Abstract

Liquid-state fermentation has been increasingly applied in the industrial glutinous rice wine (GRW) production. However, products brewed by this emerging technique possess some deficiencies in flavor quality. Therefore, this study firstly developed and optimized an innovative pulping technique by the synchronously pulping and gelatinizing treatment (Process I) to improve GRW flavor quality, and then revealed the influences of Process I on raw materials properties, oenological parameters, fermentation process, and flavor characteristics of GRW. Results show that Process I significantly (p < 0.05) enriched the soluble solid and crude protein content of glutinous rice milk by improving gelatinization degree and pulping efficiency, which consequently enhanced the microbial growth, glycolysis, and protein decomposition during the GRW fermentation process. GC–MS analysis shows that Process I sequentially significantly (p < 0.05) enhanced the esterification and Ehrlich or Harrison pathway during the fermentation process. This contributed to a higher content of key ester and alcohol compounds.

Supplementary Information

The online version contains supplementary material available at 10.1007/s10068-022-01119-7.

Keywords: Glutinous rice wine, Liquid-state fermentation, Gas chromatography-mass spectrometry (GC–MS), Volatile flavor compound, Response surface methodology

Introduction

Glutinous rice wine (GRW), also known as rice wine or sweet rice wine, is popular in many Asian countries, and GRW is a cultural identity of some regions with a distinctive cultural value in China (Huang et al., 2021).

Currently, GRW is mainly brewed through the solid-state fermentation mainly including steaming glutinous rice, cooling the cooked glutinous rice, adding starters, moving into the fermentation jars, and conducting the fermentation process (Liang et al., 2020). The entire making process is performed in an open environment without sterilization procedure so that numerous environmental microorganisms enter the raw materials and fermented glutinous rice (Huang et al., 2021). Consequently, starters, raw materials, and fermented grains can be contaminated by harmful environmental microbes from the air, workers, and tools during the making process, which leads to health risks and huge economic losses (Suzuki et al., 2008). For example, some Monascus strains produce the mycotoxin citrinin, a secondary toxin (Liao et al., 2014). In addition, solid-state fermentation makes it hard to produce GRW via modern brewing technologies, such as transporting systems and fermentation tanks on a large scale (He et al., 2016). This is mainly because the substrate has a heavy viscosity and forms agglomerates after the cooling treatment (Wang, 2018), which makes it difficult to transport via pipelines. To mitigate the health risks, microbial contamination, and low producing efficiency, researchers and engineers have developed the liquid-state fermentation through which the making process can be conducted in a close environment such as transporting and fermenting liquid raw materials via close pipelines and in large-sized tanks, respectively (He et al., 2016).

To date, most researchers and engineers make glutinous rice milk (GRM), the liquid substrate for making GRW, mainly by two pulping techniques. Through the first pulping technique, glutinous rice is firstly pulped with pulping machines at room temperature, and then the raw GRM is gelatinized at high temperature via heaters (Yue and Wei, 2002). The second technique is to directly pulp the raw glutinous rice without gelatinization treatment (Wang et al., 2021). However, products produced based on both pulping treatments show some deficiencies in flavor quality such as weak taste and insufficient product style (Yang et al., 2019, 2020). Therefore, it is crucial to develop innovative strategies to solve these problems. Nevertheless, previous studies mainly focus on developing new products and their fermentation process. Rare research reports the innovative pulping techniques enhancing the flavor quality and explores the effects of pulping or gelatinizing treatments on the making process of GRW.

To improve the flavor quality of GRW produced by the industrial liquid-state fermentation, this study aims to develop an innovative pulping technique improving the GRM flavor quality by synchronously pulping and gelatinizing the glutinous rice (Process I). After that, optimized the fermentation process using the GRM produced with this innovative technique via single-factor experiments and response surface methodology. Finally, this study revealed the effects of this innovative pulping technique on the oenological parameters, fermentation process, and flavor characteristics of GRW.

Materials and methods

Sample collection

The glutinous rice was collected from a typical glutinous rice-planting region, Dazhou, Sichuan Province of China. The nutrient content of glutinous rice used in this study was listed in Table S1. The starter was purchased from Angel Yeast Co., Ltd. 200 g GRM samples and 200 g GRW samples at different brewing phases for analyzing physicochemical properties were collected and stored at − 20 °C. The sensory evaluation panel conducted the sensory evaluation once the GRM or GRW samples were collected.

GRM preparation and GRW fermentation

The clean glutinous rice was firstly soaked in ultrapure water overnight at room temperature (12–19 °C) (with a glutinous rice-water ratio of 1:3), and then, drained the water off the soaked glutinous rice. After that, added a certain proportion of ultrapure water according to the designed experiments. Glutinous milk I (GRMI) with soaked glutinous rice and ultrapure water was synchronously pulped and heated at 100 °C and 10,000×g in the pulper for 2 min (Process I). Glutinous rice milk II (GRMII) with soaked glutinous rice and ultrapure water firstly was pulped at 10,000×g for 2 min, and then the pulp immediately was heated at 100 °C for 2 min (Process II). After that, the GRM was cooled to 30 °C, mixed with the starter, and then transferred into 2-L jars and started the fermentation process.

Single-factor test and Box-Behnken design

The single-factor test was used to study the effects of four independent variables including the glutinous rice-water ratio, starter inoculation amount, fermentation temperature, and fermentation time on physicochemical properties and a sensory score of GRM and GRW. After that, based on the results of the single-factor test, Design Expert (version 12, Minneapolis, Minnesota, USA) was employed to design the experiments using the Box-Behnken principle (Jiang et al., 2019) with four independent variables and three levels, and the sensory score was selected as the response variable. Detailed information on single-factor tests and Box-Behnken design was described in the supplementary material. The design of a four-factor three-level test was listed in Table S2. The response surface (3D) was obtained from the model analysis. The optimal value of variables was calculated from the response surface.

