Abstract

The aim of this study was to develop a new method to measure respirator protection factors for aerosol particles using portable instruments while workers conduct their normal work. The portable instruments, including a set of two handheld condensation particle counters (CPCs) and two portable aerosol mobility spectrometers (PAMSs), were evaluated with a set of two reference scanning mobility particle sizers (SMPSs). The portable instruments were mounted to a tactical load-bearing vest or backpack and worn by the test subject while conducting their simulated workplace activities. Simulated workplace protection factors (SWPFs) were measured using human subjects exposed to sodium chloride aerosols at three different steady state concentration levels: low (8×103 particles/cm3), medium (5×104 particles/cm3), and high (1×105 particles/cm3). Eight subjects were required to pass a quantitative fit test before beginning a SWPF test for the respirators. Each SWPF test was performed using a protocol of five exercises for 3 min each: (1) normal breathing while standing; (2) bending at the waist; (3) a simulated laboratory-vessel cleaning motion; (4) slow walking in place; and (5) deep breathing. Two instrument sets (one portable instrument {CPC or PAMS} and one reference SMPS for each set) were used to simultaneously measure the aerosol concentrations outside and inside the respirator. The SWPF was calculated as a ratio of the outside and inside particles. Generally, the overall SWPFs measured with the handheld CPCs had a relatively good agreement with those measured with the reference SMPSs, followed by the PAMSs. Under simulated workplace activities, all handheld CPCs, PAMSs, and the reference SMPSs showed a similar GM SWPF trend, and their GM SWPFs decreased when simulated workplace movements increased. This study demonstrated that the new design of mounting two handheld CPCs in the tactical load-bearing vest or mounting one PAMS unit in the backpack permitted subjects to wear it while performing the simulated workplace activities. The CPC shows potential for measuring SWPFs based on its light weight and lack of major instrument malfunctions.

Keywords: Handheld CPC, PAMS, portable aerosol instrument, respirator performance, simulated workplace, protection factors

Introduction

Advanced manufacturing technologies have gained a great deal of public interest due to the needs and applications of advanced industry products in many areas of human endeavors including industry, agriculture, and medicine (Endo et al. 2008; McKinney et al. 2009; Chakravarty et al. 2008). Despite obvious benefits of advanced manufacturing technologies, many open questions about the toxicity and the environmental impact of aerosolized particles have arisen. Aerosolized particles may be ingested, inhaled, or absorbed through the skin (Baroli et al. 2007). Inhalation of particles is believed to be the primary route of exposure (Birch et al. 2011). Respirators are routinely employed by workers for protection against potentially hazardous particles in the workplace.

Reliable test methods for aerosol instrumentation evaluation and selection of respiratory protection for use in aerosol technology industries are of great interest to the health and safety community, occupations, and industries. Some aerosol instruments, such as the scanning mobility particle spectrometer (SMPS) and aerodynamic particle sizer (APS), have made it possible to measure aerosol concentrations and particle size distributions in real time. However, the SMPS and APS are bulky and costly instruments, making them impractical for workplace use and more appropriate for lab-based applications. Recent advances in aerosol instrument technology have produced some new aerosol instruments in a small and light format, referred to as “portable aerosol instruments.” Some portable aerosol instruments, such as the handheld condensation particle counter (CPC), Aerasense Nano Tracer, and TSI AeroTrak are used for measuring the particle counts and providing evidence for the presence of particles in the workplace air. Other portable aerosol instruments, such as NanoScan scanning mobility particle sizer (NanoScan SMPS), portable aerosol mobility spectrometer (PAMS), and optical particle sizers (OPS) can be used to provide a more detailed assessment of workplace environments, including the particle counts and size distributions.

Some portable instrument results have previously been published (Asbach et al. 2012; Vo et al. 2018). The study of Asbach et al. (2012) targeted the intensive comparison among portable devices (NanoTracer, Nano Check, AeroTrak TM 9000, and handheld CPC) under laboratory conditions. The study of Vo et al. (2018) focused on a performance comparison of field portable instruments (CPC, PAMS, OPS, and NanoScan SMPS) to the SMPS using the same particle size range and particle concentration under laboratory conditions. These studies showed (a) different portable aerosol instruments had varied performance characteristics when measuring a range of aerosol concentrations and particle sizes and (b) the same particle size ranges and concentrations should be used for comparisons in order to minimize the variance among portable aerosol instruments under simulated workplace activities. Moreover, for the workplace use of these portable instruments, questions have arisen: (1) how to carry portable instruments while workers conduct their normal work and (2) how these portable instruments can withstand a working environment (bending, side-to-side reaching, and movement). Thus, there is a need of a new method to demonstrate the utility of these portable instruments for measuring respirator performance against aerosol particles in simulated workplace settings.

The simulated workplace protection factor (SWPF), defined as the ratio of ambient concentration of a given contaminant to that inside a respirator, is a value indicating the level of protection provided by a respirator when subjected to a simulated work environment. Several studies have measured SWPF to characterize respirator performance anticipated for usage in actual work environments (Lawrence et al. 2006; Coffey et al. 2006; Duling et al. 2007; Hauge et al. 2012; Vo et al. 2015). Although these studies provided the designed SWPF approach for bridging the gap between laboratory and workplace performance of respirators, these studies only focused on the benchtop instruments, including the TSI PortaCount Plus and SMPS.

The aim of this study was to develop a new method for measuring SWPF against aerosol particles using portable instruments while workers conduct their normal work. The specific tasks for this study were: (a) to develop a new method for carrying portable instruments for continuous measurement of particles while workers conducted their normal work and (b) to evaluate portable instruments, including a set of two handheld CPCs and two PAMSs, for respirator performance under simulated workplace activities. This laboratory-based SWPF assessment was chosen for simulated workplace protection evaluation of the portable instruments because it demonstrated (1) how to wear portable instruments while workers conduct their normal work and (2) how each instrument can withstand a working environment.

