Abstract

Innovation can be considered one of the fundamental elements for ensuring sustainability. Companies have started to enhance their sustainability level through the application of innovative practices. The importance of employing innovative social sustainability practices within the supply chain seems to have escalated with the advent of COVID-19. However, studies focusing on the social aspect of sustainability innovation when selecting suppliers during the COVID-19 disaster are non-existent. Selecting these types of suppliers can significantly help companies to be more socially innovative and obtain sustainable development targets. This work introduces a social sustainability innovation framework for assessing suppliers during the COVID-19 pandemic. A group grey-best worst method (Group GBWM) is utilized to identify the criteria weights and improved grey relational analysis (IGRA) is utilized for ranking the suppliers. Findings show that “safety and health practices”, “remote working conditions”, and “localization” are the most important social sustainability innovation criteria, respectively, in choosing suppliers during COVID-19. A manufacturing firm is utilized as an example for verifying the efficiency of the proposed model and framework. This work helps industrial experts and researchers to better understand and focus on the social aspect of sustainable innovation, particularly when selecting suppliers during the critical COVID-19 pandemic situation.

Keywords: Socially sustainable innovation, Supplier assessment, Best worst method (BWM), Grey relational analysis (GRA), COVID-19

1. Introduction

The rapid growth of industrialization has had a significant impact on economic development, community well-being and enhanced supply chain operations, but a negative impact on socio-environmental issues (de Vargas Mores et al., 2018). The demands of supply chain activities have led to increased usage of natural resources, air and water pollution, and instability in the eco-system (Moktadir et al., 2018). With the development of the manufacturing sector in emerging economies, managing resources has become a serious issue world-wide. Considering these issues, society, governmental and non-governmental bodies are imposing pressure on companies to adopt and implement sustainability initiatives. Manufacturing firms can play a significant role in supply chain sustainability by reducing the negative social and environmental effects generated by their activities (Boons and Lüdeke-Freund, 2013). In order to implement novel ideas and improvements in sustainable supply chains, creative thinking, and the development of new ideas and knowledge are essential. Within this context, innovation plays a significant role for achieving sustainability in supply chains (Neutzling et al., 2018). According to Boons and Lüdeke-Freund (2013), innovation is the process of generating novel ideas, new products, and technologies. Integrating and combining sustainability and innovation considerably affects a firm's success.

Sustainable innovation is considered a key factor for attaining long-term sustainable development. Sustainable innovation in the supply chain creates economic, environmental, and social value. Several studies have focused on sustainable innovation. Veronica et al. (2019) examined the role of stakeholders in improving sustainable innovation in Italian manufacturing firms. Zhou et al. (2020) studied the effect of awareness sharing on sustainable environmental innovation. Del Río et al. (2016) carried out empirical analysis to evaluate suppliers in emerging economies. They considered their performance in sustainable innovation to still be extremely limited and in need of more attention. Kusi-Sarpong et al. (2019) argued that firms need to take into consideration the external capabilities, factors, and strategies for their suppliers to attain their sustainable development goals. Recently, several firms have employed innovation factors, with the goal of moving towards sustainability-oriented innovation, especially for their supplier evaluation process (Jones and Zubielqui, 2017). The performance of suppliers is quite critical in the development of sustainable supply chain networks, as they supply the initial materials and goods to firms. Moreover, their performance also impacts client behavior (Bai et al., 2019).

Recently, the COVID-19 outbreak as a global pandemic shocked all businesses and supply chains all over the world (Sarkis, 2020). It has led to several challenges for supply chains like shortage of materials, lockdowns, delayed deliveries, and even bankruptcy (Karmaker et al., 2021). Governments, businesses and above all the society have responded to these challenges by closing non-essential businesses, social distancing, smaller public gatherings, cancelling populated events and meetings, etc. (Sarkis, 2020). Therefore, the pandemic has affected several aspects of economic, environmental and social aspects of businesses (Hakovirta and Denuwara, 2020) and this effect has pushed supply chains to shift their operations in a more sustainable way. For instance, to improve the social sustainability of supply chains, adequate safety measures, facilitating social distancing at the workplace and remote working, and regular health monitoring policies are required (Kumar et al., 2020). According to Hakovirta and Denuwara (2020), significance of human health with the outbreak of COVID-19 has been increasing and we need to include it in the redefinition of sustainability. It is obvious that supply chain strategies, in particular sourcing strategies, designed for a normal environment, are not very viable to deal the challenges of COVID-19 (Karmaker et al., 2021). These conditions, in particular concerns regarding the social aspect, as discussed by several scholars like Hakovirta and Denuwara (2020), motivated us to study the supplier selection problem with the lens of social sustainability innovation in the era of COVID-19 disaster. Although there have been a number of studies focusing on the social aspects of sustainable innovation, the supplier selection problem considering innovative social sustainability during the COVID-19 outbreak has not been yet investigated. To fill this gap, this work assesses the performance of some suppliers in emerging economies in terms of socially sustainable innovation performance, with the aim of improving the understanding and insights regarding this aspect, during the COVID-19 situation.

Assessing and ranking suppliers is a multiple-criteria decision-making (MCDM) process, requiring the incorporation of various assessment criteria for evaluating suppliers. Various MCDM methods have been employed in previous studies to assess and rank suppliers. According to Zimmer et al. (2016), the most widely employed techniques for sustainable supplier selection are AHP, ANP and fuzzy logic. In the MCDM process, it is unavoidable to determine relative weights of the criteria and then evaluate a finite number of alternatives in terms of the selected criteria. For the first part of the MCDM process, AHP is one of the most popular methods for criteria weighting which was first introduced by Saaty (1980). However, it has been criticized in the literature for its inconsistent results (Dyer, 1990), rank reversal (Holder, 1990), and requiring a lot comparisons for weighting (among n criteria normally n(n-1)/2 comparisons required) by experts (Rezaei, 2015). Recently, to overcome these weaknesses, Rezaei (2015) invented a novel weighting method, namely best-worst method (BWM) which only utilized 2n-3 pairwise comparisons providing more consistent results than AHP. Technical superiority of BWM over AHP in terms of several criteria like consistency ratio, minimum violation, total deviation, and conformity was discussed in Rezaei (2015). BWM has been extensively employed in several scientific studies, in particular in supply chain management field like (Ahmad et al., 2017; Malek and Desai, 2019). The original BWM could not handle uncertainties and vagueness in human decision-making very well. Therefore, several integrations with BWM has been proposed in the literature to handle the uncertainty of information and judgments in a MCDM process like ZBWM which is an integration of Z-numbers and BWM (Aboutorab et al., 2018), fuzzy BWM (FBWM) (Ecer and Pamucar, 2020), interval BWM (Hafezalkotob et al., 2020), and Grey BWM (Mahmoudi et al., 2020). We propose a novel group grey BWM, which makes it very suitable for group weighting method and handling uncertainty in judgments. There are several advantages of grey systems theory over fuzzy theory (Li et al., 2007). For instance, grey theory can deal flexibly with the fuzziness situations as well.

For the second part of a MCDM process, assessing and ranking alternatives, improved grey relational analysis (IGRA) is employed which was firstly developed by Hashemi et al. (2015). IGRA has several advantages over the traditional methods like TOPSIS and VIKOR, which are frequently employed in supplier selection studies. First, it handles the uncertainties in judgments by utilizing grey systems theory. In other words, grey-based methods are capable to provide satisfactory results using a small amount and obscure information (Fu et al., 2012). Second, IGRA has not been reported to have Rank Reversal problem, while common techniques in supplier selection like TOPSIS has it (Hashemi et al., 2015). There are several studies investigating rank reversal in MCDM methods like VIKOR (Ceballos et al., 2018) and TOPSIS (García-Cascales and Lamata, 2012). Finally, IGRA is more flexible and efficient in aggregating experts’ judgments and despite other techniques like TOPSIS, it aggregates the final result calculated for each expert and does not need to aggregate the experts’ opinions in the initial stages of the calculation process. Thus, by adding or removing an opinion, there is no need to resume the calculation from the beginning.

In this paper for the first time, a combination of a group grey best-worst method and improved grey relational analysis (Group GBWM - IGRA) is utilized to assist in the assessment. Proposing a social sustainability innovation framework for assessing social sustainable innovative suppliers during COVID-19 epidemic within an emerging economy context using a novel technique (Group Grey-BWM and IGRA) highlights the novelty of this research. The main objective of the current study is to propose a decision framework for assessing suppliers based on their social sustainability initiatives regarding the criteria relevant to the requirements of working conditions during COVID-19 pandemic. This research answers the following questions:

Q1. Which social sustainability innovation criteria are the most essential for assessing suppliers in the era of COVID-19 pandemic?