Determination of physicochemical properties of GRM and GRW and microbial population during the fermentation process of GRW

The gelatinization degree was determined by detecting enzymatic hydrolysis with some modifications based on the GRM characteristics. The total acid content was determined by measuring the titratable acidity. The content of reducing sugar was determined using the DNS method. The precipitation degree of GRM was measured by the determination testing of soybean milk with some modifications. The soluble solid content was measured at 25 °C with a refractive index detector (Taixin, Shanghai, China). The crude protein content was measured according to the Chinese National Food Safety Standard Determination of Protein in Foods (GB 5009.5-2010). The alcohol and amino acid nitrogen content were determined according to the standard method of the Chinese National Standard (GB 13,662-2018). The bacteria, yeast, and mold population were quantified by real-time quantitative polymerase chain reaction (RT-pPCR). The detailed information of methods for measuring physicochemical properties and the microbial population was described in the supplementary material.

Analyzing volatile flavor compounds of GRM and GRW

The volatile flavor compounds of GRM and GRW were determined by Headspace solid-phase microextraction-gas chromatography-mass spectrometry (HS-SPME-GC-MS). 8 mL sample supernatant was added into a headspace vial containing 3 g sodium chloride, and then added 10 μL 0.34 mg/L 2-octanol (the internal standard, Sigma-Aldrich, Shanghai, China). After that, the vial cap was sealed. A 50/30 µm divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber (Supelco, Bellefonte, USA) was used for aroma extraction at 50 °C 400 rpm for 30 min. The detailed determination method of the GM-MS was described in the supplementary material.

Sensory evaluation of GRM and GRW

The sensory evaluation of GRM was conducted based on the sensory evaluation method of soybean milk with some adjustments. The experiment was conducted by a sensory evaluation panel including 10 panelists (5 males and 5 females 20–50 years old) selected and trained according to the ISO-8586, and one of the panelists is a National First-Class Wine Assessor. The score was given according to the evaluation criteria in Table S3 in terms of color and luster, smell, taste, and texture.

Sensory evaluation of GRW was conducted based on the National Standard Determination Method of Chinese Rice Wine (GB/T 13,662-2018) with some minor adjustments. The experiment was performed by the same sensory evaluation panel on the appearance, taste, smell, texture, and style of GRW. The sensory evaluation was conducted according to the ten-point scale, including 1 point for color, 2 points for smell, 5 points for taste, 1 point for texture, and 1 point for the style. The evaluation criteria were listed in Table S4.

Statistical analysis

The experimental data were statistically analyzed by IBM SPSS (IBM, New York, USA) which conducted the analysis of variance (ANOVA), and the significant level was evaluated at p < 0.05, and extremely significant level was evaluated at p < 0.01. The response surface analysis was conducted by Design Expert version 12 (StatEase, Minneapolis, USA). The visualization of data was carried out by Origin 2018 (OriginLab, Massachusetts, USA).

Results and discussion

Effects of the process I on physicochemical properties of GRM

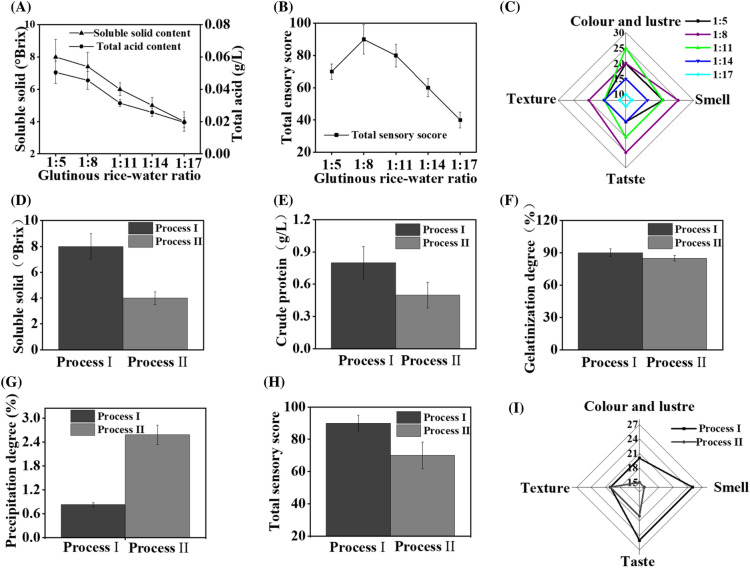

This study first explored the effects of different glutinous rice-water ratios on GRM. After the synchronously pulping and gelatinizing treatment, the content of soluble solid and total acid of GRM went down with the decreased glutinous rice-water ratio (Fig. 1A). The content of soluble solid and total acid reached the maximum, 8° Brix and 0.0505 g/L, respectively, when the glutinous rice-water ratio was 1:5. However, the sensory score got only 70 (Fig. 1B) because glutinous rice was crushed incompletely and produced a burnt taste (Fig. 1C) due to the high glutinous rice-water ratio. It is reported that a high proportion of the substrate increases the consistency during the gelatinization process (Wang, 2018). The high consistency of GRM hindered the mixture of substrates and transfer of heat, resulting in scorching the substrate at the bottom of the pulping machine in this study. At the lowest glutinous rice-water ratio of 1:17, the content of soluble solid and total acid only got 4° Brix and 0.0195 g/L (Fig. 1A) and the sensory score dropped to only 40 (Fig. 1B) because the color and luster, smell, taste, and texture of GRM considerably decreased (Fig. 1C). GRM achieved the highest sensory score of 90 with strongly typical cooked glutinous rice smell and taste (Fig. 1C) when the glutinous rice-water ratio was 1:8, at the same time, the soluble solid content reached 7.5° Brix with a high gelatinization degree.

