Abstract

The COVID-19 pandemic has resulted in unprecedented growth in the production and disposal of PPEs, face masks, gloves, face shields, and disinfectants. Daily consumption of masks and PPE has increased the plastic load on the municipality and very few plastics are taken to the recycling during the complete shut down during Covid-19. Plastic pollution is already a matter of concern that is increasing due to the negligence of humans. COVID-19 health crisis puts extra pressure on the regular waste management systems as increased daily consumption of single-use plastics around the world. It leads to the inappropriate management of waste; including mobile incineration, direct land-filling, and local burning of the waste. As the PPE kits and gowns are made of polypropylene plastic, they are non-biodegradable like any other plastics. Incineration and land-filling of plastics do not help them to degrade, even if it increases the number of pollutants in the form of microparticles.

In this paper, we discussed the research procedures to utilize the waste plastic specifically Covid-19 waste which is received from the health care clinics in Bituminous concrete for the construction of flexible roads. The main objective of the study was to investigate the effectiveness of the bituminous mix modified with Polypropylene gowns waste and to compare it with the conventional bituminous mix. This research concentrated on the Maximum Stability and Flow Value of the asphalt mixture with the waste. The measurements of the Plastic of 10%, 12.5%, 15%, 17.5 %, and 20% were utilized as substitutions for the bitumen binder in the mix. From the experimental investigation, it is concluded that the optimum bitumen content is found at 10% Plastic waste with 6.5 bitumen content. Bitumen properties also increase with the addition of PPE waste.

Keywords: COVID-19, Used PPE Kits, Bituminous mixes, Wet method, Marshall Stability Value

1. Introduction

Plastic has become a severe transboundary threat to natural ecosystems and human health but since the (COVID-19) Coronavirus disease 2019 outbreak in December 2019, there is a sudden boom in the average yearly consumption of plastic worldwide. Plastic waste generated during COVID-19 is vulnerable and highly contagious. These viruses are biologically active parasites that exist inside the host at a sub-microscopic level so the Physicians recommend the use of face masks, gowns, and face shields to prevent the spread of this deadly virus which overloads the capacity of each country or municipality, to manage and treat it adequately [1], [2].

Covid-19 medical waste is maximum plastic-based waste which can also be utilized in the flexible pavements with asphalt. Plastic roads are nothing new in India. The hot and humid climate of India is favorable to the durability of plastic roads. Different types of plastic eg. LDPE, HDPE, PET, PP, etc. have been used in asphalt pavements as a substitution for bitumen [3], [4]. This will helps the safe disposal of the plastic through its use as an additive in nature without causing much damage [5].

Covid-19 medical Plastic waste includes PPE kits, Aprons, Face masks, Face shields, goggles, gloves, long-sleeved gowns, sanitizer bottles, etc. The waste coming from the hospitals directly may contain pathogens (bacteria, viruses, parasites, or fungi) and inadequate solid waste management increased the spread of the virus. Used PPE kits by the healthcare workers in clinics and hospitals are brought in double-layered medical bags wearing hand gloves and following the instructions strictly to avoid the transmission of the virus. As the medical waste response during Covid-19 aggravated the present plastic pollution and had so many negative impacts on the environment. Re-using the PPE medical waste with bitumen in the construction of flexible pavement will not only reduce the Bio- medical waste management load but also helps in the safe consumption of the plastics in nature.

1.1. SARS-Cov-19

Coronavirus is single stranded RNA virus that is divided into four critical genera. A Coronavirus (SARS-COV-2) is one of these viruses that cause an infection in your nose, sinus, or upper throat which further causes respiratory tract infection [6]. It was first identified as a respiratory illness case in Wuhan City, China. On January 30, 2020, the WHO (world health organization) declared the COVID-19 outbreak a global health emergency and on March 11, 2020, it is declared a global pandemic.The use of face masks, face shields, and goggles to avoid touching the nostrils becomes mandatory.

