Abstract

Engineering bioenergy crops to accumulate coproducts in planta can increase the value of lignocellulosic biomass and enable a sustainable bioeconomy. In this study, we engineered sorghum with a bacterial gene encoding a chorismate pyruvate-lyase (ubiC) to reroute the plastidial pool of chorismate from the shikimate pathway into the valuable compound 4-hydroxybenzoic acid (4-HBA). A gene encoding a feedback-resistant version of 3-deoxy-d-arabino-heptulonate-7-phosphate synthase (aroG) was also introduced in an attempt to increase the carbon flux through the shikimate pathway. At the full maturity and senesced stage, two independent lines that co-express ubiC and aroG produced 1.5 and 1.7 dw% of 4-HBA in biomass, which represents 36- and 40-fold increases compared to the titer measured in wildtype. The two transgenic lines showed no obvious phenotypes, growth defects, nor alteration of cell wall polysaccharide content when cultivated under controlled conditions. In the field, when harvested before grain maturity, transgenic lines contained 0.8 and 1.2 dw% of 4-HBA, which represent economically relevant titers based on recent technoeconomic analysis. Only a slight reduction (11–15%) in biomass yield was observed in transgenics grown under natural environment. This work provides the first metabolic engineering steps toward 4-HBA overproduction in the bioenergy crop sorghum to improve the economics of biorefineries by accumulating a value-added coproduct that can be recovered from biomass and provide an additional revenue stream.

Keywords: Sorghum, Bioproduct, 4-Hydroxybenzoic acid, Shikimate, Bioenergy crop

Abbreviations: 4-HBA, 4-hydroxybenzoic acid; CaMV, cauliflower mosaic virus; CWR, cell wall residue; DAHP, 3-deoxy-D-arabino-heptulosonate; HPLC-ESI-TOF-MS, high performance liquid chromatography electrospray ionization and time-of-flight mass spectrometry; RT-qPCR, reverse transcription quantitative PCR; RuBisCo, ribulose-1,5- bisphosphate carboxylase

Highlights

-

•

First report of 4-hydroxybenzoic acid overproduction in sorghum.

-

•

Up to 40-fold increase in 4-hydroxybenzoic acid titers in biomass (1.7 dw%).

-

•

Field-grown engineered sorghum accumulates 4-hydroxybenzoic at relevant titers.

1. Introduction

Lignocellulosic biomass can be a sustainable source of sugars for the manufacturing of bioproducts such as biofuels. However, the high costs associated with crop cultivation and deconstruction of biomass to simple sugars pose some challenges to the commercialization of advanced bioproducts (Baral et al., 2019). One proposed solution to improve the economics of biofuels is the in-planta accumulation of value-added coproducts (Yang et al., 2020). In this scenario, engineered bioenergy crops not only provide carbohydrates for conversion into bioproducts but also produce valuable compounds such as polymers, platform chemicals, pharmaceuticals, flavors and fragrances that can be extracted from biomass, purified, and sold (Lin and Eudes, 2020).

Sorghum is an ideal bioenergy feedstock due to its high water use efficiency, high biomass yields, and efficient nitrogen recycling (Mullet et al., 2014). Although several studies reported on the genetic modification of sorghum to reduce its recalcitrance to deconstruction, there are only a few examples of metabolic engineering for accumulation of bioproducts in sorghum biomass (Kempinski et al., 2019; Vanhercke et al., 2019). In this work, we tested the feasibility of engineering sorghum to overproduce 4-hydroxybenzoic acid (4-HBA). 4-HBA can serve as precursor for the manufacturing of nutraceuticals (e.g. coenzyme Q10, gastrodin, and resveratrol), cosmetic ingredients (e.g. arbutin), drugs (e.g. xiamenmycin and shikonin), fibers (e.g. Vectran™), platform chemicals (e.g. muconate), and deep eutectic solvents (Wang et al., 2018, 2021). Our recent technoeconomic analysis indicated that accumulating 4-HBA at sufficient titers in sorghum biomass has the potential to improve the economics of biorefineries and offers a competitive advantage compared to microbial synthesis routes (Yang et al., 2022). This analysis considered a process involving a preliminary extraction of 4-HBA from sorghum biomass while the remaining lignocellulose is further deconstructed and converted into ethanol by fermentation. The results showed that achieving a minimum 4-HBA titer of 0.3 dw% in biomass would be sufficient to reach cost-parity with microbial production of 4-HBA from glucose, even if microbial platforms were to reach theoretical maximum yields (Yang et al., 2022).

