Summary

Re-La2Zr2O7 are promising candidates to substitute Y2O3-stabilized ZrO2 (YSZ) in gas turbine engines. Here, we present a protocol for the deposition of LaSmZrO/YSZ/NiCoCrAlYHf thermal barrier coatings via arc ion-plating physical vapor deposition (AIP-PVD) and electron-beam physical vapor deposition (EB-PVD) technique. We describe the steps for specimen preparation via polishing and grit blasting and detail NiCoCrAlYHf bond coatings deposition via AIP-PVD and LaSmZrO and YSZ ceramic coatings deposition via EB-PVD. This protocol can be expanded to other multi-layer coatings deposition.

For complete details on the use and execution of this protocol, please refer to Shen et al. (2022a).

Subject areas: Chemistry, Material sciences

Graphical abstract

Highlights

-

•

Step-by-step protocol to obtain LaSmZrO/YSZ/NiCoCrAlYHf thermal barrier coatings

-

•

Procedures for preparation of specimens via polishing and grit blasting

-

•

Detailed procedures for NiCoCrAlYHf bond coatings deposition via AIP-PVD

-

•

Detailed procedures for LaSmZrO and YSZ ceramic coatings deposition via EB-PVD

Publisher’s note: Undertaking any experimental protocol requires adherence to local institutional guidelines for laboratory safety and ethics.

Re-La2Zr2O7 are promising candidates to substitute Y2O3-stabilized ZrO2 (YSZ) in gas turbine engines. Here, we present a protocol for the deposition of LaSmZrO/YSZ/NiCoCrAlYHf thermal barrier coatings via arc ion-plating physical vapor deposition (AIP-PVD) and electron-beam physical vapor deposition (EB-PVD) technique. We describe the steps for specimen preparation via polishing and grit blasting and detail NiCoCrAlYHf bond coatings deposition via AIP-PVD and LaSmZrO and YSZ ceramic coatings deposition via EB-PVD. This protocol can be expanded to other multi-layer coatings deposition.

Before you begin

The protocol below describes the specific steps for depositing of LaSmZrO/YSZ/NiCoCrAlYHf thermal barrier coatings on nickel-superalloy substrate. However, we have also used this protocol in other multi-layer coatings deposition.

Thermal-barrier coatings (TBCs) are complex thermal insulation systems made of metallic and ceramic coatings (Padture et al., 2002; Clarke et al., 2012; Levi, 2004). The widespread application has been necessitated with the development of manufacturing technology. Thermal plasmas and electron beams are two important energy sources for deposition processing (Sampath et al., 2012; Pollock et al., 2012). Electron-beam physical vapor deposition (EB-PVD) has been a complex TBCs deposition technology for rotating blades of advanced gas turbine engines, while atmospheric plasma sprays (APS) have been a standard TBCs deposition technology for stationary blades and afterburners of advanced gas turbine engines. This protocol uses the arc ion-plating physical vapor deposition (AIP-PVD) technology for NiCoCrAlYHf bond coatings. EB-PVD technology is used to deposit LaSmZrO ceramic coatings and YSZ ceramic coatings. Further knowledge on the deposition procedure of thermal barrier coatings can also be found in the literature (Liu et al., 2021; Shen et al., 2021, 2022b, 2022c).

Preparation of specimens for deposition

Timing: 2 weeks

-

1.

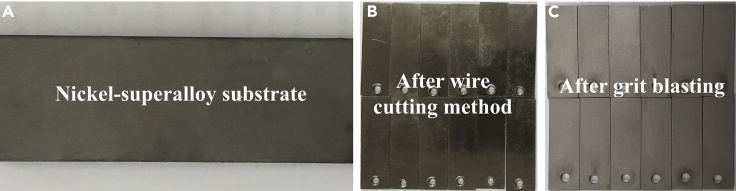

Cut the nickel-superalloy substrate materials into 30.0 mm × 10.0 mm × 1.0 mm via wire cutting method at speed below 1 mm/min (see Figures 1A and 1B).

-

2.

