Abstract

Organic chemistry provides society with fundamental products we use daily. Concerns about the impact that the chemical industry has over the environment is propelling major changes in the way we manufacture chemicals. Biocatalysis offers an alternative to other synthetic approaches as it employs enzymes, Nature's catalysts, to carry out chemical transformations. Enzymes are biodegradable, come from renewable sources, operate under mild reaction conditions, and display high selectivities in the processes they catalyse. As a highly multidisciplinary field, biocatalysis benefits from advances in different areas, and developments in the fields of molecular biology, bioinformatics, and chemical engineering have accelerated the extension of the range of available transformations (E. L. Bell et al., Nat. Rev. Meth. Prim. 2021, 1, 1–21). Recently, we surveyed advances in the expansion of the scope of biocatalysis via enzyme discovery and protein engineering (J. R. Marshall et al., Tetrahedron 2021, 82, 131926). Herein, we focus on novel enzymes currently available to the broad synthetic community for the construction of new C−C, C−N and C−O bonds, with the purpose of providing the non‐specialist with new and alternative tools for chiral and sustainable chemical synthesis.

Recent research on the biocatalytic formation of new C−C, C−N, and C−O is surveyed in this review to provide an overview of the current state‐of‐the‐art in the field as well as future perspectives.

1. Emerging Enzymes for Biocatalytic C−C Bond Formation

The formation of carbon‐carbon (C−C) bonds is arguably the most fundamental transformation underpinning organic synthesis; it enables the coupling of small building blocks to form the framework of a multitude of organic molecules including API's, natural products, and agrochemicals.[ 1 , 2 ] Transition metal based catalysts have demonstrated to be excellent tools for the construction of new C−C bonds in an asymmetric fashion, although such transformations often require expensive metal catalysts, organic solvents and harsh reaction.[ 1 , 3 , 4 ] By contrast, enzymes are highly selective catalysts which operate in water at ambient temperatures, and therefore offer a more sustainable approach to asymmetric C−C bond formation. [5] Even though enzymatic catalysis is far from reaching the plethora of transformations available through small molecule chemical catalysts, major advancements in metagenomic sequencing, recombinant DNA technology, and directed evolution since the turn of the millennium provide a promising platform to the adoption of biocatalysis in this area.[ 5 , 6 , 7 ] However, the toolbox of biocatalysts currently available to synthetic chemists for C−C bond formation is still limited by the narrow range of newly discovered enzyme classes, thus hindering their widespread application. Previously, biocatalytic C−C bond formation catalysed by aldolases, hydroxynitrile lyases, transketolases and ThDP‐dependent carboligases have been extensively employed in organic synthesis and this research is the subject of several reviews.[ 1 , 3 , 8 , 9 ] To address the issue of the narrow window of enzymatic transformations mentioned above, the discovery of enzymes capable of catalysing novel C−C bond forming reactions is essential for the broader utilisation of biocatalysis by synthetic chemists. Over the past five years, biocatalytic approaches to Friedel‐Crafts alkylation/acylation, trifluoromethylation as well as highly engineered non‐natural carbene transferases have been outlined.[ 6 , 10 ] Continued research interest in biocatalytic C−C bond formation has resulted in more novel enzymes and methodologies for carbon bond formation being reported in literature. This review examines these novel biocatalytic transformations, which include cyclisations, and the Diels‐Alder and Pictet‐Spengler reactions.

1.1. Biocatalytic cyclisations (cyclases)

Both nature, and synthetic chemists, have widely employed cyclisation reactions, enabling the generation of multi‐functional products from simple building blocks. These reactions can occur either through inter‐ or intramolecular cyclisation and involve the formation of a single C−C bond or multiple C−C bonds via a cascade process.

1.1.1. Terpene cyclases

Terpenoids are the most structurally diverse family of natural products, comprising of over 80 000 compounds which have uses in flavourings, fragrances, and pigments.[ 11 , 12 , 13 ] Impressively, the diverse family of terpenoids derive from only two isomeric C5 methyl branched precursors. [14] Molecular complexity in these biosynthetic molecules is generated through cascade cyclisation of unsaturated terpene scaffolds to cyclic terpenoids, wherein multiple fused rings are formed stereoselectively in a single step.[ 11 , 15 ] The outcome of these cyclisations are controlled by the interactions of the substrate with a hydrophobic pocket in the active site of the enzyme.[ 15 , 18 ] There are two main enzyme classes which have evolved to catalyse these transformations; class I and II terpene cyclases (Scheme 1). [12] Class I terpene cyclases are defined by their catalytic mechanism, whereby the abstraction of diphosphate instigates the cyclisation which proceeds via nucleophilic addition of the C−C double bonds onto the carbocation intermediates, and is terminated either by deprotonation or addition of water. [11] On the other hand, the mode of catalysis exhibited by class II terpene cyclases is mechanistically dissimilar to that of class I enzymes, resembling Brønsted acid catalysis. The mechanism for class II terpene cyclases relies on protonation, or epoxidation of the terminal isoprenoid C−C double bond prior to cyclisation. [16]

Scheme 1.

(A) The mechanism for cyclisation of GPP catalysed by class I terpene cyclase, cineole synthase (CS) to afford 1,8‐cineole. (B) Mechanism for the class II terpene cyclase, squalene‐hopene cyclase (SHC), showing the proton‐induced cyclisation of squalene.

1.1.2. Class I terpene cyclases

Class I terpene cyclases are metal‐dependent enzymes which catalyse the cyclisation of isoprenoid diphosphate substrates to products containing one or more fused rings.[ 12 , 15 ] During catalysis, the oligo‐prenyl precursor binds to a cluster of three Mg2+ ions resulting in loss of the substrate diphosphate group to form a carbocation‐inorganic diphosphate (PPi) pair. It is this carbocation which then undergoes cyclisation. [17] The family of class I cyclases can be split into three sub‐classes which are; monoterpene e. g. (−)‐limonene cyclase, sesquiterpene e. g. α‐bisabolol cyclases and diterpene cyclases e. g. taxadiene cyclases.[ 18 , 19 , 20 ] These three sub‐families all share a very similar catalytic mechanism, but can be differentiated by the structure of the native substrate and hence, the outcome of the cyclisation reaction. [12] The majority of research carried out on class I terpene cyclases has focused on sesquiterpene, while examples on mono‐ and diterpene cyclases are lacking.[ 11 , 21 ]

Marketed under the brand name Taxol, the diterpene paclitaxel is one of the most successful and highest grossing chemotherapeutics. [22] During a natural product screening campaign carried out in the 1960s by the National Cancer Institute (NCI) and the U.S department for agriculture, paclitaxel was first isolated from the bark of the pacific yew tree (Taxus bervifolia) and its cytotoxicity established. [23] Currently, the drug is prescribed in generic form for the treatment of ovarian, breast, non‐small‐cell lung carcinoma and Kaposi's sarcoma.[ 24 , 25 , 26 , 27 ] The industrial production of paclitaxel remains problematic, as the yield for natural harvesting can be as low as 0.001–0.05 %. [28] In order to overcome this issue, around thirty research groups were working towards a total synthesis of this diterpene during the 1990s. Nicolaou and co‐workers were the first group to publish their approach, however the synthesis required over 26 chemical steps resulting in a very low overall yield of 0.078 %. [29] Since this initial publication, only nine examples of the total synthesis of paclitaxel have been reported, all requiring numerous chemical manipulations and hindering their commercial viability.[ 30 , 31 , 32 , 33 , 34 , 35 , 36 , 37 ] Around the same time, Witherup et al. showed that large quantities of the paclitaxel biosynthetic intermediate, 10‐deacetylbaccatin III (baccatin III), could be isolated from European yew tree Taxus baccata, enabling a concise semisynthesis of paclitaxel. [38] This approach was further improved by Holton and co‐workers who outlined a 4 step semisynthesis with an overall yield of 4–5 %, which was subsequently patented and sold to Bristol‐Myers Squibb (BMS). [39] Although this approach has improved upon the previous methods and is used for the commercial production of paclitaxel, it is still ecologically demanding and requires toxic chemical reagents. This has led to a great deal of interest in exploiting synthetic biology and biocatalysis for the in vivo or in vitro preparation of paclitaxel and its analogues.

The biosynthesis of this tetracyclic diterpene is thought to contain nineteen steps, starting from isoprenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP). [28] The first committed step in the pathway involves the cyclisation of geranylgeranyl diphosphate (GGPP) to tax‐4(5),11(12)‐diene, which is catalysed by the diterpene cyclase, taxadiene cyclase (TDC1) from Taxus bervifolia (Scheme 2).[ 20 , 40 ] A biosynthetic route towards paclitaxel has the potential to overcome the ecological issues and the dependence on toxic reagents required in the semisynthetic approach. Metabolic engineering can be used to manipulate the biosynthesis of paclitaxel in bacterial or yeast has potential over plant‐cell fermentation methods. Although the cultivation of paclitaxel cell lines in the lab has shown to be commercially viable, this approach is not able to easily access paclitaxel analogues, hindering its applicability. [41] Currently, taxadiene cyclase has been exploited for taxadiene overproduction in E. coli, yeasts and Artemisia annua L, paving the way for a full biosynthetic approach to paclitacxel.[ 42 , 43 , 44 ]

Scheme 2.

(A) Structure of paclitaxel (Taxol®) (B) Polycyclisation of GGPP catalysed by TDC1 in the biosynthesis of paclitaxel.

