Abstract

Purpose

Wagashi Gassirè (WG) is a traditional cheese produced from cow milk following local processing methods in Benin. The aim of this study was to describe the milk processing methods and the preservation practices with the objective of improving WG production and sanitary quality.

Methods

A survey was carried out among 390 actors (84 dairy farmers, 165 producers, 53 traders, and 88 consumers) from two municipalities (Dassa and Nikki) in Benin.

Results

WG is highly preferred by consumers for its whiteness (63.0%), softness (24.7%), smoothness (19.2%), and firmness (13.7%). WG production is based on the coagulation of milk using Calotropis procera extracts as coagulant. Six milk processing methods, including three new WG production methods were identified, depending on how the C. procera extracts were pre-treated and used during WG production. Boiling (67%) was the most widely used as WG preservation method. The use of aluminium cooking pots (100% of WG producers), WG open-air production (66.7% of producers) and antibiotic misuse (59.3% of dairy farmers) may lead to the chemical or microbiological contamination of WG.

Conclusions

Six WG production and six preservation methods were identified after the survey among WG producers and traders. Future studies should assess the sanitary and physico-chemical quality of WG from the identified processing and preservation methods. The next step of research should be also focused on the development of specific standards to produce a better quality of WG.

Keywords: Calotropis procera, Milk, Sanitary quality, Chemical contaminants, Traditional cheese

Calotropis procera; Milk; Sanitary quality; Chemical contaminants; Traditional cheese.

1. Introduction

Around the world, a diversity of cheeses (1400 according to some estimates) is available (McSweeney et al., 2017). Cheese processing is one of the most significant methods of preserving the major milk components such as proteins, minerals, and fat. The most important step during cheese processing is milk coagulation, achieved through the addition of enzymes to the milk (Mazorra-Manzano et al., 2018). During coagulation, the casein component of the milk protein system forms a gel network that entraps fat (Mazorra-Manzano et al., 2018; Baba-Moussa et al., 2007). Four types of enzymes are used in cheese factories, which are animal rennet, genetically engineered chymosin, coagulants of microbial origin, and plant-derived clotting enzymes (Jacob et al., 2011). The plant-derived clotting enzymes are an alternative to animal rennet and have the advantage of being accessible and easy to use, even on a small scale (Rayanatou 2017). Their use is a common practice in Mediterranean, West African, and Southern European countries. In Portugal and Spain, the extract of Cynara cardunculus flowers is used to produce traditional cheeses such as Serra da Estrella, Castelo Branco, Torta Del Casar, La Serena or Los Ibores (Roseiro et al., 2003). In Mexico, extracts from Solanum elaeagnifolium have been used for production of pasta flata cheese type, known as “Asadero” while the traditional cheese "Gybna bayda", widely consumed in Sudan, is produced using the extract of the fruits of Solanum dubium (Mazorra-Manzano et al., 2018; Rayanatou 2017; Kheir et al., 2011).

In Benin, fresh cow milk is processed, generally by the sociocultural group Peulh, into a traditional local cheese called Wagashi Gassirè (WG) which remains in the country, the most consumed dairy product (Mattiello et al., 2017; Dossou et al., 2006). WG is a soft cheese obtained by hot (65–70 °C) coagulation of fresh whole milk using Calotropis procera extract that contains a plant enzyme known as calotropain (Mattiello et al., 2017; Baba-Moussa et al., 2007; Dossou et al., 2006). In Benin, WG is mainly produced in the northern part of the country where dairy farming is more developed and widespread (MAEP 2014; Kora 2005).

WG is an important source of proteins (23–36%), fats (18–27%), and minerals (1.3–1.8%) (Adeyeye 2016; Alalade and Adeneye 2006; Uzeh et al., 2006; Appiah et al., 1998). It could help to meet the daily nutritional requirements of proteins (0.8 g), calcium (2,500 mg), and other nutrients for adults (CSS 2016). WG is highly valued and consumed daily by local consumers and also by people from neighbouring countries where it is used as a meat and fish substitute in various dishes (Baba-Moussa et al., 2007). WG and other dairy products contribute to more than 50% of the annual Peulh household income (Sessou et al., 2013). Income from the marketing of dairy products provides remuneration and work motivation to Peulh women. This almost regular income allows them to provide for other household needs and gives them decision-making power and autonomy (Chabi-Toko et al., 2015). As WG also requires a vast distribution network, it is an important source of income also for other actors of this value chain besides milk processors.

Several studies have shown the presence of dioxins and polychlorinated biphenyl (0.048 pg TEQ/g wet weight) and some pesticides, such as cypermethrin (0.7 μg/kg wet weight) and chlorpyriphos-ethyl (120 μg/kg wet weight), in milk and dairy products from Benin (Vaccher et al., 2020; Ingenbleek et al., 2019; Dossou et al., 2016). However, it is not well known whether and at which step(s) of the production and distribution chain (from dairy farmers to consumers) WG may be chemically contaminated. Moreover, to our knowledge, the main factors associated with WG chemical contamination during its storage have not been precisely documented. Therefore, it is necessary to identify and describe the traditional milk processing methods to produce WG, preservation practices, and conditions of sale to propose appropriate alternatives in order to decrease the risk of chemical contamination.

2. Material and methods

The aim of this study was to identify and describe the traditional milk processing methods, WG preservation practices, and conditions of sale to develop and propose appropriate alternatives to improve WG production, storage, and sale.

2.1. Characteristics of the study area

The study was carried out in Dassa and Nikki, two municipalities of the agricultural development pole identified in Benin Republic for diversification and intensive cattle production (Figure 1). These municipalities are part of the main cattle and WG production areas in Benin. Nikki is a WG production area with a dairy processing unit. Dassa is a WG production area and a crossroad and important WG commercial and transaction area (MAEP 2014).

Figure 1.

Geographical localization of the surveyed actors.

2.2. Survey sample size and selection of respondents

This survey was carried out using a questionnaire to collect information on WG production/sale. The snowball method was used to identify the included people: dairy farmers (who had at least 10 cows), active processors (still active in the last year and with at least 10 years of experience in WG production), traders (still active in the last year and with at least 10 years of experience in WG sale), and WG consumers (Johnston and Sabin 2010). Data saturation threshold was used to determine the sample size. Consumers were randomly selected without any specific criterion.

2.3. Collected data

A semi-structured questionnaire was used for the one-to-one interviews with the different actors identified. The data collected were on: WG production (milk processing and WG preservation methods used by processors and traders); potential sources of contamination during processing, preservation, and trading; quality criteria according to processors and consumers; dairy farmers’ practices that could affect the quality of the milk used as raw material to produce WG. Data were collected in the field using the Epicollect5 system through web and mobile applications (Aanensen et al., 2009).

2.4. Production monitoring

Based on the survey results, the three (3) most used methods were monitored to determine WG production yields. A total of 24 trials of productions (8 trials per processing methods) were carried out. For each unit operation (UO), time (from start to end of the UO), temperature (at the UO end), and the ingredient quantity were measured. The production yields were determined by dividing the quantity of cheese obtained by the quantity of milk used for the production.

