Abstract

Inhibitors have evolved from their primary function of controlling swelling during hydraulic fracturing processes in shale reservoirs. This study provides a comprehensive review of recent deep eutectic solvent (DES) advancements as inhibitors in swelling inhibition techniques. The swelling inhibitory potentials and mechanisms of DESs have been studied analytically and compared to existing conventional inhibitors. The functional effects of concentration, temperature, and types of DES are explored. Data on the effect of DES on rheology, swelling, zeta potential, shale cutting recovery, surface tension, particle size distribution, XRD, and FTIR analyses are presented. Along with preparation procedures, environmental concerns and applications of DESs in several fields are discussed. This study suggests that DESs are preferable swelling inhibitors due to their inhibitory performance, cost-effectiveness, and environmental friendliness. Moreover, this review includes guidelines and recommendations for selecting and designing DES to inhibit swelling more effectively.

1. Introduction

Increased energy consumption and the depletion of conventional energy reserves have sparked a lot of interest in utilizing unconventional sources.1 If natural gas is found in a rock formation with a permeability of fewer than 1 millidarcy, it is classified as unconventional gas in the largest context.2,3 In addition to this, an unconventional source or reservoir refers to any formation with high organic content and low porosity.4−7 Coal bed methane, oil sands, tight oil and gas, gas hydrates, and shale oil and gas are examples of unconventional reservoirs.5,8,9 Shale gas is the most discussed unconventional reservoir because of its vast reserve, which accounts for about half of the total unconventional reserves.10 However, due to the unique composition of shale formations, only a small percentage of this massive reserve is technically attainable. The condition of shale gas is determined by the size of the pores: liberated gas is stored in big holes or fractures, whereas adsorbed gas is held in small pores.11

Shales are one type of sedimentary rock made up mostly of clay minerals (smectite, illite, kaolinite, chlorite, and vermiculite), as well as quartz, calcite, feldspar, and other minerals.12 Because of the presence of organic sediments, shale formation has ultralow permeability, small pore throats, and low porosity.13 These negative properties make shale oil and gas production challenging utilizing conventional production methods. As a result, advanced technologies are required to discover these vast sources, which can serve the world’s increasing energy demand. It is possible to extract a large amount of hydrocarbon from shale formations using advanced technology such as horizontal drilling and hydraulic fracturing and so on.14−16 Prior to hydraulic fracturing, horizontal drilling is typically utilized to enhance the contact surface area. Hydraulic fracturing is applied to expand the connectivity of the pores in the shale formation. The success of fracturing processes is determined by the quality of induced fracture networks as well as the after effects.17 The success and after effects of horizontal drilling and hydraulic fracturing are mostly influenced by the drilling and fracturing fluids. The drilling or fracturing fluids can be of different types such as oil-based fluids and water-based fluids.

Oil-based fracturing or drilling fluids were formerly employed and had outstanding inhibitory property. However, environmental disposal challenges, high initial costs, and safety concerns limited their use, paving the way for water-based fracturing and drilling fluids. When water-based fluids come into contact with the clay minerals in the shale formation, they cause problems like hydration and swelling. When water comes into contact with clay minerals, the negative layers attract water molecules and allow water to adsorb on the interlayer gap.18−20 Swelling of clay can obstruct shale gas production by causing a slew of issues such as particle buildup in the mud, hole collapse, tight holes, drill pipe sticking, pore plugging, reduced permeability, and so on.21−28 Swelling may also lower the diameter of fractures, decreasing the reservoir’s ultimate permeability.29 Many additives, such as inorganic salts, organic salts, surfactants, amine derivatives, polymers, and others, were added to water-based fluids to prevent these problems. The insertion of salts such as ammonium chloride, potassium chloride, and divalent brines with a high concentration was the most extensively utilized and early method. Although these salts can slow the hydration and swelling of clay, their use at high concentrations is harmful to biological and chemical environments. Furthermore, these salts are inflexible and unsuitable for mud compositions.30 KCl is sometimes combined with polymers to achieve stronger inhibition than either the KCl or the polymer alone. However, these polymers have several drawbacks, such as heat breakdown and increased viscosity at high temperatures.31,32 Ammonium compounds and derivatives have been utilized for a long time; however, they have significant drawbacks, such as ammonium salts being incompatible with anionic additives.33 Ionic liquids (ILs) have recently been employed as fracturing fluid additives to inhibit clay swelling.34 Several studies have been done to explain the inhibition performance, mechanisms, and effects of different moieties of ILs as clay swelling processes.35 However, a recent study has shown that ILs based on imidazolium are costly, hazardous, nondecomposable, and needed complicated processes and apparatuses to prepare.36

In recent years, research has focused on environmentally safe, cost-effective, easy-to-prepare, and high-performance inhibitors. DESs are fourth-generation ILs that are marketed as a more environmentally benign and cost-effective alternative to conventional inhibitors. DES is made up of large asymmetrical ions with low lattice energy, giving it a low melting point.37 This solvent is a connotation of quaternary ammonium salt and metal salt, also known as a hydrogen bond donor (HBD). The final mixture has a minor melting point compared to any of the discrete components.38 At room temperature, most of them remain in the liquid phase. Some of their appealing qualities (for example, low vapor pressure, nonflammability, and so on) have made them very attractive in the field of modern research. One of the desired aspects of using this particular solution is a specific type of chemistry attributable to its adaptable nature.39 Due to the considerable flexibility in adopting individual components and their composition, there are no limits to the number of DESs that can be generated. These qualities have sparked burgeoning attention from the scientific community in using DESs rather than ILs as solvents in a wide range of sectors.40−43 As a result, there has been plenty of potential for the improvement of fundamental research in the subject of DES.44

The most critical concern associated with shale gas production, as aforementioned, is shale hydration, which induces swelling. As a result, this issue has a direct negative influence on shale gas extraction. Studies have been conducted on this issue for decades in order to explore an appropriate inhibitor. Inorganic salts, nanosilica, polyamines, polyglycerols, surfactants, silicates, and nanocomposites have all been described as swelling inhibitors in the literature.45−49 Several reviews on shale inhibitors evaluated the influence of recently tested inhibitors, such as ILs, polymers, surfactants, and amine-based chemicals, and outlined their general inhibitory processes.50−57 Rahman et al. reviewed 23 ILs and presented the effects of chain length and cationic and anionic parts on swelling inhibition.1 Quainoo et al. presented a comprehensive review of several bioinhibitors, including their economic aspects, performance, and environmental friendliness.58 Abbas et al. provided a critical parametric review of polymeric inhibitors as well as their inhibition performance.59 A review on the application of surfactants and nanomaterials as shale inhibitors for water-based drilling fluid was discussed by Muhammed et al.60 Sivabalan et al. did a minireview where they addressed DES as the new norm for the oil and gas industry.61 However, they presented the use of DES in gas hydrate inhibition processes instead of shale swelling. Also, a minireview on the synthesis method, properties, and applications of DES was highlighted by Mr et al.62

So far, there is no other substantial review on the impact of DESs on shale swelling inhibition. The important contributions of DESs in shale inhibitory mechanisms, on the other hand, have not been rigorously studied or completely described in the open literature. Furthermore, the mechanism of swelling inhibition in the presence of DES demands a deeper investigation. Additionally, other notable qualities such as environmental friendliness and biodegradability may be important in understanding their potential industrial application. Therefore, a state-of-the-art evaluation that discusses the aforementioned concerns and makes significant recommendations on the design and application of DES in shale formation is indispensable. The ease of manufacturing of DESs led to their extensive implementation in a variety of disciplines via the trial-and-error approach.63 This research could eventually replace the hazardous chemicals used in the oil and gas industry to minimize shale swelling.

2. Fundamentals of Swelling

2.1. Shale

Shales are the most abundant sedimentary rock (approximately 60% of all sedimentary rocks) and are found in a wide range of geologic eras from the Paleozoic to the Cenozoic.64 Extrusion, dehydration, recrystallization, and cementation of weak clay constitute the most common sedimentary rock, which can be found in sedimentary basins all over the world. Muds, silts, and other sediments are transported to different environments such as the Midcontinental Shelf, lake (away from shore), delta, lagoon, Tidal Flat, Deep Marine, basins of shallow seas, river floodplains, and playas through currents and deposited there. They are compacted and formed shale rocks.

Permeability is an essential aspect to consider when exploring these unconventional sources of natural gas.67−69 The presence of natural fractures or cracks in the rock determines permeability, which allows fluid to move within the rock.70 Permeability and porosity in shale rocks are highly reliant on the mineral composition, distribution, quantity, and thermal maturity of organic matter.71 Shale rocks exhibit micro- and nanosized pores with varying degrees of water and residual organic matter.72,73 Furthermore, due to the nanometer-scale pore diameters, shale permeability is extremely low, often in the nano- to microdarcies.74−77Table 1 represents some of the petrophysical and geomechanical properties of shales.

