Graphical abstract

Keywords: Covid-PPE waste, Sustainable waste management, Construction materials, Recycled plastic composite

Abstract

One of the major challenges the COVID-19 pandemic has posed is the disposal of huge volumes of biomedical waste. It is the need of the hour to find out methods to handle the waste generated and explore novel and sustainable ways for their disposal. Personal Protective Equipment (PPE) is the main medical waste generated during the pandemic and may continue to accumulate in the post-pandemic era. This paper portrays a study on generating construction material composites from PPE waste along with the sand fillers. The work has been carried out with two different sand, River sand and Manufactured sand, in three different filler ratios. The different properties such as tensile, compression, and flexural strength of the prepared composite are detailed and compared with the existing construction materials. Durability properties such as acid resistance and moisture absorption have been studied to validate the efficacy of the developed material in the construction sector. It is observed that the PPE waste composite displays superior performance in compression, tension and flexure while compared to the other construction materials like mud bricks and cement blocks. The water absorption and acid degradation are minimal, as a result, its strength is not affected after exposure to such adverse conditions. The thermal conductivity of the composite is found to be less compared to the conventional concrete which makes it an ideal choice in tropical areas as thermal insulation material. Moving forward, this study is expected to set a new sustainable approach to utilize biomedical plastics waste to substitute cement-based construction material and hence aid a negative carbon cycle.

1. Introduction

The recent novel coronavirus disease (COVID-19) outbreak, which causes severe acute respiratory syndrome (SARS-CoV-2), has resulted in a rapid increase in infected patients worldwide. As the entire world moves forward with the vaccination and other means of control for the pandemic, it is high time to find out sustainable ways to maintain health and hygiene. The hygiene standard levels maintained during the pandemic time is expected to stay in day-to-day life for a while, for example, use of Personal Protective Equipment (PPE) kits [1]. The use of PPE has emerged as the most reliable and visible preventive control safety gear to keep the COVID-19 transmission at bay [2]. Further, PPE kits have an important role in protecting public health during the pandemic situation [3]. A detailed guideline has been provided by the World Health Organisation (WHO) for the proper disposal of PPE waste consisting of surgical masks, disposable gloves, and respirators employed in the medical sector [4].

PPE consists of polymers and materials like polypropylene, polyacrylonitrile, and polyurethane face masks [5], [6], nitrile disposable gloves latex, vinyl polymers (Government of Canada, 2020b), and other fibres (e.g. disinfectant wipes) as detailed in the recent studies [7], [8]. Typical PPEs, also referred to as PPE kits, are made up of over 50% plastics which takes up to 500 years to degrade like Polypropylene (PP), Polycarbonate (PC), and Polyvinyl chloride (PVC), etc. This also includes surgical face mask with a metal strip, gloves, goggles, full-body suits containing pant, gown with head cover and shoe cover used by the health workers [9]. The protective gear allowed health workers to approach the COVID-19 patient and enable them to serve their role efficiently without any associated risks.

A clear protocol has been set by National Disaster Management which advises all the personnel involved to wear PPE when coming in direct contact with the COVID-19 patients, both confirmed or suspected [1], [10], [11]. It has been a concern that the use of multiple folds of PPE which leads to unstable processing of the waste may harm the environment. Developing countries, which lacks the Centralized Bio-medical Waste Treatment Facilities (CBMWTF), are expected to face a huge challenge in treating the waste generated during the pandemic period. In India, an effective waste management guideline has been set up by the Central Pollution Board especially for the COVID-19, which include multiple systems for long term deployment [12]. India with 1.38 billion people, and large number of the confirmed cases being reported, is expected to generate huge amounts of waste in the hospitals [13]. There were reported cases of infection to workers due to improper disposal of medical waste and masks [14]. Hence, it becomes essential to encourage the source segregation of the medical waste and provide a more effective way of handling, storing, and disposal, to reduce the spread of the contagious disease.

