Abstract

Increasing global population and decreasing arable land pose tremendous pressures to agricultural production. The application of conventional chemical fertilizers improves agricultural production, but causes serious environmental problems and significant economic burdens. Biochar gains increasing interest as a soil amendment. Recently, more and more attentions have been paid to biochar-based slow-release of fertilizers (SRFs) due to the unique properties of biochar. This review summarizes recent advances in the development, synthesis, application, and tentative mechanism of biochar-based SRFs. The development mainly undergoes three stages: (i) soil amendment using biochar, (ii) interactions between nutrients and biochar, and (iii) biochar-based SRFs. Various methods are proposed to improve the fertilizer efficiency of biochar, majorly including in-situ pyrolysis, co-pyrolysis, impregnation, encapsulation, and granulation. Considering the distinct features of different methods, the integrated methods are promising for fabricating effective biochar-based SRFs. The in-depth understanding of the mechanism of nutrient loading and slow release is discussed based on current knowledge. Additionally, the perspectives and challenges of the potential application of biochar-based SRFs are described. Knowledge surveyed from this review indicates that applying biochar-based SRFs is a viable way of promoting sustainable agriculture.

Keywords: Biochar, Slow-release fertilizer, Sustainability, Soil amendment, Agricultural production

Graphical abstract

Highlights

-

•

Enhancing nutrient utilization in fertilizers is an urgent demand.

-

•

The development of biochar-based slow-release fertilizers is briefly summarized.

-

•

Various methods proposed for biochar-based SRFs synthesis are reviewed.

-

•

Biochar-based slow-release fertilizers are viable for promoting sustainable agriculture.

1. Introduction

Based on the prediction of the FAO, the global population will be up to 9.7 billion in 2050 [1]. To meet the rapid population growth, the world demand for food production increases sharply. Agriculture is currently the dominant channel of food supply. The contradiction between increasing global population and decreasing arable land poses tremendous pressures to agricultural production. In the past decades, the application of chemical fertilizers to agricultural production dramatically increases food production, contributing to about 50% extra crop yield [2]. With the wide utilization of chemical fertilizers, the negative impacts on the environment receive increasing attention worldwide. The over-use or suboptimal utilization of chemical fertilizers causes the decline of fertilizer efficiency and serious environmental problems. Nitrogen and phosphorus are essential elements required for crop growth, and a great quantity of nitrogen and phosphorus fertilizers are applied to agricultural production. The global demand for fertilizers, including nitrogen, phosphorus, and potassium, was 185.06 million tons in 2016, and it was predicted to be 200.92 in 2022 [3].

Nitrogen is a limiting nutrient for crop growth, and nitrogen fertilizer is the most consumed fertilizer. The global demand for nitrogen fertilizer is expected to be 111.59 million tons by 2022 [3]. Nitrogen fertilizers undergo ammonia (NH3) volatilization, nitrate (NO3−) leaching, and nitrous oxide (N2O) release, causing the serious pollution of surface water, groundwater, and atmosphere [4]. Only 20–30% N in fertilizers is taken up by crops and plants [5]. Phosphorus plays an important role in crop growth in agriculture production. Phosphorus fertilizers are rapidly consumed [6]. The global demand for phosphorus fertilizers will reach 49.10 million tons by 2022 [3]. The non-renewable phosphorus rock is depleting. The global reserves of high-quality phosphate resources will be depleted within 50–400 years, relying on phosphorus supply and demand dynamics [7]. Phosphorus fertilizers suffer from low availability of soluble phosphorus for plant uptake. Phosphorus has poor solubility, and its availability for plant uptake only occurs in the inorganic form as HPO42- or H2PO4− and H3PO4. Phosphorus is highly immobile due to soil interactions such as adsorption and precipitation, as well as the transformation into the organic form. Additionally, excessive phosphorus fertilization significantly enlarges the risk of phosphorus loss through leaching, runoff, and erosion [8]. The phosphorus loss into surface water is the major reason for eutrophication, and the accelerated eutrophication on a worldwide scale severely damages aquatic ecosystems [9].

The soluble chemical fertilizers are easily leached, runoff, and washed away. The estimated fertilizer loss in the environment includes 40–70% N, 80–90% P, and 50–70% K of fertilizers [10]. The phenomena not only cause serious environmental pollution, challenge global sustainability, but also result in significant financial loss. Moreover, excessive application of chemical fertilizers severely undermines the quality of farming lands via soil salinization and depleting organic matters [11]. To cope with the drawbacks of conventional fertilizers, slow-release fertilizers (SRFs) are purposefully designed and gain increasing global attention. SRFs are defined as fertilizers that delay their nutrient availability for plant uptake after application [12]. Compared to conventional fertilizers, SRFs have a low rate of releasing nutrients, prolonging nutrient availability for plant uptake, and diminishing nutrient loss into the environment.

Biochar is a carbon-rich solid material derived from biomass, generally produced through thermochemical the transformation of biomass feedstocks. The thermochemical processes include pyrolysis, gasification, hydrothermal carbonization, etc. (Fig. S1) [13,14]). The plant- or animal-derived biomass feedstocks are widely used for biochar fabrication. Biochar displays outstanding features for the potential application, such as large surface area, porous micro-morphology, graphitic structure, and abundant surface groups [15,16]. Due to its unique properties, biochar has been investigated for diverse applications, such as soil amendment [17], adsorption [18], waste management [19], catalysis [20,21], energy storage [22], and carbon sequestration [23]. The potential application of biochar in different fields is still in its infancy. Compared to other applications, biochar is favorable for soil amendment due to unnecessary precise regulation of molecular structure and morphology. Previous researches have proven that the soil application of biochar can promote nutrient supply and crop yield [24], ameliorate soil texture and properties [25], reduce greenhouse gas (GHG) emissions [26], and immobilize heavy metals and organic contaminants [[27], [28], [29]]. Biochar can decline the nutrients loss in soil and prolong fertilizer efficiency for plant uptake [30]. The pristine biochar has limited nutrients, and loading nutrients onto biochar is imperative to improve the fertilizer. Recently, researches on biochar-based SRFs have been reported [[31], [32], [33]]. As shown in Fig. S2, the published papers and citations notably increased in the past years, suggesting the growing research interest. With significant research advances, the summary of current knowledge about biochar-based SRFs is imperative. To the best of our knowledge, the systematic review of biochar-based SRFs has been rarely reported. In this work, the research advances on biochar-based SRFs are summarized based on the latest literature.

2. Research evolution of biochar-based SRFs

According to IBI (2012), biochar is defined as ‘‘a solid material obtained from the thermochemical conversion of biomass in an oxygen-limited environment’‘. It has attracted much attention in various fields such as agriculture, environment, and energy owing to its excellent properties. Biochar has a long history for soil application, dating back to ancient Amerindian Populations (Terra Preta de Indio), where dark earth formed through slash-and-char practice [34]. Studies on Terra Preta soils in the Amazon region verify the positive effects of biochar for soil fertility and sustainability. Numerous researches have been conducted to reveal the hiding secret of biochar for soil fertility.

Biochar manifests the properties of carbon content (23.6–87.5%), pH (5.2–10.3), surface area (0–642 m2 g−1), and cation exchange capacity (10–69 cmolc kg−1) [35]. The addition of biochar into soil produces multiple profits, including the amelioration of physicochemical and biological properties [36], the promotion of soil fertility and crop yield [37], the control of plant diseases [38], and immobilization of toxic metals and organic pollutants [15]. Also, biochar increases soil nutrient availability, cation exchange capacity and water holding capacity, and improves soil microbial community and microbe activity [4,39]. A decline of nutrient loss in soil associated with biochar addition was reported by Xiao et al. [40] Biochar promoted seed germination, crop growth, and crop production [41]. The microbe population and activity in soil were significantly improved after biochar regulation [42]. Besides nutrient retention, biochar can improve water retention in soil. Soil water holding capacity correlates to surface hydrophobicity, surface area, porosity, and surface groups of biochar [43]. Amoakwah et al. [44] found a significant increase in water retention in soil after the application of corn cob. The above studies verify the excellent benefits of biochar, suggesting that it is promising for soil application.

Nitrogen and phosphorus are essential nutrients for plant growth. The effects of biochar on nitrogen and phosphorus change in water and soil have been extensively investigated. Adsorption of nitrogen and phosphorus using biochar was significantly influenced by pyrolysis temperature and biomass feedstocks [45]. Mg-loaded biochar prepared by different biomass feedstocks was proved to be effective for nitrogen and phosphorus adsorption from aqueous solution, with a maximum adsorption capacity of 24.04 mg g−1 (NH4+-N) and 31.15 mg g−1 (TP) [46]. Iron-loaded biochar was verified to be an effective adsorbent for nitrogen and phosphorus removal from nutrient-rich wastewater [47]. Simultaneously adsorption of ammonium and phosphate from the water was obtained using biochar derived from Eupatorium adenophorum [48]. The factors influencing nitrogen and phosphorus adsorption include biochar amount, solution pH, nitrogen or phosphorus concentration, adsorption time, and temperature [49]. The adsorption mechanism involves ion exchange, hydrophobic interaction, hydrogen bonds, electronic interaction, and physical adsorption [50].

