Abstract

A series of t-butyloxycarbonyl (t-Boc) protected tetraphenylsilane derivatives (TPSi-Bocx, x = 60, 70, 85, 100%) were synthesized and used as resist materials to investigate the effect of t-Boc protecting ratio on advanced lithography. The physical properties such as solubility, film-forming ability, and thermal stability of TPSi-Bocx were examined to assess the suitability for application as candidates for positive-tone molecular glass resist materials. The effects of t-Boc protecting ratio had been studied in detail by electron beam lithography. The results suggest that the TPSi-Bocx resist with different t-Boc protecting ratios exhibit a significant change in contrast, pattern blur, and the density of bridge defect. The TPSi-Boc70% resist achieves the most excellent patterning capability. The extreme ultraviolet (EUV) lithography performance on TPSi-Boc70% was evaluated by using the soft X-ray interference lithography. The results demonstrate that the TPSi-Boc70% resist can achieve excellent patterning capability down to 20 nm isolated lines at 8.7 mJ/cm2 and 25 nm dense lines at 14.5 mJ/cm2. This study will help us to understand the relationship between the t-Boc protecting ratio and the patterning ability and supply useful guidelines for designing molecular resists.

Introduction

As predicted by Moore’s Law, the density of integrated circuits (ICs) has been improved exponentially for high-performance semiconductor devices1 and the photolithographic fabrication of nanoscale semiconductor devices requires increasingly high-resolution techniques.2,3 Extreme ultraviolet lithography (EUVL) and electron beam lithography (EBL) are key advanced lithographic technologies for the production of feature sizes lower than 20 nm.4−10 As the feature size decreases, the requirements for resists’ performance have gradually increased. It is still a great challenge to develop resist materials fulfilling all the requirements for advanced lithography such as high resolution (R) and sensitivity (S), low line edge roughness (LER), high etching resistance, and low outgassing.11−14 The traditional polymeric materials are unfavorable for achieving high-resolution lithographic patterns with low LER due to their characteristics, such as polydispersity, large molecular size, chain entanglement, and poor compatibility with photoacid generators (PAGs).15−18

Molecular glasses (MGs) are a new type of low-molecular-weight organic compounds with well-defined structures and functional groups.19−22 They combine both the merits of polymers and small molecules, such as monodispersity, amorphous character, high thermal stability, good compatibility with additives, and small dimensions.19−21,23,24 Combined with the concept of chemically amplified resists, molecular glass resists are expected to break through the trade-off of RLS (resolution, LER, and sensitivity).23−25 Up to now, most positive-tone MG resists are developed based on polyphenolic cores or rings with 100% protection of acid-labile groups. However, previous reports26−28 and our recent research23,24 demonstrated that MGs with complete protecting groups were unfavorable for high-resolution patterns. The excessive hydrophobicity of MGs may result in the defect of resist films,26 a poor adhesion to the substrate,27 and high density of blobs in patterns.28

To obtain high-quality lithographic patterns, the concept of partial protection of MGs is proposed. Partially protected MGs exhibit lower hydrophobicity, facilizing the wetting process with an alkaline developer. The unprotected hydroxyl groups in MGs enhance the adhesion to the substrate, which can avoid the peeling of the resist pattern during development.18,29 Furthermore, the partially protected MGs display a higher Tg compared to that of fully protected derivatives due to the intermolecular hydrogen bonding,30 which can alleviate the pattern collapse.31 Although partially protected molecular glass resists have been reported in several early literature studies,27,32,33 the effect of the protection ratios on lithographic performance and the reason for the difference are still to be further studied. Therefore, MGs with appropriate protecting ratios are important for development of high-performance resists.

Tetraphenylsilane (TPSi) has a branched and non-planar structure, which enables the formation of amorphous films. The modification of TPSi is facile.34−36 Up to now, TPSi derivatives have been extensively investigated in the organic optoelectronics35,36 and covalent organic framework,37 exhibiting excellent thermal stability and good film-forming characteristics. Herein, a series of TPSi derivatives with four different t-Boc protecting ratios (TPSi-Bocx, x = 60, 70, 85, 100%) were synthesized and characterized, as shown in Figure 1. They were used as positive-tone resist materials by mixing with photoacid generators (PAGs) and bases. The lithographic performances of these MG resists were extensively evaluated by using high-resolution EBL and EUVL.

Figure 1.

Structure of tetraphenylsilane derivatives with different protecting ratios.

Results and Discussion

Synthesis and Characterization of TPSi-Bocx

The procedure for synthesis of TPSi-Bocx (x = 60, 70, 85, 100%) is shown in Scheme S1. TPSi-Bocx with various t-Boc protecting ratios was obtained by controlling the feed ratio of di-tert-butyl dicarbonate (Boc2O) to the hydroxyl group. The 1H NMR spectra of all the products in DMSO-d6 are shown in Figure S1. TPSi-Boc100% exhibits two broad singlets at 1.48 and 1.47 ppm for the t-Boc protons (Ha) and a series of singlets between 8.04 and 7.40 ppm for the phenyl protons (Hb). The 1H NMR spectra of partially protective products (TPSi-Bocx, x = 60, 70, 85%) are similar to those of TPSi-Boc100%, and new protons at 10.00 and 9.94 ppm are observed, which is assigned to the unprotected hydroxyl. The degree of introduction (DI) of t-Boc is calculated from the integration ratio of phenyl protons at 8.1–6.7 ppm to the methyl protons of the t-Boc moiety at 1.5–1.4 ppm, giving the values of 59, 71, 85, and 100%. They are in good agreement with the feed ratio of Boc2O to TPSi-8OH calculated by 60, 70, 85, and 100%. The results are summarized in Table 1. It suggests that the t-Boc protective reaction can be controlled precisely to provide TPSi-Bocx with target protection ratios, which is necessary for the resist evaluation.