The increase in the use of the PPE kit will lead to massive waste generation due to its single usage. According to Wuhan report, it has been noticed a rapid increase in medical waste generation from 40 to 50 tons to 247 tons per day during pandemic [15]. One of the barriers of PPE kit reuse is that after the decontamination process, the efficiency of the material isolated from the virus reduces. This leads to a new possibility of remoulding the waste material into another useful product which will provide a sustainable approach to the waste management in comparison with the conventional incineration process. One of the innovative ways of recycling is using waste plastic as an adhesive (instead of cement) along with the existing construction materials. The requirement of cement has increased rapidly in India due to economic development which pushed cement manufacturing to 280Mt in 2014 from 100 Mt in 2001 [16], [17]. The substitution of cement, which is a major source of carbon dioxide emission [18], with alternate type of materials opens up an eco-friendly approach. Several research activities have already been carried out for utilizing the plastic waste [19], [20], [21], [22] in the concrete as a filler which will lead to lightweight concrete structure. The reports [23], [24], [25], [26] have showcased enough applications of the plastics waste as fillers in the concrete structures. The application of waste plastics for road construction along with bitumen [27], [28], [29], [30] is practiced in developing nations like Ghana, Algeria, and India. Numerous studies have been carried out with different types of plastics like Low-density polyethylene (LDPE), High-density polyethylene (HDPE), etc. incorporated in various construction materials [31], [32], [33].

In the present work, PPE waste has been used as a plastic source and as a bonding agent along with the commonly used construction materials like river sand and manufactured sand. These are used as fillers to improve the property of the composite developed and are selected based on a detailed review [34]. Various strength and durability properties are assessed, and the results are compared with those of the existing construction materials. By this approach, the waste management sector in the post-pandemic era can be rebooted which is the need of the hour.

2. Materials and methods

2.1. Materials recycling process

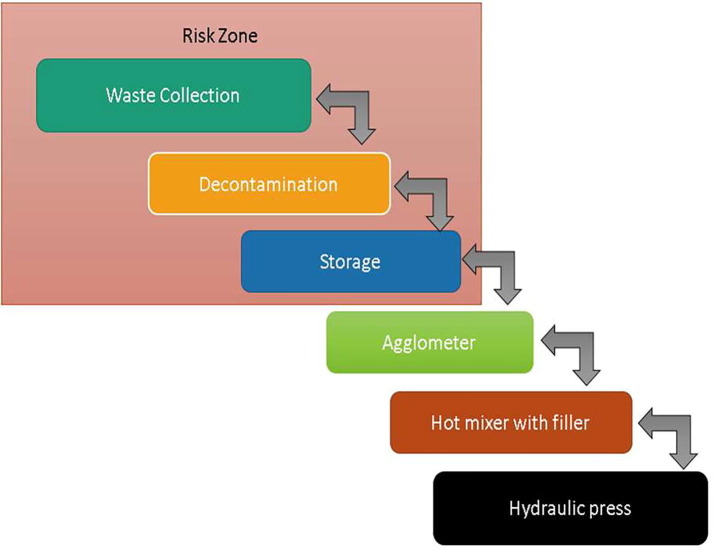

A detailed structure of the waste management from the generation, collection, transport guidelines to the waste processing side of recycling, treatment, recovery, and disposal was suggested considering the pandemic situation [35]. The material flow (Fig. 1 ) process was carefully designed in such a way that the human interaction with the contaminated waste is minimum and has been cut down to low risk by decontaminating the material soon after the collection process. The contaminated PPE waste material was collected from the health centres and processed through decontamination where the material is washed thoroughly and dried. After the decontamination, the processed material is moved to the storage facility for a minimum of 28 days. These three processes are being listed as risk zones due to the possibility of virus exposure, and hence the material handler has to follow the PPE and other safety protocols while handling the waste materials.

Fig. 1.

Raw material handling flowchart.

From the storage, the materials were moved into a shredder unit in which PPE is shredded and densified into small pieces for further processing. Densified and size-reduced material were mixed with fillers during the heat process at about 180 °C. After this process, the hot mixed polymer with filler is moved to the hydraulic press which is pressed into the desired shapes as building blocks and pavement tiles as shown in Fig. 2 .

Fig. 2.

Materials processing to product development.

2.2. Materials

2.2.1. PPE waste materials

Disposable isolation gowns are designed to be discarded after single use and are typically prepared from nonwoven materials alone or in combination with materials that offer increased protection from liquid penetration, such as plastic films [6]. Fabrics can be engineered to achieve desired properties by using fiber types, bonding processes, and fabric finishes (chemical or physical treatments). Fig. 3 presents the scanning electron microscope (SEM) image of the fiber and solid polymer content in the collected PPE waste samples used in the study. The fiber part and the solid polymer are vividly seen in the SEM image.

Fig. 3.

SEM image of collected PPE waste sample.

2.2.2. River sand

River sand finer than 2.36 mm with a specific gravity of 2.69, bulk density of 0.87 kg/l and water absorption of 2.5% is used in the study. This is naturally available in the south Indian states Kerala and Tamil Nadu and has been dried for 20 min in an oven for moisture reduction.

