Abstract

The necessity to improve the metallographic analysis systems to automate diagnostics of the condition of the metals for all their characteristics has been substantiated. The metallographic analysis algorithm based on the use of neural networks for recognizing metal microstructures and a case-based reasoning approach for determining the metal grade is proposed. The structure of a multilayer neural network to determine the metals quantitative parameters has been developed. The recognizing results by neural networks for determining the metal quantitative parameters are shown. The high accuracy of determining the metals quantitative parameters by neural networks is presented. The specialized metallographic software to automate the recognition of metal microstructures and to determine the metal grade has been developed. Comparative results of carrying out metallographic studies with the developed neural network software to determine the metals quantitative parameters are shown.

Keywords: Intelligent technologies, Neural networks, Case-based reasoning approach, Metallographic analysis, Software, Expert system

Intelligent technologies; Neural networks; Case-based reasoning approach; Metallographic analysis; Software; Expert system.

1. Introduction

Nowadays the level of industrial development is characterized not only by the overall production and the range of products as well as by indicators of their quality. An important means of solving the problem of controlling metal quality at metallurgical enterprises is the use of objective physical methods for diagnosing the technical condition of the objects, such as non-destructive methods and metallographic analysis [1]. The traditional methods of non-destructive testing are unsuitable for determining defects at an early stage of their development. The metallographic method [2, 3] is one of the methods of quality control of alloy and metal products, which is introduced into a number of existing standards. It should be noted the existing methods and tools do not solve the problems of complex automated diagnostics of the condition of the metals for all their characteristics. That’s why there is a necessity to improve the metallographic analysis systems to automate diagnostics of the condition of the metals for all their characteristics.

For the time being, there are various automated monitoring and diagnostic systems for industries. The following companies are engaged in the creation of automation systems for technological processes at enterprises: STC "Pribor", PJSC "Metallurgavtomatika", Datasolution, INFOCOM LTD, RockwellAutomation, Inc., Siemens VAI, POSCO ICT, China Iron&Steel Research Institute Group and others. These companies have developed and implemented a number of systems for automation of technological processes at various enterprises around the world. However, in the existing automated systems, the possibility of monitoring and technical diagnostics is not fully implemented.

In the construction and repair of ships, various materials are used: metals, wood, plastics, etc., which have certain chemical, physical, mechanical and technological properties that are taken into account when building and repairing ship structures. Each batch of material supplied to the shipbuilding and ship repair yards is necessarily accompanied by a document - a certificate, which indicates all its qualities; in the laboratories of the factories, the material undergoes chemical, mechanical and technological tests.

Corrosion is a spontaneous process of destruction of the metal surface during its interaction with the external environment, proceeding in most cases without supplying energy from any external source. The physical process of corrosion is explained by the fact that in nature, ferrous or non-ferrous metals that corrode are not found in a free state, and energy is expended to obtain them from minerals and ores. Metal corrosion can be divided into three types.

Chemical corrosion occurs from the action of dry gases or liquids that do not conduct electric current according to the laws of chemical reactions. Most often, chemical corrosion affects the internal surfaces of cargo tanks of oil tankers carrying light oil products with a high content of sulfur compounds and acid residues that enter into a chemical reaction with the metal. When this occurs, the destruction of the surfaces of the set in the form of local individual pits.

Biological corrosion is caused by the vital activity of various microorganisms on the underwater part of the ship’s hull. In this case, microorganisms use the metal as a nutrient medium or infect it with their secretions. Biological corrosion does not produce significant damage, but, as a rule, it is combined with other types of corrosion.

Electrochemical corrosion occurs when metal comes into contact with conductive liquids (electrolytes). In ship conditions, sea water acts as an electrolyte. The ship’s hull metal and its protective film are heterogeneous. A metal can have different internal stresses and physical conditions (temperature, water flow rate, etc.). Therefore, when a metal comes into contact with water, a lot of galvanic pairs are formed on it, as a result of which electrochemical corrosion occurs, in which the body metal, being an anode, partially passes into the electrolyte. Of all types of corrosion during electrochemical corrosion, the greatest destruction of the metal of the hull, pipelines and other ship equipment occurs. The intensity of corrosion depends on the salinity of the water, the content of oxygen in it and the chemical composition of the metal. In ship conditions, galvanic couples can most often be formed when dissimilar metals come into contact.