Q2. Which decision-making framework is the most suitable for a comprehensive evaluation of suppliers during COVID-19 outbreak?

Specifically, the main contributions of the proposed approach are:

-

•

The proposed methodology addresses the uncertainties of socially sustainable innovative suppliers under the special circumstances of COVID-19 by using grey values for both the weighting criteria and ranking the suppliers. Grey system theory is more flexible than fuzzy logic and does not require a membership function (Deng, 1989).

-

•

According to Rezaei (2015), BWM has several advantages compared to the commonly used AHP method, providing more consistent results with less need of pairwise comparisons. This study develops a linear BWM model employing grey theory and also aggregating the opinions of a group of experts by solving a single linear programming model.

-

•

This study focuses on the social sustainability innovativeness of suppliers, which is a topic very rarely mentioned in the literature and also considers the relevant social innovation criteria during the COVID-19 outbreak. To the best of our knowledge, this is the first time that the supplier selection problem in relation to the COVID-19 outbreak and social sustainable innovation initiatives has been investigated.

2. Literature review

This section starts with a review of sustainable supply chain management. Second sub-section focuses on sustainable supplier evaluation and selection. The subsequent sub-sections present sustainable innovation, social sustainability innovation, and a brief review of the COVID-19 disaster and social sustainability innovation. The research gap is identified in the last sub-section.

2.1. Sustainable supply chain management (SSCM)

Sustainable supply chain management (SSCM) is defined as the management of substances, information, funds, and resources among a firm's supply chains while considering the economic, environmental, and social aspects of sustainability goals. According to Seuring et al. (2008), firm performance can be considerably enhanced by employing sustainable supply chains; this also affects a corporation's competitiveness. Utilizing SSCM significantly reduces harmful economic, environmental, and social effects. Implementing sustainability initiatives like supplier evaluation improves cooperation among the various partners by strengthening their social and environmental performance and reducing waste (Ahmadi et al., 2017a: Hafezalkotob et al., 2020). Environmental, social, and economic perspectives have been identified as three major categories of sustainability. Corporations could attain sustainability through combining these three perspectives and should go beyond organizational boundaries, such as risk management and supplier operations transparency policies (Kusi-Sarpong et al., 2019). An increasing number of companies utilize factors such as safety and health, environmental and social standards to improve their sustainability level (Tseng, 2013). As the focus of this paper is to assess suppliers based on social sustainability innovation performance under COVID-19 situation, the next sub-section presents a brief review on sustainable supplier evaluation and selection.

2.2. Sustainable supplier evaluation and selection

SSCM requires the consideration of social and environmental factors in the traditional supplier selection problem, solely based on economic criteria. The incorporation of additional environmental and social factors into traditional supplier selection decision-making is described as sustainable supplier evaluation and selection (Ahmadi et al., 2020). Many companies have started to employ sustainability factors in their supply chain-related activities and decision-making to ensure that they remain competitive, particularly while selecting suppliers. Suppliers play a substantial role in supply chain operations with significant influence on a company's sustainability performance, so need to be carefully assessed (Azadnia et al., 2015). Most past sustainable supplier selection studies have investigated the environmental and economic aspects, but the social aspect has been given less consideration. Several pressing social problems confront supply chains including inherent safety and health issues and poor working conditions which have motivated corporations to explore the social aspect of sustainability when evaluating their suppliers, particularly in countries with emerging economies (Bai et al., 2019). According to the resource-based view, social sustainability factors are linked to the creation of a competitive advantage and enhanced economic performance. Therefore, efficient supplier selection based on sustainability factors can create the required competitive resources (Tseng, 2010; Mani et al., 2018). In the next subsection, sustainable innovation is overviewed.

2.3. Sustainable innovation

To implement sustainable supply chains, corporations must be innovative and responsive to harmful socio-environmental effects. Sustainability innovativeness can be considered as an efficient strategy which firms can use to promote their competitive advantages over their rivals (Gupta et al., 2020). Sustainable innovation includes completely new or developed products, processes, systems, and techniques that lead a reduction in negative socio-environmental impacts and enhanced quality of life (Kemp, 2000). Silvestre (2015) argued that increasing a firm's sustainability is challenging even without employing innovation factors. Sustainable innovation consists of innovative management approaches which lead to enhanced sustainability performance in the company's supply. According to Hall and Vredenburg (2003), implementing sustainability innovations is complex, since several stakeholders including customers, suppliers, non-government firms, and competitors participate in the decision-making processes, and conflicting requirements may exist. However, Silvestre (2015) claimed that innovation is a key factor for promoting sustainable practices that firms should seriously consider. Several serious social problems including poverty, corruption and human rights can influence supply chains and prevent companies from reaching their sustainability goals (Silvestre and Ţîrcă, 2019). Tariq et al. (2017) suggested that social, ethical, technological, and cultural elements should be taken into consideration as sustainable innovation attributes, which result in market, environmental and economic performance outcomes. Environmental sustainability innovation, social sustainability innovation and economic sustainability innovation are three sustainable innovation aspects. In this study we only focus on social aspect of sustainable innovation, with the aim of ranking several social sustainable innovative suppliers during COVID-19 disaster. Next sub-section reviews the social sustainability innovation.

2.4. Social innovation

Social innovation has received significant attention in the last few years (Avelino et al., 2019) and different descriptions for social innovation being offered. For example, Howaldt and Kopp (2012) describe social innovation as the incorporation of new social factors in various social contexts. Moulaert (2013) explains social innovation as innovation which can result in improved social relations and governance structure. Social innovations include employing new ideas, solving societal and environmental issues and contributing to social development (Ramani et al., 2017). According to Pol and Ville (2009), efficient innovative solutions to various existing economic, social and environmental problems that lead to social improvement and effective influence on people understanding can be defined as social innovation. Different aspects of social innovation have been explained including social change, with the goal of enhancing the quality of life (Harrisson et al., 2012). Social aspects of sustainable innovation proved system-changing initiatives that can change understandings and motivate social change (McKelvey and Zaring, 2018). Companies can create new markets, achieve competitive advantages, and obtain economic gains by building social value, employing social innovation practices, and manufacturing socially innovative products (Ozdemir et al., 2017). Unfortunately, COVID-19 epidemic has negatively impacted sustainable supply chains from different aspects. According to the objective of this study, next sub-section discusses the COVID-19 pandemic and the social sustainable innovation factors.

2.5. COVID-19 disaster and social sustainability innovation

The COVID-19 epidemic is the most destructive tragedy within the last decades, stopping normal community functioning, and badly damaging the global economy and the natural environment (Sarkis et al., 2020). Globally, the spread of COVID-19 has resulted in serious supply chain disruptions, especially in sustainable supply chains. This has had a harmful impact on brand image, material supplies, supplier heath and supply chain performance (Sharma et al., 2020). Researchers, governments, industrial decision-makers, and policy makers are quite worried about this disaster and its harmful impact on business operations and industrial policy. During this worldwide crisis, firms are trying to cope with the challenges and problems related to three sustainability dimensions (Gostin and Wiley, 2020). Health and safety practices, the wellbeing of employees, efficient communication strategies in healthcare, community safety, remote working conditions and skill improvement are some of the social sustainability initiatives adopted by corporations for diminishing the negative effects of the epidemic and preserving the social sustainability of supply chains (Sharma et al., 2020; World Health Organization, 2020). As the focus of this paper is investigating the social aspects of sustainable innovation through supplier evaluation and selection during the COVID-19 outbreak, we also examine the disaster's impact on these social aspects and determine the relevant social innovation factors for assessing suppliers. Table 1 lists the 11 social sustainability innovation criteria, both traditional and COVID-19 related ones, with detailed operational definitions for each criterion. Research gap is determined in the next sub-section.

Table 1.