2.2.3. Manufactured sand (M Sand)

The depletion of naturally occurring river sand leads to exploration of new sustainable fine aggregate in the construction sector. The manufactured sand (M sand) is an artificial sand formed by crushing hard stones into small sized angular shaped particles. It has a specific gravity of 2.6, water absorption of 3 % and passing through 2.36 mm sieve.

2.3. Sample preparation

The samples were prepared by hot mixing the shredded PPE waste material along with the filler in six different ratios as shown in the Table 1 . The sand to PPE waste content ratio was varied from 2 to 6. In house thermo-mechanical mixing was carried out in a controlled environment in which sand is heated to 180 °C. Later shredded PPE waste is added and thorough mixing is performed till the mixture reaches the required temperature (usually in 5 min duration process is completed). After this process, the hot mixed composite is transferred to mold and compressed using a hydraulic press for the preparation of panels, cylinders, cubes, and interlocking blocks. Based on the initial trails conducted, it was observed that the preparation of the blocks was difficult below the mix ratio of 2. When the mix ratio was raised above 6, the bonding of the materials did not place during processing.

Table 1.

Sample Nomenclature.

| Sample Name | PPE waste % | River Sand % | M Sand % |

|---|---|---|---|

| R2 | 33.33 | 66.67 | 0 |

| R4 | 20 | 80 | 0 |

| R6 | 14.3 | 85.7 | 0 |

| M2 | 33.33 | 0 | 66.67 |

| M4 | 20 | 0 | 80 |

| M6 | 14.3 | 0 | 85.7 |

3. Experimental investigation

3.1. Hardened stage properties – mechanical properties

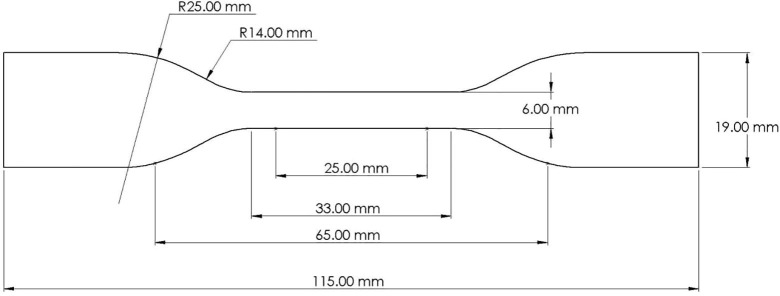

The compressive strength test is carried on cubical specimens of side 50 mm as per ASTM 695 using UTM of 40-tonne capacity. The compressive strength is expected to rise with increase in polymer content due to better bonding between the phases. Tensile strength is assessed as per ASTM 638-14 using samples of dog bone shape as shown in Fig. 4 , which was machined from the molded tiles. Cylindrical specimens of 150 mm diameter and 300 mm length were used for estimating split tensile strength using UTM of 40-tonne capacity. Flexural strength is evaluated using panels of 300 mm × 300 mm × 20 mm size by three-point flexural test as per ASTM D 9272. Three samples from each proportion are tested and average values are being reported.

Fig. 4.

Schematic representation of tensile test sample.

3.2. Durability studies

3.2.1. Water absorption

Cubical specimens of 50 mm have been used for water absorption test. The cubes are air dried for 24hr to obtain a constant weight. The specimens are then kept immersed in water for 28 days. The increase in weight of the samples after immersion has been noted to evaluate the rate of water absorption.

3.2.2. Acid resistance

Cubical specimens of 50 mm are immersed in 5% sulphuric acid solution for 28 days. The difference in weight of the samples before and after the immersion has been accounted to assess the resistance to acid attack.

3.2.3. Hardness & density

Hardness is tested as per ASTM shore D2240 using EXCEL company handheld equipment. The density of the samples is estimated using the standard density analyzing method.

3.2.4. Thermal conductivity

A thermal conductivity test is performed (ASTM – C 177-97) using hot guarded apparatus. The test panels were air-dried to remove all the moisture content. The specimens (45 cm × 30 cm × 1.8 cm) are placed on either side of the heating plate, by uniformly touching the cooling plates.

The guard heater input is given in such a way that there is no radial heat flow, which is adjusted by checking thermocouple readings. The thermo-couple readings and the input to specimen central heater (current–voltage) are recorded every 10 min till the steady-state condition is attained. The thermal conductivity is calculated using equation (1).

k = QL/2A (Th – Tc) W/mK (1)

where A is the metering area of the specimen (m2), Q is heat flow (W), Tc is cold plate temperature (K), Th is hot plate temperature (K) and L is the thickness of the specimen (m).

