Summary

Fire safety has become a major issue of public concern in the ready-made garments (RMG) sector, encouraging the Government of Bangladesh and the garment industry to step forward to rebuild consumer confidence. This thesis gathered information on the cost-effectiveness of the protection systems from several garment factories in Bangladesh. A four-step methodology was used in an attempt to adopt a systemic approach to constructing a fire safety management system (FSMS) for an offshore platform which, although the approach is general nowadays, has been applied to the case of the RMG industry. Significant changes have been made in fire safety management in the ready-made garment factories over the past few years. However, fire safety still tends to be analyzed in isolation through all fire loss that affects the garment industry. Fire loss may be seen as a set of ‘systematic’ failures, not as a result of only one reason. This study proposes an FSMS for the ready-made garment industry. It is hoped that this approach will lead not only to more effective management of fire safety, but also to the more effective management of safety, health and the environment for any organization. This study discussed the problems encountered by the management, and proposed a way to quantitatively evaluate fire risk and identify the cost-effectiveness of undertaking fire safety measures for the RMG sector of Bangladesh.

Keywords: fire, safety, management, ready-made, garments

Abstract

La sécurité-incendie (SI) dans l’industrie du prêt-à-porter (IPAP) est devenue une préoccupation publique majeure, amenant gouvernement bangladeshi et industriels à s’y intéresser, dans le but de regagner la confiance des consommateurs. Cette étude analyse les informations concernant le rapport coût-efficacité de tels systèmes dans plusieurs ateliers du secteur. Nous avons utilisé une approche systémique en quatre étapes, éprouvée dans l’étude de la sécurité des plates-formes de forage, permettant d’élaborer une stratégie globale de SI, approche qui pourrait être déclinée vers d’autres secteurs, industriels ou autres (santé, environnement...). Si des changements significatifs ont été apportés dans la SI de l’IPAP dans les années récentes, elles ne sont analysées que par le biais des pertes liées aux incendies. Cette étude se propose d’évaluer, au sein de l’IPAP, les problèmes rencontrés par l’encadrement, suggère une méthode d’évaluation quantitative du risque et démontre l’intérêt économique des mesure de SI dans l’IPAP.

Introduction

Export concentration utilizing the ready-made garments (RMG) industry is not a new phenomenon for Bangladesh because it has contributed a major portion of the GDP of Bangladesh over the last 30 years by exporting RMG products.1,2,3 This sector now exports the largest amount of ready-made garments and ranks Bangladesh as the second largest exporter to millions of factories all over the world, where 4.2 million people are employed in 4328 factories. 2,3 In 2015, garment exports were estimated to be about US$31 billion, a significant jump from US$17 billion in 2009.4,5 However this rapid and unregulated growth has resulted in a serious problem, namely fire safety management. In the rush to meet export demands, many factories have been set up with fire safety installation in buildings which are unsuitable for industrial purposes, with exit and entry points not designed for large numbers of workers to use at the same time, and where the need for industrial safety equipment was never anticipated. The industry focus has always been on the contribution that the sector was making to employment and export earnings and not on the safety of the factories.6

Garment industries in Bangladesh have a long history of industrial accidents. Major fires between 1990 and 2012 resulted in hundreds of accidental deaths, including at Tazreen Fashions Limited, Spectrum Sweater Industries, Phoenix Garments, Smart Export Garments, Garib and Garib, Matrix Sweater, KTS Composite Textile Meals, Sun Knitting and so on. Five deadly incidents between November 2012 and May 2013 brought worker safety and labor violations in Bangladesh to the fore of world attention, putting pressure on big global clothing brands such as H&M, Primark, C&A, Loblaw, Zara, Joe Fresh, Charles Vogele, Gap, Tom Tailor, Walmart, Old Navy, Nike, Tchibo, Calvin Klein, Tommy Hilfiger and other retailers to respond by using their economic weight to create change.7,8,9

In January 2013, government, workers’ and employers’ organizations adopted a tripartite statement of commitment to fire safety in the workplace in Bangladesh. In the statement, the partners recognized their individual and collective responsibility to ensure fire safety in every workplace in Bangladesh and committed to the development of a national Plan of Action on fire safety. Following a number of meetings facilitated by the International Labour Organization (ILO), the partners subsequently adopted the National Tripartite Plan of Action on Fire Safety in the Ready-Made Garments Sector of Bangladesh.10,11,12 Due to the pressure of buyers, compliance issues and increasing concern about worker safety, many of the garment industries now have fire safety measures.10,13

Cost-benefit analysis is a systematic approach to estimating the strengths and weaknesses of alternatives that satisfy transactions, activities or functional requirements for a business. Cost-benefit analysis has two purposes: to determine whether it is a sound investment or decision and to provide a basis for comparing projects. It involves comparing the total expected costs of each option against the total expected benefits to see whether the benefits outweigh the costs and if so by how much. Cost for undertaking fire safety measures encompasses consultancy cost, system installation cost and maintenance cost, whereas benefits include the value of the net reduction in property damage, injuries and fatalities, an increase in profit from order gain and concession in insurance cost.

