Abstract

Despite the significant fluctuations in global trend due to the rising trade friction and the COVID19 pandemic, the container terminals are continuously working in three technology areas including automation, electrification and digitalization. This study reviewed recent technology trends as well as relevant research topics related to the container terminals, and investigated how the trends and topics would facilitate the terminals to achieve their strategic objectives. We also studied the trends in the container terminal industry before and after the pandemic outbreak. Recent progress shows that generally the long-term plans remain unchanged while there are some changes in timeline and priorities. The findings suggest that despite the common interest in long-term plans, gaps are still identified between academia and industry interests. Future directions are discussed for these technology areas, particularly in the context of the post-pandemic world, where the limited resources should be invested to the most urgent areas.

Keywords: Container terminal, Emerging technology, Management research, Port digitalization, Port electrification, Port automation

1. Introduction

Since being introduced, container and containerization have profoundly changed and dominated the general cargo transport in the maritime shipping industry. Container ports and terminals, as a result, play a critical role in the nowadays global economy and international freight trade, handling over 80% of global trade by volume and more than 70% by value (UNCTAD, 2017). The global containerized cargo volume increased from 225 million twenty-foot equivalent unit (TEU) in 2000 to 796 million TEU in 2019. The boost of transport volume has placed rising requirements on the container handling and turnaround time in terminals.

In recent years, together with the constant pursuit of handling efficiency, container ports and terminals are having multiple objectives as a centerpiece of regional development and a vital part in the transport value chain. First, with the increasing environmental awareness, many terminal stakeholders treat sustainability as essential in their business because the air emissions from ports could severely affect the public well-being in nearby residences. Second, the growing cargo volume with lacking of skilled manpower has greatly stimulated the container terminal industry seeking digitalized and automated solutions, which are expected to operate 24 h a day and 7 days a week, to achieve higher throughput. Third, disruptive technologies, such as Internet of Things (IoT), Artificial Intelligence (AI), 5G network and blockchain, have raised both opportunities and challenges to the container terminal industry. Nowadays, rapid advancements are seen in emerging technologies, many of which have significantly improved container port and terminal efficiency.

The COVID-19 pandemic disrupted the maritime transport less severely than expected and the transport volume has rebounded since the end of 2020 (UNCTAD, 2021; Xu et al., 2021c). For container shipping, the shipping lines have benefited hugely from the escalated freight fares (Cullinane and Haralambides, 2021; Wang et al., 2021b). While for container terminals, they can hardly operate at full capacity due to the series of lockdowns and restrictions, and need to remedy the subsequent congestion on both land and sea sides (Menhat et al., 2021; Notteboom et al., 2021; Xu et al., 2021d). Such situation obviously urges transitions from human operation to a higher automation level. Admittedly, the pandemic also struck the business model and market expectation of container operation business, and caused many terminal investment plans being ceased or on hold. Therefore, whether the pandemic would accelerate or slow down the ongoing development in container terminals is worth further investigation.

As attention from the industry has increased, there is a growing body of literature that reviews the operational development in container terminals (see Steenken et al., 2004; Gharehgozli et al., 2016). The most recent summary on terminal planning can be found in the handbook by Bose (2020). The book covers topics on instruments, technologies, environment and the management of sea-side, quay-side, yard-side and land-side using methodologies of simulation, quantitative modelling, optimization, etc. Latest literature review on quay-side and yard-side operations and their integration are shown in Carlo et al. (2015) and Kizilay and Eliiyi (2020). Such popularity of literature review indicates the management research in this area, i.e., how to improve operational efficiency in the terminals, still attracts much attention.

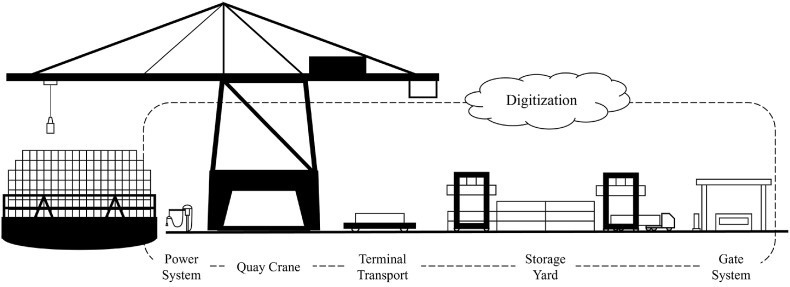

Nevertheless, this study is not aiming to conduct a comprehensive literature review on container terminal operations, but contributing to the body of literature by (1) providing management insights for port and shipping stakeholders by investigating how emerging technologies would facilitate container terminals’ strategic objectives, (2) identifying the gaps for academia between these industrial trends and current research perspectives and (3) shedding some light on how the COVID-19 pandemic impacts on these trends. We categorized the emerging technologies into six key links in a container terminal (see Fig. 1 ): quay and yard cranes, terminal transport, storage yard, gate system, power system and terminal digitization. Under each link, by presenting a summary of the industrial development and a brief review of the academic literature, the gaps between industrial trends and academia interests are obviously identified.

Fig. 1.

Schematic container port terminal layout and six key links.

The remainder of this study is organized as follows: In Section 2, we present and discuss three major emerging technology areas, i.e., automation, electrification and digitalization, and how the changes happening in the six key container terminal links are realized in these areas. In Section 3, we identify the emerging technologies in the six key container links and review current research trends in management domain. In Section 4, we discuss these emerging trends in before and post COVID-19 contexts. Section 5 is the conclusion part, in which we also point out venues for future research.

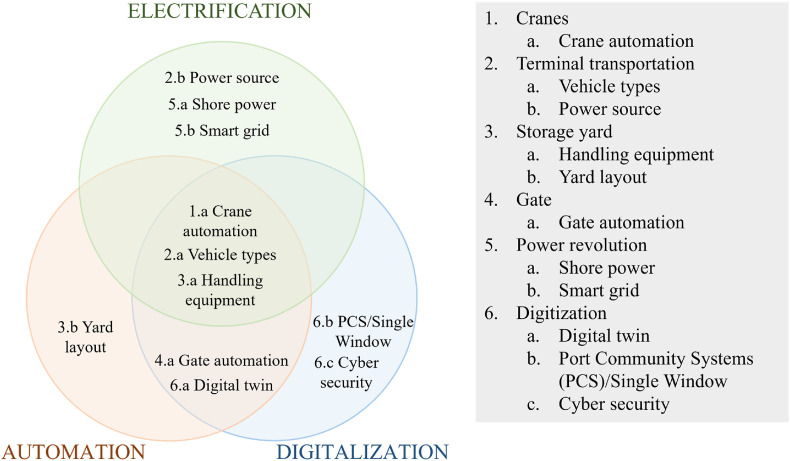

2. Technology areas

In the era of smart technology, the transportation sector is increasingly emphasizing automation, electrification and digitalization. These emerging technologies are interrelated to each other and jointly contributing to stakeholders' both financial and non-financial objectives. Container terminal automation and digitalization are closer to each other. They are critical in improving terminal efficiency and productivity and coping with challenges from growing vessel size and increasing time in port (Senarak and Mokkhavas, 2022). While automation targets to replace manual labour with automated processes (ITF, 2019), digitalization is introducing new features in current business model and helping container terminals to be future-proof. Electrification is more frequently related to container terminals’ sustainability objectives of reducing their emissions. Electric devices and vehicles are normally capable to work in digitized environment, supporting digitalization and automation applications. Emerging technology application domains in container terminal operation are categorized into these three areas (Fig. 2 ).

Fig. 2.

Container port terminal technology areas and applications domains.

2.1. Automation

As the most important interface between sea and land logistics, container terminal automation has been a very popular topic over the past decades, and it is widely adapted in key links in the terminal. This article studies the automation technologies applied to the cranes, terminal transport and the gates. Digitization technologies are also included as they facilitate automation (the difference between “digitization” and “digitalization” would be explained in the following subsection).

In digitalized and automated container terminals, Terminal Operating System (TOS) is the “brain” which coordinate all equipment and tasks crossing the whole terminal. The TOS covers the decision-making at three levels: terminal operation level, equipment control level and individual equipment level. Terminal level usually makes short-term planning decisions, for example, how vessels are moored and handled, how many quay cranes (QCs) are assigned to each vessel, where the containers are stored, how cargoes are transported between land and sea, and it also communicates with external parties such as shipping liners, truck companies, etc. Equipment control level composes of multiple sub-systems for the management of gate, QC, yard crane (YC) and vehicle. Once receiving the orders from terminal level, specific sub-system will give specific instructions to target equipment. Equipment, like an individual vehicle, will execute a given task and update the status to upper level systems at the same time. A market review of software applications can be found by Buhl and Jahn (2016).

