Abstract

As for natural gas miscible flooding in low-permeability reservoirs, studying on the phase behavior characteristic of oil–gas miscible zone has a significant meaning. In this paper, based on the reservoir characteristics of Donghe 1CIII oilfield, the evaluation of phase physical properties and minimum miscible pressure was conducted by laboratory experiments using recombined formation fluid and natural gas samples. Then, one compositional model was established to analyze the phase behavior of the miscible zone during natural gas flooding. The result shows that the fluid critical points of the miscible zone change the polynomial in the P–T diagram. More specially, the curve of critical points owns more area with higher pressure, which means that the fluid reaches a deeper miscible degree. Finally, a new chart method for gas channeling identification is proposed to evaluate the production state of the miscible zone in order to identify gas channeling. The phase envelope of the production fluid is concerned with the migration of the miscible zone. In addition, an application case in Donghe oilfield is given by means of the gas channeling-phase diagram identification method. This work could provide a theoretical basis for timely gas channeling prevention and control measures as well as improvement of the gas injection development effect.

1. Introduction

Nowadays, low-permeability reservoir development depends largely on water flooding because of the attenuation of formation energy for enhanced oil recovery (EOR) after the primary recovery.1 However, water flooding in low-permeability reservoirs has a low injection rate and a poor displacement efficiency because of the formation’s anisotropy, the natural micro-fracture effect, the special pore structure, and water damage.2−4 Hence, gas flooding becomes a promising method for EOR due to the higher injection rate and displacement efficiency.5−8

Gas injection processes have become widely used techniques for EOR.9 The injection gas widely used includes CO2, natural gas, or a gas mixture.10−12 CO2 flooding is commonly used in North America and can recover 15–25% of original oil in place.13−15 However, it is necessary to consider economic benefits; the costs of purchase, transportation, and storage of CO2 for CO2 injection are more expensive than that of natural gas.16 Natural gas sources are sufficient with the large production of natural gas in tight oil reservoirs.17 In addition, it is not affected by low reservoir permeability and formation water salinity, which can solve many problems of difficult water injection or water-sensitive reservoirs.3,16 Therefore, natural gas injection might be a promising EOR method and suitable for reservoirs lacking CO2 sources.

Natural gas flooding, according to its oil-displacement mechanism, can be divided into immiscible flooding, near-miscible flooding, and miscible flooding.18−20 Among these, miscible flooding is one of the most attractive methods of gas injection for oil recovery and is favored by petroleum workers because of the abundant reserves, good injectivity, and excellent displacement capability.21−23 The method of natural gas miscible flooding has been successfully used in the United States, Canada, and so on with good results for many years.6,24 In Canada, miscible natural gas flooding is mostly used for actual production with an average increased recovery of 27%, compared with water flooding.25 In China, Pubei oilfield increased oil recovery by 12.6% from 1989 to 2008 using natural gas miscible flooding.16 Donghe oilfield in Tarim Basin enhanced oil recovery more than 18% since 2014 by the method of hydrocarbon gas miscible plane flooding plus gravity flooding.26

Donghe 1 carboniferous reservoir has a large stratigraphic dip (4.5–12°) and a large reservoir thickness, where the crude oil has a good physical property.27 The upper sand formation is a low-permeability reservoir so that the reservoir fluid is difficult to be driven out.28 In reality, the longitudinal contradictions in Donghe reservoir were prominent and the recovery efficiency was getting worse after 20 years of water flooding development. Therefore, it is necessary to change the development mode to realize the effective utilization of the low-permeability reservoir in the sand formation. Based on laboratory test analysis, it is proposed to deploy gas injection wells in the high part of the reservoir structure and production wells in the middle and lower parts. The artificial gas cap is formed by the gravity overlap of the injection gas.29 The injection gas is gradually displaced downward and constantly contacts with crude oil to achieve the miscible phase to form gravity-assisted miscible flooding. This method is used in anticlinal or high-dip formations and improves the sweep efficiency to a large extent. Meanwhile, the surrounding gas sources provide strong support.

When the formation pressure is higher than the minimum miscible pressure (MMP), the miscible displacement process is achieved with the injection gas advancing in the formation and repeated contacting with crude oil.30−32 In this case, a miscible zone is formed, in which the composition of the fluid changes gradually from crude oil to the injection fluid.33 The miscible zone owns self-healing ability to resist the disturbance of flow as well as insulating ability to prevent further contact between the two phases of oil and gas. The oil could be completely displaced cause of the miscible zone moved with the velocity of the injection gas. However, with the gas channeling through to the producing well, most of the injection gas produces ineffective circulation, which affects the recovery factor increasing greatly and leads to a worse development effect.34 The prediction and identification of the stage between gas breakthrough and gas channeling become key factors to improve the recovery efficiency.35 However, the properties of the miscible zone constantly change with injection gas moving toward the producing well, such as component, gas–oil ratio (GOR), and spatial scale, which are difficult to effectively track the position of the trailing edge of the miscible zone. The experience of gas flooding development and theoretical analysis show that the times at which the GOR of production begins to increase rapidly, the combined water cut begins to decline, the peak yield of effect appears, and the front edge of the miscible zone reaches the production well are identical.

In this work, first, the phase physical properties and MMP were evaluated in the laboratory using samples of Donghe 1CIII oilfield. The slim tube test was used due to the fact that it is more easy to perform, repeatable, and reproducible, aiming the determination of MMP compared with the coreflood test.36−38 Second, one compositional model was established by means of professional phase behavior analysis software based on the experimental data. Building on this foundation, the slim tube simulation was conducted to study the phase behavior of the miscible zone during natural gas miscible flooding. Third, a new chart method for gas channeling identification was proposed based on the change characteristics of the phase diagram of the miscible zone. More specially, an application case in Donghe oilfield is given by means of the gas channeling-phase diagram identification method.