The objective of this study was to determine the cost-effectiveness of undertaking fire safety measures for the RMG sector of Bangladesh. This study is also concerned with determining the cost-benefit analysis of taking fire safety measures.

Materials and methods

This is an exploratory research where data have been collected from a relatively small group of respondents through a semi-structured interview. Here the research findings are not determined by quantitative analysis. Generally, qualitative research methods are used primarily as a prelude to quantitative research. It is inexpensive, fast and a small number of respondents is involved. Due to the small group involved, these exploratory research methods cannot be used to generalize to the entire population but it is very valuable for exploring an issue at the initial stage. The analysis is mainly based on primary data collected from the respondents and secondary data are only used to understand the allied issues.

Sources of primary data

The primary data were obtained by conducting survey interviews (face-to-face) with selected RMG factory owners or top management of garment industries in selected areas of Bangladesh. For the collection of data, the researcher prepared a structured questionnaire, which is included in Appendix 1. The survey was conducted on a sample of 10 garment industries that have fire safety systems. The factories were selected on a judgmental basis.14 The questionnaire contains several questions and the questions are of various types. Some questions are of a dichotomous type, some are multiple choice, and the rest are composed of both open-ended and rangebased questions. Data involve total factory values increase in revenue, amount of insurance premium paid or confidential information, and the respondents were unwilling to reveal the accurate values. Therefore, approximate values have had to be used. Again, the cost of injuries and death of employees is not included as it is very difficult to determine the value of one’s life in numerical value. All the questions are designed in such a way that the relevant information can be collected from owners or managers of garments of Bangladesh.2

Sources of secondary data

Relevant information was collected from scholarly journals, research papers and articles of different newspapers. These are collected primarily from websites on the World Wide Web. Search engines such as Google and Yahoo were also used to search for relevant information.

Sample design

The 10 ready-made garment industries were selected from Chittagong Export Processing Zone and Karnaphuli Export Processing Zone. From Chittagong Export Processing Zone we selected Pacific Jeans Limited, NHT Fashion, Universal Jeans and Jeans 2000, and from Karnaphuli Export Processing Zone Xin Chang Limited, Alamode Apparels Limited, F&F Fashion, Charm Fashion, Divine Design Limited and Nafisa Apparels Limited. The judgmental sampling method was used for this study. In this study the target population is 10 garments factories of Chittagong in Bangladesh.15,16,17

Statistical analysis

Data were analyzed using Microsoft® excel 2013/XLSTAT® (Version 2013.2, Addinsoft, Inc., Brooklyn, NY, USA).

Results and discussion

This study will give a clear view to the garment owners about the cost and benefit associated with the implementation of fire safety systems in their garment industries. It will help the factory owners to be aware of the fire safety issue, benefits and associated costs, which will help them to make decisions regarding the implementation of fire safety measures. Again, it is very important to provide better and safer working conditions because buyers from all around the world are highly concerned about safety issues. In order to improve the workers’ working conditions and minimize bad reputations, various programs have been undertaken, such as the ILO RMG Program, Better Work Bangladesh, the Accord on Fire and Building Safety in Bangladesh, the Alliance for Bangladesh Worker Safety Program and so on.6,18

In this study, the researcher mostly worked with the primary data to conduct the cost-benefit analysis of implementing fire safety systems in the garment industries in Chittagong, Bangladesh. Secondary data are used to support the analysis of primary data and help to understand the current situation of garment industries, problems, prospects etc.

Overview of the sampled garments factories

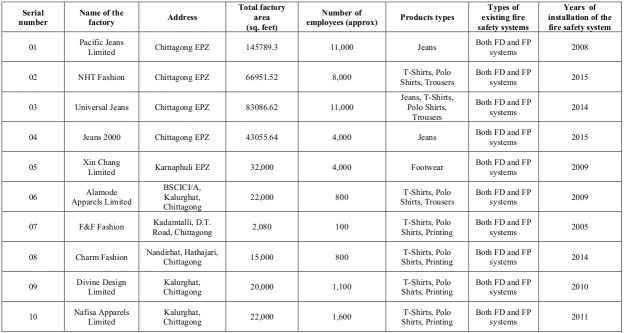

Firstly, an overview of the sampled garments industries is given in Table I by providing information such as the name of the firm, address, total factory area, number of employees, type of products produced, and type of existing fire safety systems and year of installation of the safety system in tabular form. After providing general information about the sampled industries, Table II is added to show the value of different factors (total factory value, total installation cost of fire safety system, annual maintenance, replacement, servicing cost of installed fire safety systems, cost due to taking fire safety measures and annual increase in sales, etc.) contributing directly to the total cost as well as total benefit associated with taking fire safety measures.

