Abstract

By using an independent self-assembly process that is occasionally controlled by evaporation, cellulose nanocrystals (CNCs) may create films (pure or in conjunction with other materials) that have iridescent structural colors. The self-forming chiral nematic structures and environmental safety of a new class of photonic liquid crystals (LCs), referred to as CNCs and CNC-embedded materials, make them simple to make and treat. The structure of the matrix interacts with light to give structural coloring, as opposed to other dye pigments, which interact with light by adsorption and reflection. Understanding how CNC self-assembly constructs structures is vital in several fields, including physics, science, and engineering. To constructure this review, the colloidal characteristics of CNC particles and their behavior during the formation of liquid crystals and gelling were studied. Then, some of the recognized applications for these naturally occurring nanoparticles were summarized. Different factors were considered, including the CNC aspect ratio, surface chemistry, concentration, the amount of time needed to produce an anisotropic phase, and the addition of additional substances to the suspension medium. The effects of alignment and the drying process conditions on structural changes are also covered. The focus of this study however is on the optical properties of the films as well as the impact of the aforementioned factors on the final transparency, iridescent colors, and versus the overall response of these bioinspired photonic materials. Control of the examined factors was found to be necessary to produce reliable materials for optoelectronics, intelligent inks and papers, transparent flexible support for electronics, and decorative coatings and films.

1. Introduction

A covalent acetal oxygen link forms between the C1 of one glucose ring and the C4 of the next to form cellulose, which is made up of a linear chain of glucose molecules, resulting in an elementary fibril that can be connected to form microfibrils with a width of 5–50 nm and a span of a few micrometers, with crystalline or amorphous areas.1 While fibrillation can create cellulose nanofibrils (CNFs), acid hydrolysis can yield cellulose nanocrystals (CNCs) from wood (a technique that eliminates amorphous areas). The length and diameter of CNCs have been measured to be 100–300 nm and 3–10 nm, respectively; however, this varies depending on the source of the CNC and the method of development.

A family of materials known as “liquid crystals” (LCs) display forms of matter which are neither crystalline materials nor isotropic liquids when specific conditions are satisfied (such as temperature, pressure, and concentration). Depending on how a solid transitions through mesophases to become an isotropic liquid, LCs are categorized as “lyotropic” or “thermotropic”. The growth of large-scale structures from submicron unit characteristics in the chiral self-assembly of nanoconstruction blocks can result from liquid crystal phase transformation. This phase transition offers a technique for creating useful materials with specialized physical, electrical, and optical properties.2 Amyloid fibrils3 and deoxyribonucleic acid (DNA) filaments4 are two examples of colloidal self-organizing systems that exhibit unique chirality by their bending arrangement of building parts.

In both real-world systems and model colloidal self-assembling particles like rod-like viruses,5 transferring chirality over length scales (e.g., nm, μm) is difficult. The single-handedness of many key bios-found molecules, homochirality, is ubiquitous and a key signature of life on our planet. All living organisms use l-amino acid and d-sugar almost exclusively as building blocks for proteins and nucleic acids.6 Geometrically speaking, an item is chiral if it cannot be accurately translated or rotated to produce its mirror counterpart. At almost every length scale, chirality has been seen phenomenologically; for instance, the spin and motion direction of a massless subatomic particle define its chirality. Interesting instances of macroscopic chirality include the tendrils of plants,7 the right- and left-handed (dextral and sinistral) shells of snails,8 where a single gene expression influences snail reproduction, and the astonishing expansion of solely left-handed long tusks in narwhals.9

In a colloidal suspension, bioderived nanoparticles called CNCs self-assemble to form a left-handed chiral nematic (cholesteric) phase.10 While chiral scaffolding and long-lasting photonic colorants have been produced using their propensity for self-assembly, the origin of their mesophase chirality is still a hotly debated topic.10,11 CNCs twist because of the chemical chirality of the α-1,4-d-glucose repeating unit, although it is not known how (or whether) this little twist that later causes a twist in individual CNCs is sufficient to generate chirality in the mesophase. Furthermore, chirality attribution is challenging due to the CNC population’s extremely polydisperse particle size and shape.12

Owing to its chiral spiral geometry, the CNC LC film seems to have a vibrant structural color, but internal structures also create circularly polarized reflection, giving it extraordinary optical properties. This regular nanostructure has inspired and benefited prior studies that have studied and analyzed several CNC-based photonic crystal material components.13,14 Until recently, no thorough analysis of CNC-produced photonic functional materials has been done. This review seeks to examine CNC liquid crystal formation fundamentals and some of its very recent applications. Investigated first are the basics of architectural colors, photonic crystals, and liquid crystal states. The fabrication of CNC-based color materials, as well as their optical characteristics and regulatory processes, will be discussed after that. This served as the foundation for a summary of the application research for CNC-based chiral nematic liquid crystal films in many sectors. Investigating the adaptability of structural color materials with CNC bases is another emphasis.

2. Background

2.1. Structural Color

Nature has created a wide range of substances and arranged them in such a way that their coloring shines out. Most of the coloring in living things comes from structure colors or pigment colors. Contrarily, structural colors result from organized geometrical (photonic crystal) structures that may precisely regulate the dispersion and reflection of light on a surface or the skin. It is common knowledge that when light impinges on a substance’s surface light scattering, diffraction, and diffuse scattering take place in the substance’s interior structure. During this time, the lights will once again be visible to humans, and the many colors will be audible.

As a result, the color that is seen depends on the internal structure, and if the substance’s microstructure and composition do not change, the color will also not change. Structured colors are more ecologically sound than pigments colors because they never fade, and they pose no toxicity. The two primary categories of structural colors are angle-dependent architecture colors and angle-independent structure colors. (i) For angle-dependent structural colors, depending on the angle of view, the structure has a regular inner structure in the material that shows various colors. Natural species with this type of structural color include butterfly wings,15 beetles,16 and opals.17 (ii) Angle-independent structural colors (angle-independent structural colors) generate color due to light dispersion within the short-range ordered nanostructure, and the array lacks periodicity and displays structural colors that are angle independent at longer spatial scales.

The angle-dependent structural colors that are the focus of this review can be found in the scales of the spotted parachute bird, blue-skinned mandrill,18 Morpho butterfly wings,19 and long-horned beetle20 in addition to examples provided earlier. Although structural colors have outstanding optical properties, full control over the photon transmission channel in conventional structural materials is limited, which can have a substantial impact on the development of these materials as well as their usage in photonic devices and electronic circuits. In terms of applications, photonic integrated circuits are most used in fiber-optic transmission, but they can also be found in biomedical and photonic computer applications. As a result, the structural color’s superiority in practical applications cannot be highlighted enough due to ease of processing and evidence of its widespread adoption. Color changes in these structure are also tunable, and according to principles, structural color materials change color in response to humidity,21 temperature,22 pH,23 dielectric property of solvent,24 presence of dopants,25 electrical and magnetic signals,26 enzymes,27 alcohol,28 urea, and heavy metals.29 Structural color material can be used to color encrypt30 a structure in a wide range of optical fields, not just responsive optical devices.

3. Photonic Crystal

More researchers are upgrading the color-creation method as nanotechnology advances. Structural color is made by the photonic crystal structure inside the item; therefore, the color is produced because of light interaction with the structure. On the basis of uncontrolled atom emissions and photon localization, John and Yablonovitch31 introduced the idea of photonic crystals in 1987. From a physics perspective, an organized arrangement of nanostructures with various refractive indices in space results in the formation of a photonic crystal. Recurrent variations in the index of refraction of space would control photon transmission in a manner analogous to that for the semiconductor lattice with the electric wave function; therefore, terminologies used in these two branches of science are very similar. As the electromagnetic wave passes through the photonic crystal, Bragg scattering alters it, creating an energy band structure like that of a semiconductor. A photon energy band is the name for this kind of energy band. When the disparities in refractive indices between various materials reach a critical level, electromagnetic waves with precisely matched wavelengths between photonic energy bands are prevented from passing through the crystal. The photonic bandgap is the name given to this frequency range. Optics researchers are interested in the peculiar optical features of photonic crystalline forms, such as slow light effect and negative refraction.32

Natural selection is the process through which many of the useful structures of living things developed contribute to passing genes and the allure of these animals/plants. One of the forms in biological systems that has drawn the attention of scientists from many fields is chiral photonic crystals. Since these natural patterns are produced using a range of elements, it is essential to comprehend the systematic organization in nature, with the aim of copying inspired structures within an arsenal of manmade objects such as CNCs. Nanostructures, such as those seen in beetle shells, butterfly wings, and peacock feathers, can display color without use of pigment or dyes. For instance, the iridescent Plusiotis bacardi (outer shell) of the beetle has a novel microstructure that may regulate the polarization and wavelength of reflected light.33

Scientists are trying to replicate these templates and create the material with certain qualities that are inspired by the structure of nature. However, the growth of artificial crystalline materials is still slow due to a lack of accurate photonic structural systems and efficient fabrication procedures. On the other hand, scientists started employing quick and efficient methods to search for novel materials in nature. The evolution of CNCs into a 1D chiral nanorod with excellent mechanical, photonic, and electromechanical characteristics has been facilitated by the development of characterization technologies. By adjusting the chiral nematic nanostructures, material scientists showed how to colorize CNC-based films, revealing a 1D photonic crystal feature.