Fig. 1.

Effects of process I on the GRM. Physicochemical properties of GRM made under different material-water ratios (A) soluble solid and total acid content, (B) total sensory score, (C) sensory score of four parameters. Comparison between GRM made by the process I and Process II, (D) soluble solid content, (E) crude protein content, (F) gelatinization degree, (G) precipitation degree, (H) total sensory score, (I) sensory score of four parameters

To gain a further understanding of the effects of the Process I on the GRM, this study compared the physicochemical properties of GRM made by Process I and Process II based on the optimal glutinous rice-water ratio of 1:8. The content of soluble solid and crude protein in the GRM made by process II only reached 4° Brix (Fig. 1D) and 0.5% (Fig. 1E), respectively. This result indicates that Process I enhanced the release of soluble solid and crude protein while making the GRM compared with the Process II. This is mainly because the Process I promoted the gelatinization degree of the GRM (Fig. 1F). It is reported that the high temperature can overcome attractive forces between the hydrogen-bonded starch molecules within the granule and cut the starch chain (Zhou et al., 2002). In this study, high temperature combined with high-speed cutting and grinding treatment of Process I significantly promoted the mixing and pulping treatment including transferring the heat of materials, aggravating the destruction of the spiral spatial structure of starch molecules, and promoting the disintegration of the starch granule. This inference was validated by much lower precipitation of GRMI (Fig. 1G). The process I also enhanced the flavor quality of GRM. The sensory score of GRMI reached 90, significantly higher (p < 0.05) than that of GRM II (70) (Fig. 1H). The differences were found in smell, taste, color, and luster scores. The higher content of soluble solid and less glutinous rice sediment contributed to a better taste, color, and luster, and the higher gelatinization degree might lead to a better smell score in GRMI.

Effects of different fermentation conditions on GRW

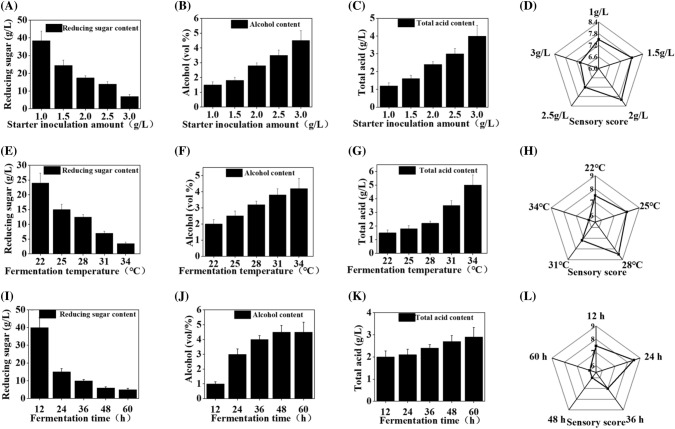

Microbial inoculation, fermentation temperature, and fermentation time are key conditions for the production of fermented food. Therefore, it is necessary to comprehensively study the effects of these processing conditions on the physicochemical properties and sensory quality of GRW produced based on an innovative pulping technique. This study first explored the effect of the starter inoculation amount on physicochemical properties and a sensory score of GRW. The fermentation process became faster with the higher starter inoculation amount, which led to higher consumption of reducing sugar (Fig. 2A), higher accumulation of alcohol (Fig. 2B), and total acid content (Fig. 2C). With the starter inoculation amount increasing to 2 g/L, the reducing sugar content decreased to 17.5 g/L, and alcohol together with total acid content increased to 2.8% and 2.4 g/L, respectively. At the same time, the sweetness, acidity, and aroma of GRW reached a balance which contributed to the highest sensory score of 8.0 (Fig. 2D). However, the sour taste and bitterness of GRW became undesirable, and the sweetness turn very weak when the starter inoculation amount was more than 2.0 g/L. Su (Su et al., 2020) reported that the excessive inoculation amount enhanced the accumulation of spoilage metabolites, resulting in the lower sensory quality.

Fig. 2.

Effects of starter inoculation amount, fermentation temperature, and fermentation time on physicochemical properties and sensory evaluation of GRW. (A, E, and I) Reducing sugar content, (B, F, and J) alcohol content, (C, G, and K) total acid content, (D, H, and L) sensory score

Fermentation temperature is one of the driving forces of the fermentation process. In this study, the GRM fermentation process was slow under the low fermentation temperature, with less decomposition of reducing sugar (Fig. 2E), less accumulation of alcohol (Fig. 2F), and total acid content (Fig. 2G); at the same time, the GRW had heavy sweetness, light acidity, and light taste. As the fermentation temperature increased to 28 °C, reducing sugar quickly dropped to 12.5 g/L, and the alcohol and total acid content reached 3.2% and 2.2 g/L, respectively, which resulted in the highest sensory score of 8.5 (Fig. 2H) with a balance between the sweetness and acidity. However, when the fermentation temperature was more than 28 °C, the consumption of reducing sugar increased too fast, which led to a high alcohol content and total acid content, resulting in an undesirable imbalance between sweetness and acidity. This is mainly because the increased treatment temperature accelerates the fermentation process by enhancing microbial carbon and nitrogen metabolism, the main synthesis pathway of volatile fatty acids such as acetic acid (De Filippis et al., 2016).