Inspired by effective N and P adsorption from water, the effects of biochar are extensively investigated on nitrogen and phosphorus in soil. Biochar was identified as an amendment to improve nitrogen removal in constructed wetland mesocosms [51]. Chicken litter biochar increased the pH of acid soil and pH buffering capacity, displayed a high affinity for N than P and K, and effectively controlled soil N availability [52]. Biochar manifested increased NH4+-N adsorption and low affinity for P in two soils [53]. Biochar has strong adsorption performance, immobilizes nitrogen and phosphorus in soil, and improves the nutrient availability for crop growth [54]. A meta-analysis for evaluating the effects of biochar on N and P availability in agricultural ecosystems manifested that biochar addition remarkably increased soil available P by 45%, but decreased NO3−-N by 12% and NH4+-N by 11% [55]. Biochar capture promoted the slow release of N in biochar amended soils and composts [56]. Simultaneous application of biochar with organic or inorganic fertilizers enhances fertilizer efficiency and crop yields. A 3-year fixed-site experiment comparing different treatments confirmed that mixing biochar with bare urea and controlled-release urea increased fertilization efficiency and rice yield [57]. Biochar had high sorption capacity to different fertilizers, and the biochar with attached nutrients can be directly used as SRFs in agricultural fields.

Due to the limited nutrients, a great amount of biochar is required as fertilizer. The storage, transportation, and application of massive biochar are highly challenging owing to the wide distribution of particle size, fragile feature, low density. During soil application, a high loss of 25% by wind-blown and 20–53% loss caused by surface runoff from intense rain events were reported [58]. Additionally, soil application of approximately 20–50 tons ha−1 biochar is questionable from the aspect of economic feasibility [59]. Because of unique features such as massive pore structure, large surface area, and abundant surface groups, biochar is promising as fertilizer carriers. To improve fertilizer efficiency, biochar-based fertilizers are fabricated by combining biochar with inorganic fertilizers through various physical or chemical techniques, such as impregnation, pelletizing, and encapsulation [31,60,61]. Biochar-based SRFs can provide nutrients for crop growth for the whole season via a single application, and reduce the stress and toxicity derived from excessive nutrients in the root zones [62]. The soil application of biochar-based SRFs displays simultaneous benefits of soil improvement, crop yields, nutrient retention, and carbon sequestration [15].

Based on the above discussion, the research evolution of biochar-based SRFs can be summarized as Fig. 1. Originated from ancient dark earth formed through slash-and-char practice, extensive researches on the hiding secret reveal the important role of biochar in soil. Biochar has a high affinity toward nutrients, including N and P in water and soil. Soil application of biochar enhances the slow-release effect of nutrients, providing an attractive strategy for reducing the economic and environmental burden of excessive conventional fertilizers. Biochar-based SRFs receive more and more global attention for sustainable agriculture.

Fig. 1.

Schematic of the research evolution of biochar-based SRFs.

3. Synthesis strategies of biochar-based SRFs

The pristine biochar obtained from direct thermochemical treatment of biomass feedstocks is generally deficient in nutrients as fertilizer. It is imperative to modify biochar to improve fertilizer efficiency. The excellent properties of biochar provide a sound platform for synthesizing biochar-based SRFs. To fabricate effective biochar-based SRFs, various methods have been proposed, such as impregnation [63], encapsulation [64], granulation [65], co-pyrolysis [66], etc. (Fig. 2). The slow-release performance of biochar-based SRFs fabricated by different methods is listed in Table 1.

Fig. 2.

Various methods for the synthesis of biochar-based SRFs.

Table 1.

Biochar-based SRFs fabricated by different methods and slow-release performance.

| Fertilizers | Preparation methods | Fabrication processes | Nutrients | Slow-release performance | References |

|---|---|---|---|---|---|

| Biochar-based P SRF | Impregnation | Corn stover was pyrolyzed at 500 °C for 30 min under limited oxygen, and the obtained biochar was immersed in KH2PO4 solution at a solid: solution ratio of 1:40 for 48 h, and then filtrated, washed, and dried at 60 °C. | 22 mg g−1 P | Bioavailable P release 40% after 5 d | [32] |

| Biochar-based P fertilizers | Co-pyrolysis | Coffee husk and poultry litter were mixed with concentrated phosphoric acid and magnesium oxide (P:Mg molar ratio 1:1). After thorough mixing, the samples were moistened by adding water and then left to rest for 16 h. After drying at 60 °C, pyrolysis was performed at 500 °C for 2 h, and samples were marked CHB (coffee husk) and PLB (poultry litter). | 201 mg g−1 P in CHB, and 178% P in PLB | Total P release 6.47% (CHB) and 8.99% (PLB) within 1 h | [67] |

| Biochar-based controlled release N fertilizer | Impregnation Granulation Encapsulation |

Biochar was produced from pyrolysis of corn stover. Biochar was added in ammonium sulfate solution (mass ratio of biochar to ammonium sulfate 1:1) and continually stirred for 20 min, and then kaolin clay was added and stirred for 20 min. The mixture was dried for 5 h at 65 °C, and then blended with methylcellulose and deionized water and pelletized into particles. The pellets were submerged in polylactic acid solution for 10 s and then air-dried at room temperature for 8 h. | – | N release 70% over 12 d in water and 25 d in soil. | [31] |

| Mg-enriched biochar fertilizer | Co-pyrolysis Impregnation |

Corn stalk was dispersed MgCl2·solution for 12 h, and the resulting mixture was completely dried at 80 °C. The dried mixture was pyrolyzed at 500 °C for 1 h under N2. The obtained biochar was added into the mixture of biogas effluent and KH2PO4 solution and stirred at 25 °C for 24 h | 200 mg g−1 N and 381 mg g−1 P | N release 18% and P release 16% at 48 h | [50] |

| Biochar-based P SRFs | Impregnation Co-pyrolysis Encapsulation |

MSRFs: Cotton straw powers were mixed with of MgCl2 solution for 2 h. After drying, the Mg-loaded biochar was prepared in a furnace under N2 at 550 °C for 2 h. Mg-loaded biochar was added into KH2PO4 solutions in a mechanical shaker at 120 rpm min−1 for 24 h at room temperature. BSRFs: 55% of cotton straw, 15% of Mg3(PO4)2 and 30% of bentonite were dispersed in distilled water and stirred at a speed of 650 r min−1 for 45 min. The dried samples were placed at 550 °C for 2 h under N2. CSRFs: BSRFs samples were thoroughly mixed with solution containing NaAlg and bentonite, and the resulting samples were gradually dripped into CaCl2 solution to generate crosslinks for wrapping BSRFs. PSRFs: starch, acrylamide, PVP, BSRFs, and N-MBA were added into boiling water, and then polymerization was performed by microwave irradiation at 300 W and stirred at a speed of 200 rpm min−1. After maintaining for 10 min, N2 was bubbled for 10 min, and then KPS was added to initiate the polymerization process |

– | P utilization efficiency 53.52% (MSRFs), 65.27% (BSRFs), 74.32% (CSRFs), and 75.83% (PSRFs) after 60 d | [68] |

| Biochar-based N/P/K fertilizers | Co-pyrolysis | Residues from biogas production collected from the anaerobic fermentation were air-dried and was ground, and then was pyrolyzed at a temperature of 500 °C for 120 min under nitrogen. Biogas residue-based biochar was mixed commercial compound fertilizer (N: P2O5: K2O = 4:3:3) with a mass ratio of 1:2. Pelletization was conducted using a universal material testing machine, and self-made cylindrical forming molds with different apertures were connected to the universal material testing machine. The pelletized RBF was dried at 25, 65, 105, 145, and 185 °C for 24 h, referred to as RBF-T (RBF-25, RBF-65, RBF-105, RBF-145, and RBF-185. | – | The cumulative N release of RBF-25, RBF-65, RBF-105, RBF-145, and RBF-185 reached 88.68%, 75.35%, 64.89%, 54.39%, and 41.71% after 413 h; the P release of RBF-25, RBF-65, RBF-105, RBF-145, and RBF-185 was 72.07%, 58.75%, 44.12%, 27.48%, and 23.93% after 413 h | [69] |

| Biochar scaffolded N SRF | Encapsulation Granulation |

Autothermal fast pyrolysis of pine biomass at 500 °C was conducted to prepare biochar. Chemical activation of the biochar was accomplished in 5% and 15% H3PO4 solution associated with heat-treated at 465 °C for 2 h under N2. The activated biochar was mixed with dry urea with ratios of 1:2, 1:3, 1:4, and 1:6. The resultant mixtures were ground finely using a mortar and then thermally (137–138 °C) treated for 75 min to melt and infuse the urea into the biochar pores. A 5% Ca-LS aqueous solution and 10% liquefied paraffin wax were added to the urea infused biochar and ground again to prepare the final composite. After manual pelletization of the urea-infused biochar fertilizer, the pellets were dried at 50–55 °C for 48 h. | N content 26.74–34.32% | Urea released in aqueous medium was 61–90% in 4320 min | [70] |