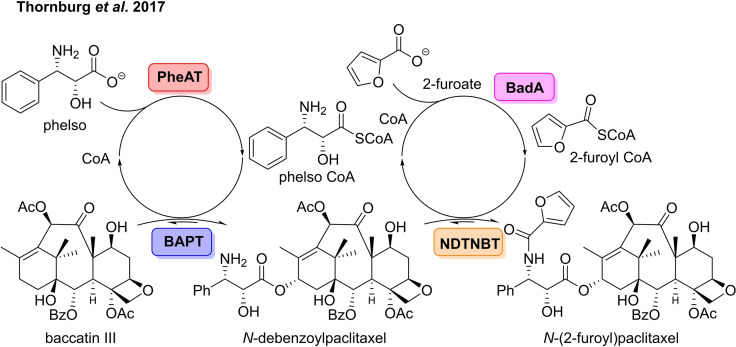

The metaphorical cherry on top of the cake for the preparation of paxitaxel would involve a streamlined biocatalytic cascade to prepare the drug and its analogues from easily accessible starting materials, reducing side‐reactions and easing subsequent isolation. Over the past twenty years, Walker and co‐workers have outlined a plethora of enzymes involved in paclitaxel biosynthesis.[ 45 , 46 , 47 , 48 ] In 2017 the group was able to use their previous knowledge to build a four enzyme cascade towards a paclitaxel analogue. [49] The cascade involved a benzoate CoA ligase (BadA), a modified nonribosomal peptide synthase (PheAT), a phenylpropanoyltransferase (BAPT), and a benzoyltransferase (NDTNBT) to furnish a paclitaxel analogue from commercially available precursor, baccatin III (Scheme 3).[ 48 , 49 , 50 ] After optimisation of the multi‐enzyme cascade, the group was able to prepare 230 ng of N‐(2‐furoyl)paclitaxel, which was show to be more cytotoxic than paclitaxel against certain cell lines. The group also demonstrated that the cascade could be used to prepare the intermediate, N‐debenzoylpaclitaxel, with 20 times greater yield than that for N‐(2‐furoyl)paclitaxel. The group have also shown that BadA can convert aroyl acids to aroyl CoA thioesters, generating an N‐aroylpaclitaxel analogue. [51] By recycling the free CoA generated in the cascade, it was possible to furnish the product in higher yield than in assays carried out without CoA recycling.

Scheme 3.

Four enzyme cascade for the preparation of paclitaxel analogues starting from commercially available baccatin III.

Sesquiterpene cyclases (STCs) catalyse the cyclisation of farnesyl pyrophosphate (FPP) to cyclic sesquiterpenes. [52] This cyclisation can proceed through four possible C−C bond forming trajectories depending on which C−C double bond reacts initially.[ 12 , 53 ] Thus, the molecular complexity generated in sesquiterpene cyclisation is far larger than those generated through monoterpene cyclisation. Recent work has focused on the transformation of non‐natural substrates catalysed by known STCs, allowing access to novel terpene architectures. Allemann and co‐workers used the amorphadiene synthase (ADS) from Artemisia annua to cyclise 12‐hydroxy FPP to afford the artemisinin precursor dihydroartemisinic aldehyde (DHAAI) (Scheme 4).[ 54 , 55 ] Artemisinin is a potent anti‐malarial drug which can be synthesised from DHAAI in four chemical steps.[ 56 , 57 ] The group scaled up the synthesis of DHAAI, incubating 12‐hydroxy FPP with purified ADS for 48 hours, obtaining DHAAI in 34 % yield. They further improved on this work, affording DHAAI in an excellent yield of 90 %, using the natural substrate under flow conditions. [58] These initial studies with chemically modified FPP substrates paved the way for further development in this area.

Scheme 4.

Formal synthesis of artemisin via biocatalytic cyclisation catalysed by the amorphadiene synthase (ADS) from Artemisia annua.

This work was built on by Kirschning et al. who reported the synthesis of novel non‐natural terpenoids through the cyclisation of heteroatom‐modified FPPs with a number of STCs (Scheme 5). [59] The cyclases used in their investigation were: patchoulol synthase (Pts) from Pogostemon cablin, viridiforene synthase (Tps32) from Solanum lycopersicum, vetispiradiene synthase (Hvs1) from Hyoscamus muticus, caryolan‐1‐ol synthase (GcoA1) from Streptomyces griseus, (+)‐T‐muurolol synthase (TmS) from Roseifexus castenholzii, pentalenene synthase (PenA) from Streptomyces exfoliatus, presilphiperfolan‐8b‐ol synthase (Bot2) from Botrytis cinerea, and cubebol synthase (Cop4) from Corinus cinereus.[ 60 , 61 , 62 , 63 , 64 , 65 , 66 , 67 , 68 ] The group initially found that the two amine‐containing FPP derivatives were not converted by any of the enzymes. The cyclisation of the oxo‐ and thio‐substrates was successfully achieved by a number of the STCs, generating a series of novel oxygen‐ and sulphur‐containing macrocycles through a single C−C bond forming step. The most unusual result observed was the formation of the tricyclic product in 36 % yield, formed from the oxo‐substituted FPP catalysed by Bot2. This tricyclic compound could have potential use in fragrances, showing olfactory properties which include ethereal, peppery and camphoric. [69]

Scheme 5.

Mono‐ and polycyclisation of non‐natural heteroatom functionalised FPP derivatives catalysed by sesquiterpene cyclases (STCs).

Then in 2020, Kirschning and co‐workers were also able to access other novel sesquiterpene backbones using non‐natural FPPs. [70] The previously reported cyclase, Bot2, was chosen as the biocatalysts for this investigation. [67] The group first prepared the cis‐FPP analogue, where one of the C11 methyl groups in FPP was shifted onto C10 in a cis‐configuration (Scheme 6A). For the cis‐FPP, enzymatic cyclisation afforded a single major product, iso‐humulene in 13 % conversion (Scheme 6B). Trans‐FPP analogues were synthesised, wherein the methyl groups on C3 and C7 of FPP were moved to C2 and C6, respectively. Also, one methyl group on C11 in FPP was transferred to C10 in a trans‐configuration. Bot2 catalysed cyclisation of the trans‐FPP derivative where R1=R2=Me R3=H afforded the cyclised product, iso‐germacrene A, in 33 % conversion. However, the trans‐FPP derivatives where R1=R3=Me R2=H was transformed into two main isomeric macrocyclic compounds, (Z,X,X)‐isomer and (Z,E)‐isomer in 33 % conversion for each. This is the first reported example of Bot2 converting a non‐natural FPP derivative into a 10‐membered macrocycle, although it is postulated that the substrate initially undergoes C1 to C11 cyclisation prior to Wagner‐Meerwein rearrangement. The novel terpenoids which were afforded through these biotransformations showed a range of olfactoric properties, which could also show potential in the flavours and perfume industries.[ 67 , 69 ]

Scheme 6.

(A) Structure of farnesyl pyrophosphate (FPP). (B) BcBOT2 mediated cyclisation of novel FPP analogues.

An alternative approach to access novel terpene sesquiterpene scaffolds is to use metagenomics to elucidate STCs which catalyse novel chemistries, enabling access to new molecular topologies. In 2016, Dickschat et al. reported the characterisation of a bacterial STC from Streptomyces pristinaespiralis, ATCC 25 486, affording a novel 5–8 bicyclic carbon skeleton. [71] The enzyme was able to convert the natural substrate FPP into a single sesquiterpene alcohol, which was isolated in 33 % yield (Scheme 7A). Using 1H NMR experiments and single‐wavelength anomalous dispersion (SAD) X‐ray crystallography the group was able to determine the structure of the novel 5–8 bicyclic product, which was named (2S,3S,9R)‐pristinol. The 8‐mebered ring structure generated by ATCC 25 486 is rarely found in sesquiterpenes, exemplifying how enzyme discovery can be used to find enzymes which can catalyse novel cyclisations. Plant species which have been used throughout history as traditional medicines can also be exploited for discovering new enzymes. [72] In 2021, Zi and co‐workers reported the discovery of a novel STC which could afford a similar 5,8‐bicyclic core. [73] The enzyme was discovered from Euphorbia ficheriana steud, the root of which is used in traditional Chinese medicine for the treatment of edema and tuberculosis.[ 72 , 74 ] The newly discovered enzyme, EfCAS, efficiently catalysed the cyclisation of FPP to cedrol and two tricho‐acorenol stereoisomers; eupho‐acorenols A and B which were characterised by NMR spectroscopy (Scheme 7B). Both products are constituents of plant volatile oils, which have application in flavour, perfume and cosmetics industries. While tricho‐acorenol is a metabolite of Trichoderma fungi, which has applications in biocontrol and biostimulant agents.[ 75 , 76 ]

Scheme 7.

Novel STCs to access 5–8 bicyclic sesquiterpene alcohols.

It has also been shown that enzymatic cyclisation can be exploited to produce highly functionalised sesquiterpene scaffolds, which can then be diversified through chemical modification. [77] Through metabolic engineering of the isoprenoid pathway in E. coli, Mou and co‐workers were able to produce the molecular scaffold, guaian‐6,10(14)‐diene, with a high degree of stereo‐ and regio‐selectivity exploiting the cyclases, STC5. [78] This enzyme catalyses the cyclisation of the natural substrate FPP to afford a guaian‐6,10(14)‐diene intermediate, which they then converted chemically into a number of bioactive compounds (Scheme 8). [79] A total of six chemical and enzymatic steps were employed to convert FPP into (−)‐englerin A with an overall yield of 14 %. They also reported the synthesis of (−)‐oxyphyllol, (+)‐orientalol E and (+)‐oriental F, achieving overall yields of 25 %, 8 % and 3 %, respectively. The evaluation of the biological activities of these compounds is currently under investigation.

