Abstract

Crises cause delays in supply chain management with resulting changes to organizations’ internal structures. The COVID-19 pandemic has deeply affected the global supply chain and, with it, the organizational structure of companies. This research discusses supply chain collaboration (SCC) by considering two important organizational competencies: organizational learning culture (OLC) and decentralization (DC). It investigates the potential impact of these intangible resources upon SCC after the COVID-19 pandemic. The theoretical model was tested by variance-based Structural Equation Modeling (SEM) using results of a questionnaire which was completed by 245 respondents. In fact, this study explores which organizational capabilities determine the SCC level specifically within the current COVID-19 pandemic period. We believe that this contribution is significant, as the level of collaboration between companies can change during risk periods. The results show that OLC have significantly positive effects on SCC. Moreover, DC plays a critical role for the relationship between OLC and SCC. In other words, this study reveals the importance of DC to observe the positive effects of OLC on SCC. Unlike previous studies which explored SCC, this research demonstrates the importance of an organization’s inherent intangible resources in order to improve relationships with suppliers. The article ends with a discussion of the findings and their implications.

Keywords: Supply chain collaboration, Organizational Learning Culture, Decentralization, Resource-based View

Introduction

With a developing and increasing global trade environment in recent times, learning about organizational learning culture (OLC) and decentralization (DC), and subsequently applying them has become a major continuing necessity for organizations. In order to survive in such a business environment, companies must have an OLC (Egan et al. 2004). Organizational learning is the process of acquiring knowledge and, if well managed, it provides a competitive advantage to companies (Chang and Lee 2007). This can be achieved through observing developments within both the internal and external business environments. For this reason, organizational learning plays a critical role in helping organizations adapt to the changing environment comfortably. In today’s dynamic business world, organizations increasingly need to focus on learning faster and better than their competition in order to maintain their profitability and performance. As argued by Hosseini et al. (2020), culture indeed enables organizations to ensure sustainability. In this regard, the OLC can also be considered to be a guide for companies with which to achieve long-term financial profits. In other words, organizations with a learning culture are able not only to survive, but also to have greater financial profits (Eisenberg 2018). In addition, such a culture can assist organizations in creating advantages for their supply chain management by increasing flexibility and speed. Furthermore, a culture of learning improves the management capability of firms, leading to better business performance (Alegre et al. 2012; Andreou et al. 2016).

Organizations which survive are most often those that can transform themselves. As technology develops, so do the needs of customers. These changes reveal the necessity to continuously offer new products and services. Organizational learning, therefore, plays an important role at this point. Through integrating learning into their culture, companies are able to quickly meet the needs of the market by considering the expectations of their customers. As stated by Mirkamali et al. (2011), an OLC is crucial in order to offer new products and services to the market. Furthermore, digitization is a critical phenomenon that affects the operations and performance of businesses. It forms the basis of the fourth industrial revolution due to its enormous impact on the supply chain (World Economic Forum 2018; Truant et al., 2021). Digitization means the use of digital technologies to provide added value to an organization’s business model (Gartner 2018). In that point, the literature reveals that digitalization has a significant positive effect on learning processes and business continuity (Gupta et al. 2022; Ratchavieng and Srinet 2021). Therefore, organizations that want to have a learning culture should give importance to information management systems, as well.

Another factor that impacts organizational performance is structure. In this study, we consider DC to be a dimension of organizational structure. DC is chiefly defined as transferring decision-making and responsibilities to sub-workers or suppliers (Cullen and Perrewé 1981; Mehralizadeh 2005; Schiefelbein and Schiefelbein 2000). Many studies within the literature show the effect on performance arising from DC. Accordingly, under certain circumstances, central organizations are found to be more effective, whereas in other cases, DC can provide more successful results. (Nasirpour et al. 2010; Gaber 2003; Wang 2010; Andrews et al. 2007). It may be considered effective to mix these two structural systems for better management under certain circumstances (Hawkins 2000).

Organizations have experienced varying consequences in response to the COVID-19 pandemic, which began in December 2019. Within this context, companies have been forced to close for a certain period of time, working hours have changed, and many employees have been working remotely. This situation affected the control of all operations, making it much more difficult to organize efficiently. It is a matter of curiosity as to whether centralized companies will maintain their characteristics under the changed working conditions after the COVID-19 pandemic ends.

In recent years, the classical concept of supply chain management (SCM) has expanded, while SCC has been discussed frequently, both in business life and in academia (Ahmed et al., 2020; Li and Chen 2019; Chiang et al. 2018). It is a strategic issue for organizations wishing to have a sustainable performance. SCC is a partnership process established by at least two independent organizations in order to carry out operations more effectively, and to ensure their mutual benefit (Cao and Zhang 2011; Parmigiani and Mitchell 2010). This cooperation can include not only firms, but also governments, universities, institutes, and R&D organizations (Lee et al. 2010; Mirc et al. 2017; Al-Tabbaa and Ankrah 2019). Meanwhile, different collaborations have been established in later years within the supply chain field, focusing upon green production (Ağan et al., 2016). Interest and awareness in SCC has increased critically; companies have found advantages such as sharing information comfortably and providing competitive advantages, while reducing overhead costs and inventory. (Soylu et al. 2006). The ultimate goal of SCC is to gain a competitive advantage within the related market (Soylu et al. 2006; Chen et al. 2017; Cao and Zhang 2011).

Many studies have discussed the SCC in the literature, however few studies have emphasized the importance of OLC and DC for supply chain operations (Chang and Lee 2007; Nasirpour et al. 2010). To fill this gap in the literature, we construct a theoretical model that the importance of OLC and DC for SCC. While establishing this structure, we consider the Resource Based View (RBV), which claims there are benefits for effective and joint usage of organizational resources, as a focal point. Strategic decisions are “the decisions that critically affect organizational well-being and survival” (Eisenhardt and Zbaracki 1992). Based on the RBV, organizations build competitive advantage through using the available resources strategically (Penrose 1959). The RBV accepts both tangible and intangible assets of an organization as resources contributing to creation of a competitive advantage (Wernerfelt 1984). While the view mainly assumes that organizations can develop a competitive advantage by creating strategic resources and capabilities (Dubey et al. 2018), the relevance of these resources varies depending on the conditions of such dynamic ecosystems, such as crises.

Having reviewed the related discussion, this study examines the effect of such organizational characteristics as OLC and DC on SCC. The main questions raised within this research are the following; (i) What is the relationship between SCC and the suggested organizational characteristics? (ii) Do these relationships change if experienced within small and medium sized enterprises (SMEs) or large firms? (iii) Do these relationships differ when the companies in a country are local or foreign? In this study, research questions were posed through cross-sectional questionnaires. The survey items were adapted from the literature. The managers of 245 businesses responded, which provided a comprehensive understanding of their companies’ inner workings and supply chains. The theoretical model for this research was tested with variance based structural equation modeling (SEM). With this study, our contribution to the literature will demonstrate the importance of OLC and DC for SCC and identify the precursors of SCC during the COVID-19 pandemic. This research provides these findings empirically with statistical analyses. We believe these results will inspire shareholders and managers to develop effective collaboration strategies in order to prevent further supply chain disruptions in the COVID-19 pandemic situation, or within similar risk environments.

The rest of the paper is organized as follows. Section 2 provides an extensive literature review on the studies regarding OLC, DC and SCC, with the theoretical development of our hypotheses building upon the research model. Sections 3 and 4 present background information about the methodology used and illustrate the results, respectively. The findings are discussed in Sect. 5. Finally, Sect. 6 provides concluding remarks and possible future research directions.

Literature review

Ensuring a learning culture that leads to performance improvement has become vital for the ability to compete in today’s changing business environment (Lau et al. 2019). This study provides evidence for the suggested relationships among OLC, DC and SCC, with explanations leading to the ways in which organization-level concepts and qualifications can be related to supply chain characteristics.