Table I. General information of the sampled factories.

Table II. Information related to the cost and benefits of having fire safety systems of the sampled factories (all are approximate values and given in BDT).

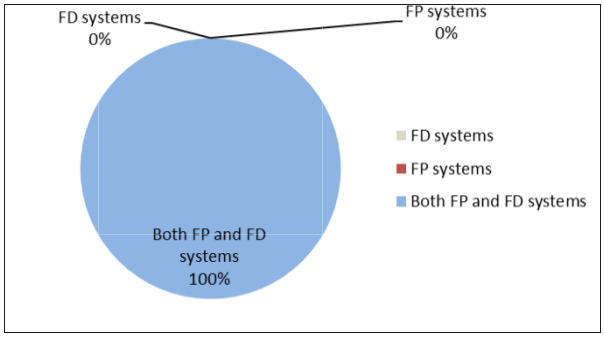

Types of fire safety systems and their implementation

Fig. 1 below shows the percentages of sample garment industries having a fire detection (FD) system, a fire protection (FP) system and both FP and FD systems. From the collected data the researcher found that among the 10 sampled garments industries, all of them have both FP and FD systems. Fire detection systems and fire protection systems are used as fire safety measures. FP systems help to suppress or control the fire. FD systems include smoke detectors, heat detectors, fire alarms, horn, strobe, control panel, etc., where FP systems include fire hydrant, sprinkler-based fire suppression system, fire extinguisher, fire bridge connection and so on.19

Both FD and FP systems are necessary to provide a proper fire safety environment. Implementing only an FD system or FP system is not a wise decision. An FD system will make people aware of the fire and help early evacuation, but cannot help to control the fire. To control and suppress the fire, factories require FP systems as well.20

Fig. 1. Type of fire safety system in the sampled factories.

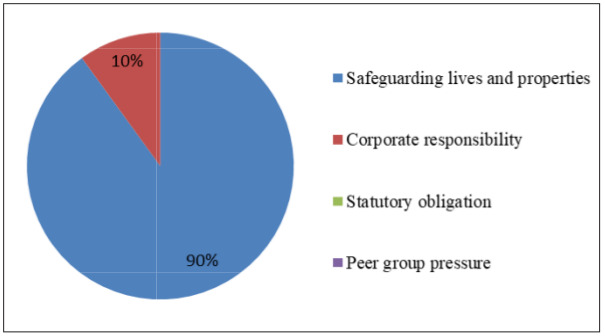

Purpose of implemented fire system in the factory

Generally, there are four types of purpose available for the implementation of fire safety systems, such as safeguarding lives and properties, corporate responsibility, statutory obligation and peer group pressure. Normally safeguarding provides garment workers and property safety, whereas corporate responsibilities to workers are only to maintain buyer requirements.21 Again statutory obligations are those obligations that do not arise out of a contract, but are imposed by law and peer pressure (or social pressure). Statutory obligation is the direct impact on people by peers, which is different from general social pressure.21 Peer pressure means the effect on an individual who is encouraged to follow their peers by changing their behaviors to conform to those of the influencing group. Peer pressure can change an individual to respond to a feeling of being influenced by a peer or peer group. Social groups affect membership groups to trade unions. However, a person may be a member or be seeking membership of a group affected by peer pressure. Fig. 2 shows the purpose of implemented fire safety systems in industries. From the collected data the researcher found that among the 10 sampled garment industries, ninety percent of them have implemented a fire protection system to safeguard lives and properties while the other one installed it only because of corporate responsibilities.

Fig. 2. Purpose of implemented fire system in the factory.

