Abstract

Current interest toward ionic liquids (ILs) stems from some of their novel characteristics, like low vapor pressure, thermal stability, and nonflammability, integrated through high ionic conductivity and broad range of electrochemical strength. Nowadays, ionic liquids represent a new category of chemical‐based compounds for developing superior and multifunctional substances with potential in several fields. ILs can be used in solvents such as salt electrolyte and additional materials. By adding functional physiochemical characteristics, a variety of IL‐based electrolytes can also be used for energy storage purposes. It is hoped that the present review will supply guidance for future research focused on IL‐based polymer nanocomposites electrolytes for sensors, high performance, biomedicine, and environmental applications. Additionally, a comprehensive overview about the polymer‐based composites’ ILs components, including a classification of the types of polymer matrix available is provided in this review. More focus is placed upon ILs‐based polymeric nanocomposites used in multiple applications such as electrochemical biosensors, energy‐related materials, biomedicine, actuators, environmental, and the aviation and aerospace industries. At last, existing challenges and prospects in this field are discussed and concluding remarks are provided.

Keywords: actuators, biomedicine, energy storage materials, fuel cells, ionic liquids‐based polymer nanocomposite, ionogels, sensors

In this study, ionic liquids based polymer composites and their exceptional physicochemical characteristics and their capability to bond by analytes via multiple interchanges, such as π–π, hydrogen interaction, ion‐exchange, electrostatic, and dipolar relations, are discussed in detail.

1. Introduction

The discovery of water and air‐stable ionic liquids (ILs) by Wilkes in 1992 has opened a new field of interest within the advanced multifunctional materials community. During the last 20 years, more focus has been paid to ILs because of their novel and adjustable physical and chemical features.[ 1 ] ILs are mainly represented as an electrolyte that is liquid and made up of ions, and has a melting point of less than 100 °C. These characteristics differentiate ILs from molten salts.[ 2 ] ILs are constituted by various organic cations, and anions that are organic or inorganic. ILs show unique properties depending on their various configurations, based on hydrogen bonding, columbic forces, and van der Waals interactions between ions, i.e., cations and anions.[ 3 ] Ionic liquids also possess a moderate vapor pressure, which is lower than their decomposition temperature. The majority of the ILs compounds are liquid at 20 °C, i.e., at room temperature.[ 4 ]

The classical configurations of ILs in ambient condition or beneath ≤100 °C can assume fused, molten, and liquids organic salts.[ 5 ] Few ILs‐based polymers are supposed to be exclusively ionic, while being defined as deep eutectic solvents (DESs) and protic ILs (PILs) that are rare with the reagent of Olah's.[ 6 ] Furthermore, ILs have a significant lower viscosity and vapor pressure, and they may not vaporize easily beneath room temperature. ILs are also soluble in various solvents, can be acid and base, have wide‐range temperature steadiness, and are much less prone to corrosion than inorganic acids and bases.[ 7 ] Because of their nominal vapor pressure, ILs do not describe the explorer threat compared to ignitable organic solvents. ILs also do not show any harmful effect on the photochemistry of the environment. Furthermore, the essential lack of vaporization in ILs provides nonflammability below room temperatures; this includes some solvents with a lower boiling point, for example, pet ether, dichloromethane acetone, etc.[ 8 ]

Structure and functions of ionic liquids have been previously discussed in scholarly works related to the characterization of ILs.[ 9 ] Focus has also been placed about the descriptions of distinct functionalities,[ 10 ] ILs with chiral center,[ 11 ] ILs conversion of a solvent's polarity,[ 12 ] bio‐based‐ILs,[ 13 ] polymerized ILs,[ 14 ] active ILs,[ 15 ] unbiased ILs,[ 16 ] protic ILs,[ 17 ] metal ILs,[ 18 ] base ILs,[ 19 ] sustainable ILs,[ 20 ] and ILs preparation routes. Herein the presented review, we try to collate a comprehensive list of details related to the general overview of polymer‐based composites’ ILs components, including a classification of the polymer matrix. Furthermore, more focus is placed on ILs‐based polymeric nanocomposites used in multiple applications (such as electrochemical biosensors, energy related materials, biomedicine, actuators, environmental and aviation and aerospace industries). We then finally discuss existing challenges and prospects in the ILs field.

2. General Overview of Ionic Liquids

ILs are usually described as compounds comprised of cations and anions having melting temperature under 100 °C. Paul Walden reported the initial IL (ethyl ammonium nitrate) in 1914, and ILs were not recognized as a significant scientific field until after nearly one century.[ 21 ] By providing atmospheric condition, in 1940, at the Rice Institute of Texas, two scientists, Frank Hurley and Tom Weir designed liquid salts. When a salt of alkyl pyridinium chloride was mixed with aluminum chloride (AlCl3) and converted into a transparent liquid, it was called an ionic liquid. Their finding about ILs remained a chemical curiosity until the following years.[ 22 ]

ILs are liquids prepared from cations and anions. Some general examples of cations and anions have been shown in Figure 1 . These cations and anions are generally connected via different types of bonds. They are related to multiple physical and chemical characteristics, with deficient to nearly negligible vapor pressure and adequate thermal strength. In previous years, major studies dedicated to ILs highlight the growth of green and sustainable chemistry. Related fundamental and applied investigations have grown exponentially and have also shown the ILs importance to science, including a broad range of possible applications (Figure 2 ). ILs are especially known as green solvents and/or composites that can replace traditional flammable organic solvents.

Figure 1.

Some common cations and anions that form ILs. Reproduced with permission.[ 23 ] Copyright 2021, MDPI.

Figure 2.

The role of ILs in different fields of research.

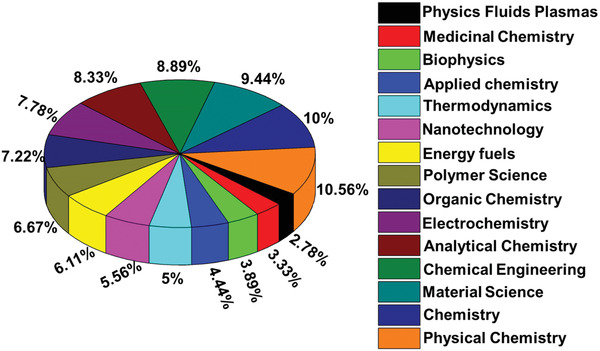

ILs as paradigmatic new classes of fluids have attracted significant attention only during the previous two decades. The number of science citation index (SCI) articles published on ILs has exponentially grown from isolated articles, to more than 5000 between 1996 and 2016; the yearly rates of growth of papers about ILs has surpassed those of other popular scientific topics. This suggests that more and more investigators are involved in the exploration of this exciting field. The investigation of ILs is a multidisciplinary endeavor that involves analytical chemistry,[ 24 ] materials science,[ 25 ] chemical engineering,[ 26 ] and environmental science.[ 27 ] Furthermore, ILs show clear advantages for the preparation, catalysis,[ 28 ] physical chemistry,[ 29 ] electrochemistry,[ 30 ] energy fuels,[ 31 ] heredity,[ 32 ] nuclear physics,[ 33 ] medicinal chemistry,[ 34 ] engineering,[ 35 ] at manufacturing and laboratory scales. Figure 3 shows that the primary emphasis of the fields of interest of ILs is centered on material science, physical chemistry, chemical engineering, and multipurpose chemistry. At the same time, they are dominant over different implementations of ILs. Due to their ongoing development, it might be helpful to manage ILs physicochemical effects and many more characteristics of significance.[ 36 ]

Figure 3.

Classification of fields of interest and applications versus the number of publications. Adapted with permission.[ 36a ] Copyright 2020, Elsevier Ltd.

ILs are liquids prepared from cations and anions. These ions are generally connected via different kinds of bonds. They are related to multiple physical and chemical characteristics, with deficient to nearly inconsequential vapor pressure, adequate thermal strength, and many more may be utilized as a green solvent and/or composite.

2.1. IL‐Based Polymer Composite

ILs constitute a new category of chemical substances for superior (multi)purpose materials, with excellent prospectives of implementation in numerous fields because of their distinctive properties and functions. The introduction of various other substances can customize the properties of the ILs; one of them is polymers. The amalgamation of ILs with a particular type of polymers opens the opportunity to increase new substances having distinct structure such as membrane, films, fibers, etc. for the stimuli‐responses with customization, as a novel proposal for highly developed multifunctional materials. Moreover, the relationship between the chosen IL charges, i.e., cations and anions, also provides a significant functionality to the composite materials when combined with the polymer chains. The amalgamation of various ILs with different polymers opens new areas of applications in the field of sensors, drug delivery, actuators, batteries and fuel cells, environment, and biomedical. The functionalities of ILs can also be instrumental in enhancing the properties of future generations of composite structural batteries; ILs composites/nanocomposites could be integrated within the battery's architecture to increase energy density and tuning of the dielectric properties. For example, an IL, namely, diethyl methylammonium trifluoromethanesulfonate ([dema][TfO]) mixed with a polymer, i.e., polybenzimidazole and an IL‐based polymer electrolytes for fuel cells fabricated having operating temperatures above 100 °C. The membrane shows better thermal stability, high proton conductivity, i.e., 108.9 mS cm−1 at 250 °C and higher conductivity stability.[ 37 ] Further, an IL‐based ionic electroactive polymer (IL‐iEAP) transducer design for highly developed applications in biological and electronic areas. The advanced functionality of this IL‐iEAP is in 3D‐printing.[ 38 ] A study shows that when alkyl imidazolium‐ and alkyl phosphonium‐based IL incorporated with biodegradable polymers composite (BPC), i.e., polylactic acid, polybutylene succinate, and polycaprolactone, which all enhance the thermal, chemical, and mechanical properties of polymers composites. Alkyl imidazolium‐based ILs provide BPC a prominent elongation quality, excellent thermal stability, and superior compatibility. On the other hand, alkyl phosphonium‐based ILs provide BPC with a better tensile loading capacity, superior thermal stability, and better multiphysics interaction.[ 3c ] Fan et al.[ 39 ] reported Ti3C2–MXene blended layer functionalized with polypyrrole and IL‐based microemulsion fragments for supercapacitor applications. The above‐fabricated film shows outstanding specific capacitance, rate capability as well as cycling stability in between 4 and 50 °C. Further, the highest gravimetric density of 31.2 Wh kg−1 (at 1030.4 Wh kg−1) was exhibited by the fabricated film at room temperature for devices that are based on symmetric super capacitors.