2.2. Electrification

The power source in the terminals is evolving for an improved environmental footprint. As diesel is the primary source to power the equipment such as cranes and vehicles, and the ships also rely on auxiliary diesel engines for power when mooring at berth, the emission issue is severe in many container terminals. The power of the crane is dependent on the terminal's energy supply, which could be either driven by its own engine or supported by the shore power system. Together with the electrification of terminal vehicles in terminal transportation and storage yard, the developments in the terminal's power revolution and digitization also improve the electrification process.

The adoption of electrical power and renewable energy in terminals is of ever-increasing importance for the environment and sustainability. Electrical terminals comprise a large number of electric loads including cranes and vehicles, shore power and refrigerated containers etc. A robust electrical grid will impact many aspects such as economics, activities, dangerous emissions, and reliability of services. Therefore, electrification is an essential part of the global transition towards Net Zero/Carbon Neutral.

2.3. Digitalization

Digitalization in this article is treated as the “process of leveraging digitization to improve business processes.” Comparing to digitization which is defined as “the process of converting information from a physical format into a digital one”, digitalization focuses more on the changes in the business model and improvements in communication within the entity and between stakeholders.1

Digitalization in ports and terminals has been rolled out worldwide. The process would improve the competitiveness of the whole maritime logistic chain, and a number of global organizations have been advocating the corresponding processes. The technology applications are not only improving the terminal efficiency but also protecting the front-line workers at sea and on land (World Bank Group, 2021). As the foundation of full automation, digitalization provides wider and faster connectivity and tons of data for analysis. For example, nowadays, one operator can remotely monitor three to four fully automated QCs with minimal level of interference; instead of sending workers to check the equipment condition physically, sensors can monitor the health of core components in real-time and analyze the collected data for predictive maintenance. Nothing of these can be achieved without digital transformation.

3. Trends in emerging technology and management research

3.1. Quay and yard cranes

3.1.1. Market development

Cranes automation: At the equipment level, the automation evolution firstly takes place on cranes and terminal transporters. The crane automatization has three phases. The first phase is to convert on-crane control into the remote control.2 Instead of putting operators on the top of the crane, the cameras capture multiple angles live-feed from the crane, and the operators use the joystick to control the crane in the cozy office environment. In the second phase, the advanced computer vision and control technology allow some operations to be executed automatically.3 The computer vision allows the crane to “see” its target precisely while the control technology can make adjustment according to the uncertain environment. For example, the QC in Shanghai is able to handle containers automatically in most operations, except the operations in the ship bay out of consideration for safety. When the operator lifts the crane hoist out of the ship bay, the computer will take over for the remaining procedures. In the third phase, all operations will be fully controlled by computers. Due to the safety concerns at the sea side, QCs prefer to be partially automated, meanwhile, the YC technology reaches the fully automatic level. The equipment is offered by ZPMC, Kalmar, ABB, etc. and has been deployed in most major container terminals such as Singapore, Shanghai, Tianjin, Rotterdam, etc.

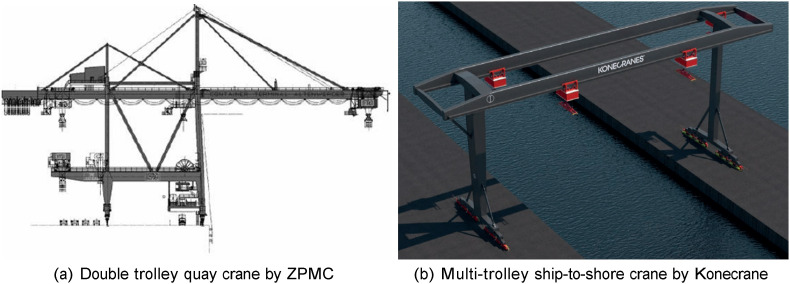

The recent innovation on QC is the double-trolley QC (DTQC) developed by ZPMC and multi-trolley ship-to-shore crane (MTSC) proposed by Konecrane. The DTQC has two trolleys attached to the front and back arms independently and a transfer platform for two trolleys to relay containers (see Fig. 3 (a)). The decoupling of the front and back arm operations significantly improves the handling efficiency. As a rough comparison, throughput of the DTQC at Qingdao port and the single-trolley QC at Tianjin port is 36.2 versus 31 moves per hour, which is 16.8% improvement. Besides in China, the users can also be found in Hamburg and Singapore, including the newly opened Tuas Finger 2 terminal.4 The MTSC shown in Fig. 3(b) is still a conceptual equipment. As the crane stretches over the ship and connects two sides of the shore with four trolleys attached, it can serve four vehicles simultaneously.5

Fig. 3.

Illustration of new quay/ship-to-shore crane. (a) Double trolley quay crane by ZPMC, b) Multi-trolley ship-to-shore crane by Konecrane.

3.1.2. Research trend

Recent research problems on quay and yard cranes mainly have two goals, i.e., (1) to improve crane efficiency to facilitate increasing container volume, and (2) to develop operation procedures for new technologies.

As all unloading and loading containers need to pass through a limited number of QCs and YCs, the operators have never stopped pushing crane handling capacity, especially QC, to a higher level. QC scheduling problem has been investigated over the years and become less popular recently (see the most recent study by Sun et al. (2021). In the meanwhile, there is an increasing number of studies on the integrated optimization of quay crane and berth allocation (see the surveys by Bierwirth and Meisel (2010); Rodrigues and Agra (2022)). The studies focus on YC operations including single YC scheduling (Galle et al., 2018; Zheng et al., 2019), twin/double YC scheduling (Zheng et al., 2018; Han et al., 2019; Zey et al., 2022), YC assignment (Wang et al., 2020) and integrated optimization, such as the integrated YC and vehicle scheduling (Chen et al., 2020) or the integrated storage location assignment and YC scheduling (Peng et al., 2021).

For new technologies, Yue et al. (2021) proposed a scheduling problem of the DTQCs and vehicles, with the consideration of the capacity of the transfer platform. Xu et al. (2021a) looked into the integrated scheduling between DTQC, vehicles and YCs. To our best knowledge, there is only one study looking into the management problem of the MTSC, which is a standard scheduling research solved with solver, heuristic algorithm and branch-and-price algorithm (Abou Kasm and Diabat, 2020).

In addition, it is assumed that the yard crane moves in Manhattan distance, i.e., to take safety into account, the trolley and gantry movements do not happen simultaneously in early days. New crane technology has allowed the trolley and gantry moving at the same time, i.e., Chebyshev movement, for higher YC handling efficiency. Hence, the travelling distance will follow a new distance metric. Although the new change will not affect most YC scheduling or relevant studies (as it is just another distance metric), it will play a significant role when task position, vehicle position, YC and vehicle scheduling are involved (Zhou et al., 2020a).

3.2. Terminal transportation

3.2.1. Market development

Vehicle types: As illustrated in Fig. 4 , vehicles are the primary equipment for transporting containers in terminals, linking the yard-side and wharf-side. The manual driving container truck (CT) has a long history and is also the most commonly deployed type nowadays. To differentiate the CT used for internal operations, it is also called the prime mover. Straddle carrier (SC) is another type of transport vehicle which is completely different from CT. With the increasing scarcity of skilled truck drivers, terminals start seeking driver-less solutions, including automated guided vehicle (AGV), automated straddle carrier (Auto-SC) and automated lifting vehicle (ALV) that can be found in some papers, as well as intelligent guided vehicle (IGV) and autonomous truck (AT). The major differences among above technologies come from four aspects: engineering design, navigation and control, infrastructure and operation.6

Fig. 4.

Illustration of terminal transport vehicles. (a) Automated/Intelligent guided vehicle, (b) Autonomous truck, (c) Straddle carrier.

3.2.2. Engineering design

-

•

CT and AT compose of tractor and trailer, and only the tractor has the power. Most CTs are driven by skilled drivers due to the complex maneuver, especially the backward moves. The AT is to retrofit existing tractor or to design a new tractor with self-decision-making capability. AGV and IGV are a single trailer vehicle with all-wheel-drive capability to perform forward, backward or even crab move easily. Instead of carrying the container on top like CT and AGV, SC carries its load underneath by “straddling” it. To interact with other types of vehicles and stack container on its own, the SC can lift the container to at most three containers high.

-

•

IGV is different from AGV in navigation and positioning technology, i.e., AGV relies on satellite and inertial navigation system (INS), while IGV relies on multi-sensor fusion positioning technologies including satellite navigation and positioning, LiDAR (light detection and ranging) SLAM (synchronous positioning and mapping), and visual SLAM. IGV and AT share similar technologies for navigation and positioning.

•Conventional AGV needs to wait for the YC at the end of the block, and can only depart when the container is picked up from or placed on the vehicle. To decouple this process, lifting AGV (LAGV), where the vehicle has two active lifting platforms to push container up, and AGV mate, which is a rack-based platform to hold the container, are developed.

