Abstract

Analysis of food is essential for safety, quality control, government regulations, and recommendations to answer basic research questions. Capillary electrophoresis-mass spectrometry (CE-MS) is a powerful hyphenated technique in food, beverages, and foodomics for analytes ranging from small organic ions and biochemical compounds to macromolecules. Advantages of CE-MS for food analysis include high efficiency, high resolution, low cost of reagent consumption, fast and green approach in various food research areas. This review offers a comprehensive evaluation of CE-MS application for food analysis published in the open literature in the last decade (July 2010-October 2020). The principles of various CE-MS modes, CE-inductively coupled plasma mass spectrometry, ionization interfaces, and sample preparation methods for multiple types of liquid and solid food analysis are compiled. The latest advances and potential trends are outlined in several food analysis areas where CE-MS could be beneficial.

Keywords: Food Analysis and foodomics, Evolution of CE-MS, Modes of CE-MS, CE-ICP-MS, Interfaces, Solid-phase extraction, Liquid-liquid extraction, QuEChERS Liquid and solid food analysis, Stereoselective food

1. Introduction

Food analysis involves the development, application, and study of analytical methodologies used for characterizing the properties of food. The examination ensures that food contains the correct type and amount of essential ingredients, and its label declarations are right or to determine the levels of nutrients present [1]. The information mentioned above is critical to evaluate the properties of food and control the quality of the produced food that is safe, desirable, and nutritious.

The analysis of food and food components is performed by scientists in all significant sectors of the food industry. Therefore, this community includes food manufacturers, food ingredient suppliers, governmental laboratories, analytical service laboratories, and academic research laboratories. There are many reasons for the analysis of food samples. The first is to ensure food safety. For example, a food may be considered unsafe if it contains toxic chemicals (e.g., pesticides, herbicides, and toxic metals), dangerous bacteria or other microorganisms (e.g., salmonella), or objectionable material (e.g., glass, wool, or insect). The second reason is quality control. The food manufacturer’s goals are to increase its market share continuously. Manufacturers routinely performed quality control to make a profit so that the food products are safe and nutritious to their customers. On the other hand, the food purchaser expects the food properties to be very similar (if not better) from its previous purchase. However, the raw ingredients and the process conditions of food may vary from batch to batch, resulting in changes in the food product's properties in an uncontrolled fashion. To control the food processing, the manufacturer must understand the final properties of food through research and development to consistently produce quality food products. The third reason for food analysis is government regulations and recommendations. There are several regulating agencies such as the United States department of agriculture (USDA), the food and drug Administration (FDA), the Environmental Protection Agency (EPA), and the National Marine Fisheries Service (NMFS). All of the agencies mentioned above are responsible for ensuring that the industrial sector provides safe and nutritional food, allowing consumers to make wise choices about their diet. To eliminate economic fraud and ensure food authenticity, these agencies strive to publish documents containing detailed information and recommendations about food testing and food safety. Finally, many scientists working in universities, government-funded national laboratories, and large food organizations performed food analysis to answer basic research questions. For example, much research is directed towards foodomics. Understanding the structure and interactions of food ingredients through omics technologies to improve public health and knowledge is essential. Thus, in both fundamental and applied food research, new and improved analytical techniques are needed to characterize foods' overall properties and ensure the role each food ingredient plays in determining food properties. The properties include food storage, heating, freezing, and mixing.

Analytical techniques typically used in food analysis includes spectroscopic methods [ultraviolet-visible, fluorescence, nuclear magnetic resonance spectroscopy (NMR), atomic and molecular mass spectrometry (MS)], and separation methods [gas chromatography (GC), high-performance liquid chromatography (HPLC), supercritical fluid chromatography (SFC) and capillary electrophoresis (CE)]. Besides, electrochemical and hyphenated methods based on combining separation to spectroscopy or spectrometry techniques are standard.

Although MS plays a crucial role in food analysis, food matrices' complexity does not allow MS to be a standalone technique. In contrast, HPLC, GC, SFC, and CE, combined with MS detector, provide sensitive, selective, and repeatable methods for food analysis applications [2]. While GC-MS is specifically applicable to the analysis of volatile organic compounds in food and food products, SFC-MS helps analyze thermally unstable and nonvolatile food components that are difficult to analyze by GC-MS. On the other hand, the analysis of polar compounds is complicated by SFC-MS. The use of HPLC-MS ensures several advantages include, quicker and less extensive extraction procedures.

Moreover, HPLC-MS ability to identify and measure a broader range of polar, semipolar, and non-polar food compounds with a wide range of molecular sizes allows this technique to be superior to GC-MS or SFC-MS. Also, LC-MS/MS is most commonly used for proteomic analysis of complex food samples where peptide masses may overlap even using a high-resolution mass spectrometer. The electromigration technique such as CE-MS in its various operational mode is particularly suited for the rapid separation of ionic, weakly ionic, and highly polar compounds with very high resolution. The main advantages include minimum sample and reagent consumption, low cost, and fast analysis. With the decrease in organic solvent consumption, it is environmentally friendly. Although CE-UV detectors' low sensitivity is the main drawback, the sensitivity is improved with CE-MS coupling. Moreover, the sensitivity of CE-MS can be further enhanced using preconcentration techniques and high-resolution mass spectrometry. However, CE-MS is not as stable and robust as LC-MS or GC-MS platforms.

1.1. Identification of studies in capillary electrophoresis-mass spectrometry

First, four databases (PubMed, Science Direct, Sci-Finder, and Web of Science) were searched with the following keywords “capillary electrophoresis mass spectrometry food analysis," "foodomics," "food analysis" "liquid food," "solid food," add meat from July 2010-Oct 2020. The flow chart for the review paper selection process and compounds involved in the food products is shown in Fig.S1. We included only studies involving electromigration techniques such as capillary zone electrophoresis (CZE), micellar electrokinetic chromatography (MEKC), capillary electrochromatography (CEC), capillary isoelectric focusing (CIEF), chiral capillary electrophoresis (CCE) coupled to electrospray ionization mass spectrometry (ESI)-MS, matrix-assisted laser desorption ionization (MALDI)-MS and inductively coupled plasma (ICP)-MS. The review excluded approaches using only NMR, UV-Vis or (MS), sensors, and ELISA. Besides, papers such as CE-UV detection and CE with conductivity or fluorescence detection are not reviewed. We removed duplicate findings using endnotes.

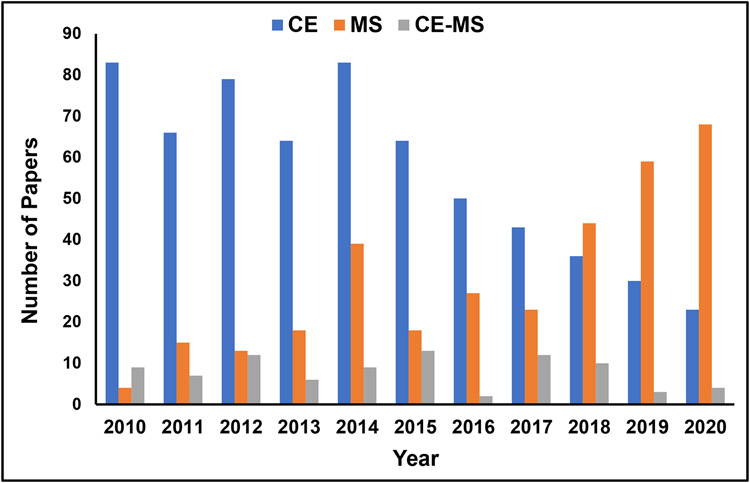

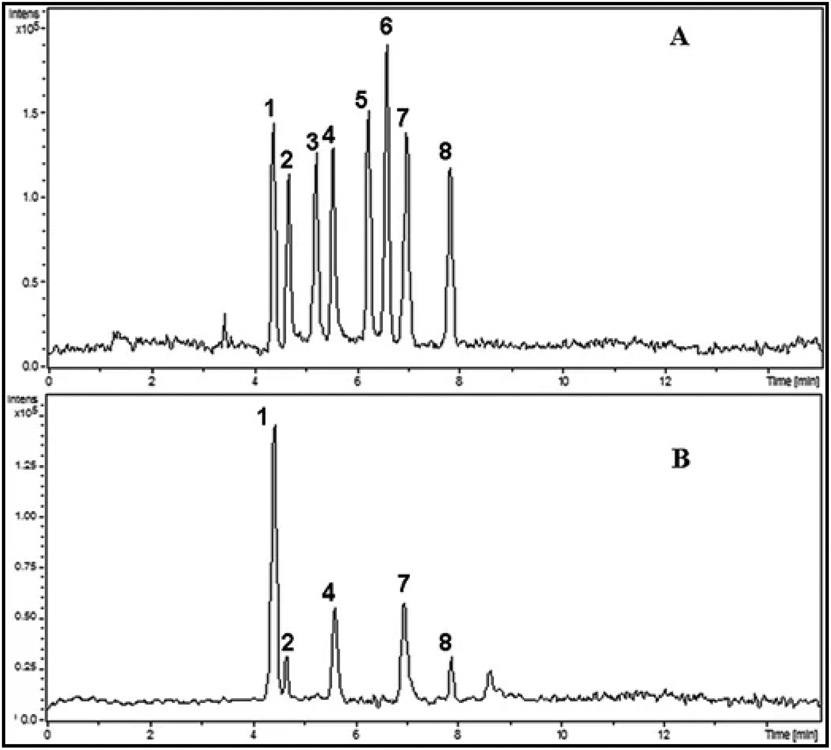

The two techniques, CE and MS, are fascinating areas for food analysis because, in an extensive range of applications, MS is employed than CE. The distribution of papers in CE-MS, MS, and CE represent 8.4% (87), 31.7% (328), and 59.9% (621), respectively (Fig.1). Interestingly, the bar plot comparison shows more papers published in the first seven years by CE than MS, whereas the reverse trend is seen in the last three years. Furthermore, a higher number of MS only papers than CE-MS is found for food analysis because MS is universal and started to be successfully employed earlier than CE-MS. Another reason could be that MS is widely applied in analytical chemistry (with or without separation). On the other hand, CE-MS is a relatively new technique introduced nearly 30 years ago [3]. This fact may account for the lack of well-defined food analysis studies related to CE-MS. In the future, as these coupled techniques become more widespread in food science, one may obtain a more well-defined comparison between CE and MS. As illustrated in Fig. S2, for a total of 87 publications found on CE-MS, 19 were associated with publication in Electrophoresis, 11 in Journal of Chromatography, 10 in Food Science, 6 in Analytica Chimica Acta, 5 in Talanta, and less than five in the various journals.

