Abstract

This paper investigates the impact of subcomponents of collaboration: information sharing, connectivity, coordination, integration, and visibility on the tea supply chain resilience of Sri Lanka during the Covid-19 pandemic. This research was carried out with mixed methods. The quantitative approach adopted a systematic random sampling technique to determine the sample size (n = 137), whereas the qualitative study used the purposive sampling technique to determine the sample size (n = 6). Self-administered questionnaires were distributed to tea supply chain professionals and structured interviews were conducted to collect data for the qualitative approach of the study. This study found that all the subcomponents of collaboration positively impacted on tea supply chain resilience during the Covid-19. Moreover, connectivity and coordination have the highest positive impact on tea supply chain resilience while the other three sub-components: information sharing, integration and visibility have significant but relatively less positive impact on supply chain resilience. Thus, tea exporting companies must prioritise, take action steps for enhancing connectivity and coordination when formulating supply chain strategies to enable supply chain resilience. The study being one of the latest empirical studies taking Sri Lankan tea supply chain as a case study, contributes to the knowledge having identified the impact of sub-components of collaboration on tea supply chain resilience during Covid-19. Sri Lanka is one of the most vulnerable middle-income countries and its economy suffered severely during the Covid-19 outbreak. The findings will be supportive in making tea supply chains much stronger, providing a robust contribution to the country’s GDP as part of Sri Lanka’s national efforts in economic rebuilding.

Keywords: Supply chain resilience, Subcomponents of collaboration, Tea industry, Covid-19

Introduction

Supply chain resilience has been acclaimed as a risk management technique over the past decade; as a research issue, its importance has subsequently grown and has sparked considerable interest in the literature (Lima et al. 2018). As such, the notion is that if people adopt a resilient approach, then their likelihood of recovery from the setback is generally high. Consequently, the validity of this concept is much important in today’s world because people face numerous interruptions during their day-to-day activities (Hosseini and Barker, 2016). Both external and internal factors can cause these disruptions. Natural disasters and manmade disasters such as terrorist attacks and wars are external factors that contribute to rise in interruptions (Christopher and Peck, 2004; Tang, 2006; Ponomarov and Holcomb, 2009; Wagner and Neshat 2010). Cost of supply, supply yields, the volume of supply, and lead times are some internal sources of distraction that contribute to a surge in interruptions. Therefore, the increasing frequency of these unexpected disruptions saw an increase in the resilience concept's interest and importance (Pettit et al. 2013; Christopher and Peck, 2004). On top of this, the world is becoming more uncertain, further aggravating the disruptions and therefore, the need for resilience has become more crucial.

According to Jüttner and Maklan (2011), flexibility, visibility, velocity, and collaboration are the formative elements of supply chain resilience. Out of these elements, collaboration is one of the most formative and essential requirements for supply chain resilience. According to Pettit et al. (2013), collaboration refers to the capacity to work effectively for mutual gain in areas such as sharing risk, postponement, and forecasting. As per Aboah et al. (2019), collaboration contains the subcomponents such as information sharing, coordination, connectivity, integration, and visibility. However, limited past research focussed on the effect of sub-components of collaboration.

Even though many studies were conducted regarding natural disasters, political interruptions, and other interruptions, limited research studies have been undertaken regarding massive pandemics and its repercussions to supply chain resilience (Maureen, Laura et al. 2020). Covid-19 is one of the major pandemics where the damage can prolong than envisaged. It has resulted in a global disaster, affecting not only human beings but also economic activities such as production, supply chain, logistics, and a variety of other industries (Ivanov et al. 2020; Golan et al. 2020; Remko 2020; Rowan and Laffey, 2020).

Concerning the Sri Lankan context, the Covid -19 impacted almost all industries that involved traditional or physical activities such as agricultural industries, service industries, etc. Specially, industries such as manufacturing that cannot be carried offsite and online were severely hit by the supply chain disruptions including logistics and shipment delays ( due to social distancing, lockdowns, port closures etc.), causing local and global level disruptions.

Tea is identified as the major agricultural exporting product of Sri Lanka which is a key revenue in the national economy. The country is considered to be the world's fourth-largest tea exporter and the world's largest conservative tea producer (Mujahid Hilal, 2019).

Further to the above, tea supply chain resilience means reducing disruptions, both in tea exports and loss of national income, is specially important in times of a pandemic crisis.

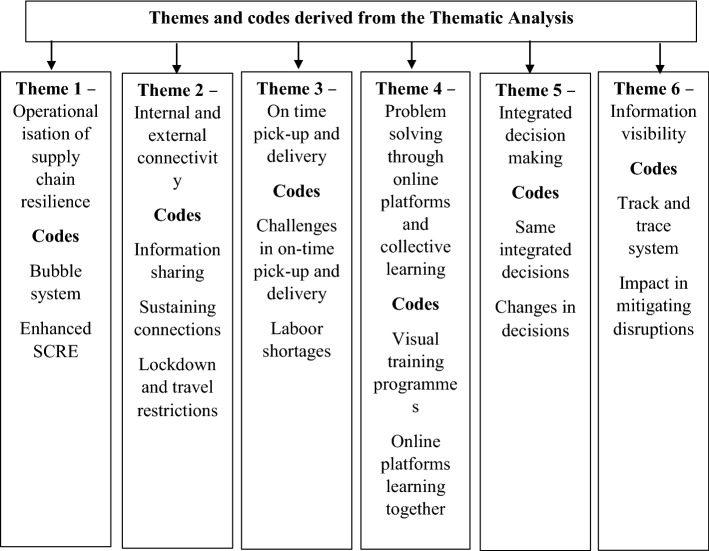

As depicted in Fig. 1, the export volume of the Sri Lankan tea industry dropped by 27.1 KG from 292.6 KG in 2019 to 265.5 KG in 2020 due to the restrictions imposed to curtail the outbreak of Covid-19. This significant drop in the tea export revenue recorded a massive loss of nearly LKR 10.5 billion while impacting the Sri Lankan economy severely.

Fig. 1.

Tea Exports of the year 2019 and 2020.

Source: Tea Export Association (2020)

As explained previously, collaboration is one of the essential elements in supply chain resilience.

Therefore, in this study, we focussed on investigating the impact of sub-components of collaboration: information sharing, visibility, connectivity, coordination, and integration on supply chain resilience during Covid 19, taking the Sri Lankan tea supply chain as a case study. Further, the study explores how the Sri Lankan tea exporting companies have deployed their supply chain resilient capabilities to survive before the Covid-19 and during Covid-19.

Accordingly, this study differs from existing literature and contributes to the literature in several ways.

Firstly, the current study fills the gap in the literature, through the in-depth investigation of the impact of subcomponents of collaboration on agricultural supply chain resilience.

Secondly, this study is the first empirical study focussing on the tea supply chain resilience during Covid 19 in the Sri Lankan context. Thirdly, through exploration of how the best performing tea exporting companies survived during Covid-19 and deployed their supply chain resilient capabilities, a greater understanding could be gained, which would enable the rest to adapt the same upon suitability.

Finally, the findings will be beneficial in formulating the action steps in designing much more resilient supply chains that can face and keep tea export firms afloat in unexpected disruptions like Covid 19 in future.

The rest of this paper is structured as follows. Section 2 explains the literature review, Sect. 3 describes data and methodology, Sect. 4 illuminates results and discussion and Sect. 5 presents the conclusion.

Literature review

Supply chain resilience

Competitors and customers continuously exert pressure on modern supply chains for timely delivery of products at low prices, high quality, with a high global scope (Ponis and Spanos, 2009). When complying with all these requirements, supply chains, often face challenges: supply shortage, transit delays, non-compliance with environmental and social sustainability issues, port delays, natural catastrophes, communication delays, political disruptions, quality concerns, operational failures, and other barriers are encountered when satisfying supply chain functions (Blackhurst et al. 2005; Chowdhury and Quaddus, 2017). According to Rwakira et al. (2015), two kinds of disruptions are identified in an organisation; some are natural disasters, while others occur from the firm’s supply chain. Therefore, these unexpected disruptions have raised much attention about implementing resilience (Pettit et al. 2013; Christopher and Peck 2004a). This means that the resilience concept plays its role in the supply chain when the firm’s supply chain faces unexpected disruptions.