Fermentation time possesses a huge influence on the physicochemical properties of rice wine (Mu et al., 2019). In this study, within a short fermentation period (within 12 h), the reducing sugar of the GRM was not fully decomposed by microorganisms, reaching 40 g/L (Fig. 2I). Consequently, the alcohol and total acid content only increased to 1% (Fig. 2J) and 2 g/L (Fig. 2K), respectively, which led to the weak flavor (7.5) (Fig. 2L). When the fermentation time was prolonged to 24 h, the residual sugar decreased to 15.5 g/L, and the content of alcohol and total acid of GRW increased to 3% and 2.1 g/L, respectively. The sweetness and acidity of GRW reached a balance (8.5, Fig. 2L). However, after the fermentation time exceeded 24 h, the sensory score obviously dropped to only 6 at 60 h (Fig. 2L) because the reducing sugar in GRM was greatly consumed (Fig. 2I), and the total acid accumulation considerably increased to 3 g/L (Fig. 2K) accordingly. Xie et al. (2021) reported that the excessive acetate accumulation during the fermentation process is the main reason for the spoilage of Chinese Rice Wine.

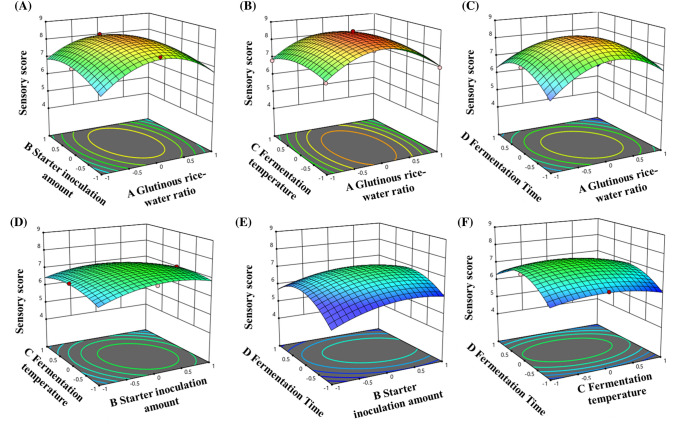

Effects of interactions between fermentation conditions on the sensory score of GRW

To obtain the optimal fermentation condition, response surface methodology with the Box-Behnken principle was employed to explore the contribution of different conditions and the interactions between fermentation conditions. Among four factors, fermentation temperature (Factor C) and fermentation time (Factor D) had significant impacts on the sensory score of GRW (p < 0.01) (Table S6). Combining with the F value in Table S6, the contribution of four factors to the sensory score of GRW was sequentially fermentation time (32.86), fermentation temperature (18.03), starter inoculation amount (3.65), and glutinous rice-water ratio (0.1803). Fei et al. (2020) reported that fermentation time is a key factor for the flavor quality of black glutinous rice wine partly because the longer fermentation period improves the accumulation of organic acids. Xiao et al. (2017) reported that temperature is the key environmental driver shaping the microbial community of Daqu (starter) which conducts the saccharification of starch or dextrin of grains during the fermentation process. In this study, it was confirmed with the increase in consumption of reducing sugar, and higher accumulation of alcohol and total acid at higher fermentation temperature.

Among the interactions between factors, the interaction between glutinous rice-water ratio and starter inoculation amount (interaction term AB), and fermentation time (interaction term AD) had extremely significant impacts on the sensory score of GRW (p < 0.01) (Table S6; Fig. 3A, C). However, the interactions between AC, BC, BD, and CD had no significant effect on the sensory score of GRW (p > 0.05). Although the glutinous rice-water ratio had no significant (p > 0.05) effect on the sensory score of GRW, the results of interaction analysis show that the glutinous rice-water ratio affected the sensory score of GRW mainly through the interaction with the starter inoculation amount and fermentation time. In the fermentation process, the glutinous rice-water ratio first affected the water content of the substrate. A lower water content increases the viscosity of the substrate, and reduces the fluidity as well as the heat transfer of the substrate, resulting in insufficient contact between microorganisms and substrate. As a result, this hinders the accumulation of metabolites (Song et al., 2008). This explains that fermentation with a high glutinous rice-water ratio requires a higher starter inoculation amount in this study. At the same time, the glutinous rice-water ratio influences the nutrient content of the substrate, and a lower glutinous rice-water ratio is a limit to the high yield of target metabolites such as ethanol (Zhang et al., 2019). In this study, the substrate with higher glutinous rice-water ratios provided sufficient carbon and nitrogen sources for microorganisms, promoting the growth and metabolism of microorganisms as well as the metabolite accumulation such as ethanol.

Fig. 3.

Response surface of variable interactions on the sensory score. (A) Interactive effect of glutinous rice-water ratio and starter inoculation amount, (B) interactive effect of glutinous rice-water ratio and fermentation temperature, (C) interactive effect of glutinous rice-water ratio and fermentation time, (D) interactive effect of starter inoculation amount and fermentation temperature, (E) interactive effect of starter inoculation amount and fermentation time, (F) interactive effect of fermentation temperature and fermentation time

Based on the contribution and interaction analysis of different fermentation conditions, the response surface analysis provided the predicted optimal fermentation condition. The predicted optimal sensory score could achieve 8.42 when fermentation was conducted with the glutinous rice-water ratio of 1: 7.142, starter inoculation amount of 1.985 g/L, and fermentation temperature of 27.052 °C, and fermentation time of 22.548 h. Combining the given optimal fermentation condition with the producing practice, the final fermentation conditions were properly adjusted as follows: 1:7 (glutinous rice-water ratio), 2.0 g/L (starter inoculation amount), 27 °C (fermentation temperature), and 22.5 h (fermentation time). After that, three trials were carried out to test the validation of the adjusted optimal fermentation condition. The results show that the sensory score reached 8.30 ± 0.25, close to the predicted optimal response value. This indicates that the model had a good fitting and reflected the effects of interactions between fermentation conditions on the sensory score of GRW.

