Abstract

The present investigation aims to find an exact solution to the problem of a free convective, viscous, radiating, chemically reacting, optically thick, non-gray, and incompressible MHD flow past an exponentially accelerated semi-infinite vertical plate in presence of a transverse magnetic field. The medium of flow is porous. Arbitrary ramped temperature and diffusion thermo effects are also considered. Rosseland approximation method is used to describe the flux that appears in the energy equation. The effects of different parameters on flow and transport characteristics are discussed with the help of suitable graphs. It is noticed that velocity field and concentration field decreases but temperature field increases with an upsurge in Schmidt number. Also, Nusselt number and skin friction rise with increasing chemical reaction parameter but lowers with increasing radiation parameter. Faster consumption of chemical substances decelerates both concentration and velocity but accelerates temperature of the fluid. An interesting outcome outcome of our investigation is that both Dufour effect and arbitrary ramped temperature diminishes fluid velocity.

Subject terms: Applied mathematics, Software

Introduction

The branch of physics that deals with the interaction of the magnetic field with electrically conducting fluid are termed Magnetohydrodynamics (MHD). Saltwater, liquid metals, plasmas, electrolytes are some common examples of such fluids. Noted Swiss scientist Hannes Alfven1 initiated the field of MHD for which he received the Noble prize in physics in the year 1970. But, due to substantial contributions from other authors like Cowling2, Shercliff3, Ferraro and Plumpton4, Roberts5, Crammer and Pai6, MHD is at present form. There are several applications of MHD in modern technologies. Geophysical and astrophysical applications of MHD are nicely elaborated by Dormy and Nunez7. Dynamo, motor, fusion reactors, dispersion of metals, metallurgy, etc. are some engineering applications of MHD. Aeronautical applications of MHD were studied exclusively by Li et al.8. Farrokhi et al.9 studied biomedical applications of MHD. Rana et al.10 investigated how microbes swim in blood flow of nano- bioconvective Williamson fluid.

Change in fluid temperature and species concentration generates density variation in the fluid mixture. This variation develops buoyancy forces that act on the fluid. The flow produced due to the buoyancy force is termed free convection or natural convection. Manh et al.11, Das and Ahmed12, Kafoussias13, Kumar and Singh14, etc. studied the effect of free convection on various MHD problems.

The porous medium contains holes or voids that are filled with solid particles which let the fluid pass through it. The mechanism of porous flow finds its applications in inkjet printing, nuclear waste disposal, electro-chemistry, combustion technology, etc. Dwivedi et al.15 studied MHD flow through the vertical channel in a porous medium while Raju et al.16 observed the MHD flow through horizontal channel taking viscous dissipation and Joule heating into account. Free convection in the porous media was investigated by Helmy17, Raju and Varma18, Pattnaik and Biswal19, Sinha et al.20, Basha and Nagarathna21.

Radiation is a form of heat transfer by electromagnetic waves. Many environmental and industrial procedures encounters with radiative convective flows. Flows of this kind take crucial role in space technology and high temperature activities. This influence many authors to perform model research on free convection with thermal radiation in several hydrodynamic and magnetohydrodynamic problems under various physical and geometrical conditions. Mbeldogu et al.22, Makinde23, Samad and Rahman24, Orhan and Ahmet25, Prasad et al.26, Ahmed and Dutta27, Takhar et al.28, Seth et al.29, Balla and Naikoti30, Siviah et al.31 are some worth mentioning researchers in this area.

The effect of chemical reaction carries a great practical significance in heat and mass transfer problems. So, many researchers studied applications of chemical reaction in different MHD flow problems. Apelblat32 investigated chemical reaction effect in a mass transfer problem with axial diffusion. Mahapatra et al.33 examined the effects of chemical reaction in a free convective flow in a porous media surrounded by a vertical surface. Andersson et al.34 and Takhar et al.35 considered the diffusion of a chemically reactive species from a stretching sheet while Ganesan and Rani36 studied the diffusion of chemically reactive species through a vertical cylinder. Muthucumaraswamy and Ganesan37, Kandasamy et al.38, Raptis and Perdikis39, etc. investigated the effects of chemical reaction in various MHD problems. Arifuzzaman et al.40 studied chemically reactive and naturally convective high speed MHD flow through an oscillating vertical porous plate.

If two non-reacting and chemically different fluids are allowed to diffuse into each other at the same temperature, the system produces a heat flux. Effect of flux due to composition gradient is defined as Dufour effect or diffusion thermo effect. Renowned Swiss scientist L. Dufour discovered this effect in 1873. This effect is nicely elaborated by Eckert and Drake41. Swetha et al.42 analyzed Dufour and radiation effects on a free convective flow in a porous medium. Reddy et al.43 studied both Soret and Dufour effects of an MHD flow past a moving vertical plate immersed in a porous medium taking Hall current and rotating system into account. Oyekunle and Agunbiade44 explored the consequences of the Dufour and Soret effect of MHD flow on an inclined magnetic field. Kumaresan et al.45 analytically investigated the Dufour effect on unsteady free convective flow past an accelerated vertical plate. Vijaya Kumar et al.46 studied Dufour and radiation effects on a free convective MHD flow past an infinite vertical plate in presence of chemical reaction. Shateyi et al.47 studied the effects of Soret, Dufour, Hall current and radiation of a mixed convective flow in a porous medium. Postelnicu48 examined the consequences of both Soret and Dufour effects on a vertical surface embedded in a porous medium.

The present investigation aims to analyze the role of the diffusion thermo effect in a free convective, radiative, and chemically reacting fluid in a porous medium with arbitrary ramped temperature. Reviewing the existing literature, we found that no work has been done taking Dufour effect and ramped temperature with arbitrary characteristic time simultaneously in a flow past an exponentially started vertical plate . The governing equations are first converted to non-dimensional partial differential equations using some dimensionless quantities. A closed-form of the Laplace transform technique is adopted to solve the equations. Effects of different flow parameters like Prandtl number, Schmidt number, magnetic parameter, thermal Grashof number, solutal Grashof number, Dufour number, chemical reaction parameter, radiation parameter, porosity parameter, etc. on temperature field, concentration field, velocity field, Nusselt number, Sherwood number, and skin friction are discussed graphically. The obtained results are also verified with previously published work. It is hoped that the present paper will be useful in designing cooling systems, flow meters, MHD generators, etc. In the field of life science, this investigation can be helpful in magnetic drug treatment, devices for cell separation, magnetic endoscopy etc. This paper will also help scientists and researchers in the field of heat and mass transfer.

Mathematical model of the problem

Equations that govern the convective flow of an electrically conducting, incompressible, viscous, chemically reactive, and radiating fluid in a porous medium in presence of a magnetic field having constant mass diffusivity and thermal diffusivity taking the diffusion- thermo effect into account are.

Continuity equation:

| 1 |

Magnetic field continuity equation:

| 2 |

Ohm’s Law:

| 3 |

Momentum equation:

| 4 |

Energy equation:

| 5 |

Species continuity equation:

| 6 |

Equation of state as per Boussinesq approximation:

| 7 |

The radiation heat flux as per Rosseland approximation is given by

Now,

So,

Therefore, Energy Eq. (5) reduces to

| 8 |

We now consider a transient MHD free convection flow of a viscous incompressible electrically conducting fluid through a porous medium past a semi-infinite vertical plate in presence of a uniform magnetic field applied normal to the plate, directed into the fluid region. Initially, the plate and the surrounding fluid were at rest with uniform temperature and concentration at all points in the fluid. At time , the plate is exponentially accelerated with velocity . The plate temperature is instantaneously elevated to , for , and thereafter when . The concentration is raised to and maintained thereafter.

To idealize the mathematical model, we enforce the following constraints-

-

I.

Except the variation in density in the buoyancy force term, all the fluid properties are constant.

-

II.

Energy dissipation occurring from friction and Joule heating is negligible.

-

III.

Compared to applied magnetic field, induced magnetic field is negligible.

-

IV.

Flow is one- dimensional which is parallel to the plate.

-

V.

The plate is electrically insulating.

-

VI.

Polarization voltage is negligible because no external electric field is applied.

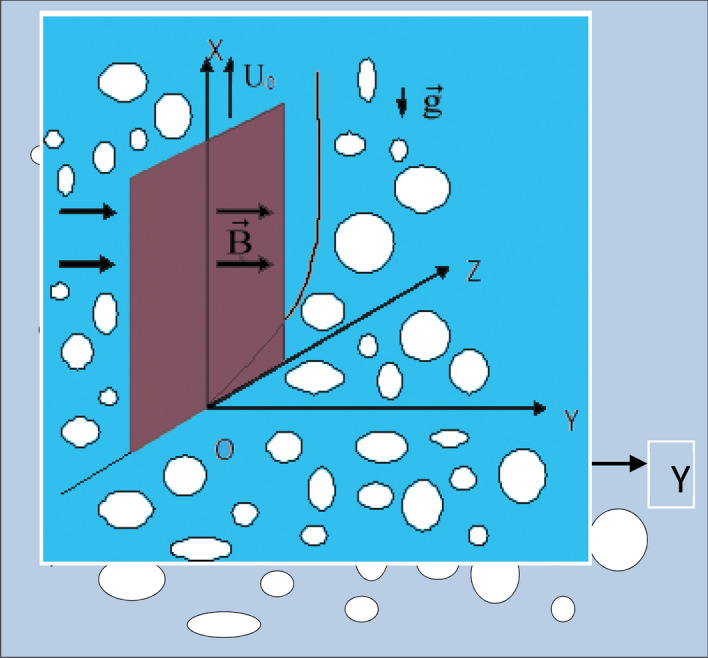

We now consider a tri- rectangular Cartesian co-ordinate system with X-axis vertically upwards along the plate, Y-axis normal to the plate directed into the fluid region, and Z-axis along the width of the plate as displayed in Fig. 1. Let be the fluid velocity and be the magnetic induction vector at the point in the fluid.

Figure 1.

Flow configuration.

Equation (1) yields,

| 9 |

Equation (2) is trivially satisfied by .

Equation (4) reduces to

| 10 |

Equation (10) gives

| 11 |

And

| 12 |

Equation (12) shows that pressure near the plate and pressure far away from the plate are the same along the normal to the plate.

