Abstract

Objectives: Intraoral scanners have shown promising results when used as an adjunct or alternative to conventional impression techniques. This study compared the accuracy of digital impression taking using an intraoral scanner versus the conventional technique.

Materials and Methods: In this in-vitro experimental study, a typodont molar tooth was prepared as the standard model and scanned by TRIOS intraoral scanner. Ten digital impressions were fabricated as such and intraoral scans were sent to the manufacturers. In the conventional method, using addition silicone impression material, a stone die was fabricated. Using a computer-aided design/computer-aided manufacturing scanner, the die was scanned, and the data were transferred to the software. After the fabrication of frameworks, the replica technique was used. The replicas’ thickness (indicative of the gap between the framework and the model and the accuracy of impression taking) was 12 points. The data were analyzed using student's t-test.

Results: The mean thickness of replicas (gap between the internal surface of frameworks and the standard model) at the three points in the buccal, lingual, mesial, and distal sections in the digital impression technique was lower than that in the conventional technique (P<0.0001). In other words, the accuracy of impressions taken by the digital method was significantly higher than those taken by the conventional method.

Conclusion: Intraoral digital scanner had significantly higher accuracy than the conventional method in all points. Thus, the digital method can be reliably used as an adjunct or alternative to the conventional method to increase the accuracy of impression taking.

Key Words: Dental Impression Technique, Computer-Aided Design, Dimensional Measurement Accuracy

Introduction

Accurate impression taking and the precision of impressions have always been a concern for dental clinicians [1]. Intraoral impressions are commonly used for simulation of intraoral conditions in the laboratory setting. Diagnosis and treatment planning and fabrication of prosthetic restorations and orthodontic and prosthetic appliances are all done based on dental casts, which are fabricated using intraoral impressions; this highlights the importance of the accuracy of impression taking and precision of impressions [2-4].

Despite the advances in the materials and techniques of impression taking, there is still a need for further advances in this respect [5]. Several techniques have been proposed to increase the accuracy of impression taking and decrease the dimensional changes of impressions by improving the quality of impression materials, eliminating the laboratory phases, and using digital instead of manual systems [6]. Impressions taken with elastomeric impression materials and custom or prefabricated trays are currently the gold standard of dental impressions. Several techniques have been evaluated for the fabrication of precise dental casts [7-9]. Despite the popularity of the conventional impassion taking method, it has some drawbacks such as a high risk of infection transmission via the impression material since the disinfection systems used for this purpose are not highly reliable [5].

To overcome the existing shortcomings of the conventional impression taking method, the computer-aided design/computer-aided manufacturing (CAD/CAM) system was introduced to the dental market. In this technology, the gypsum cast is digitized using an extra-oral scanner, and a three-dimensional (3D) digital model is fabricated for the design and preparation of restorations [10,11]. The most recent CAD/CAM technology enables digital intraoral impression taking using intraoral scanners, yielding a virtual 3D model [12-14].

Dental impressions are the tools to transfer patient information to dental laboratories. Thus, both conventional and digital impression taking modalities can be used to obtain intraoral dental information of patients. Performing the process of scanning in the patient’s mouth can significantly decrease errors related to impression taking and fabrication of models [15]. Three-dimensional intra-oral scanners have long been used for dental treatments and have undergone constant development [16].

Currently, 10 intraoral scanners are available in the market, which have differences with one another in terms of the technology used in digital cameras, the process of image recording, and designing digital models [13]. TRIOS is an intraoral scanner introduced by the 3Shape Company in 2010. Its advantages include not requiring powder for scanning and the ability to capture images at high speed.

The main concern about intraoral scanners is the dimensional accuracy of this method of impression taking, which has been a popular research topic.

Mehl et al, in 2009 [14] and Luthardt et al, in 2012 [17], evaluated the accuracy of intraoral data acquisition by intraoral scanners and reported the accuracy of this method to be lower than that of conventional techniques. Almeida et al [18], in 2014, Seelbach et al [5], in 2013, reported the accuracy of intraoral data acquisition and conventional impressions to be the same. In contrast, Zarauz et al [19], in 2016, and Ueda et al [20], in 2015, reported that intraoral scanners were more accurate than the conventional method.

Considering the existing controversies and the gap of information in this respect, this study aimed to compare the accuracy of impression taking using addition silicone impression material and data acquisition by intraoral scanners. The null hypothesis was that the accuracy of conventional and digital impression taking methods would not be significantly different.

MATERIALS AND METHODS

In this in-vitro experimental study, 10 samples were used for assessment of the accuracy of each impression technique based on previous studies [1,15]. To assess the accuracy of impression taking, the internal gaps between the fabricated frameworks and the original model were measured under a light microscope and compared between the two groups.