| Biochar and biofilm composite towards P SRF | Impregnation Encapsulation |

Compound biochar was obtained by pyrolysis of cotton stalk and montmorillonite at 400 °C. Adsorption of PO43- was conducted onto the composite biochar. Cotton straw, polyethylene glycol-400, and glycerin were mixed, and then concentrated sulfuric acid was added to react for 90 min at 160 °C to obtain liquefied cotton stalk-based polyol, which was further reacted with toluene diisocyanate at 75 °C for 20 min to obtain a bio-based membrane material. The toluene diisocyanate and the liquefied cotton stalk-based polyol were stirred at room temperature, and then the mixed liquid was coated on the surface of the composite biochar phosphate fertilizer with a brush. The coated biochar phosphate fertilizer was heated at 75 °C for 20 min. | PO43- 129.92 mg g−1 | The cumulative PO43- release after 30 d was 76%, 65%, 60%, and 53.5% (corresponding the membrane material 0%, 2%–4% and 6%). | [71] |

| Biochar-based N SRF | Impregnation Granulation Encapsulation |

Corn straw was soaked in MgCl2 for 2 h in 1:3 ratios. After drying, the sample was pyrolyzed at 500 °C for 3 h. The modified biochar was soaked in 3 M ammonium nitrate solution for 24 h and then air-dried. Polyvinyl alcohol and corn starch were used as the coating material. The biochar and coating material were mixed at a 1:5 ratio. The biochar was granulated, and 5% solution of coating material was sprayed onto the granules. | Total nitrogen 22.3% | The cumulative nitrate concentration was 886.4 mg L−1 after 24 d; the cumulative ammonium concentration was 1395.5 mg L−1 after 28 d. | [72] |

| Biochar embedded-semi-IPN based SRF | Encapsulation | Cotton stalks were heated to 600 °C for 1 h under N2 to prepare biochar. NaAlg, bentonite, biochar, NH4Cl, and K3PO4 were added in distilled water and stirred at 40 °C by mechanical stirring for 45 min. Then, AA, PVP, N-MBA, and APS solution were added into above solution. The polymerization was performed by microwave irradiation at 300 W for 4.5 min under N2. | – | The release ratios of N, P and K within 30 d were less than 80.0% | [73] |

| Bentonite modified biochar P SRF | Impregnation | Cotton straw was mixed with H-bentonite, N-bentonite, and OH-bentonite with a ratio of 1:9 and added in deionized water by mechanical stirring at a speed of 750 r min−1 for 45 min. After drying, crushing, and sieving, the samples were pyrolyzed at 600 °C for 2 h under N2. BSRFs was added into KH2PO4 aqueous solution and shaken at 120 rpm min−1 for 24 h at room temperature. | Phosphate was 245.56 mg g−1. | P release within 15 d was 72.6% | [63] |

| Biochar-coated urea | Granulation Encapsulation | (1) Urea was added to the coating machine at a speed of 80 rpm, and oxidized starch was sprayed into the machine. (2) biochar was sprinkled in after the urea particles had been uniformly coated with the oxidized starch, and the coating machine continued rotating for 5–10 min to ensure that the coated layer was tight, and then oxidized starch was sprayed again. (3) Step 2 was repeated until all the biochar had been coated onto the particles. (4) Resin was dripped in batches into a plastic container containing BCU from step 3 and embedded in a spiral oscillator to prepare BCU with protective layer I; paraffin was heated until melted and coated on BCU from step 3 with a high-pressure spray gun to prepare BCU with protective layer II. | N content 26.89–34.36% | Cumulative nitrogen release was 72.75–85.71% after 28 d | [74] |

| Biochar composite P fertilizer | Granulation Encapsulation | Wood chips were pyrolyzed at 350 °C for 1 h, and the obtained biochar was ground and sieved. Biochar fertilizers were obtained by blending (B) or coating (C) superphosphate with biochar in three proportions (5, 15 and 25% of biochar), and granulating using a rotating granulator. | Total P was 15.4–19.9% | Total P release within 1.5 h was 82% and 36% for blended biochar and coated biochar. | [75] |

| Biochar-based N/P fertilizer | Impregnation | The impregnation was done with an NPK fertilizer: oil palm kernel shell biochar was mixed NH4NO3 and KH2PO4 for 21 h at room temperature and then oven-dried at 105 °C until constant weight. | – | NO3− release was 52.9%, 77.4% for NH3 and 55.2% for PO43- after 1 h. | [76] |

| Carbon-based SRF treated by biooil coating | Granulation Encapsulation | The dried wheat straw was pyrolyzed at 400 °C for 2 h under CO2, N2 and H2O(g) atmosphere of to prepare the initial biochar. The biochar and KH2PO4 and KNO3 solution were mixed with a ratio of 2.7. After stirring and mixing, the mixture was maintained for 24 h, and then heated at a low temperature to remove the solution. The biochar was placed on the porous bottom plate of the fluidized spraying device, and the biochar particles were uniformly coated with a layer of bio-oil film, and then a desiccant was added and dried to obtain the coated carbon-based slow-release fertilizer. | – | the cumulative release of N, P, and K reached about 45% after 7 d. | [58] |

| Biochar/struvite composites as N and P fertilizer | Impregnation | A 1:1:1 M ratio of Mg2+/PO43−/NH4+ was stirred for 30 min and mixed with 10% biochar. After stirring for 30 min and aging for 24 h at room temperature, it was filtered, washed, and dried at 100 °C to obtain biochar/struvite composites. | N 4.93% and P2O5 22.19% | The accumulative release of N and P after 84 d was 10.62% and 6.84% in distilled water, and 59.32% and 59.12% in citric acid solution. | [77] |

| P-enriched biochar fertilizer | In-situ pyrolysis | E. coli fermentation waste was collected from the bio-fermentation corporation and dried in an oven at 60 °C for 2 d. Wet feedstock and dried feedstock were used for biochar fabrication. Pyrolysis was carried out in a muffle furnace at 600 °C under N2. | P content 84.7 mg g−1 | The extractable P in water and citric acid reached 52% and 61% after 5 d | [62] |

| Blended biochar pellet | Granulation | Biochar from rice hull was produced from a pyrolysis system at 400–500 °C for 4 h under O-free atmosphere. Biochar was blended with pig manure compost as a binder, mixed using an agitator for 5 min, sprayed with deionized water for 10 min, and then pelletized through the pellet machine. | – | Total water-soluble accumulative NH4+-N and PO43--P were 13.8 mg g−1 and 44.6 mg g−1 after 84 d | [78] |

| Biochar-based SRF encapsulated by waterborne copolymers | Encapsulation | Maize straw, rice straw and forest litter were dried, ground, and then heated at 500 °C for 2 h in the muffle furnace. Distilled water and PVA were mixed and was slowly raised to 90 °C with continuously stirring, and then PVP and butanol were added and continuously stirred for 2 h at 60 °C. Then, biochar was added and mixed for 1 h at 60 °C to prepare biochar-based copolymer film. Urea were in a sugar-coating machine for 0.5 h. Using a side-spray nozzle under 0.7 MPa pressure, the urea preheated granules were coated with the mixture solution of biochar and copolymer for 0.5 h. | – | Accumulative nitrogen leaching was 65.28% after 22 d. | [2] |

| Biochar-based P SRF | Co-Pyrolysis | The biomass (pine tree sawdust and switchgrass) and fertilizer (TSP and BM) were completely mixed, and pyrolyzed at 500 °C for 2 h under N2. | P content was 4.82–5.82%. | P release from TSP- and BM-composite biochar within 120 h were about 20.0 mg g−1 and 0.30 mg g−1 | [79] |

| Biochar pellets embedded with fertilizers | Granulation | Air-dried switchgrass was pyrolyzed at 525 °C for 90 s under N2 using a continuous dual auger pyrolysis process. The biochar was blended with different percentages of lignin as a binder using a mixer, and liquid fertilizer (12:4:8 = N:P2O5:K2O) was added. The biochar mixtures were pelletized using a pellet mill. The pelletized biochar was then processed at 105 or 180 °C for 24 h to dry in the oven. | K content 2.85–8.62 mg g−1, and P content 0.72–2.25 mg g−1 | K and P release was 53–62% and 49–62% within 24 h, and 78–87% and 73–78% after 18 d. | [35] |

3.1. In-situ pyrolysis

Rapid depletion of non-renewable resources such as phosphate rocks and sylvinite minerals requires recovery of nutrient elements from wastes. Biomass wastes rich in nutrients are highly attractive for fabricating biochar-based fertilizers. In some cases, the feedstocks of biomass have abundant nutrients and can be directly converted into biochar-based fertilizers. Banana peduncle [80], mushroom compost [81], and seaweeds [82] were reported to prepare K rich biochar. A few researches investigated P rich biochar from poultry litter [83], cattle carcasses [84], human manure [85], sewage sludge [86], bone waste [87], and bio-fermentation waste [62]. The phosphorus content in biochar derived from different biomass are listed in Table S1, and it ranges from 16.8 mg g−1 to 84.7 mg g−1. High P content in biochar implies the potential use as a fertilizer. K-rich banana peduncle and P-rich wastes sludge were co-pyrolyzed or treated by plasma for biochar production [88]. The biochar obtained by pyrolysis manifested a higher yield and total carbon content compared with plasma processing, but plasma processing resulted in higher nutrient content. Bioavailable P of biochar obtained by thermal plasma and slow pyrolysis was 4500–6000 and 5600 mg kg−1, respectively.