3.2.3. Navigation and control

-

•

The CT and SC drivers make the own decision to cross the terminal, following the traffic lights and speed limit. The order dispatched from TOS will appear on the in-vehicle display for the drivers to execute, or be communicated with drivers via voice. AGV, IGV, Auto-SC and AT are controlled by the TOS with operators monitoring the system in the remote office. The transport order (from the origin location to the destination location) will be dispatched to vehicle fleet management system (FMS) at equipment control level; then the FMS will compute a deadlock-free and conflict-free route, and send the instructions to the vehicles to execute.

-

•

AGV and IGV require a virtual mesh-like node-arc map, and the route is given as a series of nodes and arcs. Once the instruction is dispatched, the vehicle will follow the instruction precisely.

-

•

Depending on the AT's level of autonomous driving, the instructions of AT movement can be as precise as AGV/IGV, or as rough as CT.

3.2.4. Infrastructure

-

•

CT and AT do not require any special infrastructure as long as the road network meets the standard, e.g., pavement. With high maneuver flexibility, AGV and IGV need less room for rotating so the road network can be narrow. SC and Auto-SC, on the opposite to AGV and IGV, need more room for rotating. If SC needs to handle containers inside the yard block, the gap between container rows has to be reserved.

-

•

AGV requires transponders (also known as magnetic nails) buried beneath the road surface. The transponder is used for location correction in passive mode, and its precise coordinate is read by the AGV when it is passed over by the vehicle.

-

•

To support the fast communication between central server and individual vehicles, a highspeed and low latency wireless network is required.

3.2.5. Operation

-

•

For the normal vehicles like CT, AGV and etc, they need to temporally park at specific location and wait for handshake with cranes. Once the container is placed or picked up, the vehicle can travel to next location as per instruction. SC is different as it can temporally place the container on the ground (sometimes two stacks) and depart for next operation. The operations between SC and cranes are decoupled.

-

•

CT and AT can interact with yard block by side or at the end of the block but mostly by side because of the difficulties on maneuver, especially going backwards. AGV and IGV are suitable for both side-loading and end-loading, while SC is only suitable for end-loading as it cannot travel beneath the YC.

-

•

LAGV and AGV mate have two modes of operations: In Xiamen Yuanhai terminal, AGV mate is automated and can lift the container up from standard AGV; In Qingdao port, Shanghai Yangshan Phase IV and Rotterdam APM Terminals, AGV mate is fixed and LAGV can push the container up before entering rack and place the container independently on the rack, as illustrated in Fig. 5.

Fig. 5.

Illustration of lifting AGV by Konecranes.

There is a long list of AGV end-users: CTA container terminal in the Port of Hamburg, ECT Delta Sealand terminal in the Port of Rotterdam, Tobishima Container Terminal in Nagoya Port, Xiamen Yuanhai Container Terminal, Qingdao Port Phase I and II, and Shanghai Yangshan Port Phase IV, Long Beach Container Terminal, Tuas Terminals in the Port of Singapore. As a new technology, IGV is being tested in the Guangzhou Port Nansha Phase IV.7

As the pioneer in port-use AT, Westwell deployed the first AT in Zhuhai Port in early 2018.8 Right after the Westwell, TuSimple tested its AT in Tangshan Port.9 Rotterdam Maasvlaktes proposed the use of AT for inter-terminal container exchange in middle 2019.10 In November 2020, Beijing Trunk Technology delivered 13 autonomous container trucks to Ningbo Port, and later in 2021, another 6 autonomous trucks were delivered to Tianjin Port for live test.11 In early 2022, Tianjin Port started its second phase of testing on autonomous technology, with a mixed formation consisting of 30 manual electric trucks and 8 ATs.12 The development of the AVs has become one of the most attractive topics in the port industry.

Power source: The electric AGV is widely used in world major container ports, such as Hamburg, Rotterdam, Singapore, Shanghai, etc. To recharge the power, there are two mature technologies, faster charging station and battery swapping robot. Although the super-capacitor has been discussed a lot for urban transport, it is not keen in the terminal environment due to the concern of cargo safety. The most recent development is the hydrogen terminal tractor, which is powered by fuel cell battery and requires hydrogen refuelling station. As the project is under live testing at Valencia Terminal Europa, it can be expected to see a fleet of hydrogen vehicles running in the container terminal.13

3.2.6. Research trend

Carlo et al. (2014) is one of the earliest comprehensive reviews on transport operations in container terminals. Similar to other terminal equipment, the management related studies on terminal transport can be categorized into two levels, planning and operational. Compared with manually operated vehicles, automated vehicles can be better managed and controlled at both planning and operational levels. Using AGV as an example, many studies have been conducted on path planning (Zhong et al., 2020; Hu et al., 2021), dispatching (Hu et al., 2019; Wang and Zeng, 2022), scheduling (Chen et al., 2020; Hu et al., 2022), and coordination between AGV and other terminal equipment (Yang et al., 2018a). Among all the research problems, deadlock- and collision-free scheduling and path planning for large scale vehicle fleet are the most challenging part in AGV operations, as the operators prefer to guarantee safety with less throughput rather than go to the ground to resolve physical issues. Although conflict-free constraint (Hu et al., 2022) or deadlock detection method (Wu et al., 2022) are considered, conflict and deadlock are still resolved at route level while vehicle maneuver and node-arc map are not captured. The studies on CTs pay more attention on planning level, such as truck dispatching/deployment (Chargui et al., 2021) and truck appointment system for arrival scheduling (will be discussed in later section).

The new technologies in the AGV system, LAGV and AGV mate, have changed the conventional way of AGV operations by decoupling AGV and YC handshakes. In this case, the vehicle does not have to wait for YCs when the model is developed (Yang et al., 2018a; Shouwen et al., 2021; Zhuang et al., 2022). Although LAGV requires less coordination with other terminal equipment, it still has a high container handling time. Hence, Kumawat and Roy (2021) investigated the effect of such trade-offs on terminal performance under various design parameter settings, and compared LAGV with standard AGV. It is worth mentioning that this way of operation is very similar to SC/ALV which can decouple the handshakes with QCs and YCs. To evaluate the performance, Roy and de Koster (2018) used a network of open and semi-open queues to model the ALV-based container terminal under complex stochastic environment. With less handshakes in the operation, better scheduling such as dual cycling of LAGV with AGV mate, and ALV/Auto-SC could further improve system's efficiency.

Despite the rapid development of autonomous vehicle (AV) in technology and engineering, research in the context of container terminal is still rare. Gelareh et al. (2013) introduced a new class of Intelligent and Autonomous Vehicles (IAVs), which is to equip AGV type of vehicle with autonomous driving capability. They proposed a scheduling problem with a case study of Dublin Ferry Terminal. Kavakeb et al. (2014) provided an improved Evolutionary Algorithm in combination with Monte Carlo Simulation to identify the robust number of a new type of intelligent vehicles in container terminals. One of the cutting-edge applications of the AV is the truck platooning in which a platoon is formed by a leading truck followed by a set of trucks using semi-automated technologies. You et al. (2020) proposed a local container drayage problem using truck platooning. The benefits of the new mode can be achieved by increasing the platoon length and well coordinating the containers. For container transshipment between two seaport terminals, Chen et al. (2021b) presented an autonomous truck scheduling problem with the consideration of the fuel consumption function with respect to travel speed and platoon formation. Note that, although AT and IGV share many similar features, AT is capable of making decisions and does not require very precise control on node-arc level. Also, AT is expected to operate mixed with human-driving trucks, e.g., in Tianjin Beijiang Terminal Section C. Therefore, research problems at planning and operational levels, such as vehicle scheduling and dispatching under mixed traffic, can be considered for further investigation.

Although battery-powered electric AGV (E-AGV) has been well studied in manufacturing systems, the studies for container terminals are limited. Schmidt et al. (2015) summarized that recent technology improvement had made AGV an economically viable and environmentally-friendly option. From the management perspective, Bian et al. (2015) investigated at vehicle dispatching problem with long travelling distance which is affected by battery constraint. Gerrits et al. (2018) presented a scalable and flexible agent-based simulation model for the planning and control of AGVs. One of the agents is to maintain the battery status of the AGVs and is responsible for effective charging schedules. Ma et al. (2020) looked at the facility planning of the charging stations and the impact of the recharging policies strategies using a detailed discrete event simulation model. Xiang and Liu (2021) developed a nested semi-open queuing network model for estimating the performance of an automated container terminal with consideration of battery management. Besides the management problems for hydrogen-powered vehicles, “where to recharge”, “when to recharge” and “how long to recharge” are still top operational issues faced by E-AGVs (similar to electric AT). To add on, complex stochastic environment, non-linear battery recharging and discharging profile and battery degradation effect should be considered in above topics.

