Abstract

During this pandemic, it has become customary to wear a face waste mask to guard against coronavirus illness (COVID-19). However, huge production of face waste masks, PPE kit and gloves pose environmental risks, since existing disposal methods such as incineration and reclamation which are emitting hazardous substances. In the present study covid-19 medical waste material like waste face waste masks; gloves and PPE kit (personal protective equipment) are considered as the feedstock for the thermal degradation process. Mainly nylon, polyethylene and polypropylene compounds are present in the Covid-19 medical waste compounds, further feedstock material is subjected to physical characterization process like proximate, ultimate and thermo gravimetric analysis (TGA), to determine the moisture, ash, volatile matter and decomposition temperature respectively. The waste waste mask has lower ash content of 9.7 %, whereas gloves and other PPEs has 11.8 and 11.2 % of ash respectively. Similarly volatile matter is also higher for waste waste mask than other feed stocks. Pyrolysis process is carried out between a temperature range of 100 °C to 700 °C and the products of the pyrolysis process are pyrolytic liquid, gas and residue. The maximum pyrolytic oil is produced from waste masks, gloves and other PPE kit at 300, 350 and 320 °C respectively. The calorific value of the pyrolytic oil from waste mask, gloves and other PPE kit possess 40.85,40.11,40.31 MJ/kg respectively, which indicates that all the pyrolytic oil has closer to the diesel fuel. Therefore pyroltic oil obtained from the Covid-19 medical waste can be used as an alternative fuel for CI engine.

Keywords: Pyrolysis, Polypropylene, Face waste mask, PPE kit, Disposable plastic waste and bio-oil

1. Introduction

The novel coronavirus disease-2019 (COVID-19) was discovered in Wuhan-China, in Dec 2019. The World Health Organization (WHO) declared the current situation to be there a pandemic, citing the massive increasing of the virus-related illness, which was impacting the people of most of the world's nations in March 2020. It killed millions of people all across the world, leaving more than 100 million of people affected with the viral disease (exact statistics - As of January 29, 2021, there were 100,455,529 million verified covid-19 cases) [1]. In covid-19, a massive amount of Medical Waste (MW) was produced; almost three to six times the amount of typical municipal solid waste (MSW). Hospitals, healthcare institutions and clinics are the primary sources of MW. Apart from hospitals, home isolation treatment and the wastes created from them are also categorized as MW. Medical waste released from health care or hospitals facilities may include infectious pathogens and is thus classified as hazardous waste (HW). For the period of the covid-19 pandemic, the global prevalence of medical waste handling and disposal was not properly addressed. Several nations saw an unexpected rise in MW from healthcare or hospitals facilities that did not have the processing time or capacity to handle the infrastructure development required holding and appropriately disposing of the MW. The present covid-19 issue in the care, management, and discharge of Covid Medical Waste (CMW) is highlighted in this report. Additionally, it seeks to give appropriate answers for current issues that are overcome during the covid-19 circumstances, particularly with regard to waste management operations. Particular attention has been paid to pyrolysis an ecologically acceptable strategy, which would be an appropriate treatment procedure for changing CMW into useable energy products. BMW (Bio-medical waste) is termed as waste created by medical facilities and their connected research institutes, as defined by WHO diagnosis, healing, prevention and caring therapies in the field of animal and human healthcare are all part of the medicinal practise carried out at such places. Even garbage created by a person's healthcare operations at home is included in the BMW category. Medicinal, chemical, pathogenic, metallic (sharps), infectious and radioactive compounds are all included in BMW [2]. During the crisis of covid-19, health concerns forced the deployment of plastic bag for one-time usage in various nations. The use of plastic bags is often advantageous, and then it creates a lot of garbage, which contributes to the already overburdened waste management infrastructure in any nation. Consumers' behavior patterns would alter as a result of this temporary plastic bags used just once, since they would choose to utilize them as a barrier against contamination. If the scenario persists, Plastics that are reusable or recyclable will lose their use, and plastic bags would rise in everyday use and remain in general circulation long after the crisis [2]. Photo degradation, hydrolytic degradation, and biodegradation thermo-oxidative degradation employing microbes are all natural ways to destroy plastics in the environment. Some processes, such as photo degradation followed by thermo-oxidation, can cause plastic materials to crack. Later, due to microbial action, the carbon (C) in the polymer is converted to carbon dioxide (CO2) or used for biomolecule separation, although this process proceeds several months. As a result, plastic recycling would be the best choice [3].