Materials and methods

Respirator selection and test subjects

An N95 filtering facepiece respirator (FFR) (Model: North 7130N95: North Safety Products, Cranston, RI) was selected for this study. This N95 FFR model was selected based on (1) NIOSH approval and (2) it is a commonly used respirator in industry (Dahm et al. 2011).

Based on availability of subjects returning for multiple visits, eight subjects (four males and four females) who passed a fit test with this N95 model participated in this study. The age of the test subjects ranged from 19–65 years. This study was approved by the NIOSH Institutional Review Board (protocol number: HSRB 12-NPPTL-02) and all subjects gave written consent to participate.

Aerosol generator solutions

A sodium chloride (NaCl) solution of 0.2% in distilled water was used for this study. This solution concentration was selected to ensure that adequate particles were generated for the SWPF test as described by Vo et al. (2015).

Fit test procedures

An aerosol generator (Model 8026, TSI, Shoreview, MN) was used to produce particles and maintain room particle concentrations between 3000 and 8000 particles/cm3 for the fit test. The fit test was conducted using a PortaCount Plus (Model 8038; TSI; the fit factor range for the PortaCount Plus with the N95-Companion accessory: 1–200). Before starting a SWPF test, the fit of the N95 on the subject was tested according to the OSHA standard fit test method (OSHA Title 29, Part 1910.134). The pass/fail criterion for an acceptable fit was a minimum fit factor (FF) level of 100 to reflect the OSHA requirement for a half mask (OSHA Title 29, Part 1910.134). Subjects who passed the fit test with this N95 model participated in the SWPF test.