Table 1. Protecting Ratios and Thermal Properties of TPSi-Bocx.

| MGs | Boc2O feed ratio (%)a | DI (%)b | t-Boc weight percentage (%)c | weight loss (%)d | Td (°C)e |

|---|---|---|---|---|---|

| TPSi-Boc60% | 60 | 59 | 39 | 39 | 115 |

| TPSi-Boc70% | 70 | 71 | 42 | 43 | 124 |

| TPSi-Boc85% | 85 | 85 | 47 | 48 | 143 |

| TPSi-Boc100% | 100 | 100 | 51 | 52 | 152 |

The mol feed ratio of Boc2O to the hydroxyl group in TPSi-8OH.

DI of the t-Boc group calculated from 1H NMR.

Theoretical weight percentage of t-Boc in the TPSi-Bocx compound.

Weight loss upon thermal decomposition calculated by TGA.

The Td temperature at 5% weight loss in TGA curves.

To confirm the hydrogen bonding in the partially protected compounds, the FT-IR spectra of TPSi-Bocx (x = 60, 70, 85, 100%) were measured as shown in Figure 2. TPSi-Boc60% shows a broad peak around 3433 cm–1, confirming the presence of the unprotected hydroxyl group. With the increase of protecting ratio, the intensity of the broad peak gradually decreases and finally disappears, which completely agrees with the structure of TPSi-Bocx. The frequency of the broad peak shifted to higher wavenumber (from 3433 to 3495 cm–1) with increasing t-Boc protecting ratio, indicating a decreasing of hydrogen bonding.27 The characteristic absorptions at 1770 and 1294 cm–1 assigned to C=O and C–O–C stretching vibrations further confirmed the presence of t-Boc groups. It is anticipated that the presence of hydrogen bonding in TPSi-Bocx will contribute to the performance of resist materials.

Figure 2.

FT-IR spectra of TPSi-Bocx.

Thermal Behaviors of TPSi-Bocx

The thermal behaviors of TPSi-Bocx (x = 60, 70, 85, 100%) were investigated by thermogravimetric analysis (TGA) as shown in Figure 3. All the TPSi-Bocx (x = 60, 70, 85, 100%) compounds exhibit high thermal resistance and show a one-stage decomposition process at 115, 124, 143, and 152 °C, respectively. The tendency of thermal stability decreases with decreasing t-Boc protecting ratio (Table 1). This may be attributed to the fact that the acidic phenol group promotes the thermal decomposition reaction of TPSi-Bocx.26,38 The overall weight loss upon thermal decomposition is found to be consistent with the weight percentages of t-Boc groups in each case. This result is in good agreement with the DI measured by 1H NMR (Table 1). We try to get the glass-transition temperature (Tg) of TPSi-Bocx by differential scanning calorimetry (DSC) analysis. As an example, the corresponding DSC curve of TPSi-Boc70% is shown in Figure S2. No apparent Tg is observed before the onset of decomposition, indicating the thermal stability in the solid state below the decomposition temperature of 120 °C. The TGA and DSC measurements confirm that TPSi-Bocx can satisfy the requirements of two bake processes.

Figure 3.

TGA curves of TPSi-Bocx.

Solubility and Amorphous Characters

Solubility is the basic physical property for resist materials. The TPSi-Bocx (x = 60, 70, 85, 100%) compounds show good solubility in common organic solvents, such as ethyl acetate, tetrahydrofuran (THF), acetone, chloroform, and propylene glycol methyl ether acetate (PGMEA). It should be noted that TPSi-Boc60% is partly soluble in the developer of 2.38 wt % TMAH aqueous solution, which makes it unsuitable for positive resist materials.

To confirm the amorphous characteristic of TPSi-Bocx (x = 60, 70, 85, 100%), the powder X-ray diffraction (XRD) traces of TPSi-Bocx were recorded at room temperature (Figure 4a). It shows two broad peaks that are centered at 2θ = 12° and 18°. It suggests that TPSi-Bocx compounds are in the amorphous state and are suitable for spin-coating to form stable and uniform thin films. The spin-coated films are further investigated by atomic force microscopy (AFM). Figure 4b shows the surface topography of the TPSi-Boc70% film. The surface roughness of the TPSi-Boc70% film is only 0.32 nm in an area of 5 × 5 μm2. The other TPSi-Bocx compounds exhibit similar film properties. All these results indicate that TPSi-Bocx compounds are suitable for high-resolution lithography.

Figure 4.

(a) XRD analysis of TPSi-Bocx powder recorded at room temperature; (b) atomic force microscope image of the TPSi-Boc70% film.

Patterning Properties of the TPSi-Bocx Resists in EBL

The preliminary solubility studies indicate that the TPSi-Boc60% film is slightly soluble in 2.38 wt % TMAH aqueous solution before exposure, resulting in a reduction in image integrity upon development. Therefore, TPSi-Boc60% is not a candidate for positive-tone resist materials. The contrasts of TPSi-Bocx (x = 70, 85, 100%) resists in EBL were measured. The resist films were prepared under the general procedure (Experimental Section) and exposed on several squares (1.5 × 1.5 μm2) with varied doses of 5–666 μC/cm2. After baking and developing, the remaining thickness in each exposure square was measured by AFM. The contrast curves of TPSi-Bocx (x = 70, 85, 100%) resists are shown in Figure 5. The normalized remaining thickness (NRT) of the film first decreased slowly with an increase in dose and then decreased dramatically at a higher dose, indicating a gradual deprotection of the t-Boc groups. It is found that the contrasts (γ) of TPSi-Bocx (x = 70, 85, 100%) resists are 2.3, 1.7, and 1.4 with the dose to clear (D90) of 16, 20, and 12 μC/cm2, respectively (Supporting Information). It demonstrates that the protecting ratios of t-Boc groups in the molecules would affect the contrast of the resist. The TPSi-Boc70% resist exhibits the best performances in contrast, suggesting the potential to form high-resolution patterns.