Fire safety systems and fire accidents

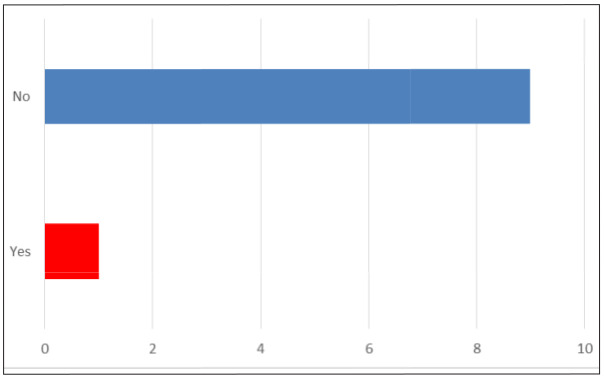

Fig. 3 shows any percentages of fire accidents after installation of the fire safety systems. Taking fire safety measures cannot stop fire accidents, but can definitely reduce the risk and loss due to the accident. Among the 10 sampled garment industries, only one underwent a fire accident. Some other sampled factories had also faced fire accidents which were not major enough to cause any considerable loss and were controlled successfully by the existing fire safety systems.

Fig. 3. Percentages of fire accidents after installation of the fire safety systems.

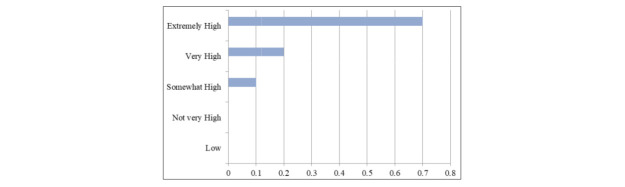

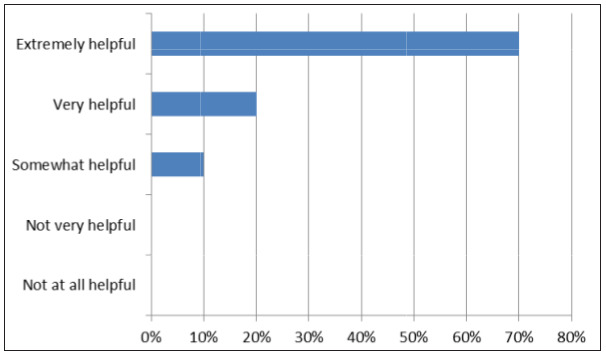

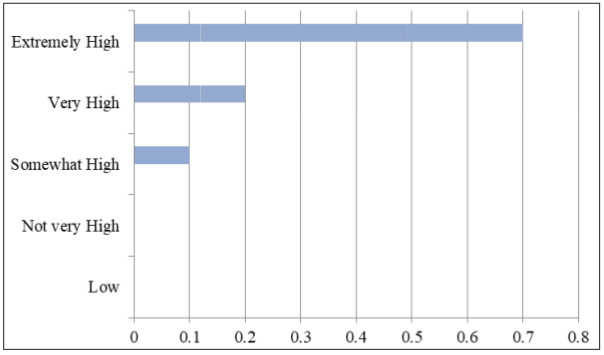

Fig. 4 shows whether the fire safety systems helped during fire accidents or not. 10% of the respondents or factory owners said that the existing fire safety measures had somewhat helped them to fight fire accidents successfully. 20% of the respondents believed that the fire safety system was very helpful, and 70% said it was extremely helpful in the case of fire accidents by controlling the fire successfully.

Fig. 4. Helpfulness of utilization of fire safety systems during fire accidents.

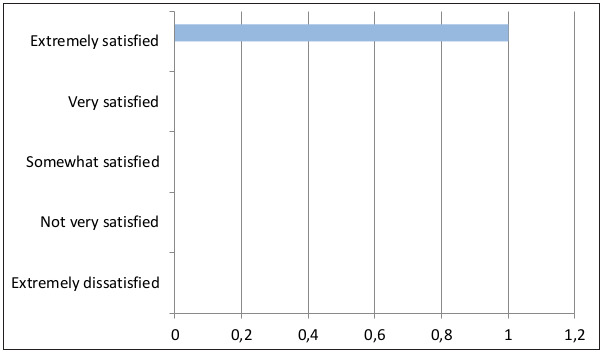

Level of productivity and confidence with the existing fire safety systems

The level of productivity of the higher authority and confidence of workers are the purposes of any business where worker safety issues are the major concern in today’s work environment. Fig. 5 shows the level of confidence with the existing fire safety systems. From the collected data the researcher found that among the 10 sampled garment industries, all of them are extremely satisfied with their productivity and confidence level and all of them have a practical training program every month in their factory and try to minimize escape from.

Fig. 5. Satisfaction level of productivity and confidence.