3.3. Storage yard

3.3.1. Market development

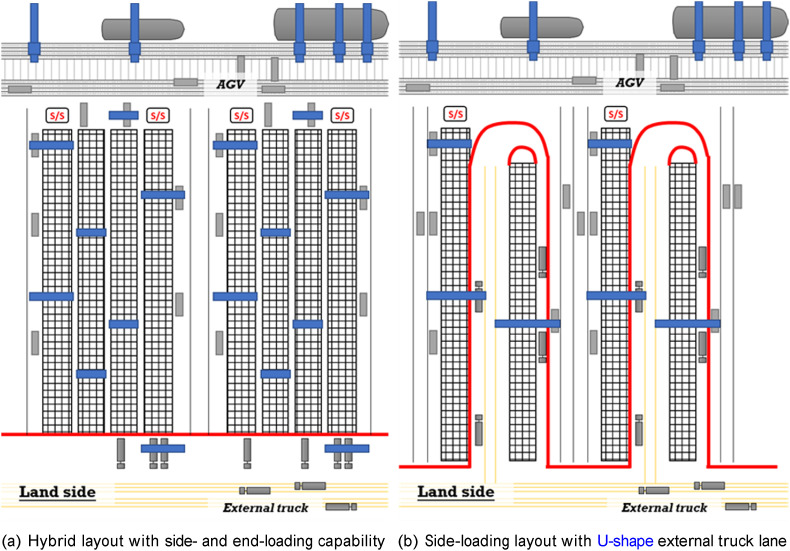

Yard layout: In recent years, there have been several new terminal layouts meant for high throughput and high storage density. Fig. 6 shows two layouts with a clear boundary between internal and external traffic. Specifically, Fig. 6(a) illustrates a hybrid layout mixed with endloading and side-loading vertical yard block. This layout has been adopted by Shanghai Yangshan Phase IV and Singapore Tuas Port. The side-loading yard block has higher throughput for storing/retrieval operations. By mixing two types of yard blocks, the layout can cater to the demands of both import/export and transshipment, while maintaining a high storage density. The layout in Fig. 6(b) is designed for higher import and export throughput as both AGV and external truck perform side-loading, which has been adopted in Guangxi Qinzhou Port.

Fig. 6.

Two types of new layout. (a) Hybrid layout with side- and end-loading capability, (b) Side-loading layout with U-shape external truck lane.

Considering the land scarcity in many port cities, for example, in Singapore, a double-storey container terminal was proposed by a joint team of National University of Singapore, Shanghai Maritime University and ZPMC in 2015. Its total capacity can reach 20 million twenty-foot equivalent unit within an area of 2.5 km2.14

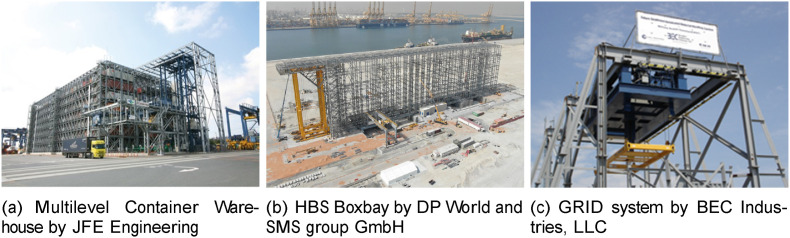

Besides the conventional terminal structure which consists of quay-side, yard-side and terminal transport, many new concepts are taking the automated storage and retrieval system (AS/RS) as a reference, i.e., instead of stacking containers directly on top of each other, the container is placed in an individual rack and is directly accessible. Fig. 7 (a) illustrates the automated container hanger in the Oi container terminal in Tokyo, which has been in operation since 2011. The advantages of the container hanger include increasing the handling volume and efficiency, and emission reduction as the hangers are electricity powered.15 Another recent development, Boxbay high bay store system (HBS), is proposed by DP World and is first built in Jebel Ali Port16 as shown in Fig. 7(b). The storage capability of the terminals is enhanced by stacking containers as high as 11 tiers, delivering more than three times the capacity of a conventional yard with enhanced performance. Recent onsite live test has shown that the system can achieve good operation performance and significant emission reduction. However, the construction cost and operation complexity will also be the primary bottleneck for promoting this concept worldwide. Another concept of container storage is to move ground transport overhead while only having containers placed on the ground. The transporters are attached to the overhead structure which offers a better accessibility. The prototype is shown in Fig. 7(c).

Fig. 7.

Prototypes of new terminal system. (a) Multilevel Container Ware-house by JFE Engineering, (b) HBS Boxbay by DP World and SMS group GmbH, (c) GRID system by BEC Industries, LLC.

3.3.2. Research trend

Recent research problems on yard storage can be summarized by three categories: (1) efficiency studies on new layouts or systems, (2) planning and scheduling studies on new layouts or systems, and (3) new approach on management.

Regarding efficiency studies, Zhou et al. (2016) developed discrete event simulation model and showed that the GRID system outperforms conventional terminal design on throughput. Li et al. (2021) evaluated three types of terminal layout, including U-shape, parallel and perpendicular layouts, using agent-based simulation approach.

For planning and scheduling studies, Xu et al. (2021a) proposed an integrated scheduling problem under U-shape layout. Although the layout is originally designed for external trucks, the study deployed AGV system for the layout in order to achieve the precise control over AGV and rail crane. The integrated scheduling coordinated two equipment on both spacial and temporal dimensions. The GRID system has attracted research attentions on container space allocation (Zhou et al., 2018a) and transporter scheduling (Zhen et al., 2018; Fibrianto et al., 2020).

Instead of reserving storage space by block or sub-block, recent yard management studies proposed flexible cluster concept (Zhou et al., 2020b; Yu et al., 2021; Wang et al., 2022a) where the number of bays, rows and tiers can be changed based on service requirement, and bay level allocation concept (Yu et al., 2022a) where the space is reserved at bay level. It is worthy of mentioning that Yu et al. (2022a) proposed a new idea on improving space utilization by splitting bay space for multiple vessels, and Wang et al. (2022a) presented a yard template design method which is applicable in hybrid layout, as well as parallel and perpendicular layouts.

In summary, relevant research on three categories are not much at this moment. It is mainly because that the technologies above are quite new to the public. Yet, there are still management challenges pending solutions, for example, efficiency study of container warehouse and Boxbay systems, coordinated scheduling in hybrid and U-shape layouts, etc. More work in the three categories can be expected.

3.4. Gate

3.4.1. Market development

Gate automation: Gate automation is not limited to container terminals, but also widely applied in other cargo facilities such as intermodal depots and airports. The container terminal gates involve a series of information transactions such as identify truck drivers, process documents, identify containers and direct drivers to container handling spot (Rodrigue et al., 2021). The adoption of gate automation solution could shorten the truck turnaround time and improve data exchange accuracy and speed.17

Recently, computer vision has helped to make operation paperless and operator-less at the gate side and there are many gate automation providers: ABB's gate automation solution emphasizes the connection between the terminal gate and the TOS. The checking-in at the gate determines the TOS operation schedule.18 WestWell tests a smart terminal gate system which can automatically detect and recognize container serial number in a short time. By linking up with an information system, this system can reduce a lot of human resources and error rate (see Fig. 8 ).

Fig. 8.

Automatic gate is powered by computer vision technology.

3.4.2. Research trend

The container terminal gate operation has been, for a long time, the bottleneck of the terminal efficiency. The traffic at the terminal gate could spill traffic over to connected links and lead to congestion and safety issues. Three solutions have been proposed: (1) extending the gate operating time and improving the gate handling efficiency (Maguire et al., 2010); (2) adjusting the number of gates (Minh and Van Noi, 2021); (3) controlling truck arrivals by time slot (Zhou et al., 2018b; Nadi et al., 2022; Li et al., 2022). The third approach has already been implemented, i.e., truck appointment system, in many terminals to deal with the increasing traffic at gate, and the recent review can be found in Abdelmagid et al. (2022).

Chao and Lin (2017) concluded that gate automation is driven by service level and facilitated by technology advancements. They confirmed the radio-frequency identification (RFID) system is a very suitable alternative to the current container number recognition system. And the smart container design could help to reduce the RFID's installation cost. However, the technology development at gate does not directly lead to new research topics. Most technologies implemented at gate are mean to improve efficiency or reduce people contact, yet have not changed the mode of operation.

3.5. Power revolution

3.5.1. Market development

In the market, European countries are the pioneers in the green port initiative. As Europe's largest seaport, the Port of Rotterdam proposed to achieve zero-emission port by 2050, by using electricity and renewable energy.19 In recent years, China has also joined the initiative and pushed the ports to upgrade their infrastructures and equipment, such as shore power for vessel power supply, electric vehicles, and electrified equipment (as discussed in 3.3).

