Abstract

Agricultural development, extensive industrialization, and rapid growth of the global population have inadvertently been accompanied by environmental pollution. Water pollution is exacerbated by the decreasing ability of traditional treatment methods to comply with tightening environmental standards. This review provides a comprehensive description of the principles and applications of electrochemical methods for water purification, ion separations, and energy conversion. Electrochemical methods have attractive features such as compact size, chemical selectivity, broad applicability, and reduced generation of secondary waste. Perhaps the greatest advantage of electrochemical methods, however, is that they remove contaminants directly from the water, while other technologies extract the water from the contaminants, which enables efficient removal of trace pollutants. The review begins with an overview of conventional electrochemical methods, which drive chemical or physical transformations via Faradaic reactions at electrodes, and proceeds to a detailed examination of the two primary mechanisms by which contaminants are separated in nondestructive electrochemical processes, namely electrokinetics and electrosorption. In these sections, special attention is given to emerging methods, such as shock electrodialysis and Faradaic electrosorption. Given the importance of generating clean, renewable energy, which may sometimes be combined with water purification, the review also discusses inverse methods of electrochemical energy conversion based on reverse electrosorption, electrowetting, and electrokinetic phenomena. The review concludes with a discussion of technology comparisons, remaining challenges, and potential innovations for the field such as process intensification and technoeconomic optimization.

1. Introduction

1.1. Conventional Methods of Water Purification

It is estimated that four billion people live in localities which are, for at least one month of the year, under conditions of severe water scarcity.1,2 One increasingly common method used to secure supplies of potable water is desalination, and so the development of desalination systems that are energy and infrastructure efficient is a critical technological challenge.3 In the most general sense, desalination is a process that is used to remove ions, colloidal particles, chemical compounds, and organic matter, referred to hereafter by the single term contaminants, from saline water. Existing methods for desalination can be broadly categorized into physical methods and chemical methods.3

Physical methods include distillation,4−6 freezing (or freeze–thaw) desalination,7,8 (liquid-phase) solvent extraction,9 membrane processes,10−12 solar desalination,13−15 and wave-powered desalination.16 Distillation, a process which appears to have been used by early experimentalists of the classical era such as Aristotle,17 involves separation of water from contaminants across the interface between a gas and a liquid by selective boiling and condensation. Modern implementations of this method include multi-stage flash distillation, multiple effect distillation, vapor compression, and humidification dehumidification, all of which are in essence a sequence of countercurrent heat exchangers.5,18−24 In a similar way to distillation, freezing desalination also uses a phase change (freezing and melting) to separate water from contaminants.25,26 Solvent extraction is used to separate contaminants based on their relative solubilities in two immiscible liquids, normally water (polar) and an organic solvent (nonpolar), where transport is driven by gradients in the chemical potential of the contaminants.27 Membrane processes are diverse in that the kind of (semipermeable) membrane used can be tuned based on the target contaminant from which the water is to be removed. These processes include microfiltration, ultrafiltration, nanofiltration, reverse osmosis (RO), and forward osmosis (FO), and they are distinct primarily in the pore sizes of the corresponding membrane.11,28−38 During operation, water is driven across a membrane by an input of mechanical work (or by a gradient in osmotic pressure in the case of FO) to retain the contaminants in a concentrated brine. Like distillation, solar desalination is said to have been employed by humans for thousands of years, originally by Greek mariners and Persian alchemists.39,40 The basis of this technology is not distinct from distillation or membrane processes; it is simply a means to generate the energy that these methods require: that is, heat for distillation or electricity for membrane processes. Wave-powered desalination is similar in principle to solar desalination methods in that it generates electricity (by the motion of submerged buoys in this case) to run a desalination process based on RO.16 Although these technologies are mature and are cost-effective for the desalination of seawater (as well as other concentrated solutions), they are inherently inefficient and energy intensive when used to treat dilute feeds or to selectively remove target contaminants from a concentrated feed, as explained in the following section. It is in these situations that selectively removing trace amounts of a desired species is preferable to indiscriminately concentrating all dissolved species in a brine.

Chemical methods, which tend to be selective in molecular separations, can be classified into two major types: the first, discussed in this section, involves no electrochemistry (i.e., the established chemical methods), and the second, introduced in sections 1.3 and 2, is based on electrokinetic and electrochemical phenomena. Established chemical methods include precipitation,41 coagulation flocculation,42 adsorption,43,44 ultraviolet, ozone, and chlorine disinfection,45 aeration,46 and ion exchange.47,48 Precipitation involves the creation of a solid (the precipitate) from a solution using a chemical referred to as the precipitant.49,50 Similarly, coagulation flocculation involves the addition of compounds (typically metallic salts) that promote the clumping of fines into larger floc, which can be readily separated from water by sedimentation, filtration, or flotation.51,52 Adsorption is a physicochemical phenomenon that is used to remove contaminants by binding them to the surfaces of an adsorbent material.44,53 Disinfection technologies in general are used to kill bacteria, viruses, and other disease-causing pathogens present in water. The most common disinfection treatments are based on ultraviolet radiation, chlorination, and ozonation, all of which inactivate the waterborne pathogen by disrupting its cellular functions.45 Aeration of water is achieved by passing air through the liquid and is typically used to remove iron or organic matter, dispel certain dissolved gases, or oxidize dissolved or suspended compounds.54,55 Ion exchange represents a broad class of processes where ions are exchanged between an electrolyte solution and a solid ion exchanger, such as polymeric resin, chelating agents, zeolites, clay, and montmorillonite.47,48,56−62 Ion exchange is in general a reversible process, where the ion exchanger is regenerated using a wash solution. Altogether, these traditional chemical methods are based on either chemical reactivity (precipitation, adsorption, and chelation), affinity for charged or functionalized surfaces (coagulation flocculation and ion exchange), or susceptibility to oxidative degradation (disinfection and aeration) of the contaminants.

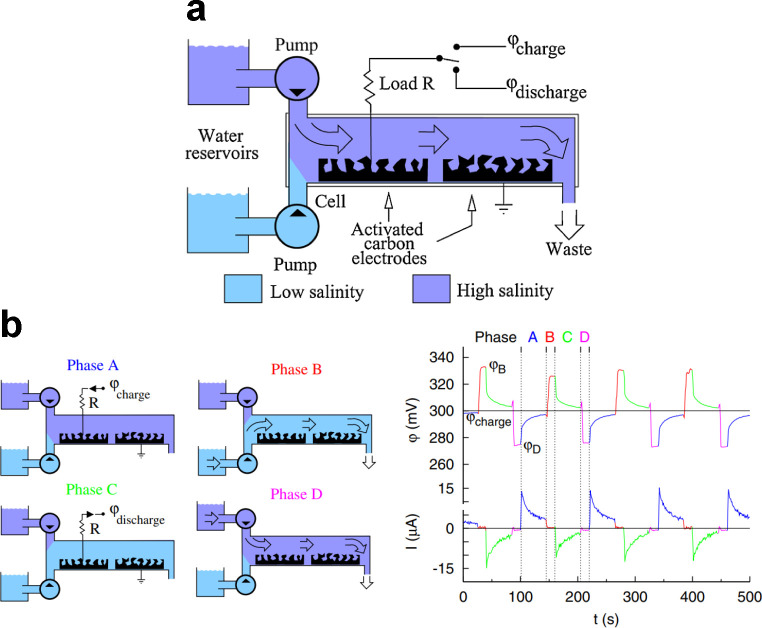

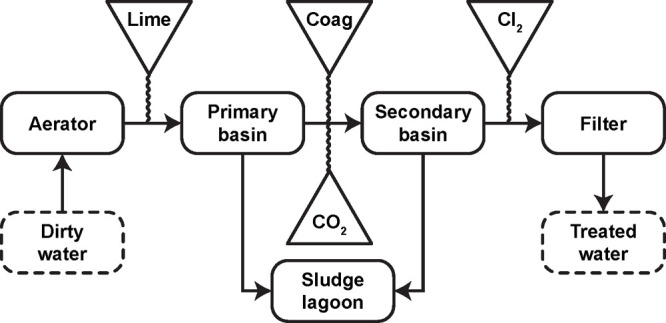

In practice, a water treatment process often combines several of the methods described above to improve the quality of water and make it suitable for a specific end use. Figure 1 shows the process diagram of a representative municipal water treatment facility, in which the water treated contains high levels of hardness and iron.63 As described in ref (63), raw water is taken from wells and sent to an aerator, where contact with air removes volatile solutes (e.g., H2S, CO2, CH4) and odorous substances (e.g., CH3SH, bacterial metabolites). Contact with oxygen further promotes iron removal by oxidizing soluble Fe(II) to insoluble Fe(III). After aeration, lime is added (as CaO or Ca(OH)2) to raise the pH and cause the precipitation of Ca2+ and Mg2+. Precipitates of these hardness ions settle from the water in the primary basin, and much of the remaining solid material is suspended and requires the addition of coagulants (e.g., Fe(III), Al2(SO4)3) to settle. Activated silica or synthetic polyelectrolytes (e.g., poly(sodium styrenesulfonate), poly(acrylic acid)) may also be added to induce coagulation or flocculation. Settling of colloidal particles occurs in the secondary basin after the addition of carbon dioxide to lower the pH. Sludge from both basins is then pumped to a lagoon, and the water is finally chlorinated, filtered, and pumped to the water mains.

Figure 1.

Process diagram of a representative municipal water treatment facility. This process combines several of the methods described in section 1.1 to improve the quality of water and make it suitable for domestic use. Adapted with permission from ref (63). Copyright 2001 CRC.

1.2. Limitations of Conventional Methods

Almost all of the methods introduced in section 1.1 have seen commercial success for a range of applications across numerous industries. Each of these methods, however, has applications and operating constraints outside of which the use of an alternative process would be more practical. For example, thermal distillation has historically been the dominant means of seawater desalination, but the most prevalent technology used today in large-scale desalination plants is RO because of its high energy efficiency and small footprint.33,64 This technology works by pumping the feed at pressures above the osmotic pressure of the solution through a membrane permeable only to water molecules (3–5 MPa for seawater).12 RO has been optimized over several decades of development for the desalination of concentrated feeds like seawater,38,65 and modern seawater RO (SWRO) plants currently require under 3 kW h m–3 of energy when including all pre- and post-treatment steps.66−69 While RO is the best available solution for city-scale seawater desalination, RO systems demonstrate poor scaling of energy demand with decreasing feed concentration, as demonstrated in Figure 2.70 For example, brackish water RO (BWRO) plants require nearly the same energy input as SWRO plants (1–3 kW h m–3), despite the fact that brackish water is less concentrated than seawater by about an order of magnitude.71 According to the van’t Hoff equation, osmotic pressure is linearly proportional to concentration for dilute solutions, which suggests that the energy demand for BWRO should be about an order of magnitude lower than for SWRO. Friction losses in RO systems, however, do not scale with salt concentration, but rather with the amount of water transported across the membrane. This intrinsic feature of RO explains the relatively high losses and poor energy efficiency of BWRO compared to SWRO.72 Because desalination of brackish water is a promising solution for water scarcity, and because removal of trace contaminants from dilute feeds is an important capability, technologies whose energy demand scales with feed concentration would be more desirable than RO for these applications.

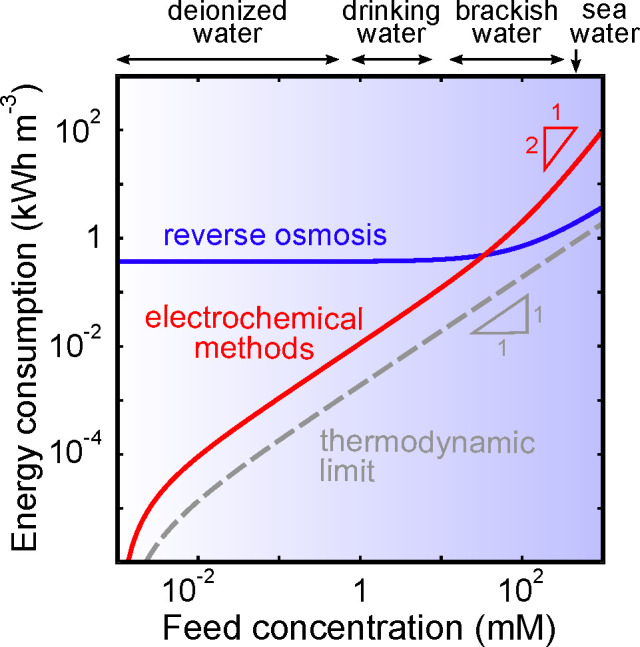

Figure 2.

Estimates of

the volumetric energy consumed by RO and a generic

electrochemical process based on the analysis in section 6.1, specifically eqs 17 and 18. These estimates assume that the feed is desalinated to a

final concentration of 1 μM; here, γ = 0.5 (water

recovery, defined as the fraction of the feed recovered as permeate)

and  10 L h–1 m–2 (productivity). Energies are compared

to the thermodynamic limit, represented by the dashed curve, and are

reported in units of kW h m–3 of diluate.

10 L h–1 m–2 (productivity). Energies are compared

to the thermodynamic limit, represented by the dashed curve, and are

reported in units of kW h m–3 of diluate.

Another notable drawback of RO plants is that they require large capital expenditures and mature infrastructure, which limits their utility for small-scale applications or in remote locations.66 Moreover, it is difficult to downscale RO systems because high-pressure pumps and resilient plumbing are required at any scale to pressurize the feed in excess of the osmotic pressure. Facile downscaling to smaller, less-expensive plants that can be introduced into small residential areas and communities would help water treatment technologies further penetrate the market. Inexpensive, small-scale plants may in fact be the most appropriate solution for developing and off-grid locations, where water scarcity is severe and commonplace, and where infrastructure may be underdeveloped or nonexistent. Small-scale portable desalination units are also in demand by industrial facilities, by mobile military units and vessels, in recreational spaces, and in the travel industry.73,74 To meet these growing and diverse needs for purified water, the technological focus should extend beyond RO by including scalable systems with lower energy demands and more flexible infrastructure requirements for treatment of brackish water and dilute feeds.