Figure 5.

Contrast curves of TPSi-Bocx resists upon exposure to a 100 keV electron beam (initial thickness: 60 nm).

The lithographic performances of TPSi-Bocx (x = 70, 85, 100%) resists were further investigated by EBL. The details about the preparation of the resist films for lithographic evaluation can be found in the Experimental Section. Figure 6 shows the typical SEM configurations performed with half-pitch (HP) 40 and 30 nm layouts for the TPSi-Bocx (x = 70, 85, 100%) resists. All the three resists can resolve the HP 40 nm pattern with LERs of 3.6, 3.8, and 4.0 nm, respectively. The different LERs suggest that TPSi-Bocx resists with lower t-Boc protecting ratios have the potential to offer higher-resolution patterns.

Figure 6.

SEM images of the lines with half-pitches of 40 and 30 nm obtained using various kinds of resists with different t-Boc protecting ratios (film thickness: 45 nm).

In the case of the HP 30 nm pattern, the quality of the lithographic pattern is strongly correlated with t-Boc protecting ratios of TPSi-Bocx materials. The TPSi-Boc70% resist exhibits the best performance, and no obvious peeling, collapses or bridging is observed. The LER is only 3.8 nm. However, a slight peeling is observed in the TPSi-Boc85% resist patterns giving a larger LER of 4.2 nm. It is difficult to get HP 30 nm patterns for the TPSi-Boc100% resist because of the blurry pattern with obvious bridging, peeling, or collapse. The results suggest that the remaining hydroxyl groups in TPSi-Bocx (x = 70, 85%) help to improve the adhesion of the resist to the Si substrate and thus restrain the peeling or collapse of patterns.18,29 Moreover, the increase of hydrogen bonding also contributes to the alleviation of pattern collapse in TPSi-Boc70% and TPSi-Boc85% resists.

To further elucidate the effect of the protecting ratios of the t-Boc group on lithography, the cross-sectional SEM images of the lithographic patterns (HP 50 nm) were presented as shown in Figure 7. A significant correlation between residual in the trench and t-Boc protecting ratios of resists is observed. These lithographic stripes have good vertical profiles from cross-sectional images of the TPSi-Boc70% resist (Figure 7a). No footing is observed in the space areas, which may be derived from clean development. Compared with the TPSi-Boc70% resist, the TPSi-Boc85% resist exhibits an obvious residue in the trench (Figure 7b) and a slight footing is observed. In the case of the TPSi-Boc100% resist, local failure like bridge increases dramatically (Figure 7c). The results confirm that the unprotected hydroxyl group plays an important role in the lithographic patterns. It is speculated that the completely protected TPSi-Boc100% resist is too hydrophobic, which reduces the wettability of the developer to the resists. The relative contact angle (RCA) of resist films against water was measured, giving values of 75°, 79°, and 83° for TPSi-Boc70%, TPSi-Boc85%, and TPSi-Boc100% resist films, respectively (Figure S3). It suggests that lower protective ratios give higher hydrophilicity, which contributes to reducing microbridge and improving the resolution of patterns. On the other hand, a higher proportion of remaining hydroxyl groups in TPSi-Bocx means more hydroxyl groups after a similar exposure. As a result, the exposed area exhibits a higher solubility in the TMAH developer, which leads to a lower degree of resist residues in the trench. The TPSi-Boc70% resist with an appropriate ratio of t-Boc and hydroxyl groups is anticipated to give high-performance patterns. It is further confirmed by the different HP lithographic patterns. The pattern profiles and line shapes of 80, 60, and 40 nm HP layouts of the TPSi-Boc70% resist in EBL were also evaluated by cross-sectional SEM (Figure S4). A rectangular cross section is observed. The line width (LW) and period measured from the cross-sectional images are in complete agreement with the result from the top-view, which indicates that the TPSi-Boc70% resist is capable of forming patterns accurately.

Figure 7.

Cross-sectional views of dense lines with HP 50 nm patterns of (a) the TPSi-Boc70% resist, (b) TPSi-Boc85%, and (c) TPSi-Boc100% resist.

Patterning Properties of the TPSi-Boc70% Resist in EUV Lithography

The EBL confirmed the best performance of patterning properties of the TPSi-Boc70% resist. Subsequently, it was further examined by EUV lithography at the Swiss Light Source (SLS) and Shanghai Synchrotron Radiation Facility (SSRF). The contrast curve of the TPSi-Boc70% resist observed in EUVL is similar to that in EBL (Figure S5), giving the contrast and sensitivity of 2.2 and 16 mJ/cm2, respectively. Figure 8a shows the EUV patterning images of pitch 70 nm under various exposure doses, together with their line width (LW) and LER values. A clear 1:1 line and space pattern is obtained at an exposure dose of 11 mJ/cm2, which is comparable to the demands of the semiconductor industry for EUV resists.39−41 With the exposure doses increasing from 11 to 28 mJ/cm2, the LWs decrease from 35 to 24 nm due to the acid diffusion. This means that the line width of the lithographic pattern can be improved by over-exposure, while the LER value remains in the range of 3.6–3.9 nm. In the case of the pitch 60 nm pattern, similar results are obtained, and a clear line pattern with a LW of 20 nm is observed at a dose of 8.7 mJ/cm2 (Figure 8b). These lithographic results certify that the TPSi-Boc70% resist has the potential to achieve higher-resolution patterns down to 20 nm.

Figure 8.

(a) High-resolution SEM images of pitch 70 nm patterns for the TPSi-Boc70% resist at various exposure doses performed at SLS; (b) SEM image of 20 nm line width pattern for the TPSi-Boc70% resist performed at SSRF with the pattern of pitch 60 nm.