Further, resilience is described as the ability to respond to unexpected disruptions and swiftly restore normalcy. Some other authors argue that resilience is not just about managing risks but also about adapting to them cost-effectively (Hamel and Välikangas, 2003; Yao and Meurier, 2012). Resilience is an evolving phenomenon; traditional risk management practices (Pettit et al. 2010) are incapable of dealing with unforeseeable incidents and hence differ from the concept of resilience that is about adaptability. Unforeseeable incidents resulting in disruptions, slowdown etc., can lead to gaps in supply chains. Therefore, it is reasonable to assume that the principle of supply chain resilience can fill these gaps by allowing the supply chain to withstand unforeseen interruptions while maintaining a competitive advantage (Pettit et al. 2010). Implementing supply chain resilience in a firm’s supply chain enables the smooth functioning of interlinked supply chain elements that will help gain the competitive advantage in the market.

Moreover, numerous interpretations of supply chain resilience have been available since its inception. According to Christopher and Peck (2004a), supply chain resilience is defined as the system's ability to return to its original position (i.e. restoring to normalcy) or shift to a new, more valuable state after being disrupted. Several other scholars define resilience as the ability to respond proactively to the impact of disruptions by determining blueprints that allow the supply chain to respond to disruption while restoring to its normal level or a more sophisticated level than the average (Jüttner and Maklan, 2011; Pereira et al. 2014). Developing and maintaining resilience is not a one-time event; but a continuous operation (Pettit et al. 2013; Scholten et al. 2014). Supply chain resilience has risen to prominence as a mechanism of handling and minimising the interruptions that affect supply chain efficiency (Cheng and Lu, 2017; Das, 2018; Tukamuhabwa et al. 2017). Therefore, essentially, organisations need to develop resilience capabilities. In doing so, the purpose is to respond to unpredictable events' negative impacts and rapidly return to their current or the best new state to achieve a resilient supply chain.

Resilience capabilities

Resilience capabilities are defined as the ability to absorb risk and respond effectively to disruptions (Azadeh et al. 2014). For example, suppose an organisation has a flexible supply base including more than one supplier. In that case, if one supplier faces an interruption, the organisation can ensure alternative and continuous supply from other suppliers (Colicchia et al. 2010). The previous studies identified redundancy, collaboration, visibility, and flexibility as essential resilience capabilities. At possible trigger points, redundancy is referred to as the strategic availability of additional capacities or inventories (Jüttner and Maklan, 2011). In addition, redundancy facilitates the extra capacity to manage disruptions, such as increased safety stocks as a buffer to sustain continuity of operations or multi-sourcing to prevent being impacted by disruptions with suppliers (Pettit et al. 2010; Klibi et al. 2010). Marchese and Paramasivam (2013) revealed possible overlaps and overlapping features among resilience capabilities.

To begin, visibility refers to the capacity to see the whole supply chain from demand to supply (Pettit et al. 2013). Secondly, flexibility is defined as swiftly adjusting to disruptions without significantly raising operating costs (Melnyk et al. 2014). Thirdly, collaboration is defined as two or more people working together to gain a competitive advantage by sharing information and making collaborative recommendations. This is to meet the needs and wants of the end customer while retaining profitability (Simatupang and Sridharan, 2002). Christopher and Peck (2004), asserted that the above-mentioned resilience capabilities such as redundancy, visibility, flexibility, and collaboration must be built in to the supply chain for it to respond swiftly to disruptions and thereby maintain the continuity of the operation.

Supply chain resilience and collaboration

For several years, businesses have struggled to improve the quality of their internal supply chains processes, such as sourcing, production, and logistics (Ellinger et al. 2002; Fawcett and Magnan, 2002). Furthermore, it was discovered that a company's willingness to interact with its upstream and downstream partners influences its performance favourably (Spekman et al. 1998). Therefore, organisations have focussed on the concept of collaboration to improve efficiency. Collaboration is defined as the firm's ability to deal with other firms to achieve a specific set of goals that benefit both parties (Min et al. 2005). Greenbaum (2004) stated that a well-focussed collaborative effort can boost revenue, minimise wastage, and develop strong connections between merchants and manufacturing partners. Moreover, it was found out that the organisations that participate in collaborative partnerships will gain enhanced transparency, higher service levels, better flexibility, higher end-customer satisfaction, and shorter cycle times (Daugherty et al. 2006). Barratt (2004) cited mutual benefit, incentives, and risk-sharing as the foundation of collaboration and the exchange of information.

Many researchers and practitioners have taken an interest in collaboration among supply chain members (Barratt and Oliveira, 2001; Danese, 2007; Nyaga et al. 2010; Ramanathan, 2012). As per Faisal et al. (2006) and Richey (2009), supply chain collaboration is the glue that binds the elements of the supply chain together during a crisis. While Pettit et al. (2013) referred supply chain collaboration as the ability to work effectively with other entities for mutual benefit in forecasting, postponement, and risk-sharing. Many scholars opined that collaboration among supply chain partners is fundamental for establishing supply chain resilience (Jüttner and Maklan, 2011bPeck, 2006; Scholten and Schilder, 2015). Having collaborations within the supply chain will assist the firms in building supply chain resilience within the organisation. Information sharing, connectivity, coordination, integration, and visibility are considered subcomponents of collaboration, a fundamental aspect of supply chain resilience (Aboah et al. 2019; Scholten and Schilder, 2015; Ponis and Koronis, 2012).

Supply chain resilience and information sharing

Sharing knowledge has received the most exposure out of all the company resources. This is because knowledge sharing is crucial to executing the company's strategic supply chain, and a lack of information in supply chains will constantly result in panic, disorganised behaviour, and high costs (Childerhouse et al. 2003; Davenport and Hall, 2002). Sharing knowledge is more than just information; it can include ‘business secrets to success/competitive edge’ and even industry-specific tips on effectively handling resilience that are not found in textbooks or covered by concepts / theories. According to Lee (2002), the efficiency of the supply chain can only be controlled by information sharing and close coordination. In general, information sharing can be described as exchanging information with another party, either proactively or reactively, by responding to a request. The shared data affects the other person's image and creates a transmitted or mutually cooperative working environment and a better awareness between the parties involved (Sonnenwald, 2016). Premus and Sanders (2008) explained information sharing as the extent to which one party in the chain communicates sensitive and proprietary information to another party. According to Kwon and Suh (2004), information sharing is critical in the trust-building process, as it allows firms to get to know each other's routines and develop conflict-resolution mechanisms.

Information sharing is valuable and advantageous in retail supply chains (Chen et al. 2000; Lee et al. 2000). Sharing of information primarily includes activities such as providing information and confirming whether the information is received. When information is initially exchanged, the recipient must determine whether the shared information is reliable, trustworthy, timely, helpful, and in a format that is easily accessible (Bailey and Pearson, 1983; Closs et al. 1997). Therefore, information transparency is recognised as a critical requirement and enabler of solid supply chain collaboration (Anbanandam et al. 2011; Holweg et al. 2005). Companies benefit from information sharing in lower inventory, lower costs, improved tracing and tracking, and more efficient capacity utilisation (Lotfi et al. 2013). To improve the outcomes of information sharing organisations should answer four key questions: what to share, with whom to share it, how to share, and when to transfer; by evaluating the quality of the answers, collaborating organisations can avoid redundancy, reduce sharing costs, and improve responses (Sun and Yen, 2005). Furthermore, sharing information between the involved parties will always require a strong interconnection. Besides, information sharing requires expertise on information management and duly handling the same and adapting to various circumstances.

Supply chain resilience and connectivity

Research by Fiksel et al. (2015) suggested that turbulence, purposeful strikes, external effects, infrastructure constraints, responsiveness, and connectedness are all causes of exploiting supply chain flaws and capabilities. As a result, linking managers through the boundaries of an organisation and distributing pertinent, correct, and timely information would assist those managers in preparing at a higher level and making more consistent decisions (Fawcett and Magnan, 2002); moreover, connectivity constructs the capacity of information sharing. According to Allred et al. (2011), organisational connectivity means the ability for data gathering and exchange via technologies of information and communication.

An organisation's connectivity is perceived as an asset that assists the supply chain in enhancing capacity (Wu et al. 2006). According to Fawcett et al. (2009), connectivity in the supply chain has a beneficial effect on preparing resolutions and coordination, while Btandon‐Jones et al. (2014) observed that connectivity in the supply chain has a beneficial influence on sharing of information. As a result of the upgraded connectivity, participants of the supply chain will reduce new product evolutionary cycles and order fulfilment lead times (Sahin and Robinson 2007; Sanders and Premus 2002). Connectivity supports supply chain networks and organisations in authorising interchange information (Prajogo and Olhager 2012; Btandon‐Jones et al. 2014; Huo et al. 2013). Better coordination occurs between the parties benefitting from having superior connectivity.

