Abstract

The growing global concern with sustainability has driven companies to rethink their business model and seek new ways to operate and face this challenge. Industry 4.0 (I4.0) has shown itself capable of contributing to the development or reformulation of organizational processes to make them more competitive and sustainable. Thus, this article aims to propose drivers for the development of corporate sustainability via I4.0. To this end, a literature review and content analysis were used as research methods to identify and analyze, in recent scientific literature, boosting elements that enable organizational processes to become more sustainable via I4.0. Based on these elements, six drivers were systematized and proposed: strategy; product and process design; energy and material resources; people; smart production; and supply chain. Each driver was discussed in light of the scientific literature to generate recommendations for companies to develop the economic, social, and environmental dimensions of sustainability. The main theoretical-scientific contribution of this work is the deepening and expansion of the knowledge block that articulates corporate sustainability with I4.0, which strengthens the basis for the development of new research on these topics and creates a reference for the analysis and discussion of empirical studies. As an applied-managerial contribution, the drivers proposed in this work will provide organizations and their managers with a point of reference to effectively move towards sustainability, making their businesses greener, fairer, and more profitable. A limitation of this study is that the proposed drivers were based on the 30 most cited articles and did not consider other sources, such as documentation from companies. Therefore, for future studies, we suggest increasing the article base and include organizational repositories and identify how SMEs can become sustainable through I4.0 in a way that strengthens the social dimension of sustainability.

Keywords: Industry 4.0, Corporate sustainability, Triple bottom line, Technologies

Industry 4.0; Corporate sustainability; Triple bottom line; Technologies.

1. Introduction

The growing commitment of companies to sustainable development has made corporate sustainability (CS) an integral part of business strategy and processes. This strategy seeks to meet the demands of stakeholders and, especially, to satisfy customers, who are increasingly attentive to the quality of the product or service and the environmental and social commitment made by companies (Engert et al., 2016; Saeidi et al., 2021). As a result, many companies are rethinking the way they do business and developing strategies for the sustainable management of their supply chain and product life cycle (Formentini and Taticchi, 2016). In addition, the prospect of offering sustainable products and services creates an opportunity for differentiation and market segmentation that meets the demands of “green” consumers (Baumgartner and Rauter, 2017). CS can be defined as sustainability applied to the business context, with a meaning more appropriate and applicable to business, management, and operations. It is usually associated with the economic, social, and environmental dimensions, known as the triple bottom line (TBL) (Engert et al., 2016; Nunhes et al., 2020). Actions based on the TBL can bring real growth to companies from a holistic perspective, considering their impacts and interrelationships. However, it is necessary for all three dimensions to be taken into account so that one (or two) does not prevail over the other(s) (Formentini and Taticchi, 2016; Hahn et al., 2015).

Given the need for companies to address the economic, social, and environmental dimensions and thus contribute to sustainable development, Industry 4.0 (I4.0) emerges as an alternative to help them manage sustainability issues (Munsamy and Telukdarie, 2019). In this context, I4.0 has stood out due to the opportunities it offers companies to boost economic performance while contributing to the enhancement of human capital, promoting improvements in working conditions, and reducing the environmental impact of processes (Manavalan and Jayakrishna, 2019; Stock and Seliger, 2016). I4.0, also known as the Fourth Industrial Revolution, can be defined as the integration of technologies such as the Internet of things (IoT), cloud computing, and big data, among others, to create digital solutions and connect the physical and virtual worlds (Li et al., 2018; Roblek et al., 2016; Santos et al., 2017; Zhong et al., 2017).

Müller et al. (2018) asserted that digitized and connected processes are transforming companies in relation to relying on intelligent and autonomous operations. I4.0 allows the development of systems capable of creating a business dynamic that connects the company with its stakeholders and, especially, with its consumers. Furthermore, through digital technologies, it is possible to capture data that allow consumer habits and consumer profiles to be defined, generating opportunities for mass customization (Luthra and Mangla, 2018; Strange and Zucchella, 2017). I4.0 and its technologies boost the vertical and horizontal integration of production systems, improving interoperability and increasing productivity. This is possible thanks to Internet-based connections, which allow complex processes to be managed in an agile manner and in real-time (Stock and Selinger, 2016). I4.0 has the potential to boost the sustainability of companies and their supply chain, as its technologies enable increased productivity and improved social and environmental well-being (Luthra and Mangla, 2018). Therefore, it is necessary to evaluate the current scenario, look to the future, and draw strategies that aim to align I4.0 technologies with sustainable development goals (Bonilla et al., 2018).

CS and I4.0 have been widely discussed in the academic community. As a result, a wide field of research in these areas has been developed. Some scientific works have been undertaken that address CS and I4.0 together. For example, Kiel et al. (2017) analyzed the implications of I4.0 for sustainability and proposed a framework relating the economic, social, and environmental benefits achieved via I4.0. Stock et al. (2018) evaluated the potential contribution of I4.0 to sustainable development with an emphasis on the social and ecological dimensions, the results of which revealed positive and negative impacts in both assessed dimensions. Luthra and Mangla (2018) analyzed the challenges in achieving supply chain sustainability via I4.0, concluding that organizational challenges were the most frequent within the sample investigated, followed by technological, strategic, legal, and ethical challenges. Haseeb et al. (2019) investigated the role of I4.0 in promoting sustainable business performance in small and medium-sized enterprises (SMEs) and evidenced that big data and the IoT have the greatest relevance for CS; they also stressed that the organizational structure must provide the necessary support for the implementation of these technologies. Ghobakhloo (2020) identified and analyzed the roles of I4.0 in relation to sustainability and concluded that the economic dimension is the first to be positively impacted by I4.0, paving the way for contributions focused on environmental and socio-economic sustainability.

These studies have presented relevant evidence on the impacts of I4.0 on CS. However, this topic offers research opportunities because many companies still face difficulties in developing and operationalizing sustainability (Tjahjadi et al., 2021). This has been corroborated by Ejsmont et al. (2020), who, when performing a bibliometric analysis to verify the impacts of I4.0 on CS, found that, although the literature provides an essential contribution to this field of knowledge, no studies were identified that presented propositions that should be adopted during the transition process to a sustainable business model via I4.0. Therefore, this work aims to fill this scientific gap, deepening and extending the studies mentioned above by formulating propositions with practical implications that will guide companies towards sustainability. Thus, the research question that guided this work is: How can I4.0 concepts and technologies help develop sustainability in companies? To answer this question, the objective of this work is to propose drivers for the development of CS via I4.0. The drivers are aimed at companies of all sizes and types of activities in the transition towards sustainability.

After this introduction, Section 2 presents a synthesis of the theoretical framework that encompasses Sustainability, Industry 4.0, and the relationship between these two themes; Section 3 describes the research method and the methodological flow with its steps; Section 4 presents the boosting elements of sustainability via I4.0. Section 5 proposes the drivers for the development of sustainability via I4.0; Section 6 discusses the relationship of the drivers and their axes with the TBL dimensions; and Section 7 presents the conclusion, suggests future research, highlights the limitations of the work, and presents the theoretical-scientific and applied-managerial contributions. Finally, the references and the Appendix are presented.

2. Theoretical background

2.1. Corporate sustainability (CS)

In 1987, the World Commission on Environment and Development (WCED) created the concept of sustainable development. This concept was detailed in the Brundtland Report, which stated that it is essential to achieve the needs of the present without compromising future generations to come up with its own needs (WCED, 1987). Since then, the term sustainability has spread throughout public and private management (Brozzi et al., 2020; Nunhes et al., 2021). Studies have sought to understand how, in the business sector, the different industrial, commercial, and service processes negatively impact the environment and society. This is because many companies extract natural resources beyond the planet's regeneration capacity, causing a decrease in biodiversity and intensifying air pollution (Oláh et al., 2020).