Shore power: Shore power (also known as “cold ironing”, “shore-side electricity”, “onshore power supply”, “alternative marine power”, and more) is an effective measure to reduce at-berth emissions. By providing electricity to the ships from the shore-side power grid, the ships can turn off auxiliary diesel engine. Many ports have adopted shore power to reduce emissions in terminals, such as Los Angeles and Long Beach, Gothenburg, Shanghai and Zhuhai (Peng et al., 2019; Xu et al., 2021b). To date, shore power facilities have been set up at more than 30 ports and the number is expected to rise fast (Wu and Wang, 2020).

Smart grid: To support the power revolution, smart grid (some literature calls it smart microgrid) is receiving more attractions as a system-level solution for the power network. A smart grid can provide efficient solutions to maximize the flexibility of terminal power demand and at the same time, increase the efficiency of the terminal power system. It also enables the terminals to integrate multiple energy sources, better manage and optimize energy usage and storage, obtain substantial energy savings, and reduce the carbon footprint. Industries from the Netherlands, Germany and Singapore are the pioneers in this aspect.20

3.5.2. Research trend

There is a growing body of literature in container terminal's power revolution as a result of the rising awareness of sustainable development in recent decades. A detailed literature review in power revolution of container terminals can be found in Iris and Lam (2019). We have reviewed recent research topics in two streams: (1) studies on shore power by using both qualitative and quantitative approaches, and (2) smart grid connecting to container terminals.

In recent years, there has been an increasing number of literatures investigating the shore power specifically for container terminals (Peng et al., 2019; Radwan et al., 2019; Xu et al., 2021b). The efforts were made to understand the difficulties of implementation, evaluation system and operation method (Innes and Monios, 2018) and control grid's disruption (Sciberras et al., 2015; Radwan et al., 2019; Mao et al., 2020). Qi et al. (2020) reviewed studies of shore power's economic challenges from the perspective of ship owners, port authorities, and governments. The basic cost models were summarized for different interested parties. Later on, Wang et al. (2021a) proposed an optimization framework on government subsidy structure to achieve the maximized subsidy efficiency of at-berth emission reduction. Chen et al. (2021a) used the evolutionary game to analyze the interaction mechanism of government, port company and power company behaviors in the background of shore-to-ship electricity implementation. Ye et al. (2022) suggested government should integrate shore power policy with Emission Control Area (ECA) to achieve overall emission control. Mathematical models have also been used to quantify the impacts of shore power in reducing emissions (Chang and Wang, 2012; Zis et al., 2014; Ballini et al., 2015; Peng et al., 2019; Wu and Wang, 2020), and some recent works are as follows: Zhen et al. (2022) constructed a nonlinear programming model to optimize the ship-borne power receiving system deployment, berth allocation, and the order of ships being served in each berth. Yu et al. (2022b) proposed a multi-objective optimization model to solve the problem of berth allocation and quay crane assignment with the consideration of daily use of shore power. Wang et al. (2022b) examined the optimal subsidy design for government-operated ports, aiming at balancing the environmental benefits and subsidy expenses.

Smart grid is still a new concept in the maritime industry. Canepa et al. (2018) introduced the smart micro-grid as an effective tool for energy management as well as a conceptual structure for the electrical infrastructure by exploiting all the technological developments. The smart micro-grid is expected to reduce cost and emissions, and increase revenues for the port authority. From the management perspective, Kanellos et al. (2017) proposed an innovative power management method for the smart grid in terminals based on multi-agent systems. Molavi et al. (2020) developed a two-stage stochastic mixed-integer programming model to explain how the use of micro-grid at a port can effectively enhance the port's performance. The most recent study is proposed by Fang et al. (2022), which developed an optimal power scheduling framework to integrate various logistic loads, including cold ironing, quay and yard cranes, and reefer areas for seaport micro-grid.

More research works in this area can be expected as many countries have made their Net Zero/Carbon Neutral commitments. However, it should be noted that even though electrification may be the long-term goal, other research outputs on such as energy efficiency and less carbon-intensive fuel are equally important. Future research could focus more on the pathways to achieve emission control targets at container terminals.

3.6. Digitization

3.6.1. Market development

Following Port Vision Rotterdam (Port of Rotterdam, 2019), the Port of Rotterdam is undergoing a magnificent digital transformation, and is committed to becoming the first digital port by 2030, and the smartest port in the world. The digital transitions are to make the port and beyond, i.e., the supply chain, from regional to global, more efficient. Similarly, digitalization is considered as the most important industry capability area in Singapore Maritime R&D Roadmap 2030 (SMI, 2021).

Digital twin: Nowadays, the IoT can be considered as an important technological revolution to the smart ports (Yang et al., 2018b). A network of IoT devices (e.g., smart sensors, wireless devices), various communication solutions and data centers make up the key infrastructure of the smart port, which have also been part of the optimization of container handling activities. Digital twin (DT) is one of the emerging concepts in the port digitalization transformation. DT, a virtual representation of a physical system, is able to facilitate system transformation without risking operations. IBM and Port of Rotterdam have been jointly developing the DT with IoT platform,21 which emphasizes on the readability and utilization of digital tools and real-time data. By using artificial intelligence to analyze all the data collected, it is possible to make accurate estimations of the future and make better decisions for better operational efficiency.

The narrow definition of the digital twin is also used by general simulation software, such as AnyLogic, Simio, as well as the port-specified simulation software FlexTerm. Simulation has been proven to be very useful to represent industry processes and logics. To further develop simulation into DT, the connectivity with IoTs or other industrial systems, such as TOS, and the integration of various data sources are essential demands.

Maritime Single Window/Port Community System: Stakeholders actively engaged in international trade need to deal with a large amount of information and paperwork due to regulatory requirements. Because of the different systems and paper forms, there is a huge burden on all stakeholders to comply with the regulations and process international trade. A remedy to this situation is the single window.

A single window is defined as “a facility that allows submission of standardized information covered by the convention to a single-entry point” (World Bank Group, 2021). International Maritime Organization (IMO) encourages to use nationwide maritime single window (MSW), “to enable all the information required by public authorities in connection with the arrival, stay and departure of ships, persons and cargo, to be submitted via a single portal without duplication” (IMO, 2019a).

To pursue the harmonization, standardization and interoperability among ports and ships, IMO (2019b) designed guidelines of setting up a MSW that aligned with the requirements from IMO Convention on Facilitation of International Maritime Traffic (FAL). In addition to defining MSW and extensively explaining the whole process of building up a MSW, the guidelines discussed the interoperability among different MSWs. The MSWs are by nature promoting interoperability, cornerstoned by the FAL Compendiums.

Since 2017, the Panama Canal Authority has selected the Panama Canal Maritime Service Portal for all vessels to declare government formalities. The authority has upgraded their Panama Maritime Single Window System, highlighted the positive effects of digitalization and informing. According to estimations, the system has reduced the need for more than 300,000 paper forms and documents, improving the efficiency and carbon footprint of transshipment procedures and saving up to 3260 h on an annual basis.22 The MSW helped the shipping lines to avoid double notification, double formalities inspection and operation delay. The introduction of MSW helped to reduce more than 300 thousand documents and had an annual save up to 3260 person hours. In 2010, the European Parliament and the Council adopted the Reporting Formalities Directive to simplify and harmonize the administrative procedure in maritime transport. Since 2017, EU member states have urged the Commission to create a true European Maritime Single Window environment (EMSWe). The EMSWe would target to provide fully harmonized interfaces to provide information across the EU and ensure true submit-only-once (European Commission, 2020).

Port community system (PCS) is a platform to optimize, manage and automate the terminal and logistics processes through a single submission of data in the transport logistics chain. Similar to the MSW, PCS also falls within the single submission portals recommendation. Therefore, it is still not well defined that whether PCS is just a gateway connecting into single window, or could act as a single window. Comparing to MSW, PCS is more like a business model that not only focuses on the communication among container terminal stakeholders, but also puts more emphases on its connections with hinterland and the entire supply chain (World Bank Group, 2021).

Cyber security: As a result of the trend of digitalization and the adoption of emerging technologies such as big data, IoT, AI and blockchain, the entire shipping industry is increasingly vulnerable to cyber attacks (World Bank Group, 2021). World major shipping lines including Maersk, COSCO, MSC and CMA CGM have all suffered cyber attacks since 2017, leading to a huge loss to the industry.23 As a vital component of the shipping industry, the digital developments in container terminals rarely considered cyber security. After a series of cyber attacks targeting major international terminals,24 awareness of cyber security in container terminals is enhancing.

3.6.2. Research trend

These years, there are some review papers on terminal digitalization, for example, Anwar (2019) and de la Peña Zarzuelo et al. (2020) covered the high-level summary on artificial intelligence, blockchain, cloud computing, IoT, 3D printing and additive manufacturing, big data and business analytics, augmented reality, as well as simulation and modeling, etc, which are suitable for readers to have an overall picture on terminal digitalization. The research work on port digitalization is reviewed in three groups: (1) adoption of Maritime Single Window and Port Community System, (2) awareness of cyber security issues and (3) application of other innovative digitization approaches.