Fabrication of the standard model:

A typodont molar tooth was prepared by a clinician with a classic chamfer margin (0.7mm depth) and served as the standard model in this study (Fig. 1).

Fig. 1.

The prepared typodont molar tooth

Digital impression taking:

Using the TRIOS intraoral scanner (3Shape®, Copenhagen, Denmark), 10 digital impressions were made according to the manufacturer’s instructions. Intraoral scans were transferred to the software. For the fabrication of frameworks, a 40μ distance was considered for the cement space (except at the finish line). Preparation was done using Ceramill® motion 2 (Amannigirrbach, Germany) milling machine on blocks made of chromium-cobalt (Ceramill NP M, Amannigirrbach, Germany) and 10 metal frameworks with a 0.5mm thickness were fabricated of the samples [1,15,20].

To fabricate samples, putty-wash impressions were made using prefabricated trays and addition silicone impression material (Elite HD, Zhermack Spa, Via Bovazecchino, Italy) according to the manufacturer’s instructions. The impressions were transferred to a laboratory and a stone die was fabricated using a dowel pin and dental stone (Velmix, Gildand, Germany).

Next, the die was scanned using New D2000 scanner (3Shape®, Copenhagen, Denmark) and the data were transferred to the software program (Fig. 2). Using the software, a 40μ distance was considered for the cement space. Preparation was done on chromium-cobalt blocks (Ceramill NP M, Amannigirrbach, Germany), and 10 metal frameworks with a 0.5mm thickness were fabricated of the samples [1].

Fig. 2.

Representative image of scans in the software

Assessment of the accuracy of impression taking:

After the fabrication of frameworks, silicone fit indicator (Fit Checker, GC, Japan) was applied into them as recommended by the manufacturer, and they were placed on the model. The frameworks were then removed and their fit was assessed. Those with marginal misfit, excessive occlusal thickness or incomplete seating on the model were excluded from the study and impression taking was repeated. Next, condensation silicone wash was applied into the frameworks (Speedex, Coltene Co, Switzerland) and they were placed on the model with finger pressure for four minutes. The force level is equal to the medium finger’s pressure. We waited 4 minutes for the setting of condensation silicone wash. Next, condensation silicone with putty consistency was placed inside the frameworks to form a replica (Fig. 3) [15,20].

Fig. 3.

The replica was made by condensation silicone

The replica was divided into four sections of mesial, distal, buccal, and lingual using a scalpel in the buccolingual and mesiodistal directions.

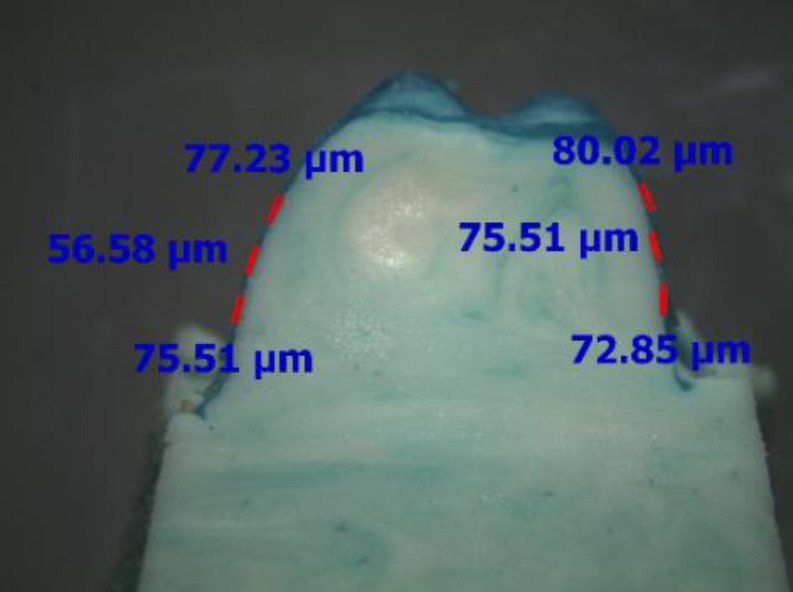

Next, three points were selected in each section, and the thickness of the replica in the respective points was measured under a light microscope (Ernst Leitz Wetzlar, Germany). These three points are selectively selected in each section. The thickness of the replica or width of the gaps was measured as an indicator of the accuracy of impression techniques in this study.

The greater the thickness, the lower the accuracy of impression techniques (Fig. 4) [15,20].

Fig. 4.

Assessment of the thickness of the replica at different points under a light microscope

Statistical analysis:

The data were analyzed using SPSS (SPSS Inc., Chicago, IL, USA). The mean, standard deviation (SD), standard error, minimum and maximum values of the thickness of the replica (gap between the internal framework surface and the standard model) in points 1, 2, and 3 in the buccal, lingual, mesial, and distal and also for all points were calculated and reported in the two methods. The Kolmogorov-Smirnov test was applied to assess the distribution of data, which showed that the data were normally distributed. Thus, student’s t-test was applied to compare the internal gap between the framework surface and the standard model (as an indicator of the accuracy of impression techniques) between the two groups. P>0.05 was considered statistically significant.