Social sustainability innovation criteria from the literature.

| Category | Criteria | References |

|---|---|---|

| Traditional social sustainability innovation criteria | Utilization of effective policies taking into consideration social indicators | Govindan et al. (2016), Bai et al. (2019) |

| Proper reaction to stakeholders’ social pressures | Tariq et al. (2017), Abdel-Basset and Mohamed (2020), Ahmadi et al. (2020) | |

| Corporate social responsibility initiatives | Gupta et al. (2020) | |

| Cultural and social principles | Koberg and Longoni (2019) | |

| Improving the firm's social image | Mani et al. (2018), Mastos et al. (2020) | |

| COVID-19 related social innovation criteria | Safety and health practices as well as wellbeing of suppliers | Gostin and Wiley (2020), Govindan et al. (2020), Remko (2020) |

| Skill improvement | Sarkis et al. (2020), Gostin and Wiley (2020) | |

| Knowledge sharing | Sharma et al. (2020), Majumdar et al. (2020), Govindan et al. (2020) | |

| Diversified portfolio of suppliers | Majumdar et al. (2020), Govindan et al. (2020) | |

| Remote working conditions | Sarkis et al. (2020), Govindan et al. (2020), Gostin and Wiley (2020) | |

| Localization | Sarkis et al. (2020), Govindan et al. (2020), Gostin and Wiley (2020), Remko (2020) |

2.6. Research gap

Several studies have appeared about assessing suppliers with regards to their performance in relation to sustainability. However, papers considering the sustainability innovation performance of emerging economy suppliers are few. Very few works have investigated supplier selection with consideration of social sustainability criteria. Corporations are often confronted with serious social challenges derived from supply chain activities especially upstream supply chains or suppliers including poor substance testing by suppliers and poor health and safety conditions (Bai et al., 2019). Several authors have investigated the impact of the COVID-19 pandemic on supply chain decisions in different contexts (e.g., Govindan et al., 2020; Sarkis et al., 2020; Majumdar et al., 2020). However, few have tried to investigate the socially sustainable innovation performance of emerging economy suppliers during the COVID-19 outbreak. To fill this gap, we concentrate on the social aspect of sustainable innovation, and a method for the assessment and selection of several potential suppliers during the COVID-19 pandemic. A detailed explanation of the proposed methods and techniques employed in this paper is presented in the next section.

3. Proposed methods

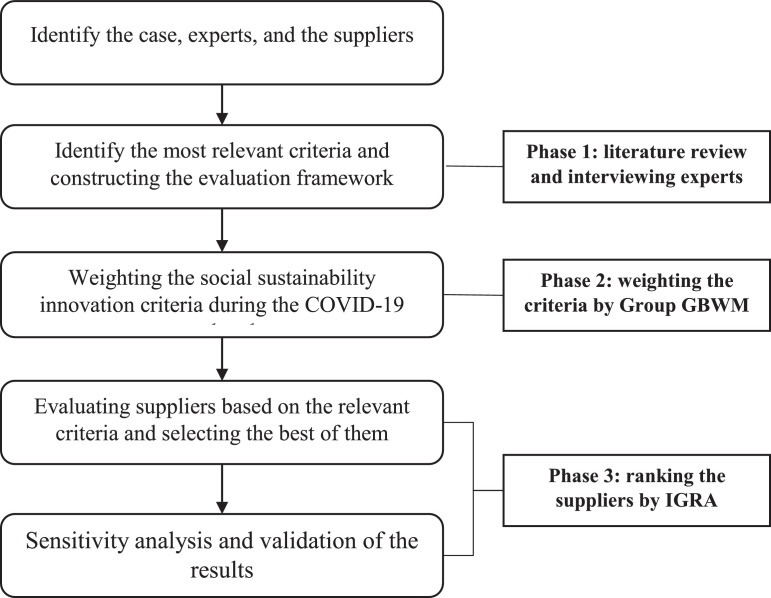

A novel three-stage methodology is proposed for socially sustainable innovative supplier evaluation and selection during the COVID-19 pandemic outbreak, as shown in Fig. 1 . First, social sustainability innovation criteria and COVID-19 related social innovation criteria were extracted from a review of the literature, and after discussion with the panel of experts and the refinement process, a social sustainable innovation framework is developed (Table 3). In the second phase, the weights of the criteria are found by using a novel group grey best-worst method (Group-GBWM). Finally, the rank of each supplier with respect to the selected criteria is obtained by using improved grey relational analysis (IGRA).

Fig. 1.

Research framework.

Table 3.

Evaluation framework for this study.

| Criteria | Operational description | Symbol |

|---|---|---|

| Safety and health practices as well as wellbeing of suppliers (SI 1) | Companies need to focus on mental health, health monitoring and the safety of their workforce and suppliers during and after the COVID-19 pandemic to diminish its impact. | B* |

| Corporate social responsibility initiatives (SI 2) | This means applying social and environmental initiatives. | W⁎⁎ |

| Improving the firm's social image (SI 3) | This means firms can enhance their social image by employing different social programs. | C1 |

| Knowledge sharing (SI 4) | Knowledge management about social distancing, personal hygiene and wearing masks in the workplace to lessen the spread of COVID-19. | C2 |

| Diversified portfolio of suppliers (SI 5) | Reducing the reliance on a limited number of suppliers during and after COVID-19 can diminish supply chains risks and threats. | C3 |

| Remote working conditions (SI 6) | This means helping employees and understanding the issues to help overcome problems with remote working during the pandemic. | C4 |

| Localization (SI 7) | Providing more employment opportunities for local people, and more reliance on the local knowledge and capacity. | C5 |

*best criterion, **worst criterion.

In practice, the input data for decision-making problems are not always certain. Accordingly, methods for considering uncertainties and vagueness have attracted scholarly and practical attention. Two of the most popular theories for considering uncertainties are grey system theory (GST) (Ju-Long, 1982) and fuzzy set theory (FST) (Zadeh, 1965). Grey theory does not use the distribution and membership function as is necessary in fuzzy set theory. According to Mi et al. (2019), several studies have developed BWM using FST and GST for uncertain conditions. Most of these studies employed FST. Only a few have utilized GST and interval numbers. This study presents a novel group GBWM which considers the uncertainties of experts’ opinions. The proposed group GBWM is an extension of the linear model of BWM proposed by Rezaei (2016) and the group BWM model developed by Safarzadeh et al. (2018).

The BWM has been combined with other methods like TOPSIS (Gupta and Barua, 2017) and VIKOR (Gupta, 2018) in several studies. However, there has been scant research integrating BWM with the improved GRA (IGRA). In this study, the IGRA proposed by Hashemi et al. (2015) is utilized to rank suppliers. Each of the three phases is discussed below.

Phase 1: Selecting the criteria

From an extensive literature review, a total of eleven social innovation criteria were identified as displayed in Table 1, and after interviewing the experts and the refinement process, the assessment framework for this study was constructed (see Table 3).

Phase 2: Weighting the criteria

3.1. Best Worst Method

Unlike AHP, the BWM only requires reference comparisons, which means that for the weighting criteria we only need to calculate two pairwise comparison vectors: (1) the preference of the most significant criterion over others; and (2) the preference of all criteria over the least significant criterion on a scale of 1 to 9. In addition, BWM improves the consistency problem by reducing the required comparisons. This method contains the following steps:

Step 1: Identify a set of criteria:

In this step, a set of n criteria are determined to evaluate alternatives.

Step 2: Determine the best and the worst criteria.

- Step 3: Identify the preferences of the most significant criterion over the other criteria, using a number between 1 and 9. The best-to-others (BO) vector can be represented as:

(1)

where represents the preference of the most significant criterion B over the other factors.

Step 4: Determine the preference of all the criteria over the worst criterion. The others-to-worst (OW) vector can be displayed as:

| (2) |

where shows the preference of criteria j over the least significant criterion W.

Step 5: Find the optimal weights

The goal is to identify the optimal weights of the criteria such that the maximum absolute difference for all j is minimized for, which can be converted into a linear programming model (Rezaei, 2016):

| (3) |

This mathematical programming model is a linear one, which has a finite optimal solution. The optimal weights are obtained by solving the model. In this linear model, is taken into consideration as an index of judgment consistency with values closer to zero displaying a higher consistency. According to Mahmoudi et al. (2020) the results of GBWM are more reliable than the ones provided by the fuzzy BWM, since the GBWM has a smaller inconsistency compared with original BWM. Before discussing the group GBWM, we briefly review the GST.