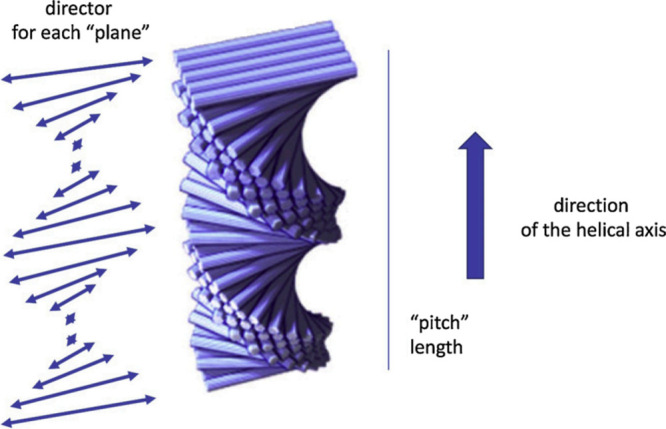

The pitch size of LCs is one of its distinguishing

characteristics.

Helices are without a doubt among the most beautiful chiral structures.

A helix is described by its periodicity (pitch, p) or wavenumber  , as well as its handedness, which is defined

as positive for a right-handed or clockwise twist and negative for

a left-handed or counterclockwise twist. The chirality concept for

molecules can be extended to particles as well; all cellulose fibrils

and crystals with detectable chirality are right-handed (making left-handed

chiral structures), according to magnified microscope images.10 Schematic pitch and chiral structures of CNCs

are shown in Figure 1.

, as well as its handedness, which is defined

as positive for a right-handed or clockwise twist and negative for

a left-handed or counterclockwise twist. The chirality concept for

molecules can be extended to particles as well; all cellulose fibrils

and crystals with detectable chirality are right-handed (making left-handed

chiral structures), according to magnified microscope images.10 Schematic pitch and chiral structures of CNCs

are shown in Figure 1.

Figure 1.

Ordering of the CNC dispersions is chiral nematic depending on solution temperature, concentration, and properties of CNCs. The length of the “pitch” is equivalent to a full director turn. Schematic displaying the structure also known as “Bouligand structure”. Copyright 2019 Springer Nature. Adapted with permission from ref (34).

3.1. Liquid Crystalline State Definitions

According to Onsager’s model,35 the volume fraction required for the production of liquid crystals is inversely related to the rod aspect ratio; therefore, if CNCs are manufactured to be longer and thinner, the initial concentration required to see the liquid crystal crossover should drop. Bacterial cellulose dispersion, which has an aspect ratio of 50 to 100 and lengths ranging from 1 to 2 μm, exhibits nematic organization much sooner than CNCs; CNF particles ought to behave similarly. However, the aspect ratio cannot be raised indefinitely to move the transition points to lower volume fractions. The fact that the volume fraction for showing glassy behavior and the liquid crystalline transition are so close together makes passing the liquid crystalline transition point one disadvantage of increasing the aspect ratio. When liquid crystal transitions from bacterial cellulose > cellulose nanofibrils > cellulose nanocrystals, a glassy state is seen due to the longer and more wavy molecules. Reaching glassiness gives kinetically arrested particles the tendency to generate chiral structures. Besides the aspect ratio, generated by the overlap of electrical double layers, electrostatic repulsive forces and attraction van der Waals forces interact with colloids and can move transition boundaries, i.e., the point of transition from isotropic to liquid crystalline and to fully liquid crystalline transition points.

Moreover, the flexibility (persistence length)

of rods can also affect transition points. It is defined as  , in which lp is the persistence length, a quantity that can be determined from

static light scattering or direct visualization measurements and can

also be used to describe flexibility. The persistence length is the

distance along a rod’s contour at which two spots’ ensemble-averaged

mutual orientation becomes decorrelated for the first time. Thus,

, in which lp is the persistence length, a quantity that can be determined from

static light scattering or direct visualization measurements and can

also be used to describe flexibility. The persistence length is the

distance along a rod’s contour at which two spots’ ensemble-averaged

mutual orientation becomes decorrelated for the first time. Thus,  for stiff rods and

for stiff rods and  for semiflexible filaments. Low aspect

ratio particles, predominantly inorganic materials like boehmite and

hematite, are hard, whereas nanotubes and cellulose fibers are more

flexible due to their length. Single-wall carbon nanotubes, for example,

have been found to have a persistence length of 30–170 μm,36 which is likewise diameter dependent.37 The rheology of biopolymer actin at higher frequencies

reveals a semiflexible nature.38 At higher

frequencies, the rheological response is a function of bending modulus

or stiffness, which is a function of persistence length.39

for semiflexible filaments. Low aspect

ratio particles, predominantly inorganic materials like boehmite and

hematite, are hard, whereas nanotubes and cellulose fibers are more

flexible due to their length. Single-wall carbon nanotubes, for example,

have been found to have a persistence length of 30–170 μm,36 which is likewise diameter dependent.37 The rheology of biopolymer actin at higher frequencies

reveals a semiflexible nature.38 At higher

frequencies, the rheological response is a function of bending modulus

or stiffness, which is a function of persistence length.39

Concentration is yet another factor in changing transition points. As the particle concentration increases, the system approaches a glassy state or transitions from an isotropic to a nematic or higher-order liquid crystalline form. Carbon nanotubes reportedly experienced the same transformation from an isotropic to a glassy state while displaying no liquid crystal states, according to previous research.40 The glassy state is initiated prior to the creation of liquid crystals due to the high polydispersity and aspect ratio of carbon nanotubes (CNTs). Higher quantities of carbon nanotubes are difficult to analyze due to the difficulty in preventing particle aggregation. Glass transition has only been noticed for highly dispersed carbon nanotubes at low threshold concentrations, and the only nematic ordering (no chirality) of carbon nanotubes has been characterized as a liquid crystal phase thus far. It is difficult to see higher-order liquid crystal phases utilizing carbon nanotubes because of the significant size variation of the tube length.

According to the authors in ref (41), polydispersity caused by end-to-end agglomeration or fragmenting of the virus as well as the existence of any impurity in solution are especially sensitive to the existence of a crystalline form in the tobacco virus. Since the population of the fd virus can be made to have a polydispersity of 1, it can be used as a model system to see the effect of parameters such as ionic strength on its transition points. In fact, Kang and Dhont42 recently found that viral suspension studies at low salt limits clearly showed a change from cholesteric (also known as chiral nematic) to the glassy state. When viral concertation is more than 12 mg/mL, the cholesteric phase is locked because the nonequilibrium texture created by shearing in the cholesteric phase no longer relaxes but instead vitrifies in a glassy state. Strong repulsive forces from nearby charged particles confine the fd virus in an electrostatic cage. Other acting factors that can influence transition points include van der Waals contacts, hydrogen bonds, electrostatic forces, the depletion process, and steric hindrance.

3.2. Interactions Affecting LCs

Colloidal definition applicable to nanosized particles such as CNCs is extendable to larger microphases such as “tactoids”. Similarly, tactoids with a surface charge are envisionable, which can have charges due to the dissociation/ionization of surface groups and the adsorption of charged molecules/ions in aqueous environments of individual CNCs. In the case of salt added, a cloud of counterions forms around the particle, balancing and screening the surface charge.43 Whenever identical nanoparticles are arranged in double layers and overlap, osmotic pressure causes a repulsive force to arise. The size of the energy barrier, U, or more accurately the contact potential between the particles, U, controls how stable a colloidal system is.

Knowing particle diffusion inside the solution or how other particles impede particle mobility is crucial, in addition to revealing particle interaction strength. One notable factor is concentration. According to Doi and Edwards’ hypothesis, the concentration regime may generally be divided into diluted, semidiluted, concentrated, and nematic regimes.39 In the diluted zone, particles can easily spin while meeting one another. In the semidilute zone, it is difficult to spin particles without causing them to interact with one another. The CNC network makes both particle rotation and translational motion troublesome in the concentration regime. Therefore, there is a point at which “tactoids” also interact.

If colloidal particles are not networked, they are often of little use in soft matter design. To produce jammed or gelled states with improved mechanical qualities, rod suspensions are frequently made at a concentration that permits prolonged rod contact. It is related to attraction strength indirectly: if attraction capacity is effectively zero (repulsion), the system with increasing particle concentration levels achieves a glassy state; otherwise, a gel is formed. The jammed or glassy state is the kinetic stalemate of the framework, whereas the gelled state is the structure created after aggregation. Charge, dispersion, depleting forces, and friction contacts44 may all have a precise and detailed impact on rod contacts; therefore, it is crucial to understand the mechanisms that lead to particle gel formation or kinetic standstill. The structural variation of a rod network is determined by this type of interparticle interaction. It is possible to create structures ranging from noninteracting rod networks to fractal clusters with rods; the same rationale is applicable to “tactoids”.