Fig. 1.

Bar plots showing trends of papers on CE, MS, and CE-MS in food analysis published in the last 10 years. Papers under CE only includes detectors such as UV, LIF, ECLD, indirect detection, and other miscellaneous detectors. Papers under CE-MS includes all CE modes coupled to ESI-MS, ESI-MS/MS, offline-MALDI-MS, and Chip-based CE-MS and DART-MS. Papers under MS only includes stand-alone ESI, APPI, APCI, and ICP-MS ionization methods with mass analyzers. On the other hand, GC-MS, LC-MS, CE-MS, PTR-MS, MALDI-TOF-MS, ambient mass spectrometry techniques such as direct analysis in real time (DART-MS) was excluded. All papers including review articles and publications before July 2010 are excluded.

This review evaluates electromigration techniques, sample preparation, and application developments regarding CE-MS for food analysis and foodomics. The articles published between July 2010 and October 2020 are reported, highlighting the critical milestones. First, the operation principles on using various electromigration techniques or CE modes coupled to MS include two standard interfaces (sheath and sheathless) and three different ion sources (ESI, MALDI, and ICP) presented. After providing an overview of the extraction methods, the various extraction methods for CE-MS are briefly discussed. The application and examples of the developed CE-MS methodologies in food analysis are correlated to food safety, food quality authenticity, bioactivity as well as food processing and storage conditions. To the best of our knowledge, no comprehensive review is conducted that integrates the papers published in the last ten years on CE-MS for food analysis in this journal.

2. Fundamentals of electromigration techniques coupled to mass spectrometry

This section will discuss the principles and mechanisms of CE-MS modes such as CZE-MS, MEKC-MS, CEC-MS, CIEF-MS, and CCE-MS used for food analysis. The basic operating principle of various electromigration techniques in CE involves applying an electric field to a submillimeter diameter capillary (such as an open tube) filled with buffer or any affinity reagent. Besides, the capillary can also be filled with micelles or a chiral reagent, packed with particles, or polymerized into a monolith. Therefore, depending on the solvent's nature or charge on the affinity reagent used to fill the capillary, an electroosmotic flow (EOF) is the bulk flow of either excess of positive or negative ions, is generated. The EOF can separate analytes based on the charge to mass ratio (z/m).

The papers published in the last decade on food analysis have utilized five capillary electromigration techniques coupled to MS. The modes include CZE-MS, MEKC-MS, CIEF-MS, CEC-MS, and CCE-MS. The benefits of on-line coupling of these techniques provide information-rich data, including highly efficient peaks in electropherogram and less noisy mass spectra. However, run times are typically longer in CE-MS than CE-UV as the commercial CE instruments required the use of capillaries with at least 50-55 cm length to reach the mass spectrometer. Besides electrospray ionization (ESI), there are reports for the on-line CE coupling to inductively coupled plasma mass spectrometry (ICP-MS) for food analysis [4].

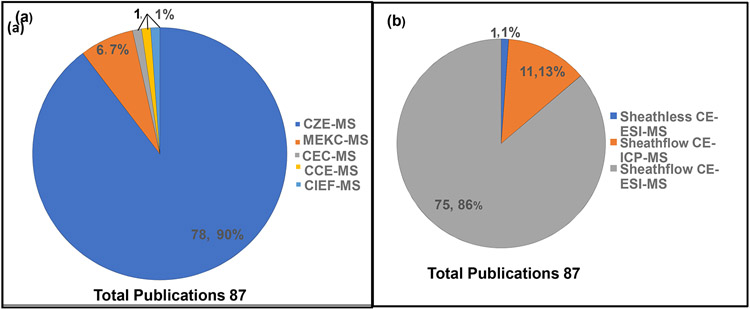

The pie charts showing the frequency of applying various types of electromigration techniques, interfaces, ionization sources, and mass analyzers are summarized in Fig.2 (a)-(d), respectively. The pie chart in Fig.2a indicates that the CZE is the preferred separation mode (~90%) coupled to MS in the last ten years for food analysis, while MEKC-MS (7%), CCE-MS, CIEF-MS and CEC-MS (1% each) are less commonly used. Fig.2b shows that most food analysis publications have used the sheath-flow interface using ESI (~86%) and ICP (13%) as ionization sources for CE, respectively, but only 1% for on-line sheathless CE-ESI-MS. This low percentage could be because the sheathless interface is recently commercialized, whereas the sheath flow interface was commercialized twenty years ago. The CE-MS in various modes utilizes the ESI (total ~76%) as the most commonly used ionization source, followed by ICP (12 %) and MALDI (2%) (Fig.2c). Therefore, electromigration techniques have predominantly used ESI only. However, there is only one publication where DART is reported as an ionization source [5]. To this date, most CE-MS food analysis studies have been performed by the time of flight (TOF) mass analyzers (Fig.2d) because it is a relatively low-cost alternative to CE-HRMS, such as orbitrap MS. Besides, TOF-MS provides high mass resolution and high mass accuracy. The latter advantage is more important for unknown peak identification, particularly in food adulteration. The pie chart in Fig.2d indicates that the frequency of mass analyzers used decreases in the following order: TOF-MS (30%) < single quad-MS (14%) < ion-trap MS (11%) < ion-trap (MS/MS) (10%) < triple quad (9%) < QTOF (8%) whereas the remaining miscellaneous mass analyzers (1-2%) are less commonly used. The fundamental principles of the separation mechanism of CZE, MEKC, CEC, CIEF, and CCE, when coupled to MS, are discussed in the following sub-sections.

Fig. 2.

Pie charts showing distribution of various (a) separation modes, (b) interfaces, (c) ionization sources, (d) mass analyzers in CE-MS.

2.1. Capillary zone electrophoresis-mass spectrometry

The technique of CZE-MS is based on the addition of a volatile buffer solution to prevent interference of salts in the ionization process. Charged analytes are separated based on their electrophoretic mobility, which is dependent on the strength of the electric field and the rate of analyte migration. This rate is directly related to the buffer's pH, as positively charged analytes have effective mobility towards the anode while negatively charged analytes have effective mobility towards the cathode. As shown in Fig. 3, under neutral to basic pH conditions, the high mobility cations with a small mass (or highest charge to mass ratio, z/m) will elute first, followed by low mobility cations with small z/m as they migrate in the same direction as EOF. It is worth noting that the neutrals cannot separate from each other in CZE-UV, but one could still detect peaks in the CZE-MS electropherogram. For example, neutral compounds will remain unionized in CZE buffer solution, but if they have an ionizable functional group in the gas phase, they could ionize in the electrospray. Thus, peaks will be eluted and reach the detector simultaneously, but one can differentiate them based on different m/z in the extract ion electropherogram (EIE). On the other hand, low mobility anions with small z/m will elute fourth, while high mobility anions elute slowest and the last in the migration order. Thus, the migration order of cations, neutral, and anions in CZE can be summarized as follows: small cations< large cations<all neutrals< large anions< small anions (Fig.3).

Fig. 3.

Schematic of solute migration in capillary zone electrophoresis (CZE)-MS under positive polarity. Note that the organic cations migrate fastest because they travel to the cathodic end (MS end), which is the same direction as the EOF travel. Neutrals travel at the same velocity as the EOF velocity and are not separated from one another. Organic anions migrate slowest because they are attracted to the positive end of the anode but are eventually pulled by the EOF toward the MS detector. The separation capillary is inserted through a stainless-steel needle and the sheath liquid and drying gas flows through the two outer tubes of the nebulizer and mixes with the CE effluent at the separation capillary tip to assist electrospray ionization (ESI).

For CZE with ultraviolet detection, nonvolatile buffers such as borate, phosphate are typically used. However, to be compatible with the ESI process, buffers used in CZE-ESI-MS must be volatile. Ammonium formate (NH4COOH)/formic acid (HCOOH), ammonium acetate (NH4CH3COO)/acetic acid (CH3COOH), ammonium hydroxide/-NH4CH3COO are commonly used buffers, which cover the total acidic, neutral, and basic pH range, respectively. One of the main drawbacks of using volatile buffers for CZE-MS is the separation is often not optimal, limiting the selectivity for separation of charged analytes. One reason is the low concentration of volatile buffer (electrolyte) used in CZE-MS, causing peak broadening due to mismatch of conductivity difference between the background buffer ions and the analytes present in food. The buffer with high ionic strength is avoided as the resulting high current limits MS detection use. Therefore, either the ionic buffer strength is adjusted, or a lower voltage is applied. Although the use of very high concentration (e.g., 1 M formic acid) and organic solvents in CZE-MS are reported to improve the separation and MS detection, the combined use of lower buffer ionic strength and high voltage often results in fast separations.

In addition to the use of uncoated capillaries, physically coated or covalently bonded capillaries are also used in CZE-MS. This use is common for analyzing basic proteins and positively charge small molecules in food products [6]. However, the positively charged compounds have a strong electrostatic affinity for the negatively charge silanol groups on the fused silica capillary wall leading to peak tailing and loss of separation efficiency. The use of coated capillary not only stabilizes the EOF, but the capillary lifetime can be extended when the capillary tip is exposed to the conventional co-axial CE-MS interface. Some of the coated capillaries used in food analysis are polyvinyl alcohol [7], hydroxypropyl cellulose [8], (N,N,N’,N’-tetraethyldiethylenetriamine [9], N-(2-hydroxypropyl) methacrylamide [9], polybrene [10], and polyethylene glycol [11].

2.2. Micellar electrokinetic chromatography-mass spectrometry (MEKC-MS)

Separation by micellar electrokinetic chromatography (MEKC) is carried out using buffers or electrolytes containing surfactant (e.g., sodium dodecyl sulfate, SDS), forming micelles at a concentration higher than the critical micelle concentration (CMC). When dispersed in buffer or electrolyte solution, these micelles are filled inside the fused silica capillaries; two distinct phases are formed, an aqueous (buffer) and a micelle forming pseudostationary phase. However, in MEKC-MS, the pseudophase is established using a volatile surfactant such as ammonium perfluorooctanoate (APFO) [12][13] or a polymeric surfactant such as polysodium undecenoyl leucine sulfate [14]. Because both electrophoretic and chromatographic principles are involved in MEKC, this CE mode extends the application to include both charged and neutral molecules. Thus, MEKC-MS has excellent potential for sensitive analysis of a wide range of small and large molecular weight compounds found in food samples.