Corrosion causes irreparable damage to the hull, pipelines and other structures of the ship, as in places subject to corrosion, the metal becomes thinner, which leads to a decrease in the strength and density of the structures and the hull as a whole. Expensive repairs must be carried out to eliminate the consequences of corrosion. It should be taken into account that most parts of ship mechanisms and hull elements are subjected to simultaneous mechanical stress and corrosion damage.

2. Literature review

There are many significant studies in the field of automation metallographic analysis, one can single out papers [4, 5, 6, 7, 8], as well as software developments of companies such as DeepLab, SPECTR MET, SIAMS, etc. In the paper [9] have proposed recommendations for the automation of metallographic analysis, which speaks of the necessity to use software image analyzers when processing the metallographic images. In this paper, the insufficient level of automation of the central factory laboratories of industrial enterprises to perform the metallographic analysis is high-lighted as well.

Authors in the study [10] resort to neural networks methods and achieve significant performance to classify microstructures images. In the study [11], convolution networks have been researched for semantic segmentation of the microstructure images. In paper [12], proposed a fully convolutional neural network to segment the metallographic images of steels. In paper [13], the neural network was used for microstructures images segmentation. A neural network for automatic segmentation of nickel alloy secondary phases from metallographic images is proposed in study [14]. These methods achieved satisfactory results in point of view metallographic analysis but they fail to work well enough on devices with limited computation resources. In addition, these methods are too heavy to apply in real-time application.

The existing methods and tools do not solve the problems of complex automated diagnostics of the condition of the metals for all their characteristics (chemical composition, structure, properties, etc.), and the methods considered in previously noted studies allow perform only quantitative metallographic analysis. Thus, there is a need to improve automated tools and methods for metallographic analysis to automate diagnostics of the condition of the metals for all their characteristics.

Other steels with special physical or physico-mechanical properties are also used in shipbuilding: malleable steels for the manufacture of small parts, carbon and alloy steels for ship forgings, and stainless steels. The latter have high corrosion resistance, are well welded; of them, wings for hydrofoils, propeller shaft linings, turbine blades, etc. are made, but they have an increased cost, therefore their use is limited.

Painting materials are used to cover all ship surfaces. These include: oil, resin and silicate paints, lead and iron minium, whitewash, varnishes, synthetic paints, enamels (based on pentaphthalic resins), ethanol paints, Kuzbass varnish, etc. For better protection of ship structures and ensuring their longer life services, paint and varnish coatings are applied to thoroughly cleaned and primed surfaces. The underwater surfaces of the hulls of marine vessels are covered with special paints that are more resistant to fouling of the hull with shells and algae.

Vessel sections are exposed to various aggressive environments: sea water, sea atmosphere, oil products, condensate, etc., which contribute to the occurrence of corrosion processes. The nature and intensity of destruction depend on many factors: the area of navigation, speed, duration of the voyage and the effectiveness of corrosion protection. Electrochemical corrosion leads to the destruction of welds and the metal around them due to the already mentioned potential difference between the weld material and the base material. If the weld metal has a more negative potential than the base material, then the weld is severely damaged. If its potential is more positive, then it is not the seam that is destroyed, but the metal in the surrounding area.

3. Methods

For preliminary processing of the metallographic images, the authors used binarization methods and filtering methods (the Prewitt filter). To recognize the metallographic images, artificial intelligence technologies such as artificial neural networks were used in the study. To solve new metallographic situations to determine the metal grade based on already known solutions, the case-based reasoning approach was used. The methods of statistical analysis to evaluate the results of the functioning of the developed automated metallographic system in the study were used. The IDEF0 notation to formalize and describe the algorithm for automated metallographic analysis was used.

4. Algorithm for automated metallographic analysis of metals based on artificial intelligence technologies

Metallographic analysis means the determination of parameters characterizing the metallographic image, which can be considered as a description, presented in the form:

| (1) |

where, is i-th metallographic image of the metal sample under examination;

is the metal grade (steel 10ChSND(S420N));

is the expert resolution of the technologist about the metal sample;

is an array of metal quantitative parameters;

is an array of metal quality parameters.

The authors propose an algorithm for the automated metallographic analysis of metals in production, the implementation of which makes it possible to determine the arrays of qualitative (Q) and quantitative (N) metals parameters. The proposed algorithm includes the 6 main operations.

Operation 1. Formation of a microstructure image in form of a function f (x,y).