Results

The mean thickness of the replicas (gap between the internal surface of frameworks and the standard model) at the three points in the buccal, lingual, mesial, and distal sections in the digital impression technique was lower than that in the conventional technique (P<0.0001). In other words, the accuracy of impressions taken by the digital method was significantly higher than those taken by the conventional method.

Table 1 shows the mean and SD of the thickness of the replicas in 12 points in the mesial, distal, lingual, and buccal sections in the digital and conventional methods. The mean maximum thickness of the replicas (gap between the internal surface of frameworks and the standard model) in the buccal, lingual, mesial, and distal sections in the digital method was significantly lower than that in the conventional method (student's t-test, P<0.0001).

Table 1.

The mean and standard deviation (SD) of the thickness of the replicas at 12 points in the mesial, distal, buccal, and lingual sections (in micron)

| Point | Impression technique |

Mean | SD | Standard error |

Minimum | Maximum | P-value |

|---|---|---|---|---|---|---|---|

| Buccal1 | Digital | 73.19 | 5.15 | 1.63 | 61.17 | 80.04 | 0.0001 |

| Conventional | 160.89 | 26.57 | 8.4 | 121.75 | 187.16 | ||

| Buccal2 | Digital | 69.25 | 7.14 | 2.26 | 56.58 | 76.17 | 0.0001 |

| Conventional | 142.78 | 21.93 | 6.93 | 121.57 | 182.02 | ||

| Buccal3 | Digital | 73.39 | 5.17 | 1.64 | 66.09 | 83.66 | 0.0001 |

| Conventional | 140.69 | 19.52 | 6.17 | 120.31 | 180.15 | ||

| Lingual 1 | Digital | 72.25 | 14.04 | 4.44 | 53.17 | 87.91 | 0.0001 |

| Conventional | 141.95 | 21.01 | 6.64 | 123.17 | 178.81 | ||

| Lingual2 | Digital | 74.96 | 8.03 | 2.54 | 62.48 | 88.93 | 0.0001 |

| Conventional | 147.16 | 22.63 | 7.16 | 121.65 | 184.24 | ||

| Lingual3 | Digital | 74.97 | 8.71 | 2.75 | 54.61 | 84.91 | 0.0001 |

| Conventional | 150.33 | 26.54 | 8.39 | 120.23 | 187.62 | ||

| Mesial1 | Digital | 66.32 | 8.77 | 2.77 | 52.98 | 83.81 | 0.0001 |

| Conventional | 166.54 | 19.91 | 6.29 | 128.48 | 187.17 | ||

| Mesial2 | Digital | 63.59 | 10.78 | 3.41 | 52.96 | 86.09 | 0.0001 |

| Conventional | 164.61 | 21.75 | 6.88 | 123.17 | 184.82 | ||

