aims at identifying specific technical and operational thresholds or ranges that might be typical for automated terminals. The first characteristic being analyzed in this regard is terminal throughput (in TEU). Most fully automated terminals handle between 2 and 4 million TEU per year (Fig. 5). Twenty-nine percent of the semi-automated terminals handle between 2 and 3 million TEU per year. However, 11% of the fully automated terminals and 22% of the semi-automated terminals handle between 250,000 and 1 million TEU. These findings demonstrate that terminal automation occurs in all terminal scales, and is not the prerogative of the largest terminal group only.

Fig. 5.

Scale of fully and semi-automated terminal capacity (TEU)

Technical characteristics

The second attribute to be analyzed in relation to R3 focuses on terminal dimensions (i.e., quay length and yard acreage) and nautical profile in terms of drafts at berth. Also here, the analysis helps to explore whether automated terminals are concentrated around a specific terminal size or nautical profile. The average acreage of the fully automated terminals (98.6 ha) is 17.2% larger than the respective size of the semi-automated ones (84.1 ha, Table 4). However, the range of terminal size varies significantly for both fully automated terminals (standard deviation = 80.5 m) and semi-automated ones (standard deviation = 69.4 m). In some cases, however, where available land was limited, terminal operators used the space available, resulting in much smaller automated terminals. The semi-automated Pasir Panjang Container Terminal 1–2–3 in Singapore has the largest acreage. The size of 24 terminals—6 fully automated terminals and 18 semi-automated ones—does not exceed 50 ha.

Table 4.

Technical characteristics of automated container terminals

| Terminal acreage (ha) | Length of berths (m) | Max draft (m) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Ave. | Range (Max–Min) | Std Dev | Ave. | Range (Max–Min) | Std Dev | Ave. | Range (Max–Min) | Std Dev | |

| Fully automated | 98.6 | 294.0–26.0 | 80.5 | 1506 | 3600–550 | 769 | 16.8 | 21.0–13.7 | 2.1 |

| Europe Atlantic | 124.6 | 265.0–80.0 | 79.2 | 1840 | 3600–1000 | 1016 | 18.4 | 19.7–16.6 | 1.6 |

| North America | 82.5 | 139.0–40.0 | 60.1 | 1164 | 1646–550 | 560 | 15.7 | 16.8–13.7 | 1.7 |

| Oceania | 41.5 | 63.0–26.0 | 19.2 | 907 | 1400–660 | 427 | 14.7 | 15.2–14.0 | 0.6 |

| Pacific Asia | 113.3 | 294.0–36.1 | 102.1 | 1700 | 2350–750 | 651 | 17.0 | 21.0–14.8 | 2.1 |

| Semi-automated | 84.1 | 318.0–13.3 | 69.4 | 1504 | 7772–330 | 1350 | 15.7 | 18.5–9.0 | 1.9 |

| Central America | 43.8 | 52.0–33.0 | 8.5 | 1012 | 2040–556 | 691 | 15.9 | 16.5–15.0 | 0.7 |

| Europe Atlantic | 83.2 | 176.0–14.0 | 72.2 | 1253 | 2850–330 | 915 | 14.5 | 17.0–9.0 | 3.5 |

| Mediterranean | 53.8 | 79.0–19.0 | 27.8 | 1192 | 1600–700 | 356 | 16.9 | 18.5–16.0 | 1.0 |

| North America | 112.7 | 152.0–68.0 | 42.3 | 1348 | 2020–823 | 612 | 15.2 | 15.2–15.2 | 0.0 |

| Oceania | 38.5 | 46.0–32.0 | 6.0 | 1010 | 1300–610 | 309 | 14.5 | 16.0–13.2 | 1.4 |

| Pacific Asia | 110.6 | 318.0–13.3 | 98.1 | 2086 | 7772–380 | 2079 | 15.8 | 18.0–11.0 | 1.8 |

| South Asia/Middle East | 82.4 | 149.0–50.0 | 34.2 | 1322 | 1862–800 | 383 | 16.1 | 18.0–14.5 | 1.5 |

| Total | 88.30 | 318.0–13.3 | 73.4 | 1505 | 7772–330 | 1208 | 16.0 | 21.0–9.0 | 2.0 |

Based on data available for 60 of the 63 terminals, the average quay length is 1480 m, without a difference observed between fully and semi-automated terminals (1506 and 1504 m, respectively).2 Once more, the standard deviation from this average is substantial for both fully automated (standard deviation 769 m) and semi-automated (standard deviation 1350 m) container terminals. The length of berths in two terminals exceeds 5000 m. There are 10 more automated terminals with berth lengths of 2000 m or longer, and 27 with berth lengths ranging between 1000 and 2000 m. The length of berths in the other 21 terminals for which data are available is less than 1000 m.

The draft at automated terminals ranges from 13.7 to 16 m. However, the situation differs in semi-automated terminals where the draft is as low as nine meters at one terminal in Europe.