1.1.1. Plastic during SARS-Cov-19

Plastic made a comeback as the life savior in Covid-19 because of its inherent properties. Plastics have contributed immensely to the healthcare sector and public health safety during the pandemic. Plastic became the first choice to avoid direct contact with the virus in the form of face shields, goggles, polypropylene gowns, suits, etc. The plastic barrier for Office Desk and Windows provides physical distance among people. Plexiglass is made up of poly (methyl methacrylate) or PMMA and is a transparent thermoplastic often used as an alternative to glass are widely used.

In India, the amount of medical waste generation is increased from 550–600 kg/day to 1000 kg/day at the time of the first phase of the Covid-19 in the city near Ahmadabad. The waste generated during the sampling of the suspected covid-19 patients, diagnosis, treatment of a huge number of patients, and disinfection purposes lot of biomedical waste and infectious waste is generated (syringes, cotton swabs, needles, bandages, used tissues, and discarded medicines, etc.). Pandemic Covid-19 leads to increases in patient and healthcare activities, one of the effects is on the quantity and composition of the medical waste in the landfill.

1.1.2. Use of PPE

PPE (Personal Protection Equipment) is used by healthcare professionals and workers to stop the risk of transmission as it covers the exposed body parts. The main aim of the PPE (gloves, goggles, medical suit, aprons, and masks) is to protect the mucous membrane in the eyes, nose, and mouth from infective droplets. The workers are exposed to many types of hazards that can be prevented or minimized by using PPE properly. This garment consists of impermeable material which helps against the absorption of blood and other body fluids. Since the outbreak of coronavirus, billions of gloves and protective masks are being disposed of every day on a global scale. To curb the spread, healthcare workers are mandated to wear PPE and the government has ordered people to wear a mask everytime they go in public places.

The PPE is formed with different kinds of materials like Low-density polyethylene (LDPE), high-density polyethylene (HDPE), Polyethylene Terephthalate (PET), and Polypropylene (PP), Polycarbonate, and Polystyrene (PS). Wearing the PPE (Personal Protection Equipment) has proven the life savior, throughout the pandemic [7].

2. Experimental program

2.1. Materials

2.1.1. Aggregates

Aggregates alone cover the major portion of any construction structure in the form of both Course and Fine aggregates, so play an important role in the construction of the bituminous pavement. Traffic loads are transferred by the wearing surface to the underlying supporting materials through the interlocking of aggregates, the frictional effect of the granular materials, and the cohesion of the fine materials in flexible pavements. The Course and fine aggregates are brought from the locally available crusher and checked for their strength and durability before employing them in the investigation works. Hence, all the MORTH and IRC recommended tests for size determination, Impact value, Crushing value and abrasion values are carried out on aggregate samples. Minimum 10–20 mm coarse aggregates and 2.36 mm sieve passed fine aggregates are used for Marshall Test. Aggregates are chosen based on their strength and toughness to withstand the repeated impacts. Following are the test results for the aggregates used for experimental programs (Table 1 ).

Table1.

Physical Properties of Aggregates.

| Property of the aggregate | IS specification | Test Result |

|---|---|---|

| Specific Gravity | 2.5–3.0 | 2.7 |

| Aggregates Crushing Value | Max 30% | 13.96% |

| Aggregates Impact Value | Less than 30 | 7.94% |

| Los Angeles Abrasion Value | Max 40% | 17.84% |

| Water Absorption | 1 | 0.352% |

2.1.2. Filler

The filler used is the Ordinary Portland cement of grade 53 which was brought from a local shop. It is passed from a 75-µm sieve during the sieve test. It is used to fill the voids, stiffens the binder, and offer permeability. The specific gravity of cement used is 3.12.