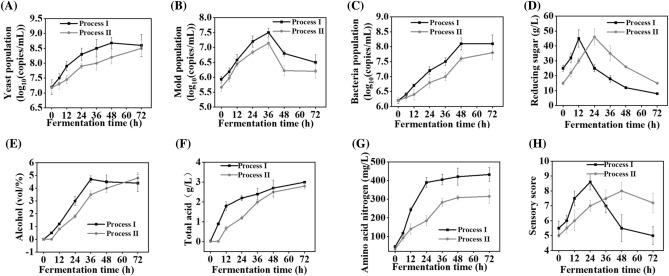

Effects of process I on the GRW fermentation process

Based on the optimal fermentation condition, this study explored the effects of Process I and Process II on the GRW fermentation process. The Process I enhanced the microbial growth and fermentation rate of GRM. Yeast (Fig. 4A), mold (Fig. 4B), and bacteria (Fig. 4C) significantly (p < 0.05) grew faster in GRMI than in GRMII. During the fermentation of GRWI, the maximum content of reducing sugar reached 45.56 g/L (Fig. 4D) within 12 h. The maximum alcohol content reached 4.7% within 36 h (Fig. 4E). The total acid and amino acid nitrogen content rapidly increased to 2.2 g/L (Fig. 4F) and 390 mg/L (Fig. 4G), respectively, within 24 h. By contrast, during the fermentation process of GRWII, the reducing sugar content only increased to 30.2 g/L at 12 h. The alcohol content reached the maximum of 4.8% till 72 h. The total acid and amino acid nitrogen content increased to only 1.2 g/L and 184.4 mg/L, respectively, within 24 h. Huang (Huang et al., 2021) reported that starch and dextrin are broken down by saccharifying microbes such as molds during the Hong Qu GRW fermentation process. Zhao et al. (2020a) reported that yeasts are the main producers of ethanol during the black glutinous rice wine fermentation process. It is reported that lactic acid bacteria (LAB) are dominant microbial communities of rice wine starters and some LAB species are organic acids producers (Huang et al., 2019; Zhao et al., 2020b). These results indicate that molds, yeasts, and LAB had a higher growth rate and metabolic activities during the GRWI fermentation process. It is reported that the appropriate increase in initial sugar concentration promotes the growth of yeast and enhances the ethanol yield during the fermentation process (Fan and Zhang, 2014; Wang et al., 2007). In this study, the GRMI made by Process I had higher soluble solid and crude protein content than GRMII made by Process II (Fig. 1D, E). GRMI provided sufficient carbon and nitrogen sources for mold, yeast, and LAB in the early growth stage, which improved the microbial growth rate and microbial nitrogen and carbon metabolism, and then rapidly enhanced the accumulation of ethanol and organic acids during the fermentation process. This consequently contributed to a higher sensory score (8.5) of GRWI than that (8.0) of GRWII (Fig. 4H).

Fig. 4.

Effects of Process I and Process II on the GRW fermentation process. (A) Yeast population, (B) mold population, (C) bacteria population, (D) reducing sugar content, (E) alcohol content, (F) total acid content, (G) amino acid nitrogen content, and (H) sensory score