The semi-automated operations at a few of the terminals in the dataset only cover a part of the entire terminal surface, as the remaining terminal acreage relies on conventional container terminal equipment. A good example is the Antwerp Gateway Terminal operated by DP World. Since 2006, Antwerp Gateway has operated 20 ASCs on about a third of the terminal acreage. The remaining two thirds of the container yard still rely on manned straddle carriers. These will gradually be phased out between 2022 and 2026 and replaced by 34 new ASCs. Other examples of automation covering only a portion of a terminal surface are the two fully automated terminals in Los Angeles, TraPac and APMT.

Container port scale

The third characteristic associated with R3 considers the scale of the ports in which the fully or semi-automated terminals are located. In particular, we explore the extent to which automated terminals are the prerogative of large container ports only, or alternatively, they can also be found in smaller and second-tier container ports. The 63 automated terminals are located in 43 different container ports. Seventeen of them operate in seven of the top 10 container ports (in terms of throughput). Nine are fully automated (one terminal in Shanghai, Singapore, Qingdao, two in Tianjin, and four in Rotterdam). Seven (two terminals in Singapore, four in Busan, and one in Hong Kong) are semi-automated.

A total of 44 of the 63 automated terminals operate in 27 of the top 100 container ports in terms of annual throughput (Fig. 6). Sixteen of these terminals are fully automated and 28 semi-automated. Fully automated terminals exist in the biggest container ports, with the exceptions being the initiatives by the Chinese government in the case of Xiamen Ocean Gate Container Terminal (fully automated since 2012) and by Hutchison Ports, in the case of Brisbane (fully automated since 2013).

Fig. 6.

Automated terminals in the top 100 ranked container ports.

Source compiled by the authors; N = 63; based on 2019 throughput; data as detailed in: Lloyd’s List top 100 container ports 2020. London: Lloyds List

Seventeen semi-automated and 2 fully automated terminals (i.e., 30% of all automated terminals) have been developed in 16 other ports with lower throughput per annum than the top 100 container ports. These are found in different regions of the world, i.e., four in Oceania (three terminals in Australia and one in New Zealand), three in Pacific Asia (in China, Indonesia, and Taiwan, respectively), three in South East Asia (one in India, two in the United Arab Emirates), and three in the Mediterranean Sea (two in Israel, and one in Italy, one in the UK, and three in Mexico). These findings show that while a significant share of automated terminals have been developed in top-ranked container ports, medium sized and even some smaller container ports are adopting automation as well.

Largest calling container vessel

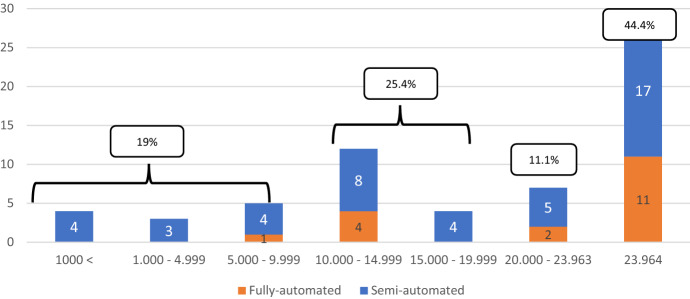

The fourth characteristic in relation to R3 deals with the largest vessel scale calling at the automated terminal. An examination of vessel scale data at port and terminal level reveals the extent to which automated terminals are mainly designed to accommodate ultra-large container vessels (ULCCs), or alternatively, might also make sense for ports who are not targeting these ULCCs. Our data shows that automation primarily takes place in terminals on the main East–West trade routes, i.e., Asia–Europe, trans-Pacific and trans-Atlantic. More than half of the automated terminals operate in ports receiving calls of containerships larger than 20,000 TEU (55.6%, Fig. 7). Twenty-eight of these 35 automated terminals (44.4%) exist in ports where the world’s largest containerships are deployed. These vessels are primarily deployed on the Asia–North Europe and Asia–Med trade routes. The transpacific trade route has seen a considerable increase in the 20,000 TEU+ vessel class in the past few years, combined with significant increases in call sizes.3 A further 25.4% of automated terminals are at ports that host calls of containerships exceeding 10,000 TEU capacity. Eleven semi-automated and one fully automated container terminals receive vessels with capacity less than 10,000 TEU. Thus, while automation is not only found in the largest terminals (Sect. 3.7) or the top-ranked world ports (Sect. 3.8), the above analysis indicates automation primarily occurs at terminals that target 10,000 TEU+ vessels.

Fig. 7.

Size of the biggest vessel calling at world ports hosting automated terminals. At the time of writing, 23,964 TEU was the capacity of the largest container vessel afloat. It concerns HMM Algeciras and sister ships measuring 228,283 gross tonnage (G.T.), 399 m length overall (LOA), 24 containers wide, and 16.52 m draft. We created a separate bar for this vessel size to indicate how many automated terminals received this largest ship size.