Polish the specimens with SiC papers (400, 600 and 1000 grit in turn). Troubleshooting 1.

-

3.

Follow the specimens by light grit blasting with 200 mesh alumina powders.

-

4.

Ultrasonically wash the specimens in distilled water for 30–60 min.

-

5.

Wash the specimens in distilled water and ethanol, and dry at 80°C–100°C for 30–60 min (see Figure 1C). Troubleshooting 2.

Figure 1.

The images of specimens

(A) Before wire cutting method, (B) After wire cutting method, (C) After grit blasting.

Key resources table

| REAGENT or RESOURCE | SOURCE | IDENTIFIER |

|---|---|---|

| Chemicals, peptides, and recombinant proteins | ||

| ZrO2 | Sigma-Aldrich | CAS: 1314-23-4 |

| Y2O3 | Sigma-Aldrich | CAS: 1314-36-9 |

| La2O3 | Sigma-Aldrich | CAS: 1312-81-8 |

| Sm2O3 | Sigma-Aldrich | CAS: 12060-58-1 |

| Ethanol | Sigma-Aldrich | CAS: 64-17-5 |

| Acetone | Sigma-Aldrich | CAS: 67-64-1 |

| Distilled water | Sigma-Aldrich | CAS: 7732-18-5 |

| Other | ||

| SiC papers | Beijing Dongxin Abrasive Tool Co., Ltd. | N/A |

Step-by-step method details

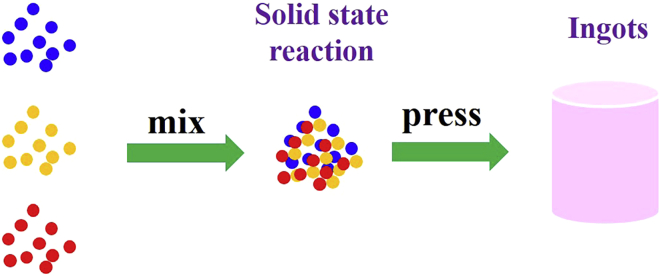

Fabrication of the ceramic ingots

Timing: 1 weeks

Synthesize the YSZ and LaSmZrO ceramic ingots by the oxide powders La2O3 (99.99%), ZrO2 (99.9%), Sm2O3 (99.99%) and Y2O3 (99.99%). The composition proportions of LaSmZrO ingots are about 45 at.% La, 5 at.% Sm, 50 at.% Zr and O as balance. The composition proportions of YSZ ingots are about 95 at.% Zr, 5 at.% Y and O as balance. (see Figure 2).

-

1.

Ball milled the appropriate proportions of oxide powders at a low speed of 50 r/min for 24 h.

-

2.

Synthesize the oxide powders by solid-state reaction at 1500°C to obtain the raw materials of ingots for 24 h.

-

3.

Mill the obtained raw materials in a high-energy ball mill at high speed of 2000 r/min for 12 h. Control the particle size of raw material from 10 μm to 50 μm.

-

4.

Dry the obtained raw materials under the atmospheric condition at 80°C–100°C for 24 h.

-

5.

Press the mixed raw materials by isostatic pressing under 150–200 MPa for 5 min.

-

6.

Sinter the mixed raw materials at 1200°C for 6 h under the atmospheric condition to obtain the ceramic ingots (see Figure 3).

-

7.

The diameter of the ceramic ingot is Φ 68.5 ± 0.5 mm, and the height of the ceramic ingot is 100 ± 5 mm. The porosity of the ceramic ingots is 30 ± 5%

-

8.

The heating rate is 10°C/min, and the cooling rate is 5°C/min during the sintering procedure.

CRITICAL: All reagents should be stored and used at room temperature (20°C–30°C) and dry environment (< 45%).

Figure 2.

A step by step schematic of the preparation of ceramic ingots

Figure 3.