2. Experimental Section

2.1. Materials

In this study, the oil and gas samples obtained from a separator are collected from Donghe oilfield in Tarim Basin in northwestern China’s Xinjiang province. The physical properties of crude oil and compositions of the recombined fluid samples are shown in Tables 1 and 2, respectively. The injection gas is prepared by Beijing Sea Spectrum Gas Company. The compositions of the injection gas used in this paper are shown in Table 3.

Table 1. Physical Properties of Crude Oil.

| type | parameters | amounts | units |

|---|---|---|---|

| reservoir condition | initial formation pressure | 45 | MPa |

| initial formation temperature | 140 | °C | |

| formation fluid properties | saturation pressure | 4.23 | MPa |

| gas–oil ratio (20 °C, 0.101325 MPa) | 15.3 | m3/m3 | |

| volume coefficient of the oil | 1.0985 | m3/m3 | |

| oil density (reservoir condition) | 0.7838 | g/cm3 | |

| oil viscosity (reservoir condition) | 3.45 | mPa·s | |

| died oil density | 0.8499 | g/cm3 | |

| composition of well-flow content | C1 + N2 | 12.02 | % |

| CO2 + C2 ∼ C10 | 39.48 | % | |

| C11+ | 48.50 | % |

Table 2. Composition of the Recombined Fluid Sample.

| oil

composition |

gas composition | well

stream composition |

|||

|---|---|---|---|---|---|

| component | mol % | wt % | mol % | mol % | wt % |

| CO2 | 0.00 | 0.00 | 4.40 | 0.73 | 0.14 |

| N2 | 0.00 | 0.00 | 11.56 | 1.91 | 0.24 |

| C1 | 0.00 | 0.00 | 61.10 | 10.11 | 0.73 |

| C2 | 0.00 | 0.00 | 8.23 | 1.36 | 0.18 |

| C3 | 0.00 | 0.00 | 6.64 | 1.10 | 0.22 |

| IC4 | 0.25 | 0.05 | 2.58 | 0.64 | 0.17 |

| NC4 | 0.34 | 0.07 | 0.95 | 0.44 | 0.12 |

| IC5 | 1.98 | 0.53 | 0.78 | 1.78 | 0.58 |

| NC5 | 1.87 | 0.50 | 0.82 | 1.69 | 0.55 |

| C6 | 5.57 | 1.75 | 1.70 | 4.93 | 1.87 |

| C7 | 7.33 | 2.64 | 0.90 | 6.27 | 2.72 |

| C8 | 9.30 | 3.73 | 0.34 | 7.82 | 3.78 |

| C9 | 7.89 | 3.57 | 0.00 | 6.58 | 3.59 |

| C10 | 7.36 | 3.69 | 0.00 | 6.14 | 3.71 |

| C11 | 6.32 | 3.48 | 0.00 | 5.28 | 3.50 |

| C12 | 4.87 | 2.93 | 0.00 | 4.06 | 2.95 |

| C13 | 4.71 | 3.08 | 0.00 | 3.93 | 3.10 |

| C14 | 3.64 | 2.59 | 0.00 | 3.04 | 2.61 |

| C15 | 3.46 | 2.67 | 0.00 | 2.89 | 2.69 |

| C16 | 2.58 | 2.15 | 0.00 | 2.16 | 2.16 |

| C17 | 2.37 | 2.10 | 0.00 | 1.97 | 2.11 |

| C18 | 2.14 | 2.01 | 0.00 | 1.78 | 2.02 |

| C19 | 1.99 | 1.96 | 0.00 | 1.66 | 1.97 |

| C20 | 1.76 | 1.81 | 0.00 | 1.47 | 1.82 |

| C21 | 1.46 | 1.58 | 0.00 | 1.21 | 1.59 |

| C22 | 1.40 | 1.60 | 0.00 | 1.17 | 1.61 |

| C23 | 1.25 | 1.49 | 0.00 | 1.05 | 1.50 |

| C24 | 1.02 | 1.27 | 0.00 | 0.85 | 1.27 |

| C25 | 0.84 | 1.09 | 0.00 | 0.70 | 1.09 |

| C26 | 0.65 | 0.87 | 0.00 | 0.54 | 0.88 |

| C27 | 0.43 | 0.60 | 0.00 | 0.36 | 0.61 |

| C28 | 0.22 | 0.32 | 0.00 | 0.18 | 0.32 |

| C29 | 0.07 | 0.11 | 0.00 | 0.06 | 0.11 |

| C30 | 0.06 | 0.09 | 0.00 | 0.05 | 0.09 |

| C31 | 0.05 | 0.08 | 0.00 | 0.04 | 0.08 |

| C32 | 0.04 | 0.07 | 0.00 | 0.04 | 0.07 |

| C33 | 0.04 | 0.06 | 0.00 | 0.03 | 0.06 |

| C34 | 0.03 | 0.05 | 0.00 | 0.02 | 0.05 |

| C35 | 0.01 | 0.02 | 0.00 | 0.01 | 0.02 |

| C36+ | 16.70 | 49.39 | 0.00 | 13.95 | 47.12 |

| Sum | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

Table 3. Composition of the Injection Gas.

| component | CO2 | N2 | C1 | C2 | C3 | IC4 | NC4 | IC5 | NC5 | C6 |

| fraction (%) | 2.28 | 0.00 | 86.02 | 8.61 | 2.35 | 0.25 | 0.35 | 0.07 | 0.07 | 0.00 |