In the fermentation industry, a great number of bacterial wastes from Escherichia coli are produced, which contain high P content. Pyrolysis was performed in a muffle furnace at 600 °C under a N2 atmosphere to obtain P-enriched biochar [62]. The biochar was rich in P (84.7 mg g−1) and did not contain toxic elements out of limits. The biomass underwent dehydration, the vaporization of organic matter, and the formation of char during pyrolysis. Surface groups of N–H, C O, C–O, and PO43- were identified by FTIR spectra, and SEM and EDS showed the uniform distribution of P in macropore biochar. The P-enriched biochar was evaluated as potential P fertilizer, and promotion of the early growth of Lactuca sativa was observed. Thermal conversion of bacterial wastes into P-enriched biochar offers a practicable strategy for recycling biomass wastes derived from the fermentation industry. There are limitations for using P-enriched biochar from feedstocks such as sewage sludge and animal manures as potential fertilizer: (i) insufficient nutrient supply to soil and crops, and (ii) the presence of toxic elements [62].

3.2. Co-pyrolysis

Co-pyrolysis of biomass with P sources is an alternative to produce biochar-based SRFs. Co-pyrolysis enables the P immobilization in biochar by adsorption and chemical bonds. Biochar-based SRFs produced through co-pyrolysis typically manifest notable advantages, such as easy synthesis, high P loading, and impressive slow-release performance [68]. Zhao et al. [89] conducted co-pyrolysis of wheat straw with different P sources (H3PO4, phosphate rock, and triple superphosphate), and found reduced carbon loss during pyrolysis, lowered microbial mineralization, and improved biochar stability. Zhao and colleagues [79] studied the co-pyrolysis of biomass (pine sawdust or switchgrass) and fertilizer (triple superphosphate or bone meal) to produce biochar-based SRFs. The formation of C-O-PO3 or C–P resulted from the reaction between Ca(H2PO4)2 and biomass carbon occurred during pyrolysis, inducing slower P release.

Premixing biomass with an acid phosphate source leads to the low pH of biochar, and constraints its soil application. The addition of alkaline sources such as MgO prior to pyrolysis can regulate biochar pH and increase the nutrients of phosphate and magnesium. Lustosa Filho et al. [90] impregnated poultry litter with triple superphosphate and phosphoric acid in the presence or absence of MgO for preparing biochar-based SRFs. The prepared SRFs lowered P release, increased the soil pH, and promoted P uptake and maize growth [91]. Compared to triple superphosphate, the biochar-based SRFs promoted P use efficiency in tropical soil and promoted Marandu grass growth [92].

Montmorillonite catalyzed the conversion of cellulose in bamboo biomass to biochar under hydrothermal conditions [93]. A few researches reported biochar/clay mineral composites, such as bentonite/biochar and calcite/biochar [94], biochar/bentonite [95], montmorillonite/biochar [96], attapulgite/biochar [97]. Co-pyrolysis of montmorillonite and bamboo powder was conducted to prepare biochar composite [39]. Montmorillonite could catalyze bamboo pyrolysis and reduce the pyrolysis temperature for biochar formation. Biochar and montmorillonite in the composite offered surface and adsorptive sites for nutrients. The adsorption capacity reached 12.52 mg g−1 for NH4+ and 105.28 mg g−1 for PO43-. The release of NH4+ and PO43- from nutrient-laden biochar composite was 0.30–4.92% and 2.63–5.09%, displaying a good slow-release effect of N and P. Microwave-assisted co-pyrolysis of biomass, nutrient, and bentonite was proposed for the synthesis of slow-release fertilizer [66]. Cotton straw was mixed with K3PO4 and bentonite in solution, and then pyrolysis was conducted under microwave irradiation with limited oxygen (Fig. 3a). The heating behavior was enhanced in the presence of bentonite and K3PO4 (Fig. 3b). SEM image exhibited biochar with intensive pore structure (Fig. 3c), and EDX analysis confirmed P and K loaded on biochar (Fig. 3d). XPS spectra of P 2p identified the presence of HPO42−, PO43−, and H2PO4− (Fig. 3e–g). FTIR indicated that surface groups notably weakened since K3PO4 or bentonite accelerated the transformation of biomass components into aromatic carbon (Fig. 3h). XRD analysis revealed the presence of Mg3(PO4)2 and Ca(H2PO4)2 (Fig. 3i). The improved slow-release effect of P was verified by the increased utilization efficiency and diminished leaching loss (Fig. 3j). Pot experiments showed the improved growth of pepper seedlings, which might be ascribed to the slow-release performance of nutrients.

Fig. 3.

a. Schematic of BSRFs synthesis via co-pyrolysis; b. microwave-assisted heating behavior; c. SEM image, and d. EDX analysis; e-g. XPS P 2p spectra; h. FTIR spectra; i. XRD spectra; j. P leaching loss and the utilization efficiency. Reprinted (adapted) with permission from [66]. Copyright 2020 American Chemical Society.

3.3. Impregnation

Due to the low content of nutrients, the impregnation of pristine biochar in the nutrient solution effectively increases nutrient content. The porous structure and large surface area offer vessels and sites for nutrient storage, which prolongs the nutrient availability in biochar for the plant. The impregnation method displays easy operation and low cost. Biochar impregnated with ammonium salts [98], phosphates [99], and nitrates [100] was reported for preparing slow-release fertilizer to diminish nutrient loss and accelerate crop growth.

The typical impregnation process can be introduced based on the study reported by Khan et al [11]. Biochar derived from wheat was produced by conventional slow pyrolysis performed at a temperature of 300 °C or 350 °C. Nutrient-loading biochar was obtained by mixing biochar and salt solutions containing nutrients (P, K, Ca, and N), stirring for 3–4 h for adsorbing nutrients, then filtered and dried (Fig. S3a). The biochar was examined by multiple characterizations (Figs. S3b–g). Micro-morphology of biochar was mainly derived from wheat biomass, and loading nutrients after impregnation was proved by EDX. FTIR analysis revealed the presence of surface groups and the incorporation of nutrients on biochar surface. TGA examination identified the stable nature of the biochar. Obvious improvement of salt index, water retention, and slow-release nutrients was confirmed after impregnating biochar with nutrients.

Similarly, corncob biochar was impregnated with macro-nutrients (N, Ca, P, K, Mg) and micro-nutrients (Na, Zn, Fe), and the improved water retention and prolonged nutrient release were confirmed [101]. The influence of pristine and P-laden biochar (saturated with KH2PO4) was researched on soil P availability and fractions. Pristine biochar decreased P availability while P-laden biochar maintained high P availability in soil available P during the incubation, verifying P-laden biochar as SRF to promote soil P efficiency [8]. The impregnation of biochar derived from oil palm kernel shell with NH4NO3 and KH2PO4 was conducted, and the impregnated biochar displayed high nutrient retention (NO3− 52.9%, NH3 77.4%, and PO43- 55.2%) [76]. The N release performance of urea-impregnated biochar, hydrochar, zeolite, and hydroxyapatite was compared. The difference in the N release was seen, and the slow N release potentially reduced N loss and increased the fertilizer efficiency [102]. Biochar obtained from pyrolyzing cow dung was used for phosphorus adsorption from an aqueous solution. The P adsorption capacity was up to 345 mg g−1 [9]. XRD and XPS analysis proved P adsorption via precipitation mechanism, and P-laden biochar promoted seed germination and lettuce growth.

The impregnation method is significantly limited by the low adsorption capacity of pristine biochar toward nutrients. To satisfy the practical application, biochar modifications using various materials, such as MgO, K2O, bentonite, and coal gangue, have been developed to enhance adsorption capacity [63,103,104]. Biochar prepared from Mg-enriched tomato tissues effectively reclaimed phosphate from an aqueous solution with a maximum adsorption capacity of above 100 mg g−1 [105]. MgO modification of biochar significantly enhanced phosphate and ammonium adsorption from wastewater [106]. Mg-enriched biochar derived from corn straw showed excellent performance for reclaiming nutrients from biogas effluent [50]. The accumulative release ratio of N and P from Mg-enriched biochar was 7 times and 6 times lower than that of chemical fertilizer. The application strikingly promoted nutrient uptake and improved corn growth, implying the promising potential in agriculture application.