For productive activities to preserve the environment and improve social well-being, Elkington (1998) proposed the TBL. This concept integrates three dimensions corresponding to the values and results of an organization, measured in social, environmental, and economic terms (Elkington, 1998). The TBL aims to expand the organizational horizons beyond the economic dimension, adding the environmental and social dimensions into the corporate structure (Jayashree et al., 2021; Nunhes et al., 2021). The environmental dimension focuses on the balance between high consumption rates and limited natural resources, covering actions such as recycling, regeneration, or the substitution of non-renewable resources for renewable ones, adopting the circular economy, implementing cleaner environmental strategies for production, etc (Campos et al., 2020; Espuny et al., 2021). The social dimension values organizational culture that aims to preserve and develop the company's human capital and considers job satisfaction, quality of life, solidarity, and the fairer distribution of goods and services (Lozano et al., 2016; Saeidi et al., 2021). The economic dimension relates to increasing the added value of goods and services, improvements in management processes and investments in innovation and technology, and initiatives that help improve the company's position in the market and its profits (Braccini and Margherita, 2018; Martinez-Conesa et al., 2017).

These three dimensions of the TBL provide the pragmatic basis for integrating corporate sustainability (CS) into the company's strategic management. At the same time, it brings out the statement that what is good for society will not necessarily be unfavorable for the company, just as what is suitable for the company should not necessarily represent a burden to society (Engert et al., 2016). CS can be defined as the systematic treatment of economic, environmental, and social issues in an interconnected and interdependent manner at different company levels (Hahn et al., 2015; Nikolaou et al., 2019). It is considered the normative foundation for the integration of sustainability at the strategic level in the company (Martinez-Conesa et al., 2017). Thus, organizations have sought to integrate CS into their business strategy, making their contributions to society effective.

2.2. Industry 4.0 (I4.0)

With the emergence of industrialization, technological innovation has acquired a permanent space in companies and led to revolutions in industry. After the successive industrial revolutions and their technological advances since the 18th century, in the first decade of the 21st century, the Fourth Industrial Revolution, also known as Industry 4.0 (I4.0), emerged. Its main characteristics are the digitalization and connection of equipment and devices, which has allowed the creation of intelligent networks and the monitoring of independent and autonomous production modules (Lu, 2017; Oesterreich and Teuteberg, 2016; Siddoo et al., 2019). I4.0 encompasses technologies that can have physical characteristics (such as additive manufacturing or sensors) or digital ones (such as cloud computing, big data, and simulation) (Bai et al., 2020; Bigliardi et al., 2020; Bortolini et al., 2017), among which we highlight those considered in the present study (see Table 1).

Table 1.

Key enabling technologies for I4.0.

| Technology | Definition |

|---|---|

| Additive manufacturing | Process of manufacturing objects from a digital prototype that deposits layer upon layer of specific materials, such as plastic, metal, ceramics, etc., mainly employing 3D printers (Bortolini et al., 2017; Ceruti et al., 2019; Santos et al., 2017; Sepasgozar et al., 2020). |

| Artificial intelligence (AI) | Computer discipline that aims to model or simulate so-called “intelligent human behaviors” such as perception, decision-making, understanding, learning, etc. This concept represents the digital brain of I4.0 and is its driving force (Lee et al., 2018). |

| Augmented reality | A set of technologies that allows the visualization of the natural environment “augmented” by the addition of computer-generated elements or objects. It includes essential components such as display or capture devices, interaction devices, and tracking systems (Bottani and Vignali, 2019; Li et al., 2018). |

| Autonomous robots | Machines that perform tasks without human intervention in different environments. Autonomous robots can make decisions that are not previously programmed, solve problems, and manage unpredictable situations (Bigliardi et al., 2020; Ingrand and Ghallab, 2017). |

| Big data | A system that gathers a large amount of structured, semi-structured, and unstructured data generated by different sources, such as equipment controllers, manufacturing systems, sensors, people, files, video, audio, etc. It identifies patterns and models that allow the generation of useful information for sustainable innovation and assists in decision making (Lee et al., 2015; Santos et al., 2017). |

| Blockchain | Dataset consisting of a chain of data packets (blocks) where one block comprises multiple transactions. It can contain multiple blocks that represent the complete record of the transaction history. Blocks can be validated over the network securely using cryptographic means (Nofer et al., 2017). |

| Cloud computing | Technology that allows the loading and storage of data and information, using the memory capacity, storage, and calculation of computers and servers hosted in datacenters interconnected via the Internet. Cloud computing enables access to applications on different platforms, such as IaaS, PaaS, SaaS, without them being installed on devices such as computers, cell phones, tablets, etc. (Liu and Xu, 2017; Wang et al., 2016a, Wang et al., 2016b). |

| Cyber-physical system (CPS)/cyber-physical production system (CPPS) | Industrial automation systems into which natural and human systems (physical space) have been integrated employing sensors, microprocessors, ports, antennas, and software so that they can work together, sharing and analyzing information with the support of big data and cloud computing (Lasi et al., 2014; Lee et al., 2015; Lu, 2017; Müller et al., 2018; Vaidya et al., 2018). |

| Cyber security | Procedures, practices, and the use of technologies that aim to ensure digital security against illicit acts and damage to computers, data, programs, and networks. It acts in the digital environment to prevent and impede the rerouting of information, unauthorized access to systems, modification of data, etc. (Culot et al., 2019; Rubio et al., 2018; Sawik, 2020). |

| Internet of things (IoT)/industrial Internet of things (IIoT)/Internet of services (IoS) | Network of interconnected and cooperative devices that follow a standard communication protocol for exchanging data with other devices and systems over the Internet. These devices range from everyday household objects to sophisticated industrial tools (Bortolini et al., 2017; Mosterman and Zander, 2016; Wang et al., 2016a, Wang et al., 2016b). |

| Simulation | Virtual reproduction of processes that include machines, people, and operational functions. Simulation allows one to test and study new methods and means of production before implementing them, making them more innovative and efficient (Rodič, 2017; Schluse et al., 2018; Vieira et al., 2018). |

There is a set of eleven core technologies involved in the Fourth Industrial Revolution, which are called Key Enabling Technologies (KETs) (EC, 2021) (see Table 1). These technologies can have physical characteristics (such as additive manufacturing or robots) or digital ones (such as cloud computing, big data, and simulation) (Bai et al., 2020; Bigliardi et al., 2020; Bortolini et al., 2017).

In the context of I4.0, many of these technologies are innovative and disruptive because they allow organizations to change the way projects, production systems, and services are managed. The connectivity and interaction between machines and people make processes more efficient and effective because the information is transmitted throughout the system, allowing better control of operations and their rapid adaptation when demand variation occurs (Ganzarain and Errasti, 2016; Moeuf et al., 2018).

2.3. Relationship between corporate sustainability (CS) and Industry 4.0 (I4.0)

I4.0 brings a new perspective for companies, as it represents an opportunity to develop fully digitalized, connected, intelligent, and decentralized value chains while improving the social and environmental conditions of the business (Brozzi et al., 2020; De Sousa Jabbour et al., 2018; Kang et al., 2016; Kiel et al., 2017). In addition, I4.0 technologies contribute to strategic management and sustainable operations by integrating systems that enable data collection and sharing (Man and Strandhagen, 2017; Stock and Seliger, 2016). I4.0 can support CS by addressing social, environmental, and economic development needs (Bonilla et al., 2018).

Among the opportunities for the development of CS via I4.0, the following stand out: the introduction of advanced technologies for products and project portfolio management to design and produce smart products in the best way in relation to social, economic, environmental, and ethical aspects (Bibaud-Alves et al., 2019); the reduction of the carbon footprint at each of the stages that make up the supply chain, observed after the implementation of I4.0 technologies and CS elements (Bag et al., 2018); the creation of a digital platform to continuously engage with consumers and collect real-time data to respond to their sustainability requirements; and enhancing workers’ skills and knowledge in new intelligent, creative environments enabled by I4.0 (Dachyar et al., 2019).

However, in addition to the opportunities that I4.0 offers for CS, there are also challenges for companies to overcome (Reis et al., 2021), including, to name but a few: the high cost of changing the traditional organizational structure or the acquisition of structures and equipment related to the implementation of I4.0 technologies, especially for SMEs (Bag et al., 2018; Ghobakhloo, 2020; Kiel et al., 2017); job losses due to process automation and IIoT training difficulties, which can create a negative impact on the operational workforce (Bag et al., 2018; Kiel et al., 2017); and insecure access to data, predisposing companies to cybercrime and industrial espionage (Kiel et al., 2017). To overcome these challenges, it is essential that the company's top executives and senior management have training and experience in information management in order to develop strategies capable of achieving the three dimensions of sustainability via I4.0 (Kiel et al., 2017; Tjahjadi et al., 2021).

