Abstract

Due to microbial infections dramatically affect cell survival and increase the risk of implant failure, scaffolds produced with antimicrobial materials are now much more likely to be successful. Multidrug-resistant infections without suitable prevention strategies are increasing at an alarming rate. The ability of cells to organize, develop, differentiate, produce a functioning extracellular matrix (ECM) and create new functional tissue can all be controlled by careful control of the extracellular microenvironment. This review covers the present state of advanced strategies to develop scaffolds with antimicrobial properties for bone, oral tissue, skin, muscle, nerve, trachea, cardiac and other tissue engineering applications. The review focuses on the development of antimicrobial scaffolds against bacteria and fungi using a wide range of materials, including polymers, biopolymers, glass, ceramics and antimicrobials agents such as antibiotics, antiseptics, antimicrobial polymers, peptides, metals, carbon nanomaterials, combinatorial strategies, and includes discussions on the antimicrobial mechanisms involved in these antimicrobial approaches. The toxicological aspects of these advanced scaffolds are also analyzed to ensure future technological transfer to clinics. The main antimicrobial methods of characterizing scaffolds’ antimicrobial and antibiofilm properties are described. The production methods of these porous supports, such as electrospinning, phase separation, gas foaming, the porogen method, polymerization in solution, fiber mesh coating, self-assembly, membrane lamination, freeze drying, 3D printing and bioprinting, among others, are also included in this article. These important advances in antimicrobial materials-based scaffolds for regenerative medicine offer many new promising avenues to the material design and tissue-engineering communities.

Keywords: Biomaterials, Scaffolds, Antimicrobial activity, Tissue engineering, Fabrication

Graphical abstract

Highlights

-

•

Antibacterial, antifungal and antibiofilm scaffolds.

-

•

Antimicrobial scaffold fabrication techniques.

-

•

Antimicrobial biomaterials for tissue engineering applications.

-

•

Antimicrobial characterization methods of scaffolds.

-

•

Bone, oral tissue, skin, muscle, nerve, trachea, cardiac, among other applications.

1. Introduction to tissue engineering and microbial resistance

Tissue engineering is currently attempting to provide breakthrough technologies capable of achieving successful results in regenerative medicine [1]. The tissue engineering regeneration strategy relies on the creation of biomimetic 3D cellular microenvironments (artificial ECM or scaffolds) that control and guide local tissue regeneration, usually made from a combination of natural and/or synthetic biodegradable biomaterials, cells and biomolecules (bioactive factors) [2]. The natural and synthetic polymers commonly used in tissue engineering include chitosan, alginate, gelatin, agarose, collagen, hyaluronic acid, carrageenan (CG), polycaprolactone (PCL), polyvinyl alcohol (PVA), polylactic acid (PLA), polyglycolide acid (PGA), poly lactic-co-glycolic acid (PLGA), poly (hydroxybutyrate-co-valerate) (PHBV) and many others [[3], [4], [5], [6], [7], [8], [9]]. Depending on the type of application, the scaffold will require specific physical-chemical (biodegradability, mechanical properties, etc.) and morphological properties (surface topology, pore size, pore distribution and interconnection, etc.) to mimic the cellular environment in vivo [10]. Most of the degradable polymers used to produce scaffolds can also release biomolecules that promote tissue regeneration, including growth factors, or antimicrobials to fight infections. The ability to manipulate physical-chemical variables (cross-linking, blends, copolymerization, etc.) enables the release dynamics to be tailored to the requirements of the application [11,12]. However, antibiotic resistance in pathogenic microorganisms has reached alarming levels and has become a serious global public health problem [13]. The use of alternative antimicrobial agents capable of dealing with antibiotic-resistant bacteria such as metal ions [[14], [15], [16]], quaternary ammonium compounds [17,18], antimicrobial peptides [19], peptoids [20], α-peptides [21], β-peptides [22], carbon-based nanomaterials [[23], [24], [25]] or combined strategies [26,27] are being given a lot of attention by researchers for their important contributions to future healthcare systems. Growth factors are often studied in cell-free tissue-engineering approaches to facilitate tissue regeneration [28]. However, their use can generate problems associated with immunogenicity, cancer risk and associated problems in cellular homeostasis [29,30]. In this context, the use of inorganic biomolecules is being studied for regeneration applications since they induce tissue regeneration without the drawbacks of growth factors [30,31]. Biometals have shown potential results in regenerative medicine, mostly because of their affordability, stability, and capacity to trigger cellular responses via signaling pathways. Biometals like zinc integrated into scaffolds are also being researched as regenerative agents [[32], [33], [34], [35], [36]] Their antibacterial qualities give them additional advantages for the prevention of infections following scaffold implantations. Biomolecules with both bioactivity and antibacterial characteristics have thus been the basis of newly discovered methods for regenerative medicine applications [[37], [38], [39]]. Some of the biomaterials used as scaffolds for tissue engineering (with no additional components) also possess intrinsic antimicrobial properties, providing a cellular microenvironment capable of stimulating cellular response and simultaneously inhibiting microbial growth [[40], [41], [42]] (Fig. 1).

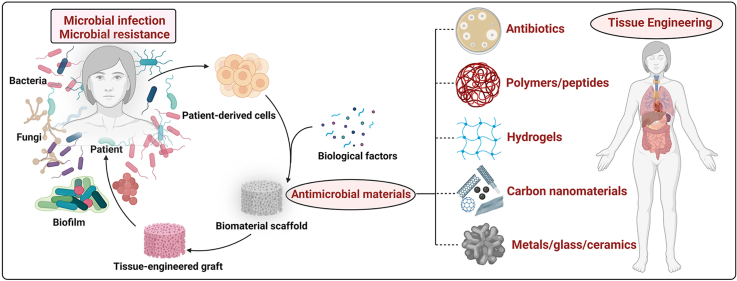

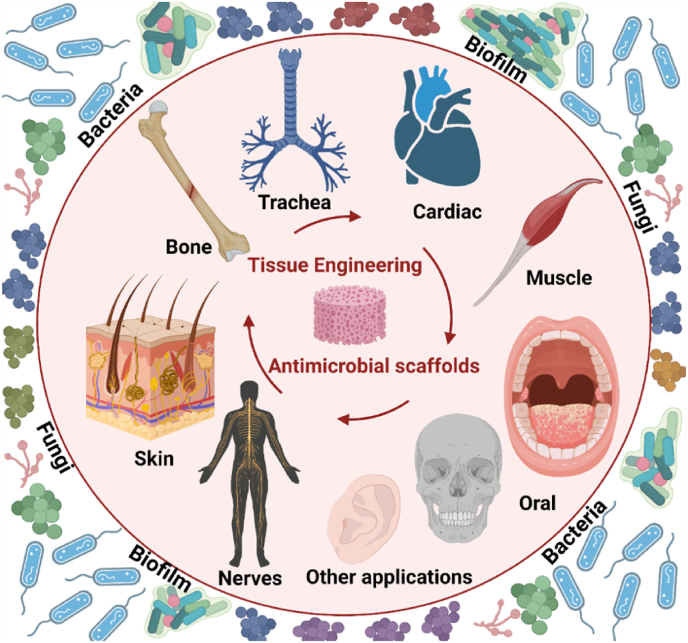

Fig. 1.

Antimicrobial scaffolds to prevent microbial infections in tissue engineering applications. Created with Biorender by Ángel Serrano-Aroca.

Since surgical infections in tissue engineering are associated with significant postoperative morbidity, increased healthcare costs and high risk of death in case of multidrug-resistant pathogens, the scientific community have been working hard on the development of antimicrobial scaffolds for the last ten years. This article reviews the current state of antimicrobial scaffolds produced for bone, oral tissue, skin, muscle, nerve, trachea, cardiac and other tissue engineering applications. The latest scaffolds developed to prevent infections produced by bacteria and fungi are also discussed in depth with detailed descriptions.

2. Production strategies for antimicrobial scaffolds

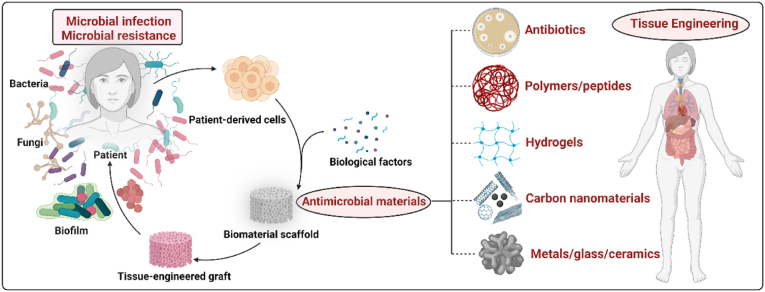

Many production techniques have been developed for porous materials to be used as scaffolds in tissue engineering applications, such as electrospinning [3,8], phase separation [43,44], gas foaming [45,46], porogen method [[47], [48], [49]], polymerization in solution [[50], [51], [52], [53], [54]], fiber mesh coating [55,56], self-assembly [57,58], membrane lamination [59,60], freeze drying [1,61,62], 3D-printing [[63], [64], [65]] and bioprinting [66], among others [67]. These methods require the use or introduction of materials with intrinsic antimicrobial activity as fillers to produce antimicrobial scaffolds. The main scaffold production methods, such as electrospinning, phase separation, gas foaming, porogen leaching, polymerization in solution, self-assembly, 3D printing and freeze drying, are shown in Fig. 2.

Fig. 2.

Production methods for antimicrobial scaffolds: (a) electrospinning; (b) phase separation; (c) gas foaming; (d) porogen leaching method; (e) polymerization in solution; (f) self-assembly; (g) 3D printing; (h) freeze drying.

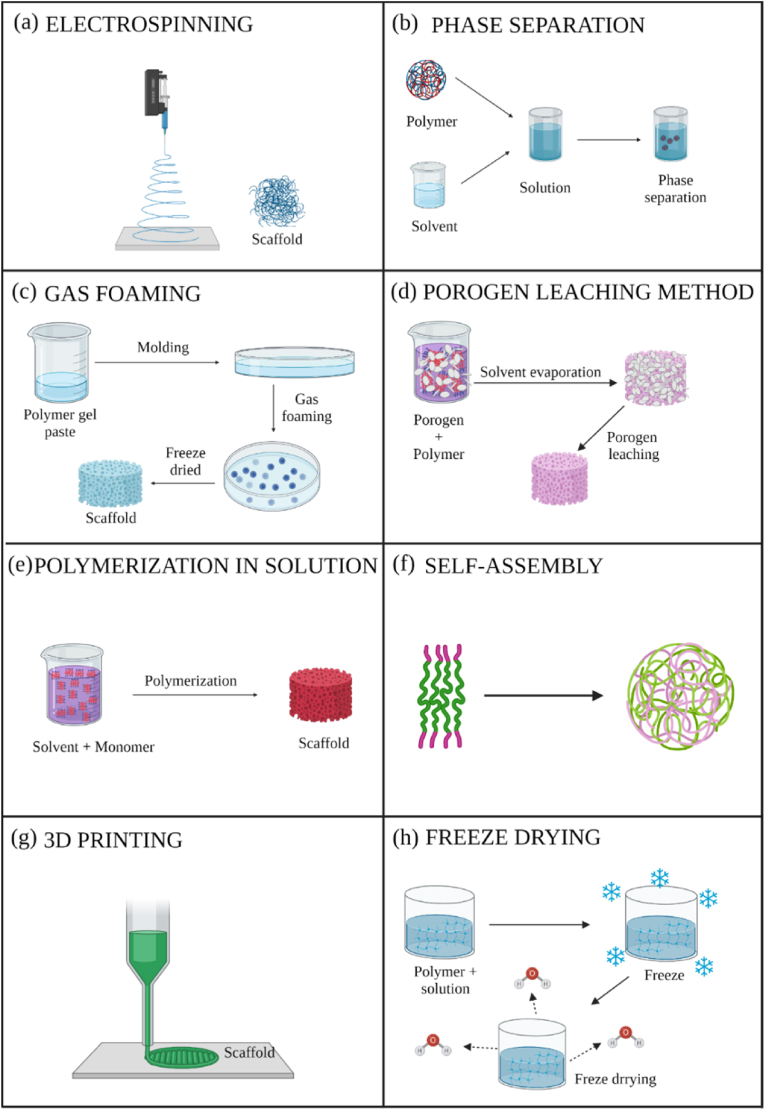

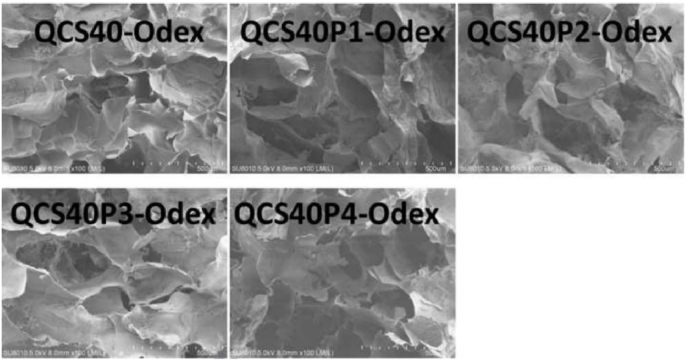

Electrospinning uses polymers for scaffold design, generating polymeric fibers controlled by an electric field between two electrodes [3,8] to produce porous substrates made of ultra-fine fibers with a large surface area, which makes them ideal environments for cell growth and subsequent tissue organization [68], e.g. antimicrobial scaffolds made of polymers with intrinsic antimicrobial activity such as chitosan (CS) (Fig. 3) [69,70].

