Abstract

This study compared the three wastewater pretreatments of ozonation, Fe2+-S2O82− and freeze-thawing (F/T) in the disintegration, anaerobic digestion (AD) and final disposal of the sludge. The F/T pretreatment increased the dewaterability and settleability of the sludge by 7.8% and 47.1%, respectively. The ozonation pretreatment formed more volatile fatty acids (VFAs), with a peak value of 320.82 mg SCOD/L and controlled the release of sulfides. The Fe2+-S2O82− pretreatment removed heavy metals through the absorption and flocculation of ferric particles formed in-situ. During the anaerobic digestion of the sludge, the ozonation pretreatment accelerated the hydrolysis rate (k) rather than the biochemical methane potential (B0) of the sludge due to the high VFA content in the supernatant. Comparatively, the F/T pretreatment facilitated the B0 with great economic efficiency by enhancing the solubilisation of the sludge. Although Fe2+-S2O82− pretreatment decreased the methane production, the ferric particle was a unique advantage in the disintegration and harmless disposal of the sludge. The digested sludge had more VFAs after ozonation pretreatment, which contributed to the recycling of carbon. In addition, the lower sludge volume could save the expense of transportation and disposal by ozonation pretreatment. Different pretreatments had different characteristics. The comparative study provided information allowing the selection of the type of pretreatment to achieve different objectives of the treatment and disposal of sludge.

Keywords: Sludge disintegration, Anaerobic sludge digestion, Effectiveness comparison, Different pretreatments

Graphical abstract

Highlights

-

•

Ozonation pretreatment contributed to form VFAs and control sulfides.

-

•

The in-situ formed ferric particle can remove heavy metals in Fe2+-S2O82−.

-

•

F/T pretreatment achieved a better performance of sludge disintegration than others.

-

•

Ozonation was more prone to promote the reduction and recycling of digested sludge.

1. Introduction

The amount of waste activated sludge generated from wastewater treatment plants (WWTPs) has increased dramatically, currently exceeding 50 million tons/year (80% moisture content sludge) [1,2]. Direct disposal of excess sludge without effective treatment poses numerous threats to the environment (including soil, air, underground water, etc.) and human health [3,4]. Achieving the reduction of excess sludge, rendering it harmless and enhancing resource recovery is crucial for eliminating environmental contaminations caused by the accumulation of sewage sludge. Waste sludge is usually comprised of organics, microbial cells and solid particles, with the dominant segment being water (>90%) [5]. But dewatering sludge is challenging due to the complex sludge floc and rigid microbial cell wall which contribute to the formation of a biological gel structure and impede the release of interstitial water and intracellular water [6,7]. Anaerobic digestion has been proven to be an effective method for sludge reduction, stabilization and resource recovery [8,9], but it is restricted due to the relatively low-efficiency of the hydrolysis caused by the complex sludge flocs. For these reasons, it has been necessary to adopt pretreatment methods for decomposing the sludge floc, damaging microbial cells and prompting the sludge hydrolysis toward a higher efficiency-anaerobic digestion with the goals of reduction, harmlessness and reclamation [10]. At present, sludge pretreatment methods are mainly divided into physical, chemical, biological and coupling.

The physical methods mainly consist of ultrasound treatment [11], microwave treatment [12], thermal hydrolysis [13,14] and F/T pretreatment [15]. Among them, F/T pretreatment can effectively destroy sludge flocs and microbial cells, improving anaerobic digestion [15,16]. After F/T pretreatment, the sludge volume index could decrease from 16.4 mg/L to 4.0 mg/L, and the acidogenic activity improve by 20% [16].

Chemical methods, such as Fenton reagent treatment [17], persulphate treatment [2,18], ferrate (VI) treatment [19,20] and ozonation treatment [21,22] are attractive for their highly-efficient operation and their high reaction rate. Ozonation treatment is an effective and green method for sludge disintegration. It can reduce the suspended solids by 49.1% and volatile suspended solids by 45.7% [22]. Ozonation pretreatment influenced the process of anaerobic digestion, by means of which pretreatment the methane production increased by 2.11 times after 30 days of digestion [23]. Persulfate pretreatment is another widespread method for sludge disintegration. It can be activated forming S· that is a kind of strong oxidative species for degrading some kinds of organic pollutants [24]. Fe2+ is generally used to activate persulfate because its ferric particle formed in-situ is useful for improving the dewaterability and settleability of the sludge [25]. The capillary suction time of the sludge decreased by 88.8% within 1 min after 1.5 mmol Fe2+/g VSS and 1.2 mmol S2O82−/g VSS pretreatment [26]. The extracellular polymeric substance (EPS) structure and microbial cell were both destroyed, leading to the release of intracellular organic matter after Fe2+-S2O82− pretreatment [27].

Ozonation pretreatment has been widely investigated and has achieved great performance in the disintegration of sludge due to its strong oxidizing property. The function of ozonation is simple, unlike Fe2+-S2O82−, which combines oxidation and flocculation [21,24]. F/T was considered a promising pretreatment to elevate the performance of the disintegration and anaerobic digestion of sludge by ice crystal and layer [28]. However, the disintegration of the sludge by chemical and physical pretreatment might release some undesirables from the cytoplasm to the supernatant by chemical that were harmful to further treatment and disposal of the sludge [29]. Considering the advantages and disadvantages of the different pretreatments, the effect of ozonation, Fe2+-S2O82− and F/T pretreatment on the disintegration, anaerobic digestion and final disposal of sludge were comparatively investigated, with the following goals: (1) demonstrating the advantages of the three different pretreatment methods on the disintegration of sludge flocs and the lyssis of microbial cells; (2) investigating the influence of the three pretreatment methods on the anaerobic digestion of sludge; (3) studying the characteristics of digested sludge from an economic perspective; (4) evaluating the harmlessness, stabilization and reduction of treated sludge.

2. Materials and methods

2.1. Sludge characteristics

The raw sludge sample was secondary sludge from the anaerobic/oxic process of Wenchang Municipal WWTPs, Harbin, China. The collected sludge was stored at 4 °C in the refrigerator before being used. The major characteristics of the raw sludge are presented in Table S1. All the experiments were completed within 48 h of sampling.

2.2. Experimental process

The study of the effect of ozonation and Fe2+-S2O82− (i.e., FeSO4·7H2O–K2S2O8 in this study) pretreatment on the disintegration of the sludge was carried out in a 500 mL flask filled with a 400 mL sludge sample. The oxidant was added to the reacting system. The concentration ratio of Fe2+ to S2O82− was constant at 4:5 (molar mass ratio) based on the previous study [26]. The ozonation system is shown in Fig. S1. The concentration of ozone (gas) was measured by sodium thiosulfate titration [30]. The dosage of the oxidant was 0.05, 0.1, 0.15, 0.2, 0.3, 0.4 and 0.5 mmol/g VS. All the samples were pretreated at the initial pH (i.e., the pH of raw sludge). During the reaction process, the sample was stirred by a magnetic stirrer at a rough speed of 600 rpm for 30 min. All the tests were analyzed in triplicate at 25 ± 1 °C.

For the F/T pretreatment, 2 L raw sludge was frozen in a plastic bottle at −20 °C for 12 h and thawed at room temperature. That was recorded as one cycle of F/T pretreatment [31,32]. After each cycle of pretreatment, a 400 mL sludge sample was collected and stored at 4 °C for the following analysis.

2.3. Biochemical methane potential (BMP) assay

The anaerobic digestion of the different samples of sludge was analyzed by BMP assay [33]. 300 mL pretreated sludge and 500 mL seed sludge were added into a 1 L thread bottle. The seed sludge was cultivated at 37 ± 1°C for 30 days before being used. The pH of the pretreated sample was adjusted to 7.0 ± 0.5, and then the sample was added to the anaerobic digestion reactor. After purging N2 for 10 min, the bottle was capped and stirred at a speed of 800 rpm at 37 ± 1°C (a diagram of the equipment is shown in Fig. S2). The volume of biogas was recorded every day by fluid-discharge. A gas chromatograph equipped with a thermal conductivity detector (Agilent-7890 A, USA) was used to detect the content of methane recording as mL CH4/g VS. The collected data was analyzed as in the previous study [33]. The detailed expression of B0 and k are shown in Text S1.

2.4. Analytical methods

The pretreated sample was first centrifuged at 3000 rpm for 10 min. Then the collected supernatant was filtered by a 0.45 μm cellulose acetate membrane. The filtrates were used to analyze the total nitrogen (TN), total phosphorus (TP), soluble chemical oxygen demand (SCOD), and VFAs according to the American Public Health Association (APHA) method [34]. The total solids (TS) and volatile solids (VS) were measured by the gravimetric method. The solubilisation of the sewage sludge was expressed as the SCOD content divided by the VS of the sludge. The settlement ratio for 30 min (SV30) was used to describe the settleability of the pretreated sample, which was the ratio of the total volume of precipitation formation to 100 mL of the sludge mixture for an undisturbed 30 min. The water content of the sludge solid was measured after the pretreated sample was centrifugated at 2000 r/min for 15 min, and then the collected solid was dried at 103–105 °C for 12 h to calculate its water content [35]. The molecular weight (MW) distribution was analyzed by the method of membrane separation in which the collected supernatant was filtrated by an ultrafiltration membrane with a molecular cutoff of 300 kDa, 100 kDa and 10 kDa, respectively (Mosu, China).