2.2. Fabrication and Properties of IL‐Based Polymer Composites

This section summarizes the recent strategies for the fabrication process of IL‐based polymer composites, such as in situ polymerization, melt mixing, solution blending, and the use of ILs as filler to the polymer matrix.

A facile and environmentally friendly route of IL‐based polymer nanocomposites fabrication involved the use of 1‐butyl‐3‐methylimidazolium bromide as ionic liquid and polyaniline as polymer matrix and was synthesized using in situ polymerization and a cationic surfactant CTAB. This method helps retain the composite's conductivity with a frequency 3 MHz and temperature 120 °C.[ 40 ] Another example of one‐pot in situ polymerization is synthesis of reduced graphene oxide (rGO)@poly(ionic liquide) (PIL)/PBO where 1‐vinyl‐3‐aminopropylimidazole tetrafluoroborate (IL) converted to poly(1‐vinyl‐3‐aminopropyl imidazolium ionic liquid) (PIL‐NH2) by in situ free radical polymerization where PIL attached to rGO by π–π conjugation with improved dielectric properties, thermal stability, and high energy density.[ 41 ] Shamsuri et al.[ 3c ] provided a review on the employment of ILs as fillers that form a biodegradable polymer composite. Such ILs‐based biodegradable polymer composites were found to exhibit dual benefits, including improvement in properties and environment‐friendly polymer matrix.

As we know, ILs are composed of different cations and anions. The selection of these during the preparation of ILs‐based polymeric nanocomposites plays a crucial role. Apart from the type of polymer matrix, ILs compositions like the size of ions, length of an alkyl chain, type of anion, and interaction between the ions could also affect the properties and hence application of the ILs‐based polymer composites. For example, ILs based on ammonium, imidazolium, and phosphonium cations could be an alternative to traditional plasticizers of PVC because of their diffusion rate. The size and molecular structure of cations and anions in an IL contribute to the diffusion rate, intermolecular interactions, and hence localization to the polymer matrix. The thermal stabilities of some of the anions (bis(trifluoromethanesulphonyl) imide, TFSI)− > (PF6) − >> (Br)− also provides a pathway to select the anion for a thermal application. In addition, the length of the alkyl chain could also participate in affecting the properties. Fedosse Zornio et al.[ 42 ] studied and compared the chemical nature of 1‐butyl‐3‐methylimidazolium, N‐trimethyl‐N‐butyl ammoniun, N‐trimethyl‐N‐hexyl ammonium as cations and bromide, hexafluorophosphate, bis(trifluoromethanesulfonyl)imide as anions in poly‐1‐(methyl methacrylate) (PMMA) polymer matrix.

One of the fundamental limitations of IL polymers is the reduced ionic conductivity at ambient temperatures. One of the suggestions provided in literature to deal with this is developing IL polymer at lower glass transition temperature that could help retain ion mobility and, hence, conductivity. One such analysis on the size of ions and mobility is carried out by Stacy et al.,[ 43 ] where they discussed how columbic and elastic forces contribute to the ion transport in poly‐ILs and how the size of ions affects the diffusion. Figure 4 shows the different properties of the ionic liquid‐based polymer.

Figure 4.

Properties of ionic liquid‐based polymer.

3. Component and Classification of Polymer Composites

3.1. Component of Polymer Composites

A requisite for economical and lightweight materials has resulted in extreme curiosity in polymers in the past few years.[ 44 ] Polymer‐based composites are polyphase compounds where different types of fillers can be reinforced inside the polymer matrix, emerging in harmonious mechanical nature which is unattainable by using polymer alone.[ 45 ] Polymer‐based composites are usually based on two components, namely, fiber and matrix.[ 46 ]

3.1.1. Fiber

Fibers, natural or synthetic, are high strength/high modulus materials. Examples of natural fibers are reinforcements extracted from jute, oil palm, sisal, date palm, hemp, and flax.[ 47 ] Typical fossil fibers are represented by glass materials, Kevlar, carbon fiber, and polyethylene.[ 48 ] The orientation and arrangement of a fiber define the composite material's structural behavior and properties.[ 49 ] Hybrid composites can be obtained by blending these two classes of fibers with any matrix material.[ 50 ]

Numerous investigators have documented the benefits of cellulosic fibers: the latter are functional, nontoxic, renewable, low‐cost, and provide essential bonding with the matrix for load‐transfer capabilities that enhance flexibility and toughness under bending, all properties that affect the structural resistance.[ 51 ] Currently, limestone powder, fly ash, brick powder, and numerous types of mineral stabilizers support the microstructure architectures of the composites.[ 52 ] Enhancement of failure resistance and stiffness have been improved by means of the use of fly ash within a composite for load‐bearing capabilities, which results in an increased lifetime of the composite materials. Asbestos present within fibers is unsafe for human's health; asbestos‐based reinforcements are therefore not much explored in fiber‐reinforced composite materials. Plant‐based fibers deliver practical aspects like cost‐effectiveness, biodegradability, accessibility, and better physical and self‐regulating characteristics.[ 53 ] Plant‐based fibers have leaf (sisal and abaca), bast (flax, jute, hemp, ramie, and kenaf), fodder and reed (rice husk), core (hemp, jute, and kenaf), seed (cotton, kapok, and coir), and all other types of fibers originated from timber and wood.[ 54 ] Figure 5 displays some common examples of natural fibers.

Figure 5.

Some common examples of natural fibers.

3.1.2. Matrix

The matrix can be a thermoset polymer like polydicyclopentadiene, epoxy resin, or polyimide or can be a thermoplastic like polystyrene (PS), polypropylene (PP), acrylic, polyesters, and epoxy resins be elastomer type.[ 55 ] The function of the matrix is to form a connection with fibers and avail a reinforcement and desired structure to the final composite. The characteristics of the matrix decide the resistance power of the polymer composites to impact damage, attack of chemicals, high‐temperature creep, and water absorption.[ 56 ] There are various thermoplastic matrices with a broad scope of refreshing characteristics. Due to its lightweight, excessive mechanical power and protection from the adverse consequence of the environment, in various applications, thermoplastics are used as absolute substances.

3.2. Classification of ILs‐Based Polymer Composites

Based on the source, the type of reinforcement and type of matrix polymer composites are classified. Figure 6 shows the classification of ILs‐based polymer composites.

Figure 6.

Classification of ILs‐based polymer composites.

3.2.1. Classification Based on Their Source

Fiber Composites

Fiber‐reinforced composites are high performing fiber‐based composites and are composed of cross‐linked cellulose‐based fiber molecules, which include resins in the fiber‐reinforced composite matrix by a patented molecular re‐engineering phenomenon, resulting in an invention of excellent structural characteristics. With the aid of molecular re‐engineering, wood's desirable material, and structural characteristics are positively cloned and clad in the fiber‐reinforced composite product, that yield more significant characteristics and performance than the existing wood.[ 57 ] Fiber‐reinforced composite materials, unlike other composites, can be recycled 20 times, allowing scrap and can be reused multiple times.

Natural Fiber Composites

These are the materials in which the fibers reinforced in nature are made up of some substances like plants and wood that act as renewable resources for carbon dioxide. Their environmental and biological durability is frequently quoted as a critical benefit to them compared to conventional materials. Natural fibers have received special attention from engineers, technologists, manufacturers, and industrialists due to their vast prospective and applications in various engineering functions in the railway, building construction, automotive, defense, packaging, and general secondary‐load bearing applications.[ 58 ] Also, natural fiber composites are cost‐effective, renewable materials that contribute to reduce CO2 and other emissions, and are environmentally friendly.[ 59 ]

Biocomposites

These are composite materials made up of matrix (resin) and reinforcement of natural fibers.[ 60 ] Biocomposites frequently mimic the living materials structure involved in the process used for maintaining matrix strengthening properties by always providing biocompatibility. The matrix part is derived with polymers like—for example—polyester and natural rubber. Those polymers are obtained from renewable and nonrenewable resources.[ 61 ] Biofibers are divided into two parts, i.e., wood and nonwood fibers, all of which present lignin and cellulose. Fibers are crucial elements in the design of biocomposites and can be obtained from biological sources like animals or plants (e.g., fibers from recycled wood, crops like cotton, flax, or hemp, desecrate paper, regenerated cellulose fiber (viscose/rayon), silk or crop processing byproducts). Biocomposites are promising materials for potential future applications in the automotive and—more generally—the transport, apparel and packaging industries. Their attractive features, i.e., sustainability and renewability and further being biodegradable, make biocomposites a “material of the future.” Easy to dispose of and because of organic fertilizers characteristic of biocomposites later than the expiration is significant advantages of biocomposites, this is not usually possible with traditional synthetic substances.[ 62 ]

3.2.2. Classification Based on the Type of Matrix

Depending upon the type of matrix, polymer composites are classified into three types.