Quaternary recycling is the technique of recovering all of the energy from plastic wastages polymer by using incineration [4]. Despite the fact that the technology aids in the generation of significant energy from waste plastic, certain airborne harmful compounds dioxins are discharged into the environment, resulting in ecological contamination, that makes the major problem today [5]. The initial step for proper handling and Covid-19 Waste treatment might be to use disinfection technology (DT). It can be disinfected in a temporary storage location at the healthcare centre before being released and sent to a large-scale waste treatment facility [6].In the storage and transportation of the covid-19 medical waste causes serious issues to the environment. In order to minimize the pollution and also producing useful energy from it. In this investigation process, the Covid-19 medical waste are used as the feedstock for the batch-type pyrolysis reactor and the physicochemical properties are carried out for the covid-19 medical waste, to identifies the elemental composition and its decomposition temperature by using proximate, ultimate and TGA analysis. Further the pyrolytic oil is subjected to fuel properties like viscosity, flash, fire point and calorific value.

2. Materials and methods

Enormous usage of gloves, waste masks, gowns and so many caring kits, causes pollution to environment during their incineration process. Furthermore, hazardous exposure from landfill open burning, dumping and firing may have an effect on health effects and have air quality [1]. The researchers are focused in the pyrolysis approach since it has a high waste breakdown rate, simple procedure, and helps solid waste controlling over existing incineration procedures. Pyrolysis is a thermal degradation method that changes polymer/plastic waste into lower molecular weight compounds in a deoxygenated atmosphere at high temperatures. [7]. While the bottom ash from plastic waste incineration contains largely water, CO2, and unburned particles known as micro plastics [7]. Many works are interested in plastic trash is converted to hydrocarbon mixtures by pyrolysis. Because it has the ability to minimize obtain chemicals, waste and replace alternative energy [8], [9]. In this study focused on advancements of waste plastic pyrolysis method, notably in the treatment of polypropylene plastic, which has not been mentioned in earlier studies. Furthermore, this research study provided a complete review of the optimize of (PP) pyrolysis product outcomes, as well as the important impacting aspects in the (PP) plastic pyro-process that need to be considered in order to maximize the liquid fuel and char yield while also improving oil quality [18], [20], [21]. The use of pyrolysis char in recent and projected future applications is expected to enhance environmental protection growth and sustainable energy production in order to achieve environmental sustainability [25], [26].

2.1. Feedstock

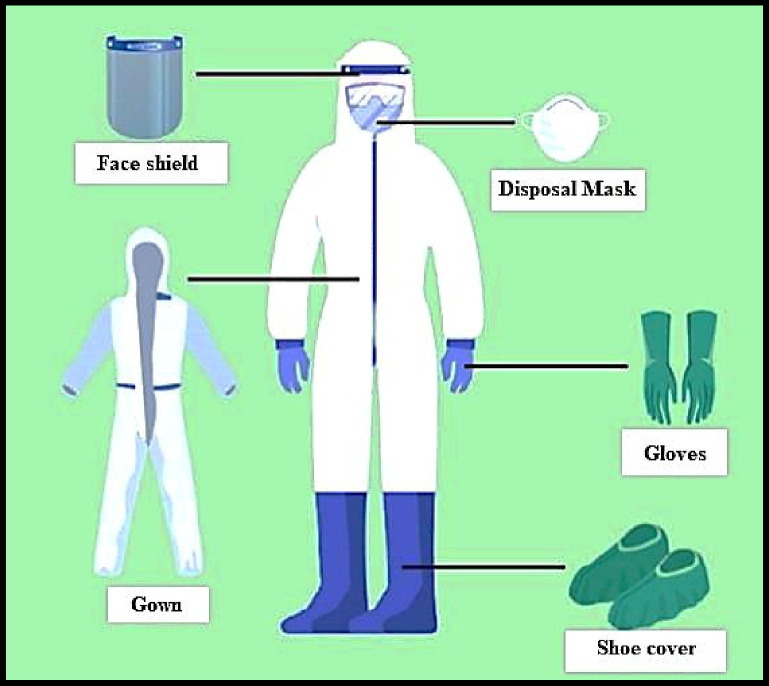

PPEs are mostly made of PP polymer, which accounts for 72 percent of the total product [10]. PP is a thermoplastic material made from the polymerization of propylene monomers. The images for the PPEs that are most commonly used by frontline healthcare staff in isolation facilities are shown in Fig. 1 . Polypropylene is a chemically and thermally stable saturated polymer having a linear chemical bond of hydrocarbon that melts at 160 °C [11]. After sterilizing process of covid-19 medical waste (gloves, waste mask, other PPE’s kit), in order to ensure that harmful virus are killed and it is collected in around of hospital in villupuram town. The collected covid-19 medical waste are consider as the feedstock for the pyrolysis process (see Fig. 2 ).

