Abstract

Yunnan Province is the major coffee cultivation region in China, and coffee beans produced in Yunnan account for approximately 99% of the total national coffee production. So far, the sensory properties of Yunnan coffee have not been subjected to descriptive analysis. Here, we selected 25 representative coffee bean samples that are produced in different cultivation areas of Yunnan and with different degrees of roasting. A total of 57 sensory descriptors have been associated with the samples, and a sensory wheel that summarizes the sensory characteristics was developed. In addition, to identify the major attributes associated with Yunnan coffee, principal component analysis was performed, and we also explored how the bean origin and degree of roasting are related to the overall sensory features of Yunnan coffee. Our results show that the growing area is an affecting factor on the aspects of “spices”, “roasted”, “sweet” and “chemical/stale”, whereas “mouthfeel” and “roasted”, and “sour/acid” levels can be influenced by the degree of roasting. The present sensory characterization may provide valuable information for future improvements of Yunnan's coffee agriculture.

Keywords: Coffee quality, Sensory analysis, Sensory wheel, Yunnan

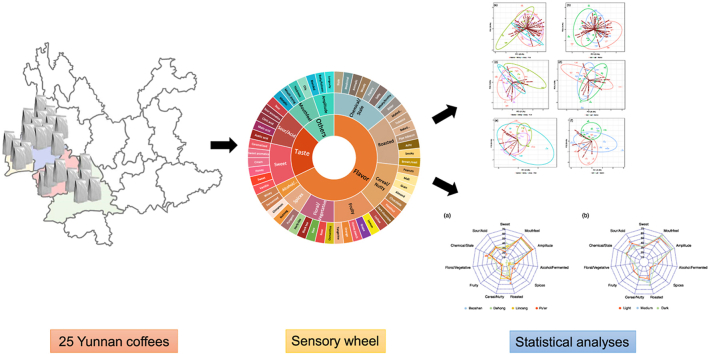

Graphical abstract

Highlights

-

•

Descriptive sensory analysis was carried out for 25 Yunnan coffee samples.

-

•

A total of 57 sensory descriptors were associated with Yunnan coffee.

-

•

Both the bean origin and the degree of roasting can effect certain aspects of the sensory characteristics of Yunnan coffee.

1. Introduction

Coffee is one of the most popular beverages throughout the world, and it has been estimated that more than 2 billion cups of coffee are consumed every day (Li et al., 2021). With an increasing demand for coffee production, the coffee plant is currently cultivated in more than 80 countries all over the world, and the coffee industry greatly shapes the agricultural economies of major coffee producing countries (Adane and Bewket, 2021; ICO, 2021; Magrach and Ghazoul, 2015; Vega et al., 2003). While the western countries, mostly in America and Europe, still represent the dominant coffee market (accounting for approximately 20% and 30% of world consumption, respectively), new markets are rapidly emerging (Kolk, 2013). For example, in China, particularly in its urban areas, coffee consumption has been constantly increasing by 20% every year, and this trend has been predicted to continue due to an increasing appreciation of coffee among the Chinese people (Wen et al., 2018). Considering the great potential of the coffee-based economy, the coffee industry in China is undergoing rapid development, with Yunnan being the major cultivation area.

Yunnan is considered an ideal region for growing arabica coffee (Coffea arabica), the main coffee species cultivated worldwide (Rigal et al., 2020). Yunnan's climate is similar to that of other major coffee-producing countries, such as Brazil and Ethiopia, with sufficient sunshine and rainfall, and substantial diurnal temperature variation. The average annual rainfall is 700–1800 mm, and the average temperature is 15–25 °C (Zhao et al., 2019). Such a coffee friendly climate renders Yunnan the top coffee producing area in China, accounting for 99% of the total national coffee production. In 2019, the total coffee cultivation area in Yunnan was 118,000 hm2, and approximately 13.9 tons of green coffee beans were produced each year, representing 1.5% of the total global coffee production (ranking 13th) (Zhao et al., 2019). In Yunnan, large-scale coffee cultivation takes place in 44 counties (or districts) of 12 cities (or autonomous prefectures), with Baoshan, Dehong and Pu'er being the major cultivation areas (Zhang et al., 2020). In these places, more than one million coffee farmers are producing a total market value of ∼260 million Chinese Yuan (∼38.6 million US dollars) each year, a number that is anticipated to continuously increase in the future. The dominant coffee variety in Yunnan is “Catimor 7963”, a hybrid between “Caturra” and “Timor”, representing 90% of the total cultivation. In addition, other varieties such as “Sarchimor”, “Typica”, “Bourbon” and “S288” can also be found but are cultivated to a much lesser extent (Li et al., 2007). It is widely known that, for most coffee varieties, they may display distinct characteristics due to different cultivation conditions (Silva et al., 2005). Therefore, while these varieties are also widely exploited in other countries for producing coffee beans, the sensory properties of Yunnan coffee are still worth investigation.

People drink coffee mainly due to its refreshing and stimulating properties; meanwhile, increasing amounts of people drink coffee simply because they appreciate its sensory properties (Arya and Rao, 2007; Samoggia et al., 2020). For coffee, its sensory properties are extremely complex, and it is considered as a combination of aroma, taste, texture and mouthfeel (Seninde and Chambers, 2020; Sunarharum et al., 2014). These properties are predominately established during roasting via a series of Maillard reactions, caramelization and other thermal reactions involving aroma precursors that are present in green coffee beans (Lee et al., 2015). A large number of previous studies have demonstrated that the roast level largely influences the composition of flavor compounds in the bean and therefore greatly impacts the final quality of the coffee drink (Baggenstoss et al., 2008). Apart from the degree of roasting, coffee sensory properties are also influenced by the brewing method, and many environmental factors, such as geographical origins, climate, altitude and temperature elevation, and shading, and nutrient availability or fertilizers also have effects on the coffee sensory profile (Stanek et al., 2021; Sunarharum et al., 2014).

To characterize the sensory quality of a certain type of food, descriptive sensory analysis is often employed (Lawless and Heymann, 2010; Murray et al., 2001). This analysis summarizes the sensory attributes of food products, thereby facilitating systematic comparisons between food products with different origins (Lawless and Heymann, 2010; Lawless and Civille, 2013). In a typical descriptive sensory analysis, a lexicon, which contains a list of descriptors, is first developed to break down the complexity of sensory perception into individual components (i.e., sensory attributes). Subsequently, these attributes are scaled, using defined products that are representative of the scale extremes, and scaled sensory lexicons are further visualized into a sensory wheel, in which sensory attributes are categorized and arranged hierarchically (Chambers et al., 2016; Spencer et al., 2016). To date, no descriptive sensory analysis has been systematically performed for Yunnan coffee, and communications among Yunnan coffee producers and the coffee market are therefore compromised due to the lack of such analysis.

In this study, our main objective was to explore the sensory attributes of coffee drinks prepared from some bestsellers of Yunnan coffee bean packages. Furthermore, we also aimed to understand how these sensory attributes are correlated with the bean's specific geographic region and the degree of roasting. To our knowledge, this is the first descriptive sensory analysis conducted for Yunnan coffee.