Scheme 8.

Highly stereoselective enzymatic synthesis of guaian‐6,10(14)‐diene precursor prior to chemical transformation to biologically active epoxy‐guaiane sesquiterpenes.

1.1.3. Class II terpene cyclases

Triterpene cyclases, such as oxidosqualene (OSC) and squalene‐hopene (SHC) cyclases, belong to the family of class II terpene cyclases.[ 80 , 81 ] The most comprehensively studied class II triterpene cyclase is the SHC from Alicyclobacillus acidocaldarius, AacSHC.[ 82 , 83 , 84 ] It converts the natural substrate squalene to the pentacyclic products hopene and hopanol. [11] SHC's have also been shown to accept terpene analogues, which has previously been outlined in several reviews.[ 1 , 80 ] On the other hand, oxidosqualene cyclases catalyse the cyclisation of squalene epoxide to form lanosterol, which is the first step in cholesterol biosynthesis. [12] Current trends in this area has focused on using substrate engineering to generate novel terpenoids, genetic engineering of SHC to manipulate the outcome of the cyclisation and also using metagenomics to discovery novel cyclases which catalyse new reactions.

Through genome‐mining, Piel and co‐workers discovered the first example of a monodomain class II terpene cyclase, merosterolic acid synthase (MstE). [85] The enzyme was shown to catalyse the cyclisation of GG‐DHB, to generate merosterolic acid A which can be further converted to the cytotoxin Merosterol A (Scheme 9). The MstE catalysed cyclisation of GG‐DHB is initiated by direct protonation of the terminal double bond, analogous to that observed for SHC's, and the carbocation is terminated by electrophilic aromatic substitution. [86] Final re‐aromatisation produces merosterolic acid A. The group also noted that transformation of the natural substrate with MstE variant Y157A produced two products, merosterolic acid A and merosterolic acid B. The tricyclic product merosterolic acid A is thought to be produced via premature deprotonation of the methyl group due to rotation of the aromatic ring no longer being stabilised by Y157.

Scheme 9.

A novel terpene cyclase catalysed polycyclisation of GG‐DHB to merosterolic acid A in the biosynthesis of cytotoxin merosterol A.

In the laboratory of Abe, an oxidosqualene cyclase was identified in the biosynthetic pathway of ascochlorin from Fusarium sp. [87] The enzyme, AsCFG, was able to cyclase the natural epoxy substrate, along with a brominated analogue, forming the unique trimethylcyclohexanone ring in the cyclised meroterpenoid products. The brominated product was found to display potent cytotoxicity towards the MCF‐7 breast cancer cell line. Building on from their previous work on fungal meroterpene cyclases, Abe and co‐workers investigated the reaction of eight linear terpenoids analogues, with nine previously reported meroterpenoid cyclases, Pyr4, CdmG, AndB, AdrI, NvfL, PrhH, Trt1, AscF and MacJ.[ 88 , 89 , 90 , 91 , 92 , 93 , 94 , 95 , 96 ] The group prepared eight epoxyfarnesyl analogues, starting from dimethylorsellinic acid (DMAO) (Scheme 10). [21] The two (10S)‐(2E,6E)‐substrates where R’=Me, R’’=OH and R’=OH, R’’=Me were cyclised by Pyr4 to afford the tetracyclic products in 49 % and 22 % conversion, respectively. CdmG was also able to catalyse the cyclisation of the (10S)‐(2E,6E)‐substrates where R’=OH, R’’=Me, affording the desired product in 24 % yield. The (10S)‐(2Z,6E)‐substrates with R’=Me, R’’=OH and R’=OH, R’’=Me were both transformed by CdmG to novel meroterpenoids in 21 % and 11 % conversion, respectively. However, the most unusual reaction observed was the AndG catalysed cyclisation of (10S)‐(2Z,6E)‐substrate with R’=Me, R’’=OH to produce the 6–5 cyclised product in 20 % conversion. Crystalline sponge‐X‐ray analysis revealed the novel 6–5 ring system connected to a further 6–5 ring system through a single C−C bond. This work has the potential to revolutionise how fungal meroterpenoids are synthesised, addressing a crucial challenge in how the pharmaceutical industry accesses these highly bioactive compounds. [21]

Scheme 10.

Enzymatic polycyclisation of synthetic epoxyfarnesyl analogues catalysed by a number of meroterpenoid cyclases.

As well as using genomics to discover cyclases which can generate novel terpenoids, it is also possible to engineer existing enzymes to influence the nature of the cyclisation and hence, the outcome of the reaction. Using site‐specific mutagenesis, Hoshino and co‐workers engineered the active‐site residues of the SHC from Alicylobacillus acidocaldarius (AaSCH) to alter the normal polycyclisation. [97] AaSCH variants with increased steric bulk inside the active site (A306T and A306V) were reacted with squalene, leading to the accumulation of 6,6,6,5‐fused tetracyclic scaffolds in high yields. The structure of the observed products shows that increasing steric bulk at position 306 of AaSHC significantly alters the stereochemical fate of the polycyclisation. Hauer et al. also used a similar approach to engineer AaSHC to catalyse a novel cyclisation of citronella. [98] The replacement of residues in the active site of AaSHC resulted in two triple mutants which catalysed the cyclisation of (R)‐citronella to (+)‐neo‐isopulegol and (−)‐isopulegol with up to >99 % dr, respectively. The product of this cyclisation, (−)‐isopulegol, is an intermediate in the synthesis of (−)‐menthol, which is widely used in pharmaceuticals, fragrances and cosmetics.[ 99 , 100 ] In 2021, the group further improved on their initial work by engineering AacSHC to access a range of apocarotenoids, which are used in flavours, fragrances and in the pharmaceutical industry. [16] Through site‐directed mutagenesis, the group could control cyclisation by anchoring dynamic substrates in the active site via designed hydrogen bonding. The native reaction of AacSHC involves polycyclisation, generating bicyclic products, on the other hand the engineered AacSHC variants were shown to only form monocyclic products. [80] Conversion of the four neryl derivatives was observed with a number of AacSHC variants (Scheme 11), however no reaction was observed for the wild‐type enzyme for any substrate. These variants catalysed a single C−C bond forming cyclisation, furnishing the corresponding 6‐membered products with ee values of >99.5 % and conversion of 5–95 %. Using the variant, AacSHC V, the group was also able to access γ‐dihydroionone at a gram‐scale in 89 % isolated yield and >99.5 % ee, replacing previous multi‐step chemical syntheses. [101]

Scheme 11.

AacSCH variants catalyse the highly stereoselective monocyclisation of neryl derivatives to furnish high‐value apocarotenoids.

1.2. Diels‐Alderases

The Diels‐Alder (D−A) reaction is one of the most powerful transformations in a synthetic chemist's arsenal, enabling the construction of multiple C−C bonds with a high degree of stereoselectivity.[ 102 , 103 ] The D−A reaction involves the [4+2] cycloaddition of a conjugate diene and a dienophile to form an unsaturated cyclohexane scaffold with a high degree of regio‐ and stereo‐selectivity. [104] These D−A reactions can be classified as either intra‐ or inter‐molecular and, depending on the substituents, the reaction can occur via the normal‐ or inverse‐electron demand (NEDDA or IEDDA).[ 102 , 105 , 106 ] The electron demand of D−A reactions depends on the difference in energy levels between the frontier molecular orbitals (HOMO and LUMO) of the diene and dienophile. [107]

As the cyclohexane ring motif is ubiquitous in natural products, it has been speculated that [4+2] cyclising enzymes are involved in the biosynthesis of these secondary metabolites.[ 108 , 109 , 110 ] However, as these enzymes can exhibit dual activities, along with the controversy over their classification, the identification of specific enzymes that catalyses these reactions has proved very challenging. [111] By the early 2000s, only three enzymes had been purported to catalyse D−A type reaction; macrophomate synthase, lovastatin nonaketide synthase (LovB) and solanapyrone synthase (Sol5), but confirming their influence on the cycloaddition step has not been easy.[ 112 , 113 , 114 ] The first publicised example of an enzyme catalysed D−A reaction was achieved via computational design of an artificial enzyme by Baker and co‐workers. [115] The group used de novo protein design to build an active site which positions the diene and dienophile in the correct orientation for the reaction to occur. In 2011, Liu et al. identified a Diels‐Alderase, SpnF, in the spinosyn A biosynthetic gene cluster of Saccharopolyspora spinosa. [116] The group found that the enzyme catalysed the intramolecular [4+2] cyclisation to generate the cyclohexene ring in spinosyn A with an estimated 500 fold rate enhancement. This is the first widely accepted example of an enzyme catalysed intramolecular D−A reaction. Since the characterisation of SpnF, technological advancements in genome mining have resulted in the discovery of many D‐Alderases in the biosynthetic pathways of bacteria, fungal and plant origins.[ 109 , 110 , 111 ]

The intramolecular D−A reaction is proposed as the key reaction step in the biosynthesis of decalin‐containing fungal polyketides.[ 110 , 117 ] These decalin‐containing natural products display a broad spectrum of biological activities. [118] In 2015, Osada and co‐workers first outlined a gene cluster, fsa, involved in the biosynthesis of a number of biologically active decalin‐containing pyrrolidin‐2‐ones in Fusarium sp. [119] Examples of these bioactive compounds includes the HIV‐1 integrase inhibitors, equisetin and phomasetin. [120] Through genetic analysis, a new enzyme, fsa2, was also identified which was involved in the [4+2] cycloaddition to form the decalin‐containing pyrrolidin‐2‐one scaffold. The group further built on this through the discovery of a homologue of fsa2 which is involved in the biosynthesis of the enantiomerically opposite trans‐decalin analogue (Scheme 12). [121] Another fsa homologue, phm7, was identified from the biosynthetic gene cluster of phomasetin in Pyrenochaetopsis sp. Phm7 was shown to catalyse the formation of the (3S,6R)‐diastereomer. Gene replacement of phm7 with fsa2 in the gene cluster also enabled the formation of the decalin skeleton with a non‐natural (3R,6S)‐configuration. This is the first example of a Diels‐Alderase being exploited to afford a non‐natural analogue, and excellently demonstrates how these enzymes have untapped potential for the production of natural products with unnatural stereochemistries.