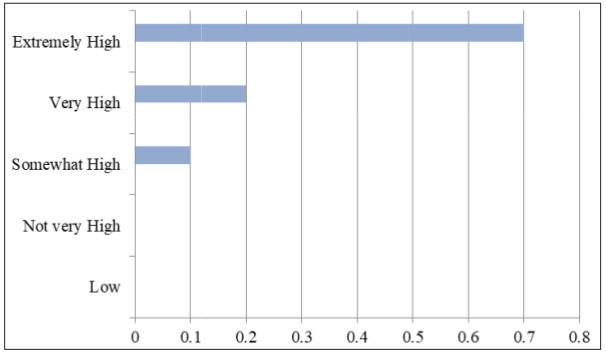

Fire safety systems and increase of sales

Revenue generation is the main purpose of any business. Again, worker safety issues are a serious concern for large markets such as the USA (27.28% of exports) and Europe (61.28% of exports), the main two markets in Bangladesh. Fig.6 shows the increase in sales after installing fire safety systems. From the collected data the researcher found that among the 10 sampled garment industries, 70% of respondents believe that sales showed an extremely high increment after installing a fire safety system, 20% of respondents believe that the increase in sales was very high, and 10% of factory owners claim that their sales have somewhat increased after taking fire safety system measures.

Fig. 6. Increase in sales after installation of the fire safety systems.

Level of satisfaction with the existing fire safety systems

Level of satisfaction with the existing fire safety systems is presented in Fig. 7. While 60% of the respondents said that they were somewhat satisfied with the installed fire safety systems, 40% found the implemented systems very satisfactory. Satisfaction with any installation is a very important consideration, which increased the level of confidence and increased productivity.

Fig. 7. Satisfaction level with the installed fire safety system.

Basement and construction characteristics and air emissions

From the collected data the researcher found that among the 10 sampled garment industries, all of them are built with concrete and brick, which are not up to the mark according to their design specification. Some machinery is extremely vibrating, therefore for proper stability and safety, the basement should be made of stone and not the regular brick chips. According to the ACCORD study, 20% of the industry buildings are built with proper safety design.2The other issue found was that among the 10 sampled garment industries, most of them use only windows as an air emission system and very few of them use other air purification systems other than windows.

Waste management in the RMG sector

From the collected data the researcher found that among the 10 sampled garment industries, none of them is aware of any kind of wastage. Everybody dumps their liquid waste into a nearby river or canal. Most of the solid waste is sold at local markets and some of the solid waste is incinerated by Pacific Jeans Limited.

Boiler safety in RMG Sector

Boiler safety conditions in the RMG sector are shown in Table III where the type of fuel, number and size of the boiler, type and number of fire extinguishers are presented. Class A for trash, wood and paper, Class B for liquids and gases, and Class C for energized electrical sources (ABC) and Carbon dioxide (CO2) are common fire extinguishers in all of the industries. Most of the factories use ABC and CO2 fire extinguishers along with water and sand. Again a diesel boiler is common in RMG industries, while nowadays compressed natural gas (CNG) is available to industries. In the ten sampled RMG factories, eight of them have a diesel boiler, where four of them have installed a CNG boiler alongside: these are Pacific Jeans Limited, NHT Fashion, Universal Jeans and Jeans 2000. Again Pacific Jeans Limited, NHT Fashion and Universal Jeans have the highest number of boilers, and NHT Fashion has the largest boiler size which in total was twenty-four tons. Universal Jeans has a total twenty-one tons and Pacific Jeans Limited have a total eighteen tons boiler. Jeans 2000 have three boilers whose total size is thirteen tons. Divine Design Limited and Nafisa Apparels Limited has two boilers which total ten and eight tons respectively. Xin Chang Limited and Alamode Apparels Limited has one boiler each, both eight tons. The highest number of fire extinguishers present in the boiler room was at Pacific Jeans Limited and NHT Fashion. Universal Jeans has eight fire extinguishers in their boiler room and Xin Chang Limited has seven fire extinguishers in their boiler room. Jeans 2000, Alamode Apparels Limited have five fire extinguishers in their boiler room. In the above subsections, the primary data to conduct the cost-benefit analysis of implementing fire safety systems in the garment industries has been presented. These data were collected through a survey questionnaire which was conducted by the researcher. These primary data are correlated with the secondary data to draw the final analysis which is described in the upcoming chapter.

Table III. Boiler information of the sampled factories.

Cost benefit analysis

In this thesis, the cost-benefit analysis of existing fire safety systems of the sampled garment industries is conducted to analyze the cost-effectiveness of fire safety systems. The researcher has taken the approximate values for determining the total cost and benefit as most of the respondents disagree or are unable to provide confidential information such as property values, increases in revenue and so on.