Tijan et al. (2019) reviewed the MSW concept and its implication on sustainable port business. With the successful global examples, the authors concluded that MSW could contribute to port sustainability economic, environmental and social aspects. However, it could be challenging to integrate single window beyond the national level. Peynirci (2021) pointed out that shipping agencies generally agreed MSW system could benefit their financial efficiency and market performance, but just played a partial role in terms of labour efficiency and process tracking because of the unfamiliarity with the new system. Carlan et al. (2016) concluded that the functionalities and design of each PCS determine the costs and benefits for terminal operators. The development of PCS is not to ensure a certain level of benefit for its users, but to maximize the joint benefit of using the collaborative platform.

Ports as the important node of international trade have attracted a growing number of literatures on its cyber security issues. Polemi (2017) studied the terminal cyber security with assessments on both entity and asset levels. The author pointed out that, together with the technology advancement, it is critical to build the cyber security awareness among the policymakers. In addition to the human factor, Senarak (2021) discussed the factors of infrastructure and procedure, and how these three factors interdependent with each other.

For the other studies, Pu and Lam (2020) proposed a conceptual framework for blockchain adoptions in maritime industry; Heilig et al. (2020) focused more on data mining for the decision-making in container terminals; Barua et al. (2020) conducted a review in developing machine learning models for applications to different aspects of international freight transportation management, including terminal operations; Zhou et al. (2021b) developed a decision support framework using digital twinning and simulation optimization for resilience assessment and recovery action optimization; Zhou et al. (2021a) reviewed research works using simulation-based methods for decision-making in terminal operations and other activities.

Container terminal digitization is a relatively new area of research and industries generally deem it as a long-term plan. Current topics in this area are scattered and are largely about specific applications. From the management perspective, stakeholders are more worried about the interoperability among digital platforms and financial benefits for committing to these initial investments. Therefore, some future works focusing on cost effectiveness and benefit realisations would be necessary.

4. COVID-19 impact

The COVID-19 pandemic has severely rocked the global economy, manufacturing, supply chain and market. In this “crisis like no other”, the global GDP was projected to decline by 4.9 percent in 2020 (International Monetary Fund, 2020). The container shipping industry, not yet recovered from the long-tailed fluctuation of the financial crisis in 2008/09, got further hit by the unpredictable and volatile demand caused by the COVID-19 pandemic and political tension.

4.1. Technology impact

A quick summary of the relationship between technologies, various types of challenges, and the pandemic is listed in Table 1 . To be specific, the restrictions on face-to-face meet-up, manpower shortage and lack of external vehicles caused a lot of difficulties to the terminal operators worldwide during the pandemic. For example, in August 2021, Ningbo-Zhoushan port suspended its operations for a few days following a positive COVID-19 case; Ports of Los Angeles and Long Beach suffered significant delays over several months in late 2021 due to the lack of manpower for port operations and driving transport vehicles.

Table 1.

Relations between technologies and challenges.

| Technologies | Benefits to Social, Economic, or Operational Challenges | Specific Benefits to the Pandemic Period |

|---|---|---|

| Handling and transport equipment automation | Require less skilled manpower and save labor cost | Reduce personal contact and maintain continuous operations |

| Gate automation | Save manpower and improve operation efficiency | |

| Port communication systems, being paperless | Improve communication and transmission efficiency | |

| New terminal layout | Improve operation efficiency | No significant impact |

| Power revolution | Boost terminal electrification and improve environmental sustainability | |

| Digital twin | Improve data transparency | |

| Cyber security | Enhance terminal safety and operational resilience |

Although the pandemic brings both operational and financial challenges to ports, it boosts port development in two aspects, digitalization and automation. To reduce person contacts, many offline procedures have been converted into online and paperless, e.g., the Hong Kong Container Terminal Operators Association has announced the full implementation of Electronic Release Order starting from 1 July 2021. Actually, paperless is not new, but due to cost concern and convenience on traditional way of operations, only a few shipping companies and ports have implemented corresponding systems before the pandemic. When the pandemic comes, digitalization in ports get accelerated everywhere.

Similarly, the pandemic stimulates the ports to turn to automation solutions, such as smart gate for truck screening, drones for inspection and surveillance, robots for coning and deconing. In the meanwhile, the construction and opening of new automated container terminals has not been affected. Tianjin Port Beijiang Terminal Section C started operation in July 2021 with a lot emerging technologies deployed (including 5G, IoT devices, autonomous truck, etc); Guangzhou Nansha Port Phase IV started operation in December 2021; DP World has built its first HBS at Jebel Ali Port and finished the pilot phase in middle 2021; The Phase 1 of Singapore's next-generation container terminal at Tuas was finished in December 2021, and new research project to develop large-scale fleet management solution for AGVs at Tuas Port was confirmed and initialized in March 2022.25

4.2. Investment impact

While the liner shipping companies are facing challenges including the seafarer's welfare, disruption of fleet inspection, maintenance and service, container port industry also confronts a series of problematic issues. For example, in April 2020, the union of the Port of Melbourne refused to handle a COSCO vessel for fears of the COVID-19.26 Six ships were seized in Hong Kong in July 2019 due to seafarers' positive virus test results, and all the crew members were obliged to quarantine on the anchored vessels.27 In addition to the direct contact with seafarers, there are potential risks of the virus spread in crane operation, vehicle driving, container handling and document processing. Therefore, ports are exploring the opportunities to utilize emerging technologies to mitigate these weak physical links.28

The impact of the pandemic on terminal investment is still ambiguous. For container shipping industry, due to the low market condition and carriers cutting their fleet capacity,29 many early-stage port investment projects are facing potential suspension and even cancellation.30 Meanwhile, as shippers are seeking alternative ports in the light of the trade conflict and avoiding dependence on a few partners, investment opportunities arise as well.31 For example, the Port of Valencia starts looking into health emergencies and surveillance.32

4.3. Shifting industry trend: an analysis

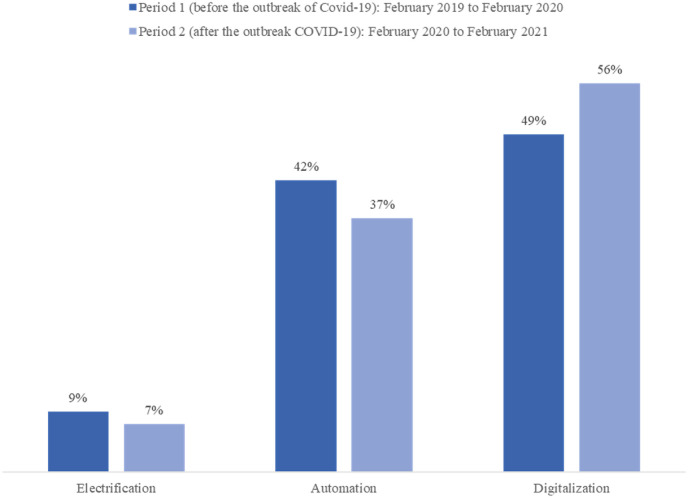

Admittedly global container terminal stakeholders have evaluated the implementation of these technologies for a long time. The outbreak of COVID-19 allowed them to revisit these proposals. To understand how the industry's focus on container port technology shifted before and after the outbreak of COVID-19, we surveyed the news with keyword “container port technology” in Google News during two periods of time (Before the outbreak (period 1): February 2019 to February 2020; After the outbreak (period 2): February 2020 to February 2021).

In total, 249 pieces of news were collected before the outbreak and 266 after the outbreak. After cleaning the stopwords, we have 127 keywords relevant to the emerging technologies that are categorized into the three technology areas: 54 in digitalization, 56 in automation and 17 in electrification.

The proportional frequency of the keywords in these three areas are presented in Fig. 9 . After the outbreak, the industry has shifted their interest from the electrification and automation areas to digitalization. To be specific, electrification attracts less attention than automation and digitalization in these two years. Topics in this area includes energy relevant words such as “power”, “hybrid” and “electronic”. Another stream of words under electrification are environmental related, like “carbon”, “emission” and “green”.

Fig. 9.

Technology trend before and after the COVID-19 outbreak.

Automation has always been a top priority of container terminals. Its relative popularity lowered from 42% to 37% because of the intensive discussion on digitalization after the pandemic. Under automation, the most frequently discussed topic is the (quay) “crane”, followed by “storage yard”. “Gate” did not emerge as a keyword before the COVID-19, but showed up after the outbreak.

The heated discussion on digitalization could be a result of a series of cyber attacks against major container shipping lines. The most popular words are “digital”, “smart” and “data”. After the pandemic, there is a drop among the words regarding exact technologies, such as “5g” and “AI”. Meanwhile, the growth of “platform”, “tradelens” and “api” indicates the industry's demand on platform upgrade. More specifically, higher requirement is placed on the platform's security, evident by the growth of interest in “blockchain”, “cyber security”, “cyber attack”, etc.