The pH of the sludge was measured by a pH analyzer (Leici, China). A particle size analyzer (Mastersizer 2000, UK) was used to analyze the particle size. For heavy metal analysis, the supernatant was first filtrated by a 0.22 μm cellulose acetate membrane, and then the filtrate was acidized by nitric acid and digested at 105 °C for 2 h to remove the organic matter. Next, the digestion liquid was detected by an inductively coupled plasma optical emission spectrometer (Agilent 5110 ICP-OES, USA) to measure the heavy metal concentration. The concentration of sulfides was detected by the methylene blue method using sodium sulfide as the standard [36]. The capillary suction time (CST) was calculated by a CST analyzer (Triton, UK).

3. Results and discussion

3.1. Sludge dewaterability and settleability

Fig. 1a shows that F/T pretreatment exhibited a higher efficiency in promoting sludge settleability compared with ozonation and Fe2+-S2O82− pretreatment. After one cycle of pretreatment, the SV30 decreased from 99.1% to 52.0%. The intracellular microbial matter swelled, and the sludge floc might be destroyed during the process of freezing. Then, microbial cell lysis reduced the volume of the sludge after thawing [5,16]. In comparison, the SV30 merely decreased to 82.3% and 88.6% in ozonation and Fe2+-S2O82− pretreatment (0.5 mmol O3 or S2O82−/g VS), respectively. In Fe2+-S2O82− pretreatment, the ferric particle formed in-situ could flocculate sludge flocs and inorganic particles, leading to a greater settleability than in the ozonation pretreatment [26].

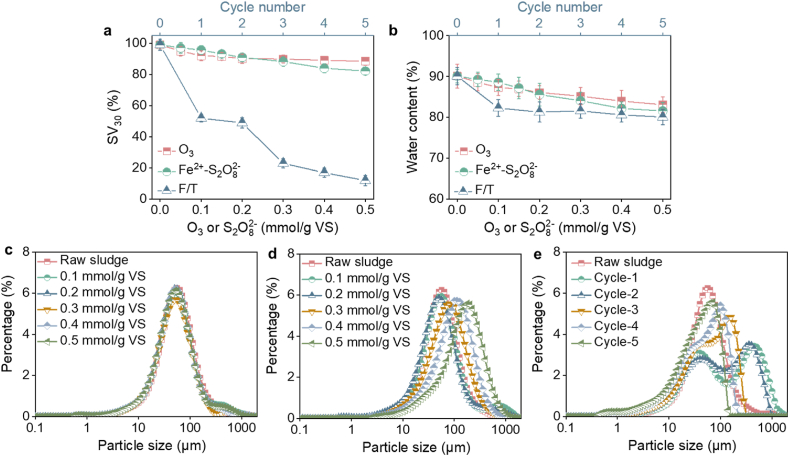

Fig. 1.

The change of SV30 (a) and water content of solid (b) after different pretreatments; and the particle size distribution after ozonation (c), Fe2+-S2O82− (d) and F/T (e) pretreatment.

The water content of the sludge solid was used to indicate the amount of dehydration for the sludge mixture [35]. In Fig. 1b, Fe2+-S2O82− pretreatment ([S2O82−]0 > 0.3 mmol/g VS) had more dehydration than that in the ozonation pretreatment. The E0 of ozone and S· was 2.07 eV and 2.5–3.1 eV, respectively, but SO4−· was more selective for reacting with organic matter [5,37,38]. So, the ozone might be consumed by released intracellular material, resulting in low dehydration [3]. For F/T pretreatment, the water content rapidly decreased to 82.3% after one cycle, but there was no further decrease with increasing operation cycles.

The particle size distribution was related to dewaterability and settleability [8,39]. The particle size of the raw sludge was mainly 1–300 μm, and ozonation pretreatment was feeble for changing it (Fig. 1c). Extracellular polymeric substances connected the particle and microorganism in the sludge mixture [40,41]. This phenomenon was changed by Fe2+-S2O82− pretreatment in which the particle size increased at 0.5 mmol S2O82−/g VS (Fig. 1d). The formed S· degraded the extracellular polymeric substances to destroy the sludge floc forming some fine flocs (or particles) (supported by Fig. 1b). The ferric particle was an advantage of Fe2+-S2O82−, which favored particle flocculation, enhancing the dewaterability and settleability of the sludge, compared with other methods of persulfate activation, such as alkali-activated persulfate and alkali-activated persulfate [26,42,43].

In Fig. 1e, there are two peaks (i.e., 0–150 and 150–1200 μm) after one cycle of pretreatment. Microbial cell lysis could release intracellular material which contained much protein (PN) and polysaccharide (PS) after F/T pretreatment [26]. The protein coagulated and flocculated cell debris and sludge flocs because of its tackiness, forming the peak of 150–1200 μm [44]. Meanwhile, some particles or flocs of sludge mixture were gathered and compacted by the promotion of the ice layer during the process of freezing, which increased the particle size of the sludge flocs [45,46]. The previous investigation also discovered a similar phenomenon that freezing pretreatment elevated the particle size of landfill sludge [46]. As cycles increased to five, the particle size distribution was similar to that of raw sludge. The new flocs formed in cycle 1 might be destroyed in the following cycles of F/T pretreatment. As mentioned above, the three pretreatments changed the physicochemical properties of the sludge (Fig. 1), influencing the components of the supernatant of the sludge, to some extent.

3.2. The release of intracellular substances

3.2.1. Sludge solubilisation

The solubilisation of raw sludge was only 0.035 mg SCOD/g VS. However, it increased to 0.291 mg SCOD/g VS after 0.1 mmol O3/g VS pretreatment because sludge flocs and microbial cells were destroyed by the oxidability of ozone, releasing organic matter into the supernatant and sequentially elevating the solubilisation of the sludge (Fig. 2a) [33]. The excessive ozone degraded the released substances and caused a moderate rise in the solubilisation of the sludge when the ozone dosage exceeded 0.1 mmol/g VS [47]. The Fe2+-S2O82− pretreatment achieved a similar change with ozonation pretreatment. However, the oxidative pretreatment was limited by the unwanted consumption of oxidants with released organic substances. The ferrate (VI) pretreatment also presented an analogous phenomenon in which the solubilisation of the sludge slowly increased when the concentration of ferrate (VI) exceeded 100 mg/L [8]. However, the solubilisation of the sludge increased to 0.457 mg SCOD/g VS after one cycle and then rose steadily in the F/T pretreatment. That result indicated one cycle pretreatment was enough to disintegrate the sludge floc.

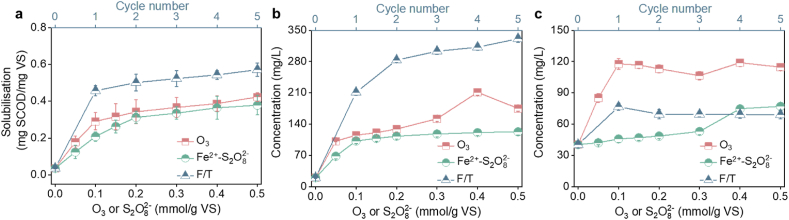

Fig. 2.

The solubilisation of sludge (a); the concentration of TN (b) and TP (c) in the supernatant after different pretreatments.

3.2.2. The release of N/P substance

Nitrogen (N) and phosphorus (P) were abundant in the excess sludge, so analyzing the difference among the three pretreatments by detecting their concentration of nitrogen and phosphorus was beneficial. The F/T pretreatment had the most TN release among all pretreatments, while the ozonation pretreatment released more TP into the supernatant (Fig. 2b ∼ 2c). F/T pretreatment could effectively destroy sludge flocs and microbial cells to improve the dewaterability and settleability (Fig. 1a ∼ 1b), and the N-containing substance would transfer from cytoplasm to the supernatant (Fig. 2b). The P-containing substance mainly existed in the cell membrane [3,48]. The formed ice crystal disrupted the cell membrane by frozen expansion rather than melting it by a chemical approach. So, there was a lower concentration of TP in the F/T pretreatment compared with in the ozonation pretreatment. Additionally, the ferric particle formed in-situ absorbed and flocculated the N/P-containing substance in the Fe2+-S2O82− pretreatment [8]. Therefore, the concentration of TN and TP in the Fe2+-S2O82− pretreatment was even lower than in the F/T pretreatment. The release of the N/P-containing substance was connected with the change of PN and PS in the supernatant that was a nutriment of the microorganism and contributed to enhancing the following sludge treatment and disposal, such as anaerobic digestion.