One engineering approach for in-planta overproduction of 4-HBA consists in the expression of Escherichia coli chorismate pyruvate-lyase (UbiC) targeted to plastids to reroute chorismate away from the shikimate pathway. For example, tobacco and sugarcane transformed with ubiC contained up to 0.52 and 0.69 dw% of 4-HBA in leaves, respectively, which were accumulated mostly as 4-HBA phenolic glucoside (McQualter et al., 2005; Siebert et al., 1996). Moreover, expression of plastid-targeted feedback-resistant 3-deoxy-d-arabino-heptulonate-7-phosphate synthase (DAHPS, AroGL175Q) from E. coli was shown to enhance the synthesis of metabolites that derive from the shikimate pathway in several plants (Eudes et al., 2018; Lin et al., 2021; Oliva et al., 2020; Tzin et al., 2012, 2013). In this study, we transformed sorghum with a construct for dual expression of ubiC and aroGL175Q in order to boost 4-HBA content in biomass (Fig. 1a).

Fig. 1.

Engineering strategy for 4-HBA overproduction in sorghum.

(a) Diagram of the shikimate pathway and engineering approach. The two E. coli enzymes targeted to plastids are 3-deoxy-D-arabino-heptulosonate (DAHP) synthase with L175Q mutation (AroGL175Q) and chorismate pyruvate-lyase (UbiC). Abbreviations: AAA: aromatic amino acids; E4P, erythrose 4-phosphate; PEP, phosphoenolpyruvate.

(b) DNA construct used for sorghum transformation. Schl1 and schl2 encode transit peptides from pea and maize ribulose-1,5-bisphosphate carboxylase (RuBisCo) small subunits, respectively. pZmCesa10 and pRubi2 designate the promoters of maize cellulose synthase10 and rice polyubiquitin2 genes. p2x35S is the enhanced 35S promoter from cauliflower mosaic virus (CaMV). T35S, TRBCS, and TNOS are the terminators from CaMV 35S, Arabidopsis RuBisCo small subunit, and Agrobacterium nopaline synthase genes, respectively. HygR denotes the aminoglycoside phosphotransferase marker gene used for plant selection. See also Supplementary Table S1.

(c) Transgene expression in two independent engineered lines (Eng-1 and Eng-2). AroG (left panel) and ubiC (right panel) transcripts were detected by RT-qPCR using mRNA obtained from the bottom part of the main stem at three different developmental stages. Transcript abundance relative to that of the PP2A sorghum gene is shown. Wild-type segregants were used as negative controls. Values are means ± SE of four biological replicates (n = 4 plants). GDP: growth differentiation point stage.

2. Materials and methods

2.1. Plant growth conditions and sampling

Plants were grown at the UC Berkeley South Greenhouse Oxford facility with a minimum temperature set at 22 °C. Seeds were germinated directly on soil (Sunshine mix #4, Sun Gro, Agawam, MA) in one-gallon pots. One tablespoon of Osmocote Plus 15-9-12 was added to the soil biweekly until the flowering stage. T1 and T2 plants were grown until seeds reached the black layer stage (i.e. full physiological maturity), after which watering was stopped and pots were allowed to dry for another 3 weeks. Growth parameters were measured at physiological maturity. For cell wall and 4-HBA analyses, plants were harvested without their panicles, further dried in an oven at 50 °C for five days, and ground into powder using a Mixer Mill MM 400 (Retsch Inc., Newtown, PA) and stainless-steel balls.

2.2. Design of the pZmCesa10:aroG-pRubi2:ubiC construct

The pZmCesa10:aroG-pRubi2:ubiC construct was obtained using the jStack cloning method (Shih et al., 2016) and the level-0 and level-1 intermediate plasmids are listed in Supplementary Table S1. For level-0 parts, the promoter sequence of the maize (Zea mays) cellulose synthase10 gene and the coding sequences of feedback-resistant DAHPS (AroGL175Q) and of chorismate pyruvate-lyase (UbiC) from E. coli, both preceded with a sequence encoding a plastid transit peptide and codon-optimized for expression in sorghum, were synthesized by GenScript (Piscataway, NJ). Sequences were flanked with BsaI or BsmBI restriction sites for level-1 cloning. The pRubi2 promoter from rice (Oryza sativa) was amplified by PCR with primers containing BsaI restriction sites (Supplementary Table S2) using a plasmid as template (a gift from Roger Thilmony, USDA) and subcloned into the backbone pBca9145 by In-Fusion cloning (Takara Bio USA, Mountain View, CA). Plasmid sequences are available at the Inventory of Composable Elements (ICE) source registry (http://public-registry.jbei.org).

2.3. Sorghum transformation and genotyping

The Agrobacterium tumefaciens strain AGL1 was used to transform the grain sorghum variety BTx430 (Sorghum bicolor (L.) Moench) as previously described, except that hygromycin (20 μg mL−1) was used for plant selection (Do et al., 2018). In the T1 generation, TaqMan Real-time PCR assays were performed on gDNA using primers specific to the octopine synthase terminator (tOCS) from the T-DNA and to the Actin7 reference gene to identify homozygous plants for the transgene and wild-type segregants (ARQ Genetics, Bastrop, TX). T1 and T2 plants were grown to full maturity to generate viable seeds.