Organic Matrix Composites

It comprises numerous short and continuous fibers bound collectively via an organic polymer matrix. These composites are usually made for load among fibers of a matrix. They are lightweight, highly stiff, and has high strength and reinforcement.[ 63 ] Basis of used polymer composite material are classified into three categories.

Thermoplastic Composites

Thermoplastic resins commonly used in composite materials are typically high‐density polyethene, PP, poly(vinylidene fluoride) (PVDF), and polylactic acid.[ 64 ] Due to their higher viscosity, they are less used as a high‐tech material because of problems related to the effective wetting of the reinforcement during thermoforming, with the formation of porosity. The thermoplastic matrices are arranged in straight chains that can change the melted form. Generally, they are prepared by heating after shaping, injection, taking out, or thermoforming earlier than cooling. In this way, the final output retains the initially designed configuration,[ 65 ] and this process can be reverted. Thermoplastic matrices are resistant to oxidation and corrosion with good electrical and thermal insulating properties; they are used in many applications as ideal materials because of their excellent properties like lightweight and resistance to environmental effect.

The thermoplastic matrices are present in the shape of unbent chains that may be altered within the melted form. In highly automated manufacturing processes, the thermoplastic matrices are warmed then assembled with injection moulding, extraction or early thermoforming. This process is reversible. Reversibility is important, because it makes thermoplastic matrices recyclable, with a significant positive impact to the life cycle of the products and the overall global warming potential of composites made with those matrices. There are numerous thermoplastics, including a broad range with exciting characteristics.[ 66 ] Those matrices can be fashioned elastic like rubber, tough like metal and concrete, or translucent like glass to obtain multiple functionalities. Those matrices do not oxidize, have an elevated protection from deterioration, and offer superior insulation for heat and electricity. Owing to their lightweight, mechanical stability, and resistance to environmental challenges, thermoplastics are excellent materials for a wide variety of uses.

Thermoset Composite

Thermoset polymer composites consist of unsaturated polyester epoxy vinyl ester that acts as resins. They are primarily used in automotive, aerospace, naval, and aeronautical applications.[ 67 ] They are liquid at room temperature and can be solidified during implementation of warm, and an additional material known as hardener. In this way they are converted by heating, a type of chemical change‐making 3D strong bond. This is a permanent change and cannot be reversed. Due to this process, the material becomes insoluble in solvents like alcohols, hydrocarbons, ketones, etc. They are harder than thermoplastic matrices, crease‐resistance, and better‐woven fibers.

Typically liquid on ambient conditions, thermosets harden when subjected to heat and a hardener stabilizer. Therefore, curing affects the behavior of thermosets, inducing a chemical conversion with three different types of bonds among molecules. This operation is permanent, and once the material is melted is not soluble anymore within the mix of solvents (such as ketones, alcohols, and hydrocarbons). These materials are stiffer compared to thermoplastic matrices and are appropriate for moulding/resin infuse reinforcements with small, long or woven fibers.[ 68 ] The most common used thermoset matrices are polyesters, phenoplasts, epoxy resins, polyurethanes (PUs), phenolic, polymides, bis‐maleimides, and silicones.

Elastomers

Elastomer polymers have the same flexible grades of natural rubber. An inactive elastomer includes extended chains of molecules that are joined with each other one by one. The molecules of elastomers may have relative motions relative to each other and distort. For better elastic properties, the base materials are vulcanized. Vulcanization makes the elastomer hard, and helps forming a better or slightly more rigid 3D structure without major detriment to the elasticity of the molecular chains. Sulfur, carbon, and diverse chemically active compounds are present within an elastomer.[ 69 ] Various formulations permit the development of artificial rubbers for different applications. Elastomers are used to manufacture pillows, specific insulators, shoe soles or tires.

Metal Matrix Composites

Metal‐based fibers are reinforcements with specific high‐toughness. They are generally used for the strengthening of metal matrices via stacking and alternate bonding. Their demand is low because of their high cost.[ 70 ] To resist high temperatures, i.e., 300 °C of metal matrices, carbon‐steel fibers are used. Some other commonly used heat resistance metal fibers are tungsten, molybdenum, and boron. Metal matrix composites require reinforcements that are stable over a wide range of temperatures, and chemically inert. Due to an increase of the melting point of the matrix material, their reinforcements becomes small.[ 71 ]

Ceramics Matrix Composites (CMCs)

CMCs are technical ceramics, as well as composite materials. They are designed with ceramic fibers embedded in a ceramic‐based matrix.[ 72 ] The single phases of CMCs are brittle, To overcome the disadvantage of monolithic ceramics (i.e., their fragility), CMCs are developed. CMCs are rigid materials and show potential failure behavior during FM bonding. Improvement of the bonding between the reinforcement and the ceramic matrix is generally obtained by using a fiber coating, known as interphase.[ 73 ] CMCs are used primarily in applications where resistance to high temperatures and corrosive environments are required. They lack toughness but are quite strong and stiff, although CMC with architected reinforcements can provide significant resistance to high‐temperature creep, even at low volume fractions of reinforcement. Matrix materials mainly used in CMCs are silicon carbide, nitrides, mullite, and aluminum oxide, whose strength is maintained up to 1649 °C. They are generally used in automobile engines, cutting tools, mining, and spacecraft applications.

Copolymer‐Based Matrix

At present polymer‐based gel electrolyte seeks much attention due to its much electrochemical applications. Further, the structure of polymer gelators is helpful for understanding the physical characteristics of ionogels (IGs). So that recently designs of these polymers attracted much interest for the enhancement in the mechanical and conductive properties of materials. Gelators are present in two forms one is homopolymers, and another is copolymers. A triblock copolymer is a good host material for mechanical robustness out of these two versions of polymers. In a triblock copolymer, both end blocks are insoluble in short ILs. Upon mixing, they aggregated in the form of hard spherical domains and increased the IGs mechanical properties. On the other hand, ILs‐soluble midblock of copolymer on mixing with IL makes the ionic conductivity robust and hence initiates the electrochemical process. In this direction, a star‐shaped copolymer was fabricated by some researchers (poly(methyl methacrylate)‐b‐polystyrene)6 ((MS)6), which acts as a polymer gelator host for polymer‐based gel electrolyte. The six‐armed copolymer exhibits enhanced mechanical characteristics, approximate elasticity ≈2.5 × 104 Pa, and better ionic conductivity ≈1.54 mS cm−1 at room temperature. Thermal stability also increases by using this star‐shaped copolymer (Figure 7a).[ 74 ]

Figure 7.

a) Diagrammatic representation of the preparation of star‐shaped block copolymers (MS)6. b) Schematic description and picture of the ECL apparatus, including an emissive gel coating comprised of Ru(bpy)3(PF6)2/(MS)6/[EMI][TFSI] within the weight proportion of 1:3:7. The size of the individually emitting region was 2 × 2 mm. c) Emission graph from ECL appliances at different Ru(bpy)3(PF6)2 absorptions from 2 to 12 wt% comparative to the part of [EMI][TFSI]. The band at λ max = 610 nm (2.04 eV) approximates to emission of Ru(bpy)3 2+ from the 3MLCT higher energy band. d) Graphs of luminance as a part of Ru(bpy)3(PF6)2 absorption beneath a used AC peak‐to‐peak potential (V pp) of 6.6 V (i.e., −3.3 to +3.3 V) on a frequency of 60 Hz. The reaction period swapped from e) anode to cathode and f) cathode to anode bias. g) Graphs of the reaction period at different frequencies. Reproduced with permission.[ 74 ] Copyright 2019, American Chemical Society.

Figure 7b illustrates a graphic chart of the electrochemiluminescent (ECL) apparatus established upon (MS)6 gels. They set the emissive gel between a couple of line‐patterned indium tin oxide (ITO) electrodes, which obtained four emitting areas. Figure 7c illustrates the ECL emission ranges on Ru(bpy)3 2+ concentrations. There was no support for the color of the emitted light upon the absorption of luminophores. It could be an emitted red‐orange light, including the highest wavelength of 610 nm at all concentrations transformed to 2.04 eV, conforming to Ru's triplet metal‐to‐ligand charge transfer (3MLCT) of Ru(bpy)3 2+. Figure 7d illustrates the reliance of luminance upon the absorption of Ru(bpy)3 2+. It marked the luminance saturation at 10 wt% of Ru(bpy)3 2+, an inadequate arrangement with additional ion‐gel‐based ECL devices, including Ru(bpy)3 2+. In principle, electrical double layers are assembled, and redox reactions appear about the electrodes when an exterior AC voltage is used. Then, excited luminophores are built through an electron transfer among redox species (i.e., Ru(bpy)3 •1+ and Ru(bpy)3•3+). These operations carried site within ≈0.5 ms irrespective of preference polarization (Figure 7e,f), which corresponds to the reaction period of this appliance. While it varied the used frequency, there was no apparent deviation in the hold duration (Figure 7g).