Although it is necessary to deal with some challenges inherent to the transformation process of the company towards CS via I4.0, there are an increasing number of arguments regarding the benefits and the promising scenario involving changing the business model (Dantas et al., 2021). For example, regarding the social dimension of sustainability, I4.0 technologies can contribute to less physical effort and aid in the decision-making process (Braccini and Margherita, 2018; Stock et al., 2018); regarding the environmental dimension, I4.0 can contribute to the rational use of energy and non-renewable resources (Müller et al., 2018); and finally, regarding the economic dimension, automation, digitalization, and the increased connectivity of the value chain leads to reduced costs, improved delivery times, enhanced quality, increased productivity, and increased revenues for companies (Braccini and Margherita, 2018).

I4.0 represents a means of transforming companies and presents new technological possibilities, such as information and communications technologies (ICTs) and automation, which communicate with each other to achieve optimal performance. In this context, CS represents the contribution of companies to improving the quality of life in society and the prosperity of the planet. Therefore, it is valid to consider these two elements as the industry's foundations, acting concomitantly to enhance their benefits (Jayashree et al., 2021).

3. Research method

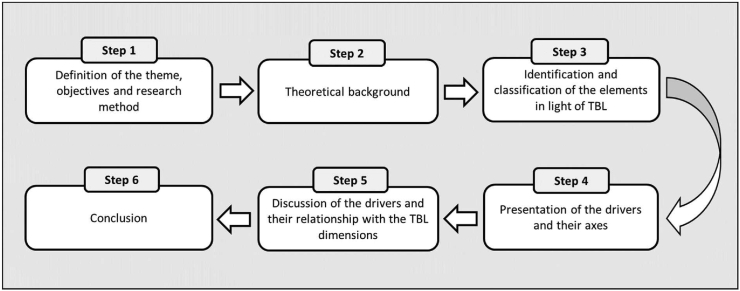

In this section, the methodological flow and the phases of the development of this article is detailed (see Figure 1).

Figure 1.

Methodological flow.

3.1. Preparation phase

In Step 1, the key elements necessary for the elaboration of this work were established, i.e. the definition of the theme, objectives, and research method. The potential of the topic was realized through a search undertaken in the Scopus database, an interdisciplinary database that covers abstracts and citations from the peer-reviewed literature in the area of management and CS (Nunhes et al., 2020). This search revealed that the opportunity to propose and discuss drivers and their boosting elements in relation to the implementation of sustainability in companies via I4.0 had not been explored, thus indicating a gap in the scientific literature. Subsequently, the objectives of the work were defined, followed by the definition of the research approach and method. Accordingly, this theoretical study follows a qualitative approach developed by using the literature review and content analysis methods.

Step 2

began with the selection of the documents to be used in the literature review and the content analysis. To search for these documents, the authors used the following search query: ((title (“Corporate Sustainability”) or title (“Business Sustainability”) or title (“Sustainable Management”) or title (Sustainability) or title (“Sustainable Development”) and title (“Industry 4.0”) or title (“Smart Factory”) or title (“Smart Manufacturing”) or title (“Digital Technologies”)) and pub year >2015. In addition, English-language articles and reviews were prioritized since it is the most widely used language in science, and the period between 2016 and 2021 was used because, during this period, the published works incorporated the latest developments in this field of knowledge. After applying these filters, the search resulted in 128 documents, from which the 30 most cited articles were prioritized, considering them as the most influential in the literature on the topic (see the Appendix). The theoretical framework was elaborated from these 30 articles, and, when necessary, other authors were added to support the fundamental concepts underpinning the development of this work.

3.2. Organization phase

In Step 3, the authors identified the boosting elements of sustainability via I4.0 in the 30 most cited articles. At this stage, the content analysis method was used. This method identifies and describes the important phenomena contained in the analyzed documents, whose results are concepts and categories that describe and allow analyzing the phenomenon (Xia et al., 2018). Content analysis can be performed using inductive and/or deductive approaches, and in this study, the authors performed both of them. The inductive analysis is used when the knowledge about a particular theme is still fragmented. Thus, considering that the initial stages of theoretical consolidation on CS and I4.0 applied jointly are still very scattered, inductive analysis was adopted to contribute to the consolidation of the integration of these two themes. Information was obtained directly from the textual data during inductive content analysis. This content needed to be analyzed in-depth to methodically identify the drivers of sustainability in companies via I4.0. There is no standardized way to perform inductive content analysis. Therefore, the reliability of this analysis can be evidenced by the quality of the description and execution of the phases of preparing, organizing, and reporting, as recommended by Elo et al. (2014). They are described respectively in steps 1 and 2; 3 and 4; and 5 and 6.

While reading the articles, elements were identified from patterns that were repeated and presented contributions to the theme of the work. After this systematic process of identifying patterns that gave rise to the elements, alphanumeric coding was used to assist in their representation. Then, codes related to content that had similar meanings were reviewed, recoded, and merged to become a single element. The coding was used to reference the elements in all subsequent analyses of the study. Finally, 44 elements were assigned identifiers from E1 to E44 and were arranged in decreasing frequency of occurrence in the articles, as shown in Table 2.

Table 2.

Elements for developing sustainability via I4.0.

| Item | Elements | TBL | Most cited articles (2016–2021) ordered from 1 to 30 |

Freq. | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | ||||

| E1 | Use IIoT, AI, and CPPSs to increase production efficiency and flexibility by interconnecting devices and processes and developing modular production in order to achieve benefits such as the efficient use of resources and reduced carbon emissions. | EC/EN | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 22 | ||||||||

| E2 | Design and develop an intelligent platform that promotes greater integration among supply chain members to increase communication, data sharing, flexibility, and productivity. | EC | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 20 | ||||||||||

| E3 | Integrate I4.0 technologies with more sustainable economic models, such as the circular economy, the sale of physical products combined with new services, and/or the sale of functionality and product accessibility instead of selling the tangible product, offering more value to the customer. | EC/EN/SO | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 18 | ||||||||||||

| E4 | Implement sensors and software to share data in real-time, plan production, and monitor resource consumption, waste generation, machine efficiency, and inventory control, which positively affect costs and profits. | EC/EN/SO | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 18 | ||||||||||||

| E5 | Create intelligent systems for monitoring energy consumption in real-time and replanning costs related to this type of consumption. | EC/EN | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 17 | |||||||||||||

| E6 | Use I4.0 technologies and principles to drive vertical and horizontal integration of production systems to shorten lead times and improve interoperability and productivity. | EC | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 16 | ||||||||||||||

| E7 | Use additive manufacturing to produce parts with lower cost, less waste generation, and longer life cycle so that they can be repaired or recovered more easily, without being replaced or removed. | EC/EN | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 15 | |||||||||||||||

| E8 | Implement an intelligent system to perform talent selection/acquisition, training, and career development, and create continuous learning programs on new knowledge and capacity development related to sustainability and I4.0. | SO | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 15 | |||||||||||||||

| E9 | Use autonomous robots to perform repetitive and dangerous tasks or those that demand a high physical load, improving workers' health and safety. | SO | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 15 | |||||||||||||||

| E10 | Include in the organizational strategy the transition to I4.0 considering the planning, purchase, implementation, and management of digital technologies in light of sustainability. | EC/EN/SO | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 14 | ||||||||||||||||

| E11 | Design smart products that use I4.0 technologies to monitor their life cycle by tracking, collecting, and analyzing data that contribute to the circular economy and greenhouse gas reduction. | EC/EN | x | x | x | x | x | x | x | x | x | x | x | x | x | x | 14 | ||||||||||||||||

| E12 | Collect data via the internet of people (IoP) to interact with customers, analyze data, identify consumption patterns, and replan products, aiming for customization. | EC/SO | x | x | x | x | x | x | x | x | x | x | 10 | ||||||||||||||||||||

| E13 | Networking machines to improve the detection of quality failures, seeking to reduce rework, rejection, material consumption, and failure rates. | EC | x | x | x | x | x | x | x | x | x | x | 10 | ||||||||||||||||||||