2.2. Experimental Apparatus

A high-temperature and high-pressure stirred vessel with a piston was used for recombining the fluid samples. The fluid phase analysis system was used to test the physical properties of the fluid samples. The main equipment was a plunger-type high-temperature high-pressure visual PVT apparatus with the model of PVT240/1500, which is produced by Sanchez Technologies Company in French. The PVT apparatus diagram is shown in Figure 1. The maximum working pressure is 150 MPa, and the operating temperature range is room temperature to 200 °C. Moreover, the measurement accuracy for pressure is 0.0001 MPa and that for temperature 0.1 °C. Additionally, the high-temperature and high-pressure electromagnetic viscosimeter made by Cambridge Viscosity Company in America was used to test the viscosity of fluid samples at different pressures. A densitometer was used to measure the density of the reservoir fluid, which is produced by Anton Paar Company. Figure 2 shows the schematic of the fluid-phase analysis system. The gas chromatography (GC) compositional analyses of the original oil and gas samples were undertaken by using a GC system (Agilent 7890, Agilent Technologies, U.S.A).

Figure 1.

Diagram of the PVT apparatus.

Figure 2.

Schematic of the fluid-phase analysis system.

The slim tube used in this study was self-constructed. Figure 3 shows the schematic of the apparatus. Table 4 gives the physical parameters of the slim tube. The stainless-steel coil is 20.0 m long with an inside diameter of 4.00 mm. The pore volume and permeability are 78.42 cm3 and 4834 mD, respectively. The injection gas was injected using a positive displacement pump. Moreover, the system pressure was maintained through a digital back pressure regulator with the model of DBPR-5, which is produced by Coretest Systems, Inc. in America. The inlet, outlet, and back pressures were measured using pressure sensors with an uncertainty of 0.01 MPa. A temperature controller was used to adjust the temperature of the experimental system with an average uncertainty of 0.2 °C.

Figure 3.

Schematic diagram of the slim tube test system.

Table 4. Physical Parameters of the Slim Tube.

| parameter | value |

|---|---|

| length (m) | 20.00 m |

| inside diameter (mm) | 4.00 mm |

| external diameter (mm) | 6.00 mm |

| pore volume (cm3) | 78.42 |

| porosity (%) | 31.2 |

| gas permeability (mD) | 4834 |

2.3. Procedure

The fluid samples were recombined according to the producing GOR and saturation pressure through the method for analysis of reservoir fluid physical properties (GB/T 26981-2020) of the State Standard of the People’s Republic of China. Specifically, the phase behavior characteristics of reservoir fluids such as saturation pressure, GOR, volume coefficient, density, and viscosity were obtained by PVT tests. Compositions of the crude oil and solution gas after single flash test were obtained by chromatographic analysis.

The slim tube test was then conducted at different pressures and with injection gas according to the measurement method for MMP (SY/T 6573-2016) of the oil and gas industry standard of the People’s Republic of China. The slim tube should be cleaned by toluene and petroleum ether and filled with toluene to the target pressure at the beginning of each experiment. The fluid samples were then injected into the slim tube to completely replace toluene. After that, the injection gas was injected using a positive displacement pump with a displacement speed of 2 mL/min. The production oil and gas were collected and measured as a function of gas injection volume. Specially, the experiment could be stopped after an injected pore volume of 1.2 PV. Based on the data, the relationship of displacement pressure, GOR, and injection pressure can be plotted.

3. Slim Tube Simulation

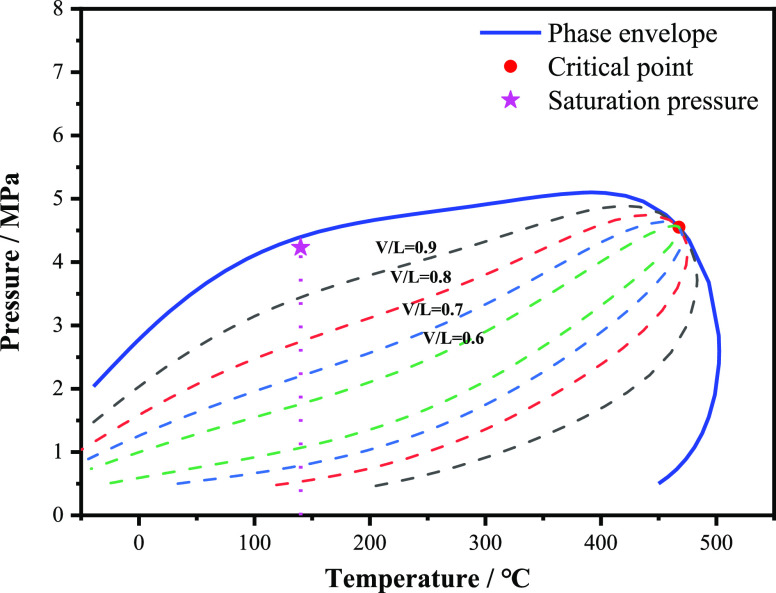

In the course of slim tube simulation, the accurate and reliable compositional model plays an important role. Specifically, the professional phase behavior analysis software of PVTsim was used and the equation of state (EOS) SRK Peneloux was chosen to establish a compositional model. The composition of crude oil of C7+ was regrouped into 12 pseudo-components under the guidance of the component chopping technique and experimental data of the PVT test. Subsequently, parameters of the EOS were adjusted to match the experimental PVT data such as the data of constant composition expansion, differential liberation, and constant volume depletion. The phase envelope of crude oil was simulated and is shown in Figure 4. Compared with the experimental data of saturation pressure (4.230 MPa), the calculated value of 4.397 MPa was acceptable with a relative error of 3.9%. Also, the other calculated parameters such as oil density, oil viscosity, and volume coefficient were also matched well. It indicates that a compositional model was established to represent the properties of the reservoir fluid, which provided reliable and accurate fluid physical parameters for the subsequent study of EOR by hydrocarbon gas injection.