| Mesial3 | Digital | 64.29 | 10.82 | 3.42 | 51.88 | 82.72 | 0.0001 |

| Conventional | 157.76 | 25.75 | 8.14 | 121.02 | 188.66 | ||

| Distal1 | Digital | 62.03 | 7.5 | 2.37 | 54.61 | 74.62 | 0.0001 |

| Conventional | 149.76 | 20.49 | 6.48 | 123.26 | 180.54 | ||

| Distal2 | Digital | 58.99 | 4.59 | 1.45 | 54.61 | 66.23 | 0.0001 |

| Conventional | 164.85 | 19.35 | 6.12 | 127.81 | 183.18 | ||

| Distal3 | Digital | 61.21 | 10.09 | 3.19 | 52.98 | 81.44 | 0.0001 |

| Conventional | 145.95 | 21.76 | 6.88 | 187.6 | 122.65 |

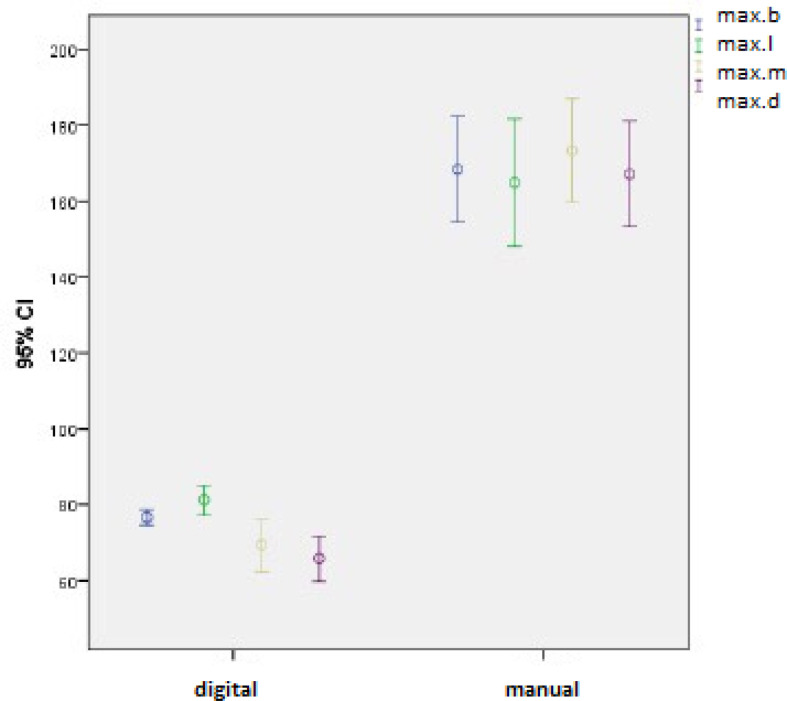

The mean and SD of the maximum thickness of the replicas in all points in the four sections are presented in Table 2. Figure 5 shows the 95% confidence interval (CI) of the mean thickness of the replicas in the four sections in the two methods. The mean thickness of the replicas at all points was 82.33±4.49μ in the digital and 185.43±2.59μ in the conventional method; the difference in this regard according to student’s t-test was statistically significant (P<0.0001). Table 3 shows the mean thickness of the replicas in the four sections.

Table 2.

The mean and standard deviation (SD) of the maximum thickness of the replicas at all points in the mesial, distal, buccal, and lingual sections (in microns)

| Point | Impression technique |

Mean | SD | Standard error | Minimum | Maximum | P-value |

|---|---|---|---|---|---|---|---|

| Buccal | Digital | 76.68 | 2.86 | 0.9 | 75.05 | 83.66 | 0.0001 |

| Conventional | 168.34 | 19.46 | 6.15 | 131.95 | 187.16 | ||

| Lingual | Digital | 81.22 | 5.52 | 1.74 | 71.22 | 88.93 | 0.0001 |

| Conventional | 164.84 | 23.41 | 7.4 | 125.96 | 187.62 | ||

| Mesial | Digital | 69.35 | 9.82 | 3.1 | 52.98 | 86.09 | 0.0001 |

| Conventional | 173.37 | 19.09 | 6.04 | 128.48 | 188.66 | ||

| Distal | Digital | 65.81 | 8.36 | 2.64 | 56.58 | 81.44 | 0.0001 |

| Conventional | 167.09 | 19.39 | 6.13 | 127.81 | 187.6 |

Fig. 5.

The 95% confidence interval (CI) of the maximum thickness of the replicas at all points in the mesial, distal, buccal, and lingual sections in the digital and conventional methods

Table 3.

The mean thickness of the replicas at all points in the mesial, distal, buccal, and lingual sections