| E14 | Deploy intelligent cameras and sensors and AI-based tracking systems to detect and report any human or machine behavior that could threaten worker safety. | SO | x | x | x | x | x | x | x | x | x | x | 10 | ||||||||||||||||||||

| E15 | Use I4.0 technologies to perform process simulations to reduce energy consumption and improve product life cycle management, including recycling. | EN | x | x | x | x | x | x | x | x | x | 9 | |||||||||||||||||||||

| E16 | Use I4.0 technologies to inform, raise awareness, and carry out satisfaction surveys, among other actions, to improve the organizational climate. | SO | x | x | x | x | x | x | x | x | x | 9 | |||||||||||||||||||||

| E17 | Plan qualification for digital work gradually, aiming to minimize the negative impact of I4.0 on workers, such as the stress caused by the need for more skills in information and communication technologies and a high degree of flexibility. | SO | x | x | x | x | x | x | x | x | x | 9 | |||||||||||||||||||||

| E18 | Improve the practical learning of workers via intelligent systems with a better human-machine interface, promoting greater productivity and job satisfaction. | EC/SO | x | x | x | x | x | x | x | x | x | 9 | |||||||||||||||||||||

| E19 | Use I4.0 technologies to achieve the UN's Sustainable Development Goals (SDGs), generating opportunities for sustainability. | EC/EN/SO | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| E20 | Adopt global data-sharing standards and protocols so that systems coupled with intelligent mechanisms can act effectively and communicate freely, promoting the sustainability of the organization's business. | EC | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| E21 | Use I4.0 technologies to develop preventive and predictive maintenance processes to extend equipment lifetime, ensure the health and safety of employees, and promote environmental management (prevention of leaks, increased use of biodegradable products, more efficient use of energy, etc.). | EC/EN/SO | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| E22 | Use intelligent equipment that can create more favorable conditions for efficient water consumption. | EN | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| E23 | Use I4.0 in logistics to optimize the volume and flow of materials, reduce the number of wrong deliveries, waiting times, logistical costs, and gas emissions from transport. | EC/EN | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| E24 | Create online platforms for sharing data between companies and stakeholders to exchange experiences and create transparent business ecosystems. | EC | x | x | x | x | x | x | x | 7 | |||||||||||||||||||||||

| E25 | Use I4.0 to design and manufacture sustainable products, improving the company's image, profitability, and market share. | EC/EN | x | x | x | x | x | x | x | 7 | |||||||||||||||||||||||

| E26 | Develop an intelligent tracking and data-protection system to ensure cyber security in a technical and administrative environment. | EC | x | x | x | x | x | x | x | 7 | |||||||||||||||||||||||

| E27 | Use I4.0 technologies to operate decentralized distribution centers close to where the products will be consumed, reducing logistics costs and environmental impacts. | EC | x | x | x | x | x | x | x | 7 | |||||||||||||||||||||||

| E28 | Use I4.0 technologies to manage industrial symbiosis, a strategy that interacts with different industrial companies to share and reuse waste, raw materials, energy, or effluents, resulting in mutual benefits from an economic and environmental point of view. | EC/EN | x | x | x | x | x | 5 | |||||||||||||||||||||||||

| E29 | Use blockchain technology (closed network and protected by encryption) to increase the reliability of the supply chain, providing accurate, reliable, and real-time data to stakeholders. | EC/SO | x | x | x | x | x | 5 | |||||||||||||||||||||||||

| E30 | Integrate digital technologies into logistical processes for monitoring disposal and the use/reuse of packaging. | EN | x | x | x | x | x | 5 | |||||||||||||||||||||||||

| E31 | Replace or modernize parts and software with newer versions of manufacturing machines (retrofit) to save material and energy, and to increase productivity. | EC/EN | x | x | x | x | 4 | ||||||||||||||||||||||||||

| E32 | Provide augmented reality glasses for performing complex cognitive tasks to improve safety, job satisfaction, and productivity. | EC/SO | x | x | x | x | 4 | ||||||||||||||||||||||||||

| E33 | Use I4.0 technologies to support decision-making, as I4.0 enables the systematization and analysis of data that will assist in more proactive decisions in manufacturing management, also benefiting triple bottom line issues. | EC/EN/SO | x | x | x | 3 | |||||||||||||||||||||||||||

| E34 | Use the IoT, IoS, and advanced simulation software for virtual prototyping to customize and simulate the production line. | EC | x | x | x | 3 | |||||||||||||||||||||||||||

| E35 | Use I4.0 technologies in resource-reuse management platforms to drive the shift towards zero waste. | EN | x | x | x | 3 | |||||||||||||||||||||||||||

| E36 | Conduct audits to identify gaps such as cyber vulnerability and crisis management strategy that hinder the transformation and maintenance of the new business model based on I4.0. | EC | x | x | 2 | ||||||||||||||||||||||||||||

| E37 | Use I4.0 technologies to enable access to sustainability reports supported by environmental management accounting without human interference, avoiding the practice of greenwashing (misleading advertising). | EC/EN/SO | x | x | 2 | ||||||||||||||||||||||||||||

| E38 | Use I4.0 technologies to improve waste management, providing savings in financial resources, environmental protection, and better health and safety for workers. | EC/EN/SO | x | x | 2 | ||||||||||||||||||||||||||||

| E39 | Apply digital twin and AI models to plan the synchronized production of custom products. | EC | x | x | 2 | ||||||||||||||||||||||||||||

| E40 | Implement digital tools for the automatic pre-processing of production data so that they are filtered, combined, included, or disregarded to facilitate their use by workers. | SO | x | x | 2 | ||||||||||||||||||||||||||||

| E41 | Carry out and monitor production in real-time through the use of smart portable terminals (tablets, smartphones, etc.). | SO | x | x | 2 | ||||||||||||||||||||||||||||

| E42 | Use the RFID system to identify, track, inspect and monitor products in real-time, improving their quality and increasing production efficiency. | EC | x | 1 | |||||||||||||||||||||||||||||

| E43 | Use I4.0 technologies to improve equipment performance, reducing idle time and energy consumption, contributing to sustainability. | EC/EN | x | 1 | |||||||||||||||||||||||||||||

| E44 | Use I4.0 technologies to implement the self-optimization of production and logistics to increase availability, reduce costs, and reduce the consumption of resources. | EC | x | 1 | |||||||||||||||||||||||||||||

Notes:(1) TBL = triple bottom line; EC = economic; EN = environmental; SO = social. (2) The "x" marks the occurrence of the elements (described in the second column) in the articles (ordered from 1 to 30). (3) "Freq." corresponds to the sum of the occurrence of each element identified in the analyzed articles.

Elements that transcend the universe of companies and that encourage the development of sustainability via I4.0 were also identified and given alphanumeric identifiers (from TH1 to TH8). These elements are related to the triple helix (TH), as shown in Table 3. These elements are proposed to encourage the development of innovation and sustainability in companies.

Table 3.

Elements related to the triple helix.

| Item | Elements | TH | Most cited articles (2016–2021) ordered from 1 to 30 |

Freq. | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | ||||

| TH1 | Create public policies that subsidize the acquisition and use of I4.0 technologies to reduce environmental impacts, such as waste generation. | G/C | x | x | x | x | x | x | x | x | x | x | 10 | ||||||||||||||||||||

| TH2 | Develop agreements between research institutes and universities with governments to encourage inter-organizational learning and between universities and companies to transfer intellectual property. | G/C/A | x | x | x | x | x | x | x | x | 8 | ||||||||||||||||||||||

| TH3 | Create smart factories and technology parks through financing and tax benefits. | G/C | x | x | x | x | x | x | x | 7 | |||||||||||||||||||||||

| TH4 | Create public policies that provide tax subsidies for acquiring I4.0 technologies that enable the development of eco-friendly products. | G/C | x | x | x | x | 4 | ||||||||||||||||||||||||||

| TH5 | Reduce trade barriers to encourage the import and export of I4.0 technologies. | G/C | x | x | 2 | ||||||||||||||||||||||||||||

| TH6 | Review government legislation to reduce cyber vulnerabilities and protect the confidentiality and integrity of public and private data. | G/C | x | 1 | |||||||||||||||||||||||||||||

| TH7 | Strengthen cooperation between government agencies and companies to obtain resources for acquiring I4.0 technologies. | G/C | x | 1 | |||||||||||||||||||||||||||||

| TH8 | Support I4.0 technological innovations through government actions, helping to promote their insertion in the market. | G/C | x | 1 | |||||||||||||||||||||||||||||

Notes: (1)TH = triple helix; G = government; C = company; A = academy. (2) The "x" marks the occurrence of the elements (described in the second column) in the articles (ordered from 1 to 30). (3) "Freq." corresponds to the sum of the occurrence of each element identified in the analyzed articles.