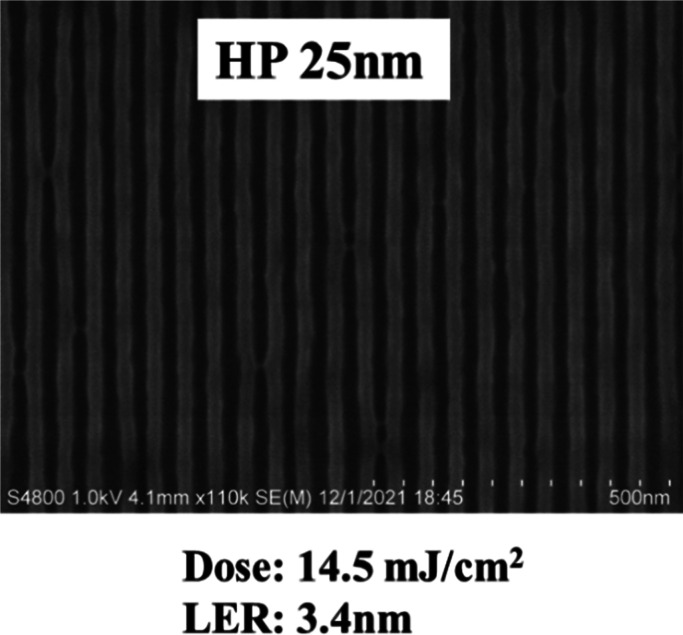

To confirm the capability of forming 1:1 line and space patterns, we further investigated TPSi-Boc70% resist performances by using a smaller feature size of HP 25 nm gratings. Figure 9 shows the typical configuration together with the exposure dose and LER. The clear resolved pattern of 25 nm lines with LER = 3.4 nm at a dose of 14.5 mJ/cm2 was obtained with the TPSi-Boc70% resist. It should be noted that outgassing is an important factor for EUV resist performance. Our previous report has revealed that the outgassing is primarily from the protecting groups and the molecular skeleton is stable almost without outgassing under the EUV exposure. Reducing the number of t-Boc groups of the resist material would decrease the outgassing.42 Actually, the outgassing of the molecular glass resist such as the spirobifluorene (SP-BOC) resist has been measured, suggesting that the molecular glass with eight t-Boc protecting groups gives an amount of 3.1 × 1015 molecules/cm2 at an exposure dose of ∼20 mJ/cm2.23 It is speculated that the outgassing of the TPSi-Boc70% resist would be smaller than that of the SP-BOC resist because reducing the number of protecting groups in molecules is expected to lead to a lower outgassing amount.43 The EUV lithographic performances demonstrate that the TPSi-Boc70% resist has the potential to be used in the semiconductor industry as EUV resist materials for the high resolution, sensitivity, and low LER.

Figure 9.

SEM images of line-and-space dense patterns of HP 25 nm performed at the SLS.

Conclusions

In summary, a series of molecular glasses based on TPSi derivatives with different t-Boc protecting ratios (TPSi-Bocx, x = 70, 85, 100%) were synthesized and characterized. The physical properties such as solubility, film-forming ability, and thermal stability are suitable for the application as positive-tone resists for advanced lithography. The EBL results indicate that t-Boc protecting ratios have a great influence on the performances of TPSi-Bocx resists. The TPSi-Boc70% resist exhibits the best performance with a resolution of 30 nm, LER of 3.8 nm, and contrast of 2.4. EUV lithography demonstrates that the TPSi-Boc70% resist can achieve excellent patterning capability down to 20 nm isolated lines at an exposure dose of 8.7 mJ/cm2 and 25 nm dense lines at an exposure dose of 14.5 mJ/cm2. It reveals that high-performance resists can be developed by appropriately modulating the t-Boc protecting ratios in MGs, giving useful guidelines for designing molecular resists.

Experimental Section

Materials and Instruments

All the standard reagents and chemicals were purchased from commercial sources and used without any further purification. Nuclear magnetic resonance (NMR) spectra were measured on an Avance ∏−400 (Bruker, Germany) by dissolving samples in DMSO-d6 and CDCl3. Thermogravimetric analysis (TGA) was recorded on a PerkinElmer TGA 4000 at a heating rate of 10 °C/min under a nitrogen atmosphere. Differential scanning calorimetry (DSC) analysis was recorded on a JCT-1 (Hengjiu, China) at a heating rate of 10 °C/min under a nitrogen atmosphere. High-resolution mass spectroscopy (HR-MS) was performed on a Solarix FT-ICR mass spectrometer (Bruker, Germany). Powder X-ray diffraction (PXRD) traces were obtained using a D8 focus XRD (Bruker, Germany) to examine the crystallinity of the bulk material. Fourier transform infrared (FT-IR) spectra were recorded by an Excalibur 3100 IR (Varian, USA). Top-view and cross-sectional scanning electron microscope (SEM) images were taken by an S4800 scanning electron microscope (Hitachi, Japan) or a Gemini SEM 360 scanning electron microscope (Zeiss, Germany). Atomic force microscope (AFM) images were taken by a Bruker Multimode 8 (Veco, USA). EB exposure experiments were performed on a Vistec EBPG 5000plus ES (Vistec, USA) at an acceleration voltage of 100 kV. Resist films were prepared by spin-coating with a CEE200X coating machine (Brewer Science CEE, USA). Resist film thickness was measured using an AST SE200-BM spectroscopic ellipsometer (Angstrom Sun, USA). A static contact angle of the resulting film against water was measured using a LAUDA Scientific OSA 200. EUV patterning properties of molecular resists were examined by using the soft X-ray interference lithography beamline (BL08U1B) on the Shanghai Synchrotron Radiation Facility (SSRF)44 and the XIL II Beamline of the Swiss Light Source (SLS). The line width (LW) and line edge roughness (LER) were measured by analyzing SEM images with ProSEM software.