Separation in MEKC is based on the analyte distribution between the pseudo phase, formed by the dispersed micelles and the buffer solution. This distribution is shown in Fig. S3. where equilibrium is established between the free and complex form of the APFO micelles with the neutral analyte. Under the electric field application, the negatively charged volatile micelles such as APFO migrates towards the anode (injector side). The neutral analyte is pulled towards the cathode (MS detector side) with the EOF. Because MEKC-MS is typically carried out under a basic volatile buffer solution, the net migration velocity of APFO micelle or the micelle's complexed form is towards the MS end. Therefore, in MEKC-MS, hydrophilic neutral analyte such as thiourea do not interact with the APFO micelle and travel at the EOF rate to elute at a dead time (to). In contrast, moderately hydrophobic neutral analyte interacts with the micelle eluting at time ta. On the other hand, hydrophobic neutral analyte interacts very strongly with the APFO micelle to elute at the micellar migration time (tmc) or sometimes remains undetected in MEKC-MS (Fig. S3., bottom electropherogram).

Ion-dipole and ion-ion intermolecular forces (IMFs) are responsible for the interaction of positively and negatively charged analytes with the APFO micelle, whereas hydrophobic and hydrogen bonding IMFs are present between the neutral analyte and the micelle. The elution order in MEKC-MS depends on these partitioning interactions of the analyte in and out of the APFO micelle. In basic buffer solution and substantial EOF, the hydrophilic cation is more strongly attracted to the buffer and will elute immediately after neutral, whereas hydrophobic cation will bind strongly with the negatively charged APFO micelle due to combined electrostatic and hydrophobic IMFs to elute last. On the other hand, both hydrophilic and hydrophobic anions are repelled by the negative charge head group of APFO but will elute before hydrophobic cationic analyte. Thus, the elution in the basic solution would follow the order: hydrophilic cation < neutral < hydrophilic anion < hydrophobic anion <hydrophobic cation. Conversely, acidic buffer solution will reverse the elution order under zero EOF and negative polarity.

The on-line hyphenation of MEKC–MS is often hampered by incorporating nonvolatile surfactant such as sodium dodecyl sulfate (SDS). This surfactant results in fouling of the ion source, causing loss of sensitivity and interference with analytes in the low molecular mass region [14]. One possible approach to solving poor ionization efficiency limitation involves using a volatile or semi-volatile surfactant, such as APFO [12][13], surfactant discussed above. Other possible approach includes the use of polymeric surfactant [14], anodically migrating micelles [15], a partial filling technique [16] and recent use of direct analysis in real-time mass spectrometry (DART-MS) [5].

The type of buffer and buffer pH is selected in MEKC-MS to generate sufficiently high EOF, allowing transport of cationic, anionic, and neutral analytes to separate and reach the detector's (MS end). However, simultaneous detection of cationic and anionic analytes are difficult because most of the commercially available on-line CE-MS instrument does not have the option of simultaneously ionizing and detecting both positive and negative ions in the ESI-MS. The APFO is the most widely used volatile surfactant reported for food analysis [12][13][17]. D’Orazio et al. [12] employed APFO to spike and separate estrogenic compounds in fifteen milk and yogurt samples. Specifically, using full-filling MEKC-MS/-MS and ion trap, the separation and identification of all the estrogenic compounds of interest were achieved without any ion-source contamination. Also, APFO is anionic, resulting in the analyte's electrophoretic mobility opposite the EOF. Typically, a basic operating pH (8.0 to 11.0) with a positive polarity is used with APFO. At this pH, there is electrophoretic mobility towards the cathode. However, the strong EOF pushes the analytes towards the anode (detector), whereas the APFO micelles may not reach the MS detection as their migration is opposite to the EOF.

2.3. Capillary electrochromatography-mass spectrometry (CEC-MS)

The CEC is a hybrid technique, which stems from two separation techniques, namely HPLC and CZE. Thus, a capillary column in CEC contains a true stationary phase (like HPLC). Instead of being pushed by the high-pressure pump, the mobile phase is forced through the capillary by the electric field, generating EOF on the fused silica capillary surface. The CEC offers the advantage of a two to three-fold higher plate number (N), a sub microliter flow rate when coupled to ESI-MS, and less consumption and disposal of toxic organic solvents compared to the use of HPLC [18]. In addition, CEC provides greater peak capacity and higher selectivity compared to CZE. However, simultaneous separation of anionic, and neutral compounds is more challenging in CEC compared to MEKC.

Furthermore, the repeatability of separation in CEC (in particular CEC-MS) is still questionable. Another hindrance is the lack of commercial CEC columns and dedicated CEC instrumentation. Both remain scarce.

Separation in CEC-UV or CEC-MS can be performed either in open-tubular, particle packed, or monolithic columns. The stationary phase is physically coated or covalently bonded to the capillary column's inner wall in the open-tubular column. In the packed, CEC-UV configuration, the silica particles are connected with organic ligands and are packed under high pressure with two frits in CEC. On the other hand, in packed column CEC-MS, one frit is needed on the inlet end, whereas the outlet end exposed to the ESI-MS end is tapered to prevent particles' movement and control the EOF [19]. Although the use of internal taper design for the CEC-MS column is promising, such particle-based columns have advantages of robustness, improved spray stability, and lower noise. The technique requires a skilled operator to make internal tapered columns. The third type of column is a monolithic column, also known as the continuous bed with continuous skeleton and microscale throughpores. The monolithic materials' most appealing aspect is their ease of preparation through in-situ polymerization processes, avoiding frit formation and column packing.

The two types of monolithic columns include polymer-based and silica-based monoliths. Polymeric monolithic columns are made via in-situ polymerization by copolymerizing organic monomers and crosslinker in the presence of porogens (organic solvents), chemicals, or photoinitiator. Silica-based monoliths are prepared by bonding silica or ODS particle together by sintering or by a sol-gel process, including hydrolysis and polycondensations of tetraalkoxysilanes. The monolithic CEC-MS is slowly attracting more and more attention. This slow progress is because of technical difficulties such as poor wetting of the monolithic column, bubble formation at the MS end, unstable EOF and irreproducible peak area, and retention time.

When designing the monolithic column for CEC-MS, three critical factors, namely, separation selectivity of analytes, the magnitude and direction of EOF, and the compatibility with the mobile phases, must be considered. To obtain successful separation on the monolithic CEC column, one of the monomers must contain ionizable functionality. For example, in situ polymerization of butyl methacrylate (BMA) monomer with EDMA as crosslinker generate very little EOF (e.g., 1.0 x 10-9 cm2 V−1 sec−1) because no ionizable moieties exist on the monolithic bed, on this type of monolithic columns. However, as shown in Fig. S4, the direction of EOF is from cathode to anode when positively charged monomer such as vinyl-benzyl trimethyl ammonium (VBTA) is added to a monolithic mixture of vinyl/alkene. In contrast, cathodic EOF is obtained when a negatively charged monomer such as acrylamido-2-methylpropane sulfonic acid (AMPs) is added to the polymerized monolith. Thus, the use of VBTA and AMPS monolithic columns provide fast separation of anions and cations, respectively. The flow rate of EOF (i.e., porosity) of a monolithic column is a critical factor because it drives the mobile phase and analytes and supports electrospray formation. A suitable flow rate of EOF for CEC-ESI is in the range of 50–300 nL/min. In addition to separation selectivity and EOF, the mobile phase's role is crucial for the successful operation of CEC-ESI-MS. A suitable mobile phase for monolithic CEC-MS should meet high electrochromatography selectivity requirements for the stationary phase. Also, sufficient porosity dictates driving the mobile phase through the stationary phase's macropores and mesopores. Moreover, the mobile phase should support a stable ESI and provide low contamination for MS detection. Like any CE-MS modes, the mobile phase in CEC-MS must contain volatile buffer additives such as formic acid/ammonium formate, acetic acid/ammonium acetate, ammonia, or short-chain volatile organic amines. Finally, a lower conductivity mobile phase could prevent joule heating and electrical arcing upon electric field application. Inorganic salts, nonvolatile surfactants, and other additives should be avoided or eliminated.

Although the number of papers reporting CEC-ESI-MS mode for food analysis published in the last decade is scarce, this mode has been applied to the food analysis in at least one publication [20]. Overall, both atmospheric pressure chemical ionization (APCI) and atmospheric pressure photoionization (APPI) are reliable ionization sources for the CEC-MS, which can be used for the potential application in food analysis.

2.4. Capillary Isoelectric focusing-mass spectrometry (CIEF-MS)

The technique of CIEF is a high-resolution technique for the separation of amphoteric molecules such as proteins and peptides containing ionizable acidic or basic groups. At a certain buffer pH, these amphoteric molecules become zwitterions. They are focused on the isoelectric point (pI) in coated capillaries filled with a mixture of ampholyte buffer, forming a pH gradient inside the capillary. Separations by CIEF is usually performed using dynamic or permanent coated capillaries containing a neutral and hydrophilic polymer to suppress EOF and prevent protein adsorption to the capillary wall [21]. A CIEF-MS system was reported to analyze milk whey protein of similar isoelectric points [22].

There is a significant effort to increase the power of CIEF by interfacing to MS to obtain structural information of the protein. However, there are several fundamental challenges associated with the coupling of CIEF with ESI-MS. First, the electrical continuity required for the electrophoretic separation has to be maintained. Second, the compatibility of nonvolatile anolyte or catholyte entering the MS detector constitutes another difficulty. Therefore, anolyte and catholyte solutions, which are classically composed of phosphoric acid and sodium hydroxide, respectively must be replaced by volatile acids or bases such as formic acid, acetic acid, and ammonia. Third, standard anticonvective gels diminished ionization efficiency resulting in unacceptable MS contamination. This issue has been recently resolved using MS-compatible glycerol [22], which reduces EOF and provides an adequate resolution of protein bands without the need for coated capillaries.

The CIEF was recently interfaced with MS using a flow-through microvial interface [23]. Two configurations were used in the CIEF-MS experiment. In the first configuration, a protocol involved a neutral coated capillary while the sample is dissolved in glycerol and sandwiched between anolyte and catholyte solution (also containing glycerol, Fig. S5A). The flow-through microvial connected to a syringe pump provided a smooth delivery of the sheath liquid (consisting of formic acid, methanol, and water). In the second configuration (Fig. S5B and S5C), the coated capillary was filled with the ampholytes–analyte mixture. The CE inlet vial contained 1% (v/v) acetic acid as anolyte, while the flow-through microvial filled by the alkaline 1.0 % (w/v) of ammonium hydroxide served as catholyte. The mobilization in the second configuration was accomplished using pressure on the inlet vial triggering the migration of formate ions in the direction of the positive electrode. This second approach allowed the protein bands to mobilize towards the MS providing a resolution of 0.02 pH units.