2. Materials and methods

2.1. Coffee bean samples

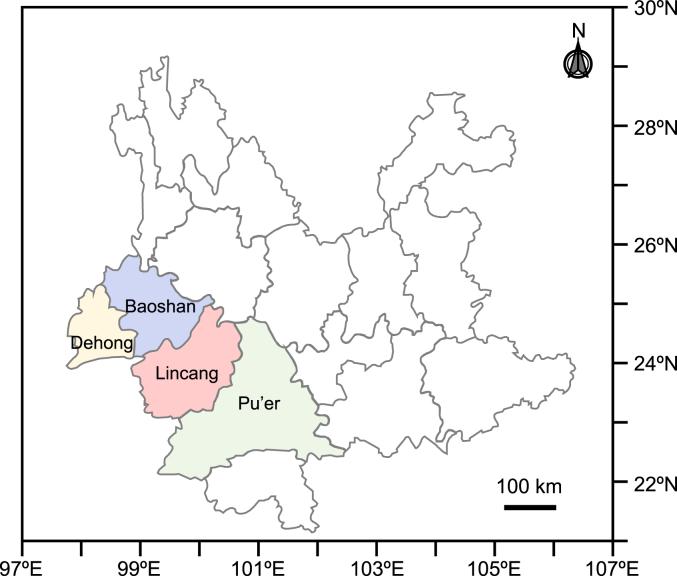

A total of 25 representative Yunnan coffees that are commercially available were purchased. Most of the manufactures of these coffee beans are listed as the local industrial leaders in an official report published by the Yunnan government (http://www.yunnancoffee.org). These beans were produced in Baoshan, Dehong, Lincang, and Pu'er (Fig. 1). Table 1 lists the detailed product information. All samples were individually stored in an opaque, air-tight container at room temperature during evaluation intervals, and they were randomly numbered prior to coffee preparation to avoid bias.

Fig. 1.

Geographical locations of the cultivation areas in which the evaluated bean samples were produced (the map of Yunnan Province).

Table 1.

Yunnan coffees evaluated in this study.

| ID | Growing area | Name | Degree of roasting | Manufacturer |

|---|---|---|---|---|

| B1L | Baoshan | Sinloy coffee* | Light | Baoshan China Coffee Food Co., Ltd. |

| B2D | Baoshan | White tiger mountain coffee* | Dark | Baoshan Chunzheng Coffee Industry Development Co., Ltd. |

| B3M | Baoshan | Gaosheng manor | Medium | Baoshan Gaolaozhuang Agricultural & Sideline Products Development Co., Ltd. |

| B4M | Baoshan | Tiansu yunnan arabica coffee | Medium | Baoshan Tianli Coffee Mill Co., Ltd. |

| B5L | Baoshan | Manlao river coffee* | Light | Yunnan Delu Coffee Co., Ltd. |

| B6L | Baoshan | Jinglan coffee | Light | Yunnan Jinglan Tropical Crops Science & Technology Co., Ltd. |

| B7L | Baoshan | Zhongka arabica coffee beans | Light | Yunnan Baoshan Zhongka Food Co., Ltd. |

| B8D | Baoshan | Xinzhai coffee* | Dark | Baoshan Xinzhai Coffee Co., Ltd. |

| B9L | Baoshan | Beaton coffee | Light | Baoshan Bestain Coffee Co., Ltd. |

| B10M | Baoshan | Hekengs coffee* | Medium | Baoshan Heke Coffee Co., Ltd. |

| B11M | Baoshan | Yunlu coffee | Medium | Baoshan Yunlu Coffee Production and Development Co., Ltd. |

| D1M | Dehong | Hogood coffee | Medium | Dehong Hogood Coffee Co., Ltd. |

| D2L | Dehong | The jura* | Light | Puer Shengbaishi Health Industry Co., Ltd. |

| D3M | Dehong | Fitbean coffee | Medium | Dehong Yunteahouse Coffee Co., Ltd. |

| D4D | Dehong | Colorful beans coffee* | Dark | Yunnan Yika Food Technology Co., Ltd. |

| L1M | Lincang | Mangka langzhu* | Medium | Yunnan Balle Coffee Co., Ltd. |

| L2D | Lincang | Xueyan* | Dark | Yunnan Balle Coffee Co., Ltd. |

| L3L | Lincang | Yunnan white olive* | Light | Pu'er Keruite Coffee Co., Ltd. |

| P1M | Pu'er | Yunfei roasted coffee beans | Medium | Yunnan Farming Group Co., Ltd. |

| P2D | Pu'er | Fibo coffee | Dark | Yunnan Balle Coffee Co., Ltd. |

| P3M | Pu'er | Kissung coffee | Medium | Pu'er Xinfeng Agricultural Development Co., Ltd. |

| P4D | Pu'er | Manya coffee | Dark | Pu'er Manya Coffee Industrial Co., Ltd. |

| P5L | Pu'er | Torch coffee* | Light | Pu'er Keruite Coffee Co., Ltd. |

| P6D | Pu'er | Aini manor coffee | Dark | Pu'er Aini Manor Coffee Co., Ltd. |

| P7M | Pu'er | Badoumai coffee* | Medium | Mojiang Jinggong Manor Specialty Development Co., Ltd. |

Note: Coffees marked with “*” were used for panel orientation.

2.2. Coffee preparation

For each bean sample, the coffee brew was prepared by using a standard semi-automatic coffee machine (BES870, Breville Pty. Ltd., Sydney, Australia), and all parameters were set as recommended in the user manual. Briefly, coffee beans were ground to coffee powder of medium-fine particle size by the grinder equipped with the coffee machine, and approximately 30 mL expresso coffee was extracted from ∼7 g powder with 9–10 bars of pressure. Subsequently, 100 ml of near-boiling water (92–94 °C) produced from the machine's auto-hot water system was immediately added into the expresso coffee, and the mixture was cooled to 55 °C for sensory evaluation.

2.3. Sensory evaluation

2.3.1. Panelists

To recruit qualified volunteers for this study, a large number of potential candidates (around 100 regular coffee consumers) were screened through multiple tests, such as questionnaire surveys, acuity tests, grade/rating tests, and interviews, focusing on examining the candidate's coffee-drinking experience and his or her ability to detect subtle sensory differences (Lawless and Heymann, 2010). Eventually, ten volunteers (five males and five females) who passed all the tests were recruited as panelists for the assessment. During the pre-training session, the panelists were informed of the background and objective of the research, along with the detailed evaluation procedure. The pre-training was conducted as described by Lawless and Heymann (2010).

2.3.2. Panel orientation

A set of 12 bean samples of different origins and degrees of roasting were used in the orientation step (Table 1). The panelists were first given around five cups of coffee to become familiar with the evaluation protocol. To generate a lexicon specific for Yunnan coffee, the panelists first sniffed three to four times to detect the odor, and then sipped the sample to evaluate the favor and taste, as well as the mouthfeel and amplitude. An initial large coffee-specific lexicon combined from other publications (Akiyama et al., 2008; Bhumiratana et al., 2011; Chambers et al., 2016; Lee et al., 2016; Liu et al., 2019; Sarrazin et al., 2000; Seo et al., 2009) was provided to the panel, and each panelist conducted his/her own evaluation of the samples at individual speed. Through several rounds of discussion, panelists filtered terms that were not related, and merged some terms with similar definitions. In the following orientation sessions, the panelists were exposed to the coffee samples prepared from 12 bean samples produced in four different regions and with different degrees of roasting (Table 1), and after discussion, adjustments, and savoring the reference when necessary, they gave consensus scores to the 12 samples, thereby ensuring that they agreed on the terms of definitions and references. A score sheet was developed with an ordinal scale of 1–15, with 1 representing extremely low and 15 representing extremely high, and it was used by the panel to scale the intensity of all descriptors.

2.3.3. Evaluation

Coffee samples were coded with numbers and presented in a randomized order to each panelist (i.e., each panelist received samples in a unique order). For each coffee sample, one panelist spent approximately 15 min to evaluate, and in one session, two or three samples were evaluated using the developed score sheet with an ordinal scale of 1–15. During the interval between evaluating different coffee samples, the panelists were asked to clean their mouths regularly with water and odorless biscuits to avoid taste fatigue. To maintain the motivation of the panelists, a number of coffee related gifts, such as coffee mugs, were provided to them when one session finished. Each coffee sample was evaluated in triplicates, and the entire evaluation took around two months. The panel performance was monitored using PanelCheck software (Version 1.4.2, www.panelcheck.com).