For fluid region far away from the plate, Eq. (11) takes the form

| 13 |

Eliminating from Eqs. (11) and (13), we get,

| 14 |

Now, Eq. (7) gives,

| 15 |

Putting value of Eq. (15) in Eq. (14),

| 16 |

Equation (8) yields,

| 17 |

Equation (6) becomes,

| 18 |

The relevant initial and boundary conditions are:

| 19 |

For the sake of normalization of the mathematical model of the problem, we introduce the following non-dimensional quantities-

The non- dimensional governing equations are

| 20 |

| 21 |

| 22 |

Subject to the initial and boundary conditions

| 23 |

Method of Solution

On taking Laplace transform of the Eqs. (22), (21), and (20) respectively, we get the following equations:

| 24 |

| 25 |

| 26 |

Subject to the initial and boundary conditions:

| 27 |

Solving equations from Eqs. (24) to (26) subject to the conditions (Eq. 27) and taking inverse Laplace transform of the solutions, the expression for temperature field , concentration field , and velocity field are as follows:

| 28 |

| 29 |

| 30 |

where

Nusselt number

The heat flux at the plate is obtained by Fourier’s law of conduction is given by

| 31 |

where is the modified thermal conductivity.

Equation (31) yields

| 32 |

where is called the Nusselt number which is concerned with the rate of heat transfer at the plate.

Equation (32) gives,

| 33 |

where

Sherwood number

The mass flux at the plate is specified by Fick’s law of diffusion is given by

| 34 |

Equation (34) gives

| 35 |

In Eq. (35), is called the Sherwood number which is associated with the rate of mass transfer at the plate.

Equation (35) yields

| 36 |

Skin friction

The viscous drag at the plate is determined by Newton’s law of viscosity is given by

| 37 |

Equation (37) gives

| 38 |

In Eq. (38), is called the skin friction or coefficient of friction which is associated with the rate of momentum transfer at the plate.

Equation (38) yields,

| 39 |

where

Result and discussion

The effects of various flow parameters associated with the flow and transport properties are examined by assigning some specific values. The results are demonstrated from Figs. 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34 and 35.

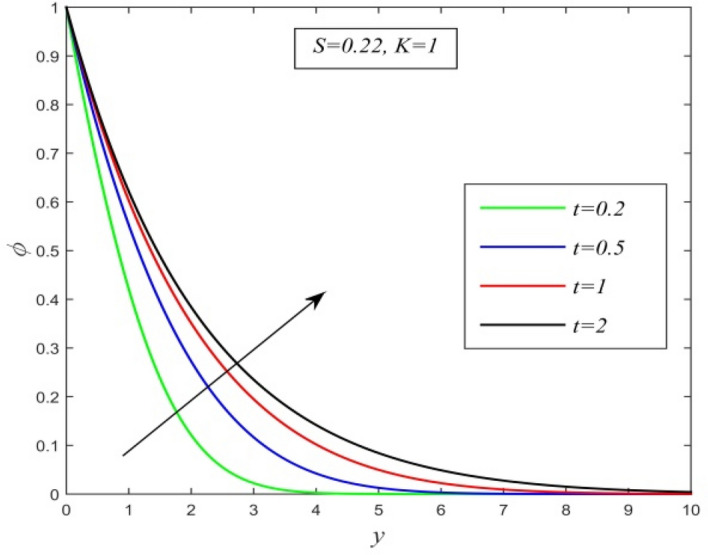

Figure 2.

versus for different t and Sc = 0.22, K = 1.

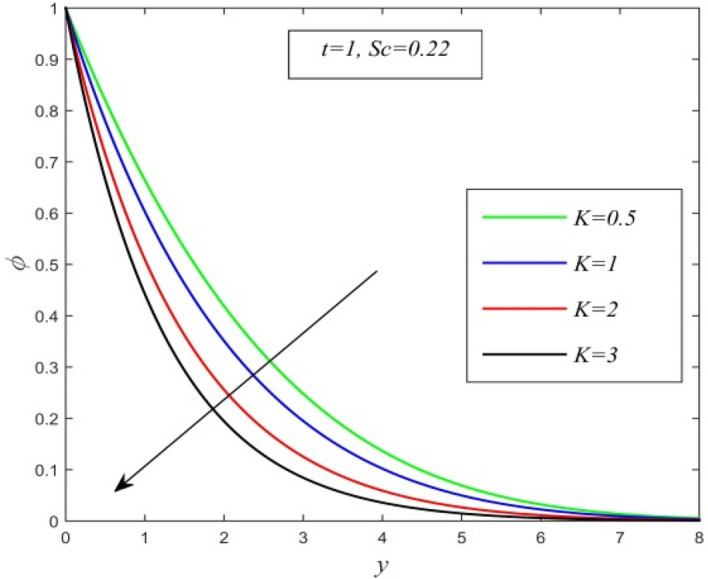

Figure 3.

versus for different K and t = 1, Sc = 0.22.

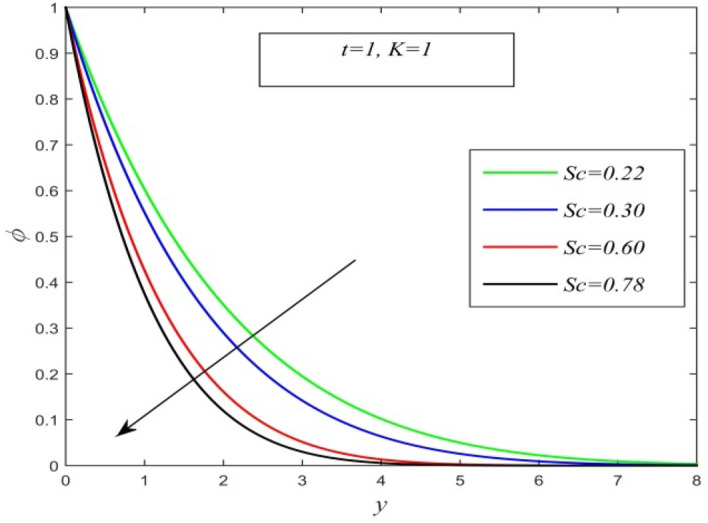

Figure 4.

versus for different Sc and t = 1, K = 0.22.

Figure 5.

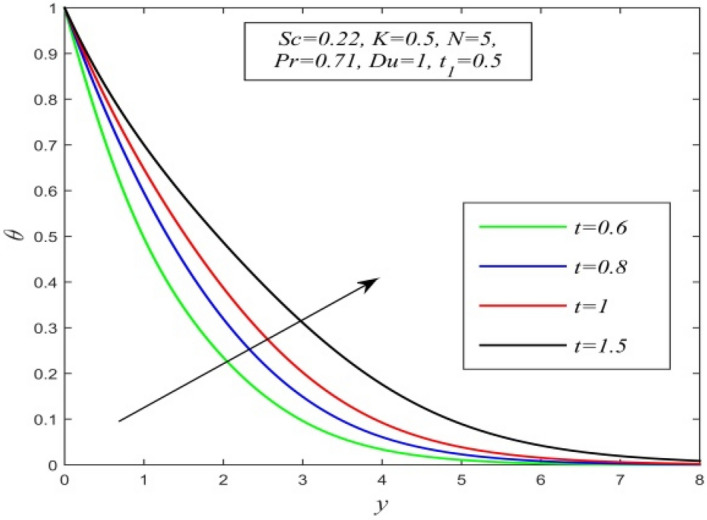

versus y for different t and Sc = 0.22, K = 0.5, N = 5, Pr = 0.71, Du = 1, = 0.5.

Figure 6.

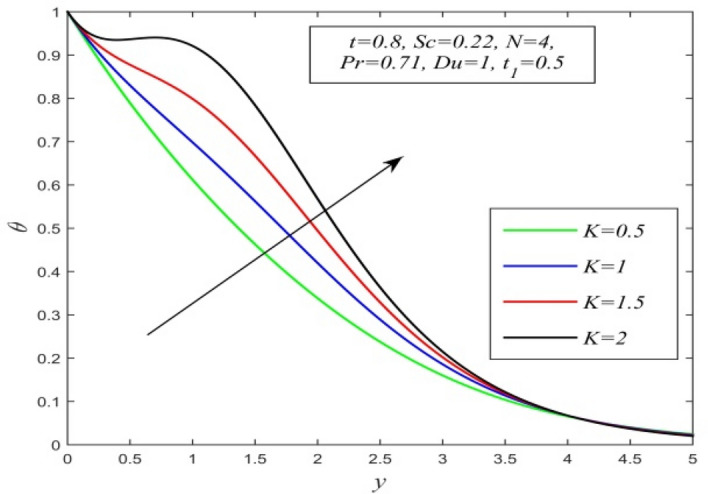

versus y for different K and t = 0.8, Sc = 0.22, N = 4, Pr = 0.71, Du = 1, = 0.5.

Figure 7.

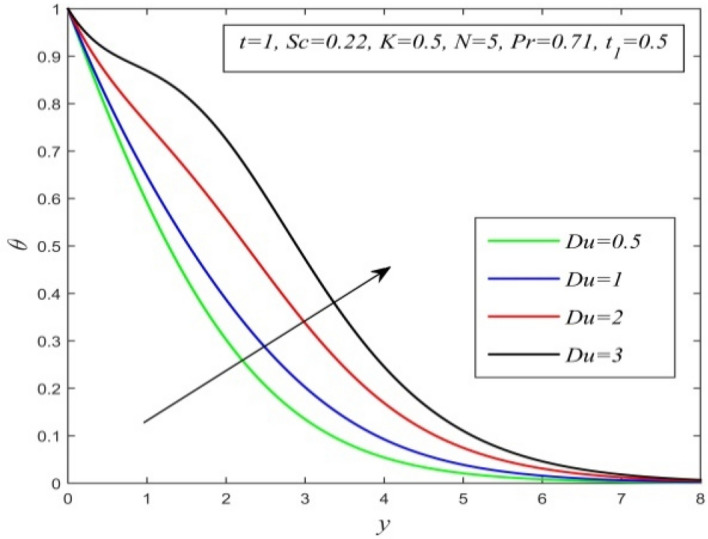

versus y for different Du and t = 1, Sc = 0.22, K = 0.5, N = 5, Pr = 0.71, = 0.5.

Figure 8.

versus y for different Sc and t = 1, K = 0.5, N = 2, Pr = 0.71, Du = 1, = 0.5.