2.4. Reverse transcription-quantitative PCR (RT-qPCR)

Total RNAs were extracted from the 5-cm bottom part of the main stem from plants in the T2 generation at three different developmental stages using the RNeasy Plant Mini Kit (Qiagen, Redwood City, CA). cDNA synthesis was conducted using the SuperScript IV First-Strand Synthesis kit (Thermo Fisher Scientific, Waltham, MA) as previously described (Hao et al., 2021). RT-qPCR was performed using 35 cycles consisting of 5 s at 95 °C for denaturation and 15 s at 60 °C for annealing and amplification. The relative quantification of aroG and ubiC transcripts was calculated using the 2-ΔCT method and normalized to the reference gene PP2A (NCBI Reference Sequence: XM_002453490.2) as previously described (Tian et al., 2021). The results are the average from four biological replicates. RT-qPCR primers are listed in Supplementary Table S2.

2.5. Metabolite extraction and quantification

Metabolites were extracted from 20 mg of dry biomass powder using 80% (v/v) methanol-water as solvent as previously described (Eudes et al., 2012). Free 4-HBA and 4-HBA glucose conjugates were analyzed using high-performance liquid chromatography-electrospray ionization time-of-flight-mass spectrometry (HPLC-ESI TOF-MS) (Eudes et al., 2013). Quantification was performed via 6-point calibration curves of standard compounds.

2.6. Cell wall composition analysis

Ball-milled biomass (1 g) was sequentially extracted using a Dionex ASE 350 accelerated solvent extractor set to 7-min static extraction cycles (Thermo Fisher Scientific, Waltham, MA). Solvents (5 ml) were water (two cycles), 80% (v/v) ethanol:water (ten cycles), 50% (v/v) methanol:chloroform (one cycle), and acetone (one cycle). Klason lignin and cell wall monosaccharides were determined on cell wall residues (CWR) using the standard NREL biomass procedure (Sluiter et al., 2008). Glucose, xylose, and arabinose from biomass hydrolysates were measured by HPLC as previously described (Lin et al., 2021). Cell-wall-bound aromatics were released from 20 mg of CWR via mild alkaline hydrolysis using a 2N sodium hydroxide solution (Eudes et al., 2012). Ferulate, p-coumarate, and 4-HBA were quantified using HPLC-ESI-QTOF-MS analysis (Eudes et al., 2013).

2.7. Saccharification assays

Biomass samples (200 mg) were pretreated with the ionic liquid cholinium phosphate for 3 h at 121 °C and the enzymatic saccharification was conducted at 50 °C for 72 h using an enzyme mixture of Cellic® CTec3 and HTec3 (9:1 v/v) (Novozymes, Bagsværd, Denmark) as previously described (Tian et al., 2021). Conditions used for saccharification assays (ionic liquid concentration, pretreatment temperature, and enzyme loadings) are considered to be suboptimal for total polysaccharide hydrolysis. For metabolite measurements, hydrolysates were filtered using 0.2 μM PVDF filters (EMD Millipore, Billerica, MA, USA) and analyzed by HPLC (Tian et al., 2021).

2.8. Field trial

Seeds (T3 generation) from lines Eng-1, Eng-2, pooled WT-1 and WT-2 (i.e., ‘wild-type segregants’), and untransformed wildtype (variety BTx430) were planted in a field trial conducted at the University of California Davis Plant Sciences Research Farm in 2021 under a USDA-APHIS Biotechnology Regulatory Services permit for regulated sorghum (#BRS 20-356-102r). Seeds were planted on a Yolo clay loam soil (fine-silty, mixed thermic Fluventic Haploxerept) on May 28, 2021. Percent germination was taken for each line, and adjusted for a target seeding rate of 197,600 seeds ha−1. The experiment was a randomized complete block design with four replicates. Row spacing was 0.76 m. Plots measured 3 × 6 m and comprised 4 rows. A commercial sorghum variety (NK8828 from S&W Seed Company, Longmont, CO) was also planted as border rows to limit edge effects. Total N-P-K fertilizer was applied at planting at a rate of 224, 91, and 22 kg ha−1, respectively. Sivanto was applied on June 22, 2021 at a rate of 481 g ha−1 for sugarcane aphid control. Irrigation water was applied utilizing surface furrow methods to satisfy the fully-watered evapotranspiration requirement for sorghum during the growing season. All panicles on each plant were covered with pollinating bags prior to anthesis to prevent pollen flow. Plot harvest took place on September 21, 2021. Panicles (heads with immature grain) were removed by hand. Remaining stover was harvested using a Wintersteiger Cibus forage chopper (Wintersteiger, Salt Lake City, UT). Subsamples of approximately 500 g of fresh weight stover material were taken from each harvested plot, and dried at 55 °C for one week in a forced air oven to determine dry matter and calculate yield. For 4-HBA analyses, stover samples were first milled using a Model 4 Wiley Mill equipped with a 1-mm mesh (Thomas Scientific, Swedesboro, NJ) and further ground into powder.