Effects of process I on volatile flavor compound components of GRW

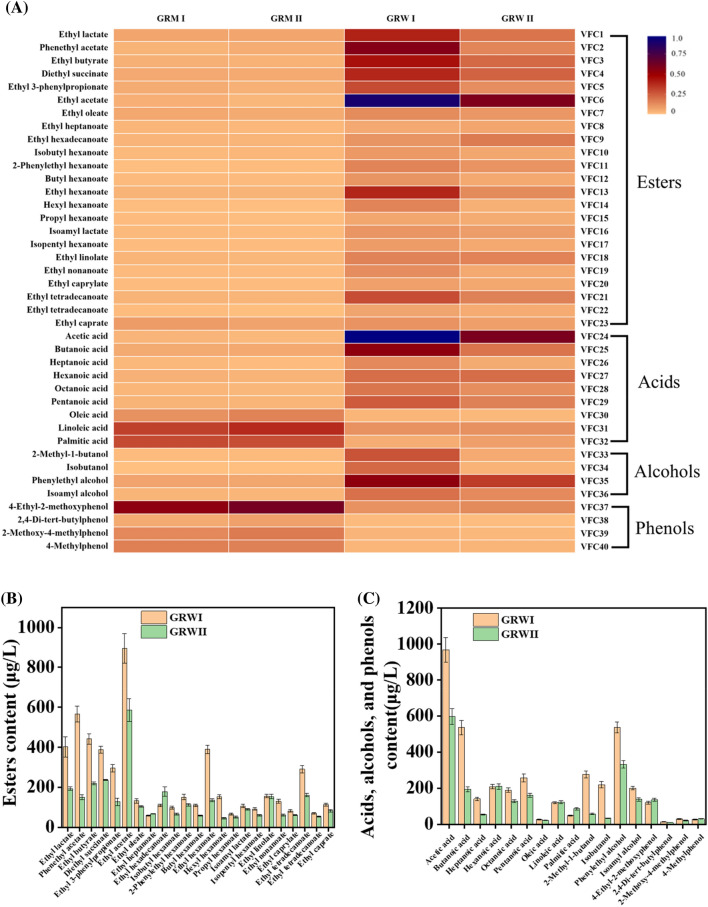

To further analyze the effect of Process I on the sensory quality of GRW, this study compared the volatile flavor compound components of GRWI and GRWII. A total of 40 volatile flavor compounds were detected in GRM and GRW samples by GC–MS, including 23 esters, 9 acids, 4 alcohols, and 4 phenols (Fig. 5A). Comparing the GRM with GRW, 3 long-chain fatty acids including palmitic acid, oleic acid, and linoleic acid and 4 phenols were from raw materials, which is in accordance with previous study (Zhou et al., 2002). On the contrary, 18 esters, 5 short-chain volatile fatty acids, and 4 alcohols of both GRWI and GRWII were mainly produced during the fermentation process. Previous studies reported that isoamyl acetate, ethyl caproate, ethyl lactate, ethyl octanoate, phenylethyl acetate, ethyl decanoate, ethyl laurate, ethyl palmitate, acetic acid, phenethyl alcohol, isobutanol, and isoamyl alcohol are mainly produced during the fermentation process (Jin et al., 2021).

Fig. 5.

Components of volatile flavor compounds in GRM and GRW. (A) Heatmap of volatile flavor compounds in GRM and GRW, (B) esters content, (C) acids, alcohols, and phenols content of GRW

Esters, contributing to fruity, floral, and sweet aromas, are crucial components of Chinese Rice Wine (Wang et al., 2019). In both GRWI and GRWII samples, esters were the major volatile flavor component, and most of the esters were ethyl esters, which is in accordance with previous studies (Jiang et al., 2020; Yang et al., 2018). Among the 23 esters, the content of 21 ester compounds of GRWI was higher than that of GRWII, and 10 esters of GRWI were significantly (p < 0.05) higher than that of GRWII (Fig. 5A, B). Among them, ethyl acetate, phenylethyl acetate, ethyl butyrate, ethyl lactate, and ethyl hexanoate were the dominant esters with the concentration of more than 400 μg/L. Jin et al. (2021) reported that ethyl acetate (pleasant fruity odor and sweet taste), ethyl butyrate (pineapple odor and sweet taste), ethyl hexanoate (winy, pineapple, and banana odors), and ethyl lactate (buttery, creamy, and fruit odors) have outstanding contributions to flavor quality of rice wine because their odor activity values (OAVs) are over or close to 1. Zhao et al. (2020a) reported that phenylethyl acetate enhances the aroma complexity of black glutinous rice wine with pear, apple, and banana aromas. Esters are synthesized from higher alcohols or ethanol with acetic acid or other organic acids via the catalysis of esterase or lipase (Procopio et al., 2011). These results indicate that Process I enhanced the esterification during the GRW fermentation process, which contributed to better flavor quality in terms of fruity, floral, and sweet aromas.

Volatile fatty acids (VFAs) play an important role in the aroma and flavor characteristics of rice wine (Zhao et al., 2020a). Among 9 VFAs in this study, acetic acid, butanoic acid, pentanoic acid, and hexanoic acid were the major fatty acids in both sorts of GRW with content over 200 μg/L (Fig. 5C). The content of acetic acid, butanoic acid, and pentanoic acid of GRWI was significantly (p < 0.05) higher than that of GRWII (Fig. 5C). These VFAs are precursors of various fatty acid ethyl esters such as ethyl butyrate and ethyl acetate making an important contribution to the sensory quality of rice wine (Jin et al., 2021). In various fermented food, fatty acids are from the degradation of lipids by lipase or esterase (Collins et al., 2003). At the same time, reducing sugar can be converted into organic acids such as acetic acid through glycolysis (Gonzalez et al., 2005). These results indicate that the Process I improved the production of VFAs during the fermentation of GRW probably by enhancing the activities of lipase or esterase or glycolysis.

Higher alcohols endowing the fruity aroma and mellow, soft, and plump tastes are key components of rice wine (Jin et al., 2021). In this study, four higher alcohols including phenethyl alcohol, isoamyl alcohol, isobutanol, and 2-methyl-1-butanol were detected from GRW samples produced by both processes (Fig. 5A). However, the content of phenethyl alcohol, isoamyl alcohol, isobutanol, and 2-methyl-1-butanol of GRWI was significantly higher (p < 0.05) than those of GRWII (Fig. 5C). Zhao et al. (2020a) reported that phenethyl alcohol (rose and honey aromas), isobutanol (polish odor), and isoamyl alcohol (balsamic odor) are important flavor components of Chinese Rice Wine because of their low thresholds and high OAVs (> 1). Park et al. (2013) reported that 2-methyl-1-butanol with fermented and malt-like odor plays an important role in forming the overall sensory complexity of rice wine. In the producing process of many fermented food, phenethyl alcohol, 2-methyl-1-butanol, isobutanol, and isoamyl alcohol are from the catabolism of phenylalanine, leucine, valine, and isoleucine via the Ehrlich pathway (Hazelwood et al., 2008) or are from the carbohydrate metabolism via Harrison pathway (Pires et al., 2014). In this study, the Process I significantly enhanced the soluble solid and crude protein content (Fig. 1D, E), which provided sufficient precursors for amino acids and reducing sugar (Fig. 4D, G). This might enhance Ehrlich or Harrison pathway and then contributed to a higher content of higher alcohols of GRWI.