3.2.3. PN, PS and VFAs

As shown in Fig. 3a ∼ 3b, among all pretreatments, the best release of PN and PS was achieved in the F/T pretreatment. After one cycle of pretreatment, the concentration of PN and PS was 2105 mg/L and 197 mg/L, respectively. One cycle of F/T pretreatment could effectively destroy sludge floc and microbial cells leading to the release of intracellular matter such as N/P-containing substance (Fig. 2b ∼ 2c). The PN and PS were major components of the cytoplasm and the EPS, which was composed of a double-layer structure, containing tightly bound EPS (TB-EPS) and loosely bound EPS (LB-EPS) [49]. Then, the process of releasing intracellular material might be from the cytoplasm to the TB-EPS/LB-EPS to the supernatant. Although the sludge flocs and microbial cells were disrupted by one cycle of pretreatment (Fig. 1a ∼ 1b and 2a), the complete release of PN and PS into the supernatant needed more cycles of pretreatment by ice crystal (Fig. 3a ∼ 3b).

Fig. 3.

The content of PN (a), PS (b) and VFAs (c), and the variation of MW distribution of organics (d) in the supernatant after different pretreatments.

Meanwhile, the concentration of PN and PS in the ozonation pretreatment was greater than in the Fe2+-S2O82− pretreatment at the same applied dosage (Fig. 3a ∼ 3b). As shown in Fig. 2a, the ozonation treatment was more effective in disrupting sludge flocs and microbial cells at the same applied dosage. Therefore, there was a high content of PN and PS in the ozonation treated sample. Moreover, the ferric particle formed in-situ could absorb and flocculate the released PN and PS [49]. As mentioned above, the oxidation treatment was limited by the unexpected consumption, applied dosage and species of the oxidant. However, the F/T pretreatment would entirely destroy sludge flocs and inactivate microbial cells by ice crystal (i.e., physical method) without excessive restriction.

Nevertheless, the interaction between the oxidant and the released substance was prone to form VFAs that methanogens could directly utilize to elevate the anaerobic digestion of the sludge but was scarce in raw sludge [4,50,51]. The VFA content only increased from the 25.10 mg SCOD/L of raw sludge to 60.49 mg SCOD/L after five cycles of F/T pretreatment, so there were only a few VFAs in the EPS and cytoplasm (Fig. 3c). In the Fe2+-S2O82− pretreatment, the VFA concentration increased to 114.17 mg SCOD/L at the condition of 0.5 mmol S2O82−/g VS. Although the improvement in dewaterability, settleability and solubilisation of the sludge by Fe2+-S2O82− pretreatment was lower than in the F/T pretreatment (Fig. 1a ∼ 1b and 2a), the S·degraded the macromolecular organics forming more VFAs in the Fe2+-S2O82−. The concentration of VFAs even increased to 320.82 mg SCOD/L by 0.5 mmol O3/g VS pretreatment. The non-selective oxidation of ozone, which was more prone to destroy microbial cells and degrade organic matter, was a key reason [52]. Ozonation and Fe2+-S2O82− pretreatment for the molecular weight distribution could degrade the macromolecular substances into small molecular substances (Fig. 3d). For instance, the percentage of 10–100 kDa substances increased from 13.68% of raw sludge to 38.21%. The chemical pretreatment decreased the molecular weight of the organic substances, generating more small molecular substances such as VFAs [51].

Therefore, the improvement of the VFA content in the supernatant might be superior in chemical pretreatment compared with physical pretreatment. According to previous study, ultrasound, microwave and high-pressure homogenization pretreatment were all incapable of changing the characteristic of released substances such as VFAs and small molecular substances [[53], [54], [55]]. In theory, high VFA content commonly indicated better anaerobic digestion of sludge, while some hazardous substance, such as heavy metals, was also released into the supernatant with the cell lysis.

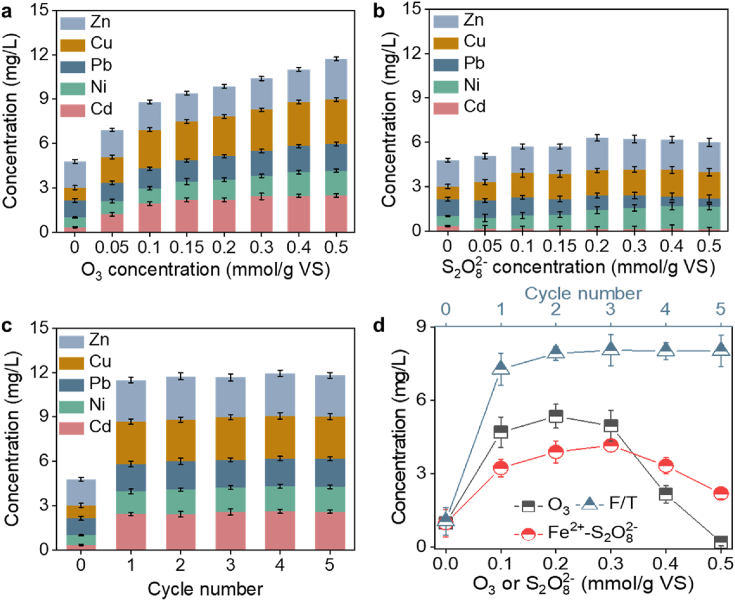

3.2.4. Heavy metals and sulfides

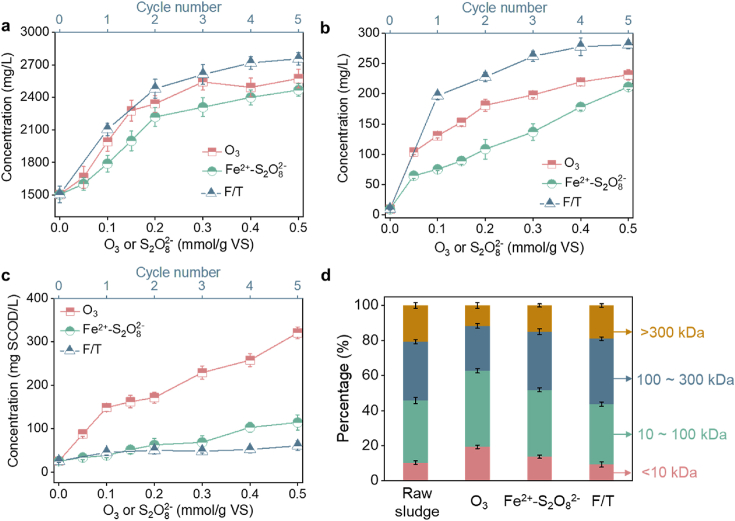

Heavy metal was poisonous for the anaerobic digestion of sludge and influenced its final disposal, so the heavy metal content was analyzed after different pretreatment methods, as shown in Fig. 4a ∼ 4c [56,57]. The total concentration of detected primary heavy metals (>0.3 mg/L) gradually increased with the dosage of ozone (Fig. 4a). It suggested microbial cell lysis and sludge floc disintegration occurred, with the release of heavy metals. According to previous study, the ozonized sludge achieved higher direct toxicity of copper (Cu) and zinc (Zn), which was a disadvantage of the ozonation pretreatment [22]. The content of heavy metal increased from 4.79 mg/L to 11.49 mg/L after one cycle of F/T pretreatment, while its content was scarcely 11.80 mg/L after five cycles (Fig. 4c). That confirmed one cycle of F/T pretreatment was effective in destroying sludge flocs and microbial cells. Other physical pretreatments, including hydrothermal pretreatment, ultrasound and microwave, were also incompetent at controlling the release of heavy metals [58,59]. The Fe2+-S2O82− pretreatment induced microbial cell lysis (Fig. 2a ∼ 2b), but only 6.00 mg/L heavy metal was in the supernatant after 0.5 mmol S2O82−/g VS pretreatment (Fig. 4b). This was attributed to the ferric particles formed in-situ that absorbed or removed the released heavy metal. So, there was a lower heavy metal content in the supernatant, which contributed to the harmless disposal of the sludge [60].

Fig. 4.

The content of primary heavy metal (>0.3 mg/L), including Zn, Cu, Pb, Ni and Cd after ozonation (a), Fe2+-S2O82− (b) and F/T (c) pretreatment; the variation of sulfides in the supernatant after different pretreatments (d).

Additionally, sulfide was considered the source of the offensive odor of sludge and a critical parameter for harmless and stable sludge treatment [8]. The sulfide concentration in the supernatant of the ozonation treated sludge sample reached a peak of 5.34 mg/L when the applied ozone dosage was 0.2 mmol/g VS (Fig. 4d). This process might be caused by the release of cytoplasm from microbial cells. However, the sulfide content was gradually reduced to 0.19 mg/L by oxidative degradation when the dosage of ozone was increased to 0.2 mmol/g VS. A similar trend of the sulfide content was found in the Fe2+-S2O82− pretreatment, which first increased to 4.15 mg/L at the condition of 0.3 mmol S2O82−/g VS and then dropped to 2.18 mg/L at 0.5 mmol S2O82−/g VS. Ferrate (VI) could also control the release of sulfide, but the concentration of sulfide by 1.25 mmol Fe (VI)/g VS pretreatment was just lower than that in raw sludge [8].