As already mentioned, deductive analysis was also performed. This type of analysis relies on a pre-existing framework, concepts, or theories for analysis and since the theory on the economic, social, and environmental dimensions of TBL are already well defined and structured in the literature, the process of classifying the elements within these dimensions meets the requirements of deductive content analysis (Xia et al., 2018). Therefore, in this work, the elements previously identified during inductive analysis were classified according to these dimensions through deductive content analysis to verify how these same elements impact the operationalization of TBL dimensions in companies. Finally, the percentage of the elements was calculated in each dimension to figure out if there was an imbalance between them.

In step 4, categorization was performed, i.e., the creation of categories (drivers) and subcategories (axes) as recommended by Moldavska and Welo (2017) for studies using content analysis. So, the elements were clustered by similarity in six drivers, each with its set of boosting elements for the development and operationalization of sustainability via the precepts and technologies of I4.0. Next, to facilitate readers' understanding and discussion of the drivers in light of the theory, the elements were sub-grouped by the similarity of themes within each driver, which led to the creation of "axes" (Moldavska; Welo, 2017).

3.3. Reporting phase

In step 5, the discussion emphasizes the importance of the equilibrium between the three dimensions of sustainability in the proposed drivers. By looking at the percentages presented, it is possible to observe that the social dimension has a lower proportion in relation to the economic and environmental dimensions. Thus, in order to contribute to minimize this inequality, some social aspects identified in articles other than the 30 initially selected were added. Thus, new searches for articles and reviews published between 2016 and 2021 on the SCOPUS platform were conducted with the aim of identifying new elements that complemented the social dimension of the TBL. To this end, the following queries were used:

-

-

For the "governance" axis of the driver "strategy: (title-abs-key ("corporate strategy" or "business strategy" or "corporate management") and title-abs-key (sustain∗) and title-abs-key ("Industry 4.0″) and title-abs-key (social)) and pubyear >2016 and (limit-to (doctype, "ar") or limit-to doctype,"re"));

-

-

For the "input management" axis of the "energy and material resources" driver: (title-abs-key (resource or input) and title-abs-key (sustain∗) and title-abs-key ("Industry 4.0″) and title-abs-key (social)) and pubyear >2016 and (limit-to (doctype, "ar") or limit-to (doctype,"re"));

-

-

For the "production planning" axis of the "smart production" driver: title-abs-key (production and planning) and title-abs-key (sustain∗) and title-abs-key ("Industry 4.0″) and title-abs-key (social)) and pubyear >2016 and limit-to (doctype, "ar") or limit-to (doctype,"re")); and

-

-

For the "logistics monitoring" axis of the "supply chain" driver: (title-abs-key ("supply chain") and title-abs-key (sustain∗) and title-abs-key ("Industry 4.0″) and title-abs-key (social)) and pubyear >2016 and (limit-to (doctype, "ar") or limit-to (doctype,"re")).

This new search allowed the identification of four complementary elements with social characteristics, which were inserted in Section 6, in their respective drivers and axes for discussion.

In Step 6, conclusions were drawn, highlighting the filling of the research gap, the answering of the research question, and the achievement of the objectives. In addition, the scientific-theoretical and applied-managerial contributions of this work were summarized. Future studies to expand and deepen the results presented in this paper were also suggested.

Assessing the reliability of qualitative research is a process with a high burden of subjectivity (Xia et al., 2018). Nevertheless, as recommended by Elo et al. (2014), how the content analysis process in this study was described and justified ensures its reliability, as the authors demonstrated the relationship between the textual data and the results achieved. Therefore, the way the process was conducted can be repeated in the future and the results obtained are considered reliable.

4. Boosting elements of sustainability via I4.0

The growing concern with sustainable corporate development makes I4.0 a relevant factor for business transformation towards sustainability (De Sousa Jabbour et al., 2018). Therefore, with the objective of helping companies in this development, 44 boosting elements were identified in the 30 most cited articles aiming to make organizational processes more sustainable via I4.0. These elements received numerical identifiers (items 1 to 44; see Table 2) and were arranged from highest to lowest frequency according to their appearance in the articles (ordered from 1 to 30). The elements were analyzed from the standpoint of the three dimensions of the TBL.

The elements classified as economic (27% of the total elements) aim to improve the organizations' processes via I4.0 technologies. These technologies can drive the vertical and horizontal integration of production systems, network machines, increase end-to-end supply chain integration, provide mass customization, etc (Braccini and Margherita, 2018; Luthra et al., 2020; Varela et al., 2019). CPS and IoT-related elements have been identified that enable real-time data exchange, which enables decreased response time in decision-making, better supply chain management, reduced lead times, and increased flexibility in operations (Beier et al., 2020; Birkel et al., 2019; Oláh et al., 2020). Thus, these elements reduce production costs, increase process efficiency and effectiveness, and improve the organization's logistics.

The elements classified as social (16%) are related to actions to improve the organizational climate, working conditions, employee satisfaction, and occupational health and safety. Elements were identified, for example, that refer to the use of networked tablets and smartphones to improve the employee learning process in new tasks, as well as the use of virtual simulation software to facilitate the understanding and analysis of information, enabling more assertive decision-making (Braccini and Margherita, 2018). I4.0 technologies can boost both social sustainability related to employees’ quality of life and that of the community in which the company is embedded, or society in general (Bai et al., 2020). However, in the analysis of the selected articles, no elements were identified that considered actions to be undertaken by companies focusing on community development via I4.0.

The elements classified as environmental (9%) are related to actions that aim to mitigate adverse environmental impacts from production processes and the life cycle of products. The use of I4.0 technologies such as IIoT and AI, for example, enables increasing the efficiency and flexibility of production, thus contributing to the efficient use of resources, reduced energy and water consumption, and decreased carbon emissions (Bonilla et al., 2018; Müller et al., 2018). Elements were identified that refer to the adoption of digital technologies in logistics processes as a way to encourage the development of reverse logistics. The transparency of data in the supply chain helps monitor material flows and the disposal, use, and reuse of packaging and other waste, minimizing the negative impacts they cause to the environment (Garcia-Muiña et al., 2019). Overall, these elements make the company produce in a more environmentally efficient way, manage its supply chain in real-time, and contribute to the achievement of UN's SDGs 9 and 12 (Bai et al., 2020; Bonilla et al., 2018; Oláh et al., 2020).

The elements classified as economic and environmental simultaneously (21%) encompass the use of software and intelligent systems in the design phase to develop more sustainable products and processes and monitor their life cycle. In this way, organizations can increase their production performance, improve energy efficiency, and decrease the amount of non-renewable natural resources used for production (Birkel et al., 2019; Luthra and Mangla, 2018; Müller et al., 2018).

The elements classified as economic and social simultaneously (9%) concern technological solutions that increase the organization's economic performance and its network of partners while promoting workers' safety, health, and satisfaction. Technologies such as blockchain, for example, can encrypt and make real-time information available to companies in a supply chain, helping to increase its reliability and effectiveness. Technologies such as augmented reality glasses and intelligent human-machine interface systems can improve productivity, promote greater safety, and facilitate worker learning (Ghobakhloo, 2020; Müller et al., 2018; Stock et al., 2018).

The elements classified as economic, environmental, and social simultaneously (18%) refer to actions related to all three dimensions of the TBL. The identified elements suggest the circular economy as a path for developing sustainable business strategy, fostering the transition from the linear model to the circular model. The adoption of I4.0 technologies is also suggested for managing the supply chain and production cycle, as well as to improve worker safety, energy efficiency, and waste management. These elements consist of using digital technologies to support decision-making by enabling the systematization and analysis of data efficiently. In this way, organizations can elaborate their planning in an integrated manner at all levels, establishing actions that include I4.0 technologies to advance sustainability (Bonilla et al., 2018; Brozzi et al., 2020).

