The SARS-CoV-2 (COVID-19) pandemic has placed a tremendous amount of strain on resources in the health care setting. One of the most pressing issues is the rapid depletion of personal protective equipment (PPE) used in the care of patients. This is a significant concern for health care workers’ health and safety. Many entities have depleted or soon will exhaust their stockpile of PPE despite adopting PPE-sparing practices as the number of COVID-19 cases in the United States increases at an almost exponential rate and manufacturers struggle to keep up with the worldwide demand. This potential shortage is particularly concerning for commonly used N95 respirators and powered-air purifying respirators (PAPRs). Recently, the US Occupational Safety and Health Administration (OSHA)1 even temporarily suspended the requirement to perform annual fit testing of respirators to allow entities to conserve respirators and preserve them for patient care. These measures are unprecedented and highlight the urgent need for entities to develop solutions to proactively address what could be potentially a grave occupational health issue.

At Duke University and Health System, we have evaluated and will begin using hydrogen peroxide vapor to decontaminate and reuse N95 respirators. In this communication, we briefly discuss the decontamination validation process and post-decontamination performance validation conducted at Duke. This validation, which is supported by previous laboratory testing, funded by the US Food and Drug Administration (FDA), demonstrated that N95 respirators still met performance requirements even after decontamination with hydrogen peroxide vapor in the laboratory setting for over 50 times.2 While previous studies have shown the applicability of the hydrogen peroxide vapor process, we have also confirmed that the respirator still functions as designed, using our standardized human N95 fit testing methodology. We will now use this internally validated and Duke Institutional Biosafety Review Committee (IBRC)–approved laboratory decontamination process in the clinical setting to dramatically extend the life of our N95 respirators. We hope that sharing our processes through this brief communication can help other entities with access to hydrogen peroxide vapor to evaluate the potential applicability of this technology at their facility or partner with those who may already have this capability, including other private-sector life science organizations.

Process/Method

We, like others, have implemented many Centers for Disease Control and Prevention (CDC)–approved N95 reuse practices, including employees reusing their own N95s for the duration of their shifts. However, this alone may not be adequate to meet our anticipated need with various centers reporting multiple-fold higher use of PPE as their caseload increases. In the interest of our workforce safety, the goal was thus to extend the life of our existing supply.

Duke University houses one of the National Institute of Allergy and Infectious Diseases (NIAID) Regional Biocontainment Laboratories (RBLs) as part of a nationwide network of high-containment laboratories and has extensive experience with the use of hydrogen peroxide vapor decontamination. In addition, Duke University Health System had past experience with hydrogen peroxide vapor in the clinical setting as part of previous high-consequence pathogen preparedness exercises. The Duke RBL, a biosafety level 3 (BSL-3) facility, contains a room specifically designed to use hydrogen peroxide vapor to decontaminate laboratory equipment and has been operational for over a decade. This room currently uses a Bioquell (Horsham, PA, USA) ClarusTM C system with a 35% hydrogen peroxide solution and distribution system to disperse hydrogen peroxide vapor into the room in a uniform fashion. In addition, we are evaluating the new Bioquell Z-2 and Bioquell ProteQ systems that will provide increased capacity and flexibility to our reprocessing needs.

The FDA-funded project, referenced previously, validated the decontamination of N95 respirators with hydrogen peroxide vapor for over 50 cycles with the reuse limiting factor being the elastic straps that started to show degradation.2 To address this, we plan to decontaminate and reuse N95s up to 30 cycles with a quality assurance (QA) step to ensure both qualitative and quantitative degradation has not occurred. A cohort of respirators will be decontaminated with every cycle and will be used in standardized quantitative fit testing to ensure the integrity of the respirators is maintained over many decontamination cycles.