4. Results & discussion

4.1. Compressive strength

Fig. 5 shows the comparison of compressive strength of composite sample exposed to acid and moisture conditions. Compression test has been carried out in three conditions, control samples without any treatment, sample which are exposed to 5% sulphuric acid for 28 days and samples immersed in water for 28 days.

Fig. 5.

Compressive strength in composite with varied filler ratio under different environment conditions.

It is observed that the compressive strength of the composite with high filler ratios reduced. This may be due to the reduction in polymer content and the increased filler ratio. This gives clear indication that polymer content gives better strength between the phases. River sand composites have slightly better compressive strength than the M sand composite. The failure pattern observed is similar in both filler composites (Fig. 6 ). The composite with a higher filler ratio M6 and R6 (1:6) has prominent surface cracks propagated both in the vertical and horizontal direction. The sample R6 has a compressive strength of 29 MPa which is slightly higher than that of M6 of 24.8 MPa. The ratio with (1:4) i.e., M4 and R4, shows improved compressive strength of 31 MPa than the M6 and R6 where slight shape deformation is observed in the horizontal direction. Several cracks were observed in this mixture of composite (Fig. 6). The composite with a higher ratio of polymer 1:2, M2, and R2 samples, shows the highest compressive strength which is more than 35 MPa. Here, the failure pattern is manifested as a single line of crack which shows that this proportion is much more stable than the other two proportions (Fig. 6).

Fig. 6.

Failure pattern of river sand composite.

The composite specimens exposed to moisture and acid environment are tested using a compression testing machine to assess its strength properties after 28 days exposure. For specimens subjected to moisture condition, it is observed from Fig. 5 that the strength of sample R6 reduced to 18.2 MPa from 29.1 MPa corresponding to control, while in the M6 it reduced to 20 MPa from 24.8 MPa. This is indicative of the improved stability of the M sand filler composite with respect to the river sand filler composite. The effect of the higher ratio of the polymer follows a similar trend, M4 has shown a strength of 24 MPa compared to 31.3 MPa of control, and 25.7 MPa for R4 against a strength of 31.4 MPa. The strength of R2 reduced to 30.7 MPa from 37.1 MPa and a similar trend for M2 where it reduces to 28.7 MPa from 35.6 MPa. Fig. 7 presents the percentage reduction in strength compared to control under moisture and acid exposure conditions.

Fig. 7.

Percentage reduction in strength under moisture and acid exposure compared to control.

As the primary application of the developed composite is for construction, the obtained results are compared with the existing construction materials. The comparison is expected to assess the feasibility of the developed material as a potential replacement for the existing materials. As per IS2185(2005) the load bearing hollow concrete blocks should have a compressive strength of 3.5 to 15.0 MPa [36].

The water absorption has been found to vary in each sample between 0.38% and 0.73% as shown in the Fig. 8 . Lower water absorption can be assigned to the absence of water absorption materials in the developed composite, as sand has a lower water absorption property and has been mechanically compressed which minimizes the presence of voids. Under acid exposure the resistance of composite prepared using river sand shows a higher value of 1.48% absorption, which shows the possibility of degradation of river sand under acid environment or chances of the void formation in the samples due to higher filler content. The reduced absorption rate in higher content M sand under water and acid exposure justifies the uniform gradation of the M sand as it is an artificially manufactured product under controlled conditions. The reduced absorption rate justifies the possibility of the application of the developed composite in the environment of acid and moisture.

Fig. 8.

Moisture/Acid absorption rate with respect to control.

4.2. Tensile strength

To check the feasibility of the developed composite under tension, the specimens were subjected to tensile loading using UTM of capacity 40 kN. From Fig. 9 , it has been observed that the R2 and M2 exhibits ultimate tensile strength of 4.2 MPa and 4.1 MPa respectively. At a lower filler ratio, the strength reduces by 3.1 MPa and 3.7 MPa for R4 and M4 respectively whereas, in the higher filler ratio R6 and M6, it has been reduced to 1.3 MPa and 1.1 MPa respectively. A study conducted by Oskouei [39] on mud with natural fibers reported a tensile strength of 0.15 MPa, which shows the applicability of the developed composite as a tensile material compared to the comparable construction materials. Emad M [37] reported that the tensile strength of construction block made of cement mortar was in the range of only 0.13–0.27 MPa [37]. Hence it can be inferred that the presence of polymer in the samples improves the adhesion characteristics and thereby the tensile properties of the resultant composite block.