The F/T pretreatment could release lots of organic matter, such as PN and PS, by one cycle (Fig. 3a ∼ 3b), but it was powerless to control the sulfide content in the supernatant, which increased to 8.00 mg/L after five cycles of pretreatment (Fig. 4d). Although the sludge floc and microbial cell could be effectively destroyed by F/T pretreatment to improve the solubilisation and reduce the volume of the sludge, there was no change in the feature of the released substance, such as the formation of VFAs and the removal of sulfide. In contrast, the Fe2+-S2O82− pretreatment was better at removing heavy metal and sulfide, and ozonation pretreatment enhanced the VFA content in the supernatant of the sludge. The release of harmful substances and the formation of VFAs were connected with the anaerobic digestion of the sludge [61].

3.3. Sludge anaerobic digestion performance

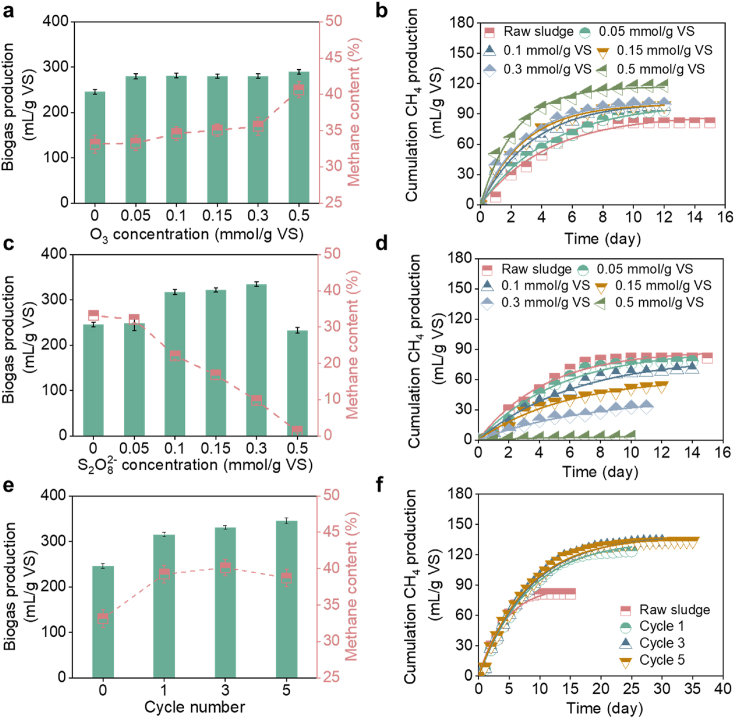

Fig. 5a ∼ 5b show the production of biogas and the methane accumulation of ozonation pretreated samples. After ozonation treatment, the production of biogas was higher than in raw sludge (245.82 mL/g VS). Interestingly, the biogas production was steady even when the dosage of ozone varied from 0.05 mmol/g VS to 0.5 mmol/g VS and only increased from 279.93 mL/g VS to 290.01 mL/g VS. The content of nutrient substance, including PN and PS (Fig. 3a ∼ 3b), rose with the applied dosage of ozone, that, in theory, might produce more biogas. However, the percentage of methane in the biogas gradually increased after ozonation pretreatment. The ozonation treated sample had more VFAs (Fig. 3c) that were easily utilized by methanogens so that methanogens became the dominant bacteria leading to an increase in the percentage of methane in the biogas [62]. Additionally, the released heavy metal influenced the microorganism metabolism and declined biogas production [63]. Therefore, a high concentration of PN and PS might achieve an inconspicuous variation in biogas production at a particular time.

Fig. 5.

The biogas production and cumulative methane production (with simulated curves of BMP data by model analysis) of different samples after ozonation (a ∼ b), Fe2+-S2O82− (c ∼ d) and F/T (e ∼ f) pretreatment.

In the Fe2+-S2O82− pretreatment, the biogas production gradually increased when the content of S2O82− was lower than 0.5 mmol/g VS (Fig. 5c). The sludge flocs and microbial cells were destroyed, releasing organic matter into the supernatant (Fig. 2 ∼ 3), which promoted microorganism metabolism, forming more biogas. However, the biogas production decreased from the 334.62 mL/g VS of 0.3 mmol S2O82−/g VS treated sample to 232.94 mL/g VS at the concentration of 0.5 mmol/g VS. It might be ascribed to the greater number of potassium ions in the sludge mixture, which inhibited biological activity in anaerobic digestion [8]. Nevertheless, the oxidative product of SO42− in the Fe2+-S2O82− treated sample can be utilized as a nutriment by sulfate-reducing bacteria, forming H2S that was toxic for methanogens, so that Fe2+-S2O82− pretreatment achieved the lowest methane production (Fig. 5d) [2,64].

The biogas production and methane production increased by 28% and 52%, respectively, after one cycle of F/T pretreatment (Fig. 5e ∼ 5f). However, the biogas production and methane production were not significantly changed after five cycles of pretreatment compared with in one cycle. Interestingly, the concentration of VFAs in the F/T treated sample after one cycle was far lower than that in the 0.1 mmol O3/g VS treated sample, but it achieved a more excellent methane production. Therefore, it was imperative to further research the characteristics of the anaerobic digestion of different samples of sludge.

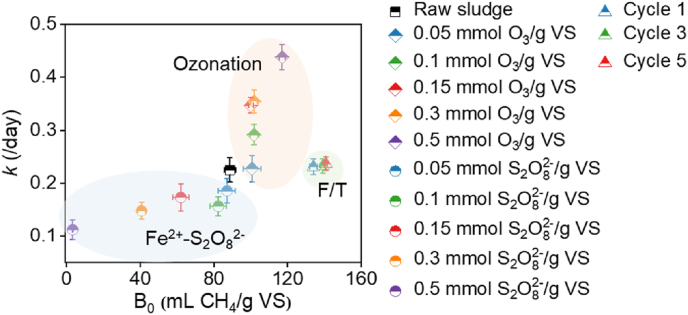

Model analysis was performed to evaluate the B0 and k of different samples (Fig. 6). The substrate model generally fitted all samples with the R2 exceeding 0.9600 (Fig. 5 and Table S2). The ozonation treatment was unable to change the B0 when the ozone dosage increased from 0.05 mmol/g VS to 0.3 mmol/g VS, but the k value rose from the 0.225/day of raw sludge to 0.354/day at the condition of 0.3 mmol O3/g VS. So, ozonation pretreatment was prone to enhance the speed of methane production rather than the biochemical methane potential due to the high content of VFAs in the treated sample (Fig. 3c) [65]. The applied ozone also induced the hydroxylation of organic substance that caused the maladjustment of methanogens, leading to a steady B0 [29]. In the Fe2+-S2O82− pretreatment, the B0 and k were both suppressed, which might be ascribed to the toxicity of H2S formed by sulfate-reducing bacteria on methanogens [2,66].

Fig. 6.

Hydrolysis rate (k) and biochemical methane potential (B0) of different samples.

In comparison, the F/T pretreatment enhanced the B0 with a plateau of the k value. The B0 increased by 51.15%, 56.90% and 58.69% in the cycle 1, cycle 3 and cycle 5 treated sample, respectively. The disintegration of sludge flocs and microbial cells lysis contributed to the release of nutriments (i.e., PN and PS) into the supernatant (Fig. 3a ∼ 3b), achieving a higher B0 in the F/T treated sample. Nonetheless, the ice crystals could not generate VFAs during the process of freezing (Fig. 3c), which may account for its being unable to increase the k value. Although the ozonation and F/T pretreatment improved the anaerobic digestion of the sludge, the characteristic of the digested sludge was relative to the final sludge disposal.