Many of the drawbacks of RO, particularly when used to treat dilute feeds, can be overcome by using the physicochemical methods introduced in section 1.1. These methods, however, have their own limitations and often require nonreusable chemicals. Solvent extraction can be both efficient and cost-effective in separating hazardous contaminants from benign feeds, but this process requires large volumes of organic extractants and sometimes toxic solvents, and the entrainment of phases yields low-quality effluents.75,76 Precipitation is another simple and cost-effective process that is commonly used to remove toxic heavy metals from water, but it produces large amounts of sediment and sludge that is often difficult and expensive to dispose of. Precipitation is also ineffective at removing ions that are present at low concentration, and its utility may be limited when the water is contaminated with multiple metals.76,77 Coagulation flocculation is often employed after precipitation to remove solid particulates from water, and this method could also be used to capture larger particles and inactivate biological agents.78,79 The applicability of this method is limited, however, because it requires nonreusable inorganic coagulants which are usually toxic.76,80 Ion exchange, on the other hand, offers a wider range of simple and well-established commercial products, many of which can be regenerated for repeated use.76,77,81 The performance of ion exchange resins and chelating agents, however, is sensitive to variations in pH, and some of these agents react with dissolved metal ions to form soluble metal complexes that lead to secondary pollution.76,77,82

1.3. Emerging Electrochemical Methods

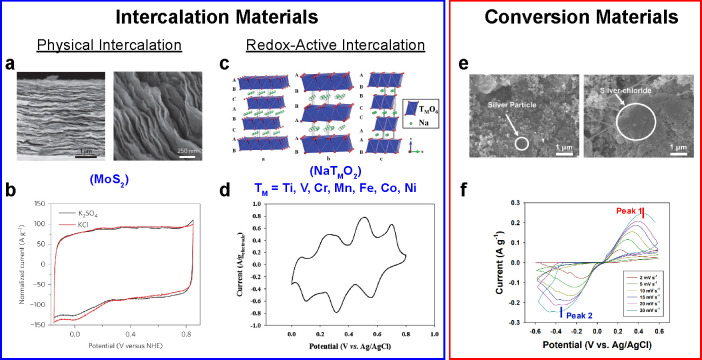

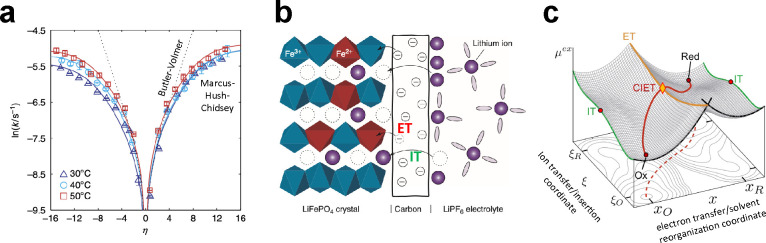

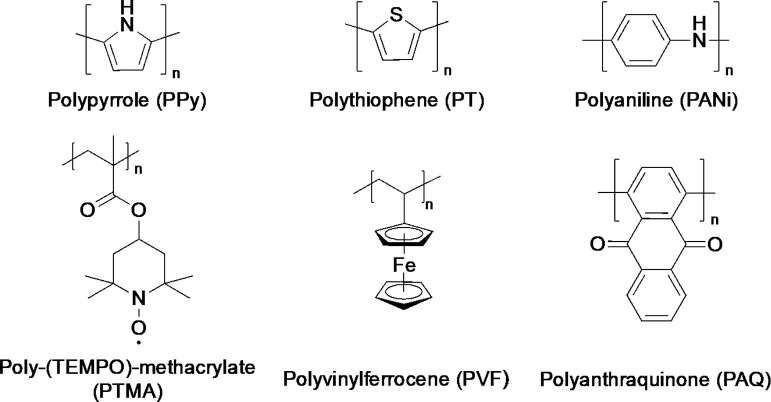

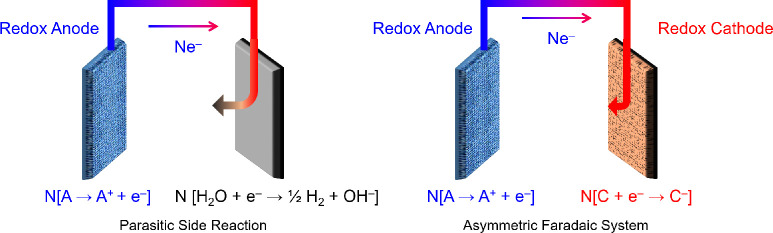

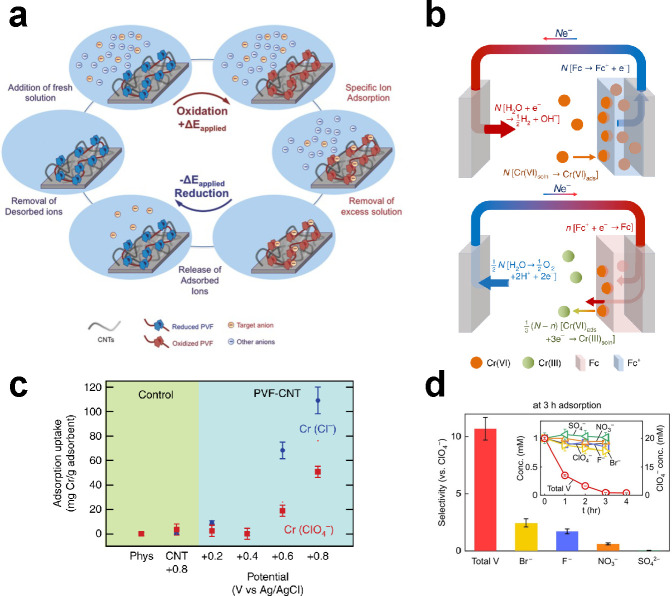

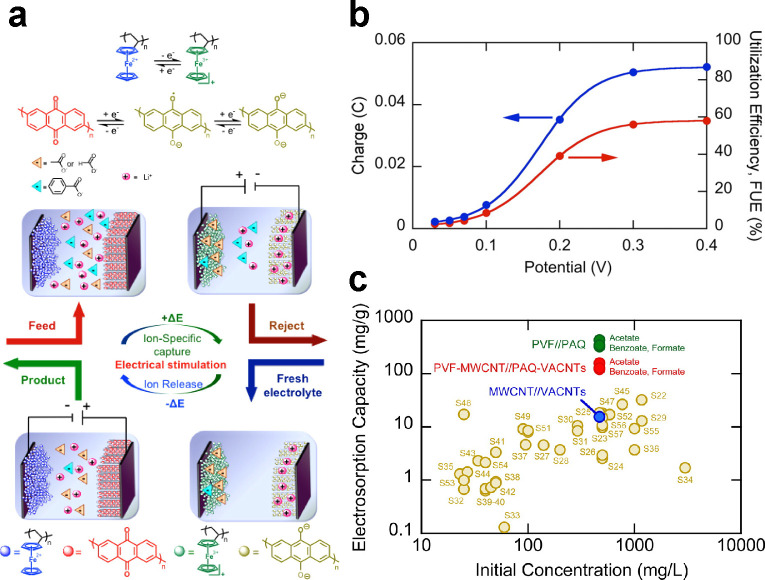

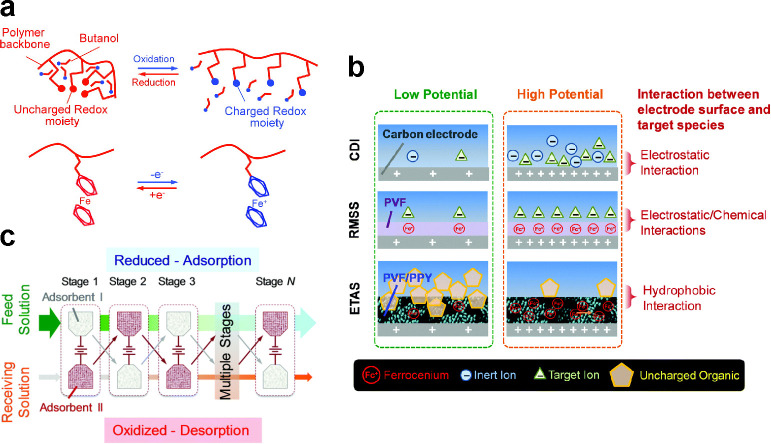

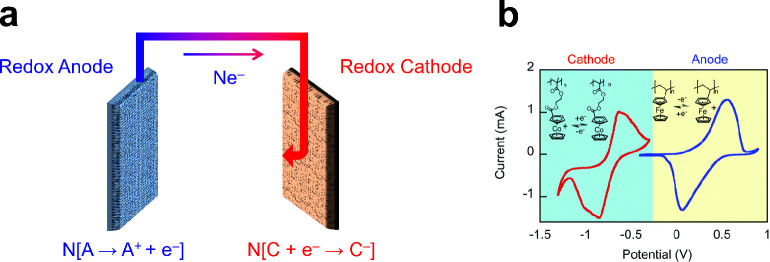

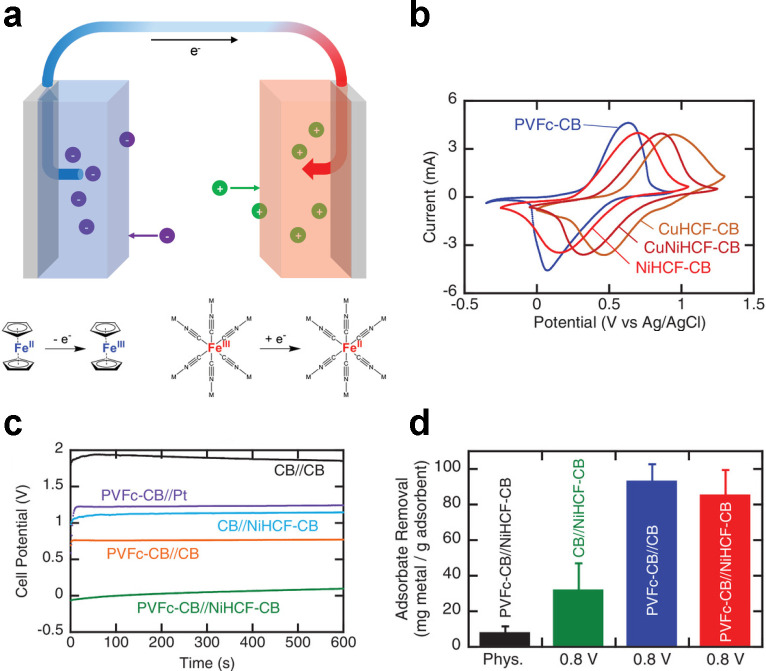

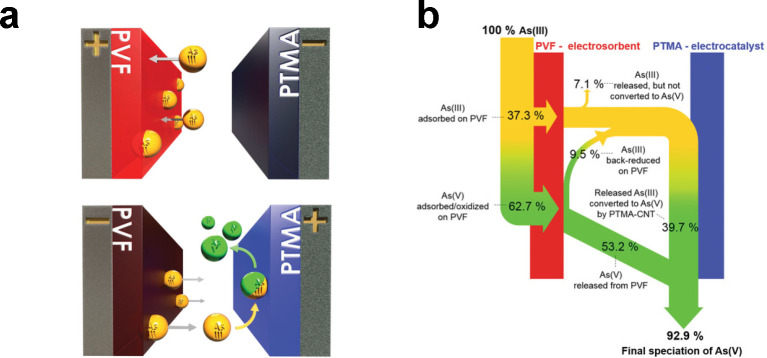

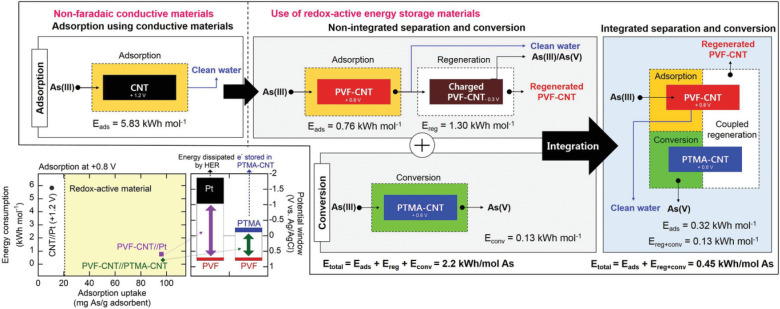

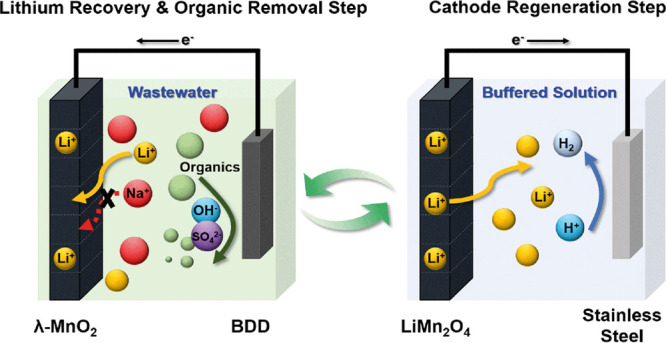

A variety of innovative techniques based either on electrokinetics or electrosorption have been proposed for water purification and ion separations, and these techniques have given rise to emerging electrochemical methods.83−91 The recent discovery of deionization shock waves in microchannels92,93 and porous media,87,94,95 for instance, inspired a new area of research in electrokinetic methods for deionization. Parallel developments in materials science have uncovered a wealth of novel electrode chemistries, where the electrosorption of ions is promoted by Faradaic reactions, to replace carbon, conventionally the material of choice in capacitive systems.86,96 These innovations have not only enhanced deionization capacity but have also imparted molecular selectivity to the electrodes. Recent examples of Faradaic platforms for water purification are based on electrochemical reduction of target contaminants,97,98 electrochemical switching of ion exchange,99−101 and molecularly selective removal of ions,86,96,102 uncharged compounds,103,104 and biomolecules (e.g., proteins).105 Many of these advances have relied on Faradaic compounds with immobilized surfaces to achieve superior electrochemical performance and chemical specificity. By modulating the binding interactions at the surfaces, the affinity of the electrodes can be tuned specifically for minority components in a feed, which in practice may be either highly valuable or seriously toxic.