Fig. 3.

Scanning electron microscope images of chitosan and PVA blended electrospun fibers at a magnification of x10000. Chitosan and PVA were dissolved in formic acid at 7% w/w and in distilled water at 9% w/w, respectively. The two solutions were mixed and electrospun in the indicated chitosan: PVA specified volume ratios of 50:50 (A), 30:70 (B) and 0:100 (C). Electrospun fibers made of a mixture of chitosan dissolved in formic acid (or 0.2 M acetic acid) at 2% w/w and mixed with a solution of 9% w/w PVA in a volume ratio of 50:50 (D). Adapted with permission from Ref. [69]. Copyright 2004 Elsevier.

The phase separation scaffold production technique is based on separating the polymeric solution into two phases by temperature changes [43]. The polymer is dissolved in a solvent to produce porous scaffolds with bioactive molecules integrated into that structure after evaporation and sublimation [44]. Phase separation can be combined with other techniques to design 3D structures with a controlled pore morphology [71]. This technique is widely used to make polymer-based scaffolds such as PLA for regenerative medicine applications [72]. The polymeric matrix can be combined with other materials with intrinsic antimicrobial properties.

The great advantage of gas foam scaffolding manufacturing techniques is that they do not require chemicals or high temperatures, which can damage cells, tissue and the microenvironment [43]. Nucleation of pores is created due to gas phase separation from the polymer, expanding the scaffold volume while reducing the polymer density [45]. The gas foaming method is often used to produce new nanocomposite scaffolds charged with a material with antimicrobial properties [46].

The porogen leaching method is commonly used to produce scaffolds with the required geometry, pore size and pore interconnection using a porogen such as salt, wax, sugar, polymers, glass, fibers, polymer microspheres, meshes, etc. [47,48,73,74]. A porogen of the desired size and shape is leached away from the polymer mixture by a suitable solvent to make the scaffold with the required characteristics [75]. This technique is often used in combination with melt molding [[76], [77], [78]] to produce degradable polymer scaffolds, which are the basis of many new developments in antimicrobial scaffolds.

Scaffolds can also be produced via polymerization in the presence of a solvent, e.g. poly (methyl methacrylate) (PMMA) sponges can be made via polymerization in solution with ethanol [51,52,79]. Poly (2-hydroxyethyl acrylate) (PHEA) porous hydrophilic sponges have also been created by polymerization in solution in the presence of water, ethanol or methanol [50,53,80]. Hybrid PHEA/PMMA sponges can be obtained by combining polymerization in solution with plasma polymerization [[81], [82], [83]]. This means antimicrobial scaffolds could be synthetized by polymerization in solution combined with the incorporation of antimicrobial nanomaterials such as graphene oxide (GO) [84].

The self-assembly technique is based on the spontaneous organization of several molecules in a given medium, forming an ordered structure with a specific function [57]. It commonly used, for example, in amphiphilic peptides in aqueous solution that link their hydrophobic residues through non-covalent bonds [85], forming 3D nanofibers for tissue engineering [58].

The membrane lamination method is used to construct layer by layer anatomically accurate three-dimensional scaffold assemblies during the manufacturing process [59,60]. The fiber mesh coating method consists of depositing a polymer solution on a porous polymer fiber mesh and subsequently allowing the solvent to evaporate [55,56].

The freeze dying technique is based on the sublimation principle and is used to manufacture porous scaffolds for tissue engineering [1,61,62]. Scaffolds with high porosity can be produced by dissolving a polymer in a solvent. After freezing the mixture, the solvent is removed by lyophilization [86]. This technique is simple and can manufacture highly porous scaffolds of a certain pore size, which are determining factors in tissue engineering [87].

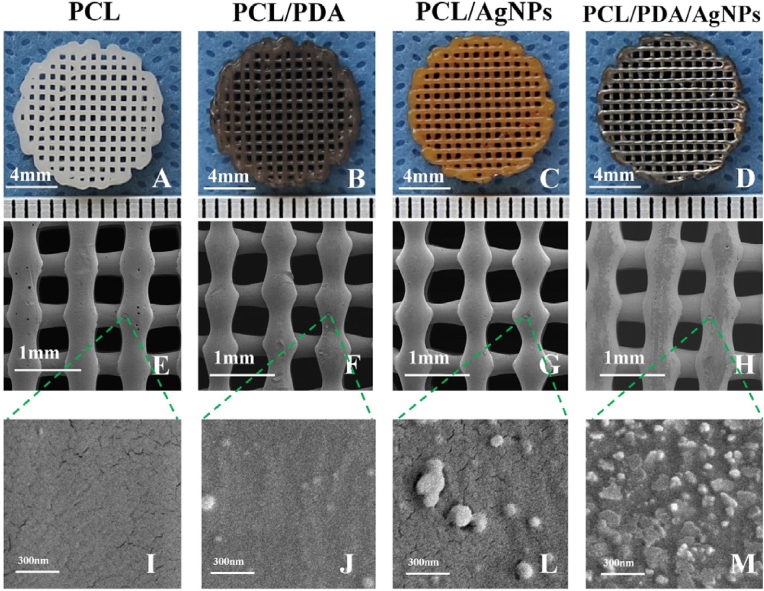

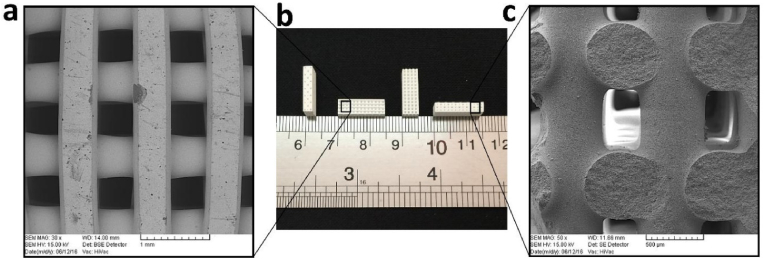

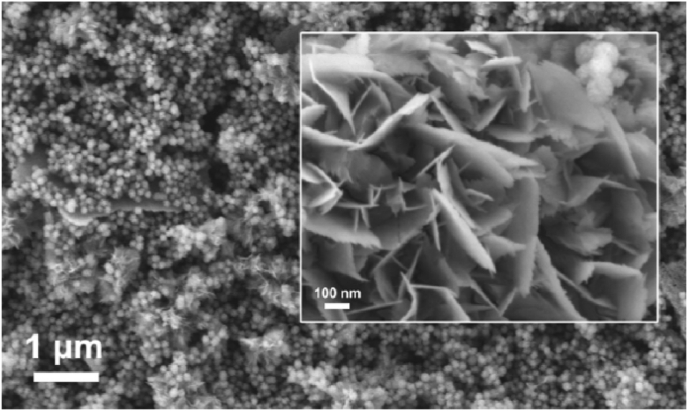

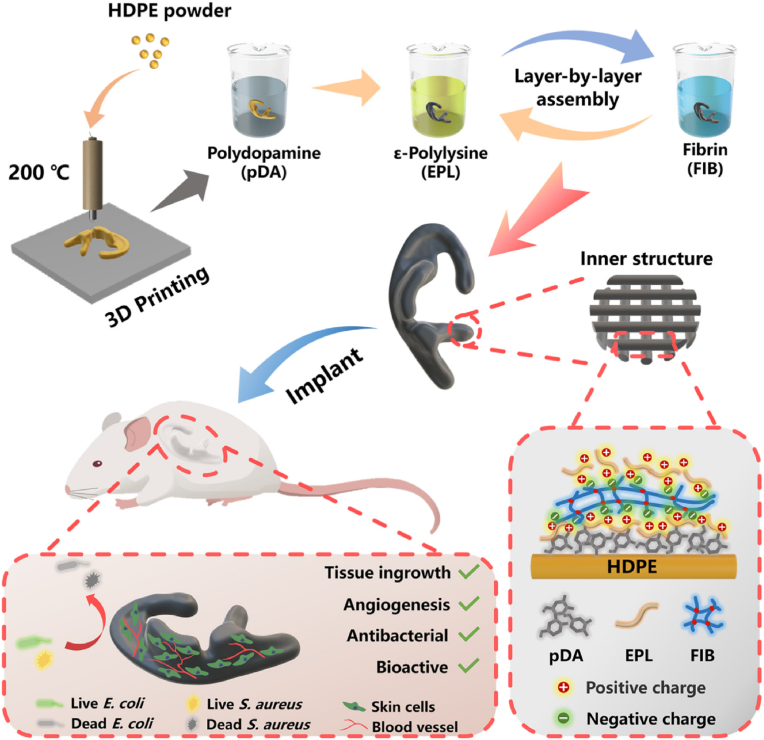

Additive manufacturing (AM) of 3D printed scaffolds is a highly reproducible method, as it can produce computer-controlled 3D porous materials [8]. The previous design of scaffold models is required by advanced computer-aided design [64,65]. The AM techniques available to create scaffolds include fused deposition modeling (FDM) [88], selective laser sintering (SLS) and stereolithography [8], among many others, e.g. antimicrobial 3D printed dual-functional PCL-based biomaterial scaffolds with self-assembly micro-nano surface, polydopamine (PDA) and enriched nano argentumo as silver nanoparticles (AgNPs) (abbreviated to PCL/PDA/AgNPs) have been made by FDM (Fig. 4) [63].

Fig. 4.

Fused deposition modeling 3D-printing scaffolds for bone tissue regeneration: morphology and surface microstructure. Scaffold images of PCL (A), PCL/PDA (B), PCL/AgNPs (C), PCL/PDA/AgNPs (D). Scanning electron microscopy photographs of PCL (E, I), PCL/PDA (F, J), PCL/AgNPs (G, L), PCL/PDA/AgNPs (H, M) scaffolds. Reprinted with permission from Ref. [63]. Copyright 2019 Elsevier.

These scaffolds not only showed good antibacterial and cytocompatibility results in vitro, but also performed well in an in vivo rabbit model, demonstrating their potential for bone regeneration due to their compatibility, antimicrobial capacity and mechanical properties [63]. The production of porous metal alloys with powerful antimicrobial properties by AM for potential biomedical applications has recently been reported [89,90].

The reproducible, automatic 3D bioprinting technique uses biomaterials, cells and growth factors to produce artificial living tissues or even an entire organ [10,91,92]. Multicellular building blocks (bioinks) are distributed layer by layer and scaled to manufacture the final construct [10].