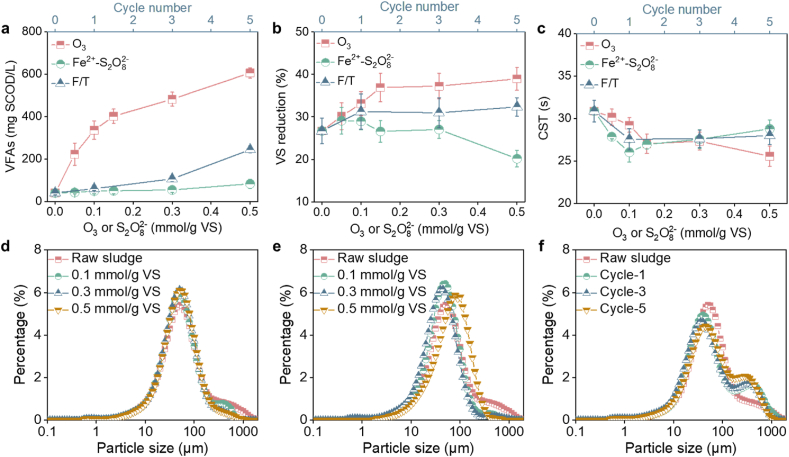

3.4. The property of the digested sludge

The concentration of VFAs in digested sludge was viable for recovering valuables that could be recycled as nutrients of microorganisms in the WWTPs or considered as raw materials for costly products [67]. After the anaerobic digestion of the sludge, the peak value of the VFA content was achieved in the ozonation treated sample, which was 605.69 mg SCOD/L at the condition of 0.5 mmol O3/g VS (Fig. 7a). It indicated the ozonation pretreatment not only improved the VFA content in the disintegrated sludge, it also promoted the biological metabolism of forming VFAs during the anaerobic digestion of the sludge. Some organic substances in the sludge mixture might be oxidized into VFAs by ozone, and macromolecular substances would be degraded to micromolecular substances (Fig. 3d) that were more easily metabolized by microorganisms producing more VFAs in the anaerobic digestion of the sludge [68].

Fig. 7.

The concentration of VFAs (a), VS reduction (b) and CST (c) of the different treated samples after sludge AD; the particle size distribution of ozonation (d), Fe2+-S2O82− (e) and F/T (f) pretreatment treated sample after AD.

In the F/T pretreatment, the VFA content only increased from 40.28 mg SCOD/L to 244.06 mg SCOD/L after five cycles. Although more organics were released in the supernatant after the F/T pretreatment (Fig. 2 ∼ 3), the freezing or thawing process was feeble for changing the structure of the released organics, resulting in a lower content of VFAs in the digested sludge compared with that in ozonation pretreatment [28]. There was also a lower content of VS in the ozonation and F/T treated sample, in which the VS reduction was 38.96% at the condition of 0.5 mmol O3/g VS and 32.25% after five cycles of pretreatment, respectively (Fig. 7b). A low sludge volume favored the following disposal, including transportation and recycling, at a low cost [67].

Additionally, the CST of the digested sludge decreased after three pretreatments, as shown in Fig. 7c. This indicated the pretreatment could promote the filterability of the digested sludge, which was prone to deep dehydration in the process of final sludge disposal [69]. Significantly, Fe2+-S2O82− pretreatment improved the filterability of the sludge when the applied dosage of S2O82− was lower than 0.1 mmol/g VS, but it would deteriorate with further increasing of the S2O82− dosage. As shown in Fig. 5d, the methane production was not completed at the condition of [S2O82−]0 < 0.1 mmol/g VS. The ferric particle formed in-situ and the microbial effect might induce a low CST of the digested sludge after Fe2+-S2O82− pretreatment [70]. However, the particle size distribution of the digested sludge (Fig. 7d ∼ 7f) was similar to the treated sample after different pretreatments (Fig. 1c ∼ 1e). Therefore, the sludge pretreatment elevated the dehydration and reduction of the digested sludge, but was feeble for changing its particle size.

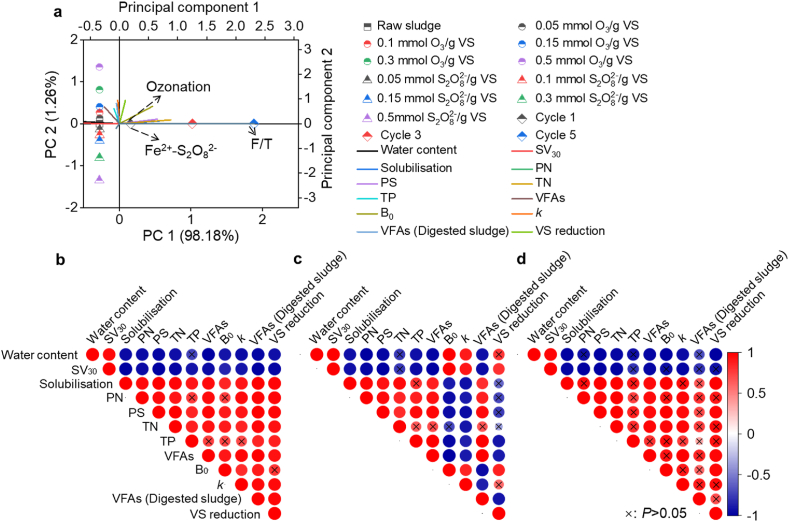

3.5. Correlation analysis

As mentioned above, the three pretreatments affected the sludge disintegration (Fig. 1 ∼ 3) and anaerobic digestion (Fig. 5 ∼ 7). Therefore, correlation analysis was used to investigate the mutual relation among the detected parameters. As shown in Fig. 8a, the RDA indicated chemical pretreatment (i.e., ozonation and Fe2+-S2O82− pretreatment) and physical pretreatment (i.e., F/T pretreatment) had different advantages in sludge disintegration. Chemical pretreatment, particularly ozonation pretreatment, was a benefit for promoting VFA generation, resulting in accelerating the anaerobic digestion rate (k). Comparatively, physical pretreatment was prone to enhance the release of organic substance and improve the B0. The RDA analysis showed there was a correlation among the detected parameters.

Fig. 8.

The RDA result of different samples (a); the statistical correlation analysis of detected parameters after ozonation (b) Fe2+-S2O82− (c) and F/T (d) pretreatment.

The VFA content in the disintegrated sludge affected the VS reduction of the digested sludge in the three pretreatments (Fig. 8b ∼ 8d). A high concentration of VFAs suggested an outstanding level of sludge floc disintegration and cell lysis which was prone to the degradation of sludge solids during the anaerobic digestion of the sludge [67]. The k had a positive correlation with the solubilisation of the sludge, PN and PS, according to the results shown in Fig. 3 ∼ 4 in the ozonation pretreatment. The solubilisation of the sludge was still connected with the B0 of the F/T treated sample (Fig. 8d). Therefore, the solubilisation of the sludge played a key role in the anaerobic digestion of the sludge, and the VFA content after disintegration might indicate the volume of the digested sludge.

3.6. Economic analysis and prospects

The economic analysis of different pretreatments at the laboratory scale evaluated their applicability and practicality (Table 1). For ozonation pretreatment, the expense of pretreatment included the electric charge of the ozonator (Rating: 80 w; Domestic electricity costs in China: 0.51 CNY/kilowatt hour) and high purity oxygen (Liming Co., China, 300 CNY/40 L). The cost of Fe2+-S2O82− pretreatment was mainly composed of the FeSO4·7H2O (Aladdin, 99 CNY/500 g) and K2S2O8 (Aladdin, 84 CNY/500 g). Meanwhile, the electric charge of the refrigerator (Rating: 150 w) was considered the expense of the F/T process in this study. As can be seen from Table 1, Fe2+-S2O82− pretreatment had economic superiority in sludge reduction at the same dosage of the applied oxidant, compared with ozonation pretreatment. Although ozonation pretreatment achieved better VS reduction after anaerobic digestion of the sludge (Fig. 7b), the cost of high purity oxygen was higher than the cost of the reagents in the Fe2+-S2O82− pretreatment. The F/T pretreatment had the best economic efficiency in methane production and VS reduction at the laboratory scale (Table 1), while the freezing equipment and sludge storage container might be expensive and complicated in practice.

Table 1.

Economic analysis of different processes in methane production and VS reduction.

| Parameters | AD performance (CNY/L CH4) | VS reduction (CNY/g VS) | |

|---|---|---|---|

| Ozonation (mmol O3/g VS) | 0.1 | 0.38 | 0.08 |

| 0.3 | 1.04 | 0.21 | |

| 0.5 | 1.46 | 0.33 | |

| Fe2+-S2O82−(mmol S2O82−/g VS) | 0.1 | 0.03 | |

| 0.3 | 0.10 | ||

| 0.5 | 0.22 | ||

| F/T (cycle) | 1 | 0.19 | 0.06 |

∗Gray area indicates the methane production in the pretreated sample was lower than that in the raw sludge.

The different pretreatments had different advantages in sludge disintegration based on the analysis of economy and efficiency. Ozonation pretreatment could effectively destroy the sludge floc (Fig. 1 ∼ 2) and then elevated the k of the anaerobic digestion of the sludge and the VS reduction (Fig. 6 ∼ 7). These characteristics of ozonation pretreatment made it suitable for the treatment of excess sludge by the urban sewage treatment plant because the amount of excess sludge was enormous, and the sludge would be immediately treated and disposed of to avoid accumulation [71,72]. The ferric particle formed in-situ and the lower price were the advantages of the Fe2+-S2O82− pretreatment, but the induced SO42− restricted the methane produced during anaerobic digestion of the sludge. So, the Fe2+-S2O82− pretreatment might be more applicable to industrial sludge such as textile-dyeing sludge [[73], [74], [75]]. There was little excess sludge in the village sewage treatment plant, so the F/T pretreatment dominated to decrease the construction cost and promote the convenience of biogas utilization [[76], [77], [78]].