OLC is suggested in this study as providing the main infrastructure for an organization to establish cooperative behavior with its supply chain partners. Accordingly, having established a learning culture can help organizations to ensure a framework that facilitates exchanges of necessary information, adaptation strategies and supportive behavior, as learning culture makes organizations creative and problem-solving (Ojha et al. 2018). As organizational culture has a significant role in shaping the structure and decision-making processes, this study assumes that learning culture has an impact on the DC of the organization and it is DC that explains a further association between OLC and SCC. Accordingly, a learning culture can help the organization to become flexible, which contributes to the empowerment and delegation by the management. This can eventually add to the openness to the environment and therefore to become likely to collaborate with the inter-organizational partners.

Through this approach, the aim of this paper is to demonstrate that a collaborating supply chain, or indeed, much of the nature of any sub-system within an organization, has roots in organization-wide issues such as culture and decision making, which are learning culture and DC in this instance. To this end, this literature review section briefly introduces and discusses each construct within the model, followed by the hypotheses development section that provides explanations concerning the relevance of examining relationships among the constructs.

Organizational learning culture (OLC)

Organizational culture is about the norms and values established within an organization and helps to shape both employees’ and organization’s behavior. There are various types of organizational culture widely discussed within the organization literature, mainly as clan, adhocracy, hierarchy and market culture, according to the framework developed by Quinn and Rohrbaugh (1983). In addition, several other dimensions can be added to this classification, depending on which values an organization adopts. This means, on what basis an organization aims to shape its behavior can be converted into a culture in a long-run. For example, an organization can establish a culture out of the bureaucratization and adapt a bureaucratic culture. In this study, learning culture has been suggested, while aiming to explain SCC via a decentralized structure.

Organizational culture can be mainly defined as a pattern of basic assumptions developed while learning to cope with the problems of external adaptation (Schein 1992). Therefore, this study has integrated organizational culture as the main antecedent of SCC, which is also maintained with the aim to adapt to the supply chain environment in better terms. The OLC has been specifically chosen as the triggering construct of the model that contributes to SCC because of has two aspects. First, organizational culture facilitates learning for supply chain parties by developing relationships that help to exchange knowledge and experiences (Zhao et al. 2011). Secondly, the specific learning culture is identified from among other types of organizational cultures, as it is critical towards boosting the organizational performance (Arefin et al. 2020).

Watkins and Marsick (1993) referred to a learning organization as it being transformed continuously and enabling employee involvement in a collective manner. Furthermore, learning organization is considered to be the ability to adjust in response to new realities when demanded by change in the work environment Gephart et al. (1996). Combined, an approach that adapts learning behavior and habits as a culture becomes critical for organizations. This points to the significance of the learning culture and investigating its effects upon periods of change, such as in the case of the current pandemic. Škerlavaj et al. (2007) identified learning culture as a set of values supporting systematic approaches in order to achieve higher-level learning through information acquisition, interpreting this information, and instituting the resulting required behavioral changes. A learning culture encourages an organization and its employees to add to their knowledge and performance regularly (Chanani and Wibowo 2019). Specifically, according to Dodgson (1993), being a learning organization has become critical, especially for larger organizations, as they attempt to develop systems which are adaptable to change. This study asserts that learning culture is a turning point that creates awareness with regard to the need for change, and thus developing a capability for collaboration with suppliers. Organizational culture has been identified as a unique organizational resource within the literature (e.g. Zahra et al. 2004; Melville et al. 2004; Özçelik et al. 2016; Ahmed et al. 2018). Moreover, Tynjälä (2013) argued that the learning culture is vital in enabling organizations to remain competitive. Teece (2015) further regarded it as a source of competitive advantage. In their study, Jin and Hong (2007) considered SCC with a reference to organizational culture, yet via the six dimensions that describing the patterns of culture as suggested by Hofstede (1994). However, so far, no study has focused on the effect of the learning culture on the organization’s supply chain management, which this study considers.

In this study, with respect to a resource-based view, the OLC is considered to be a strategic resource being valuable, non-substitutable and unique to each organization, and which contributes to its competitive advantage. In this regard, this study maintains that an OLC is an important intangible resource for organizations.

Supply chain collaboration (SCC)

The business environment of today dictates a high level of integration and collaboration between processes, especially for manufacturing (Fatorachian and Kazemi 2018). More specifically, SCC has become a critical common norm for many organizations (Ramanathan and Gunasekaran 2014). The importance of studying collaboration is that it is highly related to several positive outcomes such as sharing risks (Parkhe 1993) and the general performance (Hewett and Bearden 2001) of organizations. According to Kanter (1994), ‘collaboration’ carries the implication of ‘creating value together’. Corsten and Felde (2005) identified collaboration as a joint effort within buyer-supplier relationships. Within this collaboration are included coordination, knowledge transfer and strategic alliance. Many organizations have realized the importance of external connections and have tried to become involved in networks where resources and information are mutually interchanged (Teece 1992). Collaboration provides a basis upon which to produce improvements via partners and can assist in reconsidering current processes (Dodgson 1993). Supply chain managers look externally to meet customer needs, to share risks, capitalize on partner expertise, and even to handle market operations (Ralston et al. 2017); this is the main explanation for the operation of SCC.

Qrunfleh and Tarafdar (2014) argued that there is a positive relationship connecting SCC with an organization’s performance. Specifically, during the current pandemic, supply chains have been largely destroyed (Tanner 2021). As organizations focus on recovery and reconstruction, specifically during a disaster, the relationship between organizations is critical (Altay et al. 2018). Therefore, we believe that it is timely to examine SCC in an exploratory way. So far, SCC has been associated mostly with trust (Walter 2003), commitment (Chen et al. 2011), dependence (Fynes et al. 2005), strategy (Angerhofer and Angelides 2006), technology (Lee et al. 2011) and information sharing (Cai et al. 2010) with a view of factors affecting SCC. However, this study focuses on the organizational resources contributing to SCC. With regard to the resource-based view, this study considers a positive outcome; collaboration, which is suggested to be improved with the help of resources as a learning culture and DC and through which awareness and understanding could have changed within the impact of the pandemic. We have focused upon collaborations where the objective is to share information and provide support when necessary, as has been evidenced in the case of this crisis. Analyses of this study have been conducted with respect to the pandemic period. As will be discussed in the following sections, the pandemic period is contended as being a critical turning point for the awareness of organizations with respect to their supply chain management and their relations within this focus.

Decentralization (DC)

New business trends such as working remotely can be assumed to have increased the importance of decentralized structures after COVID-19. There is extant literature support for the relevance of organizational structure and decision-making norms to organizational performance. Aiken and Hage (1966) defined DC as the extent to which freedom is given to members of an organization within which to perform their tasks without interruption by their supervisors. Similarly, Hempel et al. (2012) stated that DC concerns the dispersion of decision-making within an organization through giving employees greater autonomy as well as increasing the flow of information. Kochen and Deutsch (1980) considered that the discretionary power within DC would include not only decision making, but also other functions such as allocation, coordination and control. Vancil (1979) referred to a decentralized organization as one in which sub-managers have the responsibility for the performance of a subunit. Therefore, it can be stated that the shift of discretion and responsibility is transferred from accountability for the whole organization to accountability for smaller subunits (Hales 1999). This study considers DC consisting of being whether decisions within an organization are made by employees as teams in a cooperative manner, or simply by single authorities. In this regard, decisions on supply chain issues play a key role.

Within the related literature, DC has been considered mostly as ‘decentralized supply chains’ (e.g. Chen 1999; Fan et al. 2003; Gatignon et al. 2010). However, this study regards DC from the point of organizational structure with regard to decision making procedures and authority-delegation policies. DC can be seen from the point of the resource-based view, since it can facilitate specific situations when organizations have scarce resources, with respect to the management by exception (Mahmood et al. 2014). Accordingly, being flexible and delegating decision-making to subordinates can be pragmatic when, for example, the resource of time is tight, or information is limited. In such circumstances, the ability to operate flexibly in decision-making can ensure that an organization performs successfully. Similar observations can be made during difficult and/or challenging times. In this regard, this study considers DC to be an intangible resource that contributes to organizational competitiveness.