2.4. Data analysis

After all score sheets were received from the panel and passed the quality test, the frequency of each descriptor was calculated as following:

where is the frequency of descriptor ; is the number of score sheets in which the descriptor was scored; is the number of coffee bean samples; is the number of panelists; and is the number of descriptors. The relative intensity of each descriptor was calculated as following:

where is the relative intensity of descriptor ; is the total of all scores the panel marked for the descriptor ; is the max intensity that a descriptor can be scored by one panelist for each coffee sample (which is 15 in this study). Using the method described in ISO 11035-1994, an indicator to show the contribution of one descriptor to the food samples was calculated as following:

A descriptor with a larger indicates that the descriptor contributes more significantly to the samples. All descriptors with % were filtered, and the remaining descriptors were used for the development of a sensory wheel and the following analyses.

The sensory wheel was constructed using Microsoft Excel. One-way ANOVA with post-hoc Tukey's HSD and principal component analysis (PCA) using the correlation matrix were conducted using R (Version 4.0.3).

3. Results

3.1. Sensory descriptors

A total of 133 candidate descriptors were provided to the panel, and after the panel orientation, 66 descriptors were included in the initial lexicon for the coffee samples made from Yunnan coffee beans (Table 2). These descriptors were divided into three categories: taste, flavor and others, which contained 12, 47 and 7 descriptors, respectively. The term “taste” refers to the basic taste modalities an assessor felt when sipping the coffee sample, whereas “flavor” was used to describe the complex combination of retronasal and orthonasal perceptions in the mouth (Koch et al., 2012). In total, 57 descriptors with an M value larger than 5% were retained for the following analyses. According to the M value, “taste” descriptors significantly contributed to the coffee samples were “sour”, “sour aromatics”, and “caramelized”, while “dark chocolate”, “brown, roast”, and “smoky” were the major “flavor” descriptors for outlining retronasal and orthonasal perceptions. The “others” category contained amplitude and mouthfeel descriptors, with “longevity”, “body/fullness”, and “oily” being the significant ones (Table 2).

Table 2.

Complete list of preliminary descriptive terms generated during panel training and the corresponding M values.

| Taste attributes | Descriptors | M valuea (%) | Flavor attributes | Descriptors | M value (%) | Other attributes | Descriptors | M value (%) |

|---|---|---|---|---|---|---|---|---|

| Sour/Acid | Sour | 65.21 | Alcohol/Fermented | Winey | 18.17 | Amplitude | Longevity | 68.39 |

| Sour aromatics | 25.34 | Fermented | 12.42 | Body/fullness | 59.18 | |||

| Citric acid | 14.45 | Cereal/Nutty | Dark chocolate | 41.52 | Blended | 53.33 | ||

| Malic acid | 5.75 | Hazelnut | 25.94 | Mouthfeel | Oily | 80.34 | ||

| Acetic acid | 5.15 | Chocolate | 23.31 | Thickness | 66.15 | |||

| Sweet | Caramelized | 39.07 | Almond | 14.34 | Mouth drying | 50.88 | ||

| Sweet aromatics | 18.13 | Grain | 8.60 | Metallic | 23.24 | |||

| Cream | 10.11 | Malt | 8.54 | |||||

| Honey | 9.61 | Peanuts | 7.12 | |||||

| Sweet | 7.86 | Chemical/Stale | Bitter | 73.15 | ||||

| Vanillin | 6.99 | Meaty/brothy | 24.16 | |||||

| Cheese | 1.07 | Salty | 16.24 | |||||

| Papery | 14.92 | |||||||

| Woody | 14.92 | |||||||

| Animalic | 11.88 | |||||||

| Medicinal | 11.58 | |||||||

| Stale | 9.55 | |||||||

| Petroleum | 3.38 | |||||||

| Rubber | 2.27 | |||||||

| Floral/Vegetative | Herb-like | 16.72 | ||||||

| Black tea | 13.48 | |||||||

| Raw | 6.44 | |||||||

| Rose | 5.18 | |||||||

| Osmanthus | 5.18 | |||||||

| Fruity | Tangerine | 11.81 | ||||||

| Orange | 7.98 | |||||||

| Honey peach | 7.96 | |||||||

| Grape | 7.66 | |||||||

| Lemon | 6.37 | |||||||

| Lychee | 5.19 | |||||||

| Mango | 4.83 | |||||||

| Strawberry | 4.26 | |||||||

| Pineapple | 4.13 | |||||||

| Tomato | 2.93 | |||||||

| Blueberry | 2.11 | |||||||

| Roasted | Brown, roast | 51.48 | ||||||

| Smoky | 43.13 | |||||||

| Ashy | 25.91 | |||||||

| Pipe tobacco | 25.03 | |||||||

| Baked sweet potatoes | 16.65 | |||||||

| Tobacco | 14.01 | |||||||

| Malted oatmeal bread | 10.17 | |||||||

| Bread | 8.31 | |||||||

| Biscuit | 3.77 | |||||||

| Spices | Cinnamon | 10.07 | ||||||

| Nutmeg | 9.95 | |||||||

| Pungent | 7.24 |

The M value is the square root of the product of the frequency and the relative intensity of a descriptor (see Materials and methods).

3.2. Sensory wheel

The descriptors were grouped into categories and presented in a three-tiered sensory wheel (Fig. 2). In the wheel, the inner tier contains the three major sensory modalities, namely, “taste”, “flavor”, and “others”; secondary descriptors that group a certain type of attributes are in the second tier; and the outer tier includes specific attributes. The “flavor” group is the most comprehensive first-tier descriptor, which contains three large secondary descriptors, namely, “chemical/stale”, “roasted”, and “cereal/nutty”, each consisting of seven to eight specific descriptors, while in the “taste” and “others” groups, “sweet” and “sour/acid” descriptors account for the largest proportion, representing the overall taste of the coffee samples. Detailed definitions of the terms included in the wheel can be found in Sensory Lexicon 2.0 issued by World Coffee Research (https://worldcoffeeresearch.org/work/sensory-lexicon).

Fig. 2.

The sensory wheel comprising 57 terms describing the sensory attributes of the 25 Yunnan coffee samples.

According to the M value, nine descriptors included in the lexicon were excluded in the sensory wheel. These descriptors were distributed in four second-tier categories, namely, “sweet”, “roasted”, “chemical/stale”, and “fruity”. Only one or two descriptors were removed in the first three categories, including “cheese”, which had the lowest M value (1.07), whereas five “fruity” terms were filtered, including “mango”, whose M value (4.83) was the highest among the removed terms (Table 2).