In this study, the synchronously pulping and gelatinizing treatment enhanced the flavor quality of GRW by directly improving the content of soluble solid and crude protein with the increased gelatinization degree and pulping efficiency. Consequently, the fermentation process of GRW including the microbial growth, metabolism, and flavor profile of GRW was significantly enhanced, which accordingly increased the generation of key esters and higher alcohols. This study provided a comprehensive and deep understanding of the effects of the synchronously pulping and gelatinizing treatment on the production of GRW from raw materials, oenological parameters, fermentation process, and flavor characteristics of glutinous rice wine, which shed new light on enhancing the flavor quality of GRW produced by the industrial liquid-state fermentation.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

We are grateful to the Application Foundation Project of the Science and Technology Department of Sichuan Province (2018JY0217); Key Scientific Research Projects of Sichuan Education Department (18ZA0541); Yibin University Doctoral Initiation Gold Project (2018RC14); International Exchange Grant for Graduate Students of Chinese Academy of Agricultural Sciences (2021).

Declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Wenyou Zhu, Email: 330343908@qq.com.

Yu Tie, Email: 874799186@qq.com.

Zhenyu Zhu, Email: 1035579721@qq.com.

Yuxia Yang, Email: yangyuxia-7@163.com.

Shao Feng, Email: 3354400956@qq.com.

Jun Liu, Email: ahjunnew@163.com.

References

- Collins YF, Mcsweeney PLH, Wilkinson MG. Lipolysis and free fatty acid catabolism in cheese: a review of current knowledge. International Dairy Journal. 2003;13:841–866. doi: 10.1016/S0958-6946(03)00109-2. [DOI] [Google Scholar]

- De Filippis F, Genovese A, Ferranti P, Gilbert JA, Ercolini D. Metatranscriptomics reveals temperature-driven functional changes in microbiome impacting cheese maturation rate. Scientific Reports. 2016 doi: 10.1038/srep21871. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fan SC, Zhang YR. Effect of initial glucose concentration on performance of gas stripping ethanol fermentation. Southwest China Journal of Agricultural Sciences. 2014;27:1062–1066. [Google Scholar]

- Fei YT, Jiang HJ, Hu FZ, Peng LY, Liu GL, Bai WD, Xiao GS. Effects of Zygosacharomyces mellis and post-fermentation on the flavor of Black Glutinous rice wine. Transactions of the Chinese Society of Agricultural Engineering. 2020;36:301–309. [Google Scholar]

- Gonzalez A, Hierro N, Poblet M, Mas A, Guillamon JM. Application of molecular methods to demonstrate species and strain evolution of acetic acid bacteria population during wine production. International Journal of Food Microbiology. 2005;102:295–304. doi: 10.1016/j.ijfoodmicro.2004.11.020. [DOI] [PubMed] [Google Scholar]

- Hazelwood LA, Daran JM, Van Maris AJA, Pronk JTD. The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Applied and Environmental Microbiololgy. 2008;74:2259–2266. doi: 10.1128/AEM.02625-07. [DOI] [PMC free article] [PubMed] [Google Scholar]

- He DP, Liang S, Liu ZB, Zhang W, Ni L. Application of liquid-state Hong Qu to the brewing of Fujian Hong Qu Glutinous rice wine. Journal of Chinese Institute of Food Science and Technology. 2016;16:133–140. [Google Scholar]

- Huan YY, Liang ZC, Lin XZ, Molnár I. Fungal community diversity and fermentation characteristics in regional varieties of traditional fermentation starters for Hong Qu Glutinous rice wine. Food Research International. 2021;141:110146. doi: 10.1016/j.foodres.2021.110146. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang ZR, Guo WL, Zhou WB, Li L, Xu JX, Hong JL, Liu HP, Zeng F, Bai WD, Liu B, Ni L, Rao PF, Lv XC. Microbial communities and volatile metabolites in different traditional fermentation starters used for Hong Qu Glutinous rice wine. Food Research International. 2019;121:593–603. doi: 10.1016/j.foodres.2018.12.024. [DOI] [PubMed] [Google Scholar]

- Jiang J, Liu YC, Li HH, Yang Q, Wu Q, Chen SX, Tang J, Xu Y. Modeling and regulation of higher alcohol production through the combined effects of the C/N ratio and microbial interaction. Journal of Agricultural and Food Chemistry. 2019;67:10694–10701. doi: 10.1021/acs.jafc.9b04545. [DOI] [PubMed] [Google Scholar]

- Jiang L, Su W, Mu YC, Mu Y. Major metabolites and microbial community of fermented Black Glutinous rice wine with different starters. Frontiers in Microbiololgy. 2020 doi: 10.3389/fmicb.2020.00593. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin Z, Cai GL, Wu C, Hu ZM, Xu XB, Xie GF, Wu DH, Lu J. Profiling the key metabolites produced during the modern brewing process of Chinese rice wine. Food Research International. 2021;139:109955. doi: 10.1016/j.foodres.2020.109955. [DOI] [PubMed] [Google Scholar]

- Liang ZC, Lin XZ, He ZG, Su H, Li WX, Guo QQ. Comparison of microbial communities and amino acid metabolites in different traditional fermentation starters used during the fermentation of Hong Qu Glutinous rice wine. Food Research International. 2020;136:109329. doi: 10.1016/j.foodres.2020.109329. [DOI] [PubMed] [Google Scholar]

- Liao CD, Chen YC, Lin HY, Chiueh LC, Shih DYC. Incidence of citrinin in red yeast rice and various commercial Monascus products in Taiwan from 2009 to 2012. Food Control. 2014;38:178–183. doi: 10.1016/j.foodcont.2013.10.016. [DOI] [Google Scholar]

- Mu Y, Su W, Yu XT, Mu YC, Jiang L, Wang HL. Untargeted metabolomics based on GC-TOF-MS reveals the optimal pre-fermentation time for Black Glutinous rice wine. International Journal of Food Properties. 2019;22:2033–2046. doi: 10.1080/10942912.2019.1705481. [DOI] [Google Scholar]