SWPF test procedures

Equipment and supplies

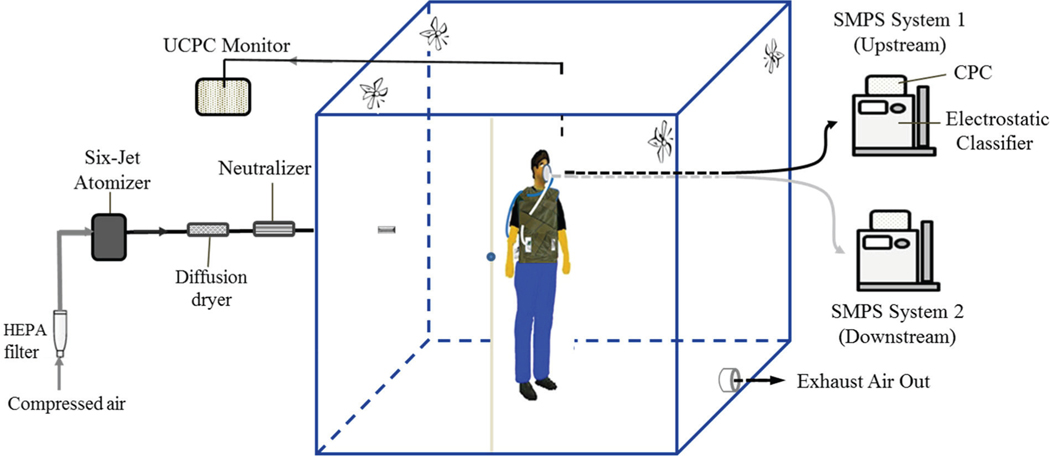

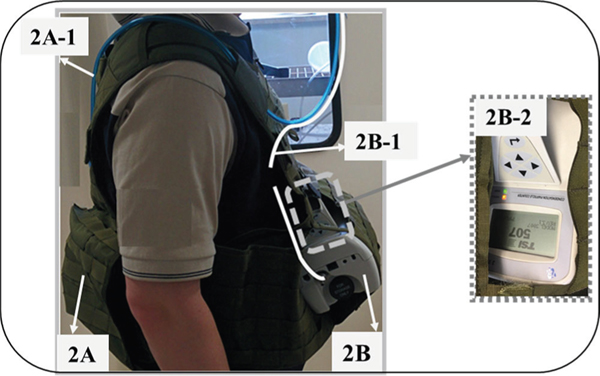

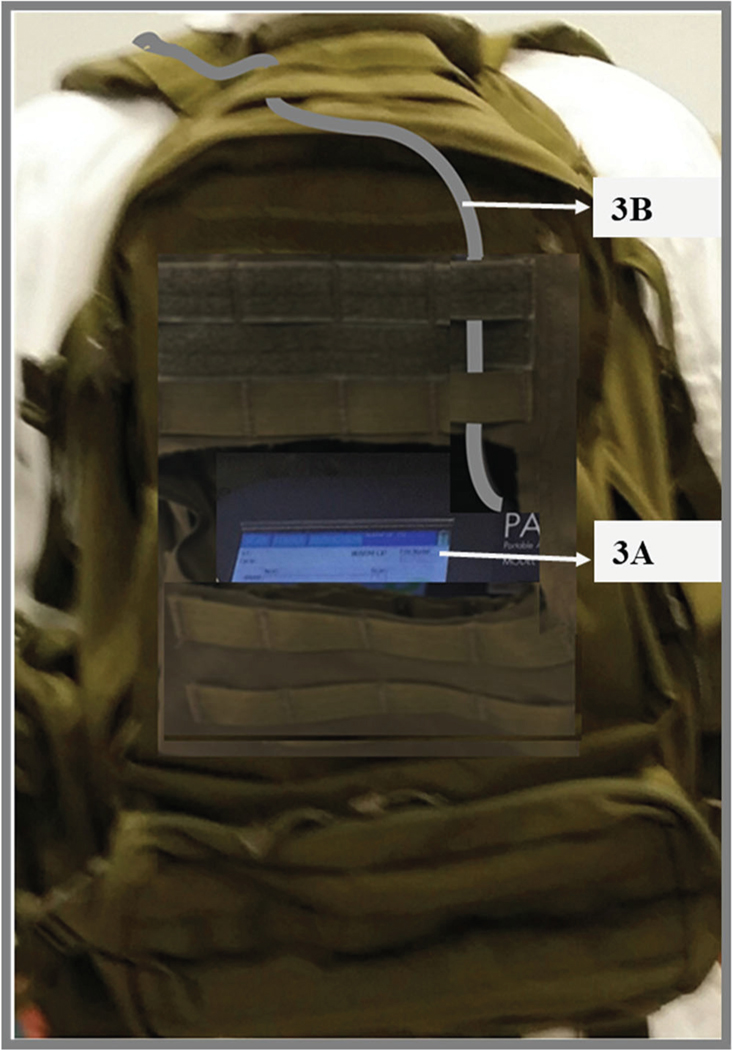

An aerosol respirator testing system consisting of an aerosol generation component, an exposure chamber portion, and a particle detection system was used for the SWPF test (Figure 1). The aerosol generation component and the exposure chamber portion were set up according to the procedure of Vo et al. (2015). The particle detection system consisted of two portable instrument types (two handheld CPCs and two PAMSs) and a reference instrument (two SMPSs). The first portable aerosol instrument type was the CPC (Figure 2; Model 3007, TSI; concentration range: 0 – 1 × 105 particles/cm3 and size range: 0.01 – > 1 μm, according to the CPC specification sheet). The second portable aerosol instrument type was the PAMS (Figure 3; Model 3310 with an external charger; Kanomax, Shimizu Suita City, Osaka, Japan; concentration range: 0.01 – 1 × 105 particles/cm3 and size range for the wide range mode: 14.5 – 862 nm, according to the Kanomax specification sheet). The reference instrument set of two SMPSs (Model 3080; TSI; concentration range: 1 – 1 × 107 particles/cm3 and size range: 0.01 – 1 μm, according to the SMPS specification sheet) are shown in Figure 1.

Figure 1.

Schematic diagram of an aerosol chamber testing system: (1) an aerosol generator system; (2) exposure chamber with a particle concentration monitor and an exhaust port; and (3) particle detection system including (a) portable aerosol instruments mounted to a load-bearing vest or backpack and carried by the test subject and (b) the reference SMPSs.

Figure 2.

Load-bearing vest instrumented with two handheld CPCs: CPC (2A) with a sample line (2A-1) used to measure the test particles outside the respirator; CPC (2B) with a sample line (2B-1) used to measure the test particles inside the respirator; a CPC control-panel screen (2B-2).

Figure 3.

Load-bearing backpack instrumented with PAMS: a PAMS control-panel screen (3A) and a PAMS sample line (3B).

Generation of test aerosols

NaCl aerosol particles for the SWPF test were generated according to the method of Vo et al. (2015). Aerosols used in this study were controlled at three different steady state concentration levels: low (8 × 103 particles/cm3), medium (5 × 104 particles/cm3), and high (1 × 105 particles/cm3) by adjusting a compressed air valve to change the generator airflow rate. These designated concentrations were selected to investigate the reaction of the portable aerosol instruments to different particle concentrations. An ultrafine condensation particle counter (UCPC, model 3776, TSI) was used to track the minute-by-minute concentration variations of chamber particles at each designated concentration.

Simulated workplace evaluation for the handheld CPC

The handheld CPC is a small, lightweight instrument (1.7 kg or 3.8 lb with batteries), so one CPC was mounted to the pouch on the front and one CPC was mounted to the pouch on the back of a tactical load-bearing vest (Blackhawk Strike Tactical Armor Carrier, Blackhawk Products Group, Norfolk, VA) (Figure 2). The CPCs were positioned to minimize potential flooding of the optics chamber with alcohol and tightly secured to the vest with a buckle strap to minimize movement. The double-sided vest instrumented with two handheld CPCs was worn over the subject’s shoulders (Figure 2). This configuration permitted subjects to move freely while performing the simulated workplace activities. This configuration also allowed the test operator to control the “power on/off” mode and adjust test parameters from the accessible control-panel screen (Figure 2b).

When the NaCl aerosol concentration in the exposure test chamber reached a designated concentration, the test subject donned the test respirator, performed the standard respirator user seal check, and wore the vest packed with the handheld CPCs (Figure 2) before entering the exposure chamber for the SWPF test. After connecting all particle sample lines to the instruments (Figure 1), the aerosol inlet was set at 0.7 liter per minute (LPM) for the CPCs as specified by the instrument manufacturer and the aerosol flow rate was set at 0.2 LPM for the SMPSs (the flow rate chosen in order to obtain the wide size range of 14 – 862 nm). One handheld CPC (in the vest) and one reference SMPS (on the benchtop) were used to measure the particles outside the respirator at the same locations (5 cm from the respirator; Figure 1) while the other handheld CPC and reference SMPS were used to determine the inside particles at the center area of the respirator between the subject’s nose and mouth (the TSI model 8025-N95 probe kit was used to draw an air sample from inside the respirator) (Figure 1). To overcome the particle loss issue among different portable instruments and reference SMPS, the same sampling conductive tubing type and tubing diameter (8-mm diameter) were used in this study.

The SWPF test was conducted using five exercises for 3 min each: (1) normal breathing while standing, (2) bending at the waist, (3) slow walking in place, (4) a simulated laboratory-vessel cleaning motion (subject’s arms moving forward-down and backward-up in a shovel-scooping-like fashion with a 30-cm distance and a rate of one completed motion every 5 sec), and (5) deep breathing. All handheld CPCs and reference SMPSs were operated simultaneously to measure the test particles outside and inside the respirator (Figure 1), and the instruments measured particle concentration over the sequential 3-min sampling periods for each exercise. Each individual exercise SWPF was calculated using Equation (1), representing the ratio of the outside concentration (Cout) and inside concentration (Cin):

| (1) |

where SWPF = simulated workplace protection factor for a given exercise; i = exercise number.

An overall SWPF obtained from the five individual SWPF exercises was calculated using Equation (2):

| (2) |

After completing testing with a five-exercise regime, the subject vacated the exposure chamber and removed the respirator in the lab. The subject then donned a new respirator and repeated the SWPF test procedure for other concentrations, and the SWPF tests for all three concentrations: low, medium, and high were performed by each subject on the same day. This procedure was repeated three times for each concentration for each test subject on three separate visits (the numbers of experiments for each concentration = 8 subjects x 1 respirator model x 5 exercises x 3 replicates).