2.5. Statistical analysis

Data from the semi-structured questionnaire were translated in a structured form and loaded in MS Excel 2013 to perform the descriptive analysis using the SAS System 9.4 software. The confidence intervals (CI) at 95% were determined for different variables before frequency comparison with the Chi-square test. The 95% CIs were calculated using the following formula: where p is the proportion and n the number of respondents for the variable. The Z-test was used to compare percentages in pairs for variables with more than two classes.

For the data on production monitoring, means were compared with a simple linear regression analysis (ANOVA). Statistical significance was set at 5%.

2.6. Ethical approval

The study protocol was approved by the Faculty of Agronomic Sciences of the University of Abomey-Calavi, Benin Republic. The survey and the production monitoring were conducted according to ethical guideline of the ethics committee of the University of Abomey-Calavi. All the interviews have been carried out with informed written consent of the respondents.

3. Results

3.1. Sociocultural status of the different actors

For this study, 390 people were interviewed using a semi-structured questionnaire in the municipalities of Dassa and Nikki (Table 1). Table 2 presents the sociocultural profile of the respondents. Dairy farmers (n = 84) were mostly men (94.0%), married (96.4%), and illiterate (92.8%). The percentage of dairy farmers younger than 30 and older than 60 years (16.7% and 25.0%, respectively) was significantly lower (P < 0.001) than that of 30–60-year-old dairy farmers (58.3%). Dairy farmers belonged to the Peulh (86.9%) and Gando (13.1%) sociocultural groups. The Gando group is found exclusively in Nikki, whereas Peulh farmers are in both municipalities.

Table 1.

Typology of the respondents in the two municipalities.

|

Typology of respondents |

Number of respondents per municipality |

Sub-total | |

|---|---|---|---|

| Dassa | Nikki | ||

| Dairy farmers | 54 | 30 | 84 |

| Processors | 90 | 75 | 165 |

| Traders | 35 | 18 | 53 |

| Consumers | 56 | 32 | 88 |

| Total | 235 | 155 | 390 |

Table 2.

Sociocultural profile of the different actors surveyed (% ± CI).

| Sociocultural characteristics | Dairy farmers (n = 84) | Processors (n = 165) | Traders (n = 53) | Consumers (n = 88) |

|---|---|---|---|---|

| Sex | ||||

| Men | 94.0 ± 5.0a | 0.0 ± 0.0a | 1.9 ± 3.8a | 51.7 ± 10.4a |

| Women | 5.9 ± 5.0b | 100 ± 0.0b | 98.1 ± 3.8b | 48.3 ± 10.4a |

| Age (in years) | ||||

| ˂30 | 16.7 ± 9.4a | 12.2 ± 7.1a | 40.0 ± 16.2a | 50.8 ± 12.4a |

| >30 and ˂60 | 58.3 ± 12.5b | 75.6 ± 9.3b | 54.3 ± 16.5a | 41.8 ± 12.2a |

| ≥60 | 25.0 ± 10.9a | 12.2 ± 7.1a | 5.7 ± 7.7b | 7.9 ± 6.7b |

| Marital status | ||||

| Married | 96.4 ± 3.9a | 95.1 ± 3.3a | 92.4 ± 7.1a | 70.8 ± 9.4a |

| Single | 3.6 ± 3.9b | 4.9 ± 3.28b | 7.6 ± 7.1b | 29.2 ± 9.4b |

| Matrimonial status | ||||

| Monogamy | 45.7 ± 10.8a | 43.9 ± 7.7a | 48.9 ± 14.0a | 79.4 ± 9.9a |

| Polygamy | 54.3 ± 10.8a | 56.1 ± 7.7a | 51.0 ± 14.0a | 20.6 ± 9.9b |

| Educational level | ||||

| None | 92.8 ± 5.5a | 92.7 ± 3.9a | 56.6 ± 13.3a | 16.8 ± 7.8a |

| Primary | 5.9 ± 5.0b | 5.4 ± 3.4b | 24.5 ± 11.6b | 24.7 ± 8.9a |

| Secondary | 1.2 ± 2.3c | 1.8 ± 2.0c | 15.1 ± 9.6b | 43.8 ± 10.3b |

| University | 0.0 ± 0.0c | 0.0 ± 0.0c | 3.8 ± 5.1d | 14.6 ± 7.3a |

| Sociocultural group | ||||

| Peulh | 86.9 ± 7.2a | 61.8 ± 7.4a | 32.0 ± 12.6a | 7.8 ± 5.6bcd |

| Gando | 13.1 ± 7.2b | 35.1 ± 7.3b | 2.2 ± 3.1b | |

| Fon | 1.2 ± 1.8c | 13.2 ± 9.1bc | 16.8 ± 7.8ac | |

| Idaatcha | 1.8 ± 2.0c | 11.3 ± 8.5bc | 24.7 ± 8.9a | |

| Mahi | 3.8 ± 5.1b | 2.2 ± 3.1b | ||

| Dendi | 9.4 ± 7.9bc | 2.2 ± 3.1b | ||

| Minan | 5.7 ± 6.2b | |||

| Baatonou | 20.7 ± 10.9ac | 14.6 ± 7.3ad | ||

| Yoruba | 3.8 ± 5.1b | 5.6 ± 4.8b | ||

| Adja | 3.4 ± 3.8b | |||

| Others | 20.2 ± 8.3a | |||

The letters a, b, c, and d notify significant difference (P <0.05) between percentages for the same variable, CI: confidence interval at 95%.

WG producers (n = 165) were only women who belonged to different sociocultural groups: Peulh (61.8%), Gando (35.1%), Idaatcha (1.8%), and Fon (1.2%). These women were mainly married (95.1%) between 30 and 60 years of age (75.6%), and illiterate (92.7%).

Traders (n = 53) belonged to many sociocultural groups: Peulh (32.0%), Baatonou (20.7%), Fon (13.2%), and Idaatcha (11.3%). WG trading was carried out almost exclusively by women (98.1%), generally married (92.4%). Approximately 44% of traders were literate.

Consumers (n = 88) were mostly younger than 60 years of age, and belonged to the same sociocultural groups as the processors and also to other sociocultural groups (Dendi, Mina, Mahi, Yoruba, and Adja). They were mostly literate (83.2%) and 14.6% had a university diploma.