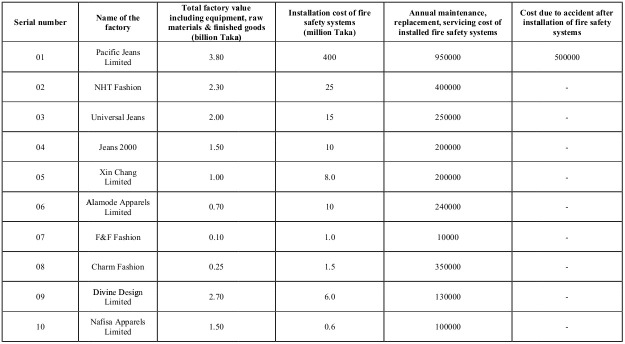

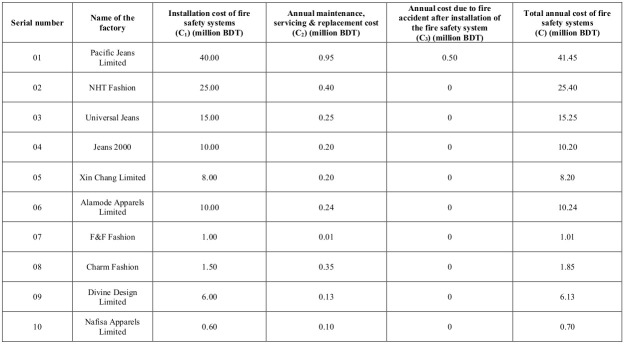

Determination of total annual cost on fire safety system

Total annual cost of fire safety systems is determined using the following equation 01; C = C1 + C1 + C1 ————— equation 01 where,

C is total annual cost of the fire safety system, C1 is installation cost of the fire safety systems, C2 is annual maintenances, servicing and replacement cost, C3 is annual cost due to fire accidents after installation of the fire safety system.

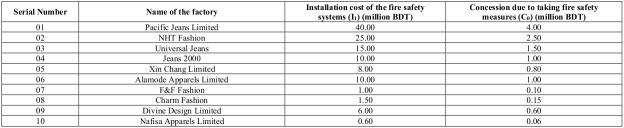

Table IV shows the installation cost of the fire safety systems, annual maintenance, servicing and replacement cost, and annual cost due to fire accidents after installation of the fire safety system, from which we can evaluate total annual cost of fire safety systems of the ten sampled RMG factories. The highest installation cost was that of Pacific Jeans Limited, which was 40 million BDT, and the lowest was Nafisa Apparels Limited, which was 0.60 million BDT. Again Pacific Jeans Limited has high annual maintenance, servicing & replacement costs, which were 0.95 million BDT, and the lowest was F&F Fashion with 0.01 million BDT. After installing a fire protection system, Pacific Jeans Limited faced one fire accident which cost them 0.50 million BDT.

After putting all data into equation 01, we can calculate the total annual cost of fire safety systems. The highest expenses were those of Pacific Jeans Limited, which were 41.45 million BDT, and the lowest was Nafisa Apparels Limited with 0.70 million BDT

Table IV. Total annual cost of fire safety systems of the sampled factories.

Determination of annual concession in insurance cost

If an RMG company installs an FD system or both FD and FP systems in their factories, they are entitled to get a 5% discount for BGMEA membership, 1% discount for installing only FD systems or 5% discount for installing both FP and FD systems.

C0 = 10% × I1 ———-— equation 02 where, C0 is Concession due to taking fire safety measures and I1) is installation cost of the fire safety systems.

Table V shows the concessions obtained due to taking fire safety measures from BGMEA for their membership. Due to high installation cost, Pacific Jeans Limited has the highest concession for BGMEA membership and F&F Fashion has the lowest concession for BGMEA membership. We can calculate concession using equation 02 and the highest concession was 4.00 million BDT and the lowest concession was 0.10 million BDT.

Table V. Concessions obtained due to taking fire safety measures of the sampled factories.

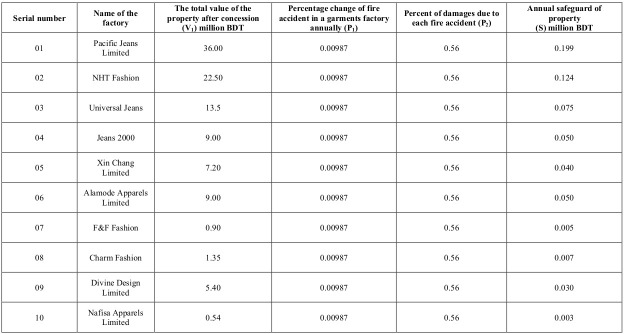

Determination of annual safeguard of property

In most of the factories the total annual safeguard of property associated with fire safety systems is determined using equation 03;