Figure 4.

Phase envelope of crude oil.

On this basis, the slim tube simulation can be conducted using the slim tube module with the transport mechanism of moving excess. The cell volume remains constant throughout the simulation, and the excess volume is transferred to the next cell. If the oil volume exceeds that of the original cell, all gas and the excess volume of oil are transferred to the next cell. If the oil volume is lower than that of the original cell, only the excess gas volume is transferred to the next cell. Moreover, the transport mechanism of moving excess is illustrated in the Figure 5. Therefore, physical parameters of interfacial tension (IFT), GOR, viscosity, and density for both liquid and gas phases and displacement efficiency can be obtained. The experimental results compared with simulation results can be analyzed to jointly determine the MMP of the oil with injection gas. Finally, the composition of the fluid in the cell was calculated and analyzed through the compositional model identified above.

Figure 5.

Schematic diagram of moving excess.

4. Results and Discussion

4.1. Determination of MMP

Typically, the optimum pressure level is known as the MMP.39 From a petroleum perspective, it is a critical parameter used to distinguish the types of immiscible or miscible flooding.40,41 The MMP was confirmed by the relationship of oil recovery and pressure which is measured by the slim tube test in the room. The oil recovery increased with the increase of pressure, while a slight increase happened after the distinct inflection point. In general, the condition that the oil recovery reaches 90–95% in the inflection point is used as the criterion of miscible flooding. In this study, the oil recovery by the slim tube test and simulation is summarized in Table 5. The MMPs were then achieved by the miscibility judgment criterion, as shown in Figure 6. The simulation MMP is 37.31 MPa with a relative error is 3.8% compared to the experiment value of 38.80 MPa. Therefore, the numerical slim tube model established has a good performance to simulate the process of the slim tube experiment.

Table 5. Data of Oil Recovery in Both the Experiment and Simulation.

| number | pressure (MPa) | oil recovery at 1.2 PV (%) | simulation oil recovery | description |

|---|---|---|---|---|

| 1 | 29.98 | 70.56 | 65.22 | immiscible |

| 2 | 32.97 | 79.03 | 77.83 | immiscible |

| 3 | 35.98 | 86.17 | 87.91 | immiscible |

| 4 | 41.95 | 94.86 | 95.27 | miscible |

| 5 | 44.98 | 95.95 | 97.14 | miscible |

| 6 | 47.97 | 96.74 | 97.92 | miscible |

Figure 6.

Oil recovery vs pressure in the slim tube test at 140 °C.

4.2. Phase Characteristics of the Miscible Zone

When the MMP is less than the formation pressure, the miscible zone is formed by the process of vaporization–condensation between natural gas and crude oil. In this work, the one-dimension slim tube model established above could reflect the fluid properties during displacement. As for the parameters of the model, the number of cells and time steps were all set to 500. The injected pore volume was 1.2 PV. More specifically, the injection gas was injected from the first cell and the fluid was produced by the 500th cell. The diagram of slim tube test procedure simulation is shown in Figure 7. Therefore, the physical parameters of fluids in cells at various time steps were calculated to study the miscible zone.

Figure 7.

Diagram of slim tube test procedure simulation.

Another thing to note is the division of the miscible zone. During the displacement process, the oil-phase composition in the affected area constantly changes due to the vaporization–condensation. It is necessary to find a method to identify the miscible zone precisely. In this study, the miscible zone was defined based on the IFT of oil and gas as well as viscosity. As shown in Figure 8, the trailing edge of the miscible zone is determined by the IFT of the oil–gas system. The closer the composition of oil and gas is, the lower the IFT will be. Therefore, the situation that the IFT of oil and gas is lower than 0.1 dyn/cm can be considered to reach the miscible state. As for the front edge of the miscible zone, it locates between the miscible zone and crude oil region. The position where the fluid viscosity is changed is seen as the front edge of the miscible zone.

Figure 8.

Diagram of fluid distribution during gas miscible flooding.

The process of gas miscible flooding was simulated at a temperature of 140 °C and a pressure higher than MMP. Through the slim tube model, the composition of the fluid along with the cell was acquired at various time steps at 40 MPa. In addition, the parameters of the fluid, such as GOR, critical point, saturation pressure, interfacial tension, viscosity, and so on, were obtained by means of the compositional model. When GOR of the production fluid began to increase, gas breakthrough occurred in the production well. The width of the miscible zone at four time steps was identified and is plotted in Figure 9 before the stage of gas breakthrough. The width of the miscible zone increases with a linear trend with the increase of the injected pore volume. It is because that the augment of the contact surface between the front edge of the miscible zone and crude oil and hydrodynamic dispersion happens. It leads the front edge to migrate faster than the trailing edge of the miscible zone.

Figure 9.

Width of the miscible zone vs time step at 40 MPa.