5. Discussion and conclusions

From the China-US trade friction to the COVID-19 pandemic, global trading and transport have dramatically changed in recent years. However, the development in container terminals stays its course to be electrified, automated and digitalized. We reviewed current development progress in the industry and recent research topics in the academia, specifically, how emerging technologies would facilitate container terminals to achieve their financial and non-financial objectives.

In the pandemic and future post-pandemic environment, it is necessary to understand whether these emerging technologies can help to go through the obstacles brought by the pandemic and if the crisis would accelerate the changes that have already been underway. Moreover, as the market is still hesitating on investing in container terminal operation industry, it is necessary to make sure the investment is spent wisely so that technologies with better improvement potential could be prioritized.

In summary, there are several noticeable management insights:

-

•

The development of hardware automation, especially cranes and yard vehicles, has been quite mature. With the challenges raised by the COVID-19, container terminals are embracing automation to ensure consistent performance, improve productivity and manage costs. Meanwhile, academia is always enthusiastic about improving algorithm and simulation for the automated devices. The critical trade-off of the container terminals is the substantial initial investment and future efficiency improvement. For example, although the AS/RS-liked container handling system may offer higher throughput, its high deployment cost makes it less compatible with the conventional terminal structure.

-

•

After a series of countries have committed to their Net Zero/Carbon Neutral road maps, the demand for container terminal sustainability is growing fast. Terminals such as Bahrains33 and Felixstowe,34 are spurring their own decarbonization processes mainly carried out by terminal electrification. In addition to switching the terminal vehicles' power source, electrification will further drive the terminal's upgrade of power systems. More importantly, electrification in container terminal could take the lead in its upstream and downstream stakeholders.

-

•

As the basis of digitalization and automation, the technology advancement in software is booming. Container terminals are experiencing digital transformation and adopting digitalization tools to be future-proof. Stakeholders generally agree with the importance of digitalization, and now are finding ways to realize it.35 The technologies such as quantum computing, autonomous driving, AI, 5G and DT have been applied to different parts of the terminal to improve operational efficiency or reduce human interference.

-

•

The COVID-19 pandemic has impacted the container port terminals and confirmed the necessity in terminal automation and digitalization and accelerated such transitions. Automating the container handling and digitizing document exchange would protect frontier workers from unnecessary contact risks. At the same time, with less manual interaction, these processes facilitate resource optimization, information sharing, remote control, etc. within container terminals and equip them with more flexibility and resilience to respond to quick changing environments (UNCTAD, 2022).

Several research directions are identified what are worth looking into for future research:

-

•

Automation is the constant topic in container terminal industry. However, it should be noted that many “automated container terminals” are not fully automated. The industry is trying to conquer the difficulties in automated coning/deconing, lashing, and loading/unloading of QC interfacing with the vessel. Further research could be done to investigate the practicality of these topics and how much they could improve terminal efficiency. In addition to the engineering design and operational method, it could be a future research direction to study the management perspective of port automation and the application of leading technologies in container port terminals. Among the key terminal links, it would be interesting to look into how gate automation could improve the overall efficiency.

-

•

The growing body of literature on container terminal electrification showcased academia's interest in sustainable and environmental-friendly development. However, the industry has less motivated on switching their power source comparing to automation and digitalization. Therefore, besides justifying how the energy revolution would benefit the environment, future research should give more political implications on how to incentivize the ports and ensure the relevant arrangements are environmentally sustainable and commercially viable.

-

•

There is an increasing awareness of terminal digitalization from both academia and industry. With a pressing need for a unified platform to facilitate communication among stakeholders, research should be done to study what type of information is needed and how different players could benefit from this scheme.

-

•

A critical issue raised by digitalization that should be investigated is the cyber security. Admittedly it is a very popular topic especially after the COVID-19 outbreak, the literature in this area is mostly exploratory. There is still a lack of studies that can explain how the emerging technologies could be applied, and how a terminal should protect themselves from cyber attack as a node in the global shipping network.

-

•

From industrial engineering discipline perspective, there are still plenty of operational and strategic challenges to be resolved for the AV, E-AGV, shore power, etc. Data analysis and machine learning could be adopted to specific topics in the DT, MSW and PCS.

The container port terminals are playing an increasingly vital role in international trade and a wide range of technologies are adopted to achieve their financial and non-financial objectives. However, it is still very important to understand how cutting-edge technologies could be implemented in container ports. In this study, we reviewed the emerging technologies in container port terminals in three areas: automation, electrification, and digitalization. We studied market development and research trend as well as the COVID-19 impacts to identify the potential directions for future academic contributions.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This research was made possible with funding support from Singapore Maritime Institute, National Natural Science Foundation of China [72101203], and Shaanxi Provincial Key R&D Program, China [2022KW-02].

In memory of a great scholar, mentor and friend, Professor Loo Hay Lee with the National University of Singapore.

2020, https://www.globalpsa.com/psa-singapore-receives-first-batch-of-double-trolley-quay-c ranes-for-tuas-port/.

2018, https://www.konecranes.com/discover/next-generation-sts-cranes-provide-model-for-the -future/.

2022, https://www.konecranes.com/equipment/container-handling-equipment/automated-guided-v ehicles/lift-agv.

2018, https://www.prnewswire.com/news-releases/westwell-creates-worlds-first-ai-container-t ruck-in-china-300629,449.html.

2019, https://www.worldcargonews.com/news/news/autonomous-trucks-for-maasvlaktes-internal-c ontainer-exchange-route-63395.

2021, https://www.globenewswire.com/news-release/2021/05/20/2233508/0/en/Port-Automated-Dri ving-Report-2021.html.

2022, https://www.porttechnology.org/news/hydrogen-terminal-tractor-under-development-as-p art-of-h2ports/.

2020, https://container-mag.com/2020/07/03/assembly-of-boxbay-high-bay-storage-system-compl eted-at-jebel-ali/.

2020, https://new.abb.com/news/detail/57450/increasing-terminal-capacity-by-10-a-case-study -in-yard-transformation.

2019, https://www.offshore-energy.biz/psa-eyes-smart-grid-technology-for-pasir-panjang-ter minal/.

2020, https://www.zdnet.com/article/all-four-of-the-worlds-largest-shipping-companies-hav e-now-been-hit-by-cyber-attacks/.

2018, https://www.zdnet.com/article/port-of-san-diego-suffers-cyber-attack-second-port-in-a -week-after-barcelona/.

2022, https://www.channelnewsasia.com/singapore/psa-singapore-astar-develop-large-scale-fle et-management-solution-agvs-tuas-port-2531,431/.

2020, https://www.porttechnology.org/news/union-refuses-to-unload-cosco-vessel-amid-covid −19-fears/.

2020, http://www.maritimebulletin.net/2020/07/24/6-ships-seized-in-hong-kong-with-positiv e-test-including-4-container-ships-many-pics/.

2020, https://www.porttechnology.org/news/coronavirus-pandemic-emphasizes-need-for-port-aut omation/.

2020, https://www.joc.com/maritime-news/container-lines/carriers-could-make-permanent-capac ity-cuts-prolonged-downturn-drewry_20200714.html.

2020, https://theloadstar.com/se-asian-ports-need-to-invest-billions-as-shippers-seek-alter natives-to-china/.

2022, https://www.zawya.com/en/business/transport-and-logistics/apm-terminals-bahrain-targe ts-net-zero-carbon-by-2040-rxph0xis.

Data availability

Data will be made available on request.

References

- Abdelmagid A.M., Gheith M.S., Eltawil A.B. A comprehensive review of the truck appointment scheduling models and directions for future research. Transport Rev. 2022;42:102–126. [Google Scholar]

- Abou Kasm O., Diabat A. Next-generation quay crane scheduling. Transport. Res. C Emerg. Technol. 2020;114:694–715. [Google Scholar]

- Anwar M. 27th Annual Conference of International Association of Maritime Economists. 2019. Digitalization in container terminal logistics: a literature review; pp. 1–25. [Google Scholar]

- Ballini F., Bozzo R. Air pollution from ships in ports: the socio-economic benefit of cold-ironing technology. Research in Transportation Business & Management. 2015;17:92–98. [Google Scholar]

- Barua L., Zou B., Zhou Y. Machine learning for international freight transportation management: a comprehensive review. Research in Transportation Business & Management. 2020;34 [Google Scholar]

- Bian Z., Yang Y., Mi W., Mi C. Dispatching electric AGVs in automated container terminals with long travelling distance. J. Coast Res. 2015:75–81. [Google Scholar]

- Bierwirth C., Meisel F. A survey of berth allocation and quay crane scheduling problems in container terminals. Eur. J. Oper. Res. 2010;202:615–627. [Google Scholar]

- Bose J.W., editor. Handbook of Terminal Planning. Springer; Cham: 2020. [DOI] [Google Scholar]