3.2. Traditional milk processing methods for Wagashi Gassirè production

3.2.1. Different steps of the traditional processing methods to prepare Wagashi Gassirè

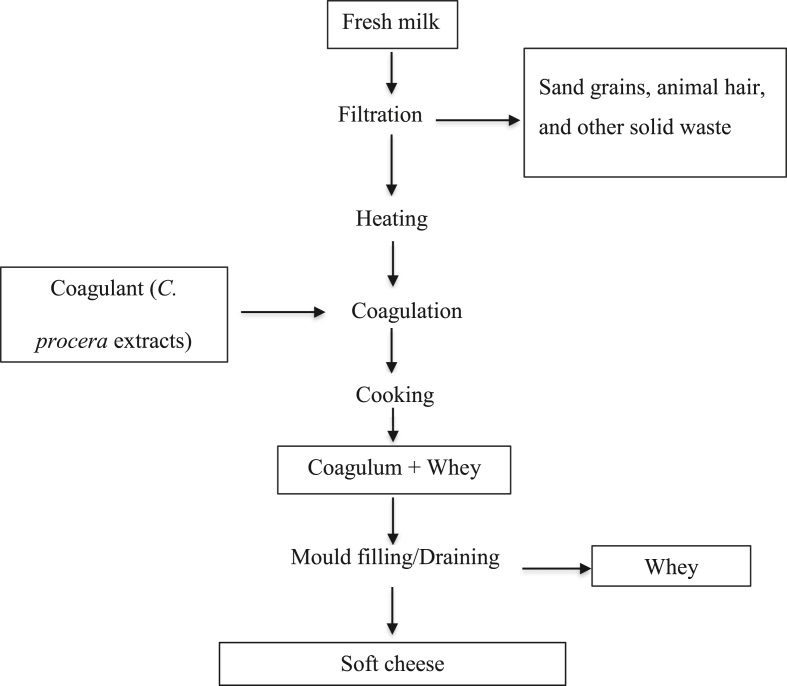

Two WG types were produced: white and coloured WG. On the basis of the processors’ responses, white WG (WWG) production was performed following ten unit operations (UO) grouped into four steps (Figure 2):

Figure 2.

Fresh milk processing into Wagashi Gassirè.

Step 1: Milk preparation for processing. In the first UO (UO1), milk was filtered. This UO was performed by 66.1% of processors. Then, filtered milk was heated (UO2: 59 °C for 20 min). Heating was done by 82.7% of processors.

Step 2: Extract preparation. WG is produced using C. procera extracts. The combination of C. procera leaves and stem was used by 66.1%, stem alone by 32.1%, and sap by 9.1% of processors. C. procera leaves alone (1.8%) and Carica papaya leaves (1.8%) were rarely used. Fermented corn supernatant (1.2%) and salt (3.6%) also were used, but always in combination with C. procera extract. Usually, for the coagulant preparation, C. procera leaves or stems were washed using well, river or tap water (UO3: 13.5%) and crushed (UO4: 95.5%). Crushed C. procera was triturated (UO5: 98.7%) with heated milk (80.8%) or water (18.0%). The resulting mixture of milk/water and C. procera was filtered (UO6: 71.2%) and used as coagulant. Some processors (UO7: 5.5%) used all the crushed extract as coagulant and then skimmed off the C. procera rubble.

Step 3: Milk coagulation. The coagulant was added (UO8: 100%) to the heated milk. After the coagulant addition, the milk became solid and the coagulum obtained was cooked (91 °C for 34 min, UO9: 100%).

Step 4: Mould filling/draining. The cooked coagulum was put into a mould (UO10: 100%): oval vegetable or plastic colanders of different sizes that allow the simultaneous draining.

The obtained WG is white and soft. These four steps were common to all the milk processing method variants.

3.2.2. Processing method variants

Milk processing variants to prepare WG depended on the used C. procera parts (sap, stem, leaves; alone or in combination) for milk coagulation, and on their pre-treatment (trituration or not in water or milk) before coagulation. In total, six WG production variants were identified on the basis of the method used to prepare the coagulant (Figure 3 and Table 3):

Figure 3.

Different Wagashi Gassirè production methods in function of the coagulant used. M1: sap, M2: leaves and stem without trituration or filtration followed by skimming; M3: trituration in milk of leaves and stem; M4: trituration in water of leaves and stem; M5: trituration of stem in milk; M6: trituration of stem in water.

Table 3.

Utilization rate of each processing method by the different sociocultural groups.

| Processing method | Number of respondents (n = 165) | Percentage | Sociocultural groups |

|---|---|---|---|

| M1 | 15 | 9.1 | Peulh, Gando |

| M2 | 9 | 5.5 | Peulh |

| M3 | 82 | 49.7 | Peulh, Gando, Fon, Idaatcha |

| M4 | 15 | 9.1 | Peulh, Gando |

| M5 | 43 | 26.1 | Peulh, Gando |

| M6 | 12 | 7.3 | Peulh, Gando |

M1: sap, M2: leaves and stem without trituration or filtration followed by skimming; M3: trituration in milk of leaves and stem; M4: trituration in water of leaves and stem; M5: trituration of stem in milk; M6: trituration of stem in water.

Method 1 (M1). C. procera sap was added to the heated milk for coagulation. This method was used by 9.1% of processors.

Method 2 (M2). C. procera crushed leaves and stems were added to the heated milk for coagulation. Then, C. procera rubble was skimmed. This method was used by 5.5% of processors.

Method 3 (M3). C. procera crushed leaves and stems were triturated in a separate small quantity of milk. The resulting solution was filtered and the filtrate was added to the heated milk for coagulation. This method was used by 49.7% of processors.

Method 4 (M4). C. procera crushed leaves and stems were triturated in a separate small quantity of water. The resulting solution was filtered and the filtrate was added to the heated milk for coagulation. This method was used by 9.1% of processors.

Method 5 (M5). C. procera crushed stem was triturated in a separate small quantity of milk. The resulting solution was filtered and the filtrate added to the heated milk for coagulation. This method was used by 26.1% of processors.

Method 6 (M6). C. procera crushed stem was triturated in a separate small quantity of water. The resulting solution was filtered and the filtrate added to the heated milk for coagulation. This method was used by 7.3% of processors.

The choice of processing variant varied among sociocultural groups (Table 3). The M2 variant was used only by the Peulh group (5.5% of all processors). Conversely, the M3 variant was the most widespread (49.7%) method and the only method used by the Fon and Idaatcha sociocultural groups. The other four methods (M1, M4, M5 and M6) were used by the Peulh and Gando sociocultural groups (45.9% of all processors).

Then, for three most used processing methods (M1, M3, and M5), according to the survey results, the production conditions (heating time/temperature, cooking time/temperature, coagulant concentration for M3 and M5) and WG yield were monitored (Table 4). The ratio of milk to C. procera was 7.9 for M3 (i.e. 7.9 g of milk was used per gram of C. procera extract) and 19 for M5 (i.e. 19.0 g of milk per gram of C. procera extract) (P <0.001). The cheese yields varied from 27.0 (M1) to 33.0% (M5), but were not significantly different among methods. These yields were obtained using coagulation (i.e. heating) temperatures that ranged from 56 to 64 °C.

Table 4.

WG production conditions and yields.

| Processing methods (mean ± SD) |

|||

|---|---|---|---|

| M1 | M3 | M5 | |

| Heating time (min) | 20 ± 12a | 23 ± 8a | 21 ± 8a |

| Heating temperature (°C) | 56 ± 9a | 58 ± 10a | 64 ± 10a |

| Ratio milk/C. procera extract (g/g) | - | 7.9 ± 3.7a | 19.0 ± 6.0b |

| Cooking time (min) | 35 ± 7a | 26 ± 12a | 30 ± 11a |

| Cooking temperature (°C) | 92 ± 3a | 90 ± 7a | 90 ± 5a |

| Mould filling/draining time (min) | 11 ± 3a | 16 ± 3a | 12 ± 7a |

| Cheese yield (%) | 27 ± 6a | 31 ± 8a | 32 ± 9a |

a and b show significant differences (P <0.05) between processing methods. SD: standard deviation.