Furthermore, by using a reversible addition–fragmentation chain transfer polymerization approach, a conductive IGs can be fabricated by using an IL 1‐ethyl‐3‐methylimidazolium bis(trifluoromethylsulfonyl)imide and a copolymer (random) poly[styrene‐ran‐1‐(4‐vinylbenzyl)‐3‐methylimidazoliumhexafluorophosphate]. The fabricated materials show better elasticity of 0.105 MPa and good ionic conductivity of 1.15 mS cm−1. Figure 8a shows synthetic pathway of poly[styrene‐ran‐1‐(4‐vinylbenzyl)‐3‐methylimidazolium hexafluorophosphate].[ 75 ]

Figure 8.

a) Synthetic pathway of poly[styrene‐ran‐1‐(4‐vinylbenzyl)‐3‐methylimidazolium hexafluorophosphate]. b) Molecular configurations of segments contained within the EC gel. c) CV of the EC gel, where the dmFc acts as an anodic ingredient and an internal measure. A Pt probe, ITO‐doped glass, and Ag‐wire were utilized as the working, counter, and quasi‐reference electrodes. Potential support of d) UV–vis absorption ranges and e) CIELAB color coordinates (L*a*b*) toward the electrochromic device (ECD), and f) photos of the ECD at different used potentials. Reproduced with permission.[ 75 ] Copyright 2018, Wiley‐VCH.

Figure 8b shows a schematic graphic of gel‐based electrochromic appliances and the chemical configurations of gel ingredients. Here, ethyl viologen bis(hexafluorophosphate) (EV(PF6)2) and dmFc were mixed within a gel comprised of P[S‐r‐VBMI][PF6] and [EMI][TFSI] as an electrochromic (EC) chromophore and anodic species. Figure 8c shows a cyclic voltammogram (CV) of the EC gel, where the redox responses of EV2+/EV+• and dmFc+/dmFc ensued reversibly. Depending upon the start potential of dmFc oxidation (−0.07 V) and EV2+ reduction (−0.65 V), it is anticipated that the device coloration to start around ≈0.6 V. UV–vis absorption ranges were documented to study the potential reliance of the optical characteristics of the apparatus (Figure 8d). Without effective absorption, a potential window less than −0.6 V was marked, excluding an expansive and weak peak at ≈450 nm originating from the dmFc. As expected from the CV investigation, it produced colored EV+• components around −0.6 V, and two firm absorption rises at ≈604 and ≈554 nm occurred. These distinct peaks became more assertive as the used potential improved due to the more elevated EV+ absorption of EV+•. It also tracked the optical variation concerning the CIELAB color coordinates (L*, a*, b*) (Figure 8e) and optical pictures (Figure 8f). Around 0.0 V, the L*, a*, and b* values ≈99.0, −3.5, and 15.4, indicating a little yellowish color because of the dmFc within EC gel. Nevertheless, a surprising decline within b* was noticed as the used potential improved, showing a color difference to blue. Identical to the UV–vis spectra effect, there was no substantial distinction within the color coordinate. At the same time, the potential was more elevated than −0.9 V. This behavior is backed through the device's pictures at different potentials (Figure 8f).

A combination of an ABA type copolymers with ILs was shown by Lodge and Ueki[ 76 ] to form an IGs. The fabricated ion‐gel‐based materials were used by various devices like the casting of solvents, printing with aerosol jet, etc. It was also found that these IGs are used in electroluminescent and electrochromic display with sensors, supercapacitors, etc. They are also a good substitute in biocompatible and biorenewable systems.[ 77 ] In this an ion gel was prepared by using self‐aggregation of triblock copolymers poly(styrene‐b‐ethylene oxide‐b‐styrene) and poly(styrene‐b‐methyl methacrylate‐b‐styrene) with IL (room temperature) 1‐ethyl‐3‐methylimidazolium bis(trifluoromethylsufonyl)imide, the ionic conductivity lies from 3 × 10−5 to 3 × 10−2 S cm−1 and specific conductance 0.3 to 10 µF cm−2.[ 78 ]

3.2.3. Classification Based on the Type of Reinforcement

Reinforcement is strong inactive and unwoven fiber‐like materials mixed with matrix to enhance the physical and mechanical properties, e.g., boron, jute whiskers, asbestos, etc. Based on reinforcement, polymer composite is classified as follows.

Fiber‐Reinforced Composites

In today's scenario, we need low cost, lightweight materials with high mechanical properties and good chemical resistance. To attain these achievements, fibers or carbon fibers composite is used as reinforcement material that adds desirable properties to composites, e.g., carbon fibers, glass fibers like metal and ceramic used latterly to make composite materials stiff and heat resistant.[ 79 ]

Fibers composite material has three integral parts.

Discontinuous face as fibers which is also known as the dispersed phase.

Continuous space as a matrix.

Interface is also known as the fine interface part.

The effect of fibers composite can be evaluated by length, structure, constituents of fibers, and the mechanical impact of the matrix. The alignment of fibers also plays an essential function in the strength of the composite, i.e., the longitudinal direction has excellent strength. Many organic as well as inorganic fibers are used as strengthening materials in the composite. Organic fibers like glass, silicon carbide, carbon fibers or graphite fibers, some multiphase fibers etc., are used, which are of the high elasticity, high thermal strength, and greater hardness compared to organic fibers. On the other hand, organic fibers with low density are stretchable and bouncy.

Laminar Composites

Laminar reinforcement composite is used to enhance the mechanical properties of structural units. Laminated composites are made from stacking various layers, leading to improvements of strength and hardness (like in the case of alumina with zirconia). Laminates are based on tape casting, which allows only a preferred orientation of the reiforcements. Laminar composites tend to be prepared using an organic matrix, leading to the stacking of layers into the different architectures.[ 80 ] Those are used primarily in electronic ceramics. Polymeric reinforcements and matrices tend to be used quite extensively in transport, aerospace, and constructions applications. Strength and toughness are achieved in laminar ceramic composites by either providing the reinforcement inside the layer, and/or reinforcing the layer interface.

Particulate Materials

Particulate reinforced composites contain hard material dispersed uniformly in a matrix. Those composites are used in engineering components because of their mechanical property. Examples are metal matrix and polymer matrix composites.[ 81 ] The composites show yield, fatigue, and strength, but in general poor ductility, especially in the case of thermoset matrices. From the early stage of the formation, cracking MS of particles or bonding damage at the matrix interface occur. Particulate‐based materials are in general classified as follows.

-

i)

Particle reinforced composites, in which particle and matrix do not interact at the atomic/molecular level. Particles are significantly stiffer than the matrix; hence load bearable, e.g., concrete.

-

ii)

Dispersed strengthened composites, in which particle and matrix interact at the atomic level, leading to strengthening, e.g., thoria dispersed nickel.

The performance of these composites is based on

particles’ diameter,

interparticle distance, and

reinforcement volume fraction.

Besides the above‐discussed reinforcement materials, other components like fillers (i.e., particle‐filled and microspheres), whiskers, flakes, directionally solidified eutectics, etc., are also used to enhance or improve various desirable sets of properties of polymer, metal or ceramic‐based composites.

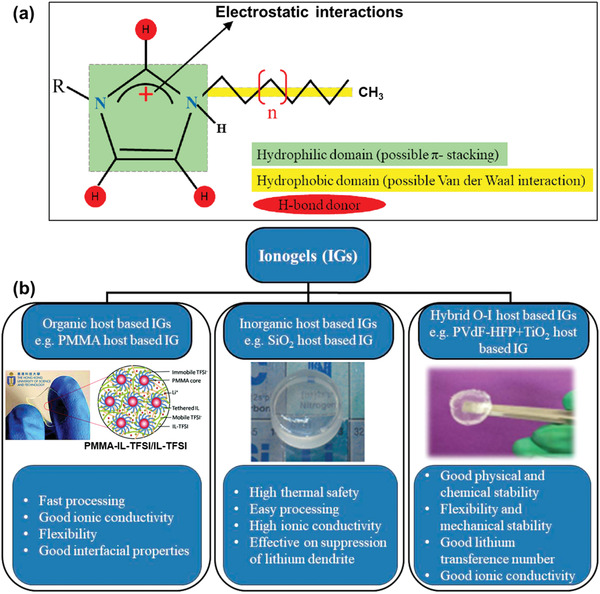

3.3. Classification Based on Ionogel

ILs consist of some distinctive chemical arrangements that can generate a series of attractive forces like van der Waals, electrostatic, Coulombic forces, and hydrogen bonds. ILs can be applied to different applications by tailoring the choice of particular cations and anions. The various interacting sites of an IL cation imidazolium are shown in Figure 9a. Based upon the specific support host of the doped ILs, IGs may be categorized within three distinct types (Figure 9b), i.e.: i) organic (polymers), host‐based IGs, ii) inorganic (oxide grids, oxide nanocomposites, etc.) host‐based IGs, and iii) hybrid organic–inorganic host‐based IGs. In IGs, ILs are generally adsorbed on the solid/porous connected network or integrated/trapped into a polymer system.