Source compiled by the authors; data of maximum vessel size calling at each port as detailed in UNCTAD Liner Shipping Connectivity Index (LSCI). Geneva: UNCTAD

The cargo mix

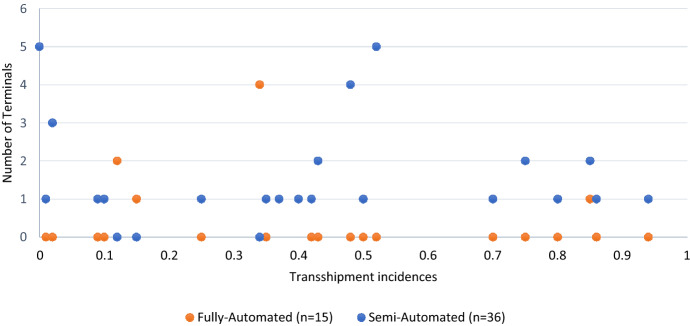

The cargo mix is the last attribute that is analyzed to answer R3. Each container terminal has a specific cargo mix. Most container terminals act as gateways for import and export cargo in relation to their captive or shared hinterlands. Other terminals combine import/export containers with sea–sea transshipment (T/S) flows whereby the containers arrive by vessel and leave on another vessel after a short dwell time at the terminal. The global port system also counts many almost pure transshipment hubs located at key locations in the liner shipping network close to strategic passageways such as the Straits of Gibraltar, the Suez Canal, the Panama Canal, and the Malacca Straits. Examples include Singapore, Freeport (Bahamas), Salalah (Oman), Tanjung Pelepas (Malaysia), Gioia Tauro, Algeciras, Tanger Med, Damietta, and Malta in the Mediterranean. These hubs have a transshipment incidence of 65 to 100% (Notteboom et al. 2019). Some regional markets seem to offer the right conditions for the emergence of several transshipment hubs (e.g., the Med or the Caribbean), such as strategic location within global shipping networks, favorable nautical conditions, land availability and a conducive regulatory framework on cabotage. At the same time, other port systems only feature minimal sea–sea transshipment activity due to unfavorable topological or regulatory conditions. For example, the “Jones Act” (Section 27 of the U.S. Merchant Marine Act of 1920), requiring ships owned and operated by US citizens or permanent residents to transport goods between US ports, is widely considered as one of the reasons behind the absence of a sea–sea transshipment market in the US port system (Brooks 2009).

Transshipment cargo typically has a shorter dwell time than gateway cargo (import/export) which makes yard management easier and results in higher land productivity for a given terminal layout. These factors might pave the way for automation.

Figure 8 shows that the relation between transshipment incidence and automation is somewhat spurious. Only one fully automated terminal is located in an almost pure transshipment hub. The other fully automated terminals are found in ports with a mixed profile (i.e., gateway cargo plus transshipment cargo) or gateway ports with a low transshipment incidence. Semi-automated terminals are found in pure transshipment ports (transshipment incidence > 65%), mixed ports (between 25 and 65%), and gateway ports (< 25%), with none of these groups having a dominant presence. Container volumes are more volatile in transshipment terminals, requiring more flexibility (Notteboom et al. 2019). Gateway terminals generally have more captive container volumes—implying less throughput volatility (Wang et al. 2019) and are, thus, better suited to automation.

Fig. 8.

Trahnsshipment incidence at ports hosting automated terminals.

Source compilation based on transshipment data collected from port authorities’ statistics and Drewry

Testing and implementation issues

Research question 4 deals with the implementation of automation projects. We particularly analyze whether some approaches to the realization and testing of automated terminals are more common than others. Terminal automation requires advanced approaches to integrated scheduling of handling equipment (Lau and Zhao 2008) to optimize and synchronize the quay, intra-terminal transport, yard, and gate operations (for an overview, see: Stahlbock and Voß 2008; Sha et al. 2021).

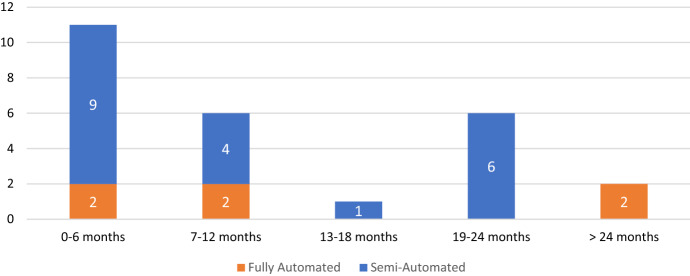

A lengthy testing and start-up period can temper the cost reduction potential of automation. Through the survey, terminal operators were asked how many months automated equipment was tested before entire operations began. Twenty-six of the 32 terminals surveyed answered this question (Fig. 9). There was a wide variation in the length of the testing period with no apparent pattern between semi-automated and fully automated terminals. Testing periods ranged from 2 months (a case where the terminal had experience from automating a previous terminal) to 37 months for a fully automated terminal, with multiple suppliers and terminal integration done by the primary equipment supplier. One other terminal reported a testing period of 36 months; in this case, the terminal operator integrated the equipment supplied by multiple vendors. Forty-two percent of the terminals had a testing period of 6 months or less.