Supply chain resilience and coordination

When the dependencies and unpredictability between supply chains intensify, this situation leads to additional requirements for coordinated decisions between its participants. Coordination is the process of arranging tasks in two or more groups to operate jointly and successfully and be well informed about each other's actions (Cao et al. 2008). Dyer and Singh (1998) claimed that creating good coordination both within and outside its borders is critical in gaining a competitive edge and increasing revenue. A similar conclusion by Jüttner and Maklan (2011) proved that coordination within and outside of the firm is a critical strategy to preventing interruptions in the firm's supply chain. Coordination will work together to speed up the dissemination of information in the event of an interruption. It discovered that a shortage of coordination results in increased inventory cost, a longer time for delivery, increased shipping costs, higher levels of damages and degradation, and worsened customer satisfaction (Lee et al. 1997). According to Chandra and Kumar (2001), improved coordination inside and across the partners of the supply chain and adjustments to the interdependent process of preparing resolutions are critical parts of integration.

Supply chain resilience and integration

Integration is recognised as the procedure by which a segment of the most comprehensive system sets off more interconnected and it allows an integrant to carry out another integrant's previously conducted tasks and vice versa (Li et al. 2005; Parast and Spillan, 2014). In addition, often many studies have discovered that integration enhances an organisation's resilience (Christopher and Peck, 2004; Jüttner and Maklan, 2011; Wieland and Wallenburg, 2013). In the meantime, Zhao et al. (2013) asserted that integration could enhance an organisation's operating capacity by improving the quality of the service, the flow of knowledge, and the flow of cash between internal and procedural procedures in cross-organisation management.

Fawcett and Magnan (2002) interpreted supply chain integration as a process with three stages. In the first proportion, supply chain integration executes narrow to information integration, in which utilisation of information technology encourages shares and transactions across members. The second proportion aims to improve integrative inter-firm methods. The most preliminary proportion of supply chain integration is about forming inter-firm alliances and the culture of joint decision-making. Various research studies have discovered that supply integration will enrich the organisation's resilience (Christopher and Peck, 2004; Jüttner and Maklan, 2011; Pettit et al. 2013; Wieland and Wallenburg, 2013). Through integration, an organisation can manage to implement supply chain resilience.

According to Fisher et al. (1997), supply chain integration enables diverse performance advantages to the firm, including a faster turnaround on investment, a quicker turnaround on assets, reduced cost, more excellent product and service quality, better customer service and etc. Besides, a complete integrated supply chain helps to produce an effective and efficient flow of data, goods services, money, and options permitting total value to be delivered to the client at an economical rate and more incredible speed, in addition to lowering expenses (Bowersox et al. 1999; Frohlich and Westbrook, 2001). According to Huo et al. (2016), the supply chain integration's primary goal was to create a joint business operation through the supply chain network, allowing it to serve as a weapon of competition. Excellent visibility between the processes is is a prerequisite for proper integration among the members.

Supply chain resilience and visibility

Supply chains confront several problems and the most significant reason for the latter is a lack of visibility within the supply chain. Therefore, many studies were conducted to assess the relevance of visibility in enhancing supply chain resilience. The extent to which the supply chain has to assess organisational and managerial information about the supply chain is defined as supply chain visibility (Barratt and Oke, 2007; Wei and Wang, 2010). The visibility of the supply chain is critical in constructing the collaboration (Barratt, 2004; Barratt and Oke, 2007). Makris et al. (2011) stressed the need for supply chain visibility to adapt to changes. Significantly, the supply chain visibility permits assessing valuable information related to the movement of the product.

Any supply chain can be improved by concentrating on five essential factors of visibility: receptiveness, planning, shared goals, trust, and forecasting (Barratt and Oliveira, 2001). Wieland and Wallenburg (2013) emphasised the feasibility of curtailing the detrimental impacts of supply chain disruptions by considering all sources of uncertainty, increasing visibility across the supply chain, and enhancing resilience (Blackhurst et al. 2005). Resultantly, the visibility embedded into the supply chain allows managers to be well informed of the changes proactively, which is a requirement for response (Wieland and Wallenburg, 2013); having greater visibility, many difficulties in a supply chain; such as the negative consequences of marketing can be minimised as well as the 'Bullwhip' effect.

Refer "Appendix 1" for Literature Review Summary Table.

Data and methodology

Data

The study deployed an online self-administered questionnaire which comprised of three (03) main sections with the first section consisting of demographic questions, the second section focusing on the tea supply chain resilience and the third section concentrating on the sub-components of collaboration (Information Sharing, Connectivity, Coordination, Integration and Visibility). A minimum of four questions and a maximum of eight questions were assigned for each variable. The questions were developed with a five-point Likert scale to measure each model variable, on an ascending scale from 1 to 5, depicting (1) strongly disagree to (5) strongly agree and the questionnaire is presented in "Appendix 2".

A systematic sampling technique was applied to collect the data that was free of bias, for the 157 tea exporting companies recognised as the population according to the Export Development Board in Sri Lanka (EDB, 2021). Using goodcalculators, the online sample size calculator the sample size was derived, with the accepted margin of error as 3% and a confidence level of 95%. Based on the results sample size of 137 was considered.

In addition to the quantitative approach, how Sri Lankan tea supply chains have deployed resilient capabilities to survive before the Covid-19 and during Covid-19 was explored. Acorndgly, six interviews were conducted. Using the purposive sampling technique, we chose the six best performing tea exporting companies based on the results received in the self-administered questionnaire. Further, the authors found that these six companies had received google ratings of over 4.6 in major tea exporting companies of Sri Lanka.

Analytical Tool

The study deployed the statistical technique of multiple regression analysis using SPSS Version 21.0 for the hypotheses testing (Fig. 2).

Fig. 2.

Conceptual framework.

Source: Author’s Illustration based on Literature

The equation is explained as follows.

where denotes the supply chain resilience of ith respondent. β1, β2, β3, β4 and β5 denote the regression coefficients for variables Information Sharing (X1), Connectivity (X2), Coordination (X3), Integration (X4) and Visibility (X5), respectively. ϵ is the random error term.

We derived the following hypotheses to assess the impact of sub-components of collaboration on tea supply chain resilience. All the summarised hypotheses are listed below.

H1 Information sharing has a significant impact on tea supply chain resilience in Sri Lanka.

H2 Connectivity has a significant impact on tea supply chain resilience in Sri Lanka.

H3 Co-Ordination has a significant impact on tea supply chain resilience in Sri Lanka.

H4 Integration has a significant impact on tea supply chain resilience in Sri Lanka.

H5 Visibility has a significant impact on tea supply chain resilience in Sri Lanka.

We deployed the thematic analysis manually for the qualitative approach since the sample size was only six tea exporting companies in Sri Lanka. This approach of data analysis is frequently utilised because it allows researchers to handle a wide range of study topics and subjects. Using semi-structured interviews data was collected (Refer "Appendix 3" for the interview guide). Codes were identified from the data gathered through the interviews and themes were derived from the codes where the researchers identified six themes altogether. Further to the above, analysis findings are demonstrated through the themes identified.

Results and discussion

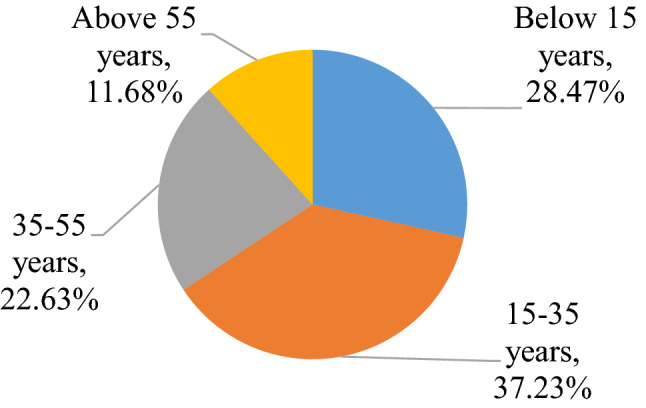

As depicted in Fig. 3, the sample consisted of 35% of the tea exporting companies with an industrial presence of 15–35 years while the minimum representation of 12% had been by companies having experiences for more than 55 years in the same business.