The composites of α-FeOOH-biochar synthesized by co-precipitation were used for phosphate adsorption from urine [57]. Phosphate adsorption was controlled by chemisorption and monolayer adsorption. The maximum adsorption capacity of phosphate was 57.4 mg g−1, while the extractable phosphate was 967.5 mg kg−1, indicating good bioavailability and a promising alternative as a slow-release fertilizer. Biochar composites were fabricated by direct pyrolysis of feedstocks and coal gangue [107]. The maximum P adsorption was 7.9 mg g−1, 4.6 times that of pristine biochar. The P-laden biochar was used as a slow-release fertilizer to improve bean seed germination and growth. Similarly, bentonite modified biochar by co-pyrolysis of cotton straw and bentonite was examined for phosphate adsorption from aqueous solution (Fig. S4a) [63]. SEM images displayed the typical structural characteristics of biochar (Figs. S4b–d). The high-resolution TEM pictures exhibited the lattice fringes assigned to MgO and CaO in biochar (Figs. S4e–g). XRD analysis (Fig. S4h) and XPS examination (Fig. S4i) also proved the presence of CaO and MgO.

In some cases, wastewater derived from different sources contains a large number of nutrients such as N and P. Biochar, after concentrating and adsorbing the nutrients from the wastewater, can be used as a soil amendment or fertilizer. Recovery of nutrients using biochar from the wastewater favors providing biochar-based SRFs for soil application and diminishing environmental problems. Previous reports manifested that biochar adsorbed N, P, and K from different sources, including urine, anaerobic digestate, landfill leachates, and livestock wastewater [108,109]. Soil improvement with the addition of digestate-enriched biochar was identified by increasing macronutrients (110–230%) and organic matter (232–514%) [110].

Interestingly, biochar/struvite composites were synthesized through crystallization-adsorption [77]. Biochar was mixed with Mg2+, PO43-, NH4+ solution (molar ratio 1:1:1), and the formation of biochar/struvite occurred. The high recovery of 99.02% N, 97.23% P and 95.22% Mg from aqueous solution formed 10% biochar/struvite. XRD patterns manifested a crystalline structure of struvite (MgNH4PO4·6H2O). SEM images showed a porous and coarse surface of biochar and the smooth and nonporous surface of struvite attached to biochar. The elements determined by EDS proved the presence of struvite. Biochar/struvite composite, as a potential slow-release fertilizer, demonstrated superior nutrient release to traditional chemical fertilizers. Wastewater containing abundant N and P can be a potential source for struvite synthesis, such as swine wastewater, calf manure wastewater, leather tanning wastewater, sewage sludge, dairy wastewater, and semiconductor wastewater [77].

Impregnation has unique advantages of easy operation and low cost, but the adsorption capacity of biochar limits the fertilizer efficiency of SRFs. Biochar modification can increase adsorption capacity toward nutrients, and the cost of the modification process should be considered. It is highly attractive to reclaim nutrients from wastewater through biochar impregnation. This strategy not only reduces the environmental pollution of wastewater such as eutrophication, but also makes full use of discharged nutrients. The limited nutrient uptake in biochar and co-existed toxic substances should be evaluated for real application.

3.4. Encapsulation

Encapsulation is a widely used method for fabrication SRFs, which coats fertilizers onto inorganic or organic substrates to reduce nutrient loss and increase nutrient utilization efficiency. Biochar-based SRFs prepared through encapsulation have been reported by many studies, such as biochar-biodegradable polymers-coated urea [111], biochar-waterborne copolymers-coated urea [2], and biochar-coated urea [112]. Biochar was co-composted with feedstocks of poultry manures and green waste, and organic coating enriched in nutrients of N and K formed on biochar surface and inner pore surface [113]. A slow-release fertilizer with rapeseed meal biochar and sodium alginate was synthesized by the graft-copolymerization process, and the water retention, nitrogen content, and its slow release of the graft copolymers were significantly improved [114]. The modified starch derived from cassava or corn as coating materials was used to prepare granular SRFs [115]. Khajavi-Shojaei et al. [72] reported granular MgCl2-modified biochar coated by polyvinyl alcohol and corn starch. Compared with uncoated MgCl2-modified biochar and chemical fertilizer, the granular coated biochar exhibited the slowest N release, the highest N content in soil and corn plant, and N utilization efficiency. A microwave-assisted method was conducted to prepare biochar-hydrogel composites [116]. Microwave irradiation accelerated structural alteration and cross-linkage reaction. The composite improved water absorbency and nitrogen release. Jia and colleagues fabricated biochar-coated urea using oxidized starch [74]. Biochar coated by urea displayed good slow-release N fertilizer for declining N loss and improving N utilization efficiency.

There exists a difference in fertilizer efficiency of biochar-coated fertilizer, which can be ascribed to biochar properties, coating materials, and encapsulation processes. Biochar with a large surface area was favorable for controlling nutrient release due to strong adsorption [117]. The alkaline groups and inorganic salts in biochar were reported to increase the loss of NH3 via volatilization [118]. The surface groups of biochar influenced the molding of granular fertilizer [119]. Various coating materials are used for the preparation of SRFs, including organic polymers and inorganic minerals [120]. Polymers, such as polyolefin, copolymers, polyvinylidene chloride, wax, and paraffin, are costly and nondegradable. Additionally, the accumulation of coating polymers deteriorates soil structure, suppresses soil nutrient cycling, and restrains microbial activity [115]. The coating SRFs tends to employ naturally biodegradable materials, including waste palm oil [121], starch [122], and chitosan and poly (vinyl alcohol) blend [123]. Green coating materials such as cotton stalk-based polyol [71], wood vinegar [124], sodium alginate, cellulose, starch, chitosan, and maltodextrin [125], were reported for the preparation of biochar-based SRFs. Biochar-based SRF was prepared using waterborne copolymers as coating materials. Biochar declined water absorbency of copolymer with an improved degradability, and favored the slower lease of coated urea [2]. Bio-oil derived from biomass pyrolysis was used for coating biochar loaded with N, P and K nutrients, and bio-oil coating effectively reinforced the slow-release capacity of nutrients [58].

Encapsulation is an important method for manufacturing SRFs with coating materials as a diffusion barrier to control nutrient release. Generally, the encapsulation process is complicated, involving the impregnation of biochar with nutrients, mixing different components (biochar, minerals, adhesive, binders, etc.), and pelletization. The complex and expensive encapsulation process notably limits the use of coated SRFs in agriculture. Coating materials have intrinsic features from agronomic, environmental, and economic perspectives. After nutrient release, the coating materials remain in soil due to poor degradability, and their accumulation over time induces potential environmental threats. Coating materials may add toxic organic matters, reduce soil permeability and microbial activity [126]. Green, bio-degradable and cheap coating materials are future directions.

3.5. Granulation

Currently, granulation or pelletization is a common method for fertilizer production. Due to brittleness, low density, and small particles, the storage and transport of biochar for soil application is highly challenging. High loss of biochar is caused by wind-blown or surface runoff from intense rain events, and the fine biochar induces the irritation of the eyes, skin, and respiratory system of humans [58,127]. In this regard, granulation is an effective option to decrease biochar loss and handling costs for soil application, and realizes practical large-scale application in agricultural practices.

Granulation of the mixtures of biochar and nutrients effectively lowers nutrient release by increasing diffusion resistance. As to biochar-based SRFs, granulation can be conducted in two ways: (i) carbonization of pelletized biomass containing nutrients and (ii) pelletization of biochar/fertilizer mixtures. For the former, impregnating the pelletized biochar with additional nutrients is necessary owing to the low nutrients derived from biomass. Poultry litter and switchgrass were blended, pelletized, and pyrolyzed at different temperatures to fabricate biochar pellets [83]. As to the latter method, after sufficient mixing biochar and fertilizer particles with uniform size, granulation is performed by disc granulation or mechanical extrusion, and binders are commonly used in the process. The biochar derived from switchgrass were mixed with liquid fertilizer and lignin, and the mixtures were granulated using a pellet mill [35]. The pellets produced by mixing biochar and manure compost was effective for NH4+-N adsorption, and the N-laden biochar pellets promoted plant growth [78].

The wheat straw biochar was mixed with diammonium phosphate, potassium chloride, and bentonite, and then a revolving drum granulation device was used for granulation with steam vapor as a binder [65]. The granulated biochar fertilizer had a total of 37% nutrients (18% N, 9% P2O5, and 10% K2O). A field experiment indicated that the granular fertilizer increased grain yield by 10.7% and maize production by 46.2%. The benefits were ascribed to increase P supply, slow nutrient release, and moisture regime for maize growth.

After impregnation with N–P–K nutrient solution prepared by dissolving ammonium nitrate, potassium dibasic phosphate, and single super phosphate, biochar was mixed with a binder of starch/PVA and granulated by extrusion [128]. The granulated fertilizer exhibited lower nutrient release and higher water retention of the amended sandy soil than conventional chemical fertilizer. The effect of granulating biochar produced by blending or coating triple superphosphate was studied on P release kinetics and plant growth [75]. Compared with triple superphosphate, the granulating biochar had lower P release, and the coating was more effective than blending for decreasing P release. Granular biochar was prepared by uniformly mixing biochar, clay minerals (bentonite and sepiolite) and urea, and subsequent mechanical pelletizing using wood vinegar as a binder [129]. Attaching urea to the particle surface of biochar and clay minerals was characterized in the composite. Leaching experiments suggested that the cumulative N release and the dissolved organic carbon of the granular biochar were remarkably decreased by above 70% and 8% compared to urea. The pot experiment revealed that the fresh maize shoot and root were increased by 14% and 25% with the application of the biochar fertilizer. The rice husk biochar was first impregnated with urea–hydrogen peroxide, and then pelletized in a disc pelletizer using kaolin as a binder [127]. The pelletization process was optimized using response surface methodology for lowering N release. Attachment of urea–hydrogen peroxide in biochar pores was proved, and the minimum cumulative N release of the granular fertilizer was 17.63%. Pot experiments showed improved cabbage growth.