- Park HJ, Lee SM, Song SH, Kim YS. Characterization of volatile components in makgeolli, a traditional Korean rice wine, with or without pasteurization, during storage. Molecules. 2013;18:5317–5325. doi: 10.3390/molecules18055317. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pires J, Teixeira JA, Branyik T, Vicente AA. Yeast: the soul of beer's aroma-a review of flavour-active esters and higher alcohols produced by the brewing yeast. Applied Microbiology and Biotechnology. 2014;98:1937–1949. doi: 10.1007/s00253-013-5470-0. [DOI] [PubMed] [Google Scholar]

- Procopio S, Qian F, Becker T. Function and regulation of yeast genes involved in higher alcohol and ester metabolism during beverage fermentation. European Food Research and Technology. 2011;233:721–729. doi: 10.1007/s00217-011-1567-9. [DOI] [Google Scholar]

- Song N, Liu XW, Hu HB, Zhao J. Study on liquor-making with uncooked materials by liquid fermentation. China Brewing. 2008;201:47–50. [Google Scholar]

- Su JJ, Yang T, Tong EJ, Zhao XY, He CH, Yang N, Xu XM, Wu FF. Optimization of brewing process for sweet rice wine from brow rice and analysis of its volatile components. Food Science. 2020;41:177–185. [Google Scholar]

- Suzuki K, Asano S, Iijima K, Kitamoto K. Sake and beer spoilage lactic acid bacteria—a review. Journal of the Institute of Brewing. 2008;114:209–223. doi: 10.1002/j.2050-0416.2008.tb00331.x. [DOI] [Google Scholar]

- Wang XK. Pretreatment of rice wine by liquid fermentation and optimization of fermentation conditions. Master Thesis, South China University of Technology, Guangzhou, Guangdong, China. (2018)

- Wang LS, Ge XY, Zhang WG. Improvement of ethanol yield from raw corn flour by Rhizopus sp. World Journal of Microbiology and Biotechnology. 2007;23:461–465. doi: 10.1007/s11274-006-9247-9. [DOI] [Google Scholar]

- Wang N, Chen S, Zhou ZM. Characterization of volatile organic compounds as potential aging markers in Chinese rice wine using multivariable statistics. Journal of the Science of Food and Agriculture. 2019;99:6444–6454. doi: 10.1002/jsfa.9923. [DOI] [PubMed] [Google Scholar]

- Wang DH, Wang Z, Hu JX, Han MY, Zhong J. Study on liquor brewing technology utilizing raw materials and analysis of product quality. Food Research Development. 2021;42:129–134. [Google Scholar]

- Xiao C, Lu ZM, Zhang XJ, Wang ST, Ao L, Shen CH, Shi JS, Xu ZH. Bio-heat is a key environmental driver shaping the microbial community of medium-temperature Daqu. Applied and Environmental Microbiology. 2017 doi: 10.1128/AEM.01550-17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xie G, Zheng H, Qiu Z, Lin Z, Peng Q, Dula Bealu G, Elsheery NI, Lu Y, Shen C, Fu J, Yang H, Han J, Lu J, Liu G. Study on relationship between bacterial diversity and quality of Huangjiu (Chinese rice wine) fermentation. Food Science and Nutrition. 2017;9:3885–3892. doi: 10.1002/fsn3.2369. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yang YJ, Xia YJ, Wang GQ, Zhang H, Xiong ZQ, Yu JS, Yu HY, Ai LZ. Comparison of oenological property, volatile profile, and sensory characteristic of Chinese rice wine fermented by different starters during brewing. International Journal of Food Properties. 2018;20:S3195–S3211. doi: 10.1080/10942912.2017.1325900. [DOI] [Google Scholar]

- Yang YJ, Xia YJ, Wang GQ, Tao LR, Yu JS, Ai LZ. Effects of boiling, ultra-high temperature and high hydrostatic pressure on free amino acids, flavor characteristics and sensory profiles in Chinese rice wine. Food Chemistry. 2019;275:407–416. doi: 10.1016/j.foodchem.2018.09.128. [DOI] [PubMed] [Google Scholar]

- Yang YJ, Hu WY, Xia YJ, Mu ZY, Tao LR, Song X, Zhang H, Ni B, Ai LZ. Flavor formation in Chinese rice wine (Huangjiu): impacts of the flavor-active microorganisms, raw materials, and fermentation technology. Frontiers in Microbiology. 2020;11:2541. doi: 10.3389/fmicb.2020.580247. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yue C, Wei HC. Study on the processing of rice wine by submeerged fermentation. Science and Technology of Food Industry. 2002;23:70–72. [Google Scholar]

- Zhang Q, Yuan XD, Bian WZ, Huo Y, Wu LS, Zhang X, Zhou WJ. Study of high-gravity ethanol fermentation by corn. Liquor Making Science and Technology. 2019;301:36–39. [Google Scholar]

- Zhao C, Su W, Mu YC, Jiang L, Mu Y. Correlations between microbiota with physicochemical properties and volatile flavor components in Black Glutinous rice wine. Food Research International. 2020;138:109800. doi: 10.1016/j.foodres.2020.109800. [DOI] [PubMed] [Google Scholar]

- Zhao XX, Wang YR, Cai WC, Yang MJ, Zhong XD, Guo Z, Shan CH. High-throughput sequencing-based analysis of microbial diversity in rice wine Koji from different areas. Current Microbiology. 2020;77:882–889. doi: 10.1007/s00284-020-01877-9. [DOI] [PubMed] [Google Scholar]

- Zhou ZK, Robards K, Helliwell S, Blanchard C. Composition and functional properties of rice. International Journal of Food Science and Technology. 2002;37:849–868. doi: 10.1046/j.1365-2621.2002.00625.x. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.