Scheme 12.

Diastereoselective Diels‐Alderases in the synthesis of decalin scaffolds.

The above enzymes, which are involved in decalin biosynthesis, CghA and Fsa2 are examples of NED Diels‐alder reactions which proceed through the endo transition state.[ 119 , 121 , 122 , 123 ] In 2019, Tang and co‐workers outlined the first example of an enzyme in this family catalysing an intramolecular IED Diels‐Alder reaction. [124] Using genome mining, the group found a Diels‐Alderase, PvhB, which is involved in the biosynthesis of varicidin A. The enzyme was demonstrated to catalyse the final step in the biosynthetic pathway, involving an intramolecular IED Diels‐Alder reaction of a carboxylate intermediate to form the varicidin A in 95 % conversion (Scheme 13A). The group also identified another IED Diels‐Alderase, IccD, which catalyses the intramolecular IED Diels‐Alder reaction in the biosynthesis of ilicicolin H, an alkaloid that displays potent antifungal activities towards a broad range of fungal pathogens. [125] IccD was found to catalyse the intermolecular IEDDA reaction from a bis‐diene, affording 8‐epi‐ilicicolin H in 60 % conversion. 8‐epi‐Ilicicolin H was then further converted to ilicicolin H via enzymatic epimerisation (Scheme 13B). These two pieces of work highlight the importance of characterising enzymes which exhibit novel reactivities and can be used to synthesis new natural product analogues.

Scheme 13.

(A) A novel Diels‐Alderase, PvhB, catalyses the endo‐selective Diels‐Alder reaction of the carboxylate intermediate in the biosynthesis of varicidin A. (B) Enzymatic IED Diels‐Alder reaction of bis‐diene to furnish 8‐epi‐ilicicolin H catalysed by a novel Diels‐Alderase, IccD.

Previously, all known examples of Diels‐Alderases were either redox‐neutral cyclases or oxidases.[ 113 , 116 , 121 , 124 , 125 , 126 ] However, Williams and co‐workers have described the first example of a reductase‐dependent Diels‐Alderase, which is involved in the biosynthesis of malbrancheamide. [127] The complex bicyclo[2.2.2]diazaoctane core of these prenylated indole alkaloids has attracted attention as a target for total synthesis strategies and these compounds also display a range of biological activities.[ 128 , 129 ] The group was able to elucidate the malbrancheamide biosynthetic pathway, revealing an enzyme catalysed [4+2] Diels‐Alder cyclisation as the fundamental step which generates the bicyclo[2.2.2]diazaoctane skeleton. The bifunctional NADPH‐dependent reductase/Diels‐Alderase, MalC, initially catalyses the reduction of the zwitterionic intermediate to furnish the azadiene intermediate. MalC subsequently catalyses the stereoselective intramolecular NEDDA cyclisation of the reduced intermediate to form (+)‐premalbrancheamide. The final step in the biosynthetic pathway involves the halogenation of premalbrancheamide, which is catalysed by the halogenase, MalA, to furnish (+)‐malbrancheamide (Scheme 14).

Scheme 14.

Biocatalytic synthesis of (+)‐malbrancheamide involving the bifunctional NADPH‐dependent reductase/Diels‐Alderase MalC.

Enzymes capable of catalysing intermolecular reactions are of significant importance, as the coupling of two molecules can be used to generate more structurally diverse products. In 2020, Lei et al reported the first example of an intermolecular Diels‐Alderase. [126] The enzymatic intermolecular Diels‐Alder reaction was proposed to occur in the biosynthesis of the isoprenylated flavonoid chalcomoracin, a natural product isolated from the root bark of the Morus plant. [130] This bark has been used extensively in Traditional Chinese Medicine and natural products from this family have shown anti‐HIV and anti‐diabetic activities.[ 131 , 132 ] Using a combination of activity‐based protein purification and proteomics analysis, termed BIP‐based target identification, the first intermolecular Diels‐Alderase, MaDA, from Morus alba was characterised. The enzyme was shown to catalyse the cycloaddition of morachalcone A and a diene to afford chalcomoracin in 51 % yield. A panel of synthetic diene and morachalcone analogues were also produced which the enzyme was able convert to several isoprenylated flavonoid derivatives. The enzyme was also shown to catalyse the cycloaddition of synthetic trihydroxylated diene with morachalcone A, furnishing guangsangon in 62 % yield. The Lei group went on to develop a chemoenzymatic total synthesis of artonin I involving Stille cross‐coupling and enzymatic intermolecular Diels‐Alder reaction. [133] Artonin I belongs to the same family of isoprenylated flavonoids, and has been shown to inhibit multidrug resistance in Straphylococcus aureus. [134] A diene analogue was synthesised via palladium catalysed cross‐coupling in 75 % yield which was then hydrolysed to the desired intermediate prior to cyclisation (Scheme 15). MaDA was then used to catalyse the intermolecular [4+2] cycloaddition with morachalcone A, affording endo‐Artonin I in 90 % yield and 99 % ee.

Scheme 15.

Chemoenzymatic synthesis of Artonin I involving the Diels‐Alderase MaDA.

1.3. Biocatalytic Pictet‐Spengler reactions

For over 100 years the Pictet‐Spengler (PS) reaction has been used by organic chemists to construct the carbon framework in a broad range of heterocyclic products. [135] The reaction involves the acid‐catalysed condensation of β‐arylethylamines with aldehydes to generate tetrahydroisoquinoline (THIQs) or tetrahydro‐β‐carbolines (TH‐β‐Cs) via an iminium intermediate. These alkaloid motifs are widespread in bioactive natural products and are important building blocks for many pharmaceutically relevant drug molecules. The most notorious family of THIQ alkaloids are the narcotic analgesics morphine and codeine which are derived from the opium poppy (Papaver somniferum). [136] The β‐carboline scaffold is also present in numerous active pharmaceuticals including the anti‐malarial cipargamin, anti‐cancer lurbinectedin and the erectile dysfunction drug tadalafil.[ 135 , 137 , 138 , 139 , 140 ] Currently, numerous strategies have been outlined for the enantioselective Pictet‐Spengler reaction including organo‐ and transition‐metal catalysis.[ 141 , 142 ] However, it was over half a century after the discovery of the chemical transformation before an enzyme catalysed Pictet‐Spengler reaction was reported. [135] The first Pictet‐Spenglerase, named strictosidine synthase (STR), catalyses the condensation of tryptamine and the monoterpenoid aldehyde secologanin followed by cyclisation to give the tetrahydro‐β‐carboline (S)‐strictosidine. [143] The substrate scope of the STR catalysed reaction is mainly limited to derivatives of secologanin as the aldehyde component, but success with various substituted tryptamines have been reported. [1] The other prominent member of the Pictet‐Spenglerase family are the norcoclaurine synthases (NCSs), which are involved in the biosynthesis of tetrahydroisoquinoline alkaloids. [144] The native reaction catalysed by NCSs involves the stereoselective C−C coupling of dopamine with 4‐hydroxyphenylacetaldehyde to afford (S)‐norcoclaurine. [135] Current research in this area has focused on the genetic engineering of current enzymes and expanding the non‐natural substrate scope of these reaction to enable the synthesis of novel alkaloids.