Table 1. Some Petrophysical and Geomechanical Properties of Shales65,66.

| property | average value/range |

|---|---|

| bulk density (mg/m3) | 2.30 |

| porosity (%) | 15 (7–30) |

| permeability (m/s) | 1 × 10–9 (1 × 10–6–10–12) |

| UCS (MPa) | 20 (3–30) |

| Young’s modulus (GPa) | 5.0 |

| Poisson’s ratio | 0.22 |

| resistivity (Ohm-m) | 0.5–15 |

Shale is a term used to describe rocks that include fine-grained particles (typically less than 4 μm in diameter). Yet they also hold silt-sized particles having a diameter of up to 62 μm. Any shale rock is classified as silty shale or clay shale according to the dominated constituents of the rock. Shale rock maintains a laminated structure with a tendency to scatter into thin layers of sharp edges, and these layers are usually parallel to the bedding-plane surface. Shale rock is mainly composed of silt and clay-sized mineral particles that are frequently referred to as “mud”. So, shale is referred to as “mudstone”. Shales are classed as carbonaceous or bituminous depending on their organic matter composition. Shale is defined as carbonaceous if the organic content in plant fragments and the depositional environment are continental or transitional. Bituminous shale is formed by organic materials from animal bits. Both types of shales have the potential to be used to produce petroleum oil and gas.78

The shale’s mineral content is a major determinant of whether the solid bitumen-hosted porosity is sustained or disrupted. When compared to a clay-rich mature shale of similar maturity, a quartz-rich mature shale retains more solid bitumen-hosted (meso and macro) porosity. As a result, a quartz-rich shale’s gas holding capacity must be greater than that of a clay-rich shale of equal maturity, organic matter type, and TOC level.79

Clay minerals are the vital components of any shale and similar types of rock. Shale formations, in particular, can have up to 70% clay content.80 In addition to clay minerals, they also contain other minerals such as quartz, feldspar, other constituents, etc. Other constituents include organic matter, iron, sulfide or carbonate minerals, and heavy minerals. Depending on the predominance of the quartz, feldspar or mica shale may be classified as quartz, feldspathic, or micaceous.81 The average chemical composition of shales is displayed in Table 2.

Table 2. Average Chemical Composition of Shales82.

| composition | SiO2 | Al2O3 | Fe2O3 | TiO2 | MnO | MgO | CaO | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| percentage | 60.9 | 18.5 | 7.2 | 0.9 | 0.1 | 2.9 | 2.4 | 1.8 | 4.0 | 0.2 |

Clays are minerals that form naturally as igneous rocks deteriorate and disintegrate.83 Clay minerals can be found in almost 90% of all hydrocarbon-producing reservoirs, not just in shale reservoirs.84,85 Clay minerals belong to the phyllosilicate family and are tiny hydrous layer silicates. With tiny particles less than 2 μm in diameter, they have a platy or flaky texture. Tetrahedral and octahedral sheets are formed by atom planes in the layered silicate.86,87 The tetrahedral sheets are composed of tetrahedra linked with adjacent tetrahedra by sharing oxygen ions at three corners, and the shared oxygen (basal oxygens) forms a hexagonal pattern. The fourth tetrahedral oxygen (apical oxygen) of all tetrahedra is perpendicular to the sheet and forms part of the adjacent octahedral sheet. Si and Al are the most common tetrahedral cations, with Fe3+ being unusual. The octahedral sheet is made up of cations (Al, Fe, and Mg) that are octahedrally coordinated by shared apical oxygens and unshared OH groups in the hexagonal hole created by the basal oxygens.88,89 Three octahedra comprise the smallest structural unit. A 1:1 layer is made up of one tetrahedral sheet and one octahedral sheet merged. OH anions constitute the unshared plane of anions in the octahedral sheet. An octahedral sheet is sandwiched between two tetrahedral sheets in a 2:l layer.83 Clay minerals based on bentonite can have thixotropic gel formation with water, high water absorption, and high cation exchange capacity in general (CEC). CEC is defined as the amount of positive charge that can be exchanged. So, the higher the value of CEC, the higher the rate of swelling in shale particles. Clay minerals’ CEC is governed by crystal size, pH, and the type of cation that can be exchanged.90 Clay minerals present in the soil environment include layer and chain silicates, sesquioxides, and other inorganic minerals.91 Clay is classified according to how the tetrahedral and octahedral sheets are arranged into layers. Types of clay mineral include allophone, kaolinite, halloysite, smectite, illite, chlorite, vermiculite, attapulgite–palygorskite–sepiolite, and mixed-layer minerals.92Figure 1 represents the basic structure of a clay particle.

Figure 1.

Basic structure of a clay particle. Reprinted with permission from ref (93). Copyright 2013 RSC Advances.

The kaoline group is a 1:1 layered mineral comprised of one tetrahedral and one octahedral sheet. Kaolinite, which is the most common mineral in this group, is dioctahedral, exhibiting Al3+ octahedral and Si4+ tetrahedral coordination with an effective surface area range from 10 to 30 m2/g. The sheets are bound together by van der Waals bonds between the tetrahedral sheet’s basal oxygens and the octahedral sheet’s hydroxyls.94 Hydrogen bonding holds layers together securely, restricting expansion and limiting the reactive area to exterior surfaces with limited cation exchange capacity. So, isomorphic substitution for Si4+ and Al3+ in this mineral is insignificant. There seems to be little, whether any, isomorphous substitution in the kaolinite group due to its lack of structural charge.95 Kaolinite has a limited potential to adsorb ions owing to its poor surface area and lack of isomorphous substitution.96 As a result, soils dominated by the 1:1 mineral have poor cation adsorption and are low in fertility. Lower CEC also indicates a lower tendency of hydration when it comes into contact with water molecules and thus a lower rate of swelling.

Among all the groups of clay minerals, the smectite group is considered an expansible group of clays. Montmorillonite [(0.5Ca, Na) (Al, Mg, Fe)4(Si, Al)8O20(OH)4·nH2O] is the most well-known member of this family. The term “smectite” has come to refer to the entire family of clays that incorporates montmorillonite.97 Smectite (montmorillonite) is a flake-like clay mineral with an expanding lattice. Each layer is made up of two tetrahedral (silica) sheets sandwiched between an octahedral sheet.98 Due to the isomorphic substitution, aluminum (Al3+) or iron (Fe2+) ions can substitute Si4+ in tetrahedral sheets. Magnesium (Mg2+) or iron (Fe2+) ions can replace the aluminum ions in the octahedral sheets. A negative charge layer forms on the mineral’s surface as a result of this substitution. Negative charges have a repulsive tendency, and they cause repulsive forces between two layers. The repulsion of two layers might cause the sandwiched silicate layers to detach, causing swelling.99 Oxygen atoms in one unit’s bottom tetrahedral sheet and another unit’s top tetrahedral sheet have a small affinity. This generates a changeable gap between layers, which is populated by swappable cations and water. Water and exchangeable cations can freely enter the interlayer region as a result, leading to layer growth of 9.6–20 Å. They also differ due to the occurrence of isomorphous substitution in the octahedral or tetrahedral layer. The cation exchange capacity (CEC) is the number of cations required to balance the charge shortfall caused by these replacements. The thermal stability of montmorillonite clays is weak. High cation exchange capacity, swelling, and shrinking capacity are all features of these minerals. As a result, they are classified as reactive clays.100 Montmorillonite has a CEC of 80–100 mequiv per 100 g.101

Bentonite is an inaccurate type of aluminum phyllosilicate clay made up of 98% montmorillonite that is formed in the presence of water by in situ devitrification of volcanic ash or mechanical and chemical weathering of the parent rock. The presence of the hydroxide group on the platelet’s edge causes this type of clay to be thixotropic.102

The major component of shales is illite clay. It has a layered structure of 2:1. Weathering of K- and Al-rich rocks under high pH conditions produces illite-type clays. Members of the illite group do not commonly accept water. Because their structures allow for partial replacement of Al onto the tetrahedral site, the surplus negative charge can be accommodated by introducing potassium (K), calcium (Ca), or magnesium (Mg) into the interlayer site. These interlayer cations of K, Ca, or Mg prohibit H2O from entering the structure. As a result, illite clays do not expand.103 Illite also has the lowest CEC, indicating that it has a lower tendency to swell when exposed to water.

Vermiculites are chemically sophisticated clay minerals that emerge when biotite and other initially ferromagnet minerals interact.97 Vermiculite is a phyllosilicate clay mineral with a 2:1 ratio. Al, Mg, and Fe are octahedral ions. It has the biggest expandable surface area of all the clay minerals and has a high cation exchange capacity. In fact, the minerals with the highest CEC in the mineral part of soils are vermiculites (Table 3); nevertheless, the presence of hydroxy–Al interlayers can significantly diminish the effective CEC.104 So, it does not expand as much as smectites despite having a higher CEC value. It has two layers of water within interlayers and exchangeable cations like Ca2+ and Mg2+. Some K+ ions are removed during weathering. In interlayer gaps, hydrated cations have taken their place.