3. Results and discussion

3.1. Generation of aroG-ubiC transgenic sorghum

The sorghum variety BTx430 was transformed with a construct containing ubiC as well as the gene encoding a feedback-resistant version of DAHPS (AroGL175Q) from E. coli (Fig. 1b). In this construct, both E. coli genes were codon-optimized for expression in sorghum and preceded with the sequence of a signal peptide for targeting UbiC and AroGL175Q to plastids (Fig. 1b). The promoter of the rice polyubiquitin gene (pRubi2) was used to drive ubiC expression constitutively whereas the promoter of a maize cellulose synthase gene (pZmCesa10) involved in the formation of secondary cell walls was selected for AroGL175Q expression to avoid possible toxicity and sterility issues (Oliva et al., 2020) (Fig. 1b). Two independent lines (Eng-1 and Eng-2) containing the dual aroG-ubiC construct and their respective wild-type segregants (WT-1 and WT-2) were selected for further characterization. Using RT-qPCR, the expression of the two transgenes was confirmed in both lines at three different developmental stages in the T2 generation. In the bottom part of the main stem, ubiC expression level was higher than that of aroG, and line Eng-2 exhibited higher abundance of both ubiC and aroG transcripts compared to Eng-1 (Fig. 1c). The transgenics showed normal growth and were phenotypically indistinguishable from wild-type controls (Supplementary Fig. S1). Overall, no differences in various parameters such as the number of days to panicle emergence, height of the main tiller, stover biomass yield, seed weight, and estimated seed number were observed between transgenics and control plants grown under controlled environment (Supplementary Fig. S1).

3.2. Content of 4-hydroxybenzoic acid in engineered sorghum

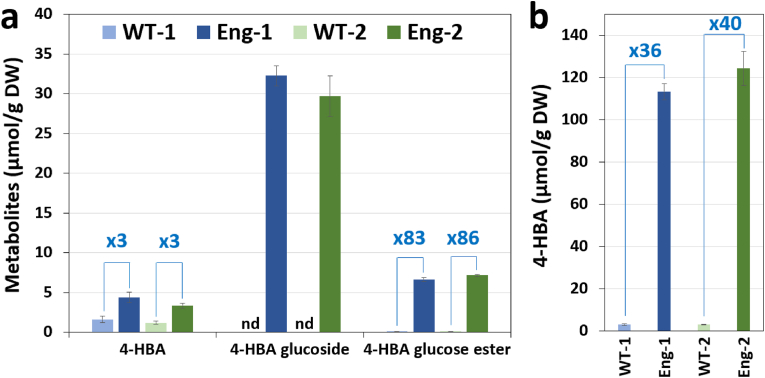

Fully mature senesced dry plants in the T2 generation were ground into powder for metabolite analyses. Using liquid chromatography-mass spectrometry, measurements of free 4-HBA and potential 4-HBA glucose conjugates were analyzed in methanolic extracts obtained from biomass samples. A small amount of free 4-HBA was detected in wild-type extracts (1.2–1.6 μmol/g dw) and increased 3-fold in engineered lines (Fig. 2a). 4-HBA phenolic glucoside, which was undetectable in wild-type extracts, reached 32.3 and 29.7 μmol/g dw in extracts from lines Eng-1 and Eng-2, respectively (Fig. 2a). Furthermore, 4-HBA glucose ester was detected and increased 83- and 86-fold in transgenics, which corresponds to titers of 6.6 and 7.1 μmol/g dw (Fig. 2a). An aliquot of the methanolic extracts was subjected to acid hydrolysis to release 4-HBA from its conjugated forms. Measurement of 4-HBA aglycone in resulting hydrolysates showed that transgenic lines Eng-1 and Eng-2 contain 113 and 124 μmol 4-HBA/g dw, which is equivalent to 4-HBA titers of 1.56 and 1.72 dw% and represents 36- and 40-fold increases compared to the titer measured in wildtypes (Fig. 2b). Since the total amount of free 4-HBA and 4-HBA glucose conjugates in methanolic extracts is below that of 4-HBA aglycone measured in acid-treated extracts, we conclude that other unidentified 4-HBA conjugate forms accumulate in transgenics.

Fig. 2.

Metabolite analysis of engineered sorghum. (a) Titers of 4-HBA and its glucose conjugates extracted from of Eng-1 and Eng-2 using aqueous methanol. nd, not detected. (b) Total extractable 4-HBA content in Eng-1 and Eng-2 after acid-hydrolysis of the methanolic extracts. The stover from fully mature senesced dry plants in the T2 generation was analyzed. Values are means ± SE of five biological replicates (n = 5 plants). DW, dry weight.

New cultures were initiated to assess 4-HBA titers during plant development in the T3 generation: Across five developmental stages, the data show that 4-HBA content measured in acid-treated methanolic extracts tends to decrease with plant age until flowering (‘booting’) and that line Eng-2 accumulates more 4-HBA than line Eng-1 at all stages (Fig. 3). The measurement of higher amount of 4-HBA in line Eng-2 compared to Eng-1 is consistent with the expression level of the transgenes in these lines, however, this trend was not observed in the T2 generation in which Eng-1 and Eng-2 plants produced comparable amounts of 4-HBA (Fig. 2b). Since all the plants analyzed were homozygous for the DNA construct, and considering that the two transgenic lines should be genetically stable in the T2 and T3 generations, differences in growing conditions that may have occurred in the greenhouse during the cultivation of T2 and T3 plants could explain these observations.