Operation 2. At the second operation, preliminary processing and analysis of the microstructure image are carried out. The array of the metal quantitative parameters under study are formed, as well as the array of its qualitative parameters:

| (2) |

| (3) |

Operation 3. At the third operation, based on the obtained quantitative parameters and the metal chemical composition, the metal grade is determined.

Operation 4. At the 4th operation, the determination of the metal properties is performed based on the arrays data of its quantitative, qualitative parameters and existing defects.

Operation 5. At the 5th operation, the metal usage group (group) is determined and a conclusion on the analyzed metal (rf) for compliance with the production requirements is formed.

| (4) |

Operation 6. At the 6th operation, sending the result of the metallographic analysis of the metal sample to the workshop is performed.

At the first operation, to form a digital metal microstructure image a metallographic microscope is used. After the metal microstructure image is formed, binarization of it is performed. It is proposed to use the Otsu’s method [15].

As it is known from source [15], from the point of view of objects recognition in the image, one of the most informative characteristics are the boundaries, i.e. image segment contours rather than the values of the object’s brightness in the image. The selection of microstructure image segment contours consists of the detection of the microstructure image objects boundaries and outlines of homogeneous regions using the Prewitt filter, as it is shown in the source [16].

Vessel sections are exposed to various aggressive environments – sea water, sea atmosphere, chemically active bulk cargo, oil products, condensate, air of various humidity, etc., which contribute to corrosion.

The intensity and nature of destruction depend on the area of navigation, speed, duration of the voyage and the effectiveness of corrosion protection. Of all the structural elements of the ship’s hull, the greatest damage is observed on oil tankers in the area of the lining of the longitudinal bulkheads between cargo and ballast tanks, where the corrosion rate of the upper belt reaches 0.3 mm/year, the lower – 0.25 mm/year. Great intensity of corrosion is also in the areas between cargo tanks, sets of sides and decks. The underwater part, the area of variable waterlines, the flooring of the second bottom in the area of ballast tanks, and the set inside the double bottom are subject to significant destruction (see Figure 1).

Figure 1.

Diagram of the proposed automated metallographic analysis.

For most of the listed structures, which are subject to electrochemical corrosion, the destruction of welds and the near-weld zone is typical due to different stationary electrode potentials between the weld material and the base material. If the weld metal has a more negative potential than the base material, the weld is strongly destroyed, if it is more positive, the seam does not collapse, but the metal near the weld is destroyed [22, 23].

After detecting the base points on the metallographic image and its vectorization, the values characterizing the microstructure image segments are calculated. The calculated values of the sine and cosine of the segment elements of the metallographic image are the input data for the neural network. In addition, the input parameter is the Prewitt gradient of the base points [16].

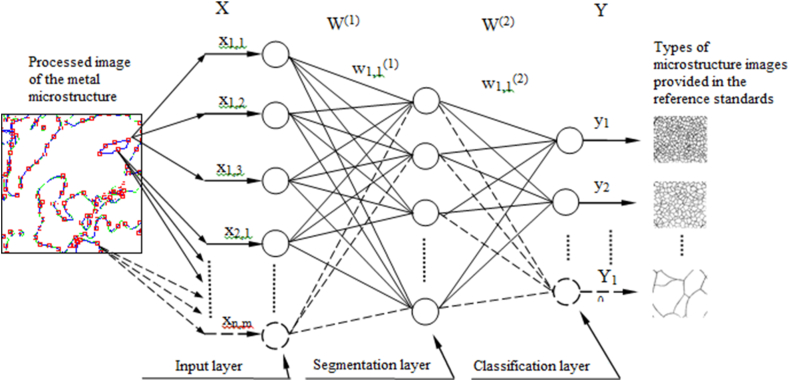

At the next operation, neural network processing of the received input values is performed with the segmentation of the metallographic image in the hidden layer to classify the metal characteristics. To process calculated values, one can use multilayer neural networks (a multilayer perceptron and a radial basis function network). The number of neurons in the input layer is calculated by multiplying by "3″ the base points number of the microstructure image (since one base point is characterized by 3 parameters: sine, cosine of the segment elements, and Prewitt gradient). The size of the output layer of the neural network is the number of metal grades to be classified.

The neural network structure for metallographic image classifying and for determining the metal quantitative characteristics is presented in Figure 2.

Figure 2.

The neural network structure for determining the metal quantitative parameters.