Fig. 9.

Length of testing period for automation equipment

Automation requires the complex interaction between different technologies and full synchronization and hardware and software integration in all aspects of terminal operations. The optimization challenges are particularly significant when terminal automation involves a patchwork of traditional and state-of-the-art solutions from different suppliers. Purchasing automation components and equipment from different suppliers can result in expensive and lengthy integration processes. Globally, based on our survey results, 75% of the terminal operators integrated the automated equipment themselves, giving them greater control over the process and the length of the testing period (Table 5). Terminal operators would be anxious to realize the benefits of automation and minimize the testing phase. There were no distinct regional patterns in how terminals were integrated. Integration of the automated equipment by the terminal operator was found around the globe.

Table 5.

Integration options for automated equipment

| Terminals that used | Total* (n = 31) | Semi-automated terminals (n = 21) | Fully automated terminals (n = 11) |

|---|---|---|---|

| Multiple equipment suppliers with integration by terminal operator | 19 | 14 | 5 |

| Multiple equipment suppliers with the main supplier as integrator | 4 | 2 | 2 |

| One supplier as a turnkey operation | 3 | 2 | 1 |

| One supplier with integration by terminal operator | 5 | 2 | 3 |

*One terminal indicated another arrangement, unspecified

The second most common option was using one supplier of automated equipment with the terminal operator doing the integration. This was the case for both semi-automated and fully automated terminals. Less typical was integration by the leading supplier of the equipment. When the lead equipment supplier did the integration, the testing ranged from 6 to 37 months. In the four cases where the lead equipment supplier undertook the integration, the terminals were in Belgium, China, and Hong Kong.

Three terminals (the two Irish and one in China) used one supplier for a turnkey operation. In all three turnkey operations, the length of the testing period was 24 months. There is, however, no correlation between the length of the testing period and whether the automation was implemented by one or more suppliers [Pearson correlation: 0.166; Sig. (2-tailed): 0.525]; or whether the automation was implemented by a terminal operator or a supplier [Pearson correlation: − 0.130; Sig. (2-tailed): 0.597, Table 6].

Table 6.

Correlations between length for realizing ROI and supplier(s) involved in implementing automation

| Length of the testing period of the automation equipment/system | Automation implemented by one or more suppliers | Automation implemented by supplier(s) with system integration by terminal operator | |

|---|---|---|---|

| Years to realize a ROI for automated system | |||

| Pearson correlation | 0.239 | − 0.031 | − 0.032 |

| Sig. (2-tailed) | 0.250 | 0.870 | 0.108 |

| N | 31 | 31 | 23 |

| Length of the testing period of the automation equipment/system | |||

| Pearson correlation | 0.166 | − 0.130 | |

| Sig. (2-tailed) | 0.525 | 0.597 | |

| N | 31 | 23 |

Recognizing the complexity of developing an automated terminal, APM Terminals recently announced an arrangement with ZPMC focused on shifting the relationship between terminal operator and equipment supplier from a transactional one to a partnership that should facilitate the integration process.

Return on investment

The last research question (R5) targets a key financial aspect of terminal automation, i.e., the ROI. Automated terminals require a significant upfront investment for equipment procurement and the necessary terminal modifications. One survey question asked terminal operators how long before they realized a return on their investment. A total of 31 of the 32 terminals that responded to the survey completed this question (Fig. 10). Sixty-one percent of the terminals indicated that it would take over 6 years to realize a return on the investment. Twenty-nine percent of the terminals realized a ROI between 5 and 6 years.

Fig. 10.

Years to reach return on investment in automated equipment—raw data

There was no discernable difference between the lengths of time a fully automated terminal took to realize a ROI compared with a semi-automated terminal. One Pacific Asia terminal reported an unlikely low ROI period of less than 1 year. That is an outlier for which we were unable to find an explanation.

There is also no correlation between the time needed for a ROI and the length of the testing period [Pearson correlation: 0.239; Sig. (2-tailed): 0.250, Table 6]. Moreover, we did not identify any correlation between the time needed for the return of investment and whether the automation was implemented by one or more suppliers [Pearson correlation: − 0.031; Sig. (2-tailed): 0.870] or whether the automation was implemented by a terminal operator or a supplier [Pearson correlation: − 0.0323; Sig. (2-tailed): 0.108].

Conclusions

This study provides a deeper understanding of where, when, under which conditions, and to what extent container terminals have been automated and who is responsible for implementing terminal automation. A wide array of temporal, institutional and spatial factors were examined in the context of answering five research questions. The research questions, the analyzed attributes per question and the main findings are summarized in Table 7.

Table 7.