S = V1 × P2 × P3 ————— equation 03 where,

V1 is total value of fire accidents in a garments factory annually, P2 is percentage change in fire accidents in factory annually, P3 is percentage of damages due to each fire accident. According to the Bangladesh Fire Service and Civil Defense, a total 48 fire accidents occurred in RMG factories from January to October 2013 and the total number of RMG factories in 2013 was 5876 (Source: BGMEA web portal).22 Using these data, percentage change of fire accidents in a garments factory annually in an RMG factory annually was 0.00987.23

Again, to determine the chances of loss due to a fire accident the researcher has considered the results of a study on “Assessment of fire risk in the readymade garment industry in Dhaka, Bangladesh” by Wadud, Huda & Ahmed (2013) where Fire Risk Index (FRI) for 60 random garment factories was assessed through surprise inspections to understand the current status of fire risk due to inadequacies.15 Results show that the mean FRI is 2.8 on the scale of 5.0, which means 56% risk. Percent of damages due to each fire accident (P2) is 0.56.

Putting the values into equation 03, we found S = V1 × 0.00987 × 0.56 ————— equation 04 after installation of fire safety system is not considered due to it being included in the total value of fire accidents in a garments factory annually.

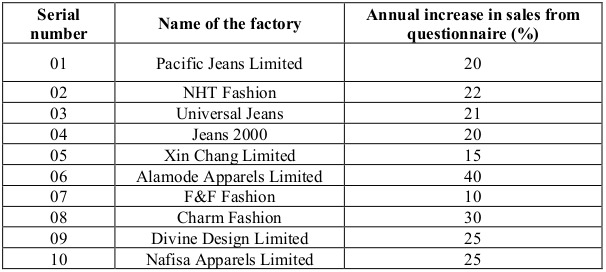

Annual increase in sales

Table VII shows an annual increase in sales, where Alamode Apparels Limited claims a 40% increase due to installing a fire safety system, while F&F Fashion claims only 10%. It is clear that installing a fire safety system always increases sales. In this cost-benefit analysis, the researcher found that for all the sampled factories the benefit of implementing fire safety systems is very high with respect to the cost associated and thus it can provide a higher annual gain. Again the performed cost-benefit ratio shows that the total cost of having fire safety systems is negligible when compared to the total benefit achieved. We can understand that for factories which have only implemented FD systems the gain can be very high as the cost is lower due to avoiding FP systems. However, only installing a fire detection system is not a wise decision as the risk of loss due to a fire accident becomes high. Moreover, if here the benefit achieved from savings of potential workers’ lives and injuries would have been considered, then the amount of total benefit would be even higher. Therefore, implementing a fire safety system is very cost-effective. Garment industry owners must take proper fire safety measures in their factories, which are beneficial in so many aspects and also very cost-effective.

Table VI. Annual safeguard of property of the sample factories.

Table VII. Annual increase in sales of property of the sample factories.

Conclusion

The ready-made garments (RMG) industry occupies a major position in the Bangladesh economy. It is the largest export industry in Bangladesh, and has experienced phenomenal growth over the last 30 years, with an alarming challenge, namely, safety, especially fire safety. But the unfortunate history of Bangladesh’s RMG factory disasters is enough evidence that fire safety systems should be installed to avoid these kinds of abnormal phenomena. Recently, factory management has shown concern and has taken the initiative to install a fire safety system to save assets such as infrastructure, raw material, as well as for their workers’ safety.

A fire safety system not only saves assets but also minimizes cost and increases sales. By installing a fire safety system, factories can safeguard their property with some insurance policy, which makes them comfortable. Today RMG factories are more concerned about maintaining fire safety management to get proper accreditation from ACCORD Alliance as well as from the government safety regulation board. Thus they can bring more foreign buyers to invest in Bangladesh’s RMG sectors, which earns more foreign currency and enhances our economic growth.

To remain successful, Bangladesh needs to remove all the structural obstacles in the factories, power supply, management of seaport, utility services and in the law and order situation. The government and the RMG sector would have to jointly work together for continued competitiveness in the global RMG market. Given the remarkable entrepreneurial initiatives and the dedication of its workforce, Bangladesh can look forward to advancing its share of the global RMG market and RMG factory owners should be joining this novel approach to workplace safety.