The backpropagation algorithm [17] to train neural networks was chosen. The mean-square error to assess the neural network classifying quality was calculated by the formula in paper [17].

The neural network was learnt on the basis of reference microstructure images described in the standards (GOST 8233-56, GOST 1778-70, ASTME1382, etc.). Examples of reference microstructure images of the steel grade 16GS(K01803) in accordance with GOST5520, which were used to train the neural network, are shown in Figure 3.

Figure 3.

Examples of reference microstructure images (Ratio Ferrite/Perlite) of the steel 16GS(K01803) from the training set.

The training sample consisted of 1100 microstructure images, of which 550 images of the "true" class and 550 images of the "false" class. Microstructure images belonging to the "true" class are a set of reference microstructure images (from GOST 8233-56, GOST 1778-70, ASTME1382, etc.). The "false" class is a set of reference images distorted by noise, which makes it possible to recognition of the incorrect metallographic images by the neural network. As a control sample, 450 metallographic images were used.

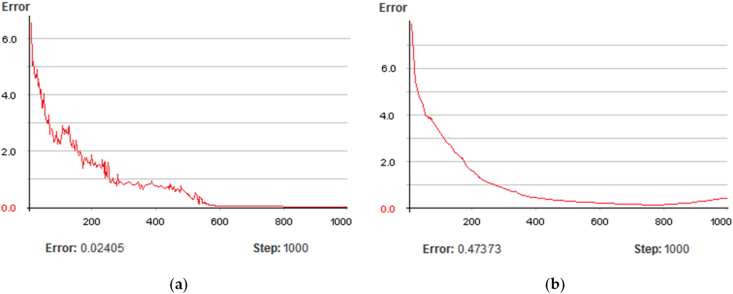

The multilayer perceptron to classify the metal grain point according to the GOST 5639-82 has the structure 550-150-10, i.e. 550 neurons in the input layer of the multilayer perceptron, 150 neurons in the hidden layer of the multilayer perceptron, 10 neurons in the output layer. Graphs of the value of the learning and classifying errors for a multilayer perceptron are presented in Figure 4. To prevent the retraining process of the neural network [18], the set of metallographic images is divided into 2 subsets, namely learning and control ones. Based on the error graphs, the optimal number of learning epochs for the multilayer perceptron with structure 550-150-10 was calculated. In this case, it was 800 epochs and the mean-square error was 0.01938. Totally 920 metallographic images were used as a test sample. Of these, 898 images were classified correctly according to GOST 5639-82.

Figure 4.

Graphs of the learning error (a) and classifying error (b) of the neural network.

The results of the created multilayer perceptrons to classify metallographic images and to determine the metal quantitative characteristics are shown in Table 1.

Table 1.

The results of the created neural networks to determine the metal quantitative characteristics.

| Standard and metal parameters | The neural network structure | Classifying error | Optimal number of the learning epochs | Total amount of the analyzed metallographic images | A number of correctly classifying metallographic images | |

|---|---|---|---|---|---|---|

| GOST 5639-82 | Grain amount | 550-150-10 | 0.0149 | 820 | 280 | 274 |

| GOST 8233-56 | Ratio Ferrite/Perlite | 400-110-10 | 0.0285 | 930 | 140 | 139 |

| Size of carbide network | 210-70-6 | 0.0319 | 900 | 210 | 202 | |

| GOST 1778-70 | Grade of line nitrides | 210-70-5 | 0.0119 | 780 | 153 | 144 |

| Grade of sulphides | 210-70-5 | 0.0098 | 890 | 186 | 173 | |

| ASTME 1382 | Size of ferrite grain | 480-140-19 | 0.0463 | 1320 | 289 | 277 |

At the next operation of the proposed algorithm, the metal grade is determined based on determined quantitative parameters and its chemical composition. The case-based reasoning approach was applied to solve the problem of determining a metal grade.

A base of precedents is creating regarding metals and their chemical composition. The algorithm to create the base of precedents consists of the 4 stages which is described in paper [19]. The experiments results of the metal grade determination based on the case-based reasoning approach are shown in Table 2.

Table 2.