Synthesis of TPSi-Bocx (x = 60, 70, 85, 100%)

TPSi-4Br

TPSi-4Br was prepared according to the literature.45 A colorless solid was obtained. Yield: 50% (5 g). 1H NMR (400 MHz, chloroform-d) δ (ppm) 7.81–7.75 (m, 2H, Ar-H), 7.64–7.35 (m, 16H, Ar-H). HRMS (EI) m/z: [M]+ calcd for C24H16Br4Si+ 651.7724, found 651.7714.

TPSi-8OMe

TPSi-4Br (6.65 g, 10.3 mmol), 3,4-dimethoxylphenlboronic acid (9.34 g, 51.3 mmol), and K2CO3 (28.52 g, 51.3 mmol) were added to a 200 mL Schlenk flask and then charged with 1,4-dioxane (90 mL) and deionized water (40 mL). The solution was evacuated and purged with nitrogen three times, and then tetrakis-(triphenylphosphine) palladium (237 mg, 0.21 mmol) was added under the nitrogen. The resulting mixture was stirred for 8 h at refluxing temperature under the protection of a nitrogen atmosphere. After being cooled to ambient temperature, the reaction was extracted with dichloromethane. The organic phase was washed with water and dried. The solvent was removed, and the residue was purified by repeated precipitation in ethanol. A white solid was obtained. Yield: 95% (12.6 g). 1H NMR (400 MHz, chloroform-d) δ (ppm) 7.79 (s, 6H, Ar-H), 7.72 (d, J = 7.0, 4H, Ar-H), 7.42 (d, J = 7.0, 6H, Ar-H), 7.13 (d, J = 8.2, 4H, Ar-H), 7.04 (s, 4H, Ar-H), 6.91 (d, J = 8.2, 4H, Ar-H), 3.90 (s, 12H, -OCH3), 3.82 (s, 12H, -OCH3). HRMS (ESI) m/z: [M + Na]+ calcd for C56H52NaO8Si+ 903.3324, found 903.3318.

TPSi-8OH

TPSi-8OMe (2.7 g, 3.07 mmol) was dissolved in CH2Cl2 (20 mL) and cooled to 0 °C with an ice bath. Then, boron tribromide (4.1 g, 16.3 mmol) dissolved in anhydrous CH2Cl2 (20 mL) was slowly introduced through a dropping funnel. After being cooled to ambient temperature, the resulting mixture was stirred for 2 h and quenched with excess water. The white precipitate was extracted with ethyl acetate. The organic phase was washed with water three times and dried. The solvent was removed, and a yellow foamy solid was obtained. Yield: 90% (2.1 g). 1H NMR (400 MHz, DMSO-d6) δ (ppm) 9.08 (s, 4H, Ar-OH), 9.01 (s, 4H, Ar-OH), 7.71–7.52 (m, 16H, Ar-H), 7.00 (s, 4H, Ar-H), 6.89 (d, J = 7.9, 4H, Ar-H), 6.79 (d, J = 7.9, 4H, Ar-H). HRMS (ESI) m/z: [M-H]− calcd for C48H35O8Si– 767.2101, found 767.2104.

General Procedure for the Synthesis of TPSi-Bocx (x = 60, 70, 85, 100%)

Taking the preparation of TPSi-Boc100% as an example, to a solution of TPSi-8OH (2.36 g, 3.07 mmol) and DMAP (0.075 g, 0.6 mmol) in THF (40 mL), di-tert-butyl dicarbonate (Boc2O) (5.36 g, 24.6 mmol) was added slowly using a dropping funnel. This mixture was stirred at room temperature for 3 h. The obtained solution was poured into dichloromethane and washed with dilute hydrochloric acid aqueous solution of PH = 5 and water. The organic layer was dried over Mg2SO4 and concentrated by a rotary evaporator. The concentrated solution was precipitated into a mixture of ethanol and water to obtain the white solid. The resulting precipitate was collected by vacuum filtration and dried at 50 °C in vacuo overnight. TPSi-Boc85%, TPSi-Boc70%, and TPSi-Boc60% were prepared using the same procedure just by changing the Boc2O amounts to 20.9, 17.2, and 14.7 mmol, respectively.

TPSi-Boc100% (protecting ratio: 100%). Yield: 88%. FTIR (KBr, cm–1): 2984 (ν C–H aromatic), 1770 (ν C=O ester), 1509 (ν C=C aromatic), 1294 and 1261 (ν C–O–C ether). 1H NMR (400 MHz, DMSO-d6) δ (ppm) 8.04 (s, 2H, Ar-H), 7.84 (s, 4H, Ar-H), 7.77 (s, 4H, Ar-H), 7.66 (s, 4H, Ar-H), 7.61 (d, J = 8.5, 4H, Ar-H), 7.50 (s, 6H, Ar-H), 7.40 (d, J = 8.4, 4H, Ar-H), 1.47 (d, J = 5.7, 72H, -OC(CH3)3). HRMS (ESI) m/z: [M + Na + K]2+ calcd for C88H100NaKO24Si2+ 815.2949, found 815.2949.

TPSi-Boc85% (protecting ratio: 85%). Yield: 90%. FTIR (KBr, cm–1): 3437 (ν OH), 2984 (ν C–H aromatic), 1770 (ν C=O ester), 1509 (ν C=C aromatic), 1294 and 1261 (ν C–O–C ether). 1H NMR (400 MHz, DMSO-d6) δ (ppm) 10.01–9.94 (m, 0.83H, Ar-OH), 8.04–6.95 (m, 28H, Ar-H), 1.47 (d, J = 5.7, 61H, -OC(CH3)3).