3.2.1. Depletion Mechanism

An essential tool for researching the basics and real-world issues in soft matter physics is the capacity to modify colloidal particle interactions from short-range repulsion to short-range attraction. The issue is closely connected to current and recent studies on clustering and stability,45 dynamical arrest,46 and gelation.47 One way of tuning interactions is to use depletion. The Asakura and Oosawa coarse-grained depletion model is the most well-known to describe such systems.48 In this model, the polymer-to-colloid size ratio and polymer concentration may be changed to adjust the potential’s range and strength.49 In the remaining sections of the manuscript, tuning depletion forces is used as a helpful strategy to adjust the chirality of CNCs to achieve a red-to-blue shift and adjustable optical behavior.

Both water-soluble polymers and mixed particles in CNC solution have the potential to cause depletion. A Pickering emulsion of oil in water was stabilized by depletion in recent research using cellulose nanofibrils (CNFs), which were generated via surface adsorption of CNCs.50 Nonadsorbing CNF50 initiates this depletion effect. According to one author, bacterium depletion flocculation can be facilitated by CNCs;51 once more, two morphologically mixed noninteracting particles cause depletion. Lekkerkerker and Tuinier52 reviewed the extensive theoretical studies on the function of hard spheres, hard rods, and thin discs as depletants given the dearth of experiments. A potent technique for changing liquid crystal structure and CNC pitch is depletion contact.

4. Liquid Crystal Formation of CNCs

This chiral nematic structure of CNC-based films offers outstanding optical capabilities due to its photonic crystal nature. The rainbow color and birefringence properties were achieved by the structure’s arrangement of chiral nematic LCs. The tobacco mosaic virus,53 cylindrical viruses (fd and M13),54 DNA fragments,55 poly(tetrafluoroethylene),56 flagella filaments,57 collagen,58 boehmite,59 cellulose,60 chitin,61 κ-carageenan,62 synthetic polypeptides (polybenzyl-l-glutamate (PBLG)),63 and polysaccharides (xanthan and schizophyllan)64 have all been observed to undergo LC phase separation based on excluded volume effects. Remarkably, all these substances exhibit structurally colored iridescence, with physically stemmed coloration displayed only by the arrangement of such structures. The research done on any of these materials can be used for CNCs and CNC materials that have chiral nematic architecture. Not all chiral chemicals produce cholesteric phases, and nematic phases, such as the tobacco mosaic virus, are usually identified exclusively in elongated inclusions (CNCs). Chiral structures have helices; most of these helices have a fluted shape and a high electric charge. How molecular chirality presents itself in the macroscopic characteristics of the chiral phases formed and what intermolecular interactions are involved are unknown.65

Onsager’s hypothesis35 states that networks of long, rigid rods interacting with only repulsive forces result in an orientational (or nematic) pattern at a critical density that is far from maximum packing. Studies for rod viruses were first undertaken, but in 1959 Marchessault et al.66 reported CNCs, a rod-like particle related to rod viruses, and this opened the door for cellulose study in LCs. In 1976, Gray et al.67 reported that hydroxypropyl cellulose, which is composed of stiff polymer chains resembling rods, may also produce chiral nematic LCs at small doses. Revol and associates reported decades later that raw materials derived from cellulose may create stable lyotropic chiral nematic liquid crystal phase structures.68,69

Nematic layers, with the directors turning slightly as the structure progresses, make up cholesteric liquid substances. The distance required to complete one full circle of the director is known as the pitch length, which is important for building helical structures. Pitch length, one of the most crucial pragmatic factors that has been the focus of much research, distinguishes the cholesteric mesophase. This classification is self-evident since pitch length in some chiral systems is on the same order of magnitude as visible-light wavelength. These systems display intriguing optical characteristics because of their pitch existence, including Bragg reflections and reduced laser emission,70 which have been used in many optical applications.71

Pitch length can be measured by looking at the peak of reflected light, or it can be directly observed using polarized optical microscopy (POM) or scanning electron microscopy (SEM); POM, however, is not very accurate. Pitch length recorded with SEM is substantially shorter than pitch length recorded using POM, according to the authors of one study. The CNC chiral photonic material pitch therefore cannot be expressed solely using the POM pitch, albeit it is helpful. An optical microscope can show a variety of stripes because of interference fringes, varying undulations, and helicoidal quasi-layers in an oblique orientation. As a result, the fringe pattern of liquid crystals is confused with these comparable inter-references.72

Gray and colleagues68 described for the first time in the research that permanent chiral nematic phases may be generated from stiff rod-like CNC suspensions made from natural cellulosic materials. Above a certain concentration, ordered chiral nematic phases naturally emerge, with the biphasic regions’ identifying tactoids. These tactoids are spherical, ellipsoidal, or spindle-shaped droplets that are subject to hydrodynamic forces and have a propensity to coalesce into uninterrupted anisotropic phases.73 According to the paper, this helical configuration of CNCs has a pitch that is in the tens of micrometers range when it is fluid but decreases to sizes below 1 μm when it is dried, causing Bragg reflections of visible light from dried films that have a photonic band gap with an iridescent color.

Reading the literature demonstrates that, like the individual CNCs that existed before “tactoids” developed, chiral organization in colloids is impacted by physics and fluid dynamics. Self-assembled CNCs’ surface charge density (i.e., the amount of sulfur present) and ionic strength, together with size and size distribution, all affect the chiral nematic pitch of the particles. For instance, in CNC suspensions formed of wood pulp, when CNC length drops, so does the pitch of the chiral nematic phase. The chiral nematic structure’s pitch size in solid CNC films is influenced by several factors, including the starting solution concentration, media ionic strength, and drying circumstances. Recent desulfation research has shown that higher sulfate concentrations increase the pitch values in solid films (effect of sulfate content or surface charge on the pitch); sulfuric dosage, temperature, and time all affect sulfur content.14

Here are some numbers from a recent study.74 The mean pitch size fell from 15 to 2 μm as the vol % climbed from 2.5 to 6.5; however, the spacing between CNCs increased from 51 nm at the beginning of anisotropic phase growth to 25 nm above 6 vol % (completely liquid crystalline phase). According to the researchers, when the volume percent increased from 2.5 to 6.5 vol %, the twist angle between adjacent CNCs increased about from 1° to 4°. The rise in magnitude of the repulsive interactions between both the charged rods as the mean distances and angles lowered was related to the twisting’s dependency on the volume fraction. Previous studies have assessed pitch values associated with CNCs as varying between 10 and 60 μm, but nothing is understood about how the pitch altered with volume fraction.69,75−77 Therefore, particle concentration influences CNC chirality.

The research is also awash with information on which factor affects CNC chirality more—surface charge or twist. Revol and Marchessault claim that the CNC chiral nematic liquid crystal phase68 was produced as a result of the twisted spiral shapes. Further research by Orts et al.78,79 revealed that the CNCs in the aqueous phase had a distorted spiral rod-like shape, as shown by in situ small-angle neutron diffraction. Araki and Kuga80 identified CNCs from bacteria in 2001.

However, chiral nematic liquid crystalline structure did not develop when the electrolyte was added to the solution. They proposed that the flat cylindrical form changed into a twisted rod shape when the electrolyte was added, resulting in a lower effective particle size. In particular, the rod shapes were inclined. Therefore, the spiral-nanorod form of CNCs plays a crucial role in the creation of chiral nematic LCs. Bacterial cellulose was hydrolyzed in sulfuric acid to form the rod-like microcrystal solution, which was subsequently separated into nematic phases by dialysis. The solution’s phase separation behavior was altered by the addition of salt, which led to its transformation into a chiral nematic structure. This behavior shows that the chirality of the particles, which is protected by repulsive forces,81 originates from their twisted shape. This perspective could be accurate since the tobacco mosaic virus (TMV) generates chiral structure and possesses structural chirality and intrinsic asymmetry as well.