| Point | Impression technique |

Mean | Standard deviation |

Standard error |

Minimum | Maximum | P-value |

|---|---|---|---|---|---|---|---|

| Buccal | Digital | 71.95 | 3.23 | 1.02 | 64.78 | 74.96 | 0.0001 |

| Conventional | 148.12 | 25.0 | 4.74 | 129.13 | 180.73 | ||

| Lingual | Digital | 74.04 | 7.2 | 2.28 | 64.62 | 87.25 | 0.0001 |

| Conventional | 146.48 | 14.55 | 4.6 | 122.61 | 166.07 | ||

| Mesial | Digital | 64.73 | 8.86 | 2.8 | 52.61 | 84.21 | 0.0001 |

| Conventional | 162.97 | 19.6 | 6.19 | 125.62 | 183.51 | ||

| Distal | Digital | 60.75 | 5.87 | 1.86 | 55.75 | 70.22 | 0.0001 |

| Conventional | 153.52 | 16.64 | 5.26 | 125.95 | 174.31 |

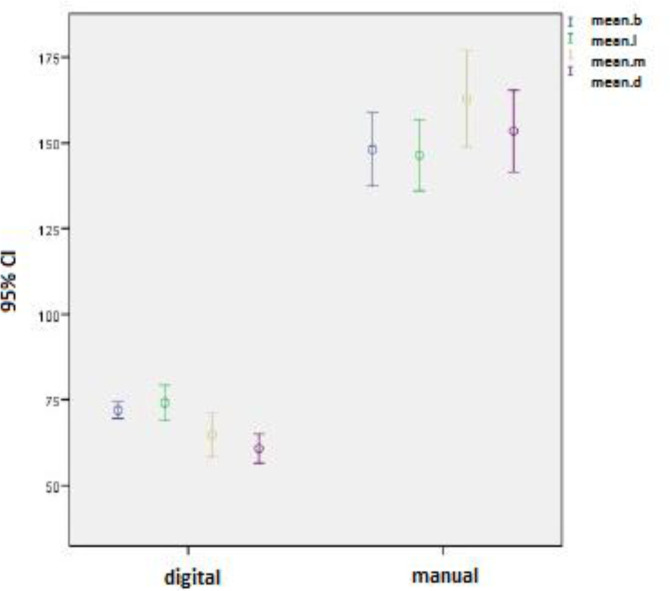

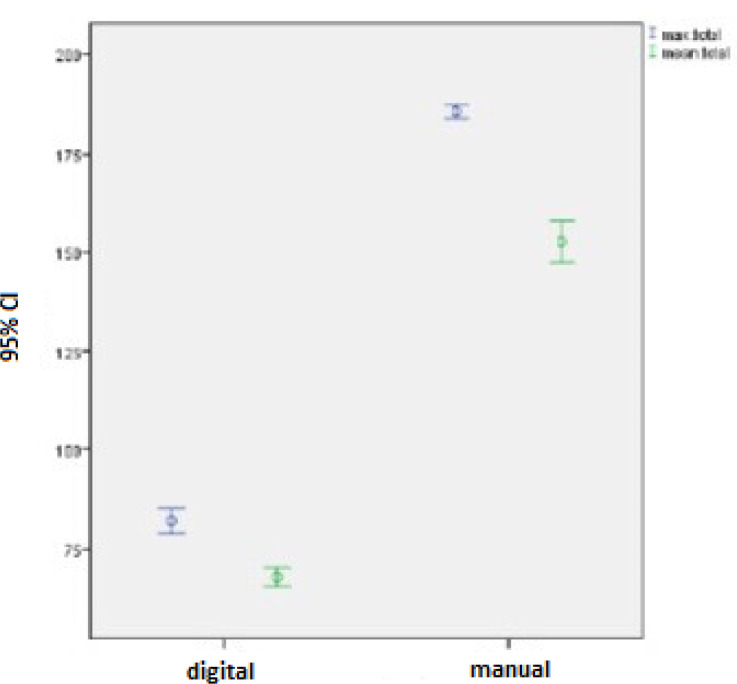

As seen in Table 3, there were significant differences in this respect between the two groups, and the mean thickness of the replicas at all points was significantly higher in the conventional method compared to the digital technique (P<0.0001). The 95% CI of the mean thickness of the replicas in the two methods is illustrated in Figure 6. Based on the results, the mean thickness of the replicas at all points in the four sections was 67.87±3.29μ in the digital and 152.77±7.38μ in the conventional method. Based on the results of student’s t-test, the difference in this respect between the two methods was statistically significant (P<0.0001). Figure 7 shows the 95% CI of the mean thickness of the replicas and the mean maximum thickness of the replicas in the four sections.

Fig. 6.

The 95% confidence interval (CI) of the mean thickness of the replicas at all points in the mesial, distal, buccal, and lingual sections in the digital and conventional methods

Fig. 7.

The 95% confidence interval (CI) of the mean and maximum thickness of the replicas at all points in the digital and conventional methods

Discussion

The CAD/CAM technology has undergone significant advances since its introduction in 1980, and intraoral scanners are currently available for use in the clinical setting [21]. In the current study, the accuracy of impression taking was compared between the TRIOS® intraoral scanner and the conventional method. The replica technique with the use of light body impression material is a reliable and reproducible technique for assessment of the accuracy of impression taking in the clinical setting [22-27]. Moreover, it has been confirmed that the gap width values obtained in this method are equal to the values obtained after cementation with glass ionomer cement [26].

The replica technique decreases the variability of samples and can be easily used in both the clinical and laboratory settings [15,28].

Considering the limitations of the putty-wash technique, such as dimensional changes and deformity, larger gaps between the internal surface of the framework and the standard model in the conventional method is somehow justified. Also, the type of tray used (prefabricated tray was used in the current study) can affect the quality and accuracy of the impressions. Also, due to errors that may occur in the laboratory, the gaps in the buccal, lingual, mesial, and distal surfaces may be different, and the quality of the final crown will be affected. Metal or plastic trays (compared to custom trays) increase the dimensional changes while the use of special (custom) trays results in the equal thickness of impression material, which increases the accuracy of the casts [29].

Additional variables affecting the dimensional accuracy of impressions in the conventional method include the susceptibility of the tray and impression materials to dimensional changes [29]. The impression accuracy in the digital method depends on two parameters, namely the resolution of the scanning system and the accuracy of the algorithm. In contrast to the conventional impression technique, the digital method enables enhancements or modifications of the scans by selecting some specific poorly scanned areas for re-scanning after preparation. Also, the digital method allows for archiving all the documents and video files, which is a great advantage. In the digital method, the respective tooth and its surrounding tissues are scanned (digital impression taking) after tooth preparation by the clinician, and the data are transferred to a computer. The software designs the restoration and transfers the related data to the milling machine. The prepared areas are marked on the blocks [30]. The shortcomings include the high cost of the device, the high cost for patients, and dependence of the success of the final restoration on the expertise and skills of the clinicians [30].