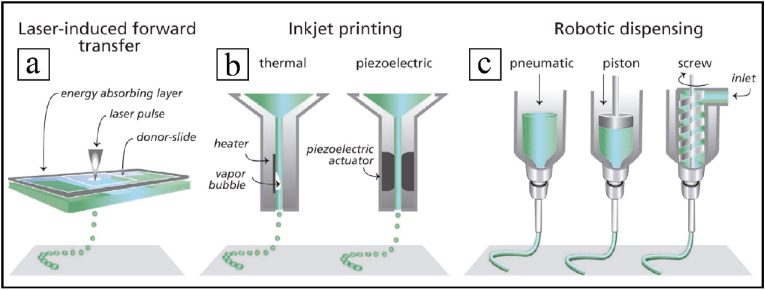

Bioprinting includes a number of different methods: laser-induced forward transfer, inkjet printing, or robotic dispensing [66] (Fig. 5), with specific requisites for bioinks. Bioprinting aims to engineer solid organs by computer-controlled systems capable of depositing biomaterials with or without cells to create solid and viable organs. However, the diversity of solid organs in terms of specific cellular and structural microenvironments, together with the demands of nutrients, is still a challenge [93,94]. Different types of tissue approaches have recently been investigated, such as blood vessels [95,96], skin [97,98], cardiac tissue [99,100], bladder and urethral tissue [10,101], cartilage [96,102] or bone [102,103], among others.

Fig. 5.

Main bioprinting technological methods: laser-induced forward transfer (a), inkjet printing (b) and robotic dispensing (c). Adapted with permission from Ref. [66]. Copyright 2013 John Wiley and Sons.

We firmly believe that bioprinting is a rapidly emerging technology that will provide a real clinical solution to the shortage of organ donors while avoiding the associated risks of transmitting diseases and immunological rejection. This method will certainly revolutionize the biomedical sector in the near future. Also, if the bioprinting design is performed with the additional aim of incorporating antimicrobial agents, the chances of success of the engineered constructs increase exponentially. A variety of antimicrobial materials can thus be used to enhance the current bioink formulations to improve biocompatibility and combat the spread of multidrug-resistant infections [104,105].

3. Antimicrobial scaffolds for tissue engineering

Tissue engineering has undoubtedly become a promising strategy for repairing damaged or diseased tissue [3] by means of highly porous materials or scaffolds capable of providing structural support for the engineered cellular environment with rapid diffusion of nutrients and metabolites [106]. If these scaffolds also incorporate new antimicrobial materials that can prevent microbial infections they will be even more promising. Controlled drug delivery materials, medical prostheses and medical devices are examples of other biomedical applications [3]. Enormous progress has been made in material engineering and the design of biomaterials that can mimic ECM [107]. Many preclinical and clinical trial studies have looked into the effect of stem cell-based therapies for tissue regeneration [108,109]. For example, human induced pluripotent stem cells are a powerful tool for the generation of specialized cells to treat diseases such as nonalcoholic steatohepatitis (NASH) [110]. Mesenchymal stem cells (MSCs) are gaining a lot of interest as perfect candidates for cell therapy and tissue engineering, due to their ability to differentiate into different cell types [111,112]. However, their potential in bioengineering is reduced when the reactive oxygen and nitrogen species levels overcome the physiological levels, which can worsen differentiation and proliferation while it favors senescence and cell death [113]. In this regard, nano-antioxidants in the form of chemical compounds, biometabolites, or protein precursors/proteins are effective in the treatment of MSCs to optimize their clinical use.

Biomaterials used as scaffolds for tissue engineering are preferably endowed with antimicrobial intrinsic or extrinsic agents to provide a 3D environment with bioactive and biocidal properties. This section describes a broad range of current antibacterial, antifungal and antibiofilm scaffolds according to their specific tissue engineering application, such as bone, oral tissue, muscle, nerve, trachea, cardiac, and skin, among others (Fig. 6).

Fig. 6.

Tissue engineering application fields for antibacterial, antifungal and antibiofilm scaffolds. Created with Biorender by Ángel Serrano-Aroca.

3.1. Antimicrobial fillers

Scaffolds containing antimicrobial fillers such as antibiotics, antiseptics, polymers, peptides, carbon nanomaterials, metals, ceramics or combined and alternative strategies have been developed to prevent and/or treat infections in tissue engineering. For example, polyhydroxyalkanoate/chitosan (PHA/CS) and 2D molybdenum disulfide-doped (2D MoS2) scaffolds have been proposed for biomedical and antimicrobial applications such as wound healing and antibacterial treatment of skin infections caused by methicillin-resistant Staphylococcus aureus (MRSA) [114]. These materials are biocompatible and also show promise for drug delivery. Other approaches consisted of creating PCL nanofibers containing Ag nanoparticles by electrospinning to produce antibacterial scaffolds [115]. Cell viability studies on this material have revealed that cytotoxicity is highly dependent on the concentration of silver nanoparticles. Brennan et at. evaluated the degradation products resulting from the acid digestion of scaffolds composed of ECM for antibacterial effects against Staphylococcus aureus and Escherichia coli. The results suggest that several low-molecular-weight peptides with antibacterial activity exist within the ECM, which may help explain the resistance to bacterial infection provided by these biobased scaffolds [116]. Biocompatible boron nitride doped polyhydroxyalkanoate/chitosan (PHA/Ch-hBN) nanocomposite scaffolds have been successfully designed and manufactured with superior antibacterial activity by means of the solvent casting technique [117]. In another study, CS-blended PLA nanofibers were successfully produced by electrospinning [118]. CS-blended PLA nanofibers exhibited antibacterial activity against E. coli and no cytotoxicity in mouse fibroblasts (L929 cell line), making them potential candidates for biomedical applications. Many types of antibacterial scaffolds that are safe and efficient for biological applications have thus been produced containing different types of antimicrobial fillers to provide the required characteristics for specific tissue engineering applications.

3.2. Antibacterial scaffolds for bone regeneration

The most widely used practice to treat large bone defects has been autologous bone grafting [119]. Unfortunately, this strategy is associated with the morbidity of the donor site, the need for one or more surgical interventions and the small amount of bone that can be removed from the patient [120]. A lot of research has been done to make bone substitutes that are structurally and functionally similar to real bone, such as highly porous 3D scaffolds that help to achieve the diffusion of nutrients and metabolites and antibacterial activity following a broad range of strategies (see Table 1).

Table 1.

Antibacterial scaffolds for bone regeneration: scaffolds with antibiotics, polymers, peptides, carbon nanomaterials, metals, combined and alternative strategies.

| Material | Fabrication method | Bacteria | Non-toxicity: cell line/animal model | Year | Ref |

|---|---|---|---|---|---|

| Scaffolds with antibiotics | |||||

| Gentamicin-contained PCL-HAp composite scaffold | Electrospinning | E. coli | Not studied | 2013 | [121] |

| CPFX loaded gelatin-HAp scaffolds | Freeze drying | S. aureus (MRSA) | Adipose derived MSCs | 2015 | [122] |

| Bioactive glass, PVA, several antibiotics | Rapid prototyping | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2017 | [123] |

| Baghdadite-vancomycin scaffolds | Space holder method | S. aureus | MG-63 osteoblast cells | 2017 | [124] |

| Vancomycin-laden mesoporous bioglass/poly (lactic-co-glycolic acid) composite scaffolds | Freeze-drying | S. aureus | Human BMSCs | 2018 | [125] |

| Poly (ε-Caprolactone) composite scaffolds with vancomycin-loaded polylactic acid-glycolic acid | 3D printing | S. aureus | Rabbit bone MSCs | 2018 | [126] |

| Levofloxacin hydrochloride-loaded mesoporous silica microspheres on nano HAp/PU | In situ foaming method | E. coli and S. aureus | L929 mouse fibroblast cells/Rabbit | 2019 | [127] |

| Macroporous agarose/nHCA scaffolds containing VEGF and cephalexin | 3D printing (GELPOR3D method) | S. aureus | MC3T3-E1 preosteoblast cells | 2019 | [128] |

| Polylactic acid-collagen-minocycline-nano HAp | 3D printing | S. aureus | hMSCs | 2019 | [37] |

| Polyetheretherketone/polyglycolide acid scaffolds with total alkaloids from semen strychnine | 3D printing | E. coli and S. aureus | hFOB1.19 osteoblast cells | 2020 | [129] |

| HA-SA–CS–VEGF and vancomycin | Microspheres-freeze drying | S. aureus | BMSCs | 2021 | [130] |

| Laponite nanoplates/amoxicillin-functionalized PLA nanofibrous scaffolds | Electrospinning | E. coli and S. aureus | hBMSCs | 2022 | [131] |

| Scaffolds with antibacterial polymers/peptides | |||||

| PCL/CS nanofibers with oligopeptides | Electrospinning | S. epidermidis | hFOB1.19 osteoblast cells | 2013 | [132] |

| O-Acrylamidomethyl-2-hydroxypropyltrimethyl ammonium chloride CS and silk modified mesoporous bioactive glass scaffolds | Surface modification | S. epidermis and S. aureus | hMSCs | 2016 | [133] |

| HACC-grafted PLGA/HAp scaffolds | 3D printing | S. aureus | Rat and Rabbit | 2018 | [134] |

| PCL/PDA/AgNPs scaffold | 3D printing | S. aureus | Rabbit BMSCs/Rabbit | 2018 | [63] |

| PLA-gelatin-nano HAp with ponericin | 3D printing | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2018 | [135] |

| nHA-starch-alginate/chitosan scaffolds | S-nitroso-N-acetyl-penicillamine (SNAP) as the NO donor | S. aureus and P. aeruginosa | 3T3 mouse fibroblast cells | 2019 | [136] |

| Collagen-PLGA microspheres-synthetic peptide | Electrospray and freeze-drying | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2020 | [137] |

| EPL/PCL/HAp scaffolds | 3D printing | S. aureus, E. coli and S. mutans | MC3T3-E1 preosteoblast cells | 2020 | [138] |

| Chitosan-vanillin-bioglass | Freeze drying | S. gordonii and S. Sanguinis | MC3T3-E1 preosteoblast cells | 2021 | [139] |

| Antibacterial peptide-modified Silk fibroin and silica NPs | Micro-extrusion 3D printing and directional freeze-casting/drying approaches | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2021 | [140] |

| Mineralized collagen fibrils and peptides, | Gelation and coating | E. coli and S gordonii | Human BMSCs | 2021 | [141] |

| Flax/silk protein-based nanofibrous scaffold | Electrospinning | E. coli and S. aureus | MG-63 osteoblast cells | 2022 | [142] |

| Scaffolds with carbon nanomaterials | |||||

| PLA-graphene and multi-walled carbon nanotubes oxides) | Solvent casting and plasma treatment | E. coli and S aureus | L-929 mouse fibroblast cells | 2016 | [143] |

| Polyetheretherketone and GO https://doi.org/10.1002/term.3168 | Dip coating | E. coli | MG63 human osteosarcoma cells | 2018 | [144] |

| Percolated composites of PCL with rGO and electrostimulation | 3D printing | E. coli and S. aureus | Human BMSCs | 2020 | [145] |

| PCL-3Dprinted fibrous scaffold and GO | Layer-by-layer | S. epidermidis and E. coli | HFF-1 human fibroblast cells | 2020 | [146] |

| rGO/gelatin/chitosan/TCP | 3D printing | E. coli and S aureus | hOB human osteoblast cells | 2021 | [147] |

| Arabubinoxylan/GO/HAp/PVA hydrogel | Freeze-drying | P. aeruginosa, E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2021 | [148] |

| GO/HAp/bacterial cellulose and β-glucan | Radical polymerization and freeze-drying | P. aeruginosa, E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2021 | [149] |

| GO encapsulated forsterite (Mg2SiO4) scaffolds | Space holder processes | E. coli and S. aureus | MG-63 osteoblast-like cells | 2022 | [150] |

| Scaffolds with metals/ceramics/glass | |||||

| PLGA/Ag-TCP scaffolds | Electrospinning | E. coli | Not studied | 2008 | [151] |

| Ag ions 3D-glass–ceramic | Sponge impregnation method | S. aureus | Not studied | 2008 | [152] |

| Boron containing bioactive glass | Foam replica technique and sintering | S. aureus | Not studied | 2009 | [153] |