Table 3. General Properties of the Four Major Clay Mineral Groups105,97,101,106.

| group name | layer type | basal spacing | CEC (mEq/100 g) |

|---|---|---|---|

| kaoline | 1:1 | 7.2 Å | 3–15 |

| smectite | 2:1 | up to 19 Å | 80–130 |

| illite | 2:1 | 10 Å | 10–40 |

| vermiculites | 2:1 | up to 14 Å | 100–150 |

2.2. Swelling

Water is introduced to the interlayer space of dried clay minerals when they are exposed to absorbed water in a controlled environment, allowing the interlayer space to swell or expand. Clay minerals’ interlayer space swells due to hydration energy forces related to particle interaction.107 Any water molecule that makes contact with a clay particle enters the dry clay’s interlayer region. Following that, anions and cations exchange electrostatic ions. The formation of repulsive van der Waals forces results from this phenomenon, which causes hydrated clay particles to expand.108

Water molecules move into the shale layers through osmosis and inflow into the interlayer voids whenever the concentration of interfacial cations is more than the adjacent water, as shale acts as a semipermeable stratum.109 The interlayer space is enlarged as a result of the migrating water molecules, inducing osmotic swelling.1 The volumetric expansion of shales is caused by another sort of swelling referred to as crystalline swelling. The hydrational force generated between the absorbed water molecules and exchangeable cations generates crystalline swelling. This force gradually weakens electrostatic forces between exchangeable cations and surface negative charges.110,111

During the drilling and hydraulic fracturing processes in petroleum reservoirs, the presence of certain types of clay minerals, such as reactive clays, induces hydration, swelling, and other destabilization complications.10 Water content variations in swelling clays can have significant volume repercussions. The layer charge density of clay minerals as well as the type of interlayer ions (monovalent or divalent) all influence the swelling capacity of clay minerals. The percent of ions present in the surrounding solution with clay minerals, the amount of water present in the clay mineral interlayer, and the quantity and types of minerals is the clay mineral composition.96 Shale swelling can cause wellbore fragility, which is among the most expensive and complicated problems to deal with during drilling operations. Moreover, the presence of water diminishes shale’s Young’s modulus (also known as brittleness).112,113

Montmorillonite, the predominant clay from the smectite group, shows more swelling behavior than any other clay mineral where the inner crystalline swelling takes place as formerly mentioned. Chemically, this type of clay consists of isomorphic substitutions in the tetrahedral sheet of Si4+ by Al3+ and Al3+ by Mg2+ in the octahedral ones. As a result of this collaboration, the negative residual charge of montmorillonite is balanced by cations in the interlayer space. Other phenomena such as the high difference in ion concentrations, mainly in cation concentration at the surface of the clay layers and pore water, also lead to the swelling behavior of clays, which is referred to as osmotic swelling.114 It has a high base exchange capacity (90–150 mequiv/100 g) and will rapidly absorb Na+ and other cations, leading to swelling and dispersion.115Figure 2 is the representation of montmorillonite clay’s structure.

Figure 2.

Structure of montmorillonite clay. Reprinted with permission from ref (116). Copyright 1987 Cambridge University Press.

3. DES: A Progressive Solvent

Due to the adaptability, DESs are now regarded as viable alternatives to traditional organic solvents.37 DESs are chemical compounds of two or three compounds with a lower melting temperature than the individual elements.117,118 The first DES was a combination of cholinium chloride and urea with a melting point of 12 °C, which was dramatically less than the melting temperatures of the starting components, which were 302 and 133 °C, correspondingly.117Figure 3 represents the preparation of DESs as a combination of choline chloride and urea.

Figure 3.

Deep eutectic solvent preparation. Reprinted with permission from ref (119). Copyright 2014 RSC Advances.

The fall in the melting point of the solution related to the melting point of each component is attributable to charge dissociation through the hydrogen bonding between the halide ion and the hydrogen donor molecule.120,121 As previously stated, DESs are produced by combining two or more economical and environmentally sustainable components, which are made when a hydrogen bond is formed between a HBD and a HBA. Choline chloride, quaternary ammonium salt, and phosphate salt are some of the most regularly utilized HBAs. Choline chloride (ChCl), which is identical with vitamin B, is the most common. It is a salt that is both nontoxic and biodegradable. With more readily available and profitable mixes of organic salts and a complexing agent, science has revolutionized the manufacture of DESs.117 The salt acts as a hydrogen bond acceptor in this mixture, while other agents act as hydrogen bond donors. Figure 4 represents a list of typical HBDs and halide salts as HBAs.

Figure 4.

Common types of HBDs and halide salts as HBAs. Reprinted with permission from ref (37). Copyright 2014 ACS Publications.

The DES combination is typically processed using one of two strategies. The heating process is one of them (frequently used in the literature). This procedure includes continuously combining and stirring two components at a temperature of about 100 °C until a uniform liquid is generated.117 The grinding process is another strategy. The compounds must be added at room temperature and smashed in a mortar for this approach to work. This process comes to an end after acquiring a liquid solution.63 Other methods of preparing DESs include the freeze-drying of aqueous solutions of the components of DESs, an evaporation method consisting of dissolving the components of DES in water, followed by evaporation at 50 °C. The resulting liquid is then placed in a desiccator in the presence of silica gel and an ultrasound-assisted synthesis of natural DES.122−124

3.1. Comparison between DESs and ILs

Though the physical properties of DESs and ILs are similar in general, the molecular level interactions and structural organization in these solvents are observed to be substantially different. The combination of ionic and molecular species in DESs results in a more structurally complicated liquid, including contributions from hydrogen bonding and electrostatic forces.125 The following attributes established ILs and deep eutectic solvents apart from each other.

DESs differ from ILs in two distinct ways. Their chemical formation process is one of them, and their source of basic components is another. A complexation between a halide salt or a hydrogen bond acceptor and a hydrogen bond donor results in DESs. The majority of DESs is derived from nonionic substances such as salts and molecular components. ILs, on the other hand, are mainly composed of ionic components that are bonded together by ionic bonds.38

In contrast to ILs, which are generated from solutions composed predominantly of one type of discrete anion and cation, DESs are formed from a eutectic mixture of Lewis or Bronsted acids and bases that can contain a variety of anionic and/or cationic species.37

Compared to DESs, ILs have a narrower range of surface tension. For instance, the surface tension of ChCl/urea (molar ratio: 1:2) was measured at room temperature (25 °C) as 52 mN m–1, while that of ChCl/ethylene glycol (molar ratio: 1:2) was 49 mN m–1. The surface tension was determined to be 46.6 mN m–1 for C4mimBF4 and 37.5 mN m–1 for 1-butyl-3-methylimidazolium tetrafluoroborate C4mim (CF3CO2)2N. When it comes to conductivity, DESs have a narrower range. The conductivity of ChCl/urea, for example, is 0.75 mS cm–1. The conductivity of C4mimBF4 and C4mim (CF3CO2)2N, on the other hand, was measured to be around 3.5 mS cm–1 and 3.9 mS cm–1, respectively.117,126−128 The enormous size of the ions and comparatively free volume in the ionic systems are thought to be the cause of this disparity.37

DESs have several advantages over typical ILs, including ease of synthesis and availability of reasonably inexpensive components (the components are toxicologically well-characterized, allowing for easy transportation for large-scale processing); nevertheless, they are less chemically inert in general.37,129 The simple mixing of the two components, usually with mild heating, is all that is required to make DESs. This allows for large-scale applicability while retaining a lower cost of production than typical ILs (such as imidazolium-based liquids).

DESs also outperformed ILs in terms of environmental issues. If biodegradability is taken into account, DESs surpassed ILs. DES and IL biodegradation rates have been studied in a variety of ways. According to the findings, DESs are more biodegradable than standard ILs. For example, the Sturm and closed-bottle test procedures were used to investigate the degradation potential of several imidazolium cations in the presence of [Br], [BF4], [PF6], [N(CN)2], [(CF3SO2)2N], and octyl sulfate as the counterions. Nonetheless, with the exception of the ILs containing octyl sulfate, no molecule demonstrated considerable biodegradation.130−133 A number of DESs were tested for biodegradability. All of the tested DESs showed a biodegradation rate of more than 69.3% after 28 days, indicating that they can all be regarded as biodegradable green solvents.134

In terms of conductivity, DESs are highly conductive, and ILs can be addressed as a moderate to highly conductive solution.135

3.2. Classification of Deep Eutectic Solvents

The researcher initially categorized DES as a liquid compound with a melting point lower than 100 °C when compared to its pure ingredients.136 The classification of DESs is illustrated in Figure 5.