Fig. 3.

4-HBA analysis in engineered sorghum across different developmental stages. Titers of 4-HBA after acid-hydrolysis of methanolic extracts are shown. The stover from oven-dried plants in the T3 generation was analyzed. Values are means ± SE of five biological replicates (n = 5 plants). Abbreviation: DW, dry weight; GDP, growth differentiation point stage.

3.3. Cell wall analyses in engineered sorghum

Cell walls are the main constituents of plant biomass and the source of fermentable substrates for the production of advanced bioproducts. The analysis of cell wall composition showed no significant difference between transgenics and controls regarding the proportion of major components including glucose (representing cellulose), xylose and arabinose (representing xylan), and lignin, as well as the aromatics p-coumarate, and ferulate (Supplementary Table S3). However, 4-HBA content measured in alkaline hydrolysates obtained from extractive-free cell wall preparations was six and four times higher in transgenics compared to controls (Supplementary Table S3). In a separate study that investigated the lignin monomeric composition in line Eng-2, we evidenced that 4-HBA formed ester end-groups on lignin (Wang et al., 2021), which was previously described in lignin fractions isolated from other plants such as willow, poplar, aspen, Neptune grass, and palms (del Río et al., 2020).

The saccharification of sorghum biomass was evaluated using ionic liquid pretreatment followed by enzymatic hydrolysis using a mixture of cell wall degrading enzymes that convert cellulose and hemicellulose into simple sugars. The biomass from engineered lines released similar amount of glucose compared to wild-type controls, but xylose yields were reduced by 6.7% and 8.5% in Eng-1 and Eng-2, respectively (Supplementary Fig. 2). Overall, this data indicates that cell walls from engineered sorghum are not substantially more recalcitrant to enzymatic hydrolysis, which is an important consideration since degrading enzymes represent an important cost in lignocellulosic biorefineries (Klein-Marcuschamer et al., 2012). Ferulate has been implicated in the formation of phenolic cross-links that reinforce the cell wall, but the involvement of 4-HBA in such a role has not been described (Mnich et al., 2020). It is plausible that 4-HBA accumulated in the cell wall of Eng-1 and Eng-2 participates in the formation of cross-links that somehow impact slightly the hydrolysis of xylan chains during saccharification.

3.4. Field-testing of engineered sorghum

The engineered sorghum lines were grown in the field in the T3 generation to evaluate their performance under natural environment. For this field trial, an equal amount of seeds from each wild-type segregants was pooled to generate a single wild-type segregant control. Seeds from a wildtype of the same variety that did not go through the transformation process was included as a second control. Plants were grown until the soft dough stage and methanol-soluble metabolites were extracted from the stover. As previously observed in the greenhouse experiment, the two engineered sorghum lines showed a large increase of 4-HBA content (30 and 44-fold) compared to control plants, which averaged 59.7 and 88.8 μmol/g DW in Eng-1 and Eng-2, respectively (Fig. 4). These titers, which are equivalent to 8.1 and 12.0 mg/g DW (or 0.8 and 1.2 dw%), are significantly lower than those measured in plants analyzed at the same developmental stage and grown in the greenhouse, but the exact reasons for this difference remain to be elucidated. Measurement of stover biomass showed slight decreases in yield for both transgenic lines (15% and 11%) compared to the wild-type controls that produced 24.9–25.3 tonnes per hectare (Fig. 4).

Fig. 4.

Field testing of engineered sorghum. (a) 4-HBA titers and (b) stover biomass yields are shown. The stover from plants in the T3 generation grown until the soft dough stage was analyzed. Values are means ± SE of four biological replicates (n = 4 plots). ‘WT’ is conventional sorghum (variety BTx430) and ‘WT segregant’ is a pool of WT-1 and WT-2 segregants. The asterisk indicates a significant difference compared to the wildtypes using the unpaired Student's t-test (*P < 0.05). DW, dry weight.

4. Conclusions

This work demonstrates that sorghum can be engineered to accumulate the valuable bioproduct 4-HBA at potentially economically competitive titers compared to microbial synthesis (i.e. > 0.3 dw%; Yang et al., 2022). Measurements of 4-HBA content during sorghum development suggests that engineered plants could be harvested either at the soft dough stage or at full maturity since 4-HBA titers remain comparable between the two stages after flowering (Fig. 3). Although higher biomass yields are typically obtained at the mature stage, the soft dough stage represents the harvest time for silage and several studies have highlighted the economic potential of using forage sorghum for biorefinery applications (Magurudeniya et al., 2021; Yang et al., 2021). Line Eng-2, which showed higher 4-HBA titers compared to Eng-1, could be further engineered to enhance 4-HBA content. Possible strategies include the additional expression of UbiC targeted to the cytosol where its substrate chorismate is also located (Qian et al., 2019; Sommer and Heide, 1998), and the expression of the recently discovered p-hydroxybenzoyl-CoA monolignol transferase to promote the attachment of readily cleavable 4-HBA esters onto lignin in cell walls (de Vries et al., 2022; Zhao et al., 2021). Considering the slight yield penalty observed in line Eng-2 under field conditions, the 4-HBA co-product trait developed in this line should be introgressed into high-yielding biomass sorghum varieties (Olson et al., 2012). Further field testing of 4-HBA-rich sorghum is needed to evaluate crop performance under various conditions such as reduced irrigation since bioenergy crops are expected to be grown on marginal lands that do not compete with food production.