Figure 9.

a) Imidazolium based IL shows various interacting sites. b) Dissimilar classes of IGs founded upon host constituents. Reproduced with permission.[ 82 ] Copyright 2021, Elsevier Ltd.

In essence, IGs are solid‐electrolyte based ILs and are prepared by the introduction of ILs into solid organic or inorganic type host substances. Compared to conventional ILs, IGs exhibit better chemical, thermal, electrochemical, and mechanical stability and good ionic conductivity.[ 82 ] During the formation of IGs, ILs act as structural media while the formation of inorganic IGs occurs. IGs carry all the characteristics of ILs except the nature of outflow. On the other hand, like ILs, they also allow shape‐changing and have many applications. As a result, IGs are used to form good types of solid electrolyte membranes used in all types of solid appliances like fuel cells, lithium batteries, dye sensitized solar cells, etc. Further, the function of IGs improved by two methods: i) introduction of organic function in solid matrix, and ii) encapsulation of some molecular moiety into the stable IL phase, this leads to fabrication of some advanced substances like sensors, drug releasing system, formation of biocatalytic membranes, etc.[ 83 ]

Fujii et al.[ 84 ] also fabricated tetra‐arm poly(ethylene glycol) (Tetra‐PEG) IGs by introducing an ILs based on imidazolium into less concentration, i.e., 3 to 6 wt% of Tetra‐PEG. The prepared Tetra‐PEG IG exhibits superior mechanical characteristics as the compression and stretching test results. This IG is also used in electrochemical devices and the formation of membrane that separate and adsorb CO2. Amino acid‐based IL is used to make tough IG membrane used in CO2 capture.[ 85 ] Further epoxy‐amine‐based IG membranes were prepared that facilitate the transport of CO2 versus CH4 in a dry either humid mixed gas supply situation that is appropriate to the separation of biogas.[ 86 ] Ueki et al. reported a composite material that was based on an IL, namely, 1‐butyl‐3‐methylimidazolium hexafluorophosphate and a triblock ABA copolymer (A = poly(ethylene oxide) B = thermo‐ and photosensitive random copolymers with N‐isopropylacrylamide and A = 4‐phenylazophenyl methacrylate including azobenzene chromophore). The composite material shows transformation from sol to gel on irradiation of UV radiation at 47 °C. The spoiled ABA IG performs a photohealing capability that depends on extreme changes in the flow of IL–polymer composite initiated by illumination of light and results into repairing by filling cracks and cracks was fixed by using gelatin with visible light.[ 87 ] Further, a triblock copolymer photoreversible gelation in an IL is synthesized by Ueki et al.,[ 88 ] which shows reversible sol–gel transformation at 53 °C. Based on photodimerization of anthracene, a photohealsble IG was fabricated as a movable dative bond. A Tetra‐PEG and anthracene‐based materials are fabricated and introduced with ILs to form an IG. Further, the photohealing of the IGs was done with the help of the photodimerization process.[ 89 ] A highly sensitive porous IGs are fabricated in which an IL 1‐ethyl‐3‐methylimidazolium bis(trifluoromethylsulfonyl) imide and a cross‐linked polymer poly(ethyl acrylate‐ran‐styrene‐randivinylbenzene) are added with each other by using in situ cross‐linking polymerization further sugar cubes inverse replication. When these porous IGs are applied over skin, the resulting ionoskins show superior sensitivity and good detection power (≈152.8 kPa−1 and 400 kPa, respectively). These ionoskins monitor various human activities like swallowing saliva, elbow bending, locomotion, bending and tapping of fingers, and air blow.[ 90 ] IGs are used in various electrochemical applications like electrochemical display, smart sensing systems, functional electrochemical energy system like production and its storage.[ 91 ]

The ion gel was deposited upon the WO3‐doped ITO probe and then positioned another ITO plate at the canopy of the gel. The ideal EC features of the apparatus contained a high coloration efficiency of ≈61.9 cm2 C−1, a significant transmittance disparity of ≈91%, and better coloration/bleaching cyclic strength around 10 000 runs. Significantly, the EC behavior was well‐synchronized, including the optical evolution (Figure 10a). The optimized areal capacitance was ≈13.6 mF cm−2. The experimental feasibility of the ECS was confirmed, as illustrated in Figure 10b. As the accumulated energy raised through charging, a more robust color intensity was followed. The accumulated energy was reusable for the process of outer electronic segments. For instance, the LED bulb hinged upon successfully while powered through four ultimately charged ECSs in sequence. Currently, an illustrative application of ECSs has been indicated. To provide the dual role of energy conversion and repository and kinds of ECSs and organic photovoltaics (OPVs) were monolithically combined via transmitting one electrode (Figure 10c).

Figure 10.

a) Galvanostatic charge–discharge (GCD) curves and in situ transmittance shifts during the CD run and apparatus pictures at eight related matters. b) Process in energy storage and power reserve way of ion gel‐depended ECS. c) Schematic description of the configuration and dual‐mode of monolithically combined OPV and ECS. The charge accumulated in the ECS is shown via a transmittance difference. Reproduced with permission.[ 91 ] Copyright 2021, American Chemical Society.

An IG was prepared by Tang et al.[ 92 ] with the addition of an IL having low toxicity, i.e., 1‐butyl‐1‐methylpyrrolidinium bistrifluoromethanesulfonylimide and a triblock polyester poly(ε‐decalactone)‐b‐poly(dl‐lactide)‐b‐poly(ε‐decalactone). A thermoplastic elastomer‐type self‐aggregated cross‐linking is formed, leading to the mechanical enhancement with same processing situations, further hydrolytic breakdown of these IGs possible due to the presence of the ester backbone.

4. Applications of ILs‐Based Polymer Composites

Polymer composites can provide a suitable platform to develop innovative materials with excellent prospective of applications in many fields. Combining a matrix with fiber allows for emerging elegant resources, which harmoniously unite the characters of definite fiber and matrix.[ 93 ] Figure 11 shows the various applications of ILs‐based polymer composites.

Figure 11.

Various applications of ILs‐based polymer composites.

4.1. ILs‐Based Polymer Nanocomposites for Sensor Applications

Sensing technology comprises many parts, like sensors; another is a data acquisition and transmission system used to verify structural deeds and conduct of structures whenever exposed to circumstances beyond one's control, like an earthquake. The structural health monitoring devices can record actual load, reactions, and forecast environmental measures[ 94 ] as a sensor polymer composite material used in various fields like medical, agriculture, defence, etc.

4.1.1. Biosensor

Biosensing incorporates an essential function in human beings living for the diagnosis of diseases and examination of diseases. The growth of susceptible, low cost, and selective devices is an excellent way to screen for diseases early. Biosensors are used extensively to recognize biomolecules like dopamine (DA), ascorbic acid (AA), and uric acid.[ 95 ] Polymer composites based on graphene (Gr) are widely used as a biosensor because of their high mechanical strength, excellent electrical conduction, and biocompatibility.[ 96 ] Gr‐based polymer composites got much attention for their practical application in enzyme biosensors, DNA biosensors, apt sensors, immunosensors, and optical biosensors.[ 97 ] It is used for enzymatic biosensors based on the detection of enzymatically generated hydrogen peroxide (H2O2), electron transfer mediator electrochemistry, and direct electrochemistry of enzyme.

The biocompatibility, comfort of transformation, and preparation of high‐performance nanocomposites of graphene oxide (GO) as well as rGO and easy electrode incorporation are the edges of the GO and rGO into biosensor implementations. Figure 12 illustrates the finding and usage of carbon nanomaterials (CNMs) and ILs and their yearly publications, showing that ILs and CNMs are currently becoming researchable fields.[ 98 ]

Figure 12.

Pie graph of usages of ILs and chronological finding and applications viewpoint of ILs and CNMs. The bar chart shows the numeral of articles every year from 2010 to 2021. Reproduced with permission.[ 98 ] Copyright 2021, MDPI.

Electrochemical Biosensor

In today's scenario, we all are dependent on various drugs for our survival. These drugs are chemical substances; sometimes, these drugs have side effects on different body parts when taken in overdoses. For monitoring these drugs, we need some analytical tools. The most suitable option for this is electrochemical biosensing. Boumya et al.[ 99 ] developed an electrochemical biosensor to detect diclofenac, an analgesic. Figure 13 shows various materials that can be used in electrochemical biosensing of diclofenac.

Figure 13.

Various materials that are used in electrochemical biosensing of diclofenac.

An electrochemical sensor that is simple protein molecularity imprinted is basically based on a chitosan/IL‐Gr customized glassy carbon electrode (GCE); the sensor exhibits superior performance for detecting bovine serum albumin (BSA).[ 100 ] Electrochemical biosensor based on IL‐based polymer composite is also used to detect microbial pathogens present in food and foodborne pathogens. Nowadays, many works are done on this, so we have also paid attention to the selectivity and sensitivity of ILs based electrochemical biosensors.[ 101 ] These electrochemical biosensors work very efficiently to detect various biomolecules in our body like enzymes, carbohydrates like glucose, proteins like myoglobin (Myo), hemoglobin (Hb), etc., for the body's proper functioning. Some of them are explained below.