3.3. Wagashi Gassirè preservation practices by processors and traders

Analysis of the semi-structured interviews of processors and traders identified six WG preservation practices: boiling, sun-drying, colouring, immersion, smoking, and frying (Table 5).

Table 5.

Distribution (% ± CI) of WG preservation methods in function of the actors, municipality, and sociocultural group.

| Preservation method | Cumulative percentage of processors and traders | Municipalities |

Actors |

Sociocultural groups | ||

|---|---|---|---|---|---|---|

| Dassa | Nikki | Processors | Traders | |||

| Boiling in water | 69.4 ± 6.3 | 62.2 ± 7.9a | 37.8 ± 7.9b | 72.7 ± 7.3a | 27.3 ± 7.3a | Baatonou, Dendi, Fon, Gando, Idaatcha, Mahi, Mina, Peulh, Yoruba |

| Boiling in salty water | 17.9 ± 5.2 | 45.9 ± 16.1a | 54.1 ± 16.1a | 75.7 ± 13.8a | 24.3 ± 13.8a | Baatonou, Dendi, Fon, Gando, Idaatcha, Peulh |

| Boiling with shea leaves | 1.9 ± 2.2 | 0.0 ± 0.0a | 100.0 ± 0.0a | 100.0 ± 0.0a | 0.0 ± 0.0a | Peulh, Gando |

| Boiling in plastic bags | 20.4 ± 5.5 | 97.6 ± 4.6a | 2.4 ± 4.6b | 73.8 ± 13.3a | 26.2 ± 13.3a | Peulh, Fon, Idaatcha, Baatonou |

| Sun-drying | 23.3 ± 5.8 | 14.6 ± 9.9a | 85.4 ± 9.9b | 85.4 ± 9.9a | 14.6 ± 9.9b | Peulh, Gando, Idaatcha, Baatonou |

| Colouring | 13.1 ± 5.3 | 20.0 ± 17.5a | 80.0 ± 17.5b | 100.0 ± 0.0a | 0.0 ± .00a | Peulh, Gando |

| Immersion in whey | 4.6 ± 3.3 | 71.4 ± 33.5a | 28.6 ± 33.5a | 100.0 ± 0.0a | 0.0 ± 0.0a | Peulh, Gando |

| Immersion in water | 3.9 ± 3.1 | 66.8 ± 37.7a | 33.3 ± 37.7a | 100.0 ± 0.0a | 0.0 ± 0.0a | Peulh, Fon, Idaatcha, Gando |

| Smoking | 2.4 ± 2.1 | 20.0 ± 35.1a | 80.0 ± 35.1a | 60.0 ± 42.9a | 40.0 ± 42.9a | Peulh, Dendi, Yoruba |

| Frying | 3.8 ± 5.1 | 0.0 ± 0.0a | 100.0 ± 0.0a | 0.0 ± 0.0a | 100.0 ± 0.0a | Dendi, Baatonou |

The letters a and b notify significant difference (P ˂0.05) between groups for the same variable, CI: confidence interval at 95%.

Specifically, WG was boiled in water (69.4%), in salty water (17.9%), or in water with shea leaves (1.9%). Sometimes, WG was packed in a plastic bag (20.4%) before boiling. Boiling in water (62.2%) and in plastic bags (97.6%) were more used in Dassa than in Nikki (37.8% and 2.4%; P <0.01).

Sun-drying (23.3%) was more common in Nikki than in Dassa (85.4% and 14.6%; P <0.0001), and more frequently done by processors than traders (85.4% and 14.6%; P <0.05).

WWG was coloured to obtain red WG using various dyes, such as sorghum cobs, sorghum panicles and teak (Tectona grandis) leaves. Sorghum cobs and panicles were soaked and then triturated or boiled with potash, bicarbonate, or salt. WWG was then immersed in the obtained coloured water. Teak leaves were only boiled to obtain coloured water for WWG colouring. Colouring was only used by processors and more in Nikki than Dassa (80.0% and 20.0%; P<0.01).

Immersion in whey (4.6%), well or tap water (3.9%) was used for short-term preservation, before selling during the same day, and only by processors.

Smoking (2.4%) and frying in oil or fat (3.8%) were less frequently used by processors and also traders. They represented less than 7.0% of all WG preservation methods. Frying was only used by traders from Nikki.

Boiling, the main preservation practice, was used by processors and traders belonging to all identified sociocultural groups. Conversely, colouring and immersion in whey were specific to the Peulh and Gando groups. Frying was not reported by Peulh participants.

3.4. Dairy farmers’ practices and Wagashi Gassirè production conditions

The dairy farmers reported that the quantities of antibiotics administered to animals did not respect the recommended doses (59.3% of interviewed farmers) and that the treated animals may be milked on treatment day (54.6%). This milk was then consumed (85.7%) or processed (83.3%). Dairy farmers said that they used herbicides (2,4-D amine salt, atrazine, prometryn, fluorometuron and glyphosate) in cotton, maize, cassava, yam, and other crop fields (79.5%).

Moreover, 66.7% of processors did not have a dedicated production room and 43.6% of the existing rooms were not protected against rain, dust, wind, and pests. The production equipment was generally rudimentary: sieves with iron filters (49.5%), plastic colanders (95.0%), aluminium cooking pots (100.0%), and plastic material for WG storage before and during selling.

According to the traders, WG sale was ambulant (28.9%) and along roads (62.2%). Containers were often uncovered (85.7%). In the various sale locations, 97.1% of traders were exposed to rain, dust, and wind.

3.5. Wagashi Gassirè quality criteria

According to the processors, WG quality mostly depended on the quality of the milk used as raw material and on the main UO of the processing methods, such as coagulation (72.4%) and cooking (14.7%). They also said that the cleanliness of the production materials, the absence of contact between milk and salt/water and the use of fresh C. procera leaves or stems were important measures. The milk used as raw material should have been milked on the day of production (30.1%). Milk from recently calved cows (colostrum) should not be used.

According to the consumers, the most important criteria to assess WG quality were: whiteness (63.0%), softness (24.7%), smoothness (19.2%), and firmness (13.7%). Other criteria were also used, such as hardness (8.2%) and the absence of oil on the product surface (1.4%). The same criteria were used also by processors, except for firmness and absence of oil on the product surface. However, the importance of these criteria varied in function of the actors. Three additional criteria were used by processors; cooked taste and aroma (6.9%), absence of rubble (2.8%), and milk aroma (0.7%). Whiteness was the most important criterion to differentiate between processors (77.8%) and consumers (63.0%) (P <0.05).