Fig. 9.

Tensile strength of composite.

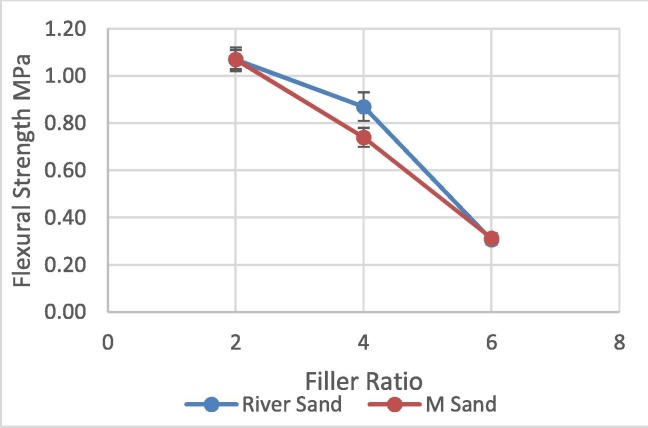

4.3. Flexural strength

Flexural strength is one of the important parameters to assess the feasibility of the developed composite as a wall panel as it will be subjected to bending loads. From the test results presented in Fig. 10 , it is observed that the panels have shown a decrease in strength due to addition of the fillers. Both the M2 and R2 sample shows a flexural strength of 1.1 MPa which declined to 0.87 MPa and 0.71 MPa for R4 and M4 respectively. The higher filler ratio samples viz. M6 and R6 exhibited a low strength of 0.31 MPa.

Fig. 10.

Variation in flexural strength.

On analyzing the crack propagation, it is evident that cross-sectional crack propagated through the sand concentrated regions across the panel (Fig. 11 ). The test values seem to be promising compared to the fiber reinforced mud ones, which has a flexural strength of 0.49 MPa [38].

Fig. 11.

Failure pattern of river sand composite panel.

4.4. Split tensile strength

From Fig. 12 it is observed that the split tensile strength decreased slightly with the increase in filler concentration in both the cases. The bonding force is expected to be high in lower filler ratio samples due to the elevated polymer content. Compared to the tensile strength, the reduction is not noticeable, which may be due to the cylindrical shape of the sample. The increase in contact surface area and improved ductility during the test causes a bulging effect. The material is expanded radially in split tensile test compared to the tensile test.

Fig. 12.

Variation in Split tensile strength.

The obtained values show good agreement with cement stabilized earth blocks which possess split tensile strength varying from 0.16 MPa to 0.79 MPa [39]. They also reported a spilt tensile strength of 0.1 MPa in the absence of cement which is lower than the presently developed composite. The failure pattern of the developed composite under split tensile strength is shown in Fig. 13 .

Fig. 13.

Failure pattern under split tensile strength.

4.5. Hardness & density

From the Table 2 , it is observed that with increase in the filler ratio the density of the composite increased. It may be assigned to the higher density of sand compared to PPE. The samples prepared using M Sand shows slightly higher density than those prepared from river sand. The fine particle nature of M sand enables better consolidation during hydraulic pressing, which in turn gives a compact structure due to the reduction in void spaces compared to reiver sand. While accessing surface hardness it has been observed that the composite with higher filler ratio possesses low surface hardness compared to low filler ratio ones. Further, the low filler ratio samples present better surface finish as the polymer content is high. On the contrary, in high filler ratio samples the surface irregularities are more due to high sand content resulting in lower hardness.

Table 2.

Density and Hardness of the developed composite.

| Sample Name | Density (kg/m3) | Hardness |

|---|---|---|

| R2 | 1475.08 | 58 |

| R4 | 1712.86 | 51 |

| R6 | 1752.39 | 42 |

| M2 | 1511.32 | 55 |

| M4 | 1746.76 | 48 |

| M6 | 1875.32 | 42 |

4.6. Thermal conductivity

Thermal conductivity is one of the important parameters required for a construction material which can lead to energy utilization and human comforts during the application. The layers of low thermal conducting PPE content inside the composite reduces the thermal conductivity as presented in Fig. 14 .

Fig. 14.

Variation in thermal conductivity.