| Porous nano-HAp/titanium/polyamide66 scaffolds containing different amounts of silver ions | Inversion technique | Not specified | F12 medium | 2010 | [154] |

| Silver-loaded coral HAp | Surface adsorption process and ion-exchange | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2010 | [155] |

| Ag 3D-Glass-Ceramic Scaffolds | Melt quenching and ion exchange | S. aureus | MG-63 osteoblast-like cells | 2011 | [156] |

| (Cu)-containing mesoporous bioactive glass | Ion exchange | E.coli | Human BMSCs | 2013 | [157] |

| (Chitlac-nAg) | Freeze drying | E. coli, P. aeruginosa, S. aureus and S. epidermidis | MG63 and Saos-2 osteoblast-like cells | 2013 | [158] |

| AgNPs containing scaffolds composed of PETA and HAp | Pressurized spray canister and expelled into molds | E. coli and S. aureus | Adipose MCSs | 2014 | [159] |

| Macroporous Gelatin/Bioactive-Glass/Nanosilver Scaffolds | Freeze-drying and crosslinking | E. coli and S. aureus | Human MSCs | 2014 | [160] |

| SiO2–CaO–P2O5meso-macroporous glass scaffolds ZnO enriched | 3D printing (rapid prototyping) | S. aureus | HOS human osteoblast-like cells osteoblasts | 2014 | [161] |

| PLGA and TCP with Mg | Unique low-temperature rapid prototyping technology | Not specified | MC3T3-E1 preosteoblast cells | 2015 | [162] |

| Bioactive glass coated with Se NPs immobilized in PLGA particles | Foam replica method | S. aureus, S. epidermidis | Not studied | 2015 | [163] |

| nZn-HAp scaffold | Freeze-gelation method | S. aureus | Not studied | 2015 | [164] |

| Silver-doped borate bioactive glass scaffold | Foam replication technique | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2015 | [165] |

| Nano-HAp/PU composite with silver phosphate particles | In situ foaming method | E. coli and S. aureus | MG63 osteoblast-like cells | 2016 | [166] |

| Zinc Cross-Linked Nanocomposite Scaffolds | Crosslinking | E. coli and B. subtilis | MG63 osteoblast-like cells | 2016 | [167] |

| Nano-HAp/polyamide 66 (nHP66)-based materials with silver ions and oxidized titanium | Thermal spraying technique | E. coli and S. aureus | Rabbit | 2016 | [168] |

| Poly (octanediol citrate)/gallium-containing bioglass composite scaffolds | Porogen-leaching technique | E. coli and S. aureus | Bovine bone specimens | 2016 | [169] |

| PVA/Ag scaffolds | Sponge replication | S. aureus | SBF fluid | 2016 | [170] |

| SiO2–Na2O–Al2O3–CaO–B2O3 Glass | Foam replication method | E. coli, S. aureus and C. krusei | Not studied | 2016 | [171] |

| Porous titanium with nanotubular surfaces releasing silver ions | 3D printing | S. aureus | Human MSCs | 2016 | [172] |

| AgNPs- PEEK | 3D printing | E. coli and S. aureus | MG-63 osteoblast-like cells | 2017 | [173] |

| Ag octahedral nanoparticle containing PCL scaffolds | Cryomilling | P. aeruginosa | Human MSCs | 2017 | [174] |

| Silver Doped HAp scaffolds | Wet precipitation method | S. epidermis and P. aeruginosa | SBF, Saos-2 human osteosarcoma cells | 2017 | [175] |

| Ag-GO nanocomposites on β-TCP bioceramic | 3D printing and soaking method | E. coli | Rabbit bone marrow stomal cells | 2017 | [176] |

| Strontium/zinc-codoped HAp porous scaffolds | Ion-exchange and a foaming method | S. epidermis | MSCs | 2018 | [177] |

| PCL/TiO2 | Electrospinning | S. aureus | hFOB human osteoblast cells | 2018 | [178] |

| Poly (l-lactic acid) (PLLA)/nano-Ag composite fibers | Electrospinning | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2018 | [179] |

| PEEK/PGA/TiO2 scaffolds | Selective laser sintering | E. coli and S. aureus | Human osteoblast-like cells | 2018 | [180] |

| TiO2 scaffolds | Dark catalysis | S. epidermis | MC3T3 preosteoblast cells | 2018 | [181] |

| PCL/HAp/ZnO scaffold | Electrospinning | S. aureus | HFOb 1.19 human osteoblast cells | 2018 | [182] |

| Silver-doping of bioactive glass scaffolds | Sol-gel method | E. coli and S. aureus | MG-63 osteoblast-like cells | 2018 | [183] |

| Polyvinyl alcohol-starch/silver HAp | Freezing thawing | E. coli and Bacillus sp. | L-529 fibroblast cells | 2019 | [184] |

| PCL/CPO Coating on BCP | 3D printing (robocasting) | E. coli and S. aureus | Not studied | 2019 | [185] |

| Biomimetic triphase pTi/CS/HAp-Se composite scaffolds | Wet-chemical method | E. coli and S. aureus | MDA-MB-231 breast cancer cells | 2019 | [186] |

| Ag- zincosilicate zeolite scaffolds | 3D printing | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2019 | [187] |

| Silver HAp based scaffolds of gelatin/alginate/PVA scaffolds | Cryogelation technique | E. coli and B. subtillus | MC3T3-E1 preosteoblast cells | 2019 | [188] |

| Silk fibroin/AgNPs scaffolds | Solvent casting | E. coli | Human MSCs | 2019 | [189] |

| Antibacterial degummed silk fiber/nano HAp/PLA with AgNPs | Cast molding method | E. coli and S. aureus | MC3T3-E1 preosteoblast cells | 2019 | [190] |

| Silver-doped nano HAp scaffolds | Electrospinning | E. coli and S. aureus | MSCs | 2020 | [191] |

| Bierarchically-structured brushite/Ag3PO4-coated Mg-based scaffoldst | Template replication method | S. aureus, E.coli and S. epidermis | MC3T3-E1 preosteoblast cells | 2020 | [192] |

| Ag pure scaffolds | 3D printing | S. aureus | Not studied | 2020 | [193] |

| PLGA/Cu(I)@ZIF-8 | 3D printing | S. aureus | Murine MSCs/Rat | 2020 | [194] |

| PLA and halloysite nanotubes (HNTs) loaded with zinc nanoparticles | 3D printed | S. aureus | MC3T3-E1 preosteoblast cells | 2020 | [195] |

| Calcium phosphate | 3D printing (direct extrusion) and crosslinking | S. aureus | L929 fibroblast cells | 2020 | [196] |

| Phosphate-free glass–ceramic scaffolds | Freeze-drying | E. coli | Adipose MSCs | 2020 | [197] |

| PHBV Scaffolds Incorporated with Zinc Oxide | Selective laser sintering | E. coli | MG-63 osteoblast-like cells | 2020 | [198] |

| Forsterite scaffolds | 3D printing and polymer-derived ceramics (PDCs) strategy | E. coli and S. aureus | Not studied | 2020 | [199] |

| Silver-coated grafted beta-glucan/hydroxyapatite nanocomposite scaffolds | Freeze-drying | DH5 alpha E. coli | MC3T3-E1 cell line | 2020 | [200] |

| Clinoenstatite-metronidazole scaffolds | Space holder method and subsequent sintering | F. nucleatum and A. actinomycetemcomitans | MG-63 osteoblast-like cells | 2021 | [201] |

| PCL/AgNPs scaffolds | 3D printing | E. coli | hFOB human osteoblast cells | 2021 | [202] |

| Carbonate apatite-silver phosphate | Disolution-precipitation reactions | S. aureus | MC3T3-E1 and Femoral defect rabbits | 2022 | [203] |

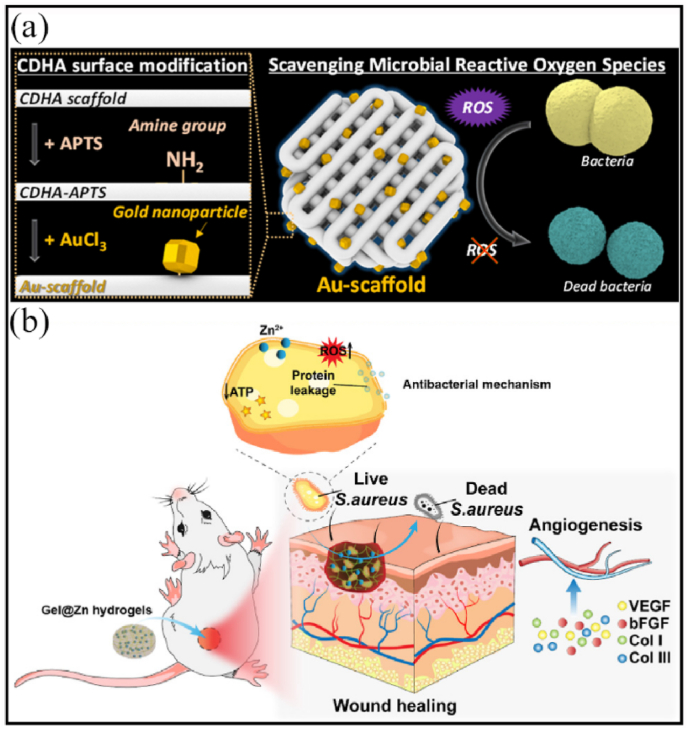

| 3D-printed scaffolds based on calcium-deficient hydroxyapatite with gold nanoparticles | 3D printing | Micrococcus luteus | MG-63 osteoblast-like cells | 2022 | [204] |

| Scaffolds produced by combined and alternative strategies | |||||

| Microsphere-integrated gelatin-siloxane hybrid scaffolds | Freeze drying | E. coli | SBF | 2008 | [205] |

| Nano-HAp/CS/konjac glucomannan scaffolds loaded with cationic liposomal vancomycin | Freeze drying | S. aureus | Not studied | 2011 | [206] |

| HACC- and HACC–Zein-modified mesoporous bioactive glass scaffolds | Solvent casting and calcination | E. coli | Human MSCs | 2013 | [207] |

| Porous Si-nano HAp scaffolds containing vancomycin and rhBMP2 | Freeze- drying method | S. aureus | Rat osteoblast cells/Rat | 2014 | [208] |

| HAp coatings with Ag ions and BMP-2 | Electrochemical deposition (ED) and electrostatic immobilization | E. coli and S. epidermidis | BMSCs; osteoblasts/Rabbit | 2014 | [209] |

| 45S5 Bioglass®-based scaffolds reinforced with genipin cross-linked gelatin | GCG coating | B. subtilis and E. coli | MG-63 osteoblast-like cells | 2015 | [210] |

| Ag-loaded SrHAp/CS porous scaffold | Freeze-drying fabrication | S. aureus | Human BMSCs | 2016 | [211] |

| TCP/SA with silver nanoparticles | 3D printing (rapid prototyping) | S. aureus | Osteoblast cells | 2016 | [212] |

| Titanium Ch + Gel + Ag and Ch + Gel + Vanco. | 3D printing | S. aureus | MG-63 osteoblast-like cells | 2017 | [213] |

| Nanostructured bredigite–amoxicillin scaffolds | Sol–gel method | E. coli and S. aureus | MG-63 osteoblast cells | 2018 | [214] |

| Poly-ε-caprolactone containing CS and vancomycin scaffolds | Supercritical Foaming | E. coli and S. aureus | MSCs | 2018 | [215] |

| Chlorhexidine-doped-PLGA/PCL (PPC) and β-TCP-doped-PLGA/PCL | Electrospinning | S. aureus and S. mutans | MC3T3-E1preosteoblast cells | 2018 | [216] |

| PLA-PGA matrix and silver/GO | Self-developed selective system laser sintering (SLS) system Selective laser sintering |