Figure 5.

Four types of DESs based on the general formula Cat+X–zY, where Cat+ (cation) is generally ammonium, phosphonium, or sulfonium; X is a Lewis base, usually a halide anion; Y represents a Lewis or Bronsted acid; and z is the number of Y molecules. Reprinted with permission from ref (37). Copyright 2014 ACS Publications.

Metal salts or metal salt hydrates are associated with organic salts or other neutral compounds in types I, II, and IV DESs, whereas the type III DES has one organic salt, often an ammonium halide with a structure comparable to that of ILs, and a hydrogen bond donor. The capability to solvate a broad range of transition metal particles, including chlorides and oxides, has stimulated interest in type III eutectics, which are mainly composed of choline chloride and hydrogen bond donors.137,138

Table 4 shows the general formula that is used to categorized four types of DESs according to their HBD and HBA.

Table 4. General Formula for the Classification of DESs37.

| type | general formula | terms |

|---|---|---|

| type I | Cat+X–zMClx | M = Zn,1,5,6 Sn,7 Fe, Al,8 Ga,9 In10 |

| type II | Cat+X–zMClx·yH2O | M = Cr11 Co, Cu, Ni, Fe |

| type III | Cat+X–zRZ | Z = CONH,12 COOH,13 OH14 |

| type IV | MClx + RZ = MClx–1 + •RZ + MClx+1– | M = Al, Zn and Z = CONH2, OH |

3.3. Physicochemical Properties of Deep Eutectic Solvents

In recent years, researchers have given extensive attention to DESs. The principal reason behind this interest is the physicochemical properties of DESs. DESs are chemically tailorable, in addition to having properties such as nonflammability, lower rate of volatility, low vapor pressure, and chemical and thermal stability. So, they can be formulated for particular applications. Major physicochemical properties of DESs such as density, viscosity, ionic conductivity, thermal stability, polarity, phase behavior, and interfacial tension are discussed in this study.

Only combinations with a melting point underneath the ideal eutectic temperature are addressed under DESs. It would not be called a “deep” solvent otherwise, as it would be indistinguishable from any other solution.139 Choline chloride and urea, for example, constitute a DES with a molar ratio of 1:2 and a melting temperature of 285.15 K. However, purified choline chloride and urea melt at 575.15 and 407.15 K, respectively.136 As previously stated, DESs are mainly composed of a HBD and a HBA. This solvent is a mixture of two or more pure chemicals, rather than a single pure molecule. We show a binary solution of A and B compounds in Figure 6, showing the equivalence points.

Figure 6.

On a binary diagram, a schematic illustration of a eutectic point. Reprinted with permission from ref (140). Copyright 2016 Wiley Online Library.

The ratio of hydrogen bond donors and acceptors can affect the solvent’s melting point reduction. The coupling of hydrogen bonds with anionic groups diminishes as the attraction of hydrogen bonds to cationic groups rises. The melting point is dropped due to this precise interaction (also referred to as low lattice energy) between the cationic and anionic groups. Most DESs have freezing values in the range between 69 and 149 °C, and yet none of the individual compounds have a freezing point lower than 150 °C.38

The density of a substance is an important physical attribute, as it has an impact on the design and functioning of a process. The percent of DESs that has been reported exhibits densities that seem to be higher than that of water. For example, metal-salt-based DESs have densities of 1.3–1.6 g·cm–3.141 Hydrophobic DESs, on the other hand, have densities that are lower than that of water.142 The temperature and composition have an impact on the density of the DES.143 According to some research, this solvent has a temperature-dependent density profile. The molecular degree of motion increases as the temperature increases, expanding volume and reducing the density of the sample. Also, solvent densities are also affected by the mole fraction of individual components.143 For instance, the densities of the DES of ZnCl2/acetamide (1:4) as well as the DES of ZnCl2/urea (1:3.5) are 1.36 and 1.63 g·cm–3, correspondingly. This difference in the densities is due to their different molecular compositions.144 The density of the DESs is between that of the associated salt and the density of the HBD utilized in their synthesis.145 The ammonium-salt-based DESs exhibit relatively low density as a result of obvious steric hindrance from alkyl chains. Densities of choline chloride-based DESs and N,N-diethyl ethanol ammonium chloride-based DESs increased when the mole percentage of glycerol increased as the HBD.143

The thermal stability of any solvent indicates how well it can endure a temperature range. Acquiring this information is vital for quality control. The melting and decomposition temperatures of DESs, which are extremely effective for their utilization for alternative solvents, are one of their most prominent qualities. These qualities govern the range of temperature through which a DES can maintain a liquid state and consequently its application range.63 Thus, according to researchers, the variety of HBDs used has a considerable impact on the thermal properties of any DES. The thermal stability of DESs is greatly influenced by the nature of the HBD. For example, DESs comprising a HBD and having greater viscosity have a higher degradation temperature, and DESs become more stable as the extent of the alkyl chain in any HBD extends. Urea, glycerol, and glucomore have a higher boiling point temperature and thus thermally stable yield DESs such as ChCl:Glyce, ChCl:Urea, and ChCl:Gluc which are more thermostable.146

Ionic conductivity is electrical conductivity due to the motion of ionic charge. The fundamental controller of conductivity is known to be viscosity; most DESs have low ionic conductivities (κ < 2 mS cm–1 at ambient temperature). Conductivity increases remarkably as viscosity decreases due to ionic species’ free mobility as the hole mobility increases.38 For example, ammonium-based salt DESs are greater in value than phosphonium-based salt DESs in ionic conductivity. According to several studies, the conductivity of DESs typically exhibits considerable non-Arrhenius behavior, which is defined as an increase in the measured rate coefficient with an elevation in reverse temperature.147−149

For any fluid, viscosity is one of the crucial properties. It controls the fluid flow properties and conductivity, thereby influencing their suitability for particular applications. In general, DESs are considered to have the highest viscosity of any other molecular solvents and ILs.37 DES possesses lower mobility of free spaces because of the presence of an immense hydrogen-bonding network between the compounds which results in a higher viscosity value. van der Waals and electrostatic interactivity also may contribute to the high viscosity of DESs.38 However, hydrophobic DESs based on dl-menthol had extremely low viscosities (7.61 mPa.s at 25 °C for a 1:3 dl-menthol/octanoic acid ratio) according to a previous study.150 Ammonium-based salt DESs have substantially lower viscosities than phosphonium-based salt DESs, according to studies. Within the ammonium group, the viscosities of the different DESs increased as their molecular weights increased. The viscosity of phosphonium-based salt DESs, on the other hand, was unaffected by their molecular weight.151 The viscosity of polyethylene-glycol-based DESs is often lower than regular DESs. At 25 °C, the viscosity of ChCl/urea (1:2 molar ratio) was determined to be around 800 mPa s.152 Depending on the nature of polyethylene glycol, its viscosity when mixed with urea is only 134.08 mPa at 25 °C.153 DESs have a linear but inverse relationship with temperature. Their viscosities decrease as temperature increases.

One of the most important physical properties of DESs is surface tension, which provides a lot of information about the molecular influence on the degree of interactions in a solution.39 Surface tension arises from the strong interactions between water molecules, called hydrogen bonding. Surface tension arises when intermolecular interactions in a liquid induce cohesive tension, which helps to minimize the surface area of the liquid’s interface with other phases in contact with the liquid. This can alternatively be expressed as the amount of energy necessary to raise the surface area of a liquid by one unit of area. Compared to other physicochemical properties, the studies correlated to the surface tension of DESs are quite narrow. The surface tension of DESs is significantly greater than that of most common solvents. The surface tension of DESs exhibited a linear relationship with temperature, with the surface tension falling as the temperature is increased, similar to the tendency for viscosity.154 Surface tensions of DESs have been found to range somewhere around 35–75 mN m–1 at 25 °C.155 The excessive addition of ChCl to glycerol is thought to impair the strength of intermolecular interactions, such as the glycerol hydrogen bonding network.38 For example, choline chloride/d-fructose has a substantial value of surface tension, which reflects their extensive hydrogen-bond network.156

Polarity is a key indicator of solvent strength, as it reflects the overall solvation capability of a solvent. This feature is frequently assessed using solvatochromic parameters, which examine the hypsochromic (blue) shift or bathochromic (red) shift of UV–vis bands for negatively solvatochromic dyes (e.g., Reichardt’s betaine dye) and positively solvatochromic dyes (e.g., Nile red) as a function of the solvent’s charge, accordingly.157 The polarity of DESs is said to be governed by the hydrogen bond donor in their molecular structure.158 When water is added to DESs, conversely, the hydrogen-bond-accepting basicity decreases, and the polarizability/polarity improves.159