Fig. 3.

Number of years in the industry or field Source: Authors' calculation based on survey data (2021)

Information presented in Table 1 indicates the variable Supply Chain Resilience, the mean value recorded is 3.6542 while the mode value is 4. These values explain the agreement of the respondents related to each question item. However, the standard deviation is recorded as 0.4842, which interprets that the respondents were having similar views as the recorded mean value; it also explains that the data set had not widespread but was dispersed around the mean value. Further, the skewness of − 0.7433 shows that data is not significantly different from the normality.

Table 1.

Descriptive Statistics Source: Authors’ calculation

| Supply Chain Resilience | Information Sharing | Connectivity | Coordination | Integration | Visibility | |

|---|---|---|---|---|---|---|

| N | 137 | 137 | 137 | 137 | 137 | 137 |

| Mean | 3.6542 | 3.9909 | 3.4489 | 3.8504 | 3.9526 | 3.6697 |

| Std. Error of Mean | 0.0361 | 0.0303 | 0.0462 | 0.0342 | 0.0273 | 0.0467 |

| Median | 3.75 | 4.00 | 3.50 | 4.00 | 4.00 | 3.75 |

| Mode | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

| Std. Deviation | 0.4842 | 0.3804 | 0.5713 | 0.3912 | 0.3889 | 0.4897 |

| Variance | 0.1781 | 0.1261 | 0.2928 | 0.1605 | 0.1021 | 0.2923 |

| Skewness | − 0.7433 | − 0.9916 | − 0.8026 | − 1.1804 | − 0.3711 | − 0.5708 |

| Kurtosis | 0.0041 | 2.6629 | 0.3637 | 2.3614 | 0.2130 | 0.4251 |

Information sharing, connectivity, coordination, integration and visibility, recorded mean values have been 3.9909, 3.4489, 3.8504, 3.9526, and 3.6697, respectively, while the mode value for all the sub-components of collaboration has been 4. Thus, the agreement for each respective question item is seen. The recorded low standard deviation values of 0.3804, 0.5713, 0.3912, 0.3889 and 0.4897 for all the subcomponents of collaboration show that only minor variations are seen in the responses received. Further, for all the subcomponents of collaboration the recorded skewness are negative values which mean data is more concentrated on the tale’s left side.

Further, for all the sub-components of collaboration the mode was recorded as 4. Further for connectivity, integration, and visibility the kurtosis value have values in the range − 0.5 to 0.5. Thus, these kurtosis values mean that the data recorded for connectivity, integration and visibility has been symmetrical. However, for information sharing and coordination the kurtosis values have been 2.6629 and 2.3614, respectively, which suggest that the data for information sharing, and coordination have been highly skewed.

Reliability and validity analysis

Since the study used survey data, there is a requirement in reporting the reliability of the internal consistency. The most often used test is Cronbach alpha to determine the instruments' internal consistency. A Cronbach Alpha of 0.7 or above implies that the instrument has good internal consistency (justifiable reliability) for the purpose of assessing the reliability of the research tool (Heale and Twycross 2015; Bhatnagar et al. 2014Koonce and Kelly 2014). According to Table 2, Cronbach alpha of above 0.7 was derived for each dimension by conducting a reliability analysis test through SPSS statistical tool. This shows that the questionnaire of this research study has a good internal consistency, and it will provide credible results for this research study.

Table 2.

Internal consistency and Sample adequacy Source: Authors’ calculation

| Variables | Observation | Cronbach’s Alpha | Kaiser Meyer Olkin (KMO) |

|---|---|---|---|

| Tea supply chain resilience | 137 | 0.820 | 0.715 |

| Information Sharing | 137 | 0.720 | 0.709 |

| Connectivity | 137 | 0.762 | 0.736 |

| Coordination | 137 | 0.726 | 0.704 |

| Integration | 137 | 0.707 | 0.677 |

| Visibility | 137 | 0.738 | 0.724 |

We also utilised the Kaiser Meyer Olkin (KMO) measure of sampling adequacy test to prove the validity of the questionnaire as shown in Table 2. According to Kaiser (1974), the following (KMO) parameters are employed as a guideline; the bare minimum should be 0.50. Values ranging from 0.50 to 0.60 are average, values ranging from 0.60 and 0.70 are acceptable, values ranging from 0.70 to 0.80 are excellent, and values above 0.90 are superb. The Table 2 summarises the Kaiser Meyer Olkin (KMO) measures for each variable of this research study. Thus, the results proves that the integration dimension has an acceptable level of validity while the individual five dimensions have an excellent level of validity.

Regression analysis

Regression analysis examines the relationship between two or more than two variables. regardless of several types of regression analysis, its root inspects the relationship between one or more independent variables on dependent variable.

In our study, supply chain resilience is the outcome variable while the five sub-components of collaboration consists of information sharing, connectivity, coordination, integration, and visibility play the role of predicting variables. To assure that the considered sub-components of collaboration are not strongly correlated to each other, multi-collinearity test was done having used the variance inflation factor (VIF) and tolerance. The VIF and tolerance was measured, and was found these to be low (Tolerance maximum level = 0.934 and VIF maximum level = 2.083), which interpreted that multicollinearity issue was not significant in the current study.

As summarised in Table 3, all the independent variables including information sharing, connectivity, coordination, integration, and visibility in the derived model are significantly predictive of supply chain resilience.

Table 3.

Regression results Source: Authors’ calculations

| Variables | Model Results |

|---|---|

| Information sharing (X1) | 0.185*** (0.045) |

| Connectivity (X2) | 0.358*** (0.058) |

| Coordination (X3) | 0.338*** (0.061) |

| Integration (X4) | 0.171*** (0.043) |

| Visibility (X5) | 0.184*** (0.044) |

| Constant | − 0.888*** (0.257) |

| R-Squared | 0.764 |

| Adj. R-Squared | 0.755 |

| Observation | 137 |

Standard errors in parentheses

***Significant at the 1% level

As per the hypotheses tests, all the relationships were identified to be positive and significant and the hypotheses were proven accordingly. The regression model results are presented in Fig. 4. Thus, information sharing, connectivity, coordination, integration, and visibility have positive significant impact on supply chain resilience. The positive coefficient, interprets that for every percentage point improvement in ‘information sharing’ the overall supply chain resilience in Sri Lankan tea export companies will increase by 0.19%. Correspondingly, the rest of the recorded positive coefficients of connectivity, coordination, integration and visibility demonstrate that for every percentage improvement of each sub-component of collaboration, 0.36%, 0.34%, 0.17% and 0.18% increases, respectively, are likely/expected in the overall supply chain resilience of Sri Lankan tea exporting companies.

Fig. 4.

Regression model results summary.

Source: Authors’ demonstration based on modelling results

Thus, based on these findings, the multiple regression model can be derived as follows. This explains more than 75% of the total variation of tea supply chain resilience suggesting good explanation power.

Thematic analysis

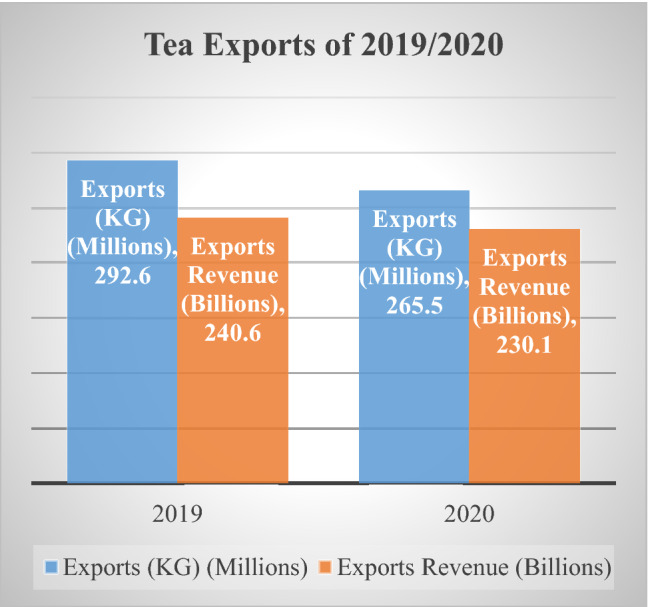

Thematic analysis is a technique for systematically recognising, arranging, and contributing insights across a data collection or set of data into meaningful patterns or themes. By focussing on a piece of data, through thematic analysis, reserchers can detect and comprehend communal or shared meanings and experiences. Simply, it is a method that can be used to identify patterns in a set of data collected (Castleberry and Nolen 2018). In this scenario, the thematic analysis was conducted manually since the sample size was small. The analysis was conducted having selected the best six tea exporting companies which had the best supply chain resilience based on the responses received in quantitative approach. The main objective of adopting a qualitative approach was due to its suitability to explore how the Sri Lankan tea supply chain used its capabilities to survive before the Covid-19 and during the Covid-19 pandemic. The interviews were conducted through telephone conversations and the authors gathered sufficient data to identify comoon themes, patterns, ideas etc., in achieving the above stated objective. According to Braun and Clarke (2006), thematic analysis is a method that identifies, analyses and records themes from a set of data collected. Likewise, the authors derived 13 codes which were then categorised into six themes (Fig. 5).