E. coli | MG-63 osteoblast-like cells | 2018 | [217] |

| Doxycycline loaded Mg–Ca–TiO2 composite scaffold | Compactation, sintering and heating | S. aureus and E. coli | MG-63 osteoblast-like cells | 2018 | [218] |

| Ultrahigh-molecular-weight polyethylene reinforced by titanium with amoxycillin impregnation | 3D printing and supercritical fluid impregnation | S. aureus, S. epidermidis and E. coli | Not studied | 2019 | [219] |

| Monticellite-CPFX scaffold | Space holder method | E. coli and S. aureus | MG-63 osteoblast-like cells | 2019 | [220] |

| Magnesium–Zinc scaffold containing tetracycline | Space holder technique | E. coli and S. aureus | Osteoblasts | 2019 | [221] |

| Xyloglucan-co-methacrylic acid/hydroxyapatite/SiO2 scaffold | Freeze-drying | E. coli, S. aureus and P. aeruginosa | Pre-osteoblast (MC3T3-E1) cell line | 2020 | [222] |

| Biomimetic scaffold composited with berberine, Ag nanoparticles and silk fibroin | Wet chemical method | S. aureus | MC3T3-E1 preosteoblast cells | 2020 | [223] |

| Zn-doped HAp and rGO | Mechanochemical process | E. coli and S. aureus | MSCs | 2021 | [224] |

| CS, carboxymethyl cellulose and Zn and Fe ions | Co-precipitation method and reeze-drying | E. coli, S paratyphy, L monocytogenes, S. aureus | MG-63 osteoblast-like cells | 2021 | [225] |

| Cu ions and cetyltrimethylammonium bromide loaded into montmorillonite | Cation exchange and intercalation | E. coli | Not studied | 2022 | [226] |

| PLA, AgNPs and GO | SLS technique | S. aureus | MG-63 osteoblast-like cells | 2022 | [227] |

| Cellulose and co-dispersed nanosystem (Fe3O4/GO) by free radical polymerization | Freeze-drying | E. coli, S. aureus and P. aeruginosa | Pre-osteoblast (MC3T3-E1) cell line | 2022 | [228] |

| PCLA scaffold with nano-hydroxyapatite coating doped green tea epigallocatechin-3-gallate | 3D printing and coating | S. aureus (MRSA) | Mouse osteoblasts (MC3T3-E1) | 2022 | [229] |

However, the antibacterial properties of recent promising scaffolds proposed for bone tissue engineering have not been studied to date. Some examples of these scaffolds include an arabinoxylan-co-acrylic acid/HAp/TiO2 nanocomposite scaffold [230] and a carrageenan/acrylic-acid/graphene/hydroxyapatite hybrid nanocomposite scaffold [231], both produced by freeze-drying. Arabinoxylan (ARX) and carrageenan are natural biological macromolecule with promising applications in biomedicine [230,231]. The antimicrobial properties of freeze-dried silver coated biocompatible scaffolds containing acrylic acid/guar gum, nano-hydroxyapatite, titanium nanoparticles and graphene oxide has so far not been tested [232]. These scaffolds showed promising results against mouse pre-osteoblast (MC3T3-E1) cell lines and increasing the amount of TiO2 in combination with GO improved physicochemical and microstructural properties, mechanical properties (compressive strength and Young's modulus), and porous properties (pore size and porosity). Another scaffold with a nacre-mimetic architecture and consisting of SrFe12O19-doped nano-layered double hydroxide/chitosan has recently been developed for bone tissue engineering [233]. The slow release of Mg2+ and Sr2+ of these scaffolds can maintain bone homeostasis and promote the formation of new blood vessels. However, their antibacterial performance has not yet been evaluated, so that it should be noted that a complete antimicrobial evaluation of developed scaffolds is essential for tissue engineering applications.

3.2.1. Antibacterial scaffolds with antibiotics

The use of scaffolds for controlled localized drug release is one of the most promising techniques in tissue engineering. The aim of this method is to act on the focus of the problem and so avoid using large concentrations of possibly toxic antimicrobials to the organism or even produce microbial resistance [234]. Vancomycin (VAN) [124,125] is one of the most commonly used antibiotic with this release technique as an antibacterial agent [127,128]. VAN-laden mesoporous bioglass/PLGA composite scaffolds have been developed for this purpose [125]. These scaffolds showed a sustained release of the antibacterial drug for more than eight weeks in vitro producing inhibition of S. aureus growth and biofilm formation. These results, along with the ability to promote osteoinduction, make these scaffolds a very promising biomaterial for bone tissue engineering. VAN-PCL scaffolds maintained their antibacterial effect for more than 4 weeks [126] and showed complete inhibition of S. aureus [215]. A new scaffold composed of hydroxyapatite (HAp), SA and CS loaded with vascular endothelial growth factor (VEGF) and vancomycin was recently reported [130]. Gentamicin [121] and tetracycline hydrochloride (TCH) [235] are two other antibiotics used as antibacterial agents in PCL scaffolds, which revealed a significant antibacterial effect, although their toxicity in cells or animal models has not been assessed.

Some studies have developed an antibacterial bone graft by immobilizing levofloxacin hydrochloride-loaded mesoporous silica microspheres on the surface of a nano-HAp/polyurethane (PU) bioactive composite scaffold. The results show considerable antibacterial activity against both Gram-positive (S. aureus) and Gram-negative (E. coli) bacteria with a drug release for up to 42 days [127]. This approach could be a very promising strategy against chronic osteomyelitis, whose mainstay treatment is the aggressive excision of necrotic bone and infected soft tissue and prolonged local antibiotic delivery [236]. 3D scaffolds for bone regeneration based on agarose, nanocrystalline apatite, VEGF, and the antibiotic cephalexin were also capable of inhibiting the growth of S. aureus bacteria [128].

Krishnan et al. developed porous gelatin-hydroxyapatite (G-HAp) scaffolds loaded with various amounts of ciprofloxacin (CPFX). They observed a reduction in the growth of S. aureus and concluded that it has the potential to be used as a local drug delivery system. This scaffold can release effective antibiotics for reducing S. aureus for 60 days, with no detrimental effects on human adipose-derived mesenchymal stem cell (ADMSCs) viability or osteogenic potential [122]. 3D printed PLA/collagen/nano HAp loaded with minocycline showed increased osteogenic activity and reduced S. aureus biofilm formation [37]. Alkaloids from Semen Strychine, which possess antibacterial, anti-inflammation and analgesic effects, were incorporated into polyetheretherketone/polyglycolide acid (PEEK/PG) scaffolds to provide a sustained release of the antimicrobial compound against E. coli and S. aureus, as well as biocompatibility [129].

A multidrug sequential release of antibiotic agents from a hierarchical 3D scaffold was reported by García-Alvarez et al. [123] and scaffolds based on nanocomposite bioceramic and PVA with three antibiotics were produced by rapid prototyping. These three antibiotics (rifampin, levofloxacin and vancomycin) were located in different compartments of the scaffold to obtain different release kinetics. The scaffolds showed good bioactivity in preosteoblasts and were able to inhibit bacteria growth and destroy Gram-positive and Gram-negative bacteria biofilms.

Laponite nanoplates/amoxicillin-functionalized PLA nanofibrous scaffolds with osteoinductive and antibacterial activity have recently been developed by electrospinning [131].

3.2.2. Scaffolds with antibacterial polymers/peptides

The intrinsic antibacterial properties of chitin, CS, cellulose and several polysaccharides of microbial origin are well known [[237], [238], [239]]. Hu et al. reported a vanillin-bioglass crosslinked 3D CS scaffold with good biocompatibility, strong antibacterial activity and capable of promoting osteoblastic differentiation prepared using a novel crosslinking technique with vanillin [139]. In other bone regeneration studies, biocomposite scaffolds containing CS were synthesized to obtain bioactive and antibacterial scaffolds [133,136]. Scaffolds based on nano-HA, starch, CS, alginate and S-nitroso-N-acetyl-penicillamine were manufactured by freeze-drying, obtaining porous scaffolds and an interconnected structure favorable to cell attachment and the growth of new tissue. Zhou et al. prepared a scaffold from a CS derivative (with an acrylamidomethyl group) with good prolonged antibacterial ability against S. aureus and E. coli [133].

Tissue regeneration, osseointegration, and bacterial accumulation in biomedical implants can be improved by surface modification [240]. For example, the surface modification of 3D printed PCL/HAp scaffolds has been performed with an antimicrobic polypeptide [138], providing favorable biocompatibility, osteoconductivity and antibacterial activity.

Electrostatic deposition of cationic oligopeptides in a PCL/CS nanofiber scaffold inhibited S. aureus while promoting osteoblast adhesion, spread, and proliferation [132]. Another strategy consists of either incorporating antibacterial peptides into the scaffolds or coating the scaffolds with them [137,140,141]. A mineralized collagen scaffold containing PLGA microspheres loaded with two antibacterial synthetic peptides was found to promote osteogenic capacity and antibacterial properties [137]. 3D printed scaffolds based on PLA/gelatin/nano HAp and the peptide ponericin showed that E. coli and S. aureus were inhibited for up to 24 h, and the inhibition could remain for up to 72 h [135]. Karamat-Ullah et al. developed a 3D hybrid aerogel-based scaffold combining an antibacterial peptide-modified silk fibroin (SF) with silica using micro-extrusion-based printing and directional freeze-casting/drying. This hybrid scaffold was found to be bactericidal against both Gram-positive and Gram-negative bacteria, and to be biocompatible with mouse embryonic pre-osteoblast (MC3T3-E1) cells [140]. 3D printed technology has also produced hydroxypropyl trimethylammonium chloride chitosan (HACC) grafted PLGA/HAp scaffolds that showed antibacterial activity against S. aureus and bone regeneration in infected bone defect models [134].

A novel flax/silk protein-based nanofibrous scaffold has recently been developed for bone regeneration [142]. This scaffold showed biocompatibility in MG-63 osteoblast cells and long-term antibacterial activity against E. coli and S. aureus. Flax holds bioactive peptides, which could promote antioxidant activity, antibacterial performance and anti-inflammation capacity [142].

Smart electroactive polymers have been developed to produce changes in electric charge distribution. These biomaterials, particularly conductive polymers, can deliver electrical signals by controlling the electric field applied to promote cell proliferation and differentiation, stimulating the regeneration of muscles, organs, and bones [[241], [242], [243]]. Electrostimulation applied to material surfaces appears to have an effective antibacterial activity against biofilm formation [244]. Electroactive polymers are promising materials for exploration in microbiology to develop novel strategies for fighting antibacterial resistance [241]. These materials can be useful as scaffolds for tissue regeneration to prevent infections associated with biofilm formation in implants, such as osteomyelitis in bone regeneration.

3.2.3. Scaffolds with carbon nanomaterials

Carbon nanomaterials (CBNs) are one-of-a-kind carbon-based materials with unique physical and biological properties such as antibacterial activity [245] and the ability to express many genes involved in tissue regeneration [246,247]. A small amount of CBNs can improve the physical and biological properties of polymers, including mechanical performance, wettability, thermal and electrical behavior, water diffusion, cell adhesion and proliferation, antimicrobial activity and degradation [7,25,61,62,[248], [249], [250], [251], [252], [253], [254], [255]].