In 2017, Ward and co‐workers reported the first example of NCS catalysing the PS reaction between the natural substrate dopamine and unactivated ketones. [145] The approach enabled stereoselective access to 1,1’‐disubstituted and spiro‐THIQs, for which there are no current asymmetric chemicals methods. [146] The group selected two wild‐type NCSs, Δ29TfNCS and CjNCS2, to screen against the natural substrate dopamine and 4‐hydroxyphenylacetone.[ 147 , 148 ] After initial investigation it was found that the wild‐type enzyme from Thalictrum flavum, TfNCS, catalysed the PS reaction. Docking studies were then used to rationally select enzyme variants with increased substrate tolerance for the ketone partner in the reaction. The TfNCS variant A79I was used in the preparative‐scale PS reaction of phenylacetone with dopamine, affording the corresponding 1,1’‐disubstituted derivative in 87 % isolated yield and 95 % ee (Scheme 16A). TfNCS A79I was also shown to catalyse the PS reaction of para‐methoxy phenyl acetone with dopamine, affording the THIQ derivative in 74 % yield and 99 % ee. Furthermore, TfNCS A79F was demonstrated to catalyse the reaction of four cyclohexanone derivatives with dopamine to furnish spiro‐THIQ derivatives in 33–58 % isolated yields. In 2021, the group built on this work by further increasing the substrate scope of the reaction towards increasingly complex ketones and a number of dopamine analogues. [149] Initially, a panel of substituted methyl ketones were examined in the PS reaction with dopamine using a panel of TfNCS variants, affording a number of substituted THIQ derivatives in 37–75 % conversion (Scheme 16B). A panel of cyclic ketones was then utilised to synthesise a number of spirocyclic THIQs. Reaction of dopamine with N‐Boc protected 4‐piperidone catalysed by TfNCS variant A79F afforded the spirocyclic THIQ in 73 % conversion after 72 h. When the carbonyl was altered to N‐Boc protected 3‐piperidone, the corresponding spirocyclic THIQ was achieved in 53 % conversion and an ee of 78 %. Substitution of the nitrogen atom to an oxygen atom in the six‐membered ring gave the THIQ derivative in 56 % conversion. Four cyclic ketones with varying ring sizes were then used to show the influence of ring size in the PS reaction. Reaction of cyclobutanone with dopamine using TfNCS variant A79F afforded the spiro‐THIQ in 52 % conversion. Increasing the ring size to cyclopentanone gave the corresponding THIQ derivative in 70 % conversion using the same TfNCS variant. Cyclohexanone was reacted two dopamine derivatives to afford the corresponding THIQs in 54 and 84 % conversion, respectively. The work carried out in this area enables the stereoselective coupling of ketones in the PS reaction, a transformation which, via current synthetic approaches is not trivial.

Scheme 16.

(A) Pictet‐Spengler reaction between dopamine and a number of substituted methyl ketones catalysed by norcoclaurine synthase mutants. (B) Pictet‐Spengler between dopamine with cyclic ketones catalysed by norcoclaurine synthase mutants.

The aldehyde scope in the NCS catalysed PS reaction has also received significant interest.[ 150 , 151 , 152 ] Hailes and co‐workers outlined a concise, stereoselective preparation of 1‐aryl THIQs utilising aryl aldehydes as the carbonyl partner in the NCS catalysed PS reaction. [153] The 1‐aryl THIQ core is present in a number of APIs including the muscarinic‐receptor antagonist solifenacin. [154] After initial screening, the TfNCS variant M97V was found to be the most productive, catalysing the reaction of benzaldehyde with dopamine, furnishing 1‐aryl THIQ in >99 % conversion with >99 % ee. Methyl substituted benzaldehydes were also examined in the PS reaction with dopamine, affording the corresponding substituted 1‐aryl THIQs in 76 %, 90 %, and 45 % conversion, respectively (Scheme 17). Several halogenated benzaldehydes were also investigated with dopamine catalysed by the M97V‐TfNCS mutant, achieving the desired THIQ derivatives in good to excellent yield and with a high degree of stereoselectivity. Although several other biocatalytic and chemically methodologies have been outlined for the stereoselective synthesis of 1‐aryl‐THIQs,[ 155 , 156 , 157 ] this approach generates the desired product in a single step from widely available starting materials.

Scheme 17.

Pictet‐Spengler reaction between dopamine and a panel of substituted benzaldehydes catalysed by wild type norcoclaurine synthase (NCS).

In 2018, Kroutil and co‐workers used STR to prepare a number of alkyl substituted tetrahydro‐β‐carbolines with a high degree of stereoselectivity. [158] These substituted tetrahydro‐β‐carbolines are key intermediates in many bioactive molecules, including the alkaloid (R)‐harmicine which displays potent anti‐Leishmania activity.[ 159 , 160 ] Four native STRs originating from different organisms were initially chosen for screening; Catharanthus roseus (CrSTR), Ophiorrhiza pumila (OpSTR), Rauvolfia serpentine (RsSTR) along with the V208A variant of RvSTR.[ 161 , 162 , 163 , 164 ] The group then examined the PS reaction between the natural substrate tryptamine and a small panel of aldehydes (Scheme 15). RsSTR was able to effectively catalyse the reaction with isovaleraldehyde and 4‐oxobutanoate, affording the corresponding tetrahydro‐β‐carboline derivatives in 77 % and 95 % conversion, respectively, and with >98 % ee. Increasing the aldehyde chain length led to a significant decrease in conversion from 45 % to 7 % but both reactions retained good enantioselectivities. Ethanal was also converted by RvSTR in 23 % conversion and with an ee of 43 %. Interestingly, it was found that all reactions afforded the corresponding (R)‐enantiomer, which is opposite to the enzymes native reaction leading to (S)‐configured products. The group scaled up the RsSTR catalysed PS reaction of 4‐oxobutanoate with tryptamine, initially affording the 1‐substituted tetrahydro‐carboline prior to spontaneous lactimisation to furnish the corresponding lactam in 67 % isolated yield and >98 % ee. Chemical reduction gave (R)‐harmacine in 62 % yield over two steps and excellent ee of >98 %. This chemoenzymatic approach to (R)‐harmacine is the shortest and highest yielding report which has been published to date.[ 158 , 165 ] This work has demonstrated a novel method for the stereoselective synthesis of pharmaceutically relevant tetrahydro‐β‐carbolines, and hence has increased the toolbox of current biocatalytic C−C bond forming reactions. The group then expanded the aldehyde scope of the STR catalysed PS reaction towards a number of substituted aromatic aldehydes. [166] Initially, two native STRs, Ophiorrhiza pumila (OpSTR) and Rauvolfia serpentine (RsSTR) were chosen for screening. However, neither of the wild‐type STRs were found to catalyse the conversion of benzaldehyde, so a ‘substrate‐walking approach’ was used to prepare a panel of variants which were subsequently transferred to RsSTR. The double mutant, RsSTR V176L/V208A, was found to efficiently catalyse the PS reaction of benzaldehyde with dopamine, affording 1‐aryl‐tetrahydro‐β‐carboline in 38 % conversion and 99 % ee (Scheme 18). A small panel of substituted aromatic aldehydes was then screened with the double RsSTR variant to determine the substrate scope in the PS reaction. ortho‐Halogenated benzaldehydes were transformed to the corresponding 1‐aryl substituted THBCs in good yields and excellent enantioselectivity. However, the para‐fluorinated derivative was not well accepted (8 % conversion and 96 % ee). meta‐Substituted derivatives were transformed by the enzyme, affording meta‐substituted 1‐aryl THBCs in 29 %, 33 %, and 24 %, respectively, in 99 % ee. Further meta‐substituted benzaldehydes were also both accepted by the enzyme, affording the corresponding THBC derivatives in low to moderate conversions and excellent ee values. This work has expanded the scope of stereoselective PS reactions, enabling the preparation of tetrahydro‐β‐carboline scaffolds which are challenging to access with current chemical approaches.

Scheme 18.

1 (A) Strictosidine synthase (STR) catalysed Pictet‐Spengler reaction between tryptamine and non‐natural aliphatic aldehydes. 2 (A) Chemoenzymatic total synthesis of (R)‐harmicine in two steps from commercially available starting materials. (B) Enzymatic Pictet‐Spengler reaction between tryptamine and benzaldehydes catalysed by a strictosidine synthase mutant.

Although the aldehyde scope of STR has been widely examined, the scope of the amine partner in the PS reaction has not generated the same amount of interest.[ 167 , 168 ] In 2019, a chemoenzymatic route towards azepino[3,4,5‐cd]‐indoles was outlined by Zou et al, involving an enzyme catalysed PS reaction of a tryptamine analogue with the natural substrate secologanin, followed by chemical transformation to attain the biologically active product. [169] Molecules containing the azepino[3,4,5‐cd] indole core have displayed dopamine receptor binding activity, showing potential as drugs for neuropsychiatric diseases. [170] The group reported the PS reaction between tryptamine analogue 1H‐indole‐4‐ethanamine and secologanin catalysed by STR1 to furnish a tricyclic intermediate with >98 % de, which was subsequently cyclised to afford the corresponding lactam in 24 % isolated yield (Scheme 19). The lactam was then converted in four steps to the azepino[3,4,5‐cd] indole with an overall yield of 26 %. This compound was found to display antimalarial activity, with an IC50 of 6.1±0.3 μM towards Plasmodium falciparum strain 3D7.

Scheme 19.

Enzyme catalysed Pictet‐Spengler reaction of non‐natural 1H‐indole‐4‐ethanolamine towards azepino‐indole scaffolds.

2. Biocatalytic C−N Bond Formation via Reductive Amination

Primary, secondary, and tertiary amines are a highly prevalent motifs in a range of biologically active molecules within the pharmaceutical, agrochemical and fine chemical markets. Amines with chiral centres are of particular interest, where biocatalytic approaches are inherently selective in generating chiral amines, outcompeting traditional synthetic approaches. [171] Figure 1 highlights the diversity of optically active molecules with a chiral amine constituent, where the relevant function is highlighted.

Figure 1.

An overview of bioactive chiral amine containing compounds.