Figure 9.

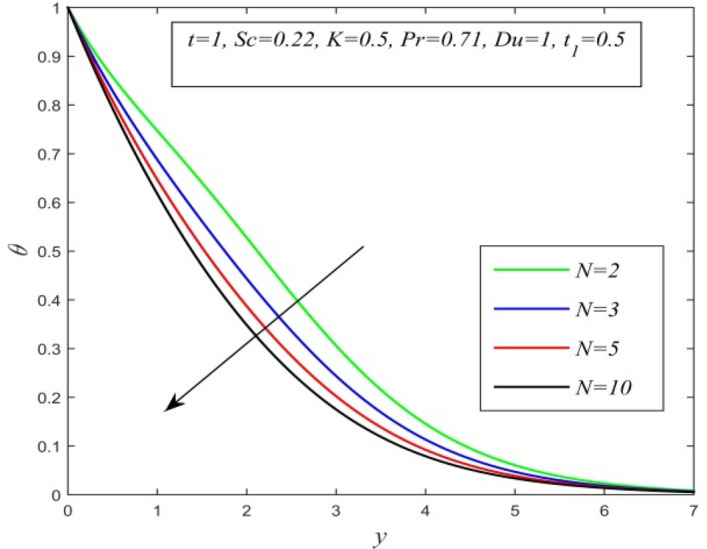

versus y for different N and t = 1, Sc = 0.22, K = 0.5, Pr = 0.71, Du = 1, = 0.5.

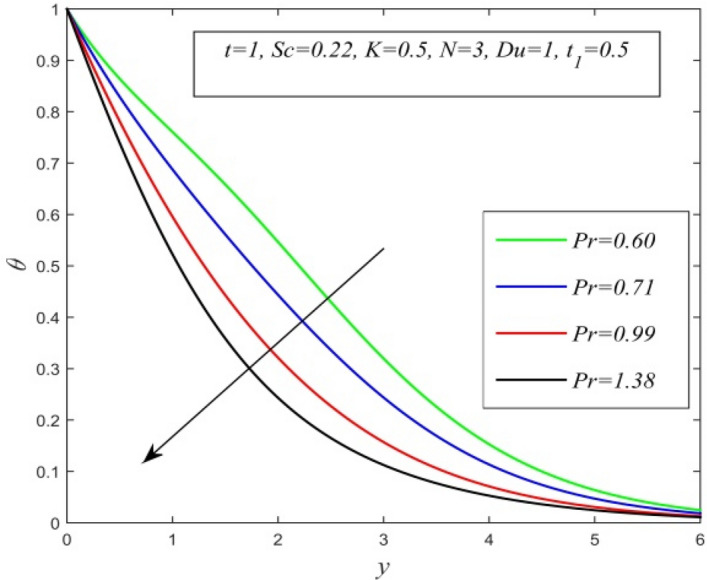

Figure 10.

versus y for different Pr and t = 1, Sc = 0.22, K = 0.5, N = 3, Du = 1, = 0.5.

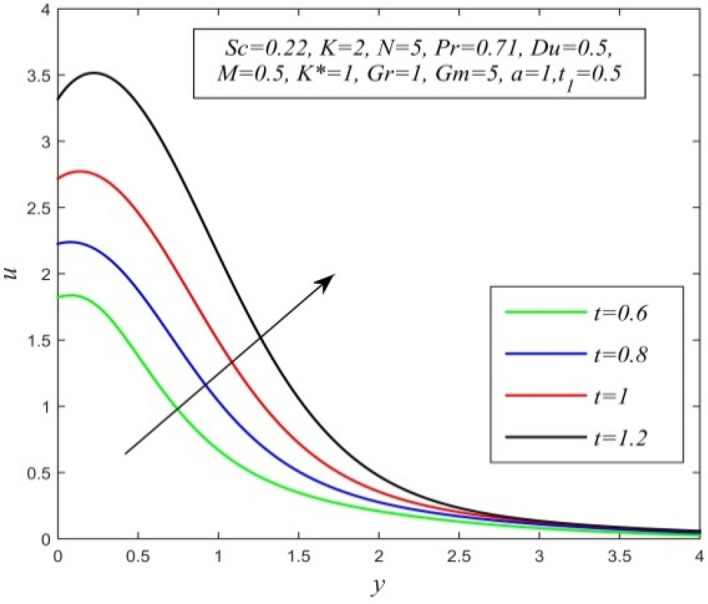

Figure 11.

u versus y for different t and Sc = 0.22, K = 2, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 10, a = 1, = 0.5.

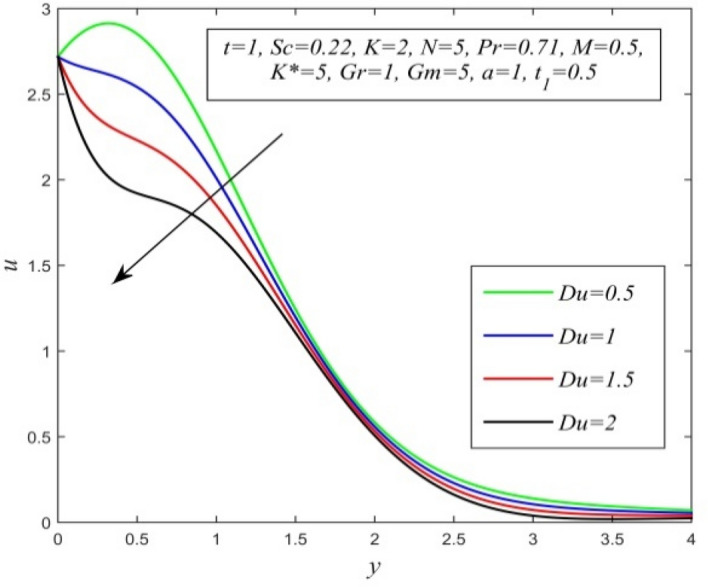

Figure 12.

u versus y for different Du and t = 1, Sc = 0.22, K = 2, N = 5, Pr = 0.71, M = 0.5, K* = 1, Gr = 1, Gm = 5, a = 1, = 0.5.

Figure 13.

u versus y for different K and t = 1, Sc = 0.22, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 10, a = 1, = 0.5.

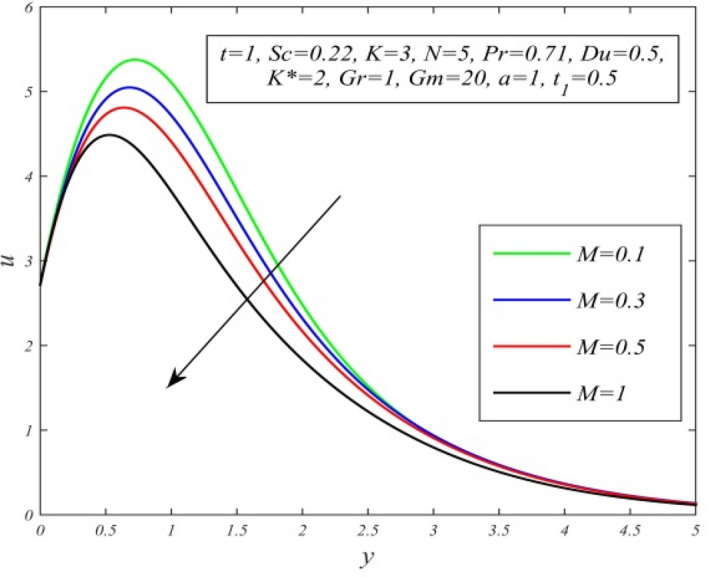

Figure 14.

u versus y for different M and t = 1, Sc = 0.22, K = 3, N = 5, Pr = 0.71, Du = 0.5, K* = 2, Gr = 1, Gm = 20, a = 1, = 0.5.

Figure 15.

u versus y for different Sc and t = 1, K = 3, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 10, a = 1, = 0.5.

Figure 16.

u versus y for different Gr and t = 1, Sc = 0.22, K = 2, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gm = 10, a = 1, = 0.5.

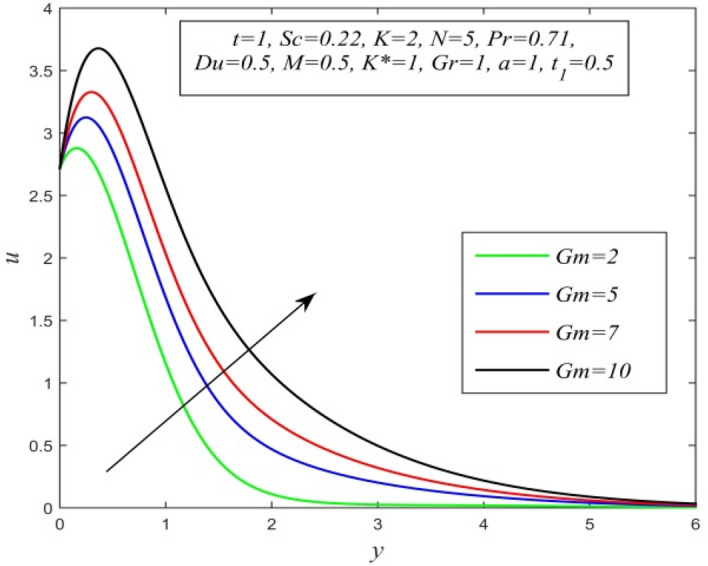

Figure 17.

u versus y for different Gm and t = 1, Sc = 0.22, K = 2, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, a = 1, = 0.5.

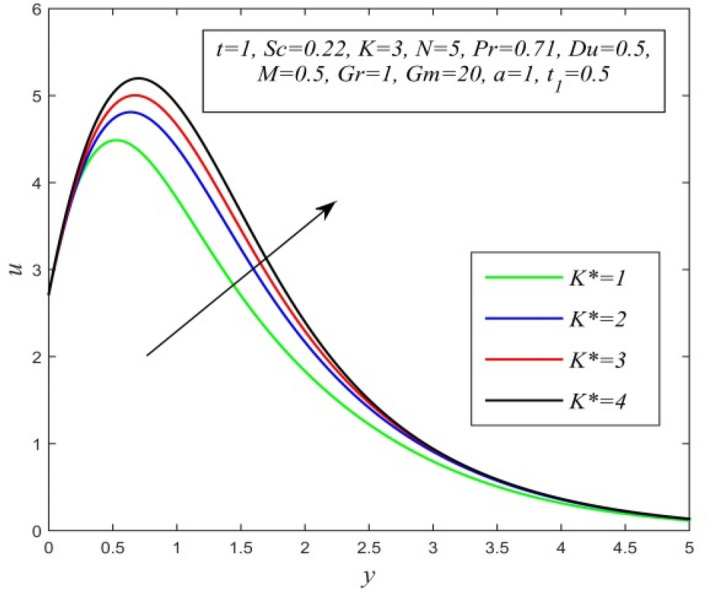

Figure 18.

u versus y for different K* and t = 1, Sc = 0.22, K = 3, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, Gr = 1, Gm = 20, a = 1, = 0.5.