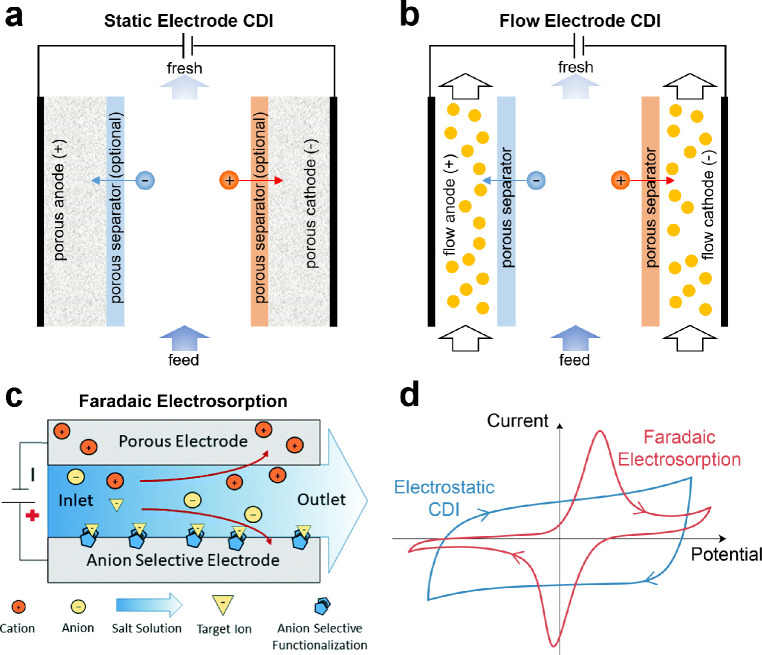

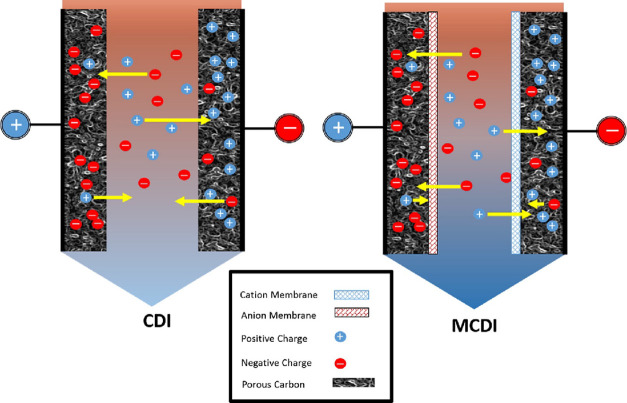

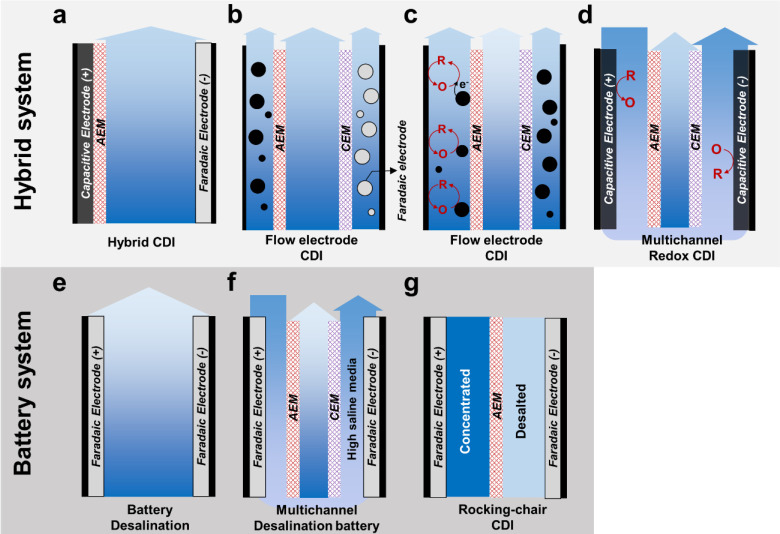

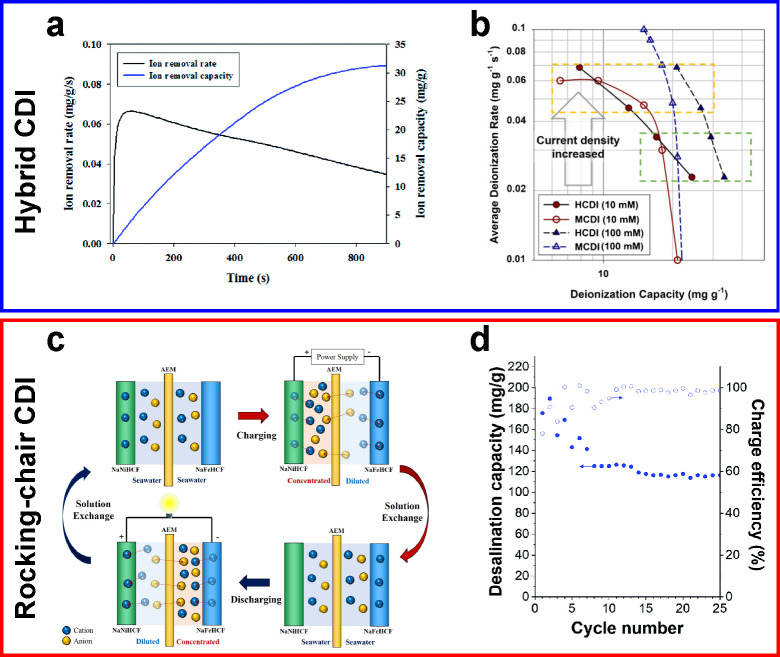

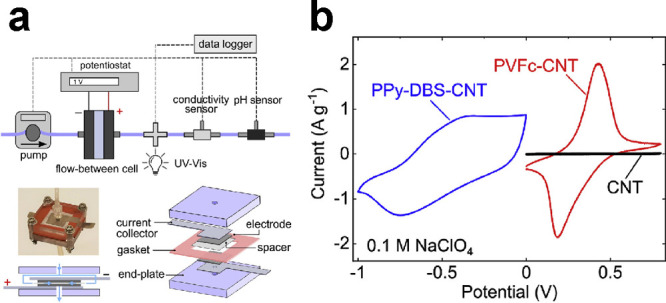

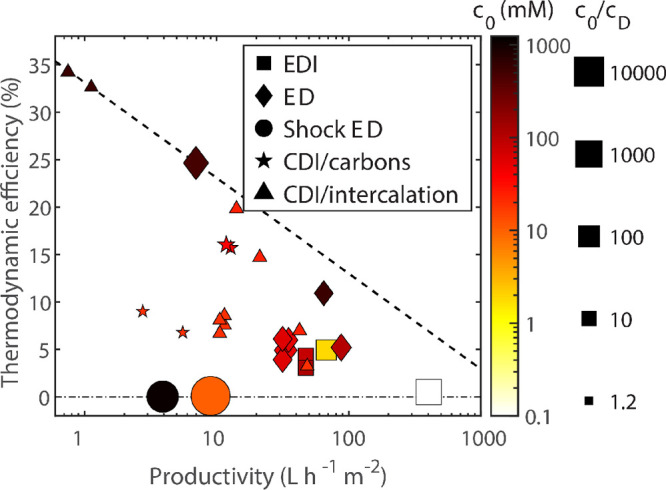

Emerging electrochemical methods include electrodeionization (EDI, sometimes called hybrid ion exchange ED),61,106−108 shock electrodialysis (shock ED),87,109 capacitive deionization (CDI),110,111 battery deionization (BDI),112,113 and Faradaic electrosorption.86,96 These technologies are unique from all of the others discussed so far in that removal of contaminants is based on their response to electric fields in solution or electrochemical reactions at electrodes. Electrochemical systems use applied electrical currents to remove contaminants from the feed by either driving separations in bulk electrolytes,61,114 electrochemically trapping them in electric double layers (EDLs),90,110,115 or intercalating them in solid electrodes (e.g., materials composed of two-dimensional, layered structures).116−118 The first of these mechanisms is governed by electrokinetics, and the second and third are forms of electrosorption, as explained in Figure 3. The primary input of energy to these systems is an applied electric potential, which makes these processes scalable without the need to be operated at extreme temperatures or pressures. Energy dissipation in electrochemical systems, however, arises from three general sources:357,1173 (i) ohmic resistance, due to hydrodynamic drag acting on moving ions in electrolytes or membranes,72 as well as electronic resistance in porous electrodes and current collectors; (ii) Faradaic reaction resistance at electrode–electrolyte interfaces, leading to activation overpotential; and (iii) concentration polarization, associated with limitations in ion diffusion. These losses all scale with the number of ions removed rather than the amount of solution process, as shown in Figure 2. These systems therefore tend to be more energy efficient compared to physical methods (and are molecularly selective) when used to treat brackish water and dilute feeds.

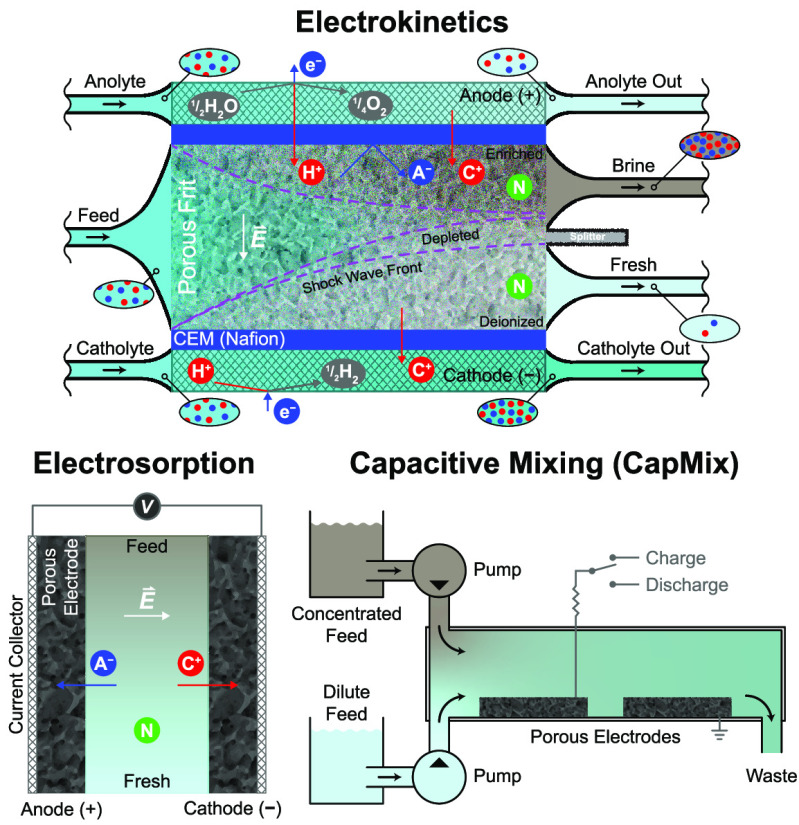

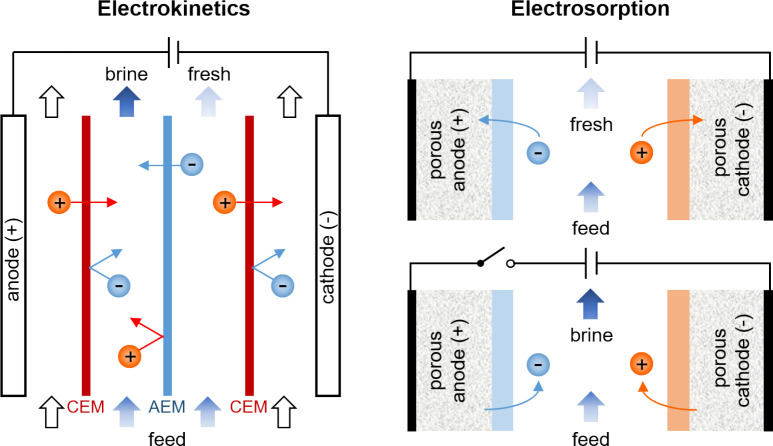

Figure 3.

Electrokinetics and electrosorption are the two main mechanisms by which contaminants are separated in any nondestructive electrochemical process. Electrokinetic processes, which are typically continuous, involve transport of charged or uncharged but dielectric119,120 species in an electrolyte in response to an applied electric field, and so removal of contaminants relies on effective mass transfer. Electrokinetic methods like EDI and shock ED use porous materials in the feed channels to increase ion removal and improve energy efficiency when the feed is dilute. Electrosorption processes are cyclic and encompass all phenomena in which the binding of contaminants is aided by an applied electric field. In addition to effective transport, electrosorption relies on favorable reaction kinetics and thermodynamics.

Among the existing electrochemical methods, electrodialysis (ED) has been studied and used for water desalination for decades, and several ED desalination plants for treatment of brackish water are currently operational in the U.S.114,121−125 The past decade, however, has seen the emergence of several novel electrochemical systems for water purification with unique functionalities and working principles compared to ED, and these are EDI,126 shock ED,87 CDI,115,127,128 and Faradaic electrosorption.86 This review summarizes the development of these novel technologies to form the basis for the emerging field of electrochemical systems for water purification and ion separations. For completeness, we also briefly discuss related microfluidic technologies, which have been reviewed in detail elsewhere.129,130 Microfluidic systems, which are driven by electrical energy, have throughputs at the scale of nanoliters and may be difficult to scale up to the volumes needed for deployment for human consumption, agriculture, or industry. Electrochemical systems instead are based on cells and stacks made of components like ion exchange membranes (IEMs), porous dielectric separators, and porous electrodes that can be produced in large areas as flat sheets or films, and thus these systems naturally have clearer pathways for scale up.