TPSi-Boc70% (protecting ratio: 70%). Yield: 90%. FTIR (KBr, cm–1): 3437 (ν OH), 2984 (ν C–H aromatic), 1770 (ν C=O ester), 1509 (ν C=C aromatic), 1294 and 1261 (ν C–O–C ether). 1H NMR (400 MHz, DMSO-d6) δ (ppm) 10.01–9.91 (m, 1.3H, Ar-OH), 8.04–6.87 (m, 28H, Ar-H), 1.47 (d, J = 5.7, 51H, -OC(CH3)3).

TPSi-Boc60% (protecting ratio: 60%). Yield: 90%. FTIR (KBr, cm–1): 3437 (ν OH), 2984 (ν C–H aromatic), 1770 (ν C=O ester), 1509 (ν C=C aromatic), 1294 and 1261 (ν C–O–C ether). 1H NMR (400 MHz, DMSO-d6) δ (ppm) 10.00–9.91 (m, 2.57H, Ar-OH), 8.04–6.79 (m, 28H, Ar-H), 1.47 (d, J = 5.7, 42H, -OC(CH3)3).

General Procedure for TPSi-Bocx (x = 70, 85, 100%) Resists and Film Preparation

The MGs were dissolved in propylene glycol methyl ether acetate (PGMEA) making a 30 mg/mL solution. A commercially available photoacid generator (PAG), triphenylsulfonium perfluoro-1-butanesulfonate (7.5 wt % with respect to MGs), and trioctylamine (0.375 wt % with respect to MGs) were added. It should be noted that the 7.5 wt % PAG content was selected for the TPSi-Boc resists according to our previous studies23,24 and other reports,27,38 to get a wide process window. The resist solution was filtered through a 0.22 μm membrane filter twice and spin-coated on a silicon wafer (3000–3500 rpm, 30 s) to form the thin film with a 38–45 nm thickness. Each 2-in. or 4-in. silicon wafer was primed with HMDS. A post-apply bake (PAB) of 100 °C for 180 s was applied to resist film using a hot plate to remove excess casting solvent PGMEA. The film was then exposed with an electron beam or EUV radiation. The post exposure baking (PEB) condition was set as 70 °C and 30 s for TPSi-Bocx resists referring to our previous reports about other MG resists.24,46 The film was developed with 2.38 wt % TMAH and then rinsed in deionized water before drying. The resulting patterns were observed using SEM or AFM.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (22090012, U20A20144, 21873106, 22073108, and 21903085). Chinese Academy of Sciences (CAS) is gratefully acknowledged. We also thank the National Center for Nanoscience and Technology for EBL experiments.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acsomega.2c03445.

NMR spectra, DSC curve, relative contact angles, SEM images, and contrast curve (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Moore G. E. Cramming more components onto integrated circuits. Proc. IEEE 2006, 11, 33–35. [Google Scholar]

- Miyazaki J.; Yen A. EUV Lithography Technology for High-volume Production of Semiconductor Devices. J. Photopolym. Sci. Technol. 2019, 32, 195–201. 10.2494/photopolymer.32.195. [DOI] [Google Scholar]

- Luo S.; Hoff B. H.; Maier S. A.; de Mello J. C. Scalable Fabrication of Metallic Nanogaps at the Sub-10 nm Level. Adv. Sci. 2021, 8, 2102756. 10.1002/advs.202102756. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li L.; Liu X.; Pal S.; Wang S.; Ober C. K.; Giannelis E. P. Extreme Ultraviolet Resist Materials for Sub-7 nm Patterning. Chem. Soc. Rev. 2017, 46, 4855–4866. 10.1039/C7CS00080D. [DOI] [PubMed] [Google Scholar]

- Gangnaik A. S.; Georgiev Y. M.; Holmes J. D. New Generation Electron Beam Resists: A Review. Chem. Mater. 2017, 29, 1898–1917. 10.1021/acs.chemmater.6b03483. [DOI] [Google Scholar]

- Sakai K.; Jung S. H.; Pan W.; Giannelis E. P.; Ober C. K. Metal Organic Cluster Photoresists for EUV Lithography. J. Photopolym. Sci. Technol. 2019, 32, 711–714. 10.2494/photopolymer.32.711. [DOI] [Google Scholar]

- Rathore A.; Pollentier I.; Cipriani M.; Singh H.; De Simone D.; Ingolfsson O.; De Gendt S. Extreme Ultraviolet-Printability and Mechanistic Studies of Engineered Hydrogen Silsesquioxane Photoresist Systems. ACS Appl. Polym. Mater. 2021, 3, 1964–1972. 10.1021/acsapm.1c00018. [DOI] [Google Scholar]

- Rathore A.; Pollentier I.; Singh H.; Fallica R.; De Simone D.; De Gendt S. Effect of molecular weight on the EUV-printability of main chain scission type polymers. J. Mater. Chem. C 2020, 8, 5958–5966. 10.1039/C9TC06482F. [DOI] [Google Scholar]

- Peter J.; Moinuddin M. G.; Ghosh S.; Sharma S. K.; Gonsalves K. E. Organotin in Nonchemically Amplified Polymeric Hybrid Resist Imparts Better Resolution with Sensitivity for Next-Generation Lithography. ACS Appl. Polym. Mater. 2020, 2, 1790–1799. 10.1021/acsapm.0c00005. [DOI] [Google Scholar]

- Manfrinato V. R.; Zhang L.; Su D.; Duan H.; Hobbs R. G.; Stach E. A.; Berggren K. K. Resolution Limits of Electron-Beam Lithography toward the Atomic Scale. Nano Lett. 2013, 13, 1555–1558. 10.1021/nl304715p. [DOI] [PubMed] [Google Scholar]