2.1.3. Bitumen

Bitumen is the residue or by-product when the crude petroleum is refined through a straight distillation process or solvent extraction process etc. In this study, the bitumen of grade (40/50) penetration was selected for all tests, which is available from the local refinery. Bitumen or asphalt are extensively used for roadway or highway construction, primarily because of their excellent binding properties. Bitumen is a black or dark-colored solid or viscous substance that consists of high molecular weight hydrocarbons derived from the distillation of petroleum or natural asphalt, has adhesive properties, and is soluble in carbon disulphide [8], [9], [10]. Following are the tests performed in a laboratory to assess the properties of bituminous materials.

-

•

Specific Gravity test IS 1202–1978

-

•

Penetration test IS 1203–1978.

-

•

Ductility test IS 1208–1978.

-

•

Softening point test IS 1205–1978 (Table 2 )

Table 2.

Physical Properties of Bitumen.

| Property of the Bitumen | Test Result |

|---|---|

| Specific Gravity | 1.006 |

| Penetration | 44.33 mm |

| Ductility | 91 mm |

| Softening point | 53° |

2.1.3.1. Tests on bitumen with the varying plastic percentage

A penetration test, softening point, ductility test, and specific gravity test on the bitumen with varying proportion of 10%, 12.5%, 15%, 17.5%, and 20% is conducted and the test results are mentioned below (Table 3 ):

Table 3.

Bitumen properties with plastic variation.

| Plastic Proportion | Specific Gravity test | Penetration test | Ductility Test | Softening point test |

|---|---|---|---|---|

| 10% PPE waste | 1.09 | 62 mm | 18 mm | 57° |

| 12.5% PPE waste | 1.08 | 60 mm | 16 mm | 74° |

| 15% PPE waste | 1.005 | 78 mm | 19 mm | 64° |

| 17.5% PPE waste | 1.90 | 76 mm | 14 mm | 80° |

| 20% PPE waste | 1.70 | 84 mm | 15 mm | 84° |

From the test results, it is clear that the addition of PPE plastic has greatly affected the bitumen properties. The softening point of the bitumen is increased with the increased plastic percentages, it shows that plastic mixed bitumen can be used in the hot regions. The penetration value of the bitumen also varies with the proportion affecting the grade of bitumen. The specific gravity of the bitumen also varies but the ductility value becomes lower with an increase in plastic. Hence, the plastic mixed flexible pavement may easily develop cracks in its surface course.

2.1.4. Plastic waste

Plastic waste used in this study was brought from the nearby healthcare clinics. Waste was collected in separate double-layered bags wearing gloves with taking all the preventive measures to keep any hazard away. The lifespan of the virus on the surfaces depends on various factors like Humidity, surrounding Temperature, and the type of the surface. The estimated time of their survival on plastic surfaces is upto3days so the bags are left untouched for 7 days to avoid any risk of contamination. After that, bags were put into the direct sunlight for the natural disinfection and spraying it with the solution of the 70% alcohol sanitizer. Following this procedure, PPE kits are then used in the experimental investigation. PPE kits are cut into small pieces of 5–8 cm with the help of a shredding machine.

2.2. Methodology

Bitumen is the key ingredient in every road construction. Asphalt pavements are more adopted than rigid or concrete pavements as they provide better durability and sound life to the road. On the asphalt courses, bituminous concrete is more commonly used. In Bituminous concrete, the mix design for the proportions is firstly designed as per the guidelines provided by MORTH.

2.2.1. Mix design

The main purpose of the mix design is to achieve sufficient workability without any segregation and long last perpetuala pavement avoiding premature cracking due to traffic loads. Mix design for the Marshall method is done precisely before employing it in the testing. The bitumen in the mix is taken 5, 5.5,6, 6.5,7, and the quantity of bitumen is excluded in gm to the total weight of the aggregates taken, which is 1200 gm. Mix design aims to provide sufficient workability to permit easy placement without the segregation, sufficient air voids in the compacted bitumen, and sufficient strength to resist shear deformation under traffic at a higher temperature (Table 4 , Fig. 1 ).

Table 4.