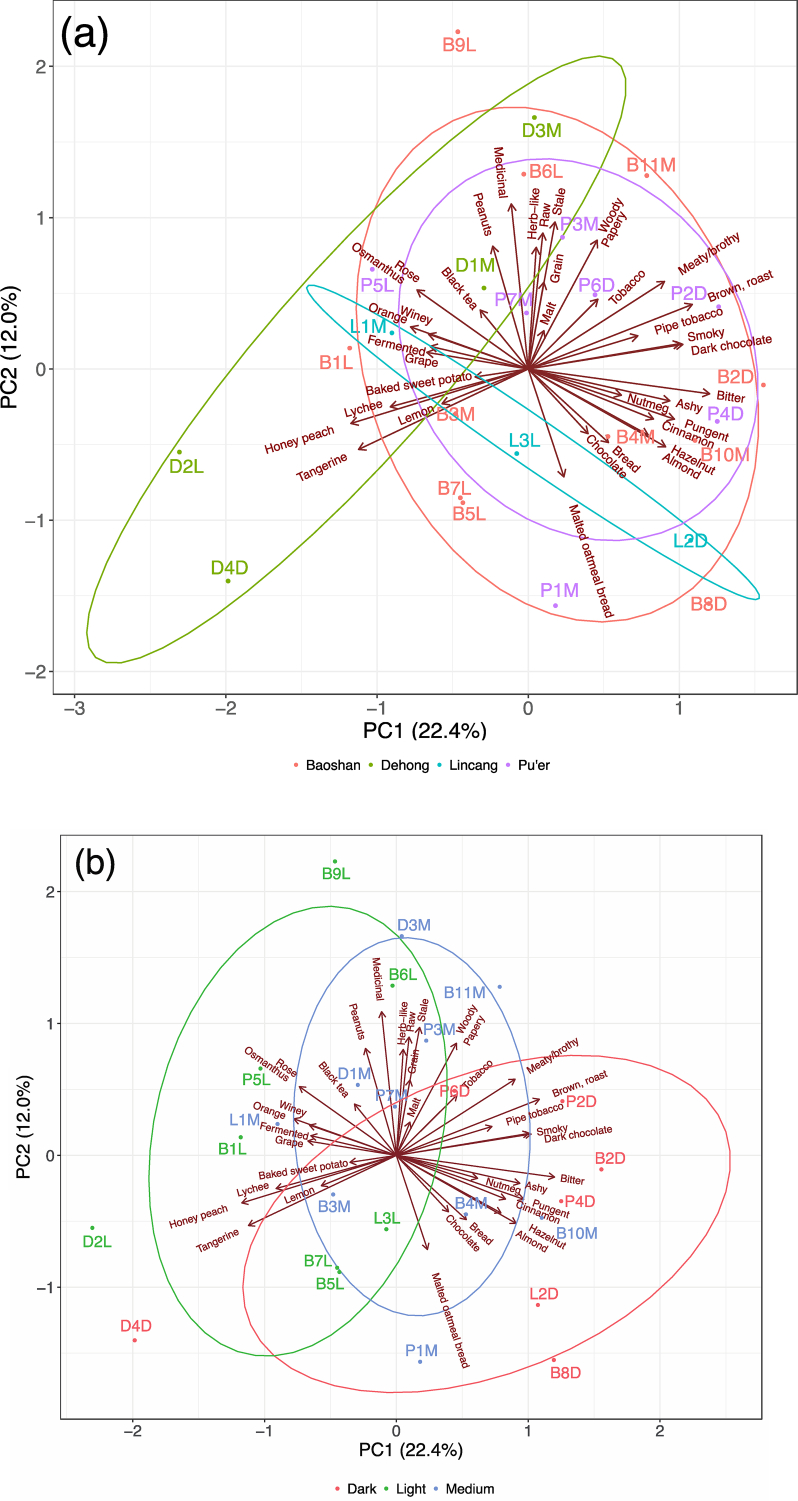

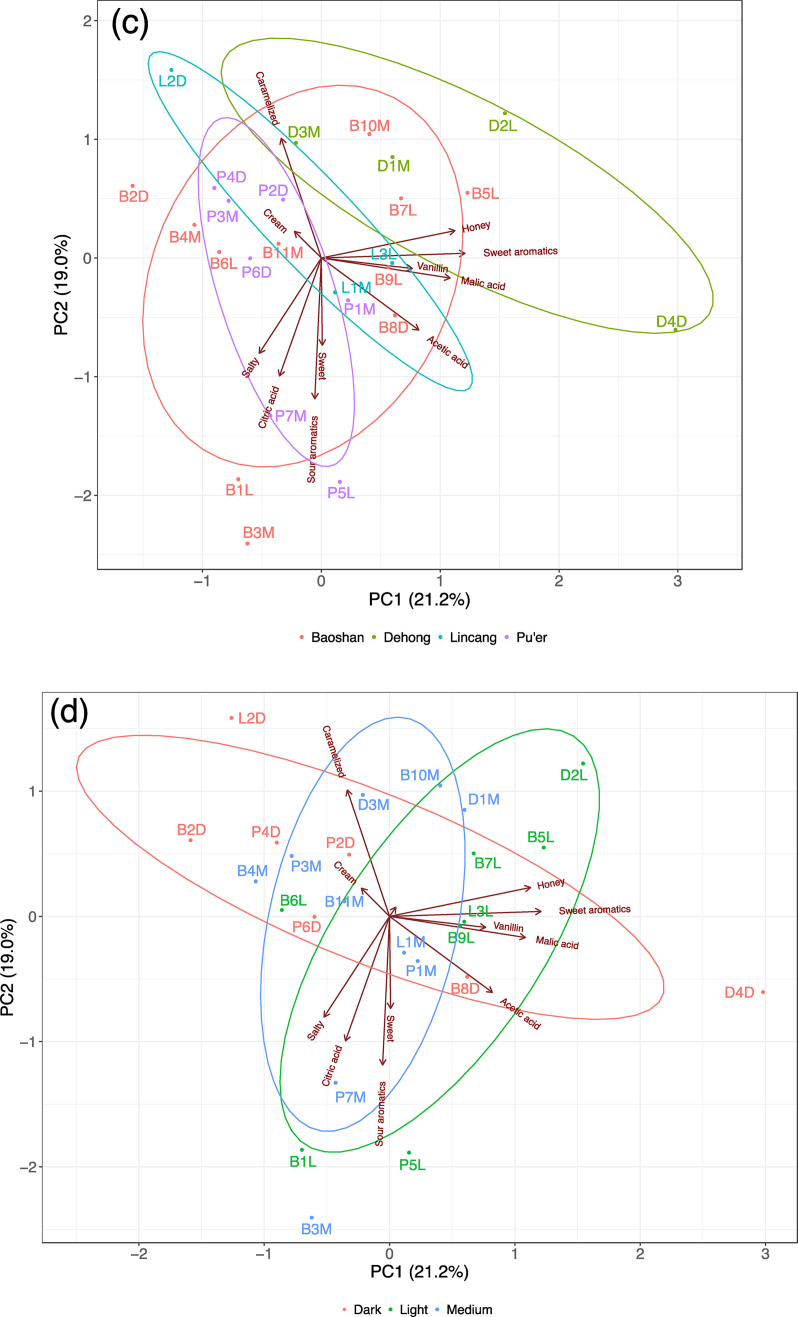

3.3. PCA analysis of the Yunnan coffee beans

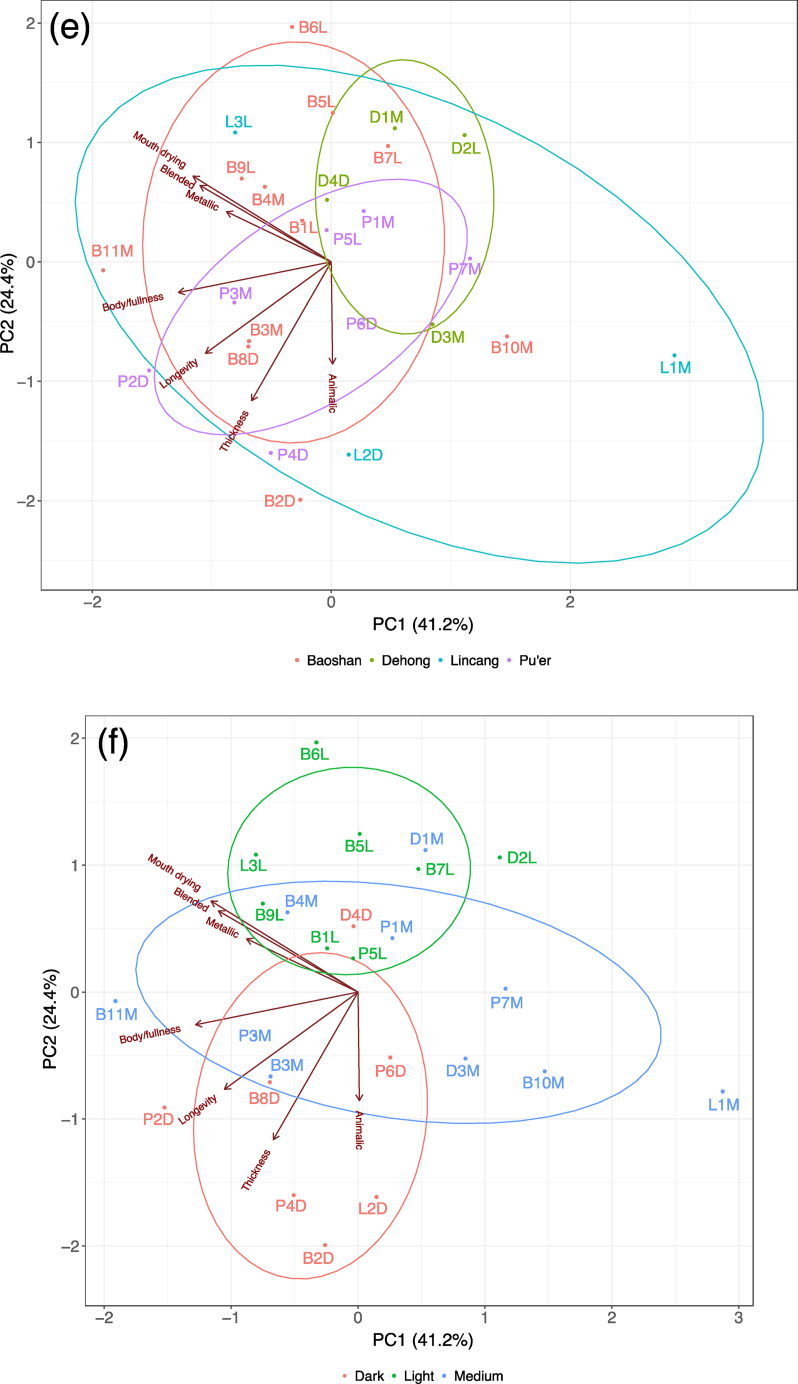

Given that a large number of descriptors were generated for our final sensory wheel, standardized PCA plots were made to show the association between the sensory attributes and the main sensory differences among the bean samples. Fig. 3 shows the PCA bi-plots for the “flavor” (Fig. 3a and b), “taste” (Fig. 3c and d) and “others” (Fig. 3e and f) descriptors.

Fig. 3.

PCA plots showing the positioning of the 39 “flavor” attributes [(a) and (b)], 11 “taste” attributes [(c) and (d)], and 7 “others” attributes [(e) and (f)] and the 20 Yunnan coffee samples (see Table 1 for labels). In (a), (c), and (d), the coffee samples are grouped according to the growing area, and in (b), (d), and (e), the coffee samples are grouped according to the degree of roasting.

In the PCA plots of “flavor” descriptors, the attributes are evenly located in the four quadrants, and the samples are not grouped together according to their origins (Fig. 3a). However, according to the first principal component (PC1), most of light roast samples are located in the left two quadrants, associating with attributes such as “grape”, “honey peach”, “lychee”, “lemon”, and “fermented”, whereas all dark roast samples except for D4D were on the right, where “dark chocolate”, “smoky”, “pipe tobacco”, “ashy”, and “nutmeg” are the major attributes (Fig. 3b). As shown in Fig. 3c, samples from Dehong and Linchang are to a large extent grouped according to their origins, while samples from Baoshan and Pu'er are positioned quite separately in the plot. With regard to the roast level, it is worth noting that dark roast samples are widely