The pellet properties are dependent on biomass characteristics and operating conditions [130]. [35] reported that the mechanical properties and nutrient release of granular fertilizer improved with increasing drying temperature. After mixing biogas residue biochar with commercial fertilizer, the binder-free granular fertilizer was synthesized using a compression mold [69]. Response surface methodology was used for the optimization of the granulation process. The physical properties of the pellets were the best under optimal conditions of diameter 7 mm, moisture content 7.84%, and compression speed 49.54 mm min−1. The excellent sustained nutrient release of the granular fertilizer was proved, and the slow-release effect of nutrients obeyed P>N>K. Although water or steam can be used for granulation, the binder-free granular biochar has poor mechanical performance for the application. Binders are used to improve the mechanical strength of biochar-based SRFs, and they include clay, sepiolite, bentonite, starch, etc. However, many organic binders may induce environmental damage owing to poor degradability. Moreover, the high cost and complex preparation limit the practical application of granular biochar-based SRFs [126].

3.6. Integrated methods

Besides the methods mentioned above, innovative approaches are proposed to synthesize biochar-based SRFs, especially for integrated methods. Biochar derived from rice husk was first mixed with phosphoric acid, then reacted with ammonia gas, and finally granulated using a small stainless-steel drum [131]. The formation of ammonium phosphate in pores of biochar was clarified. The discharge of the available nitrogen (NH4+-N and NO3−-N) from the granular fertilizers was slower than that of ammonium phosphate. Pot experiments demonstrated high N content and improved plant growth with the addition of granular biochar-ammonium phosphate. This work provides a method of manufacturing uncoated slow-release fertilizer.

An et al. [73] developed microwave-assisted co-polymerization for SRFs synthesis, and biochar was embedded into semi-interpenetrating polymer networks (Fig. S5a). SEM images displayed uniform and small pore networks of the polymer structure (Figs. S5b–d). TEM images manifested that the tiny particles assigned to K3PO4 and NH4H2PO4 were encapsulated inside the pore network (Figs. S5e–h). The stronger hydrophilicity was verified by the contact angle measurement (Fig. S5i). XRD patterns proved the presence of KH2PO4 and (NH4)2HPO4 (Fig. S5j). The presence of biochar in semi-interpenetrating polymer networks enhanced water retention, reinforced nutrient slow-release, improved the degradability of SRFs. Better growth of pepper seedlings was confirmed by pot experiments after the addition of biochar-based SRF.

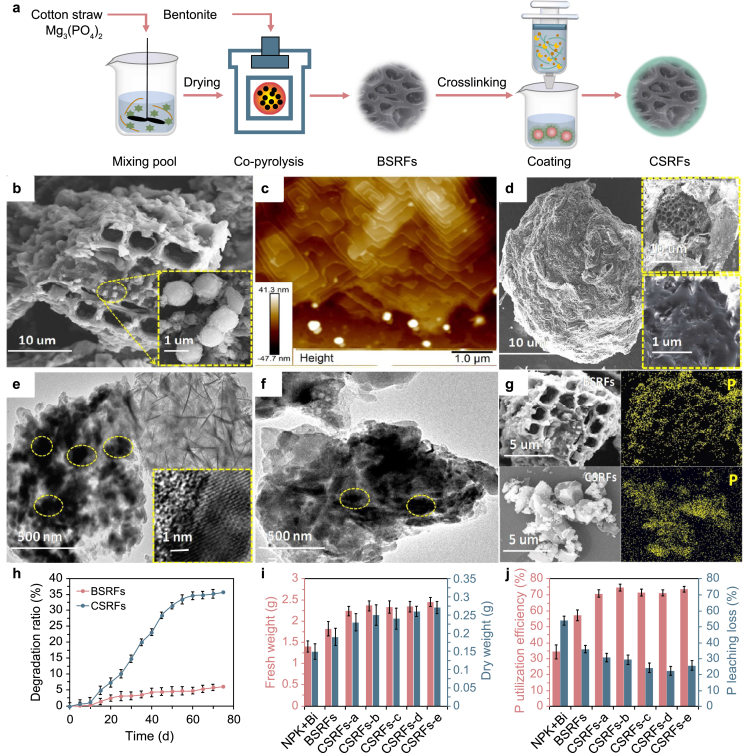

The intergradation of co-pyrolysis and encapsulation was conducted to synthesize coated biochar SRFs (Fig. 4a) [125]. SEM image showed a porous structure with randomly loaded bentonite and Mg3(PO4)2 (Fig. 4b, d). Highly ordered stripes were seen from the AFM image (Fig. 4c). TEM verified abundant fertilizer particles and irregular coating, and the dominant nutrient of P was proved by EDX analysis (Fig. 4e–g). Compared to the co-pyrolyzed SRFs, the coated SRFs had lower P release and superior degradability, and significantly improved plant growth (Fig. 4h–j). The research group further compared the performance of SRFs derived from phosphorus impregnated biochar, pyrolysis of biomass/nutrients/bentonite (BSRFs), the coated BSRFs, and co-polymerized BSRFs [68]. The co-polymerized BSRFs displayed the highest water retention and excellent P slow-release performance comparable to coated BSRFs. The good biodegradability and highest P utilization efficiency of co-polymerized BSRFs were verified.

Fig. 4.

a. Schematic of CSRFs preparation via integrating co-pyrolysis and encapsulation; b., d. SEM images; c. AFM image; e., f. TEM images; g. elemental mapping of P; h. degradation behavior of BSRFs and CSRFs; i. fresh weight and dry weight of plant, and j. P leaching loss and utilization efficiency. Reprinted (adapted) with permission from [125]. Copyright 2021 Elsevier.

An infiltration process with molten urea was developed to fabricate biochar-based fertilizer [126]. An infiltration device consisting of two glass tubes was used (Fig. S6a). The rice husk was added to the lower glass tube, the molten urea obtained at 140 °C was poured into the upper glass tube at a designed temperature in a drying oven. After the infiltration process, biochar granulation was conducted by the extrusion of the precursor. FTIR, TGA, and SEM characterizations suggested that small urea particles were evenly distributed on biochar surface with maximum N content of 29.19% (Figs. S6b–d). However, the N release and bioavailability were not investigated in this work.

A biochar-based slow-release fertilizer was fabricated by an integrated process (Fig. 5a) [70]. Pine biochar obtained by fast pyrolysis at 500 °C was mixed with the H3PO4 solutions. After shaking for 24 h and fully drying at 85 °C, the mixture was carbonized at 465 °C for 2 h under N2 atmosphere. The mixture of activated biochar and urea was ground and heated at 137 °C to infuse the urea into the pores of biochar. The granulation of the urea-infused biochar was conducted using calcium lignosulfonate solution and liquefied paraffin wax as binders. SEM-EDS, XRD, and FTIR analysis manifested urea grafting onto biochar through urea amine N and carbonyl C O bonds (Fig. 5b–d). The excellent slow-release effect of the biochar-based fertilizer was proved by slow urea release (61–90% in 4320 min), low N loss (68–71% after 41 leaching), and minor NH3–N volatilization (0.2–0.9%) (Fig. 5e–g). The developed fertilizer effectively diminished N loss from soil and provided long-term NH4+-N supply for plants.

Fig. 5.

a. Schematic of the synthesis of urea-infused biochar; b. FTIR of the slow-release fertilizers; c. XRD patterns of slow-release fertilizers prepared from H3PO4 activated biochar; d. SEM image of slow-release fertilizer; e. urea release, f. NH4+-N availability, and g. cumulative N leaching. Reprinted (adapted) with permission from [70]. Copyright 2021 American Chemical Society.

Microwave-assisted preparation of a biochar-based fertilizer containing nitrogen was proposed to enhance slow-release nitrogen and water retention [4]. Biochar adsorbed with NH4+ was uniformly mixed with acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, bentonite, cotton stalk, and potassium persulfate, and underwent complete polymerization under microwave irradiation. The biochar-based fertilizer reduced the N release (69.8% after 30 days), lowered N leaching (10.3%), and increased N use efficiency (64.27%). The fertilizer had a high water-retention capacity and improved cotton plant growth. Additionally, the good degradability was verified by the soil burial degradation test. A complex process, involving impregnation, granulation, and coating, was developed to prepare biochar-based SRFs (Fig. 6) [71]. A biofilm-derived liquefied cotton stalk was synthesized and used as coating material. SEM images manifested the porous structure of biochar and the successful loading of phosphorus nutrients. The improved growth of corn maize was observed with the addition of biochar-based SRFs, and the fertilizer with 2% biofilm showed the best efficiency.