Solvents with low vapor pressure have less possibility of losses due to evaporation during the reaction process, purification, and other operations. DES is considered to have a lower vapor pressure than any other conventional solvents.160 For DESs, the type of salt and HBD determines the range of vapor pressures. For example, urea (HBD) based DESs are found to have a lower vapor pressure than the glycol-based DESs.161 The formation of a hydrogen bond between the HBD and HBA greatly affects the vapor pressure during the synthesis of DESs. When treating solvents or utilizing them in mass and heat transfer procedures, vapor pressure data of DES solutions are very crucial.162

The hydrophilic DES’s practical application is limited to just polar molecules, which is a significant disadvantage of the solvent. HDESs, or hydrophobic DESs, are a new form of extractive media capable of extracting nonpolar organic and inorganic compounds from aquatic media.163 The development of hydrophobic DES using a variety of long-chain quaternary ammonium salts and acids for the enhancement and extraction of a variety of chemicals has been explored.164,165 One of the distinctions between hydrophilic and hydrophobic DESs is that the former often induces a substantial depression in the melting point, while the latter can produce both enormous and moderate depressions. This difference in melting point depression behavior is due to the influence of charged and polar moieties in hydrophilic DESs, resulting in extensive hydrogen bond interactions, whereas in hydrophobic (D)ESs, a large depression is only obtained when salts are present. Some applications demand this type of hydrophobic DES.142

DESs have been used in the field of electroanalytical synthesis technology over the years. As a consequence, DESs must have the potential to degrade precursors during the reaction time and under synthesis circumstances. According to the majority of studies, increasing the temperature and decreasing the mole fraction can improve the solubility of any DES.44,117 It was also reported that the solubility of the DES is governed by the DES’s own chemical structure.166

3.4. Application of Deep Eutectic Solvents in Different Fields of Interest

Negligible vapor pressure, noninflammability, chemical tolerability, solubility potential for a wide variety of substances, and water nonreactivity are some of the physicochemical characteristics that make DES a fascinating solvent. Additionally, they are simple to make utilizing low-toxicity, usually available, and low-cost substances. DESs have gained popularity as green solvents in a variety of fields, including chemistry, material engineering, and biology, due to these advantages. Figure 7 represents the application of DESs in different fields.

Figure 7.

Application of DESs in several fields.

The physical properties of DESs are similar to other ILs, and their chemical properties suggest application areas that are significantly different.

-

1.

An advanced type of water-immiscible extractant (for example, hydrophobic DES as an extractant for volatile fatty acid).167

-

2.

In the latest days, much emphasis has been placed on replacing traditional extraction processes with “green” extraction techniques. Many researchers have found that deep eutectic mixtures hold some fascinating physicochemical properties that make them an exceptional solvent in the field of extraction. DES is used as an alternative to ILs in the metal extraction process, and it is also used as an extractant for organic compounds.138,168

-

3.

Due to some other benefits such as lower cost, easier synthesis than ILs, and having an environmentally friendly profile, the use of DESs in analytical microextraction techniques is on the surge.169

-

4.

DESs have a very strong ability to solubilize different types of chemicals with nonidentical properties. Thus, they can be used as extraction media for anthocyanins, flavones, xantonoides, and many other compounds.170

-

5.

In the case of the fuel desulfurization process, it can lessen the sulfur content of fuels below the environmental regulations, which is about 10 ppm. Different types of DESs based on polyethylene glycol (PEG) could successfully remove thiophene and dibenzothiophene from fuel with extraction efficiencies ranging from 6% to 85%.171

-

6.

Some DESs perform as an excellent solvent for the elemental mercury extraction process.172

-

7.

Global warming is now one of the most alarming topics in today’s world. Our environment is now on the verge of destruction due to this problem. It is affecting our world’s atmosphere, and as a result, all living beings are suffering. We all know that excess CO2 emission is the main cause of this phenomenon. One step to reduce this vast amount of CO2 to slow down the global warming process to save our environment is to adsorb and sequestrate CO2. The significance of DESs in this domain can be influential because of their high efficiency and sustainability in the CO2 adsorption process.173,174

-

8.

Extraction of subquality natural gas usually leads to relatively high amounts of impurities, such as CO2, which have to be removed before usage. DES has the potential to capture and remove CO2 from natural gas. Thus, it is used as a low-cost and biodegradable gas sweetener in the gas industry.175

-

9.

The high thermal stability of DESs improves their ability to be used as a chemical additive or preflooding agent in the thermal enhanced oil recovery process. It improves the pure steam recovery by 12%. Produced oil has higher API gravity, lower sulfur, and more saturated hydrocarbons.176

-

10.

In the gas industry, hydrate formation is a major flow assurance obstacle. DESs have a unique ability to form a hydrogen bond with the water molecule. This makes them a novel hydrate inhibitor.177

-

11.

DES is used for the solubilization of water-insoluble drugs, transdermal drug delivery, inorganic nanoparticle synthesis, and designing polymeric and self-assembled drug carriers.178

-

12.

DESs are implemented as functional additives for starch-based plastics.179

-

13.

The production of cellulose derivatives involves the usage of DESs.180

-

14.

For the synthesis of biodiesel fuel from low-grade palm oil, DESs have been employed as catalysts.181

-

15.

In electrochemical operations, it is employed as an electrolyte in electroplating and electroless plating of metals, for example.182

-

16.

For enzyme-catalyzed epoxide hydrolysis, DESs are feasible cosolvents.183

-

17.

It is utilized to execute the biodiesel extraction machine.184

3.5. Environmental Aspects of DESs

Nowadays, DESs are considered to be the alternative to ILs. Compared to conventional ILs, DESs are relatively inexpensive, easy to synthesize, renewable, and good biocompatible organic solvents. DESs are generally touted as “green” simply because the components involved in their preparation are usually environmentally friendly.117 Also, they have been attracting scientific and technological attention due to their unique physical and chemical properties. This surging interest in DESs is attributed to their potential to be environmentally benign because of their nontoxic and biodegradable characteristics. The microbial breakdown of chemical substances is known as biodegradation. When opposed to chemical disintegration, biodegradation appears to be more environmentally safe.

A substance is called biodegradable if it is capable of being decomposed by bacteria or other living organisms, which helps them avoid pollution. A chemical should be biodegradable to be environmentally friendly. Understanding the ecological consequences and outcome of DESs requires a clear understanding of their biodegradability. Although few studies have been done on the safety of DES solvents, their nontoxic properties make them a more enticing solvent than classic ILs.185

Researchers tested the biodegradability of a variety of DESs. The closed bottle test was used by Zhao et al. to determine the biodegradability of 20 choline chloride-based DESs. After 28 days, all of the tested DESs had a biodegradation rate of >69.3%, indicating that they may all be termed biodegradable green solvents. The ability of the chemicals to cross the cell wall helps to understand their biodegradable potential. The rate of degradability for all of these DESs is considered to be attributable to the individual components used in DES synthesis of biodegradable substances such as choline chloride, urea, and glycerol.134Table 5 depicts the biodegradability rate of different DESs examined by the Closed Bottle test.

Table 5. Biodegradability of Different Types of DESs134.

| biodegradability

(%) |

|||||

|---|---|---|---|---|---|

| no. | DES and reference substance | 7 days | 14 days | 21 days | 28 days |

| 1 | ChCl/urea (1:2) | 39.7 ± 0.6 | 81.2 ± 0.7 | 90.3 ± 0.6 | 97.1 ± 0.7 |

| 2 | ChCl/acetamide (1:2) | 25.8 ± 0.5 | 62.5 ± 0.1 | 81.1 ± 0.6 | 89.5 ± 0.6 |

| 3 | ChCl/ethylene glycol (1:2) | 24.1 ± 0.5 | 58.2 ± 0.5 | 77.3 ± 0.5 | 81.9 ± 0.6 |

| 4 | ChCl/glycerol (1:2) | 46.3 ± 1.5 | 83.2 ± 0.6 | 90.9 ± 0.6 | 95.9 ± 0.7 |

| 5 | ChCl/1,4-butanediol (1:4) | 29.4 ± 0.8 | 51.6 ± 1.1 | 62.0 ± 0.1 | 73.6 ± 0.9 |

| 6 | ChCl/triethylene glycol (1:4) | 10.7 ± 1.5 | 29.7 ± 0.5 | 51.4 ± 0.3 | 69.3 ± 0.5 |

| 7 | ChCl/xylitol (1:1) | 31.6 ± 2.4 | 66.0 ± 0.6 | 77.6 ± 0.8 | 84.3 ± 0.6 |

| 8 | ChCl/d-sorbitol (1:1) | 37.4 ± 1.5 | 63.4 ± 0.4 | 80.1 ± 0.6 | 86.2 ± 0.5 |

| 9 | ChCl/p-toluenesulfonic acid (1:1) | 32.3 ± 1.4 | 72.8 ± 0.4 | 76.3 ± 2.1 | 80.4 ± 0.3 |