Seelbach et al (5) showed that the accuracy of all-ceramic crowns fabricated using intraoral scanners (Lava, CEREC, and iTero) was similar to that of the conventional method, and thus, they stated that digital methods can be used for the fabrication of fixed partial dentures in the clinical setting. Such a controversy in the results of this study and the current findings may be due to the different types of scanners used and different resolutions of the systems. Boeddinghaus et al [31] assessed the accuracy of single-tooth restorations fabricated using the Sirona (Cerec) intraoral digital impression technique in comparison with the conventional method using the replica technique. They showed that zirconia copings fabricated of a model by the intraoral digital and conventional techniques were the same in terms of the internal adaptation. Zarauz et al [19] compared the clinical results of the fit of all-ceramic crowns using conventional silicone and digital intraoral (iTero and Cadent) techniques and reported that all-ceramic crowns fabricated with the digital intraoral impression technique had clinically superior marginal fit compared to the conventionally fabricated restorations. In 2015, Ueda et al [20] compared the impression accuracy of the Lava intraoral scanner with the conventional method and reported significantly higher accuracy of the digital technique. A systematic review by Chochlidakis et al [32] revealed that the digital impression technique was superior to the conventional method in terms of the internal gap but this difference was not statistically significant. Considering the results of the aforementioned studies and those of the current study, the digital method has sufficient accuracy (equal or higher than that of conventional impressions) and can be reliably used in the clinical setting.

In the current study, the internal gap between the framework and the standard model was 51.88-88.93μ in the digital and 120.23-188.66μ in the conventional method. The gap width in the Lava COS and Cerec intraoral scanners has been reported in the range of 0-552μ using silicone replicas [33]. In previous studies, a wide range of gap width has been reported, which is in agreement with the current findings, and these gaps are in an acceptable range [33,34]. However, since in-vitro experimental settings are variable and there is no standard method to determine the accuracy of impression methods in vitro, comparison of the results of studies may not be logical.

Elastomeric impression materials are still used as the gold standard to estimate the accuracy of impressions in fixed prosthodontics. The conventional impressions have long been used for prosthetic dental treatments with acceptable results. Accurate selection of materials and manufacturing procedures are critical in this method to compensate for the expansion and shrinkage of different materials. However, not being able to control all the confounders along with human errors in this method may result in the fabrication of less accurate impressions. In the digital method, the risk of human errors is lower, and impressions that are more accurate may be obtained. Even though digital impression techniques have shown equal or even higher accuracy in recording details for prosthetic dental treatments, the conventional technique is still commonly used by the clinicians.

Studies conducted on the conventional impression taking in the laboratory setting often report higher accuracy for this technique compared to the clinical setting [35] because factors such as saliva, the gingival crevicular fluid (GCF), blood, and patient movement increase the rate of inaccuracies in impressions taken in the clinical setting. These factors also affect the accuracy of impressions taken with the use of intraoral scanners. However, digital systems enable magnification of scanned teeth on the monitor and allow for rescanning of poorly scanned areas. Thus, possible errors in impressions can be minimized. This may explain the small differences in the accuracy of digital and conventional techniques.

The current findings support the high accuracy of intraoral digital scanners. Thus, future studies are required on the efficacy of digital systems for the fabrication of feldspathic porcelain, composite inlays and onlays, and zirconia ceramic restorations. Also, the efficacy of other types of intraoral scanners used in the clinical setting must be evaluated in future studies. Finally, this study rejected the null hypothesis based on the results.

CONCLUSIONS

Within the limitations of this in-vitro study, the results revealed that the accuracy of the intraoral digital impression technique was significantly higher than that of the conventional technique. Thus, the digital technique can be used as an alternative to the conventional method in the clinical setting to increase the accuracy of prosthetic restorations.

Notes:

Cite this article as: Zarbakhsh A, Jalalian E, Samiei N, Mahgoli MH, Kaseb Ghane H. Accuracy of Digital Impression Taking Using Intraoral Scanner versus the Conventional Technique. Front Dent. 2021:18:6.

CONFLICT OF INTEREST STATEMENT

None declared.