Theoretical background and hypotheses development

Resource-based view

This section describes the related theoretical framework which was applied in this study in order to explore the suggested associations. Similar to a study on supply chains by Dubey et al. (2018), this study draws upon a current theoretical framework that is based upon the resource-based view (RBV) and the relational view. Penrose (1959) described the resource-based view as gaining organizational character from a company’s own resources. The resource-based view argued in the main that organizations can improve their competitive advantage through creating strategic resources and capabilities (Dubey et al. 2018). With regard to this view, Wernerfelt (1984) stated that the intangible assets of an organization can also be considered to be resources that contribute to competitive advantage. This study regards the OLC and decentralized structure to be competitive intangible assets which help to develop an advantage. Barney (1986) accepted that organizational culture is a source of competitive advantage. In addition, Fiol (1991) regarded organizational culture as a competitive resource, underlining that several studies have regarded organizational culture as a means with which to achieve a desired organizational result. In a study by Clulow et al. (2003), it was revealed that intangible assets such as organizational culture are in fact critical resources for organizations. Moreover, a resource-based view has been largely incorporated within studies on organizational performance (Innocent 2015). In this study, SC is considered to be the desired organizational outcome, and that it contributes to organizational success with resulting survival.

Within the literature, there are several theories used to explain SCC, as relational view, socail exchange theory, transaction cost theory, agency theory, etc. (Soosay and Hyland 2015). However, all these theories mostly focus on the relationship between the organization and its partners; whereas this study considers organizational factors that may affect suppy chain collaboration. The reason why resource-based view was applied in this study is that both a decentralized organizational structure and a culture of learning are suggested as strategic assets of the organization contributing to competitive advantage. The resource-based view focuses on organizational internal resources, that are rare, imitable, valuable and nonsubstitutable (Barney 1991). Both organizational culture and structure have been identified by Brynjolfsson et al. (2002) as intangible assets for organizations. Besides, Moran and Meso (2008) regarded organizational culture as a strategic asset. Moreover, learning itself is also considered as an intangible strategic resource (Hult et al. 2003), and specifically for supply chains (Biotto et al. 2012; Willis et al. 2016). Organizations can use their cultural motives strategically to affect their external environments (Weber 2005). With respect to the DC, the resource-based view can help to reframe the relationship between strategy and organizational structure with a better integration (Moingeon et al. 1998). Considering the outcome of this study, SCC, Defee and Fugate (2010) argued that learning orientation of supply chain partners has a significant effect on the interactions between the partners.

Informed by the resource-based view, we explored how OLC, as a resource, developes SC, which, in fact, can be considered as a positive competitive advantage in times of change. Developing collaboration with a supplier can be seen to be within the framework of relationship management and is explained by way of the resource-based view.

Hypotheses Development

The structure (e.g. centralization vs. DC) and the decision-making patterns of organizations intertwine with their learning cultures. There are many studies within the literature (e.g. Janićijević 2013) that link culture and structure. Cullen and Perrewé (1981) defined DC as transferring decision-making and management responsibilities to sub-workers or suppliers. Centralization or DC are not the means to an end but contain the means to achieve the desired outcomes for organizations. Centralization, under specific circumstances, increases efficiency, yet in some other cases, DC will yield better results (Alhamad and Aladwan 2019). At certain times, a mixture of the two structural forms may be blended for better management (Hawkins 2000). Learning organizations have a tendency to adopt decentralized structures, since centralization hinders learning (Burns and Stalker 1961). In fact, the shared values that result from the culture guide employees in performing their strategic roles and responsibilities (Schilke and Cook 2015). Furthermore, post-bureaucratic organizations tend to have a learning culture which ensures flexibility and consensus, rather than hierarchy and authority (Lee and Edmondson 2017). On the other hand, there is evidence that OLC strengthens the competencies of employees (Potnuru et al. 2019), which in turn assists them to be prone to make decisions through assuming extra initiative. Similarly, according to Choi (2020), employees feel empowered through the help of an OLC. In accordance with the related research, the first hypothesis of this study is:

H1: There is a significant and positive association between OLC and DC

The decentralized processes of decision-making and enhanced communication strengthen an organization’s ability to respond quickly to changing conditions (Zammuto and O’Connor 1992). DC mainly functions as a way with which to respond to change effectively and contributes to organizational flexibility, critical to fast response to market conditions (Hill et al. 2000). It allows organizations to incorporate the capabilities of lower-level employees, whose contributions are most often neglected by more centralized decision-makers (Richardson et al. 2002). The structural characteristics of organizations significantly affect their effectiveness in ways such as adaptability (Ranson et al. 1980). The influence of mid-level managers, which is considered to be a sign of DC, affects the quality of decisions and also overall performance (Richardson et al. 2002).

There are abundant studies in the literature linking the effects of both centralization and DC to organizational performance (Nasirpour et al. 2010; Andrews et al. 2007). Centralization limits responsiveness (Argyris and Schön 1978). In fact, for an innovative organization, a structure-enabling information flow is required. (Chesbrough 2003). Decentralized structures allow organizations to be flexible in regard to their external environment (Ogbonna and Harris 2000). A decentralized structure facilitates a participative environment for spontaneous knowledge building (Hopper 1990). Better communication helps supply chain partners to effectively coordinate their participation (Zhang and Cao 2018), and this better communication is enabled by way of decentralized structures, within which information can easily flow. In decentralized structures, vertical communication is unnecessary, enabling decisions to be made by the most competent employees (Ellis et al. 2011), which increases risk awareness within organizations. The results of a study by Kandemir et al. (2002) revealed that DC contributes to organizational alliance orientation, which in turn leads to relationship commitment. This can also be valid with regard to suppliers and ensuing intentions to collaborate with them. Combined, this study contends that making decisions in a decentralized fashion would assist organizations to collaborate with their suppliers. Accordingly, the second hypothesis of this study is:

H2: There is a significant and positive association between DC and SCC

Lee et al. (2012) argued that to handle global competition within business environments, organizations must improve their learning approach as to how this can contribute to business opportunites. In fact, managing the supply chain effectively can be considered as a way to use these business opportunities. The learning motive within an interorganizational setting was defined by Hamel (1991) as a willingness to learn from all of the parties in a relationship. Senge (1992) identified a learning organization by pointing to cooperative learning within the institution. Similarly, learning processes suggested by Marks and Louis (1999) as were shown to be collaborative in nature. As suppliers are important factors within the environment of an organization, they can be included within these two definitions of organizational learning. At this point, learning together with a supplier can be considered, which can be the source of relevant information. In this regard, it would be critical to refer to ‘relationship learning’, in which information is shared mutually, jointly defined, then integrated into a shared memory (Selnes and Sallis 2003). In fact, organizational culture itself can encourage collaboration within partnerships (Gopal and Gosain 2010). An organizational culture with an external orientation can be considered to be the major driver in a successful collaboration (Mamillo 2015). Here, culture with an external orientation is defined by Cameron and Quinn (2011) as interacting with the actors beyond their boundaries; this type of culture can then be regarded as the learning culture. Kandemir et al. (2002) pointed out that learning culture facilitates an organizational orientation for alliances, which we can consider to be collaboration with suppiers in our case, since they also define it similarly. A study by Laaksonen et al. (2008) revealed that the learning of capabilities is critical, since effective interorganizational relationships develop evolutionarily over time. An organization which is accustomed to acquiring and sharing information, largely encouraged by a learning culture, would be expected to establish collaboration with its supplier. It can be argued that this point was revealed in a study by Islam et al. (2015), where learning orientation was shown to have a positive relationship with knowledge-sharing. In this regard, knowledge-sharing can be considered as referring to collaboration with suppliers. Being informed by this discussion, this study maintains that OLC aids the collaboration of an organization with it’s suppliers. Therefore, the third hypothesis of this study is:

H3: There is a significant and positive association between the OLC and SCC

This study aims to provide an explanation for the suggested association between the learning culture and collaboration with suppliers. We suggest that structural motives and decision-making styles can assist in connecting this culture with the resulting outcome. Accordingly, organizations with learning cultures would tend to establish more centralized structures, due to the nature of information sharing. This decentralized structure, in return, would provide a basis for organizations to have better cooperation within the organization first, followed by cooperating with other parties.