Funding

This work conducted by the Joint BioEnergy Institute was supported by the US Department of Energy, Office of Science, Office of Biological and Environmental Research under contract no. DE-AC02-05CH11231 between Lawrence Berkeley National Laboratory and the US Department of Energy. Part of the work was supported by the Laboratory Directed Research and Development Program of Lawrence Berkeley National Laboratory (J.T. and T.R.N).

Author statement

C-YL and JT performed DNA clonings. APK, JH, and KN-V transformed sorghum. MYL and YT genotyped the plants. C-YL conducted gene expression analyses. YT measured agronomic traits and analyzed metabolites and cell wall components. VRP conducted saccharification assays. RK and EEKB performed LC-MS analyses. C.M.DB conducted the field trial and biomass handling. J.D. provided logistics for the field trial. AE wrote the paper. APK, TRN, EEKB, DHP, JMG, BAS, CDS, HVS, and AE supervised the research. All authors read and approved the final manuscript.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

Authors are thankful to Professor Kazufumi Yazaki (Kyoto University, Japan) for providing the 4-hydroxybenzoate glucose conjugate standards, to Dr. Roger Thilmony (USDA, Western Regional Research Center, Albany, CA) for providing the pRubi2 promoter, and to Novozymes for providing Cellic® CTec3 and HTec3. Members of our laboratories in LBNL and UC Davis who participated in bagging and harvesting of plants in the field trials are thanked for their contribution to this study.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.mec.2022.e00207.

Appendix A. Supporting Information

Supplementary data associated with this article can be found in the online version.

Appendix B. Supplementary data

The following is the Supplementary data to this article:

References

- Baral N.R., Sundstrom E.R., Das L., Gladden J.M., Eudes A., Mortimer J., Singer S.W., Mukhopadhyay A., Scown C.D. Approaches for more efficient biological conversion of lignocellulosic feedstocks to biofuels and bioproducts. ACS Sustain. Chem. Eng. 2019;7:9062–9079. doi: 10.1021/acssuschemeng.9b01229. [DOI] [Google Scholar]

- de Vries L., MacKay H.A., Smith R.A., Mottiar Y., Karlen S.D., Unda F., Muirragui E., Bingman C., Vander Meulen K., Beebe E.T., Fox B.G., Ralph J., Mansfield S.D. pHBMT1, a BAHD-family monolignol acyltransferase, mediates lignin acylation in poplar. Plant Physiol. 2022;188:1014–1027. doi: 10.1093/plphys/kiab546. [DOI] [PMC free article] [PubMed] [Google Scholar]

- del Río J.C., Rencoret J., Gutiérrez A., Elder T., Kim H., Ralph J. Lignin monomers from beyond the canonical monolignol biosynthetic pathway: another brick in the wall. ACS Sustain. Chem. Eng. 2020;8:4997–5012. doi: 10.1021/acssuschemeng.0c01109. [DOI] [Google Scholar]

- Do P.T., Lee H., Nelson-Vasilchik K., Kausch A., Zhang Z.J. Rapid and efficient genetic transformation of sorghum via agrobacterium-mediated method. Curr. Protoc. Plant Biol. 2018;3 doi: 10.1002/cppb.20077. [DOI] [PubMed] [Google Scholar]

- Eudes A., Berthomieu R., Hao Z., Zhao N., Benites V.T., Baidoo E.E.K., Loqué D. Production of muconic acid in plants. Metab. Eng. 2018;46:13–19. doi: 10.1016/j.ymben.2018.02.002. [DOI] [PubMed] [Google Scholar]

- Eudes A., George A., Mukerjee P., Kim J.S., Pollet B., Benke P.I., Yang F., Mitra P., Sun L., Cetinkol O.P., Chabout S., Mouille G., Soubigou-Taconnat L., Balzergue S., Singh S., Holmes B.M., Mukhopadhyay A., Keasling J.D., Simmons B.A., Lapierre C., Ralph J., Loqué D. Biosynthesis and incorporation of side-chain-truncated lignin monomers to reduce lignin polymerization and enhance saccharification. Plant Biotechnol. J. 2012;10:609–620. doi: 10.1111/j.1467-7652.2012.00692.x. [DOI] [PubMed] [Google Scholar]