Revealing distinctive characteristics of automated terminals in terms of physical, operating, implementation and financial attributes

| Research questions | Attributes of automated terminals | Main findings |

|---|---|---|

| R1: When and to what extent have container terminals been automated, and who is responsible for their operation? | Full or semi-automated | 29% of all automated terminals are fully automated |

| Number and temporal development | Accelerated adoption: 76% of all automated terminals opened after 2012; still, they represent only 3% of all container terminals globally | |

| Type of operator | 62% Operated by pure stevedores, 22% by carrier-related operators | |

| R2: Are there any geographic patterns in the global dispersion of automated terminals with some port regions more likely to opt for automation of terminal equipment? | Terminal location (country and region) | Automated terminals exist in all continents except Africa and Antarctica; They are located in 23 countries, evenly distributed between semi-automation and full automation; Europe Atlantic and Pacific Asia are the earliest adopters |

| R3: Are there characteristics, such as cargo volume thresholds, or a specific cargo mix between gateway (import/export) and sea–sea transshipment flows that are common to all automated terminals? | Terminal throughput (in TEU) | Terminal automation occurs in all terminal scales, and is not the prerogative of 3 million TEU+ terminals (only 30.6% of all automated terminals) |

| Quay length | Average = 1480 m (similar for fully and semi-automated terminals). Std Dev = 769 m for fully automated and 1350 m for semi-automated. Upper value of 5000 m. Less than 1000 m for about one third of all automated terminals | |

| Draft | Ranges from 13.7 to 16 m. Semi-automated terminals: lowest 9 m | |

| Terminal acreage | Average = 98.6 ha (fully automated); 84.1 ha (semi-automated). Std Dev = 80.5 m (fully automated) and 69.4 m (semi-automated). Less than 50 ha for 39% of terminals | |

| Container port scale (in TEU) | 27% of automated terminals in world's top 10 container ports; 70% in world's top 100 container ports | |

| Largest container vessel scale | Automation primarily occurs at terminals which target 10,000 TEU+ vessels; 55.6% of terminals operate in ports receiving containerships larger than 20,000 TEU | |

| Cargo mix (transshipment incidence) | Relation between transshipment incidence and automation is spurious. Only one fully automated terminal is located in an almost pure transshipment hub. Semi-automated terminals are found in pure transshipment ports, mixed ports, and gateway ports, with none of these groups having a dominant presence | |

| R4: How are terminal operators implementing their automation projects, with one or multiple suppliers, and who has integrated the terminal operating systems and equipment? | Test period | Wide variation in the length of the testing period (2 months to 37 months) with no apparent pattern between semi-automated and fully automated terminals; 43% of terminals had a testing period of 6 months or less |

| Automated equipment suppliers | High reliance on multiple equipment suppliers | |

| Integration of equipment and terminal operating system | 75% of the terminal operators integrated the automated equipment by themselves; No correlation between the length of the testing period and whether the automation was implemented by one or more suppliers or whether the automation was implemented by a terminal operator or a supplier | |

| R5: How long before a terminal operator realizes a return on investment? | Return on investment | > 6 years = 61% of terminals; 5–6 years = 29%; no discernable difference between automated and semi-automated terminals |

The 63 operating automated terminals are found in 23 countries, in all continents except Africa (and Antarctica). Most of the terminals are located in Pacific Asia and Europe. New automated terminal projects have been proposed for Busan, South Korea (PCN), New Orleans and Long Beach in the US and Chile, while others are under development. Stevedoring companies operate 39 automated terminals, carriers operate 14 terminals, financial holding companies operate 6, and joint ventures or consortia operate 4. Despite the growth in terminal automation, automated terminals still represent a small part of the operators’ global terminal portfolios. All top six global/international terminal operators (China COSCO Shipping Ports, PSA International, APM Terminals, Hutchison Ports, D.P. World and TIL), based on their share in world container port throughput for 2018–2019, (Drewry 2020) are involved in the operation of at least one automated terminal. For example, Hutchison Ports operates 52 container terminals globally, of which only 6 (11.5%) are fully or semi-automated (3 and 3, respectively). APM Terminals has involvement in 59 container terminals, 5 of which are automated terminals (8.5%), 4 fully automated, and 1 semi-automated. Of the 50 terminals controlled by PSA, only 5 (10%) are automated. D.P. World operates six other automated terminals (five semi-automated and one fully automated). TIL is involved in two and China COSCO Shipping in one.

Eighteen of the 63 terminals are fully automated, the rest semi-automated. Although the first automated terminal opened in 1993, the real acceleration has happened in the last decade with 40 terminals automated since 2013. Eleven of those 40 are in the Pacific Asia region. In light of the arrangement between APM Terminals and China's Shanghai Zhenhua Heavy Industries Company (ZPMC), the Pacific Asia region is likely to continue the acceleration toward automation. In October 2021, APM Terminals announced that it was forming a strategic alliance with ZPMC to develop a wide range of automated solutions for its global network of 76 terminals, including automated container handling equipment (APM 2021). This sort of strategic relationships could likely facilitate a more rapid conversion of conventional terminals to automation.