spread according to the PC1, while light roast and medium roast samples are more concentrated, indicating that dark roast samples display more pronounced variations in attributes such as “honey”, “sweet aromatics”, “malic”, and “vanillin” (Fig. 3d). According to the PC1 in the plots of “others” descriptors, all attributes with the exception of “animalic” are positioned in the left two quadrants (Fig. 3e and f). It is clear that samples from Dehong tend to locate in the right two quadrants while most Baoshan samples are found on the left, suggesting that samples from these two places display fairly distinct sensory properties in the aspects of “body/fulness”, “metallic”, and “blend” (Fig. 3e). As shown in Fig. 3f, light, medium and dark roast samples are grouped separately according to the PC2, and such obvious grouping demonstrates that the degree of roasting can affect sensory attributes such as “animatic”, “thickness”, “mouth drying”, “blended”, and “metallic” (Fig. 3c).

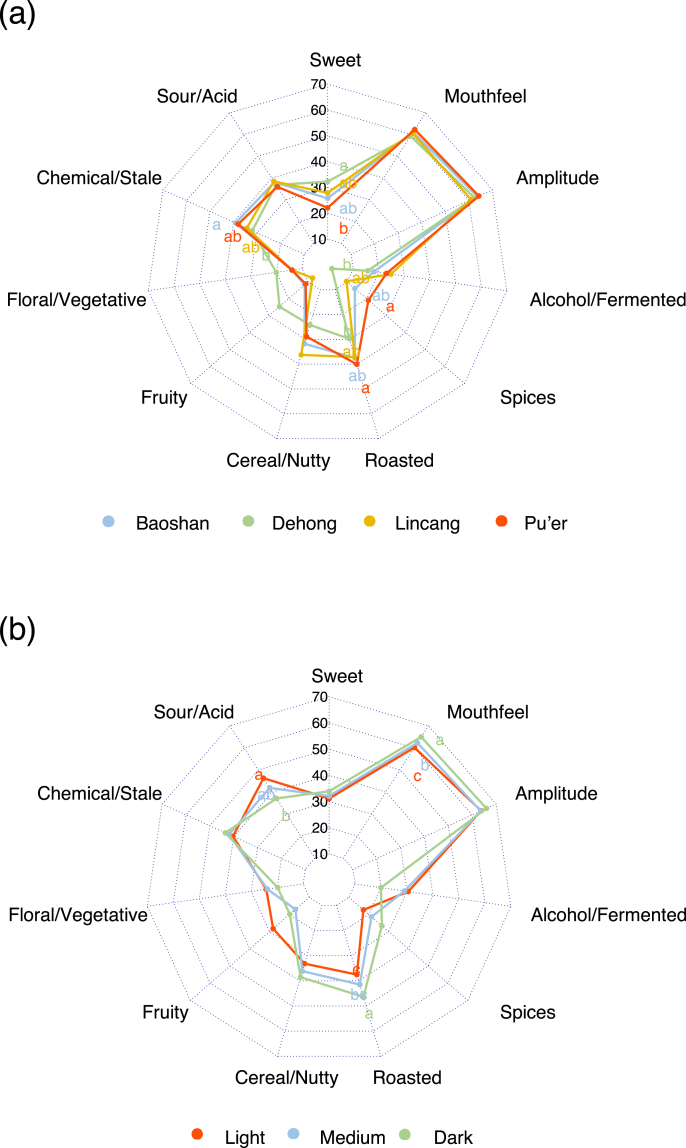

3.4. Sensory differences of the bean samples from different origins and with different degrees of roasting

To investigate how the sensory profiles vary among beans produced in different regions and with different degrees of roasting, we calculated the M value of each descriptor for the beans produced in the same region or with the same degree of roasting, and the comparisons of the sensory profiles were visualized in Fig. 4. In the spider plots, sensory profiles were plotted according to the 11 second-tier descriptors in the sensory wheel (Fig. 2), which include two taste basics and nine descriptors generally representing the sensory characteristics of Yunnan coffee, and significant differences (p < 0.05) are indicated by different letters.