References

- 1.Momen MN. Implementation of privatization policy: lessons from Bangladesh. The Innovation Journal: The Public Sector Innovation Journal. 2007;12(2):1–14. [Google Scholar]

- 2.The thing that makes Bangladesh’s garment industry such a huge success also makes it deadly – Marc Bain and Jenni Avins, Quartz, April 24, 2015. [Accessed 10 February, 2017]; Available from http://qz.com/389741/the-thing-thatmakes-bangladeshs-garment-industry-such-a-huge-success-alsomakes-it-deadly . [Google Scholar]

- 3.Hossain MK, Rana M, Ahmed F. Impact of recession on readymade garments of Bangladesh: a critical analysis. Int J Adv Res. 2016;2(9):85–90. [Google Scholar]

- 4.Adnan A, Rakib A, Rahman M. Export trend of Bangladesh: the dominance of ready-made garments industry. J Econ Bus ICT. 2015;10(1):25–31. [Google Scholar]

- 5.Muhammad A. Wealth and deprivation: ready-made garment industry. Journal of Bangladesh Economic and Political Weekly. 2011;46(34):23–27. [Google Scholar]

- 6.RMG industry of Bangladesh: Past, Present and Future. [Accessed 10 February, 2017];Dhaka Tribune. Available from:http://www.dhakatribune.com/long-form/2014/sep/16/rmg-industry-bangladesh-past-present-and-future . [Google Scholar]

- 7.Bangladesh garments: crisis and challengers. [Accessed 10 February, 2017];The Daily Star. Available from: http://www.thedailystar.net/bangladesh-garments-crisis-and-challenges-4797 . [Google Scholar]

- 8.Safety overhaul puts strain on Bangladesh garment industry. [Accessed 10 February, 2017.];Reuters. 2015 Available from: http://www.reuters.com/article/us-bangladesh-garments-insightidUSKBN0KD0N820150104 . [Google Scholar]

- 9.Venkatesan R. Clothing garment workers in safety: the case of Bangladesh. [Accessed: September 27, 2021];J Econ Political Wkly, 2013 48(28) Available from: https://www.epw.in/journal/2013/28/web-exclusives/clothing-garmentworkers-safety-case-bangladesh.html . [Google Scholar]

- 10.Ahamed F. Could monitoring and surveillance be useful to establish social compliance in the ready-made garment (RMG) industry of Bangladesh? Int J Manag Bus Stud. 2013;3(3):88–100. [Google Scholar]

- 11.Good governance in the ready made garments sector: promises and progress (2013), a follow-up on research by Transparency International Bangladesh, based on previous TIB study “RMG Sector: Problems of Good Governance and the way forward [Google Scholar]

- 12.Improving working conditions in the ready-made garment sector in Bangladesh (RMGP Program) [Accessed 10 February, 2017]; Available from: http://www.ilo.org/dhaka/Whatwedo/Projectssafer-garment-industry-in-bangladesh/lang—en/index.htm . [Google Scholar]

- 13.Ahamed F. Improving social compliance in Bangladesh’s readymade garment industry. Labour and Management in Development. 2013;13(1):1–26. [Google Scholar]

- 14.Schindler, Pamela S, Cooper DR. Marketing research. Tata McGraw-Hill Education. 2005 [Google Scholar]

- 15.David FP. Iloilo City: Social Science Institute. Central Philippine University; Philippine: 2005. Understanding and doing research: a handbook for beginners. [Google Scholar]

- 16.Gill J, Johnson P. Survey Research Design. chapter 06. Sage Publications Limited; London: 2002. Research methods for managers; pp. 96–122. [Google Scholar]

- 17.Lunsford TR, Lunsford BR. The Research Sample, Part I: Sampling. J Prosthet Orthot. 1995;7(3):105–112. [Google Scholar]

- 18.Prospects and challenges of garments industry. [Accessed 10 February, 2017];The Daily Star. Available from: http://www.thedailystar.net/prospects-and-challenges-of-garment-industry-21008 . [Google Scholar]

- 19.Akther S, Salahuddin A, Iqbal M, Malek M, Jahan N. Health and occupational safety for female workforce of garment industries in Bangladesh. J Mech Eng. 2010;41(1):65–70. [Google Scholar]

- 20.Safety is a game-changer. [Accessed 10 February, 2017];Dhaka Tribune. Available from: http://www.dhakatribune.com/opinion/op-ed/2015/04/12/safety-is-a-game-changer/ [Google Scholar]

- 21.EU sees ‘encouraging’ progress in Bangladesh RMG labour safety issues. [Accessed 10 February, 2017];Bdnews24.com. Available from: https://bdnews24.com/business/2014/10/20/eu-sees-encouraging-progress-in-bangladesh-rmglabour-safety-issues . [Google Scholar]

- 22. [Accessed 10 February, 2017];BGMEA B2B Web Portal. Available from: http://www.bgmea.com.bd/home/about/AboutGarmentsIndustry . [Google Scholar]

- 23.Wadud Z, Huda F, Ahmed N. Assessment of fire risk in the readymade garment industry in Dhaka, Bangladesh. J Fire Technol. 2014;50(5):1127–1145. [Google Scholar]