3.2. A quick review of GST

GST is a theory which aids in decision-making under conditions of uncertainty and incompleteness. Pairwise comparisons of the criteria are expressed by numerical intervals (grey numbers). In other words, the exact values of the grey numbers are not known, but the interval (lowest and highest range) covers a value assumed to be almost known (Liu et al., 2012). Generally, a grey number is written as , where and are the lower and upper limits, respectively. For grey systems, regardless of the interval of a grey number, its real value can only be one value within this range. The technique for transforming a grey number into a crisp (white) number is called whitening. Let and be two grey numbers and b a crisp number, and follow the mathematical operation:

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

| (9) |

3.3. Grey BWM

Since the traditional BWM fails to address the vagueness within subjective judgments, a novel Grey BWM is developed in this study to obtain the grey weights of the criteria. The steps of the GBWM are slightly different from that of the traditional BWM in the sense that the vectors of BO and OW are obtained by asking experts to propose a minimum and maximum limit for each pair of comparison. For instance, the interval number for pairwise comparison of one of the best-to-other judgments denotes that the relative importance of the best (the most important) criterion compared to another criterion is between the degrees of essential importance (5) and absolute importance (9). Therefore, the grey BO and OW vectors can be respectively rewritten as follows:

| (10) |

| (11) |

As discussed above, each preference is considered a grey number. Therefore, based on the linear model of BWM proposed by Rezaei (2016), we propose the following Grey BWM model:

| (12) |

where is the value of the objective function and can be considered as the inconsistency index; nearer to zero means more consistency among judgments. According to Eq. (12), each criterion we will have a grey weight which can be whitened later. The normalization constraint () includes the grey numbers and for solving the model it can be transformed into the two following constraints:

| (13) |

| (14) |

It is better to choose an a of less than 0.3 and in this study, it is set to 0.2. We must be cautious as the value of a directly influences . Therefore, after solving the model, according to the sum on the left-hand side of Eqs. (13) and (14), we need to modify the value of . In the proposed model, we considered the best and worst criteria to be the same for all decision-makers (DMs) because we found it problematic to reach a consensus on the final weights using different best and worst criteria problematic. A consensus was reached on the best and worst criteria following the of Rezaei (2015), to hold a group meeting and interviews with experts. For more information and methods for identifying the best and worst criteria please see Safarzadeh et al. (2018).

3.4. Group Grey BWM

Multiple stakeholders can contribute a variety of experiences, expertise and knowledge, and a group can better deal with uncertain situations than a single decision-maker (Grošelj et al., 2015). According to Forman and Peniwati (1998), there are two ways to aggregate independent preferences into a group decision: first, the group acts together as a whole unit and second, happens the group make a decision as a pool of individuals. The two main mathematical aggregating methods are the aggregation of individual priorities (AIP) and the aggregation of individual judgments (AIJ). For identifying the best and worst criteria, we follow the latter method and assume that the experts are acting as a coherent unit, but for weighting the criteria and evaluating suppliers, we follow the former method.

Most of the previous studies employed geometric and arithmetic means to aggregate the weights of the criteria determined by each expert. However, here, we carry out the aggregation phase in one mathematical programming model based on the novel idea proposed by Safarzadeh et al. (2018). In addition, we also found that the constraint does not assure the inequality and for some criteria this inequality desires to be an equal constraint. Therefore, the group grey BWM model, with a correction in this constraint, is reformulated as follows:

| (15) |

where the superscript k denotes the kth decision-maker, meaning that each of the first to fourth constraints should be written for every DM. It is better to set to 0.01 or even smaller, e.g., 0.001. In this study, it is set to 0.01. If the research team is interested in considering different weights for the DM judgments, model (15) can be changed as follows:

| (16) |

where represents the weight of the kth decision-maker's judgment; and stands for the consistency ratio for the kth decision-maker. In this study, we considered different weights for the DM judgment before model (16) was employed.

3.5. Improved Grey Relational Analysis

GRA is a part of the GST designed to deal with uncertainty and vagueness (Deng, 1989). This paper employs an improved version of GRA called (IGRA) which utilizes interval numbers which was first developed by Hashemi et al. (2015). Having m alternatives, here suppliers, evaluated by n factors or criteria, the matrix of the decision-making G given by the kth decision-maker is:

| (17) |

where represents the value of the jth criterion of the ith alternative judged by the kth decision-maker. The IGRA method starts with normalizing the G matrix employing the following equations:

| (18) |

| (19) |

Then, the ideal (reference) alternatives are defined by Eqs. (20) and (21):

| (20) |

| (21) |

where is the reference value related to the jth criterion; k belongs to the kth decision-maker; and the zero in the superscript is a sign of its being an ideal. Thus, the distance of each alternative to the ideal sets is computed by Eqs. (22) and (23):

| (22) |

| (23) |

Next, the grey relational coefficients for all alternatives are calculated by using Eqs. (24)–(26):

| (24) |

| (25) |

| (26) |

where is called the Grey relational coefficient; is the distinguishing factor which is usually equal to 0.5.

Afterward, a grey relational degree is calculated, as indicated in Eq. (27):

| (27) |

| (28) |

where indicates the relative weight of the jth criterion.

Finally, the lower and upper relational degrees, and the whitened one for each alternative are calculated by the following equations:

| (29) |

| (30) |

| (31) |

There is a simple rule to rank the alternatives: the larger the whitened relational degree computed by Eq. (31), the higher the rank of the alternative.

4. Case illustration

Iran is an emerging economy in southwest Asia. Social sustainable development initiatives are still immature and require much more focus, especially in the manufacturing sector (Ghadimi et al., 2017). Assessing suppliers by considering their performance in terms of the implementation of socially sustainable innovations can assist corporations to improve their social image and achieve their sustainable development targets. Corporation F, a buying company, is utilized as an example in this study to verify the applicability and efficiency of the social sustainability innovation framework and the proposed methodology. Corporation F started operations in 1990. Since then, it has manufactured a variety of tiles, with different designs and models. This corporation is one of the best tile producers in Iran and exports its products to several Asian countries.

The company decided to participate in this study to assess the innovative social sustainability performance of its suppliers. Five decision-makers including a supply chain manager, a purchasing manager, a financial manager, a general manager, and a production manager were assigned to assess the suppliers. Each manager had at least ten years of work experience and was specifically selected to partake in the assessment process. These managers are knowledgeable and professional experts in their field. There are several studies in the published literature that have employed five or fewer decision-makers. For example, Kusi-Sarpong et al. (2019) in their paper published in IJPR used only five decision-makers in their BWM analysis. In addition, Rezaei et al. (2018) made it clear that only 4-10 decision-makers are required for obtaining reliable data for MCDM analysis. Table 2 shows the details of the managers who were involved in the decision-making process from the case corporation. Several suppliers had contracts with the firm. The management of the company shortlisted seven suppliers. These seven suppliers were assessed based on their level of social sustainability innovation implementation.

Table 2.

Details of respondent managers involved in the evaluation process.

| Manager | Position | Role | Working experience (Years) |

|---|---|---|---|

| 1 | Supply Chain Manager | Managing the sourcing contract and warehouse | 15 |

| 2 | Purchasing Manager | Managing the purchasing program implementation and training | 11 |

| 3 | Financial Manager | Managing the financial budgetary of corporation | 19 |

| 4 | General Manager | Managing the daily business operations of corporation | 16 |

| 5 | Production Manager | Managing the production processes | 17 |

4.1. Application of the proposed methodology

Phase 1: Finalizing the social sustainability innovation criteria and constructing the evaluation framework for this study

After reviewing the literature, several social sustainability innovation criteria were identified (see Table 1 ). Then, a survey including these criteria was designed and sent to each of the five decision-makers (experts) for their review at different times. They were asked to vote for each criterion and identify which were more relevant to their firm's supply chains by displaying (Yes) for accepted, or (No) for rejected. Moreover, they were requested to add any other related social sustainability innovation criteria based on their experience and expertise. The research team confirmed with the decision-makers that those criteria which had been approved by at least three decision-makers would be selected for the next round of reviews. These decision-makers did not suggest any additional criteria. After round one, the results were shown to the experts and they were asked to revise their first response if they wanted. Generally, three rounds of interviews were conducted to refine the set of criteria. Finally, seven social sustainability innovation criteria were selected, and included in the final list, as indicated in Table 3 . Moreover, Table 3 also provides operational definitions of the selected criteria and the symbols used in the subsequent tables. Several studies in the published literature have applied this screening approach and employed experts input for the qualification purpose, i.e. whether a particular criterion should be selected or not for the assessment phase (see for example Kusi-Sarpong et al., 2019 and Ahmadi et al., 2017b).

Phase 2: Weighting the social sustainability innovation criteria

In this step, in a group meeting, the goals of this research, the procedure and the methods were explained, and the experts agreed upon the best and worst criteria from the final list. The experts were asked to identify the superiority of the most significant criterion over the other criteria (BO vector). Table 4 summarizes the responses of the experts as a BO vector. Data were collected from a questionnaire survey designed and sent to each of the experts to be completed. Appendix. A display a sample of the questionnaire used in this study.

Table 4.