Most automated terminals handle between 2 and 3 million TEU. While many trade publications suggest that automation needs a minimum of 1 million TEU to operate effectively, the results found that twelve automated terminals handle less than 1 million TEU, two of which are fully automated. Thus, terminal automation occurs in all terminal scales, and is not the prerogative of the largest terminal group only. Still, we also found that automation primarily occurs at terminals, small or large, which target 10,000 TEU+ vessels. If gigantism in container shipping, ports, and global logistics (Haralambides 2019) prevails, and the foreseen presence of 25,000 TEU+ ultra-large containerships (ULCS) (Ge et al. 2021) expands, it remains to be seen whether automation will be spread further as a response to the scale diseconomies produced at the port by the use of these larger vessels.

The early 2020s are marked by disruptions in global maritime supply chains, caused by the COVID-19 pandemic (Notteboom et al. 2021; Kent and Haralambides 2022). Against a backdrop of fewer vessel calls and mixed trends in the share of larger vessels calling around the globe, there is a tendency toward bigger call sizes. The foundations of the observed increases in call sizes are driven by the trends in the biggest call sizes, especially those of 6000 TEU or more (Notteboom and Pallis 2022). Record-breaking call sizes in many ports (e.g., Los Angeles, Antwerp, Felxistowe, Singapore) put pressure on yard space, berth availability and quay crane availability and productivity to accommodate such vessels. These are all important parameters in automated terminals. Today, the average size of fully automated terminals is about 100 ha, while the average size of semi-automated terminals is 84 ha. The range of terminal sizes varies significantly for both fully and semi-automated terminals, with 24 being less than 50 ha. The average quay length based on 59 of the 62 terminals is 1480 m without a significant difference between full and semi-automated terminals. Again, variability is high, with two terminals having over 5000 m of berth. All but one terminal have drafts over 14 m, with the maximum draft of automated terminals at 16 m.

Automated terminals allow terminal operators to densify their operations and maximize the use of terminal space. The expectation is that the ability to densify operations in an automated configuration might show that, for a given design capacity, automated terminals could be smaller than conventional terminals. Fully automated terminals are typically 30% larger than semi-automated terminals. Most of the automated terminals developed by the six large global terminal operators have a rather large capacity footprint. However, approximately one third of the existing automated terminals were conversions of existing conventional terminals, particularly in the United States and Europe vis à vis greenfield operations, designed initially with automation. Of the six automated terminals in the US, only one was a greenfield terminal (Virginia International Gateway, originally developed by APM). In addition, several terminals have automated only a part of their existing conventional terminals. For example, AMP Terminal in Los Angeles automated only 40 of its 196 ha. Greenfield terminals are predominately being developed in the Middle East and Asia. These are being developed in phases but their long-range plans show that they are on the larger end of the range of terminal sizes found here.

About 70% of the automated terminals operate in the top 100 container ports in the world but only 17 are found in the top ten container ports. Nine of the top ten container ports based on 2020 volumes are located in the Pacific Asia region (World Shipping Council 2022), already shown here as a hotspot for automation. The expectation is that the percentage of automated terminals in the top 10 container ports will continue to grow over time. There is no strong relationship between transshipment incidence and automation, but expectations based on cargo mix would suggest higher levels of automation in gateway ports and less in transshipment hubs. Only one fully automated terminal is in a transshipment hub, while semi-automated terminals can be found in pure transshipment ports, ports with a mixed cargo mix, and gateway ports.

The decision to automate does not always translate to successful implementation. In two cases, London Thamesport in the UK and the Outer Northern Harbor terminal in Copenhagen, the process of automating the terminals has been canceled for commercial and other reasons. In other parts of the world, intentions and decisions to develop new port infrastructure are associated with automation, but port development advancement is on hold for several reasons. One such case is Mubarak Al Kabeer Port in Kuwait.

While we find a wide variation in technical characteristics among automated terminals there are some operating characteristics that are predominant. There is a clear preference for terminal operators to undertake themselves the integration of a new automated terminal system. One terminal operator indicated on his survey that what was learned during their first terminal integration significantly reduced the time to start their second terminal. Over time, the expectation is that the testing periods will become shorter as terminal operators experience increases. Likewise, ROI results reveal that automation requires a long commitment, with most semi and automated terminals taking over six years to realize a return. The results could have been further refined had an additional response option been available for the terminal operators, such as “over ten years.”

Acknowledging that not all container terminals are candidates for automation of their equipment, this paper, therefore, contributes to the extant literature by presenting a systematic review of all global automated terminals in order to substantiate or refute any perceptions that might exist on the characteristics of these terminals, for example in terms of the minimum cargo volume needed. While it is generally believed that only certain terminals will fit the profile where unmanned automated equipment brings added value, the results here reflect a wide variation in automated container terminal features, particularly the size, container volumes, and overall port standing. No specific set of characteristics was identified that must be present for an automated terminal to materialize. Neither physical size nor volume dictates whether or not a terminal can be automated. Rather each locality presents a unique set of circumstances that terminals adapt to. The findings, however, allow a determination of the most likely attribute values of an automated terminal, while acknowledging that wide ranges are reported for automated terminals’ physical attributes, because operators have proceeded to automate under a wide variety of local conditions. Nevertheless, the optimum conditions for automation based on the most common characteristics found among the largest number of terminals can be defined. Terminal operators, port authorities and government officials can benchmark their local conditions against the presented list of technical and corporate/governance attributes shown in Table 7. Thus, our findings can provide some guidance to market actors considering automation investments, and to public and private port authority decision makers that might also commit resources to automation.