Fig. 6.

a. Schematic of the synthesis of biofilm coated biochar-based SRFs; b. SEM images; c. P leaching, d. cumulative P release loss; e. fresh weight, f. dry weight, and g. pictures of maize growth. Reprinted (adapted) with permission from [71]. Copyright 2021 Elsevier.

Each method has distinct features for fabricating biochar-based SRFs (Fig. 7). In-situ pyrolysis enables the one-step synthesis of biochar-based SRFs, but it is limited by deficient nutrients in biomass feedstocks and the potential presence of toxic elements. Co-pyrolysis is easy to control the nutrients loading, but it is highly dependent on the N and P sources. Impregnation can be easily performed, and it is promising considering recovery nutrients from wastewater. For the impregnation method, modifications of pristine biochar are commonly necessary due to low adsorption capacity toward nutrients, which increases the process cost. Encapsulation enables coating nutrients onto biochar and is highly favorable to the slow-release of nutrients. The complex and expensive encapsulation process limits the application of coated SRFs, and the potential threat of coating materials requires special attention. Granulation is effective in reducing biochar loss and handling costs for real agricultural practices, and it is commonly integrated with other methods for the fabrication of effective biochar-based SRFs. Considering the multiple requirements of low cost, easy operation, high efficiency, and environmental friendliness, it is difficult to find a versatile process that meets all applications. Currently, the integrated methods gain more and more research interests.

Fig. 7.

The advantages and disadvantages of method for fabricating biochar-based SRFs.

4. Nutrients loading mechanism

SRFs enable gradual nutrient release for long-term supply of the nutrients and avoid leaching loss, improving fertilizer efficiency, and diminishing potential threats to the environment [35]. As a nutrient carrier, biochar potential declines the release rate of nutrient and improve nutrient utilization efficiency owing to high surface area and porous microstructure, favorable surface charge, abundant surface groups, and active carbon [59]. The performance of biochar-based SRFs can be improved by exploring the basic properties and the mechanism of nutrient loading. Extensive studies provide an in-depth understanding of biochar-based SRFs. A better understanding of nutrients loading mechanism helps discover effective biochar-based SRFs and evaluating fertilizer fate in the environment.

Adsorption of pollutants using biochar has been widely investigated, and in-depth discussion of the adsorption mechanism has been reported [132,133]. The adsorption of pollutants by biochar is closely related to the properties of pollutants and biochar. In the case of metal ions, the possible mechanism includes ion exchange, surface complexation, electrostatic attraction, physical adsorption, and surface precipitation [133]. For organic contaminants, the mechanism involves hydrogen bond, pore-filling, electrostatic interaction, hydrophobic interaction, and surface complexation (Fig. S7). Most adsorption mechanisms depend on biochar properties, such as surface area, porous structure, surface groups, and mineral components. The potential adsorption effect favors attaching nutrients onto biochar and fabricating SRFs.

Biochar is an excellent carrier of nutrients such as N, P, K, attributing to the large load ability of the porous structure and strong adsorption ability toward nitrate, ammonium, phosphate, etc. Ye et al. [58] found that biochar prepared under CO2 or H2O(g) atmosphere contained more surface groups for K adsorption, and active groups on biochar surface displayed good N and P adsorption. Reclaiming phosphate from water was controlled by the adsorption mechanism of P precipitation and deposition on Mg particles in biochar [105]. Phosphorus adsorption onto MgO modified magnetic biochar was ascribed to precipitation, electrostatic attraction, ligand exchange, and metallic complexation between surface groups and metals [134]. Chen et al. [9] reported that P adsorption onto cow dung biochar was dominated by surface precipitation. Vikrant et al. [135] summarized phosphate adsorption by various biochar (Fig. 8a). Nutrient uptake onto biochar/montmorillonite composites indicated that NH4+ adsorption was mainly ascribed to surface adsorption associated with ion exchange, while PO43- adsorption was controlled by the electrostatic attraction or ionic bonding between PO43- and metal cations [39]. N adsorption onto biochar was reported through ion exchange, surface groups, and electrostatic interaction [49]. Wang et al. [107] reported the dominant mechanism of electrostatic adsorption, ligand exchange, and surface precipitation for phosphate adsorption onto coal gangue modified biochar. Zhang' group [57] conducted phosphate recovery from synthetic urine using goethite/biochar composite, and found phosphate adsorption through the Fe–OH bonds and the formed inner-sphere complexes (Fe–O–P). Luo and colleagues [50] reported the effective reclaiming of N and P nutrients from biogas effluent by Mg-enriched biochar (Fig. 8b). P release was attributed to Mg–P precipitates formed on the biochar surface and the ‘P-trap’ effect of MgO through the PO43- precipitation process. N release was dominated by the hydrogen bonds and pore-filling for N-containing organic matter, and the incarceration effect and electrostatic attraction for NH4+.

Fig. 8.

a. Phosphate adsorption on various biochar materials. Adapted with permission from [135]. Copyright 2018 Elsevier. b. Schematic of nutrient attachment onto biochar-based SRFs. Adapted with permission from [50]. Copyright 2021 Elsevier.

As discussed above, various methods such as impregnation, encapsulation, granulation, and co-pyrolysis are developed to prepare biochar-based SRFs. Based on the synthesis processes, there is a difference in of nutrient loading mechanism. Impregnation is highly dependent on the properties of biochar. The unique properties, including large surface area, porous structure, and abundant surface groups, provide favorable sites for attaching nutrients onto biochar by adsorption. Granulation mainly aims at increasing diffusion resistance to reduce nutrient leaching loss. As to encapsulation, nutrients are dominantly embedded in the internal sites of SRFs via different interactions.

Shi et al. [129] fabricated granular biochar/mineral/urea composites as potential SRFs. Urea was bound to the surface of biochar and minerals in the composites, and this occurrence enhanced the N retention. Zhao's group [79] proposed a co-pyrolysis of biomass and P fertilizers to synthesize biochar-based SRFs. The lower P release was attributed to creating stable C–O–P or C–P bonds. Increasing temperature enhanced the interactions between biochar and nutrients in the SRFs, but requiring more energy consumption and high production cost. An and colleagues conducted co-pyrolysis of bentonite and bamboo to obtain the modified biochar [63]. The enhanced P adsorption and release performance of bentonite modified biochar were attributed to (i) the creation of porous structure, (ii) the reduction of surface negative charge, and (iii) the formation of precipitation due to the presence of Ca and Mg [63]. The P-release kinetics could be effectively regulated by changing the bentonite amount.

As to coated SRFs, the coating materials on fertilizer surface are barriers that prohibit nutrient diffusion [125]. Generally, the nutrient release from coated SRFs involves: (i) transferring water into the interior of fertilizer, (ii) the dissolution of nutrients, and (iii) the nutrient release through the coating [136]. The formation of a nutrient-rich organic coating was identified [56]. The coating material attached to the inner and outer surface of co-composted biochar, and increased the water and nutrient retention through increasing hydrophilicity, mesoporosity, and redox-active moieties. The blended and coated SRFs were compared relating to nutrient release. The blended biochar/superphosphate fertilizer demonstrated relatively poor P slow release, which was restricted by the diffusion and swelling/relaxation. The coated biochar/superphosphate fertilizer displayed superior P retention controlled by the swelling/relaxation [75].

The presence of biochar was favorable for the generation of porous structure and abundant cross-linking points in biochar embedded-semi-interpenetrating polymer networks based SRF, and biochar also improved the water retention and degradability of the Semi-IPN based SRF [73]. The infiltration of molten urea onto biochar as SRFs was proposed [126]. It was found the uniform distribution of molten urea infiltrated into biochar pores. The generation of different amides occurred by the reactions between molten urea and surface groups.

As discussed above, a better understanding of the nutrient loading mechanism is obtained, providing insights into the design and fabrication of biochar-based SRFs. Currently, the slow-release mechanism is tentatively understood based on nutrient loading onto biochar. Multiple characterizations, such as X-ray diffraction, infrared spectroscopy, and X-ray photoelectron spectroscopy, can be employed to reveal the elemental variation of biochar-based SRFs. The release behavior of nutrients is commonly determined in water or solution mediums, as well as column leaching in soil or sand [11,50,71]. The schematic diagram of the column leaching device is shown in Fig. S8. Release kinetics under different conditions provides insights into nutrient release from biochar-based SRFs. Owing to the difference in methods, processes, and devices, the results reported from different researches are difficult in comparison. The elemental transformation of nutrients is still poorly investigated after applying to soil. Especially, the effect of soil environments on nutrient release is rarely reported for biochar-based SRFs.

5. Potential agricultural applications

To evaluate the fertilizer efficiency of biochar-based SRFs, plant growth experiments are imperative. The effect of biochar-based SRFs on plant growth is commonly investigated through pot experiments at a bench scale. Reports on plant growth through pot experiments are listed in Table S2. Plants of pepper, corn, mung bean, oilseed rape, and Spinacia oleracea were used, and the growth period ranged from 10 days to 6 months. Plant height, root length, biomass weight, and chlorophyll content were used as plant growth indicators. The improvement of plant growth associated with biochar-based SRFs is verified by pot experiments.