- Eudes A., Juminaga D., Baidoo E.E.K., Collins F.W., Keasling J.D., Loqué D. Production of hydroxycinnamoyl anthranilates from glucose in Escherichia coli. Microb. Cell Factories. 2013;12:62. doi: 10.1186/1475-2859-12-62. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hao Z., Yogiswara S., Wei T., Benites V.T., Sinha A., Wang G., Baidoo E.E.K., Ronald P.C., Scheller H.V., Loqué D., Eudes A. Expression of a bacterial 3-dehydroshikimate dehydratase (QsuB) reduces lignin and improves biomass saccharification efficiency in switchgrass (Panicum virgatum L.) BMC Plant Biol. 2021;21:56. doi: 10.1186/s12870-021-02842-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kempinski C., Jiang Z., Zinck G., Sato S.J., Ge Z., Clemente T.E., Chappell J. Engineering linear, branched-chain triterpene metabolism in monocots. Plant Biotechnol. J. 2019;17:373–385. doi: 10.1111/pbi.12983. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Klein-Marcuschamer D., Oleskowicz-Popiel P., Simmons B.A., Blanch H.W. The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol. Bioeng. 2012;109:1083–1087. doi: 10.1002/bit.24370. [DOI] [PubMed] [Google Scholar]

- Lin C.-Y., Eudes A. Strategies for the production of biochemicals in bioenergy crops. Biotechnol. Biofuels. 2020;13:71. doi: 10.1186/s13068-020-01707-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin C.-Y., Vuu K.M., Amer B., Shih P.M., Baidoo E.E.K., Scheller H.V., Eudes A. In-planta production of the biodegradable polyester precursor 2-pyrone-4,6-dicarboxylic acid (PDC): stacking reduced biomass recalcitrance with value-added co-product. Metab. Eng. 2021;66:148–156. doi: 10.1016/j.ymben.2021.04.011. [DOI] [PubMed] [Google Scholar]

- Magurudeniya H.D., Baral N.R., Rodriguez A., Scown C.D., Dahlberg J., Putnam D., George A., Simmons B.A., Gladden J.M. Use of ensiled biomass sorghum increases ionic liquid pretreatment efficiency and reduces biofuel production cost and carbon footprint. Green Chem. 2021;23:3127–3140. doi: 10.1039/D0GC03260C. [DOI] [Google Scholar]

- McQualter R.B., Chong B.F., Meyer K., Van Dyk D.E., O'Shea M.G., Walton N.J., Viitanen P.V., Brumbley S.M. Initial evaluation of sugarcane as a production platform for p-hydroxybenzoic acid. Plant Biotechnol. J. 2005;3:29–41. doi: 10.1111/j.1467-7652.2004.00095.x. [DOI] [PubMed] [Google Scholar]

- Mnich E., Bjarnholt N., Eudes A., Harholt J., Holland C., Jørgensen B., Larsen F.H., Liu M., Manat R., Meyer A.S., Mikkelsen J.D., Motawia M.S., Muschiol J., Møller B.L., Møller S.R., Perzon A., Petersen B.L., Ravn J.L., Ulvskov P. Phenolic cross-links: building and de-constructing the plant cell wall. Nat. Prod. Rep. 2020;37:919–961. doi: 10.1039/c9np00028c. [DOI] [PubMed] [Google Scholar]

- Mullet J., Morishige D., McCormick R., Truong S., Hilley J., McKinley B., Anderson R., Olson S.N., Rooney W. Energy sorghum--a genetic model for the design of C4 grass bioenergy crops. J. Exp. Bot. 2014;65:3479–3489. doi: 10.1093/jxb/eru229. [DOI] [PubMed] [Google Scholar]

- Oliva M., Guy A., Galili G., Dor E., Schweitzer R., Amir R., Hacham Y. Enhanced production of aromatic amino acids in tobacco plants leads to increased phenylpropanoid metabolites and tolerance to stresses. Front. Plant Sci. 2020;11 doi: 10.3389/fpls.2020.604349. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olson S.N., Ritter K., Rooney W., Kemanian A., McCarl B.A., Zhang Y., Hall S., Packer D., Mullet J. High biomass yield energy sorghum: developing a genetic model for C4 grass bioenergy crops. Biofuels, Bioprod. Bioref. 2012;6:640–655. doi: 10.1002/bbb.1357. [DOI] [Google Scholar]

- Qian Y., Lynch J.H., Guo L., Rhodes D., Morgan J.A., Dudareva N. Completion of the cytosolic post-chorismate phenylalanine biosynthetic pathway in plants. Nat. Commun. 2019;10:15. doi: 10.1038/s41467-018-07969-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shih P.M., Vuu K., Mansoori N., Ayad L., Louie K.B., Bowen B.P., Northen T.R., Loqué D. A robust gene-stacking method utilizing yeast assembly for plant synthetic biology. Nat. Commun. 2016;7 doi: 10.1038/ncomms13215. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Siebert M., Sommer S., Li S.M., Wang Z.X., Severin K., Heide L. Genetic engineering of plant secondary metabolism. Accumulation of 4-hydroxybenzoate glucosides as a result of the expression of the bacterial ubiC gene in tobacco. Plant Physiol. 1996;112:811–819. doi: 10.1104/pp.112.2.811. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sluiter A., Hames B., Ruiz R., Scarlata C., Sluiter J. Laboratory Analytical Procedure. Technical Report, NREL/TP-510-42618. National Renewable Energy Laboratory; Golden, CO: 2008. Determination of structural carbohydrates and lignin in biomass. [Google Scholar]