In order to further study the miscible zone, the time step of 50 in the slim tube model was analyzed. The front edge and trailing edge of the miscible zone were intended to the 110th cell and 63rd cell, respectively. The key phase state parameters for crude oil and injection gas are listed in Table 6, and those for the miscible zone are summarized in Table 7. The critical properties of the miscible zone varied regularly and continuously. The critical point and phase envelope for the fluid are plotted in Figure 10. It is clearly shown that the critical points changed with polynomial regularity. The critical points continued to increase when the fluid came from the crude oil zone into the mixed-phase zone and then decreased with the fluid located in the two-phase zone. The data points of the fluid in the miscible zone were at the right of the formation temperature of 140 °C, which mean that the miscible degree was not deep and the fluid exhibited crude oil properties at 40 MPa. More specifically, evaporation and extraction happened with the gas moving forward, and the fluid phase envelope in the miscible zone differs from that of crude oil. It is mentioned that the two-phase area of the fluid phase envelope became larger as the fluid position approached the trailing edge of the miscible zone. The fluid-phase envelope in the trailing edge has the deepest miscibility. After that, the phase envelope in the two-phase zone means that it needs a higher pressure to achieve the mixed state. The fluid-phase envelope could reflect the change of fluid properties well. The same phenomenon was found in other time steps, as shown in Figure 11. As the gas continues to be injected, the miscible zone migrates forward and the width of this increases gradually. However, the changes of critical points of fluids in the miscible zone at different time steps were all sited on one polynomial curve. The GOR and viscosity of the fluid in the cell were also discussed and are plotted in Figure 12 at a time step of 50. As for the fluid in the two-phase zone, the GOR was calculated when the fluids were mixed in one phase, and this led to the inflection point in the curve. The GOR dramatically increased as soon as the fluid was located in the miscible zone. The viscosity in the miscible zone was decreased in a linear trend. And fluid in two-phase zone viscosity gradually approached due to multiple contact with crude oil and injection gas in the two-phase zone.

Table 6. Key Phase State Parameters for Crude Oil and Injection Gas.

| category | critical temperature (°C) | critical pressure (MPa) | GOR (m3/m3) | saturation pressure at 140 °C (MPa) |

|---|---|---|---|---|

| crude oil | 467.61 | 4.550 | 14.2 | 4.397 |

| injection gas | –51.7 | 6.875 |

Table 7. Key Phase State Parameters for the Miscible Zone at 40 MPa and a Time Step of 50.

| cell number | critical temperature (°C) | critical pressure (MPa) | GOR (m3/m3) | saturation pressure at 140 °C (MPa) |

|---|---|---|---|---|

| 40 | –22.60 | 28.158 | 1665.7 | 44.752 |

| 50 | 116.12 | 40.570 | 999.0 | 41.014 |

| 62 | 202.13 | 39.952 | 665.7 | 40.803 |

| 63 | 249.11 | 36.760 | 554.6 | 39.434 |

| 66 | 363.80 | 22.841 | 242.9 | 30.764 |

| 70 | 423.01 | 12.978 | 111.4 | 20.241 |

| 80 | 461.65 | 5.724 | 27.2 | 7.286 |

| 90 | 466.96 | 4.678 | 15.6 | 4.726 |

| 100 | 467.55 | 4.561 | 14.3 | 4.423 |

| 110 | 467.60 | 4.551 | 14.2 | 4.398 |

| 150 | 467.61 | 4.550 | 14.2 | 4.397 |

| 200 | 467.61 | 4.550 | 14.2 | 4.397 |

Figure 10.

Critical points for the fluid in the slim tube at 40 MPa.

Figure 11.

Critical points of the miscible zone in five time steps at 40 MPa.

Figure 12.

GOR and viscosity versus cell number at a time step of 50 at 40 MPa.

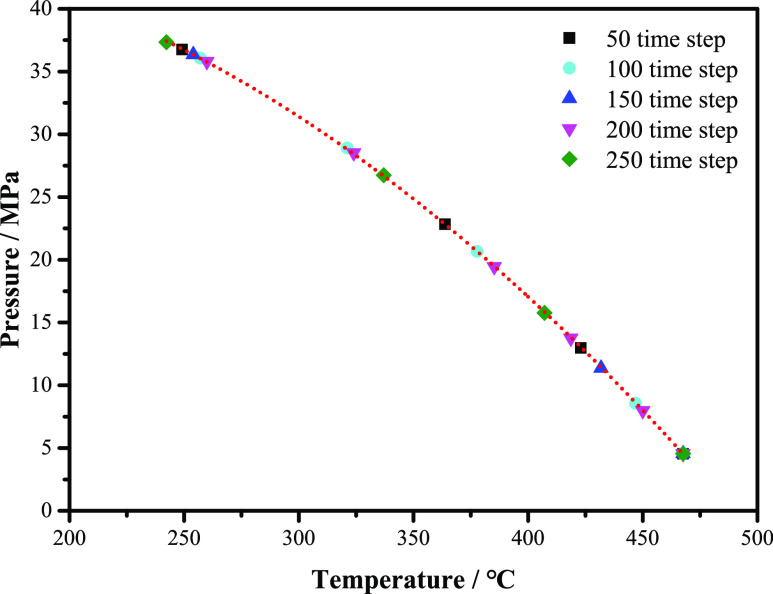

The simulation was also conducted at 45 and 50 MPa through the slim tube model. According to the analysis above, the critical points were calculated at a certain time step for each pressure. The time step of 201 was chosen, and the critical points are shown in Figure 13 at three pressures. As the pressure increased, the critical points migrated to the upper right owing to the same starting point. The area of the curve of critical points became lager. The critical points continued to increase until the temperature of 140 °C and then decreased. It is mentioned that more data points of the fluid in the miscible zone were set at the left of the formation temperature of 140 °C with higher pressure, which mean that the miscible degree was deeper and the fluid close to the trailing edge exhibited gas properties. The critical point of the trailing edge of the miscible zone moved to the left as the pressure increased, which means that the miscible degree deepens. Also, the width of the miscible zone at three pressures in the time step of 201 is shown in Figure 14. The width of the miscible zone was increased as the pressure increased. It is interesting to note that the length of the critical point curve at the miscible zone also increased with pressure, as shown in Figure 13. Therefore, the fluid critical point in the P–T phase diagram could reflect the degree and width of the miscible zone at various pressures.

Figure 13.