4. Discussion

4.1. Importance of peulh women in the Wagashi Gassirè value chain

The sociocultural group Peulh is the main actor of the WG value chain. Indeed, dairy farmers are mostly Peulh who own 95.0% of the national cattle herd (Dahouda et al., 2019; Youssao et al., 2013). In Peulh culture, milking is carried out by men and women, but milk is exclusively the property of married women who are in charge of its management (Chabi-Toko et al., 2015). In agreement, in this study, women represented less than 5.0% of dairy farmers, but more than 95.0% of processors and traders, showing their importance in this value chain. Women processed milk mainly into WG. In Benin, traditional food production actors (particularly in agri-food crafts) are mostly 30 to 50-year-old women (Assogba et al., 2019; Dah et al., 2018; Badoussi et al., 2014; Saroumi and Kpenavoun 2014). The proportion of literate participants was higher among traders than processors. Indeed, trading require skills related to travelling and accounting that are more accessible to literate people younger than 60 years of age. This may explain the higher proportion of literate and the lower proportion of older people in this group. As the main actors of WG production were illiterate women, intervention in this sector should be targeted mainly to this group.

4.2. The efficiency of milk processing and Wagashi Gassirè preservation methods

Cow milk is the main raw material used for WG production (Dossou et al., 2006). More than a third of the surveyed processors reported difficulties in obtaining milk. Milk availability depends mainly on the season. During the rainy season, milk production increases due to the abundance of fodder resources (Dah et al., 2018; Gagara et al., 2017). However, in the dry season, their scarcity leads to transhumance of dairy farmers to other areas where fodder resources are available. The transport of milk to the municipalities of origin then depends on the transport infrastructure quality (Corniaux et al., 2005).

The main operations identified for milk processing into WG were filtration, heating, coagulation, cooking, and moulding/draining, as previously reported (Anihouvi et al., 2019; Gagara et al., 2019; Dah et al., 2018; Dossou et al., 2006; Belewu et al., 2005). The main coagulant used for WG production was C. procera extract (Baba-Moussa et al., 2007). Six different methods to produce WG could be identified in function of the C. procera part used and extract pre-treatment. The utilization of these methods varied in the different sociocultural groups. The Peulh sociocultural group used all the identified methods, showing that they are the main actors of WG production. Conversely, Gando and Fon used five methods, and Idaatcha only one. Generally, the sociocultural groups living in the same geographical area used the same methods. They exchange knowledge through friendships, kinship, and intercultural marriages (Badoussi et al., 2014). Thus, the Gando, Fon, and Idaatcha might have learnt about WG production from the Peulh, who still keep some of the production secrets. Traditionally, the Gando are servants of the Peulh and would have learnt WG production while working for them (Hahonou 2011). The Idaatcha are the largest population and the most important sociocultural group in the Dassa municipality. Their know-how in WG production might be linked to intercultural relations with the Peulh during their transhumance through Dassa.

The coagulant activity of C. procera extracts is due to the presence of calotropain, a cysteine protease (Baba-Moussa et al., 2007; Dossou et al., 2006). The main plant-derived clotting enzymes with coagulant activity on milk are cysteine proteases, serine proteases, and acid proteases. Several plants with similar enzymes including calotropain from Carica papaya, and bromelain from Ananas comosus are used for milk coagulation (Rayanatou 2017; Kheir et al., 2011; Roseiro et al., 2003). However, the cheese yields obtained with papain and bromelain are lower than those obtained with C. procera and the cheese flavour is bitter (Adetundji and Salawu 2008; Elolo and Courdjo 2005). Therefore, C. procera extracts are considered as the best coagulant for WG production (Adetundji and Salawu 2008). Only C. procera leaves are used in Burkina Faso (Dah et al., 2018), whereas leaves, stem, fruits, and sap are used in Nigeria and Benin (Dossou et al., 2006; Belewu et al., 2005). Stem and leaves are crushed, mixed with milk and then filtered. The filtrate constitutes the coagulant (Dah et al., 2018). Our survey highlighted other traditional methods: the use of water for coagulant preparation (M4 and M6), and coagulant skimming without prior crushing or filtering (M2). These methods are new and are reported for the first time. Generally, plant-derived clotting enzymes are extracted by aqueous maceration (Jacob et al., 2011; Kheir et al., 2011). The plant organs (fresh or air-dried) are crushed and soaked in water at room temperature (28–30 °C). Spain and Portugal have the largest variety and production of cheeses using extracts of Cynara sp. obtained by aqueous maceration (Roseiro et al., 2003). But in our study, aqueous maceration is less used than maceration in milk. The M3 method for coagulant preparation described in this study was the most used in Benin representing about 50.0% of all WG production processes. However, C. procera sap (M1) displays the best milk clotting activity and thus should give the best cheese yield (Baba-Moussa et al., 2007). Yet, cheese yields were similar when using methods M1, M3, and M5. Additional investigations should be done starting from a milk of standard composition because cheese yields also depend on the milk quality (Rayanatou 2017; Jeantet et al., 2014). Cheese yield may vary from 20.0 to 33.0% when C. procera extracts are used (Dossou et al., 2006; Belewu et al., 2005). Furthermore, coagulant skimming instead of trituration and filtering could lead to the presence of more C. procera rubble in WG. Some processors argued that the coagulant prepared according to the M5 method would allow obtaining WG of the same colour as the milk with a good cheese yield. Similarly, the coagulant prepared according to the M6 method should minimize coagulation failure and help to obtain the whitest WG (Dossou et al., 2006). The WG production methods using leaves and stems are ancestral and allow using less C. procera plants that are becoming rare. The identified production processes should be evaluated to identify the method that best meets the consumers’ preferences, and provides the best cheese yield with good nutritional properties.

WG preservation by boiling is the main method used in Benin. In Burkina Faso, cold preservation also has been reported (Dah et al., 2018; Sessou et al., 2013; Dossou et al., 2006). Sun-drying would allow longer preservation because it considerably reduces the cheese water content, thus limiting microbial development. Conversely, frying with oil favours earlier rancidity (Sessou et al., 2013; Lahlali et al., 2008; Dossou et al., 2006). Overall, the shelf life of WG at room temperature is limited due to the different sources of chemical and microbiological contamination as well as the product characteristics (Aw, pH) and environmental conditions that promote microbial growth.

4.3. Potential sources of Wagashi Gassirè contamination

Cow milk is the main raw material used in WG production (Dossou et al., 2006). As the production is traditional, all operations are done manually, sometimes without respecting good hygiene practices, such as hand and material washing (Gagara et al., 2019). This could lead to a probable microbial contamination and reducing of the shelf life of WG. Therefore, it is necessary to increase the actors’ awareness about good manufacturing and good hygiene practices to obtain products of good sanitary quality for consumers.