| 10 | ChCl/oxalic acid (1:1) | 40.6 ± 0.4 | 61.4 ± 0.5 | 65.0 ± 0.4 | 73.4 ± 1.5 |

| 11 | ChCl/levulinic acid (1:2) | 33.9 ± 0.8 | 49.4 ± 1.0 | 67.2 ± 0.5 | 74.2 ± 2.2 |

| 12 | ChCl/malonic acid (1:1) | 34.6 ± 1.3 | 50.2 ± 0.6 | 60.8 ± 1.6 | 76.3 ± 1.3 |

| 13 | ChCl/malic acid (1:1) | 37.9 ± 0.9 | 62.9 ± 0.7 | 73.3 ± 0.6 | 79.4 ± 1.0 |

| 14 | ChCl/citric acid (1:1) | 39.5 ± 1.3 | 65.3 ± 1.6 | 75.0 ± 0.8 | 81.6 ± 0.7 |

| 15 | ChCl/tartaric acid (2:1) | 54.2 ± 1.4 | 76.4 ± 0.6 | 81.3 ± 1.0 | 84.6 ± 0.3 |

| 16 | ChCl/xylose/water (1:1:1) | 50.8 ± 1.3 | 70.6 ± 0.3 | 82.0 ± 1.1 | 89.7 ± 0.7 |

| 17 | ChCl/sucrose/water (5:2:5) | 55.6 ± 0.4 | 68.0 ± 1.9 | 87.4 ± 1.8 | 91.6 ± 0.3 |

| 18 | ChCl/fructose/water (5:2:5) | 48.4 ± 0.5 | 73.6 ± 1.3 | 88.2 ± 1.6 | 93.7 ± 1.3 |

| 19 | ChCl/glucose/water (5:2:5) | 58.6 ± 1.2 | 77.4 ± 1.0 | 89.4 ± 1.0 | 92.0 ± 0.4 |

| 20 | ChCl/maltose/water (5:2:5) | 53.0 ± 0.8 | 73.7 ± 2.0 | 84.6 ± 1.2 | 90.0 ± 0.5 |

| 21 | sodium benzoate | 57.9 ± 1.0 | 62.8 ± 1.1 | 79.0 ± 0.2 | 81.5 ± 0.7 |

The biodegradability of DESs appeared to be influenced by the HBD used: The order of amine-based DESs, sugar-based DESs, alcohol-based DESs, and acid-based DESs varied.134 Also, according to prior research, DESs made from ethylene and glycol are more biodegradable than DESs formed from glycerol as hydrogen bond donors.186,187 Choline chloride-based salts have lower toxicity than ethylene ammonium chloride-based salts.188

DESs were shown to be more carcinogenic than their constituents in several trials. Charge delocalization is considered to be the cause of this abnormality. Charge decolonization proceeds between the HBD and HBA during the development of a hydrogen bond between the DESs’ components. Delocalized charge compounds are generally more hazardous than localized charge chemicals.189−191

3.6. Prospects and Challenges of DESs

The purpose of DESs is to reduce the use and generation of hazardous substances, primarily through the promotion of innovative research on the creation of sustainable technologies. This is due to adaptability, low vapor pressure, good recyclability, low cost, chemical and thermal stability, and ease of preparation.117,192−195 DESs have hit the mainstream over the last two decades. There has been more research done to further investigate the field of numerous applications and the potential of DESs, which will serve the globe as a new and alternative solvent to the conventional one.196−199 DESs have been used in processes including greenhouse gas capture, alternate media for catalyzed reactions, analytical chemistry microextraction, stationary phase separation, therapeutic applications, and so on.200−205 Most of these solvents are nonflammable, biodegradable, and less toxic, making them environmentally beneficial.38,155,206,207 Most of these solvents have been proven to be practically eco-friendly.190,208,209 As a result, they are gaining some traction as a viable alternative to toxic solvents. DESs have been identified as low-cost IL replacements. Another concern is that ILs are expensive, yet they are only required in extremely low concentrations. Despite this, current research has revealed that the use of ILs has negative environmental consequences.210,211 On the contrary, recent studies have shown that cholinium-based liquids are less hazardous and more sustainable chemicals.212 In that case, cholinium-based DESs may be a feasible alternative to ILs.

One of the greatest impediments to the widespread usage of ionic liquids in the industry is the high expense of manufacturing them. This is mostly due to the high cost of raw ingredients as well as the time-consuming preparation and purification processes. Since with widely obtainable components producing DESs on a large scale is simpler, DESs have been found as low-cost substitutes for ILs.145 Conventional inorganic salts are inexpensive, but they must be used in high concentrations to obtain optimal inhibitory results. Based on prior research on shale swelling inhibitors, it is obvious that when compared to conventional shale swelling inhibitors including KCl, PDA, and others the amount of DESs required to suppress the rate of shale swelling is quite low.213−215 As a result, when compared to typical inhibitors, the quantity of DESs required is reduced. This lowers the cost of inhibitors. It is also less expensive than conventional ionic liquids.117 Studies showed that the swelling rate was reduced by 43.02% using traditional KCl, which had a concentration of roughly 5 wt %. With similar concentrations, DESs such as urea-DES, gly-DES, oxa-Des, and cit-DES reduced the swelling rate of the Na-bent sample by 29.38%, 21.57%, 37.31%, and 39.66%, respectively.216

Here are some of the challenges regarding this burgeoning field of interest, which are associated with today’s greatest considerations. The formulation of structure–property correlations for these DESs is becoming progressively vital to understanding their possibilities in transdisciplinary disciplines. DESs are, nonetheless, progressing steadily in the sphere of a fundamental understanding.125 The chemical composition of the different components determines the properties of DESs, which can be tuned by changing the constituent entities. Because of this, DESs are often referred to as task-specific solvents.206 The high densities and viscosities of DESs compared to conventional solvents, which could be a barrier on a large scale or in continuous-flow operations, are a significant drawback acknowledged by some studies.194 The behavior of DES mixtures and how this influences DES characteristics, specifically viscosity, which is still a major limitation of hydrophilic DES, should be studied in detail.217

The hygroscopic properties of the major DESs require more investigation since they may have an impact on the ability to stabilize and store these solvents. Studies showed that due to the hygroscopic nature of DESs stringent humidity control is required during storage and handling in order to obtain reliable data and products.218 According to studies, the inclusion of water in DESs significantly reduces the viscosity and alters the polarity, conductivity, density, and solvation qualities.219−221 So, to regulate and get the intended qualities, it will be necessary to operate DESs in a controlled environment and clearly define the target product profiles (TPPs) and related critical quality attributes (CQAs).222

4. DES as a Swelling Inhibitor

Researchers have already invented numerous compounds after many years of investigation, which were introduced as fracturing fluids to alleviate the challenging issues associated with shale swelling, including amine derivatives, surfactants, polymers, and other organic and inorganic salts. They can prevent water from combining with clay minerals, but their use is constrained by a variety of factors, including inadequate inhibitive efficacy, cost, and environmental considerations.51,52,54 A typical shale swelling inhibitor comprising more than 2% KCl will have a chloride content of more than 9500 ppm. On the contrary, surface discharge of salt brines comprising more than 3000 ppm chloride on lease or 1000 ppm chloride off lease is generally prohibited by most regulatory legislation.223 Considerations regarding managing and mixing huge amounts of salts, as well as the environmental implications of discarding unused saltwater and producing fracturing water, have encouraged researchers to look into novel clay stabilizing compounds.85 Researchers have already investigated several types of DESs as swelling inhibitors. Studies show that the inhibition ability of any type of DES is measured by determining the rheological properties, linear swelling test, XRD diffraction analysis, hot-rolling recovery test, zeta potential test, particle size distribution, surface tension measurement, and so on.214,216,224 Hence, most of the test experiments were done using a shale sample of Na-bentonite. Table 6 recapitulates all the standings and conditions under which the inhibition performance assessments were done and testified information presented by the former studies using numerous types of DESs. As previously mentioned, bentonite clay is relatively more swellable than any other clay particles. So, Na-bent was intentionally taken into account to find out the best performance given by the DESs as a swelling inhibitor. The inhibitory function of DESs was attributed to its intense electrostatic interaction and hydrogen bonding with Na-bent. DESs are adsorbed on the surface and interlayers of Na-bent, compressing the diffuse electric double layer and restricting Na-bent dispersion, attributable to choline cations, OH, COOH, NH2, and other functional groups.214,216,224

Table 6. Performance Evaluation of DESs as Potential Swelling Inhibitor.