2.5. Chiral capillary electrophoresis-mass spectrometry (CCE-MS)

Chiral separation in the electromigration technique, based on the formation of two distinct diastereomeric complexes between the chiral selector (CS) and the two enantiomers. The fundamental basis of enantioseparation is the difference in free energy (δΔG) of the formation of two diastereomeric adducts, including both enthalpic and entropic parameters. Almost all electromigration techniques coupled to MS have been applied in chiral separations. However, MEKC-MS using polymeric surfactants [14] and electrokinetic chromatography (EKC)-MS using small molecular weight chiral selectors (vancomycin, crown ethers, and sulfated cyclodextrins) are two CE-MS techniques, which are used extensively [24]. Note that the use of polymeric surfactant in MEKC-MS is very convenient and provides good separation selectivity and sensitivity. Still, using the aforementioned low molecular weight chiral selectors in EKC-MS requires a partial filling of the capillary to avoid ion suppression.

A significant number of food components are chiral. Thus, the separation and analysis of chiral compounds in food is a topic of utmost importance. One excellent review is recently published in this journal, which provided an extensive overview of various separation techniques investigated for chiral analysis in food safety, food traceability, and bioactivity [25]. While HPLC and GC have been used for chiral analysis in food science, the use of electromigration techniques for food (e.g., analysis of amino acids in vinegar) by CCE-MS is reported in section 5.4 using chiral crown ether [26].

3. Interface Development and Ionization Sources

The interface for the coupling of CE to ESI-MS or ICP-MS instruments is located between the end of the CE column and the start of the ionization source (electrospray, inductively coupled plasma) of the mass spectrometer. A correct design interface must meet the following requirements: (a) provide good electrical contact at the outlet end of the capillary; (b) minimize laminar flow due to the suction effect of the nebulizer, (c) compensate for the flow rate incompatibility between the EOF generated inside the capillary and uptake flow of the nebulizer to prevent suction resulting in a laminar flow; (e) achieving high transport efficiency of the analyte transfer to the electrospray or plasma source. The coupling of CE to ESI-MS or ICP-MS continues to be in the developmental stage. The user must understand the operational parameters of new emerging interfaces to maximize operation sensitivity. In this section, the two commercially available sheath flow and sheathless interface for ESI, as well as one for ICP-MS, are described. Also, the use of offline-MALDI interface used in food analysis is discussed. It should be noted that there are many reported interfaces for each ionization source, but only the interfaces that have been used for application in food analysis are detailed below.

3.1. Sheath flow ESI-ionization interface

The electrospray ionization (ESI) is the most widely used ionization source for on-line CE-MS coupling in food analysis because of the ease of its ability to carry out ionization for many molecules ranging from small metabolites to intact proteins. As mentioned earlier, the sheath flow and sheathless are the two commercially available interfaced used for CE-ESI-MS with sheath flow interface (Fig.S6 A-B) being used in most publications food analysis.

The co-axial sheath liquid flow interface is the most common design used for pairing CE to MS detection. Smith et al. [27] were the first to propose the co-axial delivery of a solvent (aka. sheath liquid) to the end of the CE separation capillary as an outlet electrolyte reservoir. Following the aforementioned proposed design, a triple tube sprayer (aka. nebulizer) was commercialized by Hewlett-Packard (currently known as Agilent Technologies) in 1995. As shown in Fig. S6 A, the separation capillary "c" is surrounded by the sheath liquid, which in turn is surrounded by the nebulizer gas (nitrogen). Fig. S6 B shows the actual sprayer. The ribbed ring in the middle of the sprayer could be rotated to allow the axial direction's capillary adjustment. Because the EOF rate in CE typically varies from 1-100 nL per minute, a sheath liquid consisting of an alcohol-water mixture with volatile acids or bases is added to enhance the droplet formation at the capillary tip (labeled as c with an arrow in Fig. S6 B). The sheath liquid is added typically at a flow rate of 1-10 μL/min from port b of the actual sprayer using a pneumatic HPLC pump, promoting spray formation and completing the electrical circuit. Note that the sprayer needle protruding the sprayer body in Fig.S6 B is grounded, which means a CE and ESI current return path. Moreover, the voltage is applied to the inlet side of the ESI capillary. The application of this interface is compatible with APCI [28] as well as APPI [29], as reported in several publications [30][31]. The limit of detection (LOD) reported with sheath flow interface is at least 1 μM (without preconcentration), but this may change as the recent advances in jet stream ionization technology in MS have shown improved LOD.

While the co-axial sheath liquid interface with sheath liquid flow rates of 3 to 10 μL/min is still the commonly used interface for robust and high throughput analyses, it has three significant limitations. First, a substantial dilution of the CE effluent leads to low ionization efficiency resulting in lower sensitivity. The combined EOF and sheath liquid flow is higher in flow rates than nanoflow HPLC, and thus sensitivity is lower than nano ESI. Second, the nebulizer's suction often creates band broadening, especially when wider i.d. capillaries (75 and 100 μm) are used and decrease in electrophoretic resolution of the separated peaks. Third, suppose there is no common ion present in the BGE and the sheath liquid. In that case, it may result in the co- or counterions from the sheath liquid entering the separation capillary, causing depletion of separation buffer even during the electrophoretic run. Consequently, this results in changes in migration time and peak area. New development aims for the improvement of sensitivity using a sheathless CE-MS interface. However, only in the recent past sheathless interface has been reported in food analysis [32].

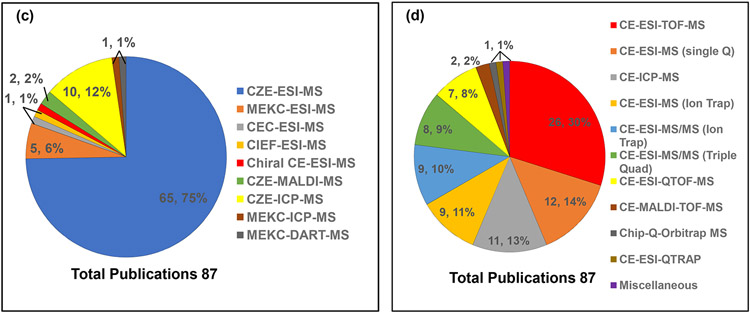

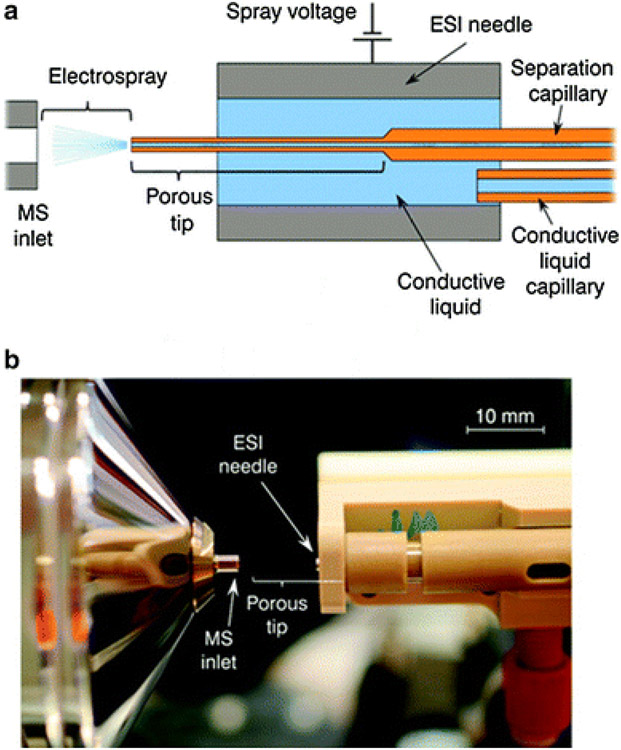

3.2. Sheathless ESI-ionization interface

Sheathless ESI-ionization interfaces allow for 10-100 folds enhanced sensitivity, low cost, and a relatively simple set-up because the separation buffer is the only liquid involved, and no dilution occurs. However, maintaining a proper and long term stable electrical contact is challenging. Moini showed a simple way to fabricate a sheathless interface by etching the capillary separation end with hydrofluoric acid making the fused silica capillary porous [33]. This porous section serves as the transport of small ions and electrons in and out of the capillary. As shown in the schematic in Fig. 4a, the capillary is inserted in a stainless steel ESI needle. A conductive liquid is delivered coaxially to the outside of the porous end, making the hydraulic electric contact between the needle and the separation capillary. This concept was implanted by Beckman Coulter in 2010 [34] but was commercialized later by Sciex Separations under the trade name of CESI-8000. In this set-up (Fig. 4b), the ESI voltage is applied to the sprayer or the MS inlet. The capillary is grounded via the conductive liquid placed in the outlet CE vial, whereas the current monitor maintains the ESI voltage.

Fig. 4.

The porous tip sheathless interface a schematic and b photograph of the prototype interface. Reproduced from [34] with permission from the American Chemical Society, copyright 2011.

One of the main limitations of porous tip design is the restriction in the availability of only 30 μm, i.d., capillary, which prevents the injection of a large sample amount. Another drawback is that only the separation capillaries with porous tips assembled with proper adapters manufactured by Sciex CESI 8000 can be used with a mass spectrometer. Furthermore, the porous tip capillaries' longevity is limited to only 200 injections. The replacement capillary can only be obtained by the manufacturer, which may increase the overall cost of analysis in food applications. Furthermore, researchers' flexibility to tune separation under different CE-MS conditions and modes is difficult as this interface can only operate under relatively low CE currents (below 10 μA). Therefore, one should carefully consider the composition and concentration of the BGE to optimize separation selectivity.