Best to Other (BO) vector.

| Most important criteria | W | C1 | C2 | C3 | C4 | C5 | DMs |

|---|---|---|---|---|---|---|---|

| Safety and health practices | (6,8) | (3,4) | (3,5) | (4,6) | (2,3) | (3,4) | Expert1 |

| (4,6) | (4,5) | (2,4) | (1,2) | (3,4) | (3,4) | Expert2 | |

| (3,7) | (5,6) | (4,5) | (2,3) | (3,4) | (2,5) | Expert3 | |

| (7,9) | (3,5) | (2,4) | (1,1) | (2,3) | (2,3) | Expert4 | |

| (6,8) | (5,7) | (5,6) | (3,4) | (1,2) | (4,6) | Expert5 |

Table 4 shows the grey judgments of the experts regarding the superiority of the most important criteria (safety and health practices as well as wellbeing of suppliers) over other criteria extracted from the questionnaire. Similarly, the experts were asked to determine the superiority of all the criteria over the worst criterion or the least important one (OW vector). Table 5 shows the grey judgments of the experts as an OW vector.

Table 5.

Other to Worst (OW) vector.

| Criteria | Least important criteria: corporate social responsibility initiatives | ||||

|---|---|---|---|---|---|

| C1 | (1,2) | (1,3) | (1,2) | (2,3) | (3,4) |

| C2 | (2,3) | (2,3) | (1,2) | (2,4) | (1,1) |

| C3 | (4,5) | (3,4) | (4,5) | (4,6) | (3,5) |

| C4 | (3,4) | (4,5) | (3,4) | (2,4) | (3,5) |

| C5 | (5,7) | (5,6) | (4,5) | (3,4) | (4,6) |

| DMs | E1 | E2 | E3 | E4 | E5 |

In this step, the optimal weights of the criteria are computed using Eq. (16). Obviously, the model requires the weights for the experts’ opinions. According to the seniority and relevance of the experts’ experience, we considered relative weights of 0.3, 0.2, 0.2, 0.2, and 0.1 for the five experts’ opinions, respectively.

As shown in Table 6 , the sum of the whitened weights is not equal to one due to the grey nature of the normalization constraints (see Eqs. (13) and (14)). Thus, normalization is carried out in the last column of Table 6. According to Rezaei (2016) values closer to zero indicate better consistency between judgments. Based on this, the pairwise comparisons made by expert 1 seems more consistent than the others.

Table 6.

Results of group GBWM.

| Symbol | Selected criteria | Grey weight | Whitened weight | Normalized weight |

|---|---|---|---|---|

| Best | Safety and health practices | (0.298,0.349) | 0.324 | 0.373 |

| Worst | Corporate social responsibility initiatives | (0.033,0.040) | 0.036 | 0.042 |

| C1 | Improving the firm's social image | (0.078,0.095) | 0.087 | 0.100 |

| C2 | Knowledge sharing | (0.091,0.092) | 0.092 | 0.106 |

| C3 | Diversified portfolio of suppliers | (0.076,0.101) | 0.089 | 0.102 |

| C4 | Remote working conditions | (0.132,0.133) | 0.133 | 0.153 |

| C5 | Localization | (0.091,0.124) | 0.108 | 0.124 |

| Sum | (0.8,0.935) | 0.868 | 1 | |

| Consistency ratios | ||||

Phase 3: Evaluating suppliers

In this study, the linguistic terms “very good”, “good”, “medium”, “poor”, and “very poor” (see Table 7 ) are used for evaluation of the suppliers according to the selected criteria.

Table 7.

Scale of grey numbers for supplier evaluations.

| Linguistic variables | Scale of grey number |

|---|---|

| Very Poor (VP) | (1.5,3.0) |

| Poor (P) | (3.0,4.5) |

| Medium (M) | (4.5,6.0) |

| Good (G) | (6.0,7.5) |

| Very Good (VG) | (7.5,9.0) |

In this phase, the DMs were asked to evaluate the suppliers to complete the decision matrix. The results of the data analysis based on the five DMs’ judgments are expressed in Table 8 . The grey relational degrees, the whitened relational degrees and the ranking of the suppliers determined by the DMs are shown in Table 9 . According to a comparison of the integrated grey relational degrees in Table 9, the ranking of suppliers is as follows:

Table 8.

Linguistic assessment of the suppliers.

| Suppliers | Experts | Best | Worst | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|---|---|---|

| Supplier 1 | Expert1 | VP | P | G | G | M | VP | G |

| Expert2 | P | G | M | M | G | G | G | |

| Expert3 | P | VP | M | M | G | G | VG | |

| Expert4 | G | P | G | G | M | VG | M | |

| Expert5 | G | VP | G | M | M | G | G | |

| Supplier 2 | Expert1 | M | VP | G | G | G | M | M |

| Expert2 | G | G | VG | G | M | M | G | |

| Expert3 | G | G | M | M | G | VG | VG | |

| Expert4 | M | VG | M | G | G | G | G | |

| Expert5 | M | G | M | M | G | G | VG | |

| Supplier 3 | Expert1 | G | G | G | M | G | M | M |

| Expert2 | VG | G | M | M | G | M | M | |

| Expert3 | M | M | M | G | M | M | G | |

| Expert4 | M | G | VG | VG | G | VG | VG | |

| Expert5 | M | G | G | G | G | G | G | |

| Supplier 4 | Expert1 | G | G | G | M | G | G | M |

| Expert2 | G | M | M | M | G | M | M | |

| Expert3 | M | M | G | VG | M | G | VG | |

| Expert4 | G | VG | G | G | G | G | G | |

| Expert5 | G | G | G | G | G | G | G | |

| Supplier 5 | Expert1 | P | G | M | M | G | M | VP |

| Expert2 | G | M | M | M | G | G | G | |

| Expert3 | VP | M | G | G | M | G | G | |

| Expert4 | P | G | VG | VG | G | M | VG | |

| Expert5 | VP | G | G | G | G | M | G | |

| Supplier 6 | Expert1 | M | VP | G | M | M | G | M |

| Expert2 | G | G | M | M | M | G | G | |

| Expert3 | G | G | M | G | G | M | G | |

| Expert4 | M | VG | G | VG | VG | G | M | |

| Expert5 | M | G | G | G | G | G | M | |

| Supplier 7 | Expert1 | M | M | VP | M | M | G | M |

| Expert2 | G | G | G | M | M | G | G | |

| Expert3 | G | G | G | G | G | M | G | |

| Expert4 | M | M | VG | VG | VG | G | M | |

| Expert5 | M | M | G | G | G | G | M |

Table 9.

Results of IGRA and ranking of suppliers.

| Suppliers | ranks | |||||||

|---|---|---|---|---|---|---|---|---|

| Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | ||||

| S1 | (0.517,0.560) | (0.655,0,683) | (0.766,0.796) | (0.834,0.850) | (0.775,0.805) | (0.700,0.731) | 0.715 | 3 |

| S2 | (0.610,0.651) | (0.493,0.530) | (0.871,0.883) | (0.579,0.619) | (0.692,0.731) | (0.637,0.673) | 0.655 | 7 |

| S3 | (0.624,0.663) | (0.517,0.550) | (0.767,0.792) | (0.726,0.754) | (0.617,0.658) | (0.644,0.678) | 0.661 | 6 |

| S4 | (0.842,0.859) | (0.487,0.527) | (0.796,0.823) | (0.575,0.616) | (0.849,0.864) | (0.693,0.723) | 0.708 | 4 |

| S5 | (0.767,0.795) | (0.657,0.679) | (0.923,0.932) | (0.629,0.670) | (0.825,0.846) | (0.752,0.778) | 0.765 | 1 |

| S6 | (0.657,0.695) | (0.383,0.427) | (0.909,0.920) | (0.810,0.829) | (0.788,0.815) | (0.681,0.713) | 0.697 | 5 |

| S7 | (0.843,0.860) | (0.730,0.748) | (0.546,0.591) | (0.807,0.829) | (0.685,0.725) | (0.714,0.744) | 0.729 | 2 |

Supplier 5 > Supplier 7 > Supplier 1>Supplier 4 > Supplier 6 > Supplier 3 > Supplier 2

Therefore, supplier 5 is determined as the best supplier based on the socially sustainable innovation criteria during the COVID-19 outbreak.

5. Sensitivity analysis

For validation of the proposed approach a two-phase sensitivity analysis is conducted. In phase one, sensitivity of weights to the pairwise comparisons judgments were checked. To this end, different lower and upper limits of grey judgments for Table 4 and 5 were considered and their effects on the final weights were investigated. It has been observed that the final weights of the criteria changed with the changing of the pairwise comparisons judgments. We have also considered two different sets of best and worst criteria and ran the calculations with the experimental data. In phase two, a sensitivity analysis was conducted on the decision parameters to study how the order of the suppliers would change given different scenarios. We investigated the effects of the set of included criteria in the decision-making process on the final results. Two scenarios were explored as shown in Table 10 . In the first scenario, the proposed model was run considering only the conventional sustainability innovation criteria and in the second scenario the model was run using only the COVID-19 related criteria. In the former case, supplier 5 was selected as the best performer while in the latter supplier 1 was determined to be the top supplier. This could be because some suppliers performed better during COVID-19 than others, while also demonstrating a satisfying performance in terms of the social sustainability innovation criteria. It is clear from Table 10 that the order of the rankings changes according to different sets of criteria considered. These results were discussed with the experts and they collectively confirmed this conclusion and told us that the output of the proposed model makes sense.