Simulated workplace evaluation for the PAMS

The weight of each PAMS was 4.5 kg (~10 lb) with batteries, so only one PAMS unit was placed inside a tactical load-bearing backpack (Blackhawk Strike Tactical Armor Carrier, Blackhawk Products Group) and the PAMS was tightly secured to the backpack with a buckle strap to minimize movement. The backpack instrumented with PAMS was carried on the back of the test subject (Figure 3). This PAMS unit was used to measure test particles inside the respirator. This configuration also allowed the test operator to control the “power on/off” mode and adjust test parameters from the accessible control-panel screen (Figure 3a). Another PAMS unit which was used for measuring test particles outside the respirator was located on a movable cart in the test chamber. The aerosol inlet of 0.7 LPM and the wide range mode (14 size channels) with a particle size range of 14–862nm were set for the PAMSs. In order to obtain the best accuracy for comparison among PAMSs and the reference SMPSs, the SMPSs were set to the same particle size distribution of the PAMSs (14̶ 862nm) by setting the SMPS aerosol flow rate at 0.2 LPM.

When the NaCl aerosol concentration in the exposure test chamber reached a designated concentration, the test subject donned the test respirator, performed the standard respirator user seal check, and wore the backpack packed with the PAMS unit before entering the exposure chamber for the SWPF test. After connecting all particle sample lines to the instruments (PAMSs and SPMSs measuring in-respirator particles or outside-respirator particles at same locations), the SWPF test was performed using the same five-exercise regime, and the outside and inside respirator samples of the PAMSs and the reference SMPSs were measured simultaneously using the same test procedure as described in the “Simulated workplace evaluation for the handheld CPC” section. The test data for each individual exercise and an overall SWPF were also calculated as described in the “Simulated workplace evaluation for the handheld CPC” section.

Comparison of the SWPF data

SWPF data measured with the handheld CPCs and the PAMSs at three concentrations were compared with those measured by the reference SMPSs in three ways: (1) comparing overall SWPF values between each portable instrument and the reference SMPS using a scatter plot as well as comparing the correlation of measured levels; (2) comparing the percentage difference of the geometric mean (GM) overall SWPF between each portable instrument and the reference SMPS for each concentration (the percent difference was calculated using Equation (3)); and (3) comparing GM overall SWPFs among portable instruments and the reference SMPSs as a function of the simulated workplace activities for each concentration.

| (3) |

Data analysis

All SWPFs, overall SWPFs, GM-overall SWPFs, and GM SWPFs as a function of the simulated workplace activities, and other data analysis were performed using Microsoft Excel 2010 software (Microsoft Corporation, Redmond, WA). Statistical significance of SWPF results was compared between each portable and each reference instruments using paired t-tests with two-tailed distribution. Statistical significance was accepted at the p < 0.05 level.

Results

Aerosol characterization experiments

Based on the concentration and particle size range of interest for this simulated workplace protection evaluation, the size distribution range of 14–862 nm was measured using the SMPS and PAMS for three different concentrations. Within this size range, ≥97% of SMPS particles were centered between 30–800 nm with a geometric mean diameter (GMD) of 106 nm, and GSD of 1.29. For the PAMS particle size distributions, ≥97% of particles were centered between 20–650 nm with a GMD of 94 nm, and GSD of 1.48.

Fit test

All eight subjects that participated in this study passed the fit test with FF values ≥100 with N95 FFRs. The results indicate that the N95 FFRs used in this study had an overall good fit performance among eight test subjects.

SWPF test

In the simulated workplace protection evaluation, two handheld CPCs were firmly fastened to the vest and one PAMS was firmly mounted to backpack, and their accessible control-panel screens were securely fixed in place during and after the SWPF routine. Results indicated that the new design of mounting the portable instrument in the vest or backpack permitted subjects to wear it while performing the simulated workplace activities.