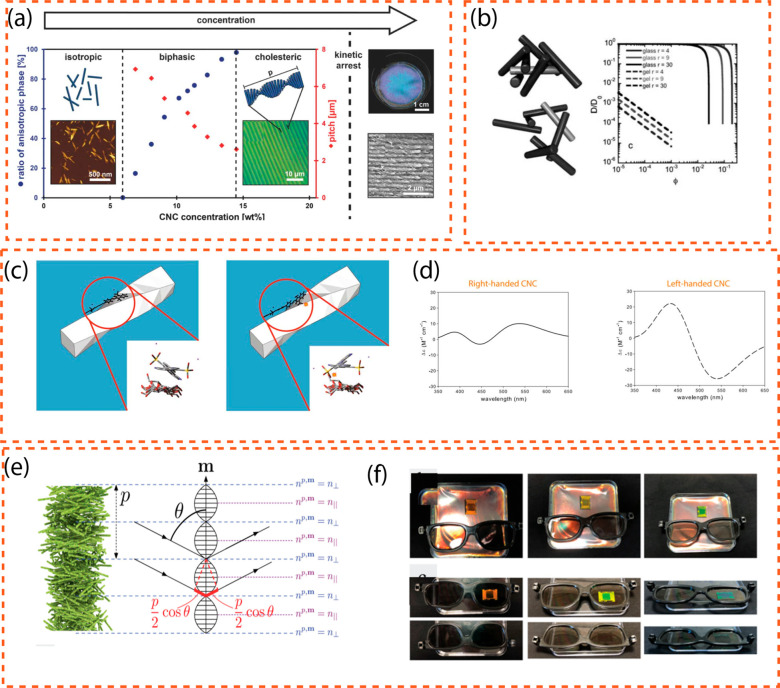

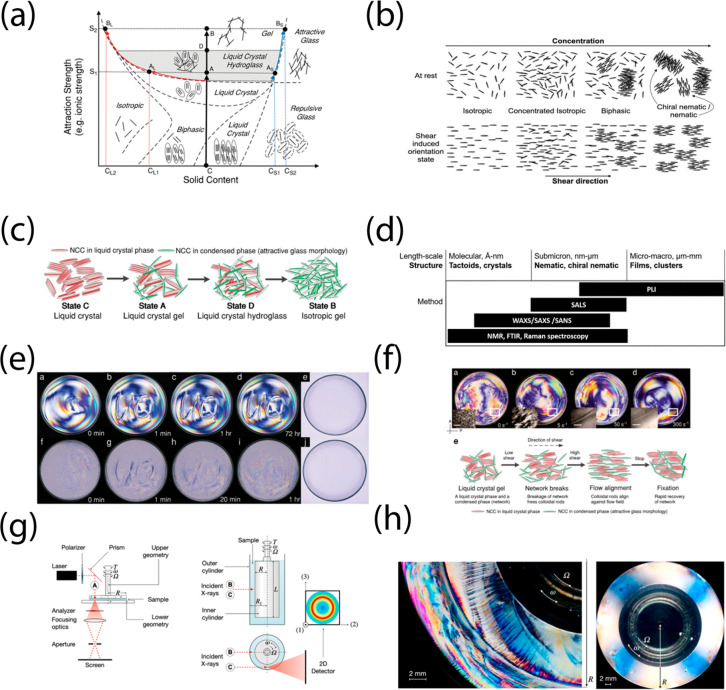

Figure 2a shows the CNC suspension self-assembly process during evaporation to generate a functionally colored film (without the addition of dye or pigment). The phase diagram depicts the change from the isotropic to cholesteric phase (blue dots) as the CNC concentration increases, as well as the accompanying equilibrium pitch (red diamonds); it is supplemented with atomic force microscopy (AFM) pictures of individual CNCs. In the top right corner, polarized optical microscope photographs of a typical cholesteric phase fingerprint image are also exhibited. Because the helical axis is orthogonal to the film, no fingerprint texture areas can be seen if the CNCs in chiral photonic films are parallel to the surface of Petri dishes. “Tactoids”, on the other hand, expand and merge by a coalescence mechanism as the CNC self-assembles to create a chiral nematic film. Faults from failed “tactoid” fusing persist in the CNC chiral photonic films, giving in a plethora of distinct fingerprint characteristics visible under POM.

Figure 2.

Chiral structure of CNC suspension. (a) CNC suspension self-assembly during evaporation to create an architecturally colored sheet (without the addition of dye or pigment). AFM images of individual CNCd are shown with the phase diagram, which shows the shift from the isotropic to the cholesteric phase when CNC concentration rises (blue dots) and the associated equilibrium pitch (red diamonds). Polarized optical microscope images of a common cholesteric phase fingerprint pattern are also shown in the upper corner. Adapted with permission from refs (97 and 98). Copyright 2016. Wiley-VCH, American Chemical Society. (b) The influence of the suspension structure on rod dynamics. Based on the ideas of Edwards and Evans83 and Krall and Weitz,84 the volume-fraction-dependent self-diffusivity of rod suspensions is computed, and the diagrams show how the CNC dynamic changes with volume fraction and charges. Adapted with permission from ref (99). Copyright 2010. Royal Society of Chemistry. (c) Circular dichroism of Congo red was induced on a twisted CNC. The top two Congo red enantiomers, A (+) and A (−), interact differently with the chiral nanocrystal surface. The A (+) enantiomer and the right-handed surface have a steric interaction on the right. The enantiomeric ratio changes due to favorable interactions between the conformation on the left, A (−), and the right-handed surface. The cartoon is not scaled. (d) Bottom CNCs with a right-handed twist bind Congo red preferentially in an orientation that generates a positive Cotton effect. Left-handed CNC cause a negative Cotton effect. Adapted with permission from ref (85). Copyright 2017. Springer Netherlands. (e) Application of Bragg’s law onto the chiral structure of CNCs. Adapted with permission from ref (100). Copyright 2020. Multidisciplinary Digital Publishing Institute. (f) Circular dichroism of CNC chiral structures explored with circularly polarized glasses. Adapted with permission from ref (100). Copyright 2020. Multidisciplinary Digital Publishing Institute.

According to hypotheses, the slowdown interactions of these two states vary very sharply because slow dynamics appear in a very narrow volume fraction range for glasses, and it shortens as aspect ratio is increased. Figure 2b shows the contrast among nanoparticle kinetics and volume fractions for glass and gel states (here denoted by r as the ratio of length over diameter). These representations were slightly altered when polydispersity was included in the equations. Exploring glassy or gel states is vital when scientists wish to lock in liquid crystalline formations in films, in addition to offering a practical method for changing the characteristics of CNC.

To lock in the liquid crystal structure, one may resort to adding coagulants. Aggregation is a thermodynamic balance between the energy required to keep particles in the aggregation state and the energy required to disperse them through thermal movement of water molecules. On the other hand, if the energy barrier falls below a certain threshold, aggregation will start. In this stage (coagulation), CNC particles/tactoids adhere and, depending on concentration, collapse or create a 3D gel readily,82 the dynamic of which is explained by theories.83,84 Later in the rheomechanical section, it will be demonstrated how the presence of a coagulant causes partial melting of LCs.

Recently, ref (85) used optically inactive Congo red produced circular dichroism to assess the structural chirality of CNCs (as depicted in Figure 2c and d). Conventional wood CNCs are expected to be 800 nm per half-twist right-handed, which is compatible with directly measured twists.10,86 Imaging the twist is problematic due to the small lengths of wood-sourced CNC (100–200 nm), and tiny structural faults generated by such a twist would be difficult to discern using diffraction methods. The dye probes the crystal’s surface, allowing these tiny characteristics to be quantified. Dong and Gray75 accurately hypothesized that the positive “Cotton effect” was created by a right-handed twist of the CNC, but the reason could not be identified without a computational investigation at the time. Recent observations,10,86,87 as well as molecular models,85,88 show that CNCs have a right-handed twist and that the cellulose crystal structure is more complicated than a flat crystal. As a result, it is reasonable to assume that the twist related to the structural chirality of CNC influences their capacity to separate, template chiral materials, or conduct chiral catalysis, as well as direct particle interactions at greater concentrations. These theoretical conclusions are compatible with the morphological findings of Usov et al.,10 who used AFM to show evidence of right-handed chirality on both bundles and single fibrils.

Due to the creation of “coffee rings” during solvent evaporation, the CNC chiral optical film has a circular iridescent structural color and is narrower in the center and broader at the boundaries. According to Bragg’s rule, the structural colors of CNC chiral photonic films are angle-dependent, which is a common property of structural colors,60 which were previously classed as angle-dependent and independent. As the angle of incidence of natural light decreases, the color of CNC chiral photonic film changes from red to blue; alternatively, when the angle of incidence is fixed, the color of CNC chiral photonic films depends on the pitch of the CNC chiral nematic framework and its helical axis orientation relative to the film normal.

The wavelength of the reflected light that produces the color transition89 is governed by the pitch of the LC, which is indicated by the letter P in most literature, a fact validated by Dumanli et al.90,91 on a CNC-based LC film. The reflected wavelength is defined by the Bragg92 equation, λ = nP sin(θ), where lambda is the reflected wavelength, P is the helical pitch, θ is the incoming light’s angle, sin(θ) = 1 when the incident light is perpendicular to the crystal plane, and n is the material’s average refractive index.93 Dumanli et al.90,91 reported that pitch predicted by the Bragg equation agreed visually with experiments. As a result, the photographs acquired with a polarized optical microscope (POM) below may give reliable proof for the cholesteric LC94 as shown in Figure 2a. There are approaches in the literature for making unnaturally architecturally colored colloids angle independent; however, these studies are beyond the focus of the current study. As previously stated, Bragg’s rule may be applied to CNC chiral character, indicating how such a structure interacts with incoming light; moreover, the CNC chiral structure reflects left-handed circular light but transmits right-handed circular light; these changes are represented in Figure 2f. Instead of measuring the absorbance of isotropic light, circular dichroism (CD) spectroscopy compares the absorption of right-handed and left-handed circularly polarized light by a material.