Fig. 1.

PPE Kit for Covid-19 Patient.

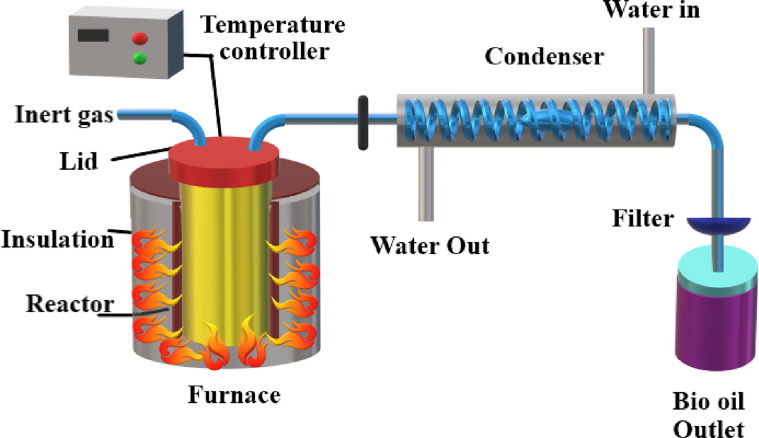

Fig. 2.

Layout of pyrolysis setup [14].

2.2. Pyrolysis process

Pyrolysis is the thermo-chemical destruction of bits and pieces at elevated heat, such as plastic trash, in an inert, deoxygenated environment [6]. Pyrolysis is a useful and successful waste management method to treat of medical and industrial solid waste, then it is a viable thermal decontamination technique for the action of COVID-19 related waste. Because of the heating and pressure, the end products of the waste pyrolysis plant are often burnable smaller molecular weight, shorter chain, and far less complex particles [12], [13], [16]. In general, gaseous end-products such as methane, carbon monoxide and hydrogen will be produced. When the working temperature is high, liquid outputs are collected the most. Acetone, acetaldehyde, acetic acid, solvent oil, tar, methanol and other organic materials are among the numerous fluid-like final yields produced [6], [17]. Apart from that, solid end-yields might be created primarily by low-temperature thermal degradation pyrolysis. As a result, coke, carbon black and char will be gathered [23], [24].

2.3. Pyrolysis setup

The pyrolysis reactor also has a thermocouples, and the ideal temperature is established by a temperature systematize process. One side of the condensing flask is coupled to tubing in the pyrolysis reactor, and liquid product is collected at the other side through into the tapered flask. In the first stage, the temperature in the reactor's inside core rises at an 8 °C/min rate before falling to 3 °C at the completion. As a consequence, the control equipmentof temperature parameter raises the heat to 500 °C and the regular power meter reads 4.8kWh (see Table 1 and Table 2 ).

Table 1.

COVID-19 Medical Waste (CMW) and their associated plastic wastes.

| Disposable sources | Medical Clinics, Research and Development sectors, Household, Hospitals, Health-care centers, Home Quarantine. |

| COVID-19 Medical Waste | Waste masks, feeding tubes, suction probes, gloves, Shoe waste masks, caps, covers, clothing, COVID test kits, respirators, syringes, oxygen pipes, saline bottles, catheters, aprons, face waste masks, goggles\glasses, and packaging bags. |

| Types of Plastic waste | HDPE(High density poly-ethylene)- PP(Poly-propylene)- PS(poly-styrene)- PET(poly-ethylene terephthalate)- LDEP (low density poly-ethylene) and PVC -(poly-vinyl-chloride) |

Table 2.

COVID-19 Plastic waste [1].

| PPE components | Raw materials |

|---|---|

| Facewaste masks | PP |

| Standard surgical waste masks | PP |

| Gowns | Mainly PP |

| Goggles | High quality PC |

| Gloves | HDPE |

| Shoe covers | PP |

| Hair nets | PP |

Where, PP – Polypropylene, PC –Polycarbonate.