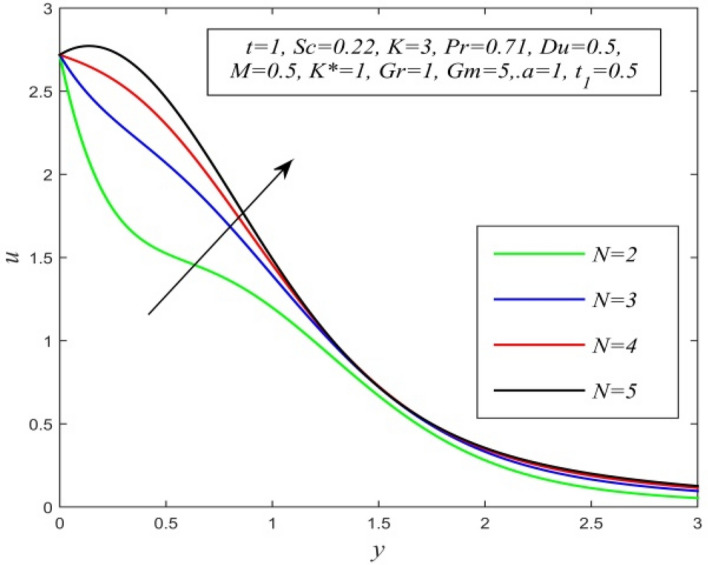

Figure 19.

u versus y for different N and t = 1, Sc = 0.22, K = 3, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 5, a = 1, = 0.5.

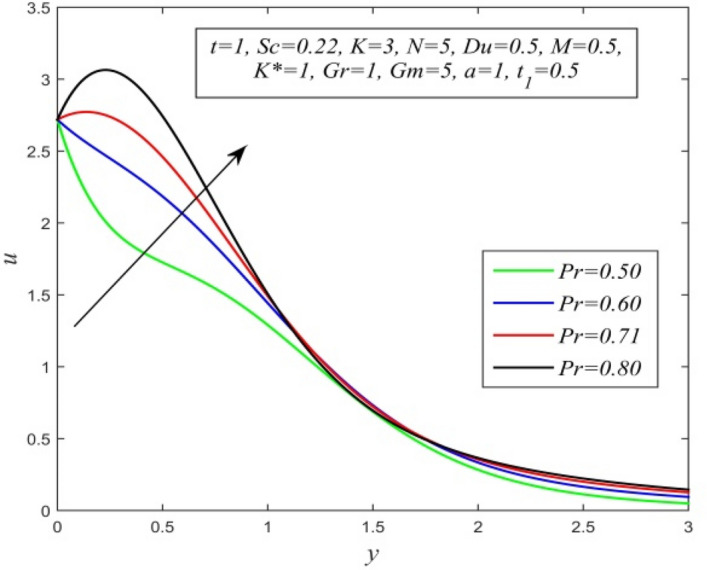

Figure 20.

u versus y for different Pr and t = 1, Sc = 0.22, K = 3, N = 5, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 5, a = 1, = 0.5.

Figure 21.

Sh versus t for different K and Sc = 0.22.

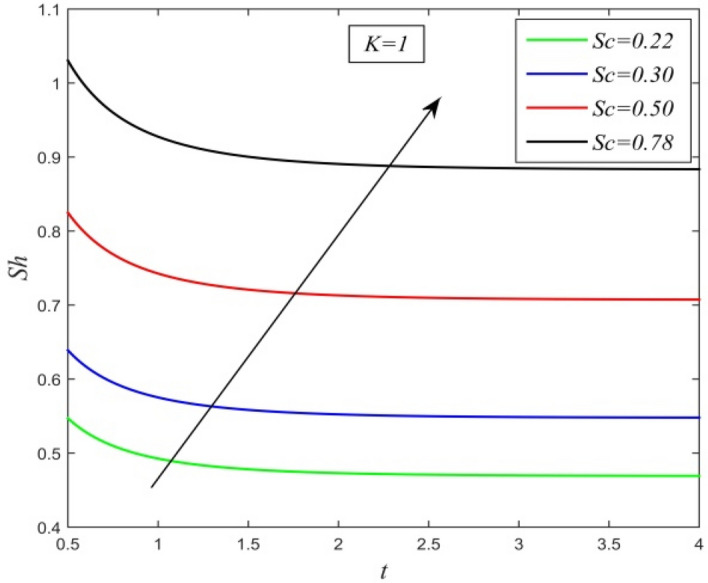

Figure 22.

Sh versus t for different Sc and K = 1.

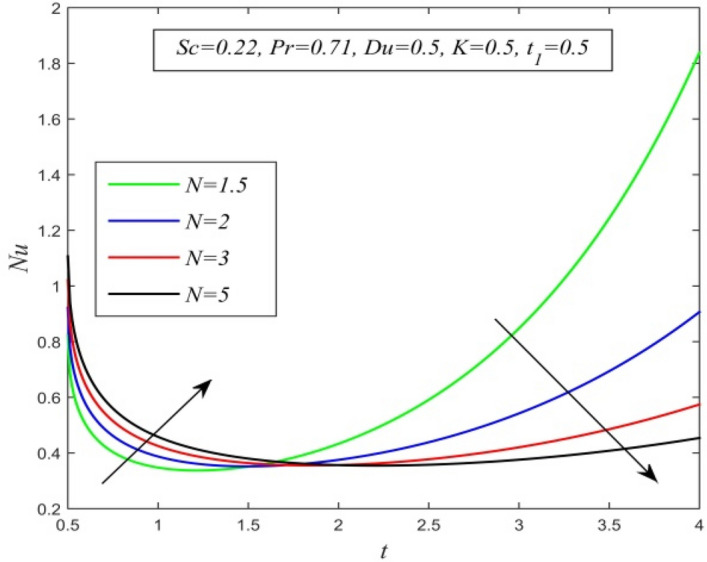

Figure 23.

Nu versus t for different N and Sc = 0.22, Pr = 0.71, Du = 0.5, K = 0.5, = 0.5.

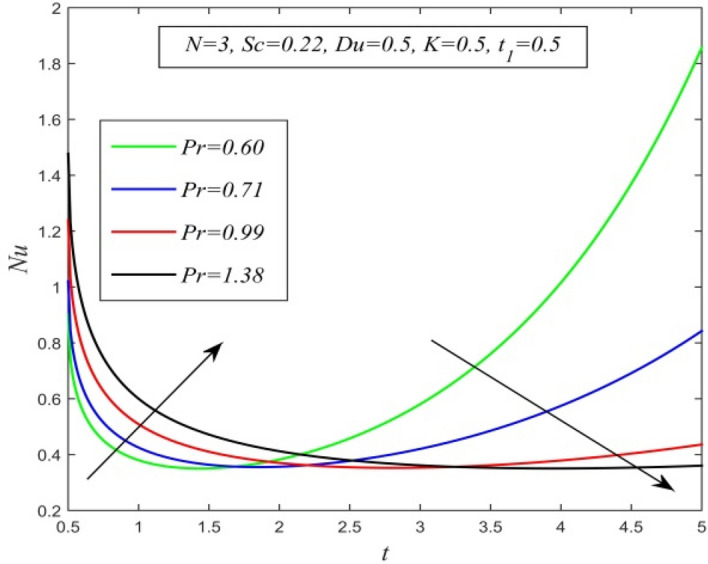

Figure 24.

Nu versus t for different Pr and Sc = 0.22, N = 3, Du = 0.5, K = 0.5, = 0.5.

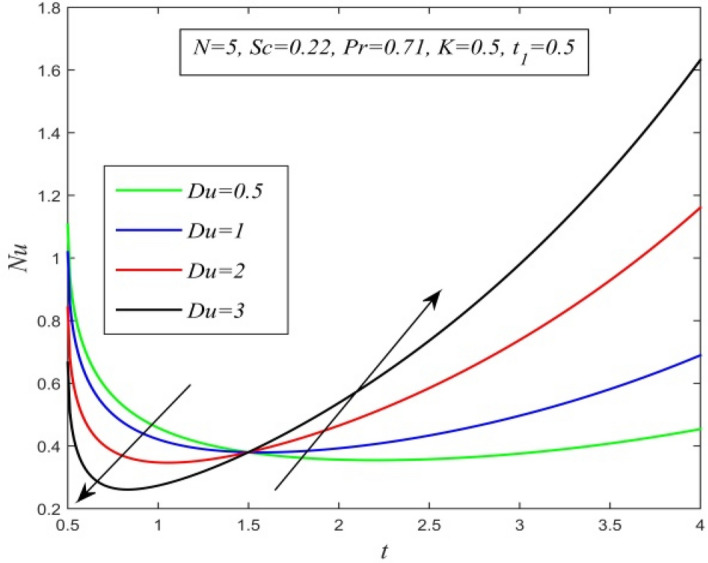

Figure 25.

Nu versus t for different Du and Sc = 0.22, N = 5, Pr = 0.71, K = 0.5, = 0.5.

Figure 26.