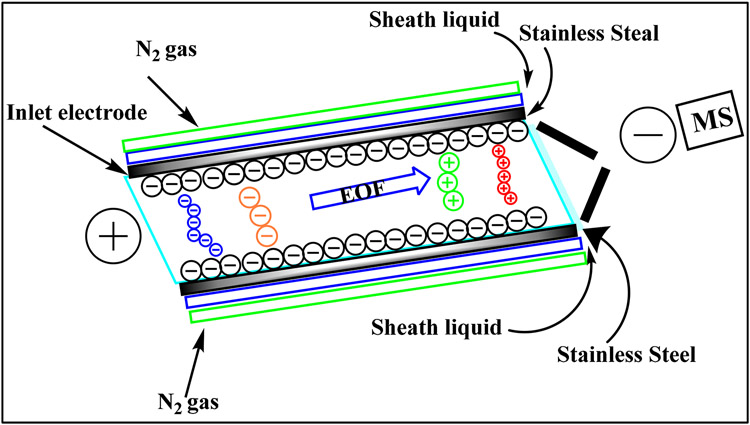

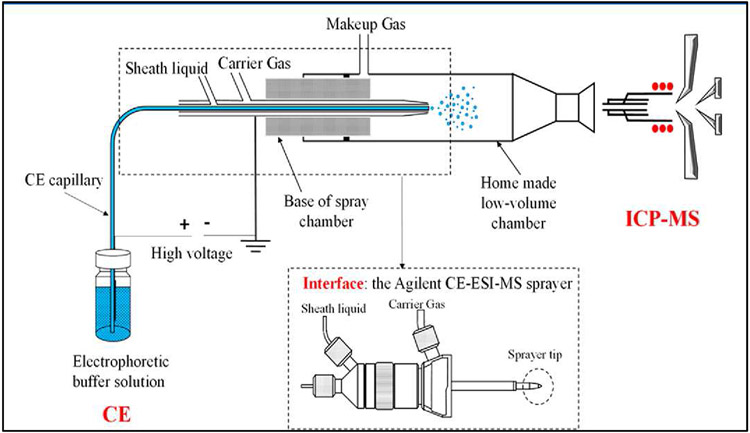

3.3. Inductively coupled plasma interface

Capillary electrophoresis interfaced with inductively coupled plasma (ICP) mass spectrometry is a powerful trace elemental analysis technique. Successful coupling of CE with ICP-MS requires maintaining a steady electrical contact at the end of the CE capillary, matching uL/min CE eluate capillary flow rate with the mL/min uptake rate of the ICP-MS, and efficient introduction of analytes from CE capillary to the plasma. To date, three types of interfaces reported in the literature are sheath-flow interface, sheathless interface, and hybrid generation interface [35]. Amongst the three types of interfaces, the sheath-flow interface is used more frequently by many researchers. Sheath liquid serves two purposes: completing the CE's electrical circuit and compensating for CE's low flow rate. Furthermore, the mixing of sheath liquid mixing could cause analyte dilution resulting in some loss of sensitivity. Some of the CE nebulizers developed for ICP-MS are concentric, cross flow, MCN-100, and ultrasonic nebulizers [36].

A typical CE-ICP-MS sheath-flow interface set up is shown in Fig. 5. This interface is the same design as the Agilent CE-ESI-MS sprayer (G1607A, Agilent Technologies, USA) used to couple CE with ICP-MS, serving as a nebulizer for the ICP-MS. The triple tube nebulizer is directly inserted into a homemade low volume chamber. The CE capillary is inserted through the sprayer's inner stainless-steel needle, and the outlet end of the CE capillary is protruded 0.1 mm beyond the sprayer tip. Sheath flow liquid is added through the sprayer's upper port (using a quaternary HPLC pump equipped with a 1:100 flow splitter), which then passes through the gap between the CE capillary and the inner stainless steel capillary and sprays together with the effluent emerging from the CE capillary. The carrier gas added through the sprayer's outermost tube for nebulization is mixed with make-up argon gas in a low-volume spray chamber and transported into the ICP torch operated at atmospheric pressure. The stainless-steel needle of the nebulizer was grounded to maintain a steady separation voltage. Within the spray chamber, larger droplets from aerosol are separated and removed. The standard spray chamber design can also cause additional dilution/loss of analytes affecting the amount of analyte transported to plasma. For these reasons, there is still much room for improvement in spray chamber designs and CE-ICP-MS interfaces. The ICP torch is typically a quartz torch in which an electromagnetic field[4][35][36] with a power of 600-1800 W is generated by high power radio frequency that ignites the argon gas (seeded with free electrons from discharge coil) producing high-temperature plasma (5000-10000 K). The analytes entering the plasma flame are ionized by collision with electrons and charged ions in the flame, then transferred to the mass analyzer.

Fig. 5.

Schematic diagram of the interface for coupling capillary electrophoresis (CE) with inductively coupled plasma–mass spectrometry (ICP-MS). Reproduced from [35] with permission from the American Chemical Society, copyright 2014.

3.4. Off-line CE-MALDI-MS interface

The coupling of CE with MALDI-MS has many advantages over CE-ESI-MS. First, it offers better tolerance to salts, enabling more selection of BGE and more comfortable adaptation of other CE separation modes. Second, the number of spectra acquired on the sample spot is not limited by the MS data acquisition rate or the time of the elution peak. Therefore, MS/MS identification from full scan MS can be easily performed for masses of interest. However, the most challenging problem for off-line CE-MALDI-MS coupling is maintaining an electrical connection of the CE effluent at the capillary terminal. An additional challenge is to minimize the decrease in sensitivity during the collection of CE effluent without disturbing the separation process and peak resolution.

The off-line hyphenation of CE with MALDI-MS enables additional sample treatment, including enrichment steps or enzymatic digestion. For food analysis, the Girault group introduced a silver-coated capillary outlet for iontophoretic sample deposition on the MALDI plate (Fig. S7) [8][37][38]. The CE effluent exiting the capillary is dipped on the MALDI target containing microliter droplets. The current breakdown typically encountered in the sheathless system is avoided using neutral coating with zero EOF. The capillary ends are lifted in and out of the MALDI droplet at 15 sec per step without compromising peak efficiency, as verified by the UV detector output.

4. Sample preparation in Food Analysis

Food products consist of a wide variety of components. For example, proteins, peptides, amino acids, fats, carbohydrates, vitamins, nucleotides, small metabolites, organic compounds, and minerals. Sample preparation is essential for analyzing samples containing complex food matrices (e.g., species identification in matrices composed of a blend of two or more species). Furthermore, food samples from different sources (solid and liquid) contain complex matrices that can interfere and compromise the sensitivity. The analysis of a specific compound in the food matrix requires homogenization, centrifugation, and interferences as the essential steps before extraction and preconcentration. These steps mentioned above should be environmentally safe, non-toxic, rapid, and automated, but high sensitivity, robustness, and cost-effectiveness are highly desirable in many cases. It isn't easy to meet all of the criteria mentioned above. However, in this section, some of the key extraction techniques reported for solid and liquid food analysis before injection in CE-MS is described. This includes, solid-phase extraction (SPE), solid-liquid extraction (SLE), liquid-liquid extraction (LLE), and QuEChERS. Other methods such as enzyme-assisted protein extraction (EPE) [39], enzyme-assisted water-phase extraction (EWME) [40], supercritical fluid extraction (SFE) [41], microwave-assisted extraction (ME) [42], ultrasound-assisted extraction (UE) [17][43], dispersive liquid-liquid microextraction (DLLME) [12][44], as well as other variants of conventional extraction techniques [8][17][41][45-49], have been reported to extract major components from food samples. Thus, only the principles behind the most commonly used sample preparation techniques for analysis for solid and liquid food samples are described in the following sub-sections. For more detailed information about the theory and applications, some excellent review articles on SPE [50], LLE [51], and QuEChERS [52] are recommended.

4.1. Solid-phase extraction (SPE)

Solid-phase extraction (SPE) is a preparative method used for selective extraction, purification, and preconcentration of analytes of interest in a wide variety of matrices from liquid to solid samples. The solid-phase extraction method is widely used in CE-MS to analyze different compounds in numerous food matrixes. The technique of SPE can either be performed off-line or on-line. Off-line SPE is carried out in cartridges/columns with a bed containing stationary phase (sorbents or cartridge) materials placed on a vacuum manifold (Fig.S8) [53]. The necessary procedure involves conditioning the cartridge with appropriate solvents, loading the sample, retaining the target analyte, washing/purifying, and finally eluting the retained analyte with a suitable strong solvent. Stationary phase materials with versatile chemistries (reversed phase, normal phase, mixed-mode, and ion-exchange) and various sorbents offer a wide range of selectivity. The SPE for food analysis improves detection, sample recovery, and quantitation accuracy and minimizes the source contamination. This improvement of SPE is because the food structure represents a complicated matrix and can be formed into different physical stages, such as concrete, viscous or liquid. Therefore, SPE steps particularly have a vital role in the determination of specific compounds in food.

4.1.1. On-line SPE

As mentioned above, SPE is customarily carried out in the off-line mode. However, several on-line attempts are reported for the CE-MS determination in food applications [54][55]. The schematic of an on-line SPE method using three different approaches is shown in Fig. S9 (a-c) [56]. In the first approach (Fig. S9a), a Teflon sleeve connects a 10 cm, latex-coated capillary (25 μm i.d., acting as a preconcentrator) to an open tubular separation capillary (75 μm i.d.,). In the second approach, small pack beds or sorbents are connected between the two pieces of open capillaries (Fig. S9b). While the use packed bed proved useful and provided higher retention and column capacity than the first approach, frits are needed to hold the packed bed in place, resulting in backpressure and irrepeatable EOF. The third on-line SPE approach (Fig. S9c) has used disks or membranes loaded with a solid sorbent. The impregnated membrane is placed in a Teflon sleeve center, which holds the two fused-silica capillaries. Care has to be taken to prevent membrane compression or any damage to the Teflon tubing wall as this may block the cartridge and decrease the liquid flow. The advantage of this fritless approach includes low pressure and higher flow rate (due to the use of smaller bed) and smaller elution volume. The potential of this on-line SPE procedure for the analysis of antibiotics [57] and alkaloids [55] is demonstrated in several CE-MS publications.

4.1.2. Off-line SPE

The application of off-line SPE to analyze versatile compounds in numerous food samples is discussed in section 5. The availability of various packings for SPE makes this technique one of the best selections for specific sample preparation needs. A brief description of different off-line SPE methods is given in the following sections, with some relevant applications in which they are used in combination with CE- MS.

The SPE columns for pesticide analysis in fresh fruits are necessary due to the diluted contaminants in the complex fruit matrix. Garcia et al. [58] have practiced SPE of pesticides by pressurized liquid extraction (PLE) using hot water at 60 °C, and 1500 psi, followed by a SPE clean-up using a mixed-mode (strong cation exchange-reversed phase) cartridges to determine seven pesticides spiked in Mediterranean summer fruits before CZE-MS analysis. At the least, 40% of watermelon, 25% of melon, 44.4% of peaches, and 33.3% of apricots presented higher minimum requirement levels.