3. Result and discussion

3.1. Feedstock characterization

The face waste mask, gloves and PPE kits has filter parts, which are made of polypropylene (PP), High quality polycarbonates etc. The proximate analysis of face waste mask has 81.2 % of volatile mater, 9.1 % of fixed matter and Ash content 9.7 % and ultimate analysis has composition of C, H, O, N are 76.1, 15.1, 7.9 and 0.9 %. The proximate analysis of gloves has 79.3 % of volatile mater, 8.9 % of fixed substance and ash substance 11.8 %. And Ultimate analysis is the composition of C, H, O, N are 77.3, 15.4, 6.2 and 1.1 %. The proximate analysis of other PPE has 79.6 % of volatile mater, 9.2 % of fixed matter and Ash content 11.2 % and ultimate analysis has composition of C, H, O, N are 75.1, 16.1, 8.1 and 0.7 % respectively. It is seen that ash contain is more for gloves than waste mask and PPE kit, this because of denser polypropylene present in the gloves. It is also seen that the other compositions are almost same for all their medical wastes. The Table 3 shows the proximate and ultimate analysis.

Table 3.

Analysis results of proximate and ultimateof the Covid-19 Plastic waste.

| wt.% | Waste mask | Gloves | Other PPEs |

|---|---|---|---|

| Proximate analysis | |||

| Moisture | 0 | 0 | 0 |

| Volatile matter | 81.2 | 79.3 | 79.6 |

| Fixed matter | 9.1 | 8.9 | 9.2 |

| Ash | 9.7 | 11.8 | 11.2 |

| Ultimate analysis | |||

| C | 76.1 | 77.3 | 75.1 |

| H | 15.1 | 15.4 | 16.1 |

| O (by difference) | 7.9 | 6.2 | 8.1 |

| N | 0.9 | 1.1 | 0.7 |

| S | N.D. | N.D. | N.D. |

3.2. Thermo gravimetric analysis (TGA)

Thermal decomposition is the heat breaking of a material in an inert environment. As a result, the optimum pyrolysis temperature needed to be calculated. The raw materials were subjected to thermo gravimetric analysis (TGA) for this purpose.

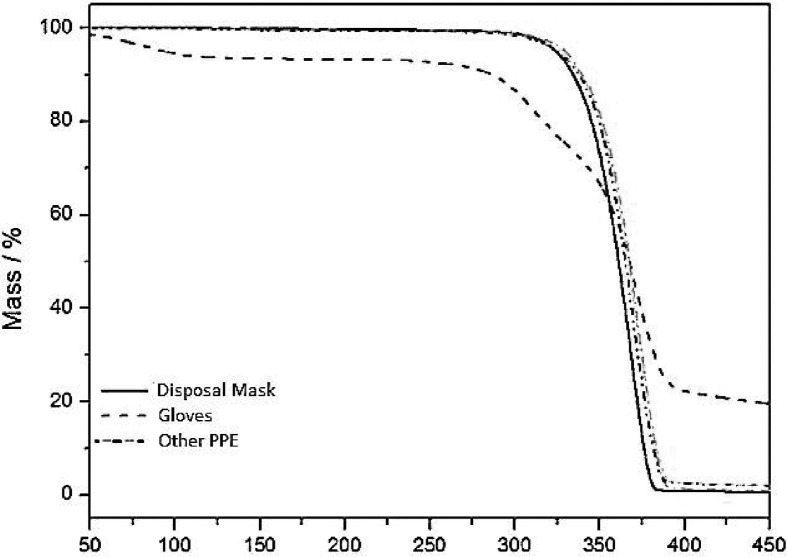

The samples were shredded into small pieces. To minimise undesirable oxidation of the material, high quality nitrogen gas at a flow rate of roughly 100 mL/min was utilised as an inert purge gas to displacing gas in the pyrolysis zone. The temperature-dependent thermogravimetric weight loss curve was shown in Fig. 3 that shows the TGA plot of a face mask, gloves, and PPE kit in a nitrogen atmosphere at a heating rate of 3 °C per minutes. The TGA of face waste mask, gloves, and PPE kit indicates that the pyrolytic zone occur in the temperature range of 300-400 °C.

Fig. 3.

TGA analysis of Covid-19 medical waste.