Table 10.

Different scenarios for sensitivity analysis.

| Scenario | Expert(s) | Criteria | Suppliers ranking |

|---|---|---|---|

| Initial | E1(0.3), E2(0.2), E3(0.2), E4(0.2), and E5(0.1) | All | S5>S7>S1>S4>S6>S3>S2 |

| Scenario 1 | E1(0.3), E2(0.2), E3(0.2), E4(0.2), and E5(0.1) | Only conventional social sustainability innovation criteria | S5>S7>S4>S6>S1>S2>S3 |

| Scenario 2 | E1(0.3), E2(0.2), E3(0.2), E4(0.2), and E5(0.1) | Only COVID-19 related criteria | S1>S7>S3>S2>S4>S6>S5 |

6. Discussion

The performance of firm's supply chain is considerably enhanced through the implementation of SSCM. Applying SSCM initiatives and programs minimizes the negative impacts of social, environmental, and economic supply chain operations and can also be taken into consideration as a key element for achieving a competitive advantage. In this context, supplier assessment can be considered a key element for promoting sustainable development in a society. Due to the existence of a variety of social issues in supply chain activities, managing and maintaining profitability has become a challenge for the organizations employing sustainable operations. Unfortunately, this situation has become much worse during the COVID-19 outbreak. Selecting suppliers that are socially sustainable innovative is an effective means of assisting firms to overcome these problems, allowing them to better ensure sustainability in their daily operations and attain their sustainability targets.

This paper constructs a social sustainability innovation framework for assessing socially innovative suppliers for an Iranian company during COVID-19 using novel Group-GBWM-IGRA technique. Our findings show several unique results for this corporation. The results show that safety and health practices, with a weight of 0.373, has the highest weight and is the most significant for the case corporation. Any supply chain, sustainable or not, should invest in the safety and health in operations as well as suppliers. In response to the COVID-19 disaster, companies across the globe should invest more in mental health initiatives for employees, conduct regular health and safety monitoring programs, to try to minimize negative impact of the pandemic. Various studies support this finding and emphasize the significance of this factor in maintaining social sustainability innovation (Kusi-Sarpong et al., 2019). Employing sustainable innovation factors such as safety and health practices benefit firms in several ways (outcome), by enhancing their social image, increasing profits, and diminishing organizational costs. During the COVID-19 pandemic, companies are facing pressing issues associated with social sustainability. Within this critical situation, the safety and health practices of employees and supply chain operations are of primary concern and have the highest priority (Sharma et al., 2020; Gostin and Wiley, 2020).

The second most important criterion is remote working conditions, with a weight of 0.153. Due to the COVID-19 outbreak, many firms across the globe have stopped their normal operations and have lessened their workforce. Many have lost their job and are experiencing difficult times. Furthermore, many employees have to work remotely. The authorities and those who manage this situation should help employees to overcome the problems related to remote working conditions (Govindan et al., 2020). Localization ranked third, with a weight of 0.124. Because of the negative impact of the COVID-19 pandemic, companies have needed to shift towards localization, instead of globalization. Providing more employment opportunities for local people, and placing more reliance on local knowledge and capacity, can be a positive response to the need to build local resilience during the COVID-19 disaster (Sarkis et al., 2020).

In addition, the findings of this paper are at odds with some of the previous articles on sustainability innovation. For example, Ahmadi et al. (2020) found that “improving the firm's social image” which was ranked sixth in our article, was ranked first in that article. Although that article took a broader perspective on sustainability innovation, their result is not surprising, since corporations need to enhance their social image and manufacture sustainable products, if they aim to achieve sustainable development. In addition, Ahmadi et al. (2020) also found that “safety and health practices” was ranked fifth amongst social sustainability innovation criteria in their paper, but it was ranked highest in our article. In light of lack of existing empirical studies to support the findings of this paper, and the fact that research on social sustainability innovation is still in early stages, it may not be surprising to find conflicting results at this stage.

Supply risk is one of the main dangers to the supply chain during COVID-19 which demands more attention and innovative initiatives. According to the results of this study, supply chain managers are recommended to make a short list of the potential suppliers which are more in line with their policies of social sustainability innovation. To prepare this list and to select the top suppliers, supply chain managers need to pay attention to the criteria proposed in this study. According to Remko (2020), there are at least two types of strategies for decreasing supply risks during COVID-19: (1) diversifying suppliers and reducing the reliance on a limited number of suppliers; and (2) making efforts to collaborate with more local and nearer suppliers. We believe that supply chain managers need to develop health and safety plans throughout the supply chain and to make sure that every partner in the chain is protecting its employees. This study proposes a novel methodology by integrating grey system theory. The method is divided into two sequential steps for supplier selection, i.e., weighting the criteria and ranking suppliers, by employing group GBWM and IGRA. It is believed that the proposed methodology has several advantages and can aid supply chain managers to consider socially sustainable innovation criteria with respect to the uncertain conditions of the COVID-19 outbreak in their supplier selection process.

7. Conclusion

Assessing and selecting suppliers plays a vital role in creating efficient sustainable innovative supply chains. Employing sustainability innovation factors in supplier evaluation problems significantly helps firms to be more innovative and contributes to achieving their long-term sustainable development targets. This is the first study to present an assessment framework comprised of social innovation factors for evaluating and ranking suppliers according to their social innovativeness during the COVID-19 outbreak using a novel methodology, which identifies the novelty of this paper. Society, including sustainable supply chains has been severely affected by the most disruptive disaster of the century, the COVID-19 pandemic. We thus considered several social innovation factors related to the COVID-19 pandemic in the assessment framework of this research. Assessment of suppliers can be addressed by MCDM techniques. Several MCDM techniques like AHP, ANP, VIKOR and TOPSIS can be utilized for dealing with these kinds of problems. Each has its own characteristics, limitations, and merits. In this work, after reviewing several methods, we introduced the novel and integrated group grey- best worst method and improved grey relational analysis (group GBWM-IGRA) to help assess seven socially sustainable innovative suppliers, using inputs from five of their corporate managers. The proposed assessment framework for evaluating suppliers from perspective of social sustainability innovation during COVID-19 circumstances and the used novel method highlight the academic contribution of this research. As part of the academic contribution, the results have significant implications for social sustainability innovation theory. The outcomes contribute to developing efficient strategies and innovative solutions for achieving social sustainability innovation in emerging economies, considering the situation of COVID-19 disaster. Now industrial managers in emerging economies can better understand and focus on the social aspect of sustainable innovation, and make better decisions, particularly when assessing their suppliers during COVID-19 disaster, which determines the practical contribution of this paper. Also, managers can particularly focus on the most important criteria obtained in this article with the target of minimizing the negative impact of COVID-19 on their supply chains. They can also move their industry towards sustainable development, which determines the implications of the study for practice. Moreover, by applying the framework, the criteria “safety, and health practices”, “remote working conditions”, and “localization” have the highest weight among social sustainability innovation criteria and need special attention and investment for achieving social sustainability innovation.

This study still suffers from several limitations, creating possibilities for further research on this topic. The first limitation is that few managers from one Iranian manufacturing company participated in the assessment. Findings of this study cannot be easily generalized to other industries and countries. Future studies may employ our framework and test other manufacturing companies in other emerging economies and rank their suppliers based on social sustainability innovation performance taking into consideration the COVID-19 disaster. Even, we expect to see a different social sustainability innovation framework in other studies. Indeed, another limitation is that the evaluation framework used contains only seven social sustainability innovation criteria. We suggest possible future works try to include more criteria in the evaluation framework and employ several sub-criteria related to each criterion which can lead to more customized and comprehensive analysis. There exist more opportunities to employ different sustainability assessment frameworks like total life cycle costing (TLCC) (Finkbeiner et al., 2010) to assess the impacts of COVID-19 on supply chain sustainability. We utilized a group grey-BWM for computing the factor weights, and IGRA for ranking the suppliers. We recommend future studies integrate fuzzy, Z, or rough numbers with BWM for handling ambiguity, and employ other methods like TOPSIS for ranking suppliers and compare their results with ours. Moreover, we suggest future authors try to extend this papers’ investigation to include order allocation among top ranked suppliers. This study only focused on the social aspect of sustainable innovation during the COVID-19 outbreak. We suggest future works extend this investigation and focus on other sustainable innovation aspects during COVID-19 and discuss the findings. Several studies attempted to redefine and re-conceptualize the sustainability in supply chains triggered by the COVID-19 like (Hakovirta and Denuwara, 2020; Sarkis, 2020), but we still need further research to develop and enrich the concept of sustainability based on the learnings and experiences of businesses during it. Businesses and supply chains have employed different policies to combat the pandemic and one interesting topic would be to explore the relationships between these resiliency policies (triggered by COVID-19) and supply chains sustainability. For instance, “localization” which was selected in this study as one of the social innovation criteria, was also mentioned in (Sarkis, 2020) as a policy towards a more resilient and sustainable supply chain. Future studies shall shed light on those practices which contribute to both resilience against pandemic disasters and sustainability. In another words, an interesting topic would be to explore the differences between sourcing and partners (here suppliers) selection problem before and after the COVID-19 with regard to sustainability and resilience.