Fig. 5.

Themes and codes derived from the Thematic Analysis.

Source: Based on authors' illustration

Operationalisation of supply chain resilience

The first theme identified mainly focussed on the main area of this research, which is supply chain resilience. Resilience is a new concept that differs from standard risk management techniques (Pettit et al. 2010), because traditional risk assessment is incapable of dealing with unexpected events. The tea exporting companies have deployed their resilient capabilities to survive during the Covid-19 pandemic than before the Covid-19 pandemic, “During the Covid-19 period, we enhanced the scope of the supply chain resilience” (Respondent #1). During the Covid-19, companies have adopted many safety measures to respond to the unexpected disruptions that can occur. “In our production department and supply department, we needed our employees to work at their full capacity. So, we have introduced a bubble system for them. In this bubble system, we have provided the same transport vehicles, washrooms, dining room for a given set of employees. As such, I think during Covid-19, our supply chain resilience became much useful and helped us mitigate the disruptions than before the Covid-19” (Respondent #1). Based on these responses, it was evident that the companies deployed strategies related to supply chain resilience during the pandemic than before the Covid-19 to a considerable extent. “We managed to survive unexpected disruptions using the resilience of the supply chain in our company way more than before the Covid-19 situation” (Respondent #6).

Internal and external connectivity

The majority of respondents indicated that the level of connectivity with their external and internal parties to share information prior to the Covid-19 pandemic differed during the Covid-19 pandemic. This was observed after analysing the consent of tea supply chain professionals regarding the supply chain's connectivity to share information during and prior to the pandemic. Connectivity across organisational boundaries is critical for sharing information; it allows for the provision of relevant, accurate, and timely data so that it may result in better and more persuasive decisions making. It is considered a valuable asset to the retail supply chains (Chen et al. 2000; Lee et al. 2000; Aycan et al. 2000). “Before Covid- 19, we were not well connected to share information, however, for some extent, we had connectivity to deal with the external parties to mitigate disruptions, especially with the tea brokering factories, but with the Covid-19 pandemic, our information sharing both internally and externally became more advanced than before” (Respondent #1). Furthermore, the respondents mentioned that due to lockdown situations and travel restrictions were difficulties in sustaining the connection. “Before the Covid-19 pandemic, we were very well linked to communicate information both internally and externally. However, due to the lockdowns and travel restrictions enforced during the Covid -19, we encountered some difficulties in sustaining the connections” (Respondent #4) (Respondent #2).

Ontime pickup and delivery

The third theme identified from the data gathered, showed more perspectives into the connectivity of the organisation. Connectivity of the organisation is vital to sustain on time pick up and deliveries. According to the data gathered through the interviews, it was evident that the respondent who was able to do on time pick-ups and deliveries before the Covid-19 pandemic has faced many challenges such as labour shortages, lack of container availability during the Covid-19 pandemic which led to delays in pick up and deliveries of their respective companies. “We had a labour issue as well as a shipment issue due to a lack of containers. We had to cut down the volumes shipped compared to the previous years because we couldn’t bear the risk of holding these, so we spoke with the buyer and informed them of the shipments volumes we can do” (Respondent #5). “We lost control over some shipment deliveries during the Covid-19 pandemic because of low vessels availability and because of the increase in freight prices. However, we still had control over deliveries within the country because exporting tea is an essential service” (Respondent #2).

Problem solving through online platforms and collective learning

Most of the tea exporting companies responded that they had collective learning programmes for their employees and labourers prior to the Covid-19 period about problem-solving through collective learning. Prior to the Covid-19 period, most companies relied on physical collective learning programmes such as brainstorming, sharing of ideas/experience etc., to solve their challenges rather than employing online problem-solving platforms. "I consider that collective learning is critical for an organisation to grow as one whole company. Every employee in the company should contribute for a common goal, which can only be achieved through concepts such as collective learning. We had many programmes in place in the organisation before Covid-19, which would build /create awareness in the employees about the potential and unexpected risks they could encounter and how to face them while working towards the company's goal. As for the use of online platforms, we didn't use online platforms daily to communicate. We always had physical meetings" (Respondent #6). This theme is directed to coordination which is a subcomponent of collaboration. Coordination is the process of arranging activities in two or more groups so that they can work together successfully and are aware of each other's actions (Cao et al. 2008). The respondents mentioned getting together and learning together in workshops will help them to better understand the disruptions and seek solutions for mitigating challenges.

Integrated decision making

Integration, according to Parast and Spillan (2014), is a collection of natural mechanisms including internal and external relationships that improve operational and strategic performance. During the interviews, the majority of selected tea exporting companies stated that they implemented some integrated decisions during the Covid-19; in addition, they replaced some integrated choices made during the supply chain meetings concerning the organisation's supply chain resilience prior to Covid-19. “From the supply chain perspective, we had to set up regular meetings and make decisions regarding the situations. Sometimes we had to modify the decisions we made before Covid-19. Significantly, when the tea auction was delayed for a month, we had to come up with new findings with the finance department to find solutions for the problems during Covid-19, and we managed these difficulties. So, I think the integrated decision making approach we adopted during Covid-19 helped to minimise our issues for a certain extent” (Respondent #1).

Information visibility

This theme was derived as the last theme from the data gathered through the interviews with the tea exporting companies. When interviewees were questioned, they were all directed to the track and trace system of the organisation which provides accurate information on the pick-ups and deliveries of the company. The track and trace system of an organisation indicated the visibility of the supply chain in an organisation. Supply chain visibility helps businesses to be aware of consumer expectations and acquire the most up-to-date market data, allowing them to manufacture goods that match the needs of their customers (Pettit et al. 2010). While some respondents were of the view that they could mitigate the issues occurred during the Covid-19 because of the track and trace system, some mentioned that the track and trace system was not much of an impact when mitigating the disruption before the Covid-19 and during the Covid-19 pandemic. “Before Covid-19, we had track and trace systems; still, we have track and trace systems. But before Covid-19, we did not use those systems frequently used. Most of the time, we did not use track and trace systems practically. We just had an idea about how to use these systems, that’s all” (Respondent #1). “We do have implemented the track and trace system but it was not that useful, as the operations run smoothly” (Respondent #3).

The current study findings with respect to information sharing and supply chain resilience are inconsistent with the findings of Kwon and Suh (2004), which stated that information sharing is essential in the trust-building process since it helps companies to learn about each other's routines and establish conflict resolution methods. Furthermore, reduced inventory, lower costs, enhanced tracking and monitoring, and more effective capacity use are all advantages of information sharing for businesses, and it helps mitigate disruptions in organisations (Lotfi et al. 2013). Past literature has proved that information sharing has a positive impact on supply chain resilience (Chen et al. 2000; Lee et al. 2000).

According to the findings of this research study, Hypothesis one (H1) has proved that information sharing has a positive impact on tea supply chain resilience in Sri Lanka during Covid-19 as a sub-component of collaboration. However, when compared to other independent variables, information sharing has the third lowest impact on tea supply chain resilience. The reason for this is the Covid-19 pandemic. Because of the Covid-19 pandemic, most of the organisations have transformed to virtual platforms, since it is new to tea exporting companies, organisations were not able to share information properly. Therefore, when implementing supply chain resilience in Sri Lankan tea exporting companies, information sharing needs to be considered as an essential factor that helps to mitigate organisation un expected disruptions. As highlighted under literature review, information sharing is can be subtle and sensitive. Probably, the sample respondents may have lacked such skills, or leadership has been inadequate on materialising benefits of information sharing—i.e. about ‘getting the best’ out of it.