Procedures

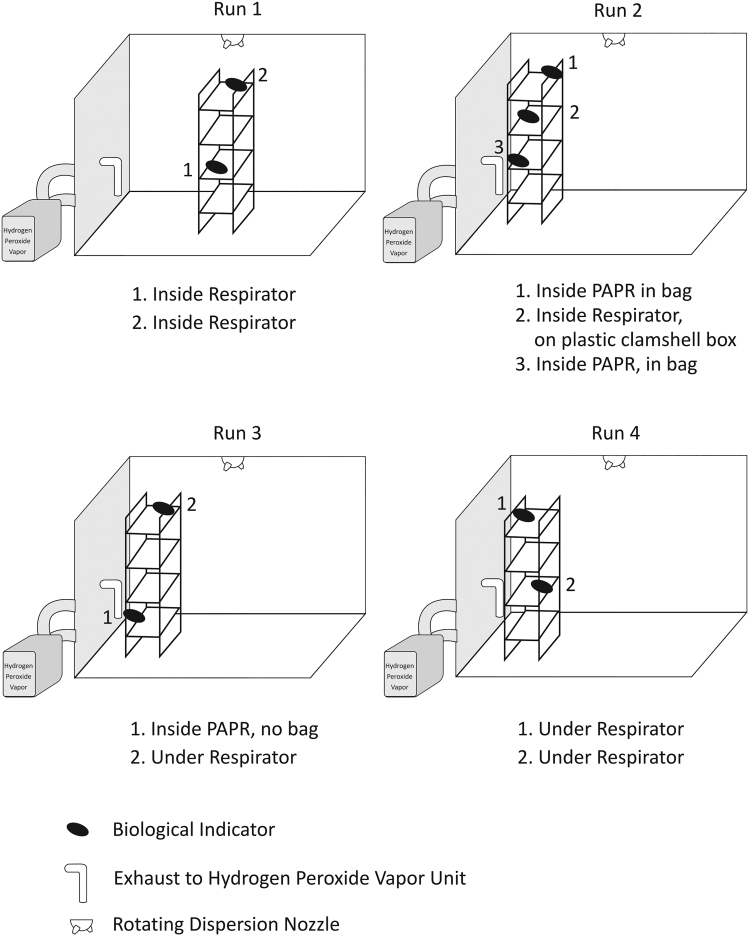

Approximately 100 3M (St. Paul, MN, USA) 1860 N95s, previously used in quantitative employee fit testing, were collected and laid out on stainless steel wire racks in our hydrogen peroxide vapor processing room in the RBL. The hydrogen peroxide vapor run consisted of the following 5 stages: conditioning, pregassing, gassing, gassing dwell, and aeration. The existing RBL hydrogen peroxide vapor standard operating procedure (SOP) was employed and requires that the processing room attain a 480+-ppm level of hydrogen peroxide vapor with a “gassing” time of 25 minutes and a “gassing dwell” time of 20 minutes. At the end of a cycle, during the aeration stage, fresh air was introduced into the room to increase the rate of catalytic conversion of hydrogen peroxide vapor into oxygen and water. This procedure leaves no residue other than water. When sufficient time had passed, we used a PortaSens II sensor (Analytical Technology, Inc., Collegeville, PA, USA) to ensure hydrogen peroxide levels were below the OSHA permissible exposure limit3 (PEL) of 1.0 ppm prior to entering the room. In addition, we validated the efficacy of the decontamination process by using 9 individual 6-log biological indicators (Geobacillus stearothermophilus spores). See Figure 1 for representation of the decontamination setup and placement of biological indicators.

Figure 1.

Placement of biological indicators (BIs) during the hydrogen peroxide vapor decontamination cycles.

Based on our previous experience with hydrogen peroxide vapor and porous materials, we anticipated the possibility of off-gassing of H2O2 from the respirators at the end of the run. For this reason, in our initial tests, we performed a quantitative and qualitative assessment for H2O2. For the quantitative assessment, the PortaSens II was used to detect H2O2 levels over a 4-hour time frame by taking readings at regular intervals by placing the probe close to the respirators. At approximately 4 hours, the levels decreased below the PortaSens II level of detection (0 ppm). In the qualitative test, 3 individuals did a qualitative smell test to determine if there were any noticeable odors. None were detected. After complete aeration, the respirators went through a QA process to ensure that there was no physical or performance degradation. The decontaminated respirators then underwent our normal quantitative fit testing process to ensure their continued performance and were tested on 2 individuals with differing facial structures with no loss of fit or seal, thereby ensuring that N95s decontaminated using this method can be placed back into circulation.

Conclusion

Using hydrogen peroxide vapor is a proven method of decontamination. Previous studies have shown that N95 respirators retain their filtering capability even after 50 cycles in a laboratory environment. We have taken this one step further to show it can be done in the real-world environment using commercially available equipment and performing fit testing on humans rather than “human forms.” We believe that N95 sparing and reuse practices are important but not sufficient given the current situation and thus will begin reuse after decontamination on a large-scale. While this alone will not solve the problem, it will allow us to process and reuse a significant number of N95 respirators or other critical items. As health care facilities operate in uncharted territories while dealing with a plethora of unanticipated day-to-day issues, solving issues that directly affect the health and safety of our health care workers is of utmost importance. Health care workers must be equipped with the appropriate PPE that they need to do their jobs with confidence. In times of global shortages, we have to improvise and adapt existing technologies for new uses. We believe that decontamination of N95 respirators with hydrogen peroxide vapor is one such solution that affords us better ability to protect our health care workers as we continue to tackle this monumental issue. To date, we have decontaminated over 100 respirators for reuse. We will continue to validate this process with other PPE and reusable hydrogen peroxide vapor–compatible medical equipment. We recommend validating this procedure with the respirator used at your facility.

Acknowledgment

The authors would like to sincerely appreciate the tireless contributions of numerous Duke staff without whom these efforts would not have been possible.

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: Decontamination testing and activities were performed in the Duke Regional Biocontainment Laboratory, which received partial support for construction from the National Institutes of Health, National Institute of Allergy and Infectious Diseases (UC6-AI058607), and the Duke School of Medicine.

ORCID iD

Nicole Greeson  https://orcid.org/0000-0001-8554-7707

https://orcid.org/0000-0001-8554-7707

References

- 1. Occupational Safety and Health Administration (OSHA). Temporary enforcement guidance—healthcare respiratory protection annual fit-testing for N95 filtering facepieces during the COVID-19 outbreak. March 14, 2020. https://www.osha.gov/memos/2020-03-14/temporary-enforcement-guidance-healthcare-respiratory-protection-annual-fit. Accessed 16 March 2020.

- 2. Final report for the Bioquell hydrogen peroxide vapor (HPV) decontamination for reuse of N95 respirators. Prepared by Battelle Columbus, Ohio. Prepared under Contract No. HHSF223201400098C. Study Number 3245. Prepared for the FDA. https://www.fda.gov/emergency-preparedness-and-response/mcm-regulatory-science/investigating-decontamination-and-reuse-respirators-public-health-emergencies. July 2016. Accessed 4 March 2020.

- 3. Occupational Safety and Health Administration (OSHA). 29 CFR 1910.1000 Table Z-1—Table Z-1 limits for air contaminants. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1000TABLEZ1. Published 9 January 2017. Accessed 16 March 2020.