| no. | author | inhibitor | abbreviated name | shale sample used | conc. (wt %)/pres. (MPa)/temp. (°C) | swelling reduction (%) | recovery rate (%) | yield point (Pa) | apparent viscosity (mPa.s) | zeta potential (mV) | XRD (Å) | surface tension (mN/m) | particle size distribution (μm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | Ma et al. (2021) | urea-choline chloride | urea-DES | Na-bent | 1–5/5/90–150 | 43.33 | NA | NA | 5–22 | –8.7 | 1.3–1.4 | 64.64 | 6–69.24 |

| 02 | Ma et al. (2021) | glycerol- choline chloride | gly-Des | Na-bent | 1–5/5/90–150 | 58.84 | NA | NA | 4–124 | –1.73 | 1.42–1.43 | 54.51 | 9–111.70 |

| 03 | Ma et al. (2021) | oxalic-choline chloride | oxa-DES | Na-bent | 1–5/5/90–150 | 28 | NA | NA | 0.7–6 | –4.12 | 1.39–1.44 | 61.38 | 6–287 |

| 04 | Ma et al. (2021) | citric-choline chloride | cit-DES | Na-bent | 1–5/5/90–150 | 23.34 | NA | NA | 1–8 | –1.96 | 1.41–1.43 | 64.90 | 7–97.58 |

| 05 | Jia et al. (2019a) | urea-choline chloride | CU-DES | Na-bent | (0.05–2) w/v%/10/25–160 | 69.54 | 75–82 | 9–49 | 10–67 | –32 to −16 | 14.36–18.46 | NA | 1–105.58 |

| 06 | Jia et al. (2019a) | urea-choline chloride | CU-DES | shale powder | (0.05–2) w/v%/10/25–160 | 72.64 | NA | NA | NA | NA | NA | NA | NA |

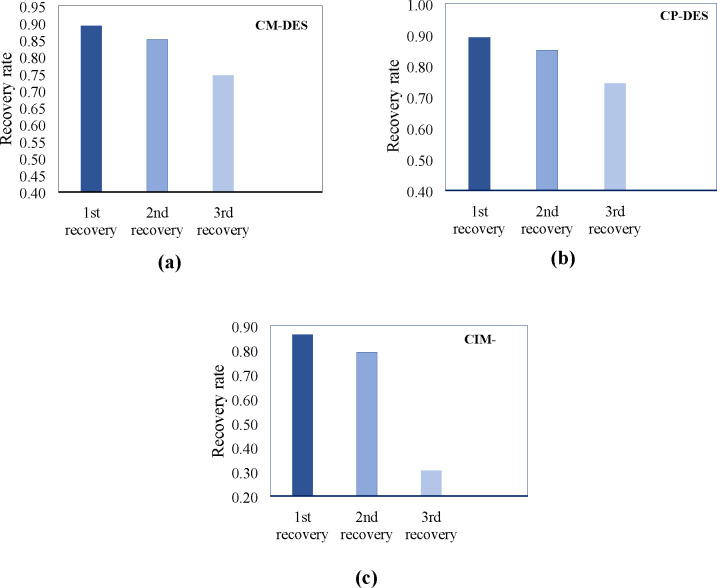

| 07 | Jia et al. (2019b) | choline chloride-propanedioic acid | CM-DES | Na-bent | 0.05–2/10/70–160 | 50–60 | 74–86.95 | 10–88 | 10–102 | –21.20 | 13.28–15.25 | 68–72.19 | 4–172 |

| 08 | Jia et al. (2019b) | choline chloride-3-phenylpropionic acid | CP-DES | Na-bent | 0.05–2/10/70–160 | 36–71 | 89–90.94 | 9–54 | 9–61 | –15.20 | 13.70–14.71 | 40.91–61.56 | 6–179 |

| 09 | Jia et al. (2019b) | choline chloride-itaconic acid and 3-mercaptopropionic acid | CIM-DES | Na-bent | 0.05–2/10/70–160 | 53–62 | 84–89.27 | 8–66 | 10–77 | –18.90 | 13.95–15.09 | 64–71.13 | 8–225 |

| 10 | Beg et al. (2021) | tetrabutyl ammonium bromide- diethanolamine | DES-I | Na-bent | NA | NA | NA | 33–66 | 29.78–59.47 | NA | NA | NA | NA |

| 11 | Beg et al. (2021) | tetrabutyl ammonium bromide- diethylene glycole | DES-II | Na-bent | 0.05–1/68.95/25–105 | NA | NA | 39.80–72.98 | 33.45–62.12 | NA | NA | NA | NA |

4.1. Rheological Parameter Analysis of Several DESs

In general, the rheological parameters are measured to know the deformation and flow behavior of any fluid. Drilling and fracturing fluids’ rheological qualities are examined on a regular basis in the petroleum industry. In addition, these properties are also used to analyze the antiswelling ability of chemicals. Clay particles absorb the water and rapidly swell once they are dispersed in water.225 In a dispersion system, the plate-like clay particles can be compounded together in three different ways, such as face-to-face (FF), edge-to-face (EF), and edge-to-edge (EE).226 The flat surface of these plate-like particles has negative charges, whereas the edges have positive charges. The dominating EF pair may build the spatial structure when the Na-bent is disseminated in water and hydrated. The constant structure of Na-bent in the dispersion system raises viscosity and therefore the yield stress value, which is accountable for considerably increasing the fluid’s flow resistance. So, it can be included that increasing swelling in clay particles resulted in a higher value of viscosity, which eventually resists the fluid flow. The system’s viscosity will increase with a higher Na-bent content in the dispersion.213 So, lower apparent viscosity (AV) and yield point (YP) values indicate a more effective inhibitor. Inhibitors are used to reduce the swelling rate of shale formation during drilling and other operations. After adding inhibitors to Na-bent, rheological parameters including AV and YP may be determined, and the inhibitors’ inhibitory ability can be easily assessed. Several studies showed that when Na-bent content reaches about 20 wt % the sample becomes too viscous to measure the AV and YP. According to research on swelling inhibitors, introducing inhibitors to shale reduces the rate of swelling. As a result, the viscosity and yield point are minimized.

Ma et al. (2021) analyzed the rheological properties of Na-bent suspension with and without adding inhibitors.216 The experiment showed that the suspension of Na-bent with increasing concentration quickly became too viscous to measure the AV value without any inhibitor. However, after adding inhibitors, the value of AV increased sharply, indicating the degree of inhibition. At a temperature of 90 °C, the AV value of 5 wt % of Na-bent was 3.50 mPa.s, but with increasing concentration up to 15 wt % the AV value reached 82.44 mPa.s. A sharp increase in the AV value indicates that the Na-bent content greatly affects the AV value. Table 7 shows that the AV values of 15 wt % of Na-bent are 1.91 mPa.s, 2.10 mPa.s, 4.96 mPa.s, 7.82 mPa.s, 4.96 mPa.s, and 6.30 mPa.s for 5 wt % of cit-DES, oxa-DES, urea-DES, gly-DES, polyether amino, and KCl, respectively. So, these inhibitors effectively reduced the AV value. Due to the adsorption of inhibitors on the surface of clay Na-bent particles, the negative charges neutralized and eventually hindered the swelling of clay.1 This action resulted in lowering the AV value. We know that at higher temperature the rate of swelling increased, so this experiment was conducted at higher temperature to assess the thermal stability of studied inhibitors. From Table 7 at 150 °C temperature, the AV value of 20 wt % of Na-bent suspension without any inhibitors is 139.42 mPa.s. The AV values were reduced to 14.74 mPa.s, 9.21 mPa.s, 4.91 mPa.s, 4.61 mPa.s, 3.38 mPa.s, and 3.38 mPa.s after the addition of 5 wt % of KCl, polyether amino, urea-DES, gly-DES, oxa-DES, and cit-DES, respectively. All the chemicals exhibited good inhibitory ability. Among these six different types of inhibitors, cit-DES presented the finest performance in reducing the AV value of dispersed Na-bent. It also holds a thermal stability during the experiment. Though the four DESs showed good antiswelling potentiality, urea-DES perform worse than other DESs.