References

- 1.Tidehag P, Ottosson K, Sjogren G. Accuracy of ceramic restorations made using an in-office optical scanning technique: an in vitro study. Oper Dent. 2014 May-Jun;39(3):308–16. doi: 10.2341/12-309-L. [DOI] [PubMed] [Google Scholar]

- 2.Akyalcin S, Cozad BE, English JD, Colville CD, Laman S. Diagnostic accuracy of impression-free digital models. Am J Orthod Dentofacial Orthop. 2013 Dec;144(6):916–22. doi: 10.1016/j.ajodo.2013.04.024. [DOI] [PubMed] [Google Scholar]

- 3.Zaruba M, Ender A, Mehl A. New applications for three-dimensional follow-up and quality control using optical impression systems and OraCheck. Int J Comput Dent. 2014;17(1):53–64. [PubMed] [Google Scholar]

- 4.Ziegler M. Digital impression taking with reproducibly high precision. Int J Comput Dent. 2009;12(2):159–63. [PubMed] [Google Scholar]

- 5.Seelbach P, Brueckel C, Wostmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Investig. 2013 Sep;17(7):1759–64. doi: 10.1007/s00784-012-0864-4. [DOI] [PubMed] [Google Scholar]

- 6.Craig RG. Review of dental impression materials. Adv Dent Res. 1988 Aug;2(1):51–64. doi: 10.1177/08959374880020012001. [DOI] [PubMed] [Google Scholar]

- 7.Chandran DT, Jagger DC, Jagger RG, Barbour ME. Two- and three-dimensional accuracy of dental impression materials: effects of storage time and moisture contamination. Biomed Mater Eng. 2010;20(5):243–9. doi: 10.3233/BME-2010-0638. [DOI] [PubMed] [Google Scholar]

- 8.Piwowarczyk A, Ottl P, Buchler A, Lauer HC, Hoffmann A. In vitro study on the dimensional accuracy of selected materials for monophase elastic impression making. Int J Prosthodont. 2002 Mar-Apr;15(2):168–74. [PubMed] [Google Scholar]

- 9.Thongthammachat S, Moore BK, Barco MT, 2nd , Hovijitra S, Brown DT, Andres CJ. Dimensional accuracy of dental casts: influence of tray material, impression material, and time. J Prosthodont. 2002 Jun;11(2):98–108. [PubMed] [Google Scholar]

- 10.Bosch G, Ender A, Mehl A. A 3-dimensional accuracy analysis of chairside CAD/CAM milling processes. J Prosthet Dent. 2014 Dec;112(6):1425–31. doi: 10.1016/j.prosdent.2014.05.012. [DOI] [PubMed] [Google Scholar]

- 11.Luthardt RG, Sandkuhl O, Herold V, Walter MH. Accuracy of mechanical digitizing with a CAD/CAM system for fixed restorations. Int J Prosthodont. 2001 Mar-Apr;14(2):146–51. [PubMed] [Google Scholar]

- 12.Beuer F, Schweiger J, Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008 May;204(9):505–11. doi: 10.1038/sj.bdj.2008.350. [DOI] [PubMed] [Google Scholar]

- 13.Fasbinder DJ. Digital dentistry: innovation for restorative treatment. Compend Contin Educ Dent. 2010;31 Spec No 4:2–11. [PubMed] [Google Scholar]

- 14.Mehl A, Ender A, Mormann W, Attin T. Accuracy testing of a new intraoral 3D camera. Int J Comput Dent. 2009;12(1):11–28. [PubMed] [Google Scholar]

- 15.Syrek A, Reich G, Ranftl D, Klein C, Cerny B, Brodesser J. Clinical evaluation of all-ceramic crowns fabricated from intraoral digital impressions based on the principle of active wavefront sampling. J Dent. 2010 Jul;38(7):553–9. doi: 10.1016/j.jdent.2010.03.015. [DOI] [PubMed] [Google Scholar]

- 16.Galhano GA, Pellizzer EP, Mazaro JV. Optical impression systems for CAD-CAM restorations. J Craniofac Surg. 2012 Nov;23(6):e575–9. doi: 10.1097/SCS.0b013e31826b8043. [DOI] [PubMed] [Google Scholar]

- 17.Luthardt RG, Loos R, Quaas S. Accuracy of intraoral data acquisition in comparison to the conventional impression. Int J Comput Dent. 2005 Oct;8(4):283–94. [PubMed] [Google Scholar]

- 18.Almeida e Silva JS, Erdelt K, Edelhoff D, Araujo E, Stimmelmayr M, Vieira LC, et al. Marginal and internal fit of four-unit zirconia fixed dental prostheses based on digital and conventional impression techniques. Clin Oral Investig. 2014;18(2):515–23. doi: 10.1007/s00784-013-0987-2. [DOI] [PubMed] [Google Scholar]

- 19.Zarauz C, Valverde A, Martinez-Rus F, Hassan B, Pradies G. Clinical evaluation comparing the fit of all-ceramic crowns obtained from silicone and digital intraoral impressions. Clin Oral Investig. 2016 May;20(4):799–806. doi: 10.1007/s00784-015-1590-5. [DOI] [PubMed] [Google Scholar]