Gradation of aggregate for the Marshall test.

| Aggregates size | Quantity taken |

|---|---|

| 12.5 mm aggregate | 100 gm |

| 10 mm aggregate | 144 gm |

| 4.75 mm aggregate | 204 gm |

| 2.36 mm aggregate | 198 gm |

| 1.18 mm fine aggregate | 488 gm |

| Filler material | 108 gm |

Fig. 1.

(a) Aggregates used; (b) Shredded Plastic used.

2.2.2. Detail of mix proportion

Five samples are prepared for each proportion. In this research work, 5–7% of bitumen content for the conventional mix was prepared. The mix proportion for the conventional mix with 10%, 12.5%, 15%, 17.5%, and 20% of squander plastics added as the replacement of binder. The test specimen is prepared with varying increments of 2.5% which gives a well-defined Marshall value of the specimen for stability and density. The specimen is the size of the cylinder with a dimension (of 7.5 × 10) cm. The size of the mould is the standard size that is used in the Marshall Stability test. In this project total of 30 cylinders are made.

2.2.3. Mixing of plastic

The wet method is adopted for the process. Squander plastic was shredded into small pieces and a certain percentage of plastic is blended in with the bitumen. Ordinarily, mixing happens when the temperature arrives at 45.5 °C however at the point when plastic is blended, it stays stable even at 55 °C. Plastic expands the dissolving point of the bitumen and causes the street to hold its adaptability during winters bringing about its long life. The bitumen was first heated to its liquid form at the temperature ranges between 110 °C and 130 °C. PPE waste of desired proportion is then added to the hot bitumen. Bitumen sticks to the shredded PPE (Garment) as it is made of woven polypropylene. Continued stirring is required at the time of mixing for the homogeneous mixture. Plastic started to melt into the bitumen as the temperature rises to 140–150 °C. A red scum (layer) is started to float over the bitumen-plastic mix but with the continued stirring into the mix, it starts to disappear leaving a consistent mix as shown in the Fig. 2 (b). The covering of the total with plastic was completed in the open skillet at a controlled temperature of around 165–175 °C. The bitumen was warmed to this temperature and afterward, the destroyed plastic was splashed in a controlled way (Temp.Controlled) to ensure that plastic don't get isolated as the size of the plastic utilized was not fine.

Fig. 2.

(a) Thin layer of plastic in Bitumen; (b) Homogenously mixed into the Bitumen.

2.2.4. Preparation of samples

The strength of the pavement was determined by using the Marshall Stability test machine with a cylinder of size 7.5 cm × 10 cm. Initially, oil is applied to the mould to ease de-moulding before casting. Thorough mixing of materials is essential for the production of a uniform course. Initially, the Bitumen is heated to the temperature of 110–130 °C then PPE plastic waste is added to make the homogeneous mix. After that oven-dried aggregates and fillers are mixed thoroughly at adequate temperature and mix them properly for a good mixture. The mixture is poured into the mould and compaction is done to expel the entrapped air into the mixture and to lessen the air voids. The sample is taken out of mould after 24hrs.

3. Testing program

Marshall Stability test is used in designing and evaluating bituminous paving mixes and is extensively used in routine paving jobs. There are two major features of the Marshall method of designing mixes namely, density–voids analysis and stability–flow test. Strength is measured in terms of Marshall Value and is defined as the maximum load carried by a compacted specimen at a standard test temperature of 60 °C. In this test compressive loading was applied to the specimen at the rate of 50.8 mm/min till it was broken. The deformation at the failure point is expressed in units of 0.25 mm and called as Marshall Flow value of the sample.

The waste plastic content of 10, 12.5, 15, 17.5, and 20% is added to check the effect of the plastic replacement on Marshall and the flow values of the test specimen. Marshall, VMA, VFB, density, flow value, and air voids values show the behavior of plastic variation in bitumen and compare it, with the conventional mix specimen with 0% addition. Table for values of Marshall and flow are given below (Table 5, Table 6, Table 7, Table 8, Table 9, Table 10 ):

Table 5.