Acknowledgements

This research is supported by the Volvo Research and Educational Foundations through the MetroFreight Center of Excellence and the University of Southern California METRANS Transportation Consortium.

Footnotes

Reference here is to the port operator; in some cases, this might be accompanied by the formation of companies where partners might hold minority equities.

We collected data on number of ship-to-shore cranes but do not know the outreach and technical characteristics of those cranes so we cannot make assumptions on crane density present in the handling of the largest vessels.

For example, the MSC Isabella, with a nominal capacity of some 23,000 TEU, broke earlier records when the Pier 400 Terminal unloaded/loaded 34,263 TEU in the port of Los Angeles in June 2020.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alho, T. 2019. Latest automation technology developments for ports and terminals. In Proceedings of the ANESCO automation conference, Madrid, Spain, 19 February 2019.

- APM Terminals. 2021. APM Terminals and ZPMC enter into strategic alliance. Press Release by APM Terminals, 21 October 2021. https://www.apmterminals.com/en/news/news-releases/2021/211021-apm-terminals-and-zpmc-enter-into-strategic-alliance. Accessed 19 April 2022.

- Bichou K, Bell M. Internationalisation and consolidation of the container port industry: Assessment of channel structure and relationships. Maritime Economics and Logistics. 2007;9:35–51. doi: 10.1057/palgrave.mel.9100170. [DOI] [Google Scholar]

- Brooks, M.R. 2009. Liberalization in maritime transport. In International Transport Forum. Paris: OECD.

- Camarero Orive A, Santiago JIP, Corral MMEI, González-Cancelas N. Strategic analysis of the automation of container port terminals through BOT (business observation tool) Logistics. 2020 doi: 10.3390/logistics4010003. [DOI] [Google Scholar]

- Drewry. 2018. Retrofit terminal automation: Measuring the market. In Presentation at container terminal automation conference, London, March 14–15, 2018.

- Drewry. 2020. Global container terminal operators: Annual review and forecast—Annual report 2020/21. Drewry Maritime Research.

- Ge J, Zhu M, Sha M, Notteboom T, Shi W, Wang X. Towards 25,000 TEU vessels? A comparative economic analysis of ultra-large containership sizes under different market and operational conditions. Maritime Economics and Logistics. 2021;23:587–614. doi: 10.1057/s41278-019-00136-4. [DOI] [Google Scholar]

- Ghiara H, Tei A. Port activity and technical efficiency: Determinants and external factors. Maritime Policy and Management. 2021;48(5):711–724. doi: 10.1080/03088839.2021.1872807. [DOI] [Google Scholar]

- Haralambides HE. Gigantism in container shipping, ports and global logistics: A time-lapse into the future. Maritime Economics and Logistics. 2019;21(1):1–60. doi: 10.1057/s41278-018-00116-0. [DOI] [Google Scholar]

- ITF. 2021. Container port automation: Impacts and implications. International Transport Forum Policy Papers, No. 96, OECD Publishing, Paris.

- Kent P, Haralambides H. A perfect storm or an imperfect supply chain? The US supply chain crisis. Maritime Economics and Logistics. 2022;24:1–8. doi: 10.1057/s41278-022-00221-1. [DOI] [Google Scholar]

- Kon WK, Rahman NSFA, Hanafiah RM, Hamid SA. The global trends of automated container terminal: A systematic literature review. Maritime Business Review. 2020;6(3):206–233. doi: 10.1108/MABR-03-2020-0016. [DOI] [Google Scholar]

- Lau HY, Zhao Y. Integrated scheduling of handling equipment at automated container terminals. International Journal of Production Economics. 2008;112(2):665–682. doi: 10.1016/j.ijpe.2007.05.015. [DOI] [Google Scholar]

- Martín-Soberón AM, Monfort A, Sapiña R, Monterde N, Calduch D. Automation in port container terminals. Procedia Social and Behavioral Sciences. 2014;160:195–204. doi: 10.1016/j.sbspro.2014.12.131. [DOI] [Google Scholar]

- McKinsey . The future of automated ports. Atlanta: McKinsey & Company; 2018. [Google Scholar]

- Miller, M. 2017. There’s a long road ahead for terminal automation. American Journal of Transportation (660), 13 November 2017, https://www.ajot.com/premium/ajot-theres-a-long-road-ahead-for-terminal-automation.

- Moody’s. 2019. Automated terminals offer competitive advantages, but implementation challenges may limit penetration, Sector-in-depth, 24 June 2019. Moody’s Investor Service.

- Navis. 2018. Navis survey: Terminal automation ‘Critical’ to survival. Port Technology International. https://www.porttechnology.org/news/survey_terminal_Automation_critical_to_short_term_survival.