The experiments results of the metal grade determination based on the case-based reasoning approach.

| Metal type | Metal parameters - Хі | The number of the precedent | Metal grade - the situation to be solved is ri |

|---|---|---|---|

| Structural Steel | 0.23С; 0.22Cr; 0.5Mn; 0.018S; 0.019P | 20 | 20пс(A 29 1020) |

| Structural Steel | 0.1С; 0.09Cr; 0.35Mn; 0.01S; 0.03P | 12 | 08кп(A 622) |

| Structural Steel | 0.2С; 0.24Cr; 0.6Mn; 0.02S; 0.02P | 19 | 20пс(A 29 1020) |

| Structural Steel | 0.12С; 0.09Cr; 0.38Mn; 0.02S; 0.027P | 13 | 08кп(A 622) |

| Structural Steel | 0.2С; 0.19Cr; 0.29Mn; 0.03Si; 0.03S | 7 | Ст3кп (A 107) |

| Structural Steel | 0.18С; 0.2Cr; 0.3Mn; 0.03Si; 0.04S | 6 | Ст3кп (A 107) |

| Structural Steel | 0.1C; 0.18 Si; 0.38 Mn; 0.02S; 0.03P | 4 | Ст1сп(A192 Gr A) |

| Structural Steel | 0.09C; 0.2 Si; 0.43 Mn; 0.03S; 0.03P | 3 | Ст1сп(A192 Gr A) |

Thus, it becomes possible to automatically determine the metal grade in accordance with metal quantitative characteristics (ratio Ferrite/Perlite, grain amount, etc.) and the known chemical composition.

5. Experimental studies of the developed software for automated metallographic analysis based on artificial intelligence technologies

To implement Operations 4, 5 and 6 of the previously proposed algorithm, the software has been developed (Figure 5). The functions of the developed software are as follows:

-

1)

function for setting by the user of the metallographic analysis type;

-

2)

function for formation of the metallographic image;

-

3)

function for preliminary processing of the metallographic image (binarization, Prewitt filter, vectorization);

-

4)

function for a quantitative estimate of the metal;

-

5)

function for a determination of the metal grade and its properties;

-

6)

function for a formation of an expert conclusion regarding the analyzed metal sample;

-

7)

function for sending the metallographic analysis results to the workshop;

-

8)

user possibility input of the base of reference metallographic images;

-

9)

function for a determination of the multilayer perceptron structure for the classifying of metallographic images;

-

10)

function for training a multilayer perceptron based on the reference metallographic images;

-

11)

function for saving the parameters of the learnt neural network and results of its functioning.

Figure 5.

Developed software for automated metallographic analysis.

To implement a case-based reasoning approach the expert system has been developed. The expert system includes the following subsystems (Figure 6).

-

1.

The subsystem for analyzing the problem situation, namely the main purpose of the subsystem is the formation of a set of input values based on the recognized image of the torpedo ladle car under study and its additional characteristics obtained. This subsystem is entrusted with the function of selecting the necessary methods for solving the current diagnostic situation with the torpedo ladle car under study in the process of its diagnostics.

-

2.

Intelligent subsystem of search for solutions, namely the main subsystem, which is assigned the functions of solving the current diagnostic situation with a torpedo ladle car, based on the implementation of a set of models and methods proposed by the authors in [1, 2]. Within the framework of this subsystem, it is proposed to use a case-based solution method [2] for those diagnostic situations in which all the necessary quantities are known for comparison with the reference state of a torpedo ladle car in various situations. If the system does not have the necessary input values, then it is proposed to use a neural network model to solve the current diagnostic situation with a torpedo ladle car.

-

3.

Subsystem of advice and explanations, namely a subsystem that is able, by means of an intelligent solution search subsystem, to offer advice or implement a solution to the task, i.e. derive a set of output values and a set of hypotheses for solving the current situation with a torpedo ladle car. At the same time, this subsystem is assigned the functions of supporting the solution of a diagnostic situation with a torpedo ladle car with various comments explaining the course of the reasoning.

-

4.

The subsystem of knowledge acquisition and system modification is designed to obtain and identify new knowledge, both from the user through the user interface and from the intelligent solution search subsystem after solving a new diagnostic situation with a torpedo ladle car. Also, this subsystem is assigned the function of modifying models and methods and the function of modifying the system. The implementation of these functions will allow changing the structure of the expert system depending on the specifics of the diagnosed object, which will make it easy to adapt the expert system for different types of torpedo ladle cars.

-

5.

The user interface is intended for the correct transmission of answers to the technologist in the process of diagnosing a torpedo ladle car in a form convenient for him or her and for manipulations with knowledge.