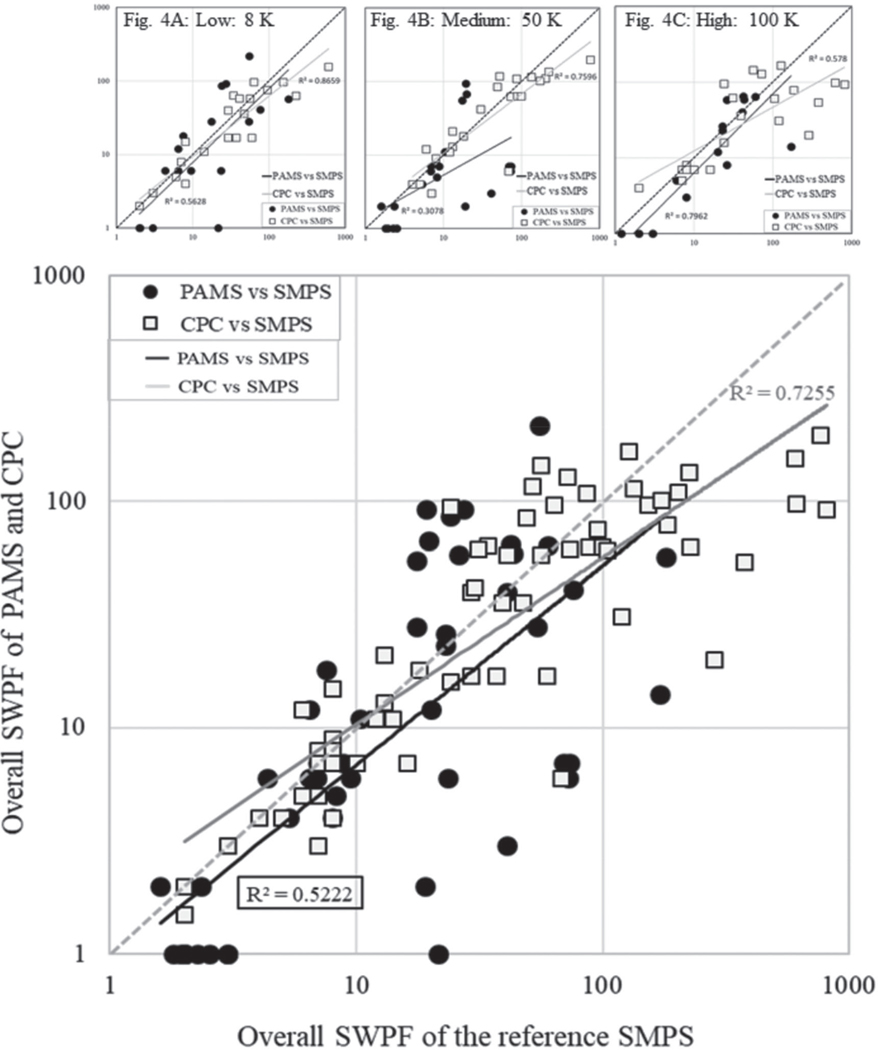

A scatter plot of the overall SWPF values measured with the handheld CPCs, PAMSs, and the reference SMPSs at three different concentrations is shown in Figure 4. The dash diagonal line in Figure 4 is a unity line in which indicates perfect agreement between the portable instrument (CPC or PAMS) and the reference SMPS. In general, the overall SWPFs measured by the CPCs were closer to the unity values than those measured with the PAMS (Figure 4). This result indicates that there was a better linear relationship among the overall SWPFs measured by the handheld CPCs and the reference SMPSs. There was a low correlation among the overall SWPFs measured by the PAMS and the SMPS with the coefficient R2 > 0.52. When analyzing the overall SWPFs at each concentration for each portable instrument, the overall SWPFs measured with the handheld CPC and SMPS in the low concentration were highly correlated with the coefficient R2 > 0.87, followed by the medium concentration with the coefficient R2 > 0.76, and the high concentration with the coefficient R2 > 0.58 (Figures 4a–c). The PAMS overall SWPFs at the high concentration compared reasonably with those measured with the SMPS with the coefficient R2 > 0.73, followed by the low concentration with the coefficient R2 > 0.56, and the medium concentration with the coefficient R2 > 0.31 (Figures 4a–c).

Figure 4.

Overall, SWPF measured by the handheld CPC and PAMS compared with those measured by the reference SMPS; the dashed line is the unity line showed perfect agreement between the portable instrument and the reference SMPS; three concentrations: low (Figure 4a, 8 K or 8 × 103 particles/cm3), medium (Figure 4b, 50 K), and high (Figure 4c, 100 K).

A summary of GM overall SWPF values measured with the handheld CPCs, PAMSs, and the reference SMPSs at three different concentrations is shown in Tables 1 and 2. In general, the paired t-tests ran for different GM overall SWPFs measured by each portable instrument (handheld CPC or PAMS) and the reference SMPS in each concentration revealed all P-values ≥0.05 (Tables 1 and 2). This indicates that there were no significant differences between the GM overall SWPFs obtained from each portable instrument and the SMPS for all three concentrations tested. As shown in Table 1, the GM overall SWPFs measured with the handheld CPC compared most favorably with those measured with the reference SMPS at the low concentration (deviations < 19%); however, the CPC had a lower agreement with the SMPS at the high concentration with the deviation of 29.79%. The GM overall SWPFs measured with the PAMS compared reasonably with those measured with the reference SMPS at the low concentration with the deviations within 25%; however, the PAMS had a lower agreement with the SMPS at the medium concentration with the deviation of 30.53% (Table 2).

Table 1.

Summary of GM overall SWPFs measured by the handheld CPC vs. reference SMPS.

| Handheld CPC vs. reference SMPS |

||||

|---|---|---|---|---|

| [Conc.] levela | SMPS GM overall SWPFb (±GSD) | CPC GM overall SWPFb (±GSD) | P-value | % ΔGM_overall SWPFc |

|

| ||||

| L | 28.56 ± 1.07 | 23.16 ± 1.16 | 0.17 | 18.91 |

| M | 36.93 ± 1.35 | 29.48 ± 1.41 | 0.23 | 20.17 |

| H | 44.18 ± 1.75 | 31.02 ± 1.84 | 0.05 | 29.79 |

[Conc.] level: Concentrations: L (low, 8 × 103 particles/cm3), M (medium, 5 × 104 particles/cm ), and H (high, 1 × 105 particles/cm3);

GM overall SWPFs of the 8-subject SWPF data (each subject data = 1 respirator model × 3 replicates × 5 exercises);

% ΔGM_overall SWPF was calculated as: [(|reference SMPS GM_ overall SWPF - portable device GM_overall SWPF|/reference SMPS GM_overall SWPF) x 100].

Table 2.

Summary of GM overall SWPF values measured by the PAMS vs reference SMPS.

| PAMS vs. reference SMPS |

||||

|---|---|---|---|---|

| [Conc.] levela | SMPS GM overall SWPF ± GSD | PAMS GM overall SWPF ± GSD | P-value | % ΔGM overall SWPF |

|

| ||||

| L | 27.97 ± 1.12 | 20.97 ± 1.23 | 0.74 | 25.03 |

| M | 23.78 ± 1.35 | 16.52 ± 1.71 | 0.62 | 30.53 |

| H | 22.19 ± 1.65 | 15.58 ± 1.92 | 0.42 | 29.79 |

[Conc.] level: Concentrations: L (low, 8 × 103 particles/cm3), M (medium, 5 × 104 particles/cm3), and H (high, 1 × 105 particles/cm3).