- Notteboom, T., and T. Pallis. 2022. World Ports Tracker, No 1, May 2022. Antwerp: International Association of Ports and Harbors (IAPH).

- Notteboom T, Rodrigue JP. The corporate geography of global container terminal operators. Maritime Policy and Management. 2012;39(3):249–279. doi: 10.1080/03088839.2012.671970. [DOI] [Google Scholar]

- Notteboom TE, Parola F, Satta G. The relationship between transshipment incidence and throughput volatility in North European and Mediterranean container ports. Journal of Transport Geography. 2019;74:371–381. doi: 10.1016/j.jtrangeo.2019.01.002. [DOI] [Google Scholar]

- Notteboom T, Pallis T, Rodrigue JP. Disruptions and resilience in global container shipping and ports: The COVID-19 pandemic versus the 2008–2009 financial crisis. Maritime Economics and Logistics. 2021;23(2):179–210. doi: 10.1057/s41278-020-00180-5. [DOI] [Google Scholar]

- Notteboom T, Pallis AA, Rodrigue J-P. Port economics, policy and management. New York: Routledge; 2022. [Google Scholar]

- Olivier D. Private entry and emerging partnerships in the container terminal industry: Evidence from Asia. Maritime Economics and Logistics. 2005;7(2):87–115. doi: 10.1057/palgrave.mel.9100131. [DOI] [Google Scholar]

- Olivier D, Parola F, Slack B, Wang J. The time scale of internationalisation: The case of the container port industry. Maritime Economics and Logistics. 2007;9:1–34. doi: 10.1057/palgrave.mel.9100169. [DOI] [Google Scholar]

- Pallis AA, de Langen PW. Seaports and the structural implications of the economic crisis. Research in Transportation Economics. 2010;27:10–18. doi: 10.1016/j.retrec.2009.12.003. [DOI] [Google Scholar]

- Pallis AA, Notteboom TE, De Langen PW. Concession agreements and market entry in the container terminal industry. Maritime Economics and Logistics. 2008;10(3):209–228. doi: 10.1057/mel.2008.1. [DOI] [Google Scholar]

- Parola F, Musso E. Market structures and competitive strategies: The carrier-stevedore arm-wrestling in northern European ports. Maritime Policy and Management. 2007;34(3):259–278. doi: 10.1080/03088830701343369. [DOI] [Google Scholar]

- Parola F, Notteboom T, Satta G, Rodrigue JP. Analysis of factors underlying foreign entry strategies of terminal operators in container ports. Journal of Transport Geography. 2013;33:72–84. doi: 10.1016/j.jtrangeo.2013.09.010. [DOI] [Google Scholar]

- Parola F, Notteboom T, Satta G, Rodrigue JP. The impact of multiple-site acquisitions on corporate growth patterns of international terminal operators. International Journal of Shipping and Transport Logistics. 2015;7(5):621–648. doi: 10.1504/IJSTL.2015.072018. [DOI] [Google Scholar]

- PEMA. 2016. Container terminal automation. PEMA Information Paper. London: Port Equipment Manufacturers Association.

- Rodrigue, J.P., and T. Notteboom. 2021. Automation in container port systems and management. T.R. News, no. 334, July–August 2021, 20–26. Transportation Research Board: The National Academy of Sciences (US).

- Rodrigue JP, Notteboom T, Pallis AA. The financialisation of the terminal and port industry: Revisiting risk and embeddedness. Maritime Policy and Management. 2011;38(2):191–213. doi: 10.1080/03088839.2011.556675. [DOI] [Google Scholar]

- Sha M, Notteboom T, Zhang T, Zhou X, Qin T. Simulation model to determine ratios between quay, yard and intra-terminal transfer equipment in an integrated container handling system. Journal of International Logistics and Trade. 2021;19(1):1–18. doi: 10.24006/jilt.2021.19.1.001. [DOI] [Google Scholar]

- Stahlbock R, Voß S. Operations research at container terminals: A literature update. Or Spectrum. 2008;30:1–52. doi: 10.1007/s00291-007-0100-9. [DOI] [Google Scholar]

- Wallis, K. 2022. Busan expects new terminal to ease congestion, boost transshipment. Journal of Commerce, February 17, 2022. https://www.joc.com/port-news/international-ports/busan-expects-new-terminal-ease-congestion-boost-transshipment_20220217.html.

- Wang P, Mileski J, Zeng Q. Alignments between strategic content and process structure: The case of container terminal service process automation. Maritime Economics and Logistics. 2019;21:543–558. doi: 10.1057/s41278-017-0070-z. [DOI] [Google Scholar]

- World Shipping Council. 2022. The Top 50 container ports. https://www.worldshipping.org/top-50-ports. Accessed 26 Jan 2022.

- Zhao Q, Ji S, Guo D, Du X, Wang H. Research on cooperative scheduling of automated quayside cranes and automatic guided vehicles in automated container terminal. Mathematical Problems in Engineering. 2019 doi: 10.1155/2019/6574582. [DOI] [Google Scholar]