As a result of the salt addition, the critical concentrations for the anisotropic phase rise, and the boundary between both the isotropic and anisotropic phases blurs. As the salt concentration was increased (the concentrations in the two phases become more similar), the limit between the phases becomes more diffuse, and as a result, the isotropic phase exhibits some birefringence between cross polarizers, making calculating the volume fraction of the phases more difficult. This finding was connected in the literature to a shift from a first-order transition, which should appear as clean phase separation, to a second-order transition, where critical fluctuations are involved, and the transition seems to be delayed. Moreover, even in the absence of sufficient salt, increasing the concentration of CNC (obtained by sulfuric acid hydrolysis) boosts the ionic strength of the suspensions since CNCs are surface charged, rendering separation difficult to quantify at high CNC concentrations. Furthermore, the addition of salts lowers the effective diameter of the CNC rods, leading to an increase in aspect ratio and a decrease in effective volume (and hence the effective volume concentration of the rods in the suspension).95

Changes in ionic strength can affect pitch length as well as transition points. Shafiei-Sabet et al.,96 for example, dispersed CNCs in deionized water or NaCl solution to modify the pitch of the systems. According to the Derjaguin–Landau–Verwey–Overbeek (DLVO) hypothesis, the equilibrium between these electrostatic and van der Waals forces drives the instability of colloid suspensions. As a result, DLVO theory allows one to substitute the original aspect ratio of rods with an effectively decreased aspect ratio (allowing for electrostatic repulsion range) and input it into Onsager theory to discover the point of transition from isotropic to nematic, and so on.

In the low-salt limit, more charges interact efficiently

further

away from the spiral–spiral contact, resulting in helical axes

that are aligned perpendicularly. The SAXS and laser diffraction measurements

reveal how the average distance between the CNCs and pitch values

changes when volume fractions (or charges) change. The angle one rod

must twist is in its neighboring vicinity, assuming that  . The twist is related to the competition

for total energy between entropic and enthalpic contributions. The

enthalpic contribution from rod–rod interactions becomes significant

when the space between rods is short, i.e., when CNC concentration

is high or salt is added. It is critical to accurately estimate these

two contributions because attractive interactions stimulate parallel

orientation while Coulombic interactions encourage orthogonal orientation.

. The twist is related to the competition

for total energy between entropic and enthalpic contributions. The

enthalpic contribution from rod–rod interactions becomes significant

when the space between rods is short, i.e., when CNC concentration

is high or salt is added. It is critical to accurately estimate these

two contributions because attractive interactions stimulate parallel

orientation while Coulombic interactions encourage orthogonal orientation.

A significant number of negative sulfate groups on rod-like CNCs hydrolyzed by sulfuric acid always cause electrostatic repulsion,1 permitting the production of stable chiral nematic mesophases (liquid crystal formation is salt-dependent). The repulsive forces between CNC rods are too large to allow CNCs alone to assemble into a chiral structure when treating CNC suspension as an ion-free media and comparing the findings to the DLVO theory; however, this is charge dependent as desulfation through the application of heat might lead to the easier formation of chiral structures.101,102 Indeed, CNC suspensions treated with long-term water dialysis to remove counterions have a high zeta-potential value and exhibit achiral nematic characteristics; desulfation in this case can act in reverse. When this CNC suspension was dried into a solid film, no iridescent hue was noticed, and no peak in the ultraviolet (UV)–vis spectrum was observed.

By screening the surface charges and reducing the steric effect, salts and polyethylene glycol (PEG) (nonabsorbing polymer) can also minimize repulsion.103 The interaxial lengths between CNC rods were estimated by determining the peak position in the SAXS curves to be smaller in salt (44.0 nm) and PEG (45.6 nm) systems compared to the original clean system (48.7 nm).74 By reducing pitch size, reducing interaxial separation, and raising interaxial tilt, adjacent CNC particles’ chiral nematic structure is maintained after drying, and the associated films display iridescence. In one trial, oxalic acid rather than sulfuric acid was used to treat CNCs. Oxalic acid was used to discover the CNC film’s brilliant snowflake-like pattern rather than sulfuric acid. More significantly, carboxylated CNCs produced by oxalic acid readily formed a LC phase by adding the cationic solutions to 1.27 wt % CNC solution.104 In brief, the chirality of the CNC suspension and films may be altered by manipulating colloidal forces; this repulsion can be controlled by altering charges or introducing a small quantity of coagulant.

Figure 2d shows that the CNC chiral photonic film has markedly sunnier iridescent structural color schemes when lighted to left circularly polarized light (L-CPL) than when lit up with unpolarized natural light, and it is almost translucent when lighted with right circularly polarized light (R-CPL). Nevertheless, with R-CPL, CNC chiral optical material has no discernible troughs. Under L-CPL, the four areas of CNC chiral photonic film have much lower transmittance than ambient light in their respective valleys, resulting in enhanced contrast and brighter iridescent colors. According to these results, the CNC chiral photonic films exhibit chiral nematic structures that are left-handed.105,106Figure 2f shows these evolutions visually with circularly polarized glasses.

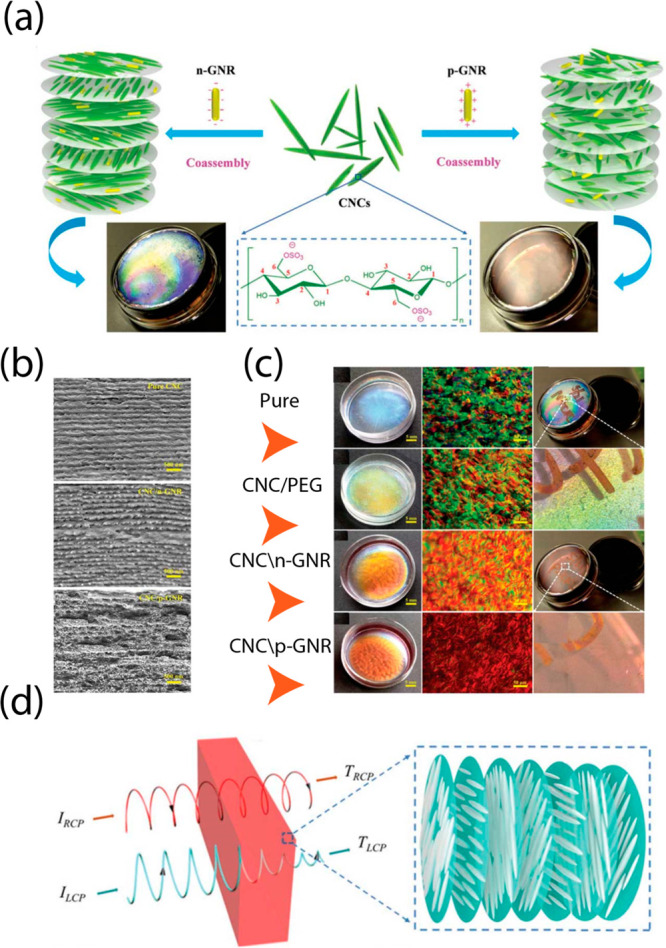

4.1. Coassembly of CNC and Other Nanoparticles

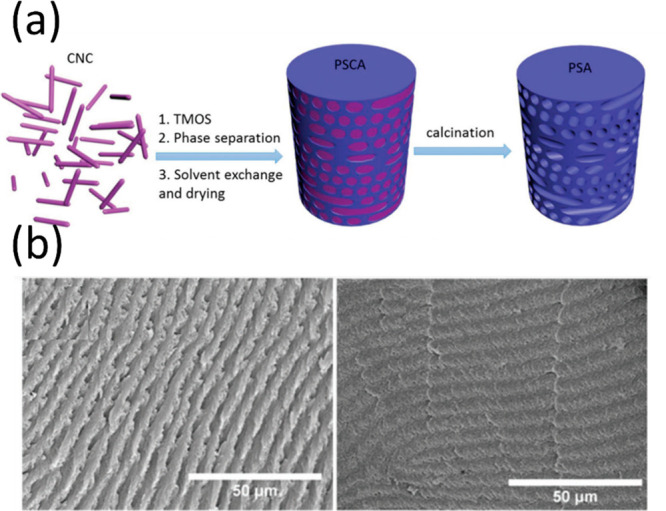

Nanoplasmonic and photonic crystals work together to provide innovative optoelectronic properties that have the potential to lead to the development of better materials and gadgets. Anisotropic gold nanorods and rod-like CNCs may be combined to form free-standing chiral–plasmonic composite films, which have the potential to exhibit chiroptical-modulated activity over a wide range. Surface plasmons, which may confine light to a subdiffraction-limited area and dramatically improve light–matter interactions, can be sustained by metal nanoparticles (in this case, gold nanorods). A design of chiral plasmonic hybrid films created by fusing gold nanorods and CNCs is shown in Figure 3a. Because the negatively charged gold nanorods were arranged uniformly and parallel to the CNC rods, the chirality of the CNCs was maintained. The chiral nematic ordering is somewhat broken as a result of positively charged gold nanorods being dispersed randomly and forming a partial agglomeration.107 Cross sections of pure CNC and CNC/n-GNR hybrid films are depicted in SEM pictures in Figure 3b. As can be observed, the pitch sizes of the CNC/p-GNR hybrid film are all twisted; however, the CNC/n-GNR hybrid film is unaffected, just like pure CNC film.

Figure 3.