The misuse of antibiotics by dairy farmers and the no respect of the withdrawal period after animal treatment are the main reasons of antibiotic residue presence in milk and dairy products (Mensah et al., 2014a). These two behaviours were reported by the majority of the dairy farmers surveyed. In Benin and in West Africa, several studies showed that milk usually contains antibiotic residues, particularly tetracyclines, beta-lactams, aminoglycosides, penicillin, sulphonamides, and macrolides (Madougou et al., 2019; Mensah et al. 2014b, 2019; Oluwafemi et al., 2018; Olatoye et al., 2016; Bagré et al., 2015; Addo et al., 2011). Therefore, dairy farmers should be trained to the use of good hygiene and husbandry practices according to the legislation recommendation. In addition, the surveyed dairy farmers reported using herbicides in crop fields. The most used pesticides in northern Benin are endosulfan (a forbidden insecticide) and glyphosate (a herbicide) (Dognon et al., 2018; Gouda et al., 2019; Adechian et al., 2015; Agbohessi et al., 2011). As some pesticide residues have been found in food consumed in Benin and West Africa, they might be present also in WG (Douny et al., 2021; Ingenbleek et al., 2019; Dossou et al., 2016).

The production and marketing conditions and the materials used also are potential sources of chemical and microbial contamination. Dust could be a source of lead contamination because it deposits on WG during production and selling (Mama et al., 2013; Ekaneme 1998). Moreover, some of the materials used for WG production and storage contain aluminium that could migrate to WG (EFSA 2008).

4.4. Impact of the Wagashi Gassirè production method on its quality

Cheese quality depends on the conditions of milk coagulation and cooking, particularly the dose of coagulant used, the temperature, and the milk quality (pH, protein, fat, and calcium content) (Jeantet et al., 2014). In cheese factories, the milk quality is standardized through specific operations, such as physical purification by filtration or centrifugation, fat content standardization by adding cream or skim milk, protein content standardization by adding casein or by ultrafiltration, pH adjustment by adding lactic leavening, and calcium content adjustment by adding calcium chloride (Rayanatou 2017). These operations allow the production of cheese of regular composition and constant quality. Since the production of WG cheese is traditional, no standardization of the milk is done. This could lead to products of variable quality. Moreover, the milk-clotting enzymatic mechanism of calotropain, similar to chymosin, is in two steps: the hydrolysis of the Phe105-Met106 peptide bond in the casein micelle-protective protein (enzymatic phase) and the release of the hydrophilic portion known as glycomacropeptide (f106-169) conducing to casein aggregation and clot formation (nonenzymatic phase) (Mazorra-Manzano et al., 2018). The enzymatic phase is temperature-dependent and affects the cheese yield and the cheese properties (Rayanatou 2017; Jacob et al., 2011). The coagulation of the milk must therefore be performed at the optimal temperature of the clotting enzyme. For WG production, calotropain activity is optimal at 70 °C (Baba-Moussa et al., 2007; Dossou et al., 2006). This temperature was not always easy to reach by processors, as shown by the monitoring performed (59 °C), because the production is traditional. Plant extracts, with enough quantity of proteolytic enzymes, have the capacity to clot milk under optimum enzymatic activity conditions and affect the cheese yield (Mazorra-Manzano et al., 2018). For instance, the peptidases from C. procera exhibited dose-dependent milk-clotting activity up to 50–60 μg to 2 mL of milk and the doses higher than 60 μg were not effective to improve substantially the milk-clotting activity (Freitas et al., 2016). For WG processing, a significant difference was observed in the quantity of crude extract of C. procera used for the processing methods M3 and M5. The similar cheese yields obtained for M3 and M3 may indicate that the crude extracts are complex in proteinase composition resulting in a different milk-clotting activity (Mazorra-Manzano et al., 2018). According to WG producers, the milk to be used must have been milked on the day of production because a long interval between milking and cheese production is associated with natural milk fermentation that decreases WG yield. This needs to be confirmed by comparative studies.

In Burkina Faso, consumers choose WG for its nutritional value, aroma, and preservation properties. However, most of them find WG less attractive than foreign cheeses and less available (Dah et al., 2018). For Beninese consumers, whiteness is the most important criterion. However, the hygiene conditions during production as well as WG aroma and presentation (packaging) should be improved to interest consumers in urban centres accustomed to European cheese.

5. Conclusion

In Benin, there are various methods to produce WG that use different C. procera parts (sap, stem, leaves; alone or in combination) and different plant extract pre-treatment (trituration or not in water or milk) before milk coagulation. WG production process, storage and sale/distribution conditions, as well as husbandry practices, and seasonality of the milk used as raw material are all factors that could affect WG sanitary quality. More research is needed to assess the sanitary quality of WG obtained using these different processing methods and preservation practices.

Declarations

Author contribution statement

Dossou Wanignon Alphonse: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Seko Orou Baké Marie Thérèse; Komagbe Gwladysd: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data.

Sessou Philippe, Youssao Abdou Karim Issiaka, Farougou Souaïbou, Hounhouigan Djidjoho Joseph, Mahillon Jacques, Mongbo Rock, Poncelet Marc, Madode Yann Eméric, Douny Caroline, Scippo Marie-Louise, Clinquart Antoine, Azokpota Paulin: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Funding statement

This work was supported by Académie de recherche et d'enseignement supérieur [PROJET WALAC].

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

We thank all survey respondents and the processors during the production monitoring for their full cooperation.

References

- Addo K.K., Mensah G.I., Aning K.G., Nartey N., Nipah G.K., Bonsu C., Akyeh M.L., Smits H.L. Microbiological quality and antibiotic residues in informally marketed raw cow milk within the coastal savannah zone of Ghana. Trop. Med. Int. Health. 2011;16(2):227–232. doi: 10.1111/j.1365-3156.2010.02666.x. [DOI] [PubMed] [Google Scholar]

- Aanensen D.M., Huntley D.M., Feil E.J., al-Own F., Spratt B.G. Epicollect: linking smartphones to web applications for epidemiology, ecology and community data collection. PLoS One. 2009;4(9):6968. doi: 10.1371/journal.pone.0006968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adechian S.A., Nasser-Baco M., Akponikpe I., Imorou-Toko I., Egah J., Affoukou K. Les pratiques paysannes de gestion des pesticides sur le maïs et le coton dans le bassin cotonnier du Bénin. Vertigo. 2015;15(2):16 534. [Google Scholar]

- Adetundji V.O., Salawu O.T. West African soft cheese ‘wara’ processed with Calotropis procera and Carica papaya: a comparative assessment of nutritional values. Afr. J. Biotechnol. 2008;7(18):3360–3362. [Google Scholar]

- Adeyeye S.A.O. A preliminary study on the quality and safety of street-vended warankasi (a Nigerian soft white cheese) from Ibadan, Oyo state, Nigeria. Br. Food J. 2016;119(2):322–330. [Google Scholar]

- Agbohessi P.T., Imorou-Toko I., Yabi J.A., Dassoundo-Assogba J.F.C., Kestemont P. Caractérisation des pesticides chimiques utilisés en production cotonnière et impact sur les indicateurs économiques dans la Commune de Banikoara au nord du Bénin. Int. J. Biol. Chem. Sci. 2011;5(5):1828–1841. [Google Scholar]

- Alalade O.A., Adeneye J.A. The effect of storage period on the chemical composition and coliform microflora of wara cheese. Int. J. Dairy Sci. 2006;1(2):126–130. [Google Scholar]

- Anihouvi E.L., Hanaa S., Anihouvi V.B., Kesenkas H. Milk and dairy products production in Benin. Akademik Gıda. 2019;17(4):508–516. [Google Scholar]