In the pyrolysis zone weight reduction of feedstock occurs in three stages based on different temperature range. The first phase of breaking down into small components at 100–150 °C results in a weight loss of 10–16 % was recorded in the first phase of decay, 75–85 % loss of weight was recorded in the second phase decay at 200–350 °C, while 15–25 % loss of weight was found in the third phase decay at 350–400 °C. Because of the increased decay rate per unit point in time, a rapid decomposition region is designated as an active region. At 320–340 °C, the weight loss of Disposal mask and Other PPEs waste becomes decrease suddenly. In the gloves waste where there sudden weight loss carried at the temperature of 260–350 °C.

3.3. Pyrolysis of disposable (COVID-19 medical waste)

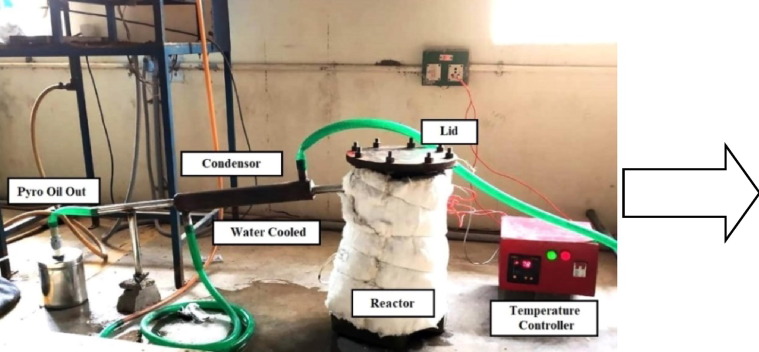

After the sterilization process of the CMW is collected and subjected to the batch type type pyrolysis reactor as shown in the Fig. 4 . Pre-treatment equipment is not required in batch type pyrolysis process, and feedstock can be fed directly into the reactor. This method is capable of processing scrap tyres, plastics, rubber, etc. The end products of this process obtained the pyrolytic oil.

Fig. 4.

Photographic view of pyrolysis setup.

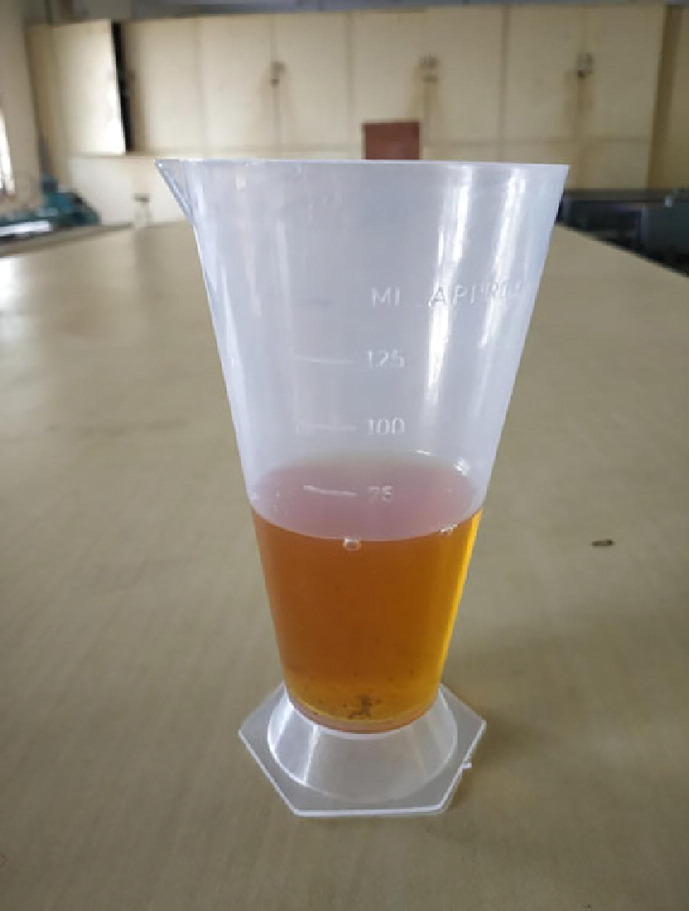

The covid-19 Medical waste was shredded into small pieces and uploaded in the reactor and the pyrolysis process is carried out for 1–2 h. Initially nitrogen gas is passed into the reactor, to ensure the absence of oxygen inside the reactor. Then the water is discharge into the condenser unit, in order to condense the volatile matter evolved during the pyrolytic process. The condensable gas is turned into pyroytic oil and it is dark brown in colour as shown in the Fig. 5 . [14], [15]. There was no solid residue (char) left after the pyrolysis. The waste mask, gloves, and PPE kits are completely thermally degraded.