Reductive amination of a compound bearing a carbonyl moiety coupled with an amine nucleophile via an iminium intermediate to the corresponding (chiral) amine is highlighted as one of the most important and diverse reactions to generate chiral amines. Chemical approaches to asymmetric reductive amination include the use of transition metal catalysis such as ruthenium or rhodium, utilising either a reducing agent [172] or H2. [173] Organocatalytic methods employ chiral Brønsted acids to induce chirality coupled with Hantzsch esters [174] or hydrosilanes [175] for the hydrogen source. Although these listed techniques are well established, there are safety and environmental concerns surrounding these approaches from the use of hydrogen as a reducing agent, to the implementation of rare, costly, and toxic metal catalysts. Furthermore, reductive amination often requires an excess of the amine to prevent over alkylation, complicating downstream work‐up procedures. [176]

Enzymatic routes in the preparation of chiral amines offer to bypass some of the above problems. These routes utilise enzymes which are biodegradable, operate under benign conditions, and present a high degree of chemo‐, regio‐ and enantioselectivity, furthering sustainable routes to chiral amines. [177] Selecting an enzyme from the chiral amine toolbox for a particular route has never been easier due to the forever expanding sequence space coupled with retrosynthetic analysis tools such as RetroBioCat. [178] Where scopes of these enzymes may overlap, the mechanism by which they operate greatly differs. This has its advantages and drawbacks for each enzyme family. Some enzymes such as oxidases and transaminases have been readily amenable to evolution enhancing substrate scopes. Nevertheless, limitations with certain families exist due to the nature of their mechanism, such as transaminases, utilising a pyridoxal 5‐phosphate (PLP) co‐factor which yield strictly primary amines, thus requiring further alkylation chemistry to access chiral secondary and tertiary amines.

However, in the past decade, tremendous efforts have been invested in enzymes that generate chiral amines through reductive amination. These enzymes will be covered in this section of the review. These include the families of amine dehydrogenases, imine reductases, N‐methylamino acid dehydrogenases, ketimine reductases, and pyrroline‐5‐carboxylate reductases. These enzymes belong to the oxidoreductase class and operate using a nicotinamide cofactor to deliver the hydride, thus generating a plethora primary, secondary and tertiary amines.

2.1. Imine reductases (IREDs) and reductive aminases (RedAms)

Imine reductases were first discovered and applied initially for the reduction of pre‐formed 5‐membered cyclic imines to generate the corresponding amine in 2010 by Mitsukura and co‐workers. [179] Two separate enantiocomplementary enzymes from Streptomyces sp. were identified generating both (R)‐ and (S)‐2‐methylpyrrolidine. Significant progress was made towards expanding the scope and applicability of these enzymes towards imine reductions, which is covered in‐depth in reviews by and Grogan et al. [180] and Mangas‐Sanchez et al. [181] As both reductive amination and imine reduction share a common imine intermediate, it seemed plausible to investigate whether IREDs could perform reductive amination. The first application of IREDs for reductive aminations was given in 2014 by Huber and co‐workers, [182] who took (S)‐IRED from Streptomyces sp. discovered by Mitsukura and co‐workers [179] and applied it for the reductive amination of 4‐phenyl‐2‐butanone in methylammonium buffer as the amine source. Following up this report quickly, different academic and industrial groups explored the use of IREDs for reductive amination,[ 183 , 184 , 185 , 186 ] although these initial studies described processes in which a basic pH and a large excess of the corresponding amine were required to obtain high conversions, hence limiting their applicability into large‐scale processes.

2.1.1. A reductive aminase from Aspergillus oryzae

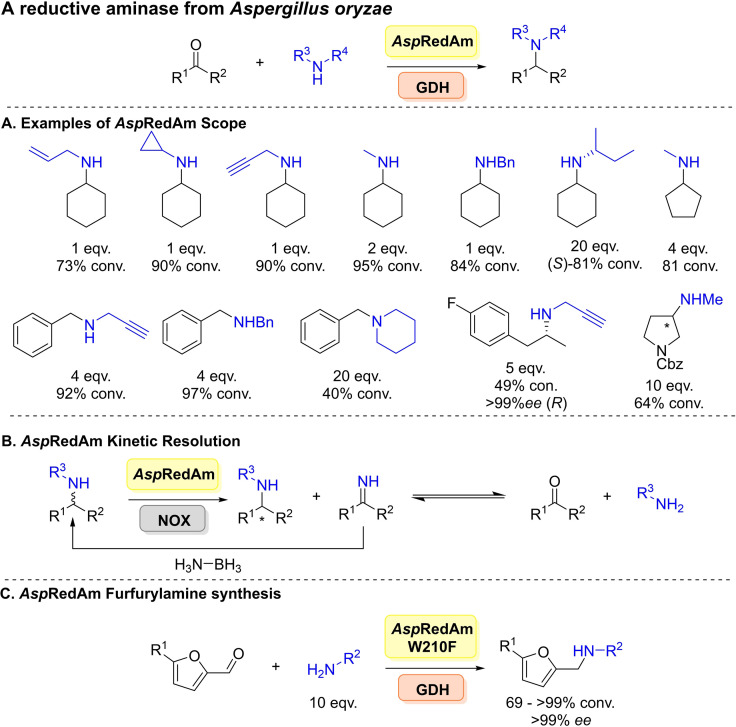

All previous reports around IRED mediated reductive aminations had demonstrated IREDs working with large excesses of amine equivalents, operating at higher pH values, where the scopes did not appear to be particularly broad, overall limiting the synthetic viability. The discovery of an enzyme and several homologues by the Turner laboratory in 2017 addressed many of these issues mentioned. [187] Where conversions of 94 % were achieved employing 1 : 1 ratios of ketone to amine, with other examples of low amine equivalents yielding high conversions. The enzyme was termed a reductive aminase from Aspergillus oryzae (AspRedAm) and was the first enzyme in the field to be of fungal origin, with two other homologues. These fungal enzymes form a specific sub‐clade within the sequence space of the IRED family as highlighted by phylogenetic analysis in later studies. [188] AspRedAm was shown to act on a broad range of aldehydes and ketones coupled with primary and secondary amines (Scheme 20A). Several studies conducted coupled with the enzyme's unusual activity in comparison to previous IREDs coined the term reductive aminase. Highlighting the enzyme catalysed both imine formation and reduction. A pH study (pH 7.0 vs 9.0) was conducted comparing rates for the reductive amination of cyclohexanone with allylamine compared to previously studied IREDs, (R)‐IRED and AoIRED, [189] demonstrating AspRedAm displayed a significantly higher specific activity irrespective of pH. Through structural data analysis, where a ternary complex was obtained with (R)‐rasagiline combined with point mutagenesis, which identified 6 key catalytic residues N93, D169, Y177, W210, M239 and Q240. The residue Q240 was further targeted to alter substrate specificity, and indeed the variant Q240A yielded the anti‐Parkinson's agent (R)‐rasagiline with 98 % ee, higher than previous reports.

Scheme 20.

A reductive aminase from Aspergillus oryzae. (A) Examples of the scope of AspRedAm. (B) Application of AspRedAm for the kinetic resolution of racemic amines combined with ammonia borane and an NADPH‐oxidase (NOX). (C) Synthesis of furfurylamines from bio‐based furans.

In a follow up study in 2018, a deeper insight into the mechanism of AspRedAm's activity and its fungal homologues was given through structural and mechanistic studies coupled with mutagenesis. [190] AtRedAm was co‐crystallised with cyclohexanone and allylamine suggesting residues Y183 was involved in carbonyl recognition and D175 involved amine recognition. A proposed mechanism was also proposed for both imine formation catalysis and imine reduction, where for productive catalysis both amine and ketone must be bound leading to domain closure and generating a smaller active site. Activity of the fungal enzymes was compared to (S)‐IRED from Streptomyces sp. and NaBH3CN, where AtRedAm gave 73 % conversion compared 4 % for the latter two after 3 h. This difference a good indication towards such activity.

Extending the synthetic scope of AspRedAm and to demonstrate its applicability in the oxidative deamination reaction direction, and rivalling scopes of enzymes such as amine oxidases. [191] AspRedAm was combined with an NADPH‐oxidase (NOX) and ammonia borane allowing for the deracemisation of primary and secondary amines (Scheme 20B). [192] Wild‐type AspRedAm was used to generate (S)‐amines and the W210 A variant to access (R)‐amines. Conversions were primarily limited to 50–60 %. Further engineering of AspRedAm was undertaken to unlock reductive aminations with a range of bio‐based furans coupled with aliphatic amines nucleophiles affording up to >99 % conversions (Scheme 20C). [193] Mutagenesis centred on residue W210, highlighting again its importance in substrate specificity. Furfurylamines are key scaffolds in the synthesis of pharmacologically active compounds and polymers, this enzymatic route surpasses the use of toxic catalysts and chemicals. It was also noted that AspRedAm displayed low ketoreductase activity, generating the corresponding alcohols from the furans.

2.1.2. Further IREDs for reductive amination

The discovery of AspRedAm ignited the field of IREDs for reductive amination, however studies conducted with AspRedAm noted its poor stability and heterologous expression levels in E. coli. [194] Therefore, using (meta)genome mining approaches to explore sequence space of greater diversity was carried out to overcome these issues. Researchers at GSK identified 90 bacterial IRED homologues, as well IREDs from other families implemented in natural reductive aminations such as pyrroline‐5‐carboxylate reductases, [195] although little to no activity was observed with these extended families. These enzymes were screened as clarified lysates where an emphasis was placed on arylamines (Scheme 21A), particularly the weak amine nucleophile aniline, previously unaccepted by IREDs. Various functional para‐, meta‐ and ortho‐substituted anilines were screened where impressively reactions (given its nucleophilicity) employed stoichiometric quantities of aniline amine partners. Regioselectivity was also investigated with benzene‐1,4‐diamine and cyclohexanone, where GSK‐IR‐1 gave full conversion to the mono‐aminated product (Scheme 21A). The synthetic viability of this enzyme collection was demonstrated with preparative scale transformations at a 400 mg scale with yields up to 51 %.