The images of LaSmZrO ingots

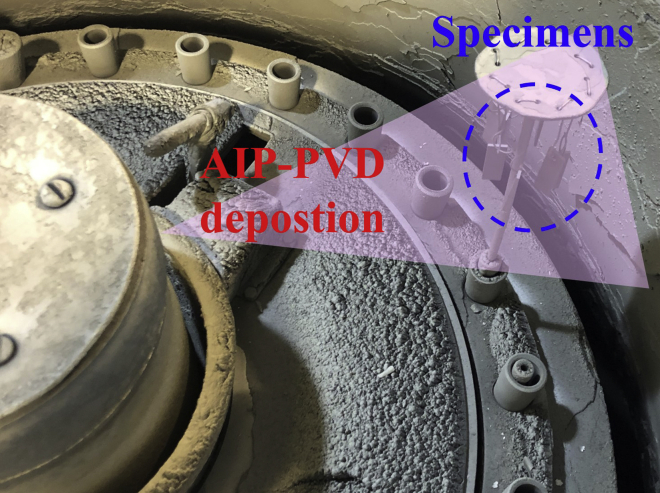

Deposition of NiCoCrAlYHf bond coatings

Timing: 2 days

Chose the NiCoCrAlYHf material for bond coatings and deposit bond coatings by AIP-PVD (A-1000, VIAM, Russia) (see Figure 4).

-

9.

Control the operating pressure below 5 × 10−2 Pa. Troubleshooting 3.

-

10.

Control the electric current at 650 A.

-

11.

Control the voltage at 20 V.

-

12.

Control the deposition time from 100 to 200 min.

-

13.

The deposition rate of NiCoCrAlYHf bond coatings is about 0.25 ± 0.5 μm/min.

-

14.

Treat the specimens with NiCoCrAlYHf bond coatings in vacuum heating process (VBF-30, Liyu Kiln, China).

-

15.

Control the operating pressured below 5 × 10−2 Pa. Troubleshooting 4.

-

16.

Control the heating temperature at 870 ± 10°C.

-

17.

Control the holding time within 3 h.

-

18.

Naturally cool the specimens to 30°C (see Figure 5).

Note: All surfaces of the specimens of the nickel-superalloy substrate should be polished and followed by lightly grit blasting.

CRITICAL: The specimens should be clean and dry in the AIP-PVD deposition process; otherwise, they affect the bond strength and failure of TBCs.

Figure 4.

Diagram of NiCoCrAlYHf bond coatings deposition via AIP-PVD

Figure 5.

The images of specimens

(A) Without NiCoCrAlYHf bond coatings, (B) With NiCoCrAlYHf bond coatings.

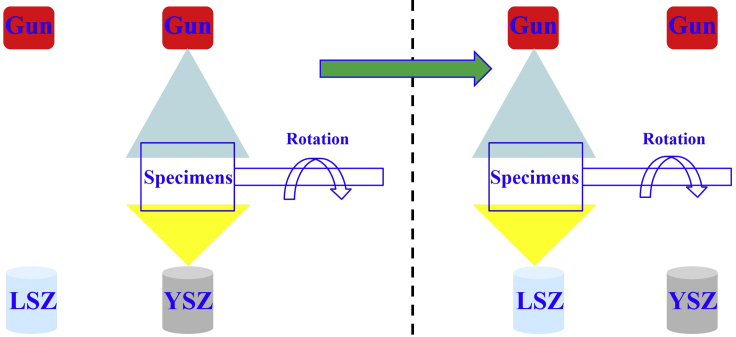

Deposition of YSZ and LaSmZrO ceramic coatings

Timing: 4 h

Chose the YSZ and LaSmZrO materials for ceramic coatings and deposit the ceramic coatings by EB-PVD (UE-207S, ICEBT, Ukraine) (see Figure 6).

-

19.

Before EB-PVD deposition, the EB-PVD equipment should need to work for a period of time to maintain the high vacuum (below 1 × 10−2 Pa) (see Figure 7A). Troubleshooting 5

-

20.

Heat the specimens to 850 ± 50°C by heating an electric gun.

-

21.

The rotation of specimens is 20 ± 5 rpm in the deposition process.

-

22.

Control the electric current at 1.1–1.5 A.