Conventional Mix results (0%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 284 | 0.54 | 2.261 | 11.78 | 10.36 | 22.14 | 46.78 |

| 2 | 5.5 | 257.28 | 0.69 | 2.270 | 10.80 | 11.39 | 22.19 | 51.32 |

| 3 | 6 | 215.82 | 1 | 2.254 | 10.82 | 12.27 | 23.10 | 53.14 |

| 4 | 6.5 | 198.64 | 0.75 | 2.262 | 9.82 | 13.30 | 23.12 | 57.52 |

| 5 | 7 | 179.92 | 0.41 | 2.252 | 9.67 | 14.18 | 23.86 | 59.44 |

Table 6.

Sample results with (10%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 270.9 | 1.25 | 2.296 | 9.78 | 10.52 | 20.30 | 51.80 |

| 2 | 5.5 | 304.11 | 1.31 | 2.21 | 12.26 | 11.12 | 23.38 | 47.57 |

| 3 | 6 | 215.82 | 0.44 | 2.18 | 13.15 | 11.87 | 25.03 | 47.44 |

| 4 | 6.5 | 198.64 | 0.95 | 2.28 | 8.47 | 13.40 | 21.88 | 61.26 |

| 5 | 7 | 179.92 | 1.65 | 2.30 | 6.81 | 14.53 | 21.35 | 68.07 |

Table 7.

Samples result in (a 12.5%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 254.4 | 0.92 | 2.11 | 16.95 | 9.68 | 26.64 | 36.34 |

| 2 | 5.5 | 300 | 1.06 | 2.19 | 13.09 | 11.02 | 24.11 | 45.69 |

| 3 | 6 | 245.64 | 1.19 | 2.16 | 13.76 | 11.79 | 25.55 | 46.14 |

| 4 | 6.5 | 285 | 0.79 | 2.16 | 13.27 | 12.70 | 25.97 | 48.90 |

| 5 | 7 | 300 | 1.46 | 2.24 | 9.41 | 14.13 | 23.54 | 60.02 |

Table 8.

Samples result with (15%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 226.86 | 0.69 | 2.13 | 15.97 | 9.79 | 25.77 | 38.02 |

| 2 | 5.5 | 333.54 | 0.93 | 2.16 | 14.28 | 10.86 | 25.15 | 43.20 |

| 3 | 6 | 142.8 | 0.68 | 2.08 | 17.04 | 11.34 | 28.38 | 39.96 |

| 4 | 6.5 | 433.92 | 1.76 | 2.23 | 10.25 | 13.14 | 23.40 | 56.17 |

| 5 | 7 | 329.96 | 1.14 | 2.21 | 10.66 | 13.93 | 24.60 | 56.35 |

Table 9.

Samples result in (17.5%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 480.2 | 2.56 | 2.18 | 13.99 | 10.03 | 24.02 | 41.74 |

| 2 | 5.5 | 258 | 1.48 | 2.15 | 14.91 | 10.78 | 25.70 | 41.97 |

| 3 | 6 | 504 | 2.03 | 2.23 | 11.00 | 12.17 | 23.17 | 52.51 |

| 4 | 6.5 | 429 | 2.28 | 2.23 | 10.45 | 13.11 | 23.57 | 55.64 |

| 5 | 7 | 400 | 1.56 | 2.19 | 11.36 | 13.82 | 25.19 | 54.87 |

Table 10.