Table 7. Yield Point (YP) and Apparent Viscosity (AV) Values of Several Inhibitors (DESs).

| author | testing medium | temp (°C) | inhibitor conc. | clay conc. | YP (Pa) | AV (mPa.s) |

|---|---|---|---|---|---|---|

| Ma et al. (2021) | water | 90 | NA | 5 wt % | NA | 3.05 |

| Ma et al. (2021) | water | 90 | NA | 10 wt % | NA | 11.45 |

| Ma et al. (2021) | water | 90 | NA | 15 wt % | NA | 82.44 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 5 wt % | NA | 4.58 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 10 wt % | NA | 4.96 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 15 wt % | NA | 6.30 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 20 wt % | NA | 7.63 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 25 wt % | NA | 16.03 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 30 wt % | NA | 35.69 |

| Ma et al. (2021) | KCl | 90 | 5 wt % | 35 wt % | NA | 70.23 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 5 wt % | NA | 4.58 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 10 wt % | NA | 4.77 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 15 wt % | NA | 4.96 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 20 wt % | NA | 6.11 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 25 wt % | NA | 9.16 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 30 wt % | NA | 13.36 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 35 wt % | NA | 19.47 |

| Ma et al. (2021) | polyether amino | 90 | 5 wt % | 40 wt % | NA | 26.91 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 5 wt % | NA | 7.63 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 10 wt % | NA | 5.92 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 15 wt % | NA | 7.82 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 20 wt % | NA | 8.40 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 25 wt % | NA | 8.40 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 30 wt % | NA | 8.97 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 35 wt % | NA | 11.64 |

| Ma et al. (2021) | urea-DES | 90 | 5 wt % | 40 wt % | NA | 22.14 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 5 wt % | NA | 4.01 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 10 wt % | NA | 3.82 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 15 wt % | NA | 4.96 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 20 wt % | NA | 5.92 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 25 wt % | NA | 6.30 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 30 wt % | NA | 7.44 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 35 wt % | NA | 8.97 |

| Ma et al. (2021) | gly-DES | 90 | 5 wt % | 40 wt % | NA | 12.40 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 5 wt % | NA | 0.76 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 10 wt % | NA | 1.15 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 15 wt % | NA | 2.10 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 20 wt % | NA | 2.29 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 25 wt % | NA | 2.86 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 30 wt % | NA | 3.82 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 35 wt % | NA | 5.34 |

| Ma et al. (2021) | oxa-DES | 90 | 5 wt % | 40 wt % | NA | 6.30 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 5 wt % | NA | 1.34 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 10 wt % | NA | 0.76 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 15 wt % | NA | 1.91 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 20 wt % | NA | 2.29 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 25 wt % | NA | 3.44 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 30 wt % | NA | 4.39 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 35 wt % | NA | 5.92 |

| Ma et al. (2021) | cit-DES | 90 | 5 wt % | 40 wt % | NA | 8.40 |

| Ma et al. (2021) | water | 150 | 5 wt % | 5 wt % | NA | 4.30 |

| Ma et al. (2021) | water | 150 | 5 wt % | 10 wt % | NA | 11.67 |

| Ma et al. (2021) | water | 150 | 5 wt % | 15 wt % | NA | 48.52 |

| Ma et al. (2021) | water | 150 | 5 wt % | 20 wt % | NA | 139.42 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 5 wt % | NA | 4.30 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 10 wt % | NA | 3.07 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 15 wt % | NA | 13.21 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 20 wt % | NA | 14.74 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 25 wt % | NA | 22.11 |

| Ma et al. (2021) | KCl | 150 | 5 wt % | 30 wt % | NA | 60.50 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 5 wt % | NA | 3.38 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 10 wt % | NA | 5.83 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 15 wt % | NA | 7.98 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 20 wt % | NA | 9.21 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 25 wt % | NA | 12.28 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 30 wt % | NA | 17.81 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 35 wt % | NA | 35.01 |

| Ma et al. (2021) | polyether amino | 150 | 5 wt % | 40 wt % | NA | 57.12 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 5 wt % | NA | 7.98 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 10 wt % | NA | 5.53 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 15 wt % | NA | 4.61 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 20 wt % | NA | 4.91 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 25 wt % | NA | 5.53 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 30 wt % | NA | 6.45 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 35 wt % | NA | 10.13 |

| Ma et al. (2021) | urea-DES | 150 | 5 wt % | 40 wt % | NA | 17.20 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 5 wt % | NA | 4.30 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 10 wt % | NA | 3.99 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 15 wt % | NA | 4.30 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 20 wt % | NA | 4.61 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 25 wt % | NA | 4.91 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 30 wt % | NA | 4.61 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 35 wt % | NA | 8.91 |

| Ma et al. (2021) | gly-DES | 150 | 5 wt % | 40 wt % | NA | 14.13 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 5 wt % | NA | 1.84 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 10 wt % | NA | 3.69 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 15 wt % | NA | 3.69 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 20 wt % | NA | 3.38 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 25 wt % | NA | 4.30 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 30 wt % | NA | 5.22 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 35 wt % | NA | 7.98 |

| Ma et al. (2021) | oxa-DES | 150 | 5 wt % | 40 wt % | NA | 13.21 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 5 wt % | NA | 3.99 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 10 wt % | NA | 4.61 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 15 wt % | NA | 3.99 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 20 wt % | NA | 3.38 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 25 wt % | NA | 4.30 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 30 wt % | NA | 5.53 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 35 wt % | NA | 7.98 |

| Ma et al. (2021) | cit-DES | 150 | 5 wt % | 40 wt % | NA | 14.74 |

| Jia et al. (2019a) | DI water | 25 | NA | 4% | 11.81 | 15.78 |

| Jia et al. (2019a) | DI water | 25 | NA | 8% | 24.54 | 35.14 |

| Jia et al. (2019a) | DI water | 25 | NA | 12% | 55.61 | 78.88 |

| Jia et al. (2019a) | DI water | 25 | NA | 16% | 124.27 | 142.35 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 4% | 10.87 | 11.12 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 8% | 10.25 | 11.47 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 12% | 10.56 | 11.83 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 16% | 10.56 | 12.91 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 20% | 11.18 | 13.98 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 24% | 14.91 | 20.08 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 28% | 29.83 | 51.63 |

| Jia et al. (2019a) | KCl | 25 | 5 w/v % | 32% | 82.64 | 102.19 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 4% | 9.32 | 10.40 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 8% | 9.94 | 11.12 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 12% | 10.56 | 11.83 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 16% | 10.25 | 12.19 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 20% | 10.25 | 12.91 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 24% | 12.43 | 17.21 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 28% | 24.85 | 38.37 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 32% | 46.29 | 69.20 |

| Jia et al. (2019a) | PDA | 25 | 2 w/v % | 36% | 90.72 | 114.38 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 4% | 10.87 | 10.76 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 8% | 10.25 | 10.76 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 12% | 10.25 | 11.47 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 16% | 10.25 | 12.91 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 20% | 10.87 | 14.34 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 24% | 11.50 | 17.21 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 28% | 22.37 | 40.88 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 32% | 42.25 | 67.77 |

| Jia et al. (2019a) | ChCl | 25 | 1 w/v % | 36% | 73.32 | 102.91 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 4% | 9.63 | 10.40 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 8% | 9.94 | 11.12 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 12% | 9.94 | 11.47 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 16% | 9.94 | 12.55 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 20% | 10.56 | 13.63 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 24% | 11.18 | 15.78 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 28% | 14.91 | 18.65 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 32% | 18.64 | 22.23 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 36% | 23.61 | 36.57 |

| Jia et al. (2019a) | CU-DES | 25 | 1 w/v % | 40% | 49.71 | 67.05 |

| Jia et al. (2019b) | water | 70 | NA | 5% | 11.51 | 16.10 |

| Jia et al. (2019b) | water | 70 | NA | 10% | 50.02 | 63.90 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 5% | 9.16 | 11.43 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 10% | 9.39 | 12.21 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 15% | 10.57 | 12.99 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 20% | 14.32 | 21.30 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 25% | 33.35 | 45.71 |

| Jia et al. (2019b) | KCl | 70 | 5 w/v % | 30% | 104.50 | 126.75 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 5% | 8.69 | 9.87 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 10% | 8.69 | 10.39 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 15% | 8.92 | 11.95 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 20% | 11.04 | 15.58 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 25% | 23.48 | 30.65 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 30% | 51.66 | 67.27 |

| Jia et al. (2019b) | PDA | 70 | 2 w/v % | 35% | 109.43 | 121.56 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 5% | 9.39 | 10.91 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 10% | 9.16 | 11.43 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 15% | 9.39 | 12.47 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 20% | 10.80 | 12.73 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 25% | 14.56 | 16.88 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 30% | 28.65 | 31.95 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 35% | 50.72 | 58.70 |

| Jia et al. (2019b) | CM-DES | 70 | 1 w/v % | 40% | 88.30 | 102.08 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 5% | 9.16 | 9.35 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 10% | 8.92 | 10.13 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 15% | 9.39 | 10.39 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 20% | 9.63 | 10.65 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 25% | 10.10 | 14.55 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 30% | 16.20 | 19.22 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 35% | 26.54 | 33.77 |

| Jia et al. (2019b) | CP-DES | 70 | 1 w/v % | 40% | 54.48 | 61.56 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 5% | 8.69 | 10.91 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 10% | 8.92 | 11.43 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 15% | 9.63 | 11.43 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 20% | 10.57 | 12.47 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 25% | 16.20 | 18.70 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 30% | 21.60 | 25.97 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 35% | 41.33 | 45.97 |

| Jia et al. (2019b) | CIM-DES | 70 | 1 w/v % | 40% | 66.22 | 77.14 |