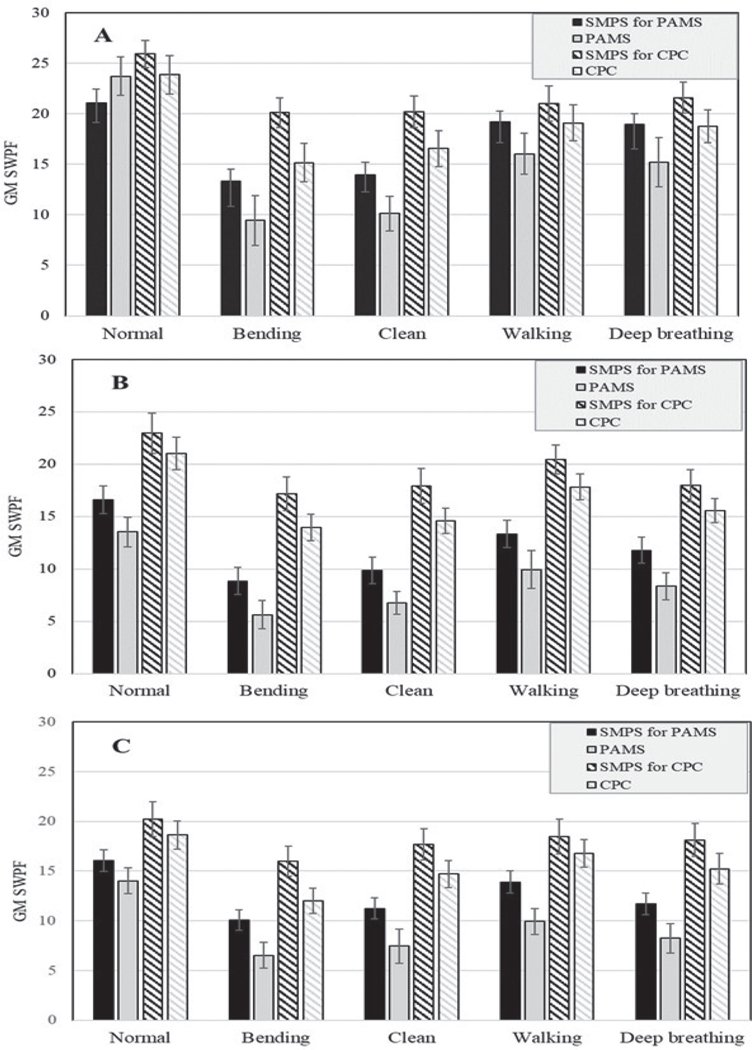

The GM SWPFs measured by the handheld CPC, PAMS, and the reference SMPS as a function of the simulated workplace activities for three different concentrations are shown in Figure 5. In general, the GM SWPFs measured by the handheld CPC, PAMS, and the SMPS had similar trends in order of decreasing GM SWPFs: normal breathing > walking > deep breathing > cleaning > bending for all three concentrations (Figure 5). The CPC had a highest agreement with the SMPS for the normal breathing exercise for all three concentrations (deviations < 9%) while the CPC had a lowest agreement with the SMPS for the bending exercise with the deviations within 24% (Figure 5). When comparing among exercises between the PAMS and the reference SMPS, the PAMS agreed better with the reference SMPS for the normal breathing exercise for all three concentrations (deviations < 18%) while the PAMS had a lower agreement with the SMPS for the bending exercise with the deviations within 36% (Figure 5).

Figure 5.

The GM SWPF values (± GSD) (n = 24; 1 respirator model × 3 replicates × 8 test subjects) measured by the CPC, PAMS, and the reference SMPS as a function of test exercises at three concentrations: low (Figure 5a, 8 × 103 particles/cm3), medium (Figure 5b, 5 × 104 particles/cm3), and high (Figure 5c, 1 × 105 particles/cm3).

SWPF test observations

The advantages and limitations of each portable instrument type used for continuous measurement of particles under simulated workplace activities are shown in the Table 3. For the handheld CPC, it is a lightweight device (1.7 kg), so workers can wear both CPCs while conducting the normal work (Table 3). The CPC also had no major instrumental failure (any unsolved instrument problem after refreshing is defined as a major failure) during a test period. The CPC had a minor disadvantage with a bending activity, causing the CPC to tilt during operation; however, tilt condition normally corrected itself and only 4% problem cases (6 cases out of 144 trials) occurred with the CPC during bending (Table 3). The PAMS is a heavier device (~5 kg), so workers could not wear both PAMSs while conducting the normal work. In several cases, the PAMS had some limitations: (1) a charger problem with the corona current becoming unstable during a test period, resulting the PAMS to stop recording; (2) an extended delay time for a charger to stabilize (the corona current gets close to a normal level of 5 ± 1 μA) after cleaning or resetting; and (3) a minor issue with a bending activity, causing the PAMS to tilt during operation; however, tilt condition normally corrected itself (Table 3). Results in Table 3 also show that there were 10% problem cases (14 cases out of 144 trials) with the charger issue for the PAMS obtained throughout the course of this study. However, only 4% problem cases (3 cases out of 72 trials for one PAMS carried in the backpack) occurred with the PAMS during bending (Table 3).

Table 3.

Summary of SWPF test observations for the handheld CPC and PAMS

| Summary of SWPF test observations |

|||||

|---|---|---|---|---|---|

| Disadvantages |

|||||

| Portable Instrument | Advantages | # trials (Conc. Level)A | # bending issuesB | # issues | |

|

| |||||

| Handheld CPC 3007 | Observations on subjects: * CPC is lightweight (1.7 kg or 3.8 lb). ) *Easy to mount 2 CPCs to a vest and wear them when conducting normal work Observations on CPCs: Withstand workplace environment up to 6 h. |

Observations on subjects: None Observations on CPCs: * Able to measure only particle counts (not particle size). * The CPC showed tilt condition when bending at the waist > 50o, but the tilt condition normally corrected itself. |

48 (L) 48 (M) 48 (H) |

2 2 2 |

0 0 0 |

| PAMS |

Observations on subjects: Can mount one PAMS to a backpack and wear it when conducting normal work. Observations on PAMSs: * Able to measure particle counts and sizes. * Withstand workplace environment up to several hours if routinely cleaning the charger. |

Observations on subjects PAMS is heavy (~5 kg or 11 lb), so can carry only one in the backpack. Observations on PAMSs: * The PAMS showed tilt condition when bending at the waist > 50o (normally corrected itself). * Need to clean the charger during sampling to avoid a problem (charger failure). * Extended period for charger to stabilize. |

48 (L) 48 (M) 48 (H) |

1 1 1 |

5 4 5 |

(Conc. Level): Concentrations: L (low, 8 × 103 particles/cm3), M (medium, 5 × 104 particles/cm3), and H (high, 1 × 105 particles/cm3).