1.4. Outline of This Review

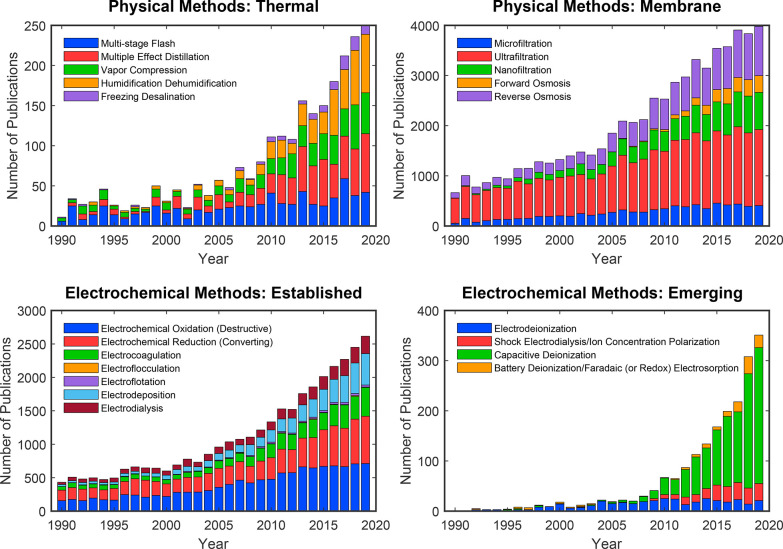

Conventional electrochemical methods, which exploit Faradaic electron transfer reactions at electrodes to drive chemical or physical transformations, have been previously reviewed, particularly in their use for removal of organic matter,131 organic compounds,132−137 inorganic contaminants,138−142 and microorganisms143−145 as well as for degradation of various contaminants and micropollutants.123,146−149 The technologies on which many of these publications focus are well established and currently used in industry. We begin the review by introducing these established electrochemical transformation methods and the broad range of applications for which they are used (section 2). We then build on the existing literature and related reviews68,105,115,118,123,126,150−155 by emphasizing the principles and applications of emerging electrochemical methods for desalination, water purification, and ion separations (sections 3 and 4). As shown in Figure 4, several of these emerging methods have developed only in the last 10 years and have been reviewed either briefly or independently of other methods. To provide a foundation for our discussion, we examine recent developments in electrokinetic phenomena and electrosorption for water purification and selective ion separations. See refs (76) and (118) for tables that summarize the advantages and disadvantages of techniques used for water purification, including many of the emerging methods discussed here.

Figure 4.

Number of publications per year for various methods used for water purification or ion separations. The technologies considered here are broadly classified as either physical (top row) or electrochemical (bottom row). This review focuses on electrochemical methods, and special attention is given to the emerging methods, including shock ED, CDI, and Faradaic electrosorption. The literature search was performed using Elsevier’s Scopus database with the search field TITLE-ABS(···).

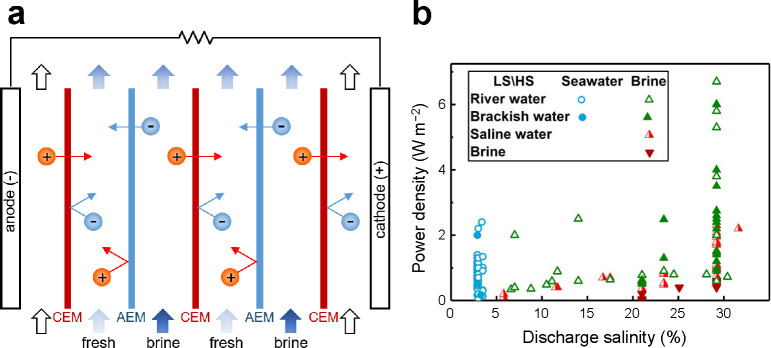

In section 3, we explain (nondestructive) methods based on electrokinetics, which may either include or exclude membranes. Two methods in the class of membrane-based systems are ED and EDI, where the membrane plays a critical role in the removal of charged species. Ions can be separated from the bulk fluid directly, however, by virtue of the electrokinetic phenomena, without much contribution from the membrane itself. Key developments have also been made in the class of “semimembraneless” systems (i.e., systems in which the feed is partitioned into fresh and brine streams across a deionization shock wave that functions as a virtual interface), which include microfluidic (or nanofluidic) concentration polarization and shock ED. These methods are both based on the phenomenon of concentration polarization, which arises due to extreme gradients in the concentration of ions in solution. In section 4, we describe electrosorption, the phenomenon that is responsible for sorption in electrochemical systems, and how this process is used for desalination and molecular separations. (These separations are often nondestructive, but in certain cases, they may involve electrochemical conversion or degradation of the contaminants.) This explanation is followed by an overview of CDI techniques as well as recent innovations in Faradaic (or redox-active) materials and their broad use in chemical and environmental processes. With these methods explained, we introduce inverse methods of energy conversion that convert gradients in salinity to energy (section 5). We conclude by discussing the energetics, thermodynamic and technological challenges, and prospects of electrochemical methods for water purification and ion separations (sections 6 and 7).

2. Electrochemical Transformations

In the general areas of water purification and wastewater treatment, a variety of electrochemical processes have been developed to remove contaminants ranging from ions to colloidal particles. For example, chemical coagulation flocculation, flotation, precipitation, and redox (reduction and oxidation) can be improved by applying electric fields.156−158 In this section, we discuss nonelectrosorptive electrochemical methods that are well established and reviewed extensively in the literature, namely electrochemical oxidation, electrochemical reduction, electrocoagulation, electroflotation, and electrodeposition.98,146,156−160 These processes involve Faradaic reactions at electrodes to drive chemical or physical transformations of ionic or molecular solutes. For example, electrochemical redox reactions are used primarily when the objective is to degrade or convert nonbiodegradable organic contaminants and certain inorganic compounds (e.g., cyanides, thiocyanates, sulfides) and disinfect water. In section 3, we examine both traditional and emerging electrokinetic methods based on ED, which rely on coupled transport phenomena in electrolyte solutions. We then discuss in section 4 electrosorption systems (both capacitive and Faradaic) for selective ion removal based on various functional materials, including porous carbon, inorganic crystals, and polymers.90,115

2.1. Electrochemical Oxidation

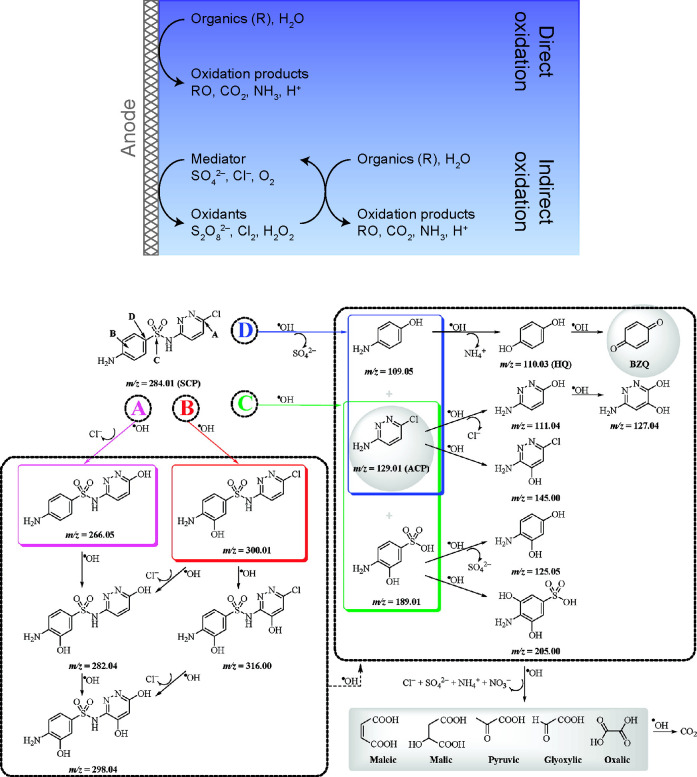

Electrochemical oxidation is a chemical reaction involving the loss of one or more electrons by an atom or a molecule at the anode when an electrical current is passed through the system.146,161,162 In the context of water treatment, electrochemical oxidation generates reactive oxidizing agents called free radicals that interact with the contaminants and degrade them, as explained in Figure 5.123 Superoxide (O2•–), hydroperoxyl (HO2•), hydroxyl (HO•), and sulfate (SO4•–) radicals are examples of reactive agents that can degrade organic and organometallic contaminants by initiating a radical oxidation chain (see refs (123), (146), and (163−167) for lists of common reaction pathways by which these radicals are formed).136,168−170 Superoxide and hydroxyl are two of the most important radicals in free-radical chemistry, and they are both believed to be key species in oxidative processes.163,164,171 While superoxide is normally a nucleophile and reducing agent,164,172 it exists in equilibrium with the hydroperoxyl radical, which can behave as an oxidizing agent in various biological and chemical reactions.173−177 (In general, superoxide is a weak reducing agent, but in the presence of solids or cosolvents that are less polar than water (e.g., H2O2), superoxide becomes reactive and can degrade halogenated aliphatic compounds,178,179 including perfluorocarboxylic acids,180,181 via nucleophilic attacks.182) The hydroxyl radical oxidizes both organic and inorganic compounds with high reaction rates, such that its action occurs only in the region where it is produced.183 The degradation process begins with formation of the reactive oxidizer, followed by initial attacks on target molecules and their breakdown into biodegradable intermediates. Subsequent attacks on these intermediates by the oxidizer can lead to their mineralization (i.e., production of water, carbon dioxide, and inorganic salts), as shown in Figure 5.123,146 Another class of oxidizers is obtained by the oxidation of chloride ions to generate active chlorine (Cl2), which may disproportionate to hypochloric acid (HClO) or hypochlorite (ClO–) depending on the pH. Although these species can effectively oxidize various contaminants in real wastewaters (e.g., landfill leachates, textile effluents, olive oil wastewater, tannery wastewater),97 this approach has the drawback of producing chlorinated organic compounds during the electrolysis, which is the main limitation of electrochemical oxidation.97,184 These chlorinated byproducts increase the toxicity of the effluent because they tend to be much more persistent than what is initially present in the feed.185−187 In the absence of chloride electrolytes, however, electrochemical oxidation can be reliably used for disinfection, wastewater treatment, groundwater treatment, soil remediation, wastewater sludge conditioning, and odor and taste removal.146,188−190

Figure 5.

Electrochemical oxidation is an established destructive, nonelectrosorptive method that is used to degrade most organic contaminants and certain inorganic compounds. (top) The method involves formation of reactive oxidizers that interact with contaminants either at the anode surface (direct oxidation) or in the bulk (indirect, or mediated, oxidation).123 Reproduced with permission from ref (191). Copyright 2017 Royal Society of Chemistry. (bottom) Complex organic compounds, such as the sulfonamide antibiotic sulfachloropyridazine, are degraded and mineralized by the attack of reactive oxidizers at key reaction sites (designated by the letters A–D). In this example, hydroxyl radicals can attack four unique sites on sulfachloropyridazine to yield different primary cyclic byproducts, all of which are eventually transformed into CO2. Reproduced with permission from ref (192). Copyright 2012 American Chemical Society.

In the 1990s, researchers became increasingly aware that the anode material is an especially important consideration in the design and optimization of electrochemical oxidation processes.193−196 (The cathodes are usually stainless steel plates, platinum meshes, or carbon felt electrodes.) The results obtained by several groups indeed demonstrated that the choice of anode influences the selectivity and efficiency of organic compound oxidation.165,197 According to a model proposed by Comninellis,194 anode materials are divided into active anodes (e.g., carbon, platinum, iridium oxides, ruthenium oxides) and nonactive anodes (e.g., antimony-doped tin oxide, lead dioxide, boron-doped diamond).97 Active anodes have low oxygen evolution overpotential and are good electrocatalysts for oxygen evolution, while nonactive anodes have high oxygen evolution overpotential and are poor electrocatalysts for oxygen evolution. Anodes based on boron-doped diamond (BDD) have received considerable attention due to their chemical stability, high electrical conductivity, resistance to corrosion even in harsh environments, and wide window of electric potential.198 As a result, BDD is generally viewed as one of the most effective and energy efficient anodes for mineralization of organic contaminants, although its use in practice is limited due to high manufacturing costs.198 Moreover, BDD (as well as other anodes) promotes the oxidation of chloride to chlorate (ClO3–) and perchlorate (ClO4), which are water-soluble disinfection byproducts that are exceedingly mobile in aqueous solutions and are highly persistent under typical water conditions.97,146 Because disinfection byproducts in drinking water are usually regulated, their concentrations should be monitored and controlled when performing in-line electrolysis.