- Appiah F., Ellis W.O., Mathias J., Oduro I. Studies on tradtional cheese (Woagashie) production in the Ashanti region. J. Ghana Sci. Assoc. 1998;1(1):96–104. [Google Scholar]

- Assogba M.F., Anihouvi D.G.H., Iko Afé O.H., Kpoclou Y.E., Mahillon J., Scippo M.-L., Hounhouigan D.J., Anihouvi V.B. Processing methods, preservation practices, and quality attributes of smoked and smoked-dried fishes consumed in Benin. Cogent Food Agric. 2019;5(1) [Google Scholar]

- Baba-Moussa F., Baba-Moussa L., Ahissou H., Bokossa I., Capo-Chichi B., Toukourou F., Sanni A. Propriétés coagulantes de Calotropis procera et ses possibilités d’utilisation en industrie agro-alimentaire. Revue. Cames. 2007;5:7–12. [Google Scholar]

- Badoussi E., Azokpota P., Madodé Y.E., Kayodé P.A.P., Dossou A., Soumanou M., Hounhouigan D.J. Variations in the traditional processing methods of Pentadesma butyracea butter in northern Benin. Food Chain. 2014;4(3):261–274. [Google Scholar]

- Bagré T.S., Samandoulougou S., Traoré M., Illy D., Tchamba G.B., Bawa-Ibrahim H., Bouda S.C., Traoré A.S., Barro N. Détection biologique des résidus d’antibiotiques dans le lait et produits laitiers de vache consommés à Ouagadougou, Burkina Faso. J. Appl. Biosci. 2015;87:8105–8112. [Google Scholar]

- Belewu M.A., Belewu K.Y., Nkwunonwo C.C. Effect of biological and chemical preservatives on the shelf life of West African soft cheese. Afr. J. Biotechnol. 2005;4(10):1076–1079. [Google Scholar]

- Chabi-Toko R., Adegbidi A., Lebailly P. Valorisation des produits laitiers dans les ménages Peul du Nord-Est du Bénin. Int J Biol Chem Sci. 2015;9(6):2716–2726. [Google Scholar]

- Corniaux C., Duteurtre G., Dieye P.N., Poccard-Chapuis R. Les minilaiteries comme modèle d’organisation des filières laitières en Afrique de l’Ouest: succès et limites. Rev. Elev. Med. Vet. Pays Trop. 2005;58(4):237–243. [Google Scholar]

- CSS (Conseil Supérieur de la Santé) 2016. Recommandations nutritionnelles pour la Belgique. Avis n° 9285. [Google Scholar]

- Dah P.A., Guira F., Tankoano A., Traore K., Sawadogo-Lingani H., Savadogo A. Cheese processing, marketing, utilisation, and consumption in Burkina Faso. Curr. J. Appl. Sci. Technol. 2018;29(5):1–12. [Google Scholar]

- Dahouda M., Boubacar A.M.Y., Dossa L.H., Dotche O.I., Ahounou S.G., Kiki S.P., Youssao I.A.K. Stratégies d’alimentation et gestion des ressources alimentaires dans les élevages bovins des Communes de Nikki, Kalalé et N’Dali au Nord Est Bénin. Rev. Int. Sci. Appl. 2019;2(2):48–70. [Google Scholar]

- Dognon S.R., Dognon H.R., Youssao A.K.A., Scippo M.-L., Youssao A.K.I. The use of pesticides in agriculture in North East Benin. Int. J. Agron. Agric. Res. 2018;12(6):48–63. [Google Scholar]

- Dossou J., Atchouke G.D., Dabadé D.S., Azokpota P., Montcho J.K. Évaluation comparative de la qualité nutritionnelle et sanitaire du lait de différentes races de vaches de quelques zones d’élevage du Bénin. Eur. Sci. J. 2016;12(3):140–159. [Google Scholar]

- Dossou J., Adote S., Soulé H. Université d’Abomey-Calavi, Abomey-Calavi; Bénin: 2006. Production et transformation du lait frais en fromage peulh au Bénin. Rapport de guide de bonnes pratiques. [Google Scholar]

- Douny C., Zoumenou Y.M.B.G., Aïna M., Toko I.I., Igout A., Guedegba L., Chabi S.K., Kestemont P., Scippo M.L. Contamination of water, sediment and fish with residues of pesticides used in cotton production in Northern Benin. Arch. Environ. Contam. Toxicol. 2021;81:367–385. doi: 10.1007/s00244-021-00888-2. [DOI] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority) Safety of aluminium from dietary intake. EFSA J. 2008;754:1–34. doi: 10.2903/j.efsa.2008.754. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ekaneme O. The street food trade in Africa: safety and socio-environmental issues. Food Control. 1998;9(14):211–215. [Google Scholar]

- Elolo G.O., Courdjo R.L. Propriétés physico-chimiques et réactivité comparées des agents coagulants végétaux dans la fabrication du fromage frais wagasi. J. Rec. Sci. Univ. Lomé. 2005;7(1):159–164. [Google Scholar]

- Freitas C.D.T., Leite H.B., Oliveira J.P.B., Amaral J.L., Egito A.S., Vairo-Cavalli S., Lobo M.D.P., MonteiroMoreira A.C.O., Ramos M.V. Insights into milk-clotting activity of latex peptidases from Calotropis procera and Cryptostegia grandiflora. Food Res. Int. 2016;87:50–59. doi: 10.1016/j.foodres.2016.06.020. [DOI] [PubMed] [Google Scholar]

- Gagara M.H., Sessou P., Dossa F., Ahounou S., Azokpota P., Youssao I., Gouro A.S., Farougou S. A study on the indigenous methods of processing milk in Niger. Curr. Agric. Res. J. 2019;7(2):213–223. [Google Scholar]

- Gagara M., Sessou P., Ahounou S., Azokpota P., Youssao I., Farougou S., Soumana G.A. Analyses of constraints related to milk production in Liptako Gourma in Niger. Afr. J. Agric. Res. 2017;12(23):1949–1958. [Google Scholar]

- Gouda A.I., Imorou Toko I., Imorou Idrissou M., Spanoghe P., Scippo M.-L., Sidi Z., Djagbe T., Kestemont P., Schiffers B. The transfer of insecticides used in cotton production to aquatic ecosystems in the cotton basin in northern Benin. Int. J. Sci. Res. Environ. Sci. Toxicol. 2019;4(1):1–15. [Google Scholar]

- Hahonou E.K. Past and present African citizenships of slave descent: lessons from Benin. Citizen. Stud. 2011;15(1):75–92. [Google Scholar]

- Ingenbleek L., Huc R., Pereirac L.L., Paineauc A., Coletc I., Konéd A.Z., Adegboyee A., Hossouf S.E., Dembélég Y., Oyedele A.D., et al. Sub-Saharan Africa total diet study in Benin, Cameroon, Mali and Nigeria: pesticides occurrence in foods. Food Chem. 2019;2 doi: 10.1016/j.fochx.2019.100034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jacob M., Doris J., Rohm H. Recent advances in milk clotting enzymes. Int. J. Dairy Technol. 2011;64(1):14–33. [Google Scholar]