Fig. 4.

Spider plots showing the mean scores for the 11second-tier descriptors in the sensory wheel that were associated with coffee samples produced in different regions (a) and with different degrees of roasting (b). The letters represent statistical grouping defined through an ANOVA followed by Tukey's Post hoc tests. Samples that are significantly different (p < 0.05) are shown with different letters.

For the four groups of beans with different origins, significant differences were found in the descriptors of “sweet”, “chemical/stale”, “roasted”, and “spices”. Three of these descriptors are significantly different between Dehong and Pu'er samples, with Dehong coffees being less strong in “spices” and “roasted” and having a higher degree of “sweet” (Fig. 4a). Considering “chemical/stale”, Banshan samples display a significantly higher intensity than Dehong samples (Fig. 4a). As shown in the sensory profiles plotted based on the roast levels, in comparison with light roast coffees, dark roast coffees received significantly higher scores in the “mouthfeel” and “roasted” groups of descriptors while their “sour/acid” level is significantly lower. Notably, dark, medium and light roast coffees show pairwise significant differences regarding their intensities in “mouthfeel”, indicating that the degree of roasting can greatly affect the mouthfeel of Yunnan coffee (Fig. 4b).

4. Discussion

Sensory analysis has been widely carried out for coffee in the past, including brewed (filter) coffee, instant coffee, and espresso or expresso-milk coffee (Maeztu et al., 2001; Narain et al., 2004; Navarini et al., 2004; Nebesny and Budryn, 2006; Seo et al., 2009). However, no such attempt on coffee samples from China has been reported. In this study, we conducted descriptive sensory analysis on 25 Yunnan coffees. We first identified 66 descriptors, and 57 of them were used to develop a sensory wheel, which outlines the overall sensory profile of Yunnan coffee. Given that Yunnan coffee is still a minor player in the market and their sensory properties are unlikely to be distinctly different from coffees from other counties, in this study we did not de novo develop an initial large lexicon; instead, we took advantage of a comprehensive reference lexicon developed using more than 100 different coffee samples from various major coffee growing countries (Chambers et al., 2016), and this lexicon was further expanded by adding descriptors from a number of other coffee sensory studies. The usage of this well-built and comprehensive lexicon enabled a more efficient and accurate evaluation of Yunnan coffee beans, in particularly considering that our panelists were not professionals. In the set of descriptors identified here, there are three large groups of “cereal/nutty”, “fruity” and “floral/vegetative” descriptors (Table 2, Fig. 2), and these descriptors were found to be positively correlated with pleasant perceptions (Kreuml et al., 2013; Nebesny and Budryn, 2006). Given that arabica coffee is the main species in Yunnan, our sensory wheel is unsurprisingly similar to the sensory wheels generated for popular coffee beans produced in other countries, and such result is also reflected by the high scores Yunnan coffee beans received for cup quality (Spencer et al., 2016; Zhang et al., 2014). In terms of the differences in comparison with wheels generated for other beans, our wheel owns a smaller number of “fruity” descriptors (lacking, e.g., “apple”, “peach” and “pear”), while other negative descriptors, such as “rubber” and “petroleum” do not appear, indicating that Yunnan coffee's sensory profile is converged and shows a high average quality (Fig. 2).

We speculate that the differences between sensory qualities of Yunnan coffee and other coffees stem from the following reasons. In general, elevation is one environmental factor being often positively associated with coffee quality and price (Avelino et al., 2005; Bertrand et al., 2012; Martins et al., 2020; Tolessa et al., 2017). The altitude of the four coffee production regions included in this study ranges from 700 to 1700 m above the sea level, which is similar to the altitude range in Brazil's coffee production regions but lower than the altitude in Ethiopia. Bertrand et al. (2012) concluded that the mean air temperature during seed development is the main reason for the positive effects of elevation, and they also concluded that cool climates might result in more positive quality attributes. Therefore, Yunnan's mild annual temperature might play a major role for determining the sensory profile. In addition, agricultural practices have also been linked to coffee quality, such as cultivation and harvest methods (Sunarharum et al., 2014). In most coffee farms in Yunnan, production is still in small-scale, and cultivation is largely not standardized, leading to large variations in soil fertility (Zhao et al., 2019). The above reasons may also explain the sensory differences detected among beans from different regions in Yunnan (Fig. 3, Fig. 4). In particular, Baoshan has the highest average elevation among the four regions, and its rainfall is lower than the other three regions (Huang et al., 2010).

Coffee cup quality is not only determined by green beans, but also significantly influenced by commercial processing steps, such as roasting, grinding, and brewing. Numerous studies have demonstrated that among these steps, roasting has the largest impact on coffee aroma and taste (Buffo and Cardelli-Freire, 2004; Esquivel and Jiménez, 2012; Redgwell et al., 2002). During roasting, the temperature is elevated to 180–240 °C for 8–15 min. Under such extreme conditions, a large number of complex chemical reactions take place, such as Maillard reactions; Strecker degradation; breakdown of sulphur amino acids, hydroxy-amino acids, proline and hydroxyproline; degradation of trigonelline, the quinic acid moiety, pigments and lipids. Hundreds of substances associated with coffee sensory properties are formed or released directly from these reactions or through interactions between intermediate products (Buffo and Cardelli-Freire, 2004). A previous study by Bhumiratana et al. (2011) found that coffee prepared through light roasting is usually less sour and sweeter than medium or dark roasted ones, while darker roasting contributes to typical “coffee” attributes. In this study, we found a similar trend, with light roasted beans showing significantly lower intensity scores of “sour/acid”, whereas medium and dark roasting giving rise to significantly higher scores of the “mouthfeel” and “roasted” groups of descriptors (Fig. 4b). Such sensory differences are likely because excessive roasting would lead to certain changes in the concentrations of volatile substances, which are major determinants of coffee cup quality (Baggenstoss et al., 2008; Buffo and Cardelli-Freire, 2004).

One weakness of our study is that we only used commercially available beans. On the one hand, the exact coffee been variety information is not available to us, and on the other hand, different processing standards may result in variations of final cup quality. For example, there are three major green coffee bean processing techniques—dry processing (natural), wet processing (washed), and semi-dry (semi-washed) processing. Previous efforts have found that dry processing may give the coffee drink a more intensive medicinal flavor whereas wet processing can increase acidity and richness of the aroma (Sunarharum et al., 2014). Furthermore, while the initial lexicon we employed is of high quality, the usage of the translated version might bring inaccuracies into our analysis. It has been reported that sensory descriptors are affected by culture and language, so the comparison between Yunnan coffee with other coffee samples using sensory wheels should be interpreted with caution (Hayakawa et al., 2010).

The present work can be extended in multiple ways. For example, a detailed analysis of the chemical components of the Yunnan coffee beans may provide more objective support to our sensory property assessment. Recently, Barbosa et al. (2019) analyzed the correlation between the composition of 66 green Arabica coffee bean samples and their brews' sensory qualities; they found that levels of caffeine, protein, chlorogenic acids and total titratable acidity in the green coffee beans are negatively correlated with coffee quality, while high ratios of sucrose/total titratable acidity and cafestol/kahweol are associated with higher quality of coffee brews. Therefore, it would be interesting to conduct a similar detailed analysis as such chemical results may not only be indicative of the overall quality of Yunnan coffee beans, but also may provide relevant information for coffee improvement programs. Furthermore, the health effect of coffee intake has been linked with coffee quality (Gonzalez de Mejia and Ramirez-Mares, 2014; Kolb et al., 2020). Notably, a number of bioactive compounds, such as caffeine, chlorogenic acids and derivatives, trigonelline, nicotinic acid, 5-hydroxymethylfurfural, theobromine, and theophylline have been associated with a variety of significant bioactivities, including antioxidant activity, anticarcinogenic activity and antimutagenic activity (George et al., 2008; Rodrigues and Bragagnolo, 2013). Hence, to comprehensively characterize the quality of Yunnan coffee, it would be important to also take these bioactive compounds into consideration in future chemical analyses.