The thermal conductivity of the samples prepared from river sand was found to be 0.17 W/mK, 0.22 W/mK and 0.35 W/mK for the samples R2, R4, and R6 respectively. In the M Sand samples, the increase in thermal conductivity of the composite with increase in filler is lower compared to the river sand samples. This can be attributed to the high thermal conductivity of river sand [40]. While comparing with the mud bricks of thermal conductivity ranging from 0.23 to 0.355 W/mK [41], the developed composite exhibits better utility as thermal insulators. Additionally, it offers superior thermal insulation compared to concrete whose thermal conductivity value ranges from 0.86 to 1.16 W/mK [42].

4.7. SEM observation

The microstructure of the samples was studied using SEM to assess the interaction between the polymer and the fillers at various ratios. It has been observed from Fig. 15 that the increase in the filler ratio reduces the bonding, as the polymer content contributes to the bonding property. The micrographs of R2, R4, and R6 samples, indicates that the polymer to filler interaction has been reduced with increase in the sand content. It is evident that the better bonding in composite is due to the adhesion between the phases. The sand-to-sand bonding is zero in the absence of bonding agent, which justifies the reduced mechanical strength for the samples with high filler ratio.

Fig. 15.

SEM image of composite with fillers.

A similar observation has been made in M sand samples M2, M4, and M6. Micro voids are seen in composites with high filler ratios which are vulnerable to water and acid absorption affecting the mechanical and durability properties of the product.

5. Application in construction sector

Based on the test results, it is inferred that the developed composite possesses better strength and durability than the conventional materials. Accordingly, they can be recommended for various applications in the construction sector. Fig. 16 presents the images of the PPE filler composite moulded as construction block, wall panel and as interlocking blocks. To enhance the construction process with minimum skilled labour and materials, interlocking blocks with M4 have been prototyped. This interlocking shape can be compared to Lego construction and the suggested shapes provide provision for rebar to go through it vertically as a structural reinforcement. Since the thermal properties of the composite are observed to be superior to the cementitious materials, they are recommended for the development of wall panels.

Fig. 16.

Construction materials developed with waste PPE sand composite.

6. Conclusion

Along with the various health hazards and the associated trauma, the recent COVID-19 pandemic is posing challenges in waste management, especially in proper disposal of personal protective equipment (PPE). The present study reports the development of a new composite using PPE waste along with river sand and M sand as fillers. The developed composite yielded promising results with better strength and durability properties in comparison with conventional construction materials like mud blocks and other traditional cementitious materials.

-

•

Compressive strength of 25 MPa and above is observed in case of composite with lower filler ratios, which shows the potential benefit of the developed composite as a construction material. Gradual crack propagation observed during the failure of the composite justifies the elimination of a catastrophic failure of the structure made of such blocks.

-

•

Reduced water absorption and subsequent low reduction in compressive strength suggest the application of the developed composite in tropical regions.

-

•

An increased acid resistance justifies the usage of the composite in acid rain prone regions and other acid rich environment like factories. It is also observed that the acid absorption has lower impact on compressive strength.

-

•

The tensile and flexural strength reports to a better strength value compared with mud bricks and the other conventional construction materials.

-

•

Thermal conductivity of the sample is observed to be lower compared to the cementitious construction materials which will help to bring down energy consumption and demand in long run.

As M sand and River sand had shown almost similar properties, preparation and deployment of the composite can be based on the availability of the material. Overall, the study opens up opportunities for the effective utilization of PPE waste in the construction sector.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Our work has been guided by the humanitarian initiatives of Mata Amritanandamayi Devi, the chancellor of Amrita Vishwa Vidyapeetham. She has been our inspiration and source of constant support. Our sincere gratitude also goes towards the researchers in AMMACHI Labs and the Civil Engineering Department of Amrita Vishwa Vidyapeetham. We thank them for their unending support.

Footnotes

Peer review under responsibility of Karabuk University.

References

- 1.Organization W.H., et al. World Health Organization, Tech. Rep.; 2020. Water, Sanitation, Hygiene, and Waste Management for the Covid-19 Virus: Interim Guidance, 23 April 2020. [Google Scholar]

- 2.Herron J.B.T., Hay-David A.G.C., Gilliam A.D., Brennan P.A. Personal protective equipment and covid 19-a risk to healthcare staff? Br. J. Oral Maxillofac. Surg. 2020;58(5):500–502. doi: 10.1016/j.bjoms.2020.04.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Liverman C.T., Larson E.L., editors. Preventing transmission of pandemic influenza and other viral respiratory diseases: personal protective equipment for healthcare personnel: update 2010. National Academies Press; 2011. [PubMed] [Google Scholar]