Other prominent anodes include dimensionally stable anodes (DSAs, also called mixed metal oxide electrodes) and substoichiometric titanium oxide anodes.97,199,200 DSAs are fabricated by coating a substrate such as titanium with several kinds of metal oxides, including RuO2, IrO2, and PtO2. These anodes exhibit high conductivity and corrosion resistance, and recent studies showed that doping DSAs with metal and nonmetal elements can further improve their performance.201−204 Moreover, the use of nanotechnology has gained traction in the field of electrode fabrication to increase the porosity and active surface area of the anodes.205,206 Anodes based on substoichiometric titanium oxide (TinO2n–1) also display high conductivity and corrosion resistance, and their many advantages and long service life have led to their broad use in fuel cells, lead-acid batteries, and, most recently, wastewater treatment.207−210 Ganiyu et al. prepared a Magnéli-phase Ti4O7 electrode by plasma deposition and compared it to DSA and BDD anodes for the degradation of the beta-blocker propranolol211 and the analgesic paracetamol.212 These studies showed that the Ti4O7 electrode can achieve similar or better removal of organic carbon compared to DSAs and BDD. Several methods have been reported in the literature to improve the performance of substoichiometric titanium oxide electrodes, and these methods include plasma spraying,213 which produces doped functional coatings, and high-temperature sintering, which produces an electrode with extensively interconnected macropores.210

Most anodes used in electrochemical oxidation produce highly active hydroxyl radicals on their surfaces,214 and treatment of wastewater with these materials requires adequate flow of the contaminants toward them. When the concentration of pollutants near the anode is low, the process rate is limited by mass transfer of these species to the surface of the electrode.97 Common methods to overcome this limitation include gas sparging,215 incorporation of turbulence promoters,97 and use of nanoengineered materials.216−218 Most importantly, the efficiency of electrochemical oxidation can be improved with the indirect (or mediated) oxidation method, which avoids the production of oxygen by generating precursors that are transformed to active oxidizers. Persulfate (S2O82–), percarbonate (C2O6), and hydrogen peroxide (H2O2) are examples of precursors that can be produced using BDD anodes.219−221 These species are relatively stable at ambient conditions and generate highly active inorganic radicals that enable mediated oxidation of organic contaminants.97 Michaud et al. experimentally tested the production of precursors using BDD and observed that persulfate is produced with high current efficiency when the electrolyte is concentrated in sulfate (SO42–) and the process temperature is low.219 The persulfate precursor is activated to generate sulfate radicals, and this step requires a transition metal catalyst or sufficient energy.222 Activated persulfate can then oxidize organic compounds, and this approach has been used to treat groundwater and soils contaminated with biorefractory organic species.97

In recent years, there have been significant advances in the design, synthesis, and use of nanostructured electrodes for electrochemical oxidation.218 Nanoengineered materials exhibit new and improved properties, such as an increase in the number of active sites and an improvement in electrical conductivity, and these materials can promote heterogeneous catalysis at electrode surfaces.218 According to Du et al., a wide range of nanostructured cathodes have been reported in literature, and they can be divided into four categories: cathodes based on carbon nanomaterials such as carbon nanotubes (CNTs) and graphene,223,224 carbon cathodes doped with heteroatoms such as fluorine and nitrogen,225,226 metals or metal oxides deposited on carbon,227−229 and metal oxide cathodes.230,231 In most studies, these electrodes are used for electrosynthesis of H2O2 via oxygen reduction, and the structural morphology and composition of functional groups largely affect cathode performance.224,232,233 Du et al. also explain that there exists a large variety of nanostructured anodes, which can be divided into four categories similar to those of the nanostructured cathodes: anodes based on carbon nanomaterials such as CNTs and nanostructured BDD,234−237 anodes doped with heteroatoms such as fluorine and boron,238,239 metals or metal oxides deposited on carbon,240−242 and metal or metal oxide anodes.243−246 Most articles published on nanostructured electrodes report improvements in the kinetics of HO• production and pollutant oxidation due to the synergistic effects of greater stability, electrical conductivity, electrochemical reactivity, and active-site exposure.218 Even though nanoengineering has enabled major advances in improving electrode stability, more efforts are needed to demonstrate stability for long-term use, and standard protocols must be established to assess the lifetime and reliability of these systems.218

Over the past two decades, scale up of anode systems has gained attention, where the focus has been on increasing the throughput of laboratory-scale systems while retaining performance and reliability.247,248 At the same time, electrochemical advanced oxidation processes have been developed to improve the efficacy and applicability of conventional electrochemical oxidation.146,249−251 These specialized variants of electrochemical oxidation introduce Fenton’s reaction chemistry,192,252,253 photoelectrocatalysis,254 sonoelectrolysis,146 and aerobic or anaerobic digestion (using microbial electrochemical technologies)255−258 to the standard process.259 In conventional electrochemical oxidation, the reactive oxidizers are often (but not always) produced at the anode surface; the advanced variants facilitate additional generation of oxidizers in the bulk.146,197 Although these oxidative processes are more widely studied and used (because they usually lead to mineralization of the contaminants), treatments based on electrochemical reduction have been gaining interest because they enable partial recovery of chemicals as well as production of value-added substances.97

2.2. Electrochemical Reduction

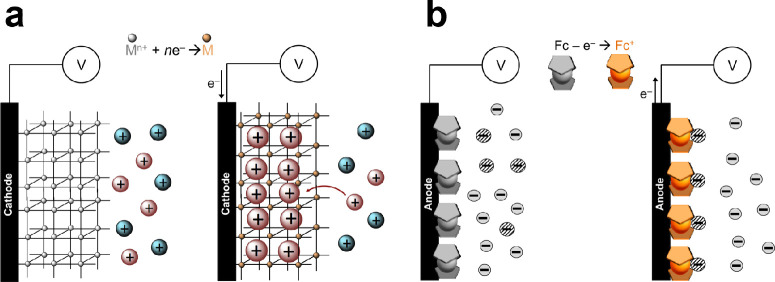

Electrochemical reduction, the complementary process to electrochemical oxidation, is a chemical reaction involving the gain of one or more electrons by an atom or a molecule at the cathode when an electrical current is passed through the system.123 Similar to electrochemical oxidation, electrochemical reduction can occur either directly on the surface of the cathode or indirectly in the bulk by the action of a reducing agent generated at one of the electrodes.98 This process is typically used to treat water contaminated with heavy metal ions (see section 2.5 also),123,260 inorganic anions (e.g., bromate, perchlorate),261,262 or halogenated organic compounds (e.g., organic volatile halides, chlorofluorocarbons, polychlorohydrocarbons, polyhalophenols)97,98 by converting these species into more benign products. As shown in Figure 6, the mechanism of this conversion usually involves the removal of halogen atoms or the reduction of aldehydes and ketones to produces less toxic species.97,123

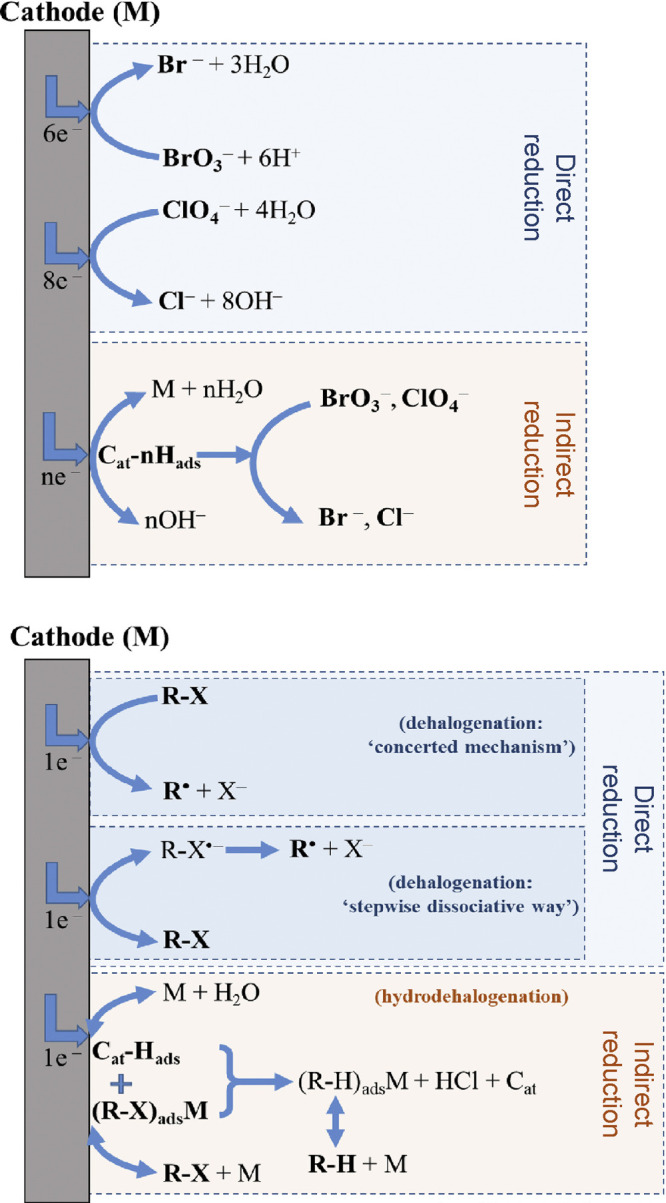

Figure 6.

Electrochemical reduction is an established conversion method that is used to treat oxidized contaminants, such as (top) inorganic and (bottom) organic halides (R-X). The method involves formation of high energy electrons or reactive species that interact with contaminants either at the cathode surface (direct reduction) or in the bulk (indirect reduction). M refers to the cathode material (i.e., the catalyst, Cat); Cat-Hads, (R-X)adsM, and (R-H)adsM are the hydrogen atom, organic halide, and dehalogenated organic compound (R-H), respectively, adsorbed on the cathode. Reproduced with permission from ref (98). Copyright 2020 Elsevier.

Among the major parameters that determine the efficiency of electrochemical reduction are catalyst loading, cathode potential, and water quality.98 Generally, an increase in catalyst loading improves reduction activity, though only up to a limit beyond which activity either steadies or even decreases as the distance for electron transfer increases.263 In the case of nanosized catalysts such as palladium, the particles can aggregate at higher loading, which results in excessive local evolution of hydrogen bubbles that restrict access of the contaminants to the catalyst.264 As is the case for catalyst loading, a reaction will have an optimal operating cathode potential above which the abundance of hydrogen bubbles produced could inhibit adsorption of contaminants.265,266 Electrochemical reduction is also sensitive to the quality and characteristics of the feed, which influence performance and electrode lifetime.98 Performance typically improves at lower pH (due to increased formation of adsorbed hydrogen),267,268 at higher ionic strength (due to smaller EDLs),98 and in the absence of certain species (e.g., organic matter, electrocatalyst poisons, competing ions).264,269

The choice of electrode is another critical design parameter that influences the mechanism of electrochemical reduction, as it impacts the reaction pathway, selectivity, and energy consumption.97,98 An effective catalyst enables strong bonding on the surface of the substrate.98 From among the many materials investigated to date, electrodes based on silver, nickel, and carbon hold prominent positions due to their high electrocatalytic activity, robustness, and inexpensiveness with respect to conversion of halogenated contaminants.97,98 Noble metals such as palladium, platinum, and ruthenium are also effective materials for electrocatalytic hydrodehalogenation,263 especially when combined with other elements to produce bimetallic catalysts.270−272 These bimetallic catalysts can even be modified by adding nanosized or anchored materials to further improve their electrocatalytic efficiency.263,273,274 The main limitation of metallic catalysts, however, is their high cost, which makes the use of carbon-based materials an attractive alternative.98,275 Some of the most effective carbon-based catalysts involve nanostructured polymer coatings that selectively adsorb halogenated compounds,276,277 but the electrocatalytic activity of modified carbon materials in general is low.278 Activity can be improved by combining nanostructured carbons such as reduced graphene oxide (RGO) with metallic electrodes.264

In general, electrochemical reduction is an effective method not only for treatment of pollutants, such as volatile organic halides and chlorofluorocarbons, but also for their transformation into value-added products.97 This capability can be achieved by selective removal of halogens as well as by carboxylation or carbonylation of the organic compounds. The combination of electrochemical reduction and electrosynthesis is another way by which wastewater can be treated and upgraded for synthesis of value-added organic products.279,280 Moving forward, it will be important to assess and improve the stability and lifetime of electrocatalytic materials for use in practical applications.

2.3. Electrocoagulation and Electroflocculation

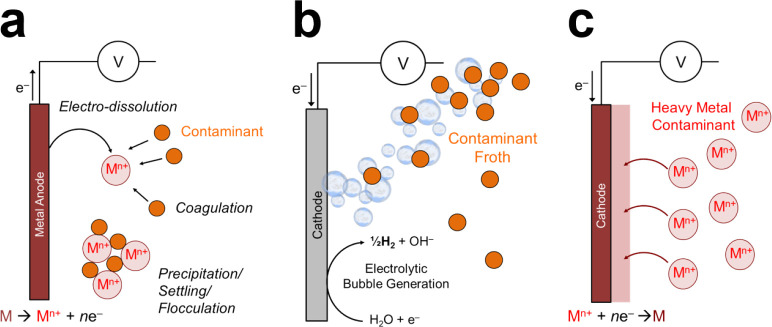

The two-step process of electrocoagulation and electroflocculation relies on the dissolution of metal anodes to induce the formation of flocs, which trap contaminants and enable their removal by settling, sedimentation, precipitation, or flotation.156,281−285 This method was patented in 1906 by Dieterich for treatment of sewage in London and bilge water from ships using iron and aluminum as sacrificial anodes.286,287 As shown in Figure 7, the crucial electrochemically mediated step relies on in situ oxidation of the appropriate metal surfaces (often aluminum or iron)288 to produce metal ions which then form flocs that facilitate the removal of solids, organic species, and inorganic compounds.158 What follows is essentially ordinary coagulation: the (typically negative) surface charge of the contaminants is neutralized, which destabilizes them and causes them to form aggregates that can be removed by settling, sedimentation, precipitation, or flotation.289 Electrocoagulation is regularly used in industrial applications, such as removal of heavy metals, remediation of wastewater, and treatment of produced water.290,291,1269 To improve the performance of electrocoagulation for wastewater treatment, numerous studies have sought to integrate this technology with other processes, such as peroxidation or a more specialized biological process, both of which facilitate the removal of organic matter.292

Figure 7.

Established nondestructive, nonelectrosorptive methods of water purification. (a) Electrocoagulation and electroflocculation is a two-step process by which metal anodes are dissolved to induce formation of flocs that trap contaminants for removal by settling, sedimentation, precipitation, or flotation. (b) Electroflotation produces bubbles by water redox to transport lighter contaminants or flocs by flotation. (c) Electrodeposition is based on the electrochemical deposition of metal ions in solution onto an electrode.