Bending issues: 6 cases out of 144 trials for 2 CPCs carried by test subjects at 3 concentrations and 3 cases out of 72 trials for one PAMS carried by test subjects.

Discussion

The overall SWPFs across three concentration levels of low, medium, and high show that the handheld CPC had a relatively good agreement with the reference SMPS. A possible explanation for good agreement between the CPC and the reference SMPS is that both measurements rely on the similar particle charge correction and errors in sizing propagate to the number concentration measured. The overall SWPFs measured with the PAMS had a lower agreement with the reference SMPS data across the three concentrations (R2 > 0.52). Some possible explanations for this include: (1) each instrument had different particle charge corrections which yielded different number particle concentrations and (2) the propagation of error in computing upstream and downstream particle concentrations measured by each instrument, resulting in different SWPFs. Figure 4 shows a few good numbers of SWPF less than 10 for both CPC and PAMS, as well as the reference SMPS. A possible reason for this is physical activity, such as the bending and cleaning motion, may cause a respirator to slip on the subject’s face decreasing the seal performance, resulting in lower SWPF values on all instruments. Figures 4a–c also show some numbers of the PAMS trials apparently resulted in SWPFs of 1 at all three particle concentrations. A possible reason for this is the surface of the electrodes inside of the PAMS external charger may collect small particles and dust during the test period to cause its corona current to become unstable, effecting particle count readings. In addition, many overall SWPF values were below 100 compared to the fit test data (FF values ≥ 100). Some possible explanations for this include: (1) different instruments yielded different performance (PortaCount used in the fit test vs. CPC, PAMS, and SMPS used in the SWPF test); (2) benchtop instrument used in the fit test vs. vest-CPC or backpackPAMS; (3) different exercises used; and (4) different test conditions (room conditions vs. test chamber conditions).

The overall SWPFs at each concentration were remarkably different for each portable instrument. The CPC overall SWPFs compared most favorably with those measured with the reference SMPS at the low concentration (R2 > 0.87), but not for the high concentration (R2 > 0.58). The PAMS overall SWPFs showed relatively good agreement with the reference SMPS at the high concentration (R2 > 0.73), but not for the medium concentration (R2 > 0.31). Similar research conclusions about aerosol instrumentations were reported by Mills et al. who found that different aerosol instruments reacted quite differently to the different aerosol concentrations (Mills et al. 2013). The possible reasons for the differences are that each instrument may have its own specified size and concentration ranges and each instrument measurement relies on its own particle charge corrections and errors in counting and post-processing to the number particle concentrations measured by each instrument (Vo et al. 2018).

Generally, the GM overall SWPFs measured with the handheld CPC and the PAMS compared reasonably with those measured with the reference SMPS at three concentrations (deviation range of 18.91–29.79% for the CPC and 25.03–30.53% for the PAMS). The first possible reason for the difference between the portable instruments and the reference SMPS is that the portable instruments have low accuracy compared with the benchtop reference SMPS. For example, the specification sheet of the handheld CPC specifies the measurement accuracy to be ±20%. The second possible reason is that each instrument measurement relies on its own particle charge corrections and post-processing to the number particle concentrations. In addition, the portable instruments worn by the test subjects might yield more variance in their accuracy specification when measuring particles under simulated workplace activities. Thus, the differences with the deviations within 20% can be considered as a good comparability between the portable instruments and the reference SMPS, and the differences with the deviations within 30% can be considered as a reasonably comparable; however, the differences with the deviations ≥31% can be considered as a poor agreement between the portable instruments and the reference SMPS.

The GM SWPFs measured by the handheld CPC, PAMS, and the reference SMPS as a function of the simulated workplace activities had similar trends in order of decreasing GM SWPFs: normal breathing > walking > deep breathing > cleaning > bending for all three concentrations. This trend showed the GM SWPFs measured by the CPC, PAMS, and the reference SMPS decreased when simulated workplace movements increased from less movement (normal breathing) to more movement (bending, cleaning motion with side-to-side reaching). This indicated more physical activity, such as the bending and cleaning motion, may cause a respirator to slip on the subject’s face decreasing the seal performance, resulting in lower SWPF values. In addition, the data in Figures 5b and 5c showed that SWPFs measured with the reference SMPS were lower for the PAMS trials than the CPC trials. It should be noted that in this study each set of two portable instruments (two vest CPCs or two PAMSs) and the reference SMPSs were operated simultaneously to measure the test particles outside and inside the respirator; therefore, test conditions and parameters, such as temperatures, relative humidity, wet/dry particles, and other parameters might have varied on different test days, contributing to these differences.

The SWPF test observations for each portable instrument type show that both handheld CPCs and PAMSs had a minor issue with the bending exercise with about 4% problem cases obtained throughout the course of this study. A possible explanation for this is that when these instruments were bent passed 50°, a sloping position might cause alcohol within the instruments to flow to the optics, producing a “tilt condition” message; however, the tilt condition normally corrected itself and is not a major issue. In general, the handheld CPC yielded better performance over the PAMS for two reasons: (1) the CPC is a lightweight instrument, so workers can wear both CPCs to collect test particles outside and inside the respirator simultaneously while the PAMS is a heavier device, so workers couldn’t wear both PAMSs for the same purpose (one PAMS unit was mounted to the backpack and the other unit was on a movable cart); and (2) the handheld CPC had no major instrumental failure during a test period while the PAMS had two major instrumental issues with a charger problem and an extended delay time for a charger to stabilize after cleaning or resetting. However, the handheld CPC was able to measure only particle concentrations while the PAMS was capable of measuring both particle concentrations and size distributions. Thus, these results could be used to illustrate considerations for selecting a portable instrument for specific interests, such as measuring particle concentrations, SWPFs, or determining particle sizes.