Coassembly of CNCs with other ingredients. (a) Schematic of the hybrid chiral plasmonic films made from charged GNRs and CNCs. The negatively charged gold nanorods were distributed evenly and parallel to the CNC rods. The chiral nature of CNCs is maintained. The positively charged gold nanorods are dispersed at random and aggregate in part. There have been reports of CNC nanorod gelation and flocculation with some chiral nematic ordering perturbed. Adapted with permission from ref (107). Copyright 2019. Wiley-VCH. (b) SEM of cross-section images of pure CNC, CNC/n-GNR hybrid film, and CNC/p-GNR hybrid film. Adapted with permission from ref (107). Copyright 2019. Wiley-VCH. (c) Photographs of pure CNC film, CNC/PEG film, CNC/n-GNR film, and CNC/p-GNR film in liquid and dried forms. Adapted with permission from ref (107). Copyright 2019. Wiley-VCH. (d) Diagram showing the path of circularly polarized light through a left-handed chiral-structured CNC film. Passive left-handed circular polarization light is produced by the chiral photonic film’s preferential reflection of incident light, whereas passive right-handed circular polarization light is transmitted. Adapted with permission from ref (107). Copyright 2019. Wiley-VCH.

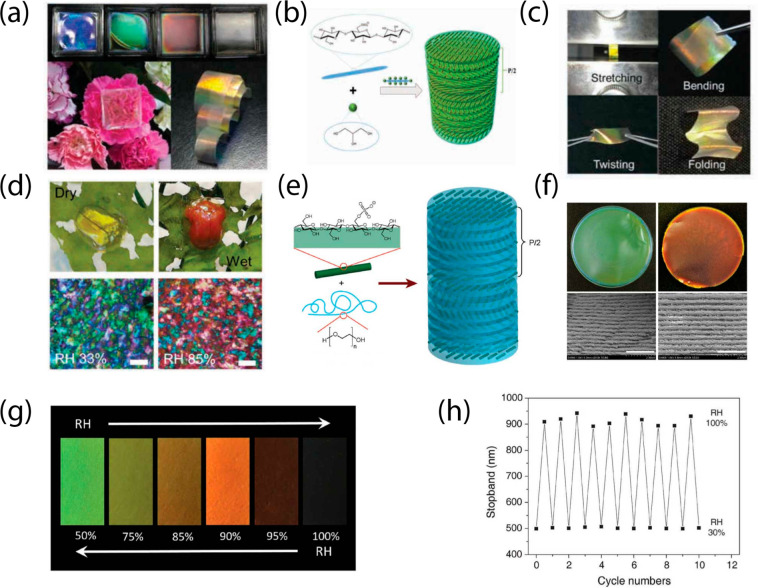

As shown in Figure 3c, four different types of chiral-structured iridescent composite sheets were produced by gently evaporating water for 2 days at 30 °C and a RH of 80%. The pristine CNC films have a prominent blue color with several iridescent color zones because of the chiral structure’s helix orientation. Remarkable are the clear pure CNC films’ photonic crystal properties and vivid iridescent chiroptical activities. Due to the steric stabilization produced by PEG, the CNC-PEG film reflects yellow principally with a small red shift observed in comparison to the CNC film. Surprisingly, the presence of gold nanorods causes a large red shift to be seen. While there is no agglomeration and a more uniform color on the CNC/n-GNR hybrid film, this is not the case on the p-GNR hybrid film. Because of electrostatic interactions, p-GNR will prevent CNC from forming a chiral nematic structure, but n-GNR, which is present at the same concentration, is dispersed uniformly inside the helix conformation and encouraged to do so.

The pure CNC film shows significant birefringence and multidomains with variable sizes and orientations because of the lack of control over helix alignment during evaporation. PEG incorporation hardly modifies the domain color but has no discernible effect on the appearance of birefringent and “fingerprint” textures. On the POM pictures, the as-prepared CNC/GNR composite films show a progressive transition in the domain color from brilliant green to dark red. The CNC/n-GNR hybrid film exhibits a more constant iridescent color than the CNC/p-GNR film. According to the seeming flat appearance, the structured helix patterns are all still present in the solid sheets (spaced parallel lines). The fingerprint texture pattern of the CNC/n-GNR hybrid film is cleaner and more organized when compared to pure CNC and CNC/PEG films. The fingerprint texture pattern is less distinct and more blurry on the CNC/p-GNR film.

Due to their left-handed helical shape, chiral cellulose films may selectively reflect and transmit incoming light to produce circularly polarized light (CPL) with opposing helicity states.105 The inherent capacity of chiral cellulose materials to convert incoming light into passive left-handed CPL (L-CPL) through selective reflection and passive right-handed CPL (R-CPL) through transmission is shown in Figure 3d. There is a distinction between L-CPL and R-CPL in terms of absorption.

Xu et al. noted that the interlamellar splitting and self-assembly process among graphene oxide (GO) suspensions (an LC-forming suspension) in nematic or lamellar phases can be synchronized by the addition of hydrophobic substances like silica nanoparticles via an entropy-driven depletion mechanism.108 Another method for generating depletion forces in each system is to utilize a polymer that does not interact with CNC particles. If macromolecules do not adsorb at the particle interface, the exclusion of polymer segments from particulate volumes results in an effective entropic pull between particles known as depletion interaction. The anionic polyelectrolyte carboxymethyl cellulose (CMC) has greater osmosis over nonionic polymers at the same molecular mass, as reported in ref (109). This is because the increased radius of gyration brought on by intramolecular charge repulsion makes CMC an anionic polyelectrolyte. Because anionic CMC chains do not adsorb on them, they can promote depletion-induced self-assembly CNC nanoparticles, according to the literature. Nonadsorbing micelles, such as those used in protein crystallization, can likewise induce depletion pressures on CNC particles. The inclusion of nonadsorbing compounds in the suspensions causes these difficulties.

4.2. Parameters Influencing Chirality

Pure hard rod CNC suspensions, as previously mentioned, exhibit remarkable phase transitions. The inclusion of nonadsorbing polymers as depletants influences these transitions; these additives have a considerable effect on the isotropic–nematic (I–N) phase transition of CNC suspensions.52,110 Depletion effects may be used to change colloidal stability, expand the coexistence of regions in I–N transitions, and fine-tune the angle of twisting of chiral structures. Scientists in the literature were startled by depletion effects since adding a nonadsorbing polymer resulted in the stabilization111 of graphene oxide suspensions rather than the predicted instability. Furthermore, the viscosity of the suspension was lowered by many orders of magnitude.111 The formation of smectic fibrils at intermediate depletion strengths resulted in a polymorphic shift from two-dimensional crystalline monolayers at mild depletion to one-dimensional columnar fibers at strong depletion;112 the agent’s concentration and molecular weight can be fine-tuned to fine-tune the strength of depletion. The usual growth period, according to the author, differed by more than 6 orders of magnitude, needing days for big platelets to mature, minutes for smectic fibrils to develop, and milliseconds for columnar fibers to form. Aside from the fundamental rod–rod contact (thermodynamic), kinematics plays a significant role in the structure’s creation.

Depletion can also be caused by other nonabsorbing noninteracting nanoparticles, as was previously described. When dextran, a depletion agent, is introduced to the biphasic zone, the coexistence (isotropic and nematic phases) region is greatly increased. The isotropic phase is where dextran preferentially divides. After solidifying the CNC/PEG and CNC/salt suspensions, the interaxial angle between CNC rods widened. The interparticle distance was simply connected to the salt content; however, it was shown that the angle depended on both ionic species and ionic strength as explained in terms of interaction energies. CNC films made by suspension casting have been demonstrated to create left-handed chiral nematic structures that polarized incident light and reflected left-handed light.113 Simulations show that a mixed particle system, like the GO dispersion and silica nanoparticle used in ref (108), can similarly activate depletion mechanisms.114 The depletion interaction and its influence on distinct colloidal particles with diverse geometries are thoroughly explained in ref (115). DNA can also cause the clay liquid crystalline part to swell.116

Finally, the addition of polymer lengthens the pitch in some circumstances and generates a red shift in the light that is reflected; this happens in scenes where the polymer is located between CNC rods and pushes the sheets apart, lengthening the pitch. The variety of characteristics has an impact on the degree of red shift such as flexibility, rigidity, the radius of gyration, and binding between the polymer and CNC rod;117 on the other hand, nonadsorbing polymers118 or polymers with low molecular weight103 act as depletion agents, and pitch size decreases as polymer concentration increases. Widening the reflection spectrum appears to be essential for the development of broadband applications to produce novel photonic crystals. Authors119 generated films of CNCs that exhibit circularly polarized reflection throughout the visible spectrum (broadened) using micelles. The optical characteristics of additional chiral nematic LCs, which are now utilized extensively in display technologies,119 may be modified using this innovative technique. Micelle helped in the process of self-assembly that causes CNCs’ cholesteric stage to deform.

To describe the procedure, “tactoid” formation—a process similar to crystallization in polymers—occurs when the solvent evaporates, the loading of CNC rises, and “tactoids” form.120 A constant film with chiral nematic order results from the tactoids’ fusion and deposition. Nevertheless, because micelles are present, they become caught in the CNC’s liquid crystal domains’ developing lamellar structure and prevent the domains from merging into long-range homogeneous structures. Authors hypothesized121 that the accumulation of the micelles between cholesteric domains is due to the exclusion effect of dense LCs on large-size nanostructures.122 Additionally, at the micelle–liquid crystal phase contact, these micelles show a reorientation impact on the LC mesogens that precludes the flat alignment of CNCs in each stratum. The micelles cause the domains in the film to tilt as compared to the usual horizontal deposition direction brought on by gravity. The micelles, however, collapse as the CNCs continue to dry, leaving a heterogeneous CNC film.