-

6.Information storage subsystem contains three components:

-

-database – it is designed to store quantitative information about mobile mixers

-

-base of precedents – it is designed to store a set of precedents used to solve a known situation with a torpedo ladle car;

-

-knowledge base – it is designed to store facts about the torpedo ladle car and the rules for their definition in the form of products.

-

-

-

7.

The subsystem of integration with external sources of knowledge is intended for the interaction of the expert system with different information systems, with the aim of obtaining new knowledge and adapting the system to a new production complex.

Figure 6.

Functional structure of the expert system.

In course of the study, the experiments were carried out to recognize metallographic images of different grades steels by developed software. The results of the metallographic analysis to determine the percentage of carbon in steel grade 10ChSND(S420N) are summarized in Table 3.

Table 3.

Results of image analysis for carbon content and determination of the structural component.

| Analyzed steel microstructures | Processing time, min | Structural component of the steel | Carbon, % (С) | Non-metal inclusions | Resistance to rupture, МPа |

|---|---|---|---|---|---|

|

0.22 | Ferrite and Perlite | 0.23 | Oxides (amount = 2) | 530 |

|

0.34 | Ferrite and Perlite | 0.55 | Oxides (amount = 3) | 550 |

|

0,27 | Ferrite and Perlite | 0.80 | Oxides (amount = 3) | 500 |

The results of recognition of images of microstructures of steel casings of the torpedo ladle cars created by neural networks are summarized in Table 4. Metallographic studies of the torpedo ladle car casings are carried out after they are transferred from the operating mode to the diagnostic mode in order to determine the current state of the metal from which their casing is made. In the case of torpedo ladle cars, non-destructive metallographic testing is applied using portable metallographic microscopes. The formation of metallographic images of torpedo ladle cars is carried out after the torpedo ladle cars are taken out of normal operation, which is explained by the possible high temperature of the surface of the ladle car casing, with which it is necessary to contact by the metallographic microscope. As shown in [2, 3], under the influence of high temperatures, the steel from which the torpedo ladle car casing is made changes its structure.

Table 4.

The results of the functioning of image recognition of microstructures of steel casings of torpedo ladle cars created by neural networks in the developed software.

| Neural network structure | Recognition Error | Optimal number of training epochs | Total amount of the analyzed alloy images | A number of correctly recognized images |

|---|---|---|---|---|

| 1500-500-100-10 | 0.943 | 2000 | 590 | 545 |

| 1500-500-500-50 | 1.384 | 2000 | 590 | 468 |

| 1000-300-140-20 | 0.883 | 2200 | 590 | 581 |

| 1000-600-280-30 | 0.994 | 2500 | 590 | 499 |

| 1200-300-100-20 | 1.141 | 3000 | 590 | 556 |

| 1200-600-280-30 | 1.294 | 3300 | 590 | 570 |

| 1100-400-150-20 | 1.141 | 3000 | 590 | 556 |

| 1100-450-180-30 | 0.784 | 2100 | 590 | 543 |

| 1100-600-200-50 | 0.971 | 2500 | 590 | 572 |

The use of these created neural networks makes it possible to recognize defects in the steel of the torpedo ladle car casings, thereby automatically determining its technical condition after exposure to high temperatures. Experiments have shown that the best neural network structure in this problem is the “1100-600-200-50”-structure.

The developed software has passed the testing stage at the Alchevsk Iron and Steel Works in the Central Works Laboratory. By means of the developed software, an experiment was carried out to recognize images of steel microstructures. The results of an assessment of the developed software functioning are shown in Table 5. The set of metallographic images to assess the developed software was 290 images.

Table 5.

Assessment of the developed software functioning at the Alchevsk Iron and Steel Works in the Central Laboratory.

| Metallographic Systems to compare | Average time of metallographic analysis (including image recognition), min | Deviation of grain parameters in the analyzed metallographic image,% |

|---|---|---|

| Ordinary (outdated) metallographic system without developed software | 18 | 5–10 |

| New metallographic analysis system with developed software (based on neural networks) | 5 | 3–4 |

| Metallographic systems (Videotest, SIAMS etc) | 7 | 5–8 |

The results of an experimental study of both systems in relation to the problem of determining the steel grain size are given in Table 6.

Table 6.