Ethical approval

This article does not contain any studies with human or animals performed by any of the authors.

CRediT authorship contribution statement

Seyed Hamid Hashemi Petrudi: Conceptualization, Formal analysis, Methodology, Visualization, Writing - original draft. Hadi Badri Ahmadi: Conceptualization, Investigation, Writing - original draft. Abdul Rehman: Writing - review & editing. James J H Liou: Writing - review & editing.

Declaration of Competing Interest

All authors declare that they have no conflict of interests.

Editor: Dr. Paula De Camargo Fiorini

Appendix A. Questionnaire

Dear Respondent:

This questionnaire has been designed to determine the relative importance (weight) of criteria, for ranking the suppliers from the perspective of social sustainability innovation during the COVID-19 disaster.

Section 1: Weighing the Criteria

Questionnaire Completion Guide: To weight the social sustainability innovation criteria, it is necessary to measure the preference of the most important criterion over other criteria, and the preference of all criteria over the least important criterion. First, determine which is the most important and least important criterion in your opinion. When you have written the most important criterion in the table below, then you need to determine how much more important this criterion (the most important criterion) is than the other criteria. In comparison, you need to consider the relationship of the row to the column, using numbers from 1 (equal preference) to 9 (much more important) to compare the pair of criteria. For example, using the number 3 means that criterion 3 is more important than the corresponding column criterion. The same is true for the second table. You must first identify the least important criterion and then specify how much less important it is than the other criteria (the least important criterion).

Note that there are lower and upper limits in the two tables below. That is, you need to specify the minimum and maximum superiority between standard pairs in pairwise comparisons. For example, if the most important criterion for you is "Remote working conditions", you can specify that the most important criterion in Table 1 is, in your opinion, at least 5 and at most 7 times more important than the criterion of "Localization".

| Least important criteria (Corporate social responsibility initiatives) | Upper Limit | Lower Limit |

|---|---|---|

| Safety and health practices | ||

| Corporate social responsibility initiatives | ||

| Improving the firm's social image | ||

| Knowledge sharing | ||

| Diversified portfolio of suppliers | ||

| Remote working conditions | ||

| Localization |

|

Most important criteria |

||||||||

|---|---|---|---|---|---|---|---|---|

| Safety and health practices | Corporate social responsibility initiatives | Improving the firm's social image | Knowledge sharing | Diversified portfolio of suppliers | Remote working conditions | Localization | ||

| Safety and health practices | Lower Limit | |||||||

| Upper Limit | ||||||||

Section 2: Suppliers Rating

Please consider a specific product X and rate its suppliers based on the afore-mentioned social sustainable innovation criteria, using the range from very poor, poor, medium, good to very good.

| Suppliers | Safety and health practices | Corporate social responsibility initiatives | Improving the firm's social image | Knowledge sharing | Diversified portfolio of suppliers | Remote working conditions | Localization |

|---|---|---|---|---|---|---|---|

| Supplier 1 | |||||||

| Supplier 2 | |||||||

| Supplier 3 | |||||||

| Supplier 4 | |||||||

| Supplier 5 | |||||||

| Supplier 6 | |||||||

| Supplier 7 |

References

- Abdel-Basset M., Mohamed R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. J. Cleaner Prod. 2020;247 [Google Scholar]

- Aboutorab H., Saberi M., Asadabadi M.R., Hussain O., Chang E. ZBWM: The Z-number extension of Best Worst Method and its application for supplier development. Expert Syst. Appl. 2018;107:115–125. [Google Scholar]

- Ahmad W.N.K.W., Rezaei J., Sadaghiani S., Tavasszy L.A. Evaluation of the external forces affecting the sustainability of oil and gas supply chain using Best Worst Method. J. Cleaner Prod. 2017;153:242–252. [Google Scholar]

- Ahmadi H.B., Lo H.W., Gupta H., Kusi-Sarpong S., Liou J.J. An integrated model for selecting suppliers on the basis of sustainability innovation. J. Cleaner Prod. 2020;277 [Google Scholar]

- Ahmadi H.B., Petrudi S.H.H., Wang X. Integrating sustainability into supplier selection with analytical hierarchy process and improved grey relational analysis: a case of telecom industry. Int. J. Adv. Manuf. Technol. 2017;90(9-12):2413–2427. [Google Scholar]

- Ahmadi H.B., Kusi-Sarpong S., Rezaei J. Assessing the social sustainability of supply chains using Best Worst Method. Resour. Conserv. Recycl. 2017;126:99–106. [Google Scholar]

- Avelino F., Wittmayer J.M., Pel B., Weaver P., Dumitru A., Haxeltine A., Kemp R., Jørgensen M.S., Bauler T., Ruijsink S., O'Riordan T. Transformative social innovation and (dis) empowerment. Technol. Forecast. Soc. Change. 2019;145:195–206. [Google Scholar]

- Azadnia A.H., Saman M.Z.M., Wong K.Y. Sustainable supplier selection and order lot-sizing: an integrated multi-objective decision-making process. Int. J. Prod. Res. 2015;53(2):383–408. [Google Scholar]

- Bai C., Kusi-Sarpong S., Badri Ahmadi H., Sarkis J. Social sustainable supplier evaluation and selection: a group decision-support approach. Int. J. Prod. Res. 2019;57(22):7046–7067. [Google Scholar]

- Boons F., Lüdeke-Freund F. Business models for sustainable innovation: state-of-the-art and steps towards a research agenda. J. Cleaner Prod. 2013;45:9–19. [Google Scholar]

- Ceballos B., Pelta D.A., Lamata M.T. Rank reversal and the VIKOR method: an empirical evaluation. Int. J. Inf. Technol. Decis. Making. 2018;17(02):513–525. [Google Scholar]

- de Vargas Mores G., Finocchio C.P.S., Barichello R., Pedrozo E.A. Sustainability and innovation in the Brazilian supply chain of green plastic. J. Cleaner Prod. 2018;177:12–18. [Google Scholar]

- del Río P., Peñasco C., Romero-Jordán D. What drives eco-innovators? A critical review of the empirical literature based on econometric methods. J. Cleaner Prod. 2016;112:2158–2170. [Google Scholar]

- Dyer J.S. Remarks on the analytic hierarchy process. Manag. Sci. 1990;36(3):249–258. [Google Scholar]

- Ecer F., Pamucar D. Sustainable supplier selection: a novel integrated fuzzy best worst method (F-BWM) and fuzzy CoCoSo with Bonferroni (CoCoSo'B) multi-criteria model. J. Cleaner Prod. 2020;266 [Google Scholar]

- Finkbeiner M., Schau E.M., Lehmann A., Traverso M. Towards life cycle sustainability assessment. Sustainability. 2010;2(10):3309–3322. [Google Scholar]

- Forman E., Peniwati K. Aggregating individual judgments and priorities with the analytic hierarchy process. Eur. J Oper. Res. 1998;108(1):165–169. [Google Scholar]

- Fu X., Zhu Q., Sarkis J. Evaluating green supplier development programs at a telecommunications systems provider. Int. J. Prod. Econ. 2012;140(1):357–367. [Google Scholar]

- García-Cascales M.S., Lamata M.T. On rank reversal and TOPSIS method. Math. Comput. Modell. 2012;56(5-6):123–132. [Google Scholar]

- Ghadimi P., Dargi A., Heavey C. Making sustainable sourcing decisions: practical evidence from the automotive Industry. Int. J. Logist. Res. Appl. 2017;20(4):297–321. [Google Scholar]

- Gostin L.O., Wiley L.F. Governmental public health powers during the COVID-19 pandemic: stay-at-home orders, business closures, and travel restrictions. JAMA. 2020;323(21):2137–2138. doi: 10.1001/jama.2020.5460. [DOI] [PubMed] [Google Scholar]