The significant positive impact of connectivity and supply chain resilience derived through the findings are in consistent with the findings of Fawcett et al. (2007). This study also has emphasised the connectivity of managers across organisational boundaries, delivers relevant, timely, and accurate data which would help the organisations in making better consistent decisions while helping to mitigate the unexpected disruptions (Fawcett et al. 2007).

The significant positive impact of coordination on supply chain resilience is also in consistent with the study findings of Malone and Crowston (1994). As per Malone and Crowston (1994), coordination regulates interdependencies among activities to achieve the goals. Further, Dyer and Singh (1998) stated that creating efficient coordination inside and outside a company's borders is critical to gaining a competitive edge and maximising profits. Even in disruptions, the proper coordination between members will help to mitigate the disturbance.

The findings regarding the significant positive impact of integration and supply chain resilience are in consistent with previous research findings having stated that integration is an important factor for a company's success (Huo 2012; Zsidisin et al. 2015). In addition, past researchers also emphasised that integration increases a company's resilience (Christopher and Peck 2004; Jüttner and Maklan 2011; Wieland and Wallenburg 2013).

Finally, the study finding of significant positive impact of visibility on supply chain resilience is on par with the study findings which indicates that by enhancing the visibility across the supply chain, it is possible to mitigate the negative consequences of supply chain interruptions and improve the supply chain resilience (Jüttner and Maklan 2011; Blackhurst et al. 2005). However, when compared with the rest of the sub-components of collaboration, visibility has relatively less positive impact on supply chain resilience. As per Barret and Oke (2007), organisations can achieve visibility through improved decision-making, responsiveness, and product efficiency. Therefore, in this scenario, the reason to have less visibility could be weak responsiveness, delays in decision-making, and product inefficiencies occured due to the Covid-19 pandemic. Further, based on the thematic analysis it was found that, the best performing tea exporting companies in terms of resilient supply chains during the Covid 19, has been focussing mainly on being connected internally and externally which ensured the on-time deliveries and pickups. Moreover, the findings further stated that, having online collective learning platforms with availability and visibility of information enabled them in successful integrated decision making which was essential in mitigating the challenges encountered during an unexpected disruption like Covid 19.

Conclusion

The study results indicated that all the five sub-components of collaboration significantly positively impacted tea supply chain resilience in Sri Lanka during the Covid-19 pandemic. Accordingly, information sharing, connectivity, coordination, integration, and visibility in the tested model were found to be significantly predictive of supply chain resilience. However, out of all five subcomponents of collaboration, ‘connectivity’ has the highest positive impact on tea supply chain resilience, while coordination has the second highest strong positive relationship with tea supply chain resilience. The thematic analysis findings also suggested that connectivity enabled tea exporting companies in Sri Lanka during Covid-19 to reduce delivery time and on-time pickups.

In addition, the findings of the thematic analysis stated that best performing tea exporting companies in Sri Lanka during the Covid-19 had used connectivity, information and collective learning via online platforms. In doing so, their purpose was to make effective integrated decisions which enabled these companies to carry out operations productively despite the severity of Covid 19 unexpected disruption.

The current study fills the literature gap mentioned by Aboah et al. (2019), as no study so far has examined the impact of subcomponents of collaboration on supply chain resilience. Thus, this study is the first to investigate the effect of subcomponents of collaboration on supply chain resilience, having taken Sri Lankan tea exporting companies during the Covid-19 pandemic as a case study. The findings of this study will support as a guideline for respective authorities to regulate the effect on supply chain resilience during massive pandemic situations like the Covid-19 and also in disasters of similar magnitude. In addition, these findings can contribute to strengthening the sub-components of collaboration in better formulating the strategies which enable supply chain resilience in agricultural supply chains. Supply chain resilience, through its ability to restore normalcy, assists in sustaining the competitive edge, business survival, and minimising loss of key revenue sources of the economy. Considering the country’s export basket (weak exports and essential imports), this is crucial for a developing country like Sri Lanka for economic rebound post-pandemic.

Further, this study is the first empirical study focussing on the tea supply chain resilience in the Sri Lankan context. Thus, the findings of our study will also assist the Sri Lankan tea exporting firms in effective formulation of supply chain strategies inculcating the subcomponents of collaboration assigning more weight to connectivity and coordination. Such an approach would reduce the severity of unexpected disruptions like Covid-19 or similar disasters in future.

Recommendations

There is a need for more comprehensive research studies and evidence-based literature on the supply chain resilience of the Sri Lankan tea industry due to the lack of research in this arena.

This framework only focusses on the impact of sub-components of collaboration when assessing tea supply chain resilience in Sri Lanka; therefore, we recommend that future researchers expand the scope of the study to consider the inclusion of additional factors or use some controls that are relevant in studies on tea supply chain resilience.

The qualitative approach of the present study focussed on the six best performing tea exporting companies in terms of resilient supply chains during Covid 19. However, in future studies, the sample size could be expanded to include companies operating in diverse geographical locations. N-Vivo, MXQDA could be considered as tools for qualitative analysis instead of the manual thematic analysis conducted in our study.

Connectivity and coordination were found to have the highest significant positive impact on the tea supply chain's resilience. Future researchers could dig deeper through a qualitative study to understand the behaviour of a firm being connected and coordinated, and explore the sensitivity of these variables, and gear up the company in being resilient in the supply chain.

Having the framework tested and identifying how it has been replicated in other industries and countries apart from the Sri Lankan tea exporting companies would increase the generalisability of the findings. It would also unveil the bigger picture of how supply chain resilience can occur, evolve and differ among various sectors, countries and regions.

Limitations

This research study encountered several limitations: the quantitative phase findings and analysis were based only on 137 tea exporting companies in Sri Lanka. Furthermore, the findings and analysis of the qualitative phase of this study were limited to six Sri Lankan tea exporting companies. Therefore, conducting future research studies at a broader level will enable the tea exporting firms to capture the holistic picture of the overall supply chain resilience of tea exporting firms in Sri Lanka.

Appendix 1: Literature review summary table

See Table 4.

Table 4.

Literature Review Summary Table Source: Author's development based on Literature

| Variable | Paper title | Year | Author | Research methods | Variables studied |

|---|---|---|---|---|---|

| Supply chain readiness, response and recovery for resilience | 2017 | Chowdhury and Quaddus |

Quantitative study sample 10 respondents from the apparel manufacturing companies 5 were from suppliers/accessory-producing companies Qualitative study sample five apparel manufacturers, three suppliers and an academic to ensure that the question content |

supply chain readiness, response and recovery, supply chain performance, supply chain risk mgt culture, learning and development, support factors, supply chain orientation | |

| Supply chain resilience in a developing country context; a case study on the interconnectedness of threats, strategies and outcomes | 2017 | Tukamuhabwa, Stevenson and Busby | Case study | Supply chain disruptions, Redundancy | |

| Achieving supply chain resilience: the role of procurement | 2014 | R. Pereira, Christopher and L. da Silva | Systematic Literature Review | complexity, financial weakness, lack of capacity, lack of collaboration, lack of information | |

| The role of collaboration in supply chain resilience | 2014 | Scholten, Scott and Fynes | Case study | Collaboration | |

| Ensuring Supply Chain Resilience: Development and Implementation of an Assessment Tool | 2013 | Pettit, Croxton and Fiksel | Qualitative |

Vulnerability factors Controllable capability factors |

|

| Supply chain resilience in the global financial crisis: an empirical study | 2011 | Jüttner and Maklan | Qualitative—Content Analysis | Supply chain resilience, Supply chain vulnerability, supply chain risk management | |

| ERP II systems to support dynamic, reconfigurable and agile Virtual Enterprises | 2009 | Ponis and Spanos | Qualititative | Supply chain management, integration, virtual enterprises and ERP | |

| An empirically derived agenda of critical research issues for managing supply-chain disruptions | 2005 | Blackhurst et al | Case study |