4. Conclusions

F/T, Fe2+-S2O82− and ozonation pretreatment were comparatively studied in regards to their ability to enhance the disintegration, anaerobic digestion and final disposal of sludge. The F/T pretreatment improved the dewaterability and settleability of the sludge more than the other pretreatments. The ferric particle formed in-situ in the Fe2+-S2O82− pretreatment promoted the sedimentation of sludge flocs due to its flocculation and absorption. All the pretreatments could promote the disintegration of sludge flocs and the lysis of microbial cells, leading to the release of intracellular matter. However, ozonation and Fe2+-S2O82− pretreatment could oxidize organic substances, forming more VFAs and small molecular substances, but F/T pretreatment was feeble for that. Model analysis indicated ozonation pretreatment contributed to an increased k value due to the high concentration of VFAs, but F/T pretreatment easily improved the B0 with better economic efficiency by great sludge solubilisation. Fe2+-S2O82− pretreatment caused the methane production to deteriorate, due to the poisonousness of H2S for methanogens. Ozonation pretreatment achieved a lower sludge volume and generated more VFAs for the digested sludge, which contributed to the reduction and harmlessness of the sludge disposal and treatment. In contrast, Fe2+-S2O82− pretreatment was more economical in VS reduction than that in ozonation pretreatment. Finally, all pretreatments improved the filterability of the digested sludge, but failed to change the particle size distribution.

Acknowledgements

This study was supported by the State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology) (No. 2019TS04).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.ese.2021.100132.

Contributor Information

Wei Qiu, Email: qiuweihit@126.com.

Jun Ma, Email: majun@hit.edu.cn.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Xu Y., Geng H., Chen R., Liu R., Dai X. Enhancing methanogenic fermentation of waste activated sludge via isoelectric-point pretreatment: insights from interfacial thermodynamics, electron transfer and microbial community. Water Res. 2021;197 doi: 10.1016/j.watres.2021.117072. [DOI] [PubMed] [Google Scholar]

- 2.Zhen G., Lu X., Niu J., Su L., Chai X., Zhao Y., Li Y.Y., Song Y. Inhibitory effects of a shock load of Fe(II)-mediated persulfate oxidation on waste activated sludge anaerobic digestion. Chem. Eng. J. 2013;233:274–281. [Google Scholar]

- 3.Jin L., Zhang G., Zheng X. Effects of different sludge disintegration methods on sludge moisture distribution and dewatering performance. J. Environ. Sci. 2015;28:22–28. doi: 10.1016/j.jes.2014.06.040. [DOI] [PubMed] [Google Scholar]

- 4.Pang H., He J., Ma Y., Pan X., Nan J. Enhancing volatile fatty acids production from waste activated sludge by a novel cation-exchange resin assistant strategy. J. Clean. Prod. 2021;278 doi: 10.1016/j.jclepro.2020.123236. [DOI] [Google Scholar]

- 5.Carrère H., Dumas C., Battimelli A., Batstone D.J., Delgenès J., Steyer J.P., Ferrer I. Pretreatment methods to improve sludge anaerobic degradability: a review. J. Hazard Mater. 2010;183:1–15. doi: 10.1016/j.jhazmat.2010.06.129. [DOI] [PubMed] [Google Scholar]

- 6.Ye F., Liu X., Ying L. Effects of potassium ferrate on extracellular polymeric substances (EPS) and physicochemical properties of excess activated sludge. J. Hazard Mater. 2012;199:158–163. doi: 10.1016/j.jhazmat.2011.10.071. [DOI] [PubMed] [Google Scholar]

- 7.Zhang X., Lei H., Kai C., Zhang L., Han W., Liang H. Effect of potassium ferrate (K2FeO4) on sludge dewaterability under different pH conditions. Chem. Eng. J. 2012;210:467–474. [Google Scholar]

- 8.He H., Liu Y., Wang X., Huang Z., Xu C., Yang T., Zhang Z., Wang L., Ma J. Effects of newly prepared alkaline ferrate on sludge disintegration and methane production: reaction mechanism and model simulation. Chem. Eng. J. 2018;343:520–529. [Google Scholar]

- 9.Ma Y., Liu Y. Turning food waste to energy and resources towards a great environmental and economic sustainability: an innovative integrated biological approach. Biotechnol. Adv. 2019;37(7) doi: 10.1016/j.biotechadv.2019.1006.1013. [DOI] [PubMed] [Google Scholar]

- 10.Zhang Z., Li X., Liu H., Gao L., Wang Q. Free ammonia pretreatment enhances the removal of antibiotic resistance genes in anaerobic sludge digestion. Chemosphere. 2021;279 doi: 10.1016/j.chemosphere.2021.130910. [DOI] [PubMed] [Google Scholar]

- 11.Ruiz-Hernando M., Simón F., Labanda J., Llorens J. Effect of ultrasound, thermal and alkali treatments on the rheological profile and water distribution of waste activated sludge. Chem. Eng. J. 2014;255:14–22. [Google Scholar]

- 12.Qiang Y., Lei H., Yu G., Xin F., Li Z., Wu Z. Influence of microwave irradiation on sludge dewaterability. Chem. Eng. J. 2009;155:88–93. [Google Scholar]

- 13.Menardo, Balsari, Dinuccio, Gioelli Thermal pre-treatment of solid fraction from mechanically-separated raw and digested slurry to increase methane yield. Bioresour. Technol. 2011;102:2026–2032. doi: 10.1016/j.biortech.2010.09.067. [DOI] [PubMed] [Google Scholar]

- 14.Wang H., Liu J., Zhang Z., Li J., Zhang H., Zhan Y. Alkaline thermal pretreatment of waste activated sludge for enhanced hydrogen production in microbial electrolysis cells. J. Environ. Manag. 2021;294 doi: 10.1016/j.jenvman.2021.113000. [DOI] [PubMed] [Google Scholar]

- 15.Montusiewicz A., Lebiocka M., RoEj A., Zacharska E., PawOwski L. Freezing/thawing effects on anaerobic digestion of mixed sewage sludge. Bioresour. Technol. 2010;101:3466–3473. doi: 10.1016/j.biortech.2009.12.125. [DOI] [PubMed] [Google Scholar]

- 16.Phalakornkule C., Nuchdang S., Khemkhao M., Mhuantong W., Wongwilaiwalin S., Tangphatsornruang S., Champreda V., JirapratKitsuwan, Vatanyoopaisarn S. Effect of freeze–thaw process on physical properties, microbial activities and population structures of anaerobic sludge. J. Biosci. Bioeng. 2017;123:474–481. doi: 10.1016/j.jbiosc.2016.11.005. [DOI] [PubMed] [Google Scholar]

- 17.Mo R., Huang S., Dai W., Liang J., Sun S. A rapid Fenton treatment technique for sewage sludge dewatering. Chem. Eng. J. 2015;369:391–398. [Google Scholar]

- 18.Zhang R., Lu X., Tan Y., Cai T., Han Y., Kudisi D., Niu C., Zhang Z., Li W., Zhen G. Disordered mesoporous carbon activated peroxydisulfate pretreatment facilitates disintegration of extracellular polymeric substances and anaerobic bioconversion of waste activated sludge. Bioresour. Technol. 2021;339 doi: 10.1016/j.biortech.2021.125547. [DOI] [PubMed] [Google Scholar]

- 19.Guo B., Hu J., Zhang J., Wu Z., Li Z. Enhanced methane production from waste activated sludge by potassium ferrate combined with ultrasound pretreatment. Bioresour. Technol. 2021;341 doi: 10.1016/j.biortech.2021.125841. [DOI] [PubMed] [Google Scholar]

- 20.Liu Y., Wang L., Ma J., Zhao X., Huang Z., Mahadevan G.D., Qi J. Improvement of settleability and dewaterability of sludge by newly prepared alkaline ferrate solution. Chem. Eng. J. 2015;287:11–18. [Google Scholar]

- 21.Hodaei M., Ghasemi S., Khosravi A., Vossoughi M. Effect of the ozonation pretreatment on biogas production from waste activated sludge of tehran wastewater treatment plant. Biomass Bioenergy. 2021;152 doi: 10.1016/j.biombioe.2021.106198. [DOI] [Google Scholar]

- 22.Zhang J., Zhang J., Tian Y., Li N., Kong L., Sun L., Yu M., Zuo W. Changes of physicochemical properties of sewage sludge during ozonation treatment: correlation to sludge dewaterability. Chem. Eng. J. 2016;301:238–248. [Google Scholar]

- 23.Cardeña R., Moreno G., Bakonyi P., Buitrón G. Enhancement of methane production from various microalgae cultures via novel ozonation pretreatment. Chem. Eng. J. 2017;307:948–954. [Google Scholar]