- Govindan K., Muduli K., Devika K., Barve A. Investigation of the influential strength of factors on adoption of green supply chain management practices: an Indian mining scenario. Resour. Conserv. Recycl. 2016;107:185–194. [Google Scholar]

- Govindan K., Mina H., Alavi B. A decision support system for demand management in healthcare supply chains considering the epidemic outbreaks: a case study of coronavirus disease 2019 (COVID-19) Transp. Res. Part E. 2020;138 doi: 10.1016/j.tre.2020.101967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Grošelj P., Stirn L.Z., Ayrilmis N., Kuzman M.K. Comparison of some aggregation techniques using group analytic hierarchy process. Expert Syst. Appl. 2015;42(4):2198–2204. [Google Scholar]

- Gupta H., Barua M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Cleaner Prod. 2017;152:242–258. [Google Scholar]

- Gupta H. Evaluating service quality of airline industry using hybrid best worst method and VIKOR. J. Air Transport Manag. 2018;68:35–47. [Google Scholar]

- Gupta H., Kusi-Sarpong S., Rezaei J. Barriers and overcoming strategies to supply chain sustainability innovation. Resour. Conserv. Recycl. 2020;161 [Google Scholar]

- Hafezalkotob A., Hafezalkotob A., Liao H., Herrera F. Interval MULTIMOORA method integrating interval Borda rule and interval best–worst-method-based weighting model: case study on hybrid vehicle engine selection. IEEE Trans. Cybern. 2020;50(3):1157–1169. doi: 10.1109/TCYB.2018.2889730. [DOI] [PubMed] [Google Scholar]

- Hakovirta M., Denuwara N. How COVID-19 redefines the concept of sustainability. Sustainability. 2020;12(9):3727. [Google Scholar]

- Hall J., Vredenburg H. The challenge of innovating for sustainable development. MIT Sloan Manag. Rev. 2003;45(1):61. [Google Scholar]

- Harrisson D., Chaari N., Comeau-Vallée M. Intersectoral alliance and social innovation: when corporations meet civil society. Ann. Pub. Cooperat. Econ. 2012;83(1):1–24. [Google Scholar]

- Hashemi S.H., Karimi A., Tavana M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015;159:178–191. [Google Scholar]

- Holder R. Some comments on the analytic hierarchy process. J. Oper. Res. Soc. 1990;41(11):1073–1076. [Google Scholar]

- Howaldt J., Kopp R. Challenge social innovation. Springer; Berlin, Heidelberg: 2012. Shaping social innovation by social research; pp. 43–55. [Google Scholar]

- Jones J., de Zubielqui G.C. Doing well by doing good: A study of university-industry interactions, innovationess and firm performance in sustainability-oriented Australian SMEs. Technol. Forecast. Soc. Change. 2017;123:262–270. [Google Scholar]

- Karmaker C.L., Ahmed T., Ahmed S., Ali S.M., Moktadir M.A., Kabir G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: exploring drivers using an integrated model. Sustain. Prod. Consum. 2021;26:411–427. doi: 10.1016/j.spc.2020.09.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kemp R. Technology and Environmental Policy—Innovation effects of past policies and suggestions for improvement. Innovat. Environ. 2000;1:35–61. [Google Scholar]

- Koberg E., Longoni A. A systematic review of sustainable supply chain management in global supply chains. J. Cleaner Prod. 2019;207:1084–1098. [Google Scholar]

- Kumar A., Luthra S., Mangla S.K., Kazançoğlu Y. COVID-19 impact on sustainable production and operations management. Sustain. Oper. Comput. 2020;1:1–7. [Google Scholar]

- Kusi-Sarpong S., Gupta H., Sarkis J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2019;57(7):1990–2008. [Google Scholar]

- Li G.-D., Yamaguchi D., Nagai M. A grey-based decision-making approach to the supplier selection problem. Math. Comput. Modell. 2007;46(3):573–581. [Google Scholar]

- Liu S., Fang Z., Yang Y., Forrest J. General grey numbers and their operations. Grey Syst. 2012 [Google Scholar]

- Long D. Control problems of grey systems. Syst. Control Lett. 1982;1(5):288–294. [Google Scholar]

- Mahmoudi A., Mi X., Liao H., Feylizadeh M.R., Turskis Z. Grey Best-Worst Method for Multiple Experts Multiple Criteria Decision Making Under Uncertainty. Informatica. 2020;31(2):331–357. [Google Scholar]

- Majumdar A., Shaw M., Sinha S.K. COVID-19 debunks the myth of socially sustainable supply chain: a case of the clothing industry in South Asian countries. Sustain. Product. Consumpt. 2020;24:150–155. doi: 10.1016/j.spc.2020.07.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Malek J., Desai T.N. Prioritization of sustainable manufacturing barriers using Best Worst Method. J. Cleaner Prod. 2019;226:589–600. [Google Scholar]

- Mani V., Gunasekaran A., Delgado C. Enhancing supply chain performance through supplier social sustainability: an emerging economy perspective. Int. J. Prod. Econ. 2018;195:259–272. [Google Scholar]

- Mastos T.D., Nizamis A., Vafeiadis T., Alexopoulos N., Ntinas C., Gkortzis D., Papadopoulos A., Ioannidis D., Tzovaras D. Industry 4.0 sustainable supply chains: An application of an IoT enabled scrap metal management solution. J. Cleaner Prod. 2020;269 [Google Scholar]

- McKelvey M., Zaring O. Co-delivery of social innovations: exploring the university's role in academic engagement with society. Industr. Innovation. 2018;25(6):594–611. [Google Scholar]

- Mi X., Tang M., Liao H., Shen W., Lev B. The state-of-the-art survey on integrations and applications of the best worst method in decision making: Why, what, what for and what's next? Omega. 2019;87:205–225. [Google Scholar]

- Moktadir M.A., Ali S.M., Rajesh R., Paul S.K. Modeling the interrelationships among barriers to sustainable supply chain management in leather industry. J. Cleaner Prod. 2018;181:631–651. [Google Scholar]

- Moulaert F.ed. Edward Elgar Publishing; 2013. The international handbook on social innovation: collective action, social learning and transdisciplinary research. [Google Scholar]

- Neutzling D.M., Land A., Seuring S., do Nascimento L.F.M. Linking sustainability-oriented innovation to supply chain relationship integration. J. Cleaner Prod. 2018;172:3448–3458. [Google Scholar]

- Ozdemir S., Kandemir D., Eng T.Y. The role of horizontal and vertical new product alliances in responsive and proactive market orientations and performance of industrial manufacturing firms. Industr. Market. Manag. 2017;64:25–35. [Google Scholar]

- Pol E., Ville S. Social innovation: Buzz word or enduring term? J. Socio-economics. 2009;38(6):878–885. [Google Scholar]

- Ramani S.V., SadreGhazi S., Gupta S. Catalysing innovation for social impact: the role of social enterprises in the Indian sanitation sector. Technol. Forecasting Soc. Change. 2017;121:216–227. [Google Scholar]

- Remko V.H. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 2020;40(4) [Google Scholar]

- Rezaei J. Best-worst multi-criteria decision-making method. Omega. 2015;53:49–57. [Google Scholar]

- Rezaei J. Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega. 2016;64:126–130. [Google Scholar]

- Rezaei J., Kothadiya O., Tavasszy L., Kroesen M. Quality assessment of airline baggage handling systems using SERVQUAL and BWM. Tourism Manag. 2018;66:85–93. [Google Scholar]

- Saaty T.L. McGraw-Hill; New York (1980): 1980. The Analytic Hierarchy Process. [Google Scholar]

- Safarzadeh S., Khansefid S., Rasti-Barzoki M. A group multi-criteria decision-making based on best-worst method. Comput. Ind. Eng. 2018;126:111–121. [Google Scholar]

- Sarkis J., Cohen M.J., Dewick P., Schröder P. A brave new world: lessons from the COVID-19 pandemic for transitioning to sustainable supply and production. Resour. Conserv. Recycling. 2020;159 doi: 10.1016/j.resconrec.2020.104894. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sarkis J. Supply chain sustainability: learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020;41(1) [Google Scholar]

- Seuring, S., Sarkis, J., Müller, M., Rao, P., 2008. Journal of Cleaner Production, Sustainability and supply chain management–an introduction to the special issue. volume 16, issue 15, 1545-1551.

- Sharma A., Adhikary A., Borah S.B. COVID-19 ’s impact on supply chain decisions: strategic insights for NASDAQ 100 firms using twitter data. J. Bus. Res. 2020;117:443–449. doi: 10.1016/j.jbusres.2020.05.035. [DOI] [PMC free article] [PubMed] [Google Scholar]