Similarly, in their research model, Lee et al. (2012) identified the three suggested variables as learning culture, DC and collaboration, providing explanations for associations among them. These three constructs are suggested in our study as being related in the sense that a decentralized structure provides a bridge between organizational learning adaption with the intention to collaborate with supplying parties. We believe that achieving SCC requires an organization-wide understanding of sharing and openness which can be maintained by the existence of a culture and decision-making structure. Accordingly, a learning culture can provide an open environment of inquiry and sharing, which can result in a decentralized approach to decision-making when employees are trained to learn, share, and accumulate experience. In this manner, an inner environment of sharing and cooperation can be reflected to the outer environment, which includes supply chain parties, allowing the organization in general to establish a relationship of collaboration within its supply chain. Having reviewed the relevant literature so far, no explanation has yet been found for an assumed relationship between learning culture and collaboration with suppliers. Sparked by this gap, this study contends the final hypothesis as:

H4: DC mediates the relationship between the OLC and SCC

In this study we have explored the importance of an OLC and DC upon SCC, but we tend to differ regarding analysis of the effects of organizational learning upon SCC directly, as well as taking into account the mediating effects of DC. Moreover, this research tests the strength of these relationships within the COVID-19 pandemic, being a major crisis time forcing organizations to increasingly focus upon their competitive abilities. We aim to contribute to the literature by providing empirical evidence regarding the effects of organizational learning and DC upon SCC within the circumstances of a pandemic. This contribution is important, because the level of collaboration between companies often changes during risky periods. The goal of this research is to show some of the changes evolving in relationships that have occurred between OLC, DC, and SCC during the COVID-19 pandemic.

Research methodology

A detailed description of the approaches that were employed for this study is discussed within this section. Diverse methodologies were performed in order to justify the selection of the models as well as to test the proposed research hypothesis. The research methodology incorporates various analysis approaches. First, the descriptive statistics of the items, sample distribution, data screening, and data collection are presented. Next, the description of the scales, Partial Least Square (PLS), factor loadings, and measurement models are examined. Then, multicollinearity analysis, confirmatory factor analysis, and measurement models are examined. Also, Structural Equation Modeling along with the mediation analysis, multi-group analysis, and comparison tests are performed.

Partial least squares structural equation modeling (PLS-SEM)

Various advantages of using the PLS-SEM approach have been reported in the literature. First, there are significant advantages over ordinary Covariance-Based Structural Equation Modeling (CB-SEM), when there is a relatively small sample size and accompanying restrictive assumptions. The PLS-SEM methodology was selected for this research over CB-SEM, since it has been highly recommended for a research study with either a small sample, non-normal data, or formative measures (Marcoulides and Saunders 2006; Ringle et al. 2012). Moreover, it is considered to be a soft-modeling approach because of its aspect of less rigid distributional assumptions about the research sample. Therefore, PLS-SEM was utilized as an alternative approach to the CB-SEM. As well, PLS-SEM was seen as a complementary tool for the CB-SEM since they compete against each other (Chin and Newsted 1999). Considering all the advantages, PLS-SEM is very robust to deviations from normality based on the Monte Carlo Simulation results (Cassel et al. 1999).

Proposed model

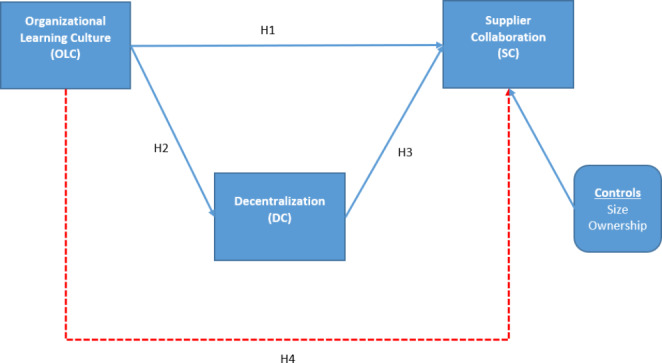

The proposed research model is shown in Fig. 1. Direct as well as indirect paths are indicated in the model illustration. The blue full lines represent the direct paths, while the red dotted line indicates the indirect path in the illustration. The four proposed hypotheses are also noted on the model, together with firm size as well as the ownership, as the control variables. The control variable size has two categories within small and large firms. Small firms are designated as having less than 250 employees, while the large firms are described as having 250 or more employees. Finally, the control variable ownership incorporates two categories: domestic and foreign firms.

Fig. 1.

Proposed model

(H1, H2, and H3 indicate the direct paths while H4 indicates the mediation role of DC between OLC and SC)

Sample

Before the survey questions were distributed, the requisite information relative to the research project was provided to the participants, and the objective of the research was thoroughly explained. The participants were assured that there would be no right or wrong answer at the same time that they were also assured that their answers will be kept anonymous. These initial steps of providing the required information and informing the participants about the objective of the study helped to minimize any anxiety before responding to the survey. As a result of the preliminary results, 245 out of the 402 possible participants agreed to join the research, which yielded a response rate with a ratio of 61%. The survey was collected in early 2021, when the COVID-19 pandemic was at its peak worldwide. Before performing further analysis, the raw data research was subjected to the data preprocessing phase, which is a crucial step before testing the hypothesis (Hair et al. 2019).

This study depends on a unique dataset collected through a cross-sectional surveys. Based on the extant literature, scales of SCC, OLC, and DC are used as constructs. The revised survey was translated into Turkish. This translated questionnaire was then sent to a random sample of medium- and large-sized companies. In order to have homogeneous data, only manufacturing companies within Turkey were considered for this research. Approximately 1,000 firms were potentially identified for our survey. Professional online networks were employed to contact the managers of these companies. The respondents were located in different but related departments, such as supply chain, procurement, marketing, etc. A total of 245 complete questionnaires were actually returned. The raw dataset was subject to further data cleaning processes. The initial descriptive statistics revealed that there were no missing values in the raw data. As well, the univariate, as well as multivariate outlier detections, were performed; the results indicated that there were no significant outliers in the research sample. In the last stage, the final sample size available for further analysis was 245 records.

Descriptive statistics

There were two demographic variables in the research sample which were also used as control variables in the further section. The frequency analysis results are shown in Table 1, which showed that 75.92% of the participants came from domestic firms while only 24.08% were from foreign firms. The firm size had two categories: small and large. 44.9% of the participants were from small firms, while 55.1% were from large firms. Moreover, the results indicated that 33.06% of the participants were purchasing managers, while 4.9% held quality control officer positions in their firms. Finally, the results revealed that 22.45% of the participant’s firms were in the service sector, 17.14% were in the metal sector, 12.25% were in the food and agriculture sector, 8.57% were in the automotive sector, and 6.53% were in the textile sector.

Table 1.

Frequency analysis of the demographic variables

| Variable | Categories | Frequency | Percent |

|---|---|---|---|

| Ownership | Foreign | 59 | 24.08 |

| Domestic | 186 | 75.92 | |

| Total | 245 | 100 | |

| Size | Small | 110 | 44.9 |

| Large | 135 | 55.1 | |

| Total | 245 | 100 | |

| Position | Quality control officer | 12 | 4.90 |

| Planning officer | 28 | 11.43 | |

| Purchasing manager | 81 | 33.06 | |

| Supply chain supervisor | 39 | 15.92 | |

| Production manager | 32 | 13.06 | |

| Senior management | 16 | 6.53 | |

| Other | 37 | 15.10 | |

| Total | 245 | 100.00 | |

| Sector | Food / Agriculture | 30 | 12.24 |

| Service | 55 | 22.45 | |

| Metal | 42 | 17.14 | |

| Automotive | 21 | 8.57 | |

| Textile | 16 | 6.53 | |

| Other Production | 81 | 33.06 | |

| Total | 245 | 100.00 |

Small sized firms with < 250 employees; Large sized firms with ≥ 250 employees

Foreign Ownership; Domestic Ownership

The summary of research items based upon descriptive statistics is provided in Table 2. The total sample size was 24. The items of the OLC ranged between one and six, DC ranged between one and seven, and SC ranged between one and five. The mean values, as well as the standard deviations of the items, are provided within the results, which demonstrate that there is no significant variation around mean values.

Table 2.