- Sommer S., Heide L. Expression of bacterial chorismate pyruvate-lyase in tobacco: evidence for the presence of chorismate in the plant cytosol. Plant Cell Physiol. 1998;39:1240–1244. doi: 10.1093/oxfordjournals.pcp.a029326. [DOI] [PubMed] [Google Scholar]

- Tian Y., Lin C.-Y., Park J.-H., Wu C.-Y., Kakumanu R., Pidatala V.R., Vuu K.M., Rodriguez A., Shih P.M., Baidoo E.E.K., Temple S., Simmons B.A., Gladden J.M., Scheller H.V., Eudes A. Overexpression of the rice BAHD acyltransferase AT10 increases xylan-bound p-coumarate and reduces lignin in Sorghum bicolor. Biotechnol. Biofuels. 2021;14:217. doi: 10.1186/s13068-021-02068-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tzin V., Malitsky S., Zvi M.M.B., Bedair M., Sumner L., Aharoni A., Galili G. Expression of a bacterial feedback-insensitive 3-deoxy-D-arabino-heptulosonate 7-phosphate synthase of the shikimate pathway in Arabidopsis elucidates potential metabolic bottlenecks between primary and secondary metabolism. New Phytol. 2012;194:430–439. doi: 10.1111/j.1469-8137.2012.04052.x. [DOI] [PubMed] [Google Scholar]

- Tzin V., Rogachev I., Meir S., Moyal Ben Zvi M., Masci T., Vainstein A., Aharoni A., Galili G. Tomato fruits expressing a bacterial feedback-insensitive 3-deoxy-D-arabino-heptulosonate 7-phosphate synthase of the shikimate pathway possess enhanced levels of multiple specialized metabolites and upgraded aroma. J. Exp. Bot. 2013;64:4441–4452. doi: 10.1093/jxb/ert250. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vanhercke T., Belide S., Taylor M.C., El Tahchy A., Okada S., Rolland V., Liu Q., Mitchell M., Shrestha P., Venables I., Ma L., Blundell C., Mathew A., Ziolkowski L., Niesner N., Hussain D., Dong B., Liu G., Godwin I.D., Lee J., Rug M., Zhou X.-R., Singh S.P., Petrie J.R. Up-regulation of lipid biosynthesis increases the oil content in leaves of Sorghum bicolor. Plant Biotechnol. J. 2019;17:220–232. doi: 10.1111/pbi.12959. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang S., Bilal M., Hu H., Wang W., Zhang X. 4-Hydroxybenzoic acid-a versatile platform intermediate for value-added compounds. Appl. Microbiol. Biotechnol. 2018;102:3561–3571. doi: 10.1007/s00253-018-8815-x. [DOI] [PubMed] [Google Scholar]

- Wang Y., Meng X., Tian Y., Kim K.H., Jia L., Pu Y., Leem G., Kumar D., Eudes A., Ragauskas A.J., Yoo C.G. Engineered sorghum bagasse enables a sustainable biorefinery with p-hydroxybenzoic acid-based deep eutectic solvent. ChemSusChem. 2021;14:5235–5244. doi: 10.1002/cssc.202101492. [DOI] [PubMed] [Google Scholar]

- Yang M., Baral N.R., Simmons B.A., Mortimer J.C., Shih P.M., Scown C.D. Accumulation of high-value bioproducts in planta can improve the economics of advanced biofuels. Proc. Natl. Acad. Sci. U.S.A. 2020;117:8639–8648. doi: 10.1073/pnas.2000053117. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yang M., Dahlberg J., Baral N.R., Putnam D., Scown C.D. Identifying forage sorghum ideotypes for advanced biorefineries. ACS Sustain. Chem. Eng. 2021;9:7873–7881. doi: 10.1021/acssuschemeng.1c01706. [DOI] [Google Scholar]

- Yang M., Liu D., Baral N.R., Lin C.-Y., Simmons B.A., Gladden J.M., Eudes A., Scown C.D. Comparing in-planta accumulation with microbial routes to set target for a cost-competitive bioeconomy. Proc. Natl. Acad. Sci. U.S.A. 2022 doi: 10.1073/pnas.2122309119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao Y., Yu X., Lam P.-Y., Zhang K., Tobimatsu Y., Liu C.-J. Monolignol acyltransferase for lignin p-hydroxybenzoylation in Populus. Native Plants. 2021;7:1288–1300. doi: 10.1038/s41477-021-00975-1. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.