-

23.

Control the voltage at 20 kV.

-

24.

The deposition rate of YSZ coatings is about 3.5 ± 0.5 μm/min with the electric current about 1.3–1.5 A.

-

25.

The deposition rate of LaSmZrO coatings is about 3.0 ± 0.5 μm/min with the electric current about 1.1–1.3 A.

-

26.

Control the deposition time from 60 to 90 min.

-

27.

Naturally cool specimens to 30°C (see Figure 7B).

CRITICAL: The specimens should be clean and dry in the EB-PVD deposition process; otherwise, they affect the bond strength and failure of TBCs.

Figure 6.

Diagram of YSZ+LaSmZrO ceramic coatings deposition via EB-PVD

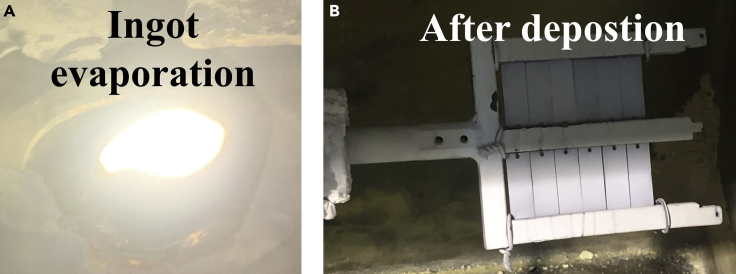

Figure 7.

The images of EB-PVD deposition process

(A) Ingot evaporation, (B) After YSZ+LaSmZrO ceramic coatings deposition.

Expected outcomes

This protocol provides the procedure for depositing LaSmZrO/YSZ/NiCoCrAlYHf thermal barrier coatings on nickel-superalloy substrate via AIP-PVD and EB-PVD. In this regard, we deposited the NiCoCrAlYHf bond coatings by controlling the electric current (650 A), voltage (20 V), and deposition time (100–200 min). After NiCoCrAlYHf bond coatings deposition, the heating treatment in vacuum pressure was introduced to NiCoCrAlYHf bond coatings. After that, we deposited the LaSmZrO+YSZ ceramic coatings by controlling the electric current (1.1–1.5 A) and deposition time (60–90 min). Furthermore, the ceramic coatings compatible with EB-PVD deposition were also demonstrated after a well-controlled fabrication of the ceramic ingots.

For thermal barrier coatings application, the LaSmZrO exhibited low thermal conductivity (1.69 W/mK at 800°C) and high thermal expansion coefficient (9.72 × 10−6 K-1 at 1500°C). In addition, the LaSmZrO/YSZ thermal barrier coatings exhibited an obvious feathery microstructure and relatively good thermal durability (Shen et al., 2022a). The thermal barrier coatings deposition protocol not only adds flexibility to ceramic coatings deposition but also results in thermal cycling life and thermal shock life. The protocol would be expanded to other multi-layer coatings deposition (Re-La2Zr2O7/YSZ, Re-Gd2Zr2O7/YSZ, and Re-ZrO2/YSZ) by controlling the EB-PVD process.

Limitations

The composition and morphology of ceramic coatings were sensitive to the electric current in EB-PVD deposition. However, the control standard of electric current was not extensively determined in EB-PVD deposition. Thus, the optimal parameters vary depending on the EB-PVD and AIP-PVD systems. The optimal parameters for each ceramic coating should be further established.

Troubleshooting

Problem 1

Difficulty polishing the surface of specimens with SiC papers (in ‘‘Preparation of specimens for deposition’’).

Potential solution

The specimens should be polished by SiC papers (400, 600 and 1000 grit in turn) with distilled water. After polishing, the roughness of specimens should be below 1.2 μm.

Problem 2

Difficulty determining the cleaning of the specimen’s surface before the AIP-PVD deposition process. (in ‘‘Preparation of specimens for deposition’’).

Potential solution

The specimens are followed by light grit blasting at least 20 min. After grit blasting and cleaning, the color of specimens should be uniform. The specimens should be free from stains and metallic luster (see Figure 1C).