Experimental determination of the steel grain size using an ordinary system and a developed system.

| No. of the experiment | Ordinary metallographic analysis system without developed software |

Upgraded metallographic analysis system with developed software |

||

|---|---|---|---|---|

| evaluated grain size | real grain size | evaluated grain size | real grain size | |

| #1 (steel C 70W2) | 3 | 2 | 4 | 4 |

| #2 (steel C 70W1) | 5 | 6 | 5 | 5 |

| #3 (steel C 70W1) | 8 | 6 | 6 | 6 |

| #4 (steel A 622) | 2 | 4 | 6 | 4 |

| #5 (steel A 622) | 10 | 8 | 9 | 8 |

| … | … | … | … | … |

| #55 (steel S420N) | 9 | 8 | 9 | 9 |

| #56 (steel S420N) | 5 | 5 | 5 | 5 |

| #57 (steel S420N) | 6 | 6 | 6 | 6 |

| #58 (steel S420N) | 7 | 6 | 7 | 6 |

| #59 (steel S420N) | 8 | 6 | 8 | 8 |

| #60 (steel S420N) | 5 | 5 | 5 | 5 |

The experimental data in Table 5 indicate that in the proposed automated metallographic system in 96.7% of cases (58 out of 60) the value of the steel grain size was correctly calculated, and in the ordinary metallographic system (without proposed tools), it was done only in 89% of cases (96 out of 108).

6. Discussion

To assess the reliability of differences between the systems, a method for assessing the reliability of the results of a statistical study, based on the Student’s t-test, was used [21]. Determine the errors of representativeness and the number of degrees of freedom:

| (5) |

| (6) |

| (7) |

Determine the reliability of the difference between systems P1 and P2:

| (8) |

The value of t obtained in the experiment is greater than the tabular value of , therefore, the differences between P1 and P2 can be considered significant at p < 0.01. Thus, the reliability of the differences between options P1 and P2 suggests that the proposed automated metallographic system (with developed software) turned out to be more effective than the standard metallographic system in determining don’t of the main steel characteristic - steel grain size.

In the future, the proposed tools can be effectively used to assess a wide class of objects in the metallurgical industry, for example, to assess the metal state of the pipes, long steel products, etc. In addition, the developed algorithm and software can be used for metallographic testing of the ladle car hull to assess the current state of the metal from which their hull is made. In the case of ladle cars, non-destructive metallographic testing is applied using portable metallographic microscopes.

7. Conclusions

Due to corrosion damage to sea vessels, significant metal losses occur and, as a result, high economic costs for the elimination of these damage. The share of work on the elimination of corrosion damage accounts for 20–30% of the total cost of the ship’s factory repair approximately. During the operation of the ship, the crew does a lot of work to eliminate corrosion damage, especially in the areas of underwater sides, decks and superstructures, which also applies to corrosion costs. Dock repair of the ship can be attributed to the cost of corrosion elimination by at least 60%. Due to corrosion damage, frequent breakdowns and related repairs of many ship pipelines, pumps and ship structures occur. Taking into account the losses in the material, labor costs to eliminate the consequences of corrosion damage, it must be borne in mind that economic losses also include the cost of equipment that fails prematurely or is idle due to the destruction of individual parts and parts, so it is necessary to constantly look for sources of reduction these losses.

The general results of the study are:

-

1.

An algorithm for automated metallographic analysis of metals based on artificial intelligence technologies has been proposed. The proposed algorithm uses neural networks and the case-based reasoning approach, which allows for the adaptation of the proposed metallographic analysis tools for any enterprise.

-

2.

The expert system software was developed to recognize the metallographic images for determining the technical condition of torpedo ladle cars. Evaluation of the effectiveness of the developed expert system software demonstrated an increase in the efficiency of diagnostic operations, which is expressed in a decrease in the amount of time spent on diagnosing the state of torpedo ladle cars for individual indicators by 6 times. The developed software makes it possible to determine the grade and steel quantitative parameters (ratio Ferrite/Perlite, grain amount, etc.).

Declarations

Author contribution statement

Vitalii Emelianov: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Anton Zhilenkov: Performed the experiments; Wrote the paper.

Sergei Chernyi & Anton Zinchenko: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Elena Zinchenko: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work is partially supported by the Ministry of Science and Higher Education of the Russian Federation as part of World-class Research Center program: Advanced Digital Technologies (contract No. 075-15-2020-903 dated 16.11.2020).

Data availability statement

Data included in article/supp. material/referenced in article.