- Buhl R., Jahn C. Fraunhofer IRB Verlag; 2016. Terminal Operating Systems 2016: an International Market Review of Current Software Applications for Terminal Operators. [Google Scholar]

- Canepa M., Frugone G., Bozzo R. Trends and Challenges in Maritime Energy Management. Springer; 2018. Smart micro-grid: an effective tool for energy management in ports; pp. 275–293. [Google Scholar]

- Carlan V., Sys C., Vanelslander T. How port community systems can contribute to port competitiveness: developing a cost–benefit framework. Research in Transportation Business & Management. 2016;19:51–64. [Google Scholar]

- Carlo H.J., Vis I.F., Roodbergen K.J. Transport operations in container terminals: literature overview, trends, research directions and classification scheme. Eur. J. Oper. Res. 2014;236:1–13. [Google Scholar]

- Carlo H.J., Vis I.F., Roodbergen K.J. Seaside operations in container terminals: literature overview, trends, and research directions. Flex. Serv. Manuf. J. 2015;27:224–262. [Google Scholar]

- Chang C.C., Wang C.M. Evaluating the effects of green port policy: case study of kaohsiung harbor in taiwan. Transport. Res. Transport Environ. 2012;17:185–189. [Google Scholar]

- Chao S.L., Lin Y.L. Maritime Business Review; 2017. Gate Automation System Evaluation: A Case of a Container Number Recognition System in Port Terminals. [Google Scholar]

- Chargui K., Zouadi T., El Fallahi A., Reghioui M., Aouam T. Berth and quay crane allocation and scheduling with worker performance variability and yard truck deployment in container terminals. Transport. Res. E Logist. Transport. Rev. 2021;154 [Google Scholar]

- Chen X., He S., Zhang Y., Tong L.C., Shang P., Zhou X. Yard crane and agv scheduling in automated container terminal: a multi-robot task allocation framework. Transport. Res. C Emerg. Technol. 2020;114:241–271. [Google Scholar]

- Chen J., Xiong W., Xu L., Di Z. Evolutionary game analysis on supply side of the implement shore-to-ship electricity. Ocean Coast Manag. 2021;215 [Google Scholar]

- Chen S., Wang H., Meng Q. Autonomous truck scheduling for container transshipment between two seaport terminals considering platooning and speed optimization. Transp. Res. Part B Methodol. 2021;154:289–315. [Google Scholar]

- Cullinane K., Haralambides H. Global trends in maritime and port economics: the COVID19 pandemic and beyond. Marit. Econ. Logist. 2021;23:369–380. [Google Scholar]

- de la Peña Zarzuelo I., Soeane M.J.F., Bermúdez B.L. Industry 4.0 in the port and maritime industry: a literature review. J. Industrial Inform. Integ. 2020 [Google Scholar]

- European Commission European maritime single window environment. 2020. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32019R1239

- Fang S., Wang C., Liao R., Zhao C. IET Renewable Power Generation; 2022. Optimal Power Scheduling of Seaport Microgrids with Flexible Logistic Loads. [Google Scholar]

- Fibrianto H.Y., Kang B., Hong S. A job sequencing problem of an overhead shuttle crane in a rail-based automated container terminal. IEEE Access. 2020;8:156362–156377. [Google Scholar]

- Galle V., Barnhart C., Jaillet P. Yard crane scheduling for container storage, retrieval, and relocation. Eur. J. Oper. Res. 2018;271:288–316. [Google Scholar]

- Gelareh S., Merzouki R., McGinley K., Murray R. Scheduling of intelligent and autonomous vehicles under pairing/unpairing collaboration strategy in container terminals. Transport. Res. C Emerg. Technol. 2013;33:1–21. [Google Scholar]

- Gerrits B., Mes M., Schuur P. 2018 Winter Simulation Conference (WSC) IEEE; 2018. A simulation model for the planning and control of AGVs at automated container terminals; pp. 2941–2952. [Google Scholar]

- Gharehgozli A.H., Roy D., De Koster R. Sea container terminals: new technologies and OR models. Marit. Econ. Logist. 2016;18:103–140. [Google Scholar]

- Han X., Wang Q., Huang J. Scheduling cooperative twin automated stacking cranes in automated container terminals. Comput. Ind. Eng. 2019;128:553–558. [Google Scholar]

- Heilig L., Stahlbock R., Voß S. Handbook of Terminal Planning. Springer; 2020. From digitalization to data-driven decision making in container terminals; pp. 125–154. [Google Scholar]

- Hu H., Chen X., Wang T., Zhang Y. A three-stage decomposition method for the joint vehicle dispatching and storage allocation problem in automated container terminals. Comput. Ind. Eng. 2019;129:90–101. [Google Scholar]

- Hu H., Yang X., Xiao S., Wang F. Anti-conflict agv path planning in automated container terminals based on multi-agent reinforcement learning. Int. J. Prod. Res. 2021:1–16. [Google Scholar]

- Hu Y., Yang H., Huang Y. Conflict-free scheduling of large-scale multi-load agvs in material transportation network. Transport. Res. E Logist. Transport. Rev. 2022;158 [Google Scholar]

- IMO . 2019. Electronic Business.https://www.imo.org/en/OurWork/Facilitation/Pa ges/ElectronicBusiness-default.aspx URL: [Google Scholar]

- IMO . 2019. Guidelines for setting up a maritime single window.https://wwwcdn.imo.org/localresources/en/OurWork/Facilitation/FAL/20related/20non mandatory/20documents/FAL.5-Circ.42.pdf URL: [Google Scholar]

- Innes A., Monios J. Identifying the unique challenges of installing cold ironing at small and medium ports–the case of aberdeen. Transport. Res. Transport Environ. 2018;62:298–313. [Google Scholar]

- International Monetary Fund World Economic Outlook Update, June 2020 – a crisis like no other, an uncertain recovery. 2020. https://www.imf.org/en/Publica tions/WEO/Issues/2020/06/24/WEOUpdateJune2020/ Technical Report. URL:

- Iris Ç., Lam J.S.L. A review of energy efficiency in ports: operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019;112:170–182. [Google Scholar]

- ITF . Singapore Maritime Institute; 2019. Container Port Automation: Impacts and Implications. Technical Report.https://www.itf-oecd.org/sites/default/files/docs/container -port-automation.pdf URL: [Google Scholar]

- Kanellos F.D., Volanis E.S.M., Hatziargyriou N.D. Power management method for large ports with multi-agent systems. IEEE Trans. Smart Grid. 2017;10:1259–1268. [Google Scholar]

- Kavakeb S., Nguyen T.T., Yang Z., Jenkinson I. European Conference on the Applications of Evolutionary Computation. Springer; 2014. Identifying the robust number of intelligent autonomous vehicles in container terminals; pp. 829–840. [Google Scholar]

- Kizilay D., Eliiyi D.T., et al. A comprehensive review of quay crane scheduling, yard operations and integrations thereof in container terminals. Flex. Serv. Manuf. J. 2020:1–42. [Google Scholar]

- Kumawat G.L., Roy D. AGV or Lift-AGV? performance trade-offs and design insights for container terminals with robotized transport vehicle technology. IISE Transactions. 2021;53:751–769. [Google Scholar]

- Li X., Peng Y., Huang J., Wang W., Song X. Simulation study on terminal layout in automated container terminals from efficiency, economic and environment perspectives. Ocean Coast Manag. 2021;213 [Google Scholar]

- Li N., Haralambides H., Sheng H., Jin Z. Computers & Industrial Engineering; 2022. A New Vocation Queuing Model to Optimize Truck Appointments and Yard Handling-Equipment Use in Dual Transactions Systems of Container Terminals. 108216. [Google Scholar]

- Ma N., Zhou C., Stephen A. Simulation model and performance evaluation of batterypowered AGV systems in automated container terminals. Simulat. Model. Pract. Theor. 2020 [Google Scholar]

- Maguire A., Ivey S., Golias M., Lipinski M., et al. 51st Annual Transportation Research Forum. Transportation Research Forum; 2010. Relieving congestion at intermodal marine container terminals: review of tactical/operational strategies. [Google Scholar]

- Mao N., Cheng J., Li Y., Zhi X., Xu H. IOP Conference Series: Earth and Environmental Science. IOP Publishing.; 2020. Comprehensive evaluation method and case study on the promotion and application effectiveness of shore power supply systems. [Google Scholar]

- Menhat M.N., Zaideen I.M.M., Yusuf Y., Salleh N.H.M., Zamri M.A., Jeevan J. Ocean & Coastal Management; 2021. The Impact of COVID-19 Pandemic: A Review on Maritime Sectors in malaysia. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Minh C.C., Van Noi N. Maritime Business Review; 2021. Optimising Truck Arrival Management and Number of Service Gates at Container Terminals. [Google Scholar]