Electrocoagulation has been extensively studied, often using iron electrodes, for specialty separations and wastewater treatment, particularly to remove light organic pollutants such as oils, dyes, and humic particles.293 In addition, electrocoagulation can be used with aluminum electrodes to remove heavy metal ions, including Ag+, Zn2+, Cu2+, Ni2+, and Cr6+,294−296 as well as halide ions.297 Compared to classical coagulation, electrocoagulation has several advantages that lower its operating cost. For example, the cationic coagulant is generated in situ by a chemical reaction on the sacrificial electrode, and this feature limits the introduction of counterions from chemical reactants that contribute to the formation of sludge.298 Electrocoagulation thus requires no separation of unreacted counterions from the chemical coagulant in solution, which are usually removed to meet discharge standards.299 The reduced formation of sludge also lowers expenses associated with handling and disposal of this waste. Another advantage of electrocoagulation is that the electrochemical reactions that drive this process produce OH–, which eliminates the need for external chemical agents to regulate pH.300 These reactions also produce gaseous H2, which could be captured and used subsequently as a fuel.301

In contrast to classical flocculation, which requires the input of large amounts of chemicals, electroflocculation relies on Faradaic (anodic) dissolution to dose the system with the coagulant, a property that enables finer control and easier handling of the process. Complexation of the released metal ions, such as Al3+ or Fe3+, with hydroxides produces monomeric (Al(OH)2+ and Al(OH)2+) or polymeric species (Al13(OH)34) that then flocculate with organic compounds (e.g., dyes) and further promotes precipitation by either sedimentation or flotation.302 Despite their advantages, however, electrocoagulation and electroflocculation exhibit operational challenges, such as electrode passivation, sludge deposition on the electrode, nonuniform dissolution of the anode, and inconsistent production of the coagulant, all of which undermine performance under long-term, continuous operation.303 The sacrificial anode is also consumed over time, which necessitates periodic replacement of the electrode, and the high concentration of residual (metal) ions requires a post-treatment step prior to discharge.304 But because of their operational simplicity, low cost, and versatility, electrocoagulation and electroflocculation remain active areas of research.305

2.4. Electroflotation

Electroflotation is often used in conjunction with electrocoagulation and electroflocculation for electrochemical–physical separations.306−309 Electroflotation relies on the electrolytic process of water redox, in which bubbles are formed to transport lighter contaminants or flocs by flotation. The key driving Faradaic reaction for electroflotation is the electrolysis of water at both electrodes (O2 evolves at the anode and H2 at the cathode). The first proposed use of electroflotation is attributed to Elmore in a patent from 1905 for mining separations,310 and this process has since been expanded to handle a range of contaminants such as oils and low-density suspended particles in mining water and groundwater, among others.306 The primary limitation of electroflotation is the difficulty of controlling the uniformity of bubble evolution.158,311 Careful optimization of current densities and voltage windows is therefore crucial for effective performance.139,282,308,312

Electroflotation has several features that are attractive for applications in water treatment. For example, this process can be used to recover valuable components from wastewater without the need for chemical reagents.313 The reason is that electroflotation generates gaseous O2 and H2, which are more active than the gases used in conventional flotation (e.g., natural gas, air, N2). Electroflotation can also produce bubbles with diameters of 1–30 μm, which leads to better dispersion, finer distribution, and longer residence times of the bubbles in solution.314−316 This feature facilitates the flotation of fine particles in a way that is difficult to achieve by classical flotation. Finally, the energy consumption of electroflotation is in the range of 0.1–0.5 kW h m–3, and it decreases as the electrical conductivity of the solution increases.314

2.5. Electrodeposition

The process of electrodeposition is synonymous with electroplating and is one of the earliest applications of electrochemistry, especially in metallurgical processing.139,317−319 While many of these plating methods are major sources of heavy metal pollution, the same electrochemical principles have been used to treat industrial wastewater and sometimes even to recover and reuse discharged materials. As an example, copper electrodeposition is commonly used to print circuit boards and manufacture electronics. Recovery of copper from spent parts, however, has also been an application of electrochemical methods that combine leaching, ED, and electrodeposition from wastewater.320,321

Electrodeposition involves the application of cathodic overpotentials to induce the electrochemical deposition (or reduction) of metal ions in solution onto an electrode. In other words, this process is direct electrochemical reduction of metal ions adsorbed on an electrode surface. Electrodeposition can effectively handle both copper and arsenic wastes, often with the production of pure elemental copper depending on the electrochemical parameters.322,323 This method has also been used for secondary recovery of residual copper from low-content tailings derived from waste electrical cable.324 These applications of electrodeposition rely on the same principle of removing metal ions from aqueous solutions that is used to charge aqueous metal flow batteries, such as zinc–air,325 zinc–bromine,326 zinc–iron,327 and lithium–air batteries.328

2.6. Challenges and Limitations

Established nonelectrosorptive processes exhibit irreversible side reactions that consume significant amounts of energy and reduce current efficiency.287 Depending on the complexity of the electrochemical matrix, a number of byproducts can be produced, some of which passivate the electrodes and further diminish performance.282,287,329 For example, even though there were attempts as early as the late 1800s to implement electrocoagulation and electroflotation at scale, these processes never evolved into mainstream technologies because of their prohibitively high operating costs.282 Electrocoagulation and electroflotation have also lacked systematic studies aimed at scaling up the processes and optimizing their operating parameters.282,305 These methods, however, remain promising for localized and small-scale applications, and they continue to offer interesting avenues for scientific research in interfacial science, electrochemical engineering, and reactor design.

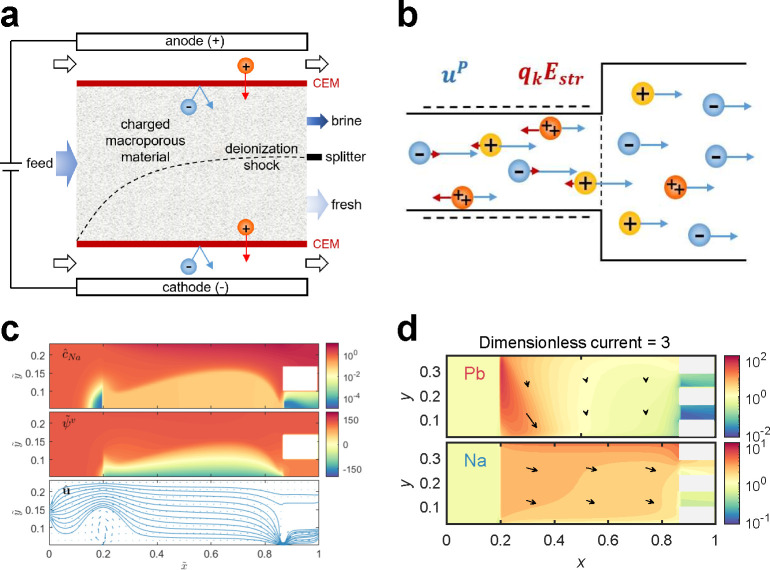

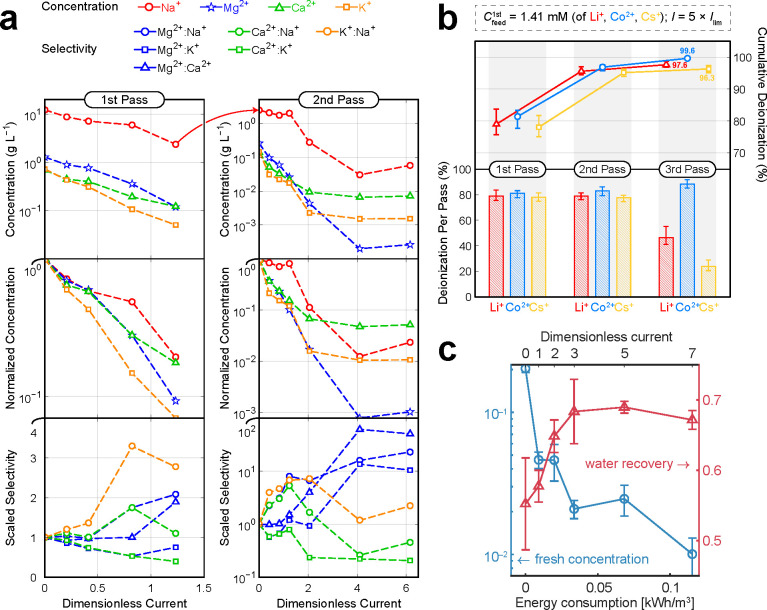

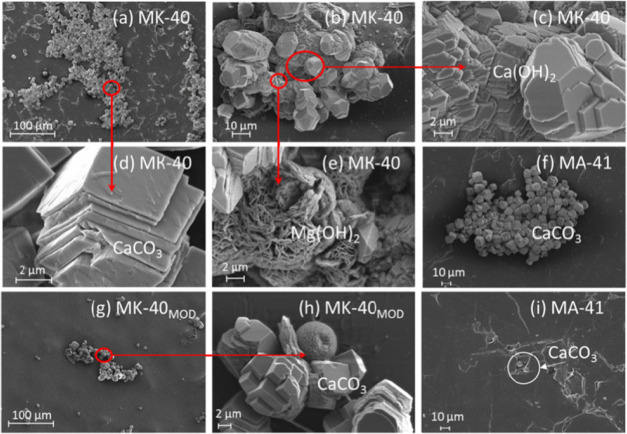

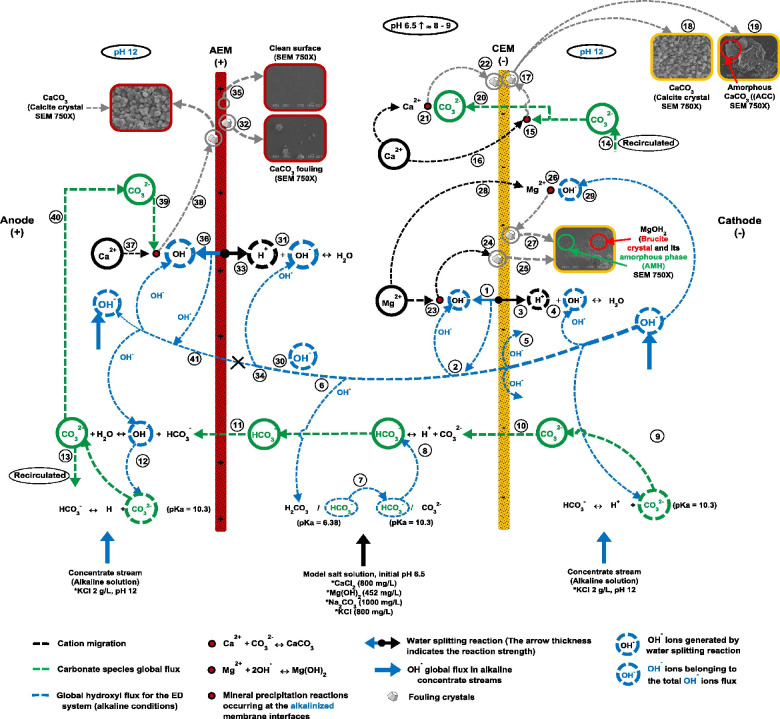

3. Electrokinetic Separations

When current is applied across a pair of electrodes, ions and larger particles in solution are transported by electromigration and electrokinetic phenomena,91,330−332 such as surface conduction, electroosmosis, and electrophoresis. Water purification by electrokinetics is based on the transport of contaminants in an electrolyte, and methods of this kind can be used to remove both organic159,333−335 and inorganic68,115,153,336 ions from water. Electrokinetic methods such as ED, EDI, and shock ED are continuous and involve an electric field that is perpendicular to the direction of fluid flow. These methods also include IEMs to fractionate the feed into diluate and concentrate streams. EDI and shock ED are similar in that a porous material (e.g., ion exchange resin beads, ceramics, clays, porous glass) is used to enhance mass transfer across the liquid to the solid phase. This unique feature of EDI and shock ED allows for currents beyond the ideal diffusion-limited current and makes these methods well suited to remove trace contaminants from dilute feeds. In this section, we briefly discuss the operating principles and basic physics of ED and EDI. We then focus on the emerging method known as shock ED, which is being reviewed for the first time. Our discussion of shock ED is preceded by an examination of the key developments in microfluidics and electrokinetic modeling that inspired the invention of shock ED as a method for water purification and ion separations. We conclude this section with a discussion of fouling phenomena and methods to overcome them in electrokinetic systems.

3.1. Electrodialysis

3.1.1. Basic Principles of Electrodialysis

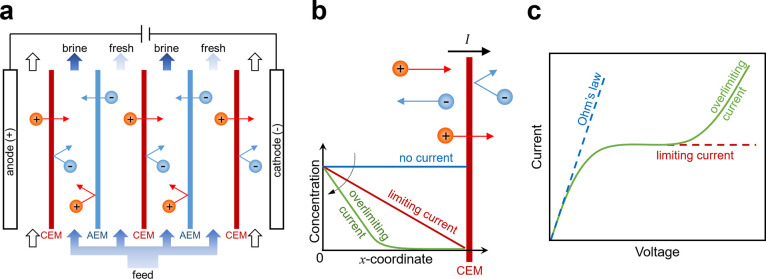

ED is a membrane-based electrochemical method that was developed in the 1950s114,337 for desalination of brackish water and for ion separations.338−343 The operating principles and underlying physics of this method are summarized in Figure 8 (see refs (152 and 153) for detailed reviews of membrane phenomena in ED). The process begins by passage of the feed through a stack of parallel, nonporous cation and anion exchange membranes (CEMs and AEMs; see refs (344 and 345) for detailed reviews of IEMs and the state of their development). At the same time, direct current (DC) is applied across the stack, perpendicular to the direction of flow to separate ions in alternating channels of fresh water (diluate) and brine (concentrate). In the sections where diluate is produced, cations pass through CEMs and anions through AEMs on the opposite side, which lowers the concentration of uncharged salt in a boundary layer that grows into the channel downstream. In the sections where concentrate is produced, anions are retained by CEMs and cations by AEMs, which results in boundary layers of increasing salt concentration.338,346,347 Once the boundary layers span the entirety of the channels, a condition termed “fully developed” forced convection,348 the dissolved salts have been effectively transported from diluate channels into neighboring concentrate channels for discharge.

Figure 8.

Operating principles and underlying physics of ED. (a) The feed flows through a stack of channels separated by alternating CEMs and AEMs, across which a current is applied. These channels are filled with spacer material that physically separates the membranes, promotes turbulent mixing, and inhibits ICP and the formation of laminar boundary layers near the membranes.349,350 The concentration profiles of the ions exhibit axial growth of boundary layers of depletion and enrichment in the diluate and concentrate channels, respectively. Adapted with permission from ref (346). Copyright 1968 Elsevier. (b) Ion fluxes near a CEM and the associated convection–diffusion boundary layers, which become more strongly depleted with increasing current until the diffusion limit is reached. (c) The current–voltage relationship reaches a plateau at the limiting current, while overlimiting current, which results in an extended zone of ion depletion, is observed at higher voltages.