Summary statistics of the items

| Items | N | Minimum | Maximum | Mean | Std. Deviation |

|---|---|---|---|---|---|

| OLC1 | 245 | 1 | 6 | 4.22 | 1.49 |

| OLC2 | 245 | 1 | 6 | 4.03 | 1.49 |

| OLC3 | 245 | 1 | 6 | 3.83 | 1.56 |

| OLC4 | 245 | 1 | 6 | 4.11 | 1.59 |

| OLC5 | 245 | 1 | 6 | 3.19 | 1.69 |

| OLC6 | 245 | 1 | 6 | 3.78 | 1.53 |

| OLC7 | 245 | 1 | 6 | 4.14 | 1.50 |

| DC1 | 245 | 1 | 7 | 4.58 | 1.88 |

| DC2 | 245 | 1 | 7 | 3.77 | 1.73 |

| DC3 | 245 | 1 | 7 | 3.58 | 1.99 |

| DC4 | 245 | 1 | 7 | 4.45 | 1.81 |

| SC1 | 245 | 1 | 5 | 4.01 | 1.01 |

| SC2 | 245 | 1 | 5 | 3.92 | 1.00 |

| SC3 | 245 | 1 | 5 | 4.07 | 0.98 |

| SC4 | 245 | 1 | 5 | 3.20 | 1.49 |

OLC: Organizational Learning Culture

DC: Decentralization

SC: Supplier Collaboration

The construct items in this research paper were modified/adapted arising from prior studies in the literature. The items were based upon multi-item scales; the original language of the items was in English. Before sending the survey questions to the participants, the items were subject to purification steps incorporating back-translation methodology (Brislin 1970, 1986): the questions were first translated from English to Turkish by a bilingual expert in this field, then to ensure the content quality of the questions, the questions were translated back from Turkish to English by another bilingual expert in the field. Therefore, the accuracy of the translations was ensured through joint translation in order to alleviate possible contradictions.

The survey’s items incorporated the Likert scale of measurements, which was developed for each construct and are highly recommended within the related literature. The 7-item measurement for OLC used for this study is the scale developed by Yang (2003). This scale is a short version of the one developed by Marsick and Watkins (2003), and can be employed separately, thereby creating a single measurement of a learning culture. OLC was measured with the 7-point Likert scale, ranging from 1 (strongly disagree) to 7 (strongly agree). For DC, we used the 4-item scale developed by Zahra et al. (2004). The scale is 7-points Likert, ranging from 1 (strongly disagree) to 7 (strongly agree). Finally, we measured SC with the 4-item collaboration scale developed by Carr and Pearson (1999). The scale is 5-point Likert, where 1 means not at all and 5 means to a great extent.

The sample consisted of both Turkish and multinational corporations that operate within Turkey. We controlled for ownership type, measuring it with a categorical variable, where 0 represented a domestic company and 1 denoted a multinational one. Furthermore, we controlled for size then measured it again with a categorical variable, where 0 represented a small company and 1 denoted a large company. With regard to size, companies with less than 250 employees were categorized as small, while companies with over 250 employees were categorized as large.

Exploratory and confirmatory analysis

In this section, the PLS-based factor analysis was performed in order to investigate the factor loadings of the survey items. There were 15 items in the constructs: seven from OLC, four from DC, and four from Supplier Collaboration (SC). These indicated items were subject to the PLS-based factor analysis. No items were eliminated following the initial analysis, since the factor loadings of the corresponding items were relatively high. The results of the factor loadings are shown in Table 3. Chin (1998) suggested 0.7 for the PLS-factor loadings. The results showed that the factor loadings of the items were near to or greater than 0.7, with OLC1 being 0.69 and SC4 being 0.67, both of which were very close to 0.70. Furthermore, according to Hair et al. (2019), the minimum factor loadings should be 0.35 when the sample size is 250, while the minimum factor loading should be 0.40 when the sample size is 200. Considering that the sample size of this research paper was 245, the minimum factor loading of constructs was 0.67, significantly greater than the suggested minimum value of 0.35. Thus, the factor loadings were satisfactory and could be used for further analysis.

Table 3.

PLS-based factor loadings

| Items | OLC | DC | SC | Cronbach’s Alpha | Composite Reliability |

|---|---|---|---|---|---|

| OLC1 | 0.69 | 0.52 | 0.36 | 0.90 | 0.92 |

| OLC2 | 0.74 | 0.51 | 0.32 | ||

| OLC3 | 0.74 | 0.53 | 0.34 | ||

| OLC4 | 0.86 | 0.50 | 0.45 | ||

| OLC5 | 0.79 | 0.57 | 0.40 | ||

| OLC6 | 0.82 | 0.56 | 0.42 | ||

| OLC7 | 0.88 | 0.55 | 0.41 | ||

| DC1 | 0.54 | 0.87 | 0.48 | 0.84 | 0.89 |

| DC2 | 0.53 | 0.74 | 0.33 | ||

| DC3 | 0.52 | 0.81 | 0.45 | ||

| DC4 | 0.51 | 0.87 | 0.49 | ||

| SC1 | 0.47 | 0.40 | 0.84 | 0.77 | 0.85 |

| SC2 | 0.43 | 0.43 | 0.78 | ||

| SC3 | 0.42 | 0.40 | 0.87 | ||

| SC4 | 0.38 | 0.30 | 0.67 |

OLC: Organizational Learning Culture is adapted from…

DC: Decentralization

SC: Supplier Collaboration

As well, the discriminant validity was satisfied, since each item had a higher factor loading on its construct compared to the other constructs while each item also had a higher loading than the cross-loading on the row level as well as in the column level.

Regarding the reliability measures, the Cronbach’s alpha of OLC was 0.9, DC was 0.84, and SC was 0.77, all of which are greater than the suggested value of 0.70. Also, the composite reliability measures were 0.92 for OLC, 0.89 for DC, and 0.85 for SC, which are all greater than the suggested value of 0.70. The results of Cronbach’s alpha and composite reliability indicated that the reliability of the constructs was satisfied, since the values of the reliability measures were all significantly greater than the suggested threshold value of 0.70.

Before performing baseline analysis to test the research hypothesis, the question of multicollinearity between the independent latent variables was investigated. Variable Inflation Factors (VIF) were used to examine the multicollinearity issue. It was seen that OLC and DC were the independent variables in the model. The VIF’s results showed that the value of VIF of OLC was 3.05 and VIF of DC was 3.05, both of which were significantly less than the recommended threshold value of 10 (Hair et al. 2019). Therefore, there were no multicollinearity issues between the independent variables.

The confirmatory factor analysis (CFA) was applied to the research model, with three constructs following the factor analysis. The maximum likelihood (ML) method was selected during CFA. The construct’s validity was checked by using CFA. The standardized regression weights, t-statistics, p-value, and the fit measures of the model are provided in Table 4. Accordingly, the results of the goodness of fit measures were  ;

;  df= 1.98; the goodness of fit index was (GFI)= 0.92; the normed fit index was (NFI)= 0.93; the comparative fit index was (CFI)= 0.96; the relative fit index was (RFI) = 0.91; the incremental fit index was (IFI)=0.96; the Tucker-Lewis index was (TLI)=0.95; and the root mean square error of approximation was (RMSEA)= 0.055. The results of the fit measures revealed that the model fit indices were met. Therefore, sufficient evidence of good model fit was obtained (Hu and Bentler 1999). Furthermore, the standardized regression weights of the items were all statistically significant (p-value<0.001). Finally, the results showed that the convergent validity was satisfied, since the items are statistically significantly loaded to their respective constructs.

df= 1.98; the goodness of fit index was (GFI)= 0.92; the normed fit index was (NFI)= 0.93; the comparative fit index was (CFI)= 0.96; the relative fit index was (RFI) = 0.91; the incremental fit index was (IFI)=0.96; the Tucker-Lewis index was (TLI)=0.95; and the root mean square error of approximation was (RMSEA)= 0.055. The results of the fit measures revealed that the model fit indices were met. Therefore, sufficient evidence of good model fit was obtained (Hu and Bentler 1999). Furthermore, the standardized regression weights of the items were all statistically significant (p-value<0.001). Finally, the results showed that the convergent validity was satisfied, since the items are statistically significantly loaded to their respective constructs.