CRediT authorship contribution statement

Jiayi Ma: Investigation. Jinping Li: Formal analysis, Funding acquisition. Hong He: Investigation, Writing – original draft. Xiaoling Jin: Investigation. Igor Cesarino: Conceptualization, Writing – review & editing. Wei Zeng: Conceptualization, Supervision, Writing – review & editing. Zheng Li: Conceptualization, Supervision, Project administration, Formal analysis, Writing – original draft, Writing – review & editing, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

We are thankful to the volunteers who participated in the sensory evaluation, and Dr Feifei He from Yunnan University for providing assistance in panel recruitment. This work was supported by a grant from Yunnan University (to J.L.).

Handling Editor: Dr. Maria Corradini

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.crfs.2022.07.010.

Contributor Information

Wei Zeng, Email: zengw@zafu.edu.cn.

Zheng Li, Email: zhengli@ynu.edu.cn.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- Adane A., Bewket W. Effects of quality coffee production by smallholders on local land use and land cover in Yirgacheffe, southern Ethiopia. J. Land Use Sci. 2021;16:205–221. https://doi:10.1080/1747423x.2021.1893844 [Google Scholar]

- Akiyama M., Murakami K., Hirano Y., Ikeda M., Iwatsuki K., Wada A., Tokuno K., Onishi M., Iwabuchi H. Characterization of headspace aroma compounds of freshly brewed arabica coffees and studies on a characteristic aroma compound of Ethiopian coffee. J. Food Sci. 2008;73:C335–C346. doi: 10.1111/j.1750-3841.2008.00752.x. [DOI] [PubMed] [Google Scholar]

- Arya M., Rao L.J.M. An impression of coffee carbohydrates. Crit. Rev. Food Sci. Nutr. 2007;47:51–67. doi: 10.1080/10408390600550315. [DOI] [PubMed] [Google Scholar]

- Avelino J., Barboza B., Araya J.C., Fonseca C., Davrieux F., Guyot B., Cilas C. Effects of slope exposure, altitude and yield on coffee quality in two altitudeterroirs of Costa Rica, Orosi and Santa María de Dota. J. Sci. Food Agric. 2005;85:1869–1876. doi: 10.1002/jsfa.2188. [DOI] [Google Scholar]

- Baggenstoss J., Poisson L., Kaegi R., Perren R., Escher F. Coffee roasting and aroma formation: application of different time-temperature conditions. J. Agric. Food Chem. 2008;56:5836–5846. doi: 10.1021/jf800327j. [DOI] [PubMed] [Google Scholar]

- Barbosa M.S.G., Scholz M., Kitzberger C.S.G., Benassi M.T. Correlation between the composition of green Arabica coffee beans and the sensory quality of coffee brews. Food Chem. 2019;292:275–280. doi: 10.1016/j.foodchem.2019.04.072. [DOI] [PubMed] [Google Scholar]

- Bertrand B., Boulanger R., Dussert S., Ribeyre F., Berthiot L., Descroix F., Joet T. Climatic factors directly impact the volatile organic compound fingerprint in green Arabica coffee bean as well as coffee beverage quality. Food Chem. 2012;135:2575–2583. doi: 10.1016/j.foodchem.2012.06.060. [DOI] [PubMed] [Google Scholar]

- Bhumiratana N., Adhikari K., Chambers E. Evolution of sensory aroma attributes from coffee beans to brewed coffee. LWT-Food Sci. Technol. 2011;44:2185–2192. doi: 10.1016/j.lwt.2011.07.001. [DOI] [Google Scholar]

- Buffo R.A., Cardelli-Freire C. Coffee flavour: an overview. Flavour Fragr. J. 2004;19:99–104. doi: 10.1002/ffj.1325. [DOI] [Google Scholar]

- Chambers E., Sanchez K., Phan U.X.T., Miller R., Civille G.V., Di Donfrancesco B. Development of a “living” lexicon for descriptive sensory analysis of brewed coffee. J. Sens. Stud. 2016;31:465–480. doi: 10.1111/joss.12237. [DOI] [Google Scholar]

- Esquivel P., Jiménez V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012;46:488–495. doi: 10.1016/j.foodres.2011.05.028. [DOI] [Google Scholar]

- George S.E., Ramalakshmi K., Rao L.J.M. A perception on health benefits of coffee. Crit. Rev. Food Sci. Nutr. 2008;48:464–486. doi: 10.1080/1040839070152-2445. [DOI] [PubMed] [Google Scholar]

- Gonzalez de Mejia E., Ramirez-Mares M.V. Impact of caffeine and coffee on our health. Trends Endocrinol. Metabol. 2014;25:489–492. doi: 10.1016/j.tem.2014.07.003. [DOI] [PubMed] [Google Scholar]

- Hayakawa F., Kazami Y., Wakayama H., Oboshi R., Tanaka H., Maeda G., Hoshino C., Iwawaki H., Miyabayashi T. Sensory lexicon of brewed coffee for Japanese consumers, untrained coffee professionals and trained coffee tasters. J. Sens. Stud. 2010;25:917–939. doi: 10.1111/j.1745-459X.2010.00313.x. [DOI] [Google Scholar]

- Huang J., Li Y., Yang S., Huang J., Yang B., Yang Y., Li S., Guo R., Cheng J. Comparative research on the quality of Coffea arabica from different producing areas. Trop. Agric. Eng. 2010;34:7–10. (In Chinese), CNKI:SUN:RDZW.0.2010-04-003. [Google Scholar]

- International Coffee Organization . 2021. Trade statistics.http://www.ico.org/trade_statistics.asp Retrieved from. [Google Scholar]

- Koch I.S., Muller M., Joubert E., van der Rijst M., Naes T. Sensory characterization of rooibos tea and the development of a rooibos sensory wheel and lexicon. Food Res. Int. 2012;46:217–228. doi: 10.1016/j.foodres.2011.11.028. [DOI] [Google Scholar]

- Kolb H., Kempf K., Martin S. Health effects of coffee: mechanism unraveled? Nutrients. 2020;12:1842. doi: 10.3390/nu12061842. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kolk A. Mainstreaming sustainable coffee. Sustain. Dev. 2013;21:324–337. doi: 10.1002/sd.507. [DOI] [Google Scholar]

- Kreuml M.T., Majchrzak D., Ploederl B., Koenig J. Changes in sensory quality characteristics of coffee during storage. Food Sci. Nutr. 2013;1:267–272. doi: 10.1002/fsn3.35. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lawless H.T., Heymann H. vol. 2. Springer; 2010. (Sensory Evaluation of Food: Principles and Practices). [Google Scholar]

- Lawless L.J.R., Civille G.V. Developing lexicons: a review. J. Sens. Stud. 2013;28:270–281. doi: 10.1111/joss.12050. [DOI] [Google Scholar]

- Lee L.W., Cheong M.W., Curran P., Yu B., Liu S.Q. Coffee fermentation and flavor—an intricate and delicate relationship. Food Chem. 2015;185:182–191. doi: 10.1016/j.foodchem.2015.03.124. [DOI] [PubMed] [Google Scholar]

- Lee L.W., Cheong M.W., Curran P., Yu B., Liu S.Q. Modulation of coffee aroma via the fermentation of green coffee beans with Rhizopus oligosporus: II. Effects of different roast levels. Food Chem. 2016;211:925–936. doi: 10.1016/j.foodchem.2016.05.073. [DOI] [PubMed] [Google Scholar]