The classification of the elements according to the TBL, and their frequency, revealed a small imbalance among the three dimensions of sustainability, with a greater weight for the elements related to the economic dimension (27%) compared to the elements related to the social (16%) or environmental (9%) dimensions when considered separately. Thus, the authors suggest that future studies develop research that strives for this balance between the three dimensions in order to promote the development of sustainability in companies in a more equitable way.

In addition to identifying the boosting elements based on the TBL, the analysis of the articles allowed the identification of eight elements related to the triple helix capable of positively impacting companies that are seeking the development of sustainability through the implementation of I4.0 technologies. These elements have more circumstantial characteristics since they refer to actions that result from the collaboration among government, companies, and academia in the sense of encouraging technological development in the pursuit of sustainability. This trilateral collaboration, known as the triple helix, is a model proposed by Professors Leydesdorff (University of Amsterdam) and Etzkowitz (Stanford University) with the goal of creating conditions for knowledge capitalization and innovation development (Kalenov and Shavina, 2018; Scalia et al., 2018) and that can contribute to the development of CS.

In this more circumstantial context, the eight identified elements were organized in Table 3 according to their frequency of appearance in the 30 most cited articles and classified according to the entities of the triple helix.

The seven elements classified as government and company simultaneously refer to actions that result from collaboration between governments and companies to enable the creation of technology parks and the development of I4.0 technologies that contribute to sustainable development. In this sense, elements were identified that suggest the following initiatives: the creation of public policies that aim to fiscally or financially subsidize the acquisition of I4.0 technologies that enable the reduction of environmental impacts, such as waste generation, and the development of eco-friendly products (TH1, TH3, TH4, TH7); the review of government legislation to reduce cyber vulnerabilities and thus ensure the safety, security, and sustainability of the supply chain network (TH6); and government support for the development of technological innovations and their insertion in the market by reducing import and export tariffs for I4.0 technologies, which contributes to the economic sustainability of firms (TH5, TH8) (Bag et al., 2018; Fatimah et al., 2020; Lin et al., 2017).

The one element (TH2) classified as government, company, and academia simultaneously refers to the collaboration among governments, companies, and academia and aims to foster the implementation of I4.0 in companies with a focus on sustainable development. Thus, this element proposes the establishment of agreements between these three sectors to promote: the improvement of products and processes through next-generation digital technologies; the acceleration of the development of green technologies; inter-organizational learning; and the transfer of intellectual property (Furstenau et al., 2020; Lin et al., 2017).

This section presented 44 boosting elements of corporate sustainability via I4.0 (Table 2) and 8 elements related to the triple helix (Table 3). As shown in the tables, some of these elements occur much more frequently than others in the analyzed articles (ordered from 1 to 30), as is the case of element E2 (Table 2), which, compared to element E44 appears 20 times more frequently. Similarly, element TH1 (Table 3), when compared to element TH8, appears with a frequency 10 times higher. According to the information presented in these two tables and the analyses performed on the articles, one can see that it is practically a consensus among researchers and practitioners in the area that the elements with the highest frequency are the most relevant. Taking as an example the boosting elements in Table 2, we highlight the following: E1 suggests adopting I4.0 technologies at the stage when processes are designed so that planning, operations, and equipment can become autonomous and reliable. E2 complements this direction and suggests that project development should also consider platforms that include supply chain members in initiatives related to sustainability. E3 recommends that the company integrate digital models into its strategic management to contribute to the circular economy. E4 and E5 are elements focused on resource monitoring, especially energy and water, and waste management, in order to create optimal conditions in terms of process input and output.

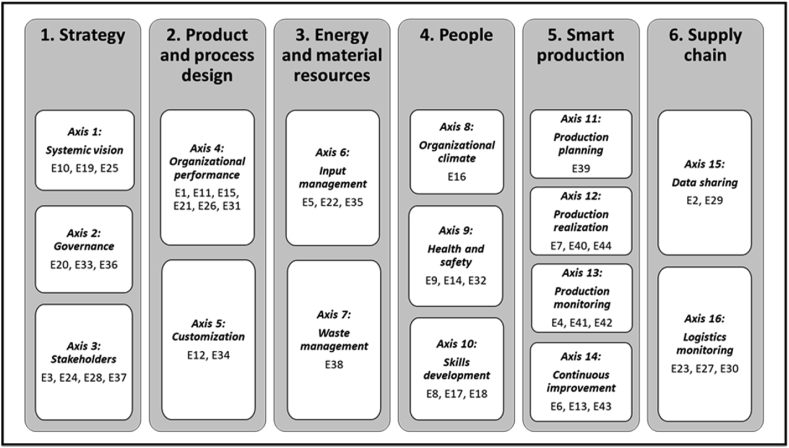

5. Drivers for the development of sustainability via I4.0

The 44 elements presented in Table 2 were carefully analyzed and, during this analysis process, the similarities among them were observed. Based on this similarity, the elements were grouped into categories, which in this work we denominated "drivers", related to the business context. Subsequently, the elements that make up each driver were analyzed again, generating subcategories within the drivers, denominated "axes". This subdivision aims to simplify the use of drivers by companies and to better highlight their scientific contribution to the theory. Figure 2 presents a framework with the proposed drivers, their axes, and their respective elements, identified numerically.

Figure 2.

Framework with drivers and axes for the development of sustainability in companies via I4.0.

In the following sub-sections, the drivers will be discussed in light of the scientific literature and the author's expertise.

5.1. Strategy

The “strategy” driver comprises elements that allow the company's top management to establish the most appropriate ways to plan, carry out, and achieve its sustainability objectives and goals via I4.0. The elements of this driver were distributed along three axes: systemic vision; governance; and stakeholders.

The “systemic vision” axis includes elements that point to the need to have a better overall understanding in relation to implementing sustainable actions via 4.0, from strategic decision-making to the operationalization of these actions in the company's different activities (E10) (García-Muiña et al., 2020). Thus, I4.0 technologies, such as the IoT and advanced simulation software, are recommended to design more sustainable products and create or improve processes that are more effective. Furthermore, these technologies improve the company's image and increase its profitability and market share (E25). E19 highlights that I4.0 technologies can contribute to the achievement of the UN's SDGs 9 and 12.

The “governance” axis comprises elements that suggest the use of I4.0 to control critical processes and promote transparency in the sharing of economic, environmental, and social data, which contributes to achieving sustainability (Tiwari and Khan, 2020). Via I4.0 technologies, top management has access to systematized data previously analyzed by intelligent systems in a fast and reliable way, allowing for more objective and secure decision-making to benefit the development of sustainability (E33) (Bag et al., 2021). To successfully implement I4.0, the company must consider conducting audits to identify gaps related to cyber vulnerability and weaknesses, such as poor crisis management strategy or even its absence (E36) (Bag et al., 2018). Regarding the transparency and effectiveness of data sharing, it is recommended that companies adopt global standards and protocols so that intelligent systems communicate in real-time, enabling information exchange between companies and between companies and their stakeholders, thus helping to promote businesses’ economic sustainability (E20) (Tiwari and Khan, 2020).

The “stakeholders” axis highlights the use of I4.0 technologies as a strategy to foster: cooperation for the supply chain to perform sustainable actions; information transparency, and society's access to sustainability reports; and data-driven customer value creation and propositions by offering more sustainable products or services (Müller et al., 2018). To this end, the elements that make up this axis propose the creation of online platforms so that companies can share successful experiences among themselves and create transparent business ecosystems that follow the precepts of sustainability. Thus, it is recommended that organizations start adopting this type of platform structure to ensure higher quality inputs and greater security in business negotiations, as well as to improve the long-term planning of their activities (E24) (Birkel et al., 2019). Also from the perspective of strategic cooperation, the elements suggest using I4.0 technologies to manage waste reuse with the ultimate goal of industrial symbiosis. This strategy aims for interaction among different industrial companies related to sharing and reusing waste, raw materials, energy, or effluents, resulting in mutual benefits from an economic and environmental perspective (E28) (Stock et al., 2018). Regarding the relationship with the customer and society, it is recommended that companies disclose their actions through sustainability reports comprising information and data processed through smart devices, without human interference, thus avoiding the practice of greenwashing (E37) (Bonilla et al., 2018). Finally, integrating I4.0 with more sustainable economic models is suggested, such as the circular economy and new disruptive business models based on smart data that offer shared functionality for the customer instead of product ownership. This model benefits companies by helping customers achieve their goals using fewer products while also bringing benefits from the standpoint of eliminating pollution and environmental liabilities (E3) (Bonilla et al., 2018; Garcia-Muiña et al., 2020; Ghobakhloo, 2020; Li and Found, 2017; Stock et al., 2018).