Critical points of the miscible zone at pressures of 40, 45, and 50 MPa and a time step of 201 (filled dots mean the miscible zone, and hollow dots mean the two-phase zone; black square: 40 MPa, blue circle: 45 MPa, pink triangle: 50 MPa).

Figure 14.

Width of the miscible zone vs pressure at a time step of 201.

4.3. Gas Channeling-Phase Diagram Identification

Gas channeling is the biggest problem in gas flooding. As the development continues and the injected pore volume multiples accumulate, the injected gas front portion forms a dominant flow channel along the highly permeable layer of the formation. Once the injection front breaks through to the production well, gas channeling will occur. The sweep efficiency of the injected gas to the original formation fluid will be greatly reduced, thus affecting the significant improvement of oil recovery. In the above study, the curve of the critical point and the corresponding phase envelope could reflect the width and position of the miscible zone at various displacement pressures. The phase envelope of the produced fluid was further analyzed in this paper. When the GOR began to increase, the front edge of the miscible zone coming into the production well and the gas breakthrough occurred. At this stage, the recovery ratio of oilfields increased rapidly. Figure 15 shows the GOR of the produced fluid and oil recovery at a formation pressure of 45 MPa. It was divided into three stages, the crude oil recovery stage, miscible zone recovery stage, and gas channeling stage, based on GOR and oil recovery by the division of the miscible zone. In the first crude oil recovery stage, the GOR remained constant and oil recovery increased cause of the production of crude oil. In the second miscible zone recovery stage, the GOR began to increase and oil recovery continued to increase. It is mentioned that the crossover point of the GOR curve was defined as the gas channeling warning point. After the gas channeling warning point, the increase rate of oil recovery decreased. The trailing edge of the miscible zone came into the production well in a short time and the gas channeling occurred. In the third gas channeling stage, the GOR increased rapidly and oil recovery remained almost constant. The gas channeling warning GOR is 342 m3/m3 and the gas channeling GOR is 1110 m3/m3 at the formation pressure. Moreover, the curve of critical points of the production fluid was consistent with that of the fluid in the displacement at various time steps and 45 MPa. Based on the above research, the new chart method of gas channeling identification was proposed based on fluid phase envelopes and employed at a formation pressure of 45 MPa, as shown in Figure 16. In the method, the phase envelopes in which the fluid owned GORs of 342 and 1110 m3/m3 were defined as the gas channeling warning boundary and gas channeling boundary, respectively. The production fluid phase envelope plotted lower than the gas channeling warning boundary was under normal production conditions. When the phase envelope plotted is both higher than and lower than the gas channeling boundary, the trailing edge of the miscible zone would reach the production well soon. After the phase envelope was higher than the gas channeling boundary, gas channeling occurred and the injected gas began to circulate invalidly. Effective prediction of gas channeling in oilfield development is especially important for improving the oilfield development effect and scheme optimization.

Figure 15.

GOR and oil recovery in miscible gas flooding.

Figure 16.

Chart of the gas channeling-phase diagram identification method.

The PVT data of well-flow contents three times were obtained with the help of other labs, and the compositions are shown in Table 8. Then, the phase diagrams were simulated and drawn, as shown in Figure 17. As for time 201806, the phase diagram showed that the miscible zone has broken through. The produced GOR was 75.8 m3/m3. At the next sample, at time 201901, the curve was in the gas channeling warning area. The produced GOR was 426.5 m3/m3. As for time 201906, the curve was close to the gas channel boundary, which means that the trailing edge of the miscible zone was about to reach the production well. By this time, the produced GOR was 909.5 m3/m3. The oil field data showed the method validity of gas channeling-phase diagram identification.

Table 8. Composition Data of Well-Flow Contents.

| composition, mol % |

|||

|---|---|---|---|

| component | 201806 | 201901 | 201906 |

| CO2 | 1.23 | 0.40 | 0.25 |

| N2 | 1.30 | 1.97 | 2.09 |

| C1 | 38.15 | 71.53 | 77.42 |

| C2 | 3.97 | 7.09 | 7.64 |

| C3 | 1.54 | 2.06 | 2.15 |

| IC4 | 0.50 | 0.32 | 0.29 |

| NC4 | 0.40 | 0.36 | 0.35 |

| IC5 | 1.16 | 0.39 | 0.26 |

| NC5 | 1.11 | 0.40 | 0.27 |

| C6 | 3.16 | 1.01 | 0.63 |

| C7+ | 47.49 | 14.48 | 8.65 |

Figure 17.

Gas channeling judgment in Donghe oil field.

6. Conclusions

The MMP of the oil sample in Donghe 1CIII oilfield obtained by the slim tube test and numerical simulation is 38.80 and 37.31 MPa, respectively. The relative error is 3.8%, which indicates that the compositional model could correctly reflect crude oil–natural gas system properties.

The injection natural gas and crude oil can reach the miscible phase at the formation pressure. The width of the miscible zone increases with the increase of the gas injection volume as well as displacement pressure before the mass transfer channel is built. The critical points in the P–T phase diagram for the miscible fluid changed with polynomial regularity and owned more area with the increase of pressure. The longer the critical point curve of the miscible fluid in the P–T phase diagram is, the greater the degree and width of the miscible zone is.

One chart method for gas channeling identification was novel proposed. The phase envelopes of the production fluid were used to identify the position of the miscible zone. The gas channel warning boundary as well as the gas channeling boundary are given in the P–T diagram decided by produced fluid GOR by means of numerical simulation. More specially, the samples obtained by well sampling or separator were analyzed in the laboratory and the phase envelope was further used to identify the production state. The method is well applied to Donghe 1CIII oilfield. This study has a certain guiding effect on the gas injection scheme of the oil field with similar reservoir characteristics and development modes and can be used to forewarn the gas channeling cycle and gas channeling severity in advance.