Samples result with (20%) Plastic Addition.

| Sr. no. | Bitumen Content | Stability Value | Flow value | Bulk Density Gm | Air void (%) Vv | Bitumen (%) Vb | VMA (%) | VFB (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 254.4 | 2.56 | 2.17 | 14.47 | 9.97 | 24.44 | 40.80 |

| 2 | 5.5 | 300 | 1.70 | 2.20 | 12.66 | 11.07 | 23.74 | 46.64 |

| 3 | 6 | 245.64 | 1.80 | 2.21 | 11.78 | 12.06 | 23.85 | 50.58 |

| 4 | 6.5 | 369 | 1.43 | 2.23 | 10.18 | 13.15 | 23.34 | 56.37 |

| 5 | 7 | 310 | 1.30 | 2.2 | 11.19 | 13.85 | 25.04 | 55.30 |

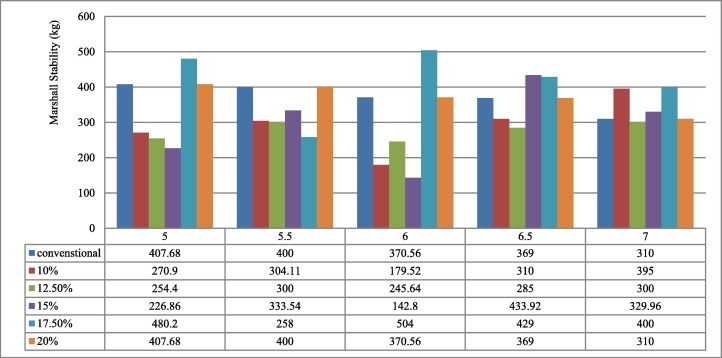

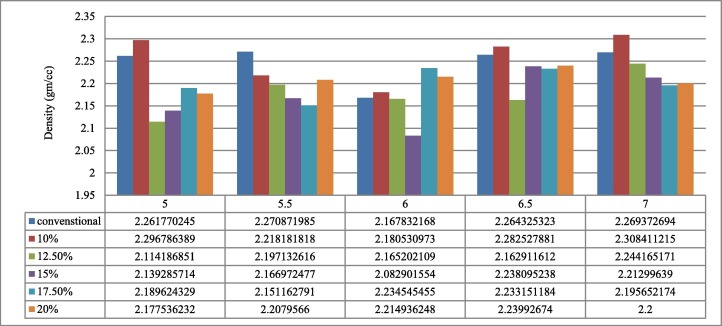

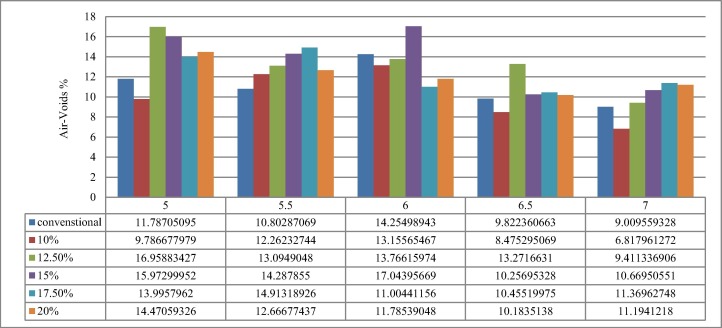

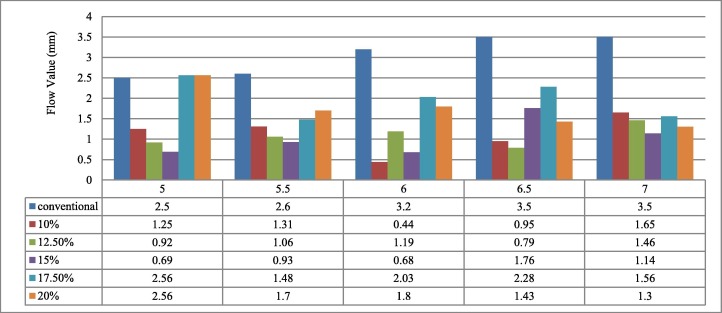

Graphs show results for plastic replacement with Marshall Value, Air voids, Density, and Flow value as follows (Fig. 3, Fig. 4, Fig. 5, Fig. 6 ).

Fig. 3.