Tong et al. [59] used C-18 SPE steps to determine one microcystin (MC-LR) peptide after removing the extra water from the crude algae sample. Based on the mass scan spectrum, MC-LR in crude algae in lake water samples was confirmed. According to Catala-Clariana et al. [60], milk-derived functional foods are precursors of many different bioactive peptides that may remain latent until being released by enzymatic proteolysis during gastrointestinal digestion or food processing. Milk emulsions were diluted with a citrate buffer containing dithiothreitol and urea followed by a comparison of different reversed-phase commercial C18 and C8 silica(50 mg of sorbent) and polymer-based (30 mg and 10 mg sorbent) Strata X and hydrophobic-lipophilic balance (HLB) SPE columns. The octadecylsilyl (C18) and StrataX cartridges could provide the best clean-up results for infant formula analysis, while HLB cartridges were specific for extraction of 13, 8, and 6 peptides of IF1, IF2, and IF3, respectively. Better extraction with C18 than with the C8 cartridges suggested that retention was mainly based on hydrophobic interactions. The polymeric sorbents, i.e., HLB and Strata-X, showed good HLB, but the average results obtained with HLB suggested that StrataX were more hydrophobic than HLB. Although the combined use of C18 and StrataX cartridges provided excellent coverage of the IF's low molecular mass peptides, the use of all three SPE columns was recommended for comprehensive coverage. In another communication [61], the same research group reported an identical SPE protocol to identify a total of three (788, 1007, and 868) low molecular mass peptides with C18 cartridges in IF1, IF2, and IF3, respectively, and another three (311, 1328, and 1959) peptides with StrataX cartridges by CZE-MS.

Two main classes of antibiotics, such as quinolones (QN) in milk [57] and aminoglycosides (AGS) in honey [62] was performed using on-line and off-line SPE procedures, respectively. Gonzalez et al. [57] evaluated molecularly imprinted polymers (MIP) as a sorbent for constructing an on-line SPE. One of the significant advantages of the MIP is that they allow the introduction of high volumes of milk sample. Using MIPs is very specific compared to the partitioning process carried out when other sorbents are used. The authors found that the retention of the QNs at high flow rates was not complete, and the use of a high injection pressure could lead to erroneous or irreproducible results. Nevertheless, the method was selective and allowed sensitive multi-residue determination of QNs antibiotics of veterinary use in milk. In the subsequent study [57], the MIPs was also used for the off-line SPE extraction of nine AGs from a complex matrix such as honey, providing a higher selectivity and a lower sample manipulation. The use of MIP was shown to be a powerful extraction tool in a simple sample clean-up step.

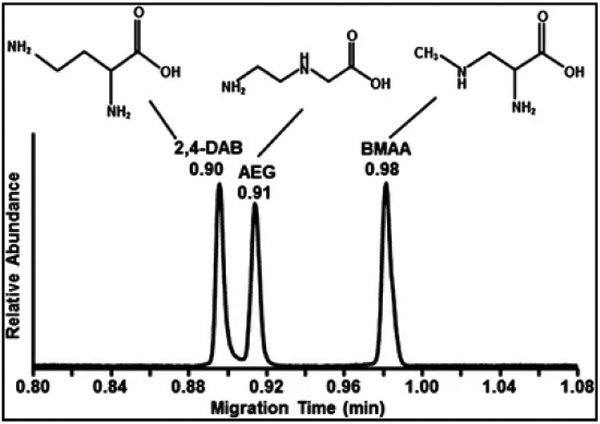

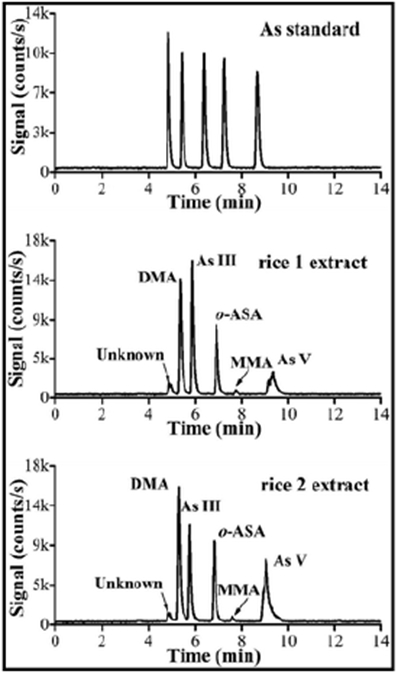

Two types of toxins, paralytic shellfish toxin (PST) [63] and neurotoxin [64], in seafood (muscles and lobster) are reported. In the first study [63], even when using a reversed-phase C-18 cartridge, the CZE with conductivity and MS method suffered from significant interferences from the shellfish matrix. On the other hand, MEKC with fluorescence detection was successfully used for PST screening of a mussel sample. The study demonstrated the superiority of MEKC with fluorescence detection for the screening of PSTs in shellfish samples. In the second study [64], using a mixed-mode cation exchange SPE column, lower conductivity of the extract allowed field amplified stacking in CE-MS. This stacking causes the final step of the clean-up after SPE involved redissolution in a low conductivity solvent such as methanol without deteriorating neurotoxin's peak shapes β-N-methylamino-L-alanine (BMAA) and its isomers.

Melamine (MEL), 2,4,6-triamino-1,3,5-triazine is an emerging contaminant, illegally added to dairy products such as milk, infant formula, and pet food to increase nitrogen content, artificially boosting the protein level [65]. Commercially synthesized MEL can contain structural by-products, such as ammeline (AMLN), ammelide (AMLD), and cyanuric acid (CYA). Two SPE columns were compared in spiked blank powdered milk and contaminated powdered milk. The mixed-mode cation exchange column allowed the extraction of MEL and AMLN, but not AMLD and CYA. A new SPE Strata column was also tested with a protocol developed by the manufacturer. Still, peak shapes obtained for MEL and AMLN were not satisfactory, while AMLD and CYA could not be detected at a concentration lower than ten ppm.

Endocrine-disrupting compounds (EDCs) are chemicals or mixtures of chemicals that interfere with how the hormones in the human work. Some EDCs such as chlorophenols, alkylphenols, bisphenol-A (BPA), 4-tertbutyl-phenol (t-BP), and 4-tertbutyl benzoic acid (t-BBA), could enter food at several stages of food production and via the plastic packaging material. The combined use of restricted access material (RAMs) and polymeric SPE column was reported for the extraction, preconcentration, and efficient removal of sugar from honey. Thus, allowing the preconcentration of a greater SPE column volume for analysis of several EDCs in honey [66].

The β-carboline alkaloids (HAlks), a family of compounds with antidepressant effects, are found at trace levels (<25 mg kg−1 algae) in the edible invasive algae Undaria pinnatifida, aka. wakame. Tascon and coworkers' studies for on-line SPE found that peak areas, hence SPE efficiency using the C18 sorbent, were shallow for harmaline, which was the most polar of the three alkaloids [55]. The authors concluded that on-line SPE-CE-MS using C-18 cartridges is a powerful method to detect and quantify trace levels of alkaloids in complex plant extracts, with potential application in quality control, food safety, and foodomics.

Human milk oligosaccharides (HMOs) and galactooligosaccharides (GOS), have a profound influence on the development of the neonatal gastrointestinal system. For example, these oligosaccharides affect how microbial colonization occurs in the intestine, which influences the intestinal absorption and metabolism of food components. Furthermore, the immune system act as receptor analogs for pathogenic bacteria, preventing constipation [67]. However, very little is known about oligosaccharides' fate in the breast- and formula-fed babies' colon. The oligosaccharides from feces were extracted after centrifugation, filtration, and inactivation of the fecal enzymes. The carbohydrates from fecal extracts were cleaned by SPE using a graphitized carbon column cartridge. The cartridge was first washed with 80/20 acetonitrile/water containing 0.1 % TFA to remove monomers and lactose by eluting 2% acetonitrile solution. In contrast, the remaining carbohydrate was eluted with 40 % ACN/60% water, 0.05% TFA, followed by drying the sample residue and redissolving in water for analysis by CE-MS [68].

The determination of organotin compounds at trace level in plastic food packaging materials is needed for food safety. Because of the complexity of organotin and sample treatment procedures, analysis is quite challenging. In a recent report [32], the extracts of four organotin compounds from food packaging samples were cleaned using ultrasonic extraction, and then preconcentration was performed using C18 SPE cartridges. Satisfactory recoveries (80.27–101.56%) for all four organotins were obtained at three different concentration levels with %RSDs in the range of 2.56–7.89 (n = 3). The authors found no significant matrix effect for the determination of the organotin residues in food packaging materials.

4.2. QuEChERS

QuEChERS, a type of SPE technique that stands for Quick, Easy, Cheap, Effective, Rugged, and Safe, is a specialized modern extraction technique for liquid samples or solid dissolved in water. Lehotay and Anastassiades first designed this method in 2003 to analyze pesticides in fruits and vegetables in 2003 [69]. Overall, QuEChERS is typically carried out in two main steps. First, the sample is added to a mixture of water and acetonitrile followed by extraction with salts (e.g., MgSO4, NaCl, sodium citrate, and NaCOOCH3) by vigorous shaking and centrifugation. The salts' addition results in phase separation between water and acetonitrile, and hydrophobic analytes are extracted in the organic layer. In the second step, the sample clean-up is accomplished with dispersive solid-phase extraction. In some cases, the organic layer is treated with sorbent materials (e.g., silica, primary-secondary amine, C-18, etc.) for cleaning up the residual matrix. Fig.S10 outlines the difference in recipes for QuEChERS in the Association of Analytical Chemistry (AOAC) and the European official methods (EOM) [70].

The QuEChERS method has many advantages over traditionally used extraction techniques. Some of the benefit of QuEChERS includes accurate analytical results and high extraction recoveries, saves time and labor, reduces the cost of waste disposal due to decrease in hazardous solvent consumption, requires a lower supply of laboratory glassware with a decreasing number of sample preparation steps. Rajczak et al. recently reviewed QuEChERS for food applications [52].

Although the QuEChERS method's popularity has skyrocketed in recent years for analysis of samples by LC-MS and GC-MS, there are few reports for its application in CE-MS analysis of food. For example, QuEChERS has been used as a sample preparation method for trace analysis in food samples by CE-MS [7][54][71][72]. Concerning salts' use to induce phase separation, MgSO4 and NaCl were tested in most applications where QuEChERS was used for CE-MS. However, ammonium formate as buffering salts (in place of sodium citrate) to improve polar compounds' recoveries has been reported only on one occasion [72]. The reported examples of QuEChERS are pesticides in sugarcane juice and tomato [54], pesticides in corn [7], benzimidazole in eggs [72], EDC in honey [73]. As mentioned earlier, all of the food samples have used AAOC to analyze isoflavones in soy biscuit [71], which have followed the EOM recipe.