Acknowledgments

This work was financially supported by the Technology Research Project of PetroChina Company Limited, Research on Technology for Deep or Ultra-deep Oil and Gas Reservoirs Development (2021DJ1001).

The authors declare no competing financial interest.

References

- Xu B. CO2 miscible flooding in low permeability sandstone reservoirs and its influence on crude oil properties. Pet. Sci. Technol. 2017, 35, 2024–2029. 10.1080/10916466.2017.1377235. [DOI] [Google Scholar]

- Sun W.; Tang G. Q.. Visual study of water injection in low permeable sandstone. J. Can. Pet. Technol. 2006, 45. 10.2118/06-11-02 [DOI] [Google Scholar]

- Zeng L.; Liu H. Influence of fractures on the development of low-permeability sandstone reservoirs: A case study from the Taizhao district, Daqing Oilfield, China. J. Pet. Sci. Eng. 2010, 72, 120–127. 10.1016/j.petrol.2010.03.009. [DOI] [Google Scholar]

- Hoffman T.; Sonnenberg S.; Hossein K.. The benefits of reinjecting instead of flaring produced gas in unconventional oil reservoirs. Unconventional Resources Technology Conference, 2014.

- Yu H.; Chen Z.; Lu X.; Cheng S.; He Y.; Shi L.; Xian B.; Shi T. Experimental study on EOR performance of natural gas injection in tight oil reservoirs. IOP Conf. Ser.: Mater. Sci. Eng. 2019, 252, 052021. 10.1088/1755-1315/252/5/052021. [DOI] [Google Scholar]

- Mohan H.; Carolus M. J.; Biglarbigi K.. The potential for additional carbon dioxide flooding projects in the United States. SPE Symposium on Improved Oil Recovery, Tulsa, Oklahoma, USA, 2008.

- Tang W.; Sheng J. J. Huff-n-puff gas injection or gas flooding in tight oil reservoirs?. J. Pet. Sci. Eng. 2022, 208, 109725. 10.1016/j.petrol.2021.109725. [DOI] [Google Scholar]

- Monette M.; Nguyen Q. P. Investigation of the effect of gas compositions on low-tension-gas flooding. J. Pet. Sci. Eng. 2021, 207, 109140. 10.1016/j.petrol.2021.109140. [DOI] [Google Scholar]

- Farzad I.Evaluating reservoir production strategies in miscible and immiscible gas-injection projects. Latin American & Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, 2007.10.2118/108014-MS.

- Yu Y.; Meng X.; Sheng J. J. Experimental and numerical evaluation of the potential of improving oil recovery from shale plugs by nitrogen gas flooding. J. Unconv. Oil Gas Resour. 2016, 15, 56–65. 10.1016/j.juogr.2016.05.003. [DOI] [Google Scholar]

- Naseri A.; GhareSheikhloo A. A.; Kamari A.; Hemmati-Sarapardeh A.; Mohammadi A. H. Experimental measurement of equilibrium interfacial tension of enriched miscible gas–crude oil systems. J. Mol. Liq. 2015, 211, 63–70. 10.1016/j.molliq.2015.05.008. [DOI] [Google Scholar]

- Bath P. G. H. Status report on miscible/immiscible gas flooding. J. Pet. Sci. Eng. 1989, 2, 103–117. 10.1016/0920-4105(89)90057-0. [DOI] [Google Scholar]

- Yongmao H.; Zenggui W.; Binshan J.; Yueming C.; Xiangjie L.. Laboratory investigation of CO2 flooding. Nigeria International Conference & Exhibition, 2004.

- Shen P. P.; Liao X. W.. The Technology of carbon dioxide stored in geological media and enhanced oil recovery; Petroleum Industry Press, 2009; pp 47–52. [Google Scholar]

- Song C.; Yang T.. Optimization of CO2 flooding schemes for unlocking resources from tight oil formations. Society of Petroleum Engineers—SPE Canadian Unconventional Resources Conference, CURC 2012, 2012; p 1.

- Guo P.; Wang Z.; Tan G.; Yang K.; Zhang M.. Case analysis on hydrocarbon alternative gas miscible flooding in PuBei oil field. SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 2003.

- Lino U. D. R. A.An evaluation of natural gas huff “n” puff field tests in Brazil. SPE Latin America/Caribbean Petroleum Engineering Conference, 1994.

- Cao M.; Gu Y. Physicochemical characterization of produced oils and gases in immiscible and miscible CO2 flooding processes. Energy Fuels 2012, 27, 440–453. 10.1021/ef301407k. [DOI] [Google Scholar]

- Hao M.; Liao S.; Yu G.; Lei X.; Tang Y. Performance optimization of CO2 Huff-n-Puff for multifractured horizontal wells in tight oil reservoirs. Geofluids 2020, 2020, 1–13. 10.1155/2020/8840384. [DOI] [Google Scholar]

- Zhao F.; Zhang M.; Hou J.; Hou L.; Hao H.; Wang P.; Guoyong L. U. Determination of CO2 miscible condition and near-miscible region flooding in low permeability reservoir. Oilfield Chem. 2018, 35, 273. 10.19346/j.cnki.1000-4092.2018.02.016. [DOI] [Google Scholar]

- Chen Z.; Hao Y.; Yingchun J. I.; Wei X.; Zeng X.; Formation mechanism and characterization method of CO2-crude oil miscible zone. Pet. Geol. Recovery Effic. 2020, 27, 57. 10.13673/j.cnki.cn37-1359/te.2020.01.008. [DOI] [Google Scholar]

- Farajzadeh R.; Andrianov A.; Zitha P. L. J. Investigation of immiscible and miscible foam for enhancing oil recovery. Ind. Eng. Chem. Res. 2010, 49, 1910–1919. 10.1021/ie901109d. [DOI] [Google Scholar]

- Jaubert J.; Avaullee L.; Pierre C. Is it still necessary to measure the minimum miscibility pressure?. Ind. Eng. Chem. Res. 2002, 41, 303–310. 10.1021/ie010485f. [DOI] [Google Scholar]

- Jablonowski C.; Singh A.. A survey of CO2-EOR and CO2 storage project costs. Society of Petroleum Engineers—SPE International Conference on CO2 Capture, Storage, and Utilization, 2010, 2010.