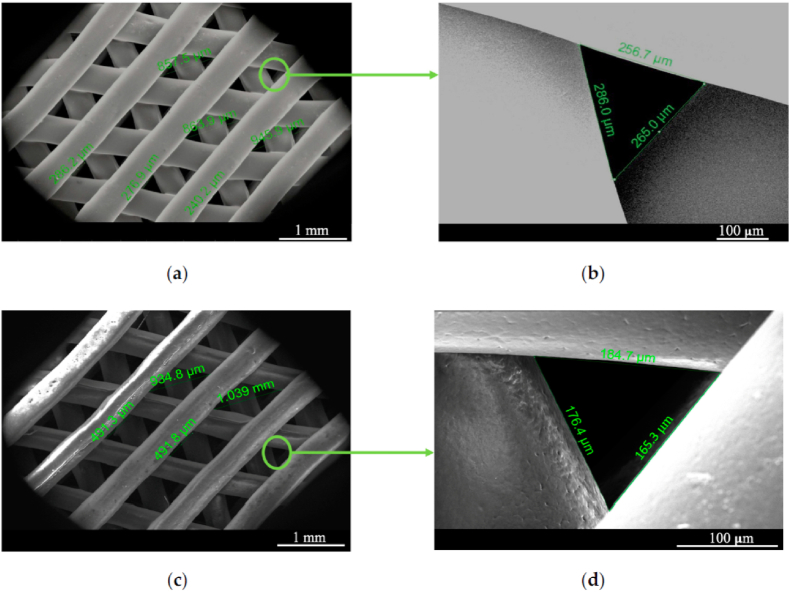

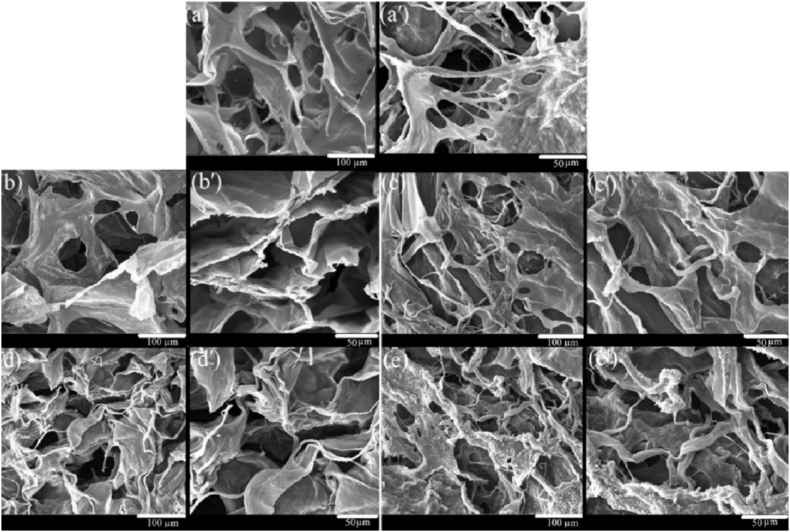

Composites containing carbon nanomaterials with antibacterial and osteogenic activity have recently been reported [256]. Some researchers have developed 3D printed scaffolds with electroactive properties that are composed of percolated PCL composites with thermally reduced graphene oxide (TrGO), whose antibacterial activity has been tested for use in tissue engineering applications [145] (Fig. 7).

Fig. 7.

(a) PCL scaffold (top view); (b) details and pore size; (c) scaffold with conductive TrGO particles (top view); (d) detailed image of a scaffold pore. Reprinted with permission under a Creative Commons CC BY 4.0 License from Ref. [145]. Copyright 2020 MDPI.

The results showed that applying an electrical stimulus of 30 V for 3 h to the surface of the 3D-printed electroactive scaffolds containing GO completely eradicated bacterial growth (S. aureus) on the scaffold surface. However pure scaffolds without GO possessed bacterial attachment after electrostimulation [145]. In addition to the greater bactericidal effect, the presence of highly conductive rGO linked to electrostimulation seems to increase cell viability. Recently, Lu et al. reported 3D printed scaffolds based on rGO, gelatin, CS and tricalcium phosphate (TCP) with good antibacterial activity (against S. aureus and E. coli) and without adverse effects on osteoblast viability and proliferation [147].

GO, which has low electrical conductivity, has also demonstrated antimicrobial properties. Melo et al. prepared a layer-by-layer PCL-3D printed fibrous scaffold with GO at different concentrations. The results showed good antibacterial behavior against Gram-positive and Gram-negative bacteria, and the ability to promote cell adhesion [146]. In another study, antibacterial capacity and in vitro osteogenesis were demonstrated by a GO-decorated microporous scaffold prepared with polyetheretherketone (PEEK), a semi-crystalline polymer used for orthopedic and spinal implants [144]. Khan et al. fabricated a composite hydrogel based on the polysaccharide ARX, GO nanosheets, HAp and PVA with bonding interactions between the components. The seeded preosteoblasts showed significant proliferation with no significant toxicity, while antibacterial activity against selected Gram-positive and Gram-negative bacteria was confirmed [148]. In a second study, the authors used GO and HAp to prepare nanocomposite scaffolds with bacterial cellulose and β-glucan. It was found that increasing the amount of GO has a positive impact on antibacterial activity and cell behavior [149].

A combination of different carbon nanomaterials has also been reported. For example, polymeric matrices of PLA and high concentrations of GO/carbon nanotubes (50/50% w/w of filler) were prepared by solvent casting and treated with oxygen plasma to enhance wettability [143]. The scaffolds had significant cell adhesion, showed no cytotoxicity and reduced bacterial proliferation. Several approaches using carbon nanomaterials in combination with silver nanoparticles have also given good results both as antibacterial and osteogenic biomaterials [176,217]. It should be noted that particle size is the most important characteristic that affects the antimicrobial behavior of carbon nanomaterials. The high surface-to-volume ratio of the nanoparticles (NPs) can adhere to microbial cells and affects cell membrane integrity, structural components and metabolic processes [257], which makes these new materials very promising in the field of tissue engineering, both as bioactive and biocide agents.

1% GO encapsulated forsterite (Mg2SiO4) scaffolds recently showed a porosity of 76%–78% with pore size of 300–450 μm, good cell biocompatibility, enhanced cell proliferation and potent antibacterial performance for bone tissue engineering [150].

3.2.4. Scaffolds with metals/ceramics/glass

Several studies in the field of antimicrobial scaffolds are based on silver (Ag), zinc (Zn), magnesium (Mg) or strontium (Sr) ions, due to their known antibacterial properties. Nanocomposite antibacterial scaffolds were prepared by loading AgNPs with an adsorption process. Overall, the results show that AgNPs confer good antibacterial properties on composite scaffolds to impede early infections [158]. Scaffolds composed of TiO2 nanotubes manufactured by 3D printing and silver ions were subsequently incorporated into their surface. The antimicrobial effect against S. aureus was found to continue for two weeks [172].

Some researchers have developed AgNPs containing antibacterial scaffolds composed of pentaerythritol triacrylate-co-trimethylolpropane tris (3-mercaptopropionate) (PETA) and HAp. These scaffolds showed osteoinductive and degradable properties capable of stimulating the proliferation of bone progenitor cells, did not affect cell viability and inhibited the proliferation of S. aureus and E. coli [159]. Gelatin/bioactive glass/AgNP scaffolds showed good cytocompatibility to human mesenchymal stem cells (hMSCs) and antibacterial capacity against E. coli and S. aureus [160]. Researchers investigated the antimicrobial activity of Ag octahedral nanoparticles containing PCL scaffolds, which showed antibacterial activity, osteogenic differentiation and no adverse effects on hFOB and hMSCs cells [174,202].

Polymeric PLA scaffolds with metals such as silver, which give a final result of antibacterial activity, showed osteogenic differentiation and no cytotoxicity to human cells [179]. A continuous Ag+ release can last more than 3 weeks, which can be useful in long-term bone implants. Zhang et al. synthesized a brushite/Ag3PO4-coated Mg-Nd-Zn-Zr scaffold to substitute bone [192]. This new scaffold demonstrated high antibacterial activity against Gram-positive and Gram-negative bacteria, with appropriate degradation characteristics and cytocompatibility. Arjunan et al. manufactured a pure Ag scaffold and demonstrated its antibacterial efficacy against S. aureus [193]. SF films with AgNPs have also been developed, since silk fibroin is a suitable biomaterial for bone tissue engineering. SF/AgNPs scaffolds showed cytocompatibility and an effective antibacterial effect against Gram-negative and antibiotic-resistant bacteria [189]. Silver-coated bioactive nanocomposite scaffolds have been developed using a polymeric matrix of beta-glucan biopolymer, acrylic acid, and nano-hydroxyapatite through free radical polymerization and freeze drying [200]. These scaffolds showed an antibacterial effect against DH5 alpha E. coli with no cytotoxicity in MC3T3-E1 cells.

Some researchers have combined silver with other materials to prepare antibacterial scaffolds. For example, silver-doped HAp scaffolds (HAp/Ag) reduced E. coli, S. aureus and S. epidermis bacterial populations while maintaining cytocompatibility with mammalian cells [175,191,258]. PVA-starch/HAp/Ag scaffolds prepared by freezing-thawing also demonstrated antibacterial activity against Gram-positive Bacillus and Gram-negative E. coli [184]. In another study, Deng et al. developed Ag-decorated 3D printed PEEK scaffolds via catecholamine chemistry. The antibacterial tests performed indicated that these Ag-PEEK scaffolds showed significant antibacterial effects against Gram-negative and Gram-positive bacteria and could support the proliferation of MG-63 osteoblast cells [173]. In another study, Wang et at [187]. proposed Ag-incorporated zincosilicate zeolite scaffolds with compressive strength and a Young's modulus similar to human cancellous bone. The scaffolds showed good antibacterial and bioactivity, indicating their potential as antimicrobial materials for bone substitutes. Antibacterial degummed silk fibers (ADSF) in combination with nano-HAp and PLA have been prepared, including Ag-nanoparticles as a reinforcing material [190]. The biological and antibacterial assessments showed that the ADSF/nano HAp/PLA composites had good bioactivity and antibacterial properties.

Bioactive glass-ceramic scaffolds [152,156] or coral hydroxyapatites [155] combined with Ag ions have been reported as a good approach for preparing scaffolds with antibacterial properties. In a similar approach, gelatin composite scaffolds were made by gelatin, alginate, PVA, nano-silver and HAp. These reinforced scaffolds showed antibacterial activity against Gram-positive and Gram-negative bacteria, as well as good biocompatibility in MC3T3-E1 preosteoblast cells [188].

Scaffolds with TiO2 have shown strong antibacterial activity [180,181]. PCL/TiO2 nanocomposite coatings were developed with a good bioactive performance against osteoblast cell lines and excellent antimicrobial behavior against S. aureus [178]. TCP/silver/PLGA scaffolds (TCP/Ag/PLGA) with a proven prolonged antibacterial effect against E. coli [151] have also been reported. Some researchers developed HAp scaffolds with Ag/TiO2/PA66 [154], Sr, Zn [164,177], or Ti6Al4V (pTi), CS and selenium (Se) (pTi/CS/HAp-Se) [186]. They observed osteoblast proliferation, tumor cell growth inhibition and bacterial viability with pTi/CS/HAp-Se scaffolds. Jiang et al. developed nano HAp/PU scaffolds with varying concentrations of Ag3PO4 particles for the repair of infectious bone defects [166]. The incorporation of Ag3PO4 in nano HAp/PU scaffolds increased their antibacterial potential against both Gram-positive and Gram-negative bacteria. The antibacterial tests and cytocompatibility evaluation revealed that nano HAp/PU scaffolds with 3% w/w Ag3PO4 had stronger antimicrobial effects and satisfactory cytocompatibility.

A novel porous nano HAp/polyamide 66 (nHP66)-based nanoscaffold material containing varying concentrations of silver ions (Ag+) (TA-nHP66) and oxidized titanium (TiO2) was developed successfully in an experimental osteomyelitis study in rabbits [168]. Porous osteoinductive TA2-nHP66 scaffolds with a composition of 0.64% w/w of Ag+ and 2.35% w/w of TiO2, were shown to have strong antibacterial activity against S. aureus and E. coli in vitro and S. aureus in vivo.

A new biomaterial composed of PLA, halloysite nanotubes loaded with ZnO nanoparticles was prepared by 3D printing [195]. The scaffolds so prepared showed osteoinductive potential. The external coating with gentamicin preserved the osteogenic properties and reduced bacterial growth. Zhu et al. prepared a forsterite scaffold by combining 3D printing and polymer-derived ceramics that contain biometal Mg [199]. The scaffolds showed efficient photothermal-induced antibacterial activity.