Fig. 5.

Pyrolysis oil.

3.3.1. Yield rate of pyrolysis products

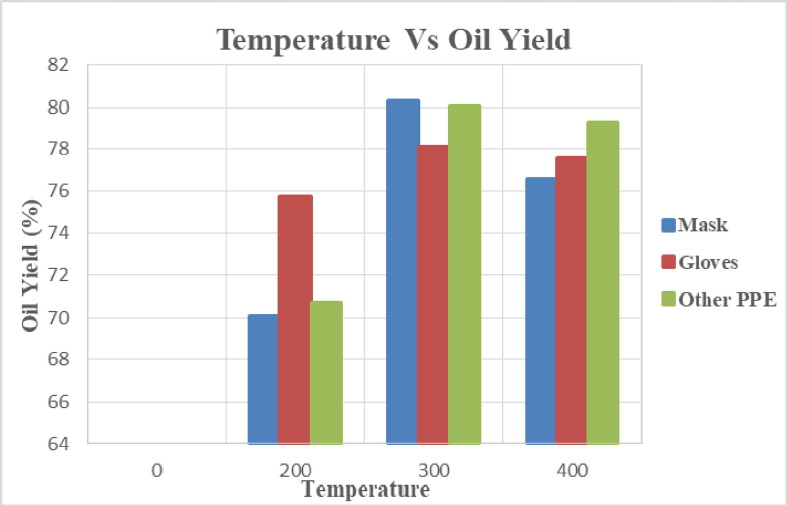

The pyrolysis process was carried out at various temperature ranges, where the maximum oil yield rate varies from one feedstock to another feedstock. From the Fig. 6 shows the yield rate of pyrolytic oil at various temperatures At 200–250 °C temperature, pyrolytic oil yield rate from waste mask, gloves and other PPE kits are 70.1 %, 75.7 % and 70.7 % respectively. Similarly at 300–350 °C and 350–400 °C, pyrolytic oil yield rate for waste mask, gloves and other PPE kits are 80.3 %, 78.1 % and 80.1 %, 76.6 %, 77.6 % and 79.3 % respectively. It is concluded that maximum pyrolytic oil yield rate is lies between the temperature ranges of 300–350 °C. Among the covid-19 medical waste, waste waste mask has a higher pyrolytic oil yield rate than other medical waste. The residence time refers to the amount of time the case will remain in the pyrolysis chamber, which affects the final output. Prolonged residence time accelerates the decay of the main product, resulting in the creation of more thermally stable products such as low molecular weight hydrocarbon. The heating rate determines the response rate and sets the particle temperature profile. In thermal analysis improving the heating rate results in greater temperatures for weight loss.

Fig. 6.

Yield rate of Pyrolytic oil.

3.4. Fuel properties – Pyrolytic oil from Covid-19 medical waste

The fuel qualities of the liquefied oil generated in the thermal cracking bythe process of pyrolysis were reported in Table 4 . Waste mask, gloves, and other PPE all have experimental calorific values beyond 40 MJ/kg, which are regarded a lot of energy usage. Overall, the physicochemical characteristics of plastic products pyro-oil, those of commercial diesel and gasoline were very comparable, as shown in Table 4. Consequently, plastic pyro-oil offers a great deal of promise for usage as an alternative to fossil fuels. For Waste mask, density (0.85 kg/m3), viscosity (up to 4.07 mm2/s), flash point (30 °C), pour point (−8 °C), and energy content (40.8 MJ/kg), For gloves, density (0.88 kg/m3), viscosity (up to 5.07 mm2/s), flash point (28 °C), pour point (−5 °C), and energy content (40.1 MJ/kg).For Other PPEs, density (0.84 kg/m3), viscosity (up to 3.89 mm2/s), flash point (30 °C), pour point (−7 °C), and energy content (40.31 MJ/kg) of the liquid oils generated by Covid medical waste pyrolysis are comparable to ordinary diesel.

Table 4.