- 24.Zhen G., Lu X., Wang B., Zhao Y., Chai X., Niu D., Zhao A., Li Y., Yu S., Cao X. Synergetic pretreatment of waste activated sludge by Fe(II)–activated persulfate oxidation under mild temperature for enhanced dewaterability. Bioresour. Technol. 2012;124:29–36. doi: 10.1016/j.biortech.2012.08.039. [DOI] [PubMed] [Google Scholar]

- 25.Zhen G., Lu X., Kato H., Zhao Y., Li Y.Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017;69:559–577. [Google Scholar]

- 26.Zhen G., Lu X., Zhao Y., Chai X., Niu D. Enhanced dewaterability of sewage sludge in the presence of Fe(II)-activated persulfate oxidation. Bioresour. Technol. 2012;116:259–265. doi: 10.1016/j.biortech.2012.01.170. [DOI] [PubMed] [Google Scholar]

- 27.Zhen G.Y., Lu X.Q., Li Y.Y., Zhao Y.C. Innovative combination of electrolysis and Fe(II)-activated persulfate oxidation for improving the dewaterability of waste activated sludge. Bioresour. Technol. 2013;136:654–663. doi: 10.1016/j.biortech.2013.03.007. [DOI] [PubMed] [Google Scholar]

- 28.Xu Y., Wu Y., Zhang X., Chen G. Effects of freeze-thaw and chemical preconditioning on the consolidation properties and microstructure of landfill sludge. Water Res. 2021;200 doi: 10.1016/j.watres.2021.117249. [DOI] [PubMed] [Google Scholar]

- 29.Zhen G., Lu X., Li Y.Y., Zhao Y. Combined electrical-alkali pretreatment to increase the anaerobic hydrolysis rate of waste activated sludge during anaerobic digestion. Appl. Energy. 2014;128:93–102. [Google Scholar]

- 30.Du H., Wu Y., Wu H., Li F. Effect of ozone pretreatment on characteristics of dissolved organic matter formed in aerobic and anaerobic digestion of waste-activated sludge. Environ. Sci. Pollut. Res. 2021;28:1–12. doi: 10.1007/s11356-020-10596-4. [DOI] [PubMed] [Google Scholar]

- 31.Hu K., Jiang J.Q., Zhao Q.L., Lee D.J., Wang K., Qiu W. Conditioning of wastewater sludge using freezing and thawing: role of curing. Water Res. 2011;45:5969–5976. doi: 10.1016/j.watres.2011.08.064. [DOI] [PubMed] [Google Scholar]

- 32.Li K., Ye Z., Wang F., Li H. The effect and mechanism of freeze/thawing combined with chemical treatment on sludge dewaterability. Acta Sci. Circumstantiae. 2010;30:536–543. [Google Scholar]

- 33.Wei W., Zhou X., Wang D., Sun J., Wang Q. Free ammonia pre-treatment of secondary sludge significantly increases anaerobic methane production. Water Res. 2017;118:12–19. doi: 10.1016/j.watres.2017.04.015. [DOI] [PubMed] [Google Scholar]

- 34.Eaton A.D., Clesceri L.S., Greenberg A.E., Franson M.A.H. Standard methods for the examination of water and wastewater. Am. J. Public Health Nation's Health. 1966;56:387–388. doi: 10.2105/ajph.56.3.387. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Xin F., Deng J., Lei H., Bai T., Fan Q., Li Z. Dewaterability of waste activated sludge with ultrasound conditioning. Bioresour. Technol. 2009;99:1074–1081. doi: 10.1016/j.biortech.2008.07.055. [DOI] [PubMed] [Google Scholar]

- 36.Riesz P., Berdahl D., Christman C.L. Free radical generation by ultrasound in aqueous and nonaqueous solutions. Environ. Health Perspect. 1985;64:233–252. doi: 10.1289/ehp.8564233. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Matzek L.W., Carter K.E. Activated persulfate for organic chemical degradation: a review. Chemosphere. 2016;151:178–188. doi: 10.1016/j.chemosphere.2016.02.055. [DOI] [PubMed] [Google Scholar]

- 38.Thalmann Basilius, von Gunten, Urs Kaegi, Ralf Ozonation of municipal wastewater effluent containing metal sulfides and metal complexes: kinetics and mechanisms. Water Res. 2018;134:170–180. doi: 10.1016/j.watres.2018.01.042. [DOI] [PubMed] [Google Scholar]

- 39.Klai, Nouha, Ram, Saurabh Kumar, Sellamuthu Balasubramanian, Rajeshwar Dayal, Tyagi Critical review of EPS production, synthesis and composition for sludge flocculation. J. Environ. Sci. 2018;66:225–245. doi: 10.1016/j.jes.2017.05.020. [DOI] [PubMed] [Google Scholar]

- 40.Nouha K., Kumar R.S., Balasubramanian S., Tyagi R.D. Critical review of EPS production, synthesis and composition for sludge flocculation. J. Environ. Sci. 2018;66:225–245. doi: 10.1016/j.jes.2017.05.020. [DOI] [PubMed] [Google Scholar]

- 41.Teng M., Yu D., Cao B., Wang D., Zhang W. Variations in distribution and composition of extracellular polymeric substance (EPS) of biological sludge under potassium ferrate conditioning: effects of pH and ferrate dosage. Biochem. Eng. J. 2016;106:37–47. [Google Scholar]

- 42.Bilgin Oncu N., Mercan N., Akmehmet Balcioglu I. The impact of ferrous iron/heat-activated persulfate treatment on waste sewage sludge constituents and sorbed antimicrobial micropollutants. Chem. Eng. J. 2015;259:972–980. [Google Scholar]

- 43.Lee K.-M., Kim M.S., Lee C. Oxidative treatment of waste activated sludge by different activated persulfate systems for enhancing sludge dewaterability. Sustain. Environ. Res. 2016;26(4):177–183. [Google Scholar]

- 44.Basuvaraj M., Fein J., Liss S.N. Protein and polysaccharide content of tightly and loosely bound extracellular polymeric substances and the development of a granular activated sludge floc. Water Res. 2015;82:104–117. doi: 10.1016/j.watres.2015.05.014. [DOI] [PubMed] [Google Scholar]

- 45.Koo Ananth, Gill Tip splitting in dendritic growth of ice crystals. Phys. Rev. 1991;44(6):3782–3790. doi: 10.1103/physreva.44.3782. [DOI] [PubMed] [Google Scholar]

- 46.Wu Y., Xu Y., Zhang X., Lu Y., He X., Song B., Zhang Y., Ji J. Experimental study on treating landfill sludge by preconditioning combined with vacuum preloading: effects of freeze-thaw and FeCl preconditioning. Sci. Total Environ. 2020;747 doi: 10.1016/j.scitotenv.2020.141092. [DOI] [PubMed] [Google Scholar]

- 47.Manterola G., Uriarte I., Sancho L. The effect of operational parameters of the process of sludge ozonation on the solubilisation of organic and nitrogenous compounds. Water Res. 2008;42:3191–3197. doi: 10.1016/j.watres.2008.03.014. [DOI] [PubMed] [Google Scholar]

- 48.Kim D.H., Jeong E., Oh S.E., Shin H.S. Combined (alkaline+ultrasonic) pretreatment effect on sewage sludge disintegration. Water Res. 2010;44:3093–3100. doi: 10.1016/j.watres.2010.02.032. [DOI] [PubMed] [Google Scholar]

- 49.Zhen G., Lu X., Su L., Kobayashi T., Kumar G., Zhou T., Xu K., Li Y.Y., Zhu X., Zhao Y. Unraveling the catalyzing behaviors of different iron species (Fe2+ vs. Fe0) in activating persulfate-based oxidation process with implications to waste activated sludge dewaterability. Water Res. 2018;134:101–114. doi: 10.1016/j.watres.2018.01.072. [DOI] [PubMed] [Google Scholar]

- 50.He Z.W., Liu W.Z., Gao Q., Tang C.C., Wang L., Guo Z.C., Zhou A.J., Wang A.J. Potassium ferrate addition as an alternative pre-treatment to enhance short-chain fatty acids production from waste activated sludge. Bioresour. Technol. 2017;247:174–181. doi: 10.1016/j.biortech.2017.09.073. [DOI] [PubMed] [Google Scholar]

- 51.Li L., He J., Xin X., Wang M., Xu J., Zhang J. Enhanced bioproduction of short-chain fatty acids from waste activated sludge by potassium ferrate pretreatment. Chem. Eng. J. 2017;332:456–463. [Google Scholar]

- 52.Lee W.S., Chua A., Yeoh H.K., Ngoh G.C. A review of the production and applications of waste-derived volatile fatty acids. Chem. Eng. J. 2014;235:83–99. [Google Scholar]

- 53.Liu X., Xu Q., Wang D., Wu Y., Fu Q., Li Y., Yang Q., Liu Y., Ni B.-J., Wang Q., Yang G., Li H., Li X. Microwave pretreatment of polyacrylamide flocculated waste activated sludge: effect on anaerobic digestion and polyacrylamide degradation. Bioresour. Technol. 2019;290 doi: 10.1016/j.biortech.2019.121776. Bioresour Technol. [DOI] [PubMed] [Google Scholar]