4.3. Solid-liquid extraction (SLE)

Solid-liquid extraction (SLE) is a sample preparation method used to extract analytes of interest from solid samples. Typically, solid pieces are mixed in a suitable solvent using vortex, ultrasonication, or centrifugation to dissolve analytes into the solvent, which is further purified or filtered. A schematic model of SLE features a straightforward extraction process in which the solute (i.e., a compound of interest) is separated from a mixture of solids by dissolving it in a suitable solvent (Fig. S11). There are three constituents in SLE extraction. These constituents are composed of a solute, insoluble solids, and solvent. In the first step, a sample is dried and ground into a powder to increase its surface area, enhancing its extraction rate. In the next step after extraction, the soluble compounds are separated from the solids by filtration. Selection of a suitable solvent for use in extraction is mandatory. Various factors such as solvent polarity, the particle size, and solid-to-liquid ratio can affect the extraction efficiency. Also, extraction conditions such as time, temperature, and mechanic agitation need to be carefully considered.

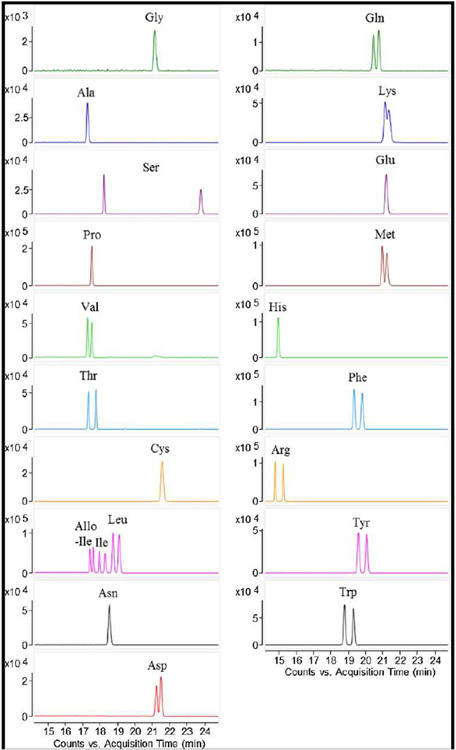

In CE-MS of food analysis, SLE is the most widely used technique for extracting polar analytes in solid food materials using polar solvents. Typical SLE solvents used for food samples are water, methanol, ethanol, acetonitrile, acetone, dichloromethane, and dimethyl sulfoxide as pure solvents as well as the combination of two or more solvents. Food materials from various sources and types require processing/grinding into a fine powder before performing SLE. Application of SLE in CE-MS analysis of variety of food materials is demonstrated in the following publications: metabolites in edamame [74]; soybean [75]; avocado [76]; rat’s liver [77]; lettuce [11]; fish [78]; grounded coffee [79]; ham, [80]; and mice liver tissues [81]. Besides, SLE is also reported for fatty acids in cheese/freeze-dried coffee [82] and tea leaves [83]; Cr in yeast tablet [84]; Ziram and Zineb in cabbage [43], saxitoxin in fish [85]; peptides in soybean and nutraceutical tablets [86][87]; sudan dyes in chili products [88][89]; furosine in grains [90]; melamine in milk powder [20]; amino acids in royal jelly products[91]; caffeine in Chinese white tea leaves [5]; 5-OH-methyl-furfural in food products (cereals, barley, coffee) [92]; allergens in milk [38]; lysozyme in cheese [93]; nucleotides in baby foods [94]; alkaloids in algae [95]; thiamine and thiamine phosphate in meat [96].

4.4. Liquid-liquid extraction (LLE)

Liquid-liquid extraction is the second most widely used method for retrieving analytes from aqueous food samples by CE-MS. The LLE is based on the principle that a solute or an analyte is a partition in a particular proportion between two immiscible solvents. The solvents are typical, aqueous (water), and non-aqueous (organic). A mixture of aqueous/organic solvent is used for extracting the analyte of interest from interfering compounds. For CE-MS analysis, a small volume of the aqueous sample containing analytes is mixed with water-immiscible solvents in a centrifuge tube, mostly by vortex or sonication to allow analyte transfer from aqueous to the organic phase. Examples of typical organic solvents used in LLE of food samples are acetonitrile, methanol, ethanol, chloroform, etc. The LLE method's main advantages are the easy availability of solvents and the use of cost-effective apparatus. However, low sample recoveries, limited selectivity, and labor-intensive protocols have limited the use of LLE. Examples of the use of LLE in CE-MS of food samples are analysis of metabolites in seaweed [97]; rat plasma [98]; soybean [99]; milk [100]; mice plasma [101]; isoflavones in soy drink [102]; biogenic amines in beer/wine [103]; phenolic compounds in almond [104]; amino acids in oils [105]; betaines in oils [106]; EDCs in honey [73]. Three of the microscale variants of LLE used to extract liquid food samples are dispersive liquid-liquid microextraction (DLLME), vortex-assisted surfactant enhanced emulsification liquid-liquid microextraction (VSLLME), and freeze-out LLE, which are described briefly in the following sections.

4.3.1. DLLME

This type is a miniaturized version of the LLE technique that utilizes a ternary solvent system: aqueous sample, dispersion solvent (soluble in aqueous and extractor solvents), and extractor solvent (immiscible with water). This extraction technique is carried out by injecting a mixture of dispersion solvent (e.g., ACN) and extractor solvent (e.g., CHCl3) into a centrifuge tube containing liquid samples (in water) or solid samples (first extracted in aqueous solvent). The mixture is then shaken vigorously until droplets are formed and centrifuged. The sedimented droplets containing the analyte is dried, reconstituted in a suitable solvent, and finally injected into the CE-MS system. In DLLME, partitioning of analytes into the extraction phase happens immediately due to the droplets' very high collective surface area. As a result, high enrichment factors are obtained. Another benefit of DLLME is low solvent consumption relative to other liquid extraction methods. Dairy food products present a complex sample matrix, and the removal of interfering components from this matrix is challenging. Examples of DLLME applications are pointed out in CE-MS analysis of estrogenic compounds in milk/yogurt [12] and benzimidazole in meat [44].

4.3.2. VASLLME

This mini-extraction is a modified version of DLLME that utilizes surfactants such as SDS or Tween-20 solution as an emulsifier solvent. The procedure is performed precisely as DLLME. One example in food analysis is the extraction of pesticides in juice samples by MEKC-MS using 100 mM AFPOA as an emulsifier is reported [13]. A stepwise sample preparation procedure using vortex assisted surfactant enhanced liquid-liquid microextraction (VASLLME) is illustrated in Fig. S12. The process involves adding 5 g of juice in a 50-mL falcon tube and centrifuged for 10 min at 9509 rcf. Next, the upper aqueous layer was transferred into a 15-mL falcon tube with conical bottom. A mixture of 530 mL aliquot of 100 mM APFO, pH 9.0 (emulsifier, 530 μL), and 1300 mL of chloroform (extraction solvent) was quickly added into the falcon tube. The tube was closed and vortexed for 30 s, centrifuged for 10 min at 9509 rcf. The sedimented organic phase was removed using a syringe and collected in a glass vial. The chloroform was evaporated using a gentle nitrogen stream until dryness. The final residue was reconstituted with 250 mL of 75 mM APFO pH 9.0, vortex for 2 min. Finally, the solution is filtered and injected into the CE-MS. The procedure mentioned above resulted in a sample throughput of approximately 15 samples/h with a preconcentration factor of 20.

In general, the above-mentioned variants of LLE are both quick and straightforward, but they do have some drawbacks. The procedure needs sample pH adjustment, filtration, or centrifugation, depending on the sample pretreatment required, which increases the total sample preparation time.

5. Applications of CE-MS in Safety, Quality, and Adulteration

Food evaluations involve assessment of food for the presence of harmful: (a) microbial agents (bacteria, virus, parasites, toxic microalgae) and (b) chemical compounds (pesticides, industrial and environmental contaminants, veterinary drugs, toxins, and allergens). Besides, adulteration and other fraudulent practice and packaging might also compromise food safety. The data obtained to meet these objectives as mentioned above by various modes of CE-MS for both new and established chemicals found in liquid and solid food samples are summarized in Table 1 and Table 2, respectively, and are discussed below:

Table 1:

List of the sample preparation methods used in CE-MS analysis of liquid food

| Sample Type |

Target Compounds |

Extraction Method |

Extraction Protocol | CE-MS Conditions | Ref |

|---|---|---|---|---|---|

| Rabbit serum | Whey proteins (β-lactalbumin, Lactoglobulin A, Lactoglobulin B, Bovine serum Albumin, Casein Lactoferrin, Ribonuclease A) | No pretreatment | N/A, except matrix effect was evaluated using 1 mL of 10 times-diluted serum added to 48 mL of glycerol–H2O containing 0.5 mL Pharmacia Biotech ampholine (pH 4–6) and 0.5 mL Beckman ampholyte (pH 3–10) | CIEF: bare fused-silica capillary (80 or 100 cm length, 50 μm i.d., 375 μm o.d.) BGE: 1% (v/v) ampholyte mixture (pH 3-10) (1% v/v) and 1% (v/v) ampholine mixture (pH 4-6) in 30: 70 (v/v) glycerol: H2O. Anolyte: 1 mM glutamic acid/50 mM formic acid in glycerol:H2O medium; Catholyte: 1 mM lysine/100 mM ammonia. Focusing: +30 kV for 16 min. Mobilization: cathodic (50 mbar pressure), constant voltage at +30 kV. SL:1% formic acid in 80:20 (v/v) MeOH/H2O; 6 μL/min; ESI-MS: Positive +4.5 kV; SC: DGT 350 °C, NGT 100 °C, NP: 55 kPa | 22 |

| Honey | Endocrine disruptors (4-t-BP, 4-t-BBA, BPA, PCP 2,4,5-TCP, 2,4-DCP) | RAM and SPE | RAM: 4 mL of honey injected in RAM (pump A). At 10 min, RAM set-up to elution and analyte collected in MeOH using pump B. SPE: Oasis HLB cartridge preconditioned with 5 mL AcOET, 5 mL ACN, 5 mL H2O. About ~3.5 mL of sample loaded and cartridge dried (15 min vacuum @ 15 mmHg). Elution with 0.5 mL ACN and 3 mL AcOET. Evaporate to dryness, reconstitute in 60/40 % MeOH/H2O |