- Manouras T.; Argitis P. High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results. Nanomaterials 2020, 10, 1593. 10.3390/nano10081593. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Goldfarb D. L. Evolution of patterning materials towards the Moore’s Law 2.0 Era. Jpn. J. Appl. Phys. 2022, 61, SD0802. 10.35848/1347-4065/ac5534. [DOI] [Google Scholar]

- Kim S. K. Line-Edge Roughness from Extreme Ultraviolet Lithography to Fin-Field-Effect-Transistor: Computational Study. Micromachines 2021, 12, 1493. 10.3390/mi12121493. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Peng X.; Huang X.; Liu R.; Zhang Y.; Zhang S.; Liu Y.; Min Y. Photoresist Film-Forming Agent: Development and Future. Chin. J. Appl. Chem. 2021, 38, 1079–1090. [Google Scholar]

- Kang S.; Lavery K.; Choi K. W.; Prabhu V. M.; Wu W. L.; Lin E. K.; De Silva A.; Felix N.; Ober C. A comparison of the reaction-diffusion kinetics between model-EUV polymer and molecular-glass photoresists. Proc. SPIE 2008, 6923, 692317. [Google Scholar]

- Koyama M.; Imai K.; Shirai M.; Hirai Y.; Yasuda M. Effects of acid diffusion and resist molecular size on line edge roughness for chemically amplified resists in EUV lithography: computational study. Jpn. J. Appl. Phys. 2021, 60, 106505. 10.35848/1347-4065/ac26e5. [DOI] [Google Scholar]

- Toriumi M.; Itani T. Inhomogeneity of photoacid generators in methacrylate-type EUV resist film studied by molecular dynamics simulations. Jpn. J. Appl. Phys. 2015, 54, 06FE02. 10.7567/JJAP.54.06FE02. [DOI] [Google Scholar]

- Kudo H.; Watanabe D.; Nishikubo T.; Maruyama K.; Shimizu D.; Kai T.; Shimokawa T.; Ober C. K. A novel noria (water-wheel-like cyclic oligomer) derivative as a chemically amplified electron-beam resist material. J. Mater. Chem. 2008, 18, 3588–3592. 10.1039/b805394d. [DOI] [Google Scholar]

- De Silva A.; Felix N. M.; Ober C. K. Molecular glass resists as high-resolution patterning materials. Adv. Mater. 2008, 20, 3355–3361. 10.1002/adma.200800763. [DOI] [Google Scholar]

- Dai J.; Chang S. W.; Hamad A.; Yang D.; Felix N.; Ober C. K. Molecular Glass Resists for High-Resolution Patterning. Chem. Mater. 2006, 18, 3404–3411. 10.1021/cm052452m. [DOI] [Google Scholar]

- Nishikubo T.; Kudo H. Recent Development in Molecular Resists for Extreme Ultraviolet Lithography. J. Photopolym. Sci. Technol. 2011, 24, 9–18. 10.2494/photopolymer.24.9. [DOI] [Google Scholar]

- Yang D.; Chang S. W.; Ober C. K. Molecular glass photoresists for advanced lithography. J. Mater. Chem. 2006, 16, 1693–1696. 10.1039/b514146j. [DOI] [Google Scholar]

- Chen J. P.; Hao Q. S.; Wang S. Q.; Li S. Y.; Yu T. J.; Zeng Y.; Zhao J.; Yang S. M.; Wu Y. Q.; Xue C. F.; Yang G. Q.; Li Y. Molecular Glass Resists Based on 9,9’-Spirobifluorene Derivatives: Pendant Effect and Comprehensive Evaluation in Extreme Ultraviolet Lithography. ACS Appl. Polym. Mater. 2019, 1, 526–534. 10.1021/acsapm.8b00235. [DOI] [Google Scholar]

- Peng X. M.; Wang Y. F.; Xu J.; Yuan H.; Wang L. Q.; Zhang T.; Guo X. D.; Wang S. Q.; Li Y.; Yang G. Q. Molecular Glass Photoresists with High Resolution, Low LER, and High Sensitivity for EUV Lithography. Macromol. Mater. Eng. 2018, 303, 1700654. 10.1002/mame.201700654. [DOI] [Google Scholar]

- Yang D. X.; Frommhold A.; Xue X.; Palmer R. E.; Robinson A. P. G. Chemically amplified phenolic fullerene electron beam resist. J. Mater. Chem. C 2014, 2, 1505–1512. 10.1039/c3tc31896f. [DOI] [Google Scholar]

- Seki H.; Kudo H.; Oizumi H.; Itani T.; Nishikubo T. Extreme Ultraviolet Resist Fabricated Using Water Wheel-Like Cyclic Oligomer with Pendant Adamantyl Ester Groups. Jpn. J. Appl. Phys. 2011, 50, 121602 10.1143/JJAP.50.121602. [DOI] [Google Scholar]

- Chang S. W.; Ayothi R.; Bratton D.; Yang D.; Felix N.; Cao H. B.; Deng H.; Ober C. K. Sub-50 nm feature sizes using positive tone molecular glass resists for EUV lithography. J. Mater. Chem. 2006, 16, 1470–1474. 10.1039/b514065j. [DOI] [Google Scholar]

- Tsubaki H.; Arutani S.; Takizawa H.; Goto T. EUV resist materials for 20 nm and below half pitch applications. Proc. SPIE 2012, 8325, 832509. [Google Scholar]

- Takasuka M.; Okada Y.; Hayashi H.; Echigo M. Development of molecular resists based on Phenyl 4 calixarene for EBL. Proc. SPIE 2011, 7972, 797223. [Google Scholar]

- De Silva A.; Lee J. K.; André X.; Felix N. M.; Cao H. B.; Deng H.; Ober C. K. Study of the structure-properties relationship of phenolic molecular glass resists for next generation photolithography. Chem. Mater. 2008, 20, 1606–1613. 10.1021/cm702613n. [DOI] [Google Scholar]