Table 4.

Measurement model results

| Latent Variable | Item | Standardized Reg. Weight | T-stat. | P-value |

|---|---|---|---|---|

| OLC | OLC7 | 0.88 | Scaling | . |

| OLC6 | 0.79 | 16.75 | *** | |

| OLC5 | 0.76 | 14.52 | *** | |

| OLC4 | 0.84 | 17.34 | *** | |

| OLC3 | 0.66 | 11.78 | *** | |

| OLC2 | 0.69 | 11.88 | *** | |

| OLC1 | 0.62 | 10.84 | *** | |

| DC | DC4 | 0.80 | Scaling | . |

| DC3 | 0.68 | 12.82 | *** | |

| DC2 | 0.66 | 10.71 | *** | |

| DC1 | 0.84 | 14.43 | *** | |

| SC | SC4 | 0.51 | Scaling | . |

| SC3 | 0.85 | 6.19 | *** | |

| SC2 | 0.69 | 5.85 | *** | |

| SC1 | 0.78 | 6.09 | *** |

;

;  df= 1.98; GFI= 0.92; NFI= 0.93; CFI= 0.96; RFI= 0.91; IFI=0.96; TLI=0.95; RMSEA=0.055

df= 1.98; GFI= 0.92; NFI= 0.93; CFI= 0.96; RFI= 0.91; IFI=0.96; TLI=0.95; RMSEA=0.055

OLC: Organizational Learning Culture

DC: Decentralization

SC: Supplier Collaboration

***p < 0.001

The relationship between a latent variable and its corresponding indicators can either be in the form of reflective or formative in the PLS-based SEM methodology. For this research model, a reflective modeling approach was chosen, since it has significant advantages over the formative modeling approach. The advantages of the reflective approach are: (i) variation in the construct causes variation in the item measure; (ii) dropping an item from the model does not affect the construct, and (iii) the indicators are correlated with the latent variable at a high level (Podsakoff et al. 2003).

Before testing the research hypotheses, the construct reliability and discriminant validity were examined. The results of the item-based reliability are given in Table 5. The measurement model analysis included descriptive statistics, average variance extracted values, composite reliability, correlation coefficients, and the square root of average variance extracted value at the diagonal of the matrix of each construct. The obtained statistics investigated the discriminant validity, reliability, and convergent validity of the constructs (Hair et al. 2019).

Table 5.

Descriptive statistics, correlation analysis and reliability measures of latent variables (N: 245)

| Latent | Variables | LV1 | LV2 | LV3 |

|---|---|---|---|---|

| LV1 | OLC | 0.793 | ||

| LV2 | DC | 0.420** | 0.823 | |

| LV3 | SC | 0.379** | 0.324** | 0.774 |

| . | AVE | 0.629 | 0.678 | 0.599 |

| . | C.R. | 0.922 | 0.894 | 0.854 |

| . | Alpha | 0.900 | 0.841 | 0.766 |

| . | Mean | 3.901 | 4.094 | 3.799 |

| . | Std. Deviation | 1.228 | 1.526 | 0.845 |

OLC: Organizational Learning Culture; DC: Decentralization; SC: Supplier Collaboration

C.R: Composite Reliability; AVE: Average Variance Extracted; S.D.: Standard Deviation; Alpha: Cronbach’s Alpha

The elements on the diagonal are the square root of AVE, while the elements on the off diagonals are the correlations between latent variables

The bold values at the diagonal of the matrix denotes the values of AVE (Average Variance Extracted)

*p < 0.05; **p < 0.01; LV: Latent Variable

The factor loadings (Table 3) showed that the individual item reliability was satisfied, since the factor loadings of all the included items were significantly greater than the suggested cut-off value (Chin 1998; Hair et al. 2019). The values of composite reliability were 0.922 (OLC), 0.894 (DC), and 0.854 (SC), significantly higher than the recommended cut-off value of 0.70 (Nunnally, 1987). Moreover, the values of Cronbach’s Alpha were 0.900 (OLC), 0.841 (DC), and 0.766 (SC), also higher than the threshold value of 0.70. Therefore, the constructs’ reliability was met.

Additionally, two important statistics were employed to examine the discriminant validity: (i) the Average Variance Extracted (AVE) and (ii) the square root of AVE values versus the correlation coefficients of the latent variables (Fornell and Larcker 1981). The results showed that the AVE values were higher than the recommended cut-off value of 0.50. Moreover, all the square roots of AVE values on the diagonal of the correlation matrix were higher than the correlation coefficients of constructs, when placed off-diagonal. As a result of these two important statistics, the proposed latent variables in the model were separated or different from the rest.

In summary, the measurement model with related analysis results showed that the individual item reliability measures were satisfied. Therefore, the PLS-based SEM analysis could be performed in the following section in order to test the proposed hypotheses.

Common method, Social Desirability, and response biases

We have addressed the issue of common method bias by using two crucial approaches. First, we examined the variance inflation factors (VIF): both VIF values of DC and OLC were 3.05, which is relatively lower than the suggested threshold value of 3.3 (Kock 2015). Therefore, the proposed research models were not negatively affected by the common method bias since the VIF values were less than the suggested value of 3.3. Second, we utilized Harman’s Single Factor approach (Harman 1960). Without a rotation, we included all the items of the survey into a single factor using the Exploratory Factor Analysis method. Following this analysis, we obtained 34.9% of variance, explained by the new common latent factor, which is significantly less than the recommended cut-off value of 50% (Harman 1960).

With the use of the method described by Armstrong and Overton (1977), the non-response bias was tested. The early respondents to the surveys were compared with the latter ones. Firstly, the comparison of the responses between the early and late respondents showed no statistically significant differences (p > 0.05). Secondly, when cross-checking a randomly selected group of 100 non-respondent firms with respondent firms, there were no significant differences identified for any organizational portion (such as number of employees, years of operation, etc.). Lastly, according to Rose et al. (2007) a relatively high response rate can prevent a non-response bias. In this research, the return rate was approximately 24.5%. It is thought that this ratio has provided an adequate representation for the total sample. The literature says that when several features of an object are defined at the same time, participants feel less pressure to defend the relevant one. The knowledge that each answer may be entered accurately prevents a social desirability bias (Tomassetti et al. 2016). Therefore, in advance of the survey, information was conveyed that there could be no right or wrong answers. In addition, there was no question about the identity of the participants.

Structural equation modeling-hypothesis testing

PLS-based SEM was employed in order to test the proposed hypotheses. The justification for using PLS-SEM is that the sample size of the research project was relatively small, so that there are significant advantages in terms of least restrictive assumption-free features (Chin 1998). Accordingly, Smart PLS v.2 with bootstrapping resampling was selected to test the statistical significance of the relationship between the latent variables (Ringle et al. 2005). Furthermore, bootstrapping with a recommended 5000 resamples was used in order to obtain the standard errors and t-statistics for the path coefficients during the analysis (Henseler et al. 2009). The path analysis results are presented in Table 6.

Table 6.

PLS-based structural equation modelling results

| Path | Beta | T-Stat. | Result | ||

|---|---|---|---|---|---|

| OLC | → | SC | 0.424*** | 4.179 | H1 Supported |

| OLC | → | DC | 0.823*** | 32.321 | H2 Supported |

| DC | → | SC | 0.168** | 2.010 | H3 Supported |

| Ownership | → | SC | -0.050 | 1.306 | Control |

| Size | → | SC | 0.049 | 1.173 | Control |

OLC: Organizational Learning Culture; DC: Decentralization; SC: Supplier Collaboration

*p < 0.10; **p < 0.05; ***p < 0.01

R 2 (DC) = 67.66%; R 2 (SC) = 59.90%

The coefficient of determination (R2) shows the percentage of the explained variance in the dependent variable which can be explained by the independent variables. Namely, the values of R2 were used to examine the explanatory power of a structural equation model. The threshold values of the coefficient of determination were 0.67-Substantial. 0.33-Moderate, and 0.19 - Weak (Höck and Ringle 2006). The results from PLS-SEM indicated that 67.66% of the variation in DC could be explained by the variation in OLC, while 59.9% of the variation in SC could be explained by the variation in OLC and DC.