- 4.Organization W.H., et al. World Health Organization, Tech. Rep.; 2020. Rational Use of Personal Protective Equipment for Coronavirus Disease (covid-19): Interim Guidance, 27 February 2020. [Google Scholar]

- 5.Czigany T., Ronkay F. “Editorial corner–a personal view”, ´ eXPRESS. Polymer Lett. 2020;14(6):510–511. [Google Scholar]

- 6.Leonas K.K., Jones C.R., Hall D. The relationship of fabric properties and bacterial filtration efficiency for selected surgical face masks. J. Textile Apparel, Technol. Manage. 2003;3:1–8. [Google Scholar]

- 7.Sattar S.A., Maillard J.-Y. The crucial role of wiping in decontamination of high-touch environmental surfaces: review of current status and directions for the future. Am. J. Infect. Control. 2013;41(5):S97–S104. doi: 10.1016/j.ajic.2012.10.032. [DOI] [PubMed] [Google Scholar]

- 8.Ammendolia J., Saturno J., Brooks A.L., Jacobs S., Jambeck J.R. An emerging source of plastic pollution: environmental presence of plastic personal protective equipment (ppe) debris related to covid-19 in a metropolitan city. Environ. Pollut. 2021;269 doi: 10.1016/j.envpol.2020.116160. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Park C.-Y., Kim K., Roth S. Global shortage of personal protective equipment amid COVID-19: supply chains, bottlenecks, and policy implications. Asian Develop. Bank. 2020;130 [Google Scholar]

- 10.Selvakumar K., Gopi V., SMH FS C.S., Divya S. “Hospital preparedness for emergency in India (hope-i) to combat covid-19 outbreaks”, Studies in Indian Place. Names. 2020;40(70):4226–4236. [Google Scholar]

- 11.H. Kumar, A. Azad, A. Gupta, J. Sharma, H. Bherwani, N.K. Labhsetwar, R. Kumar, Covid-19 creating another problem? sustainable solution for PPE disposal through LCA approach, Environment, Development and Sustainability, pp. 1–15, 2020. [DOI] [PMC free article] [PubMed]

- 12.M. Aggarwal, Pollution watchdog releases guidelines to handle covid19 biomedical waste, MONGABAY, vol. 30, p. 2020,24 March 2020.

- 13.Rajendrakumar A.L., Nair A.T.N., Nangia C., Chourasia P.K., Chourasia M.K., Syed M.G., Nair A.S., Nair A.B., Koya M.S.F. Epidemic landscape and forecasting of sars-cov-2 in India. J. Epidemiol. Global Health. 2021;11(1):55. doi: 10.2991/jegh.k.200823.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.C. Abhimanyu, Fighting from the bottom, India’s sanitation workers are also frontline workers battling covid, The Indian Express, 19 April, 2021. J. Wang, Z. Chen, X. Lang, S. Wang, L. Yang, X. Wu, X. Zhou, and Z. Chen, Quantitative evaluation of infectious health care wastes from numbers of confirmed, suspected and out-patients during covid-19 pandemic: A case study of Wuhan,” Waste Management (New York, Ny), vol. 126, p. 323, 2021. [DOI] [PMC free article] [PubMed]

- 15.McNally, James Dayre, Katie O'Hearn, Shira Gertsman, Margaret Sampson, Lindsey Sikora, Anirudh Agarwal, Anne Tsampalieros, Richard Webster. Microwave-and heat-based decontamination for facemask personal protective equipment (PPE): Protocol for a systematic review. OSFPREPRINTS, (2020).

- 16.Oss H.G., Padovani A.C. Cement manufacture and the environment part ii: environmental challenges and opportunities. J. Ind. Ecol. 2003;7(1):93–126. [Google Scholar]

- 17.Hanle L.J., Jayaraman K.R., Smith J.S. Environmental Protection Agency; Washington DC: 2004. Co2 Emissions Profile of the US Cement Industry. [Google Scholar]

- 18.Thorneycroft J., Orr J., Savoikar P., Ball R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018;161:63–69. [Google Scholar]

- 19.Sharma R., Bansal P.P. Use of different forms of waste plastic in concrete–a review. J. Cleaner Prod. 2016;112:473–482. [Google Scholar]

- 20.Ismail Z.Z., Al-Hashmi E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manage. 2008;28(11):2041–2047. doi: 10.1016/j.wasman.2007.08.023. [DOI] [PubMed] [Google Scholar]

- 21.Rai B., Rushad S.T., Kr B., Duggal S.K. Study of waste plastic mix concrete with plasticizer. Int. Scholarly Res. Notices. 2012;2012:1–5. [Google Scholar]

- 22.Siddique R., Khatib J., Kaur I. Use of recycled plastic in concrete: a review. Waste Manage. 2008;28(10):1835–1852. doi: 10.1016/j.wasman.2007.09.011. [DOI] [PubMed] [Google Scholar]

- 23.B. Jaivignesh, A. Sofi, Study on mechanical properties of concrete using plastic waste as an aggregate, in IOP Conference Series: Earth and Environmental Science, vol. 80, no. 1. IOP Publishing, 2017, p. 012016.