Physical Properties of COVID-19 Plastic waste.

|

Physical Properties |

|||||

|---|---|---|---|---|---|

| Calorific value (MJ/kg) | Density @ 15 °C (gm/cm3) | Viscosity (mm2/s) | Pour point (°C) | Flash point (°C) | |

| Feedstock (Covid Medical Wastes) | |||||

| Waste mask | 40.8 | 0.85 | 4.07 | −8 | 30 |

| Gloves | 40.1 | 0.88 | 5.07 | −5 | 28 |

| Other PPE | 40.31 | 0.84 | 3.89 | −7 | 29 |

| Commercial Standards Value (ASTM 1979) | |||||

| Gasoline[19] | 42.5 | 0.780 | 1.17 | – | 42 |

| Diesel[19] | 43.0 | 0.807 | 1.9–4.1 | 6 | 52 |

4. Conclusions

The covid-19 medical face waste mask, gloves, and other PPE equipment were subjected to pyrolysis process and the following results are obtained.

-

•

Proximate and ultimate analysis, identifies that covid-19 medical waste has zero moisture content and it possess higher volatile matter

-

•

The maximum pyrolytic yield was achieved for the waste mask at a temperature of 300 °C, gloves at a temperature of 350 °C and other PPEs at 320 °C.

-

•

The maximum yield rate was found at temperature of 300–350 °C, when the oil yields of Waste mask, gloves and other PPE kits are 80.3 %, 78.1 % and 80.1 %.

-

•

The fuel properties of waste mask, gloves and other PPE kit were closer to the diesel fuel. Where there calorific value of the pyrolytic oil of waste mask, gloves and other PPE kit possess 40.85,40.11,40.31 MJ/kg respectively.

Hence it is concluded that the Covid-19 medical waste as a potential for usage of feedstock in the pyrolysis process and the pyrolytic oil derived from Covid-19 medical waste has been used as an alternative fuel without any modification in engine.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

The authors are unable or have chosen not to specify which data has been used.

References

- 1.World Health Organization, 2020a. Coronavirus Disease (COVID-19) Outbreak Situation. The World Health Organization. https://www.who.int/publicationsdetail/covid-19-strategy update.

- 2.Sharma H.B., Vanapalli K.R., Cheela V.S., Ranjan V.P., Jaglan A.K., Dubey B., Bhattacharya J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID - 19 pandemic. Resour. Conserv. Recycl. 2020:105052. doi: 10.1016/j.resconrec.2020.1050. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Grigore M. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling. 2017;2(4):24. doi: 10.3390/recycling2040024. [DOI] [Google Scholar]

- 4.Wang H., Li Z., Liu Y., Zhang X., Zhang S. Degradation of poly(ethylene terephthalate) using ionic liquids. Green Chem. 2009;11(10):1568. doi: 10.1039/b906831g. [DOI] [Google Scholar]

- 5.Barcelo D. An environmental and health perspective for COVID-19 outbreak: meteorology and air quality influence, sewage epidemiology indicator, hospitals disinfection, drug therapies and recommendations. J. Environ. Chem. Eng. 2020;8:104006. doi: 10.1016/j.jece.2020.104006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Verma A., Budiyal L., Sanjay M.R., Siengchin S. Processing and characterization analysis of pyrolyzed oil rubber (from waste tires)-epoxy polymer blend composite for lightweight structures and coatings applications. Polym. Eng. Sci. 2019;59:2041–2051. [Google Scholar]

- 7.Yang Z., Lü F., Zhang H., Wang W., Shao L., Ye J., He P. Is incineration the terminator of plastics and microplastics? J. Hazard. Mater. 2021;401:123429. doi: 10.1016/j.jhazmat.2020.123429. [DOI] [PubMed] [Google Scholar]

- 8.M.M. Harussani, S.M. Sapuan, A. Khalina, R.A. Ilyas, M.D. Hazrol, Review on green technology pyrolysis for plastic wastes, in: Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020. Institute of Tropical Forest and Forest Products (INTROP). Universiti Putra Malaysia, Serdang, Selangor, 2020, pp. 50–53.

- 9.Sharuddin S.D.A., Abnisa F., Daud W.M.A.W., Aroua M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016;115:308–326. [Google Scholar]

- 10.3M Personal Safety Division, 2018. Technical Specification Sheet: 3MTM Particulate Respirator 8210, N95.