- 20.Ueda K, Beuer F, Stimmelmayr M, Erdelt K, Keul C, Guth JF. Fit of 4-unit FDPs from CoCr and zirconia after conventional and digital impressions. Clin Oral Investig. 2016 Mar;20(2):283–9. doi: 10.1007/s00784-015-1513-5. [DOI] [PubMed] [Google Scholar]

- 21.Kachalia PR, Geissberger MJ. Dentistry a la carte: in-office CAD/CAM technology. J Calif Dent Assoc. 2010 May;38(5):323–30. [PubMed] [Google Scholar]

- 22.Kohorst P, Brinkmann H, Dittmer MP, Borchers L, Stiesch M. Influence of the veneering process on the marginal fit of zirconia fixed dental prostheses. J Oral Rehabil. 2010 Apr;37(4):283–91. doi: 10.1111/j.1365-2842.2009.02053.x. [DOI] [PubMed] [Google Scholar]

- 23.Kokubo Y, Nagayama Y, Tsumita M, Ohkubo C, Fukushima S, Vult von Steyern P. Clinical marginal and internal gaps of In-Ceram crowns fabricated using the GN-I system. J Oral Rehabil. 2005 Oct;32(10):753–8. doi: 10.1111/j.1365-2842.2005.01506.x. [DOI] [PubMed] [Google Scholar]

- 24.Kokubo Y, Ohkubo C, Tsumita M, Miyashita A, Vult von Steyern P, Fukushima S. Clinical marginal and internal gaps of Procera AllCeram crowns. J Oral Rehabil. 2005;32(7):526–30. doi: 10.1111/j.1365-2842.2005.01458.x. [DOI] [PubMed] [Google Scholar]

- 25.Kokubo Y, Tsumita M, Kano T, Sakurai S, Fukushima S. Clinical marginal and internal gaps of zirconia all-ceramic crowns. J Prosthodont Res. 2011 Jan;55(1):40–3. doi: 10.1016/j.jpor.2010.09.001. [DOI] [PubMed] [Google Scholar]

- 26.Rahme HY, Tehini GE, Adib SM, Ardo AS, Rifai KT. In vitro evaluation of the "replica technique" in the measurement of the fit of Procera crowns. J Contemp Dent Pract. 2008 Feb;9(2):25–32. [PubMed] [Google Scholar]

- 27.Tsumita M, Kokubo Y, Ohkubo C, Nagayama Y, Sakurai S, Fukushima S. Clinical evaluation of marginal and internal gaps of zirconia-based 3-unit CAD/CAM fixed partial dentures. Prosthodont Res Pract. 2007;6(2):114–9. [Google Scholar]

- 28.Boening KW, Wolf BH, Schmidt AE, Kastner K, Walter MH. Clinical fit of Procera AllCeram crowns. J Prosthet Dent. 2000 Oct;84(4):419–24. doi: 10.1067/mpr.2000.109125. [DOI] [PubMed] [Google Scholar]

- 29.Eames WB, Sieweke JC. Seven acrylic resins for custom trays and five putty-wash systems compared. Oper Dent. 1980;5(4):162–7. [PubMed] [Google Scholar]

- 30.Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009 Jan;28(1):44–56. doi: 10.4012/dmj.28.44. [DOI] [PubMed] [Google Scholar]

- 31.Boeddinghaus M, Breloer ES, Rehmann P, Wostmann B. Accuracy of single-tooth restorations based on intraoral digital and conventional impressions in patients. Clin Oral Investig. 2015 Nov;19(8):2027–34. doi: 10.1007/s00784-015-1430-7. [DOI] [PubMed] [Google Scholar]

- 32.Chochlidakis KM, Papaspyridakos P, Geminiani A, Chen CJ, Feng IJ, Ercoli C. Digital versus conventional impressions for fixed prosthodontics: A systematic review and meta-analysis. J Prosthet Dent. 2016 Aug;116(2):184–90. doi: 10.1016/j.prosdent.2015.12.017. [DOI] [PubMed] [Google Scholar]

- 33.Brawek PK, Wolfart S, Endres L, Kirsten A, Reich S. The clinical accuracy of single crowns exclusively fabricated by digital workflow--the comparison of two systems. Clin Oral Investig. 2013 Dec;17(9):2119–25. doi: 10.1007/s00784-013-0923-5. [DOI] [PubMed] [Google Scholar]

- 34.Grenade C, Mainjot A, Vanheusden A. Fit of single tooth zirconia copings: comparison between various manufacturing processes. J Prosthet Dent. 2011 Apr;105(4):249–55. doi: 10.1016/S0022-3913(11)60040-1. [DOI] [PubMed] [Google Scholar]

- 35.Ali AO. Accuracy of digital impressions achieved from five different digital impression systems. Dentistry. 2015;5:5. [Google Scholar]