The results of the path analysis showed a significant positive relationship between OLC and SC (β = 0.424, p < 0.01), between OLC and DC (β = 0.823, p < 0.01), and between DC and SC (β = 0.168, p < 0.05). Therefore, H1, H2, and H3 were supported.

Mediation analysis

Further analysis with mediation methodology was employed in order to investigate the mediating role of DC upon the relationship between OLC and supplier collaboration (SC). Baron and Kenny’s (1986) four steps as well as Hayes’s (2017) methodologies were followed for this analysis.

First, the indirect effects of OLC on SC via DC were tested by applying Hayes’ (2017) methodology with the module PROCESS 3.5 (Hayes 2019), which incorporates a bias-corrected bootstrapping approach in order to determine whether the indirect effect was significant. Preacher and Hayes (2008) suggested using 5000 bootstraps resamples in order to obtain a 95% confidence interval with the indirect effects.

The results are presented in Table 7 with effect sizes, bootstrap-based standard error, bootstrap-based lower limit confidence interval, and bootstrap-based upper limit confidence interval. The effect is considered statistically significant if the value of zero is not included between the lower limit confidence interval (LLCI) and upper limit confidence interval (ULCI). The results revealed that DC mediated the relationship between OLC and SC, since the lower and upper confidence interval did not include zero. Based upon mediation analysis, H4 was supported.

Table 7.

Indirect effect between OLC and SC through DC

| Path | Effect | BootSE | BootLLCI | BootULCI |

|---|---|---|---|---|

|

H4: OLC→DC →SC Supported |

0.085* | 0.042 | 0.017 | 0.186 |

*Denotes that the effect is statistically significant since the zero value is not included within lower and upper confidence levels

BootSE: Bootstrap Standard Error

BootLLCI: Bootstrap Lower Limit Confidence Interval

BootULCI: Bootstrap Upper Limit Confidence Interval

OLC: Organizational Learning Culture

DC: Decentralization

SC: Supplier Collaboration

Robustness analysis

The robustness of the baseline model results using Hayes’ (2017) approach was further investigated by using Baron and Kenny’s (1986) four steps methodology. This is illustrated below, step by step. The independent variable (X) is OLC; the mediator variable (M) is DC; and the dependent variable (Y) is SC. The control variables (Size and Ownership) were also incorporated into the analysis.

Step 1

Test for path c alone by conducting a simple regression analysis with X predicting Y.

Fig. 2.

Relationship between X and Y

Step 2

Test for path a alone by conducting a simple regression analysis with X predicting M.

Fig. 3.

Relationship between X and M

Step 3

Test for path b alone by conducting a simple regression analysis with M predicting Y.

Fig. 4.

Relationship between M and Y

Step 4

Test for path c` (c-prime) alone by conducting a multiple regression analysis with X and M predicting Y.

Fig. 5.

Relationships of X and M to predict Y

After first confirming that a significant association existed from steps 1 through step 3, step 4 was used to determine whether there was either a full or partial mediation. Full mediation exists if X is no longer significant when M is controlled in step 4, while partial mediation exists if X and M both significantly predict Y in step 4.

These results are provided in Table 8. OLC had a significant relationship with SC and DC which indicated that steps 1 and 2 were met. Also, DC had a significant relationship with SC, thus step 3 was also met. Finally, OLC and DC had a significant relationship with SC. The results showed that DC partially mediates the relationship between OLC and SC. The results from Tables 7 and 8 support each other, showing that DC mediated the relationship between OLC and SC.

Table 8.

Mediating role of DC between OLC and SC (OLC→DC →SC)

| (1) | (2) | (3) | (4) | |

|---|---|---|---|---|

| Independent variables | Step1: SC | Step2: DC | Step3:SC | Step4:SC |

| OLC | 0.39*** | 1.00*** | 0.31*** | |

| (10.63) | (21.41) | (4.96) | ||

| DC | 0.29*** | 0.082** | ||

| (9.15) | (1.99) | |||

| Ownership | -0.046 | -0.13 | -0.058 | -0.036 |

| (-0.43) | (-0.97) | (-0.52) | (-0.33) | |

| Size | 0.018 | 0.16 | 0.0079 | 0.0053 |

| (0.20) | (1.35) | (0.08) | (0.06) | |

| Constant | 2.29*** | 0.20 | 2.67*** | 2.27*** |

| (12.17) | (0.86) | (14.99) | (12.10) | |

| N | 245 | 245 | 245 | 245 |

| R 2 | 0.34 | 0.68 | 0.28 | 0.34 |

| F-Stat. | 40.62*** | 168.09*** | 30.57*** | 31.32*** |

t statistics in parentheses

*p < 0.10, **p < 0.05, ***p < 0.01

The baseline PLS-based SEM model was subjected to further analysis. Multi-Group Analysis was performed in order to determine whether the coefficients were significantly different between small and large-sized firms as well as between foreign and domestic firms. First, the baseline model was subjected to multigroup analysis with firm size as the grouping variable (Small vs. Large.) The sample was split into two groups with small-sized firms that had less than 250 employees, while large-sized firms had 250 employees or more. The results are provided in Table 9. Accordingly, the coefficients were not significantly different between the small and large-sized firms (p-values > 0.05).

Table 9.

Multi group analysis between small and large sized firms

| Path coefficients’ difference | P-value | |||

|---|---|---|---|---|

| Path |

between small and large sized firms βSmall - βLarge |

Small vs. Large | ||

| OLC | → | SC | -0.184 | 0.414 |

| OLC | → | DC | 0.025 | 0.639 |

| DC | → | SC | 0.271 | 0.225 |

| Ownership | → | SC | 0.021 | 0.842 |

Small sized firms with < 250 employees vs. Large sized firms with ≥ 250 employees

c) Comparison between foreign and domestic ownership.

Similarly, the baseline PLS-based model was subjected to another multi-group analysis using ownership as the grouping variable. The firms were split into two groups: foreign or domestic firms. The analysis results are provided in Table 10. The results revealed that the coefficient of the baseline research models was not significantly different between foreign and domestic firms (p-value > 0.05).

Table 10.

Multi group analysis between foreign and domestic ownership

| Path | Path coefficients’ difference | P-value | ||

|---|---|---|---|---|

|

between foreign and domestic βForeign – βDomestic |

Foreign vs. Domestic | |||

| OLC | → | SC | -0.173 | 0.508 |

| OLC | → | DC | 0.033 | 0.478 |

| DC | → | SC | 0.098 | 0.703 |

| Size | → | SC | 0.019 | 0.910 |

Foreign Ownership vs. Domestic Ownership

In the final section of the robustness analysis, the t-test for independent samples was employed for the latent variables by using size and ownership as grouping variables. The results are summarized in Table 11. They indicated that the Mean OLC of the large size firms was significantly higher than the mean OLC of the small size firms; the mean DC of the large size firms was significantly higher than the mean DC of the small size firms, and the mean SC of the large size firms was not significantly higher than the mean SC of the small size firms at a 5% significance level, but it was weakly significantly higher at a 10% significance level.

Table 11.

Comparison tests based on independent samples T-test

| Variable | Group | Obs. | Mean | H0: _Small = _Small = _Large _Large |

|---|---|---|---|---|

| OLC | Small | 110 | 3.681 | t-stat: -2.564; df: 243 |

| Large | 135 | 4.080 | p-value:0.011 | |

| DC | Small | 110 | 3.775 | t-stat: -2.999; df: 243 |

| Large | 135 | 4.354 | p-value:0.030 | |

| SC | Small | 110 | 3.698 | t-stat: -1.699; df: 243 |

| Large | 135 | 3.881 | p-value:0.091 | |

| Variable | Group | Obs. | Mean |

H0:  _Foreign = _Foreign = _Domestic _Domestic

|

| OLC | Foreign | 59 | 4.303 | t-stat:2.929; df: 243 |

| Domestic | 186 | 3.773 | p-value:0.004 | |

| DC | Foreign | 59 | 4.623 | t-stat: 3.109; df: 243 |

| Domestic | 186 | 3.926 | p-value:0.002 | |

| SC | Foreign | 59 | 3.996 | t-stat:2.066; df: 243 |

| Domestic | 186 | 3.737 | p-value:0.040 |

Small sized firms with < 250 employees vs. Large sized firms with ≥ 250 employees

Foreign Ownership vs. Domestic Ownership

Finally, the mean OLC of the foreign firms was significantly higher than the mean OLC of the domestic firms; the mean DC of the foreign firms was significantly higher than the mean DC of the domestic firms, and the mean SC of the foreign firms was significantly higher than the mean SC of the domestic firms at a 5% significance level.