Field experiment for evaluating biochar-based SRFs is imperative before widespread application for agricultural production. Recently, field studies on the application of biochar-based SRFs to agricultural production were reported. Field experiments reported by [137] exhibited that the low amount (less than 0.1%) of biochar-based compound fertilizer induced the improvement of maize yield and soil fertility and the significant decline of Cd contents in maize grains. Yan and colleagues conducted a field experiment in a tea orchard to examine the impact of biochar-based fertilizer on the yield and quality of tea and microbial community in soil [138]. Biochar-based fertilizer improved soil properties and altered bacterial and fungal diversity and community, and its application significantly enhanced the yield and quality of tea, which were positively related to some plant beneficial microbes. Experiments in field vegetable production indicated that biochar-based fertilizer treatment manifested higher yield, plant N uptake, and nitrogen use efficiency [139]. A 3-year field experiment in Northeast China was conducted to examine the impacts of biochar and controlled-release urea on rice yield and nitrogen-use efficiency [124]. Mixed application of bare urea, controlled-release urea, and biochar effectively improved rice yield and fertilization efficiency for sustainable agricultural production. Additionally, field studies were reported on the alternative benefits of biochar-based fertilizers [26]. conducted field experiments in a rice paddy field to reveal the mitigation of CH4 emission in a rice paddy field after the addition of biochar-based SRF [138]. performed field experiment in a karst mountainous area, and found that biochar-based fertilizer was effective for soil restoration by improving the complexity of microbial-related networks and soil nutrients. Similarly, Gao et al. [140] reported the improved bacterial communities of brown earth soil by biochar-based fertilizer. A field study in a subtropical Moso bamboo plantation indicated that the application of biochar-based fertilizer was effective for the mitigation of N2O emissions from subtropical plantation soils [33].

6. Perspectives and challenges

Numerous related researches have been reported, but the development of biochar-based SRFs for real application is still in its infancy. Currently, there are challenges from the aspects of (i) the synthesis of effective biochar-based SRFs, (ii) the evaluation of nutrient release and bioavailability, and (iii) the long-term assessment of a real application. The research perspectives are also discussed in terms of the above aspects.

The development of biochar-based SRFs aims to improve fertilizer utilization efficiency and diminish nutrient loss into the environment. Pristine biochar is not favorable as fertilizer due to the low content of nutrients, and the loading nutrients is limited to the poor adsorption and stabilization effects onto biochar. To improve the nutrient content, modifications are commonly conducted to increase the adsorption capacity or nutrient attachment of biochar. Phosphorus is a limiting nutrient for crop growth, but the non-renewable P resources are being depleted with a high P fertilizer consumption of above 20 Tg year−1 [6]. Recycling P from P-rich sources is a promising alternative to mitigate phosphate rock depletion. Biomass feedstocks, for example, fermentation wastes containing abundant phosphorus (7445 mg kg−1), manure and sludge contain high P, and be used to produce P-enrich biochar [62]. For wastewater, human urine accounts for below 1% of the total volume but contains above 50% of total phosphorus in wastewater [141]. Phosphorus is an indicator of surface water quality. Excessive phosphorus causes serious eutrophication, which threats the aquatic ecosystems and increases the economic burden. Effective reclaiming phosphate from P-enriched wastewater biochar benefits wastewater treatment and fertilizer production. Additionally, co-composting biochar with compost feedstocks containing abundant nutrients and organic carbon effectively strengthens the agronomic performance of biochar as a soil amendment [113].

Due to brittleness, low density, and small particles, high loss of biochar is caused by wind-blown or surface runoff from intense rain events. Moreover, the storage and transport of biochar for soil application are highly challenging. Granulation is an effective option to decrease biochar loss and handling costs for large-scale applications in agricultural practices. Encapsulation is highly efficient to enhance nutrient release, but the degradability of coating materials should be fully evaluated. Various methods developed for biochar-based SRFs have distinct features, and it is difficult to find a versatile process meeting all applications. According to previous reports, more and more complex processes are used to fabricate efficient SRFs. Additionally, researches currently focus on lowering nutrient release, but the precise control of nutrient release meeting the requirement of crop growth requires more effort in future work. Biochar-based SRFs require these features: (i) low production cost, (ii) simple fabricating process, (iii) environmental friendliness, (iv) excellent slow-release performance for nutrients, and (v) high bioavailability for crop growth. Therefore, finding a strategy for synthesizing biochar-based SRFs meeting these requirements is still imperative in future studies.

An in-depth understanding of nutrient slow release is imperative for fertilizer synthesis and evaluation of a real application. Although research advances on the mechanism of nutrient loading have been obtained, an in-depth understanding of the slow-release mechanism of nutrients from biochar-based SRFs is still insufficient [56]. Nutrient adsorption onto biochar via multiple interactions plays an important role in loading nutrients in biochar-based SRFs. Nutrient barrier or chemical reactions are also involved in nutrient uptake onto biochar. The nutrient release from biochar-based SRFs should be quantitatively evaluated. The nutrient release can be determined in water or solution mediums, and column leaching in soil or sand is also employed to examine the leaching loss of nutrients. The results obtained from different studies cannot be compared due to the difference in methods, processes, and devices. Proposing standard methods for determining the nutrient release is helpful to evaluate the slow-release performance of as-prepared biochar-based SRFs. Release kinetics under different conditions provides insights into nutrient capture and the trade-off between leaching loss and bioavailability. In addition, the revelation of interactions between nutrients and soil environments is of high importance to understand the slow-release mechanism of nutrients from biochar-based SRFs.

There are debates about the “net absolute benefits” of biochar application [110]. Some researchers argue that massive application biochar may induce soil toxicity from heavy metals [142,143]. Others claim that the high adsorption capacity of biochar restraints nutrient supply for plant uptake due to strong binding vital nutrients [144]. Additionally, biochar addition to soils does not lead to consistent crop yield improvement, and plant growth responded to biochar varies significantly. Therefore, the mechanism behind the capture and subsequent release of nutrients from biochar-based SRFs is not sufficiently understood.

The application of biochar-based SRFs can be an applicable strategy to alleviate soil deterioration and climate change by GHG emission reduction, carbon sequestration, and soil nutrient retention improvement. Zhang et al. reported biochar-based SRFs applied in rainfed maize cropland in China increased crop production by above 20% and reduced N2O emission by more than 30% over conventional fertilizer [145]. It was reported that carbon sequestration was up to 2.3 tons ha−1 in corn fields after applying biochar and cow manure compost, and the mitigation of equivalent CO2 emission was estimated to be 7.3–8.4 tons ha−1 [146]. Fidel et al. evaluated the potential reduction of GHG emissions from biochar-amended soils [147]. Biochar declined 27% soil CO2 emissions for the entire season of maize growing, and the NO2 reduction was observed in continuous cropping systems [147]. Dong and colleagues found that the addition of biochar-based SRF significantly reduced CH4 emissions by 33.4% during the rice-growing season, which was ascribed to the different species of N in slow-release fertilizer and available potassium in soil [26]. The long-term evaluation of GHG emissions associated with biochar-based SRFs application should be further examined.

Besides fertilizer efficiency, biochar has additional benefits, including increased soil texture, water retention, cation exchange capacity, and microbial diversity [110]. Biochar amendment can reduce the availability of potentially toxic metals while remediating contaminated soils due to the high adsorption capacity. Biochar-based fertilizer increased the microbial biomass of nutrients, changed the microbial community, and improved bacterial community network complexity [148]. Liao et al. also reported the improved microbial activity, stimulated soil nitrification, and reduced denitrification by shifting the microbial communities toward the nitrifying bacteria after applying biochar-based N fertilizer [149].

Water supply is a critical factor in agriculture production. The fertilizers with high water retention are preferable, especially in arid and semiarid regions. Superabsorbent polymers (SAPs) with excellent water absorption capacity are commonly used to improve the water retention of soil. The incorporation of nutrients into SAPs can be a promising strategy to improve the water retention of SRFs [150]. It was found that SAPs-based SRFs were highly appropriate for the application in drought land due to long-term retention of soil moisture [151]. Kenawy et al. synthesized sugarcane bagasse-g-poly (acrylamide)/attapulgite composites with excellent swelling capacity, and pointed out that the composites as SRFs can be regulated for nutrient release ratio by changing the attapulgite amount in the copolymerization process [152]. Cotton stalks and bentonite were proved to increase water retention, reduce nutrient leaching loss, and decline the degradability of biochar-based SRFs [4]. Biochar-based SRFs prepared by co-polymerization manifested better water retention, P slow-release, and biodegradability compared to the fertilizer fabricated by co-pyrolysis [68]. The application of biochar-based SRFs is promising for climate change migration, soil amendment, and crop production in future agricultural practice. A better understanding of the effects of the biochar-based SRFs influence on soil properties, GHG emission, and carbon sequestration still needs extensive researches, especially for long-term field studies. The additional benefits of biochar-based SRFs enhance sustainable agriculture in future applications.

7. Conclusions