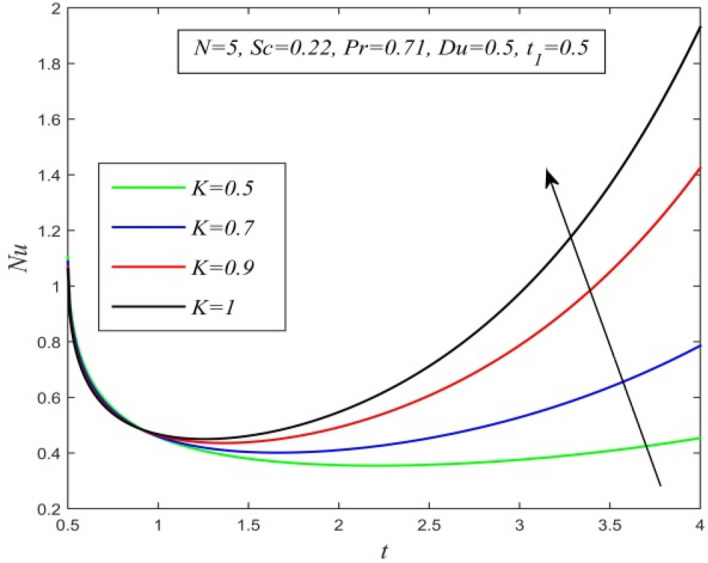

Nu versus t for different K and Sc = 0.22, N = 5, Pr = 0.71, Du = 0.5, = 0.5.

Figure 27.

Nu versus t for different Sc and N = 5, Pr = 0.71, Du = 0.5, K = 0.5, = 0.5.

Figure 28.

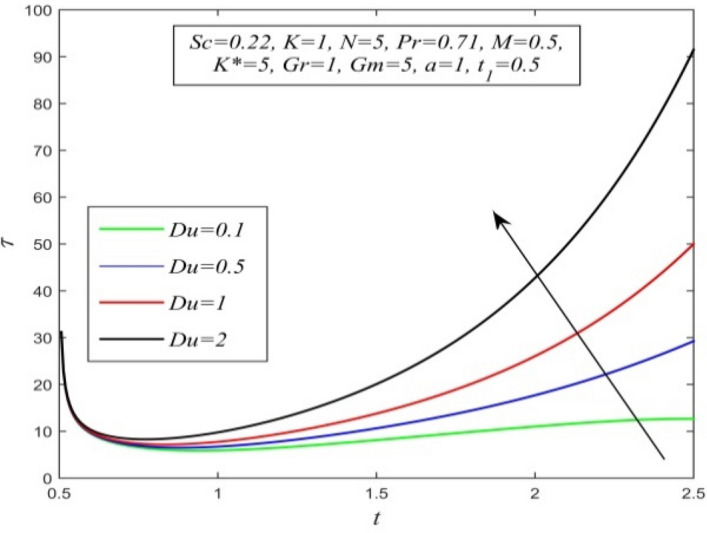

versus t for different Du and Sc = 0.22, K = 1, N = 5, Pr = 0.71, M = 0.5, K* = 5, Gr = 1, Gm = 5, a = 1, = 0.5.

Figure 29.

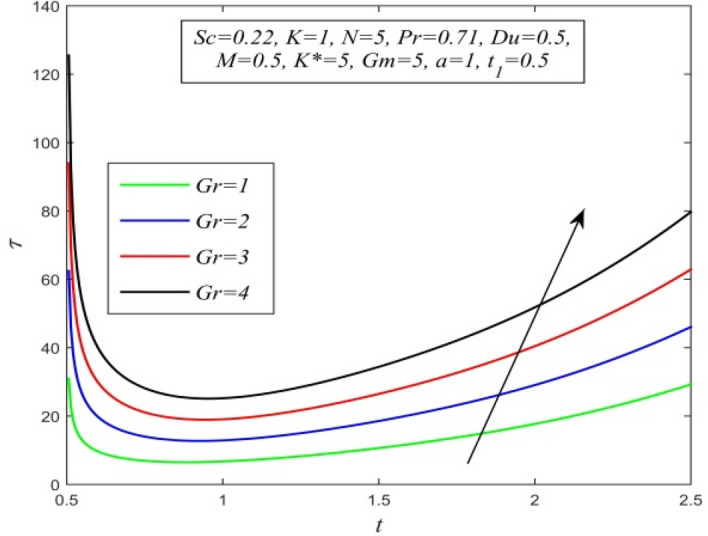

versus t for different Gr and Sc = 0.22, K = 1, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 5, Gm = 5, a = 1, = 0.5.

Figure 30.

versus t for different K and Sc = 0.22, N = 5, Pr = 0.71, Du = 1, M = 0.5, K* = 3, Gr = 1, Gm = 5, a = 1, = 0.5.

Figure 31.

versus t for different K* and Sc = 0.22, K = 1, N = 3, Pr = 0.71, Du = 0.5, M = 0.5, Gr = 1, Gm = 10, a = 1, = 0.5.

Figure 32.

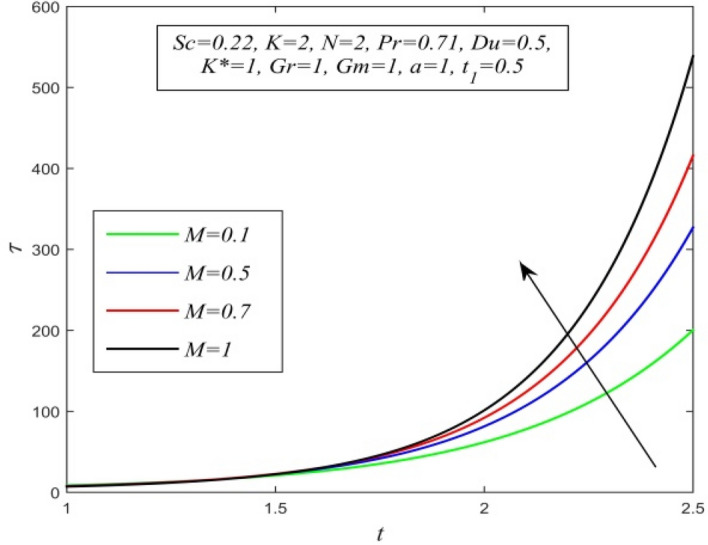

versus t for different M and Sc = 0.22, K = 2, N = 2, Pr = 0.71, Du = 0.5, K* = 1, Gr = 1, Gm = 1, a = 1, = 0.5.

Figure 33.

versus t for different Sc and K = 2, N = 3, Pr = 0.71, M = 0.5, Du = 0.5, K* = 3, Gr = 1, Gm = 5, a = 1, = 0.5.

Figure 34.

versus t for different N and Sc = 0.22, K = 1, Pr = 0.71, M = 0.5, Du = 0.5, K* = 5, Gr = 5, Gm = 10, a = 1, = 0.5.

Figure 35.

versus t for different Pr and Sc = 0.22, K = 3, N = 5, M = 0.5, Du = 0.1, K* = 5, Gr = 5, Gm = 5, a = 1, = 0.5.

Figures 2, 3 and 4 display the variation of concentration field versus normal co-ordinate y. Figure 2 admits that the concentration field keeps on increasing with time. Figure 3 reveals that there is a comprehensive fall in the concentration field for increasing chemical reaction parameter. A faster chemical reaction consumes chemical substances present in the fluid rapidly and as a result concentration of the fluid declines. The behaviour of concentration profiles for various fluids such as hydrogen (Sc = 0.22), helium (Sc = 0.30), water vapour (Sc = 0.60) and ammonia (Sc = 0.78) are demonstrated in Fig. 4. It suggests that a higher Schmidt number lowers the concentration field. Thus higher mass diffusivity hikes the concentration field.

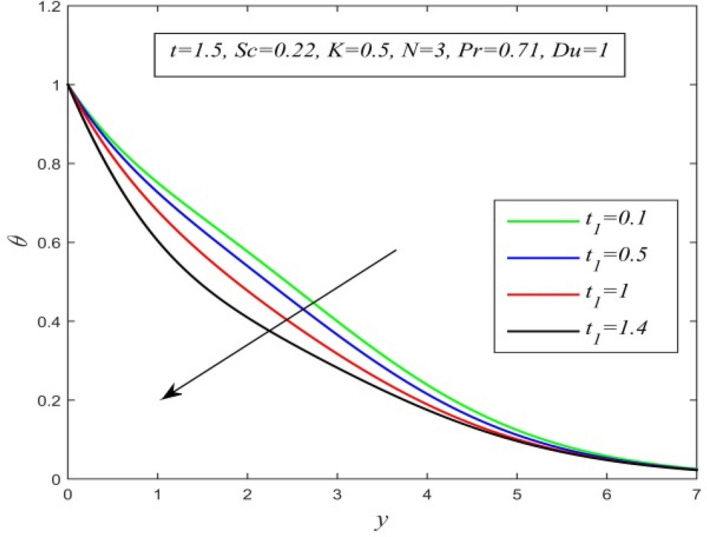

Figures 5, 6, 7, 8, 9 and 10 illustrate the variation of temperature field versus normal co-ordinate y. Figure 5 suggests that the temperature field escalates with time. Figure 6 shows that the temperature field upsurges with increment in chemical reaction parameter. Increasing chemical reaction parameter upsurges collision between fluid molecules and as a result temperature of fluid hikes. Figure 7 displays that increasing the Dufour number hikes temperature field. An increment in the Dufour number indicates a comprehensive rise in concentration gradient over temperature gradient. Hence, increasing concentration gradient upsurges the temperature field. Figure 8 suggests that the temperature field elevates with an uplift in Schmidt number. Thus, the temperature field decreases with increasing mass diffusivity. The temperature field decelerates with increasing radiation parameter as noticed in Fig. 9. It is in agreement with the fact that radiation tends to decline temperature. The nature of temperature profiles for various fluids such as oxygen (Pr = 0.60), air (Pr = 0.71), ammonia (Pr = 1.38) etc. are demonstrated in Fig. 10. It shows that the temperature field falls with ascending values of the Prandtl number. This informs that the temperature field accelerates with higher thermal diffusivity.