Declaration of interest’s statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Smallman R.E., Ashbee K.H.G. Elsevier; 2013. Modern Metallography: the Commonwealth and International Library: Metallurgy Division; p. 224. [Google Scholar]

- 2.Gordon Y., Kumar S., Freislich M., Yaroshenko Y. The modern technology of iron and steel production and possible ways of their development. Steel Translat. 2015;45(9):627–634. [Google Scholar]

- 3.Colpaert H. ASM International; USA: 2018. Metallography of Steels: Interpretation of Structure and the Effects of Processing; p. 699. [Google Scholar]

- 4.Martyushev N., Skeeba V. The method of quantitative automatic metallographic analysis. J. Phys. Conf. 2017;803:12094. [Google Scholar]

- 5.DeCost B.L., Holm E.A. A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 2015;110:126–133. [Google Scholar]

- 6.Bezyazychnyi V.F., Palamar’ I.N., Azikov N.S. Automation of analysis of the structure of a material with details based on controlled functional systems. J. Mach. Manufact. Reliab. 2020;49:341–346. [Google Scholar]

- 7.Wu W.-H., Lee J.-C., Wang Y.-M. A study of defect detection techniques for metallographic images. Sensors. 2020;20:5593. doi: 10.3390/s20195593. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Chen Dali, Liu Yang, Liu Shixin, Liu Fang, Chen Yangquan. Framework of specific description generation for aluminum alloy metallographic image based on visual and language information fusion. Symmetry. 2020;12:771. [Google Scholar]

- 9.Niezgoda S.R., Kanjarla A.K., Kalidindi S.R. Novel microstructure quantification framework for databasing, visualization, and analysis of microstructure data. Integrating Materials and Manufacturing Innovation. 2013;2(1):1–27. [Google Scholar]

- 10.Lin J., Ma L., Yao Y. Segmentation of casting defect regions for the extraction of microstructural properties. Eng. Appl. Artif. Intell. 2019;85:150–163. [Google Scholar]

- 11.Long J., Shelhamer E., Darrell T. Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA. 2015. Fully convolutional networks for semantic segmentation; pp. 3431–3440. [Google Scholar]

- 12.Azimi S.M., Britz D., Engstler M., Fritz M., Mücklich F. Advanced steel microstructure classification by deep learning methods. Sci. Rep. 2018;8:2128. doi: 10.1038/s41598-018-20037-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Ma B., Ban X., Huang H., Chen Y., Liu W., Zhi Y. Deep learning-based image segmentation for al-la alloy microscopic images. Symmetry. 2018;10:107. [Google Scholar]

- 14.De Albuquerque V.H., Silva C.C., Menezes T.I., Farias J.P., Tavares J.M. Automatic evaluation of nickel alloy secondary phases from SEM images. Microsc. Res. Tech. 2011;74:36–46. doi: 10.1002/jemt.20870. [DOI] [PubMed] [Google Scholar]

- 15.Vijayalakshmi D., Malaya Kumar Nath. Taxonomy of performance measures for contrast enhancement. Pattern Recogn. Image Anal. 2020;30:691–701. [Google Scholar]

- 16.Dougherty G. Springer; 2013. Pattern Recognition and Classification; p. 206. [Google Scholar]

- 17.Kenji S. InTech; 2013. Artificial Neural Networks: Architectures and Applications; p. 264. [Google Scholar]

- 18.Suresh Kumar P., Behera H.S., Anisha Kumari K., Nayak J., Naik B. Advancement from neural networks to deep learning in software effort estimation: perspective of two decades. Comput. Sci. Rev. 2020;38:100288. [Google Scholar]

- 19.Richter M.M., Weber R. Springer; 2013. Case-Based Reasoning; p. 546. [Google Scholar]

- 21.Toutenburg Helge, Shalabh . Springer; 2009. Statistical Analysis of Designed Experiments; p. 624. [Google Scholar]

- 22.Rodkina А., Ivanova O., Kramar V., Dushko V., Zhilenkov A., Chernyi S., et al. Simulation and selection of a protection types in the design stage of ships and offshore structures. Brodogradnja. 2022;73(2):59–77. [Google Scholar]

- 23.Yemelyanov V., Chernyi S., Yemelyanova N., Varadarajan V. Application of neural networks to forecast changes in the technical condition of critical production facilities. Comput. Electr. Eng. 2021;93:107225. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. material/referenced in article.