5.2. Product and process design

The “product and process design” driver relates to elements that contribute to developing more sustainable product and process designs through the use of I4.0 technologies. The elements that make up this driver were distributed along two axes: organizational performance; and customization.

The “organizational performance” axis encompasses elements that promote the increased performance of products and processes in the design phase. E11, for example, aims to design smart products so that their life cycle can be monitored and tracked, enabling data to be collected and analyzed more effectively. These procedures contribute to the development of the circular economy by enabling decision-makers to identify any waste of resources and waste management failures in real-time, enabling an immediate corrective action plan to be implemented. From the perspective of process design, the adoption of cyber-physical production systems (CPPSs), intelligent tracking and data protection systems, and the use of the IIoT and AI are recommended (Tiwari and Khan, 2020). These technologies contribute to production planning, autonomous and fast operations, and equipment reliability (E1, E15, E26). In this way, the company can use energy more sustainably, reduce greenhouse gas emissions, and provide cybersecurity in technical and administrative environments (Müller et al., 2018). E21 proposes the development of preventive and predictive maintenance processes via I4.0 technologies to extend the useful life of equipment, ensure employee safety, replace products with a negative environmental impact with environmentally friendly products, etc (Bonilla et al., 2018; Franciosi et al., 2018). E31 suggests replacing or modernizing parts, machines, and software with newer versions (retrofit) to save material and energy and increase productivity (Müller et al., 2018).

The “customization” axis comprises elements that suggest the use of I4.0 technologies to develop products and processes geared towards the customer's real needs. Thus, these elements suggest the use of the IoT and the IoS to interact with consumers, collecting and analyzing data to identify their consumption patterns in order to allow the development or replanning of products (E12). Together with the use of advanced simulation software, these technologies can also be used to perform virtual prototyping and production line simulation (E34) (Beier et al., 2020).

5.3. Energy and material resources

The “energy and material resources” driver comprises elements that help companies manage the inputs required for the production process and the waste arising from these processes. The elements of this driver were distributed along two axes: input management; and waste manag-ement.

The “input management” axis consists of elements that suggest using I4.0 technologies to monitor the inputs used in production processes and the product life cycle in real-time. For example, intelligent systems and big data processing platforms contribute to creating optimal conditions for energy and water consumption (E5, E22) and assist in managing material consumption throughout the product life cycle (Garcia-Muiña et al., 2019; Stock et al., 2018). In this way, the company improves its cost replanning and results related to zero waste and reduced greenhouse gas emissions, thus contributing to economic and environmental sustainability (E35).

The “waste management” axis comprises an element that encourages the use of I4.0 technologies to improve waste management, providing financial resources savings, environmental protection, and better health and safety for workers (E38). Companies can use IoT technology in waste recovery processes to generate energy or convert waste into raw materials to form new products, reducing environmental impacts (Fatimah et al., 2020). The use of these technologies has also been observed in automated waste dumps to track and monitor waste in real-time, thus avoiding environmental penalties and fines (Bányai et al., 2019).

5.4. People

The “people” driver includes elements that contribute to improving human resource management using I4.0 technologies. It positively impacts individuals’ professional development, both from a technical and behavioral point of view, and contributes to increasing their performance and job satisfaction (Piwowar-Sulej, 2021). The elements of this driver were distributed along three axes: organizational climate; health and safety; and skills development.

The “organizational climate” axis highlights the use of I4.0 technologies to inform and raise workers’ awareness, and conducting internal satisfaction surveys, among other actions, aiming to contribute to continuously improving the atmosphere in the work environment and employee performance. Therefore, the use of integrated Internet-based information networks is recommended to interconnect people, machines, and devices, facilitating the flow of information and data (E16) (Birkel et al., 2019). In this way, the interaction between people happens faster and more efficiently, making the work environment more participatory and dynamic (Braccini and Margherita, 2018).

The “health and safety” axis comprises elements that aim to preserve human capital's physical and psychological integrity and thus generate greater quality of life at work. For example, the installation of smart cameras and sensors and AI-based localization systems improve the human–machine interface and detect unsafe working conditions (E14) (Bai et al., 2020), the use of autonomous robots in performing repetitive, dangerous, or physically demanding tasks decreases or eliminates employee exposure to hazardous conditions (E9) (Brozzi et al., 2020), and the adoption of augmented reality glasses aids the performance of complex cognitive activities by decreasing employee mental stress (E32) (Stock et al., 2018). Therefore, it is recommended that companies also use I4.0 technologies to benefit their employees because working in safe and healthy conditions increases job satisfaction. This is reflected in lower absenteeism rates and increased productivity, which positively impacts social and economic sustainability.

The “skills development” axis comprises elements that contribute to prospecting, selecting, qualifying, and integrating the most suitable people for each job, thus increasing the mastery of ICTs and reducing stress due to lack of technical competence related to I4.0 technologies (E8, E17). To achieve these benefits, companies should incorporate I4.0 technologies into sustainability training and enhance employees' hands-on learning via intelligent systems with improved human–machine interfaces (E18) (Paravizo et al., 2018; Chaim et al., 2018; Salah et al., 2019; Beier et al., 2020; Birkel et al., 2019; Oláh et al., 2020). In this way, developing employees’ competence in I4.0 technologies means that the company can count on more productive and motivated people in the work environment.

5.5. Smart production

The “smart production” driver comprises elements that make production processes more efficient, autonomous, and customizable via I4.0. The elements of this driver were distributed along four axes: production planning; production realization; production monitoring; and continuous improvement.

The “production planning” axis comprises one element aimed at planning, controlling, and optimizing the application of resources and the synchronization of personalized production based on I4.0 technologies. To achieve these goals, it is recommended that companies use the digital twin and artificial intelligence (AI) models, as through them it is possible to virtually simulate the real conditions of the processes to generate different production scenarios and thus predict what the results would be based on the changes made in the virtual environment (E39). These technologies provide managers with a holistic view of the functioning of the production system, enabling them to analyze the environment in advance and prepare themselves by creating action plans and strategies based on the scenarios identified in the simulations (Ghobakhloo, 2020). In this way, E39 contributes to the economic sustainability of companies as it enables greater flexibility and production efficiency in the face of market volatility and diversity and the demand for customized products. In addition, productivity can be increased with better planning for material, energy, and human resources.

The “production realization” axis contains elements that indicate the use of I4.0 technologies to increase processes’ efficiency and flexibility. This leads to increased productivity and decreased resource use, waste generation, and operating costs. One way to achieve these goals is through additive manufacturing. This process makes the manufacture of products and parts possible with lower production costs, less waste generation, and a longer life cycle, contributing to environmental sustainability (E7) (Oláh et al., 2020; Nara et al., 2021). Additionally, the following are recommended: the use of digital tools for the automatic pre-processing of production data to improve decision-making (E40) (Beier et al., 2020); and the use of digital connectivity to enable the automated and self-optimized production of goods and services without human interventions (E44) (Beier et al., 2020), thus generating economic benefits. Therefore, it is recommended to adopt these elements to promote better integration of systems and machines and an improved human-machine interface, enabling more agile, intelligent, and decentralized production, with positive effects on all dimensions of sustainability.