Enzyme's Biosensors

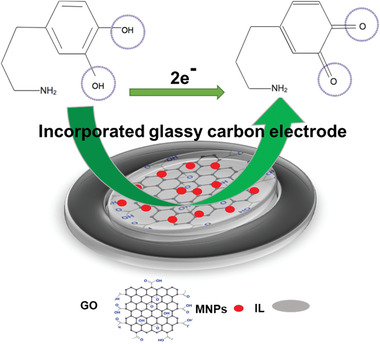

Enzymes are chemically protein molecules; they work like a catalyst in our bodies, which is why they are also known as biocatalysts. Enzymes control all biochemical activities in our body like digestion, protein synthesis, DNA replication, etc. ILs enhanced the performance of various enzymes for biosensing of various materials—IL–polypyrrole–Au (IL–PPy–Au) composite used for enzyme immobilization for H2O2 sensing. A new electrochemical biosensor based on enzyme has the benefit of IL–PPy–Au composite to immobilize horseradish peroxidase (HRP) on the GCE. The synthesized C12–PPy–Au–HRP/GCE based biosensor has an excellent electrochemical activity for detecting H2O2.[ 102 ] An IL‐based polymer composite based on cholesterol oxidase (Chox) enzyme acts as a biosensor. It has an outstanding performance for the cholesterol of a less quantity of 0.5 to 5 mm having excellent sensitivity, less responding time, and more stable repeatability.[ 103 ] The above‐mentioned IL‐based amperometric biosensor was prepared by using chitosan (Chi)–IL (1‐butyl‐3‐methyl imidazolium tetrafluoroborate) [BMIM][BF4],[ 104 ] which is a cross‐linked matrix, and gold nanoparticles (AuNPs) onto thiol (‐SH) based multiwalled carbon nanotubes (MWCNTs) with cholesterol oxidase (Chox) enzyme. The synthesized biosensor is designated as‐MWCNT(SH)–Au/Chi–IL/Chox. Figure 14 shows the fabrication of the CNT‐MNPs/ILs‐based biosensor electrode.

Figure 14.

Fabrication of CNT‐MNPs/ILs‐based biosensor electrode.

Lu et al.[ 105 ] prepared an HRP‐based biosensor, which has no reagent and works on the direct transfer of an electron between enzyme and electrode. It shows direct electrochemistry as well as bio‐electrocatalysis of HRP for H2O2. To prepare this HRP biosensor, the composite material is made up of Chi with room temperature‐based IL [BMIM][BF4]. This gives an efficient method for realizing the electrochemistry of various enzymes and exploring third‐generation biosensors.

Glucose Biosensors

Glucose (Glu) is a carbohydrate, and they are known as body fuel; in this, Glu comes into the monosaccharide part of carbohydrates. Glu is the most straightforward carbohydrate that our body absorbs directly and uses in the various metabolic process of the human body. Glu breaks down into gluconic acid during respiration and releases a tremendous amount of energy. However, sometimes due to some catalytic activities, it increases body blood sugar levels, leading to significant problems like kidney failure, liver failure, etc., this condition is known as diabetes.[ 106 ] In this way, various enzymatic and nonenzymatic biosensors developed from time to time. The enzyme‐based sensor, namely, Glu oxidase (GOD), catalyzes the glucose to facilitate the recognition of the Glu amount in the blood.

On the other hand, in the case of a nonenzymatic sensor, a suitable substance is fabricated on the sensor's surface, which goes with the catalytic activity against glucose to catalyze the Glu[ 99 ] suitably. A nonenzymatic electrochemical Glu sensor was fabricated that was made up of mixed NPs of Ni–Pd modified IL–rGO on the GCE.[ 107 ] The detection of Glu using this sensor shows that it had a broad array of linear Glu detection, i.e., from 0.0002 to 10.0 mm and a limit of detection of 0.03 µm and sensitivity of 1504.61 mA mm −1 cm−2.[ 108 ] An enzymatic glucose biosensor was developed based on GOD and HRP enzymes. Further, it is combined with an IL‐based polymer composite. The above‐discussed biosensor was prepared as with which a 3D microporous (3DM) N[3‐(trimethoxy silyl) propyl] aniline (PTMSPA) polymer blended with an IL. [BMIM][BF4] deposited on electrode of ITO by electrodeposition method, in which PS spheres were used as a sacrificial template. The 3DMPTMSPA‐IL composite had distinctive characteristics like a huge available surface, better biocompatibility, and outstanding chemical stability, an ideal bioassay. The Glu biosensor was prepared by immobilizing GOD and HRP on the surface of 3DM composite film by using Nafion (Nf) as binding material. The biosensor known as Nf–GOD–HRP/3DM–PTMSPA–IL/ITO has an electrochemical performance for glucose over a large concentration array having excellent selectivity as well as sensitivity. It is used in the detection of Glu in the serum of humans.[ 109 ] Figure 15 shows the arrangement of the Glu self‐energy biosensor designed established upon an enzymatic biofuel cell.

Figure 15.

Schematic arrangement of the Glu self‐energy biosensor designed established upon an enzymatic biofuel cell.

Regarding the Glu biosensors above, the Glu biosensors based on the electron transfer mechanism paid much attention due to the absence of mediators and are referred to as third‐generation biosensors. These IL‐based Glu biosensors are very important to detect blood sugar levels due to their high sensitivity and selectivity.

Hemoglobin and Myoglobin

Hb and Myo both are proteins and bind oxygen to transport it to the body, but the primary difference between them is that Hb is a heterotetrametric protein and present in erythrocytes; on the other hand, Myo is a monomeric protein and found in muscles tissue in which it is intracellular storage site of oxygen. The IL‐based composite resources can be widely utilized as an immobilization matrix to capture proteins and enzymes. Hb was selected as a sample protein to study the hybrid method. A novel composite material, Hb–Chi–BMIMBF4/GC, gives a good electrochemical sensor platform for reduction–oxidation proteins and enzymes, and it has various electrochemical applications in biosensors, direct electrochemistry, and biocatalysis.[ 110 ] A novel electrochemical biosensor was prepared by immobilizing Hb on a DNA customized carbon IL electrode (CILE) using [EMIM][BF4] as the modifier. The obtained electrochemical impedance spectroscopy (EIS) peaks on the customized electrode show that the Nf and DNA composite material gives a unique biocompatible microenvironment for maintaining the indigenous construction of Hb and enhancing the rate of direct transfer of Hb by using the basal electrode. The electrochemical variable of Hb in the composite film was additionally considered by using the outcomes of the charge transfer coefficient (α) and the apparent heterogeneous electron transfer rate constant (k s) as 0.41 and 0.31 s−1. The prepared electrochemical biosensor exhibited outstanding electrocatalytic performance for reducing trichloroacetic acid (TCA), H2O2, NO2 −, and the noticeable Michaelis–Menten constant (K M app) for the electrocatalytic response were deliberated, respectively.[ 111 ] Figure 16 shows the study overview of EIS, which is being used under electrochemical study.

Figure 16.

A study overview of EIS, which is being used under electrochemical study.

A noble electrochemical biosensor was prepared to spot acrylamide and was based on Hb capture in IL‐carbon paste. The Hb–carbon IL paste electrode (Hb/CILPE) was examined using various electrochemical techniques. The planned biosensor shows superior sensitivity and low observation limit for AA with the standard sample preparation method. That is why the Hb/CILPE must be used for direct electrochemical determination of acrylamide in food samples.[ 112 ]

The molecularly imprinted technique is a good substitute for biomolecules recognition systems, including immunoreactions, enzyme‐catalyzed reactions, aptamer, etc. For this, the IL 1‐3‐vinyl imidazole bromide was prepared and used to invent a molecularly imprinted layer for making electrochemical sensing of Myo. This layer was decorated on a GCE modified with MWCNT using the IL as the functional monomer. The sensing behavior of the customized electrode was studied by using the hexacyanoferrate structure as an electrochemical reduction–oxidation probe. The outcomes show that the sensor has better selectivity, excellent sensitivity, competent techniques for medical diagnostics, environment protection, and food safety.[ 113 ]

A unique biosensor that is made up of electro‐co‐deposition of Myo, sodium alginate (SA), Fe3O4–graphene (Fe3O4–GR) composite on the CILE was constructed by using Nf as the thin layer making substance to develop the constancy of protein immobilized on the electrode's surface, and the fabricated electrode was represented as Nf/Myo–SA–Fe3O4–GR/CILE. The invented third‐generation biosensor showed a wide linear range from 1.4 to 119.4 mmol L−1, less detection limit as 0.174 mmol L−1 (3σ), better stability and reproducibility for the reduction of TCA, which would be effective of being a potential biosensing proposal in the electroanalysis and electrocatalysis. Further, a biosensor was prepared for the recognition of H2O2 that was based on a Myo composite of Nf and a room temperature IL, namely, 1‐butyl‐3‐ methyl‐imidazolium chloride [(BMIM)Cl]. The projected biosensor has an inferior detection boundary as compared to many other biosensors that was based on IL–heme protein and it excluded from general interference in H2O2 biosensors.[ 114 ]