Supply-chain management, sourcing, supply-chain disruptions, supply-chain uncertainty, supply-chain risk |

|

| Building the resilient supply chain | 2004 | Christopher and Peck | Qualitative | Supply chain resilience, supply chain collaboration, agility, supply chain visibility and supply chain velocity | |

| To be resilient, an organisation must dramatically reduce the time it takes to go from 'that can't be true'to 'we must face the world as it is.' | 2003 | Hamel and Valikangas | Systematic Literature review | Resilience | |

| Resilience capabilities | Modelling and improvement of supply chain with imprecise transportation delays and resilience factors | 2014 | Azadeh et al | Qualitative study where a model was created in order to consider in which the disruption may occur in a transportation system | supply chain resilience, supply chain and transportation system, visibility and redundancy |

| Analysis of the Reliability and Validity of a Mentor’s Assessment for Principal Internships | 2014 | Melnyk et al | Quantitative study, the prinicipal internship mentors assessment was used to collect data and 229 educational leadership internship completers were the sample | reliability, integration | |

| The Ripple Effect How manufacturing and retail executives view the growing challenge of supply chain risk | 2013 | Marchese and Paramasivam | Qualitative study | Supply chain risk, Ripple Effect | |

| Ensuring supply chain resilience: Development and implementation of an assessment tool | 2013 | Pettit, Croxton and Fiksel | Quantitative study, development of a measurement tool named Supply Chain Resilience Assessment and Measurement, data gathered from seven global manufacturing and service firms. Used mixed method triangulation | supply chain resilience, supply chain performance | |

| Supply chain resilience in the global financial crisis: An empirical study’, Supply Chain Management | 2011 | Jüttner and Maklan | Qualitative study in which data was collected through three longitudinal case studies with three supply chains | supply chain risk, supply chain resilience, supply chain vulnerabilities | |

| Increasing supply chain resilience in a global sourcing context’, Production Planning and Control | 2010 | Colicchia, Dallari and Melacini | Qualitative analysis, in depth analysis | supply chain risk management, in bound supply chain resilience | |

| The design of robust value-creating supply chain networks: A critical review | 2010 | Klibi, Martel and Guitouni | Qualitative study based on supply chain network | supply chain robustness, supply chain network | |

| Building the Resilient Supply Chain | 2004 | Christopher and Peck | Qualitative study | Risk management, risk analysis, supply chain management | |

| The Collaborative Supply Chain | 2002 | Simatupang and Sridharan | Qualitative study | Supply chain, supply chain resilience, supply chain collaboration | |

| Collaboration | The role of collaboration in supply chain resilience | 2015 | Scholten and Schilder | Case study | Collaboration |

| Ensuring supply chain resilience: Development and implementation of an assessment tool | 2013 | Pettit, Croxton, and Fiksel | Quantitative study, development of a measurement tool named Supply Chain Resilience Assessment and Measurement, data gathered from seven global manufacturing and service firms. Used mixed method triangulation | supply chain resilience, supply chain performance | |

| Supply chain collaboration for improved forecast accuracy of promotional sales | 2012 | Ramanathan | case study approach | collaboration, information exchange, supply chain | |

| Supply chain resilience in the global financial crisis: An empirical study’, Supply Chain Management | 2011 | Jüttner and Maklan | Qualitative study in which data was collected through three longtidunial case studies wih three supply chains | supply chain risk, supply chain resilience, supply chain vulnerabilities | |

| The supply chain crisis and disaster pyramid, A theoretical framework for understanding preparedness and recovery | 2009 | Richey | literature from the resource‐based view (RBV) of the firm, communication theory, competing values theory, and relationship management theory | supply chain management, contingency planning | |

| Designing CPFR collaborations: Insights from seven case studies | 2007 | Danese | Seven case studies of supply networks whose central firms operate in different sectors have been analysed | Collaborative Planning, Forecasting, and Replenishment (CPFR) | |

| Mapping supply chains on risk and customer sensitivity dimensions | 2006 | Faisal et al | Graph theoretic approach | supply chian management, risk management, consumer behaviour | |

| Reconciling supply chain vulnerability, risk and supply chain management | 2006 | Peck | Qualitative study | supply chain management, corporate governance, vulnerability | |

| Supply chain collaboration: What’s happening? | 2005 | Min et al | Supply chain executives provided insights into collaboration. Survey data, personal interviews, and a review of the collaboration literature | supply chain resilience, supply chain collaboration | |

| Understanding the meaning of collaboration in the supply chain | 2004 | Barratt | Systematic Literature Review | supply chain management, supply chain collaboration | |

| Maximizing the Retailer/Manufacturer Relationship: The Notiva Retail Collaboration Solution | 2004 | Greenbaum | Qualitative Study | Collaboration | |

| The relationship between the learning organisation concept and firms’ financial performance: An empirical assessment | 2002 | Ellinger et al | managerial responses to the Watkins and Marsick Dimensions of the Learning Organisation Questionnaire (DLOQ) instrument along with both perceptual and objective measures of firms' financial performance | collaboration, supply chain performance | |

| Supply chain collaboration: exploring the early initiatives -part one | 2001 | Barratt and Oliveira | Survey,IDEF0 Process Mapping and the Questionnaire | Collaborative Planning, Forecasting, and Replenishment (CPFR) | |

| An empirical investigation into supply chain management: A perspective on partnerships | 1998 | Spekman, Kamauff and Myhr | Qualitative Study | Supply chain management, supply chain partnership, collaboration | |

| Information sharing | Challenges in sharing information effectively: examples from command and control | 2016 | Sonnenwald | Qualitative study- data collected through inerviews with military persons and 3 types of battlefield training simulations | |

| Evaluation of supply chain collaboration: A case of apparel retail industry in India | 2011 | Anbanandam, Banwet, and Shankar | Quantitative study which was conducted using graph theory. In order to collec data, conducted a survey | top management commitment, information sharing, trust among supply chain partners, long term relationships, risk and reward sharing | |

| Information sharing in global supply chain alliances | 2008 | Premus and Sanders | Quantitative study which was carried using survey methodology with the OEM manufacturing firms | Supply chain problem areas, degree and type of information shared | |

| Information supply chain: A unified framework for information-sharing | 2005 | Sun and Yen | Qualitative study | Information supply chain, supply chain management | |

| Factors affecting the level of trust and commitment in supply chain relationships | 2004 | Kwon and Suh | Quantitative study | Trust, Commitment, Asset specificity, behavioral uncertainty, information sharing, perceived satisfaction, partners reputation, perceived conflicts | |

| Information flow in automotive supply chains—Identifying and learning to overcome barriers to change | 2003 | Childerhouse et al | Quantitative study—cardiff business process change model | cultural barriers, technological barriers, organisational barriers, finance barriers | |

| Organisational knowledge and communities of practice | 2002 | Davenport and Hall | Qualitative study | Motivation, Economic rewards | |

| Aligning supply chain strategies with product uncertainties | 2002 | Lee | Quantitative study | Retailers ordering decision, manufacturers ordering decision | |

| Quantifying the bullwhip effect in a simple supply chain: the impact of forecasting, lead times, and information | 2000 | Chen et al | Quantitative study | Demand forecast, order lead times | |

| Value of information sharing in a two-level supply chain | 2000 | Lee, So and Tang | Quantitative study | Retailers ordering decision, manufacturers ordering decision | |

| Information technology influences on world class logistics capability | 1997 | Closs, Goldsby and Clinton | Mixed method, conducted interviews with world class logistics firms | Accuracy, External connectivity, Flexibility | |

| Development of a Tool for Measuring and Analyzing Computer User Satisfaction | 1983 | Bailey and Pearson | Quantitative Study | Accuracy, Confidence, Timeliness, Relevancy | |

| Connectivity | From Risk to Resilience | 2015 | Fiksel et al | Quantitative | Global supply chain, downside risk and Risk Management |

| A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness | 2014 | Brandon-Jones et al | contingent resource-based view and survey method | Supply chain resilience, robustness, information sharing, connectivity and visibility | |

| The Effects of Competitive Environment on Supply Chain Information Sharing and Performance: An Empirical Study in China | 2014 | Huo, Zhao, and Zhou | Survey method | Competitive environment, information sharing and supply chain performance | |

| Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration | 2012 | Prajogo and Olhager | Survey, chi-square test and confirmatory factor analysis | Logistics integration, information integration, performance and Supply chain integration | |

| Information technology as an enabler of supply chain collaboration: A Dynamic-Capabilities perspective | 2011 | Allred et al | Exploratory multi method research framework and case study data collection interview process | Supply chain performance and supply chain collaboration | |

| The moderating role of barriers on the relationship between drivers to supply chain integration and firm performance | 2009 | Fawcett et al |

in-depth interviews, extensive review of the literature, survey method and moderated multiple regression analysis |