Bioactive glass scaffolds have many advantages such as osteoconductivity and osteoinductivity, making them an ideal scaffold for bone tissue engineering applications [259]. The development of multifunctional bioactive scaffolds that combine angiogenesis activity, a capacity, and antibacterial performance for regenerating lost bone tissues is of great importance in this field [260]. The antimicrobial activity of selenium nanoparticles (SeNPs) has also been reported [261,262]. Adding Ag+ to bioactive glasses has been investigated to produce antibacterial glasses [263]. Bioactive glass scaffolds have also been developed with delivery systems. Poly (octanediol citrate) bioactive glass scaffold containing zinc and gallium ions demonstrated antibacterial activity against Gram-positive and Gram-negative bacteria as well as cytocompatibility with human cells [169]. Silver-doped bioactive glass scaffolds showed antibacterial activity against S. aureus and E. coli. The scaffolds mimicked cancellous bone in terms of architecture and mechanical properties [170,183]. Some researchers obtained bioactive glass scaffolds from a soda-lime glass powder consisting of microspheres belonging to the SiO2–Na2O–Al2O3–CaO–B2O3 system [171] and compared this new scaffold with the 45S5 Bioglass® scaffold and found its antibacterial activity to be higher against C. krusei. Other researchers modified the 45S5 Bioglass® scaffold to improve its characteristics. For example, Gorriti et al. added free boron to 45S5 Bioglass® scaffold and the bactericidal effect increased by 55% [153]. A new 45S5Bioglass®/PLGA/SeNPs scaffold was fabricated to combine the antimicrobial properties of SeNPs with the osteoinductive capacity of bioactive glass to achieve bone regeneration [163].

Scaffolds made of borosilicate bioactive glass doped with varying amounts of Ag2O showed a sustained release of Ag + over more than 8 weeks and resistance against colonization by the bacterial strains E. coli and S. aureus [165]. Phosphate-free glass-ceramic porous scaffold is another example of antibacterial bioglass scaffolds. This can be synthesized by a three-step method involving slurry preparation, induction of porosity by surfactant-assisted foaming, followed by freeze-drying and sintering [197]. Hayashi et at. fabricated antibacterial honeycomb scaffolds by a procedure consisting of the replacement of their principal component (carbonate apatite) for silver phosphate on their surface [203]. Scaffolds containing 9.9·10−4% w/w silver phosphate showed antibacterial activity against S. aureus and allowed MC3T3-E1 preosteoblast proliferation and differentiation. They also prevented bacteria from growing in a rabbit with a femoral defect, which had S. aureus in it and new bone started to grow two weeks after surgery.

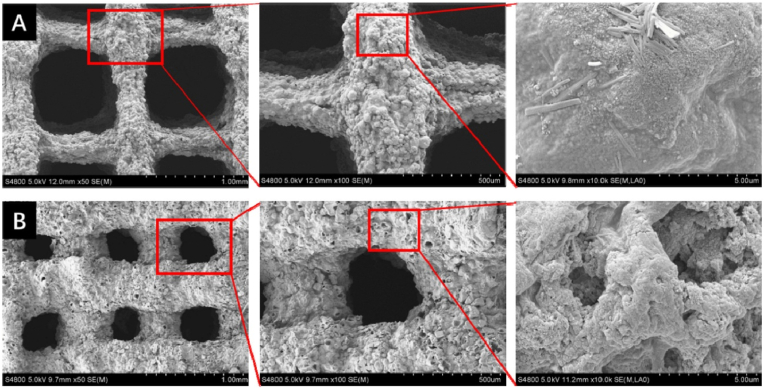

Hypoxia is one of the key factors that can affect scaffold implantation and lead to cell necrosis and microbial infection [264]. To solve this problem, oxygen-releasing bioceramic scaffolds were fabricated from biphasic calcium phosphate (BCP) powder [185] (Fig. 8).

Fig. 8.

View of sintered robocast biphasic calcium phosphate scaffolds for bone tissue engineering. Optical (b) and scanning electron microscope view from the top (a) and cross-section (c) of the ceramic scaffold. Reprinted with permission from Ref. [185]. Copyright 2019 Elsevier.

Calcium phosphate scaffolds with specific designs in terms of pore size, shape, and porosity can be precisely produced by AM technology [196]. In situ, the porous 3D printed bioceramic material was crosslinked with SA and freeze-dried. Scanning electron microscope (SEM) images revealed that the crosslinked scaffold has a multi-level porous structure compared to the uncross-linked one (Fig. 9).

Fig. 9.

(A) Uncrosslinked scaffold after freeze-drying, the printed struts shrunk sharply and showed one-level macroporous structures. (B) Crosslinked scaffold after freeze drying showed multi-level porous structures. Reprinted with permission from Ref. [196]. Copyright 2020 Elsevier.

At the same time the scaffolds were loaded with berberine, a quaternary ammonium compound with antibacterial activity and showed both antibacterial and bone-promoting functions. In vitro studies indicated that the 3DP scaffolds had low cytotoxicity with a beneficial effect on MC3T3 cell adhesion and proliferation [196].

Copper-containing mesoporous bioactive glass (Cu-MBG) scaffolds stimulate the hypoxia-inducible factor (HIF)-1a and VEGF expression in human bone marrow-derived mesenchymal stromal cells (BMSCs). Antibacterial Cu-MBG scaffolds promoted the osteogenic differentiation of human BMSCs and maintained a sustained release of ibuprofen [157]. Magnesium (Mg) has also been reported to possess antibacterial activity [265]. For example, a PLGA/Mg scaffold fabricated by a low-temperature rapid-prototyping technique showed an ability to inhibit bacterial growth and biofilm formation [162].

Zinc is an essential element with intrinsic antibacterial and osteoinductive capacity [266]. Zinc cross-linked scaffolds significantly reduced the growth of Bacillus subtilis and E. coli by 70 and 81%, respectively [167]. PCL-ZnO nanofibrous scaffolds have been developed with antibacterial activity against S. aureus and are also capable of inducing early mineralization with ZnO concentration-dependent degradation [182]. ZnO-enriched meso-macroporous glass scaffolds were prepared by Sánchez-Salcedo et al. The results showed that the porous structure was suitable for osteoblast growth and that the Zn ions released exhibited antibacterial properties against S. aureus [161]. ZnO nanoparticles have also been incorporated into PHBV to produce antibacterial porous scaffolds [198].

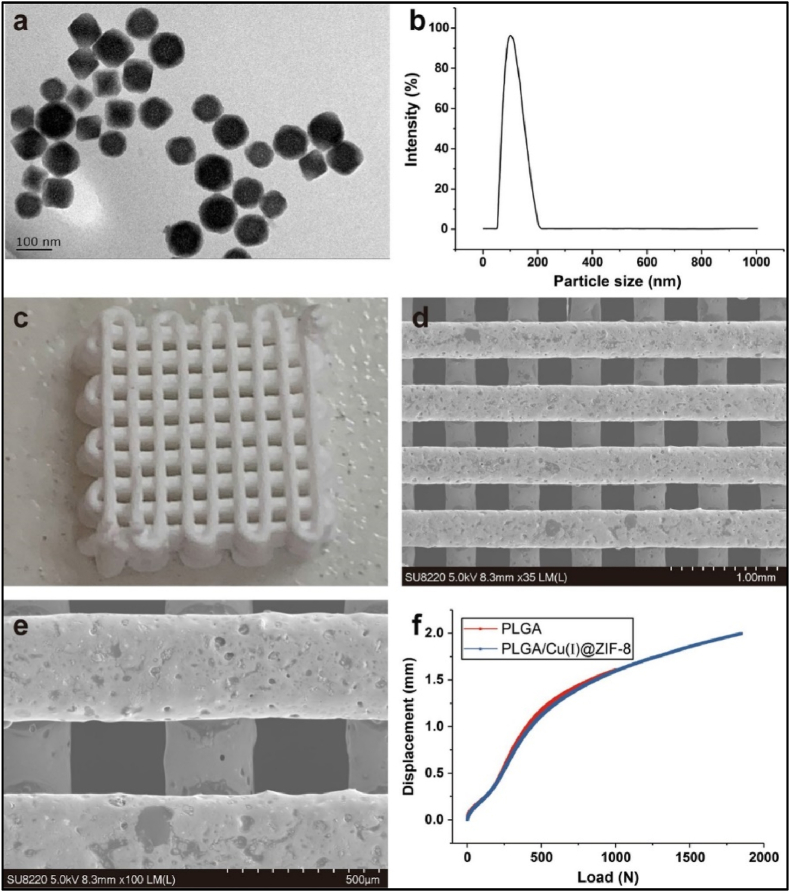

PLGA is one of the most commonly used polymer biomaterials for producing bone tissue engineering scaffolds, since this biodegradable copolymer does not have any side effects when used as a medical material [267,268]. A novel PLGA/Cu(I)@ZIF-8 scaffold for infected bone repair was created by combining antibacterial copper-loaded-zeolitic-imidazolate-frameworks (ZIF-8) and PLGA [194], as shown in Fig. 10.

Fig. 10.

Scaffolds composed of copper-loaded-zeolitic-imidazolate-frameworks (ZIF-8) and PLGA (PLGA/Cu(I)@ZIF-8): (a) Transmission electron microscope (TEM) image of Cu(I)@ZIF-8 nanoparticles; (b) Particle size distribution of Cu(I)@ZIF-8 nanoparticles; (c) digital image; (d, e) TEM images of PLGA/Cu(I)@ZIF-8 scaffolds; (f) Load–displacement curve of PLGA and PLGA/Cu(I)@ZIF-8 scaffolds. Reprinted with permission under a Creative Commons CC BY 4.0 License from Ref. [194]. Copyright 2020 Springer Nature.

3D-printed biocompatible scaffolds based on calcium-deficient hydroxyapatite (CDHA) with gold nanoparticles showed effective antibacterial activity against Micrococcus luteus for bone tissue engineering [204].

Bio-ceramic clinoenstatite (MgSiO3) scaffolds of different micropore sizes were fabricated by the space holder method and subsequent sintering [201]. They showed good mechanical strength as well as biocompatibility in MG63 cells and controlled drug-release potential of metronidazole (MET) towards the Fusobacterium nucleatum and Aggregatibacter actinomycetemcomitans bacteria.

3.2.5. Antibacterial scaffolds produced by combined and alternative strategies

Biological and antibacterial properties of titanium implants are required to prevent implant-associated infections and promote cell attachment of orthopedic devices. Several antimicrobial scaffold delivery systems have been developed in this research line as an emerging technology for the reconstruction of bone and cartilage tissue defects [269]. A reinforced hybrid scaffold consisting of continuous and porous layers of titanium and ultrahigh-molecular-weight polyethylene (UHMWPE), a polymer with good compatibility, and a subsequent amoxycillin impregnation were prepared to prevent the appearance of opportunistic infections [219]. As a result, the contact of Gram-positive and Gram-negative bacterial cultures (S. aureus, S. epidermidis and E. coli) with the hybrid polymeric scaffolds suppressed microorganism growth and colony formation. A new bioactive monticellite-ciprofloxacin (Mon-CPFX) scaffold was created by the same researchers using the space holder method [220]. This scaffold showed good cell attachment and growth, suitable compression performance and drug release and an excellent antibacterial capacity [220]. In another study, Thanyaphoo reported on Si-nano HAp scaffolds loaded with vancomycin or recombinant human bone morphogenetic proteins (rhBMP-2) which showed potential to be used as a drug delivery system to kill S. aureus [208].

Ceramic porous scaffolds loaded with antibiotics have also been proposed as an alternative approach. Bakhsheshi-Rad et al. prepared biocompatible bredigite–amoxicillin scaffolds with good antibacterial activity against both S. aureus and E. coli bacteria [214]. Doxycycline in a low concentration in a Mg–Ca–TiO2 composite scaffold showed no cytotoxic behavior against MG63 cells but did have efficient antibacterial activity against Gram-positive and Gram-negative pathogens [218].

Layer-by-layer electrospinning was used to construct chlorhexidine-doped PLGA/PCL (PPC), PLGA/PCL (PP), and β-tricalcium phosphate-doped-PLGA/PCL (PPβ) [216]. The three-layer electrospun membranes showed high strength, good cell adhesion, promoted osteoconductive properties and enhanced antimicrobial properties. Other researchers have engineered scaffolds that combine several strategies. For example, Xie et al. studied the antibacterial activity of AgNPs combined with Hap, CS, and bone morphogenic protein-2 (BMP-2) [209]. Ti bars with BMP/CS/Ag/HAp coatings were implanted into rabbit femurs [209]. In another study, an Ag-loaded strontium hydroxyapatite (SrHAp)/CS scaffold (Ag-SrHAp/CS) was prepared to analyze its biocompatibility, osteoinductivity, and antibacterial activity [211]. The Ag ions released from the scaffold inhibited the growth and attachment of S. aureus. In another study, Mg and Zn ions were combined with the antibiotic tetracycline to prepare a scaffold by the space-holder technique [221]. The results indicated that the engineered Mg–Zn scaffolds containing 1–5% of tetracycline had good potential for bone tissue healing due to their good biocompatibility and antibacterial activity.