- Li G., Yang S., Huang J., Li S., Wang M. Investigation and collection of coffee germplasm in Yunnan. Trop. Agric. Sci. Technol. 2007;30:17–19. doi: 10.16005/j.cnki.tast.2007.04.005. (In Chinese) [DOI] [Google Scholar]

- Li Z., Zhang C., Zhang Y., Zeng W., Cesarino I. Coffee cell walls—composition, influence on cup quality and opportunities for coffee improvements. Food Qual. Saf. 2021;5:1–21. doi: 10.1093/fqsafe/fyab012. [DOI] [Google Scholar]

- Liu C., Yang Q., Linforth R., Fisk I.D., Yang N. Modifying Robusta coffee aroma by green bean chemical pre-treatment. Food Chem. 2019;272:251–257. doi: 10.1016/j.foodchem.2018.07.226. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maeztu L., Andueza S., Ibanez C., Paz de Pena M., Bello J., Cid C. Multivariate methods for characterization and classification of espresso coffees from different botanical varieties and types of roast by foam, taste, and mouthfeel. J. Agric. Food Chem. 2001;49:4743–4747. doi: 10.1021/jf010314l. [DOI] [PubMed] [Google Scholar]

- Magrach A., Ghazoul J. Climate and pest-driven geographic shifts in global coffee production: implications for forest cover, biodiversity and carbon storage. PLoS One. 2015;10 doi: 10.1371/journal.pone.0133071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Martins P.M.M., Batista N.N., Miguel M., Simao J.B.P., Soares J.R., Schwan R.F. Coffee growing altitude influences the microbiota, chemical compounds and the quality of fermented coffees. Food Res. Int. 2020;129 doi: 10.1016/j.foodres.2019.108872. [DOI] [PubMed] [Google Scholar]

- Murray J.M., Delahunty C.M., Baxter I.A. Descriptive sensory analysis: past, present and future. Food Res. Int. 2001;34:461–471. doi: 10.1016/S0963-9969(01)00070-9. [DOI] [Google Scholar]

- Narain C., Paterson A., Reid E. Free choice and conventional profiling of commercial black filter coffees to explore consumer perceptions of character. Food Qual. Prefer. 2004;15:31–41. doi: 10.1016/S0950-3293(03)00020-X. [DOI] [Google Scholar]

- Navarini L., Cappuccio R., Suggi-Liverani F., Illy A. Espresso coffee beverage: classification of texture terms. J. Texture Stud. 2004;35:525–541. doi: 10.1111/j.1745-4603.2004.35504.x. [DOI] [Google Scholar]

- Nebesny E., Budryn G. Evaluation of sensory attributes of coffee brews from robusta coffee roasted under different conditions. Eur. Food Res. Technol. 2006;224:159–165. doi: 10.1007/s00217-006-0308-y. [DOI] [Google Scholar]

- Redgwell R.J., Trovato V., Curti D., Fischer M. Effect of roasting on degradation and structural features of polysaccharides in Arabica coffee beans. Carbohydr. Res. 2002;337:421–431. doi: 10.1016/S0008-6215(02)00010-1. [DOI] [PubMed] [Google Scholar]

- Rigal C., Xu J., Hu G., Qiu M., Vaast P. Coffee production during the transition period from monoculture to agroforestry systems in near optimal growing conditions, in Yunnan Province. Agric. Syst. 2020;177:102096. doi: 10.1016/j.agsy.2019.102696. [DOI] [Google Scholar]

- Rodrigues N.P., Bragagnolo N. Identification and quantification of bioactive compounds in coffee brews by HPLC-DAD-MSn. J. Food Compos. Anal. 2013;32:105–115. doi: 10.1016/j.jfca.2013.09.002. [DOI] [Google Scholar]

- Samoggia A., Del Prete M., Argenti C. Functional needs, emotions, and perceptions of coffee consumers and non-Consumers. Sustainability. 2020;12:5694. doi: 10.3390/su12145694. [DOI] [Google Scholar]

- Sarrazin C., Le Quéré J.-L., Gretsch C., Liardon R. Representativeness of coffee aroma extracts: a comparison of different extraction methods. Food Chem. 2000;70:99–106. doi: 10.1016/S0956-7135(99)00116-4. [DOI] [Google Scholar]

- Seninde D., R, Chambers E. Coffee flavor: a review. Beverages. 2020;6:44. doi: 10.3390/beverages6030044. [DOI] [Google Scholar]

- Seo H.-S., Lee S.-Y., Hwang I. Development of sensory attribute pool of brewed coffee. J. Sens. Stud. 2009;24:111–132. doi: 10.1111/j.1745-459X.2008.00198.x. [DOI] [Google Scholar]

- Silva E.A.D., Mazzafera P., Brunini O., Sakai E., Arruda F.B., Mattoso L.H.C., Carvalho C.R.L., Pires R.C.M. The influence of water management and environmental conditions on the chemical composition and beverage quality of coffee beans. Braz. J. Plant Physiol. 2005;17:229–238. doi: 10.1590/S1677-04202005000200006. [DOI] [Google Scholar]

- Spencer M., Sage E., Velez M., Guinard J.X. Using single free sorting and multivariate exploratory methods to design a new coffee taster's flavor wheel. J. Food Sci. 2016;81:S2997–S3005. doi: 10.1111/1750-3841.13555. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stanek N., Zarębska M., Biłos Ł., Barabosz K., Nowakowska‐Bogdan E., Semeniuk I., Błaszkiewicz J., Kulesza R., Matejuk R., Szkutnik K. Influence of coffee brewing methods on the chromatographic and spectroscopic profiles, antioxidant and sensory properties. Sci. Rep. 2021;11 doi: 10.1038/s41598-021-01001-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sunarharum W.B., Williams D.J., Smyth H.E. Complexity of coffee flavor: a compositional and sensory perspective. Food Res. Int. 2014;62:315–325. doi: 10.1016/j.foodres.2014.02.030. [DOI] [Google Scholar]

- Tolessa K., D'Heer J., Duchateau L., Boeckx P. Influence of growing altitude, shade and harvest period on quality and biochemical composition of Ethiopian specialty coffee. J. Sci. Food Agric. 2017;97:2849–2857. doi: 10.1002/jsfa.8114. [DOI] [PubMed] [Google Scholar]

- Vega F.E., Rosenquist E., Collins W. Global project needed to tackle coffee crisis. Nature. 2003;425:343. doi: 10.1038/425343a. [DOI] [PubMed] [Google Scholar]

- Wen Z., Bi X., Lu W. Discussion on the trend of Chinese coffee consumption. Farm. Prod. Process. 2018:69–70. doi: 10.16693/j.cnki.1671-9646(X).2018.01.047. (In Chinese) [DOI] [Google Scholar]

- Zhang H., Li J., Zhou H., Chen Z., Song G., Peng Z., Pereira A.P., Silva M.C., Várzea V.M.P. Proceedings of the 24th International Conference on Coffee Science. 2014. Arabica coffee production in the yunnan Province of China. [Google Scholar]

- Zhang X., Yang L., Zhao Y., Peng Z., Qiu Y., Xu X., Huang J. Brief analysis of the standardization level of coffee industry in China. Chinese J Trop Agric. 2020;40:133–137. doi: 10.12008/j.issn.1009-2196.2020.12.022. (In Chinese) [DOI] [Google Scholar]

- Zhao M., Wu T., Tang J., Ma G., Guo T., Xiao Z., Su L., Zhou H., Bai X. Status quo and variation of soil fertility in different altitude of Coffea arabica L. Chin J. Trop. Crop. 2019;40:629–637. doi: 10.3969/j.issn.10002561.2019.04.002. (In Chinese) [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.