Depletion and enrichment of salt in unsupported electrolytes lead to self-generated diffusional electric fields that impede the transport of active ionic species through the phenomenon of ion concentration polarization (ICP). These electric fields arise to maintain electroneutrality via redistribution of the inactive (typically oppositely charged) ionic species. The additional internal voltage drop associated with variations in salt concentration relative to that of electrical conduction in a uniform bulk electrolyte (Ohm’s law) is termed the concentration overpotential. When the salt concentration tends to zero, the concentration overpotential diverges and leads to a diffusion-limited current, as long as the transport is dominated by electrodiffusion in a neutral unsupported electrolyte without the creation of any additional ions.331,351,352 For example, the mobilities of cations and anions in an electrolyte are comparable but may differ considerably in an IEM or a nanochannel with charged surfaces.353 Salt depletion dramatically increases the electrical resistivity of the solution, which leads to significant departures from Ohm’s law as shown in Figure 8, and limits the achievable rate of ion removal by ED.338−341,354 The current–voltage relationship for ICP in a symmetric (z:z) binary electrolyte resembles that of an ideal diode:

| 1 |

where I is current, Ilim is the diffusion-limited current (or limiting current),95z is charge, V is voltage, F is Faraday’s constant, R is the universal gas constant, and T is temperature. The maximum diffusion-limited current, Ilim, is approached when a large potential difference (relative to the thermal voltage, RT/F ≈ 26 mV at room temperature), V, is applied to the system and as the salt concentration in the diluate sections approaches zero.

The theory of ED was pioneered by Peers,355 after which it was extended for arbitrary transference numbers by Rosenberg and Tirell356 as well as for fully developed convection by Sonin and Probstein.346 A useful approximation for the limiting current is given by the Peers equation,

| 2 |

where c0 is the bulk salt concentration, D is the effective salt diffusivity for coupled diffusion and electromigration (usually taken to be the ambipolar diffusivity in a dilute, binary electrolyte,357,358 although concentration dependent corrections can be significant359), τα is an effective transference number for counterions that selectively cross the solution–membrane interface (τα = 1 for an ideal membrane or electrode),339−341τβ is the transference number for counterions in the solution, and δ is the effective boundary layer thickness. This thickness scales as δ/H ∼ Pe–1/3 in the Lévêque approximation,338,346,348,360 where Pe = UH/D is the Péclet number, defined by the channel spacing, H, and characteristic fluid velocity, U. This theory is based on a boundary layer analysis of the steady convection–diffusion equation for an uncharged binary electrolyte,338,348 where the flow is assumed to be fully developed and unidirectional and axial diffusion is neglected, as is usual for forced convection in straight pipes and channels.348,361 Similar boundary layer approximations can be derived for membraneless flow batteries with forced convection over (selective) redox electrodes instead of IEMs.362 Extensions for turbulent flow,363 including effects of screen spacers to promote turbulent mixing,364 were incorporated in a general equivalent circuit model of ED by Belfort and Guter.365 Theoretical models were also used to calculate the pH profile366 and analyze ion selectivity (e.g., K+ versus Ca2+,347 NO3– versus Cl–367) in ED.

In practical systems, the ideal diffusion-limited current is always exceeded when the applied voltage is sufficiently high, and possible mechanisms of this “overlimiting current” have been extensively studied in membrane science.153,368 In bulk liquid electrolytes, there are two main kinds of mechanisms responsible for overlimiting current: electrochemical and electrokinetic.369 Electrochemical mechanisms involve charge regulation370−376 and self-ionization of water molecules,72,355,377 both of which may lead to current induced membrane discharge378 (i.e., loss of ion selectivity) and in turn passage of co-ions that would otherwise be repelled by the membrane. Electrokinetic mechanisms are based on the Rubinstein–Zaltzman electroconvective instability, where the EDL (either in379 or out of equilibrium380,381) between the depleted solution and the membrane becomes hydrodynamically unstable to electroosmosis and in turn drives bulk vortices that transport ions to the membrane faster than by diffusion.382−387 In ED, electroconvective mixing can enable overlimiting current and improve the transport of ions,388 although at the expense of greater energy consumption compared to operating below the limiting current. These observations led the scientific community to develop ways to control electroconvection, including the use of topological heterogeneity, for example by patterning the surface of an IEM,387,389−392 and pulsed electric fields.393−397 Phenomena resembling electroconvection also arise in metal electrodeposition, and they strongly influence the formation of patterns.398,399 Understanding and controlling these instabilities in bulk electrolytes is a grand challenge, the solution to which could lead to novel electrochemical systems that benefit from operating in the exotic regime of overlimiting current despite the higher energy demand.

The efficiency of ED depends on device structure (e.g., spacer thickness and geometry, number of cell pairs in the stack), membrane properties (e.g., material chemistry, concentration of the fixed ionic moiety),364,400−404 electrode design (e.g., capacitive flow or membrane electrode, electrode redox couple),405 operating conditions (e.g., electric potential, current density, hydrodynamics, temperature), and feed composition.114,406 On the basis of their structure, commercial IEMs are classified as either homogeneous or heterogeneous.407 A homogeneous IEM generally displays higher conductivity and permselectivity compared to a heterogeneous membrane because the latter comprises a larger insulating phase in its matrix as a result of the fabrication method.408,409 A heterogeneous IEM, on the other hand, often has greater mechanical strength and is less expensive to manufacture.410 The heterogeneous structure of such a membrane also promotes electroconvection and mass transfer by localizing the migration of ions through the conductive parts of the membrane.387,411−415 Because a commercial ED stack may contain 300–500 cell pairs,416 the conductivity of the membrane will largely determine the overall conductivity of the stack, which in turn influences the energy consumption of the process. Another critical feature of IEMs is their resistance to the formation of deposits (e.g., organic fouling, inorganic scaling), which degrade the performance of the membranes and negatively affect the quality of the water produced.417,418 Much research has therefore been devoted to developing IEMs that have improved antifouling properties,419−422 as discussed in section 3.6.

3.1.2. Electrodialysis With Bipolar Membranes

One class of ED systems that remains an active area of research is based on bipolar membranes, which facilitate water dissociation without the need for chemicals.114,344,423−425 Bipolar membranes are fabricated by combining a CEM and an AEM, with a hydrophilic contact region separating the two IEMs. It is at this contact region where water is split into H+ and OH–, which migrate into acid and base compartments, respectively, when an electric potential is applied. The primary benefits of using bipolar membranes with ED are that they catalyze the production of H+ and OH– at voltages lower than what is needed for standard electrolysis at an electrode, reduce the amount of concentrate generated, and increase the recyclability of the waste by recovering ions from the feed as acids and bases.58,426,427 The use of a bipolar membrane, however, also introduces an electrical resistance to the system that lowers the current efficiency. This decrease in efficiency is overcome by lowering layer resistance and incorporating weak ion exchange groups in the membrane.428 As a result, the energy required to produce H+ and OH– with commercially available bipolar membranes is nearly equal to the theoretical minimum value428 (the theory of bipolar membranes is discussed extensively in refs (425), (428−432)).

ED systems with bipolar membranes have several applications, one of which is the recovery of acids and bases from salts produced by chemical reactions or neutralization.433−436 Because ions must first be separated to produce these acids and bases (e.g., Li+ for LiOH, Na+ for NaOH, SO42– for H2SO4), this process desalinates a concentrated feed in the same way as conventional ED.434,437−439 The first industrial process to employ ED with bipolar membranes was developed by Aqualytics to recover HF and HNO3 from pickling baths in the steel industry.434,440 Although commercial use of this technology remains limited due to the high cost, low permselectivity, and short lifetime of existing bipolar membranes,114,434 novel applications are rapidly emerging, such as pH control, carbon capture, production and recovery of ammonia, and energy storage.425

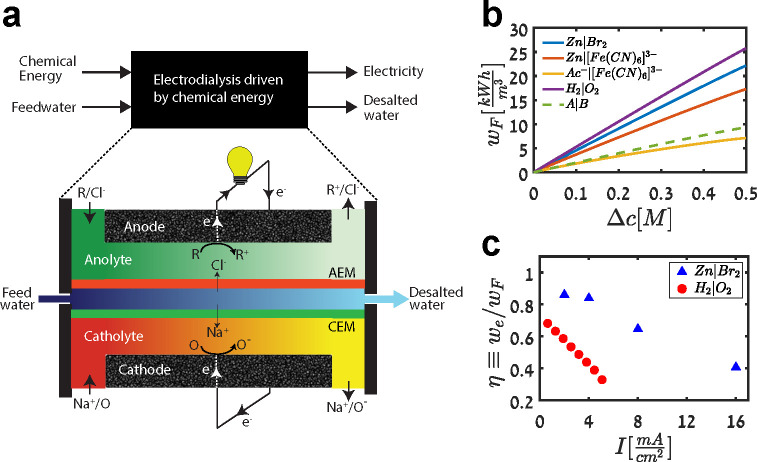

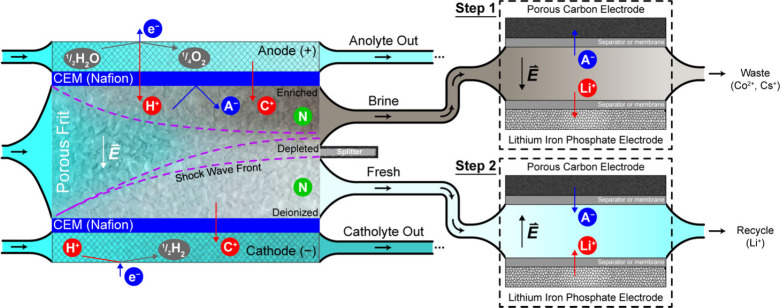

3.1.3. Electrodialysis Driven by Chemical Energy

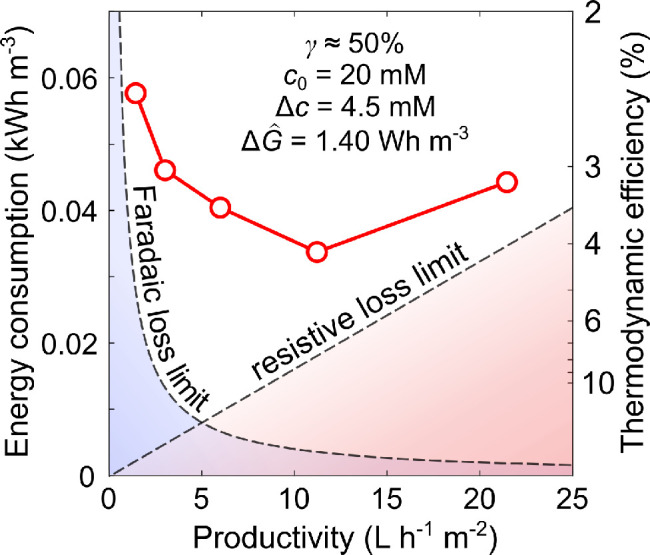

Recently, chemical energy was used in ED to simultaneously drive separations and generate electricity (Figure 9a).441−444 Inspired by microbial desalination cells,445,446 these ED systems are driven by inorganic redox couples, but they do not actually employ microbes because the use of microorganisms can limit electricity production and salt removal rates.447 ED cells driven by chemical energy can simultaneously produce clean water and generate electricity by performing a combined reaction–separation process that is thermodynamically spontaneous. Atlas et al. calculated the maximum available energy from this combined process, as shown in Figure 9b, and quantified the thermodynamic efficiency of cells driven by chemical energy, as shown in Figure 9c.447 The authors also found that, for certain chemistries, up to 25 kW h m–3 of electricity can be produced. This technology can thus generate significant excess electricity, well above what is that needed for pre- and post-treatment of the feed, which is approximately 1 kW h m–3 for seawater.68

Figure 9.

Operating principles of chemical energy ED. (a) Schematic of an ED cell driven by chemical energy, where a reductant R and oxidant O are used to drive desalination and generate electricity. Adapted with permission from ref (441). Copyright 2019 Elsevier. (b) Calculations of the maximum available energy from an ED cell driven by chemical energy for various redox couples. (c) Measured thermodynamic efficiency of ED cells driven by hydrogen–oxygen and zinc–bromine redox couples. Reproduced with permission from ref (447). Copyright 2020 The Electrochemical Society.