Scheme 21.

Further examples of IREDs for reductive aminations. (A) Screening of 90 genomic IREDs towards arylamine synthesis. (B) Screening of 45 bacterial genomic IREDs. (C) Screening of 90 additional genomic enzymes with aniline reaction intensifications.

Further bacterial sequence space was surveyed in a collaboration between Pfizer and University of Manchester, where 45 bacterial enzymes were investigated, 27 enzymes being novel (Scheme 21B). [196] These enzymes were screened across a panel of ketones with methylamine, where most enzymes generated the (S)‐configured product. New scopes for these enzymes were investigated to demonstrate how IREDs can effectively yield tertiary amines through the coupling of cyclohexanone with pyrrolidine in 71 % yield.

Very recently, researchers at the University of Manchester have identified considerable sizes of IRED collections, with the initial being identified by Montgomery and co‐workers in collaboration with Johnson Matthey included 90 enzymes covering many taxa across the tree of life. [197] Where reaction intensifications were performed with cyclohexanone and aniline by exploring the use of co‐solvents to increase conversions without enzyme engineering (Scheme 21C). Using pIR‐89 81 % conv. was achieved with 50 mM ketone and 2 amine equiv. with 200 μL cyclohexane. Structure‐activity relationships were also performed as screening with a variety of ketone and amine substrate combinations, it was noticed that there was significant activity levels between different enzymes with high sequence identity and similar expression levels. This was then used to inform rational engineering, although this had marginal effect on the activity between the wild‐type and the variants. These 90 genomic enzymes were then blended with an additional >200 enzymes of metagenomic origin, where parental organisms are largely unknown to give an IRED toolbox of 384 enzymes. [188] Generating the largest and most sequentially diverse panel of IREDs reported to date (Figure 2). By exploring metagenomics sequence space it is hoped that this would yield enzymes with greater substrate scopes, enhanced biocatalytic properties and new activities. This work was done in collaboration with Prozomix Ltd., where enzymes were arrayed in 384‐well microtitre plates for ease of enzyme accessibility and screening (Figure 2A). Coupled with this was the development of a formazan‐based colorimetric screen, a first for IREDs, which was then used characterise these enzymes across 36 diverse substrates as products of both cyclic imine reductions and reductive aminations. These enzymes were then applied to further the synthetic scope of IRED mediated reductive aminations across 3 separate avenues (Figure 2B). Where enzymes were shown to accept acetophenone derivatives (up to 99 % conv.) and dimethylamine derivatives (up to 86 %), both constituting key building blocks in a number of APIs. A new scope for IRED‐mediated reductive aminations was also demonstrated coupling β‐keto ester derivatives with a number of amine partners on preparative scale to give yields of up to 91 %, where both pairs of enantiomers could be obtained in excellent ee values (>99 %). This metagenomic collection was then expanded to yield a variety of N‐substituted α‐amino esters forming key scaffolds in a number of bioactive molecules such as N‐methylated analogues of peptides and peptidomimetics, [198] where previous IREDs were unable to yield such products. [187] These were again carried out at a preparative scale (50 mM) with >20 different transformations where separate wild type enzymes were able to afford both enantiomers for each product (Figure 2C). It was noted that depending on the substrate combinations employed, the enantioselectivity of the enzyme would invert, an observation previously noticed within this enzyme family.

Figure 2.

(A) Metagenomic IREDs for reductive amination. (B) Application of metagenomic IREDs, with the products of the reductive amination given. (C) Further applications of metagenomic IREDs in the synthesis of N‐substituted α‐amino acids with select products of the reactions given.

Höhne and co‐workers also described the spectrophotometric characterisation through NAPDH consumption assays using purified IREDs from Streptomyces tsukubaensis and Streptomyces ipomoeae, Activity data was generated from a combination of 663 reductive aminations. [199] However, limitations arise from requiring purified enzymes limiting its use to screen large number of variants. Furthermore, as recently shown, enzymes in this family possess ketoreductase side activity. [193] Piperazine is a common building block in several pharmaceuticals such as vestipitant [200] and mirtazapine. [201] Interestingly, piperazine may also act as an amine nucleophile in reductive aminations. In a study by Nestl and co‐workers, piperazine derivatives were synthesised from 1,2‐carbonyl and 1,2‐diamine substrates via a double reductive amination mechanism (Scheme 22A). [202] A vast range of architectures were formed, with 13 fully validated through by chromatographic analysis. Where both alkyl and aryl N‐ and C‐substituted products were formed, giving a diverse and novel set of API building blocks.

Scheme 22.

Additional examples of IRED mediated reductive aminations. (A) Synthesis of piperazines from 1,2‐carbonyl and 1,2‐diamine substrates. (B) Synthesis of β‐fluoroamines. (C) Synthesis of primary amines using thermotolerant Nf/NfisRedAm. (D) Synthesis of 1,3‐diazepanes via intramolecular reductive amination with the generation of the suvorexant scaffold given.

Recently in further work, Grogan and co‐workers identified additional fungal homologues (Nf/NfisRedAm) to AspRedAm which were applied to the challenging reductive amination of α‐fluoroacetophenones with ammonia (Scheme 22B), methylamine and allylamine as donors yielding β‐fluoro primary or secondary amines with >90 % conversion and 85–99 % ee. [203] The transaminase route to such compounds is limited to 50 % due to the kinetic resolution required. It was also observed with α‐fluoroacetophenones the IRED could yield the corresponding alcohol, where control reactions determined the IREDs ketoreductase activity, a 2nd observation of such activity. Additionally, these enzymes were termed reductive aminases, although a large excess of amine was used to achieve the amine product. The same 2 enzymes (Nfis/NfRedAm) were also recently applied to the synthesis of a wide variety of primary amines, rivalling scopes seen with transaminases and amine dehydrogenases (Scheme 22C). [204] The study by Mangas‐Sanchez demonstrated the synthetic viability of these fungal enzymes through their thermotolerance, structural properties and catalytic properties achieving 14,000 TNs and space time yields of yields 8.1 g L−1 h−1 in the generation of (R)‐2‐aminohexane in a continuous flow reaction system. Eighteen examples in total were given were the (R)‐configured product was primarily generated using ammonium chloride as the amine source.

In a first example of intramolecular reductive amination with IREDs, Yao and co‐workers carried out site‐saturation mutagenesis and generating iterative combinatorial libraries to give a 61‐fold improvement towards intramolecular reductive aminations accessing 1,4‐diazepane products employing IR‐1‐Y194F/D232H to yields the (R)‐configured amines and wild‐type IR‐25 to give the (S)‐enantiomers (Scheme 22D). [205] 1,3‐Diazepanes are found in number of APIs including ripasudil, fasudil and survexetant. The latter compound the substructure was synthesised with an impressive 81 % yield and >99 % ee, along with 10 other preparative scale transformations.

2.1.3. IREDs operating at industrial scale

A further appeal of this enzyme family is their ability to readily operate at industrial scale. Researchers at GSK implemented a robotics screening platform in the directed evolution of an IRED for the asymmetric reductive amination and concomitant kinetic resolution towards a lysine‐specific demethylase‐1 inhibitor, GSK2879552 at the time in phase II clinical trials for small cell lung cancer and acute leukaemia (Scheme 23A). [206] Chemical approaches in the synthesis of the target require, 1. the classical resolution of the amine donor, 2. a low temperature reductive amination and 3. subsequent multiple work‐up procedures requiring vast amounts of solvents. Initial screening of their collection of 90 enzymes identified GSKIR‐46, where a 43 % yield of the product was obtained on a 5 g scale. Over 3 rounds of directed evolution, screening nearly 10,000 variants, a variant M3 (Y142S; L37Q, A187V, L201F, V215I, Q231F, S258N; G44R, V92K, F97V, L198M, T260C, A303D) was yielded with an >38,000‐fold improvement over the wild‐type, where the enzyme was engineered towards several factors including increased substrate and biocatalyst loading, stereoselectivity and yield. The enzyme was also engineered towards operating under acidic conditions to aid substrate solubility, where previous reports had only described IREDs operating under neutral to basic conditions. Both residues L198M and L201F were identified as residues to interact with substrate stabilisation at the dimer interface. The group also noted initially library design was a challenge due to the nature of IREDs dynamic mechanism and few mutagenesis studies. M3 was then used for the reductive amination on a kilogram scale giving 84.4 % isolated yield and 99.7 % ee. They also investigated the use hydrogen‐borrowing cascade starting from the alcohol via the in situ aldehyde, although this was not viable due to reaction equilibrium issues and requiring additional amine loadings. Very recently, researchers at Pfizer have reported two large‐scale processes for the preparation of APIs involving RedAms. Firstly, they investigated the use of a RedAm for the synthesis of an amino alcohol intermediate in the synthesis of a cyclin‐dependent kinase (CDK) 2/3/4 inhibitor (Scheme 23B). [207] The initial process involved a transaminase‐mediated reductive amination although issues concerning product isolation prompted the authors to reconsider the route by using an IRED with benzylamine as coupling partner. After initial screening, a wild‐type enzymes IR007 was used as a template for evolution in efforts to improve activity and stability. The final variant IR007‐143 was able to convert the substrate in 43 % conversion and in 98 % ee with a substrate concentration of 50 g L−1. They have also followed the same approach to design a novel process towards the synthesis of the Janus kinase 1 (JAK1) inhibitor abrocitinib (Scheme 23C). [208] After initial screening, the RedAm from Streptomyces purpureus (SpRedAm) proved to be the best candidate for evolution. Initially, 93 positions were selected for single site saturation mutagenesis, followed by recombination of beneficial mutations and further recombination under final process conditions, yielded a variant SpRedAm−R3‐V6 able to achieve the desired diastereomer in 92.5 % conversion, >99 % d.r., and 73 % isolated yield at a 230 kg scale (100 g L−1 concentration) using 1.5 equivalents of methylamine.