The biodegradable polyester PLA, approved by the Food and Drug Administration (FDA) for direct contact with biological fluids, is a promising biodegradable polymer for the fabrication of biocompatible scaffolds [270]. However, it is not antibacterial and needs to be combined with antibacterial agents to provide protection against infections. These combinations can be very simple; for example, mixing, polymeric PLA scaffolds with metals such as silver or carbon nanomaterials, which provide antibacterial activity, osteogenic differentiation and no cytotoxicity to human cells [179,217]. PLA is a relatively hydrophobic polymer that can be combined with hydrophilic polymers such as collagen (COL), minocycline hydrochloride (MH) and citrate-hydroxyapatite nanoparticles (cHApNPs) to reduce bacterial adhesion and biofilm formation [37]. The presence of minocycline hydrochloride also enhances the biological properties of the composite material. These scaffolds can inhibit S. aureus, which is a major pathogen in bone-associated infections because of its ability to adhere and form biofilms on bone and/or implants [271].

The gelatin-siloxane hybrid scaffold with gentamicin sulfate is another example of a scaffold with excellent bioactivity and antibacterial capacity [205]. Li et al. coated the 45S5 Bioglass® scaffold with genipin cross-linked gelatin (GCG) and further incorporated it with poly (p-xylyleneguanidine) hydrochloride (PPXG) to produce a biocompatible scaffold with antibacterial activity against Gram-positive and Gram-negative bacteria [210].

The combination of antimicrobial polymers (particularly CS) and antibiotics is another strategy to treat bone biofilm infection or provide antibacterial activity. Nano HAp/CS/Konjac glucomannan scaffolds [206] and PCL/CS [215] loaded with vancomycin have demonstrated antimicrobial activity. Another strategy is the combination of multiple antibacterial agents to prevent the use of toxic levels. The synergistic effects of silver ions and the antibiotic vancomycin, together with the antimicrobial CS, were assessed in a scaffold prepared from CS/gelatin/Ag and loaded with vancomycin [213]. A CS/carboxymethyl cellulose with Zn and Fe integrated hydroxyapatite (ZFHAp) scaffold has also been proposed [225]. The combination of the antibacterial properties of CS and the release of Zn ions (5% of ZFHAp) resulted in a robust antibacterial activity and good biocompatibility with bone cells.

Some researchers have developed different mesoporous bioactive glass (MBG) scaffolds [207], which are very brittle and lack antibacterial activity. To avoid these disadvantages, a novel modified MBG scaffold was developed with prolonged antibacterial activity and demonstrated biocompatibility with hMSCs [207]. Scaffolds produced by other alternative strategies, such as baghdadite-vancomycin scaffolds reloaded with a drug for 6 h presented antibacterial activity against S. aureus [124]. Hu et al. demonstrated that berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds showed enhanced antibacterial performance [223].

Xyloglucan-co-Methacrylic Acid/Hydroxyapatite/SiO2 nanocomposite scaffolds showed important properties for bone tissue engineering such as potent antimicrobial activity against several Gram-positive and Gram-negative strains, porosity with substantial mechanical strength, biodegradability, biocompatibility and cytocompatible behavior [222].

Recently, Yu et al. developed a novel antibacterial PGA-based scaffold produced by cation exchange of montmorillonite (MMT) with Cu+2 and the intercalation of cetyltrimethylammonium bromide (CTAB) into the interlayer of MMT [226] that showed superior antibacterial activity.

An antibacterial metal in combination with carbon nanomaterials has been proposed as a new approach. Ag-GO nanohybrids, prepared by AgNPs in situ grown on GO, were introduced into PLA to produce biocompatible and antibacterial scaffolds using the SLS technique [227].

In another study, Zn-doped HAp/rGO nanocomposites were prepared using a mechanochemical process [224]. Zn doping in combination with rGO promoted alkaline phosphatase (ALP) activity and proliferation of MSCs as well as antibacterial performance.

Polymeric nanocomposite scaffolds composed of cellulose and co-dispersed nanosystem (Fe3O4/GO) were very recently produced by free radical polymerization and freeze drying [228]. These electroactive scaffolds showed good biocompatibility in a pre-osteoblast (MC3T3-E1) cell line and potent antibacterial activity against Gram-positive S. aureus and Gram-negative E. coli and Pseudomonas aeruginosa. Using another approach combining different strategies, a 3D-printed PCLA scaffold with nano-hydroxyapatite coating doped green tea epigallocatechin-3-gallate promoted bone growth and inhibited multidrug-resistant bacteria colonization [229].

3.3. Antibacterial scaffolds for skin regeneration

Soft tissue infections in open fractures, burns or diabetic complications are some of the main causes of high morbidity [272]. Functional antibacterial skin tissue scaffolds are being developed to treat large and deep skin defects (see Table 2). Several strategies are being investigated to treat and promote wound healing, such as the release of antibiotic drugs or antibacterial biometals, the use of polymers, biopolymers or peptides with intrinsic antibacterial properties, the incorporation of nanomaterials with antibacterial properties, such as carbon nanomaterials, or the combination of different strategies. This section describes the different approaches developed in recent years.

Table 2.

Antibacterial scaffolds for skin tissue engineering applications.

| Material | Fabrication method | Bacteria | Non-toxicity: cell line/animal model | Year | Ref |

|---|---|---|---|---|---|

| Scaffolds with antibiotics | |||||

| PLA, PCL and CPFX | Jet spraying | Bacillus subtilis and E. coli | Dermal fibroblast | 2017 | [273] |

| PLGA electrospun fibers containing CPFX | Electrospinning | P. aeruginosa, S. aureus and S. epidermis | Not studied | 2018 | [274] |

| CPFX-modified degradable hybrid PU-PLA porous scaffolds | Polymerization | E. coli, S. aureus and P. aeruginosa | Not studied | 2020 | [275] |

| Alginate, methylcellulose and Laponite | 3D printing | S. aureus and S. epidermidis | Not studied | 2021 | [272] |

| Porcine acellular dermal matrix hydrogel blended with vancomycin | Decellularization, digestion and load | S. aureus and Enterococcus | Mouse embryonic cells (NIH3T3 cells)/Rat | 2021 | [276] |

| Microstructural nanofibrous mats/gentamicin-loaded hydrogel scaffold | Electrospinning | S. aureus and P. aeruginosa | Human dermal fibroblast cells/rat | 2022 | [277] |

| Scaffolds with metals/glass | |||||

| PCL nanofibers containing different ratios of calcium peroxide with or without ascorbic acid | Electrospinning | E. coli and S. epidermis | hFOB human osteoblast cells | 2011 | [278] |

| Cellulose–polymer–Ag nanocomposite fibers | Rotating the preweighed and washed cellulose fibers | E. coli | Not studied | 2013 | [279] |

| PCL/gelatin nanofibrous scaffolds coated with silver | Electrospinning | B. cereus and E.coli | HSF human splenic fibroblast cells | 2016 | [280] |

| Silver nanoclusters/nanoparticles hemostatic material | 3D printing | E. coli, P. aeruginosa, S. aureus and MRSA | A549, U251, HepG2, HBE/Rabbit | 2018 | [281] |

| Radio sterilized pig skin + AgNPs | Impregnation | S. aureus and S. maltophilia | MSCs | 2018 | [282] |

| SiO2–CaO mesoporous bioactive glass NPs with silver | Microemulsion-assisted sol-gel method | S. aureus and P. aeruginosa | 3T3 fibroblast cells | 2019 | [283] |

| S-AgNPs loaded PVA nanofiber | Electrospinning and Cross-lining | E. coli and S. aureus | Not studied | 2019 | [284] |

| PVA/Starch cryogel scaffold combined with AgNPs | Cryogelation technique | P. aeruginosa | Not studied | 2019 | [285] |

| PGS/PCL nanofibers with calcium peroxide | Electrospinning | S. aureus | BMSCs | 2020 | [286] |

| PCL nanofibrous mat with silver sulfadiazine | Electrospinning | S. aureus and P. aeruginosa | Human dermal fibroblasts/Rat | 2020 | [287] |

| Bioglass-based scaffolds coated with AgNPs | Sponge replication technique | S. aureus, P. aeruginosa and C. albicans | Not studied | 2020 | [288] |

| Silica-based nanocomposites hydrogel scaffolds | Crosslinking | E. coli and S. aureus | Endothelial progenitor cells/Mice | 2020 | [289] |

| PCL and Ag-magnetite NPs | Co-precipitation and electrospinning | E. coli and S. aureus | Human melanocytes/Rats | 2021 | [290] |

| Lignin-agarose hydrogel-silk fibroin and zinc chromide NPs | Crosslinking | P. aeruginosa | Hu02 fibroblast cells/Mice | 2021 | [291] |

| Gelatin-based and Zn2+-incorporated composite hydrogels | Polymerization in solution | E. coli and S. aureus | NIH-3T3 cells/Mice | 2022 | [292] |

| Scaffolds with antibacterial polymers/peptides | |||||

| Quaternary chitin/partially deacetylated chitin nanofibers | Freeze-shaping and drying | E. coli and S. aureus | L929 mouse fibroblast/Rat | 2017 | [293] |

| PCL/CS scaffold | 3D printing | S. aureus and S epidermis | L929 mouse fibroblast cells | 2018 | [294] |

| CS/aminoacid hydrogels | Dissolution | Not specified | SBF fluid | 2018 | [295] |

| Biomimetic Composite Nanfibrous Scaffolds | Electrospinning | S. aureus | Human immortalized epidermal cells | 2019 | [296] |

| ECM from decellularized mammalian tissue and ECM (CS) | Decellularized | E. coli and S. aureus | HMEC-1 endothelial cells | 2020 | [297] |

| Micro/nanostructured poly (butylene-succinate-co-adipate) | Phase separation | S. epidermidis | HaCaT keratinocyte cells | 2020 | [298] |

| Silk fibroin and vitamin K3 carnosine peptide | Electrospinning | S. aureus, E. coli and P. aeruginosa | HGF1, NIH 3T3 fibroblast cells/Rat | 2021 | [299] |

| Silk fibroin/Gelatin and CM11 peptide | Freese-drying | S. aureus, E. coli, P aeruginosa | Hu02 fibroblast cells | 2022 | [300] |

| Scaffolds with carbon nanomaterials | |||||

| PHBV, collagen and rGO | Electrospinning | E. coli and S. aureus | 3 T3-L fibroblast-like cells | 2017 | [301] |

| Isabgol and rGO | Freeze-drying | E. coli and S. aureus | NIH 3T3 fibroblast cells/Winstar rats | 2018 | [302] |

| PU, polyhexamethylene guanidine hydrochloride and GO | Freeze-drying | E. coli and S. aureus | HaCaT keratinocyte cells/Micet | 2020 | [303] |

| Cellulose, graphene quantum dots | Solvent casting | S. aureus, E. coli, P. aeruginosa | Human fibroblast | 2022 | [304] |

| Calcium alginate, PHBV and graphene nanoplatelets | Solvent casting | Not studied | Human keratinocyte (HaCaT) cells | 2022 | [305] |

| Scaffolds produced by combined strategies and alternative methods | |||||

| Quercetin-Containing PLGA Nanofibrous Scaffolds | Electrospinning | S. aureus and K. pneumoniae | KB epithelial cells | 2012 | [306] |

| Honey/CS nanofibrous scaffolds loaded with natural materials | Electrospinning | E. coli, S. aureus, MRSA and P. aeruginosa | Human fibroblast cells/Mice | 2016 | [307] |