Discussion

This study aimed to explore the organizational predecessors of SCC, based upon perceptual data collected from supply chain managers. In this context, the effects of OLC and DC, which are contended to be important organizational resources, were tested by the research. The findings of the study mainly revealed that both OLC and DC are precursors of SCC. It was also found that DC has a mediating effect upon the relationship between OLC and SCC. Variance-based PLS analysis indicated that the organizational structure determined the SCC level. Additionally, in the paired comparisons, the average of large firms was found to be significantly higher compared to that of small firms for all variables (OLC, DC, and SCC). The same result was also valid when comparing foreign companies to domestic ones. In other words, the average for foreign firms was statistically higher than that of domestic companies for all factors. In short, this work provides a number of theoretical and managerial contributions to supply chain research.

Implications for theory

The decision-making mechanisms of organizations are related to their learning culture. In the literature, the relationship between learning culture and organizational structure was discussed (Janićijević 2013). Although in some cases, centralization may increase efficiency, in general it is clear that DC has a positive impact upon organizational effectiveness (Alhamad and Aladwan 2019). It can be claimed that learning organizations prioritize decentralized structures because they consider centralization to be an obstacle to learning (Burns and Stalker 1961). As in the aforementioned studies, the within research showed that organizations which have a learning culture tend to result in a more decentralized structure.

Decentralized organizational structures enable companies to respond quickly to changing conditions (Zammuto and O’Connor 1992) and lead to organizational flexibility in decision-making processes (Hill et al. 2000). In other words, centralization may limit responsiveness (Argyris and Schön 1978). The extant studies claim that decentralized organizations communicate easily with the external environment such as suppliers and customers (Ogbonna and Harris 2000; Hopper 1990; Kandemir et al. 2002) also claimed that DC leads to cooperation between companies. As in the literature, the analyses of this research indicated that a decentralized structure encourages collaboration with suppliers.

Based upon a resource-based view, the current study proposes a model illustrating whether SCC is directly and/or indirectly affected by an OLC and DC. Our results showed that OLC and DC assist the achievement of an effective SCC level. This is especially important in times of crisis such as the COVID-19 pandemic. Company managers should select suppliers with whom they can work under extra-ordinary conditions. This can be made possible with advanced SCC conditions. While attempting to explain the relationship between OLC and SCC, we also noted that DC, as an organizational resource, is important since it mediates the link between OLC and SCC. As a result, it has become obvious that by employing a decentralized company structure, companies with an advanced learning culture are better able to collaborate with their suppliers. Issues such as the supply of raw materials and the timely and uninterrupted delivery of finished products are critically important in times of crisis. Due to the potential volatility in supply chains in times of crisis, cooperation with suppliers should be a major priority. Thus, companies must institute various institutional resources (such as OLC and DC) in advance.

Additional analyses with control variables were conducted in this study. Companies with less than 250 employees were classified as being small firms. When assuming company size as the control variable, no change is observed in the validity of the hypotheses. The same situation holds true when considering organizational ownership (foreign and domestic) as another control variable. Therefore, the effects of OLC and DC on SCC are valid in this discussion regarding supplier collaboration. The findings indicated that OLC and DC place critical pressures upon SCC. In addition, when OLC, DC and SCC were analyzed separately, it was seen that the averages of large firms were statistically higher than small firms. This result highlights the fact that the relationships of large companies with suppliers are therefore stronger, as compared to small companies. A similar implication is also valid when considering foreign companies. The averages for each factor (OLC, DC and SCC) of foreign companies were significantly higher than domestic companies. This outcome can be explained by the operational flexibility and financial strength of multinational companies. Due to having established many locations around the world, they may have more experience with crises. In addition, it is possible to argue that more investments are made in the internal structures of foreign companies, compared to domestic ones.

Implications for practice

The COVID-19 pandemic is an unprecedented crisis for supply chains. It has been revealed that there is a serious relationship between supply chain resilience and sustainability. For this reason, these two phenomena should be considered together (Sarkis 2021). The literature points out some concepts such as “collaborative management,” “proactive business continuity planning,” and “financial sustainability” as examples of the most important risk reduction strategies in times of crisis like the COVID-19 pandemic (Kumar et al. 2021). Therefore, organizations should give importance to cooperation with their suppliers to increase supply chain resilience. The common feature of the institutions that most successfully manage the COVID-19 crisis is having a strong collaboration with local supply chains. Thus, supporting local networks within the supply chains can help to build more vigorous resilience in the face of future shocks (Bassett et al. 2021). These findings show that SCC is vital for corporations to provide sustainability in their operations.

Knowledge sharing, being a part of the learning culture, strengthens cooperation among suppliers and/or organizations. (Selnes and Sallis 2003; Kandemir et al. 2002; Laaksonen et al. 2008; Islam et al. 2015) drew attention to the collaboration between companies in terms of improving the learning culture. Therefore, the literature reveals that, for organizations, it is advantageous to be in contact with other stakeholders that also prioritize learning. Similarly, the results of this research demonstrate that the learning culture is an important factor leading to collaboration between companies. In other words, companies which improve themselves through continuous learning and remain open to innovations communicate easily with their suppliers. Additionally, the literature shows that firms should seriously consider research and development projects (R&D), artificial intelligence applications and information management systems to foster their learning cultures (Armani et al. 2020; Modgil et al. 2021). As mentioned above; in times of a crisis such as COVID-19, the importance of the OLC increases because it brings much valuable knowledge to organizations and managers. Thus, during these times, organizations need to increase collaboration with their suppliers in order to avoid potential disruptions in their supply chain. Therefore, companies should integrate the OLC before problems surface. Moreover, in order to share knowledge, organizations which have a learning culture tend to set up decentralized structures. This situation leads organizations toward better internal cooperation and as a result, with other parties (Lee et al. 2012).

We believe that these findings will provide valuable implications showing how the interactions of organizational resources can build SCC. First of all, we can confidently claim that companies need to have a learning culture, as it enables SCC. This culture contributes to developing collaboration with suppliers. Therefore, it is important for organizations to invest in a learning culture. Moreover, it stimulates the development of a decentralized structure. This outcome points out that a company with a learning culture is prone to assign various responsibilities to employees at the lower levels. Furthermore, according to the results of this research, it can be claimed that when employees take initiative, this helps to build a strong collaboration with suppliers.

Limitations and Future research

As with all studies, this study has some limitations. The survey was collected within a specific country, so data from different cultures could be collected for future studies, making it possible to compare results among various countries. Meanwhile, the survey was collected from companies that were operating in varying sectors of manufacturing. It is possible to obtain more specific findings by considering the responses from a specific industry, such as automotive or food. In other words, if only one specific sector is analyzed, differing results may be revealed. Additionally, the questionnaire was often completed by supply chain and manufacturing experts. If the opinions of employees in departments such as marketing and finance are taken into account, the analyses may yield richer results. Finally, different moderators such as the use of information systems (IS) or supply chain orientation could be added to the conceptual model for a broader discussion.

Empirical tests can be included in future studies by adding other organizational resources such as information systems and knowledge storage, to the research model. In particular, the effect of trust upon suppliers with SCC may be examined. In addition, different research questions can be explored, such as: does DC trigger the trust of suppliers?; within which sectors did DC increase during the COVID-19 pandemic period?; under which conditions does DC display disadvantages with SCC?; what is the role of information systems within the relationship between OLC, DC and SCC? Answers to these questions in future studies can either be studied empirically with survey-based methodology or through in-depth interviews with professionals. Moreover, future studies could discuss how the SCC level varies by comparing different countries and/or cultures.

Conclusion