- 54.Nabi M., Zhang G., Zhang P., Tao X., Wang S., Ye J., Zhang Q., Zubair M., Bao S., Wu Y. Contribution of solid and liquid fractions of sewage sludge pretreated by high pressure homogenization to biogas production. Bioresour. Technol. 2019;286 doi: 10.1016/j.biortech.2019.121378. [DOI] [PubMed] [Google Scholar]

- 55.Yin X., Han P., Lu X., Wang Y. A review on the dewaterability of bio-sludge and ultrasound pretreatment. Ultrason. Sonochem. 2004;11(6):337–348. doi: 10.1016/j.ultsonch.2004.02.005. [DOI] [PubMed] [Google Scholar]

- 56.Appels L., Degrève J., Bruggen B., Impe J.V., Dewil R. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion. Bioresour. Technol. 2010;101:5743–5748. doi: 10.1016/j.biortech.2010.02.068. [DOI] [PubMed] [Google Scholar]

- 57.Huang S.-C., Chang F.-C., Lo S.-L., Lee M.-Y., Wang C.-F., Lin J.-D. Production of lightweight aggregates from mining residues, heavy metal sludge, and incinerator fly ash. J. Hazard Mater. 2007;144:52–58. doi: 10.1016/j.jhazmat.2006.09.094. [DOI] [PubMed] [Google Scholar]

- 58.Babel S., del Mundo Dacera D. Heavy metal removal from contaminated sludge for land application: a review. Waste Manag. 2006;26(9):988–1004. doi: 10.1016/j.wasman.2005.09.017. [DOI] [PubMed] [Google Scholar]

- 59.Yue Y., Zhang J., Sun F., Wu S., Pan Y., Zhou J., Qian G. Heavy metal leaching and distribution in glass products from the co-melting treatment of electroplating sludge and MSWI fly ash. J. Environ. Manag. 2019;232:226–235. doi: 10.1016/j.jenvman.2018.11.053. [DOI] [PubMed] [Google Scholar]

- 60.Hu S., Hu J., Sun Y., Zhu Q., Hou H. Simultaneous heavy metal removal and sludge deep dewatering with Fe(II) assisted electrooxidation technology. J. Hazard Mater. 2020;405 doi: 10.1016/j.jhazmat.2020.124072. [DOI] [PubMed] [Google Scholar]

- 61.Wei W., Wang Q., Zhang L., Laloo A., Duan H., Batstone D.J., Yuan Z. Free nitrous acid pre-treatment of waste activated sludge enhances volatile solids destruction and improves sludge dewaterability in continuous anaerobic digestion. Water Res. 2017;130:13–19. doi: 10.1016/j.watres.2017.11.050. [DOI] [PubMed] [Google Scholar]

- 62.Yu L., Bule M., Ma J., Zhao Q., Frear C., Chen S. Enhancing volatile fatty acid (VFA) and bio-methane production from lawn grass with pretreatment. Bioresour. Technol. 2014;162:243–249. doi: 10.1016/j.biortech.2014.03.089. [DOI] [PubMed] [Google Scholar]

- 63.Zhou W., Chen X., Wang Y., Tuersun N., Ismail M., Cheng C., Li Z., Song Q., Wang Y., Ma C. Anaerobic co-digestion of textile dyeing sludge: digestion efficiency and heavy metal stability. Sci. Total Environ. 2021;801 doi: 10.1016/j.scitotenv.2021.149722. [DOI] [PubMed] [Google Scholar]

- 64.Gutierrez O., Sudarjanto G., Ren G., Ganigue R., Jiang G., Yuan Z. Assessment of pH shock as a method for controlling sulfide and methane formation in pressure main sewer systems. Water Res. 2014;48:569–578. doi: 10.1016/j.watres.2013.10.021. [DOI] [PubMed] [Google Scholar]

- 65.Yin D.-M., Mahboubi A., Wainaina S., Qiao W., Taherzadeh M.J. The effect of mono- and multiple fermentation parameters on volatile fatty acids (VFAs) production from chicken manure via anaerobic digestion. Bioresour. Technol. 2021;330 doi: 10.1016/j.biortech.2021.124992. [DOI] [PubMed] [Google Scholar]

- 66.Dhar B.R., Youssef E., Nakhla G., Ray M.B. Pretreatment of municipal waste activated sludge for volatile sulfur compounds control in anaerobic digestion. Bioresour. Technol. 2011;102:3776–3782. doi: 10.1016/j.biortech.2010.12.020. [DOI] [PubMed] [Google Scholar]

- 67.Zan F., Huang H., Guo G., Chen G. Sulfite pretreatment enhances the biodegradability of primary sludge and waste activated sludge towards cost-effective and carbon-neutral sludge treatment. Sci. Total Environ. 2021;780 doi: 10.1016/j.scitotenv.2021.146634. [DOI] [PubMed] [Google Scholar]

- 68.Chen X., Tang R., Wang Y., Yuan S., Wang W., Ali I.M., Hu Z.-H. Effect of ultrasonic and ozone pretreatment on the fate of enteric indicator bacteria and antibiotic resistance genes, and anaerobic digestion of dairy wastewater. Bioresour. Technol. 2021;320:124356. doi: 10.1016/j.biortech.2020.124356. [DOI] [PubMed] [Google Scholar]

- 69.Zhou X., Wang Q., Jiang G., Liu P., Yuan Z. A novel conditioning process for enhancing dewaterability of waste activated sludge by combination of zero-valent iron and persulfate. Bioresour. Technol. 2015;185:416–420. doi: 10.1016/j.biortech.2015.02.088. [DOI] [PubMed] [Google Scholar]

- 70.Wang Z., Liu T., Duan H., Song Y., Lu X., Hu S., Yuan Z., Batstone D., Zheng M. Post-treatment options for anaerobically digested sludge: current status and future prospect. Water Res. 2021;14 doi: 10.1016/j.watres.2021.117665. 0.1016/j.watres.2021.117665. [DOI] [PubMed] [Google Scholar]

- 71.Hechmi S., Hamdi H., Mokni-Tlili S., Ghorbel M., Khelil M.N., Zoghlami I.R., Benzarti S., Jellali S., Hassen A., Jedidi N. Impact of urban sewage sludge on soil physico-chemical properties and phytotoxicity as influenced by soil texture and reuse conditions. J. Environ. Qual. 2020;49(4):973–986. doi: 10.1002/jeq2.20093. [DOI] [PubMed] [Google Scholar]

- 72.Ozaki N., Yamauchi T., Kindaichi T., Ohashi A. Stormwater inflow loading of polycyclic aromatic hydrocarbons into urban domestic wastewater treatment plant for separate sewer system. Water Sci. Technol. 2019;79(7):1426–1436. doi: 10.2166/wst.2019.143. [DOI] [PubMed] [Google Scholar]

- 73.Liang J., Ning X.A., An T., Sun J., Zhang Y., Wang Y. Degradation of aromatic amines in textile-dyeing sludge by combining the ultrasound technique with potassium permanganate treatment. J. Hazard Mater. 2016;314:1–10. doi: 10.1016/j.jhazmat.2016.04.018. [DOI] [PubMed] [Google Scholar]

- 74.Lin K.-H., Lai N., Zeng J.-Y., Chiang H.-L. Residue characteristics of sludge from a chemical industrial plant by microwave heating pyrolysis. Environ. Sci. Pollut. Res. Int. 2018;25(7):6487–6496. doi: 10.1007/s11356-017-1003-1. [DOI] [PubMed] [Google Scholar]

- 75.Ning X.A., Feng Y., Wu J., Chen C., Wang Y., Sun J., Chang K., Zhang Y., Yang Z., Liu J. Effect of K2FeO4/US treatment on textile dyeing sludge disintegration and dewaterability. J. Environ. Manag. 2015;162:81–86. doi: 10.1016/j.jenvman.2015.07.001. [DOI] [PubMed] [Google Scholar]

- 76.Li Y.-S., Xiao Y.-Q., Qiu J.-P., Dai Y.-Q., Robin P. Continuous village sewage treatment by vermifiltration and activated sludge process. Water Sci. Technol. 2009;60(11):3001–3010. doi: 10.2166/wst.2009.715. [DOI] [PubMed] [Google Scholar]

- 77.Mamera M., van Tol J.J., Aghoghovwia M.P., Mapetere G.T. Community faecal management strategies and perceptions on sludge use in agriculture. Int. J. Environ. Res. Publ. Health. 2020;17(11) doi: 10.3390/ijerph17114128. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 78.Zhang R., Zheng H., Zhang H., Hu F. Study on the influence of social capital on farmers' participation in rural domestic sewage treatment in nanjing, China. Int. J. Environ. Res. Publ. Health. 2020;17(7) doi: 10.3390/ijerph17072479. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.