- Jeantet R., Croguennec T., Garric G., Brulé G. 2ème édition. Lavoisier; Paris: 2014. Initiation à la technologie fromagère. [Google Scholar]

- Johnston L.G., Sabin K. Échantillonnage déterminé selon les répondants pour les populations difficiles à joindre. Methodol Innovations. 2010;5(2):38–48. [Google Scholar]

- Kora S. 2005. Contribution à l’amélioration de la technologie de production du fromage peulh au Bénin. Thèse d’ingénieur agronome, Université d’Abomey-Calavi. [Google Scholar]

- Kheir S.E.O., El Owni O.A.O., Abdalla M.O.M. Comparison of quality of sudanese white cheese (Gibna Bayda) manufactured with Solanum dubium fruit extract and rennet. Pakistan J. Nutr. 2011;10(2):106–111. [Google Scholar]

- Lahlali R., Bajji M., Serrhini M.N., Jijakli M.H. Modelling the effect of temperature, water activity, and solute on the in vitro growth of the biocontrol yeast Pichia anomala strain K. Biotechnol. Agron. Soc. Environ. 2008;12(4):353–359. [Google Scholar]

- Madougou A.M., Douny C., Moula N., Scippo M.-L., Delcenserie V., Daube G., Hamani M., Korsak N. Survey on the presence of antibiotic residues in raw milk samples from six sites of the dairy pool of Niamey, Niger. Vet. World. 2019;12(12):1970–1974. doi: 10.14202/vetworld.2019.1970-1974. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mazorra-Manzano M.A., Moreno-Hernández J.M., Ramírez-Suarez J.C. In: Biotechnological Applications of Plant Proteolytic Enzymes. Guevara M.G., Daleo G.R., editors. Springer; Mar del Plata: 2018. Chapter 2 -Milk-clotting plant proteases for cheesemaking; pp. 21–41. [Google Scholar]

- MAEP . 2014. Etude des filières lait et viande. Rapport définitif sur la filière lait, Cabinet SIMITEC Groupe, Cotonou, Bénin. Ministère de l’Agriculture de l’Elevage et de la Pêche. [Google Scholar]

- Mama D., Dimon B., Aina M.P., Adounkpe M., Ahomadegbe J., Youssao A., Kouazounde A., Kouanda S.P., Moudachirou M. Transport urbain au Benin et pollution atmosphérique: évaluation quantitative de certains polluants chimiques de Cotonou. Int. J. Biol. Chem. Sci. 2013;7(1):377–386. [Google Scholar]

- Mattiello S., Caroprese M., Matteo C.G., Fortina R., Martini A., Martini M., Parisi G., Russo C., Zecchinia M. Typical dairy products in Africa from local animal resources. Ital. J. Anim. Sci. 2017;15(19):740–754. [Google Scholar]

- McSweeney P.L.H., Ottogalli G., Fox P.F. In: Cheese: Chemistry, Physics and Microbiology. fourth ed. McSweeney P.L.H., Fox P.F., Cotter P.D., Everett D.W., editors. Academic Press; San Diego: 2017. Chapter 31 - diversity and classification of cheese varieties: an overview; pp. 781–804. [Google Scholar]

- Mensah S.E.P., Aboh A.B., Salifou S., Mensah G.A., Sanders P., Abiola F.A., Koudandé O.D. Risques dus aux résidus d’antibiotiques détectés dans le lait de vache produit dans le Centre Bénin. J Appl Biosci. 2014;80(1):7102–7112. [Google Scholar]

- Mensah S.E.P., Koudandé O.D., Sanders P., Laurentie M., Mensah G.A., Abiola F.A. Résidus d’antibiotiques et denrées d’origine animale en Afrique: risques de santé publique. Rev. Off. Int. Epizoot. 2014;33(3):975–986. [PubMed] [Google Scholar]

- Mensah S.E.P., Sessou P., Nata C., Adjahoutonon K.Y.K.B., Lahamy O., Farougou S. Mode d’utilisation des antibiotiques dans les élevages de bovin laitier sédentaires au nord-ouest du Bénin. J. Anim. Plant Sci. 2019;42(2):7198–7206. [Google Scholar]

- Olatoye I.O., Daniel O.F., Ishola S.A. Screening of antibiotics and chemical analysis of penicillin residue in fresh milk and traditional dairy products in Oyo state, Nigeria. Vet. World. 2016;9(9):948–954. doi: 10.14202/vetworld.2016.948-954. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oluwafemi F., Oluwabamiwo B.F., Oluwatosin O.O., Akinrinade O.R., Kolapo A.L. Assessment of microbiological and residual antibiotics status in milk sold in Abeokuta, Ogun State. Nigeria Turk J. Agric. Food Sci. Technol. 2018;6(6):642–651. [Google Scholar]

- Rayanatou I.A. 2017. Étude de la coagulation du lait par l’extrait de feuilles de Calotropis procera en réponse au contexte laitier dans la région de Maradi, au Niger. PhD diss., Université Bretagne Loire Agro Campus Ouest. [Google Scholar]

- Roseiro L.B., Barbosa M., Ames J.M., Wilbey R.A. Cheesemaking with vegetable coagulants - the use of Cynara L. for the production of ovine milk cheeses. Int. J. Dairy Technol. 2003;56(2):76–85. [Google Scholar]

- Saroumi Y., Kpenavoun S. Chain Seminar; Nairobi, Kenya: 2014. Valorisation du lait de vache par les femmes Peulhs au Benin: analyse de l’efficacité des systèmes de transformation agro-alimentaire du lait local en fromage. Poster Presented at the ILRI-CTA African Dairy Value. [Google Scholar]

- Sessou P., Farougou S., Azokpota P., Youssao I., Yèhouenou B., Ahounou S., Sohounhloué D.C.K. Endogenous methods for preservation of wagashi, a beninese traditional cheese. Afr. J. Agric. Res. 2013;8:4254–4261. [Google Scholar]

- Uzeh R.E., Ohenhen R.E., Rojugbokan A.K. Microbiological and nutritional qualities of dairy products: nono and wara. Nat. Sci. 2006;4(3):37–40. [Google Scholar]

- Vaccher V., Ingenbleek L., Adegboye A., Hossoud E.S., Konée A.Z., Oyedele A.D., Kisito C.S.K.J., Dembélég Y.K., Huh R., Malaka I.A., et al. Levels of persistent organic pollutants (POPs) in foods from the first regional Sub-Saharan Africa total diet study. Environ. Int. 2020;135 doi: 10.1016/j.envint.2019.105413. [DOI] [PubMed] [Google Scholar]

- Youssao I.A.K., Dahouda M., Attakpa E.Y., Koutinhouin G.B., Ahounou G.S., Toleba S.S., Balogoun B.S. Diversité des systèmes d’élevages de bovins de race bovine Borgou dans la zone soudanienne du Bénin. Int J Biol Chem Sci. 2013;7(1):125–146. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.