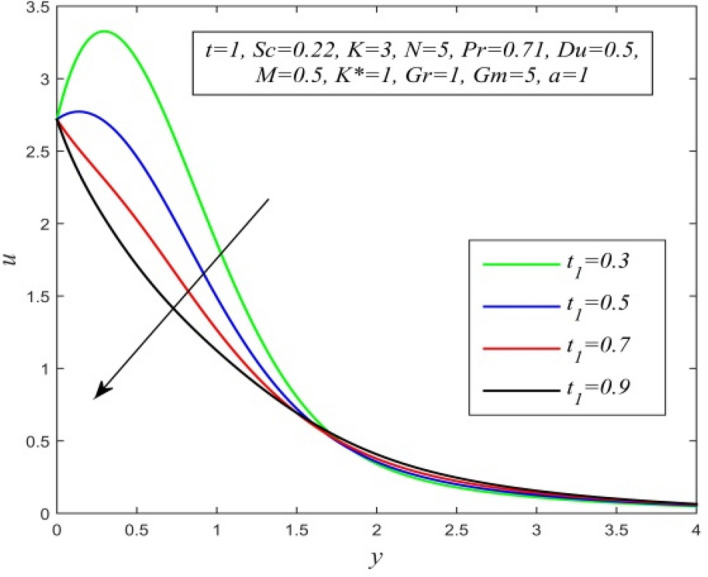

Figures 11, 12, 13, 14, 15, 16, 17, 18, 19 and 20 depict the variation of velocity field versus normal co-ordinate y. Figure 11 reveals that as time progresses, the velocity field increases. Figure 12 admits that the velocity field declines considerably as the Dufour number rises. Consequently, a large concentration gradient relative to the temperature gradient results in a dip in the velocity field. Figure 13 shows that velocity reduces with increasing chemical reaction parameter. This is because increasing chemical reaction parameter accelerates the process of collision between fluid molecules and as a result, kinetic energy is lost. Velocity falls with increasing magnetic parameter as noticed in Fig. 14. Application of transverse magnetic field produces a resistive force known as Lorentz force, which slows down fluid velocity. Figure 15 exhibits that increasing Schmidt number decrease velocity field. Thus, high mass diffusivity escalates fluid velocity. Velocity field upsurges in a thin layer adjacent to the plate and its nature take reverse turn outside the layer as thermal Grashof number upsurges as demonstrated in Fig. 16. So, thermal buoyancy force hikes velocity in a small layer surrounding the plate but lowers velocity outside the layer. Velocity rises with increment in solutal Grashof number as noticed in Fig. 17. Thus, solutal buoyancy force upsurges velocity. Hence higher mass diffusivity raises velocity field but increasing thermal diffusivity reduces velocity. Increasing porosity parameter means the fluid gets more free space to flow. As a result fluid velocity hikes. This phenomenon is reflected in Fig. 18. Increasing radiation parameter accelerates fluid velocity as observed in Fig. 19. The reason behind it is that when the radiation increases, chemical bonding between the fluid molecules becomes weak so that velocity hikes. Figure 12 shows that ascending values of Prandtl number uplift velocity. Thus, higher thermal diffusivity diminishes velocity.

Figures 21 and 22 demonstrate the variation of Sherwood number versus time t. Sherwood number increases with increment in chemical reaction parameter as noticed in Fig. 11. From Fig. 22, it is observed that increasing Schmidt number upsurges Sherwood number. This result establishes the fact that higher mass diffusivity accelerates the process of mass transfer from the plate to the fluid.

Figures 23, 24, 25, 26 and 27 exhibit the variation of Nusselt number versus time t. Nusselt number increases for a small time but decreases thereafter for increasing radiation parameter as noticed in Fig. 24. Thus, radiation increases the rate of heat transfer from the plate to the fluid for a small time and decreases afterward. Figure 26 shows that the Nusselt number hikes for a small time but declines thereafter with ascending values of the Prandtl number. So, higher thermal diffusivity lessens the rate of heat transfer for a small time but increases as time progresses. From Fig. 25 and Fig. 27, it is observed that the Nusselt number declines for a small time but upsurges thereafter with increment in Dufour number and Schmidt number respectively. Figure 26 shows that higher chemical reaction parameter hikes Nusselt number. Increasing chemical reaction parameter suggests a hike in heat generation. So, the process of heat transfer is accelerated.

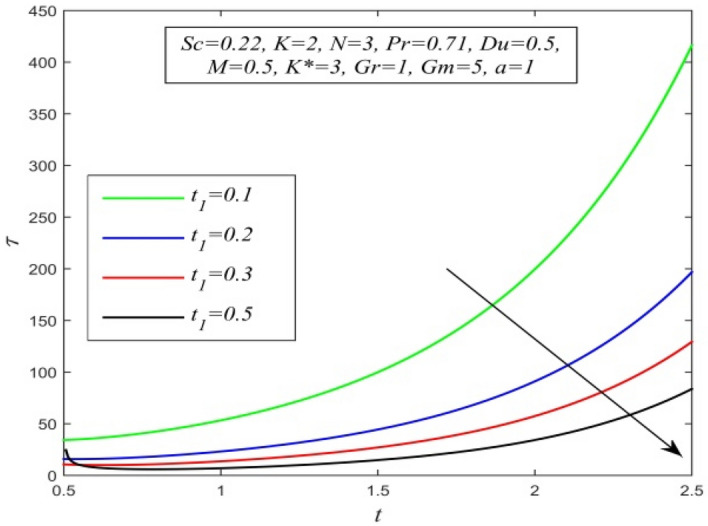

Variations of skin friction versus time t are demonstrated in Figs. 28, 29, 30, 31, 32, 33, 34 and 35. Figure 28 admits that there is a comprehensive rise in skin friction as Dufour number hikes. Thus, the concentration gradient generates more frictional resistance compared to the temperature gradient. Skin friction uplifts with increment in thermal Grashof number as noticed in Fig. 29. Thus, thermal buoyancy force hikes frictional resistivity at the plate. Skin friction hikes with an upsurge in both chemical reaction parameter and porosity parameter as shown in Fig. 30 and Fig. 31 respectively.Fig. 32 reveals that increasing magnetic parameter raises skin friction. Hence Lorentz force accelerates frictional resistivity of the plate. Higher Schmidt number hikes skin friction as displayed in Fig. 33. Therefore, increasing mass diffusivity lowers the frictional resistance of the plate.Fig. 34 and Fig. 35 give us an idea that enhancement in radiation parameter and Prandtl number lowers skin friction.

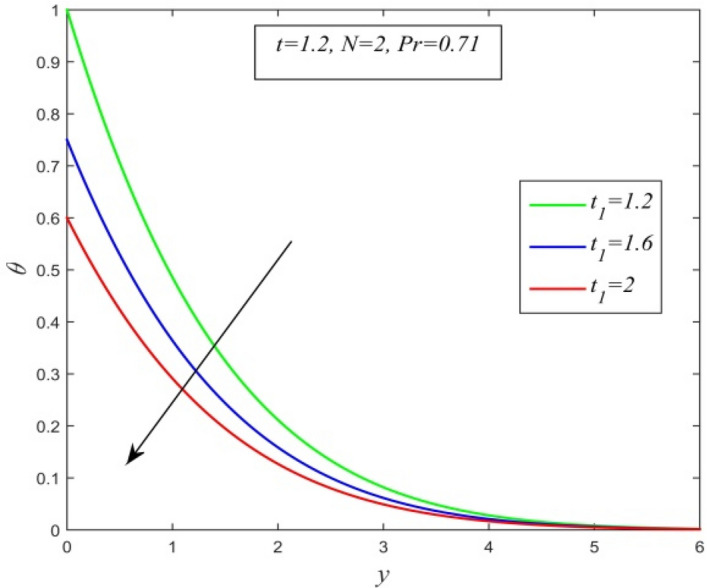

Figure 36 and Fig. 37 reveal that ascending critical time for rampedness lowers both temperature and velocity of the fluid respectively. Thus, arbitrary ramped temperature has inverse effect on both temperature and velocity fields. It is observed from Fig. 38 that increasing critical time for rampedness hikes Nusselt number. This means that arbitrary ramped temperature effect has a tendency to accelerate the rate of heat transfer from the plate to the fluid. Figure 39 shows that increasing critical time for rampedness declines skin friction. Thus arbitrary ramped temperature weakens the rate of momentum transfer from the plate to the fluid.

Figure 36.

versus y for different and t = 1.5, Sc = 0.22, K = 0.5, N = 3, Pr = 0.71, Du = 1.

Figure 37.

u versus y for different and t = 1, Sc = 0.22, K = 3, N = 5, Pr = 0.71, Du = 0.5, M = 0.5, K* = 1, Gr = 1, Gm = 5, a = 1.

Figure 38.

Nu versus t for different and N = 5, Sc = 0.22, K = 0.5, Pr = 0.71, Du = 0.5.

Figure 39.

versus t for different and Sc = 0.22, K = 2, N = 3, Pr = 0.71, Du = 0.5, M = 0.5, K* = 3, Gr = 1, Gm = 5, a = 1.

Numerical values of Nusselt number Nu against different time t, Dufour number Du and radiation parameter are analyzed in Table1. It is observed that for a small time, the Nusselt number decreases with increment in Dufour number but its behavior reverses as time progresses. An opposite behavior is noticed for increasing radiation parameter. This asserts that a high concentration gradient decelerates but radiation accelerates the process of heat transfer from the plate to the fluid. This is in complete agreement with our results from Fig. 23 and Fig. 25.Numerical values of skin friction against different time t, chemical reaction parameter K, radiation parameter N, Dufour number Du, thermal Grashof number Gr and solutal Grashof number Gm are demonstrated in Table2. It is noticed that ascending values of time, chemical reaction parameter, Dufour number, and thermal Grashof number hike skin friction whereas ascending values of radiation parameter and solutal Grashof number declines the value of skin friction. This is in accordance with our result from Fig. 30 and Fig. 28, Fig. 29 and Fig. 34 respectively.

Table 1.

Computational values of Nusselt number for various t, Du and N when Pr = 0.71, Sc = 0.22, K = 0.5, = 0.5.

| t | Du | N | Nu |

|---|---|---|---|

| 0.5 | 0.5 | 5 | 1.1016 |

| 0.5 | 1 | 5 | 1.0184 |

| 0.5 | 1.5 | 5 | 0.9302 |

| 2 | 0.5 | 5 | 0.3564 |

| 2 | 1 | 5 | 0.3926 |

| 2 | 1.5 | 5 | 0.4288 |

| 0.5 | 0.5 | 2 | 0.9218 |

| 0.5 | 0.5 | 3 | 1.0204 |

| 0.5 | 0.5 | 4 | 1.0730 |

| 2 | 0.5 | 2 | 0.3753 |

| 2 | 0.5 | 3 | 0.3565 |

| 2 | 0.5 | 4 | 0.3552 |

Table 2.