In contrast, soft polymer molecules can intercalate into the cholesteric phase of CNCs to generate a homogeneous film123 when water-soluble polymers or melting elastomer latex is used. Finally, CNC lyotropic chiral nematic LCs were deposited into CNC films with considerable disorder due to submicrometer-sized micelles produced by an anionic surfactant. Chirality has a relationship with CNC polydispersity as well. According to Lekkerkerker and Tuinier,52 large biphasic range development is a direct result of CNC polydispersity and has been found in other polydisperse rod-like colloidal suspensions as well. For example, graphene oxide suspensions display comparable behavior, and the authors observed that the biphasic suspension’s compositional range was extremely large due to platelet polydispersity.

As a final note explaining the difference in chiral behavior of CNCs on nonadsorbing and adsorbing polymers, the addition of polymer increases pitch length in some circumstances and creates a red shift in the reflected light, and the polymer chains are implanted between CNC rods and increase the CNC interaxial distance. The degree of red shift is determined by key characteristics such as flexibility, rigidity, the radius of gyration, and binding between the polymer and CNC rod;117 on the other hand, nonadsorbing polymers118 or polymers with low molecular weight103 act as depletion agents, and pitch size decreases as polymer concentration increases.

To summarize, pitch length varies with salt and CNC concentration, and fractionation due to centrifugation or phase change results in shorter or longer rod separation; this fractionation results in an increase or decrease in pitch size.124 Whenever repulsive contacts are adjusted, such as screening charges with salt or reducing surface charge via healing, pitch length is decreased. Swelling stretching causes an increase in pitch size, and compression provides a reduction in pitch size.

4.3. Orientation

Liquid crystal arrangement and direction are equally important and demand particular study. SAXS and small-angle neutron scattering (SANS) scattering have also been used to some extent to examine the structural characteristics of the ordered chiral nematic CNC phase. According to SANS data, CNC rods in chiral nematic suspension that is magnetically or shear aligned are packed more densely parallel to the chiral nematic axis than perpendicular to it.78,79 Additionally, Orts et al.78,79 have demonstrated that rod spacing reduces as CNC concentration and added electrolyte content increase. Until now, attempts to control CNC director orientation have only used external fields, shearing, and the use of electrical or magnetic fields, all of which have varied degrees of success.

Fibers with diamagnetic anisotropy align under static magnetic fields. Carbon fibers,125 carbon nanotubes,126 polyethene fibers,127 cellulose fibers, and so forth undergo magnetic alignment. The experiments in which liquid crystalline fibers of these comparable rods are magnetically aligned can be simply expanded to CNCs. Because cellulose fibers are diamagnetic, the chiral nematic axis aligns parallel to the static magnetic field, and several studies on chiral nematic phases formed from cellulose fiber suspension have been reported.128 Magnetic field application is the only method reported thus far that can control the helix’s direction. Although the literature has a footprint in using microfluidics to construct such structures, enhancing and changing orientation, particularly with relation to CNCs in their LC form, has not been recorded.

This method can deploy and position CNCs due to the negative diamagnetic anisotropy of CNCs, which have a rod directly proportional to the magnetic field. CNCs tend to align perpendicular to an externally applied magnetic field. The cholesteric phase may be aligned experimentally at modest magnetic fields (μ0H ∼ 0.5T), allowing for angular control of the domains’ helical direction.129 Because the rods of a cholesteric CNC suspension are all perpendicular to the helix axis, when placed in a sufficiently powerful magnetic field, the helix will be uniformly aligned in the field direction. It has been empirically verified by Revol et al.69 and Kimura et al.130 that the magnetic field caused the parallel organization of a helical axis to the magnetic field direction, and magnetic field rotation (periodic) caused crystal unwinding as the suspension transitioned from liquid crystals to an isotropic state. Removal of the magnetic field also led to complete dissolution and relaxation of liquid crystalline phases.

Other observations involve the magnetic orientation of CNCs; literature searches indicate that magnetic fields have not been investigated for their impact on tactoid fusing. Furthermore, by observing its dispersion within the solution, tactoid nucleation may be made more homogeneous. Tactoid nucleation may be organized and studied similarly to polymer crystallization; thus, investigating ways to enhance or reduce it can be influential in the field. Although it did cause a disruption in liquid crystals in one study, a magnetic field was not employed to change the location of an isotropic to nematic or nematic to chiral nematic transition. Magenic fields’ influence on tactoids’ orientation can be paired with depletion forces. According to one account,130 magnetic field alignment takes 5 h at 1 T; there are outstanding questions in this area regarding the influence of salt and depletion force or concentration on the rate of alignment and the effect they may have on accelerating or decelerating the rate of alignment. Paramagnetic nanoparticles, such as Fe2O3,131 can also be painted onto particles to increase their sensitivity to magnetic fields and the pace of alignment. One study132 found that altering a fluid’s viscosity from water to n-methyl formamide (NMF) under a 0.7 T magnetic field might alter chiral orientation. The cholesteric with the least viscosity also showed the biggest rise in order prior to equilibrium and plateauing when the magnetic field was introduced. The greater viscosity suspensions, however, showed nothing after the first field influence in terms of temporal variations.

Viscosity has an impact on CNC ordering. CNC-water is more viscous than CNC-NMF. It thus struggles more to rotate in a magnetism. Since the rate of orientation is related to the solution’s viscosity, CNC “tactoids” can be utilized as a probe for microrheological purposes. Similar to the fluorescence recovery after a photo bleaching probe,133 this probe can provide information on the pore structure and degree of confinement of the area around the CNC “tactoid” probe. The rate at which different rods in distinct suspensions are oriented can potentially be a factor in “tactoid” variations.

Magnetic flux was also employed to create well-coordinated nematic liquid crystalline and liquid crystal specimens of virtually monodisperse TMV.41 Onsager35 developed a theory for the phase transition in LCs using TMV as well. When a nematic specimen is exposed to a magnetic field, positive diamagnetic (opposite to CNCs) anisotropic virus particles quickly align in the field’s direction at an applied field of 22k gauss. When the field is withdrawn, the particles misalign once more, which is expected behavior for CNCs or rods with a similar structure. According to research, the pitch of CNC-based films reduces as the magnetic field strength increases. Both the pitch and the homogeneity of the film may be altered.

Habibi et al.134 also used an AC field to generate highly directed low concentrations of CNC distributed in cyclohexane. The findings revealed that rod-shaped particles became parallel to the direction of the electric field rather than the magnetic field’s orientation direction.134 The authors used in situ small wide-angle X-ray scattering diffraction (SAXS/WAXD) techniques to study the GO nematic liquid crystal phase during polymer crystallization, concentrating on their hierarchical structure. It was reported that GO LC and polymer crystals coexist in the GO polymer complex, where polymer crystallizations influence the overall liquid crystallinity. While polymers crystallize in bulk or at the interface depending on the cooling rate, interfacial PEG crystallization on GO increases both GO alignment and PEG crystal orientation.

PEG with GO prefers to crystallize at the interface or in the bulk, depending on the crystallization kinetics, which ultimately influences the predominant direction of GO LCs. This work demonstrates another possible application of crystallization for ordering LCs.135 To the best of our knowledge, no study has been published in the literature that reports on the ordering of CNC LCs employing polymer crystallization. Similar ordering through application of an electric field has been observed in clay suspensions;136 similarly anomalous photothermal deformation of gels doped with uniaxially aligned nanosheets adsorbed with a dye is observed in one study. Only the colored portion of the gel is photothermally distorted when exposed to light.137

De France et al.138 demonstrated that cooperative ordering favors field orientation. Magnetic fields of 0.56–1.2 T were insufficient to orient samples containing 1.65 and 4.13 wt % of CNC, a goal previously achieved for CNC made from tunicates.139 They concluded that achieving orientation may necessitate a larger field, a higher CNC aspect ratio, and greater concentration. Using long CNCs, orientation was accomplished by untwisting the helix and, as a result, increasing the pitch size (red shift).139 The procedure works best for suspension toward the low concentration size of the cholesteric regime that is accompanied by a minimum viscosity. It is also possible to create films with consistently oriented helices by beginning with a fairly low CNC content and progressively evaporating the solvent under a consistent magnetic field.