The “production monitoring” axis comprises elements related to assessing the performance of the production process, identifying bottlenecks, possible failures, and idle machines, and thus obtaining higher quality and productivity. For this, it is suggested that companies adopt: RFID systems to identify, track, and inspect products, increasing production and shipping efficiency (E42) (Meng et al., 2018); portable terminals, such as tablets and smartphones, linked to sensors to monitor production in real-time (E41) (Bag et al., 2018); and sensors and software to monitor resource consumption, waste generation, machine efficiency, and inventory control (E4) (García-Muiña et al., 2019). These elements interact with the three dimensions of sustainability by making it possible to eliminate human error, speed up the shipping process, prevent theft or counterfeit goods, and improve inventory control.

The “continuous improvement” axis comprises elements that facilitate the constant improvement of production in order to continuously improve results in process performance and product quality. Therefore, the following are recommended: adopting I4.0 technologies that detect quality problems, thus decreasing rework, rejects, failure rates, and material and time waste (E13) (Stock et al., 2018); improving equipment performance by reducing idle time and energy consumption (E43) (Yazdi et al., 2018); and driving the vertical and horizontal integration of production systems by shortening lead times and improving machine interoperability and productivity (E6) (Müller et al., 2018). Therefore, continuous improvement via I4.0 contributes to economic and environmental sustainability by decreasing costs and resource consumption as the need for rework is reduced.

5.6. Supply chain

The “supply chain” driver is related to elements that improve information management, the vertical integration of the chain, and the efficient use of inputs among supply chain members via I4.0 technologies. It has positive impacts on environmental management and the carbon footprint. The elements of this driver are distributed along two axes: data sharing; and logistics monitoring.

The “data sharing” axis comprises elements that highlight the need to design and develop intelligent platforms and use blockchain to achieve greater integration among supply chain members in order to increase communication, data sharing security, flexibility, and productivity (E2, E29) (Braccini and Margherita, 2018; Luthra et al., 2020; Stock et al., 2018).

The “logistics monitoring” axis comprises elements that reduce logistics costs and negative environmental impacts by integrating digital technologies into logistics processes to monitor packaging disposal, use, and reuse (E30) (Birkel et al., 2019; Stock et al., 2018). The use of I4.0 technologies in logistics is recommended to optimize the volume and flow of materials, reduce the number of erroneous deliveries, waiting time, and pollutant gas emissions from transportation, and promote the efficient use of the transportation fleet (E23) (Birkel et al., 2019; Braccini and Margherita, 2018). In addition, the elements of this axis suggest the use of the IoT, CPSs, and big data to operate decentralized distribution centers close to where products will be consumed, contributing to the reduction of logistics costs and environmental impacts (E27) (Birkel et al., 2019; Brozzi et al., 2020; Ghobakhloo, 2020).

6. Discussion

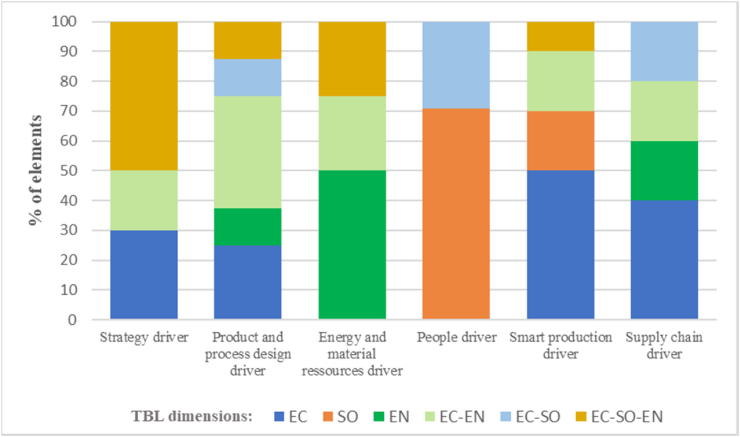

6.1. Proportion of TBL-related elements

The critical analysis and classification of elements as per TBL showed an imbalance between its three dimensions. Elements with economic characteristics accounted for 27% of the total, against 16% of those with social characteristics and 9% whose characteristics were environmental. When these elements include more than one dimension simultaneously, there is a greater balance between economic and environmental (EC-EN) with 21% and those classified as economic, social, and environmental (EC–SO–EN) with 18%. The elements classified as economic and social (EC-SO) account for only 9% of the total elements. Figure 3 presents the percentage distribution of the elements according to their classifications in relation to TBL.

Figure 3.

Distribution of elements according to their TBL classification.

Elements that simultaneously include social and environmental dimensions were not identified in the articles. Therefore, based on the distribution observed in Figure 3, it can be seen that the social dimension was the one that obtained the lowest overall percentage, with 16% of elements with only social aspects and 9% of elements with social aspects associated with economic aspects. This result shows that researchers need to make efforts to highlight and strengthen the social dimension in order to provide more balanced TBL dimensions (Henry et al., 2019).

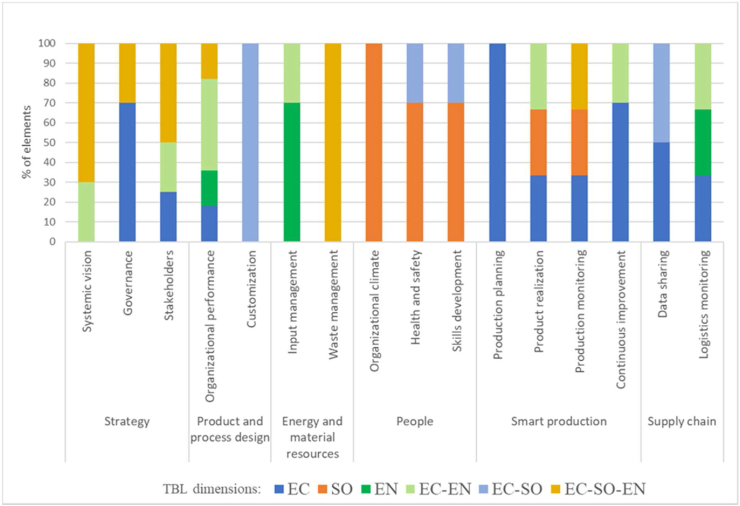

Clustering the elements into drivers allowed mitigating this imbalance since the drivers are permeated by all three dimensions of the TBL, with a single exception for the "People" driver, which contemplates only the economic and social dimensions (Figure 4).

Figure 4.

Relationship between drivers and TBL dimensions.

When the actions in these elements are implemented following the proposed drivers, there is a better balance between the economic, social, and environmental dimensions. Thus, the results of these actions are enhanced (Hahn et al., 2015). In the present work, since the social dimension appears with the lowest overall percentage of boosting elements, we tried to identify which drivers and axes were most critical in order to fill this gap. Figure 5 illustrates in which drivers and, specifically, in which axes the social dimension is non-existent or appears in a lower percentage. These are: "strategy/governance", "energy and material resources/input management", "smart production/production planning", and "supply chain/logistics monitoring".

Figure 5.

Relationship of drivers and their axes with the dimensions of the TBL.

6.2. Imbalance of social elements

The percentages illustrated in graphs contributed to speeding up the process of analysis, as graphical measurements improve the understanding of the contents of certain fields of knowledge and enable more illustrative comparisons to be made (Kaczynski et al., 2008). Then, new searches for articles and reviews were conducted, as explained in the research method section, with the aim of identifying new elements that could complement the social dimension of the TBL. As a result, four new elements were identified (Table 4), one for each drive/axis with few or no elements related to the social dimension.

Table 4.

Complementary elements related to the TBL social dimension.

| Driver/axis | Element | Author(s)/Year | |

|---|---|---|---|

| 1 | Strategy/governance | Engage IT governance in strategic planning so that it can support and/or mitigate issues related to the organizational human resource base and its ability to handle digitized manufacturing. | Ghobakhloo and Fathi (2020) |

| 2 | Energy and material resources/input management | Develop circular model based on I4.0 technologies to promote the reuse of productive waste, contributing to local job creation and community quality of life. | Nascimento et al. (2019) |

| 3 | Smart production/production planning | Adopt a collaborative virtual platform to assist in production planning, selecting partners that are adequate to the company's sustainability purpose and located in regions that register high unemployment rates or present a condition of social vulnerability. | Mladineo et al. (2018) |

| 4 | Supply chain/logistics monitoring | Introduce human-centric I4.0 technologies for developing logistics monitoring processes. | Sgarbossa et al. (2020) |