- Oizumi H.; Tanaka Y.; KumiSe T.; Shiono D.; Hirayama T.; Hada H.; Onodera J.; Yamaguchi A.; Nishiyama I. Patterning capability of new molecular resist in EUV lithography. Microelectron. Eng. 2007, 84, 1049–1053. 10.1016/j.mee.2007.01.052. [DOI] [Google Scholar]

- André X.; Lee J. K.; De Silva A.; Felix N.; Ober C. K.; Cao H. B.; Deng H.; Kudo H.; Watanabe D.; Nishikubo T. Phenolic molecular glasses as resists for next generation lithography. Proc. SPIE 2007, 6519, 65194B. [Google Scholar]

- Young-Gil K.; Kim J. B.; Fujigaya T.; Shibasaki Y.; Ueda M. A positive-working alkaline developable photoresist based on partially tert-Boc-protected calix 4 resorcinarene and a photoacid generator. J. Mater. Chem. 2002, 12, 53–57. 10.1039/B106278F. [DOI] [Google Scholar]

- Fournier J. H.; Wang X.; Wuest J. D. Derivatives of tetraphenyl methane and tetraphenylsilane: Synthesis of new tetrahedral building blocks for molecular construction. Can. J. Chem. 2003, 81, 376–380. 10.1139/v03-056. [DOI] [Google Scholar]

- Li X.; Bai Q.; Li J.; Lu F.; Sun X.; Lu P. Synthesis and properties of wide bandgap polymers based on tetraphenylsilane and their applications as hosts in electrophosphorescent devices. New J. Chem. 2018, 42, 3344–3349. 10.1039/C7NJ04213B. [DOI] [Google Scholar]

- Sobarzo P. A.; Jessop I. A.; Mariman A. P.; González A. F.; Saldías C.; Schott E.; Zarate X.; Hauyon R. A.; Recabarren-Gajardo G.; González-Henríquez C. M.; Tundidor-Camba A.; Terraza C. A. New thiophene-based poly(azomethine)s bearing tetraphenylsilane moieties along their backbone. Optical, electronic, thermal properties and theoretical calculations. Eur. Polym. J. 2020, 130, 109658 10.1016/j.eurpolymj.2020.109658. [DOI] [Google Scholar]

- Zhang B.; Yan J.; Wang Z. Microporous Polybenzoxazoles with Tunable Porosity and Heteroatom Concentration for Dynamic Adsorption/Separation of CO2 Mixed Gases. J. Phys. Chem. C 2018, 122, 12831–12838. 10.1021/acs.jpcc.8b03031. [DOI] [Google Scholar]

- Niina N.; Kudo H.; Oizumi H.; Itani T.; Nishikubo T. Synthesis and property of noria (water-wheel like macrocycle) derivatives with pendant alkoxyl and adamantyl ester groups, and their application for extreme ultraviolet resist. Thin Solid Films 2013, 534, 459–464. 10.1016/j.tsf.2013.02.016. [DOI] [Google Scholar]

- Han J.; Lim H. S.; Kim J. H.; Choi S.; Shin J. B.; Bae C. W.; Yoo I. Y.; Shin B. H.; Lee E. K.; Joo H. S.; Seo D. C.; Chun J. S. The factors affecting improvement sensitivity, CDU, and resolution in EUV resist. Proc. SPIE 2014, 9048, 90482R. [Google Scholar]

- Luo C.; Xu C.; Lv L.; Li H.; Huang X.; Liu W. Review of recent advances in inorganic photoresists. RSC Adv. 2020, 10, 8385–8395. 10.1039/C9RA08977B. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang Z.; Yao X.; An H.; Wang Y.; Chen J.; Wang S.; Guo X.; Yu T.; Zeng Y.; Yang G.; Li Y. Recent Advances in Organic-inorganic Hybrid Photoresists. J. Microelectron. Manuf. 2021, 4, 21040101. [Google Scholar]

- Chen L.; Xu J.; Yuan H.; Yang S. M.; Wang L. S.; Wu Y. Q.; Zhao J.; Chen M.; Liu H. G.; Li S. Y.; Tai R. Z.; Wang S. Q.; Yang G. Q. Outgassing analysis of molecular glass photoresists under EUV irradiation. Sci. China-Chem. 2014, 57, 1746–1750. 10.1007/s11426-014-5122-y. [DOI] [Google Scholar]

- Sugie N.; Takahashi T.; Katayama K.; Takagi I.; Kikuchi Y.; Tanaka H.; Shiobara E.; Inoue S. Resist outgassing characterization based on the resist compositions and process. Proc. SPIE 2013, 8679, 86792E. [Google Scholar]

- Zhao J.; Yang S. M.; Xue C. F.; Wang L. S.; Liang Z. F.; Zhang L.; Wang Y.; Wu Y. Q.; Tai R. Z. The recent development of soft X-ray interference lithography in SSRF. Int. J. Extrem. Manuf. 2020, 2, 12005. 10.1088/2631-7990/ab70ae. [DOI] [Google Scholar]

- Chan L. H.; Lee R. H.; Hsieh C. F.; Yeh H. C.; Chen C. T. Optimization of high-performance blue organic light-emitting diodes containing tetraphenylsilane molecular glass materials. J. Am. Chem. Soc. 2002, 124, 6469–6479. 10.1021/ja0255150. [DOI] [PubMed] [Google Scholar]

- Hu S. W.; Chen J. P.; Yu T. J.; Zeng Y.; Guo X. D.; Wang S. Q.; Li Y.; Yang G. Q. A novel dual-tone molecular glass resist based on adamantane derivatives for electron beam lithography. J. Mater. Chem. C 2022, 10, 9858–9866. 10.1039/D2TC01339H. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.