CZE: Bare fused silica capillary (75 μm i.d), BGE: 15 mM NH4OAc, pH 11.0. Injection and voltage: 15 mbar,17s,+22kV. SL: 3% (v/v) NH4OH in MeOH, 0.78 mL/min; ESI-MS: Negative, −4.0 kV SC: ESI −4000 V; DGF: 2 L/min; DGT: 100 °C; NP: 2 psi |

66 |

| Chili tomato sauce | Sudan dyes (Sudan I Sudan II Sudan III Sudan IV) | LLE | 1.0 g sample mixed with 10 mL of (3:2:1, v/v/v) acetone/DCM/MeOH, vortexed (2 min), sonicated (5 min), and centrifuged (5 min @10000 rpm). Supernatant dried, residue suspended (1 mL of acetone containing IS), and diluted (50:50 (v/v) 60 mM NH4HCO3 / 50 mM SDS + 30% ACN) | MEKC: Uncoated fused silica capillary (80 cm length, 50 μm i.d). BGE: 40 mM NH4HCO3 + 25 mM SDS + 32.5% (v/v) ACN (pH 8.0). Injection and voltage: 0.5 psi, 6s; +25 kV. SL: 0.1% formic acid in 50: 50 IPA/H2O, 4 μL/min. ESI-MS: Positive, + 4.5 kV. SC: DGF: 4 L/min; DGT: 200 °C; NP: 4 psi | 89 |

| Vegetable oils | Non-protein AAs (Ornithine, b-alanine, GABA, Alloisoleucine, Citrulline, Pyroglutamic acid) | LLE | 40 g of oils extracted with 160 mL of MeOH/CHCl3 (2:1 v/v) and left at −20 °C overnight. Centrifuged (15 min @ 4000 x g, 4°C) and upper phase washed with 40 mL CHCl3 and 100 mL H2O. Aqueous phase dried (80°C) and derivatized with butanol before injection | CZE: Uncoated fused-silica capillary (50 μm id with 60 cm of length). BGE: 0.1 M formic acid (pH 2.0). Injection and voltage: 50 mbar, 50s; +25 kV. SL: 0.1% formic acid in 50:50 IPA/H2O, 3.3 μL/min; ESI-MS: Positive, +4.5 kV. SC: DGF: 3 L/min; DGT: 300 °C; NP: 2 psi | 105 |

| Vegetable oil | Betaines (Proline betaine, Glycine betaine, Carnitine, Rigonelline) | LLE | 40 g of oils extracted with 160 mL of 2:1 (v/v) MeOH/CHCl3 and left at −20 °C (overnight). Mixture centrifuged (15 min @ 4000 x g, 4°C) and upper phase washed with 40 mL CHCl3 and 100 mL H2O using centrifugation. Aqueous phase dried at 80°C and derivatized with ButOH before injection | CZE: Uncoated fused-silica capillary, 50 μm id, total length of 60 cm. BGE: 0.1 M formic acid (pH 2.0). Injection and voltage: 50 mbar 50 sec, +25 kV. SL: 0.1% FA in 50:50 IPA/H2O, 3.3 μL/min. ESI-MS: Positive, +4.5 kV; SC: ESI +4.5kV DGF: 3 L/min; DGT: 300 °C; NP: 2 psi | 106 |

| Honey | Endocrine disruptors | LLE and QuEChERS | LLE: 9.0 mL of n-hexane added to the spiked diluted honey and centrifuged (10 min @ 3900 RCF). Upper organic phase dried (N2 at 40 °C), reconstituted [300 μL of an aq. solution 14%(v/v) MeOH and 1%(v/v) of 28% (w/w) NH4OH solution], vortex and filtered (0.45-μm cellulose filter) collected directly in 100 mL CE vial. QuEChERS: 10mL spiked-diluted honey placed in centrifuge tubes containing a mixture of salts accompanying in the kit and centrifuged (10 min @ 3000 RCF). 1 mL of the upper aqueous-organic phases cleaned with PSA supplied with the kit by centrifugation (1 min @ 3000RCF) and dried. Reconstituted as explained in the LLE procedures | CZE: Fused-silica capillaries (100 or 50 μm id) with a total length of 87 cm to MS, 20 cm to the UV. BGE: 15 mM NH4OAc (pH 11.0 adjust with 28% w/w NH4OH); Injection and voltage: 50 mbar over either 16 s or 50 s for the 100-μm id and 50-μm id capillaries, respectively; ~13.2 and 12.4% of the total capillary length, +22kV with ramp of 7s. SL: 70:30 %(v/v) IPA/MeOH, 10 μL/min. ESI-MS Negative, −4 kV; SC: DGF: 7 L/min ; DGT: 350 °C ; NP: 4 psi | 73 |

| Japanese sake (wine) | Metabolites (organic acids, amino acids, peptides, and sugar) | Filtration | Sake samples centrifuged (15 min @ 9,100g), filtered (5 kDa cutoff membrane filter), and analyze immediately by CE-TOFMS | CZE of cationic metabolite: fused silica capillaries (100 cm × 50 μm I.D). BGE: 1 M formic acid. BGE: 5 mM NH4OAc (pH 8.5). Injection and voltage: 5 k Pa for 30s, +30 kV. SL: 1:1 MeOH/−H2O, 0.1 μM hexakis (2, 2-difluoro-ethoxy) phosphazene. 10 uL/min, ESI-MS: +4kV. CZE of anionic metabolite: COSMO(+) capillary (110 cm × 50 μm I.D),). BGE: 50 mM NH4OAc (pH 8.5). Injection and voltage: 50 mbar, 30s, −30 kV. SL: 5 mM NH4OAc, 0.1 μM hexakis (2,2-difluoroethoxy) phosphazene, in 1:1 MeOH/H2O,10 mL/min. ESI-MS: −3.5kV. SC:DGF: 10 L/min; DGT: 300 °C; NP: 69 kPa. | 45 |

| Soy drinks | Isoflavones (Daidzin, Genistin Daidzein, Genistein Formononetin, Biochanin A, Glycitein Apigenin) | LLE | Ethanol mixed with sample (2:1) centrifuged (30 min @ 5000 rpm), filtered (0.45 μm nylon syringe filter). A 100 μL of filtrate diluted with 1.0 mL H2O and injected in CE-MS | CZE: Uncoated 75 μm capillary with a total length 57 cm to MS, 50 cm to the UV. BGE: 15 mM NH4OAc (pH 11.0 adjust with NH4OH). Injection and voltage: 50 mbar 5s, +25 kV. SL: 0.5% HOAc in 1:1 (v/v) IPA/-H2O,10 μL/min. ESI-MS:Positive, +3.5 kV; SC: ESI 3500 V; DGF: 6 L/min; DGT: 350 °C; NP: 5 psi | 102 |

| Balsamic vinegar, liquid coffee, and soft beverages | 5-hydroxy-methylfurfural | LLE | 300 mg sample dissolved in 6 mL of 1% TCA solution, vortexed (2 min), ultrasonicated (10 min), vortexed (2 min), and centrifuged (10 min @ 9000 rpm, 4 °C). Extracts filtered (0.20 mm nylon filter) and mixed with 6 mL of 500 mg/L FMK solution to obtain a concentration of 5 mg/L in a final volume of 600 μL | CZE: Untreated fused-silica capillary (50 μm i.d. and effective length of 60 cm). BGE: 50 mM formic acid (pH 3.0 adjust with 0.5 M NH4OH). Injection and voltage: 50 mbar, 10s, +25 kV.SL: 0.1% FA in 50% MeOH, 3 μL/min. ESI-MS: Positive, +3.5 kV, SC: DGF: 2 L/min; DGT: 200 °C; NP: 10 psi | 92 |

| Bovine milk | Quinolones (Danofloxacin, sarafloxacin, difloxacin, enrofloxacin, ciprofloxacin flumequine marbofloxacin oxolinic acid) | In-line SPE | 25μL acetic acid added to 5 g of bovine milk and centrifuged (9000 rpm, 10 min) for protein precipitation. 1mL of supernatant mixed with 2 mL of 50 mM NH4OAc buffer pH 5.0 and defatted by centrifuging (5 min @ 9000 rpm) with 3mL of n-hexane. 0.5mL of aqueous phase mixed with 1mL of 50 mM NH4OAc (pH 5.0), filtered, and injected | CZE: Bare fused-silica capillary of 130 cm total length ×50 μm id (360 μm od). BGE: 50 mM NH4OAc (pH 9.1 adjust with 5 M NH4OH). Injection and voltage: 2bar, 15 min, +25 kV. SL: 50:49:1 (v/v/v) IPA/H2O/FA, 3 μL/min. ESI-MS: Negative, 4kV; SC: DGF: 6 L/min; DGT: 150 °C; NP: 4 psi | 57 |

| Banana, tomato, and peach juices | Carbamate pesticides | VSLLME | 5 g of juice centrifuged (10 min @ 9509 rcf) and the supernatant collected (15 mL falcon tube). Mixture of 100 mM APFO, pH 9.0 (emulsifier, 530 μL) and CHCl3 (extraction solvent, 1300 μL) injected into the sample tube, vortexed (30 s), and centrifuged (10 min @ 9509 rcf). Sedimented organic phase removed (with syringe) and CHCl3 evaporated under N2. Residues redissolved (250 mL of 75 mM APFO pH 9.0), filtered and injected into CE | MEKC: Bare fused-silica capillary(90 cm total length, 50 μm ID, 375 μm OD. BGE: 100 mM perfluorooctanoic acid (pH 9.0 adjust with 15 M NH4OH). Injection and voltage: 50 mbar, 30 sec, +23 kV. SL: 99.9:0.1 (v/v) IPA/FA, 1.66 μL/min; ESI-MS: Negative, −4.8 kV; SC: DGF: 8 L/min; DGT: 180 °C; NP: 0.082 MPa | 13 |

| Blueberry Juice | Organic acids (succinic acid, citric acid, salicylic acid malic acid, benzoic acid sorbic acid, ascorbic acid, tartaric acid) | Filtration | Juice sample diluted with BGE (1:10), centrifuged (10,000 r/min, 25,152 g for 10 min), and filtered (0.22 μm membrane) | CZE: Bare fused-silica capillary (50 μm i.d × 70 cm). BGE: 40 mM NH4OAc (pH 6.0 adjust with 1 M HOAc), +22 kV. SL: 7.5 mM HOAc in 70:30 (v/v) IPA/H2O, 6 μL/min. ESI-MS: Positive, +4 kV; SC: ESI 4 kV; DGF: 6 L/min; DGT: 350 °C; NP: 12 psi | 108 |