Neurotransmitters

Neurotransmitters (NTs) are endogenous hormones that assume a significant role in various brain functions; an anomalous amount of these NTs causes many bodily, psychotic, and neurodegenerative ailments like Alzheimer's, Parkinson's, and Huntington's disorder. That is why, their sensitive and vigorous recognition is an immense clinical consequence—the electrochemical recognition of NTs done by enzymatic and nonenzymatic methods.[ 115 ] Epinephrine (EP) is the most essential NTs in mammalians’ central nervous system. Change in EP concentration results in many disorders, so the detection of EP is essential. Unfortunately, EP and AA exist simultaneously in a biological system. The oxidation of AA takes place near the potential of EP at mainly solid electrodes resulting in a coincidental voltametric reaction for EP and AA.[ 116 ] To overcome this problem, one can use a modified electrode that can selectively detect the EP in the existence of AA. A new rGO composite GCE modified with IL crystal (ILC), 1‐butyl‐1‐methylpiperidinium Hexa‐fluoro‐phosphate [BMPM][PF6] and cyclodextrin (CD/ILC/RGO/ILC/GC) was made by the mechanical casting of every layer. The personalized electrode was used for the detection of some NTs like DA, EP, norepinephrine (NEP), levodopa (L‐DOPA), 3,4‐dihydroxy‐phenylacetic acid, and serotonin (ST).[ 117 ] Atta et al.[ 118 ] synthesized a new carbon‐composite electrode, i.e., based on ILC [BMPM][PF6] and nickel oxide NPs. They were successfully used as an electrochemical sensor to detect paracetamol in a sample of human urine and some NTs like DA, NEP, L‐DOPA, and ST. Further, an electrochemical biosensor that was used to know the presence of DA and generally based on IL decorated GO supported NPs of gold (Au), i.e., (IL–GO–AuNPs) that was coated on a GCE.[ 119 ] Figure 17 shows the schematic illustration of the electrochemical sensors for detecting DA incorporated GCE.

Figure 17.

Schematic depiction of the electrochemical sensors for detecting DA on incorporated GCE.

4.1.2. Humidity Sensor

Humidity is an essential factor for living beings and the environment. The observation of the evolution and role of humidity plays a crucial function in various fields, like medicine, farming and electronics corporations, and health observance. Different components like ceramics, Gr, and polymers promote humidity sensors. Thermoplastic and thermoset‐based composites with natural fibers like flax, hemp, and choir and special stacking sequences also show sensitivity and shape change capabilities based on the level of surrounding relative humidity.[ 120 ] It is however a significant challenge to design humidity sensors with all the most desirable properties, i.e., brilliant linearity, high sensitivity, small hysteresis, fast response time, and many more.[ 121 ] Detection of low humidity is always a challenge. In that case, IL ligands were evenly established in a framework of UIO‐66 to enhance the hydrophilic nature of the sensing substances.[ 122 ] Figure 18 shows the preparation of the humidity sensor and a description of the layers.

Figure 18.

The graphical preparation of humidity sensor and description of the layers.

Fernandes et al.[ 123 ] synthesized a new humidity sensor that was based on polymer composites comprising IL [BMIM][FeCl4] and the PVDF. The moisture reaction of the [BMIM][FeCl4]/PVDF sensor materials consisting of various IL amounts was analyzed by changing the resistance through changeable relative humidity (RH) from 35 to 90% RH at a steady temperature of 25 °C. Figure 19a shows an interaction, i.e., ion–dipole in between PVDF and [BMIM][FeCl4] in humidity sensing is present. The reproducibility of various specimens’ sensors was estimated using [BMIM][FeCl4]/PVDF compounds to replicate humidification/dehumidification processes. The outcomes are exhibited in Figure 19b via curve, the function of time is resistance for five humidity processes beneath a humidity deviation from around 35% to 90% RH and consistent heat of 24 °C. The sensor delivers significant constant resistance for the five humidity processes. Figure 19c illustrates the evolution of the resistance, including the humidity; the most elevated resistance values are marked for the lower humidity (35%), the resistance is decreasing with growing humidity accumulation.

Figure 19.

a) A interaction, i.e., ion–dipole in between PVDF and [BMIM][FeCl4] in humidity sensing. b) Humidity sensor responsivity to the [BMIM][FeCl4]/PVDF with distinct constituents of [BMIM][FeCl4]. c) Sensor sensitivity toward fluctuating humidity circumstances to the [BMIM][FeCl4]/PVDF through diverse components of [BMIM][FeCl4]. Reproduced with permission.[ 123 ] Copyright 2019, American Chemical Society.

4.1.3. Piezoresistive Sensor

In the case of piezoresistive sensors, resistivity is dependent on the strain. Acrylate‐based polymers are used in union with ILs to support the manufacturing of elastic piezoresistive touch‐based sensors. The execution of the piezoresistive sensor was valued up by the degree of the cross‐linking and molecular heaviness of the matrix that controls the ability of movement of the polymeric chains and IL domain. The polymerization and cross‐linking are managed by changing UV exposure time and the amount of cross‐linking agent, respectively, which finally impact the sensitivity of the sensors. It was manifest that the piezoresistive behavior turned into the reorganization of polymeric chains and IL domains within the composite formed through the contortion of the components.[ 124 ] Piezoresistive strain gauge sensors are the most widely used sensor among all types of strain gauges used to measure acceleration, force, torque, pressure, and vibration. IL/polymer composites (1‐ethyl‐3‐methyl‐imidazolium tetrafluoroborate [EMIM][BF4]/2‐[[(butylamine) carbonyl]oxy]ethyl acrylate (BACOEA)) were fabricated to use as sensing substances for stretchable piezoresistive tactile sensors.[ 125 ] The activity of the piezoresistive sensors was explored with the extent of cross‐linking and polymerization of the IL/polymer composites.[ 126 ]

The complete living sensing process is displayed in Figure 20a. Figure 20b illustrates the response 5 cm from the sensing instrument through the terminus. Besides, these sensors might respond to exhaling on various frequencies within concurrent due to graphdiyne's quick absorption, desorption, and response characteristics to water elements. As expressed in Figure 20c, the breathing rate obtained using the resulting curve is consistent with the identical respiration swiftness, demonstrating the probability of quantifiable examination of respiratory velocity. Here, a distinct reaction toward one breathing duration is depicted in Figure 20d, including the puff humidity growing from 20% to 35%. The puff rate enriched quite following vital moves, abruptly breath, and respiration techniques demonstrated in Figure 20e. Figure 20f illustrates instrument interpretation under profound breathing occurrences.[ 127 ]

Figure 20.

a) Visual illustration of the breathing process. b) Appliance retort to biological breathing. c) Instrument retort to diverse breathing swiftness. d,e) Substantial indication retort to extinction and breath while regular breathing and behind entire movement breathing duration. f) Appliance arrangement under deep breathing occurrences. Reproduced with permission.[ 127 ] Copyright 2022, Elsevier Ltd.

Table 1 shows the IL‐based biosensing materials and their different applications.

Table 1.

Ionic liquid‐based biosensing materials and their different applications

| Sr. no. | Name of IL | Materials | Applications | Refs. |

|---|---|---|---|---|

| 1. | [BMIM][TfO] (trifluoromethyl sulphonate) + [EMIM][TFSI] (Bis(trifluoromethyl sulphonate) imide) | Propylene carbonate | Ammonia sensing | [ 128 ] |

| 2. | [BMIM][BF4] | Chitosan | Protein and enzyme sensing | [ 110a ] |

| 3. | [VEIm][DCA] (1‐Vinyl‐3‐ethyl imidazolium dicyanamide) | Ammonium persulphate and silica | Self‐relieving sensor for detection of respiration | [ 129 ] |

| 4. | [BMIM][PF6] | Poly‐N‐succinimidyl acrylate | Glucose sensor | [ 130 ] |

| 5. | [EMIM][BF4] | 2‐[[(butylamino) carbonyl]oxy]ethyl acrylate | Piezoresistive tactile biosensor | [ 126 ] |

| 6. | [BMIM][FeCl4] | Poly(vinylidene fluoride) | Humidity sensor | [ 123 ] |

| 7. | [BMIM][TFSI] | Propylene carbonate | Ammonia sensor | [ 128 ] |

4.2. ILs‐Based Polymer Nanocomposites for Energy Related Applications

As the population increases rapidly, the energy demand also increases. A possible material to be used to meet energy management requirements from various alternative energy sources is an ILs‐based polymer composite for broad energy production applications. the integration of ILs to the solid polymer electrolytes could also improve the ionic conductivity, due to superior energy density, broad electrochemical window, thermal stability, minor vapor pressure, and flameproof.[ 131 ] ILs also used to develop quasi‐solid‐state electrolytes (QSSEs), which affect the activity of quasi‐solid state lithium metal batteries, enhancing the ionic conduction of selected electrolytes with their stability. ILs are also used to prepare high‐responding electrodes because of their distinctive microstructures.[ 132 ] As we discussed above, IL polymer‐based composites have many applications in the field of batteries like QS lithium metal batteries (QS‐LMBs), lithium‐ion batteries (LIBs),[ 133 ] lithium‐oxygen batteries,[ 134 ] as well as in supercapacitors (SCs),[ 135 ] fuel cells,[ 136 ] etc.