Computational values of skin friction for various t, K, N, Du, Gr and Gm when Pr = 0.71, Sc = 0.22, a = 1, M = 0.5, K* = 0.5, = 0.5.

| t | K | N | Du | Gr | Gm | |

|---|---|---|---|---|---|---|

| 1 | 1 | 5 | 0.5 | 1 | 1 | 9.1499 |

| 1.5 | 13.2425 | |||||

| 2 | 20.4193 | |||||

| 1 | 2 | 5 | 0.5 | 1 | 1 | 9.9629 |

| 3 | 11.2420 | |||||

| 5 | 16.8475 | |||||

| 1 | 1 | 2 | 0.5 | 1 | 1 | 9.7355 |

| 5 | 9.1499 | |||||

| 7 | 8.9585 | |||||

| 1 | 1 | 5 | 1 | 1 | 1 | 10.1642 |

| 2 | 14.2214 | |||||

| 3 | 18.2786 | |||||

| 1 | 1 | 5 | 0.5 | 1 | 1 | 9.1499 |

| 3 | 21.4736 | |||||

| 5 | 33.7974 | |||||

| 1 | 1 | 5 | 0.5 | 1 | 1 | 9.1499 |

| 3 | 7.9392 | |||||

| 5 | 6.7286 |

Comparison of result

To check the validity of our result, we have compared one of our results with Seth et al.49 who considered the unsteady free convective MHD flow of a chemically reactive, radiative flow past a moving vertical plate immersed in a porous medium. In absence of Dufour and chemical reaction effects and for vanishing Schmidt number (i.e., Du = 0, K = 0 and Sc = 0), expression of temperature field of the present problem is

Figure 40 and Fig. 41 display the temperature field versus normal co- ordinate y for different obtained by Seth et al.49 and present authors respectively. Both figures uniquely expresses the fact that temperature field declines for ascending values of critical time of rampedness. Hence, an excellent agreement of results between present authors and Seth et al.49 is observed.

Figure 40.

Scanned graph of temperature field versus y for different when t = 1.2, N = 2, Pr = 0.71 drawn by Seth et al.49.

Figure 41.

temperature field versus y for different when t = 1.2, N = 2, Pr = 0.71, Sc = 0, Du = 0,K = 0.

Table 3 display the variation of Sherwood number for different K, Sc and t obtained by Asogwa et al.50, Seth et al.51, Kataria and Patel52 and present authors respectively. This table indicates that current study is in line with the results obtained by these authors.

Table 3.

Comparison of computational values of Sherwood number for various K, Sc and t obtained by Asogwa et.al50, Seth et. Al51, Kataria and Patel52 and present authors.

| K | Sc | T | Asogwa et. al50 (isothermal condition) | Seth et. al51 (isothermal condition) | Kataria and Patel52 (isothermal condition) | Present study (isothermal condition) |

|---|---|---|---|---|---|---|

| 5 | 0.66 | 0.4 | 1.8320 | 1.8320 | 1.8320 | 1.8320 |

| 5.1 | 0.66 | 0.4 | 1.8493 | 1.8493 | 1.8493 | 1.8493 |

| 5.2 | 0.66 | 0.4 | 1.8664 | 1.8664 | 1.8664 | 1.8664 |

| 5 | 0.7 | 0.4 | 1.8867 | 1.8867 | 1.8867 | 1.8867 |

| 5 | 0.8 | 0.4 | 2.0170 | 2.0170 | 2.0170 | 2.0170 |

| 5 | 0.66 | 0.5 | 1.8238 | 1.8238 | 1.8238 | 1.8238 |

| 5 | 0.66 | 0.6 | 1.8201 | 1.8201 | 1.8201 | 1.8201 |

| 5 | 1.24 | 0.4 | 2.5111 | – | – | 2.5117 |

| 5 | 2.01 | 0.4 | 3.1971 | – | – | 3.1971 |

Conclusion

The prime purpose of the present work was to study exclusively the effects of radiation, chemical reaction and Diffusion thermo effect of an unsteady MHD flow past a moving vertical plate embedded in a porous medium with ramped temperature. The behavioral study of flow and transport characteristics under the action of different parameters was carried out with aid of graphs. The prominent outcomes of the present work are as follows:

-

i.

Velocity field, concentration field, and temperature field accelerate with time.

-

ii.

Fluid gets thinner rapidly as chemical reaction parameter and Schmidt number hikes.

-

iii.

Radiation and Lorentz force resists fluid velocity.

-

iv.

Higher mass diffusivity results in a fall in Nusselt Number, Sherwood number, and skin friction.

-

v.

Radiation slow down rate of momentum transfer.

The solution of the present work also validates with the previous result obtained by Seth et al.47, Asogwa et al.48, Seth et al.49 and Kataria and Patel50 in particular case.

The governing equations of the present problem are solved using Laplace transform technique. The problem is idealized by imposing some realistic constraints (e.g., viscous dissipation, Joule heating, effect of suction, induced magnetic field are neglected for mathematical simplicity). The same problem may be re- investigated by removing or reducing number of constraints. In this context, some numerical and computational techniques like Runge- Kutta method, shooting method, Crank- Nicolson method etc. may be suggested.

Supplementary Information

Acknowledgements

The authors are grateful to the Department of Mathematics, Gauhati University, Guwahati for their valuable support while preparing the manuscript.

List of symbols

Surface acceleration parameter

Magnetic flux density

Strength of the applied magnetic field

Molar species concentration

Specific heat at constant pressure

Concentration susceptibility

Concentration far away from the plate

Concentration at the plate

Mass diffusivity

Dufour number

Gravitation acceleration vector

Gravitational acceleration

Thermal Grashof number

Solutal Grashof number

Thermal diffusion ratio

Porosity parameter

Current density vector

Chemical reaction rate

Chemical reaction parameter

Magnetic parameter

Radiation parameter

Pressure

Prandtl number

Fluid velocity vector

Radiation heat flux vector

Radiation heat flux

Schmidt number

Time

Critical time for rampedness

Non- dimensional critical time for rampedness

Fluid temperature

Temperature at the plate

Undisturbed temperature

X-component of fluid velocity

Plate velocity

Greek symbols

Coefficient of viscosity

Electrical conductivity

Stefan-Boltzmann constant

Fluid density

Fluid density far away from the plate

Thermal conductivity

Mean absorption constant

Volumetric coefficient of thermal expansion

Volumetric coefficient of solutal expansion

Kinematic viscosity

Subscripts

Refers to physical quantity at the plate

Refers to physical quantity far away from the plate

Author contributions

S.S. has conducted the theoretical and graphical investigation of the problem and prepared the manuscript. Prof. N.A. supervised the whole investigation and reviewed the manuscript.

Data availability

All data generated or analysed during this study are included in this published article and its supplementary information files.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-022-15603-x.

References

- 1.Alfven H. Discovery of Alfven waves. Nature. 1942;150:405–406. doi: 10.1038/150405d0. [DOI] [Google Scholar]

- 2.Cowling TG. Magnetohydrodynamics. Wiley Interscience; 1957. [Google Scholar]

- 3.Shercliff JA. A Text Book of Magnetohydrodynamics. Pergamon Press; 1965. [Google Scholar]

- 4.Ferraro VCA, Plumpton C. An Introduction to Magneto-Fluid Mechanics. Clarendon Press; 1966. [Google Scholar]

- 5.Roberts PH. An Introduction to Magnetohydrodynamics. American Elsevier Pub. Co.; 1967. [Google Scholar]

- 6.Crammer KR, Pai SI. Magneto Fluid Dynamics for Engineers and Applied Physicist. McGraw-Hill Book Co.; 1973. [Google Scholar]

- 7.Dormy, E., & Nunez, M. Special Issue: Magnetohydrodynamics in astrophysics and geophysics—Introduction. Geophys.Astrophys.FluidDyn.101, 169–169 (2007).

- 8.Li Y, Zhang B, Xiao L, Wang Y, He G. Applications and prospects of magnetohydrodynamics in aeronautical engineering. Adv. Mech. 2017;47:452–502. [Google Scholar]

- 9.Farrokhi, H., Otuya, D.O., Khimchenko, A. & Dong, J. Magnetohydrodynamics in biomedical applications. NanofluidFlowPorousMed.IntechOpen (2019).

- 10.Rana, B.M.J., Arifuzzaman, S.M., Islam, S., Reza-E-Rabbi, S.K., Al- Mamun, A., Mazumder, M., Roy, K.C., & Khan, M.S., Swimming of microbes in blood flow of nano- biconvective Williamson fluid. Therm.Sci.Eng.Prog.25 (2021).

- 11.Manh TD, Nam ND, Abdulrahman GK, Moradi R, Babazadeh H. Impact of MHD on hybrid nanomaterial free convective flow within permeable region. J. Therm. Anal. Calorim. 2020;140:2865–2873. doi: 10.1007/s10973-019-09008-8. [DOI] [Google Scholar]

- 12.Das UN, Ahmed N. Free convective MHD flow and heat transfer in a viscous incompressible fluid confined between a long vertical wavy wall and a parallel flat wall. Indian J. Pure Appl. Math. 1992;23(4):295–304. [Google Scholar]

- 13.Kafoussias NG. MHD thermal- diffusion effects on free- convective and mass- transfer flow over an infinite vertical moving plate. Astrophys. Space Sci. 1992;192:11–19. doi: 10.1007/BF00653255. [DOI] [Google Scholar]

- 14.Kumar A, Singh AK. Unsteady MHD free convective flow past a semi- infinite vertical wall with induced magnetic field. Appl. Math. Comput. 2013;222:462–471. [Google Scholar]

- 15.Dwivedi K, Khare RK, Paul A. MHD flow through vertical channel with porous medium. Int. J. Appl. Eng. Res. 2018;13(15):11923–11926. [Google Scholar]

- 16.Raju KVS, Reddy TS, Raju MC, Narayana PVS, Venkataramana S. MHD convective flow through porous medium in a horizontal channel with insulated and impermeable bottom wall in the presence of viscous dissipation and Joule heating. Ain Shams Eng. J. 2014;5(2):543–551. doi: 10.1016/j.asej.2013.10.007. [DOI] [Google Scholar]

- 17.Helmy KA. MHD unsteady free convection flow past a vertical porous plate ZAMM- Z. Angew. Math. Mech. 1998;78(4):255–270. doi: 10.1002/(SICI)1521-4001(199804)78:4<255::AID-ZAMM255>3.0.CO;2-V. [DOI] [Google Scholar]