- Taiyi Z.; Xiangui L.; Zhengming Y.; Yutian L.; Yapu Z.; Ying H.; Chunsheng X. Research progress on application of natural gas to enhance oil recovery in tight reservoirs. Appl. Chem. Ind. 2020, 49, 190–195. [Google Scholar]

- Shiyi Y.; Qiang W.; Junshi L.; Haishi H. Techonology progress and prospects of enhanced oil recovery by gas injection. Acta Pet. Sin. 2020, 41, 1623–1632. [Google Scholar]

- Liao T.; Hu J.; Lai F.; Duan Y. Reservoir characteristics of Donghe well No.1 in Tarim Basin. Int. J. Min. Sci. Technol. 2014, 24, 719–724. 10.1016/j.ijmst.2014.07.001. [DOI] [Google Scholar]

- Fan K.; Zhu W.; Zhou D.; Gao S.; Hu Z. Effect of interlayers in thick sandstone reservoir for gas injection: a case study of Donghe 1 Carboniferous oil reservoir in Tarim Basin. Acta Pet. Sin. 2015, 36, 475–481. [Google Scholar]

- Diwu P. X.; Sun C. Z.; Liu R.; Zhao W. Y. Artificial gas cap flooding technology of complex fault block reservoir. Adv. Mater. Res. 2014, 1073–1076, 2272–2275. 10.4028/www.scientific.net/amr.1073-1076.2272. [DOI] [Google Scholar]

- Amao A.; Siddiqui S.; Menouar H.. A new look at the minimum miscibility pressure (MMP) determination from slimtube measurements. Proceedings—SPE Symposium on Improved Oil Recovery, 2012; p 1

- Fazlali A.; Nikookar M.; Agha-Aminiha A.; Mohammadi A. Prediction of minimum miscibility pressure in oil reservoirs using a modified SAFT equation of state. Fuel 2013, 108, 675–681. 10.1016/j.fuel.2012.12.091. [DOI] [Google Scholar]

- Jaubert J.-N.; Wolff L.; Neau E.; Avaullee L. A very simple multiple mixing cell calculation to compute the minimum miscibility pressure whatever the displacement mechanism. Ind. Eng. Chem. Res. 1998, 37, 4854. 10.1021/ie980348r. [DOI] [Google Scholar]

- Hill S.; P F. I. Channeling in packed columns. Chem. Eng. Sci. 1952, 1, 247–253. 10.1016/0009-2509(52)87017-4. [DOI] [Google Scholar]

- Gao Y.; Zhao M.; Wang J.; Zong C. Performance and gas breakthrough during CO2 immiscible flooding in ultra-low permeability reservoirs. Pet. Explor. Dev. 2014, 41, 88–95. 10.1016/s1876-3804(14)60010-0. [DOI] [Google Scholar]

- Duan X.; Hou J.; Zhao F.; Ma Y.; Zhang Z. Determination and controlling of gas channel in CO2 immiscible flooding. J. Energy Inst. 2016, 89, 12–20. 10.1016/j.joei.2015.01.014. [DOI] [Google Scholar]

- Xie K.; Lu X.; Pan H.; Han D.; Hu G.; Zhang J.; Zhang B.; Cao B. Analysis of dynamic imbibition effect of surfactant in microcracks of reservoir at high temperature and low permeability. SPE Prod. Oper. 2018, 33, 596. 10.2118/189970-pa. [DOI] [Google Scholar]

- Xie K.; Cao B.; Lu X.; Jiang W.; Zhang Y.; Li Q.; Song K.; Liu J.; Wang W.; Lv J.; Na R. Matching between the diameter of the aggregates of hydrophobically associating polymers and reservoir pore-throat size during polymer flooding in an offshore oilfield. J. Pet. Sci. Eng. 2019, 177, 558–569. 10.1016/j.petrol.2019.02.076. [DOI] [Google Scholar]

- Zhang K.; Jia N.; Zeng F.; Li S.; Liu L. A review of experimental methods for determining the Oil–Gas minimum miscibility pressures. J. Pet. Sci. Eng. 2019, 183, 106366. 10.1016/j.petrol.2019.106366. [DOI] [Google Scholar]

- Shokrollahi A.; Arabloo M.; Gharagheizi F.; Mohammadi A. H. Intelligent model for prediction of CO2–reservoir oil minimum miscibility pressure. Fuel 2013, 112, 375–384. 10.1016/j.fuel.2013.04.036. [DOI] [Google Scholar]

- Adekunle O.; Hoffman B. T. Experimental and analytical methods to determine minimum miscibility pressure (MMP) for Bakken formation crude oil. J. Pet. Sci. Eng. 2016, 146, 170–182. 10.1016/j.petrol.2016.04.013. [DOI] [Google Scholar]

- Shokir E. M. E. CO2-oil minimum miscibility pressure model for impure and pure CO2 streams. J. Pet. Sci. Eng. 2007, 58, 173–185. 10.1016/j.petrol.2006.12.001. [DOI] [Google Scholar]