- 11.Verbeek J.H., Rajamaki B., Ijaz S., Sauni R., Toomey E., Blackwood B., Tikka C., Ruotsalainen J.H., Balci F.S.K. Personal protective equipment for preventing highly infectious diseases due to exposure to contaminated body fluids in healthcare staff. Cochrane Database Syst. Rev. 2020;(4):1–147. doi: 10.1002/14651858.CD011621.pub4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Xue Y., Kelkar A., Bai X. Catalytic co-pyrolysis of biomass and polyethylene in a tandem micropyrolyzer. Fuel. 2016;166:227–236. [Google Scholar]

- 13.Kairytė A., Kremensas A., Vaitkus S., Czlonka S., Strakowska A. Fire suppression and thermal behavior of biobased rigid polyurethane foam filled with biomass incineration waste ash. Polymers (Basel) 2020;12:683. doi: 10.3390/polym12030683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Thamizhvel R., Suryavarman K., Velmurugan V., Sethuraman N. Comparative study of gasification and pyrolysis derived from coconut shell on the performance and emission of CI engine. Mater. Today:. Proc. 2021 doi: 10.1016/j.matpr.2021.05.350. [DOI] [Google Scholar]

- 15.Thamizhvel R., Sethuraman N., Sakthivel M., Prabhakaran R. Experimental investigation of diesel engine by using paper cup waste as the producer gas with help of down-draft gasifier. IOP Conf. Series: Mater. Sci. Eng. 2020 doi: 10.1088/1757-899X/988/1/012015. [DOI] [Google Scholar]

- 16.Thamizhvel R., Vinodraj S., Sethuraman N. Performance On Biomass Gasification Of Groundnut Shell In Down Draft Fixed Bed Reacter. IJMPERD. 2020;10(3):4963–4970. [Google Scholar]

- 17.Sethuraman N., Surya Varman K., Venkatakrishnan R., Thamizhvel R. An experimental investigation of crude glycerol into useful products by using IC engine in dual fuel mode. Mater. Today:. Proc. 2021;44:3914–3918. doi: 10.1016/j.matpr.2021.02.160. [DOI] [Google Scholar]

- 18.Onwudili J.A., Insura N., Williams P.T. Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: Effects of temperature and residence time. J. Anal. Appl. Pyrolysis. 2009;86:293–303. [Google Scholar]

- 19.Ahmad I., Khan M.I., Khan H., Ishaq M., Tariq R., Gul K., et al. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy. 2014;12:663–671. [Google Scholar]

- 20.Selvakumar Dharmaraj, Veeramuthu Ashokkumar, Rajesh Pandiyan, HeliSitiHalimatul Munawaroh et al., Pyrolysis: An effective technique for degradation of COVID19 medical wastes, Chemosphere (2021). [DOI] [PMC free article] [PubMed] [Retracted]

- 21.Harussani M.M., Sapuan S.M., Umer Rashid A., Khalina R.A.I. Pyrolysis of polypropylene plastic waste into carbonaceous char: Priority of plastic waste management amidst COVID-19 pandemic. Sci. Total Environ. 2022 doi: 10.1016/j.scitotenv.2021.149911. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Katsigiannis A.S., Bayliss D.L., Walsh J.L. Cold plasma for the disinfection of industrial food contact surfaces: An overview of current status and opportunities. Compr. Rev. Food Sci. Food Saf. 2022 doi: 10.1111/1541-4337.12885. [DOI] [PubMed] [Google Scholar]

- 24.Vanapalli Kumar Raja, Sharma HariBhakta, Ranjan VedPrakash, Samal Biswajit, et al. Challenges and strategies for effective plastic waste management during and post COVID19 pandemic. Sci. Total Environ. 2021 doi: 10.1016/j.scitotenv.2020.141514. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Zhou H., Chunfei W., Onwudili J.A., AihongMeng Y.Z., Williams P.T. Polycyclic aromatic hydrocarbons (PAH) formation from the pyrolysis of different municipal solid waste fractions. Waste Manage. 2015 doi: 10.1016/j.wasman.2014.09.014. [DOI] [PubMed] [Google Scholar]

- 26.Sharuddin S.D.A., Abnisa F., Daud W.M.A.W., Aroua M.K. Pyrolysis of plastic waste for liquid fuel production as prospective energy resource. IOP Conf. Series: Mater. Sci. Eng. 2018 [Google Scholar]

Further reading

- 22.“Waste-to-Energy”, Springer Science and Business Media LLC, 2022.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The authors are unable or have chosen not to specify which data has been used.