- 18.Raju MC, Varma SVK. Unsteady MHD Couette flow through a porous medium with periodic wall temperature. i-manager’s J. Future Eng. Technol. 2011;6(4):7–11. doi: 10.26634/jfet.6.4.1480. [DOI] [Google Scholar]

- 19.Pattnaik P, Biswal T. Analytical solution of MHD free convective flow through porous media with time dependent temperature and concentration. Walailak J. Sci. Technol. 2015;12:749–762. [Google Scholar]

- 20.Sinha A, Ahmed N, Agarwalla S. MHD free convective flow through a porous medium past a vertical plate with ramped wall temperature. Appl. Math. Sci. 2017;11(20):963–974. [Google Scholar]

- 21.Basha PMS, Nagarathna N. Heat and mass transport on MHD free convective flow through a porous medium past an infinite vertical plate. Int. J. Appl. Eng. Res. 2019;14(21):4067–4076. [Google Scholar]

- 22.Mbeledogu IU, Amakiri ARC, Ogulu A. Unsteady MHD free convection flow of a compressible fluid past a moving vertical plate in the presence of radiative heat transfer. Int. J. Heat Mass Transf. 2007;50(9–10):326–331. [Google Scholar]

- 23.Makinde OD. Free convection flow with thermal radiation and mass transfer past a moving vertical porous plate. Int. Commun. Heat Mass Transfer. 2005;32(10):1411–1419. doi: 10.1016/j.icheatmasstransfer.2005.07.005. [DOI] [Google Scholar]

- 24.Samad MA, Rahman MM. Thermal radiation interaction with unsteady MHD flow past a vertical porous plate immersed in a porous medium. J. Nav. Archit. Mar. Eng. 2006;3(1):7–14. doi: 10.3329/jname.v3i1.924. [DOI] [Google Scholar]

- 25.Orhan A, Ahmet K. Radiation effect on MHD mixed convection flow about a permeable vertical plate. Heat Mass Transf. 2008;45:239–246. doi: 10.1007/s00231-008-0428-y. [DOI] [Google Scholar]

- 26.Prasad NR, Reddy NB, Muthucumaraswamy R. Transient radiative hydro-magnetic free convection flow past an impulsively started vertical plate with uniform heat and mass flux. Theoret. Appl. Mech. 2006;33(1):31–63. doi: 10.2298/TAM0601031P. [DOI] [Google Scholar]

- 27.Ahmed N, Dutta M. Analytical analysis of magnetohydrodynamic (MHD) transient flow past a suddenly started infinite vertical plate with thermal radiation and ramped wall temperature. J. Heat Transfer ASME. 2014;136:0411703. [Google Scholar]

- 28.Takhar HS, Gorla RSR, Soundalgekar VM. Radiation effects on MHD free convection flow of a radiating gas past a semi-infinite vertical plate. Int. J. Numer. Methods Heat Fluid Flow. 1996;6(2):77–83. doi: 10.1108/09615539610113118. [DOI] [Google Scholar]

- 29.Seth GS, Tripathi R, Sharma R, Chamkha AJ. MHD double diffusive natural convection flow over exponentially accelerated inclined plate. J. Mech. 2016;33(1):87–99. doi: 10.1017/.2016.56. [DOI] [Google Scholar]

- 30.Balla CK, Naikoti K. Radiation effects on unsteady MHD convective heat and mass transfer past a vertical plate with chemical reaction and viscous dissipation. Alex. Eng. J. 2015;15(3):661–671. doi: 10.1016/j.aej.2015.04.013. [DOI] [Google Scholar]

- 31.Siviah S, Muraligoud G, Murali G, Reddy MCK, Raju S. Unsteady MHD mixed convection flow past a vertical porous plate in presence of radiation. Int. J. Basic Appl. Sci. 2012;1(4):651–666. [Google Scholar]

- 32.Apelblat A. Mass transfer with chemical reaction of first order, effect of axial diffusion. Chem. Eng. J. 1982;23(2):193–203. doi: 10.1016/0300-9467(82)80011-7. [DOI] [Google Scholar]

- 33.Mahapatra N, Dash GC, Panda S, Acharya M. Effects of chemical reaction on free convection flow through a porous medium bounded by a vertical surface. J. Eng. Phys. Thermophys. 2010;83:130–140. doi: 10.1007/s10891-010-0327-1. [DOI] [Google Scholar]

- 34.Andersson HI, Hansen OR, Holmedal B. Diffusion of a chemically reactive species from a stretching sheet. Int. J. Heat Mass Transf. 1994;37(4):659–664. doi: 10.1016/0017-9310(94)90137-6. [DOI] [Google Scholar]

- 35.Takhar HS, Chamkha AJ, Nath G. Flow and mass transfer on a stretching sheet with a magnetic field and chemically reactive species. Int. J. Eng. Sci. 2000;38(12):1303–1314. doi: 10.1016/S0020-7225(99)00079-8. [DOI] [Google Scholar]

- 36.Ganesan P, Rani HP. On diffusion of chemically reactive species in convective flow along a vertical cylinder. Chem. Eng. Process. 2000;39(2):93–105. doi: 10.1016/S0255-2701(99)00018-5. [DOI] [Google Scholar]

- 37.Muthucumaraswamy R, Ganesan P. Effect of chemical reaction and injection on flow characteristics in an unsteady upward motion of and isothermal plate. J. Appl. Mech. Tech. Phys. 2001;42(4):665–671. doi: 10.1023/A:1019259932039. [DOI] [Google Scholar]

- 38.Kandasamy R, Perisamy K, Prabhu KKS. Effects of chemical reaction, heat and mass transfer along a wedge with heat source and concentration in the presence of suction or injection. Int. J. Heat Mass Transf. 2005;48(7):1388–1394. doi: 10.1016/j.ijheatmasstransfer.2004.10.008. [DOI] [Google Scholar]

- 39.Raptis A, Perdikis C. Viscous flow over a non- linearly stretching sheet in the presence of a chemical reaction and magnetic field. Int. J. Non-Linear Mech. 2006;41(4):527–529. doi: 10.1016/j.ijnonlinmec.2005.12.003. [DOI] [Google Scholar]

- 40.Arifuzzaman SM, Khan MS, Mehedi MFU, Rana BMJ, Ahmmed SF. Chemically reactive and naturally convective high speed MHD fluid flow through an oscillatory vertical porous plate with heat and radiation absorption effect. Eng. Sci. Technol. Int. J. 2018;21(2):215–228. [Google Scholar]

- 41.Eckert ERG, Drake RM. Analysis of Heat and Mass Transfer. McGraw-Hill Book Co.; 1972. [Google Scholar]

- 42.Swetha R, Reddy G, Varma SVK. Diffusion- thermo and radiation effects on MHD free convection flow of chemically reacting fluid past an oscillating plate embedded in porous medium. Proc. Eng. 2015;127:553–560. doi: 10.1016/j.proeng.2015.11.344. [DOI] [Google Scholar]

- 43.Reddy GJ, Raju RS, Manideep P, Rao JA. Thermal diffusion and diffusion thermo effects on unsteady MHD fluid flow past a moving vertical plate embedded in porous medium in the presence of Hall current and rotating system. Trans. A. Razmadze Math. Inst. 2016;170(2):243–265. doi: 10.1016/j.trmi.2016.07.001. [DOI] [Google Scholar]

- 44.Oyekunle TL, Agunbiade SA. Diffusion- thermo and thermal- diffusion effects with inclined magnetic field on unsteady MHD slip flow over a permeable vertical plate. J. Egypt. Math. Soc. 2020;28:51. doi: 10.1186/s42787-020-00110-7. [DOI] [Google Scholar]

- 45.Kumaresan, E., Vijaya Kumar, A.G. & Prakash, J. Analytical investigations of diffusion thermo effects on unsteady free convection flow past an accelerated vertical plate, Front.HeatMassTransf.10 (2018).

- 46.Vijaya Kumar AG, Reddappa B, Babu KR, Vijaykumar Varma S. Dufour and radiation effects on unsteady MHD freee convective heat and mass transfer flow past an infinite vertical plate in the presence of a chemical reaction. JP J. Heat Mass Transf. 2013;8(1):1–24. [Google Scholar]

- 47.Shateyi, S., Motsa, S.S. & Sibanda, P. The effects of thermal radiation, Hall currents, Soret, and Dufour on MHD flow by mixed convection over a vertical surface in porous media. Math.Probl.Eng. (2010).

- 48.Postelnicu A. Influence of a magnetic field on heat and mass transfer by natural convection from vertical surface in porous media considering Soret and Dufour effects. Int. J. Heat Mass Transf. 2004;47:1467–1472. doi: 10.1016/j.ijheatmasstransfer.2003.09.017. [DOI] [Google Scholar]

- 49.Seth GS, Sharma R, Kumbhakar B. Heat and mass transfer effects on unsteady MHD natural convection flow of a chemically reactive and radiating fluid through a porous medium past a moving vertical plate with arbitrary ramped temperature. J. Appl. Fluid Mech. 2016;9(1):103–117. doi: 10.18869/acadpub.jafm.68.224.23961. [DOI] [Google Scholar]

- 50.Asogwa K, Bilal S, Animasaun I, Mebarek-Oudina F. Insight into the significance of ramped wall temperature and ramped surface concentration: The case of Casson fluid flow on an inclined Riga plate with heat absorption and chemical reaction. Nonlinear Eng. 2021;10(1):213–230. doi: 10.1515/nleng-2021-0016. [DOI] [Google Scholar]

- 51.Seth GS, Hussain SM, Sarkar S. Hydromagnetic natural convection flow with radiative heat transfer past an accelerated moving vertical plate with ramped temperature through a porous medium. J. Porous Med. 2014;17(1):67–79. doi: 10.1615/JPorMedia.v17.i1.50. [DOI] [Google Scholar]

- 52.Kataria H, Patel RH. Effects of chemical reaction and heat generation/ absorption on magnetohydrodynamic (MHD) Casson fluid flow over an exponentially accelerated vertical plate embedded in porous medium with ramped wall temperature and ramped surface concentration. Propuls. Power Res. 2019;8(1):35–46. doi: 10.1016/j.jppr.2018.12.001. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data generated or analysed during this study are included in this published article and its supplementary information files.