- 24.Patil P.S., Mali J., Tapkire G.V., Kumavat H. Innovative techniques of waste plastic used in concrete mixture. Int. J. Res. Eng. Technol. 2014;3(9):29–32. [Google Scholar]

- 25.Babafemi A.J., Savija B., Paul S.C., Anggraini V. Engineering ˇ properties of concrete with waste recycled plastic: a review. Sustainability. 2018;10(11):3875. [Google Scholar]

- 26.M. Suganya, D. Sathyan, K.M Mini, Performance of concrete using waste fiber reinforced polymer powder as a partial replacement for fine aggregate, Mater. Today: Proceed., 5 (11), 24 114–24 123, 2018.

- 27.Gawande A., Zamare G., Renge V., Tayde S., Bharsakale G. An overview on waste plastic utilization in asphalting of roads. J. Eng. Res Studies. 2012;3(2):1–5. [Google Scholar]

- 28.Naskar M., Chaki T.K., Reddy K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blend. Thermochim Acta. 2010;509(1-2):128–134. [Google Scholar]

- 29.Appiah J.K., Berko-Boateng V.N., Tagbor T.A. Use of waste plastic materials for road construction in ghana. Case Stud. Constr. Mater. 2017;6:1–7. [Google Scholar]

- 30.Manju R., Sathya S., Sheema K. Use of plastic waste in bituminous pavement. Int. J. ChemTech. Res. 2017;10(08):804–811. [Google Scholar]

- 31.Nouali M., Derriche Z., Ghorbel E., Chuanqiang L. Plastic bag waste modified bitumen a possible solution to the algerian road pavements. Road Mater Pave. Des. 2020;21(6):1713–1725. [Google Scholar]

- 32.Mohan H.T., Masson L., Kolathayar S., Sharma K.A.K., Krishnan A.G., Thiviya S., Mohan R. IEEE Global Humanitarian Technology Conference (GHTC) IEEE; 2017. Transforming urban waste into construction blocks for a sanitation infrastructure: a step towards addressing rural open defecation; pp. 1–9. [Google Scholar]

- 33.Mohan H.T., Jayanarayanan K., Mini K.M. Recent trends in utilization of plastics waste composites as construction materials. Constr. Build. Mater. 2020 [Google Scholar]

- 34.You S., Sonne C., Ok Y.S. Covid-19’s unsustainable waste management. Science. 2020;368(6498):1438. doi: 10.1126/science.abc7778. [DOI] [PubMed] [Google Scholar]

- 35.Kou S.C., Poon C.S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009;31(9):622–627. [Google Scholar]

- 36.IS 2185. (2005). Code of practice for concrete masonry units-specifications, Part 1 (3d Revision). New Delhi: BIS.

- 37.Emad M., Soliman N.M., Bashandy A.A. Recycled aggregate high-strength concrete. Int. J. Civil Eng. Technol. (IJCIET) 2019;10(9):128–146. [Google Scholar]

- 38.Mostafa M., Uddin N. Effect of banana fibers on the compressive and flexural strength of compressed earth blocks. Buildings. 2015;5(1):282–296. [Google Scholar]

- 39.Elahi T.E., Shahriar A.R., Islam M.S. Engineering characteristics of compressed earth blocks stabilized with cement and fly ash. Constr. Build. Mater. 2021;277 [Google Scholar]

- 40.Mohan H.T., Whitaker F., DanielGaskell, Mohan R., Mini K.M., Mini M., et al. Performance assessment of recycled ldpe with sand fillers. Mater. Today:. Proc. 2021;42:1526–1530. [Google Scholar]

- 41.Binici H., Aksogan O., Bodur M.N., Akca E., Kapur S. Thermal isolation and mechanical properties of fibre reinforced mud bricks as wall materials. Constr. Build. Mater. 2007;21(4):901–906. [Google Scholar]

- 42.Kim K.-H., Jeon S.-E., Kim J.-K., Yang S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003;33(3):363–371. [Google Scholar]