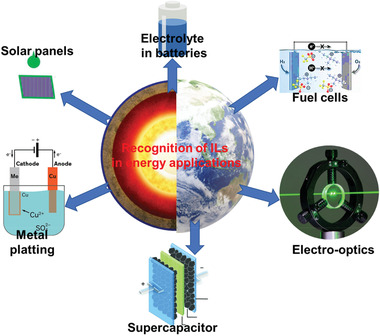

The concept of using IG, i.e., IL‐based polymer gel as electrolytes, is a new advance in science that pulls great attention due to their properties and hence applications in energy storage. The combination of ionic liquid and polymer allows to form a solid gel‐like structure that results in superior properties as well as can be used in lithium cell assembly due to their physicochemical properties.[ 137 ] Besides that, Hernández et al.[ 138 ] have also reported a synthesis route for poly(ionic) electrolytes that they successfully synthesized via anion exchange resin and explained their broad scope of poly(ionic) electrolytes toward energy storage technologies. Some energy‐related applications of ILs are discussed in this section. Figure 21 illustrates representation of the recognition of ILs in different energy‐based applications.

Figure 21.

Representation of the recognition of ILs in different energy‐based applications.

4.2.1. Batteries

ILs are used in batteries due to their safety characteristics in terms of overheating, short circuits, battery explosions, caused by liquid electrolytes. ILs have undergone some significant advances in different areas for the development of battery cells. ILs have also been used to prepare the slurry for producing electrodes, as electrolyte additive in solid electrolyte interphase (SEI), and as a solid polymer electrolyte in various polymer composites.[ 139 ] Many IL electrolyte‐based batteries are present, like lithium‐based, aluminum‐based, dual‐graphite batteries, etc. We discuss more those below.

Lithium Ion‐Based Batteries with Ionic Liquid Electrolyte

There are many Li‐based batteries like LMBs, which are nonrechargeable, known as primary batteries, LIBs and Li–polymer based batteries known as a secondary battery. Li+‐based batteries are an essential part of today's scenario due to their daily‐used gadgets like cell phones, watches, computers, tabs, sports equipment, electric vehicles, etc. The coming‐era batteries need the advancement of new ingenious polymers, which is beneficial for better fulfillment on behalf of power density, cyclability, unrefined resources availability, light heaviness, printability, elasticity, and supportability as security.[ 140 ] High‐thermal stability is expected in IL Li‐based battery. Li electrodes‐based batteries mainly deal with two problems: poor activity and safety problems. So, the characteristics of the junction of two surfaces and the Li–metal surface/electrolyte interactivity are essential to solve the rest problems and improve this appliance. Ternary polymer electrolytes are an excellent option made by poly(ethylene oxide) (PEO), Li salts, and various ILs present in the middle of two Li–metal blocks. The robust cooperation in the electrolytes and the Li‐atoms affects the structure of the electrolyte at its interface area, where minute and flat ions are present in a sound described area along with Li+‐ions and with many self‐diffusion coefficients. On the other hand, large ions like (methyloxymethyl) triethyl phosphonium [P222mom]+ enhance the density of PEO on the inner side because of the more significant number of species present at the interface. So, the structure‐dynamic characteristics at the interface of electrolyte and Li–metal surface can be improved by selecting particular ILs in ternary polymer electrolytes, which prevent the development of SEI above the exterior part of the electrode in this way enhance the activity of the battery.[ 141 ]

Thermal management is also the main problem in the growing use of batteries. Due to this safety concern, extremely thermally conductive (TC) substances are required. Carbon nanotube (CNT) or fibers filled PVDF having superior TC is the best alternative to traditional electrode substances that carry PVDF and lampblack in Li+ cells. Just only adding 8 wt% of graphene nanoflakes, the TC of nanofiber separators of polyacrylonitrile can be enhanced by 3.5 to 8.5 W (m K)−1.[ 142 ] Li‐ion batteries with liquid electrolytes have limitations like low power and energy density, safety, etc. To overcome these problems, solid electrolytes develop, i.e., QSSEs and all‐solid‐state electrolytes. Lately, ILs as a biodegradable substance have paid much concern to emerging QSSEs because of their outstanding properties, like thermally and chemically stable, integrated configuration over an extended variety of working temperatures, more electrochemical stability window, better ionic conduction over normal room temperature with incombustibility. The prepared ILs is categorized as a conventional, solvate, and renewable ILs which is completely bio‐based for the LMBs with QSSEs. The traditional ILs are broadly based on imidazolium, quaternary ammonium, pyrrolidinium, piperidinium, and many more.[ 132 ]

Some scientists synthesized a novel polymerizable IL monomer, i.e., as a repeating unit, linking a meth acryl functional group with the positively charged ion in an IL molecule with comparatively revoked potential windows. A polymer‐based electrolyte is obtained by reacting a small polymer with a binary Li‐IL. The obtained electrolyte shows an outstanding rate discharge property for a Li‐based polymeric battery; it retains 83% of its discharge capacity and comparatively superior cycle activity. This new Li–polymer cell is fireproof and free from leakage, user friendly, big size lithium secondary, i.e., rechargeable battery.[ 143 ]

Aluminum‐Based Batteries with ILs‐Based Electrolyte

Reviews of the literature have shown that imidazolium salts or amide ligands (such as urea) can make IL electrolytes or quasi‐IL electrolytes for secondary aluminum batteries. Batteries formed on aluminum provide an applicable option due to their three‐electron redox potential, constancy in the metallic form, and much natural occurrence. The advances of this type of battery are based on fireproof electrolytes with less noxious is essential for reducing safety dangers and environmental effects. Due to this motive, ILs have been proposed for energy‐storing because of their little vapor pressure and more oversized electrochemical windows. A new type of ILs, known as IL analogues or so‐called DESs, usually produced by a mixture of a strong Lewis acid metal halide and Lewis's base ligands, have obtained much consideration due to its own equivalent electrochemical and physical characteristics with less expenditure and lower ecological footmark.[ 144 ] A 1:1.5 1,2‐ dimethyl‐3‐propylimidazolium chloride:AlCl3 electrolyte is used for new rechargeable cell with positive graphite electrode and aluminum as negative electrode works as reversible chlorine (Cl) intercalation electrode. So, separating the membrane between anodic and cathodic electrolytes is not required. 1.7 V average discharge voltage was produced for 1–10 mA g−1 graphite, and more than 150 cycles were obtained at the positive electrode at 100% depth of discharge.[ 145 ]

Dual Graphite Batteries with IL‐Based Electrolyte

In previous years, much focus has been devoted to the development of cation intercalation‐based batteries, but anions had no consideration or less consideration in the electrolyte. Anion intercalation was achieved through a highly concentrated acid solution as an electrolyte, but significant security concerns made this implementation less valuable. The double graphite interpolates melted electrolyte‐based batteries that gain attention on implementing anion interject graphite as the positively charged electrode in batteries when we used IL as electrolyte at room temperature.[ 146 ] A battery that shows high reversibility and capacity detention and brings a capacity is a new aluminum–graphite dual‐ion battery (AGDIB) in an electrolyte, i.e., ethyl‐methyl carbonate, having superior energy density.

Figure 22a diagrammatically shows the early and charged conditions of the AGDIB. At charging, PF6 − anions within the electrolyte interpolated in the cathode made from graphite. The Li+ ions in the electrolyte deposition upon the aluminum counter probe to construct an Al–Li alloy. Figure 22b illustrates galvanostatic charge–discharge (GCD) arcs of the AGDIB, showing a specific anion intercalation/deintercalation shape within graphite. The battery's usual galvanostatic charts are displayed in Figure 22c. Figure 22d additionally exhibits the CD capabilities and approximating coulombic competence of the AGDIB while the rate capability trials. Figure 22e represents the stability cycling interpretation of the AGDIB on a current velocity of 2 C. Figure 22f displays an assessment of the AGDIB with different leading electrochemical energy storage (ESS) machinery.[ 147 ]

Figure 22.

a) Diagrammatic description of the AGDIB in the primary condition (up) and the charged form (down). b) GCD arc of the AGDIB at 0.5 C. Insets are the battery's dQ/dV differential curve and a picture illustrating a single AGDIB cell igniting up two yellow LEDs within a sequence. c) CD arcs of the AGDIB beneath different current rates. d) Rate capacities and compare coulombic efficiencies of the AGDIB. e) The stability cycle trial outcome of the AGDIB at a current speed of 2 C. f) Execution comparison of the AGDIB with traditional ESS appliances and different newly documented progressive energy storage apparatuses, while DGB defines dual‐graphite battery. Reproduced with permission.[ 147 ] Copyright 2019, Wiley‐VCH.

Natural graphite electrodes are studded and compared with a synthetic graphite electrode (KS6) via CD test. It was found that a dual‐natural graphite battery shows better performance than a dual‐KS6‐graphite battery, e.g., having superior discharge plateau and best plateau retention. The dual‐graphite system's principle is known by doing a cyclic voltammetry (CV) test. An invented dual‐graphite battery (DGB) formed from the pure [EMIM][TfO] IL electrolyte having a charge/discharge voltage between 1.0 and 3.9 V. The outcomes show that the EMIM+ cations exhibit much stable intercalation/deintercalation property as compared to the TfO− anion. The main benefit of the [EMIM][TfO]–DGB includes the well‐being measurement of the IL electrolyte and the plentiful electrode resources. Moreover, the [EMIM][TfO] IL contains only C, H, O, N, F, and S atoms; this IL is an excellent and promising material for upcoming electrochemical energy storage devices.[ 148 ]