Scheme 23.

IREDs operating at industrial scale. (A) Schober and co‐workers for the directed evolution IR‐46 in the synthesis of a lysine‐specific demethylase‐1 inhibitor, GSK2879552.

Furthermore, researchers at Johnson Matthey also highlighted the viability of IREDs for reductive amination at scale. [209] Bornadel and co‐workers described the necessary considerations for scaling up and IRED reductive amination between cyclohexanone and cyclopropylamine. Given the nature of reductive amination, as it is multi‐factorial reaction, design of experiment (DoE) was implemented studying different reaction conditions to give the optimal parameters. DoE identified the most influential parameters to be ketone and amine concentration, temperature and IRED loading. When the reaction was moved from batch to fed‐batch of amine and ketone this allowed for a successful scale up of the reaction. A 90 % isolated yield was achieved with 750 mM ketone concentration, with turnover numbers of 48,0000.

Finally, researchers at Novartis have recently used the IRED‐mediated reductive amination reaction to access the H4 receptor antagonist ZPL389 to compare machine‐learning guided directed evolution with classical approaches such as deep mutational scanning (DMS) and error‐prone PCR (epPCR). [210] The best performing variant obtained via DMS and epPCR was used at a gram scale obtaining the desired product in 72 % isolated yield and >99 % ee.

2.1.4. IREDs in flow biocatalysis

An emerging and promising area of biocatalysis is the use of flow biocatalysis where enzymes are (co‐)immobilised through various approaches to support resins. This approach offers to improve the efficiency of biocatalytic reactions through improved enzyme stability, enzyme recyclability, improves scalability and overcomes previously incompatible cascades.

The first example of this technique was given in 2019, as previously mentioned AspRedAm displays poor stability. In an effort to improve this, AspRedAm was immobilised on EnginZyme's EziG™’s Amber support where AspRedAm was studied for the reductive coupling of cyclohexanone with allylamine, where activity was significantly higher for the co‐immobilised 34 % soluble enzyme vs 90 % immobilised. [194] As IRED mediated reductive amination in a multi‐enzyme system, optimisation where multiple enzymes are co‐immobilised is a challenge. As such a DoE approach was taken to improve immobilisation of enzymes for reductive amination, where a computer aided work‐flow was used to mechanistically and empirically model predictions for optimal space‐time yields with minimal cofactor and co‐substrate requirement. [211] Hydrocinnamaldehyde and allyamine was used as the model reaction. All factors of the IRED reaction were studied, where testing all combinations of factors would have required 729 experimental runs, instead through DoE only 17 runs were needed from the empirical modelling. Two preparative scale transformations were performed with one being a cost‐effective strategy and another to maximize space time yields at all costs, where both methods achieved expected and good results.

Addressing previously incompatible cascades by taking a reaction compartmentalisation approach and using switching valves to alter the direction of the intermediate products towards different downstream enzymes. Mattey and co‐workers immobilised different alcohol oxidases to generate in situ aldehydes to be then fed to a number of aminating enzymes including IREDs and RedAms, where transaminases were also employed to also give the analogous primary amine (Scheme 24A). [212] Initially a range of benzyl alcohol derivatives were studied when galactose oxidase (GOase) variant M3‐5 was combined with either ω‐TA or an IRED to give primary and secondary amines, respectively. Typically, in the presence of amines galactose oxidase's copper centre is inactivated. Furthering this approach, cross reactivity between IREDs for reductive amination and ω‐TA's can be an issue in a ‘one‐pot’ process. To overcome this limitation, a TA‐IRED cascade was constructed in compartmentalised approach where pIR‐79 combined BmTA gave N‐butylcyclohexylamine from butanal in 85 % conversion via butylamine generated from BmTA. It also seemed plausible to extend this system to start from the primary alcohol, where a 6‐enzyme system was used to generate the final secondary amine with 92 % steady state conv. (Scheme 24B). Finally, screening the Turner/Prozomix metagenomic IRED collection identified pIR‐80 active towards the natural product 4O‐methylnorbelladine, a scaffold of the dementia API galantamine. pIR‐80 was combined with GOase M3‐5 to generate isovanilin which was reductively coupled by the IRED with tyramine to generate 4O‐methylnorbelladaine (Scheme 24C), due to its insolubility this allowed for a facile product isolation. The application of IREDs for reductive amination in flow has allowed for greater synthetic versatility of these enzymes.

Scheme 24.

IREDs in flow. (A) An overview of the MPIR‐packed bed system with the AlOx (alcohol oxidase) in cascade with the either a transaminase (TA) or IRED. (B) A 6‐enzyme compartmentalised system to access secondary amines. (C) Combing GOase M3‐5 with pIR‐80 to access 4O‐methylnorbelladaine from isovanillyl alcohol and tyramine.

2.1.5. IREDs in cascades

Multi‐enzymes biocatalytic cascades are one of key steps towards delivering more renewable synthesis of chemicals. Cascades provide the convenient synthesis of many high‐value materials starting from inexpensive starting materials. Cascades also circumvent having to isolate challenging intermediate materials thus reducing time and waste from work‐up materials.

In 2017 Montgomery and co‐workers substituted an AmDH for AspRedAm in the direct alkylation of amines with alcohols in a hydrogen borrowing cascade combined with a non‐selective alcohol dehydrogenase (ADH) (Scheme 25A). [213] Where the IRED is advantageous over the AmDH in being able to generate both secondary and tertiary amines. This cascade is also redox neutral generating water as the sole by‐product in a first example of biocatalytic hydrogen autotransfer for the direct preparation of secondary amines. A range of secondary amines were generated in excellent yields and selectivities. This cascade was then extrapolated further starting from unfunctionalised cycloalkanes employing a P450 BM3 variant to carry out the hydroxylation (Scheme 25B). [214]

Scheme 25.

IREDs in cascades. (A) AspRedAm implemented in hydrogen‐borrowing cascades for the alkylation of amines, ADH=alcohol dehydrogenase. (B) Extending the hydrogen borrowing cascade to unfunctionalised cycloalkanes by employing a P450 BM3 variant. (C) N‐alkylation of primary amines with primary alcohols or primary carboxylic acids, CholOx=choline oxidase.

The hydrogen borrowing approach although redox neutral inherently suffers from issues around reaction equilibria. Ramsden and co‐workers offered an alternative to this through by combining AspRedAm with an alcohol oxidase or carboxylic acid reductase (CAR) starting from the alcohol or carboxylic acid, respectively (Scheme 25C). [215] Both enzymes due to the nature of their mechanism are irreversible in their reactions, overcoming equilibrium issues. The cascade generated a plethora of secondary aliphatic and aryl amines. Although this approach is limited to the in situ aldehyde formation due to primary enzymes of the cascade.

2.2. Amine dehydrogenases (AmDHs) for reductive aminations

Amine dehydrogenases (AmDHs) are another synthetically relevant class of oxidoreductases that can carry out asymmetric reductive aminations of carbonyls with inexpensive ammonium salts to generate the corresponding (chiral) primary amines. These enzymes are typically coupled with a formate dehydrogenase cofactor recycling system where ammonium formate can be used as the amine and reductant source, favouring atom economy. Initially AmDHs were evolved from amino acid dehydrogenases (AADHs) through point mutations directing the substrate specificity away fr6 m amino acid acceptance. These reports have been extensively reviewed by Sharma et al. [215] and Patil et al. [217] In this survey we focus on later reports on the recent synthetic applications of engineered AADHs and discovery of wild‐type AmDHs.

2.2.1. Substrate scopes of engineered AmDHs from AADHs

The first AmDH variants were generated by the Bommarius group via active site engineering of the leucine dehydrogenase from Bacillus stearothermophilus (L‐AmDH), the phenylalanine dehydrogenase PheDH from Bacillus badius (F‐AmDH), and a chimeric AmDH [218] (Ch1‐AmDH) generated by combination of the N‐terminus from F‐AmDH, [219] and residues 146–160 from L‐AmDH. [220]

Investigating the scope of F‐AmDHs in a collaboration between the Li group and GSK, [221] directed evolution was carried out on PheDH from Rhodococcus where NNK libraries of residues K66 and N262 of the carboxylate binding pocket were generated, where the mutant N66Q/N262C (TM_pheDH) was able to aminate 4‐phenyl‐2‐butanone and phenylacetone, a moiety of the API selegiline. Expansion of the binding pocket by 2 Å allowed greater substrate accommodation. The variant was able to generate the enantiopure product from phenylacetone in 98 % ee. Furthermore, preparative scale reactions of 4‐phenyl‐2‐butanone were shown on a 15 mM scale giving 95 % conv. and 2800 turnover numbers with respect to NAD+. Although substrate scope remained narrow.