Problem 3

Difficulty controlling the operating pressure in AIP-PVD deposition. (in ‘‘Deposition of NiCoCrAlYHf bond coatings’’).

Potential solution

Before NiCoCrAlYHf bond coatings deposition, the AIP-PVD equipment should be bombard the NiCoCrAlYHf target via high voltage (300V) and electric current (650A) for about 10–30 min to keep a high vacuum (below 5 × 10−2 Pa).

Problem 4

Difficulty controlling the operating pressure in vacuum heating process pressure. (in ‘‘Deposition of NiCoCrAlYHf bond coatings’’).

Potential solution

Before vacuum heating process pressure, the equipment should be maintained at 950°C for 24 h to keep a high vacuum (below 5 × 10−2 Pa).

Problem 5

Difficulty controlling the high vacuum in EB-PVD deposition. (in ‘‘Deposition of YSZ and LaSmZrO ceramic coatings’’).

Potential solution

Before EB-PVD deposition, the EB-PVD equipment should evaporate the YSZ ingot from 0 A to 1.5 A. After that, the electric current should be maintained at 1.5 A for about 30 min to keep a high vacuum (below 1 × 10−2 Pa).

Resource availability

Lead contact

Further information and requests for resources and reagents should be directed to and will be fulfilled by the lead contact, Zaoyu Shen (shenzaoyu@163.com).

Materials availability

This study did not generate new unique reagents.

Acknowledgments

This protocol is supported by Beijing Natural Science Foundation (2224107), the Young Elite Scientists Sponsorship Program of the China Association for Science and Technology, National Science and Technology Major Project (J2019-IV-0003-0070 and J2019-IV-0002).

Author contributions

Z.L.: conceptualization, experimental, writing – original draft; Z.Y.S.: investigation, funding, writing – original draft; G.X.L.: investigation; data curation, formal analysis.

Declaration of interests

The authors declare no competing interests.

Data and code availability

This study did not generate any datasets and code.

References

- Shen Z., Liu G., Zhang R., Dai J., He L., Mu R. Thermal property and failure behavior of LaSmZrO thermal barrier coatings by EB-PVD. iScience. 2022;25:104106. doi: 10.1016/j.isci.2022.104106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Padture N.P., Gell M., Jordan E.H. Thermal barrier coatings for gas-turbine engine applications. Science. 2002;296:280–284. doi: 10.1126/science.1068609. [DOI] [PubMed] [Google Scholar]

- Clarke D.R., Oechsner M., Padture N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012;37:891–898. [Google Scholar]

- Levi C.G. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004;8:77–91. [Google Scholar]

- Sampath S., Schulz U., Jarligo M.O., Kuroda S. Processing science of advanced thermal-barrier systems. MRS Bull. 2012;37:903–910. [Google Scholar]

- Pollock T.M., Lipkin D.M., Hemker K.J. Multifunctional coating interlayers for thermal-barrier systems. MRS Bull. 2012;37:923–931. [Google Scholar]

- Shen Z., Liu G., He L., Mu R., Dai J. Thermal property and failure behaviors of Gd doped LaZrCeO coatings with feathery microstructure. npj Mater. Degrad. 2022;6:17. [Google Scholar]

- Shen Z., Liu G., Dai J., Huang B., Mu R., He L. Thermal property and failure mechanism of LaDyZrO thermal barrier coatings by electron beam physical vapor deposition. Mater. Today Phys. 2022;24:100696. [Google Scholar]

- Liu Z., Shen Z., Liu G., He L., Mu R., Xu Z. Sm-doped Gd2Zr2O7 thermal barrier coatings: thermal expansion coefficient, structure and failure. Vacuum. 2021;190:110314. [Google Scholar]

- Shen Z., Liu G., Mu R., He L., Xu Z., Dai J. Effects of Er stabilization on thermal property and failure behavior of Gd2Zr2O7 thermal barrier coatings. Corros. Sci. 2021;185:109418. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

This study did not generate any datasets and code.