Supply chain integartion, supply chain management | |

| The impact of information technology on supply chain capabilities and firm performance: A resource-based view | 2006 | Wu et al | Field interviews and confirmatory factor analysis | Capabilities of supply chain and information technology | |

| The rhetoric and reality of supply chain integration | 2002 | Fawcett and Magnan | Cross-functional mail survey and case study interveiws | Integration and supply chain management | |

| Flow Coordination and Information Sharing in Supply Chains: Review, Implications, and Directions for Future Research | 2002 | Sahin and Robinson | Systematic Literature Review | Supply chain management,e-business, supply chain coordination and inventory management | |

| It applications in supply chain organisations: a link between competitive priorities and organisational benefits | 2002 | Sanders and Premus | Quantitative | Competitive priorities,it applications and organisational performance measures | |

| Coordination | Supply chain resilience in the global financial crisis: an empirical study | 2011 | Jüttner and Maklan | Systematic Literature Review | Supply chain risk management, Supply chain resilience and supply chain vulnerability |

| How are supply chains coordinated? An empirical observation in textile‐apparel businesses | 2008 | Cao et al | Case study | Supply chain management andvertical marketing | |

| Enterprise architectural framework for supply‐chain integration | 2001 | Chandra and Kumar | Qualitative | Enterprise economies,supply chain management and supply chain | |

| The Relational View: Cooperative Strategy and Sources of Interorganisational Competitive Advantage | 1998 | Notably, Dyer and Singh | Qualitative |

Relation specific assets,knowledge sharing routines,complementary resources and capabilities,effective governance |

|

| Information Distortion in a Supply Chain: The Bullwhip Effect | 1997 | Lee, Padmanabhan, and Whang | Quantitative | Demand Signal Processing, Rationing Game,Order Batching and Price Variations | |

| Integration | The effects of competitive environment on supply chain information sharing and performance: An empirical study in China | 2016 | Huo et al | Quantitative research which was conducted using regression analyis and structural equation modelling | Organisational commitment, managers multi skilling, employees multi skilling, supplier integration, internal integration, customer integration, competitive performance |

| Ensuring supply chain resilience: development of a conceptual framework | 2013 | Petti et al | Quantittative Research Study | External pressure, connectivity, sensitivity,resource limit, turbulance, customer disruptions, deliberate threats | |

| The influence of relational competencies on supply chain resilience: a relational view | 2013 | Wieland and Wallenburg | Quantitative study which was used structural equation modelling | communication, cooperation, integration, agility, robustness, supply chain customer value | |

| The impact of supply chain risk on supply chain integration and company performance: a global investigation | 2013 | Zhao et al | Quantitative study which was used structural equation modelling | Supply delivery risk, demand variability risk, supplier integration, internal integration, customer integration, customer satisfaction, competitive performance | |

| Supply chain resilience in the global financial crisis: An empirical study’, Supply Chain Management | 2011 | Jüttner and Maklan | Systematic Literature review | supply chain risk management, supply chain vulnerability, supply chain resilience | |

| Building the Resilient Supply Chain | 2004 | Christopher and Peck | Qualitative Study | Supply chain engineering, supply chain collaboration, agility, supply chain risk management culture | |

| Supply chain information-sharing: Benchmarking a proven path | 2002 | Fawcett and Magnan | Qualitative Study | culture, leadership styles | |

| Arcs of integration: An international study of supply chain strategies | 2001 | Frohlich and Westbrook | Quantitative study | access to planning systems, sharing production plans, packaging customisation, delivery frequencies | |

| twenty-first century logistics: making supply chain integration a reality | 1999 | Bowersox et al | Quantitative Study | communication, agility, robustness | |

| What Is the Right Supply Chain For Your Products | 1997 | Fisher | Qualitative study- case study | Volume, volatility, order line value, order line weight | |

| Visibility | The influence of relational competencies on supply chain resilience: a relational view | 2013 | Wieland and Wallenburg | Structural equation modeling (SEM) | Communication, cooperation, integration, resilience supply chain resilience, supply chain agility and robustness |

| Supply chain control logic for enabling adaptability under uncertainty | 2011 | Makris, Zoupas and Chryssolouris | Case study | supply chain adaptability, buyer behaviour modelling, Bayesian networks | |

| The strategic value of supply chain visibility: increasing the ability to reconfigure | 2010 | Wei and Wang | Cross-sectional mail survey | supply chain visibility, dynamic capabilities, reconfigurability, strategic value | |

| Antecedents of supply chain visibility in retail supply chains: A resource-based theory perspective | 2007 | Barratt and Oke | Qualitative—Indepth semi-structured interview | Supply chain management, visibility | |

| An empirically derived agenda of critical research issues for managing supply-chain disruptions | 2005 | Blackhurst et al | Case study |

Supply-chain management, sourcing, supply-chain disruptions, supply-chain uncertainty, supply-chain risk |

|

| Supply chain collaboration: exploring the early initiatives -part one | 2001 | Barratt and Oliveira | Survey, IDEF0 Process Mapping and the Questionnaire | Collaborative Planning, Forecasting, and Replenishment (CPFR) |

Appendix 2: Survey quesionnaire

Operationalizing resilience through collaboration in the sri lankan tea supply chain during COVID-19

Dear Sir/Madam,

The following questionnaire will only take 10–15 min to complete. We assure that the data gathered will remain confidential and will be only used for research purposes.

| SECTION B | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Below are the statements which describe the tea supply chain indicators. Please indicate to what extent you agree or disagree with each statement. (1 = Strongly Disagree, 2 = Disagree, 3 = Neutral, 4 = Agree, 5 = Strongly Agree) | |||||||||

| Tea supply chain resilience | 1 | 2 | 3 | 4 | 5 | ||||

| In my organization, the supply chain has the capacity to react quickly to the disturbances that happen during the Covid-19 | |||||||||

| In my organization, the supply chain has the capacity to provide appropriate responses for crisis scenarios that occurred during the Covid-19 | |||||||||

| In my organization, the supply chain was able to react quickly for the critical situations during Covid-19 | |||||||||

| In my organization, the supply chain was capable of preventing the Covid-19 disruptions before it occurs | |||||||||

| In my organization, a flexible strategy plan was used to eliminate the delays in the tea supply chain during Covid-19 | |||||||||

| In my organization, there were sufficient resources to prepare for the emergencies that arose during the Covid-19 | |||||||||

| In my organization, the supply chain possessed the potential to recover from the disruptions during a shorter period | |||||||||

| In my organization, the supply chain had the capability to recover from the disruptions by investing less amount of money | |||||||||

| IV-1: Information sharing | |||||||||

| In my organization, connecting internally and externally to share information through the tea supply chain during Covid-19 was possible | |||||||||

| In my organization, suppliers’ willingness to share information benefitted to mitigate supply chain disruptions during the Covid-19 pandemic | |||||||||

| In my organization, information shared by the suppliers are up-to-date during the Covid-19 pandemic | |||||||||

| In my organization, accurate information sharing throughout the tea supply chain was helpful to achieve organization’s targets during Covid-19 pandemic | |||||||||

| IV-2: Connectivity | |||||||||

| In my organization, the ability to connect digitally within the tea supply chain during Covid-19 pandemic is high | |||||||||

| In my organization, connecting transportation modes during Covid-19 was possible without any issues | |||||||||

| In my organization, the cost of connecting digitally was affordable to the organization during Covid-19 pandemic | |||||||||

| In my organization, on time pickup and delivery were implemented without any obstructions during Covid-19 pandemic | |||||||||

| IV-3: Coordination | |||||||||

| My organization was capable of communicating across the internal and external functions of the organization during Covid-19 pandemic | |||||||||

| In my organization, the social interaction in the organization and the tea supply chain is high during Covid-19 pandemic | |||||||||

| In my organization, collective learning of the tea supply chain disruptions during Covid-19 helped to avoid unexpected risks | |||||||||

| In my organization, solving problems through online platforms collectively, raised the efficiency of the tea supply chain during Covid-19 pandemic | |||||||||

| IV-4: Integration | |||||||||

| In my organization, integration among the internal tea supply chain functions helped to maintain a better relationship during Covid-19 pandemic | |||||||||

| In my organizations, meetings held in the supply chain department during the Covid-19 pandemic helped to face the disruptions that happened in the tea supply chain | |||||||||