The concept of chemical energy ED was tested with a variety of redox chemistries, including zinc–bromine,441 zinc–air,154 aluminum–air,443 hydrogen–oxygen,447−451 and acid–base452 couples. In particular, the hydrogen–oxygen couple is promising, as it relies on relatively inexpensive gas-phase reactants, and the product of the chemical reaction is simply water (Figure 9a); cells that use the hydrogen–oxygen chemistry are termed “desalination fuel cells.”444,447 Other chemistries that rely on liquid-phase reactants or that produce a waste product complicate disposal of the brine.441,443 The hydrogen–oxygen chemistry, however, exhibits relatively low thermodynamic efficiency relative to other chemistries, such as zinc–bromine, mainly due to losses at electrodes attributed to (platinum) catalyst poisoning by halide ions in the brine (Figure 9c).447,453 Therefore, a crucial area of research is the design and development of inexpensive catalyst materials tailored to long-term operation in desalination fuel cells. Asokan et al. demonstrated the use of chloride-tolerant, iron-based catalysts for oxygen reduction in a desalination fuel cell, which opens the field of nonplatinum group metal catalysts for these systems.454

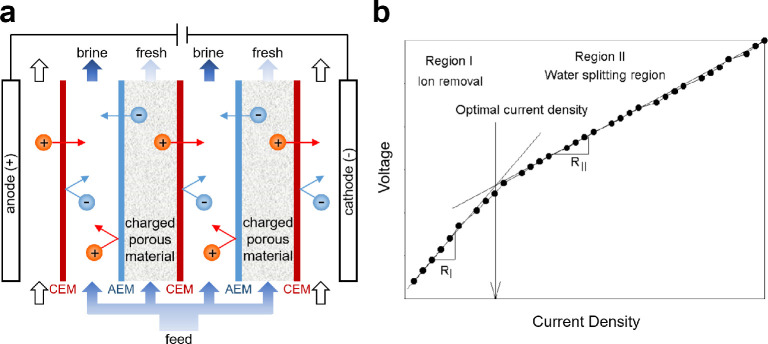

3.2. Electrodeionization

EDI, shown in Figure 10a, is typically used to generate highly pure products by processing feeds with low levels of dissolved solids (e.g., RO permeate).126,455−459 This method originated in the late 1950s with the intent of enabling extreme deionization of contaminated feeds by packing the channels of an ED stack with charged porous media or conductive ion exchange resin beads.61,106 The purpose of these conductive materials is to reduce the ICP observed in ED by enhancing transport of ions via electrokinetic phenomena (see Figure 11c and Figure 13). As in ED, ions are depleted in the diluate compartments of an EDI stack and are concentrated in the adjacent (concentrate) compartments because of the permselective properties of the IEMs. To deionize the electrolyte while maintaining reasonable conductivity across the stack, however, a conductive material such as ion exchange resin is needed to lower the resistivity of the electrolyte in the diluate compartments.61,460 As shown in Figure 10b, there is an optimal current density that is believed to coincide with the limiting current introduced in section 3.1.461 Another, more subtle reason ion exchange resin is used in the diluate compartments in EDI is to regulate the pH of the product streams by exploiting the relationship between the applied electrical current and the equilibrium concentrations of H+ and OH– in solution.462

Figure 10.

Design and operating principles of EDI. (a) As in ED, ions are depleted in the diluate compartments of an EDI stack and are concentrated in the adjacent (concentrate) compartments due to the permselective properties of the IEMs. In EDI, however, the use of a charged porous material (usually ion exchange resin) enables extreme deionization by boosting the conductivity of the electrolyte in the diluate compartments. (b) Typical current–voltage relationship in EDI, which reveals the existence of two regions with distinct resistivities (characterized by the slope of the graph). Reproduced with permission from ref (461). Copyright 2005 Springer.

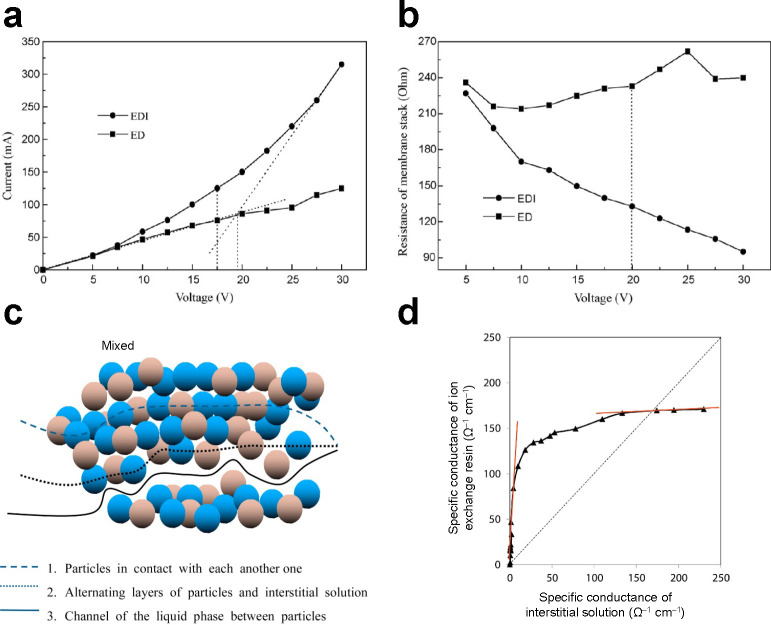

Figure 11.

Role of ion-exchange resin in EDI. Comparison of (a) current–voltage and (b) resistance–voltage relationships in ED and EDI. Reproduced with permission from ref (464). Copyright 2009 Elsevier. (c) Schematic of the three pathways for charge transport in a mixed bed. (d) Specific conductance of the ion exchange resin versus that of the interstitial solution. Reproduced with permission from ref (469). Copyright 2015 Elsevier.

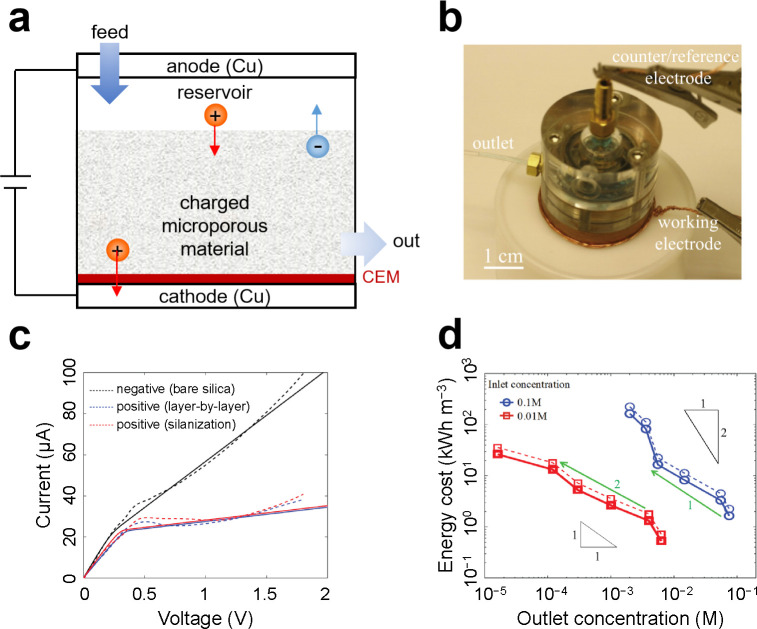

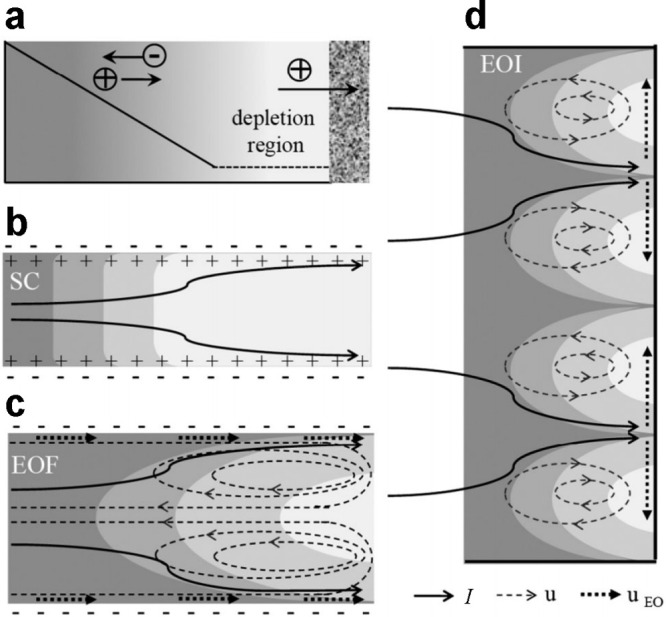

Figure 13.

Schematic representations of common mechanisms to sustain overlimiting current in a microchannel between a reservoir on the left and a CEM on the right. The volume average conductivity in (a) exhibits classical linear diffusion (continuous line) up to a region of depletion (dashed line), where charge carriers are transported by (b) surface conduction, (c) electroosmosis, or (d) electroconvection (visualized experimentally by Gu et al.564). The relative contributions of these effects depend on the width of the channel, such that surface conduction dominates in narrow channels and electroconvection in wide ones. Reproduced with permission from ref (527). Copyright 2011 American Physical Society.

As illustrated in Figure 8c, a typical ED cell exhibits a dramatic increase in electrical resistivity when salt is depleted from the diluate compartments. Because the concentration of ions in these compartments is smaller near the membranes than it is in the bulk, water dissociation occurs and reduces current efficiency.463,464 The use of ion exchange resin (whether as loose beads or as a wafer83,465,466) in EDI mitigates this effect by promoting transport in a conductive medium, which functions as a bridge for ions between membrane pairs. The current–voltage curves in Figure 11a,b show that EDI maintains increasingly higher conductivity (or lower resistivity) than ED as a function of applied voltage.126 Pathways of charge transfer in the ion exchange bed of an EDI cell are often studied using the porous plug model467−469 introduced by Wyllie and co-workers.470 The overall conductivity of the ion exchange bed is the sum of the conductivities of the ion exchange resin and interstitial solution. These conductivities are sustained via three different pathways, namely the resin (solid), the interstitial solution (liquid), or both (solid–liquid), as shown in Figure 11c. Alvarado et al. studied these pathways using an EDI cell as a mixed bed to treat a synthetic solution containing chromium at concentrations up to 250 mg L–1.469 In this system, nearly 82.9% of the electric charge was transported by the combined solid–liquid pathway, whereas only 0.6% was transported by the interstitial solution alone. In total, the ion exchange resin, alone or in combination with the interstitial solution, contributed to approximately 94% of ion transport, which underscores the crucial role of ion exchange in driving charge transfer in EDI (Figure 11d).

In addition to facilitating the migration of ions, ion exchange resin enables operation beyond the limiting current, at which diffusion of ions becomes the rate-limiting step in electrochemical separations.471 Operating in the regime of overlimiting current leads to water dissociation and exotic electrokinetic phenomena like the electroconvective instability,368,472,473 as was microscopically visualized by Park and Kwak as well as Stockmeier et al.474,475 In EDI, water dissociates due to the presence of bipolar zones formed at points of contact between resin particles and either other resin particles or IEMs.26,465 As the ion exchange resin traps ions, H+ and OH– produced by water dissociation act as charge carriers and regenerate the resin through the process of electroregeneration.106 Water dissociation is also important when complete removal of weakly ionized species, such as silicon and boron, is needed to produce ultrapure water. The OH– generated by this dissociation reacts with silicon and boron as follows:476

| 3a |

| 3b |

| 3c |

Once the neutral species SiO2 and H3BO3 become ionized, they are readily transported into the concentrate compartment and discharged.

Another useful function of the ion exchange resin in EDI is that, as a selective medium, it preferentially removes ions based on their affinity to the resin.57 Selective separation of ions with similar charge and size can be achieved by controlling the mobility of these ions with a complexing agent.477,478 For example, Taghdirian et al. used a complexing agent made of ethylenediaminetetraacetic acid (EDTA) to separate Ni2+ from Co2+.478 This complexing agent formed a strong bond with Ni2+, which produced a negatively charged complex whose mobility was inhibited in the bed of cation exchange resin. On the other hand, Co2+ remained a free cation that could readily enter the gel phase of the resin. By removing Co2+, the molar ratio of Ni2+ to Co2+ in the solution was increased from 3 to over 150.478

Although the microscopic mechanisms of EDI have received much less attention compared to those of ED, there have been several efforts to mathematically model107,459,479−482 and numerically simulate483−486 the process of EDI. Early descriptions of EDI proposed that the removal of ions occurs in two steps.487 First, ions diffuse from the bulk to the liquid–solid (resin) interface, where counterions are exchanged with mobile ions on the resin. Second, the adsorbed counterions are transported toward and across the corresponding IEM, where they are released into the concentrate compartments. Removal of ions is controlled by the rate of diffusion from the aqueous phase to the surface of the solid.126,487 This rate is determined by the properties of the solid surface, the thickness of the liquid layer through which ions diffuse, and the concentration gradient between the two phases. When a current is applied beyond what is needed for the electromigration of ions to the surfaces of the resin, water molecules dissociate into H+ and OH–, which replace the ions that have adsorbed on the resin.126

3.3. Electrokinetics in Nanochannels and Membranes

While nanofabricated devices are difficult to manufacture at scale, the scalable polymeric IEMs used in ED, EDI, and shock ED are essentially made of a network of nanoscale pores with high charge densities, as shown in Figure 12a.337,344,488,489 This nanoscale structure promotes selectivity based on the charge of an ion and on chemical interactions between the ion and the pore walls.490 IEMs are an integral component of many electrochemical methods of ion separations, and this fact underpins the development of membrane properties like conductivity and selectivity.337,344,491,492 There also exist exciting opportunities for enhanced separations as well as reduction in fluidic resistance using engineered nanoscale conduits like CNTs493−496 and graphene,497−499 but the success of these technologies in practice requires a high density of channels and a scalable and controlled fabrication process.

Figure 12.

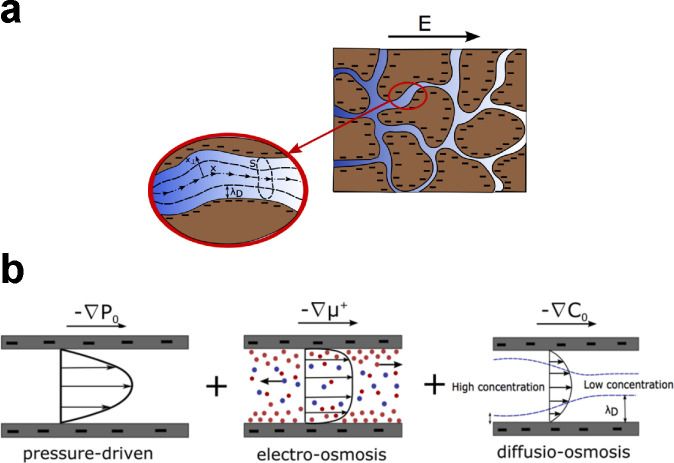

Electrokinetic transport in charged porous media. (a) Schematic of a charged porous medium with solid (brown) and porous (blue) domains. Ion and fluid transport occur along the center axes of pores. The thickness of the EDLs and the amount of surface charge influence the electrokinetic coupling. (b) Fluid can flow due to gradients in pressure, electric field, or electrolyte concentration. Ion separations use these modes of transport to impart selectivity based on electric charge. Reproduced with permission from ref (507). Copyright 2017 American Chemical Society.