Bitumen Content with Plastic V/s Marshall Stability.

Fig. 4.

Bitumen Content with Plastic v/s Density.

Fig. 5.

Bitumen Content with Plastic v/s Air Voids.

Fig. 6.

Bitumen Content with Plastic v/s Flow Value.

4. Conclusion

Air-Void content present in the bituminous mix is limited to 3% as specified by MORTH; below the specified limit the mix becomes plastic and unstable. The addition of the 15% PPE plastic into the bitumen content 6 increases the void content to the maximum.

Voids in mineral aggregates (VMA) and VFB is seen to increase more than the conventional mix at bitumen content 6, with 15% PPE waste in bitumen. On the other hand, VFB content is 10% at bitumen content 7.

-

1.

A decrease in flow value (%) is noted with the increased plastic content.

-

2.

The volumetric and Marshall property of the mix is in acceptable trends satisfying the MORTH limits.

-

3.

The use of waste plastic in bituminous concrete is safe and sustainable for roadconstruction.

-

4.

Marshall Stability value is increased in plastic mixed bitumen than conventional mix with 0% addition and bitumen with 10% waste plastic exhibits better results.

-

5.

The optimum bitumen content is observed at 6.5 with 10% plastic addition, hence the use of plastic is recommended.

-

6.

From the lab investigations, it is observed that with the increase of the PPE-Plastic waste, properties of the bitumen including penetration, softening point, and specific gravity also increased.

-

7.

Use of the waste plastic in flexible pavements shows good results as compared with conventional pavements.

-

8.

Helps inthe Safe disposal of Covid-19 waste sustainably, without causing harm to the environment and society.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

No data was used for the research described in the article.

References

- 1.S. Bhattacharjee, Statistical Investigation of Relationship Between Spread of Coronavirus Disease (COVID-19) and Environmental Factors Based on Study of Four Mostly Affected Places of China and Five Mostly Affected Places of Italy arXiv2003.11277v1 [Preprint]. [cited 2020 March 24], 2020. Available from: https://arxiv.org/abs/2003.11277.

- 2.Abad F.X., Pintó R.M., Bosch A. Survival of enteric viruses on environmental fomites. Appl. Environ. Microbiol. 1994;60(10):3704–3710. doi: 10.1128/aem.60.10.3704-3710.1994. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Swami Vidula, Abhijeet J., Karan P. Use of waste plastic in the construction of bituminous road. Int. J. Eng. Sci. Technol. 2012;4(5):1–5. [Google Scholar]

- 4.Sultana S.K., Prasad K.S.B. Utilization of waste plastic as a strength modifier in surface course of flexible and rigid pavements. Int. J. Eng. Res. Appl. 2012;2(4):1185–1191. [Google Scholar]

- 5.Yadav A. Use of waste plastic in flexible pavement construction – A case study. Imperial J. Interdisc. Res. (IJR) 2016;2(9) ISSN: 2454-1362. [Google Scholar]

- 6.Muthuraman Y., Lakshminarayanan I. A review of the COVID-19 pandemic and its interaction with environmental media. Environ. Challenges. 2021;3:100040. doi: 10.1016/j.envc.2021.100040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Parashar N., Hait S. Plastics in the time of COVID-19 pandemic: Protector or polluter? Sci. Total Environ. 2021;759:144274. doi: 10.1016/j.scitotenv.2020.144274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.IRC (Indian Road Congress) IRC; New Delhi, India: 2009. IRC: 111: Specifications for Dense Graded Bituminous Mixes. [Google Scholar]

- 9.BIS (Bureau of Indian Standard) BIS; New Delhi, India: 1978. IS 1203-1978: Indian Standard specifications and guidelines for testing of properties of bitumen. [Google Scholar]

- 10.BIS . BIS; New Delhi, India: 1981. IS 1209–1981: Indian Standard specifications and guidelines for testing of flash and fire point of bitumen. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.