Considering the positivity of the dielectric anisotropy of CNCs, an electric field can act to unwind the helix. Habibi et al.134 demonstrated a uniform CNC alignment in films obtained through drying CNC suspension in the presence of electric fields with moderate to strong frequencies. For the GO suspension, macroscopic orientation of LCs was reported to be readily tunable by an external field. However, an electric field widely used for liquid crystal display switching is inapplicable to graphene oxide LCs. Under the application of an electric field, the negatively charged graphene oxide platelets underwent electrophoretic migration toward the cathode. After, the platelets accumulated at the cathodes and became electrochemically reduced. The authors suggested that instead of the application of an electric field a magnetic field or mechanical deformation is preferable to successfully control the alignment of crystals. Indeed, after prolonged annealing at room temperature under a magnetic field, shear-induced morphology disappeared, and a typical nematic “schlieren texture” emerged.140 A group of sites where the director alignment is inconsistent define the “schlieren texture” of nematic LCs. These points correspond to disclination lines viewed end on. These “schlieren textures” are also visible in other liquid crystalline materials that display the texture stems from physics and superstructure as opposed to chemistry.140,141

Later, under the application of a strong magnetic field (0.25 T), induced alignment could be monitored; the domains with different liquid crystal orientations initially separated by disclinations were gradually reoriented and merged into larger domains. Due to the weak magnetism of the bare platelets, complete alignment took several hours. Decorating the platelets with iron oxide (Fe2O3) maintained the liquid crystallinity in an aqueous medium and completed field-induced alignments within several seconds under the same strength of the magnetic field. The liquid crystallinity of the suspension could also be maintained under mixing with a polymer matrix. Nanocomposites prepared with poly(acrylic acid) (PAA)/graphene oxide displayed birefringent schlieren texture under crossed polarizers. Under drawing by hand, and SEM, the authors found platelets to be highly aligned and stretched along the mechanical drawing direction.

Li et al.142 reported photonic crystals with controllable structural color made from lyotropic graphene oxide solution using a simple colloidal self-assembly technique. They reported that graphene oxide with enormous flake sizes of roughly 2.4 μm had iridescent colors in certain configurations. After sonication, the structural color of huge flake size dispersion vanished, illustrating the importance of aspect ratio in the creation of photonic crystals.142 It was also revealed that changing the GO concentration may easily modify the light reflected from the graphene oxide solution. One of the most effective ways of aligning GO dispersion is to use an electric field. Novel reflecting color display applications can be realized by combining the photonic crystalline ability of LCs with electrical alignment. Song et al.143 did indeed create an electrically erasable and rewritable structured reflecting electrode design. The liquid crystal was manufactured of graphene oxide. By switching the direction of the electric field, writing and erasing may be done alternatively since color reflection only happens when the GO is parallel to the substrate. The change from darkness to light, however, happens exceedingly slowly. The likelihood of new GO liquid crystal suspension uses is anticipated to increase noticeably because of these photonic crystals.

The length across nematic planes all along the cholesteric axis is shorter than the length among rods in a nematic planes in a 2.4 T magnetic field when microfibril suspension displays asymmetrical chiral nematic organization.78 A CNC from a microcrystalline CNC was employed in conjunction with poly(vinyl alcohol) (PVA) by Kvien and Oksman.144 In that example, the authors claimed to have attained CNC alignment by using a 7 T strong magnetic field. They created transparent, birefringent films of 90 μm thickness with a final concentration of 2 wt % of CNC (4.21 GPA) under these conditions and reported that it was significantly lower than the storage modulus measured in the transverse direction (6.19 GPA). This finding confirmed the idea that CNCs were perpendicular to the applied field.

Furthermore, the shear flow will provide uniaxial CNC alignment, which is another manipulation tool for directing the direction of the unwinding helix. Films with uniform nanorod alignment produced by shearing and X-ray study of liquid crystalline CNC alignment during shear flow revealed complicated behavior with significantly variable outcomes depending on shear rate.145 The orientation of CNC in a microfluidic chip has also resulted in full orientation of individual CNCs,146 but there is no report on orienting LCs in the same direction.

Other natural ways to arrange colloids have been documented in the literature. For example, grafting fluorescent dyes onto the ends of filamentous viruses produced a hydrophobic patch whose attraction could be adjusted by modifying the bound dye molecules. Increasing the tip attraction, according to computer simulation, stabilizes the smectic phase at the expense of the nematic phases.

The nematic state can be totally repressed for a direct isotropic liquid to smectic phase transition147 if the tip attraction is strong enough. A similar strategy may be utilized to tune CNC particles if tweaking liquid crystalline formation or a specific LC phase of CNC is preferred over a common chiral nematic phase of CNCs. Performing an analogous experiment for CNCs and guiding the liquid crystal formation self-assembly process, on the other hand, may be tricky.

5. Mechanical Properties

CNC films are hard and brittle by nature. Brittleness is caused by the fact that CNC rods are inflexible and unable to relieve external stress through deformation, and there is no flexible connection between CNC rods other than hydrogen bonds, allowing fractures to develop easily.148 CNC-based photonic materials can be produced to overcome these restrictions by assembly, postprocessing, or lamination with other nonbrittle components; for example, CNCs can be doped with weakly interacting chemicals that minimize brittleness while retaining structure formation. In the literature, this was done using a zwitterionic surfactant,98 neutral or anionic polymer,123 amino resins,149 or sol–gel precursors and cross-linked latex nanoparticles.150 CNCs with cholesteric layouts may also accept tiny nanoparticles such as plasmonic gold nanorods that enable complicated chiroptical effects151 without altering the phase.152 Weaver et al.153 reported, via modeling and texture analysis, that a pitch of 75 μm can permit a variety of toughening processes that can inhibit fracture propagation.153 Bouligand and colleagues154 reported that the mechanical characteristics of natural high-performance biobased composite materials are derived from liquid crystal self-assembly, lending credence to their results.

The twisted plywood, or Bouligand, structure is the most prevalent microstructural motif in natural materials with high mechanical strength and toughness, including as bone and the mantis shrimp dactyl club155 (see Figure 1). Similarly, the cuticle of lobsters156 and other marine microorganisms153 has remarkable fracture toughness, in addition to aesthetic characteristics. These materials are isotropically toughened by a low volume fraction of soft, energy-dissipating polymer and the “Bouligand” structure itself via shear wave filtering and fracture twisting, deflection, and arrest. Because CNCs spontaneously self-assemble into chiral nematic films when cast from solutions, they are appealing candidates for bottom-up production of these structures. The ability to manipulate a material’s nanoscale architecture enables fine-tuning of its physical characteristics and associated functionalities. Application of these structures in elastomers to produce an energy dissipation mechanism for increasing the toughness of composites is unexplored and recommended. Similarly in free-standing aerogels, tuning the chiral structure of the components increases the specific strength and toughness of CNC aerogels by up to 137% and 60%, respectively, which is equivalent to the greatest values recorded for cellulose nanofibrils or nanocrystals.157 The resultant aerogels exhibit a significant link between the mesopore percentage and selective light reflection as a function of mechanical load (iridescence). The authors reported that chiral-nematic ordering considerably increases pore compression mechanical performance under load.157

The network of pore canals that helps toughen the material while simultaneously supplying components for self-healing is a crucial aspect of biological composites that has yet to be reproduced in man-made materials. CNC composites might be formed with or around a network of synthetic nano-/microconduits that help supply minerals or photopolymerizable monomers to damaged regions. These property improvement paths are still available and provide fertile ground for the development of CNC-based composites. The characteristics of the minority macromolecular phase in natural composites, which provides binding and energy adsorption, remain unknown. Most likely, these polymers are firmly packed in the nanoscale domains between the ordered mineral crystallites. As is generally known, the characteristics of a confined polymer differ substantially from those of a free polymer. The ordered, alternating arrangement of CNCs and polymers in CNC “Bouligand” composites, as well as the flexibility to change the CNC–CNC spacing, give an excellent opportunity to investigate natural polymer characteristics under confinement. Furthermore, the polymers used may be stimuli-responsive, allowing the “Bouligand” composites to be environmentally sensitive. The Bouligand arrangement has the greatest benefit for impact resistance and bending properties in carbon-fiber-reinforced composites. These characteristics for CNC Bouligand composites of films, however, have not been measured. As a result, more study in the field is required to overcome the uncertainties.

In practice, CNC has been mixed with polymers to increase mechanical properties like nature-inspired architectures. The incorporation of CNC films into larger laminar structures has been studied to achieve enhanced mechanical or optical properties. By inserting CNC films into the polymer, thin sandwiched structures with brilliant structural color, enhanced mechanical properties, and shape memory features were developed. Depositing CNC films onto either face of a birefringent membrane, similar to the jewel beetle chrysin resplendens,158 enables simultaneous reflection of both left- and right-handed circularly polarized light. The sample optical mechanism was created by impregnating micrometer size planar gaps in CNC films with a nematic LC, producing a comparable birefringent layer that may be actuated by temperature or electric fields to change the reflected spectrum or polarization state.159

One method for improving the mechanical properties of CNC films is to mix them with water-soluble polymers. There are several methods for incorporating chiral photonic films into PVA or an epoxy resin; moreover, CNCs’ inherent twist topology and uneven surface charge distribution make them easier to arrange into chiral nematic structures.10 The critical concentration at which CNCs become anisotropic is defined by the aspect ratio and surface charge. During the phase separation and concentration produced by water evaporation, the tactoids rearrange and unite to form massive “tactoids”, which is comparable to the Ostwald ripening process of emulsions.73 According to the authors, the fusing of CNC “tactoids” is poor during rapid water evaporation, and only sections of the CNC film are in the liquid crystal structure as “tactoids” in the final CNC films. Water evaporation at the edge of a Petri dish happens quicker than in the core region due to the “coffee ring” effect, resulting in a mass shift from the center to the periphery. The exceptional mechanical properties of CNC chiral nematic LCs make sulfate CNC appropriate for research.