Conclusions

The findings presented herein demonstrate that the new design of mounting two handheld CPCs in a tactical load-bearing vest or mounting one PAMS unit in a backpack permitted subjects to wear it while performing the simulated workplace activities. The measurement capabilities of the handheld CPC and the PAMS were compared to those of the reference SMPS. In general, the overall SWPF values measured with the CPCs showed a higher correlation to those measured with the reference SMPS than those measured with the PAMS. Under simulated workplace activities, all handheld CPCs, PAMSs, and the reference SMPSs showed a similar GM SWPF trend, and their GM SWPFs decreased when simulated workplace movements increased. Although the PAMS was capable of measuring both particle concentrations and size distributions, the SWPF results show better performance for the handheld CPC over the PAMS based on its light weight and lack of major instrument malfunctions during a test period; thus, the CPC shows potential for measuring SWPFs. The results from this study should inform the selection of portable instruments for specific interests, such as measuring particle concentrations, SWPFs, or determining particle distribution when assessing respirator performance in the workplace.

Acknowledgments

This study was partially supported by the NIOSH Nanotechnology Research Center (NTRC). The authors want to thank Ms. Judi Coyne (NIOSH NPPTL, Pittsburgh, PA), Dr. Kevin H. Dunn (NIOSH DART, Cincinnati, OH), Dr. Susan Xu (NIOSH NPPTL, Pittsburgh, PA), and Ms. Caitlin M. McClain (NIOSH NPPTL, Pittsburgh, PA), for their valuable review comments for the manuscript.

Footnotes

Disclaimer

The findings and conclusions in this manuscript are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health (NIOSH), Centers for Disease Control and Prevention. Mention of company names or products does not constitute endorsement by NIOSH.

References

- Asbach C, Kaminski H, von Barany D, Kuhlbusch TAJ, Monz C, Dziurowitz N, Pelzer J, Vossen K, Berlin K, Dietrich S, et al. 2012. Comparability of portable nanoparticle exposure monitors. Ann Occup Hyg. 56(5): 606–621. doi: 10.1093/annhyg/mes033 [DOI] [PubMed] [Google Scholar]

- Baroli B, Ennas MG, Loffredo F, Isola M, Pinna R, LopezQuintela MA. 2007. Penetration of metallic nanoparticles in human full thickness skin. J Invest Dermatol. 127(7): 1701–1712. [DOI] [PubMed] [Google Scholar]

- Birch ME, Ku BK, Evans DE, Ruda-Eberenz T. 2011. Exposure and emissions monitoring during carbon nanofiber production-part I: elemental carbon and iron-soot aerosols. Ann Occup Hyg. 55(9):1016–1036. doi: 10.1093/annhyg/mer073 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chakravarty P, Marches R, Zimmerman NS, Swafford ADE, Bajaj P, Musselman IH, Pantano P, Draper RK, Vitetta ES. 2008. Thermal ablation of tumor cells with antibody-functionalized single-walled carbon nanotubes. Proc Natl Acad Sci USA. 105(25):8697–8702. doi: 10.1073/pnas.0803557105 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coffey CC, Lawrence RB, Zhuang Z, Duling MG, Campbell DL. 2006. Errors associated with three methods of assessing respirator fit. J Occup Environ Hyg. 3(1):44–52. doi: 10.1080/15459620500455398 [DOI] [PubMed] [Google Scholar]

- Dahm MM, Yencken M, Schubauer-Berigan M. 2011. Exposure control strategies in the carbonaceous nanomaterial industry. J Occup Environ Med. 53:S68–S73. [DOI] [PubMed] [Google Scholar]

- Duling MG, Lawrence RB, Slaven JE, Coffey CC. 2007. Simulated workplace protection factors for half-facepiece respiratory protective devices. J Occup Environ Hyg. 4(6):420–431. doi: 10.1080/15459620701346925 [DOI] [PubMed] [Google Scholar]

- Endo M, Strano MS, Ajayan PM. 2008. Potential applications of carbon nanotubes. Carbon Nanotubes. 111: 13–61. [Google Scholar]

- Hauge J, Roe M, Brosseau LM, Colton C. 2012. Real-time fit of a respirator during simulated health care tasks. J Occup Environ Hyg. 9(10):563–571. doi: 10.1080/15459624.2012.711699 [DOI] [PubMed] [Google Scholar]

- Lawrence RB, Duling MG, Calvert CA, Coffey CC. 2006. Comparison of performance of three different types of respiratory protection devices. J Occup Environ Hyg. 3(9):465–474. doi: 10.1080/15459620600829211 [DOI] [PubMed] [Google Scholar]

- McKinney W, Chen BT, Frazer D. 2009. Computer controlled multi-walled carbon nanotube inhalation exposure system. Inhalation Toxicol. 21(12):1053–1061. doi: 10.1080/08958370802712713 [DOI] [PubMed] [Google Scholar]

- Mills JB, Park JH, Peters TM. 2013. Comparison of the DiSCmini aerosol monitor to a handheld condensation particle counter and a scanning mobility particle sizer for submicrometer sodium chloride and metal aerosols. J Occup Environ Hyg. 10(5):250–258. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Respiratory Protection, 29 C.F.R. Sect. 1910.134 (2006). [Google Scholar]

- Vo E, Horvatin M, Zhuang Z. 2018. Performance comparison of field portable instruments to the scanning mobility particle sizer using monodispersed and polydispersed sodium chloride aerosols. Ann Work Exposures Health J. 62(6):711–720. doi: 10.1093/annweh/wxy036 [DOI] [PubMed] [Google Scholar]

- Vo E, Zhuang Z, Horvatin M, Liu Y, He X, Rengasamy S. 2015. Respirator performance against nanoparticles under simulated workplace activities. Ann Occup Hyg. 59(8): 1012–1021. doi: 10.1093/annhyg/mev042 [DOI] [PMC free article] [PubMed] [Google Scholar]